Page 1

ADJUSTABLE SPEED DRIVE NETWORK INTERFACE

ICC

INDUSTRIAL CONTROL COMMUNICATIONS, INC.

INDUSTRIAL CONTROL COMMUNICATIONS, INC.

INDUSTRIAL CONTROL COMMUNICATIONS, INC.INDUSTRIAL CONTROL COMMUNICATIONS, INC.

ETH-100

ETHERNET COMMUNICATIONS INTERFACE

FOR THE TOSHIBA 7-SERIES AND 9-SERIES

ADJUSTABLE SPEED DRIVES

April 2002

ICC #10449-1.100-000

Page 2

Introduction

Thank you for purchasing the ICC, Inc. ETH-100 Ethernet Communications Interface

for the Toshiba 7-Series and 9-Series Adjustable Speed Drives. Before using the

ETH-100 interface, please familiarize yourself with the product and be sure to

thoroughly read the instructions and precautions contained in this manual. In

addition, please make sure that this instruction manual is delivered to the end user of

the drive units with which the ETH-100 interface is connected, and keep this

instruction manual in a safe place for future reference or drive/interface inspection.

This instruction manual describes the device specifications, wiring methods,

maintenance procedures, supported functions and usage methods for the ETH-100

Ethernet communications interface.

In conjunction with this manual, the following manuals are supplied by Toshiba, and

are essential both for ensuring a safe, reliable system installation as well as for

realizing the full potential of the ETH-100 interface:

• Toshiba TOSVERT VF-S7 Series Instruction Manual

• Toshiba TOSVERT VF-S9 Series Instruction Manual

• Toshiba TOSVERT VF-A7 Series Instruction Manual

• Toshiba G7 Series Operation Manual

• Toshiba VF-S7 Industrial Inverter Serial Communications Option Manual

If you do not have copies available of the documents relevant to your installation,

please contact Toshiba or your local Toshiba distributor to obtain them, or copies

may be downloaded from http://www.tic.toshiba.com

Before continuing, please take a moment to ensure that you have received all

materials shipped with your kit. These items are:

• External ETH-100 interface in DIN rail mountable case

• 2 meter DB9-RJ45 MMI port cable (part number 10425)

• This manual

(subject to availability).

1

Page 3

ETH-100 Ethernet Interface User's Manual

Part Number 10449-1.100-000

Printed in U.S.A.

©2001-2002 Industrial Control Communications, Inc.

All rights reserved

Industrial Control Communications, Inc. reserves the right to make changes and

improvements to its products without providing notice.

Notice to Users

INDUSTRIAL CONTROL COMMUNICATIONS, INC.’S PRODUCTS ARE NOT

AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE-SUPPORT

DEVICES OR SYSTEMS. Life-support devices or systems are devices or systems

intended to sustain life, and whose failure to perform, when properly used in

accordance with instructions for use provided in the labeling and user's manual, can

be reasonably expected to result in significant injury.

No complex software or hardware system is perfect. Bugs may always be present in

a system of any size. In order to prevent danger to life or property, it is the

responsibility of the system designer to incorporate redundant protective mechanisms

appropriate to the risk involved.

2

Page 4

Usage Precautions

Operating Environment

• Please use the ETH-100 only when the ambient temperature of the

environment into which the ETH-100 is installed is within the following

specified temperature limits:

Operation

Storage

• Avoid installation locations that may be subjected to large shocks or vibrations.

• Avoid installation locations that may be subjected to rapid changes in

temperature or humidity.

: -10 ∼ +50°C (+14 ∼ +122°F)

: -40 ∼ +85°C (-40 ∼ +185°F)

Installation •••• Wiring

• Do not touch charged parts of the drive such as the terminal block while the

drive’s CHARGE lamp is lit. A charge will still be present in the drive’s internal

electrolytic capacitors, and therefore touching these areas may result in an

electrical shock. Always turn all drive input power supplies OFF, and wait at

least 5 minutes after the CHARGE lamp has gone out before connecting

communication cables or motor wiring.

• Proper ground connections are vital for both safety and signal reliability

reasons. For proper grounding procedures, please refer to the section in this

manual pertaining to grounding (section 4).

• Route all communication cables separate from the drive’s input/output power

wiring.

• To avoid the possibility of electric shock due to leakage currents, always

ground the drive’s E/GND terminal and the motor. To avoid misoperation, do

not connect the ETH-100’s GND terminal to either of the above-mentioned

grounds or any other power ground.

• When making connections between the ETH-100 and the drives, do not use

cables that exceed 5 meters in length.

• For further drive-specific precaution, safety and installation information, please

refer to the appropriate Toshiba documentation supplied with your drive.

Other Precautions

• Internal drive EEPROMs have a limited life span of write cycles. Observe all

precautions contained in this manual and Toshiba manuals regarding which

drive registers safely may and may not be repetitively written to.

• Do not touch or insert a rod or any other item into the ETH-100’s case while

power is applied, as this may lead to electrical shock or device damage.

• Commission the disposal of the ETH-100 to a specialist.

• Because the ETH-100 derives its control power from the connected drives,

removing power to all connected drives will also cause the ETH-100 to lose

power.

3

Page 5

TABLE OF CONTENTS

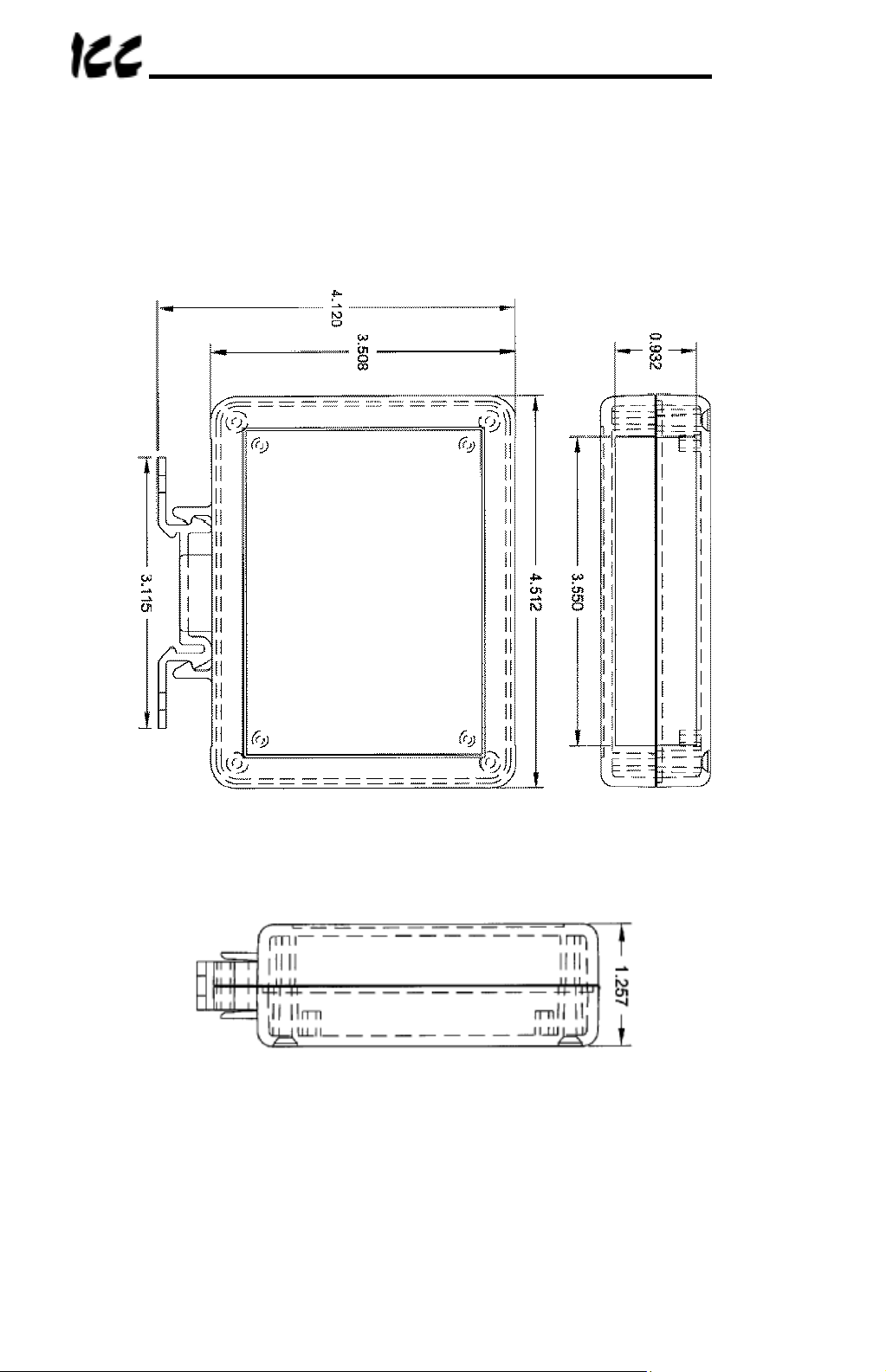

1. Mechanical Diagrams........................................................................... 6

1.1 Enclosure.........................................................................................................6

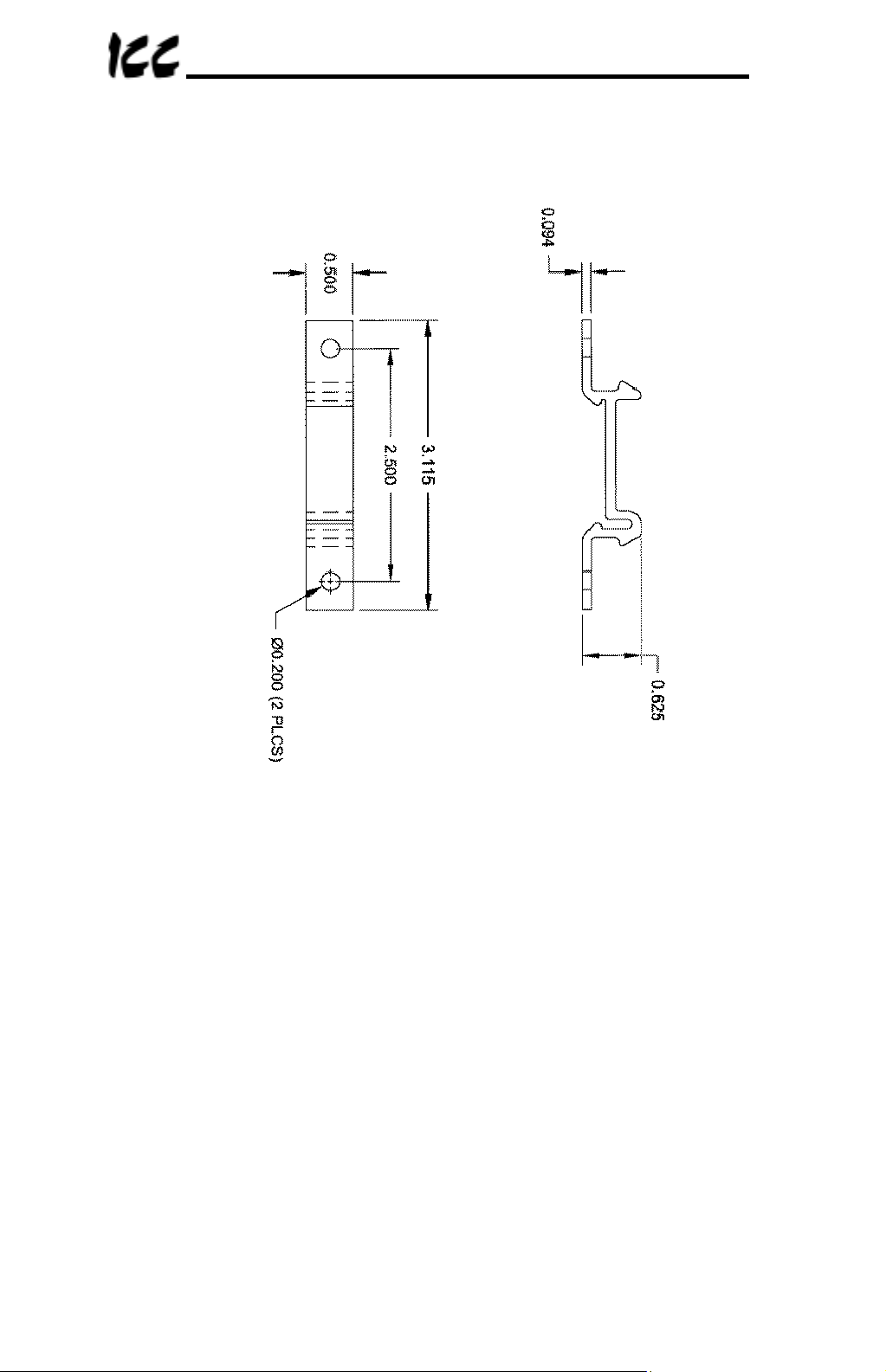

1.2 Mounting Clip ...................................................................................................7

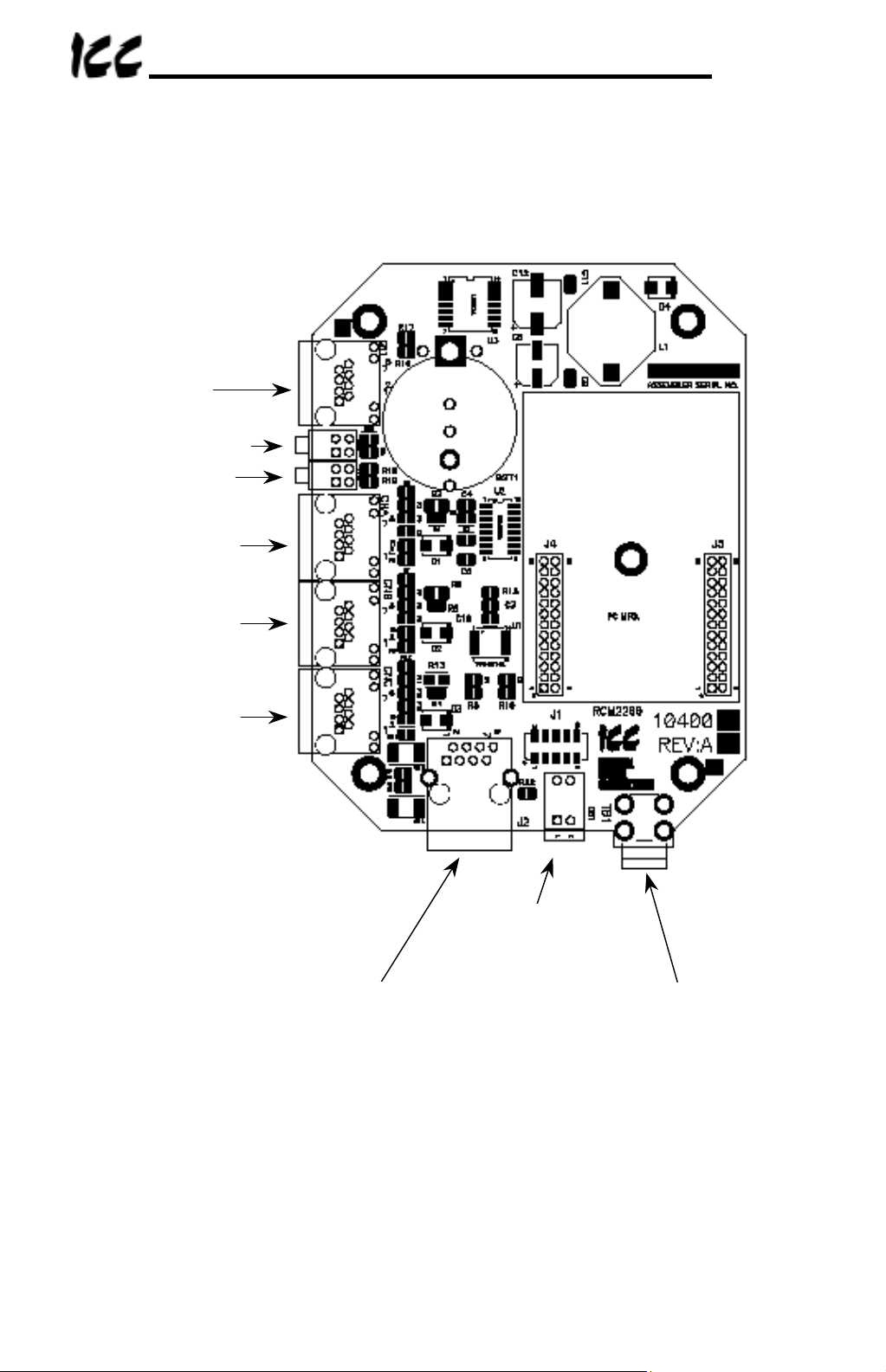

1.3 External Interface .............................................................................................8

2. Feature Summary ................................................................................. 9

3. Installing The Interface ...................................................................... 12

3.1 Installation for G7 Drives................................................................................12

3.2 Installation for S7, S9 and A7 Drives..............................................................13

4. Grounding ........................................................................................... 15

5. Environmental Specifications ........................................................... 16

6. Maintenance And Inspection............................................................. 17

7. Storage And Warranty........................................................................ 18

7.1 Storage ..........................................................................................................18

7.2 Warranty ........................................................................................................18

8. Console Configuration....................................................................... 19

8.1 RS232............................................................................................................19

8.1.1 Requirements..........................................................................................19

8.1.2 Connection..............................................................................................19

8.1.3 Application Configuration ........................................................................19

8.2 Telnet.............................................................................................................21

8.2.1 Requirements..........................................................................................21

8.2.2 Connection..............................................................................................21

8.2.3 Application Configuration ........................................................................21

8.3 Command Overview.......................................................................................22

8.4 Console Configuration Backup.......................................................................24

9. LED Indicators .................................................................................... 25

9.1 Module and Ethernet Indicators......................................................................25

9.2 Drive Connector Indicators.............................................................................25

9.3 MMI Connector Indicators ..............................................................................26

10. Modbus TCP/IP ................................................................................... 27

10.1

Drive Channel Access ................................................................................27

10.2

Supported Modbus Functions.....................................................................27

10.3

Modbus/Drive Register Mappings ...............................................................28

4

Page 6

10.4

Register Remap Function ...........................................................................29

10.5

ASD Scan Registers ...................................................................................30

10.6

Modbus Programmable Pointer Registers ..................................................30

10.7

Register Access Notes ...............................................................................31

10.8

Performance Tips .......................................................................................32

10.9

Exceptions and Troubleshooting.................................................................34

11. Embedded Web Server.......................................................................35

11.1

Setup Page.................................................................................................36

11.2

Modbus Page .............................................................................................37

11.3

Channels Page ...........................................................................................38

11.3.1 Channel Select........................................................................................39

11.3.2 ASD Scan Register Configuration ...........................................................40

11.3.3 Programmable Pointer Registers Configuration ......................................41

11.3.4 Drive Test Commands.............................................................................42

12. Firmware Updates...............................................................................43

12.1

Requirements .............................................................................................43

12.2

Connection .................................................................................................43

12.3

Using The RFU Utility .................................................................................44

12.3.1 Required Files.........................................................................................44

12.3.2 First-time configuration............................................................................44

12.3.3 Transmitting Firmware Files ....................................................................46

12.4

Wrap-Up .....................................................................................................46

13. Notes....................................................................................................48

5

Page 7

1. Mechanical Diagrams

1.1 Enclosure

(All units are in inches)

6

Page 8

1.2 Mounting Clip

(All units are in inches)

7

Page 9

1.3 External Interface

MMI port

Network Link/Act LEDs

Module Status /

Network Status LEDs

ASD Channel A

ASD Channel B

ASD Channel C

Ethernet Network

Configuration

DIP switches

SHIELD grounding terminal

(refer to Section 4).

Note that for clarity the above diagram shows the ETH-100 unit removed from its

case. However, it is not necessary to remove the unit from its case in order to

install or configure the ETH-100.

8

Page 10

2. Feature Summary

The ETH-100 interface provides a wide array of network data access and drive

control features. Combined with the flexible configuration and standard 10BaseT

Ethernet/Internet connectivity, this allows powerful networked control and monitoring

systems to be designed. This in turn provides easy and direct data transfer

capabilities to PLCs, PC-based control systems and a wide array of

manufacturing/ERP and plant control software packages.

Network

IEEE 802.3 10BaseT Ethernet compliant. Shielded RJ45 connector accepts

standard CAT5-type 8-conductor unshielded twisted-pair (UTP) patch cables.

Drive Connections

The ETH-100 provides support for simultaneous connection of three Toshiba 7-series

or 9-series drives via the drives’ common serial (aka logic level) communication

ports. All drives share a common IP address. Drive connections use the same

standard RJ45 style 8-conductor UTP patch cables: any standard CAT5 Ethernet

cable (found in most electronics stores) 5 meters or less in length can be used to

connect the ETH-100 to the drives.

Power Supply

Self-contained. Powered directly from the connected drives. Drives can be

connected to the ETH-100 on any channel (A, B or C) in any order or combination.

When more than 1 drive is connected to the unit, the ETH-100 will draw its control

power from the drive with the highest power supply voltage.

Supported Protocols

Current support for Schneider Electric Modbus TCP/IP, release 1.0. Conformance

Class 0 and partial Class 1 compliant. Allows up to 8 simultaneous Modbus TCP/IP

client connections.

Text-Based Console Configuration

The unit can be configured via a simple text-based console interface, available locally

over RS232 by using the enclosed MMI cable or remotely over Ethernet via a telnet

session.

Embedded Web Server

Unit configuration and drive monitoring and control are also provided via an

embedded web server using the HTTP protocol. The ETH-100’s web server feature

provides direct access and control via standard web browsers such as Microsoft

Internet Explorer and Netscape Navigator.

9

Page 11

Drive AutoScan Algorithm

Connections to the drives are automatically established and continuously monitored.

No drive configuration needs to be performed to connect the ETH-100 to the drives.

Just plug it in – it’s that simple.

User-Configurable Scan Registers

In order to provide faster access to internal drive data, the user has the ability to

program up to 8 ASD registers per channel to be locally mirrored within the ETH-100.

This greatly increases the speed with which accesses to these registers can be made

by the network master.

Programmable Pointer Registers

16 Modbus programmable pointer registers are provided to allow “bundling” of

disassociated registers. This allows registers which may be scattered around the

Modbus register map to be accessed by issuing only 1 Modbus transaction request.

When combined with the user-configurable scan registers, this feature provides

accessibility of any combination of ASD registers with fast response in a single

Modbus transaction.

Indicators

• 1 green “LNK” LED that is on whenever a valid Ethernet connection is detected.

• 1 red “ACT” LED that flashes whenever data is transferred across the Ethernet

network.

• 1 bicolor red/green “MS” LED that indicates module status information.

• 1 bicolor red/green “NS” LED that indicates network status information.

• 2 green LEDs on each of the drive communication connectors and on the MMI

port connector.

Refer to section 9 for more detailed information about the LED indicators and their

meanings.

Selectable Grounding

Switch SW1 #2 allows the ground plane to be split into 2 different sections: one for

the main control circuitry and another for the Ethernet network connector shield and

associated magnetics. The latter ground point is accessible for external termination

via the GND screw terminal located on the bottom of the unit. Refer to section 4 for

more information related to grounding.

MMI Port Connector

RS232-level. Use the DB9-to-RJ45 MMI cable supplied with the ETH-100 kit to

interface with the unit for either console-based configuration or flash firmware

downloading.

10

Page 12

Field-Upgradeable

As new firmware becomes available, the ETH-100 unit can be upgraded in the field

by the end-user. Refer to section 12 for more information.

Versatile 3-Way DIN-Rail Mounting System

The unit’s enclosure is provided with a mounting clip attached to the rear of the unit.

This clip allows the unit to be mounted 3 different ways:

• For DIN rail mounting, snap the mounting clip onto a standard DIN rail, and

then snap the unit enclosure onto the clip’s retaining tabs. This allows easy

removal or repositioning of the unit on the DIN rail during wiring.

• For panel mounting, the mounting clip can be bolted directly to a flat panel via

the two bolt holes at the top and bottom of the clip. Refer to section 1.2 for

mounting clip mechanical details. Once the mounting clip is securely

attached to the panel, the unit enclosure can be snapped onto the clip’s

retaining tabs.

• For fixed DIN rail mounting, a combination of the above two techniques can

be employed. First, snap the mounting clip onto a DIN rail and position it in its

desired location. Then, the mounting clip can be bolted to the DIN rail support

panel, securing it in place. Lastly, the unit can be snapped onto the fixed

mounting clip.

In all cases, the unit can be easily unsnapped from the mounting clip to temporarily

provide easier access to the configuration switches or network connector.

11

Page 13

3. Installing The Interface

The ETH-100 connects to each drive via the drive’s common serial (logic level)

communication port, typically located on either the main drive control board (G7), on

the front of the drive enclosure under a small snap-on cover (A7, S9), or on the righthand side of the drive enclosure under a small snap-on cover (S7). Although no

drive parameters need to be configured in order to use the ETH-100, it is

advantageous to check that the drive’s common serial communication data rate is set

to its maximum speed. Because the ETH-100 will communicate to each drive only at

the drive’s configured data rate, this will provide the fastest response time for driveto-network data transfers. For information on checking the drive’s common serial

communication data rate, refer to the appropriate manual supplied with your drive.

Note that the common serial communication parameters of each drive are handled

independently by the ETH-100, which means that different drive families may be

connected to different channels of the unit in any combination, and that the drives

connected to each channel may simultaneously communicate to the unit at

completely different baud rates, parity settings, etc.

Installation of the ETH-100 Ethernet interface should only be performed by a qualified

technician familiar with the maintenance and operation of the connected drives. To

install the ETH-100, complete the following steps:

3.1 Installation for G7 Drives

1.

connected have been turned OFF and are locked and tagged out.

2.

capacitors to discharge before proceeding to the next step. Do not touch any

internal parts with power applied to the drive, or for at least 5 minutes after

power to the drive has been removed. A hazard exists temporarily for

electrical shock even if the source power has been removed. Verify that the

CHARGE LED has gone out before continuing the installation process.

3. Attach the mounting clip and unit enclosure in your desired manner (refer to page

11 for more information).

4. Remove the drive’s front cover / open the drive’s cabinet door (refer to the

appropriate drive manual for instructions how to do this).

5. The drive’s Electronic Operator Interface (EOI) can communicate with the drive

via either the RS485/RS232 channel (CNU1/CNU1A) or the common serial

channel (CNU2/CNU2A). Because the ETH-100 uses the common serial

channel, the EOI must be configured to use the RS485/RS232 channel. If the

drive to be connected is currently using CNU2 (on the drive control board) and

CNU2A (on the EOI), then this connection must first be switched over to CNU1

(on the drive control board) and CNU1A (on the EOI). Refer to Toshiba’s

documentation for any precautions or notices regarding this connection change.

CAUTION!

DANGER!

Verify that all input power sources to the drives to be

Wait at least 5 minutes for the drive’s electrolytic

12

Page 14

If the EOI is already connected via the RS485/RS232 channel, then no change is

required.

6. Connect the drive’s common serial communication port (CNU2) to one of the

channels (A, B or C) of the ETH-100 with the communication cable

(communication cable is not included with the interface kit). When choosing

cables for this connection, standard 24 AWG category 5 (CAT5) unshielded

twisted-pair (UTP) 8-conductor cables found in Ethernet networks in most office

environments can be used. The maximum allowable length for these cables is 5

meters. Although there are many varieties and styles of CAT5 UTP cables

available, ICC strongly recommends using only high-quality cables from reputable

manufacturers to guarantee optimal noise immunity and cable longevity. Ensure

that each end of the cable is fully seated into the modular connector, and route

the cable such that it is located well away from any drive input power or motor

wiring. Also take care to route the cable away from any sharp edges or positions

where it may be pinched.

7. Reinstall the drive’s front cover / close the drive’s cabinet door.

8. Repeat steps 1, 2, 4, 5, 6 and 7 to connect other drives as needed.

9. Connect the Ethernet network cable to the shielded RJ45 connector marked

“Network” on the bottom of the unit. If a ground cable is going to be used, attach

the ground cable to the screw terminal marked “GND” on the bottom side of the

unit (refer to section 4). Ensure that the network cable is fully seated into the

modular connector, and route the cable such that it is located well away from any

drive input power or motor wiring. Also take care to route the cable away from

any sharp edges or positions where it may be pinched.

10. Take a moment to verify that the ETH-100 and all network cables have sufficient

clearance from drives, motors, or power-carrying electrical wiring.

11. Turn the power sources to all connected drives ON, and verify that the drives

function properly. If the drives do not appear to power up, or do not function

properly, immediately turn power OFF. Repeat steps 1 and 2 to remove all

power from the drives. Then, verify all connections. Contact ICC or your local

drive distributor or manufacturer for assistance if the problem persists.

3.2 Installation for S7, S9 and A7 Drives

1.

connected have been turned OFF and are locked and tagged out.

CAUTION!

Verify that all input power sources to the drives to be

2.

3. Attach the mounting clip and unit enclosure in your desired manner (refer to page

13

DANGER!

capacitors to discharge before proceeding to the next step. Do not touch any

internal parts with power applied to the drive, or for at least 5 minutes after

power to the drive has been removed. A hazard exists temporarily for

electrical shock even if the source power has been removed. Verify that the

CHARGE LED has gone out before continuing the installation process.

11 for more information).

Wait at least 5 minutes for the drive’s electrolytic

Page 15

4. Remove the drive’s common serial communication port cover (refer to the

appropriate drive manual for instructions how to do this). Do not discard this

cover, as it should be reinstalled to minimize contamination of the port’s electrical

contacts if the interface is ever disconnected from the drive.

5. Connect the drive’s common serial communication port to one of the channels (A,

B or C) of the ETH-100 with the communication cable (communication cable is

not included with the interface kit). When choosing cables for this connection,

standard 24 AWG category 5 (CAT5) unshielded twisted-pair (UTP) 8-conductor

cables found in Ethernet networks in most office environments can be used. The

maximum allowable length for these cables is 5 meters. Although there are many

varieties and styles of CAT5 UTP cables available, ICC strongly recommends

using only high-quality cables from reputable manufacturers to guarantee optimal

noise immunity and cable longevity. Ensure that each end of the cable is fully

seated into the modular connector, and route the cable such that it is located well

away from any drive input power or motor wiring. Also take care to route the

cable away from any sharp edges or positions where it may be pinched.

6. Repeat steps 1, 2, 4 and 5 to connect other drives as needed.

7. Connect the Ethernet network cable to the shielded RJ45 connector marked

“Network” on the bottom of the unit. If a ground cable is going to be used, attach

the ground cable to the screw terminal marked “GND” on the bottom side of the

unit (refer to section 4). Ensure that the network cable is fully seated into the

modular connector, and route the cable such that it is located well away from any

drive input power or motor wiring. Also take care to route the cable away from

any sharp edges or positions where it may be pinched.

8. Take a moment to verify that the ETH-100 and all network cables have sufficient

clearance from drives, motors, or power-carrying electrical wiring.

9. Turn the power sources to all connected drives ON, and verify that the drives

function properly. If the drives do not appear to power up, or do not function

properly, immediately turn power OFF. Repeat steps 1 and 2 to remove all

power from the drives. Then, verify all connections. Contact ICC or your local

drive distributor or manufacturer for assistance if the problem persists.

14

Page 16

4. Grounding

Grounding is of particular importance for reliable, stable operation. Communication

system characteristics may vary from system to system, depending on the system

environment and grounding method used. The ETH-100 interface is provided with a

“GND” screw terminal on the bottom of the unit. This “GND” terminal constitutes an

effective “chassis ground”, and is directly connected to the metallic housing of the

shielded RJ45 Ethernet network connector and to the appropriate locations on its

integrated isolation magnetics.

This chassis ground plane is physically separate from the ETH-100’s control logic

ground plane, which is directly referenced to the CC (control common) terminal on

the connected drives. Switch SW1 #2 on the ETH-100 unit, however, provides a

method to selectively connect these 2 ground planes together.

When switch SW1 #2 is ON (switch in the “down” position when looking at the bottom

of the ETH-100 unit end-on), the ETH-100’s control logic ground plane and chassis

ground plane are connected together. In this configuration, no external GND wire

should be connected to the unit’s GND terminal. In this case, the chassis ground

plane is directly connected to the drives’ CC reference, and Toshiba typically

recommends that the CC reference of the drives not be connected to earth ground.

Refer to your drive’s instruction manual for specific information about the CC terminal

and ground connections.

In some high-noise environments or under unusual wiring conditions, it may be

possible to obtain improved Ethernet communication characteristics by referencing

the ETH-100’s “chassis ground” to a localized earth ground. In these cases, place

switch SW1 #2 in the OFF (up) position and connect the GND screw terminal to an

appropriate ground connection.

Please be sure to consider the following general points for making proper ground

connections:

Grounding method checkpoints

1. Make all ground connections such that no ground current flows through the case

or heatsink of a connected drive.

2. Do not connect the ETH-100’s GND terminal to a power ground or any other

potential noise-producing ground connection (such as a drive’s “E” terminal).

3. Do not make connections to unstable grounds (paint-coated screw heads,

grounds that are subjected to inductive noise, etc.)

15

Page 17

5. Environmental Specifications

Item

Operating Environment

Operating Temperature

Storage Temperature

Relative Humidity

Vibration

Grounding

Cooling Method

Specification

Indoors, less than 1000m above sea level, do not

expose to direct sunlight or corrosive / explosive gasses

-10 ∼ +50°C (+14 ∼ +122°F)

-40 ∼ +85°C (-40 ∼ +185°F)

20% ∼ 90% (without condensation)

5.9m/s

Selectable split ground planes

Self-cooled

2

{0.6G} or less (10 ∼ 55Hz)

16

Page 18

6. Maintenance And Inspection

Preventive maintenance and inspection is required to maintain the ETH-100 Ethernet

interface in its optimal condition, and to ensure a long operational lifetime.

Depending on usage and operating conditions, perform a periodic inspection once

every three to six months. Before starting inspections, always turn off all power

supplies to connected drives, and wait at least five minutes after each drive’s

“CHARGE” lamp has gone out.

DANGER!

to the drives, or for at least 5 minutes after power to the drives has been

removed. A hazard exists temporarily for electrical shock even if the source

power has been removed.

Inspection Points

Do not touch any internal parts with power applied

• Check that the dust covers for all unused RJ45 ports are seated firmly in their

connectors.

• Check that the drive and Ethernet communication cables are not loose. Reseat if

necessary.

• Check that there are no defects in any attached grounding wire terminal crimp

points. Visually check that the crimp points are not scarred by overheating.

• Visually check all wiring and cables for damage. Replace as necessary.

• Clean off any accumulated dust and dirt.

• If use of the ETH-100 is discontinued for extended periods of time, apply power at

least once every two years and confirm that the unit still functions properly.

• Do not perform hi-pot tests on the drives or ETH-100 interface, as they may

damage the units.

Please pay close attention to all periodic inspection points and maintain a good

operating environment.

17

Page 19

7. Storage And Warranty

7.1 Storage

Observe the following points when the ETH-100 interface is not used immediately

after purchase or when it is not used for an extended period of time.

• Avoid storing the unit in places that are hot or humid, or that contain large

quantities of dust or metallic dust. Store the unit in a well-ventilated location.

• When not using the unit for an extended period of time, apply power at least once

every two years and confirm that it still functions properly.

7.2 Warranty

The ETH-100 Ethernet Communications Interface is covered under warranty by ICC

for a period of 12 months from the date of installation, but not to exceed 18 months

from the date of shipment from the factory. For further warranty or service

information, please contact Industrial Control Communications or your local

distributor.

18

Page 20

8. Console Configuration

The ETH-100 typically requires configuration prior to communicating on an Ethernet

network. Configuration is achieved via a text-based console interface, accessible

over an RS232 serial channel and a telnet interface. The following are the factoryset values of the most important Ethernet parameters:

IP Address................ 10.0.0.101

Netmask ................... 255.255.255.0

Default Gateway ....... 10.0.0.2

If these parameters do not match with your network settings, they will need to be

modified.

8.1 RS232

The console is accessible via an RS232 interface for direct connection to a

computer’s serial (COM) port. This is performed by using the included DB9-RJ45

cable to connect the ETH-100’s MMI port to the computer’s serial port. This will

typically be the initial configuration channel, as the telnet interface can only be

accessed once the network parameters have already been established and the

device is communicating on the Ethernet network.

8.1.1 Requirements

All that is needed is a computer with a standard serial (COM) port containing some

sort of communications software (such as HyperTerminal, shipped with Microsoft

Windows operating systems) and the included MMI cable (ICC part number #10425).

Any communications software and PC will work, provided they support ASCII

communications at 38.4kbaud.

8.1.2 Connection

The ETH-100 ships from the factory with a dust cover installed in the MMI port. To

minimize contamination of the port’s electrical contacts, keep this dust cover in place

whenever the MMI port is not in use.

Connect the RJ45 end of the MMI cable to the MMI port, and connect the other end

to the computer’s serial port. Make sure that switch SW1 #1 is in the “OFF” position.

8.1.3 Application Configuration

As previously mentioned, any PC communication software and PC serial port can be

used. The software configuration example given here will be for Windows

HyperTerminal communicating via COM1.

Figure 1 shows the “Connect To” tab of the properties window for COM1. Figure 2

shows the window that appears when “Configure” is selected in the “Connect To” tab.

Figure 3 shows the “Settings” tab of the properties window. Most of these settings

19

Page 21

are their default values: usually the only change needed is the “Bits Per Second”

setting shown in Figure 2.

Figure 1: HyperTerminal Configuration Screen #1

Figure 2: HyperTerminal Configuration Screen #2

20

Page 22

Figure 3: HyperTerminal Configuration Screen #3

8.2 Telnet

The console is also accessible via a Telnet interface for remote administration over

Ethernet once the unit is communicating on the network. The Telnet console uses

well-known port 23. Note that although only 1 telnet console session can be active at

any given time, the telnet console and RS232 console operate independently and can

be used simultaneously.

8.2.1 Requirements

All that is needed is a computer with telnet software that can access the ETH-100

over the Ethernet network. Telnet software is typically included as a standard

component of Microsoft Windows and other PC operating systems.

8.2.2 Connection

No special connections are required, other than the PC running the Telnet application

must be able to logically connect to the ETH-100 to be configured.

8.2.3 Application Configuration

Although any software vendor’s Telnet client application can be used, the

configuration example given here will use the Microsoft Windows Telnet application.

To start the Telnet application, simply type “telnet” at either a DOS (command)

prompt or in the “Start…Run” window. Once the telnet client screen opens, the

target device can be accessed simply by typing “open” at the Telnet prompt with the

ETH-100’s IP address as an argument. Refer to Figure 4.

21

Page 23

Figure 4: Telnet Menu

8.3 Command Overview

The console provides standard access and configuration methods for the various

network parameters and application configuration parameters supported by the ETH-

100. The number and type of supported console commands may vary with different

console version and application version firmware. This section will present an

overview of the supported console commands.

It is important to note that unless otherwise indicated, each of these commands will

become effective immediately after it has been successfully entered. This may have

several repercussions; for example, if you change the IP address of the device via

the Telnet console, then you will lose the telnet connection to the device (as it was a

connection to the old IP address) and therefore must re-connect to the console if you

wish to continue changing parameters. Also note that the console commands are not

case-sensitive.

This command shows the console version and an overview of all available

Help:

commands. As indicated in the returned help information, typing “Help <command>”

with a specific command will return help information specific to that command. Refer

to Figure 5 for the help command output via Telnet. All further display screens

shown in this manual will be from Telnet, although they will look identical when

accessed via the serial channel (MMI port).

22

Page 24

Figure 5: "Help" Command Via Telnet

Echo:

“Echo OFF” will disable the echoing of typed characters.

Set:

which allows setting a different configuration parameter. To set a parameter, two

arguments are required: the parameter’s name and the value to set it to. Figure 6

shows an example of changing the IP address of a device to 192.168.1.1. After this

command is entered, the device will then reconfigure itself to allow network access

via the IP address 192.168.1.1.

“Echo ON” (default setting) will echo typed characters back to the user.

The “Set” command actually encompasses several subcommands, each of

Figure 6: "Set" Command Overview and Implementation

Show:

information (IP Address, Netmask and Gateway) is configurable via the “set”

command. The “I/O Parameter” field lists the current console’s primary

communication parameter (port number 23 for the Telnet console and baud rate

38400 for the serial console). The “Firmware Ver” field indicates the current

application firmware version of the ETH-100. Refer to Figure 7.

23

This command displays current configuration information. Some of this

Page 25

Figure 7: "Show" Command Overview

8.4 Console Configuration Backup

The console configuration is backed up in the ETH-100’s battery backed SRAM. This

allows the console configuration to be restored upon power-up. Although the battery

inside the ETH-100 is rated to last approximately 10 years with no other power

supplied to the unit (and longer when power is supplied to the unit), it may eventually

require replacement at some point in the product’s lifetime. When this happens, the

IP address, netmask, and default gateway settings will be lost upon power-down.

To ensure that these important settings can be recovered in the event of a battery

failure, it is recommended that you record your IP address, netmask, and gateway

settings in the notes section (section 13) of this manual for future reference.

24

Page 26

9. LED Indicators

The ETH-100 unit contains many different LED indicators, each of which conveys

important information about the status of the unit, connected drives and Ethernet

network. These LEDs and their functions are summarized here.

9.1 Module and Ethernet Indicators

The module and Ethernet indicators are located between the MMI port and the

Channel A drive port. Figure 8 indicates the functions of these LEDs (perspective is

with MMI port to the left of the LEDs).

ACT (Ethernet ACTivity)

Flashes red when network

activity is detected

NS (Network Status)

Currently reserved

LNK (Ethernet LiNK)

Solid green when valid

network link exists

MS (Module Status)

Currently reserved

Figure 8: Module and Ethernet Indicators

9.2 Drive Connector Indicators

Each drive communication channel RJ45 connector contains two integrated green

LEDs. Figure 9 indicates the functions of these LEDs.

Network Access

Blinks in 0.1s-long bursts

when channel is accessed

by Ethernet client

Drive Link

Solid green when a logical

connection exists with the

attached drive

Figure 9: Drive Connector Indicators

The Network Access indicator is useful for confirming that a specific drive channel is

being accessed correctly by the Ethernet client (master), while the Drive Link

indicator provides an easy method of determining that the ETH-100 and drive are

successfully exchanging data, independent of Ethernet activity.

25

Page 27

9.3 MMI Connector Indicators

The MMI port RJ45 connector also contains two integrated green LEDs. Figure 10

indicates the functions of these LEDs.

Active Sockets Indicator

Blinks in 0.25s-long bursts

separated by 2s of OFF

time: number of consecutive

blinks indicates number of

open TCP/IP sockets

(client connections)

Figure 10: MMI Connector Indicators

Reserved

Currently reserved

The Active Sockets indicator is helpful in determining how many TCP/IP sockets are

currently allocated to Ethernet clients (masters). As indicated in Figure 10, the

number of currently-allocated sockets can be determined by counting the number of

concurrent short blinks. Each stream of short blinks is terminated by 2s of

continuous off time, after which the next stream of short blinks begins.

26

Page 28

10. Modbus TCP/IP

The ETH-100 interface supports Schneider Electric’s Modbus TCP/IP protocol,

release 1.0. The ETH-100 is conformance class 0 and partial class 1 compliant, and

allows up to 8 simultaneous Modbus TCP/IP client connections (sockets). Socket

timeouts are set to 30s, which means that if a particular open socket experiences no

activity for more than 30s, then the interface assumes that the client has experienced

some sort of unexpected problem, and the ETH-100 will close that socket.

10.1 Drive Channel Access

Each specific drive channel (Channel A, Channel B and Channel C) is accessed via

the “Unit Identifier” (UI) field of a Modbus TCP/IP packet. Drive channel A is

accessed when the UI field is set to “1”, channel B is accessed when the UI field is

set to “2”, and channel C is accessed when the UI field is set to “3”. Any other UI

setting is invalid and will result in a GATEWAY PATH UNAVAILABLE exception

(Modbus TCP/IP exception code 0A).

10.2 Supported Modbus Functions

The ETH-100 interface supports the Modbus TCP/IP function codes indicated in

Table 1.

Table 1: Supported Modbus TCP/IP Functions

Function Code Function

3 Read multiple registers 0

6 Write single register 1

16 Write multiple registers 0

Class

27

Page 29

10.3 Modbus/Drive Register Mappings

The ETH-100’s Modbus TCP/IP interface acts as a relatively straightforward network

gateway for the attached drives. By and large, Modbus TCP/IP holding registers (04

registers) are directly mapped to corresponding Toshiba drive registers (also referred

to as “communication numbers” in Toshiba documentation) with a direct 1-to-1

correspondence. The relationship between Modbus TCP/IP holding registers and

their Toshiba drive register counterparts is as follows:

Modbus TCP/IP holding register = Toshiba drive register + 1

This means that in order to access a specific Toshiba drive register, simply add 1 to it

and access that Modbus TCP/IP holding register. The reason for this offset is due to

the fact that Toshiba drive registers begin at number 0, while Modbus holding

registers begin at number 1.

As an example of this relationship, let’s say that we would like to access parameter

“Acceleration Time #1” on a Toshiba S9 drive connected to the ETH-100. According

to the relevant Toshiba Serial Communications Manual, we see that “Acceleration

Time #1” resides at drive register number 0x0009 (note hexadecimal notation). By

adding 1 to this value, we obtain 0x000A (10

that must be used to access this drive parameter.

In order to avoid any possible confusion regarding this register-mapping scheme, this

manual will always explicitly use the terms “drive register” or “Modbus register” where

the intention may not be clear. If the term “register” is used alone, then “Modbus

register” will be the intended meaning by default.

With only 2 exceptions (discussed below), the ETH-100 does not in any way modify

or otherwise alter valid register access requests originating from the Modbus TCP/IP

client. By adhering to this design parameter, the availability and interpretation of any

Modbus registers is entirely determined by the attached drive(s). In this way, the

ETH-100 allows itself to become virtually “transparent” on the network, essentially

allowing the Modbus TCP/IP client to carry on a dialog directly with the drives. This

technique also allows a wide array of drive families and capacity classes to be

implemented without compatibility concerns.

The two exceptions to the previous paragraph are as follows:

), which is the Modbus holding register

10

1. Register remapping option. The ETH-100 can be configured to alter a portion

of the mapping relationship for register-limited clients. Refer to section 10.4

for a discussion pertaining to register remapping.

2. The status register (drive register 0xFE01) typically does not contain any

information indicating whether the attached drive is faulted or not. For ease

of client application programming, therefore, the ETH-100 will indicate a

connected drive’s faulted status in bit #14 of this register (normally, this bit is

”reserved” by the drive). Refer to Table 2 for an example modified status

register from an S9 drive. Because the specific format of the status register

depends on the drive family and firmware implementation, please refer to your

drive’s Serial Communications Manual for the exact structure of this bitmapped register. NOTE: This added feature is only available if drive register

0xFE01 is configured to be one of the selectable scan registers (refer to

section 10.5 for more information regarding scan registers).

28

Page 30

Table 2 : Example Status Word (ASD Register 0xFE01) Format

Bit Function 0 1

15 Reserved -14 Faulted status Not faulted Faulted

13 Reserved -12 Reserved -11 Reserved --

High Byte

10 Run / stop status Stopped Running

9 Forward / reverse status Forward Reverse

8 Jog status Not jogging Jogging

7 DC injection braking status Not DC injection

braking

DC injection

braking

6 Accel / decel #1/#2 status #1 #2

5 Reserved -4 Reserved -3 Reserved --

Low Byte

2 Reserved -1 Reserved -0 Reserved --

10.4 Register Remap Function

Some Modbus client software does not allow access to more than 10,000 Modbus

holding registers. As the standard ETH-100 mapping provides a simple 1-to-1

correspondence between Modbus holding registers and ASD registers (ASD register

number + 1 = Modbus holding register number), this can cause certain critical ASD

registers to be inaccessible from these clients. Specifically, Toshiba drives typically

place communication control registers and status registers in the 0xFAxx to 0xFFxx

ASD register region. For example, “Communication Frequency Command” is

typically assigned to ASD register number 0xFA01, which is accessible via Modbus

holding register 0xFA01 + 1 = 0xFA02, which is 64002 in decimal. As this Modbus

holding register number is higher than 10,000, this register would not be accessible

via register-limited clients unless the ETH-100 performed register remapping.

“Remap OFF” (default setting) does not modify the register mapping between the

ASD registers and the Modbus holding registers: a simple 1-to-1 correspondence

exists. “Remap ON” modifies the ASD register mapping slightly to allow access to

the drive’s critical control and status registers by Modbus clients that are limited to

accessing 10,000 holding registers max.

With the Remap parameter set to “ON”, the ETH-100 will add 0xF000 (61440

incoming ASD register accesses between 0x0A00 and 0x0FFF (Modbus holding

registers 0x0A01 – 0x1000). In this way, register-limited clients need only write to

Modbus holding register 0x0A02 (2562

) to set the Communication Frequency

10

Command. Similarly, “Current Output Frequency” is typically located at ASD register

10

) to

29

Page 31

0xFD00 (Modbus holding register 0xFD01), which can therefore be accessed via

Modbus holding register 0x0D01 (3329

When register remapping is enabled, only accesses to Modbus registers 0x0A01 –

0x1000 are affected: the normal locations for the critical control and status registers

remain unaffected and can still be accessed (i.e. Communication Frequency

Command will be updated via writes to either register 0x0A02 or 0xFA02: both will

write to ASD register 0xFA01).

Refer to section 11.2 for further information regarding configuration of the register

remap selection.

) when register remapping is enabled.

10

10.5 ASD Scan Registers

Scan registers are used to define ASD registers that the user wishes to access

quickly. ASD registers that are configured to be scan registers will have their data

mirrored locally on the ETH-100. Requesting the data from or writing data to an

ASD register that is set up to be a scan register will take less network time because

the ETH-100 simply accesses a local value instead of initiating a transaction with the

ASD to process the data.

Refer to section 11.3.2 for further information regarding configuration of the scan

registers.

10.6 Modbus Programmable Pointer Registers

Programmable pointer registers (PPR) allow the user to access non-consecutive

.

Modbus registers with only one Modbus transaction

0xFC00 ~ 0xFC0F are reserved by the ETH-100 to access the registers defined in

the PPR section of the "channels" page of the ETH-100's embedded web server. For

example, if you would like to continuously read the data from ASD registers 0xFD00,

0xFE01, 0xFE04 and 0xFE05, the standard Modbus register configuration would

require 3 read commands to be issued: one reading 1 Modbus register starting at

register 0xFD01, one reading 1 Modbus register starting at register 0xFE02, and one

reading 2 Modbus registers starting at register 0xFE05. To conserve network

bandwidth and speed processing time, however, the programmable pointer registers

can be used to allow the same information to be accessed, but by only issuing 1

command which reads 4 Modbus registers.

To configure this function, enter the register numbers of the Modbus registers you

would like to continuously access into the PPR section of the embedded web server's

"channels" page (refer to section 11.3.3). For example, we could set PPR register

location 0xFC00 to a value of 0xFD01 (the first Modbus register number we want to

access), register location 0xFC01 to a value of 0xFE02, register location 0xFC02 to a

value of 0xFE05, and register location 0xFC03 to a value of 0xFE06. The 4 registers

that are to be monitored can now be accessed simply by issuing 1 Modbus holding

register read command with a length of 4 starting from Modbus register location

0xFC00. The returned data will be the data obtained from ASD registers 0xFD00,

0xFE01, 0xFE04, and 0xFE05 (in that order). IMPORTANT: Note that PPR values

refer to MODBUS registers. That is, Modbus registers = ASD registers + 1.

Modbus register locations

30

Page 32

Refer to section 11.3.3 for more information regarding programmable pointer

registers and their configuration.

10.7 Register Access Notes

This section contains some helpful notes and reminders that further detail the

interface unit and drives’ behavior.

• Remember that drive registers and Modbus registers are offset by 1.

Accessing the lowest valid Modbus register (0x0001) will access drive register

0x0000.

• The data values written to ASD registers that are configured as scan registers

are not checked for range. Therefore, if a value outside the valid range of

adjustment for a “write” scan register is written, the write will be acknowledged

by the ETH-100, but the drive will not accept the invalid value.

• All register writes use the drive’s RAM / EEPROM data write (“W”) command

except for those registers configured to be “write” scan registers, which use

the drive’s RAM data write (“P”) command. For all writes that target the

drive’s EEPROM, be sure to follow Toshiba’s guidelines regarding the number

of times a specific register can be written without risk of EEPROM damage.

• For those drive families which do not have an explicit FREQUENCY MODE

SELECTION or COMMAND MODE SELECTION parameter setting

corresponding to the common serial channel (i.e. S7 and S9), remember that

bits #14 and #15 of the communication command register (drive register

0xFA00) must be set to enable network frequency and network commands,

respectively.

• For safety, when a new “write” scan register is entered, the ETH-100 will set

that register’s initial local value to 0.

• Attempting to access a programmable pointer register that has not been

configured with a register value (i.e. the “Points To…” field shows up blank on

the configuration web page) will result in a Modbus 02 exception (ILLEGAL

DATA ADDRESS).

31

Page 33

10.8 Performance Tips

This section offers several configuration tips which can help to optimize the

performance of communications with the ETH-100 and attached drives.

1. Configure Modbus programmable pointer registers to also be drive scan

registers. In the example configuration shown in Table 3, Modbus registers

FC00 ~ FC07 are configured to point to the ASD scan registers. In this case, a

Modbus transaction beginning at address FC00 with a length of 8 can be

processed extremely fast. Of course, pointer registers can still be accessed if

they are not configured as scan registers, but the transactions are slower, as they

require transferring the request to the drive for processing.

Table 3: Efficient Scan/PPR Configuration

ASD Scan Registers Modbus Pointer Registers

Register R/W Value Register Points To…

FA01 Read FC00 FA02

FA00 Read FC01 FA01

FD00 Read FC02 FD01

FE01 Read FC03 FE02

FC90 Read FC04 FC91

FE03 Read FC05 FE04

FE42 Read FC06 FE43

FA22 Read FC07 FA23

2. Don’t leave a gap in the access sequence. For optimal network response,

make sure all of the pointer registers that you are going to access are also

configured to be ASD scan registers. The ETH-100 is most effective when all of

the pointer registers that are going to be accessed are also ASD scan registers.

In the example shown in Table 4, the high-speed processing of a Modbus register

read starting at register 0xFC00 with a length of 8 will be delayed by the necessity

to interact with the drive to obtain the values of drive registers 0xFC90 and

0xFE03.

Table 4: Inefficient Scan/PPR Configuration

ASD Scan Registers Modbus Pointer Registers

Register R/W Value Register Points To…

FA01 Read FC00 FA02

FA00 Read FC01 FA01

FD00 Read FC02 FD01

FE01 Read FC03 FE02

FC04 FC91

FC05 FE04

FE42 Read FC06 FE43

FA22 Read FC07 FA23

32

Page 34

3. Group read and write registers together in the programmable pointer list

and access them with separate Modbus commands. The ETH-100 can

process read requests and write requests faster when they are grouped together

rather than the master having to issue multiple transactions to access disjoint

registers. This is especially true when the registers to be accessed are also

configured as ASD scan registers. Pointer registers can be accessed in any

combination of starting register and length. In the setup below, you would

optimize ETH-100 efficiency by having two Modbus transactions: one read

request with a length of 6 starting at register FC00, and one write request with a

length of 2 starting at register FC08.

Table 5: Grouping Read and Write Registers In The PPR List

Modbus Pointer Registers

(Also configured to be ASD READ

scan registers)

Register Points To… Register Points To…

FC00 FE03 FC08 FA02

FC01 FE06 FC09 FA01

FC02 FD01 FC0A

FC03 FE02 FC0B

FC04 FC91 FC0C

FC05 FE04 FC0D

FC06 FC0E

FC07 FC0F

Modbus Pointer Registers

(Also configured to be ASD

WRITE scan registers)

33

Page 35

10.9 Exceptions and Troubleshooting

Although by no means exhaustive, Table 6 provides some possible causes behind

some of the most common errors experienced when using the Modbus TCP/IP

interface.

Table 6: Troubleshooting Reference

Problem Possible Cause

Register addressing is off by 1 Refer to Section 10.3 for Modbus/drive mapping

• Ensure at least one of the connected drives is powered on

Modbus TCP/IP client cannot establish

communication with the ETH-100

Drive does not respond to network

commands / frequency command

ILLEGAL FUNCTION exception

(Modbus exception code 01)

• Check that the drive and Ethernet communication cables

are fully seated into their respective communication ports

• Check the Ethernet communication parameters (IP

address, etc.)

• Check drive’s frequency mode and command mode

selection parameters

• Where applicable, confirm the values of bits #14 and #15

of communication command word

• Confirm that communication frequency command value is

between lower limit and upper limit frequencies

The indicated Modbus function is not supported: refer to section

10.2 for a list of supported functions

ILLEGAL DATA ADDRESS exception

(Modbus exception code 02)

ILLEGAL DATA VALUE exception

(Modbus exception code 03)

NEGATIVE ACKNOWLEDGE exception

(Modbus exception code 07)

GATEWAY PATH UNAVAILABLE

exception (Modbus exception code 0A)

GATEWAY TARGET DEVICE FAILED TO

RESPOND exception

(Modbus exception code 0B)

The targeted drive register (or one in a group of targeted

registers) does not exist: check the drive’s supported register

list

The value written was rejected by the drive as invalid: check the

value and drive setting range

• An attempt was made to write to a drive register while the

drive was running that does not accept writes while the

drive is running

• An attempt was made to write to a read-only register

• Confirm that the drive communication cable is fully seated

into the drive’s and ETH-100’s communication ports

• Confirm that the drive communication cable is not routed

near the drive’s input power or motor wiring or any other

electrical noise-producing cables or equipment

Unit Identifier (UI) was invalid: UI must be 1 ∼ 3

The targeted drive is not online or failed to respond:

• Confirm that the targeted drive is powered-on

• Confirm that the drive communication cable is fully seated

into the drive’s and ETH-100’s communication ports

• Confirm that the drive communication cable is not routed

near the drive’s input power or motor wiring or any other

electrical noise-producing cables or equipment

34

Page 36

11. Embedded Web Server

The ETH-100 interface contains an embedded web server (also known as an HTTP

server), which allows users to access the unit’s internal data in a graphical manner

with web browsers such as Microsoft Internet Explorer or Netscape Navigator. In this

way, the unit and connected drives can be monitored, configured and controlled from

across the room or from across the globe.

The ETH-100’s web pages are best viewed with either Internet Explorer version 5.x

and later, or Netscape Navigator version 6.x and later.

To access the unit’s embedded web server, just enter its configured IP address into

the address (URL) field of your web browser. Surfing the ETH-100’s web pages is

the same as surfing the Internet’s world-wide web. Refer to Figure 11 for an

example.

Figure 11: Embedded Web Server Access – Setup Page

35

Page 37

11.1 Setup Page

The setup page is the initial page that is displayed when the unit’s IP address is

accessed via a web browser. Refer to Figure 11 for a screen shot of the setup page.

This page contains the ETH-100’s basic identification and configuration parameters:

Note that the ETH-100 requires valid user authentication whenever any configuration

information is modified. This will appear as a browser popup box that will request the

user name and password. The initial factory-set value for the username is “admin”,

and the password is blank (i.e. do not enter a password). Note that the username

and password are case-sensitive, and that the authentication will remain in effect

from that point until all browser windows are closed.

Firmware Version:

MAC Address:

IP Address:

Subnet Mask:

Default Gateway:

Current Date & Time:

Update Date & Time:

Username & Password:

By clicking “cancel” before clicking “apply”, all configuration data will be reset to the

last applied values. Clicking “help” will open a new browser window displaying some

basic help information.

The current firmware version and the date it was created.

The unique 48-bit Ethernet MAC ID for this device.

The IP address of the device (i.e.: 10.0.0.100).

The Subnet Mask of the device (i.e.: 255.255.255.0).

The Default Gateway of the device (i.e.: 10.0.0.2).

The current date and time set on the device.

To change the date: select the check box next to “Date”,

change the date to the desired values, and click Apply. If

the check box is not selected, the values in the date

fields will be ignored.

To change the time: select the check box next to “Time”,

change the time to the desired value, and click Apply.

The time is represented in Military (24 hr.) format. If the

check box is not selected, the values in the time fields will

be ignored.

To change the authentication username for modifying the

ETH-100’s configuration parameters: select the check

box next to “Username”, type your desired user name

(max 10 characters), and click apply. You will be

required to enter the current username and password to

update your username to its new value. Contact ICC if

you cannot remember your username.

To change the authentication password for modifying the

ETH-100’s configuration parameters: select the check

box next to “Password", type your desired password

(max 10 characters), and click apply. You will be

required to enter the current username and password to

update your password to its new value. Contact ICC if

you cannot remember your password.

36

Page 38

11.2 Modbus Page

The Modbus page can be accessed by clicking on the “Modbus” tab located at the

top of the browser window. Refer to Figure 12 for a screen shot of the Modbus Page.

Figure 12: Embedded Web Server Access – Modbus Page

This page provides access to the unit’s register remap function. To change the

register remap selection, simply click on the radio button corresponding to the

desired value. Refer to section 10.4 for a discussion pertaining to register

remapping.

This page also displays the number of Modbus TCP/IP sockets that have been

allocated by network clients. Refer to section 10 for more information about Modbus

TCP/IP sockets.

37

Page 39

11.3 Channels Page

The Channels page can be accessed by clicking on the “Channels” tab located at the

top of the browser window. The initial page displayed will appear as in Figure 13

Figure 13: Channels Page Initial Screen

38

Page 40

11.3.1 Channel Select

Use the “Select” drop-down box to select the desired channel. The screen that is

displayed will appear as in Figure 14. The channel select section on this screen will

display the currently selected channel and its online/offline status. A channel is

defined to be online if a logical connection has been made with an ASD connected to

that channel.

Figure 14: Channels Page After Channel Selection

39

Page 41

11.3.2 ASD Scan Register Configuration

Scan Register Setup Information:

• Scan register values refer to ASD registers, NOT Modbus registers.

• There are 8 possible scan register values for each of the 3 channels. Not all 8

values need to be configured. The ETH-100 will only mirror those scan registers

that have a displayed value.

• Each active scan register must be configured as read or write.

! A read scan register will be continuously polled from the ASD.

! A write scan register will be continuously written to the ASD. When a new

write scan register is added to the list, or when a write scan register value is

changed, its internal write value will be set to 0 for safety.

• To clear a scan register value, the user must CLEAR the value displayed on the

web page interface and click apply.

• To add a new scan register value in an empty location, the user must enter a

valid hexadecimal number, provide read/write information using the drop-down

box, and click apply.

• Scan register values that are already displayed can be changed without providing

a read/write value. The previous read/write value will be retained in this case.

• Scan register values and read/write values are stored in non-volatile flash

memory, and will be saved when the unit is powered off.

• Refer to section 10.5 for more information about ASD scan registers.

Figure 15: ASD Scan Register Interface

40

Page 42

11.3.3 Programmable Pointer Registers Configuration

Modbus Programmable Pointer Register Setup Information:

• Programmable pointer register values refer to MODBUS

• There are 16 pointer registers for each of the three channels. Not all 16 registers

need to be configured.

• A pointer register can be accessed by making a request to Modbus registers

FC00 ~ FC0F. Any of these 16 registers can be defined as the starting register

for the transaction. Any number of these registers can be accessed with one

Modbus transaction (provided that all registers being accessed are valid).

• To clear a pointer register value, CLEAR the value displayed on the web page

interface and click apply.

• To add a new pointer register value in an empty location, enter a valid non-zero

hexadecimal number (0000 is an illegal MODBUS address) and click “Apply”.

• Pointer register values are internally stored in nonvolatile flash memory, and will

be saved when the unit is powered off.

• Refer to section 10.6 for more information about programmable pointer registers.

registers.

Figure 16: Pointer Registers Interface

41

Page 43

11.3.4 Drive Test Commands

Drive test commands can be used to test the communications between the ETH-100

and your ASD. To run the ASD connected to the currently selected channel, click

“Run” and submit a valid frequency command in the “FC” field. Clicking “Run” writes

a value of 0xC400 to ASD register 0xFA00 (communication command). Submitting a

valid frequency command writes that value to ASD register 0xFA01 (communication

frequency command). Note that the “FC” field expects floating-point values; entering

“53.43” will send a frequency command of 53.43 Hz to the drive.

Note that if you run the ASD from the embedded web server, bits #15 and #14 of the

ASD’s communication command register (0xFA00) are set, which indicates

“communication channel priority” to the drive. Local control of the drive will therefore

be disabled until you click ”Stop”, which writes a value of 0x0000 to ASD register

0xFA00.

Figure 17: Drive Test Commands Interface

42

Page 44

12. Firmware Updates

The ETH-100’s embedded firmware resides in flash memory that can be updated in

the field. Firmware updates may be released for a variety of reasons, such as

custom firmware implementations, firmware improvements and added functionality as

a result of user requests.

ICC is continually striving to enhance the functionality and flexibility of our products,

and we therefore periodically release new embedded firmware to achieve these goals

and meet customer requests. Flash firmware files and all related documentation

(such as updated user manuals) can be downloaded as complete board support

packages (referred to as BSPs) from http://www.iccdesigns.com

users check this Internet site prior to installation, and then periodically afterwards to

determine if new support packages have been released and are available to upgrade

their unit.

12.1 Requirements

. It is suggested that

Besides the new firmware file, firmware updates require a PC with a Windows

operating system (95/98/NT/2000) and a serial port, the Rabbit Field Utility

application (refer to section 12.3), and the MMI cable included with the ETH-100 kit

(ICC part #10425).

Please be sure to read the firmware release notes and updated user’s manual

(included with the BSP) prior to updating your firmware for any important notices,

behavior precautions or configuration requirements. For example, upgrading to a

new firmware version may reset user-configurable parameters (console settings) to

their factory-default value. If the release notes indicate this, be sure to manually

record all of your console settings prior to starting the update procedure for later

reentry.

12.2 Connection

The ETH-100 ships from the factory with a dust cover installed in the MMI port. To

minimize contamination of the port’s electrical contacts, keep this dust cover in place

whenever the MMI port is not in use.

IMPORTANT

communication application while its internal firmware is being updated. Therefore, be

sure to shut down the system to a known safe state prior to initiating the firmware

update procedure.

Connect the RJ45 end of the MMI cable to the MMI port, and connect the other end

to the computer’s serial port. Move switch SW1 #1 to the “ON” (down) position: this

will place the ETH-100 into the “firmware download” mode. Whenever switch SW1

#1 is “ON”, the ETH-100 can only download firmware to its flash: all other application

functions (such as Ethernet communications, console access etc.) will be disabled.

: Note that the ETH-100 will not be operating the system control and

43

Page 45

12.3 Using The RFU Utility

Support for downloading new application firmware to the ETH-100 is provided by the

free Rabbit Field Utility

Windows platforms. The RFU utility can be downloaded from ICC’s home page at

http://www.iccdesigns.com

configuration and firmware download procedures.

12.3.1 Required Files

When first downloaded, the RFU utility files are compressed into one self-extracting

.EXE distribution file. Create a folder (such as c:\RFU), place the distribution file in

this folder, and then execute it. This will extract the following files into that same

folder:

•

RFU.EXE (executable download utility)

•

RABFIELD.HLP (help file)

•

COLDLOAD.BIN (CPU bootstrap firmware)

•

PILOT.BIN (pilot BIOS firmware for downloading)

The distribution file is then unneeded and can be deleted if desired. To run the RFU

utility, double-click on the RFU.EXE file icon.

(RFU), which is a 32-bit application that runs on Microsoft

. The remainder of this section will detail the RFU utility

12.3.2 First-time configuration

The first time the RFU utility is run on a computer, several configuration items need

to be confirmed. These configuration items are retained in the computer’s registry

from that point on, so reconfiguration is not required unless certain parameters (such

as which serial port to use on the computer) are changed.

The two configuration items that need to be confirmed are the communications and

bootstrap loaders path. First, select the “Setup…Communications” menu item (refer

to Figure 18).

Figure 18: RFU Main Screen

The Communications Options window shown in Figure 19 then appears. Confirm

that the settings are as shown, with the possible exception of the “Comm Port”

setting, which depends on the COM port you are using. Click “OK” when complete.

44

Page 46

Note: It is possible that certain computers may have difficulty communicating at a

sustained 115kbaud rate, which may result in communication errors during firmware

downloading. If this occurs, try setting the “baud rate” parameter shown in Figure 19

to a lower value.

Figure 19: Communications Options Window

Next, select the “Setup…Boot Strap Loaders” menu item. The “Choose Loaders”

window shown in Figure 20 then appears. Confirm that the correct paths to the

COLDLOAD.BIN and PILOT.BIN files are entered. Enter the correct paths if

necessary.

Figure 20: Boot Strap Loaders Window

45

Page 47

12.3.3 Transmitting Firmware Files

When a board support package (BSP) has been downloaded and unzipped, the flash

firmware file will be the one with “.BIN” as its file name extension.

Once the RFU utility has been configured, the flash firmware files can be downloaded

to the ETH-100 by two different methods. The simplest way is to drag the application

firmware .BIN file’s icon and drop it onto the RFU utility’s main screen. This will

automatically initiate the download process.

Alternatively, select the “File…Load Flash Image” menu item (refer to Figure 21).

Figure 21: Load Flash Image Menu Selection

The flash image (.BIN file) selection window will then appear (refer to Figure 22).

Browse to the location of the flash image file to download and select it. Clicking “OK”

will then initiate the download process.

Figure 22: Flash File Selection Window

While downloading, the RFU utility will indicate the download status. Once complete,

summary information will be displayed in the bottom status bar.

12.4 Wrap-Up

Once downloading is complete, close the RFU utility, move switch SW1 #1 on the

ETH-100 unit back to the “OFF” (up) position to leave “firmware download” mode,