Page 1

TOSHIBA

E6580496 0

ULTRA-COMPACT

DIGITAL INVERTER

VF-SX

OPERATION MANUAL

JUNE, 1993

Page 2

TOSHIBA

TOSHIBA VF-SX INVERTER

OPERATION MANUAL

TABLE OF CONTENTS

INTRODUCTION ............................................................ I-l

CHAPTER 1 Inspection Procedure Upon Receipt

CHAPTER 2 Proper Environment for Installation

CHAPTER 3 External Views and Connection Diagrams

3.1 External Views.................................................3-2

3.2 Connection Diagrams .......................................... 3-4

CHAPTER 4 Application Precautions

CHAPTER 5 Wiring Guidelines and Warnings

5.1 Inverter Wiring................................................5-2

5.2 Installation of a Molded Case Circuit Breaker (HCCB)

5.3 Installation of a Primary Magnetic Contactor (HC)

5.4 Installation of an Output Magnetic Contactor (MC)

5.5 Installation of an External Overload Relay

5.6 Installation of an Input Reactor...............................5-6

5.7 Incorrect Wiring and Incorrect External Components

5.8 Basic Wiring Recommendations ................................. 5-7

Chapter 6 Standard Connections ........................................ 6-1

6.1 Examples of Standard Wiring .................................. 6-2

6.2 Terminal Functions ........................................... 6-7

Chapter 7 Parameter Groups

7.1 Definitions of SX Drive Group Parameters

7.2 Parameter Group Tables

Chapter 8 Basic Operation Theory

8.1 Operation of the Touchpad Control Panel

8.2 Display Modes.................................................. 8-4

8.2.1 Drive Mode................................................... 8-5

8.2.2 Monitor Mode

8.2.3 Programming Mode............................................8-10

8.2.4 Jogging Mode from the Touchpad..............................8-11

8.3 PANEL/REHOTE Control ........................................ 8-12

8.4 Selection of Stopping Method from the Touchpad

8.5 Starting the Drive from the Touchpad

8.6 Changing Frequency from the Touchpad

8.7 Error Reset................................................... 8-17

8.8 Warning Displays

8.9 Fault Relay Information ..................................... 8-19

.................................................

.......................................

..............................................

.......................................

........................................

............................................

...........................

.........................

......................

..............................

........

............

............

..................

..........

....................

.....................

..........................

..........................

...............

I-I

2-1

3-1

4-1

5-1

5-4

5-5

5-5

5-6

5-6

7-1

7-2

7-3

8-1

8-2

8-8

8-12

8-14

8-16

8-18

Page 3

^_____________________TOSHIBA

CHAPTER 9 Fundamental Operation Parameters and Functions [GC~ .F] . 9-1

9.1 Setting of Voltage and Frequency Characteristics

9.1.1 Maximum Frequency [fH]

9.1.2 Base Frequency [UL]

9.1.3 Torque Boost [Ub]

9.1.4 V/f Patterns [P t].........................................9-8

9.2 Upper Limit Frequency and Lower Limit Frequency [U L ,L L] 9-9

9.3 Forward and Reverse Run [f,rj

9.3.1 Operation from the Touchpad ............................... 9-10

9.3.2 Operation Using External Signals

9.4 Acceleration and Deceleration

9.4.1 Acceleration and Deceleration Time [R C C I },

.........................................

...........................................

______________________

.....................................

...................... .........

.........................

...............................

............

9-4

9-4

9-5

9-7

9-10

9-11

9-14

[dèe / ], [R C C d], [d E C c]..............9-14

9.4.2 Acceleration/Deceleration Pattern [Pt / ], [Pt P] . . 9-15

9.4.3 Selection of Acceleration/Deceleration 1 and 2

[Rd^], [Rd^F]

9.5 Setting of Standard Parameter Groups [ t ^ P]

.......................................

............

9-17

9-19

Chapter 10 Terminal Selection Parameters [GC.S t]

10.1 Command Mode Selection [ cnodi

10.2 Frequency Setting Commands [P fl R d]

10.3 Parameter Setting Disable Function [PR 0 d]

10.3.1 Security Considerations and Parameter [PR Od] .... 10-4

10.4 Input Terminal Selection [ I t b]

10.5 Output Terminal Selection [Otb]

10.6 Low Speed Signal Output and Speed Reached Signal Output

.........................

.......................

...............

...................

.............

......................

[LF], [LFHL], [FrCH], [CCH], irrCH] , 10-7

10.6.1 Low Speed Signal Output Frequency [ i. F] and Speed

Reached Logic Signal [ LFHL]

10.6.2 Speed Reached Signal Output irCH]

10.7 Frequency Setting via Remote Control Signals

10.7.1 Types of Frequency Setting Signals

10.7.2 RR Terminal Input Priority C C ], [ I U I O] . . 10-12

10.8 Frequency Setting Signals [P / ], [F*“P I ] and

[PP], [P —PP]

10.9 Jogging Run via Remote Control [ tJ 0 0], [d SEP] 10-14

10.10 Multiple Speed Run [ST.D], [StI — StI] . . 10-17

......................... ....................

................... .........

.................

..............

.....................

10-1

10-2

10-3

10-3

10-4

10-6

10-7

. . . 10-7

10-9

10-10

10-12

Page 4

______________________TOSHIBA

_____________________

3

Chapter 11 Protection Parameters [ Gr.Pn

11.1 Regenerative Discharge Braking Selection [P b] and

Overvoltage Limiting Action Selection [OP 5 b]

11.2 DC Injection Braking Start-up Frequency [dbF],

DC Injection Braking Voltage [ dbU] t and DC Injection

Braking Time [d b b]..................... .............11-4

11.3 Emergency Stop [EScP]

11.3.1 Emergency Stop from the Touchpad...........................11-6

11.3.2 Emergency Stop Using Remote Control Signals

11.3.3 Emergency DC Injection Braking Stop Control Time

[fdbfc] ................................................11-8

11.4 Retry [T try]

11.5 Power Control Function [UuC]........................... 11-10

11.6 Electronic Thermal Protective Level [b Hf~] 11-11

11.7 Stall Prevention Function Activation Level [5 fc /.] ... 11-11

11.8 Electronic Thermal Protection Characteristic Selection

[0 L il]

11.9 Retention of Trip [t^CL]

Chapter 12 Control and Communication Parameters [ 0 f. C C ] 12-1

12.1 Differences Between Startup Frequency and Operation Starting

Frequency....................................................12-2

12.2.1 Start-Up Frequency [F~5t]

12.2.2 Operation Starting Frequency [ Frurt]

12.2.3 Operation Starting Frequency Hysteresis [ FHdS] . . . 12-4

12.3 Jump Frequency and Jump Bandwidths [ F J.H],

[ F J / ] and [ b F <J / ], [ F J d ] and [ b F J (? ].

[ F J 3 ] and [ b F J 3 ] 12-5

12.4 PWM Carrier Frequency [CF] and

Motor Tone Selection [CF5]

12.5 Output Voltage Adjustment rPOUb] and Power Voltage

Compensation Function [ ppddi .......................... 12-6

12.6 Automatic Torque Boost [ Rub]

12.7 Slip Frequency Compensation [5FC]

.............................................

.....................................

.............................................

....................

................................

.............................

......................

.................................

.........................

.................

.... 11-1

.............

.............

11-2

11-6

11-7

11-8

11-11

11-11

12-3

12-4

12-6

12-8

12-10

Page 5

TOSHIBA

Chapter 13 Meter Adjustment Parameters [ Gr.RH] ............. . . . . 13-1

13.1 Meter Connections [FnRfl] . ......................... 13-2

13.1.1 Connection of a Frequency Meter [F fl]

13.1.2 Connection of an Ammeter [R /7]

13.2 Frequency Setting Signal [rr—b], [rr—C]

13.3 Universal Unit Multiplication Factor [d 5 P (?]

Chapter 14 General Drive Specifications

14.1 Drive Specifications ....................................... 14-2

14.2 External Dimensions ........................................ 14-4

Chapter 15 Options.......................................................15-1

15.1 Input Reactor

15.2 Radio Noise Reduction Filter

15.3 Braking Resistor ........................................... 15-2

15.4 Connection Cable ........................................... 15-2

Chapter 16 Error Displays, Explanations, and Remedies

16.1 Inverter Trip Causes and Remedies

16.2 Other Errors and Remedies

Chapter 17 Maintenance and Inspection ................................... 17-1

Chanter 18 Storage and Warranty ....................................... 18-1

18.1 Storage..................................................’ ] 18_2

18.2 Warranty...................................................] 18-2

Appendix....................................................... H-1

APPENDIX 1 — TABLE OF TRIP CODES AND WARNING CODES

APPENDIX 2 ~ INPUT TERMINAL INFORMATION AND OUTPUT TERMINAL

INFORMATION

APPENDIX 3 — LEO ALPHANUMERIC CROSS REFERENCE

..............................................

...................................

.................................................

..........................

..........................

..............................

.........................

..............

................

............

..................

............

.....................

! ! A-2

13-2

13-3

13-5

13-7

14-1

15-2

15-2

15-1

16-2

16-4

A-3

A-4

Page 6

TOSHIBA

i-i

IHTRODUCTIOH

Thank you for purchasing the Toshiba Compact Inverter "TOSVERT VF-SX".

The VF-SX variable speed drive Is a high performance Inverter that has numerous

built-in functions, making It suitable for many applications. This Inverter Is

very easy to program and operate. All instructions are entered via the membrane

keyboard panel (the "touchpad"). The latest technology and features, including

current limit, auto-restart, dynamic braking, and stall prevention are Included.

This product offers flexible operation for numerous applications, and helps

prevent nuisance tripping, even for difficult loads and applications.

Please thoroughly review this manual before attempting use of the VF-SX drive,

so that the features of this drive can be properly applied for each unique

applIcatlon.

Please keep this manual for future reference, operation, and maintenance of the

VF-SX drive.

Always ground the Inverter in accordance with Article 250 of the National

Electrical Code or Section 10 of the Canadian Electrical Code, Part I. The

grounding conductor should be sized In accordance with NEC Table 250-95 or CEC,

Part I, Table 16.

See Chapter 6 for simplified power and control wiring instructions and

recommendations.

Page 7

Page 8

TOSHIBA

CHAPTER 1 Inspection Procedure Upon Receipt

1-1

Page 9

1-2

1. Inspect the Toshiba Model VF-SX variable speed drive. Confirm that no

parts have been damaged during transit.

2. Confirm that the model number inscribed on the nameplate is the same as

that ordered.

3. If the inverter will not be placed in service immediately upon receipt,

store the device in a dust free environment. Be sure the room is

ventilated with cool, dry air. Store this device in its original packing

material whenever possible.

4. Every reasonable precaution is taken during the production, packaging, and

shipping of this device to prevent damage to the unit before installation.

If there is any damage upon receipt, contact the dealer and the freight

company immediately.

TOSHIBA

Page 10

TOSHIBA

CHAPTER 2 Proper Environment for Installation

2-1

Page 11

2-2

The VF-SX inverter Is a solid state device. Use caution to install the device

in the proper environment, as instructed in the general recommendations shown

below. See Chapter 14 for detailed specifications of the proper operating

environment.

1. Confirm that the input power supply is within +/- 10% of the nominal

voltage. The protective circuit will activate and trip if the permissible

input voltage range is exceeded. Extreme voltage conditions may damage

the inverter.

2. Do not install the inverter in places where high temperature or humidity

are present. Do not install in dusty environments, or environments

contaminated with metal particles or metallic powder.

3. Do not mount the inverter on any device subject to intense vibration.

4. Operate the inverter only in an environment between -10 deg C to 40 deg C.

The inverter generates heat when operating. When it is installed on a

subpanel or backplate be sure there is adequate ventilation on all sides

of the inverter, including the back of the inverter where the heat sinks

are located. In high ambient temperatures it may be necessary to remove

the stick-on seal on the top of the inverter to allow more ventilation

through the Inverter.

Certain electrical equipment, if installed too near the inverter, may

5.

cause malfunctions. Examples of this type of equipment can include:

If a magnetic contactor is installed near the inverter install a

A.

urge suppression device across the coil of the contactor to prevent

surging magnetic fields from interfering with the operation of the

inverter.

Do not install the inverter near fluorescent lighting.

B.

Keep other heat generating electrical equipment, such as resistors

C.

or heaters, away from the inverter.

Always properly ground the inverter chassis to prevent electrical noise

6.

and nuisance tripping. Proper earth ground should not exceed 100 ohms.

Install the inverter ONLY on incombustible subpanels, such as a metal

7.

subpanel. If the inverter is installed on a heat insulating subpanel then

mount the inverter on a metal subpanel first, and attach this assembly to

the insulated subpanel.

Always have at least 10 centimeters free space above and below the

8.

inverter. Always have at least 5 centimeters free space on EACH side of

the inverter. If more than one inverter is mounted in a row, leave at

least 10 centimeters between each drive, from side to side. If fans are

installed in the enclosure or near the drives this space requirement may

be reduced. Consult the Toshiba factory for details.

TOSHIBA

Page 12

TOSHIBA

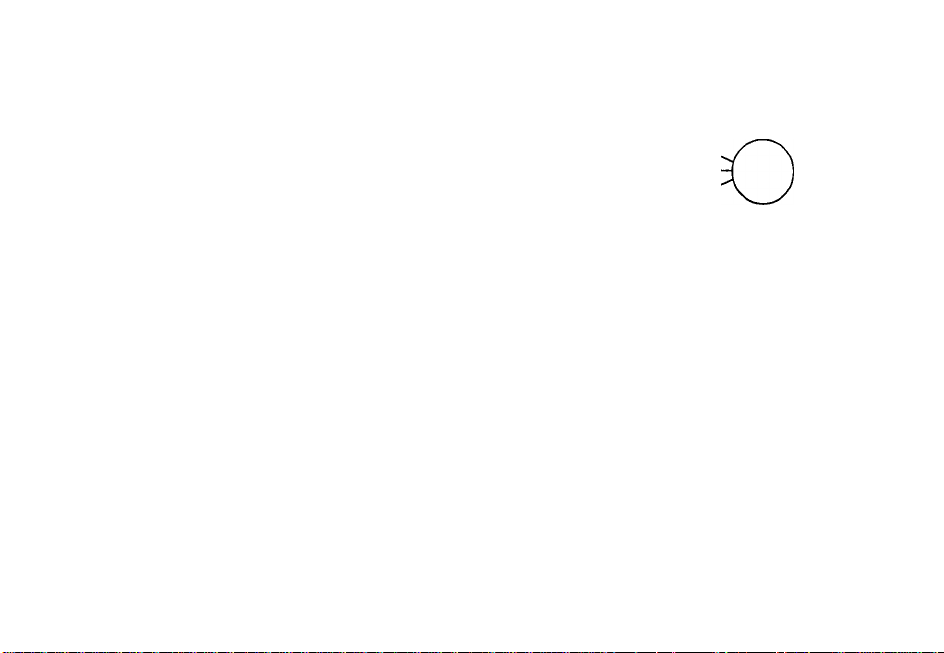

CHAPTER 3 External Views and Connection Diagrams

3-1

Page 13

3-2

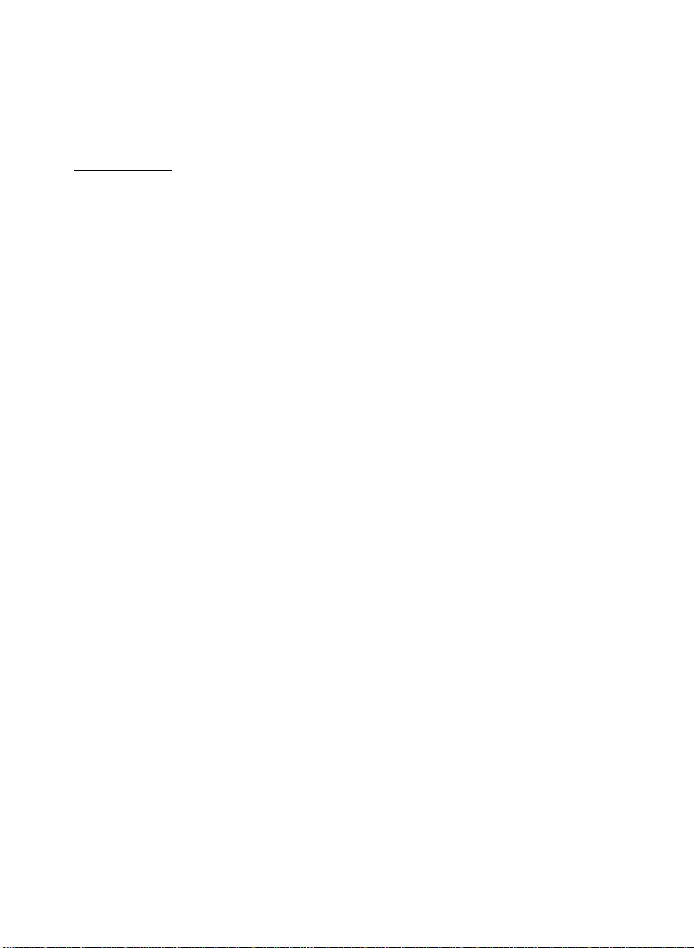

3.1 External Views

TOSHIBA

REMOVE THIS SEAL

WHEN USING THE

INVERTER IN A HOT

PLACE

TOUCHPAD CAN

BE REMOVED

UPPER COVER

DOES NOT NEED

TO BE REMOVED

UNLESS THE

EXTERNAL SIGNAL

SELECTION

JUMPERS ARE

CHANGED

LOWER COVER MUST

BE REMOVED WHEN

THE TOUCHPAD IS

REMOVED OR WHEN

WIRING IS

CONNECTED TO THE

TERMINALS

PRESS THE LOWER COVER

ON BOTH SIDES (AS

SHOWN) SWULTANEOUSLY.

PULL THE COVER FORWARD,

TO INSTALL THE COVER,

insert the COVER CLASPS

IN THE BOTTOM HOLES,

ROTATE THE TOP OF THE

LOWER COVER BACK INTO

POSTITON, AND GENTLY

PRESS UPPER CLASPS INTO

PLACE

FOUR

INSTALLATION

HOLES

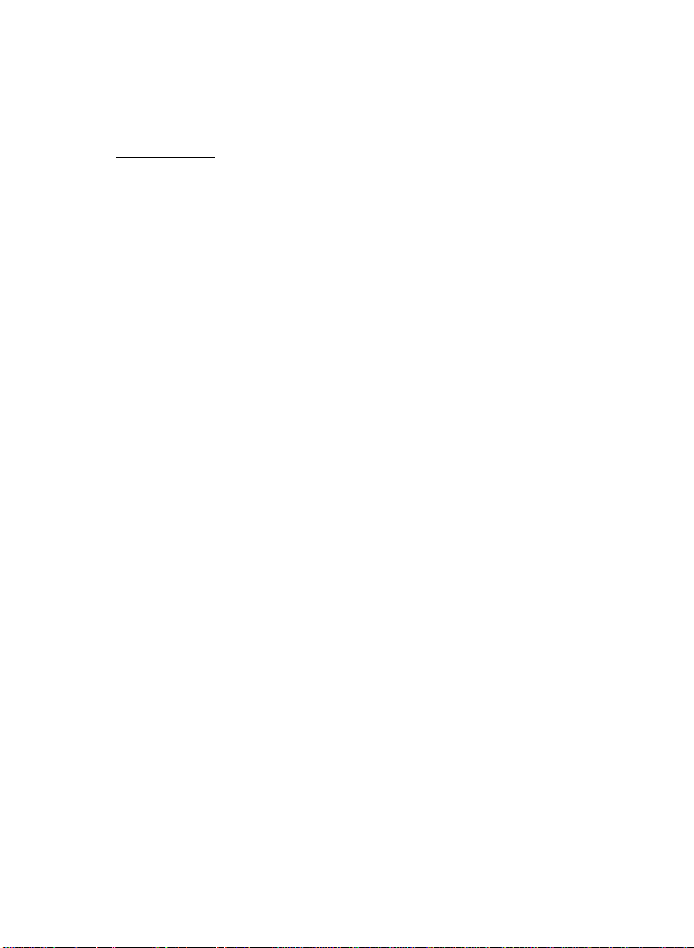

Page 14

CONTROL CIRCUIT

TERMINAL BLOCKS

MAIN CIRCUIT

TERMINAL BLOCKS

THESE terminal

BLOCKS ARE FOR

INPUT, OUTPUT,

GROUND, AND

OPTIONAL BRAKING

RESISTOR

CONNECTIONS

TOSHIBA

LOWER COVER INLET

CONNECTOR FOR

TOUCHPAD OR

TOUCHPAD EXTENSION

CABLE

SCREW HOLD FOR

TOUCHPAD

TO REMOVE UPPER

COVER, INSERT A

BLADE SCREWDRIVER

UNDER 4 CLASPS

AND LIFT GENTLY

CHARGE I AMP

DO NOT CHANGE WIRING

OR REMOVE UPPER

COVER WHEN LIT

3-3

Page 15

SINGLE PHASE

MCCB

POWER » ►

SUPPLY ^

SmOLE PHASE * ^

2Ù0.230VAC, 50/60HZ

RESET

FORWARD

REVERSE'

: : ¿‘ÎNTÊWloâC

MULTI- / : 1 f ■■■■

FUNCTION T T .............

SIGNAL \ ! ■...............

INPUT ^ ‘

AUTO +

REFERENCE

.......

....

■

........

..........................

ANALOG INPUT

. \AUtO :

^

] i

♦DBR NOT AVAILABLE ON SINGLE PHASE 1/8, 1/4HP UNITS.

VF-SX

RST

F

R

ST

cc

SSl

JOG/SS2

BX/SS3

AD2

PP

RR

CC

PA PB

GND(E)

D

FAULT

T1(U),

T2(V),

T3(W)

FLA

FLB

' FLC

FM/AM.

CC

P24

LOW/LL

RCIVUL,

M

FAULT SIGNAL

OUTPUT

FREQUENY/CURRENT

r*‘™X"*:i.SipNAL

I \SCAl£r

• ; 1mA

+24VÒC

T MULTI- FUNCTION

i SIGNAL OUTPUT

MAX

TOTAL

la

w

N»

O

O

CD

n

D»

"t

A>

B

(/)

CO

Page 16

THREE PHASE

MCCB

POWER

--------------

SUPPLY

--------------

THRBBPHÂSB ’ *

200 - 230VAC, 5(V60Hz

RESET

* FORWi^

i « RÌBvSiSÈ''

! isINTERLOCK

....

MULTI- / ; ± -

FUNCTION f ;

SIGNAL \ '

INPUT ^

................

ANALOG INPUT

iAUTO

¡REFERENCE

+ .¡.j..

..........

..............

;vAUTO

ÌìjìanrTv;;],

-.JÎÏ7

*DBR NOT AVAILABLE ON THREE PHASE 1/8, I/4HP UNITS.

L1(R)

U(S)

L3CD

RST

F

R

ST

cc

SSI

JOG/SS2

EX/SS3

AD2

PP

- RR

; CC

}■ IV

DBR*

PA PB xi(U)

VF-SX

FAULT

RELAY.

□ □ □

□ □ □

GND{E)

7T

■fi

FM/AM -

LOW/LL

RCHAJL

T2(V)

T3(W)

FLA

FLB

FAULT SIGNAL

OUTPUT

FLC

FREQUENY/CURRENT

-■‘•FtnX—

: ¡SCALE/'

I ;AT

: MmA

cc

i +24Vdc

P24

..f-...

MULTI- FUNCTION

M

MAX

TOTAL

SIGNAL OUTPUT

O

C/3

s

5

>

Page 17

Page 18

TOSHIBA

CHAPTER 4 Application Precautions

4-1

Page 19

4-2

1. If the drive is very lightly loaded (approximately 5*) or if the inertia

of the driven load is very small, the drive may become unstable. The

result could be abnormal vibration or overcurrent trip. If this condition

persists lower the PWM carrier frequency (parameter [C F]). See Chapter

12 for instructions.

2. Unstable results may occur if:

A. The output rating of the drive is less than the output rating of the

motor.

B. The drive is used with a motor with special ratings, such as an

explosion proof motor, or a motor specially built for high inertia

applications.

C. The drive is used with a pulsing load, such as a load requiring

repeated piston type operation.

3. The motor will coast to stop if the power is lost. If an immediate stop

or very quick deceleration of the motor is required use an auxiliary brake

device. Select the appropriate stopping method as described in Chapter 11

for an emergency stop.

4. GROUNDING

The inverter should be grounded in accordance with Article 250 of the

National Electrical Code or Section 10 of the Canadian Electrical Code,

Part I. The grounding conductor should be sized in accordance with NEC

Table 250-95 or CEC, Part I, Table 16.

TOSHIBA

Page 20

TOSHIBA

CHAPTER 5 Wiring Guidelines and Precautions

5-1

Page 21

5-2

This chapter of the manual discusses some of the basic wiring configurations and

external devices commonly associated with the installation and application of

variable speed drives. Local codes, specifications, requirements, and operating

conditions may require the addition of other devices or modifications to the

following basic recommendations.

TOSHIBA

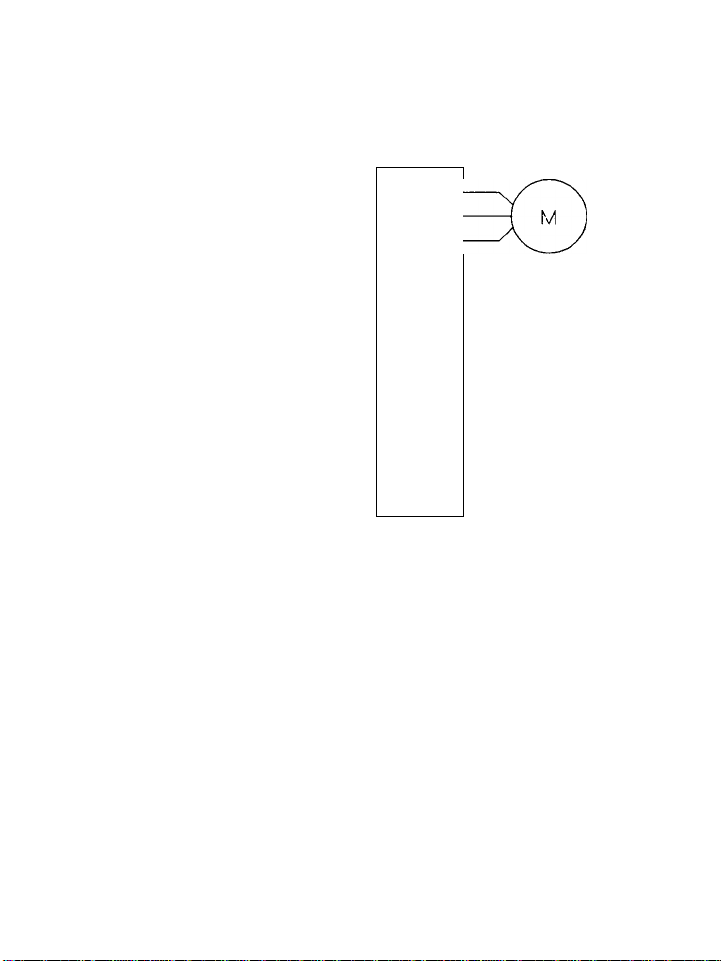

5.1 Inverter Wiring

(Refer to Figure 5.1 and 5.2)

1. It can be difficult to remove the upper cover after wiring, so change the

jumper selectors J1 or J2 on the internal PC board for "external signal

selection" before wiring the inverter. See Chapter 6 for the approximate

location of jumpers J1 and J2 inside the drive.

When a signal between 0 to 5V is used as frequency signal, switching the

jumper is necessary. Refer to Chapter 10, Table 10-9 for details.

2. Always turn the main line power OFF and confirm that there is no voltage

present with a testing tool before connecting power, motor leads, or

control wires.

3. WTOJIN^ Wait until the "CHARGE" lamp has turned off before working on

the drive. An internal capacitor stores electrical charge in the inverter

and electrocution may result due to inadvertent contact with this

capacitor. Do not touch the terminals or remove the cover while the

"CHARGE" lamp is on. This indicator is located in the lower right-hand

side of the drive near the terminal blocks, and it is a brightly lit red

LED when the drive is fully charged.

4. WARNING: Do not wire input power to the output terminals (U, V, W) of the

drive, this will damage the drive. Before energizing, confirm that motor

leads are attached to terminals U, V, and W and that the main power leads

are attached to terminals R, S, and T.

5. Exercise caution when wiring the control signals, as shown.

A. Install a surge suppressor on any electromagnetic coil on any

contactor wired to the drive. This includes line and load side

contactors.

B. Use shielded wire or twisted pair wire for control circuit wiring.

Keep this wire isolated from power wire.

C. Always isolate the input control signals from the main power wiring.

This restriction applies to all control terminals except FLA, FLB,

and FLC.

6. Wire sizes:

A. For wire to an ammeter, wire to a frequency meter, and wire carrying

input speed reference signals, use at least 16 gauge shielded wire.

B. For all other control wiring, use at least 12 gauge PVC coated wire.

Page 22

TOSHIBA

Inverter Main Circuit Terminal Block

Figure 5.1 Main Circuit Wiring

, 5-3

Page 23

5-4

TOSHIBA

MCCB

MC

R

U

V

s

W

T

F

Forward

Run/Stop

—oln

---

L_o o

----

/^jr^MCCB-Trip Coil

—

FLB

FLC

R

h

CC

Reverse

FLA

Figure 5.2 Simplified Power and Control Wiring

Run/Stop

5.2 Installation of a Molded Case Circuit Breaker (MCCB)

1. Install a molded case circuit breaker (HCCB) on the line side of the drive

for protection of the incoming power wiring only.

2. Turn the drive ON and OFF via control devices or the touchpad whenever

possible, and not by manual operation of the HCCB or MC. Use the control

terminals F. R, and CC to receive control signals from the appropriate remote

control devices.

Page 24

TOSHIBA

5-5

5.3 Installation of a Primary Magnetic Contactor (MC)

1. Install a magnetic contactor (HC) on the line side of the inverter to prevent

restart after either a loss of power, a trip of an external overload relay, or

an operation of the internal drive protective device.

2. The VF-SX has an internal fault detection relay. The HC can be opened when

the inverter protective circuit operates by connecting this contact point to the

primary MC operation circuit.

3. The inverter can be used without an HC. In this case use a shunt trip style

main breaker (MCCB) and open the main circuit by tripping the breaker when the

inverter protective circuitry operates.

4. When using a braking resistor with an overload relay, install an HC or an

MCCB with shunt trip on the line side of the inverter. Connect these devices so

that the power circuit will open when the internal fault detection relay (Ft) or

externally installed overload relay operates. Emergency stop is also possible

by connecting the overload relay contact point between the terminals of SS3 (EX)

and CC of the inverter. See Chapter 11 for details of the Emergency Stop

parameter.

5. Use control signals on terminals F, R, and CC for frequent starting and

stopping. Avoid turning the inverter on and off with the primary HC.

6. Always install a surge suppressor across any contactor coil.

5.4 Installation of an Output Magnetic Contactor (MC)

1. Avoid starting and stopping the motor with an output contactor (HC) installed

between the inverter and the motor. Excessive surge currents could damage the

output devices of the drive. Use control signals on terminals F, R, and CC

instead.

2. For Bypass Operation; Be sure the motor has stopped and the drive is OFF

before turning on the bypass contactor to run the motor directly from line power.

Use an external timer, PLC, or similar device as required. Always make sure that

the bypass contactor does not allow voltage to backfeed into the inverter output

terminals.

Page 25

5-6

TOSHIBA

5.5 Installation of an External Overload Relay

1. An electronic overload relay is standard on the VF-SX drive. However, for

the following applications Toshiba recomtnends Installing an overload relay that

coordinates with the internal solid state relay and the motor connected to the

drive. Connect the external relay between the drive and the motor.

A. When using a motor with non-standard current ratings, or the motor

ratings are not comparable to standard duty motors.

B. When operating a single motor smaller than the rating of the drive.

C. When operating several motors simultaneously from the drive. In this

case Install an overload relay on EACH motor.

2. When applying the VF-SX drive to a constant torque load, change the

electronic overload characteristics, or Install a separate overload relay. See

Chapter 11, Parameter [ bHrj.

3. When a motor continuously runs at low speeds it is recommended to use a motor

with an Internal overload relay, for additional protection.

5.6 Installation of an input Reactor

An input reactor Is used to suppress high frequency elements and sudden changes

In power fluctuations. Install an Input reactor when the Inverter Is connected

to electrical systems with the any of the following characteristics:

1. When the power capacity Is 200 KVA or more and the power capacity is

10 times or more than the Inverter capacity.

2. When the Inverter Is connected to the same system as a thyristor

commutation type controller.

3. When the inverter Is wired to an electrical system which also

contains a distortion source such as an arc furnace or a large

capacity inverter.

5.7 Incorrect Wiring and Incorrect External Components

WARHINS:

DO NOT INSTALL A POWER FACTOR IHPROVEHENT CAPACITOR ON THE INVERTER INPUT OR

OUTPUT. Current and voltage surges associated with the use of power factor

capacitors can damage the drive components.

If power factor correction is required add an optional input line reactor to

correct power factor.

Page 26

TOSHIBA

Radio Freouencv Interference

During operation of the drive there may be noise generated by the drive in the

frequency range associated with radio transmission signals. This noise may

adversely affect sensitive electronic equipment near the drive. If this

condition persists install a RF/EMI (Radio Frequency or Electromagnetic

Interference) filter on the input to the drive. Shield the motor leads in

metallic conduit. These steps will reduce radio frequency interference.

Contact Toshiba for details, or see Chapter 15.

WARWIH6:

Do not operate or energize the inverter before checking between the motor and the

inverter for mis-wiring or short circuits in the motor. Do not operate the drive

if the motor is shorted. Do not ground the neutral point of the motor star

winding.

5-7

5.8 Basic Wiring Recommendations

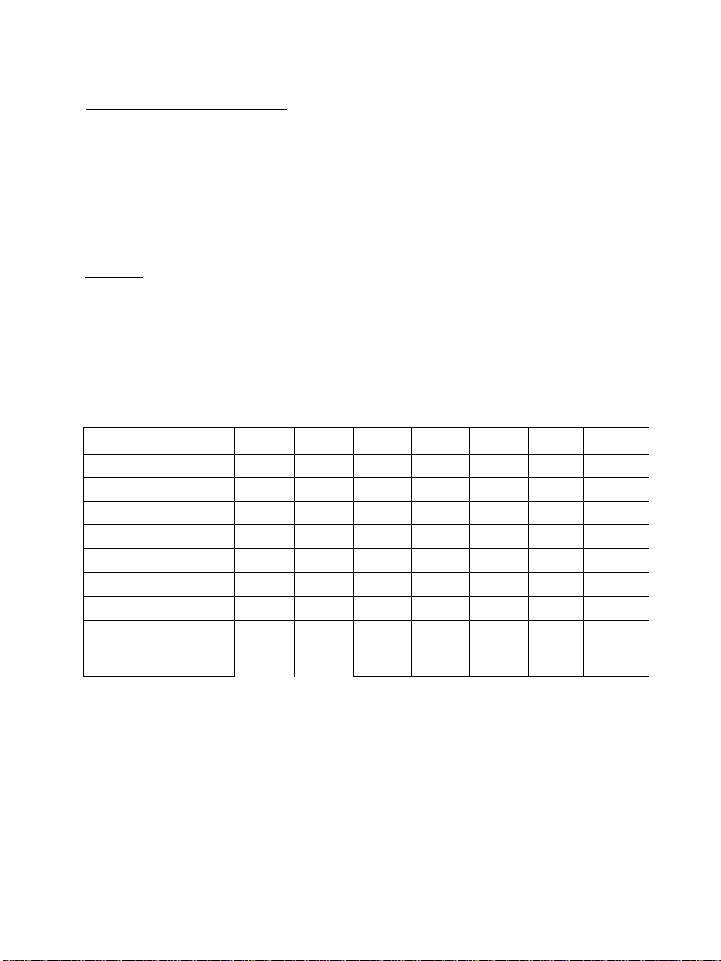

TABLE 5-1: BASIC WIRING RECOHMENOATIONS

2007UP

DRIVE MODEL VFSX- 2001UP

KW RATING 0.1 0.2

HP RATING

1/8 1/4

MCCB SIZE 5 A

HC AMPS (1) 12 A

OL RELAY RATING 0.7 A

POWER WIRE SIZE 12 GA

CONTROL WIRE SIZE 18 GA

WIRE SIZE FOR

REGENERATIVE

BRAKING RESISTOR

N/A N/A 14 GA

2002UP 2004UP

0.4 0.75

1/2

5 A 5 A 10 A

12 A 12 A

1.3 A 2.3 A

12 GA

12 GA

18 GA

18 GA 18 GA

2015UP1

1.5

1 2

15 A 20 A

12 A 12 A

4.2 A

6.6 A

12 GA 12 GA

18 GA

14 GA

12 GA 12 GA 12 GA 1

2022UP12037UP1 1

2.2 3.7 1

3 5 j

30 A 1

12 A

18 A 1

9.3 A 15 A 1

12 GA 10 GA 1

18 GA 18 GA 1

NOTES:

1.

Always use a surge suppression device on the coil of the MC contactor.

Use shielded cable on control circuits. See Figure 5.2.

2.

3.

Use 10 gauge wire or larger for ground circuit.

4.

Power wire sizes in table above are minimum size. For cable lengths over

100 feet, or where voltage drops may cause application problems, larger

wire may be required.

Page 27

Page 28

TOSHIBA

Chapter 6 Standard Connections

6-1

Page 29

6-2

The items printed in Italics in this chapter are Paraaeter names.

Refer to Chapter 7 for a list of all parameter names and Chapters 8 through 13

for instructions to set or adjust the parameters.

TOSHIBA

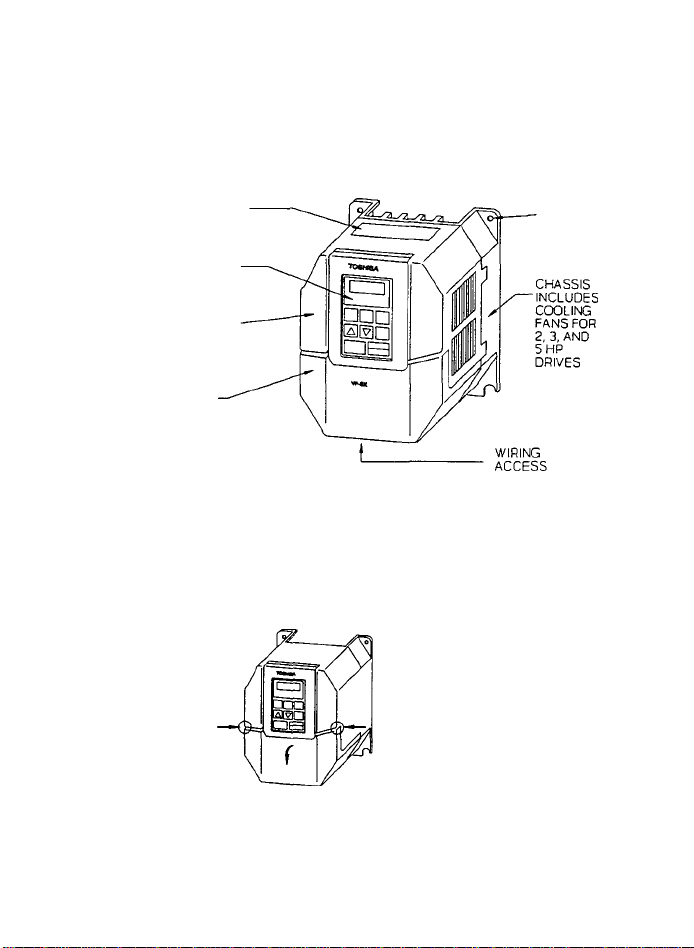

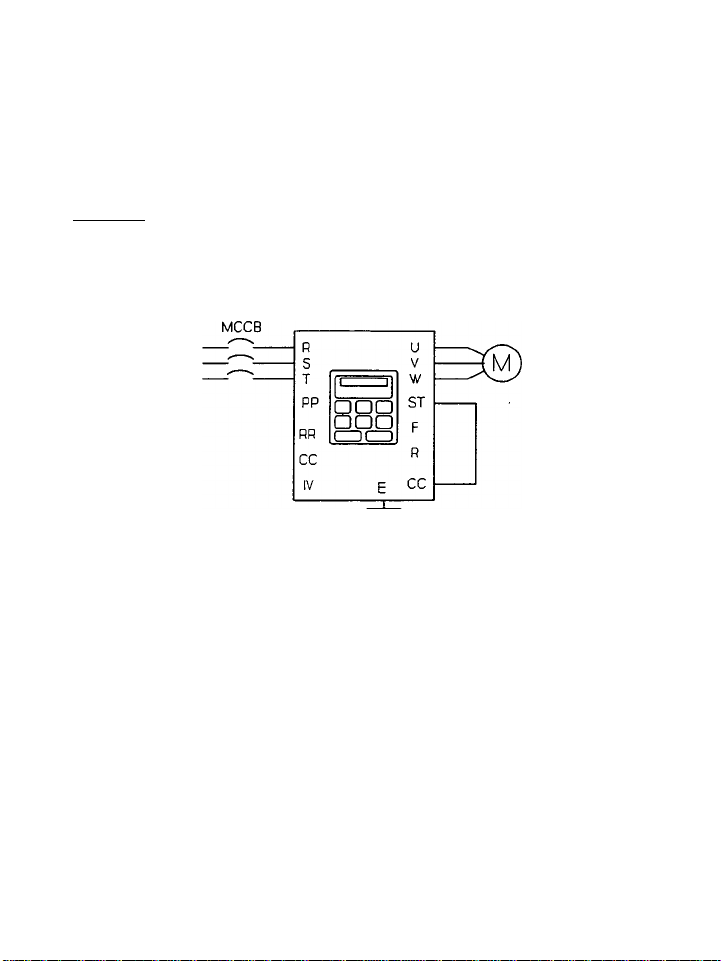

6.1 Examples of Standard Wiring

Example 1: To set the operation frequencies, and conduct forward/reverse run

and/or decelerating stop from the touchpad.

5X DRIVE

Figure 6.1

Setting: In the parameter group [Ci~. 5 t ] the Coaaand Mode Selection is set

to 3 (control terminal or touchpad input). Also, in the same parameter group,

the Frequency Setting Mode Selection is set to 3 (control terminal or touchpad

input). All Model VF-SX drives are shipped with these settings as the factory

default settings.

In Figure 6.1 above:

1. Incoming power is 200-230 volts, three phase, 50 or 60 Hz.

2. A factory installed jumper is present between terminals ST and CC.

3. All drive operation is from the touchpad control panel.

Page 30

TOSHIBA

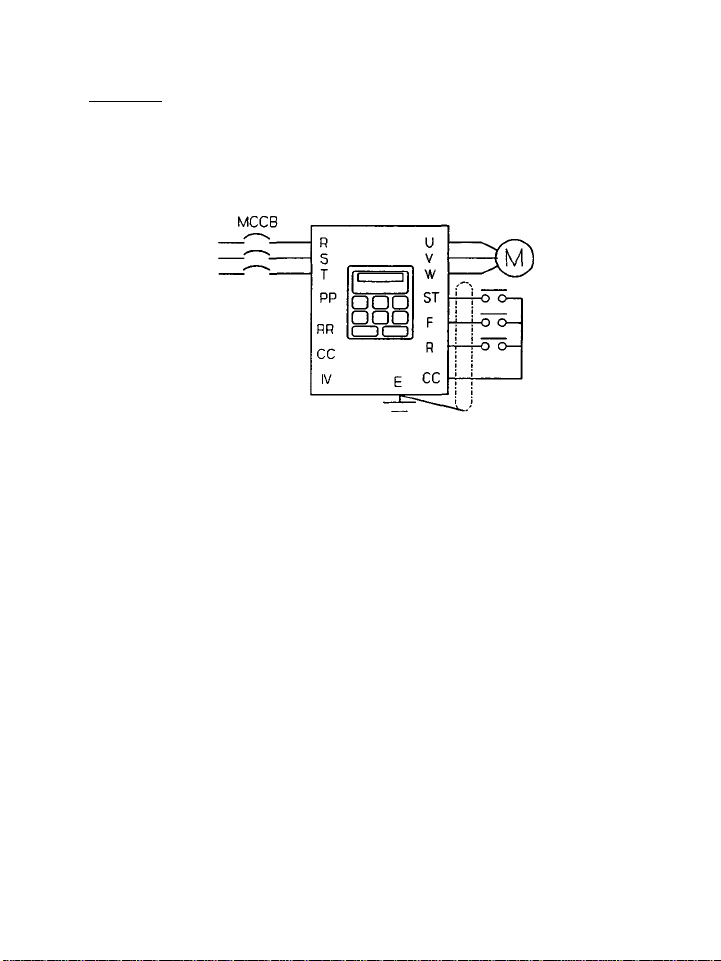

Example 2: To set the operation frequencies from the touchpad, and conduct

forward/reverse run, decelerating stop, and/or coast!ng-to-stop with external

signals.

6-3

5X DRIVE

Figure 6.2

Setting; In the parameter group [0 l~. 5 t ] the Command Mode Selection is set

to 3 (control terminal or touchpad input). Also, in the same parameter group

the Frequency Setting Mode Selection is set to 2 (only touchpad input valid).

In Figure 6.2 above:

1.

Incoming power is 200-230 volts, three phase, 50 or 60 Hz.

2.

When the ST-CC contact is open the drive will "Coast-to-Stop".

3.

When the ST-CC contact is closed, and the F-CC contact is closed the

drive will run "Forward". If the F-CC contact is opened the drive

will decelerate stop.

4.

When the ST-CC contact is closed, and the R-CC contact is closed the

drive will run "Reverse". If the R-CC contact is opened the drive

will decelerate stop.

Page 31

6-4

Example 3: To set the operating frequencies with external signals and conduct

the forward/reverse run and decelerating stop from the touchpad.

TOSHIBA

5X DRIVE

Figure 6.3

Setting: In the parameter group [C S fc ] the Comand Mode Selection is set

to 2 (only touchpad input valid). In the same parameter group the Frequency

Setting node Selection is set to 1 (only terminal input valid). When the

external signals are input at Terminal IV (see case 3 above), set Teminal IV

Input, also in parameter group [0i~. 5 fc], to 1 (engaged). In this case, the

current input on the IV terminal (4-20mA) will be the standard default setting.

When a 0-5V signal is the required control signal, set the jumper JP2 on the PCB

to V. When a O-IOV signal is to be chosen the input will be from terminals RR

and CC. When using 0-5V set the jumper JPl on the PCB to 5V.

In Figure 6.3 above:

1. Incoming power is 200-230 volts, three phase, 50 or 60 Hz.

2. Speed reference signal #1 is a potentiometer.

3. Speed reference signal #2 is a O-IOV DC control input signal.

4. Speed reference signal #3 is a 0-20mA, 4-20raA, or 0-5V DC control

input signal.

5. Jumpers JPl and JP2 are shown in their approximate location on the

internal printed circuit board, behind the front cover.

Page 32

TOSHIBA

Example 4: To set the operation frequencies, and conduct forward/reverse run,

decelerating stop and coasting stop with external signals.

6-5

SX DRIVE

Figure 6.4

Setting: In the parameter group [0 f~. S t ] the Comand Mode Selection is set

to 3 (control terminal or touchpad input), and the Frequency Setting Mode

Selection to 3 (control terminal or touchpad input). These are the standard

default settings. To carry out automatic operation with case 3 (4-20mA signal)

from remote controls and manual operation with the case 1 potentiometer set the

RR Terainal Input Prioritization to 1 and IV Input to 1. Manual setting values

are then accepted if the potentiometer is turned to generate a voltage between

RR and CC. Emergency stop is possible from the touchpad when the

pressed twice.

In Figure 6.4 above:

1.

Incoming power is 200-230 volts, three phase, 50 or 60 Hz.

2.

Speed reference signal #1 is a potentiometer.

3.

Speed reference signal #2 is a O-IOV DC control input signal.

4.

Speed reference signal #3 is a 0-20mA, 4-20mA, or 0-5V DC control

input signal.

5.

Jumpers JPl and JP2 are shown in their approximate location on the

internal printed circuit board, behind the front cover.

key is

Page 33

6-6

Example 5: To set the VF-SX Inverter for operation when a braking resistor is

connected. (This resistor is an optional device.)

Setting: Set the Regenerative Discharge Braking Selection to 2. (Enable the

braking resistor overload detection.)

In Figure 6.5 above:

1. Incoming power is 200-230 volts, three phase, 50 or 60 Hz.

TOSHIBA

Figure 6.5

Page 34

TOSHIBA

6-7

6.2 Terminal Functions

The arrangement of the control and power terminal blocks Is shown in figures 6.6,

6.7, and 6.8. The functions associated with the parameters listed on the

terminal blocks are shown in Table 6-1.

Control Circuit Terminals

nST AD2 CC SS1

R

F

SS2

CJOG)

ST

PP PR

CC

Figure 6.6

Nain Circuit Terminals (Three Phase)

E/G R/L1

S/L2 T/L3

Figure 6.7

Hain Circuit Terminals (Single Phase)

E/G L1/L [L2)

L3/N

Figure 6.8

SS3

CGX3

PM

CC

CC

CAMD

IV

CC

U/T1 V/T2 W/T3

T2/V

T1/U

T3/W

RCH

CUD

FLA FLB

LOW

CLL)

PA

PA

flc

P24

PB

PB

Page 35

Page 36

Chapter 7 Parameter Groups

TOSHIBA

7-1

Page 37

7-2

TOSHIBA

7.1 Definitions of SX Drive Group Parameters

[Cr.U]: USER PARAHETERS

This display shows all parameters which have been phanged from factory preset

values. This is a quick, easy way to examine drive parameters and tell at a

glance which parameters or functions have been changed, without having to search

through all the menus to examine each parameter and compare the value to the

factory preset value.

[ G r. F ]: FUNDAHEHTAL PARAHETERS {See Chapter 9)

This set of values contains adjustable parameters considered "fundamental” to

drive operation and application. These include acceleration and deceleration

times, base frequency, forward and/or reverse operation, upper and lower

operating frequency limits, and options for the Volts Per Hertz (V/f) ratios.

The option to reset the drive to all factory preset values or clear all past

trips is available from this menu.

[C r. 5 fc]: TERHINAL SELECTION PARAMETERS (See Chapter 10)

This set of values defines how different input and output terminals will function

during drive operation and affect drive operation. Virtually all commands

required for remote control or automatic operation of the drive are found in

these parameters. These functions allow the drive to signal when an upper or

lower limit has been reached, if the drive is running in forward or reverse, and

if the drive is accelerating or decelerating. Enabling or disabling various

control terminals and setting up multiple speed running conditions is available

from this menu.

[ C r. P r ]: PROTECTIVE FUNCTION PARAMETERS (See Chapter 11)

This set of values defines the type and amount of motor protection which will be

enabled during operation of the motor and driven load. Emergency stop, DC

injection braking, restart or "retry", current and voltage limits, stall enable

and parameters, and trip history are located in these parameters. The

programmable settings of the electronic overload as recognized by the National

Electrical Code are included in this section.

[Cr.C C] : CONTROL AND COMMUNICATION PARAMETERS (See Chapter 12)

This set of values identifies critical frequency parameters. These include the

PWH carrier frequency, motor tone selection, initial startup frequency, jump

frequency for critical resonance protection, automatic torque boost, slip

frequency compensation, and frequency hysteresis, which precludes rapid ON/OFF

cycling around a setpoint.

[Or .R fl]: METER ADJUSTMENT PARAMETERS (See Chapter 13)

These parameters control and adjust the scaling of the signals which drive remote

ammeters or frequency meters, provide bias and gain adjustments, and define the

Universal Unit Multiplication Factor, an output scaled to Hz, but user defined

to some other parameter other than frequency.

Page 38

TOSHIBA

7.2 Parameter Group Tables

TABLE 7-1: BASIC LIST OF PARAMETER GROUPS

7-3

Paraneter Group

TABLE 7-2: PARAMHER GROUP [ Cr.U j - USER MODIFIED PARAMETERS

1 Fwtction Title

1 Ranoe ■ant

1 * Oisplty of user «edified

B paranetert

* Only the parameters that have a set value that differs from the standard

default value will be displayed.

* When the parameter value is changed to be the standard default value, as

listed in the tables below, that parameter will be removed from this group.

u User Parameter

F

Fundamental

Sfc

: Selection of Terminal

Pr

: Protection

CC

: Control and Communication

Rf l

: Adjustment of AH/FH Meter

Adjuitaent

(Accordinp to each peraaeter

adjuatnent range)

unit Shi|T

Page

Page 39

7-4

TOSHIBA

TABLE 7-3: PARAMETER GROUP [ Cr.f] -

Function Title Adjustaent

Koxiaua Frequency

Bate Frequency

Torque Boost

V/f Pattern

Upper Liait Frequency

Lower Liait Frequency

Forward/Reverse Run

Selection

Acceleration Tiae 1

Deceleration TIae 1

Acc./Dec. 1 Pattern PE 1

Acceleration Tiae 2

Deceleration Tiae 2

Acc./Dec. 2 Pattern PEE

Acc./Dec. 1 or 2

Selection

Frequency for

Switching Between

Acc./Dec. 1 and 2 <*)

Drive Mode Selection

FH

uL

ub

Pt

UL

LL

Fr

RCCl

dECI

RCCP

dECP

RdE

RdEF

EUP

30 -- 240

25 — 240

0 — 30

0: Constant Torque

1: Variable Torque

0.5 — Naxiaua Frequency

0 -- Upper Halt Frequency

0: Reverse Run

1: Forward Rtn

0.1 - 3600

0.1 - 3600

0: Linear

1: S-Character 1

2: S'Character 2

0.1 - 3600

0.1 - 3600

0: Linear

1: $-Character 1

2: S'Character 2

0: Acceleratlon/Deceleration 1

1: Acceleratlon/Deceleration 2

2: Changeover of Acc./Dec.

Pattern 1 or 2

0 -- Kaxiaui Frequency

0: No Input Is Envied

1: General Purpose 50 NZ

Settings

2; General Purpose 60 M2

Settings

3: Standard Default Value

Settings

4: Clear Past Errors

FUNDAMENTAL PARAMETERS

Range

Unit Shlp-

0.1 KZ

0.1 KZ

IX

0.1 HZ 80

0.1 HZ 0 9-9

0.1 Sec 10

0.1 Sec 10 9-14

0.1 Sec 10

0.1 Sec 10

0.1 NZ 0 9-17

User

aent

Setting

80 9-4

60

3 9-7

0 9-8

1 9-10

0

1

0

<•*)

Page

9-5

9-9

9-14

9-15

9-14

9-14

9-15 1

9-17

9-19

The parameters marked with an asterisk (*) wi11 be displayed as detailed parameters

only when the parameter in the row imnediately above this function is selected for

adjustment or review.

(**)

(**) "0" is always displayed for this parameter

Page 40

TOSHIBA

TABLE 7-4: PARAMETER GROUP [ C T. 5 t ] - TERMINAL SELECTION PARAMETERS

Ftnetton

CoMMnd Mode Selection

Frequency SeCtfno Mode

Selection

Pereieeter Setting Oluble

Selection

Input Tenelnel Selection

Output Tenelnel Selection

Low-Speed SIgnel Output

Frequency

Low-Speed SIgnel Logic

Selection

Speed-Reech Frequency

(If other then "0*):

Speed Selection Reeched

(•)

Speed Reeched Detection

Renge (*)

IV Input

<*>

IV Point 1 Setting Signel

IV Point 1 Frequency

IV Point 2 Setting Signet

IV Point 2 Frequency

RR Tenelnel Input

Prioritizetlon

•logging Run Frequency

(Other then 0 HZ)

•Jogging Stop Pettem (*)

Title

cnod

FnOd

pnod

1 bb

Obb

LF

LFHL

FrCH

rCH

rrCH

1 u 1 n

p 1

F-P 1

P8

F-p e

rrCC

JOG

dSbP

AdJuBtaent

Range

0: No Input Is Enabled

1: Only Reaote Input Valid

2: Only Touchpad Input Valid

3. Use Tenelnel or Tnuchped

0: Ho Input Is Enabled

1: Only Renote Input Valid

2: only Touchpad Input Valid

3: Use Teminal or Touchpad

0: Setting Disabled

1: Setting Enabled

0: SS2, SS3

1: MG , SS3

2: SS2, EX

3: .JOO, EX

0: LL, Ul

1. LOU, UL

2. LL, RCN

3. LOU, RCN

0 — Maxinun Frequency

0: Open Collector Output OFF

1: 0^ Collector Output ON

0 -- Maxiaui Frequency 0.1 HZ 0

0: Signal is output when

Aec/Dec is conpleted.

1: Specified frequency reach

signal output.

0 -- Maxinun frequency 0.1 KZ02.5

0: Disengaged

1: Engaged

0 -- 100

0 -- Maxinun Frequency

0 •• 100

0 -- Maxinun Frequency

0: Nomal

1: RR Prioritized

0-20

0: Decelerating stop

1: Coasting stop

2: DC injection braking stop

Uhlt

0.1 Hz 0.5

1 X

0.1 KZ

1 X

0.1 KZ

0.1 HZ

Shlp-

User

nent

Setting

3

3

1

0

3

0

0 10-12

20

0

100

80

0

0 10-U

0 10-U

Page

10-2

10-3

10-3

10-4

10-6

10-7

10-7

10-7

10-7

10-8

10-12

10-12

10-12

10-12

10-12

7-5

Page 41

7-6

TABLE 7-4: PARAMETER GROUP [CT. 5 t] - TERMINAL SELEaiON PARAMETERS (CON'T)

The parimeters narked by an asterisk (*) will be displayed as detailed parameters only

when the parameter in the row Immediately above this function Is selected for

adjustment or review.

TOSHIBA

Page 42

TOSHIBA

TABLE 7-5: PARAMETER GROUP [GC.P T] - PROTECTIVE FUNCTION PARAMETERS

1 Fwictlon Title Adjuataent

1 Regenerative

1 Discharge Braking

1 Selection

1 Overvoltage Liniting

1 Action Selection

DC Undervoltage

Startva» Frequency

(Other than 0) (*)

DC Injection Braking

Voltage

DC Injection Braking

Tiae

Eaiergency Stop

(2> Eaergency DC

Injection Braking

Stop Control Tiaie (*)

Retry Selection

Power Control

Function Selection

Electronic Thenaal

Protective Level

Stall Prevention

Activation Level

Electronic Theraal

Protection

Characteristic

Selection

Trip Retention

Selection

Pb

OP55

dbP

dbu

dbt

ESbP

Edbb

rkrd

UuC

EHr

SEL

Din

ErCL

0: Regenerative Discharge

1: Regenerative Discharge

2: Regenerative Discharge

0: Engaged

1: Disengaged

0 -• 10 0.1 KZ 0 11-^

0 -* 20

0 •• 5

0: Coasting Step

1: Decelerating Stop

2: Eaergency DC Injection

0 - 10

0: OFF

1: ON

0: OFF

1: on

10 •• 100 1 X 100

10 -- 150,

(200: Mon-operating)

0: Standard Motor without SS

1: Standard Motor with SS

2: VF Motor without SS

3: VF Motor with SS

(Mete: SS - Soft Stall)

0: Clear with Power OFF

1: Retain Even with Power

Range

Braking Disengaged

Braking Engaged without

Overload Protection

Braking Engaged with

Overload Detection

Braking Stop (EDB)

OFF

0.1 Sec00

0.1 Sec 0.1

unit

1 X

1 X 150

Ship-

User

sent

Setting

0 11-2

0

0

0

0

0

0

7-7

Page

11-2

11-A

11-A

11-6

11-8

11-8

11-10

11-11

11-11

11-11

11-13

The parameters marked with an asterisk (*) will be displayed as detailed parameters

only when the parameter in the row immediately above this function is selected for

adjustment or review.

Page 43

7-8

TOSHIBA

TABLE 7-6: PARAHETER GROUP [О Г.С C] - CONTROL AND COMMUNICATION PARAMETERS

1 Function Title Adjustment Unit Skip- User

1

H Stort'Up Frequency Setting

Operation Starting

Frequency

Operation Starting

Frequency Hysteresis

Junp Frequency

Jump Frequency 1 <*)

Jump Width 1 (*>

Jiep Frequency 2 (*>

JuRp Width 2 (*)

Juap Frequency 3 (*)

Jinp Width 3 (*)

F-5t

Frun

FH3S

FJ.n

FJ 1

b h и 1

Fja

bFija

FJ3

0 -- Maximus Frequency

0: Juap Function OFF

0 -* Maximum Frequency

0-30

0 -- Maximus Frequency 0.1 HZ 0 12-5

0 •• 30

0 -- Maximus Frequency 0.1 HZ

0-30

Range

0.5 - 10

0 — MaximuR Frequency 0.1 HZ

1: Jimp Fiaiction Engaged

0.1 HZ 0.5

0.1 HZ 0 12-4

0.1 HZ 0 12-5

0.1 HZ 0 12-5

0.1 HZ 0 12-5

0.1 HZ 0

■ant Setting

0.5 12-4

0 12-5

0 12-5

bF J3

PWM Carrier Frequency

Motor Tone Selection

Output Voltage Adjustment

Power Voltage Coapensation

1 Automatic Torque Boost

No-load current (*)

Naxiaua torque boost value

(•)

Slip Frequency

Coapensation

No-load current (*)

Motor slip frequency

rating <*>

CF

CF5

po ut

PRdJ

Rub

CUrO

ubH

5FC

CUrO

SFr

0.5 - 3 0.1

0: Monotonous Tone

1: Integral Tone

0 -- 100 (0 - 120) 1 X 100

0: Not Cospensated

1: Compensated

0: Engaged

1: Disengaged

0 -- 50 IX

0 -- 30 1X

0: Not compensated

1: Compensated

0 •• 50 IX

0 -- 10 0.1 HZ 3

kHZ

2

0

0

0 12-8

10 12-9

6 12-9

0 12-10

10 12-11 1

Page

12-3

12-5

12-6

12-6

12-6

12-6

12-11 1

The parameters marked with and asterisk (*) will be displayed as detailed parameters

only when the parameter in the row immediately above this function is selected for

adjustment or review.

Page 44

TOSHIBA

7-9

TABLE 7-7: PARAMETER GROUP [ C T. fl /7] - PARAMETERS FOR METER ADJUSTMENT

Fwtion Title Adjustment

Connected Meters Adjustment

(See Below) Connection

(0) Frequency Meter

Adjustment (*)

(1) Anneter Adjustment (*}

Adjustment of the RR input

terminal bias

Adjustsient of the RR input

terminal gain

Universal Unit Multiplication

Factor

The parameters marked with an asterisk (*) will be displayed as detailed parameters

only when the parameter in the row immediately above this function is selected for

adjustment or review.

FnRfl

Ffl

Rfl

rr—b

rr-0

dSPE

Range

0: Frequency Meter

(See Chapter 13} 13-2

0 - 255 1

0 -■ 255 1

0: OFF, or

0.01 -■ 200

unit Ship-

User

ment Setting

0

64

128 13-5

0 13-7

Rage

13-2

13-3

13-5

Page 45

Page 46

TOSHIBA

Chapter 8 Basic Operation Theory

8-1

Page 47

8-2

This portion of the manual explains some of the most simple methods of operation

of the Toshiba VF-SX variable speed drive.

OPERATION FROM THE TOUCHPAD IS ASSUMED FOR ALL EXAMPLES IN THIS CHAPTER. UNLESS

OTHERWISE NOTED.

TOSHIBA

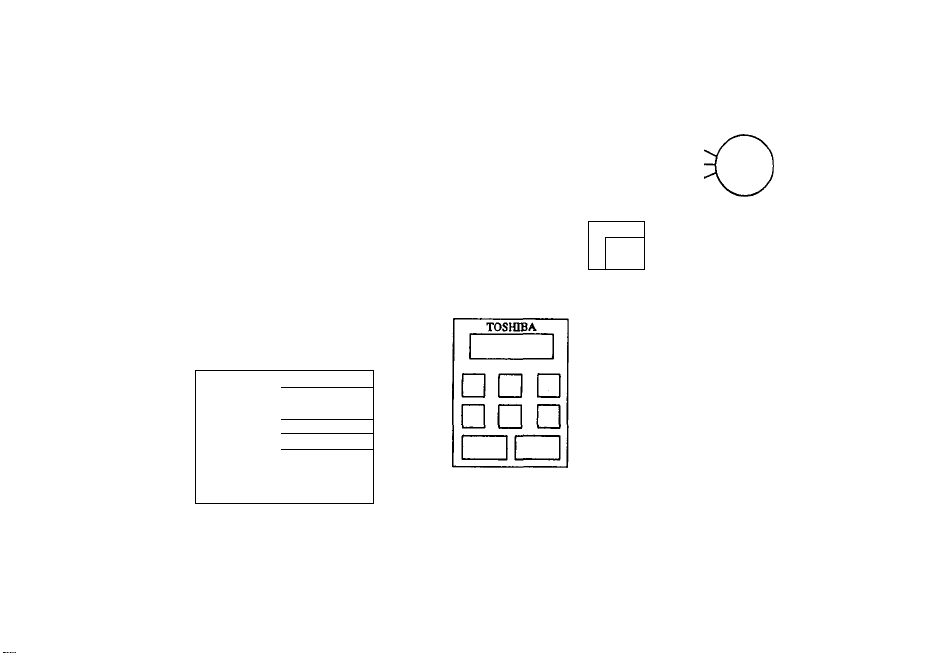

8.1 Operation of the Touchpad Control Panel

The inverter operation, functions, and data settings can be monitored with the

touchpad control panel.

TOSHIBA

O № O SE C O

Q PANEL CONTROL

_________

PANEL/

REMOTE

A V

RUN

Figure 8.1 Layout of the Control Panel (Touchpad)

MON

PRO

ENTER

STOP

RESET

Page 48

TOSHIBA

8-3

PANEL/

REMOTE

The "PANEL/REHOTE" key is used to switch the SX drive

between panel control (operation from the touchpad) and remote

control - control from remote signals attached to the correct

input terminal blocks.

The "HON" (Monitor) key is used to make the display show any

monitored value available, such as forward or reverse run, % amps,

assigned run frequency, past trip data, or other items. See 8.2.2

in this chapter for a complete explanation.

The "PRG" (Program) key is similarly used to switch the

drive from other modes of operation to the "Program’ mode, and

thereby allow programming or changing of the numerous parameters

as required to match operating conditions.

The "UP ARROW" key is used to increase parameter settings,

scroll upwards through program group parameters, or upward through

monitor values.

The "DOWN ARROW’ key is used to decrease parameter setting,

scroll downwards through program group parameters, or downward

through monitor values.

The "ENTER" key is used to select or set a value of any

parameter such as run frequency or other data into permanent

memory.

Page 49

8-4

TOSHIBA

STOP

RESET

O Hz O SEC

O PANEL CONTROL

The "RUN" key is used to start operation of the drive,

is valid ONLY when the "PANEL CONTROL" LED is lit.

The "STOP/RESET" key stops operation of the drive, when the

drive is in "PANEL CONTROL" mode. Emergency stop operation is

possible by pressing this key TWICE, when the drive is in any

other mode. The inverter is reset from this key (depress for 1

second, minimum) after a trip.

This 7 segment, 4 digit LED display shows

operating frequency in DRIVE mode, the status of a

variety of data in the MONITOR mode, the title of the

parameter groups, and the values of these parameters

o*

in the PROGRAMMING mode. In the event of a trip, the

cause of this trip is displayed. The "Hz", "SEC",

"X", or "PANEL CONTROL" LED’s will be illuminated as

appropriate in all modes.

It

8.2 Display Modes

The Toshiba Model SX inverter has four types of operation and display modes, as

shown below:

1. Drive Mode

2. Monitor Mode

3. Programming Mode

4. Jogging Mode

For basic drive operation, this section of the manual will discuss all of these

modes as they apply when using the touchpad to operate the drive. There are many

options for remote control of the drive discussed in later chapters of this

manual.

Enter Monitor Mode by pressing the l“°"l key. To re-enter Drive Mode press thpl I

key again. Enter Programming Mode by pressing the s key. To return to Drive

Mode press the E^Z] key again. If there is no input within 3 seconds from

depressing the or the drive will automatically return to Drive Mode

and display the frequency.

Page 50

TOSHIBA

8-5

8.2.1 Drive Mode

The Drive Mode is automatically selected every time power is initiated to the

drive. In this mode the inverter output frequency monitoring and the frequency

setting coraniand value is taken from non-volatile memory and implemented. A

status warning (indicating a possible trip] is displayed during operation, if

this condition is warranted. Trip information for any type of trip is displayed

whenever the inverter is tripped OFF. The LED monitor display will show these

trip codes.

If no warning or trip has occurred the LED display shows the frequency value.

This is the frequency which the drive sends to the motor. When the drive is

first energized the display will read 0.0. The "HZ" LED beneath the LED

display will be lit, indicating the display is showing a value of frequency.

A status warning indicator is a one of three flashing characters to the left of

the frequency in the LED display. These characters indicate an overcurrent

condition, an overvoltage condition, or an overload condition. Under most

circumstances, if these conditions are not cleared the drive will eventually

trip.

If the drive does trip, the trip code indicating the cause of that particular

trip will be displayed on the LED monitor display. See Chart 1 below for a

summary of all trip codes. See Chapter 16 for a brief discussion about potential

solutions to drive trips.

1. Setting or Changing an Output Frequency

To implement a frequency change press the or keys while the drive is

in the Drive Mode. If the frequency command value is changed during operation,

the operating frequency will also change accordingly. If the frequency command

value is different from the operating frequency then acceleration or deceleration

will occur, based on the accel/decel time parameters currently programmed in the

drive. It is possible to prevent a frequency change from the touchpad, by

changing the parameter Frequency Setting Mode Selection [FHOd]. See

Chapter 10.

2. Status Warning

A warning character and a frequency value are sometimes displayed alternately on

the LED display when running in the drive mode. The following three warning

characters can be displayed:

[C]

.....

When a current more than the overcurrent stall level is detected.

[P]

.

When a voltage more than the overvoltage stall level is detected.

[L]

.....

When the overload trip parameter ( tHr ) calculates that output

current has exceeded more than approximately 75X of the trip value.

Page 51

8-6

These alarm displays will turn off automatically when the alarm conditions no

longer exist. Typically, the drive will eventually trip OFF if any one of these

conditions persists. See section 8.8 in this chapter for more details.

3. Trip Information

If the VF-SX drive trips while in the Drive Mode, the cause or type of this trip

will be displayed immediately on the LED monitor display. The display will

continuously flash a trip code indicating the cause of the trip. Furthermore,

the registered trip status can be read out from drive memory.

The flashing trip display will remain on continuously until the power is turned

"OFF" or the trip is cleared. Refer to Section 8.7 — Error Reset, (in this

chapter) for instructions to clear a trip, return to the Drive Mode, and run the

drive.

Table 8-1 below shows a list of all trip codes which the drive can display. This

information is also available in the Appendix.

Table 8-2 below shows an example of a drive trip occurrence, and of the data

stored for examination in drive memory when a trip occurs. Six other parameters

describing the software versions and past'trip history can also be observed by

stepping further into the menu shown in this Table. Press the or keys

to scroll through this data. If the I“”"! key is pressed next the initial trip

code will be shown.

If the or keys are pressed continuously during this procedure, the

displayed item will change every 0.5 seconds and display in order. The display

can be changed to the trip information display status by pressing the key

at any time during this procedure.

TOSHIBA

Page 52

TOSHIBA

TABLE 8-1: LIST OF TRIP CODES AND EXPLANATIONS

8-7

Display

OCI

0C9

OC3

OCL

OCR

OP

op e

OH

OL

E

SEP

E rrP

Err3

1 OLr

Explanation

Overcurrent trip (OC) during acceleration.

Overcurrent trip (OC) during deceleration.

Overcurrent trip (OC) during operation.

Load side overcurrent (output terminal check trip at start

up).

Arm overcurrent (GTR check) trip at start.

Overvoltage (OP) detected on DC bus.

Overvoltage (OP) detected on DC bus during deceleration.

Inverter overheating (OH) trip.

Motor overload (OL) trip.

Emergency Stop.

EEPROM abnormality (adjustment or other data).

RAH abnormality.

ROM abnormality.

Overload trip In regenerative discharge braking resistor.

Page 53

8-8

TABLE 8-Z: SAMPLE OF TRIP OCCURRENCE

TOSHIBA

1 Key

1 Guide

s

0

0

0

[V]

0

0

Use of the

or scroll

Display

0C3

: 50.0

: Fr F

: 60.0

: C ISO

■.S 100

: P 90

II Mil

11

. II

key at any time will allow review of the previous item or value,

"upward" through these values in the opposite direction.

Drive Mode (flashing display). Motor coasts. I

Operating frequency during trip.

Operation direction during trip.

Operating frequency command value during trip.

Load current during trip, in %.

Input voltage during trip (* of 200 VAC)

Output voltage during trip.

Input terminal status during trip. (See

Appendix).

Output terminal status during trip. (See I

Appendix). 1

Explanati on I

8.2.2 Monitor Mode

The Monitor Mode allows a user to examine the status of several key operating

conditions of the drive. These conditions are listed in Table 8-3. Consult the

Appendix in the back of this manual as well, for an Interpretation of the input

and output terminal Information.

This mode is activated by depressing the LIIll key, when running in the Drive

Mode. To return to the Drive Mode press the key again. To go to the

Programming Mode press the 0 key.

S

Page 54

TOSHIBA

TABLE 8-3: MONITOR OPERATION EXAMPLES OF THE DRIVE WHILE IN DRIVE MODE

8-9

Key

Guide

[3 E

® S

® S

S ®

Display

0.0

: Fr F

: 60.0

: C 50

-.0 100

: P 15

II Mil

l>

li

: u / гo

: UE 0

:0C3^I

: oн«г

: 0P^3

: OL^H

: Fr F

Explanation

Drive mode (frequency is displayed)

Forward [F] / Reverse [f*].

Frequency connand value.

Load current (%) being monitored.

Input voltage (X of 200 VAC) being

monitored.

Drive output voltage (*)

Input terminal information (refer to

Appendix).

Output terminal information (refer to

Appendix).

The version number of software on the drive

CPU.

The version number of software on the

EEPROH.

(Display alternates) The most recent trip.

(Display alternates) The second most recent

trip.

(Display alternates) The third most recent

trip.

(Display alternates) The fourth most recent

trip.

Operation direction display, (rollover to

the 1st menu item).

Page 55

8-10

If either the Li:=J or 1_LJ keys are pressed continuously during the above

procedure, the display will scroll every 0.5 seconds to the next item.

At any time during the HONITOR operation depress the or 1"^°et| ¡(gyj

which will cause the inverter to revert to the Drive Mode, or depress the

E3

key and enter to the Programming Mode. Switching to the "REMOTE" mode to

implement some form of remote control is also possible, but only if the drive is

stopped. The arrow key above in the trip history display shows that the

data is alternately displayed every 0.5 seconds.

TOSHIBA

8.2.3 Programming Mode

This mode is activated by pressing theEHl

to the Drive Mode press the

the l“°"l key.

The Programming Mode is used to examine and revise all the drive parameters,

including the parameter display, setting functions, and adjustment functions.

Parameter Settings and Display Function

The following procedure describes how to set or change the parameters values.

A.

Enter the Programming Mode (Press the key.)

B.

In the group display state, select the desired group parameter with

the E]i^] keys, press the FHI key, and move to the parameter

name display state.

C.

After entering the parameter name display state, select the desired

parameter name with the [AIFI keys, press the key, and move

to the value display state.

In the value display state, set the data with the lAjIA]

D.

E.

Store the new values into the main memory with the

Refer to section 1 of this chapter for a description of how to operate the

touchpad keys. Refer to Chapter 7 for the list of all drive parameters.

key again, or to enter the Monitor Mode press

key from the Drive Mode. To return

keys.

key.

Page 56

TOSHIBA

8-n

8.2.4 Jogging Mode from the Touchpad

This mode is used to operate the inverter at a low speed for brief intervals.

Short time operation ("inching") can be performed easily. The following

operations make use of the touchpad. U is also possible to use remote control

signals for the [JOC] feature. See Chapter 10 for instructions.

NOTE: Remember to set the Jog Run Frequency [ JOC] and Jog Stop

Pattern [l/5 t P]before using the Jog feature. See the Chapter 10 for

instructions.

After these parameters are set, enter the Jogging Mode with touchpad control by

performing the following programming steps. Be sure the "PANEL CONTROL" LED is

ON.

TABLE 8-4: KEYSTROKES TO ENTER JOG FUNCTION FROM THE TOUCHPAD

Keys

EEH

S

1 R U n|

Q

Display

: Or.U

:FJ00

-.rJOG

5.0

0.0

Explanation

Press the key TWICE. The Jogging mode is not

activated by any other keys. When using the touchpad

for jogging, and the jog frequency is set to some

value other than 0 HZ, the jogging mode is activated

by the second EZZl keystroke. When nai using the

touchpad or when the jogging run frequency is not

set, the second keystroke of the EEEl will return

the drive to drive mode (frequency display).

Press the key to "jog run" reverse.

Press the key to "jog run" forward.

The jog setting frequency will be output to the motor

while the key is depressed.

The return to the Drive Mode press the key.

Page 57

8-12

TOSHIBA

8.3 PANEL/REMOTE Control

Either the "PANEL" mode or the "REMOTE" mode of drive control may be selected.

In the "REMOTE" mode any commands from the touchpad are ignored (except EMERGENCY

STOP). A brief explanation of the Emergency Stop function is shown in Section

8.4 in this chapter. See Chapter 11.3 for a complete explanation of the

EMERGENCY STOP function.

In the "PANEL" mode all commands from control signals connected to the terminal

blocks are ignored, including speed pots and 4-20mA input signals.

Switching between the "PANEL" and "REMOTE" modes is accomplished with thel^SI!]

key on the touchpad. This setting can only be changed while the drive is

stopped. The LED display shows 0.0 when the drive is stopped.

The Comand Mode can be set so that "PANEL" control or "REMOTE" control is never

possible. See Chapter 10, parameter [ cnod ], for an explanation.

When power is first turned ON the drive is energized in the drive mode. If the

drive is controlled from the touchpad the LED indicating "PANEL CONTROL" will be

illuminated. If the drive is not controlled by the touchpad this LED will not

be on, and the drive will accept input control signals from the terminal blocks.

I PANEU I

8.4 Selection of Stopping Method from the Touchpad

The following three methods can be selected for stopping the drive from the

touchpad. All three methods use the eHiI key to implement a stop command to the

motor from the drive, as described below.

METHOD 1 — Ramp Stop When the Drive is in Panel Control

Step 1. Press the EIIIS key on the touchpad.

The drive will DECELERATE at the programmed rate to a complete stop.

Page 58

TOSHIBA

METHOD 2 — Coasting Stop When the Drive Is In Panel Control

8-13

Step 1. Press the ElIlS key on the touchpad.

The frequency display is removed from the LED display and

[ C b L ] is displayed on the LED screen.

Step 2. Press the key on the touchpad.

METHOD 3 — Emergency Stop When the Drive is NOT in Panel Control

Step 1. Press the eE113 key on the touchpad.

Step 2.

The drive will turn off power to the motor and the motor will COAST

to a stop as the driven load allows.

The drive mode is activated and the LED will display [E 0 F F]

Press the 1"^^^ key again.

[E] (flashing) will be displayed on the LED and Emergency Stop will

be activated. Emergency Stop can be Coasting, Decelerating, or DC

Injection Braking type, depending on the programmed parameters for

this method of stopping.

STOP

[E 5 E P] (Emergency Stop) Settings are:

Coasting Stop

Decelerating Stop

Emergency DC Injection Braking Stop

When E is selected also set the DC injection braking time [Ec/fa E],

DC injection braking start frequency [dbF], and the DC injection

braking amount [dbU],

When [E 5 t P] - E is chosen (Emergency DC Injection Braking Stop),

and the DC injection braking is NOT required during nonnal stop, set the

DC injection braking time to [ dbt] . 0.

Page 59

8-14

TOSHIBA

The Emergency Stop command Is a command to forcibly stop the operation by

depressing the Inverter unit keys on the touchpad when the drive Is not

controlled from the touchpad. This cannot be prohibited by any setting of

the Command Mode. The emergency stop will be regarded as a trip and will

be registered as a past error In the trip history section of the drive

memory.____________________________________________________________________

8.5 Starting the Drive from the Touchpad

After confirming all wiring Is connected to the proper terminals, the Inverter

may be operated using factory default settings, via the touchpad. This Is the

most simple mode of operation for the Inverter. This can serve as a simple test

for the Inverter/load combination. (See Chapter 6 for a brief look at the most

simple methods of control and power wiring for the drive.)

The factory default settings for all parameters are shown In Chapter 7.

It Is recommended to start the Initial run at a low frequency/speed for any test

operation.

Table 8-5 shows the touchpad keystroke sequency for starting the drive.

CAUTION:

Page 60

TOSHIBA

TABLE 8-5: STARTING THE DRIVE FROM THE TOUCHPAD

8-15

Procedure

Power On

IPANEU 1

|pq^e[

|ei^er[

pp U N j

I^E °Et|

Turn on power to the Inverter with the HCCB. If the

display shows [OFF], the proper operating conditions

are not set, and operation will not be possible. Close

the connection between terminals ST and CC. Operation is

possible if rO.Ol is displayed.

Change to Panel Control by pushing the key. The

"PANEL CONTROL" LED will turn on. Operation from the

touchpad will now be possible. If the lf55Z!l button is

pushed again, the light will turn off, and touchpad

control will be deactivated.

Adjustment of the operating frequency/speed is

accomplished from the and keys on the touchpad.

When these keys are depressed the "PANEL CONTROL" light

will flicker, indicating the numerical value in the LEO

display is changing. When the desired frequency is shown

press the key and the display will alternately show

F C and the frequency, in order. When the key is

depressed the assigned running frequency is stored in the

drive’s memory.

Depressing this key will energize the output circuits.

The frequency display will begin to increase at the

programmed acceleration rate, and the motor will begin to

rotate.

Depressing the ImMiI key will cause the inverter to ramp

the load to a stop at the programmed deceleration rate.

Operation

IPANEU 1

IMNEU 1

CAUTION:

If the power switch Is turned OFF during step 4 above, the motor will coast

to stop. However, DO HOT stop the Inverter In this fashion unless there is

an emergency. Always avoid starting and stopping the Inverter from the

power switch.

________________

____________________

Page 61

8-16

TOSHIBA

8.6 Changing Frequency from the Touchpad

The running frequency can be changed before the drive ever runs the motor. Be

sure the drive is in the "PANEL CONTROL" mode.

Continuously depress the or keys on the touchpad. The display will

rapidly scroll through the frequencies available to run the motor. Fine tune the

desired frequency by pressing the arrow keys, incrementing the frequency by 0.1

HZ each time.

When the desired running frequency is displayed in the LEO display.

press l:

___

procedure assigns the running frequency, and loads this value into memory.

If the 1ZZ3 key is depressed at this time the drive will accelerate to this

frequency. The time of acceleration will be determined by the acceleration

parameters iRCCI ] or [Rccг ] in memory.

If the arrow keys are depressed to change frequency while the drive is running,

the load will begin to accelerate or decelerate at the rate programmed for these

parameters.

TABLE 8-6: CHANGIN8 THE FREQUENCY DURING OPERATION

I. This frequency and F 0 will alternate on the LED display. This

Procedure

[a]®

1 ENTER I

Operation

The frequency can be changed during operation by

pressing the key or key. This causes the

operation frequency of the motor/load and the LED

display to change simultaneously.

The operation frequency can be changed without pressing

the key, but when the power is turned OFF, the

frequency setting value will return to the value before

changes were made.

Page 62

TOSHIBA

8-17

8.7 Error Reset

In the event that the Inverter should trip, the fault relay (Ft) will change

state. See Part 9 or this chapter for more information about the fault relay.

The inverter can be reset after a trip, by removing the cause of the trip. To

reset a trip perform any of the following steps:

1. Turn off incoming power to the inverter for at least 10 seconds.

2. Provide momentary "short circuit" or jumper between terminals RST and CC.

3. Reset the drive from the EHn key on the touchpad.

The touchpad key will clear a fault when operated as shown in Table 8-7.

TABLE 8-7: CLEARING A FAULT WITH THE "STOP/RESET" KEY

Touchpad

Operation

RTlipl fSTOPl

[resH

Hold the button down for approximately 1 second, until

Function

[ C L i~] appears on the LED display.

Momentarily depress the same key. The drive will clear and

reset itself, when all trip causes and errors have been

removed.

NOTE: Some drive trip occurrences are caused by a timed overload calculation in

drive software. Usually this condition is due to the motor being operated in a

overcurrent condition, which may cause an unsafe level of motor heating. If this

calculation determines that the motor may still be too hot to re-energize, then

the drive will not reset until enough time has passed for the motor to cool down.

In some cases this period can last for several minutes, preventing reset for this

length of time.

If this drive/motor overload combination occurs the drive monitor LED display

will continue to display the trip indication parameter, even after the reset

procedure shown in Table 8-7 is implemented, until the drive software will allow

a reset.

Page 63

8-18

TOSHIBA

8.8 Warning Displays

When attempting to set a frequency parameter using the and keys,

it is possible to try to adjust some parameters above or below certain limiting

values. If this occurs the drive will alternately display the maximum or minimum

frequency available and warning indicators [H/ ] or [t.0].

[H I ] Warning: The setting value is beyond its upper limit or the

[L 0] Warning: The setting value is beyond its lower limit or the

Frequency parameters that are limited by the [F H] (Maximum Frequency),

[ i. L ] (Lower Limit), or lUL ] (Upper Limit) cannot be set to exceed these

values. An example of this type of frequency parameter would be the multispeed

run frequencies. (See Chapter 10). In some cases, the set value may be exceeded

as a result of changing the [ FH], lULi. and/or [L L] values. In this

case, if the parameter that has exceeded the range is selected, a warning will

be displayed, but only when this parameter is viewed, and the or iteyj

are depressed. When either of these keys is depressed the set value will change