TRANE

R

Installation

Operation

Maintenance

IND-SVN01A-E4

(Jan 2010)

TRANE

R

TRANE Quantum

TM

Air Handler

Model: CLCPEuro

CLCPXP

TRANE

R

TRANE

R

Notice

World enviromental scientists have

concluded, based on the best currently

available evidence, that ozone in our

upper atmosphere is being reduced

due to the release of CFC fully

halogenated compounds.

The Trane Company urges that all

HVAC servicers working on Trane

equipment, or any manufacturer’s

products, make very effort to eliminate,

if possible, or vigorously reduce the

emission of CFC, HCFC and HFC

refrigerants to the atmosphere

resulting from installation, operation,

routine maintenance, or major service

on this equipment. Always act in a

responsible manner to conserve

refrigerants for continued use even

when acceptable alternatives are

available.

Refrigerant used in any type of airconditioning or refrigerating equipment should be recovered for reuse,

recovered and / or recycled for reuse,

reprocessed (reclaimed), or properly

destroyed, whenever it is removed from

equipment. Never release to the

atmosphere!

Safety Considerations

The equipment covered by this manual

is designed for safe and reliable

operation when installed and operated

within its design specifcation limits. To

avoid personal injury or damage to

equipment or property while installing

or operating this equipment, it is

essential that qualified, experienced

personnel perform these functions

using good judgement and safe

pratices.

See the following cautionary

statement.

Warning and Cautions

Notice that WARNING and CAUTION

appear at appropriate intervals

throughout this manual.

WARNING indicates a potentially

hazardous situation that could result

in personal injury or death.

CAUTIONs are designed to alert you

to conditions that could result in minor

personal injury or equipment damage.

i

WARNING

!

CAUTION

!

TRANE

R

Contents

General Information

Foreword

Warranty

Unit Description

Model Nomenclature

Receiving

Nameplate

Delivery Check

Resolving Shipping Damage

Storage Consideration

Outdoor Storage

Rigging and Handling

Rigging and Handling

Off Loading

Moving to Position On Site

Forlift Trucks

Roller Movement

Installation

Foundation

Erection

Assembly and Installation

External Connection

Frame to Frame Connection, CLCP-euro

Panel to Frame Connection, CLCP-euro

Paneling, CLCP-euro

Frame to Frame Connection, CLCP-XP

Panel to Frame Connection, CLCP-XP

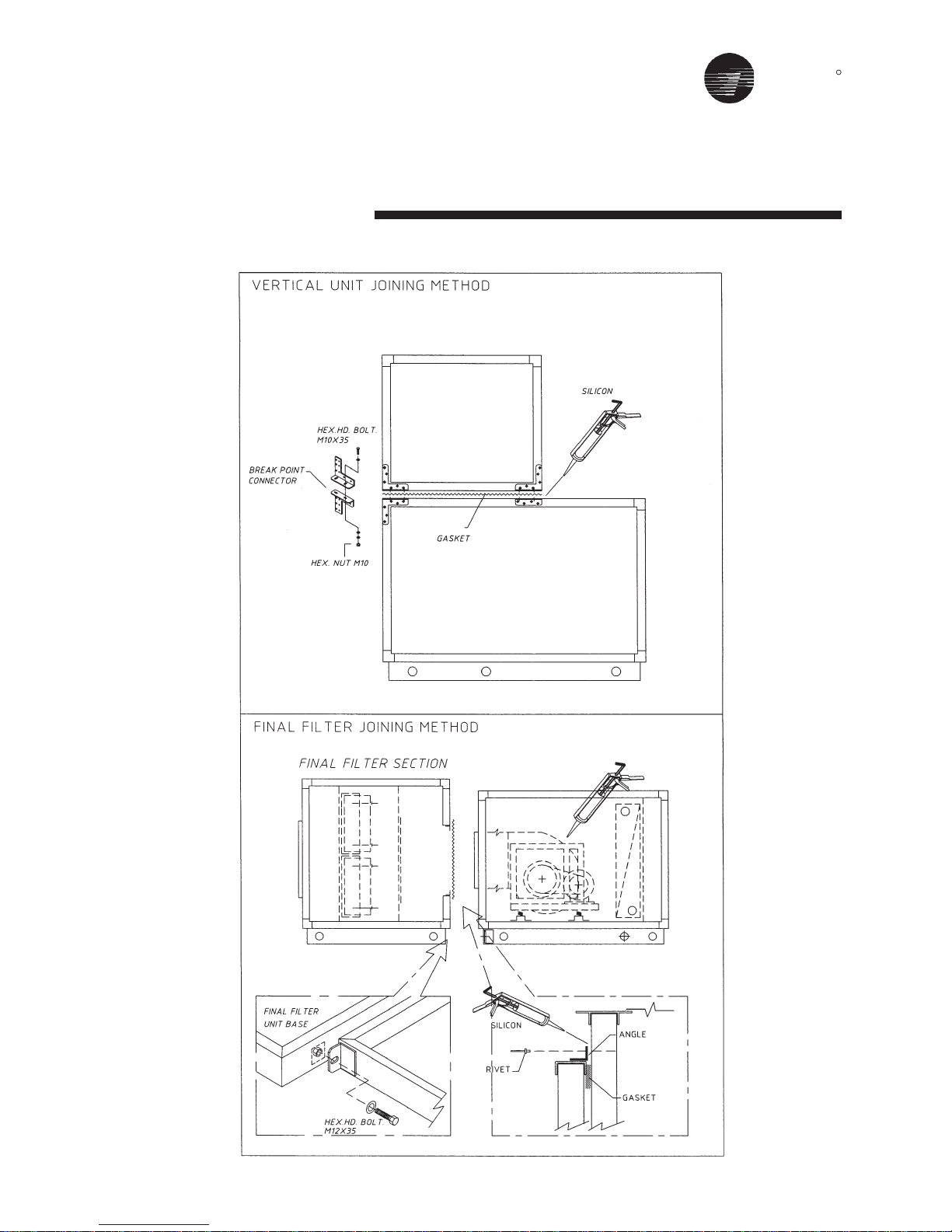

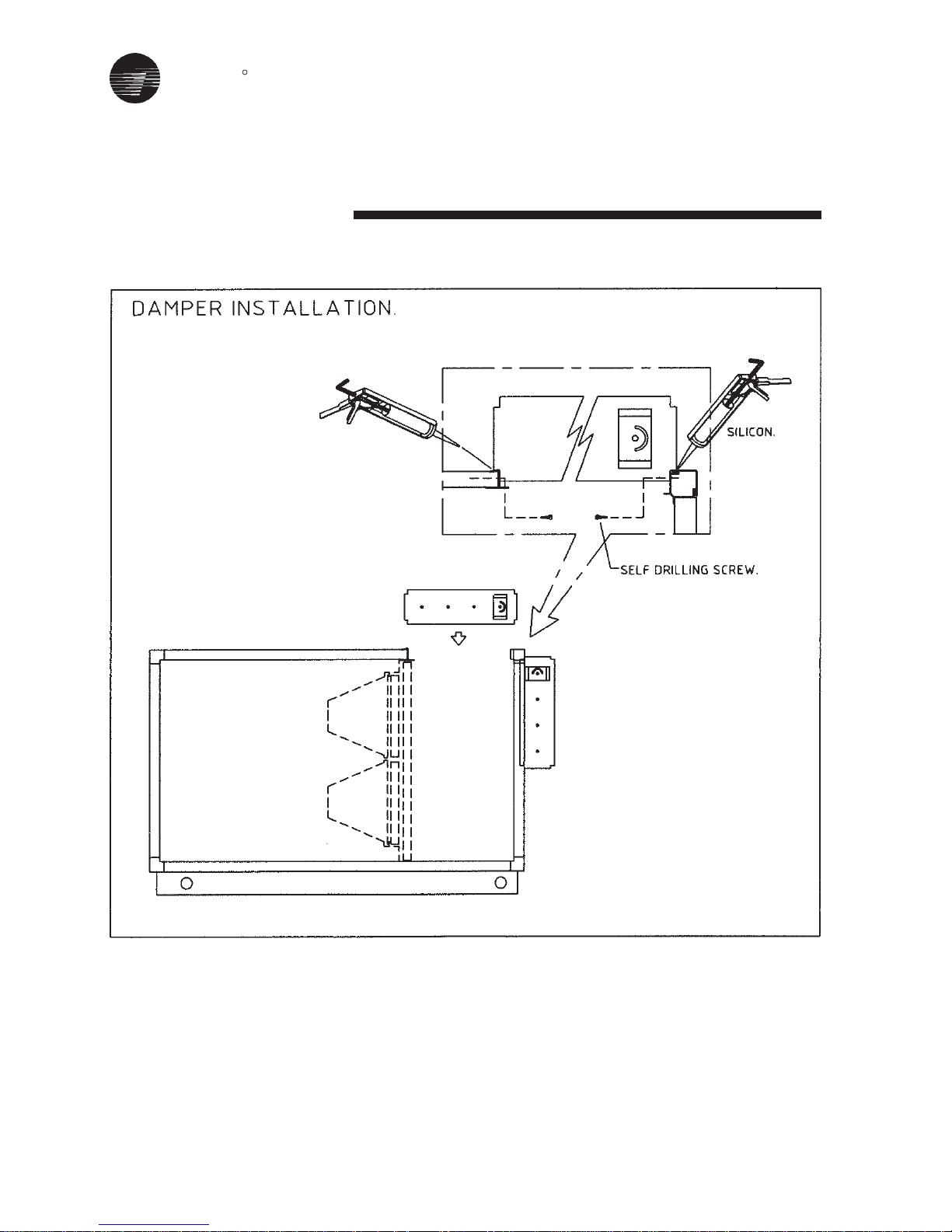

Vertical Unit / Final Filter / Damper Joining Method

Piping

Start-Up

Start-Up Procedures

Maintenance

Periodic Maintenance Checklist

Maintenance Plan

Trouble Analysis

General

Pulley and Belt

Appendix A-Unit Weight, CLCP-euro

Appendix B-Unit Weight, CLCP-XP

Appendix C-Fans and Arrangement

Appendix D-Filter ad Qty

Appendix E-Motor Performance Data

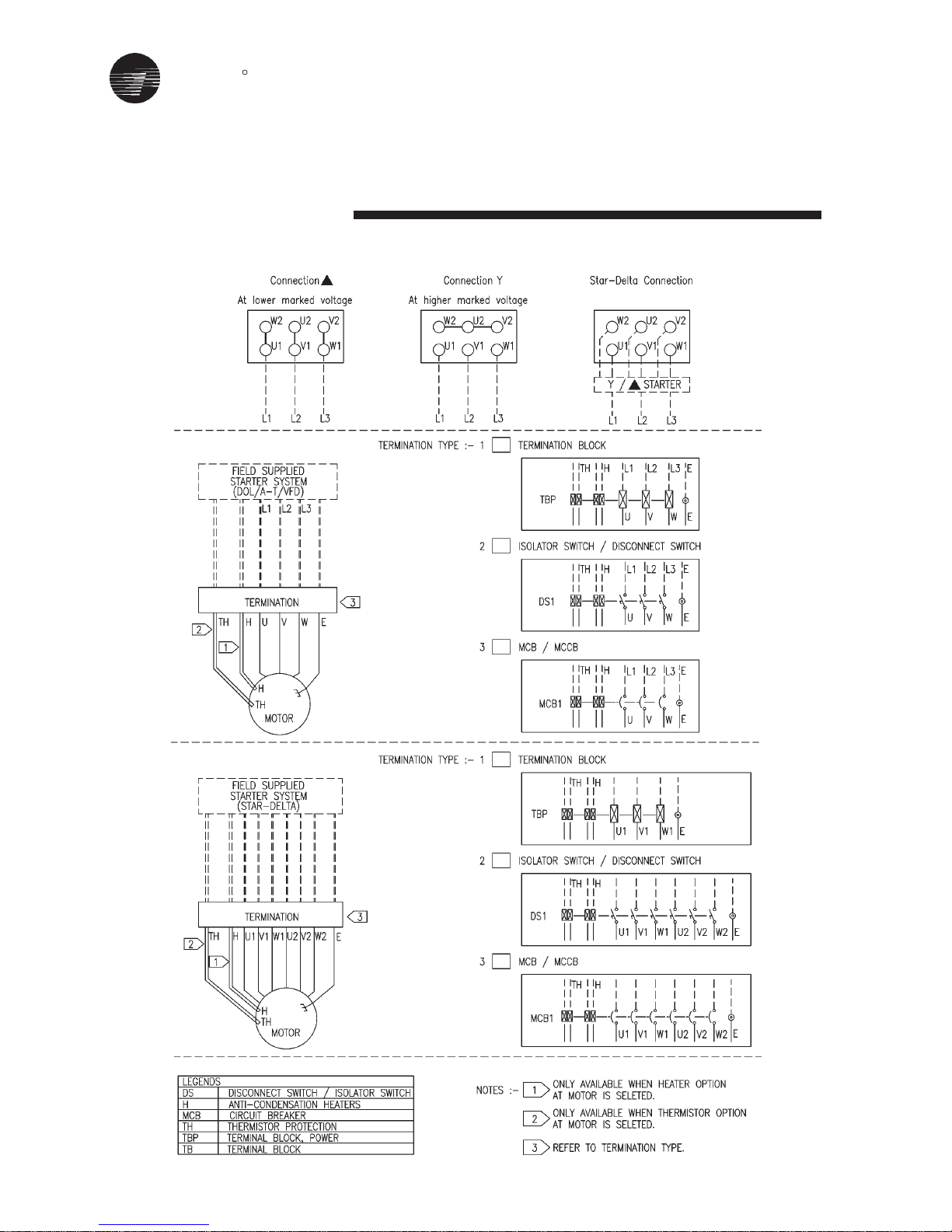

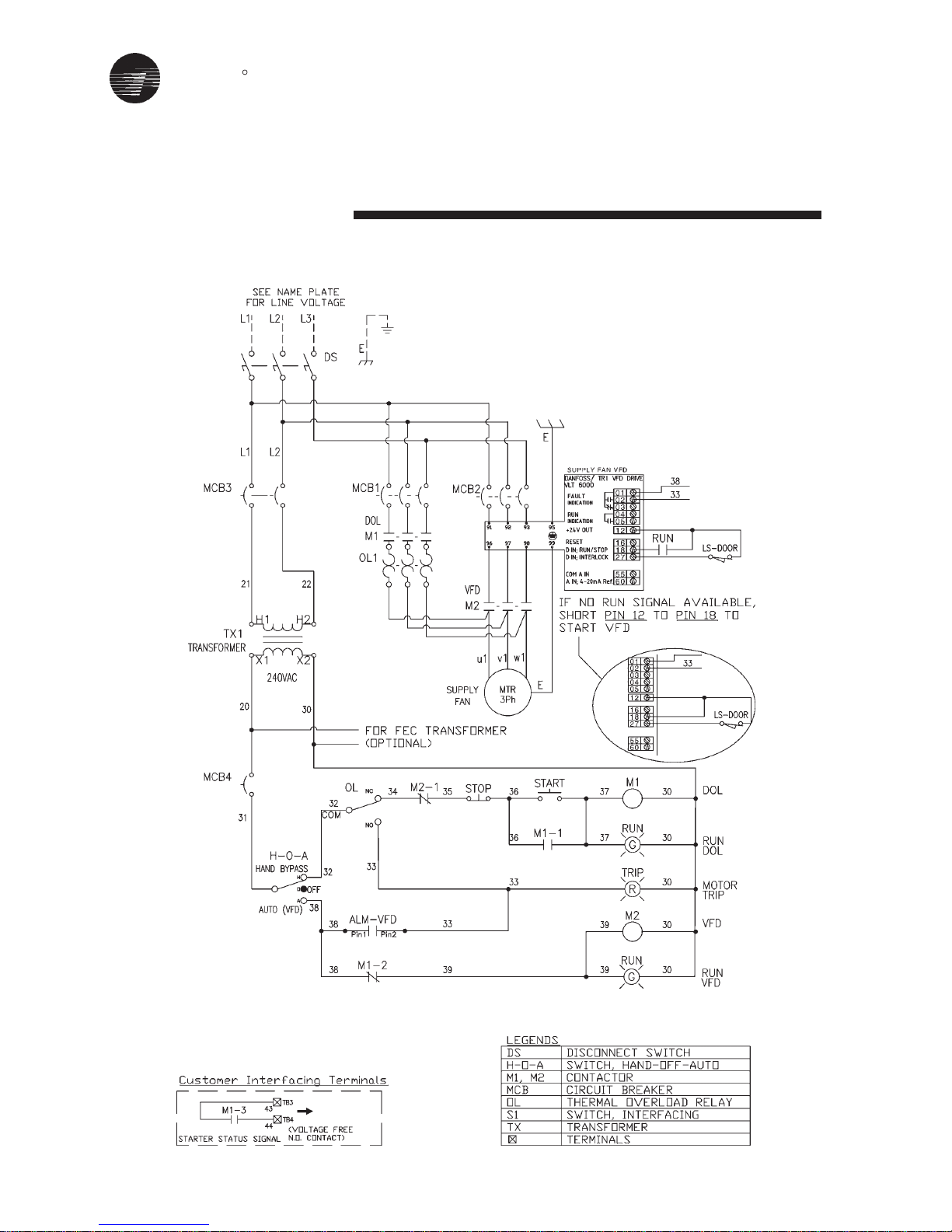

Appendix F-Typical Wiring Diagram

Safety Recommendations, Maintenance Contract and Training

Pre - Start Up Checklist

1

4

5

7

9

24

26

33

63

TRANE

R

General Information

• Foreword

These installations, operation and

maintenance instructions are given as

a guide to good practice in the

installation, commission into service,

operation and periodic maintenance

by the user, of TRANE Quantum

TM

Air

Handler. They do not contain full

service procedures necessary for the

continued successful operation of this

equipment; the services of a qualified

technician should be employed

through the medium of a maintenance

contract with a reputable service

company.

• Warranty

Trane’s standard warranty covers the

equipment. It does not cover damage

due to misuse, lack of maintenance,

or failure to comply with the

manufacturer’s instructions or

recommendations.

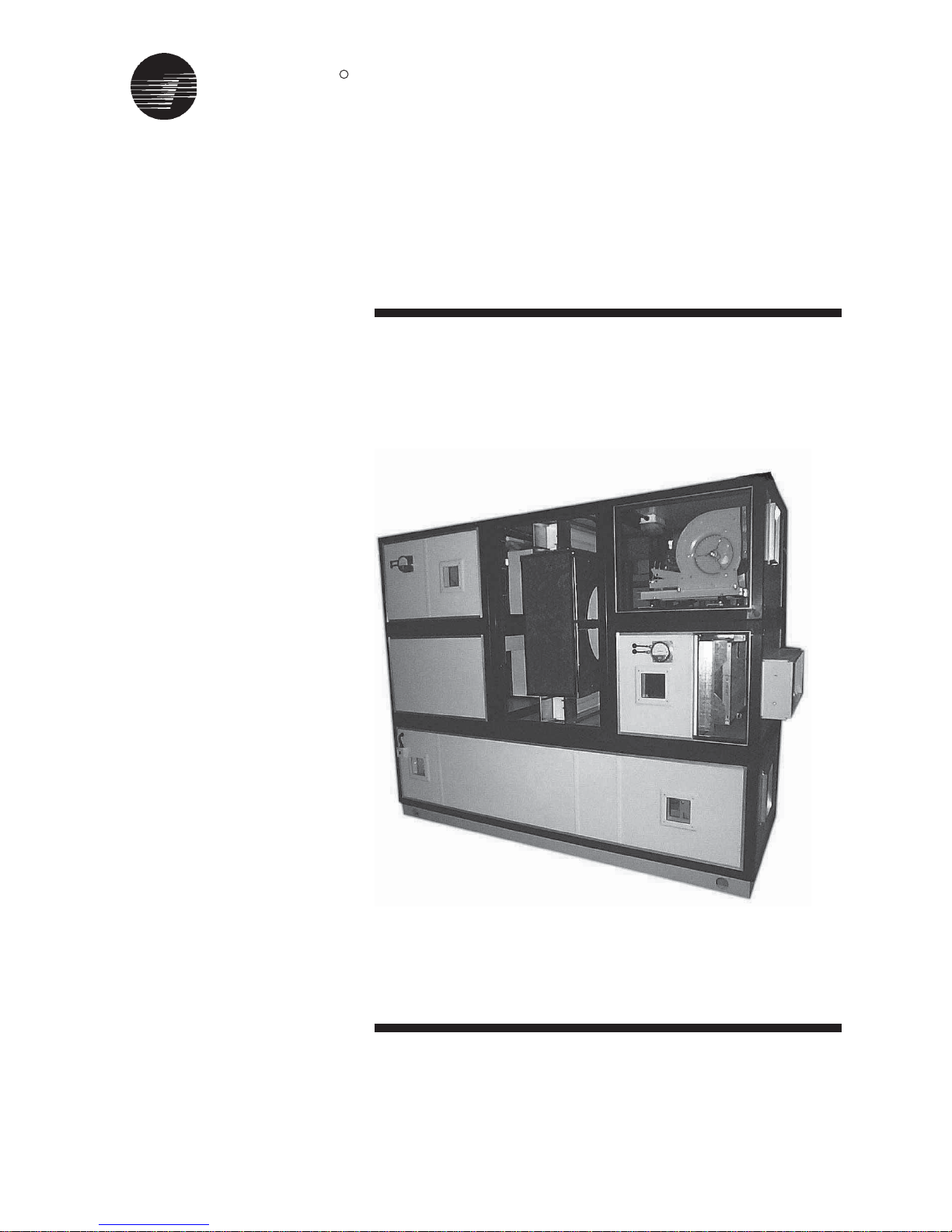

• Unit Description

TRANE QuantumTM Air Handler are

Central Station Air Handlers designed

for a variety of controlled air application.

The basic unit consists of a fan,

heating and/or cooling coils, filters and

air dampers. See product catalogue for

list of available modules and options.

The TRANE Quantum

TM

Air Handler are

designed for cooling load conditions

of 1000-65000 nominal CFM. Fans are

double width, double inlet, centrifugal

types with forward curved, backward

curved, and airfoil blade designs.

To insure fan motor assembly stability

the unit ships with shipping brackets

located between the fan support frame.

These spacers must be removed prior

to fan operation, to assure proper

vibration isolation.

Units ship as complete units, sections

or subassemblies. Each section is

provided with a nameplate (label)

which includes type of section, unit

serial number, customer tag number

and unit model number.

1

TRANE

R

2

CLCPXP

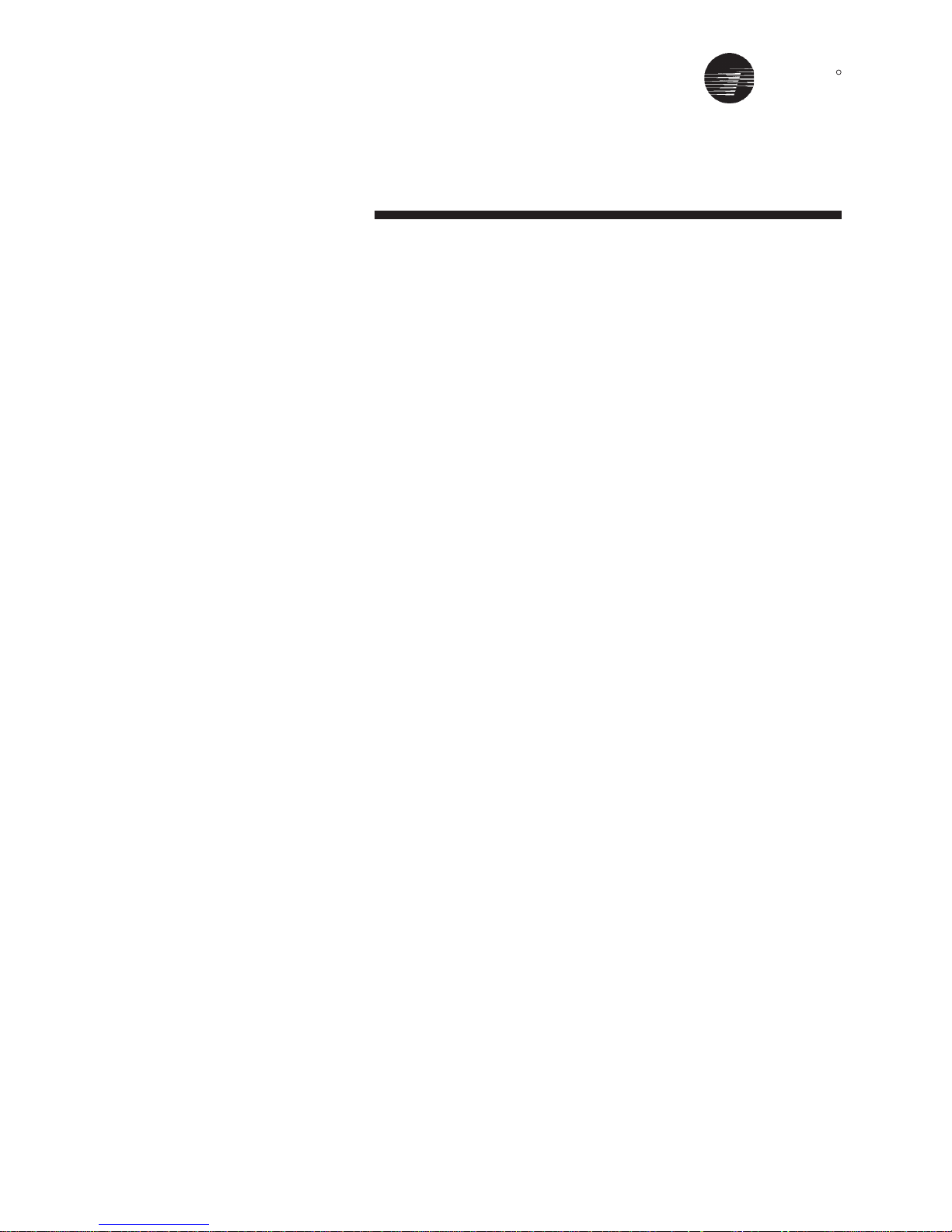

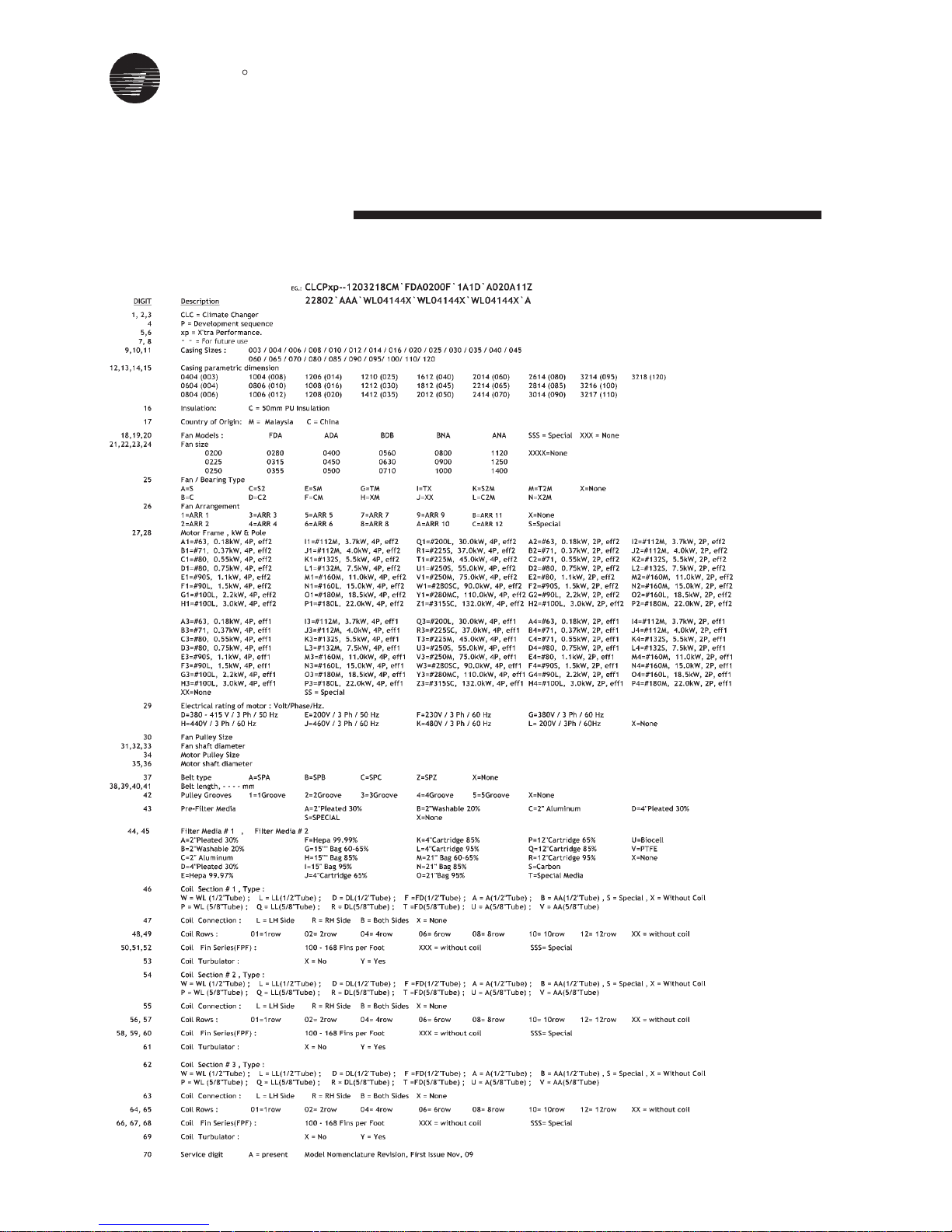

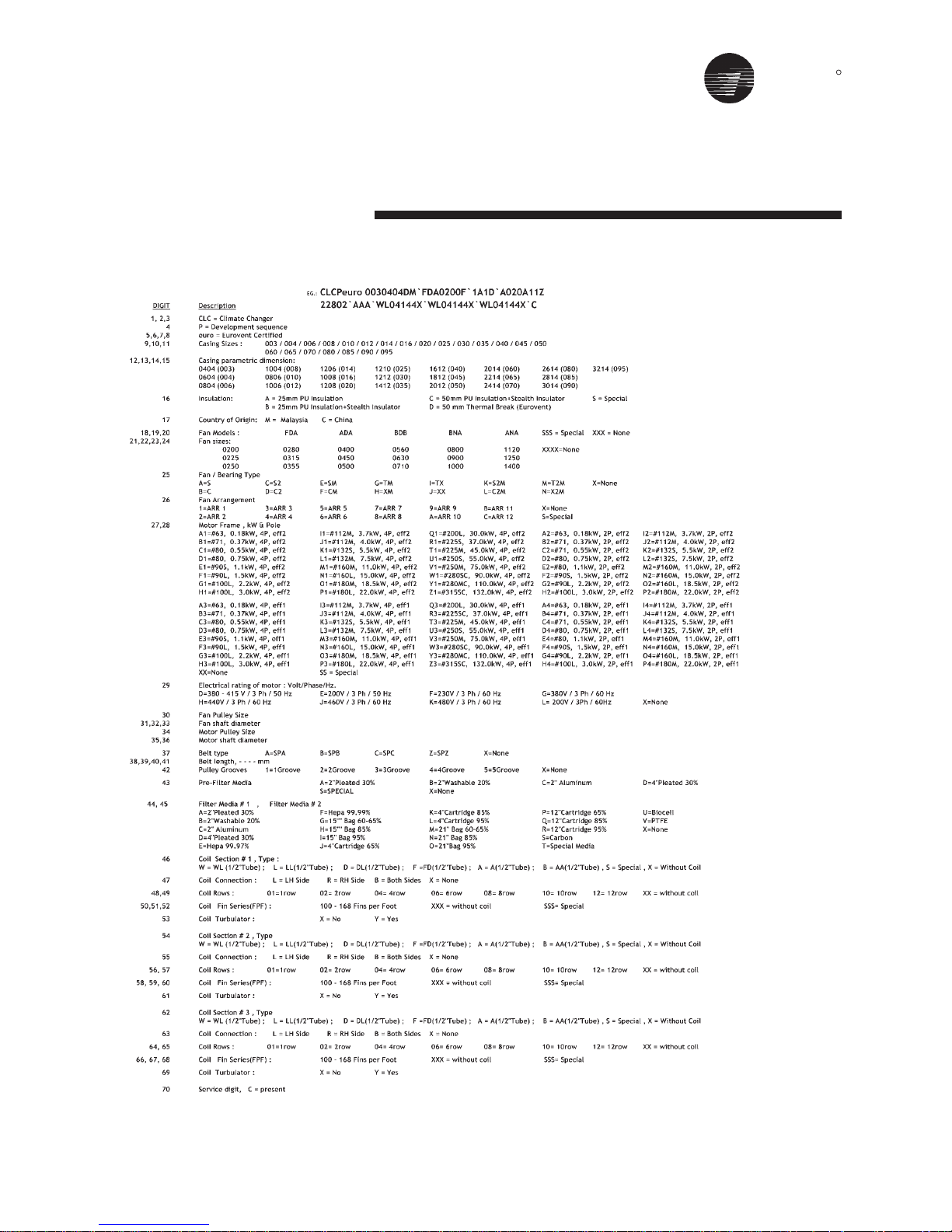

Model Nomenclature

TRANE

R

CLCPEURO

Model Nomenclature

3

TRANE

R

• Resolving Shipping

damage

If damage is found or items are

missing:

1. Report all claims of shipping

damage to the delivering carrier

(transporter) immediately, and

schedule an inspection.

2. Make specific notations concerning

the damage on the freight bill.

3. Keep damaged material in the same

location as received. It is the

receiver’s responsibility to provide

reasonable evidence that damage

was not incurred after delivery.

4. Photograph damage if possible.

5. Do not move or discard damaged

freight packaging materials.

6. Notify the Trane sales representative

of the damage and arrange for

repair. Do not attempt and arrange

for repair. Do not attempt to repair

the unit without consulting the sales

representative. TRANE IS NOT

RESPONSIBLE FOR SHIPPING

DAMAGE.

• Storage Considerations

When storing a TRANE QuantumTM Air

Handler, for a period of time before

installation, it must be protected. The

warranty will not cover damages to

the unit do to negligence during

storage. Indoor storage is ideal and

requires only a few special pre-

cautions.

To protect the unit from damage due to

the elements and prevent it from

possibly becoming a contaminant

source for indoor air quality (IAQ)

Receiving

problems, the unit should be stored

indoors.

When outdoor storage is necessary,

several things must be done to prevent

damage.

• Outdoor Storage

1. Select a well-drained area,

preferably a concrete pad or

blacktop surface.

2. Place the unit(s) on a dry surface or

raised off the ground to assure

adequate air circulation beneath unit

and to assure that no portion of the

unit contacts standing water at any

time.

3. Allow proper clearance around the

unit to perform periodic inspection

and maintenance of the equipment

while in storage.

4. Keep the equipment in the original

shipping container for protection

and ease of handling.

5. Cover the unit securely with a

CANVAS tarp.

6. Ensure that the canvas tarp is

secure.

7. Do not stack units.

8. Do not pile other material on the

units.

9. Loosen belt tension on drive belts.

4

• Nameplate

All of TRANE QuantumTM Air Handler

are identified by a multiple-character

model number. lts use enables owner/

operator, installing contractors, and

service technicians to define the

operation, components and options for

a particular unit. Be sure to refer to the

information printed on the unit

nameplate (figure1) when ordering

replacement or requesting service.

• Delivery Check

All unit sections are securely fasten to

skids for shipping and handling

purpose.

Upon receipt of the unit(s), inspect for

damage that may have occurred during

shipment and any items, which were

ordered but did not arrive with the unit.

Complete the following checks:

1. Visually inspect the exterior unit

casing and all accessories for any

dents, punctures or shipping and

handling damage.

2. Cut all banding (if applicable) loose

from skid, but do not remove the

skids.

3. Check all access doors to confirm

that they are secured with latches.

4. Manually rotate the fan wheel to

ensure free movement of the shaft

and bearings

Inspect the fan housing for any

foreign objects.

5. Inspect the coil(s) for fin damage.

Figure 1

TRANE

R

Rigging and Handling

5

Rigging and Handling

Confirm that factory installed (if any)

attachment brackets are in place and

screws tight, before rigging. The unit

will ship either assembled or as

sections. Before preparing the unit for

lifting, estimate the approximate center

of gravity for lifting safety. Because of

placement of internal components, the

unit weight may be unevenly

distributed, with more weight in the coil

and fan area. Approximate unit weights

are given in Appendix A & B.

Always apply good rigging procedures

when lifting a unit. Before hoisting the

unit into position, be sure that a proper

method of rigging is used, with straps

or slings and spreader bars for

protection and safety during lifting.

Always test-lift the unit to determine

exact unit balance and stability before

hoisting it to the installation location.

DO NOT LIFT THE UNIT WITHOUT

TEST-LIFT FOR BALANCE AND

RIGGING. DO NOT LIFT THE UNIT

ABOVE PERSONNEL. FAILURE TO

OBSERVE THESE WARNINGS MAY

RESULT IN PERSONAL INJURY,

DEATH OR EQUIPMENT DAMAGE.

(See Appendix A & B for components

weight).

NEVER ASSEMBLE OR BOLT

SECTIONS OR SUBASSEMBLIES

TOGETHER BEFORE RIGGING.

ALWAYS RIG SECTIONS OR

SUBASSEMBLIES AS RECEIVED

FROM THE FACTORY.

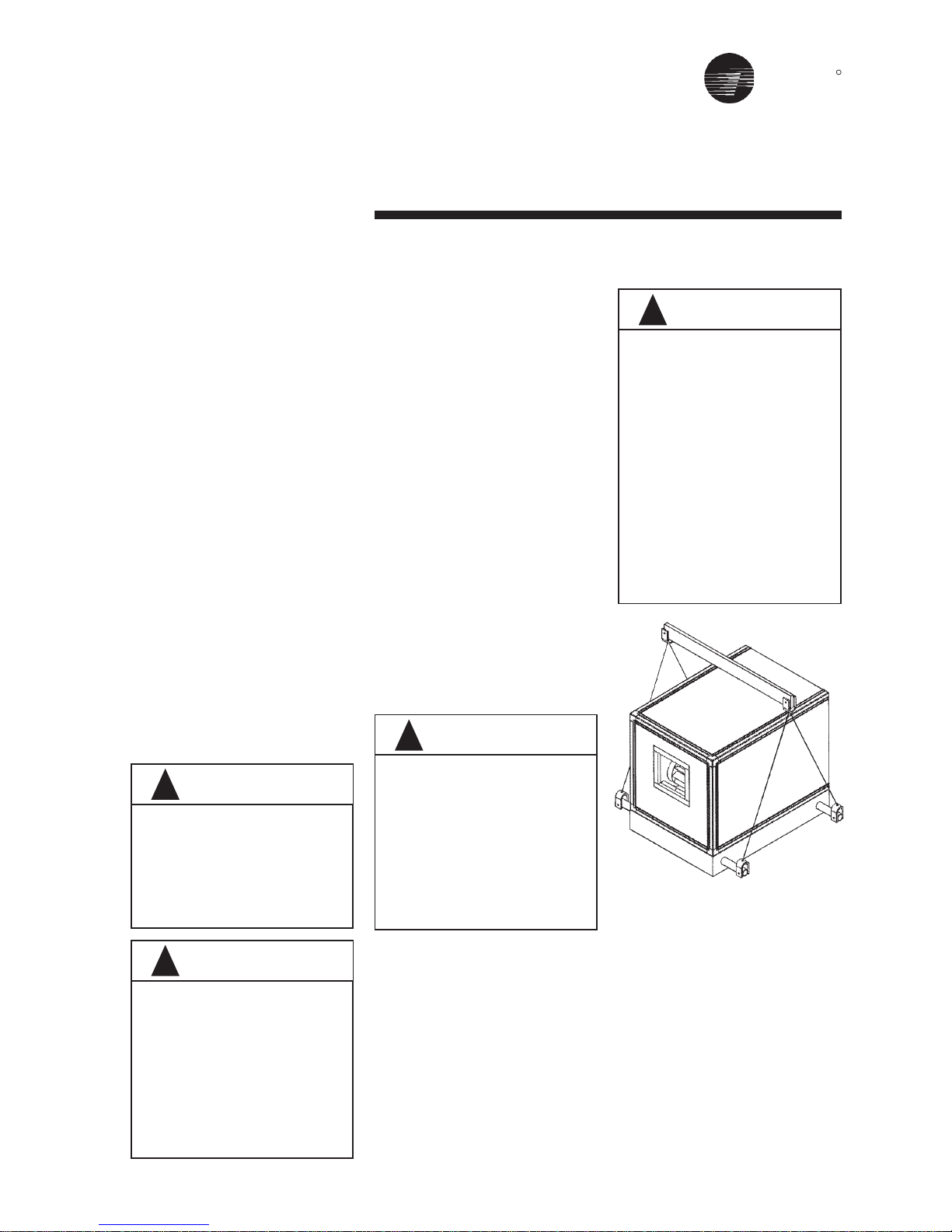

Off Loading

A specific lifting method for offloading

the units is recommended as follows

(See Figure 2):

1. 75mm-diameter lifting holes,or

certified lifting lugs, are provided on

the unit base frame.

2. ALL LIFTING POINTS in one axis of

the unit must be used when

offloading and moving the unit.

3. Slings and speader bars are to be

provided by the rigger and attached

to ALL LIFTING POINTS.

4. The minimum rated lifting capacity

(vertical) of each sling and spreader

bar should be no less than the

shipping weight.

5. The unit must be lifted with care,

avoiding shock load by lifting the unit

slowly and evenly.

WARNING

!

Moving To Position On Site

TRANE QuantumTM Air Handler are

supplied in sections modules, flat

packed, or as a complete unit, in

accordance with the relevant assembly

drawings. Any necessary use of force

during unloading or movement of the

units must only be applied via the unit

base frame or shipping pallet.

NEVER LIFT THE UNITS BY COIL

CONNECTIONS OR BY ANY OTHER

PROTRUSIONS.

THE ROOF IS NOT DESIGNED TO BE

WALKED ON, BUT IF THIS IS

UNAVOIDABLE, ENSURE A MORE

EVEN WEIGHT DISTRIBUTION BY

THE USE OF BOARDS.

FAILURE TO DO SO MAY RESULT IN

SEVERE PERSONAL INJURY OR

DEATH.

Figure 2

WARNING

!

WARNING

!

WARNING

!

ENSURE SLINGS DO NOT FOUL ON

UNIT PROTRUSIONS.

THE CENTRE OF GRAVITY WILL

VARY PER UNIT... POSITION THE

SLING AND SPREADER BARS

CAREFULLY TO COMPENSATE FOR

THIS.

TRANE

R

Rigging and Handling

6

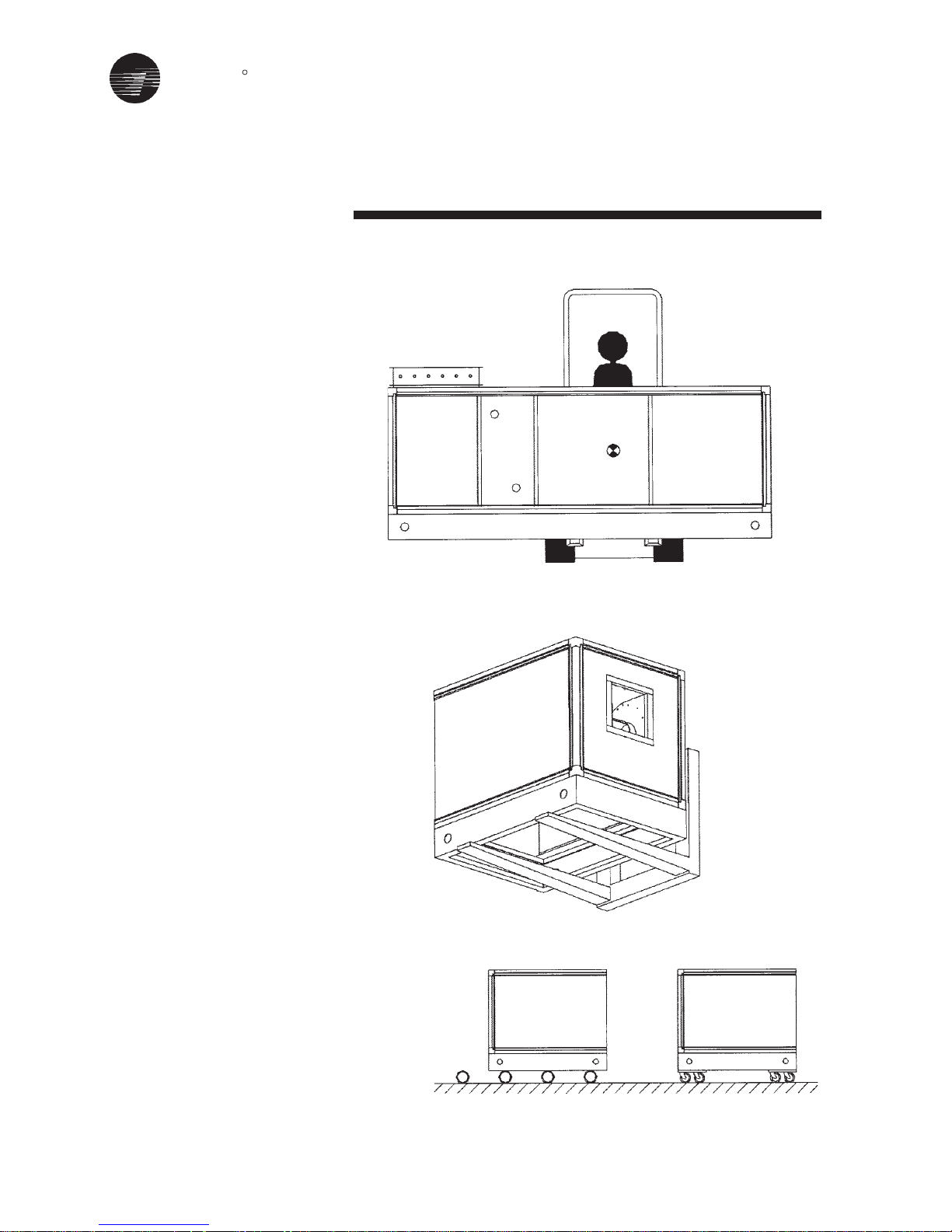

Forklift Trucks

The forks must only be applied under

the unit base frame and not against

the unit base frame. The lift point

should be as near as possible to the

centre of gravity (see Figures 3 and 4).

In the case of larger units the use of

several forklift trucks may be required.

Roller Movement

Units fitted with base frames may be

moved on roller trolley or tubular rollers

(see Figure 5).

Figure 3

Figure 4

Figure 5

TRANE

R

Installation

7

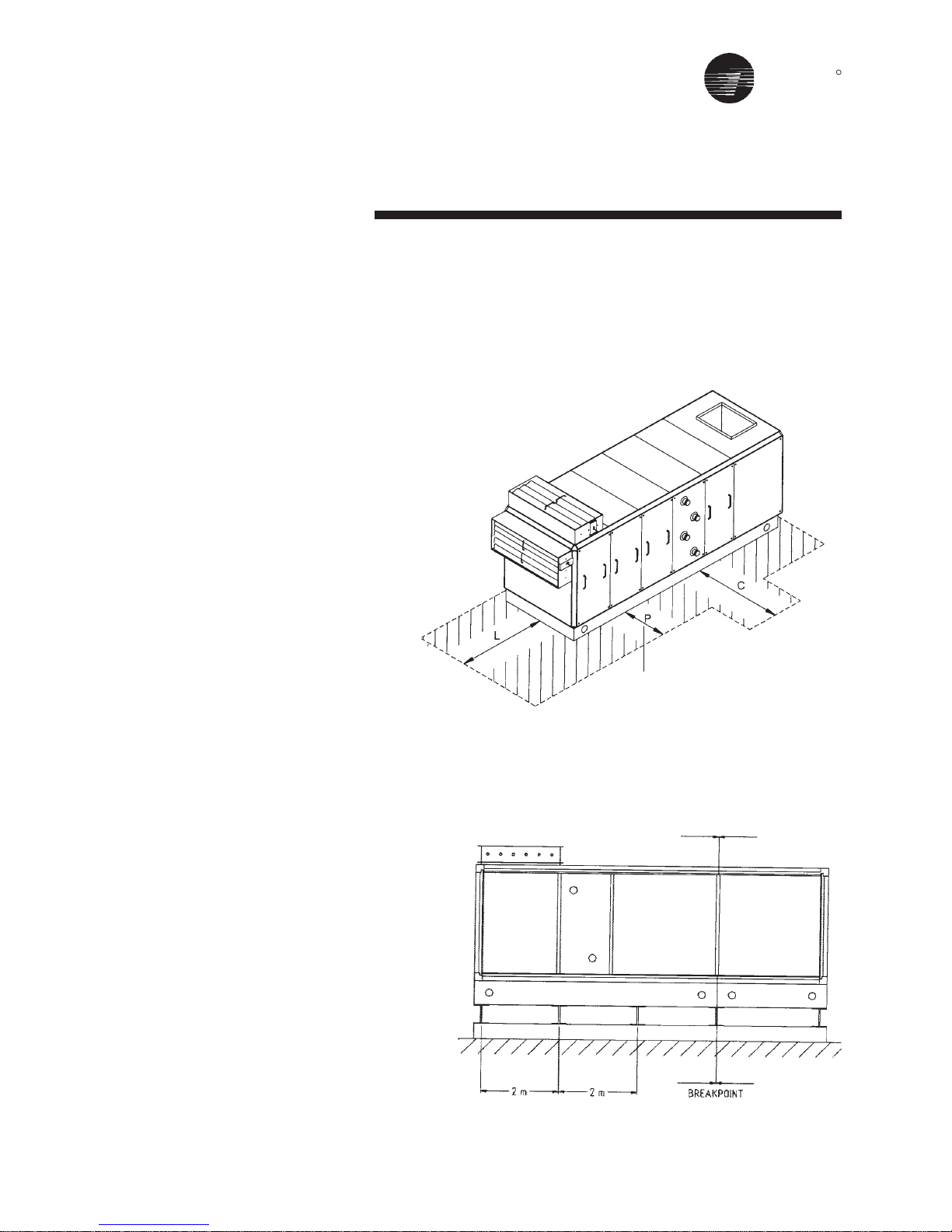

Foundation

When selecting and preparing the unit

site, follow these guidelines:

1. Ensure that the site can support the

total weight of the unit. Unit weight

figures only provide total gross

weights and do not include the

additional weight for water in any

coils.

2. Confirm that the foundation of the

mounting platform is large enough

to include the unit dimensions plus

service plus service access.

3. The floor or foundation must be

level for correct coil drainage and

condensate flow.

4. Provide adequate lighting for

maintenance personnel to perform

maintenance duties.

5. When the unit is positioned on site,

there must be sufficient space

around the unit to ensure that correct

operation and effective main-

tenance can be carried out. Figure

6 gives recommended space

allowances.

• On the designated access side of

the unit, working areas must have

minimum 1 mtr, space (P).

• Allowance for coil connections,

dimension “C” must be dimension

200mm + unit width.

• A clear unobstructed area before

and after an air intake or discharge

is required to ensure correct air

movement. The width of the area

must be >= the width of the unit, and

the depth (dimension “L”) must be

>= 0.5 x the overall unit height.

Complete reinforced concrete

foundations are suitable or strip

foundations may also be used (see

Figure 7).

In the case of strip foundations,

concrete or steel supports are

premissible, but support is required

under breakpoints and every 2 m along

the unit base.

Figure 7 - Air Handling Unit Steels Foundation

Figure 6

P = 1 MTR min

TRANE

R

Installation

8

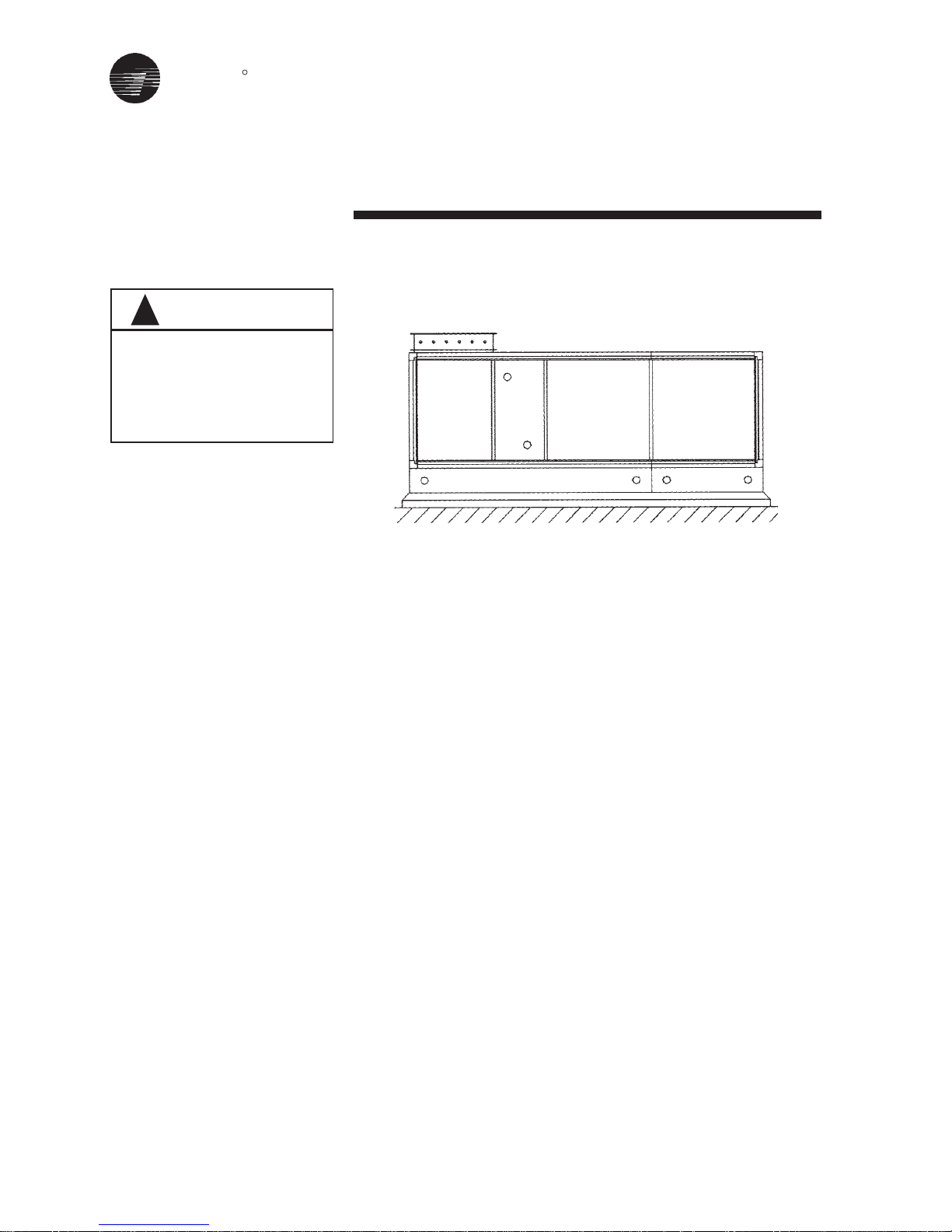

Erection

To minimize noise transmission,

insulation material such as cork

slabbing (TICO pads) or rubber pad

may be placed between the unit base

and the foundation (see Figure 8).

Figure 8 - Air Handling Unit Plinth Foundation

IMPORTANT

!

FAILURE TO PROVIDE A LEVEL

PLINTH OR SUPPORT WILL

RESULT IN DOORS JAMMING

AND AIR LEAKS FROM THE

CASING.

TRANE

R

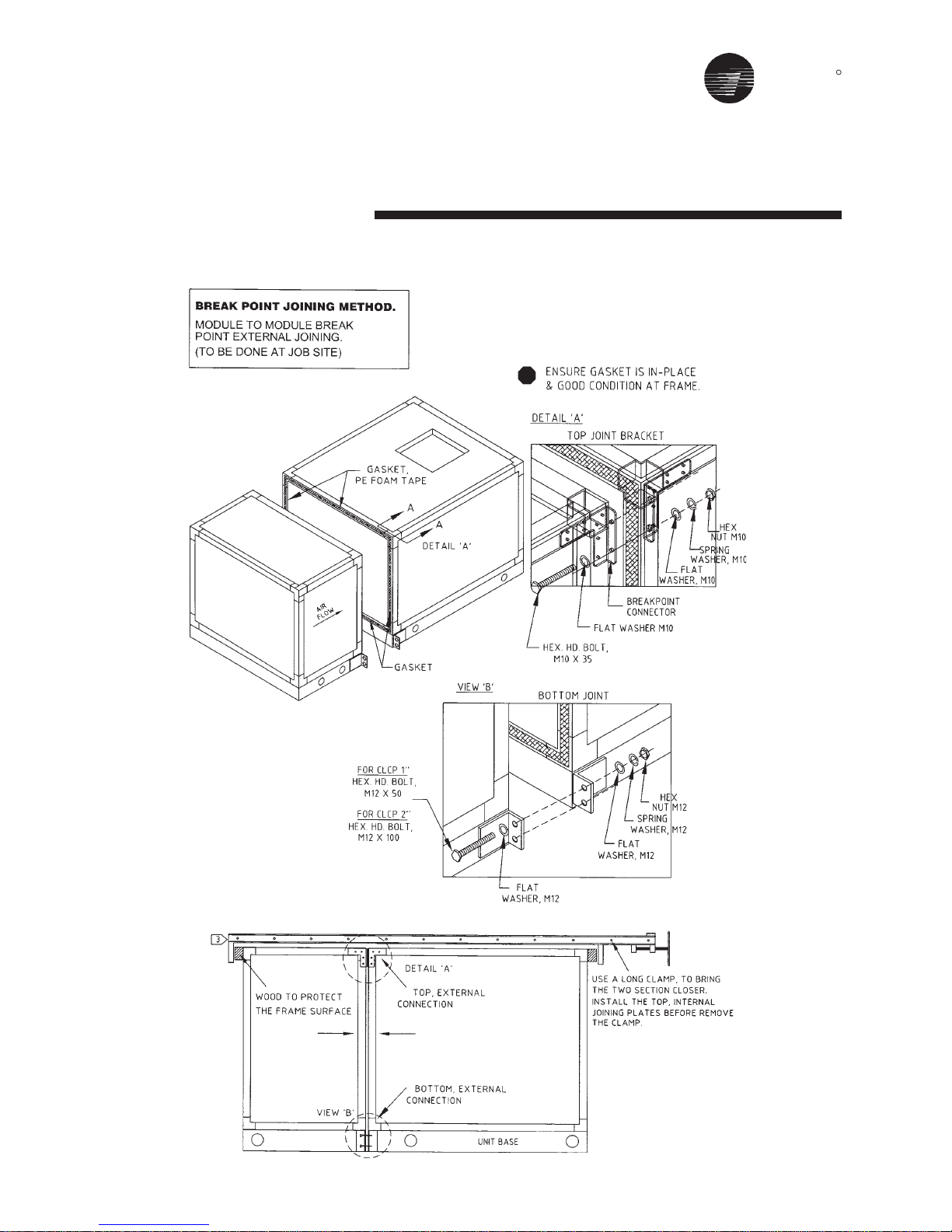

Assembly & Installation

CLCPEuro & CLCPXP

(External connection)

9

TRANE

R

Assembly & Installation

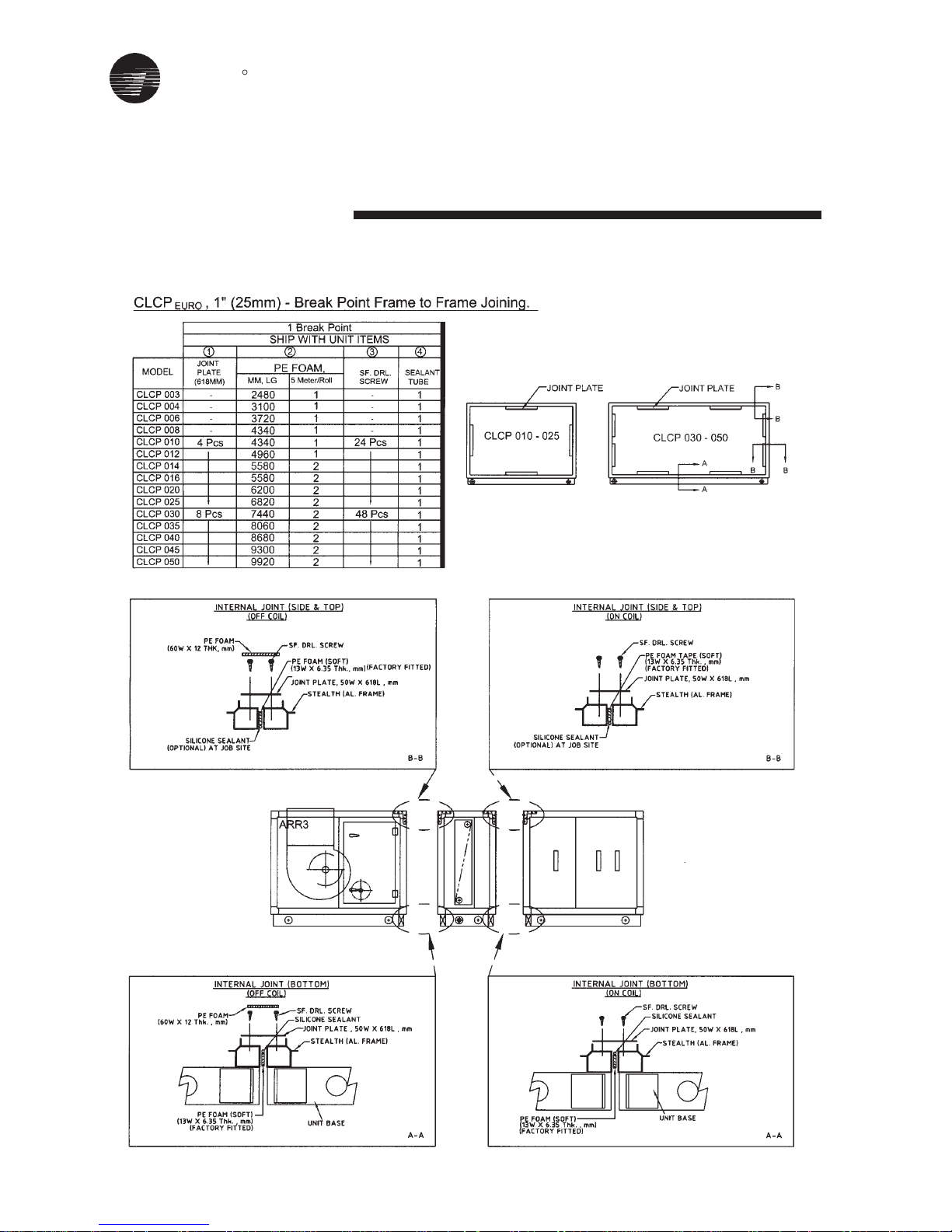

CLCPEuro Break Point (25mm) - Frame to Frame

10

TRANE

R

11

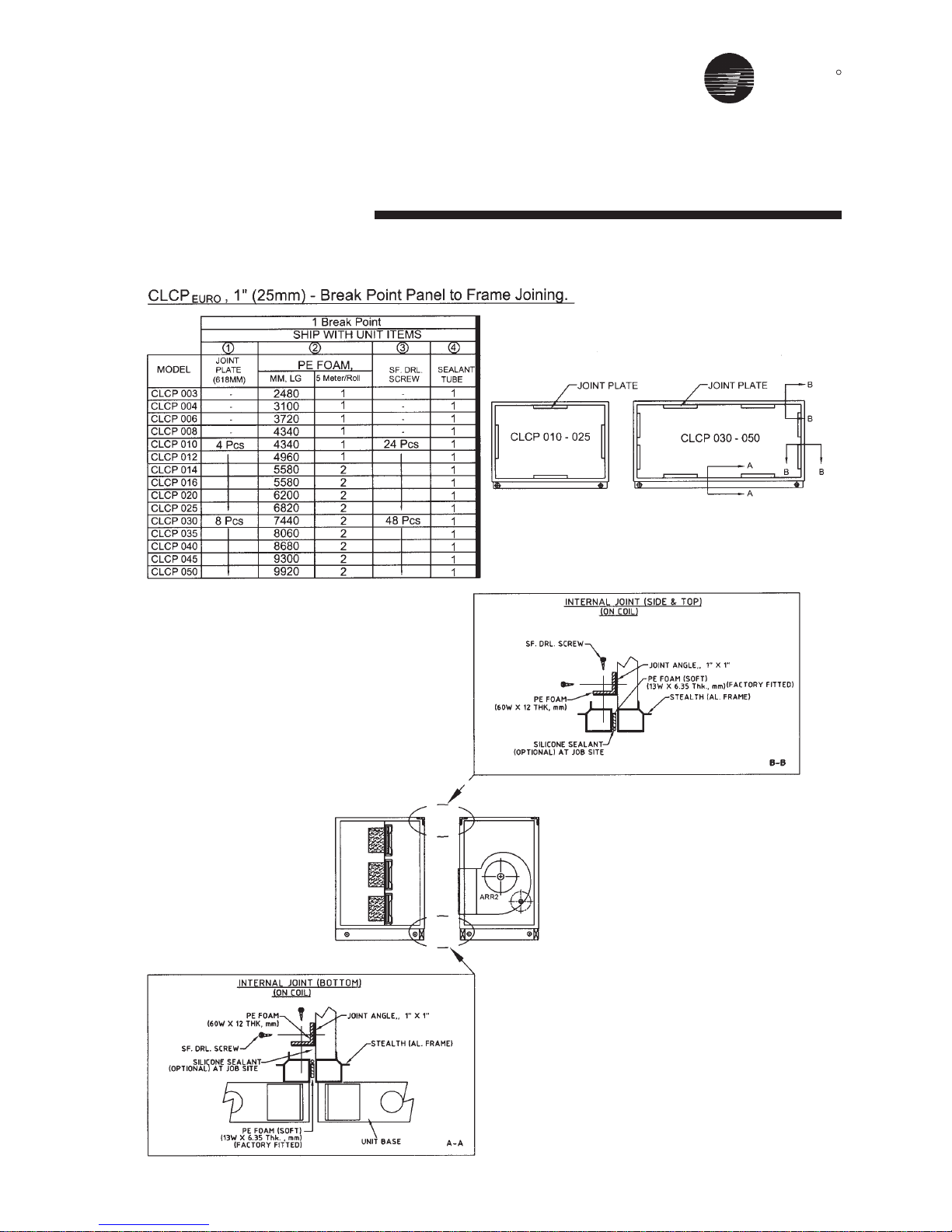

Assembly & Installation

CLCPEuro Break Point (25mm) - Panel to Frame

TRANE

R

12

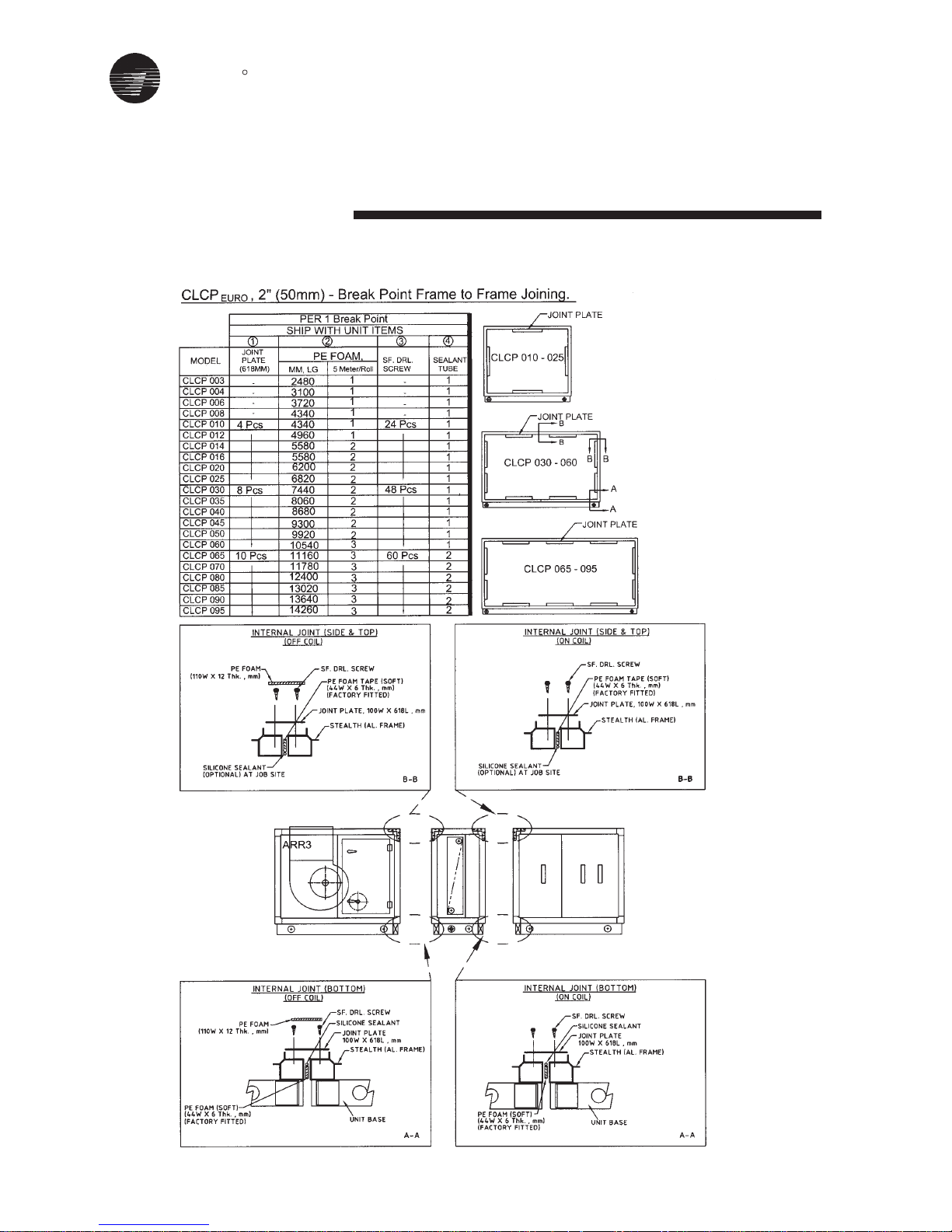

Assembly & Installation

CLCPEuro Break Point 2” (50mm)- Frame to Frame

TRANE

R

Assembly & Installation

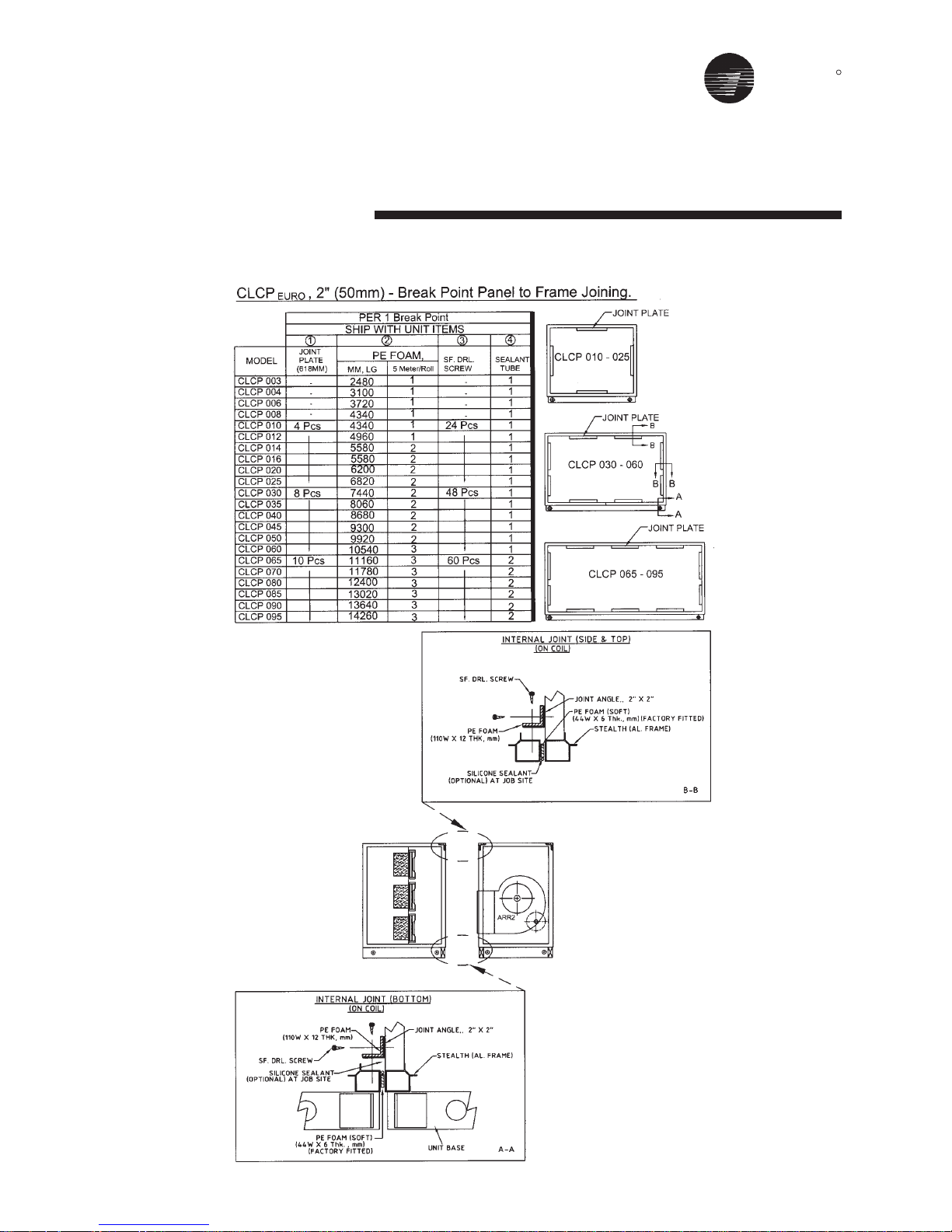

CLCPEuro Break Point 2” (50mm)- Panel to Frame

13

TRANE

R

Assembly & Installation

CLCPEuro Paneling

14

TRANE

R

Assembly & Installation

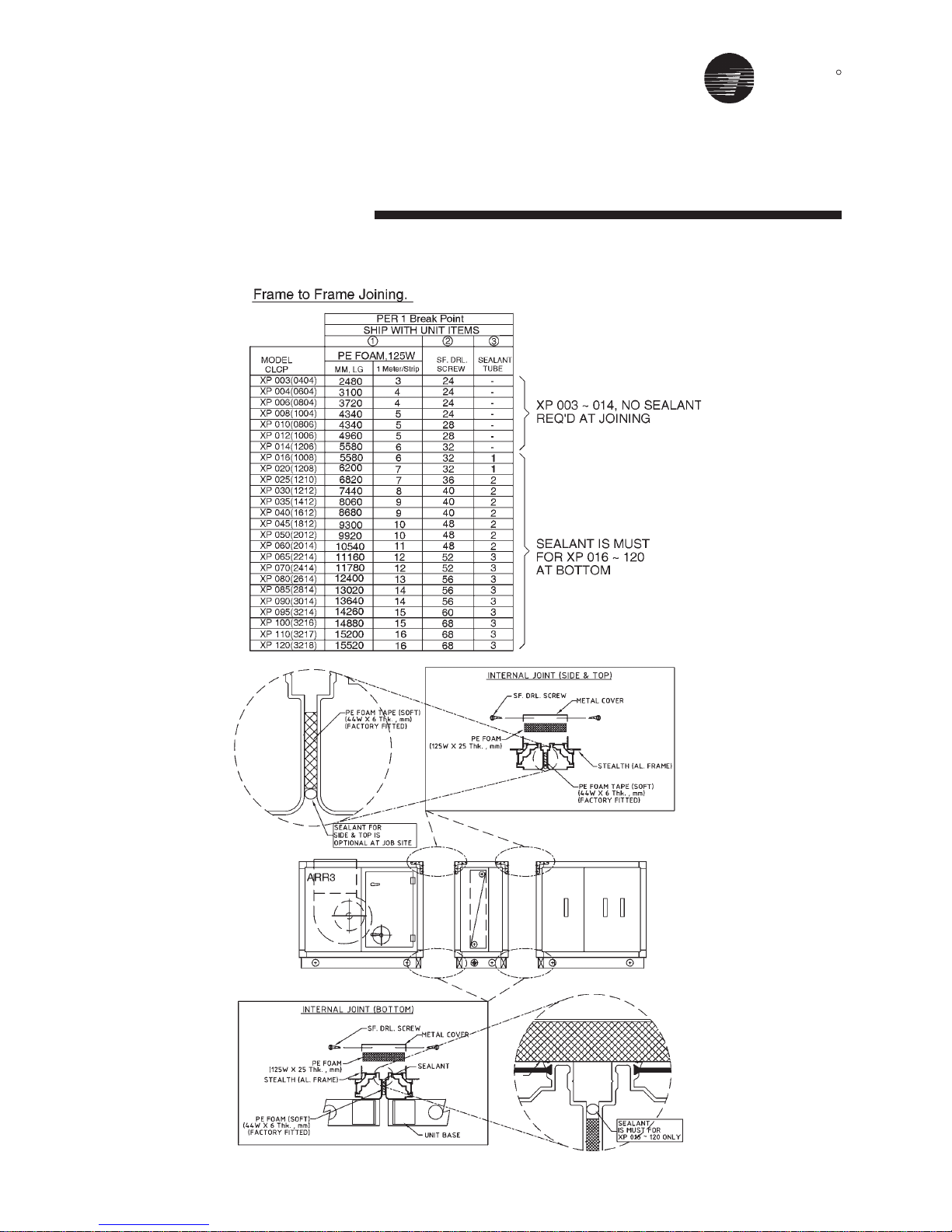

CLCP-XP - Break Point

15

TRANE

R

Assembly & Installation

CLCP-XP - Break Point

16

TRANE

R

17

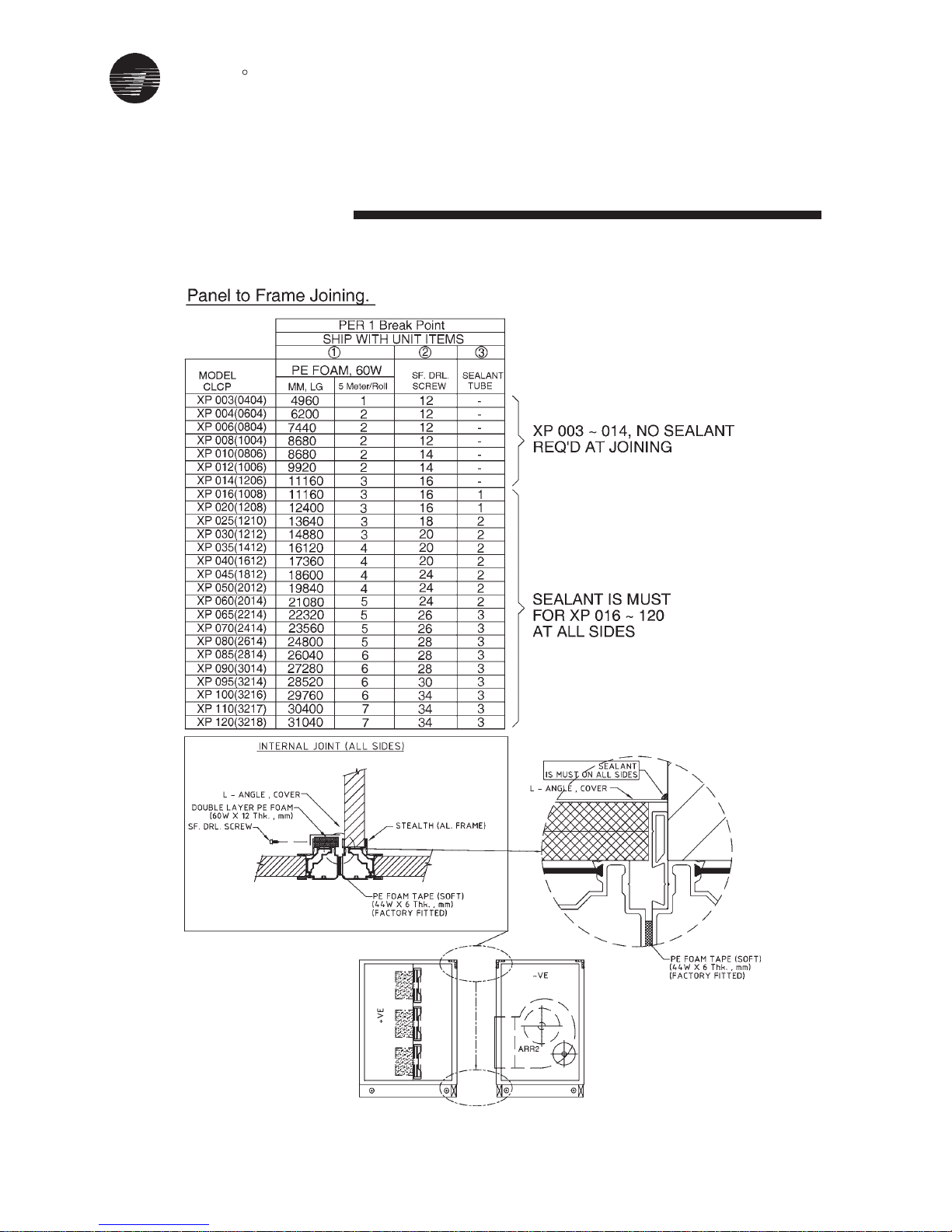

Assembly & Installation

CLCP

TRANE

R

Assembly & Installation

CLCP

18

TRANE

R

19

Assembly & Installation

Piping - Condensate Drain

Pan Connections

On cooling section(s) the drain pan

should always be connected directly

to a trap to ensure proper drainage of

condensate.

Male-threaded, 1-1/2" BSPT condensate drain connection is provided on

one side of the coil section. The main

drain lines and trap must be the same

size as the drain connection.

Pitch the connection line horizontal or

downward toward an open drain and

install a plugged tee to facilitate

cleaning. Condensate lines should not

be connected to a closed drain. This

is to avoid the possibility of drawing

sewer gasses into the unit.

Drain traps must be primed. lf they

are not, the trap is essentially nonexistent and the drain pan will likely

overflow.

CAUTION

!

Units With More Than One

Drain Pan

With the Trane QuantumTM Air Handler,

each module can be ordered with or

without a drain pan.

When more than

one module has a drain pan, you must

trap each module individually.

Connecting all drains to a common line

with only one trap will result in

condensate retention, and possible

water damage to the air handler or

adjoining space.

If a module has a drain pan for cleaning

purposes only, it does not need a trap;

however a cap or shut off valve should

be installed on the drain connection.

Only modules handling condensate,

such as a cooling coil module or

eliminator module, require a trap.

Figure 9

through

Figure 10

are

examples of typical installations.

IMPORTANT

!

Figure 9

Drain Pan Trapping for module under Negative Pressure

H = (1” for each 1” of

maximum negative

pressure) + 1”

J = 1/2 H

L = H + J + Pipe diameter +

Insulation

Figure 10

Drain Pan Trapping for module under Positive Pressure

K = min. 1/2”

H = 1/2” plus maximum

total static pressure

Failure to provide adequate

condensate piping may result in

water damage to the equipment or

building.

The applicable "rule of thumb" for

amount of condensate may as high

as 6 lbs/hr/ton for units serving areas

with high latent heat.

TRANE

R

Assembly & Installation

Chilled Water

Piping - Coil Connection

General Coil Piping Recommendation

Refer to Figure 11 for typical cooling /

heating and steam coil piping.

Proper installation, piping and trapping

is necessary to assure satisfactory coil

operation and to prevent operational

damage. Water inlet and outlet

connections protrude through the coil

section side panel. Follow standard

piping practices when piping to the

coil. Note the following:

1. Support all piping independently of

the coils.

2. Provide swing joints or flexible

fittings in all connections that are

adjacent heating coils in order to

absorb thermal expansion and

contraction strains.

3. When attaching piping to the coil

header, make the connection only

tight enough to prevent leaks, the

maximum recommended torque is

200ft-lbs.

4. Teflon tape or teflon piping

compound should not be used

because of its high lubricity, teflon

makes it easier to tighten the pipe

to the header joint past the point

where an effective seal is created,

thus damage to the coil could result.

5. "White Zinc" compound / pipe

sealer on all threaded connection

is recommended, instead.

20

NOTE: DRAIN AND VENT CONNECTIONS ARE PROVIDED AS

STANDARD ON COIL HEADERS.

IF EXTENDED DRAINS AND VENTS

ARE REQUIRED, THEY MUST BE

FIELD PROVIDED

.

Figure 12

Completely stress-free connections

are essential. The pipework of the coils

should be arranged to facilitate easy

removal of the coil for any required

maintenance purposes.

Figure 11

Typical Piping for Water Coil

IMPORTANT

!

To avoid damaging the coil

connections it is essential to grip

the pipe connection whilst

applying counter pressure to

tighten the joint (see Figure 12).

Use “Back-up wrench” when

attaching piping to coils, on

threaded connections.

TRANE

R

5.

6.

7.

8.

9.

10.

Assembly & Installation

Steam Coil Piping

Type A, AA Steam Coils

These are for central system, industrial

and process application with one row,

opposite-end connections. Maximum

standard operating limits:

Copper tubes: 100 psig and 400oF

Type AA coils feeds alternate tubes.

Refer to Figure 13 for typical steam coil

piping.

1. lnstall a 1/2 inch, 15 degree swing

check vacuum breaker in the

unused condensate return tapping

as close as possible to the coil.

2. Vent the vacuum breaker line to the

atmosphere or connect it to the

return main at the discharge side of

the steam trap.

Note: Vacuum breaker relief is

mandatory when the coil is controlled

by a modulating steam supply or a two-

position (ON-OFF) automatic steam

supply valve.

3. Run the return pipe at the full size of

the steam trap connection except for

the short nipple screwed directly

into the coil condensate connection.

Do not bush or reduce the coil return

tapping size.

4. Proper steam trap selection and

installation is necessary for

satisfactory coil performance and

service life. For installation, use the

following steps:

• Select trap based on maximum

possible condensate rate.

• Locate the steam trap discharge

at least 12 inches below the

condensate return tapping, this

provides sufficient hydrostatic

head pressure to overcome trap

losses and assure complete

condensate removal.

• Float and thermostatic traps are

recommended because of gravity

drain and continuos discharge

operation.

• Use float and thermostatic traps

are recommended because of

gravity drain and continuos

discharge operation.

• Use float and thermostatic traps

with atmospheric pressure gravity

condensate return, with automatic

control or where the possibility of

low-pressure supply steam exists.

• Use bucket traps ONLY when the

supply steams in unmodulated

and 25 psig or higher.

• Always install strainers as close

as possible to the inlet side of the

trap. Do not modulate Type A, AA

coils. Use two position (ON-OFF)

steam supply controls.

Use a V-port modulating valve to

obtain gradual modulating action.

Do not modulate systems with

overhead or pressurized returns

unless the condensate is drained

by gravity to a receiver (vented to

the atmosphere) and returned to

the main by a condensate pump.

At start-up on units with fresh air

dampers, slowly turn the steam on

full at least 10 minutes before

opening the fresh air.

Pitch all supply and return steam

piping down minimum of 1-inch

per 10 feet in the direction of flow.

Do not drain the steam mains or

take-off through the coils. Drain the

mains ahead of the coils through

a steam trap to the return line.

Overhead return require 1 psig of

pressure at the steam trap

discharge for each 2 - feet

elevation to assure continuous

condensate removal.

AV - Automatic or manual air vent

GV - Gate valve

VB - Vacuum breaker

OV - Automatic two-position control valve

21

Figure 13

Typical Piping for Steam Coil

MV - Magnetic valve

FT - Float and thermostatic steam trap

ST - Strainer

CAUTION

!

Condensate must flow freely from

coil at all times to prevent physical

coil damage from water hammer,

unequal thermal stresses, freeze-up

and/or corrosion.

Complete the following recom-

mendations to prevent coil

damage.

CAUTION

!

Caution: Always open the steam

supply control valve slowly to

prevent possible coil damage.

TRANE

R

coil as possible. Base filter-

drier selection on a minimum

pressure drop of 2 psi at the design

condition.

1. Install moisture indicator/sight

glass between the expansion valve

and filter-drier. The moisture

indicator/ sight glass must be sized

to match the size of the liquid line at

the thermal expansin valve.

2. Size liquid line shutoff valve with an

access port using the selected liquid

line OD, and install it close to the

condenser.

3. Minimize use of other valves, tube

bends and reducers since these

items tend to increase pressure

drop and to reduce subcooling at

the expansion valve.

4. The Thermal Expansion Valve (TEV)

must be selected for proper size

and capacity. The size of the TEV

should cover the full range of

loadings. Check that the valve will

successfully operate at the lightest

load condition. Select expansion

valves with external equalizer

connections, and those designed

to operate against a back pressure

of 20 pounds per square inch

higher than actual evaporator

pressure.

5. Install the TEV directly in the coil liquid

connection (distributor) provided.

The liquid distributor must be in a

true vertical position.

Suction Line Components

Install suction line pressure tap on the

leaving side of the evaporator coil near

the TEV sensing bulb location.

Accurate superheat measurement and

thermal expansion valve adjustment

demands that suction pressure be

22

Assembly & Installation

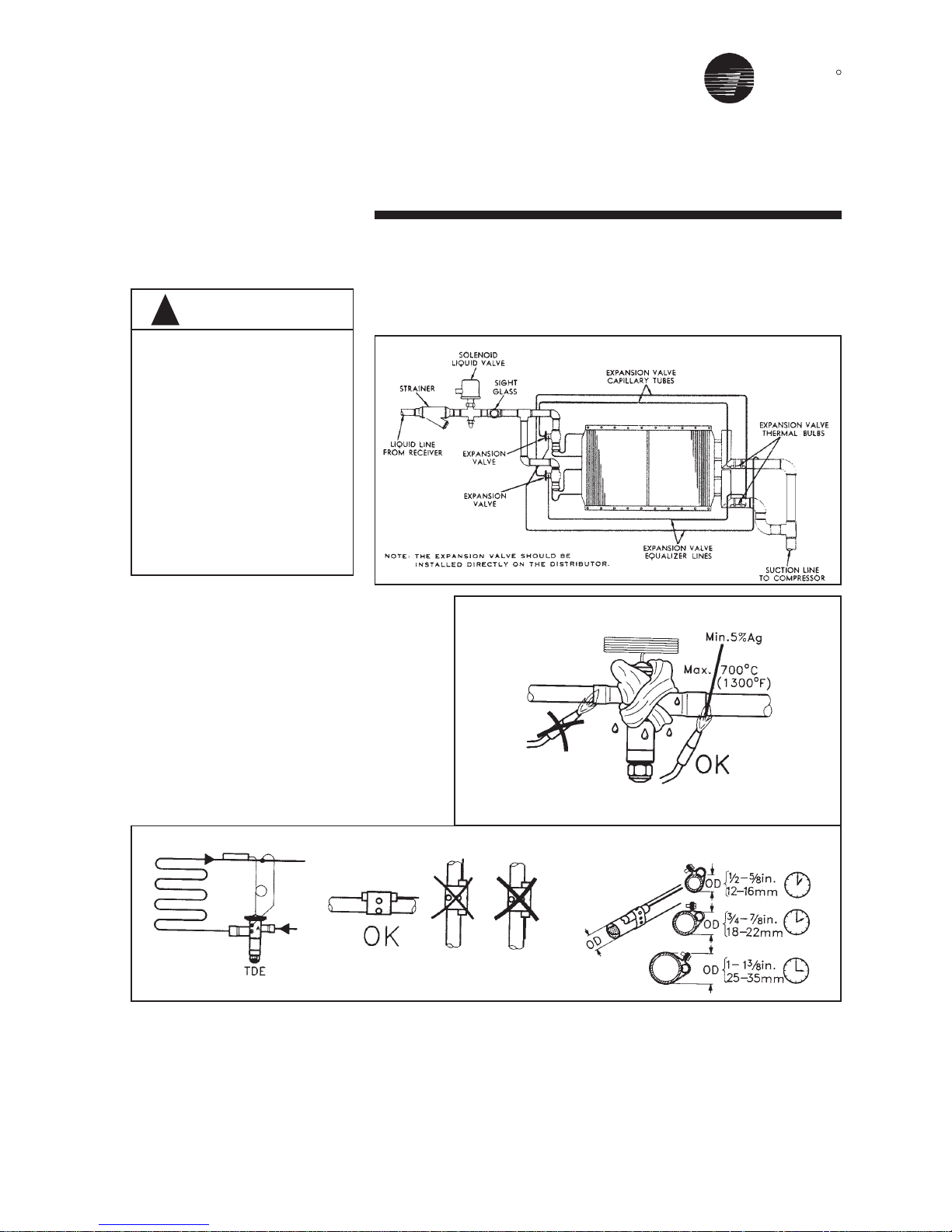

Refrigerant Coil Piping

TYPE FD COILS HAVE BEEN

DEHYDRATED AND CHARGED WITH

A HOLDING CHARGE OF DRY

NITROGEN. 10-20 PSIG TO

PREVENT LEAKS AND SYSTEM

CONTAMINATION, DO NOT BREAK

THE SEALS UNTIL THE COIL IS

INSTALLED.

1. Follow accepted refrigeration piping

practices and safety precautions for

typical refrigerant coil piping and

components.Specific recommen-

dations are provided with the

condensing units, including

instructions for pressure-testing,

evacuation, and system charging.

General recommendations for

component selection and line

sizing follow.

2. Leak-test the entire refrigeration

system after all piping is complete.

3. Charge the unit according to

approximate weight requirements,

operating pressures and super-

heat / subcoling measurements.

4. Adjust the thermal expansion valve

setting if necessary.

General Refrigerant Piping

Recommendations

IMPORTANT: REFER TO THE NOTE

ON THE INSIDE FRONT COVER OF

THIS MANUAL REGARDING

HANDLING OF REFRIGERANTS.

Liquid Line Components

Trane recommends the use of a

properly sized liquid line filter-drier

installed upstream from the expansion

valve and as close to the evaporator

measured near the evaporator coil.

Liquid Line Sizing

All compressors have a Refrigerant

Charge Limit (RCL) that must not be

exceeded. Since the RCL and

pressure drop are in direct conflict with

each other, Trane recommends that the

liquid line be sized as small as

possible, while maintaining a low

enough pressure drop to ensure

5°F(3°C) of subcooling at the

expansion valve.

Suction Line Sizing

Suction line tubes must be sized to

maintain refrigerant vapor velocities

that are high enough to ensure oil

entertainment under all operating

conditions.

It is not necessary to pitch horizontal

suction lines toward the compressor

when refrigerant coils is used with

Trane condensing units that are

designed with a gas trap in the suction

line just prior to the compressor.

TRANE

R

23

Assembly & Installation

Figure 14

Typical Piping for Refrigerant Coil

To avoid equipment malfuntion,

use care when brazing or solder-

ing so that distributor tubing is not

restricted or blocked. To braze

Thermostatic Expansion Valves

(TXV) avoid direct flame (figure 15)

to the valve body and avoid

excessive heat on diaphragm. As

an extra precaution. a wet cloth may

be around the body and element

during brazing operation.

CAUTION

!

Figure 15

Solder Technique

Note: Flame should heat away from

TXV element

TRANE

R

Start - Up

Perform the following steps prior to

starting the unit.

1. Inspect electrical connections. They

should be clean and secure.

Compare actual wiring with specific

diagrams provided on the unit.

2. Check piping and valves for leaks.

Open or close the valves to check

for proper operation. Drain lines

should be open.

3. If equipped with a refrigerant coil,

charge and leak-test the unit and

get it ready for operation according

to instructions provided with the

condenser equipment.

4. Check that all air filters are in place

and positioned properly. Under

Periodic Maintenance, see section

titled “Air Filters.”

5. Close and secure all unit access

doors. Check that the latch set

screws are tight.

6. Remove all foreign material from the

CAUTION

!

drain pan and check drain opening

and condensate line for obstruc-

tions.

7. Prime the DRAIN TRAP.

Start-up Procedures

After completing all start-up checks

and procedures, the unit may be

started. The following checks and

adjustments should be made during

initial start-up:

24

The use of untreated or

improperly treated water

in unit coils may cause

scaling, erosion, corrosion, algae, smile or other

equipment damage.

Consult a qualified water

treatment specialist to

determine if water

treatment is required. The

Trane Company assumes

no respon-sibility for

equipment damage

caused by untreated or

improperly treated water.

If the unit was stored for an extended

period of time, the following items

should be checked before starting the

unit.

1. Inspect motor bearings for moisture

and rust. Replace bearings if

necessary and repack with new

grease.

2. Check motor winding. An

acceptable winding resistance

reading is from 6 meg-ohms to

infinity. If reading is less than

5 meg-ohms, winding should be

dried out in an oven or by a

blower.

3. Inspect the entire motor for rust and

corrosion.

4. Lubricate the motor as instructed in

the section titled “Periodic

Maintenance,” or as indicated by the

maintenance tag on the motor.

5. Bump-start unit and observe the fan

wheel for proper rotation, as

indicated by rotation arrow located

on fan housing.

6. Measure the motor voltage and

ampeage on all phases to ensure

proper operation. The readings

should fall within the range given

on the motor nameplate.

Maximum allowable voltage imbalance

is two percent. Voltage imbalance is

defined as 100 times the sum of the

deviation of the three voltage from the

average, divided by twice the average

voltage. For example, if the three

measured voltages are 221, 230 and

227, the average would be 226 volts.

WARNING

!

Disconnect electrical

power prior to access into

a fan or ductwork. Even

when locked out

electrically, fans may

cause injury or damage if

the impeller is subject to

“wind-milling.” The

impeller should be

secured to physically

restrict rotational movement. Failure to secure

impeller can cause severe

personal injury r death.

Disconnect electrical

power source when

connecting or disconnecting electrical wires for

test procedures. Do not

open service access

doors while the unit is

operating. Failure to

exercise caution or while

inspecting. unit operation

may result in injury or

death from electrical

shock, air movement or

rotating parts.

TRANE

R

Sheave Alignment

Align the fan and motor sheaves by

using a straightedge. The straightedge

must be long enough to span the

distance between the outside edges

of the sheaves. For more details refer

to maintenance section.

Start - Up

25

The percent of voltage imbalance is

then calculated:

In this example, 2.2 percent imbalance

is not acceptable and the power

company should be notified to correct

it.

7. Check unit vibration if the fan speed

is changed more than 5% from the

original designed rpm, or if parts

such as shafts, fan wheels, bear-

ings, or other drive components are

replaced. Do not exceed max. fan

rpm.

8. Pay particular attention to any

vibration, noise or overheating of the

motor and fan bearings.

(Bearings may run warm during

break in.)

Excessive Vibration

EXCESSIVE VIBRATION MUST BE

CORRECTED TO PREVENT BEARING AND SHAFT DAMAGE. SEE THE

SECTION TITLED “TROUBLESHOOTING” FOR DETAILS ON THE

COMMON CAUSES FOR VIBRATION.

Determine Fan RPM

Fan rpm can be determined by using a

strobe-type tachometer, or revolution

counter.

100 x {[226-221] + [230-226] + [227-226]}

2 x 226

= 2.2% (Unacceptable)

TRANE

R

Maintenance

Periodic Maintenance

Checklist

The following checklist describes the

suggested maintenance schedule to

maintain proper operation of the unit.

Detailed procedures for owner-

operator maintenance checks are

given after this checklist.

After 48 Hours Operation

Belts have acquired their permanent

stretch. Readjust but do not overtighten.

Weekly

Observe unit weekly for any change

in running condition and any unusual

noise.

Every Month or weekly

Check air filters. Clean or replace if

clogged or dirty. Change bag filters

when pressure drop is 1-inch W.G.

Every Three to Six Months

Check greasing on fan and motor.

Align fan and motor sheaves (pulley).

Tighten sheaves setscrews to the

proper torque.

Check and adjust fan belt tension.

Tighten electrical connection.

lnspect coils for dirt build-up or coil

freeze up

Every Year

lnspect the unit casing for corrosion.

lf damage is found, clean and repaint

the surface with a rust-resistant primer

and vinyl chlorinated lacquer.

Clean the fan wheels and fan shaft.

Remove rust with emery cloth and

apply a coat of LPS#3 or an equivalent.

lnspect the condensate drain pan

and drain line, remove sludge or

foreign materials that might obstruct

proper drainage. Remove obstacles.

Check damper linkages, set-screws

and blade adjustment for proper

damper operation.

lnspect the control and power box

wiring for secure connections and

insulation.

Rotate the fan wheel and check for

obstruction in the fan housing. The

wheel should not rub on the fan

housing. Adjust the center if necessary

and tighten wheel setscrews to the

Disconnect electrical power prior to

access into fan or ductwork. Even

when locked out electrically, fans

may cause injury or damage if the

impeller is subject to "windmilling".

The impeller should be secured to

physically restrict rotational

movement can cause severe

personal injury or death.

proper torque.

Check condition of gasketing and

insulation around unit, door and

damper.

Examine flex connections for cracks

or leaks. Repair or replace damage

material.

WARNING

!

26

Disconnect electrical power and

allow rotating parts to stop before

servicing the unit. Exercise caution

if unit must be on for test or

maintenance procedures. Failure to

do so may result in injury or death

from electrical shock or moving

parts.

WARNING

!

IMPORTANT

!

Small & Medium size fans are

furnished shielded bearings. The

bearings are lubricated for life

and maintenance free. If re-

lubrication is necessary, on

larger fans it is recommended to

use a lithium base grease

suitable for all temperatures

within the operational limits.

TRANE

R

Maintenance

27

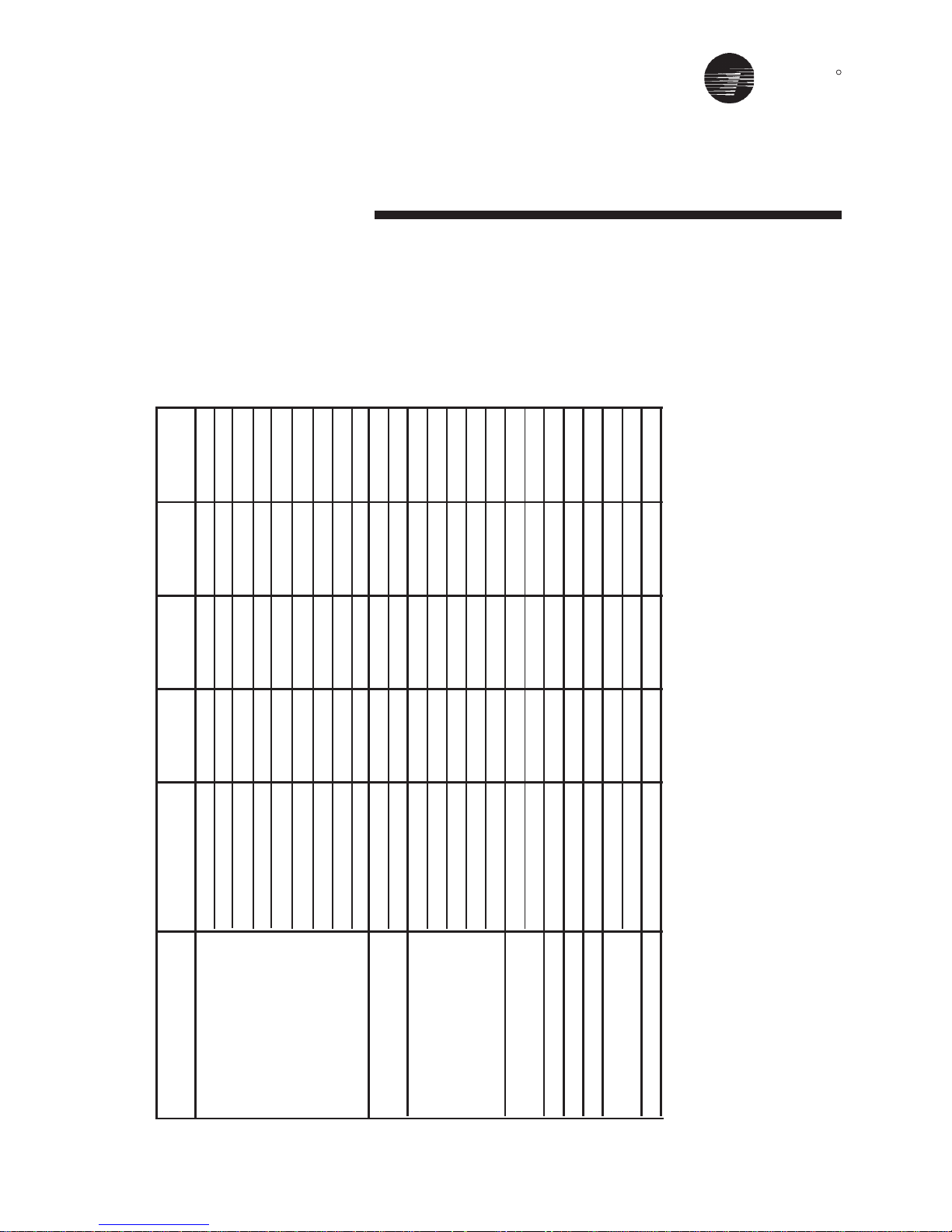

Maintenance Plan

The following table (see Table 1) gives recommended maintenance intervals for the CLCP unit. Intervals are base upon

normal running conditions, in a moderate climate, and assuming 24 hour running.

Units operating outside these guideline may require shorter or longer maintenance intervals.

Component

Fan / Motor

Filter

Coils

Humidifiers

Dampers

Attenuators

Inlet / Outlet

Energy Recovery Componetnts

Controls

Check the

following

Fan In General

For Corrosion

Flexible Connection

Anti-Vibration Mounts

Drainage

Fan Bearing

Motors In General

Motor Bearing

Belt Drive In General

Panel Or Bag Filters

Roll Filters

Fin Block / Fin Bundle

Frost Protection

Drainage

Drop Eliminator

Steam Coils

Scaling

Condensate Drain

Dampers

Scilencers

Hoods And Louvers

Plate Heat Exchangers

Themal Wheel

Control Box And Wiring

Table 1 - Recommended Maintenance Intervals

Weekly

Yes

Yes

Yes

Monthly

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

3 - 6 Monthly

Yes

Yes

Yes

Yes

Yes

Yes\

Yes

Yes

Annual

Yes

Yes

Yes

Yes

Yes

TRANE

R

Maintenance

The maintenance interval periods are

stated, guidelines only. Any large

deviations in the pattern of usage may

necessitate further maintenance

attention.

1. Fan

If the fan / motor assembly is going to

be stored for two weeks before use,

the fan should be rotated by hand at

weekly intervals to avoid bearing

damage.

If storage will be over one month it is

recommended that the belts be

slackened as well.

Check for soiling, damage, corrosion,

and any tendency to bind. Clean as

necessary.

Check that the flexible connection are

securely fixed.

Check the function of all antivibration

mounts.

Check for any obstructions or

blockages of the air intakes and

discharges.

Check the traps for leaks or blockages

and prime as necessary.

2. Bearing Test

Check that the fan bearing is tightened

and is not unduly noisy, by sounding it

using a metal bar as a conductor.

Where a belt guard has been supplied,

check that it is fitted correctly.

If there is any irregular noise or

knocking, renew both bearings. Fan

bearing are greased for life, but larger

units with standard bearings require

annual lubrication. These have grease

nipple. In the case of extreme running

conditions, lubricate in accordance

with the following recommendations:

Recommended lubricants;

ALVANIA

GREASE 3 (SHELL)

MOBILUX 3 (MOBIL)

BEACON 3 (ESSO)

SKF 28 (BALL BEARING

GREASE)

3. Fan Motors

lnspect periodically for excessive

vibration or temperature. Operating

conditions will vary the frequency of

inspection and lubrication. Contact the

motor manufacturer or Trane for

lubrication instruction. Most smaller

frame motors comes without grease

nipple where the bearings are

permanently sealed.

The motors with double shielded

bearings are lubricated for life and

cannot be relubricated.

W.E motors up to 132 frame and TECO

and Brook Hansen motors up to 180

frame comes with sealed for life

bearings, while motors above this

28

WARNING: DISCONNECT POWER

SOURCE FOR MOTOR

LUBRICATION. FAILURE TO DO SO

MAY RESULT IN INJURY OR DEATH

FROM ELECTRIAL SHOCK OR

MOVING PARTS.

!

To re-lubricate the motor, complete the

following:

1.Turn the motor off. Make sure it

cannot accidentally restart.

2. Remove the relief plug and clean out

any hardened grease.

3. Add fresh grease through the fitting

with low pressure grease gun.

4.Run the motor for few minutes to

expel any excess grease through

the relief vent.

5. Stop the motor and replace the relief

plug.

Table2

Motor Greasing lntervals

Standard condition: 8 hour operation

per day with rated or light loading in a

clean and low vibration environment.

Severe condition: 24 hour operation per

day with rated/light loading or in a dirty/

dusty environment or where the motor

is subject to vibration/light shock

loading.

Grease Type:

TECO/Brook Hansen motor - Use

Esso Unirex Lithium N3 grease.

W.E motor - Use Shell Alvania R3.

range, have open bearings with "flush

through" re-greasing facilities.

IMPORTANT

During maintenance operation

the unit must be compelety

isolated and precautions teken

to prevent any premature restart.

IMPORTANT

Do not overlubricate bearings.

Excessive pressure caused by

overlubrication can displace

bearing grease seals or cause

grease to overheat the bearing,

resulting in premature bearing

failure.

TRANE

R

4. Air Filters

Appendix D provides filter size, type and

quantity. To replace throwaway filters,

install new filters with the directional

arrows pointing in direction of airflow.

To clean permanent filters wash under

a stream of water to remove dirt and

lint. Remove oil filter (aluminum or

grease filter) with a wash of mild alkali

solution. Rinse in clean, hot water and

allow to dry. Coat both sides of the filter

by immersing or spraying it with Air

Maze Filter Lote W or equivalent. Allow

to drain and dry for about 12 hours.

5. Drain Pans

Inspecting Cleaning

The condensate drain pan and drain

line must be checked to assure that

the condensate drains as designed.

This inspection should occur a

minimum of every six months or more

often as dictated by operating

experience.

For units with sloped drain pans: If

evidence of standing water or

condensate overflow exists. steps

should be taken to identify and remedy

the cause immediately. Refer to the

troubleshooting section of this manual

for possible causes and solutions. If

microbial growth in the drain pan is

observed, it should be cleaned and

removed immediately. Drain pans

should be cleaned using the following

procedure:

1. Disconnect all electrical power to the

unit.

2. Don the appropriate personal

protective equipment (PPE).

3. Remove all standing water.

4. Use a scraper or other tools to

remove any solid matter. Remove solid

matter with a vacuum device that

utilizes high efficiency particulate

arrestance (HEPA) filters with a

minimum efficiency of 99.97% at 0.3

micron particle size.

5. Thoroughly clean the contaminated

area(s) with a mild bleach and water

solution or an EPA-approved sanitizer

specifically designed for HVAC use,

Carefully follow the sanitizer

manufacturer’s instructions regarding

the use of the product.

6. Immediately rinse the drain pan

thoroughly with fresh water to prevent

potential corrosion from the cleaning

solution of the drain pan and drain line

components.

7. Allow the unit to dry thoroughly before

putting the system back into service.

8. Determine and correct the cause of

the microbial contamination.

9. Be careful that the contaminated

material does nit contact other areas

of the unit or building. Properly dispose

of all contaminated materials and

cleaning solution.

6.Coil Cleaning

Steam, hot water and chilled water

coils should be kept clean to maintain

maximum performance. lf fins become

dirty, clean with steam and detergent,

hot water spray and detergent, or one

of the commercially available chemical

coil cleaners. Rinse coils throughly

after cleaning.

In the event of coils being out of com-

mission for some time, it is advisable

to completely drain down the coil. On

each occasion when refilling is

undertaken, check that the coil is

effectively vented.

Periodic cleaning of the coils is

required.

Dirty coils have increased airside

pressure drops and reduced heat

transfer, thus unbalancing the cooling

or heating system.

Cleaning

In the event that fin edges have been

bent, they can be straightened with the

aid of a coil comb.

The cleaning is carried out with the unit

intact using a powerful vacuum cleaner

on the dust-contamainated side. If the

unit is very dirty it will need to be

removed and wet cleaned.

If required, soft cleaning brushes may

be used ensuring that the heat

exchanger fin are not damaged.

Frost protection

Check that frost protection is working

before the commencement of each

winter period. Ensure that the frost

sensor is correctly installed and fitted

and is working within the correct

temperature range.

Drop eliminator

Check the cleanliness of the droplet

separator section and the blades

annually. If the blades are dirty, remove

and clean them. Contamination can

result in damage through water

droplets in the system’s performance.

Ensure that the blades are correctly

repositioned and that they are not

distorted.

Maintenance

29

Follow all directions provided with

chemical cleaners to avoid personal

injury and/or coil damage.

Commercially available chemical

cleaners may contain caustic or

hazardous agents.

WARNING

!

TRANE

R

Maintenance

Direct expansion coils

Never use hot water or steam to clean

these coils. During normal opeartion,

the fin block must not ice up. If this

occurs, check the refrigeration system.

Refrigerant coils should be kept clean

to maintain maximum performance. If

fins become dirty, clean with cold water

and detergent or one of the

commercially available chemicals coil

cleaners. Rinse coils thoroughly after

cleaning.

7. Coil Winterization

Provisions must be made to drain

those coils that are not in use when

subjected to freezing temperature.

To drain these coils, blow out the coils

with compressed air, fill and drain the

tubes with full-strength ethylene glycol

several times, and then drain the coil

as completely as possible.

30

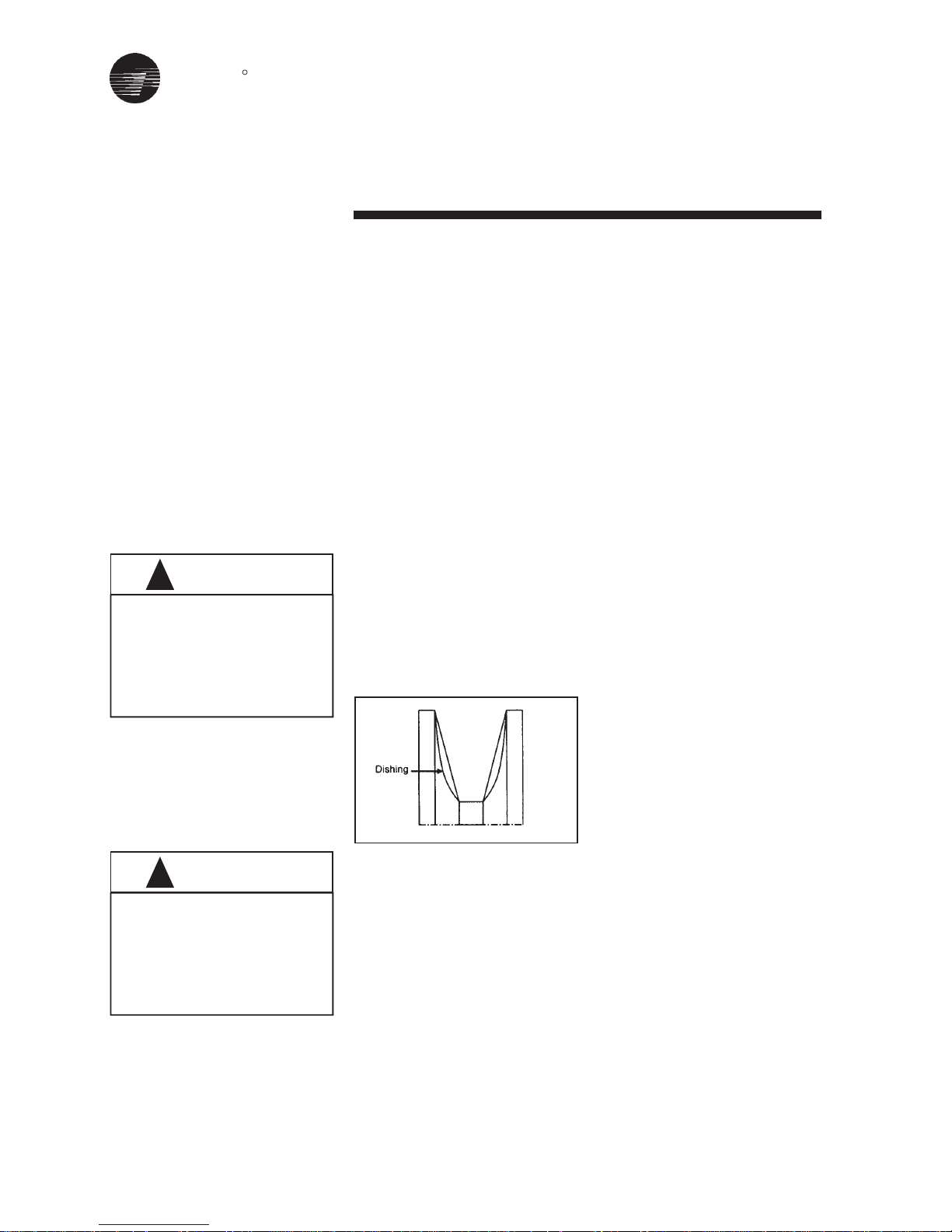

8. Pulley and Belt

Proper installation techniques will

assure that you get full service life and

minimum down time from your belt

drives.

1. Turn machine OFF and lock out

power source.

2. Remove belt guard, loosen motor

mounts and shorten center distance

between pulleys. Remove old belts.

3. lnspect. Repair or replace drives

components.

• Clean oil, grease and debris from

pulleys, remove rust with wire

brush.

• lnspect and replace damage

pulleys. Get your moneys worth

from a new set of belts by checking

and replacing worn or damaged

pulleys. ln the long run,

replacement pulley cost will more than

be recovered in increased belt life,

reduced downtime, and lower

maintenance expenses.

Check following:

a) Worn groove sidewalls, "Dishing"

should not exceed 1/32"(0.8mm) for

individual belts. With a banded belt,

dishing should not exceed 1/

64"(0.4mm). When a banded belt

rides too low in worn pulley

grooves the tie band can be cut by

the flanges between the grooves.

b) Shiny pulley groove bottoms. This

is a sure sign that the belt has

bottomed out. The resulting

slippage shortens belt life.

c) Wobbling and/or damaged pulleys.

Generally caused by improper

pulley or bushing installation,

wobbling and/or damaged pulleys

can unbalance a drive, wear out

belt rapidly, and damage bearings

and bend shafts.

Check and repair worn bearings and

bent shafts.

4. Select replacement belts.

Replace all belts on a drive with a new

matched set.

a) Do not mix old and new belts on a

drive. A new belt will ride higher in

the pulley groove and operate at a

higher tension than an old belt.

Running them together will

damaged the new belt as it cannot

carry its share of the load.

b) Do not mix belt from different make,

because dimensions and

constructions will vary running such

"Mis-Matched" belts will not give full

service life.

c) Replace with correct type and cross

section belt. Matched SPA section

belt with SPA section pulleys. Do not

put a SPA belt section on a SPB

section pulley. Also dimensionally

similar belts can have very different

horsepower rating.

5. lnstall new belts

• Loosen the drive take up and place

the new belts on the pulley. Press

the belts with your hand to position

the slack of each belt on the same

side of the drive. lf the slack is on

different sides. start up loads can

break belt tensile cords.

• Do not pry or force belts onto the

pulleys. This can break the load

carrying tensile cords of the belt

Never use steam or hot water to

clean a refrigerant coil. Dangerous

pressures may be built up by

improper application of heat

resulting in equipment damage oe

personal injury.

WARNING

!

Failure to properly drain and vent

coils when not in use during freezing

temperatures may result in coil

freeze-up damage. Drain and vent

hardware provided by installing

contractor.

CAUTIONS

!

TRANE

R

and the belts will break or turn over

shortly after installation.

• Take up sleck until belts fit snugly.

6. Check pulley alignment.

• Place a straight edge across

pulleys faces to correct alignment.

• Check parallel position of shafts

and correct alignment or grooves.

• Note: Mount pulleys as close to

bearing as possible.

31

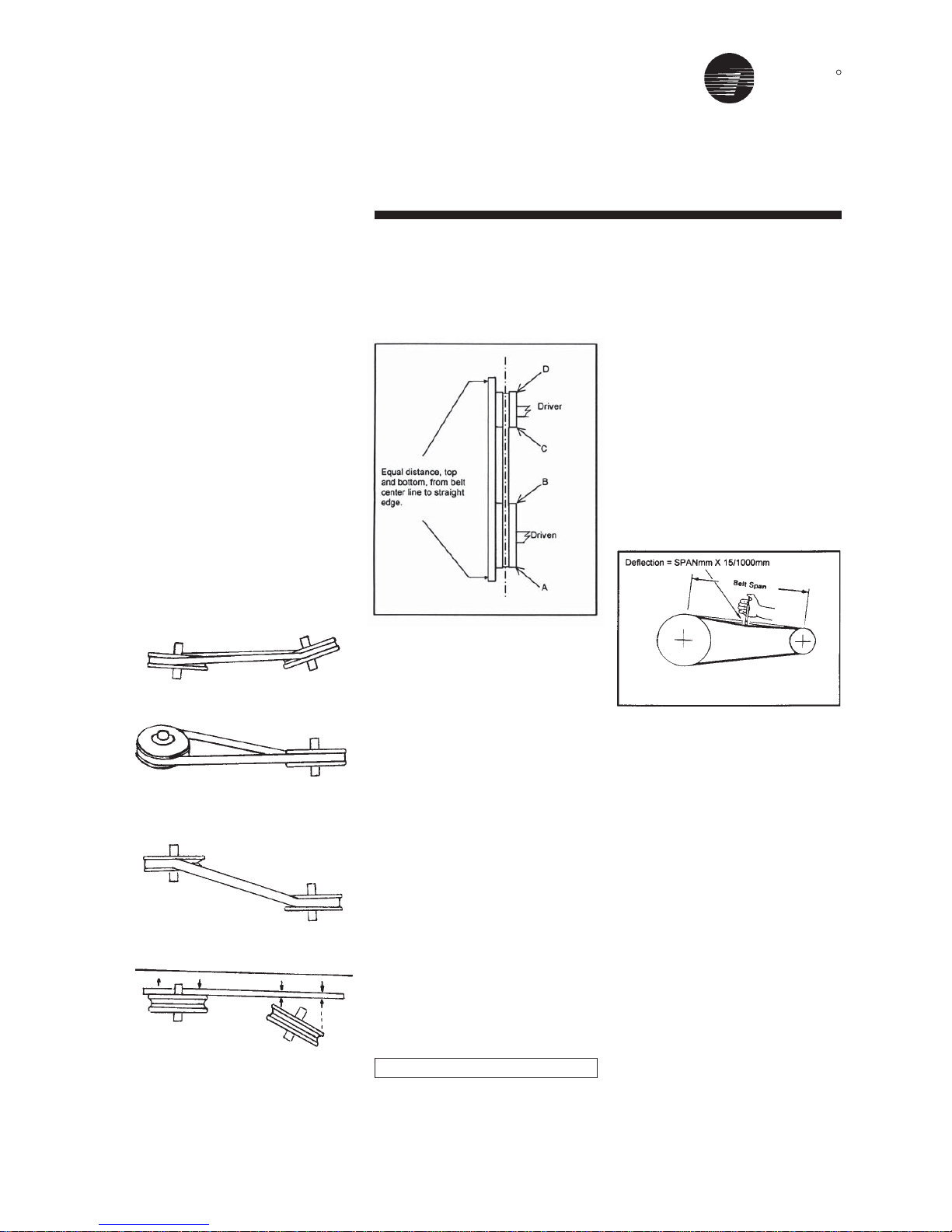

Figure 16

Sheave Alignment

Fan Belt Tension

Note: Fan belt tension should be

checked at least twice during the first

day of operation, since there is a rapid

decrease in tension until belts are run

in.

Proper belt tensioning is required to

ensure maximum bearing and drive

component life and is based on fan

brake horsepower requirement.

Belt Tension Measurement

Check the belt tension as follows:

Measure the span length mm of the

drive. With a belt tensioner at the

center of the span. apply a force K

(perpendicular to the span) large

enough to deflect the belt 15mm per 1

meter of span. Refer to figure 17.

The deflection force for the belt should

be within the minimum and maximum

force shown in the Table 3. When the

tension drops to the minimum value,

readjust to the maximum value.

To measure belt tension, use a belt

tensioner as shown in Figure 18.

Determine actual deflection by

depressing one belt with the belt

tensioner and measuring the

deflection relative to the other belts or

to belt line. Adjust the belt tension to

the correct force (Newton) and tighten

all setscrews to the proper torques.

Figure 17

Belt Tension Measurement

Maintenance

Note: Store belts in a cool, dry place

out of direct sunlight.

Types of sheave and shaft misalignment

Horizonal Angular

Vertical Angular

Parrallel

Align with straightedge along

sheave faces

DEFLECTION = SPAN mm X 15/1000mm

TRANE

R

Maintenance

32

Figure 18

Belt Tension Measurement

TRANE

R

General

Use the tables in this section to assist in identifying the cause or causes of a malfunction in Air Handler operation. The

column header RECOMMENDED ACTION will suggest repair procedures.

Note: These tables are intended as a diagnostic aid only. For detailed repair procedures, contact your local Trane Service

Company.

Trouble Analysis

Loosen bearing setscrews and realign

Grease bearing(s) (Plummer block)

Retension belts

Apply grease

Clean surface of grease and purge

Correct alignment and check that shaft is level

Check across AC line. Correct voltage if

possible

Check line phases and terminal block

connection. Reduce system load, fan

driven speed or increase motor capacity

Remove fan cover, clean fan and replace

cover

Reduce load or replace with larger motor

Replace motor fan / clean

Check pulley alignment

Remove items used for transport only

Retension belts

Replace vibration isolator

Align drive

Tighten motor mounting bolts

Replace bearings and seals

Remove interference in motor fan housing

Remove item and repair

Replace bearings and seals

Retighten hub

Re-tension and align

Clean belts and pulleys; check for grease

leaks

Remove obstruction

Replace with full set

Change at advised dirty condition

Check unit running conditions

Replace with filter

sizes as supplied from Trane

Poor alignment

Inadequate lubrication

Overtensioned belts

No lubricant (plummer block type)

Overlubrication

Misaligned bearing

Low line voltage

Short circuit, phase to earth (open Phase)

Overloaded motor

Motor fan is clogged with dirt preventing

proper ventilation

Overloaded motor

Motor fan damaged

Poor pulley alignment

Transport brackets not removed

Overtensioned belts

Fan / unit vibration isolator collapsed

Misalign drive

Motor mounting bolts loose

Worn motor bearings

Fan rubbing on fan cover

Fan rubbing on inlet cone or guard

Worm fan bearings

Loose impeller

Incorrect tension or alignment

Dirt or grease on belts

Belts rubbing

Odd belts being fitted

Blocked with dirt

Air velocity too high

Filter wrong size

Bearing noise

Bearing is excessively hot

Motor stalls

Motor overheats

Excessive vibration

Excessive vibrator

Excessive motor noise

Excessive fan noise

Premature belt wear

Filter collapsing

Symptom Probable Cause Recommended Action

33

TRANE

R

34

Trouble Analysis

Repair or replace blade

Tighting lever fixings

Refit actuator correctly

Prevent bypass with block-off

Clean and unblock tubes

Check water pumps, valves and lines for

obstructions

Provide proper water temperature

Prevent bypassing with block-off

Clean and unblock tubes

Check fan-operating conditions

Check sensing bulb location and TXV operation

Check for blockage in distributor and tube

Repair damaged part

Check support and alignment of pipework and

rectify

Check frost protection method and correct, improve

Trapping of steaam supply

Resize / fit trap and check air break arrangement

Clean trap and refit

Clean drain line

Level unit

Design trap per unit installation instructions

Reduce fan speed

Design trap per unit installation instructions

Repair leaks

Insulate surfaces

Replace filters

Reduce filters bypass

See “Standing water” symptom

See “Wet interior insulation” section

Adjust tension

Replace belt or belt set. Check sheave alignment

Replace sheaves

Replace sheaves

Realign drive with MVP sheave set at mean pitch

diameter

Check for leaky bearings. Clean belts and sheaves

Adjust tension

Remove obstruction or realign drive for clearance

Check belt tension and overhung load

Replace sheave with larger one

Blade bent

Spindle or mechanism loose

Actuator loose

Air is by passing coil

Coil tubes are blocked

Incorrect airflow (CFM)

Incorrect water flow rate (GPM)

Incorrect water temperature

Air is by passing coil

Coil tubes are blocked

Incorrect airflow

Expansion valve not operating

Poor refrigerant distribution

Header / exposed pipe damage

Cracks in joints due to strain of pipework

on headers

Swelling of joints due to frost

(Water-hammer Steam Coils)

Incorrect hydraulic trapping

Blockage in trap

Plugged Drain Line

Unit not level

Improper trap design

Coil face velcity too high

Improper trap design

Drain pan leaks / overflows

Condensation on surfaces

Missing filters

Filter bypass

Standing water in drain pan

Moisture problems

Motor is poorly positioned

Worn or damaged belt

Worn Sheaves

Worn Sheaves

Misalign belt

Grease or oil on belts

Belt slipping

Belts rubbing

Excessive overhung load due to

overtensioned drive

Excessive overhung load due to a small

Damper seizing

Low coil capacity (Chilled Water)

Low coil capacity (Refrigerant)

Leaking Coil

Drain pan overflow

Standing water in drain pan

Wet interior insulation

Excess dirt in unit

Microbial growth (mold) inside

air handler

Loose fan belt

Short belt life

Rapid motor bearing wear

Symptom Probable Cause Recommended Action

TRANE

R

35

Trouble Analysis

Pulley and Belt

TRANE

R

36

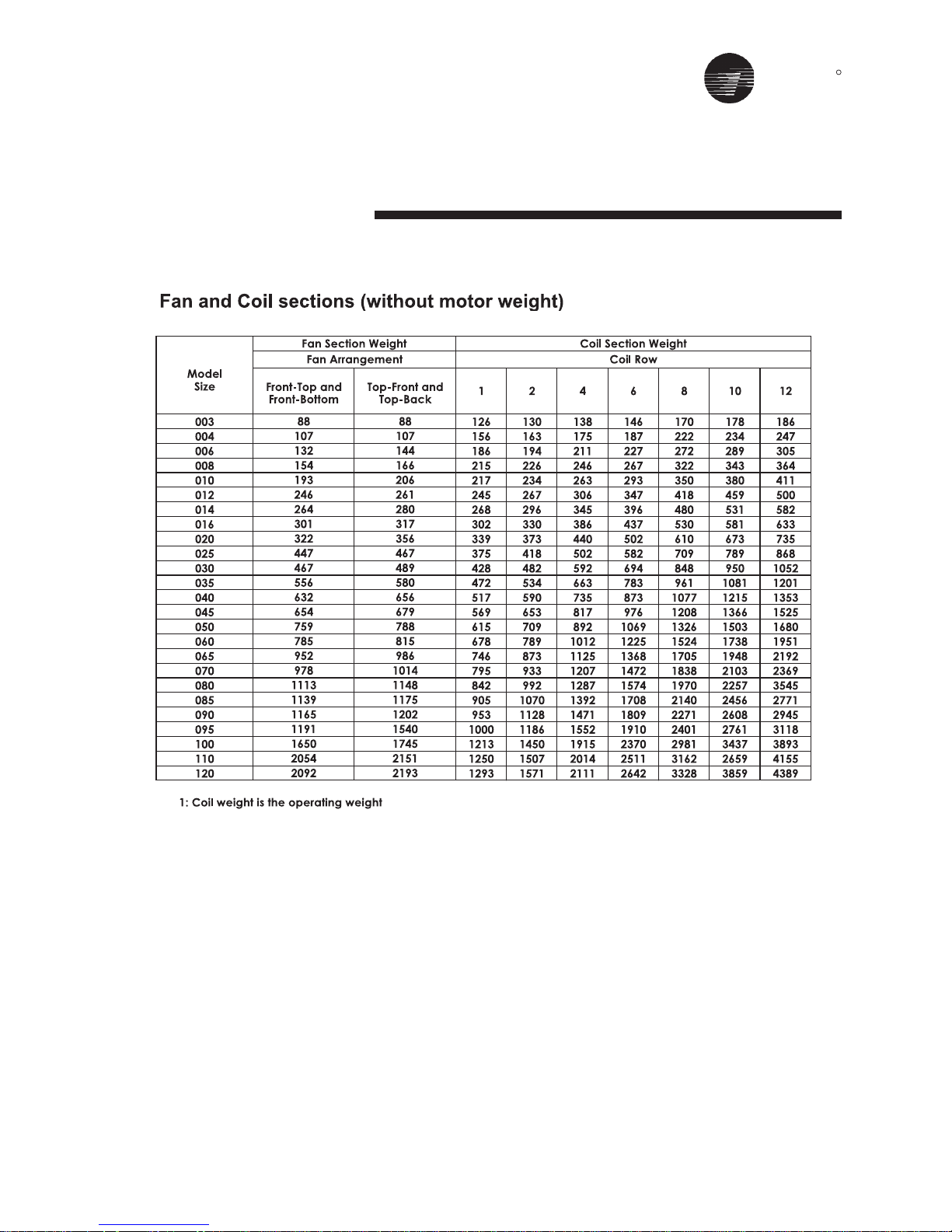

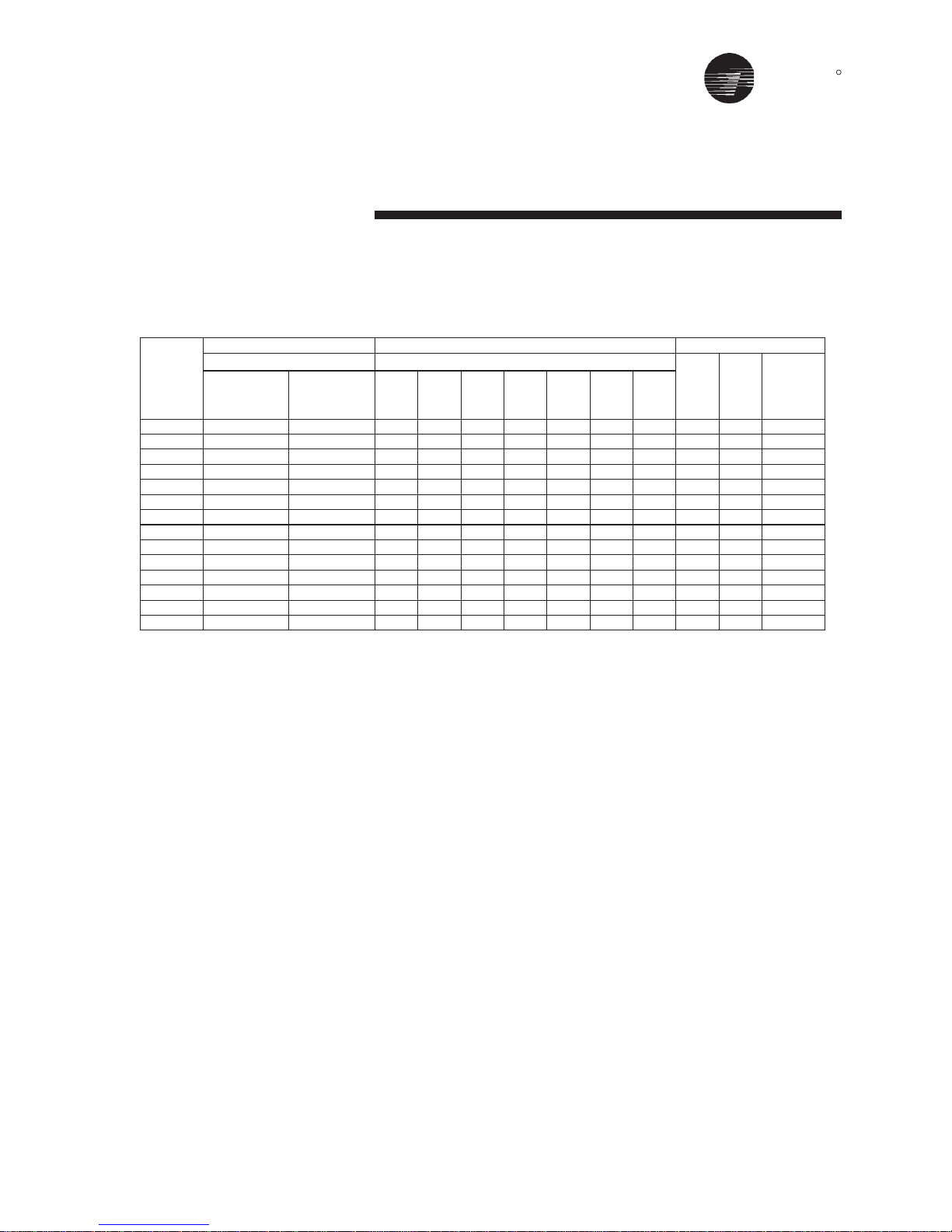

Appendix A

HDT - Unit Weight (CLCPEURO)

50mm Casing

HDT Unit Weight (kg) _ Fan and Coil Sections (without motor weight)

25mm Casing

1. Coil weight is the operating weight.

TRANE

R

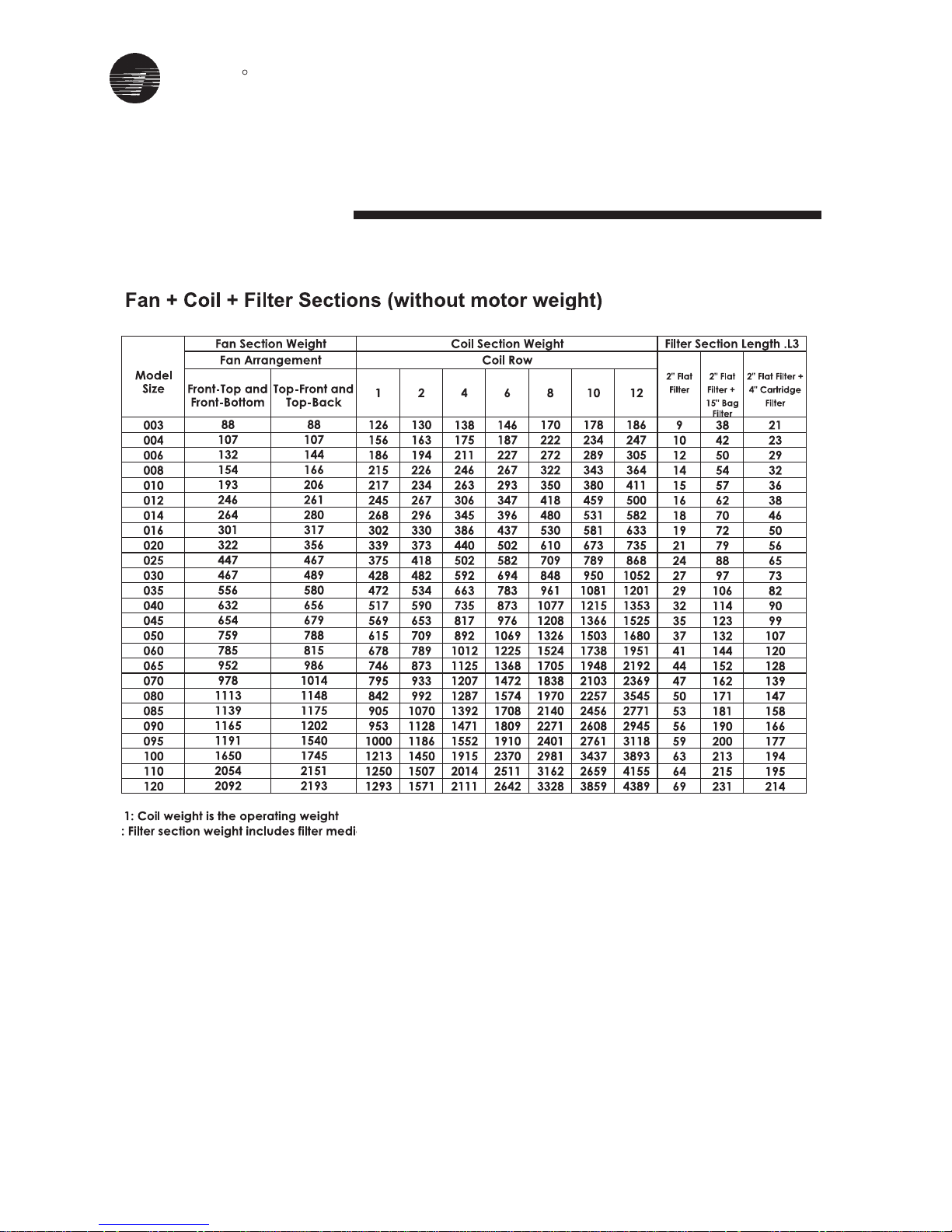

Appendix A

HDT - Unit Weight (CLCPEURO)

37

Fan + Coil + Filter Sections (without motor weight)

50mm Casing

25mm Casing

1. Coil weight is the operating weight.

2. Filter weight include filter media.

TRANE

R

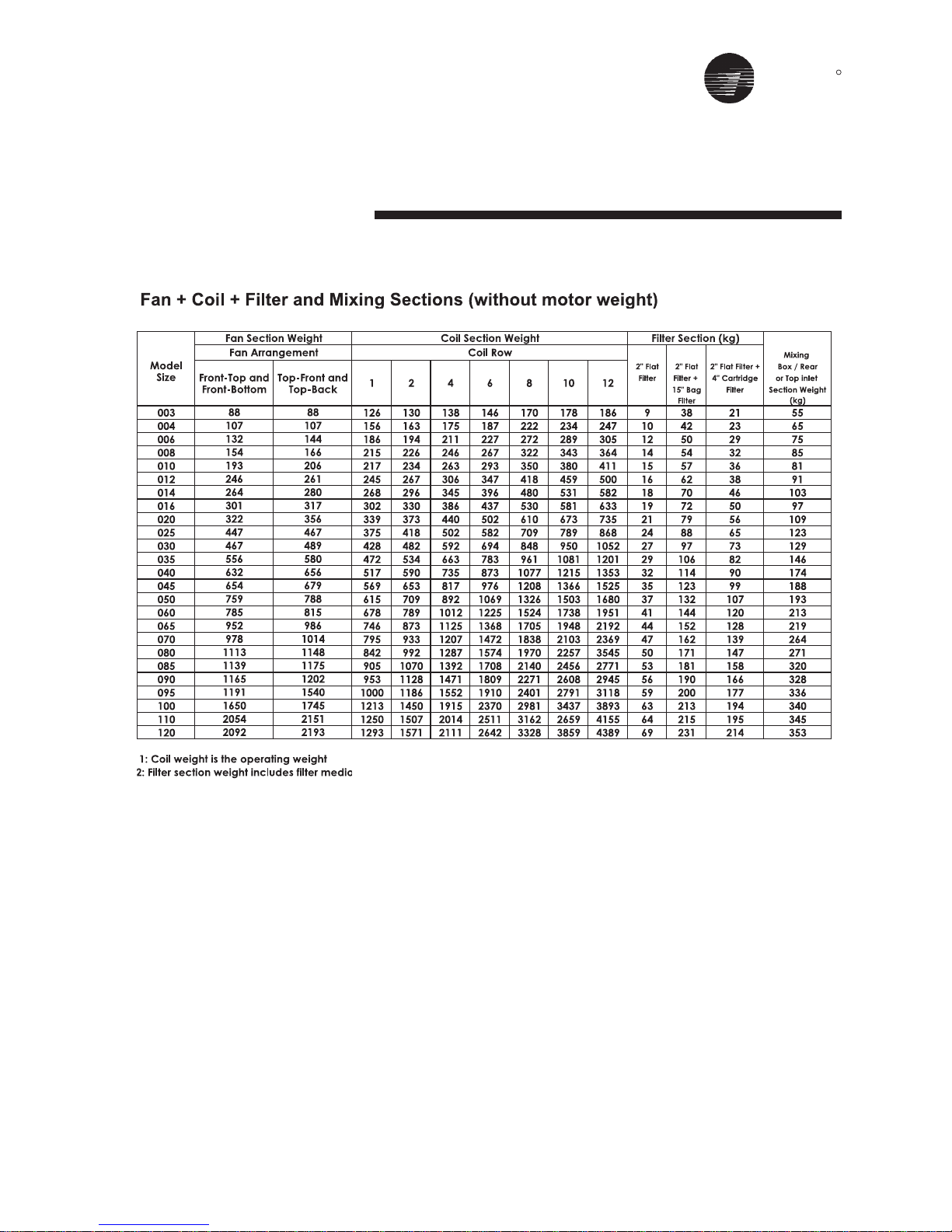

Appendix A

HDT - Unit Weight (CLCPEuro)

38

Fan + Coil + Filter and Mixing Sections (without motor weight)

50mm Casing

25mm Casing

Note:

1. Coil weight is the operating weight.

2. Filter weight includes filter media.

TRANE

R

Appendix A

VDT - Unit Weight (CLCPEuro)

39

Note:

1. Coil weight is the operating weight.

Fan and Coil Sections (without motor weight)

50mm Casing

25mm Casing

TRANE

R

Appendix A

VDT - Unit Weight (CLCPEuro)

40

50mm Casing

Fan + Coil + Filter Sections (without motor weight)

25mm Casing

Note:

1. Coil weight is the operating weight.

2. Filter weight includes filter media.

TRANE

R

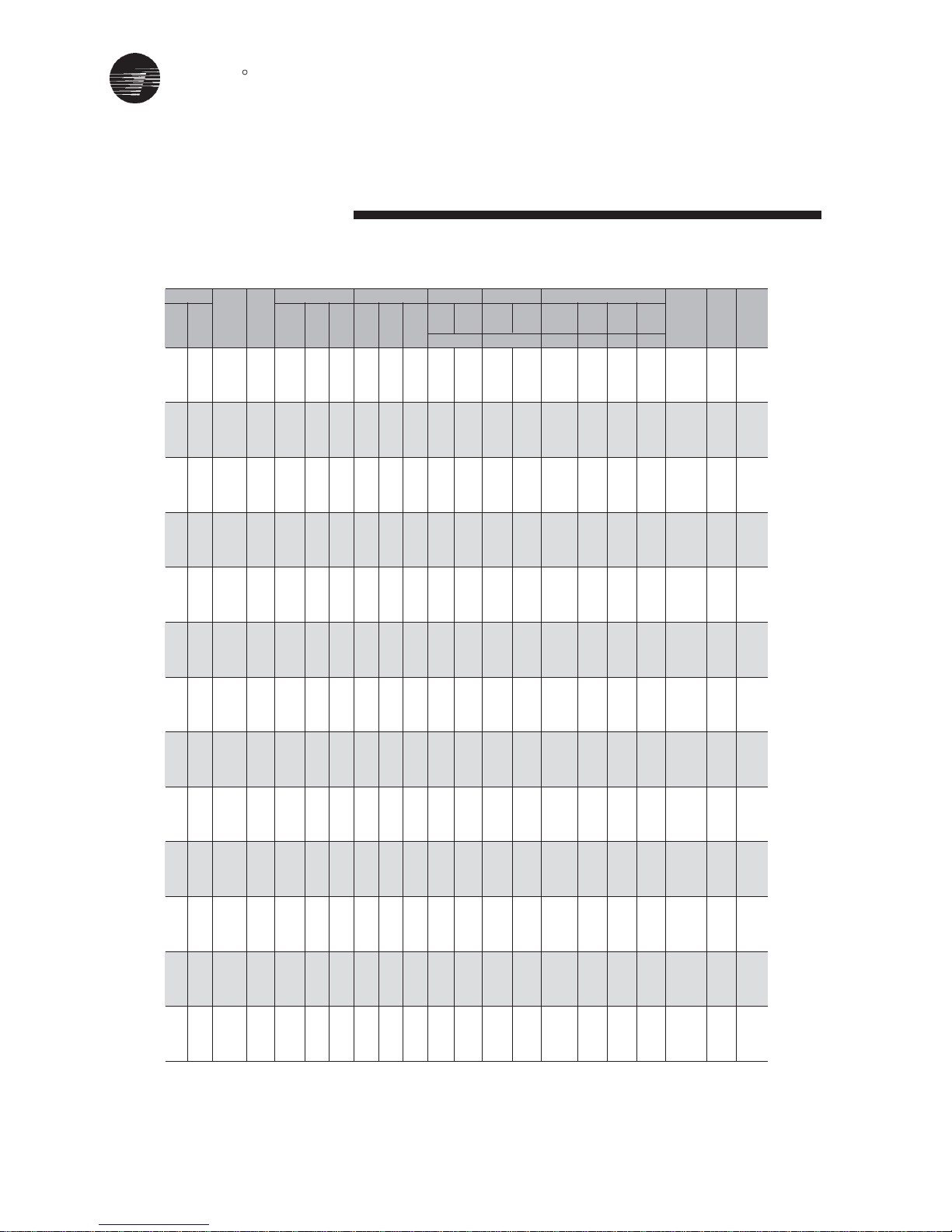

Appendix B

HDT - Unit Weight (CLCPXP)

41

TRANE

R

Appendix B

HDT - Unit Weight (CLCPXP)

42

TRANE

R

Appendix B

HDT - Unit Weight (CLCPXP)

43

TRANE

R

Appendix B

VDT - Unit Weight (CLCPXP)

44

TRANE

R

Appendix B

VDT - Unit Weight (CLCPXP)

Fan + Coil + Filter Sections (without motor weight

)

tion Length .L3

Model

2" Flat 2" Flat 2" Flat Filter +

Size

Filter Filter + 4" Cartridge

15" Bag Filter

Filt

er

003

153 158

165 173

189 197 205

938 21

004

190 197 209 221 246 258 271

10 42 23

006

227 236 252 268 302 319 335

12 50 29

008

262 273 293 314 357 378 399

14 54 32

010

289 306 335 365 410 440 471

15 57 36

012

327 349 388 429 486 527 568

16 62 38

014

361 389 438 489 558 609 660

18 70 46

047886736955805254424610

19 72 50

328167896506345674244020

21 79 56

7101839858847866485145520

24 88 65

61

2141112101678477466016030

27 97 73

973195219311089068337966530

29 106 82

6451804107217801949408137040

32 114 90

437157517141702184

01488008540

35 123 99

722 746

755 780

540 561

638 662

378 412

510 531

313 329

350 366

229 242

288 302

162 174

190 202

103 103

132 132

Front-Top and Top-Front and

Front-Bottom Top-Back

6 8 10 12124

thgieWnoitceSlioCthgieWnoitceSnaF

woRlioCtnemegnarrAnaF

45

TRANE

R

Appendix CFans and Arrangement

Fan Size and Diamete

r

Fan Discharge Arrangements

Model Size Fan size

Fan size

Diameter (mm)

003

FC 200

200

BC 200

004

FC 225

225

BC 225

006

FC 250

250

BC 250

008

FC 280

280

BC 280

010

FC 315

315

BC 315

012

FC 400

400

BC 400

014

FC 400

400

BC 400

016

FC 450

450

BC 450

020

FC 500

500

BC 500

025

FC 560

560

BC 560

030

FC 560

560

BC 560

035

FC 630

630

BC 630

040

FC 710

710

BC 710

045

FC 710

710

BC 710

050

FC 800

800

BC 800

060

FC 800

800

BC 800

065

FC 900

900

BC 900

070

FC 900

900

BC 900

080

FC 1000

1000

BC 1000

085

FC 1000

1000

BC 1000

090

FC 1000

1000

BC 1000

095

FC 1000

1000

BC 1000

100

FC 1120

1120

BC 1120

110

BC 1250 1250

120

BC 1250 1250

46

TRANE

R

Appendix DFilter and Quantity

47

Filter Dimension (Nominal) and Arrangemen

t

Flat Filter, Bag Filter & Cartridge Filter

10

TRANE

R

Appendix DFilter and Quantity

48

Filter Dimension and Arrangement

High Capacity Filter - CLCP Euroonly

TRANE

R

Appendix DFilter and Quantity

49

Filter Dimension and Arrangement

Final Filter (HEPA)

TRANE

R

Appendix ETECO MOTOR Performance Data

380 / 415V - 50Hz, 2/4/6/8 Poles

50

Motor types AEEB and AEVB, Class F insulation, 380 / 415V - 50HZ, Eff 2.

Output

HP KW

Full

Load

Speed

(RPM)

Frame

Size

% Efficiency

Full

Load

3/4

Load

1/2

Load

Full

Load

3/4

Load

1/2

Load

% Power Factor Current (A) Current (A)

Full

Load

Full

Load

Locked

Rotor

Locked

Rotor

Full

Load

Locked

Rotor

PullUpPull

Out

2730

1345

920

710

2810

1395

925

710

2755

1405

915

695

2805

1405

940

700

2810

1415

940

690

2825

1400

930

705

2840

1425

950

705

2865

1435

955

715

2865

1440

955

720

2870

1445

950

720

2905

1445

960

720

2880

1450

975

720

2940

1455

970

730

63

63

71

80

71

71

80

90S

71

80

80

90L

80

80

90S

100L

80

90S

90

100L

90S

90L

100L

112M

90L

100L

112M

132S

100L

100L

132S

132M

112M

112M

132M

160M

112M

112M

132M

160M

132S

132S

132M

160M

132S

132M

160M

160L

160M

160M

160L

180L

61

64

61

52

75

71.5

66

64.5

75

71.5

68

70

78

76.5

74

68

80.5

76.5

75

74.5

81

78.5

76

75.5

83.5

81

81

81.5

85

83.5

85

82.5

86

85

83

84.5

86

86

85

84.5

87

86

84.5

85.5

88

88.5

88

86

89

89.5

89

89

57.5

63

56

46

74

70.5

63

61

75.5

71

67.5

70

78.5

76

71

66.5

81.5

76.5

73

74.5

81

78.5

76

75

84.5

81

81

81.5

8.55

83

85.5

81

86.5

84.5

82.5

84

87

86.5

85.5

83.5

86

86

84

85.5

88

89

87

86

89

90

89.5

89.5

50.5

57

48

37

69.5

65.5

57

53.5

73

64

62.5

65.5

75.5

72.5

66.5

61

80

69.5

68

71

79

75.5

70.5

71

83.5

78.5

78

79

84

80

84

77.5

86

83

81

81.5

86

84.5

84

80.5

83.5

84.5

82

83

86.5

87.5

84.5

84.5

87

89

88.5

88

77.5

68.5

64

47.5

85

70.5

67.5

60.5

86

74.5

72

70

88

77

71

66

887.5

79

68.5

67.5

88

81

75.5

67

89

82.5

76.5

74

89

82

81

67

91

82

78

71

90.5

82

80.5

74.5

88

82.5

77

75.5

89

86

79

76

89

86.5

84

78

69.5

58.5

54

41

77

61

56.5

48.5

78.5

65

60.5

59

81

66

60.5

56.5

81

68.5

57

59

82

72.5

65

59

84

75

63

63.5

83.5

73.5

75.5

58

88.5

77

71

62.5

87.5

76

74.5

64.5

85.5

75.5

70

65.5

87.5

81.5

71.5

65.5

85.5

82.5

80

70.5

58.5

45.5

43.5

34

65

48.5

45

39

66

51.5

48

47

68

52.5

48

45.5

70

55.5

44.5

47

70.5

59

52

46.5

74

62

50

50.5

74

61

64

45

82.5

65

59

50

79.5

64

62.5

51.5

79

63.5

58

53

82.5

71.5

59.5

53

77.5

74.5

71

58.5

0.60

0.64

0.72

1.15

0.88

1.12

1.27

1.45

1.32

1.59

1.74

1.74

1.65

1.92

2.16

2.52

2.41

2.82

3.31

3.39

3.18

3.56

3.95

4.48

4.58

5.09

5.71

5.64

6

6.62

6.59

8.2

7.24

8.13

8.75

9.45

8.01

8.84

9.11

9.91

11.1

12

13.1

13.2

14.5

14.9

16.3

17.4

21.5

22

22.7

24.5

2.7

2.6

2.5

3.5

5.9

5.7

5.5

5.5

8.7

8.7

8.2

7.9

10.9

10.9

10.9

9.8

17.5

16.4

16.4

15.3

22.9

21.8

21.8

19.7

34.9

32.8

32.8

31.7

43.7

49.1

43.7

43.7

61.1

63.2

57.9

55.8

61

61

60

60

83

83

83

83

104

104

104

104

156

156

156

156

0.55

0.59

0.66

1.05

0.81

1.03

1.16

1.33

1.21

1.46

1.59

1.59

1.51

1.76

1.98

2.31

2.21

2.58

3.03

3.10

2.91

3.26

3.62

4.10

4.19

4.66

5.23

5.16

5.49

6.06

6.03

7.51

6.63

7.44

8.01

8.65

7.33

8.09

8.34

9.07

10.2

11

12

12.1

13.3

13.6

14.9

15.9

19.7

20.1

20.8

22.4

2.5

2.4

2.3

3.2

5.4

5.2

5.0

5.0

8

8

7.5

7.2

10

10

10

9

16

15

15

14

21

20

20

18

32

30

30

29

40

45

40

40

56

58

53

51

56

56

55

55

76

76

76

76

95

95

95

95

143

143

143

143

0.066

0.135

0.197

0.256

0.129

0.260

0.392

0.511

0.198

0.387

0.595

0.783

0.259

0.517

0.772

1.037

0.387

0.769

1.158

1.578

0.514

1.037

1.561

2.059

0.767

1.528

2.292

3.089

1.013

2.023

3.040

4.061

1.258

2.502

3.773

5.004

1.391

2.763

4.202

5.545

1.874

3.767

5.671

7.561

2.520

5.006

7.445

10.081

3.703

7.483

11.225

14.915

335

220

260

360

320

275

220

190

300

260

230

170

240

265

200

185

270

210

230

205

260

220

200

185

245

240

200

215

310

300

200

265

290

250

210

200

290

240

190

200

205

240

250

200

215

260

265

200

215

235

240

220

335

215

245

350

270

240

215

185

260

245

215

140

230

250

185

165

250

190

215

180

240

195

190

150

245

210

185

200

280

275

190

245

265

210

175

180

265

220

175

180

185

200

230

180

190

220

225

190

180

190

210

195

340

240

280

370

310

270

240

265

280

280

230

205

270

270

240

230

280

250

270

220

270

255

230

240

290

270

250

250

320

340

270

310

330

310

280

270

325

310

260

270

260

280

310

270

260

300

300

270

285

280

280

260

0.002

0.002

0.007

0.010

0.002

0.005

0.009

0.017

0.002

0.007

0.012

0.023

0.005

0.009

0.017

0.033

0.006

0.014

0.023

0.046

0.010

0.017

0.033

0.065

0.014

0.033

0.058

0.138

0.023

0.046

0.125

0.180

0.042

0.065

0.151

0.343

0.042

0.085

0.151

0.344

0.063

0.103

0.217

0.484

0.076

0.143

0.400

0.588

0.147

0.297

0.588

1.233

9

9

12

20

12

12

20

23

12

20

20

27

20

20

23

37

20

23

27

37

23

27

37

45

27

37

45

68

87

37

68

77

44

43

65

107

45

45

77

128

68

68

77

127

68

77

128

151

128

128

151

206

9.5

9.5

13

18

13

13

18

24

13

18

18

27

18

18

24

37

18

24

27

37

24

27

37

47

27

37

47

70

37

37

70

80

47

45

68

115

47

47

80

120

70

70

80

135

70

80

120

148

120

120

148

205

0.180.25

0.37

0.5

0.55

0.75

1

0.75

1.5

1.1

2.2

3

3

4

3.7

5

7.5

5.5

7.5

10

15

11

1.5

2

5.5

4

380 Volts 415 Volts Kg-m %FLT %FLT %FLT Kgm² Kg Kg

Torque

Rotor

GD²

Approx

Weight

AEEB

Approx

Weight

AEVB

Voltage

Factor

200

2.08

220

1.89

346

1.2

365

1.13

400

1.04

420

0.99

440

0.94

500

0.83

550

0.75

Note :

1. For ampere values of other voltage motors, multiply the 415 volt values by the following factors:

2. FLT = fult-load torque

3. Data are subject to revisions without notice.

TRANE

R

51

Appendix ETECO MOTOR Performance Data

380 / 415V - 50Hz, 2/4/6/8 Poles

Motor types AEEB and AEVB, Class F insulation, 380 / 415V - 50HZ, Eff 2.

Voltage

Factor

200

2.08

220

1.89