Page 1

TOSHIBA

E6580516

High-Performance Inverter

Instruction Manual

TOSVERT VF-A5

200V

400V

1. Make sure that this Instruction Manual is delivered to the end

user of the inverter unit.

2. Read this manual before installing or operating the inverter

unit, and store it in a safe place for reference.

0.4

0.75

--55kW

~75kW

NOTICE

TOSHIBA CORPORATION

© 1994

Ver. no-'

Page 2

Safety Precautions

This inverter is for driving a 3-phase motor, and must not be used for other applications.

[I] Always observe the following items to prevent electrical shock.

1. Do not touch charged parts such as the terminal block while the CHARGE lamp is lit. A charge will still

be present in the electrolytic capacitors, and therefore, touching these areas may result in an electrical

shock. Always turn the inverter’s input power off before wiring the motor terminals. Walt at least five

minutes after the "CHARGE' lamp has gone out, and then confirm that the capacitors have fully

discharged by using a tester, etc., that can measure high-voltage DC.

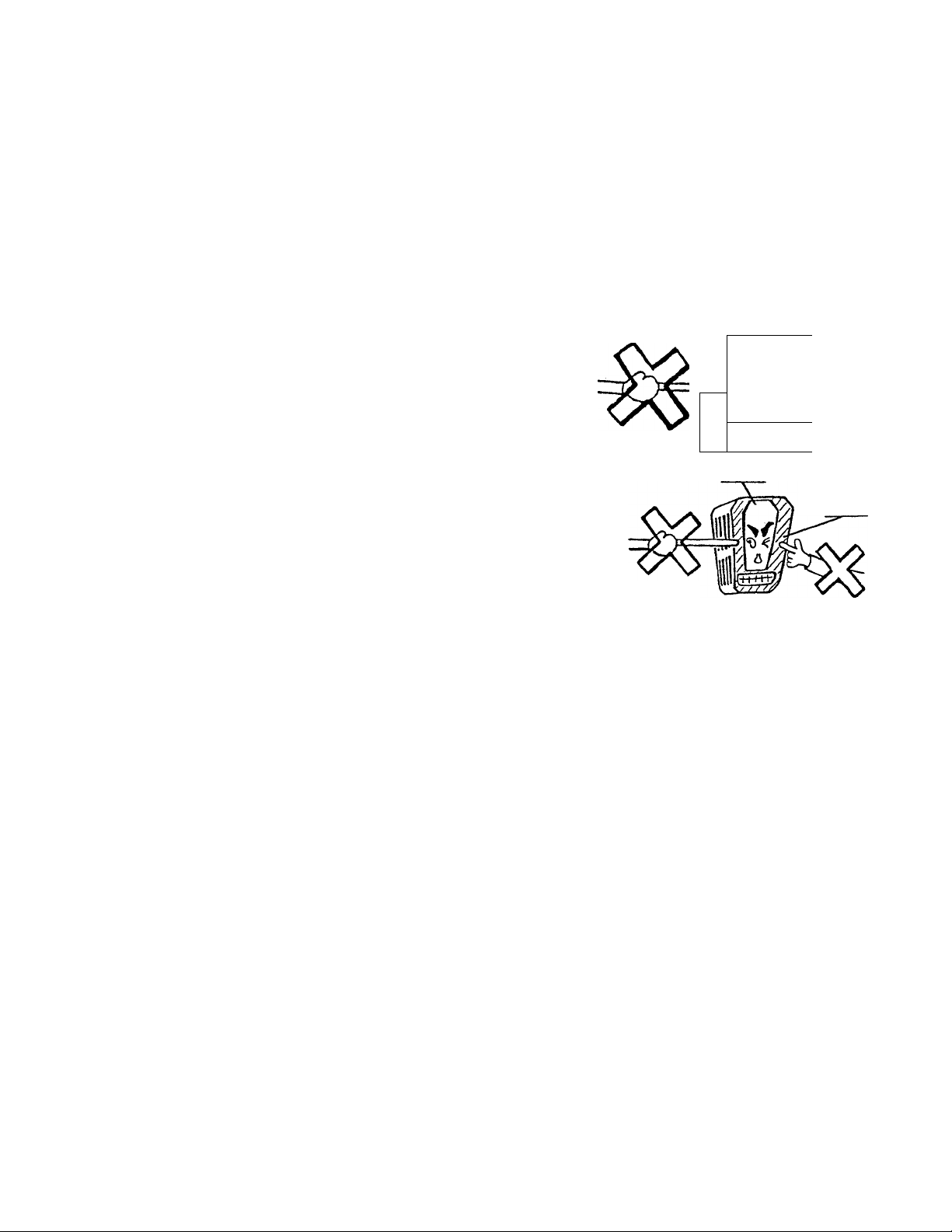

2. Do not touch or insert a rod or any other item into the

inverter while power is applied (there are high voltage areas

on the PCB), as this may lead to electrical shock or inverter

damage.

(When operating with the cover removed, charged areas will

be exposed, so always install the unit inside a panel so that

it cannot be easily touched.)

Never attempt to modify the inverter unit.

3. Ground the unit’s G/E terminal and the motor. (Electric

shock may occur due to leakage currents.)

[n] Retry function

1. This inverter has a "retry function" that automatically resets the unit when a fault trip occurs. Observe the

following points when this function is selected.

Even if the inverter has fault tripped, take care to not get caught in the motor or equipment. When the

"retry function" is selected, the inverter will automatically start after the designated time. (Refer to page

78.)

Take special care when an overload trip occurs, as the "retry function" may activate after a delay of up

to 5min.

[m] Observe the following points to prevent fire.

->/7

Ijili

'I

1111

llll

L=y

Control section

(W/hen cover is removed)

/

High voltage area

1. Confirm the inverter’s rating nameplate, and connect a 3-phase input power source within the rated range

to the RA.1, S/L2, and TA- 3 power source terminals.

If an Incorrectly-rated power source is connected to the inverter, such as when a 400V power source is

connected to a 200V inverter, the inverter’s internal components may explode.

2. No fuse is contained in the inverter, so instail a suitable non-fuse breaker (MCCB) on the inverter’s input

power source.

(Refer to Table 5-1 on page 14 for Examples of selecting equipment for wiring.)

[IV] Refer to the following chapters for other precautions.

Chapter 1 Acceptance Inspection and Precautions

Chapter 2 Installation Precautions Page 2

Chapter 4 Cperation Precautions Page 5

Chapter 5 Wiring Precautions Page 9

Chapter 12 Maintenance and Inspection Page 102

....

Page 1

Page 3

introduction

Thank you for purchasing the Toshiba High-Performance Inverter TOSVERT VF-A5'.

The *VF-A5" inverter has many various functions built in for use with a 3-phase induction motor. All Operations

of this unit are done via the easy-to-use keyboard-type operation panel. A blind function (Refer to page 50) that

dispiays only those functions required for operation, and an edit function (Refer to page 29) that automatically

collects parameters that differ from their defauit settings are used to make basic operation and setting easier.

Advanced control technology features (sensorless vector control, feedback control, current limit, retry, and stall

prevention functions) are built in, so that the inverter wiil not trip easily, and will provide unparaileied reliability.

Please read this manual thoroughly before use to properly understand the correct use of the outstanding

functions of the 'VF-A5'.

This manual should be stored by the user of the *VF-A5* for reference during maintenance and inspection.

Symbois used in this manual are as shown below. Understand them before reading this manual.

1. LED display character codes; Refer to page 123

2. To indicate a parameter display on the operation panel in this manual:

Example rWcT~t

To indicate a panel key:

Example ENTER key

The box

Note) The box

is not used when indicating parameter group names and parameter settings.

is not used when displaying parameters in tables.

Page 4

Table of Contents

1. Acceptance Inspection and Precautions ...................................................... 1

2. Installation Precautions ................................................................................. 2

3. External View and Component Names

4. Operation Precautions .................................................................................... 5

5. Wiring Precautions

.........................................................................................

6. Standard Connections ................................................................................. 15

6.1 Standard Connection Example ............................................................................... 15

6.2 Terminal Functions ................................................................................................... 18

7. Operation and Adjustment ............................................................... 27

7.1 Operation Panel ........................................................................................................ 27

7.2 Basic Operation ...................................................................................................... 28

7.3 Operation Modes ................................................................................................. 32

7.3.1 Standard Monitor Mode ....................................................................... 32

7.3.2 Status Monitor Mode ............................................................................ 35

7.3.3 Settings Monitor Mode

7.3.4 JOG Run Mode

7.4 Operation Mode Selection ....................................................................................... 40

7.4.1 Operation Mode Changeover .................................................................. 40

7.4.2 Run/stop Command [ cnod in Cr.ut ] ............................................. 40

7.4.3 Frequency Command Source Setting Function

[ FnOd in Cr.ut ] 40

7.4.4 Parameter Setting Function [ pnod in Cr-.ufc ] ... 41

7.4.5 Standard Parameter Value Reset Function

[ I h HP I in Hr.ut ]

7.4.6 Selection of Stopping Method from the Panel

7.4.7 Fault Reset ................................................................................................. 44

.........................................................................................

8. Parameter Explanations ............................................................................... 45

1. c r.F V/f settings .......................................................................................... 45

V/f pattern ® ..................................................................................... 46

V/f pattern 0 ..................................................................................... 47

Acceleration/deceleration time settings

Acc/Dec patterns, Acc/Dec pattern adjustment,

Low/High .......................................................................................... 49

Blind function selection

Upper limit/lower limit frequencies

Reverse operation disable selection ............................................ 51

.......................................................

.............................................................................

.........................................................

..................................

.......................................

.................................................................

..............................................

42

43

3

9

36

39

48

50

51

-1 -

Page 5

2. Cr.Pn Acc/dec #1 and #2 selection

.............................

.............. 52

Panel feedback control ................................................................ 53

Panel reset selection ................................................................... 53

Fundamental parameter switching............................................... 54

3. C t-.S t Input terminal selections 0 ............................................................ 55

Input terminal selections 0

.........................................

56

Output terminal selections 0 ................................................... 57

Output terminal selections 0 ........................................................ 58

Low speed, acceleration/deceleration

complete, speed reach output signals.......................................... 59

Input/output terminal response time selections .... 60

Commercial power/lNV switching ............................................... 61

Output terminal pulse frequency selection

RR input special function selection

........................................

.............................

62

62

4. Or.BC Run frequency control .................................................................. 63

Start-up frequency/End frequency................................................ 64

Jump frequencies........................................................................ 65

PWM carrier frequency ............................................................... 66

5. Cr-.SF Preset speed operation 0 .............................................................. 67

Preset speed operation 0

............................................................

68

Frequency priority selections ...................................................... 69

Jogging operation ....................................................................... 70

Frequency setting input signal characteristics ............................ 71

6. Cr-.Pr- Electronic thermal protection 0 ..................................................... 72

Electronic thermal protection 0

...................................................

73

DC injection braking settings 0 ............................................... 74

DC injection braking settings 0 .................................................... 76

Dynamic braking operation

Emergency stop

..........................................................................

........................................................

77

78

Retry function ............................................................................. 78

Regeneration power ride-through control

...................................

79

Auto-restart ................................................................................. 79

Trip function selections ............................................................... 80

Output short circuit detection selection ....................................... 80

Fault trip saving .......................................................................... 81

7. Cr.Pt Pattern run 0................................................................................. 82

Pattern run 0 ............................................................................... 83

- II -

Page 6

8. Cr.ufc Panel operation permission

Industrial application parameters selection

.........................................................

...........................

84

85

Standard setting mode selection ................................................ 85

Command/frequency mode selections ....................................... 86'

Status monitor display selections

Blind function selection

.............................................................

..............................................

87

87

Units settings ............................................................................. 88

9. Cr-.on Meter adjustment parameters ............................................................ 89

9. Device Specifications ............................................................................................. 90

9.1 Model and Standard Specifications..................................................................... 90

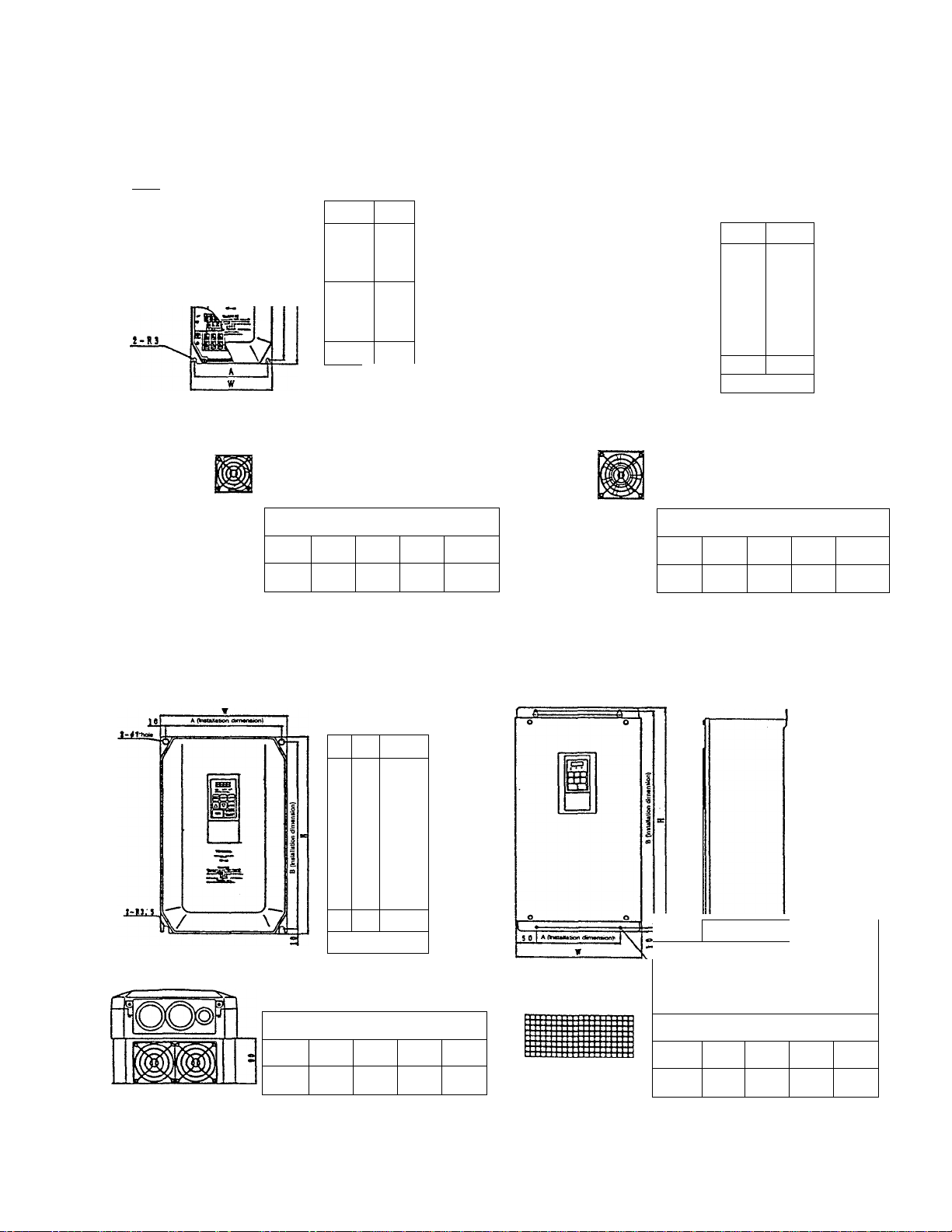

9.2 External Dimensions........................................................................................... 93

10. Options ..................................................................................................................... 95

11. Error Displays and Troubleshooting

.....................................................................

97

11.1 Inverter Trip Causes and Remedies .................................................................. 97

11.2 Other Fault Troubleshooting

...........................................................................

101

12. Maintenance and Inspection ................................................................................ 102

12.1 Preventive Maintenance and Periodic Inspection

12.2 Component Replacement

................................................................................

.............................................

102

103

13. Storage .................................................................................................................... 104

14. Warranty .................................................................................................................. 104

Appendix

Appendix Table 1. Parameter list ............................................................................. 105

Appendix Table 2. List of trips ................................................................................. 121

Appendix Figure 1. Input terminal information ......................................................... 122

Appendix Figure 2. Output terminal information ...................................................... 122

Appendix Figure 3. Character codes ....................................................................... 123

Appendix Table 3. Standard default settings per inverter capacity ... 124

Appendix Table 4. Industrial application parameters

..................................................

125

Appendix Table 5. Changed settings memo ............................................................ 142

- Ill

Page 7

1. Acceptance Inspection and Precautions

(1) Confirm that the unit has not been damaged during shipment.

(2) Confirm that the model noted on the rating nameplate is as ordered.

(3) Whpn storing the unit temporarily after purchase, store it in dust-free, well-ventilated location.

(4) Special care is taken during product manufacturing, packaging, and shipment. If any problems are

discovered, however, please contact your dealer immediately.

Details of rating nameplate

Applicable —

power source

Capacity —

Rated output

voltage

Details of model No.

SOURCE 200-220V-50HZ

CAPACITY 6. 5 kVA

LOT NO. i

0UtSS4«91PC 3 MADE IN JAPAN

Type

r

------------V

A.

K

TRANSISTOR INVERTER

TYPE-FORM VFA5- 2037 P

FREQUENCY 0. l~80Hz

200<-230V-eOife

( 0. Ol-iOO) Hz

CURRENT 16. 5 A

VOLTS 200-23OV

r----------------------

AC MOTOR 3. 7 kW MAX.

--------------------------------------- ., I

TOSHIBA CORPORATION

Model No.

Model

n

2

5

O

3

p Y

T

J

----------------

11 I

Option PCB

and special

codes

A

2 2

Inverter model

<

-----

Rated output frequency

<

-----

Rated output current

<— Applicable motor capacity

,

Model name

TOSVERT

VF-A5 series

A: General pur

pose highperformance

Input voMage

2; 200V-230V

4: 380V-460V

8: DC power source

input

(200V class output)

9: DC power source

input

(400V class output)

Standard

motor

capacity

0.4kW : 004

0.75kW; OOr

1.5kW : 015

2.2kW : 022

3.7kW : 037

5.5kW ; 055

7.5kW : 075

IlkW : 110

15kW : 150

18.5kW: 185

22kW : 220

30kW :300

37kW :370

45kW : 450

55kW : 550

75kW ; 750

Additional

functions

E: Fully enclosed

F: External

heatsink

N: GTR7

modification

Y: Other

(nonstandard)

None: Standard

Operation

panel

P: Installed

B; Not installed

UL-listed;

UP, UB

Option PCB and special specification codes

AOD: Special specification code (OD are numbers)

M: 12-bit binary input PCB 4526A installed

Q: Expansion terminal block PCB 4514A installed

R: Expansion terminal block PCB 4514B installed

S: Expansion terminal block PCB 4514C installed

T: Expansion terminal block PCB 4514D installed

J: Expansion terminal block PCB 4515A installed

K: Expansion terminal block PCB 4515B installed

D: Expansion terminal block PCB 4515C installed

V: RS485 communication PCB installed

W: TOSLINE-FIO communication PCB installed

X; TOSLINE-S20 communication PCB installed

- 1 -

Page 8

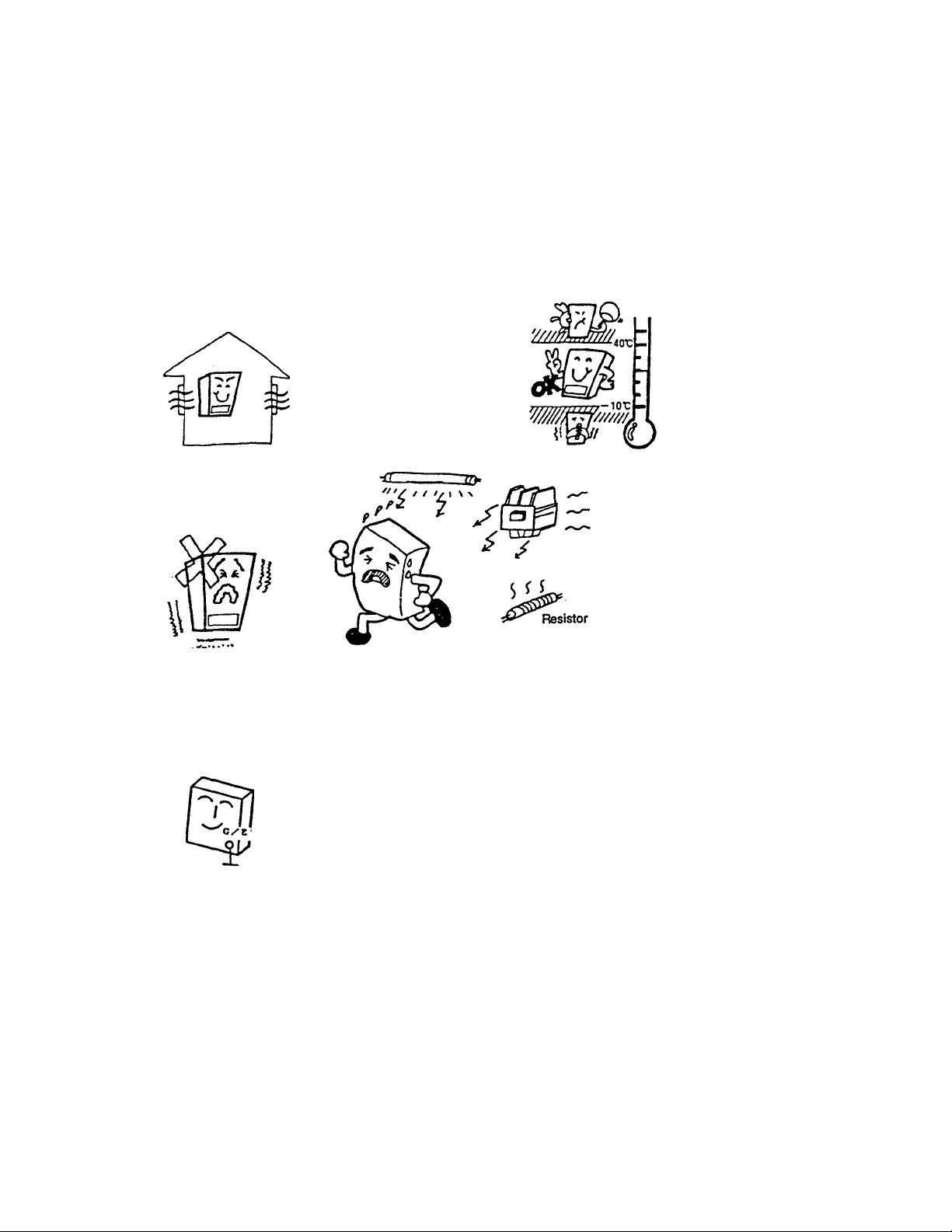

2. installation Precautions

This inverter is an electronic control unit. Take special care concerning the installation environment.

Confirm that the input power is within ±10% of the rated value. If the input power voltage range

tolerances are exceeded during use, the protective circuits may function or the inverter may be

damaged.

Avoid instaliation in hot and humid locations,

where condensation or freezing may occur, or

where water, dust, or metal chips may come into

contact with the inverter.

Install in a location

free of corrosive gases

or cutting fluids, etc.

Do not install the unit

in locations that

experience large

vibrations.

Ground the G/E

terminal to prevent

electrical shock and

Attach the unit to a non-combustible material such as a metal panel. To

ensure adequate ventilation, maintain the following installation spaces, and

always install the unit vertically in the longitudinal direction. When instailing

malfunction due to

noise.

ua/iL

10cm or more

5cm or more

5cm or more

ri

10cm or more

7777777 ‘

Use the unit within an ambient temperature of

-10 to 40°C.

Because the inverter radiates

heat, when installing in a

panel take special care

concerning ventilation and

panel space. Removal of

the cover is recommended

when using in a panel to

ensure maximum longevity

and reliability.

The inverter may malfunction if the

following types of devices are

installed nearby, so use proper

precautions.

• Solenoids ■

• Brakes

• Electromagnetio contactors

- Ruorescent iights

> Resistors

---------

- Install a surge killer

on the exciting coil.

Keep away from the inverter

multiple inverters in a row, leave a clearance of

at least 10cm between each unit. This clearance

can be reduced depending on the environment

or by adding fans.

g

(For 37kW and larger units, leave a clearance of

at least 20cm above and below the inverter to

allow for fan replacement and wire bending

space.)

Contact the Engineering Department for further

details.

Inverter life depends greatly on the ambient temperature. Make sure

that the ambient temperature of the installation location does not exceed the

maximum ambient temperature rating (40°C). ^

Measure the temperature at the positions shown in the diagram on the right,

and confirm that it is less than the maximum ambient temperature rating

(40°C). (50°C or less when the cover is removed.)

22kW and larger units can be used up to an ambient temperature of 50°C.

(Do not remove the cover from 22kW and larger units.)

* Always install the inverter in the longitudinal direction on a vertical surface.

- 2

Sett

Measurement position

Measurement position

Page 9

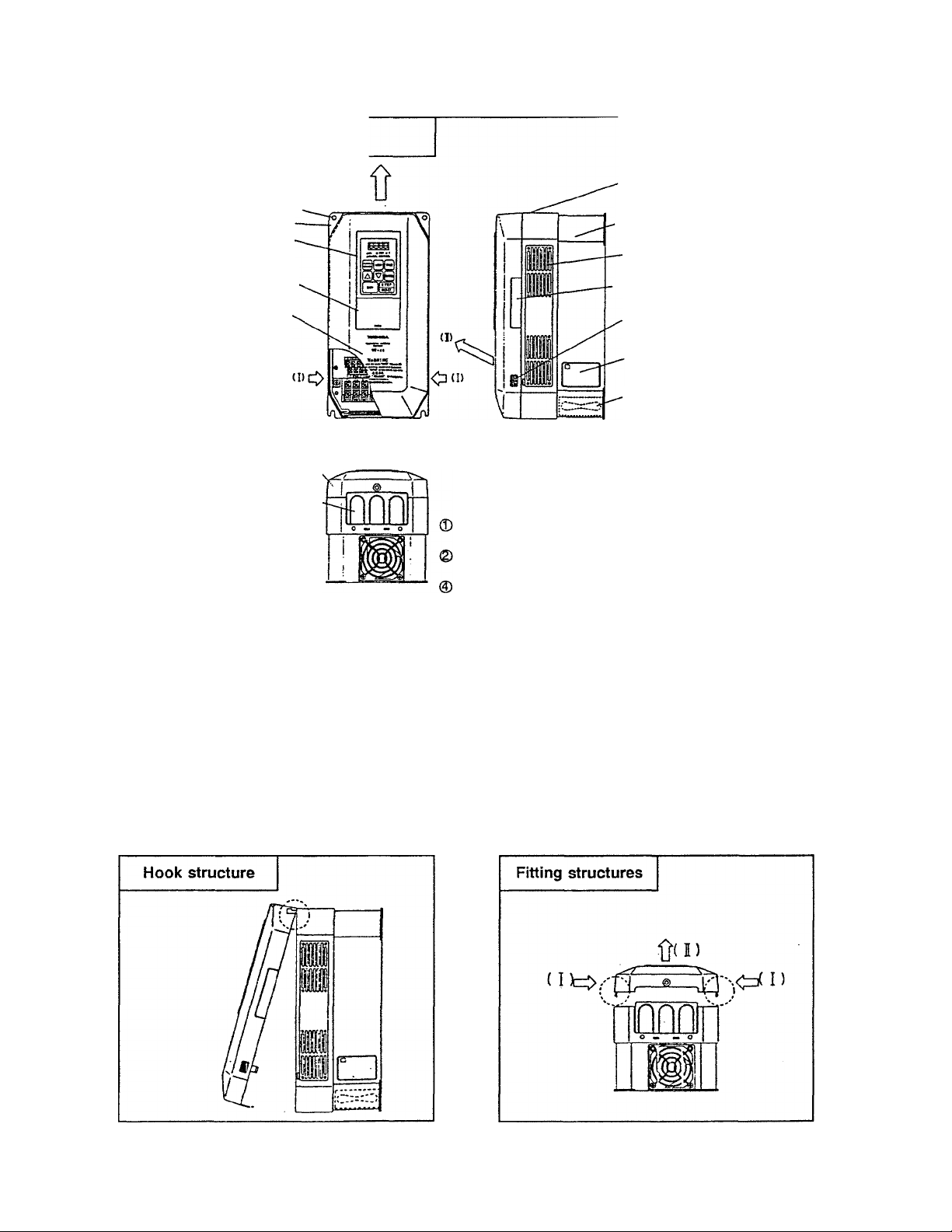

3. External View and Component Names

3.1 Component Explanation (I)

0 Cooling air exhaust port

® Mounting hole (4 holes)

® Mounting bracket

® Operating panel

® ROM interface window

(semi-transparent)

® Front cover warnings

@ Cover (plastic)

©) Wiring access plate: '

Always cut out the wiring

ports as necessary.

When using an 11kWor larger unit,

make slits in the rubber bushing

with nippers or a knife as

shown below.

© Upper caution sticker;

Always remove this sticker when the ambient

temperature is high.

® Ventilation slots:

A cover-up plate option is available for fully-sealed

applications.

_ \

Slit

Rubber

bushing

© Upper caution sticker

® Chassis (plastic)

© Ventilation slots

0 Optical cable access slot

for installation of optical

communication options.

© Finger clasp for

removing cover

O Rating nameplate

© Cooling fan

Operating panel: removable

Refer to section 3.3 Removal of operating panel.

ROM interface window: removable

Refer to section 3.3 Removal of ROM interface window.

Cover

Always read the cautions ® on the front of the cover and remove

the cover when wiring.

Refer to section 3.2 Removal of cover.

H the ambient temperature of the inverter unit exceeds 40°C when

mounted in a panel, remove the cover. The unit can then be used

up to a temperature of 50°C.

3.2 Removal of Cover

1)

For 7.5kW and smaller... Place your fingers on the finger clasps for removing the cover shown In the 3.1 Component Explanation

(I) drawing. Apply force in the direction of the arrows (1), and pull the cover up in the direction of arrow

(n). The cover will come off.

For 11~18kW... Remove the two screws on the cover wiring iniet, and then remove the cover like the 7.5kW models.

For 22kW and larger... Wait for the "CHARGE* lamp on the cover (sheet metal) to go out. Then remove the four screws holding

the cover (six screws for 37kW and larger), and the cover will come off.

- 3 -

Page 10

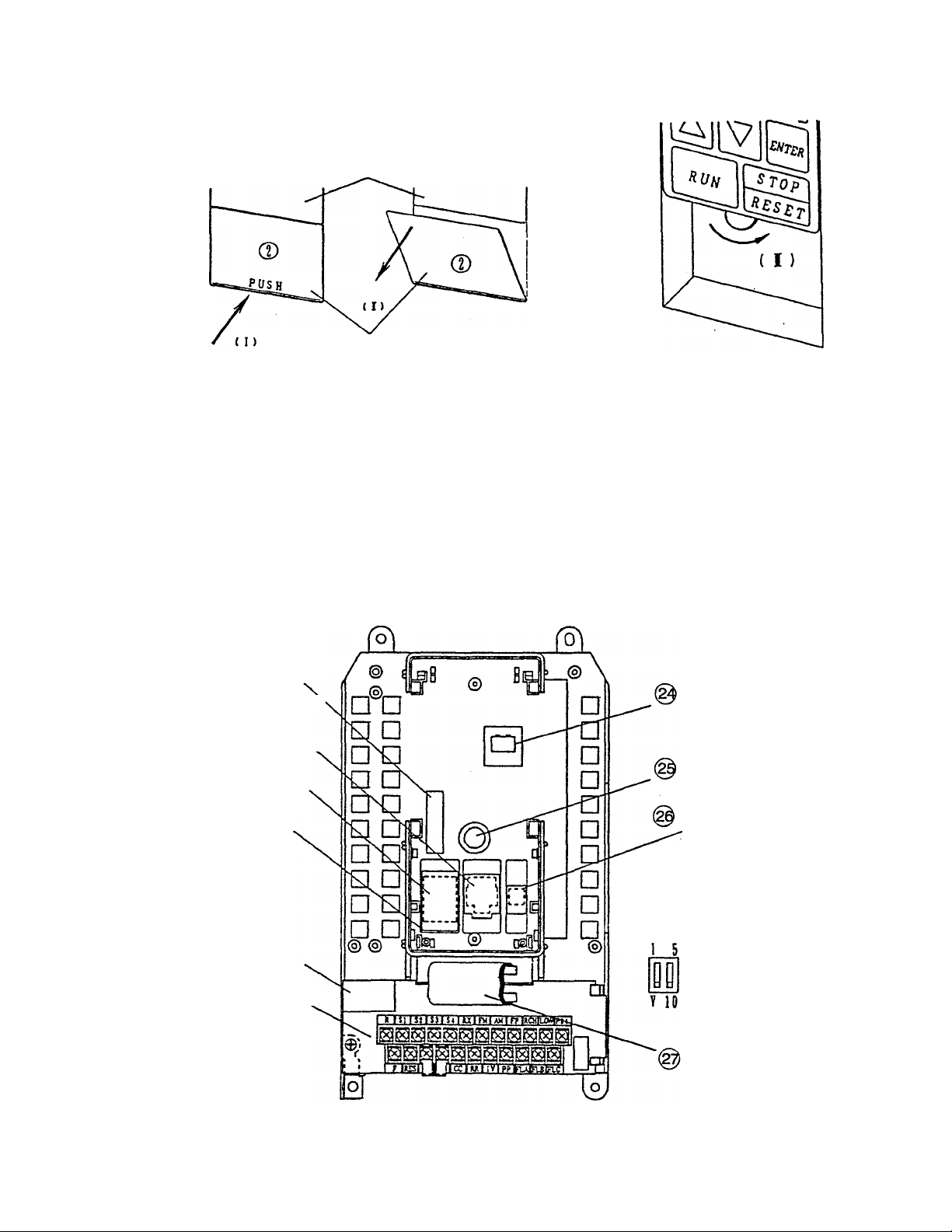

3.3 Removal of the ROM Interface

Window and Operation Panei

Operation panel

ROM interface window

(I) Press where the word PUSH is located.

I

The top of the window will open.

1

(n) Hold the top of the window, and

pull it out in the direction of

the arrow (II).

( iV )

(m) The operation panel attachment

screw can now be seen. Turn it

in the direction of the arrow

(HI) until it completely

loosens.

(TV) When the screw has

completely loosened, pull the

operation panel out in the direction

of the arrow (TV).

3.4 Component Explanation (II)

@ Option connector

(40-pin)

^ RS232C communicatioiY

connector

(Modular 6-pin)

@ Option ROM socket

ROM cover

Option connector

(20-pin)

Control terminal block

Operation panel

connector

Operation panel

attachment stud

Changeover switch for

frequency setting

signal inputs

IV terminal l/V changeover switch

RX terminal 10V/5V changeover switch

- 4 -

Flat cable

(for control terminal block)

Page 11

4. Operation Precautions

Observe the following points when using the VF-A5 inverter

4.1 Cautions Regarding Motor

Comparison with com

mercial power source

operation:

Running at low-speeds:

Adjustment of overload

protection level:

Running at speeds

exceeding 60Hz:

The VF-A5 inverter uses a sinusoidal-wave PWM method, but the

output voltage and output currertt will be distorted waveforms which

closely approximate sinusoidal waveforms, instead of complete

sinusoidal waveforms. In comparison to operating with the commercial

power source, the motor temperature rise, noise and vibration will

increase slightly.

When the inverter is used in combination with a general purpose

motor and run at low speeds, the motor’s cooling effect will decrease.

Therefore, the output load must be reduced to less than the rated

load. If the motor is to be run at the rated torque even at low speeds,

use a Toshiba 'VF motor* specially designed for use with inverters.

When used with a VF motor, the inverter’s overload protection level

must be adjusted. (Refer to pages 72, 73 for details.)

When using this inverter with a general purpose motor, the overload

protection of the VF-A5 is performed by use of an overioad detection

circuit (electronic thermal relay) that meets a general purpose motor’s

reduced load characteristics. The reference current value for this

electronic thermal relay is set to the inverter’s rated current value;

therefore, this may need adjustment depending on the motor.

When operating at a frequency that exceeds 60Hz, motor vibration

and noise wiil increase. Furthermore, this type of operation may be

limited by the motor’s mechanical strength and bearing construction,

so please contact the motor manufacturer for further information.

Load equipment lubrication

method:

Ultra-light loads and lowinertia loads:

Measures for instability

phenomena:

When driving an oil-lubricated speed reduction gear or geared motor,

the lubrication may deteriorate at low-speeds, so contact the speed

reduction gear manufacturer for information on usable variable-speed

areas.

Instability phenomena, such as abnormal vibration or overcurrent

trips, may occur when operating with an ultra-light load at a load ratio

of 5% or less, or with a load having an extremely small moment of

inertia In these cases, lower the carrier frequency. (Refer to page 66)

Instability phenomena may also occur when using the inverter with the

following types of motors or loads, so always confirm applicability

before use.

(1) Combination with motor exceeding recommended applicable

motor rating.

(2) Combination with special motors such as explosion-proof motors.

(3) Combination with special loads having severe rotational

fluctuations, such as piston-type movements.

- 5 -

Page 12

Braking during power off:

The inverter will enter the coast-stop state when the power source is

turned off. The motor will therefore not stop immediately. To stop the

motor immediately, install an auxiliary brake unit. Dynamic braking

units and mechanical braking units are available, so select one that

suits your specific appiication.

Loads that generate a

negative torque:

Motors with brakes:

The overvoltage protection or overcurrent protection may function and

trip the inverter when used with loads that generate a negative torque,

in this case, a braking resistor that meets the load condition must be

instalied.

If a motor with a brake is directly connected to the inverter, the

voltage when the motor is started will be low, which may result in the

brake not being released. In this case, separately wire the brake

circuit and motor main circuit. In addition, there is a delay in the time

to when the inverter output stops if the inverter’s ST to CC control

terminal connection is released, so use of the circuit configuration in

Fig. 4-1 is recommended.

In Fig. (a), the brake power is turned ON and OFF via MC2 and MC3.

If a circuit configuration as shown in the drawing is not used, a bound

current may flow during braking and may cause an overcurrent trip.

The brake power can also be turned ON and OFF using the low-

speed signal LOW as shown in Fig. (b).

(Non-excited brake)

Fig.4.1 Circuit configuration for motor with brake

In some cases, such as in hoist applications, turning the brake ON and

OFF by using low-speed detection (LOW terminal function) may be better,

so contact your dealer for further details.

4.2 Cautions Regarding the inverter

Inverter’s overcurrent

protection:

Overcurrent protection is used as the VF-A5 inverter’s protection

function, and the current setting level is set to match the largest

applicable motor. Therefore, when operating a motor that is smaller

than the inverter capacity, the overcurrent level and electronic thermal

protection parameters must be readjusted. (Refer to pages 72, 73.)

Page 13

Running with light loads:

Operating a large capacity motor with a light load using a small

capacity (kVA) inverter must be avoided. The output peak current will

increase due to the current ripple, and overcurrent trips may

frequently occur.

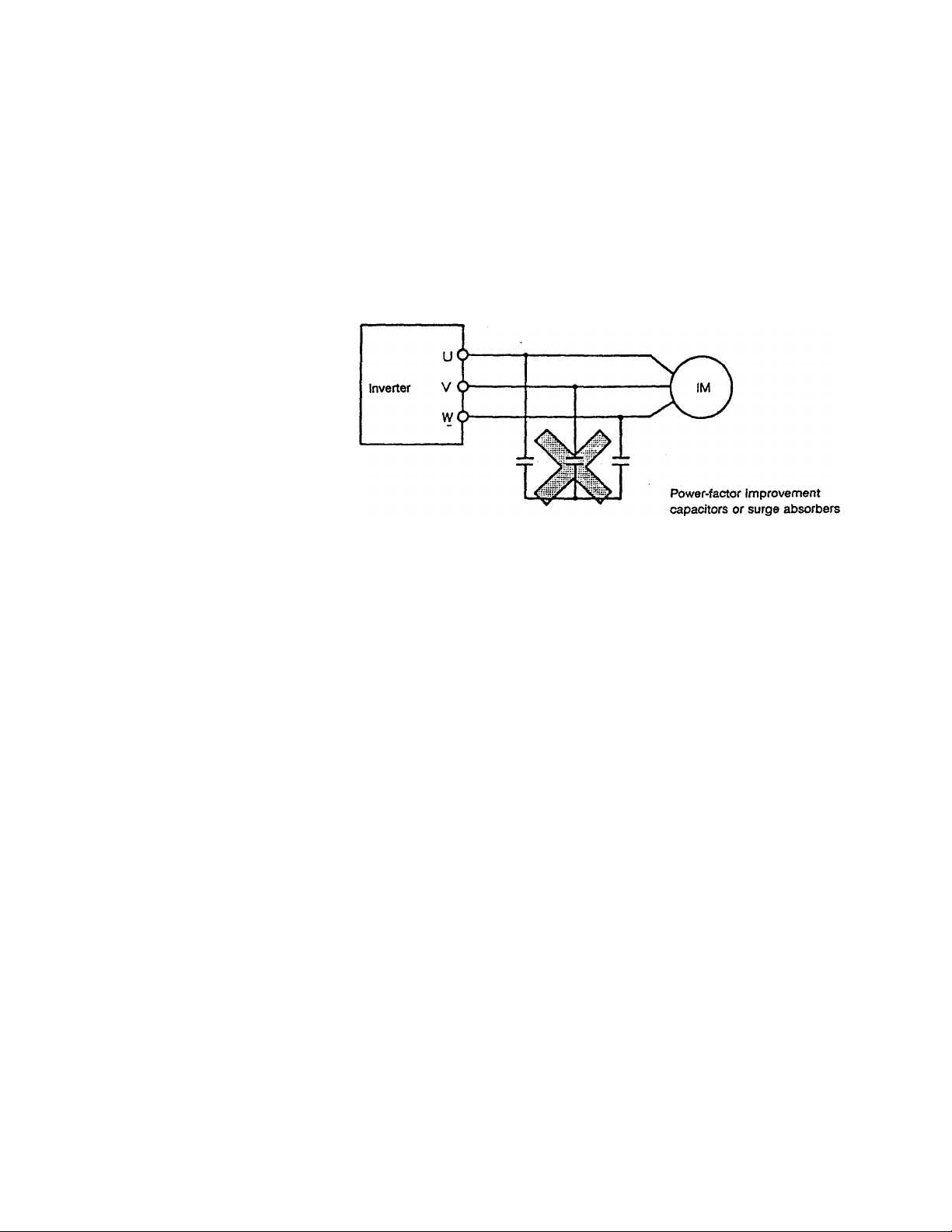

Power-factor improvement

capacitors;

Use with voltage sources

other than the rated voltage:

Protection device for

lightning surges:

Power-factor improvement capacitors must not be installed on the

inverter’s output. When operating a motor with power-factor

improvement capacitors installed, remove the capacitors, or the

inverter may fault trip or the capacitors may be damaged.

Use with voltage sources other than the rated voltage is not possible.

If necessary, use a transformer, etc., to increase or decrease the

source voltage to the rated voltage.

A DSA (lightning surge absorber) is used for protection in the unit. If a

surge voltage exceeding 2600 to 3600V peak is applied, the device

will light like a glowing electrical discharge. This will cause no

problems if the condition does not continue for an extended period of

time.

(Refer to Fig. 6-2-1 Fig. ® on page 21.)

7 -

Page 14

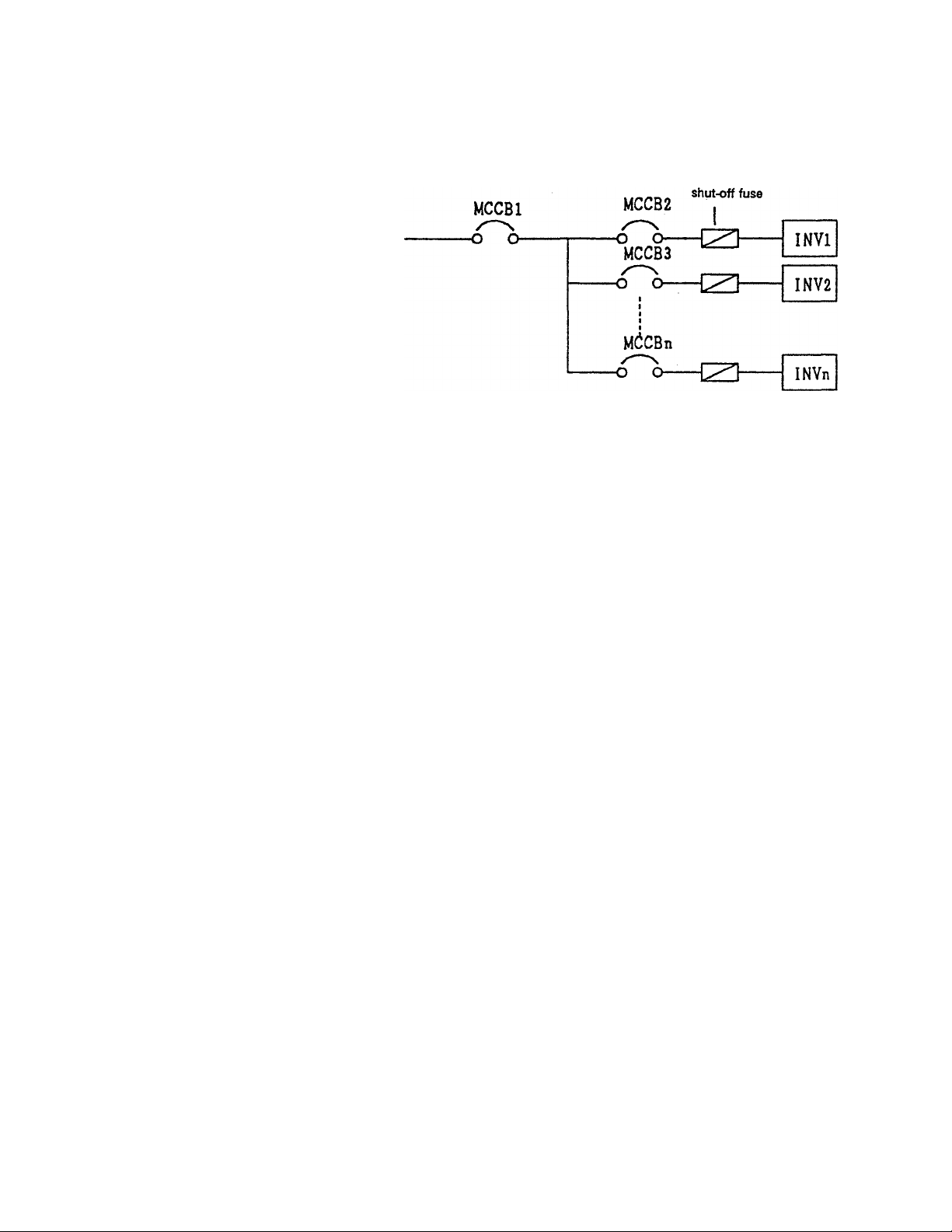

Use of multiple inverter

units:

Observe the following points when using multiple inverter units on the

same power source line.

High-speed

As Shown above, there is no fuse installed in the inverter’s main

circuit, if a short circuit fault occurs in the inverter, not only MCCB2

will trip, but the main breaker MCCB1 may also trip.

Select the shut-off characteristics of MCCB1 and MCCB2 so that a

selective shutdown can be executed and only MCCB2 trips. If the

optimum characteristics cannot be selected, install a high-speed shut

off fuse after MCCB2. (Refer to page 14 for MCCB selection.)

4.3 Inverter Disposal Precautions

Observe the following points when disposing of the inverter.

Explosions from

incineration:

Gasses from plastics:

Disposal method:

Placing the inverter in an incinerator may be dangerous, as the

electrolytic fluid used in the electrolytic capacitors may expand and

explode.

The plastic used for the cover, etc., may generate poisonous gases

when incinerated.

Commission the disposal of the inverter to a specialist.

- ft -

Page 15

5. Wiring Precautions

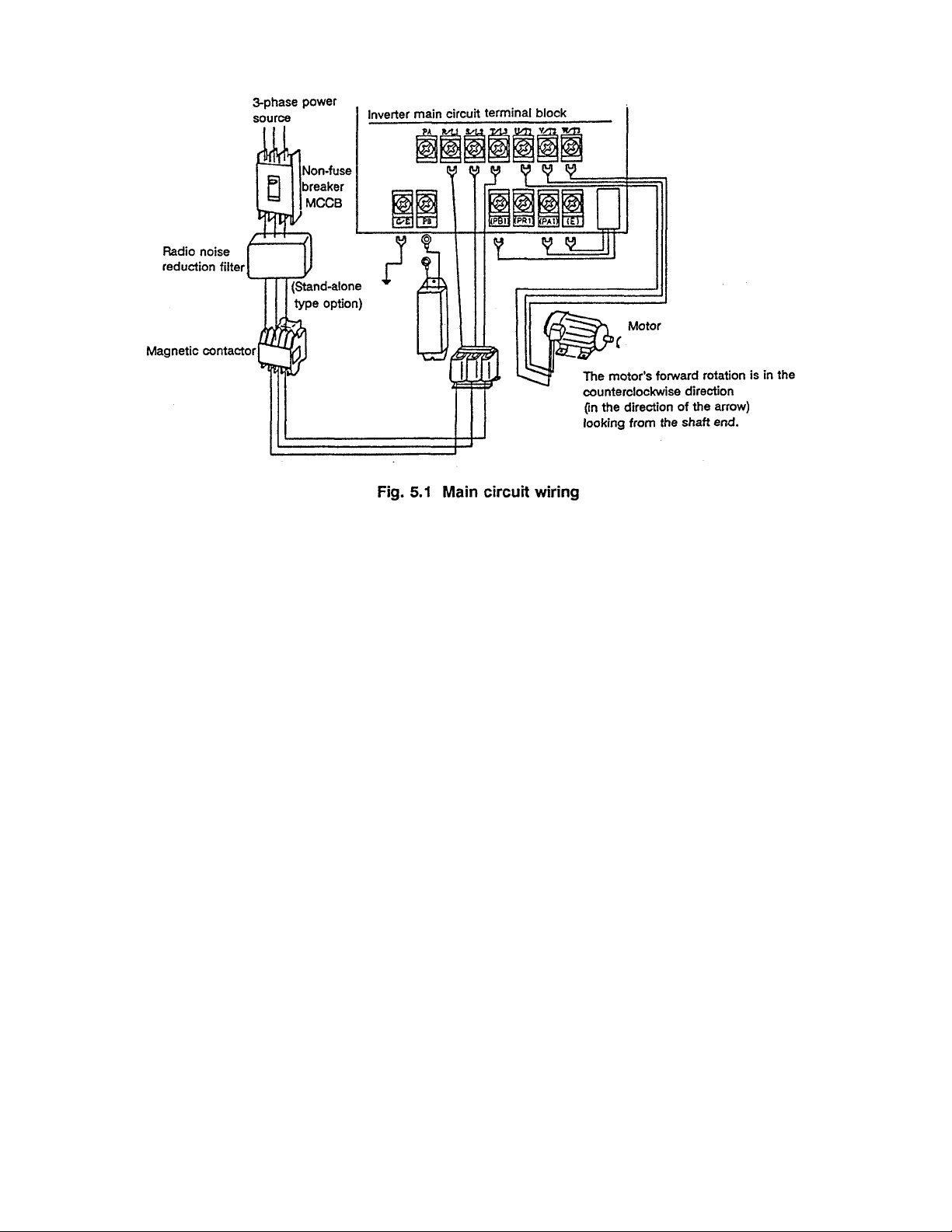

5.1 Connection to Main Circuit (Refer to page 11, Fig. 5.1.)

Observe the following precautions when making connections to the inverter.

Confirmation of power OFF:

Electrical shock preventionconfirmation of charge

dissipation:

Confirmation of main circuit

connections:

Separation of power source

and motor wiring:

Separation of control and

main power supplies:

Always turn the primary power distribution panel switch OFF, and

confirm with a tester that a voltage is not present before beginning

wiring to the inverter.

Before changing the wiring, wait at least five minutes after the

•CHARGE“ lamp inside the inverter has gone out, and then confirm

that the capacitors have fully discharged by using a tester, etc., that

can measure high-voltage DC. The internal electrolytic capacitors are

charged, and there is a danger of electrical shock If the charged

areas are touched while the "CHARGE' lamp is on. Do not touch the

terminal block or remove the upper cover while the lamp is lit

The inverter will be damaged If the input power source is applied to

the motor terminals (U/T1, V/T2, W/T3). Always confirm the wiring for

the power source terminals (R/L1, S/L2, T/L3) and motor terminals

(U/T1, V/T2, W/T3) before turning the power on.

To prevent problems due to radio-frequency noise, etc., do not bundle

the wiring to the input power terminals (R/L1, S/L2, T/L3) and the

motor terminals (U/T1, V/T2, VJfTS) together.

In order to maintain the control power supply to display faults or to

operate the communication options while the main circuit power is

shut down, remove the two shorting bars (between R/L1-R0, S/L2-S0)

on the control power supply terminal block. Connect the control

power to a power source that is separate from the main circuit supply.

5.2 Connection of Control Signals

Observe the following points when making control signal connections.

Rating of relay contacts:

Power wiring for control

circuit:

Control wiring wire sizes:

Isolation from main circuit:

Use a relay intended for use with micro-current (min. applicable load

rating less than 4mA-24V.), and install a surge killer on the relay’s

exciting coil.

Use shielded wiring or twisted-pair wiring for the control circuit, and

separate the wiring from the main circuit wiring.

The following wiring sizes for the control circuit are recommended.

Frequency setting signal input, frequency meter, ammeter: shielded

wire that is 0.3mm® or larger

Other signals: Vinyl-insulated wire that is 0.75mm® or larger

All control terminals other than FLA, FLB and FLC are connected to

Internal electronic circuits, so input signals must always be electrically

isolated from the main circuit.

9-

Page 16

Ratings of connected

meters:

Connect a full-scale 1 mAdc DC ammeter or full-scale 7.5Vdc-1 mA DC

voltmeter to the control terminals.

Rating of FL signal contacts:

External use of control

power:

Open collector outputs:

Frequency-setting

potentiometer:

5.3 Other Precautions

Use of crimp-on terminal

lugs:

The contact rating of the protection operation detection relay (FL) is

250Vac (cos0=O.4) 30Vdc-1A.

A max. of 24Vdc-100mA can be used from the P24 control power

terminal to drive external relays.

The RCH and LOW control terminals are open-collector outputs, and

can output a max. 24Vdc-50mA. Use of a 24Vdc OMRON MY1 relay

(RY) is recommended.

Always install a diode (200V-1A class)

for surge absorption. Take special note

of the diode polarity to avoid incorrect

application.

Use a potentiometer rated at 1k to 10kO-1/4W for the frequency

setting Input signal.

The clearance between terminals on the inverter main circuit terminal

block is small, so use sleeved crimp-on terminal lugs for all main

circuit terminals. Take special care during connection so that the

terminal lugs do not make contact with neighboring terminal lugs.

P2<

RCH

Grounding terminal:

Built-in braking resistor

Internally-connected (E)

terminal:

The main circuit wiring is shown in Fig. 5.1.

(For 3.7kW or less, not showing control power terminals RO, SO)

Always ground the G/E grounding terminal with a wire that is 3.5mm®

or larger.

For inverter capacities that are 3.7kW or less, a built-in braking

resistor is connected between the main circuit terminals (PA1) and

(PB1), providing dynamic braking as a standard feature.

The (E) terminal is for internal connections, so do not remove

connections from it or make any external connections to it.

-10 -

Page 17

Note) A DC reactor (stand-alone type option) can be installed on 5.5kW and larger units. (Refer to the

function of main circuit terminals PO and PA on page 18.)

Installation of non-fuse breaker

(1) Install a non-fuse breaker (MCCB) for wiring protection on the input power source side.

(2) Avoid frequent starting/stopping by turning the non-fuse breaker ON and OFF.

(3) Start and stop by turning terminals F to CC (or R to CC) ON and OFF.

Installation of primary magnetic contactor

(Refer to page 14; Examples of selecting equipment for wiring.)

(1) When using an external braking resistor, install a magnetic contactor (MC) or non-fuse breaker with

trip coil (MCCB) on the inverter's power supply input side for protection. Make sure that the power

circuit can be opened with the built-in fault detection relay (FL).

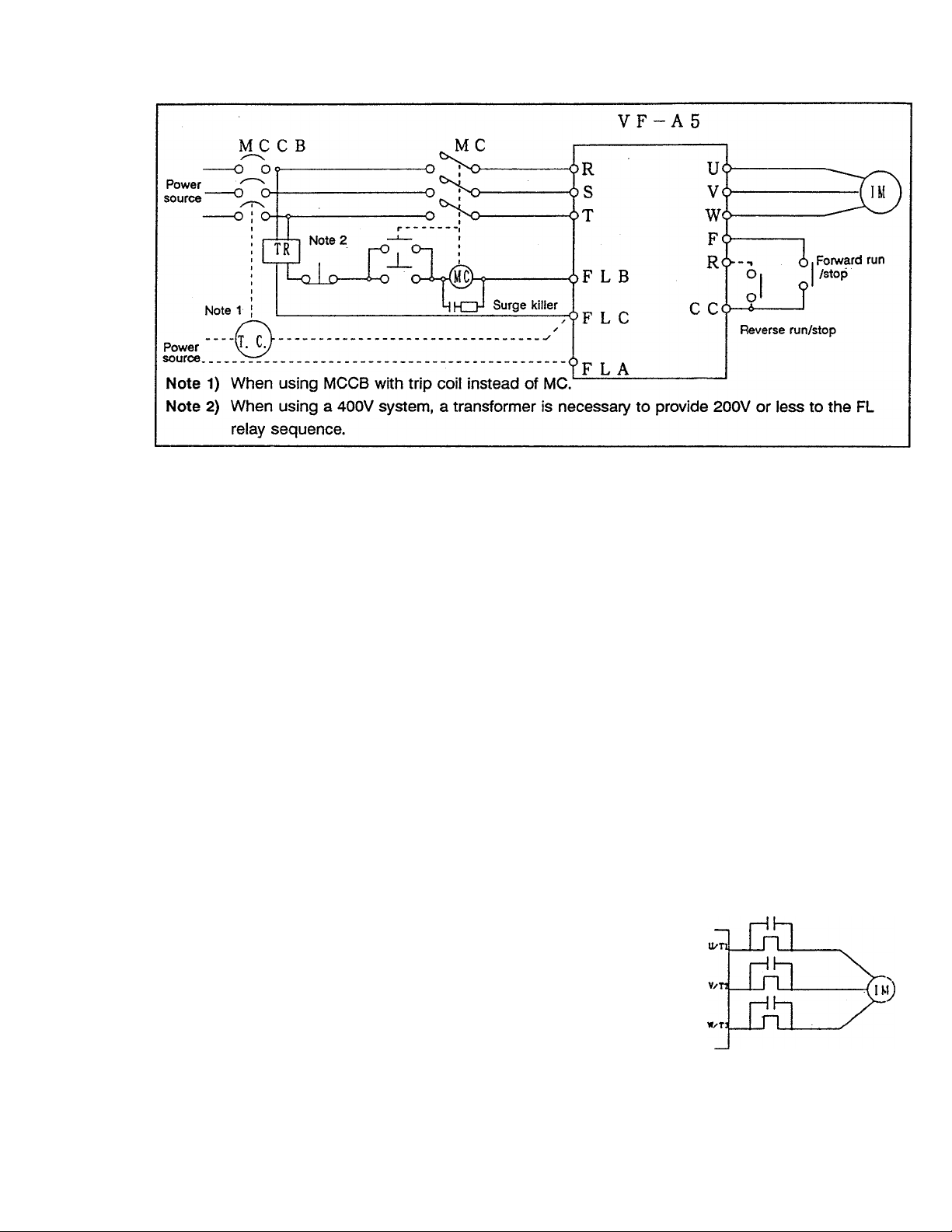

(2) The VF-A5 has a built-in fault detection relay (FL). Connect the contacts of this relay to the primary side

magnetic contactor (MC) operation terminals, so that the MC can be opened when the inverter’s

protection circuit functions.

The fault detection relay (FL) contacts (250VAC-1A cos0=O.4) can be directly connected on 200V

systems. When using a 400V system, a transformer must be used to create 200V or less for the FL

sequence.

If the MC exciting current exceeds the FL contact rating, install another relay step.

(3) Turn terminal F (or R) to CC ON and OFF to frequently start and stop. Due to repeated inrush currents

when the power is turned on, the life of the inverter will be shortened when the primary magnetic

contactor is used to start and stop, so do not use this method to start and stop frequently.

(4) Install a surge killer on the magnetic contactor (MC) exciting coil.

-11

Page 18

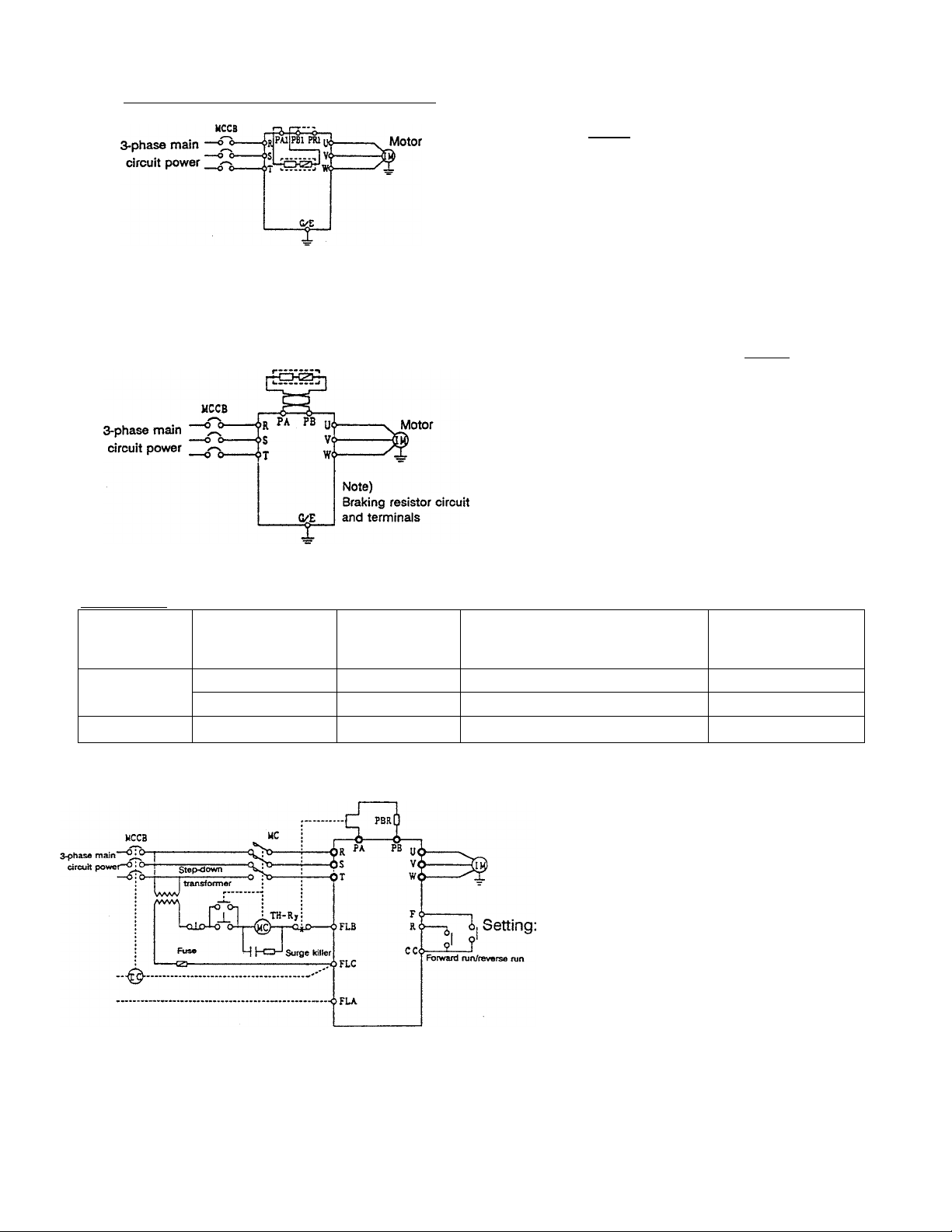

Fig. 5.2 Wiring example using a magnetic contactor

installation restrictions of secondary-side magnetic contactors

(1) As a rule, if a magnetic contactor is installed between the inverter and motor, do not turn it ON/OFF

while running. (If the secondary-side contactor is turned ON and OFF while running, a large current

may flow in the inverter, causing inverter damage and failure.)

(2) A magnetic contactor may be installed to change the motor or to change to the commercial power

source when the inverter is stopped. Always use an interlock with the magnetic contactor in this

situation so that the commercial power supply is not applied to the inverter’s output terminals.

Installation of overload relay (thermal relay)

(Refer to page 14; Examples of selecting equipment for wiring.)

(1) The VF-A5 has a built-in overload protection function that uses an electronic thermal relay. However,

in the following cases, the thermal relay operation level must be adjusted or an overload relay matching

the motor’s characteristics must be installed between the inverter and motor.

0When using a motor having a rated current value different from a Toshiba general-purpose motor.

(Adjust the electronic thermal level)

©When running a single motor with an output less than the specified standard applicable motor, or

when running several motor simultaneously (An overload relay must be installed on each motor.)

Note) If the motor cables for a 400V class inverter are long, the thermal

relay may malfunction. In this case, lower the carrier frequency (refer

to adjustment parameters on page 66), or install a 0.1/r to O.SpF-

1000V film capacitor between the input/output terminals of each

phase’s thermal relay.

< Example > When using external thermal relays, the inverter can be externally fault-tripped and

immediately stopped by using the following method (Fig. 5.3).

12

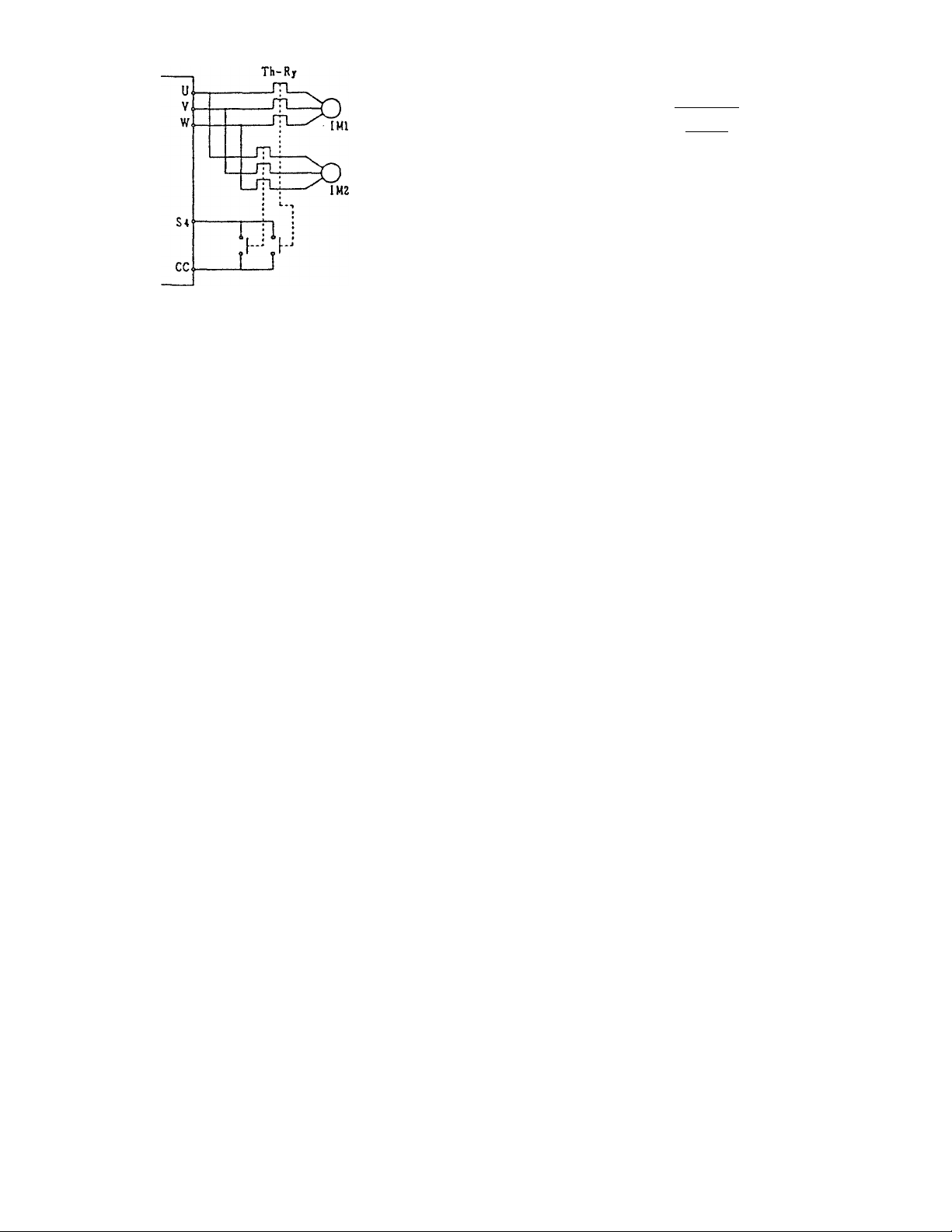

Page 19

Note) In this case, ensure that S4 is set to 'Emergency

stop function", by setting | /h H [in

0 r. 5 h to ID.

If the Th-Ry functions, the inverter will display

• E ', and fault trip.

* Other unused terminals can also be used instead of the S4

terminal.

Fig. 5.3 Wiring example using external thermal relays

C r. 51 etc., indicate the LED display on the operation panel. (Refer to Appendix 3, Character

codes, on page 123. The boxed items indicate a parameter or panel operation key.

When using the VF-A5 to drive a Toshiba VF motor*, designed exclusively for constant torque/inverter-

(2)

driven applications, set the electronic thermal protection characteristics for a VF motor.

(Refer to pages 72, 73, Electronic Thermal Protection.)

For protection measures, use of a motor with an imbedded-type thermal relay in the motor coil is

(3)

recommended when running a motor at low speeds.

Restrictions on the installation of power-factor improvement capacitors (both input/output)

Do not install power-factor improvement capacitors on the input or output sides of the inverter. Large

currents containing high frequency elements may flow to the capacitors and adversely affect them.

Capacitors on the output side may cause the inverter to overcurrent trip. Install an input reactor or De

link reactor (optional) for power-factor improvement.

Countermeasures against radio wave interference

The inverter may cause radio wave interference to audio equipment, etc., used near the inverter. In this

case, install a radio noise reduction filter (optional) on the inverter’s power source side, or shield the

cables to the motor with a conduit to reduce the interference. Contact your dealer for further details.

Cautions concerning ground faults

Verify that there are no incorrect connections between the motor and inverter and that there are no

short circuits in the motor before beginning operation. Do not ground the neutral point of a starconnected motor.

Installation of an input reactor

An input reactor can be used to improve the input power-factor, to suppress high harmonic elements,

and to miminize the risk of damage to the inverter that may be caused by sudden power fluctuations.

Always install an input reactor when connecting the inverter to the following types of systems.

(1) When power source capacity is SOOkVA or more, and when power source capacity is greater than

the inverter capacity by a factor of 10 times or more.

When connecting the inverter to the same power system as thyristor-commutated control

(2)

equipment.

When connecting the inverter to the same power system as a distorted-wave generation source,

(3)

such as an arc furnace or thyristor-switched converter unit.

Leakage currents

Leakage currents may increase slightly depending on the connection method.

(1) When multiple inverters are connected to one ELCB, increase the ELCB current sensitivity value.

(2) Keep the wiring length between the inverter and motor as short as possible.

(3) Use an ELCB with high-harmonic suppression.

-13

Page 20

Voltage

dass

200V

class

400V

class

Appncabfe

motor

m

0.4

0.75

1.5

2.2

3.7

5.5 -2055P

7.5 -2075P

11

15 -2150P

18.5 -2185P

22 -2220P

30 -2300P 200

37

45 -2450P

55 -2550P

75 -2750P

0.75

1.5 -4015P 10

2.2

3.7

5.5

7.5 -4075P

11

15 -4150P 60

18.5

22

30

37

45 -4450P 150

55

75

Inverter

Model

-2004P

-2007P 10

-2015P 15

-2022P

-2037P 30

-211 OP

-2370P

-4007P

-4022P 10

-4037P 15

-4055P

-4110P

-4185P 75

-4220P

-4300P

-4370P

-4550P

-4750P 225

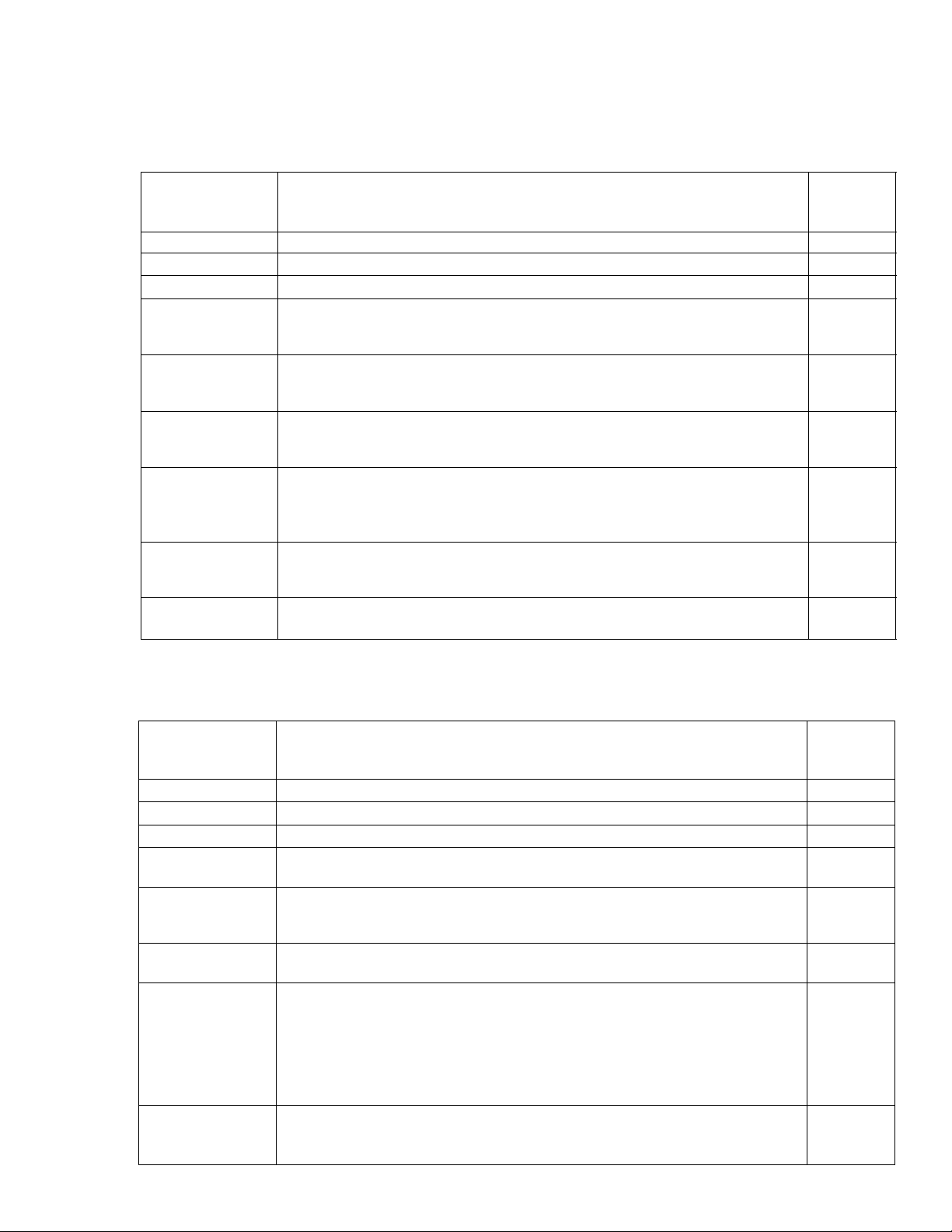

Table 5.1: Examples of selecting equipment for wiring

Non-fuse breaker

(MCC8)

Rated

current

Toshiba

(A)

model

SS30

5

SS30

SS30

20 SS30

SS30 18

ESSO

50

EH100

60

EH100

100

125 EH225

EH225

125

EH225 93

150

EH225

EH225 180

225

EH400

250

EH400 220

250

500 SH600

SS30

5

SS30 9

SS30

SS30 9

SS30

30

30 SS30

ESSO 33 C35A

50

EH100 48

EH100 50

100 EH100

EH225 80 C80A

125

EH225 93

125

EH225 180 C180A 85

175 EH225

EH225

Magnetic

contactor (MC)

Toshiba

Rated

current

model

(Note 1)

(A)

C12A 2.3

12

12 C12A

12 C12A

12 C12A 9.3

C20A 15

35 C35A

50 C50A 28

65 C65A 43

C80A

80

93 C100A 70

C100A 85

180 C180A 108

C180A

220 C220A 162

C220A

300 C300A

9 C12A 2.3

C12A 3.6

9 C12A 5.0

C12A

17

C20A

17

C25A 15

C50A 28

C50A 35

50 C50A 43

C100A

180 C180A 108

220 C220A

Overload relay

Th-Ry

cunvnt value

_ w

{Reference

vfeue]

4.2

6.6

22

57

138

198

3.6

8

11

22

57

70

138

Toshiba

model

T11A

T11A

T11A

Til A

T20A

T35A

T35A

T65A

T65A

T80A

T125A

T125A

T150A

T180A

T220A

T400A

Til A

T11A

Til A

T11A

T20A

T20A

T35A

T35A

T35A

T65A

T65A

T80A

T125A

T125A

T150A

Surge killer

Model

(Note^

Toshiba

model SS-2

Marcon

Bectronics

RFM2E224KD

Model SS-2

Marcon

Bectronics

RFM2H104KD

(400V system)

(Note 6)

Wire size

Main

ciicuit

(mm^

(Notes)

Control

dfcuit

(mm^

(Note 4)

Dynamic

braking

(mm®)

2.0

2.0

2.0

2.0

3.5

0.75 or

larger

5.5

8.0

or

14

14

22

38

38

60

22

100

100

60

100

100x2

2.0

22

38

38

38

60

100

14

2.0

2.0

2.0

3.5

5.5

0.75 or

larger

2.0

3.5

8.0

22

or

(Note 1) When selecting a magnetic contactor (MC) with 2a auxiliary contacts and using the auxiliary contacts for the control circuit,

parallel the 2a contacts to improve contact reliability.

(Note 2) Install a surge killer on the magnetic contactor or relay exciting coil.

(Note 3) The wire sizes for the input side R, S, T and output side U, V, W are shown. These sizes apply only when the wiring length is

(Note 4) Use shielded wire.

(Note ^ Use a wire size 3.5mm® or more for the grounding wire.

(Note 6) 200V system: type SS-2 or Marcon Bectronics RFM2E224KD

less than 30m. Increase the wire sizes when the length exceeds 30m.

- 14 -

Page 21

6. standard Connections

Refer to the operation selection expianation (7.4 Operation mode seiection, page 40), and parameter list

(page 105).

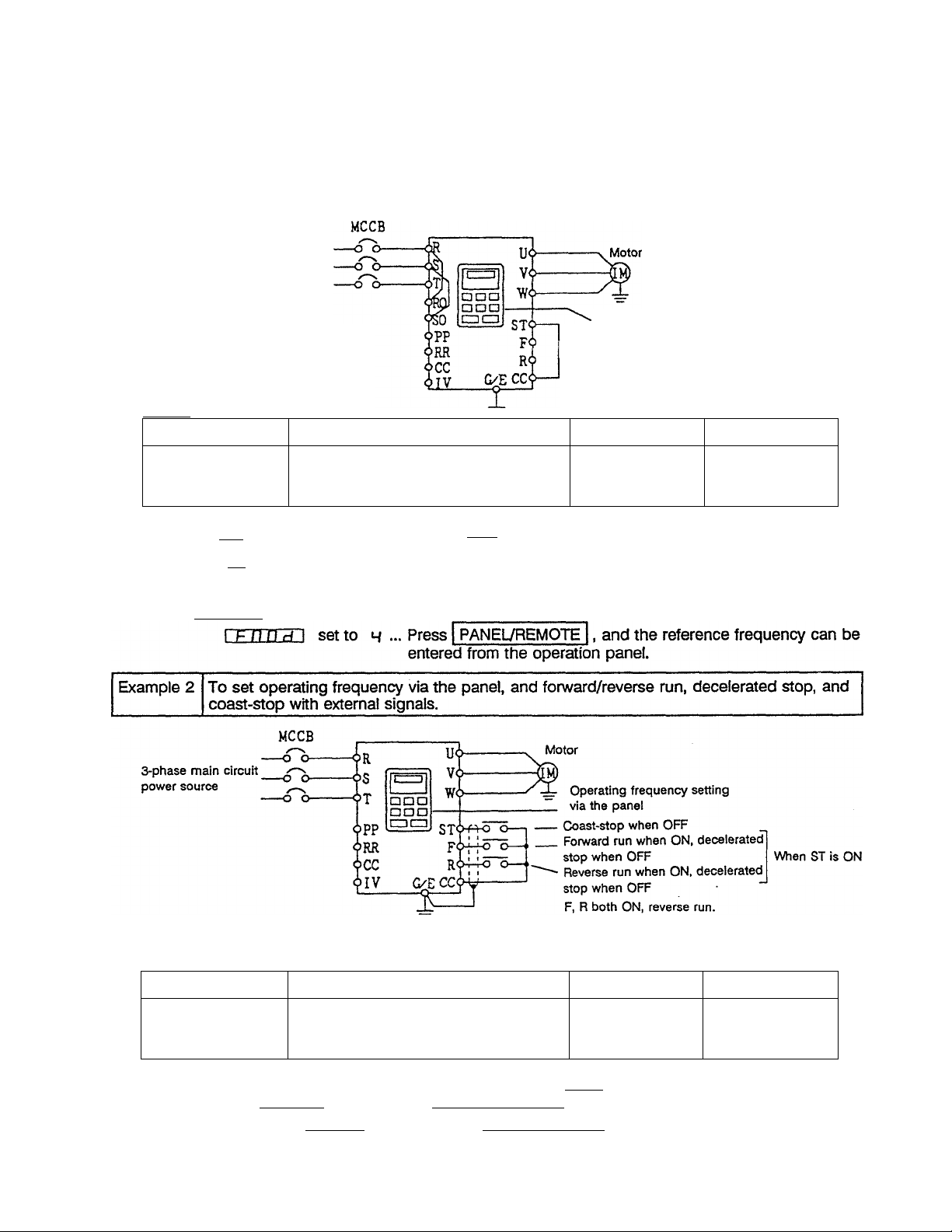

6.1 Standard Connection Example

Example 1 To set run frequency, forward/reverse run, and decelerated stop via the panel.

3-phase main circuit

power source

Operating frequency setting

In standard configuration, F)0 and SO

are connected with jumpers to the main

circuit terminals. (Only for 30kW and smaller)

(Refer to page 18.)

Setting

Parameter group Parameter

Gi-.Ut

C r-.U k

C no d (Command mode selection)

F nOd (Frequency setting mode

selection)

via the panel

These are jumpered at shipment.

Setting value

Reference page

Bci H №••

2orH Notes)

40

40

Note 1)

rrwod:

rrwj'B:

set to B ... Press RUN to start running,

set to H ... Press PANEUREMOTE , then

RUN

to start running.

* Refer to page 28 '7.2 Basic Operation* for the operation methods.

Note 2) I F n n rl I set to B ... The reference frequency can be set only from the operation panel.

Setting

Parameter group

Or-.ut

0 r.U k

C nod (Command mode selection)

F nod (Frequency setting mode

Parameter

Setting value Reference page

1 OT H Not»3)

B

selection)

40

40

twice.Note 3) Emergency stop is possible from the panel by pressing STOP

I r n n H 1 set to / ... Running from operation panel is not possible.

I r n n r/1 set to M ... Press rPANELVREMOTE , and running is possible from the

operation panel by pressing RUN

15 -

Page 22

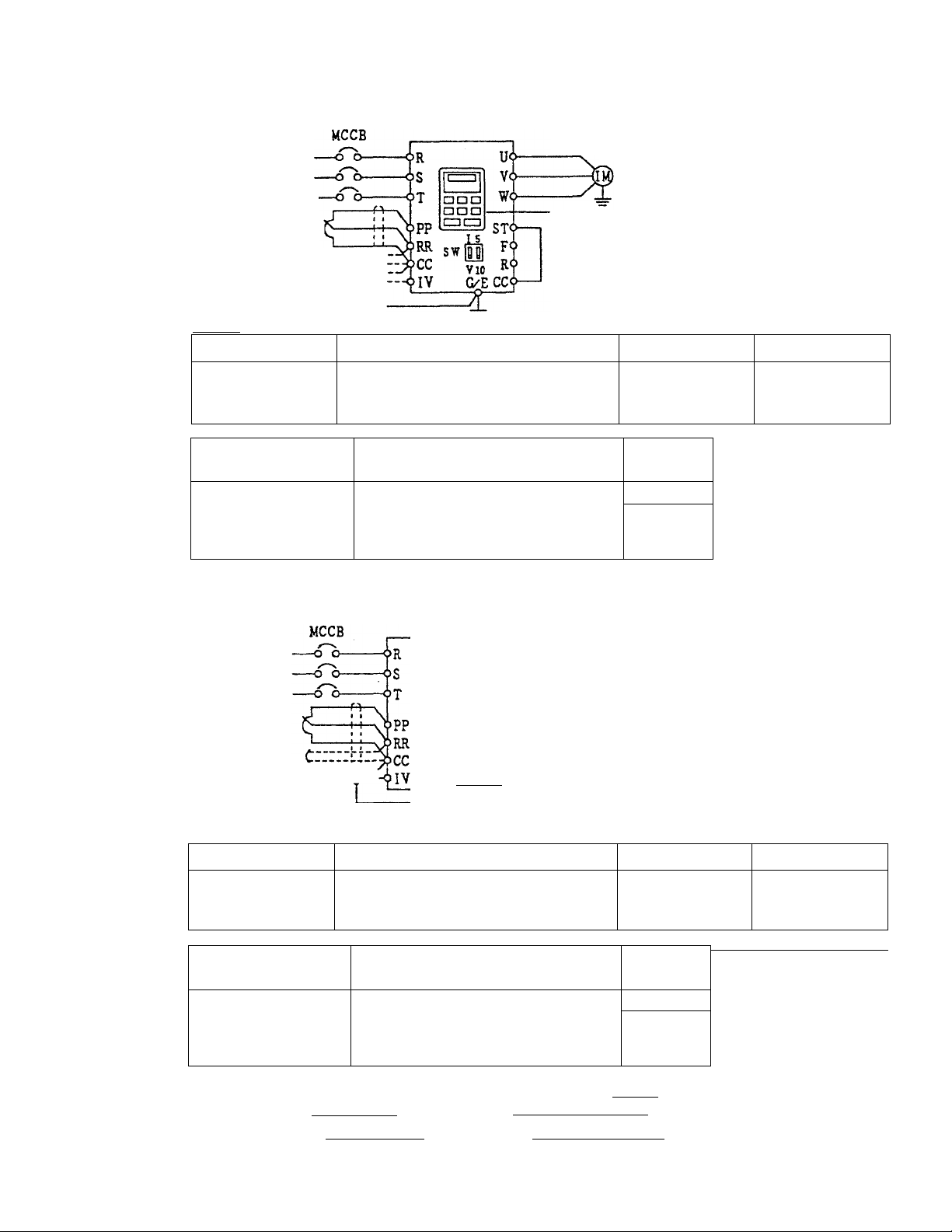

Example 3

To set operating frequency with external signals, and forward/reverse run and

decelerated stop with the panel.

__________

________

3-phase

main circuit

power source

0 Potentio

meter

@0~10Vdc

® 4~20mAdc Crirriy

0~10Vdc

Setting

Parameter group

Gr.Ub

Cr.Ut Fnod (Frequency setting mode

External operating

frequency signal

® Potentiometer

0 0~10Vdc

® 4~20mAdc

0~10Vdc

Example 4

Motor

Operating via the panel

or T

The switches are under the ROM

interface window. (Refer to page 4.)

Parameter

E no d (Command mode selection)

Setting value

1

Reference page

40

40

selection)

Cr.5F F[ 1 Setting value

Switch

SW

1

!

d

E

V side

1 side

V side

Note 5) Refer to page 69.

To set operating frequency, forward/reverse run, decelerated stop, and coast-stop via

external signals.

3-phase

main circuit

power source

0 Potentio

meter

@0~10Vdc

0 4~20mAdcCrrrrryir

I s

sw|m

VIO

G/ECC<^

Setting

Parameter group

Gr-.Uk

Er.Ub

E no d (Command mode selection)

F n Dd (Frequency setting mode

Parameter

selection)

External operating

frequency signal

Cr.5F FCI Setting value

0 Potentiometer

© 0~10Vdc

© 4~20mAdc E

0~10Vdc

STy-fA-o

FQ-i-fö”

R64-4-0

/

1

E

Motor

Coast-stop when OFF

Forward run when ON, decelerated-

stop when OFF

Reverse run when ON, decelerated

stop when OFF

F, R both ON, reverse run

Setting value

/ 0 r 4 Note 3)

/ 0 r 4 Note 4)

Switch

V side

1 side

V side

Note 5) Refer to page 69.

When

ST is ON

Reference page

40

40

Note 4) Emergency stop is possible from the panel by pressing STOP | twice.

I F n D dl set to / ... The reference frequency can only be input from the terminal block.

1 F n Dd 1 set to 4 - Press | PANELVREMOTE |, and the reference frequency can be

entered from the operation panel.

16

Page 23

Example 5 When using built-in braking resistor

(Note) Move PR1 wiring to PB1

Example 6 When connecting a braking resistor (optional)

Note) Select a braking resistor that is higher than the min. tolerable resistance value (refer to page 95). For

22kW and larger units, the separate GTR7 (dynamic braking circuit) option is required,

a) When using an optional braking resistor with temperature fuse

Braking resistor

Setting: Set I Pbi in parameter group Cr.Pr

Setting: for 5.5kW and larger units, set I P b I in

(For 3.7kW and smaller units)

(dynamic braking selection) to 5 (dynamic

braking with overload detection).

The built-in braking resistor is connected to the

PB1 terminal (refer to page 23) at shipment.

parameter group ür.P r (dynamic braking

selection) to S (dynamic braking with overload

detection).

When using the built-in braking resistor with 3.7kW and smaller units, avoid the use of an external braking

resistor. However, parallel connection is possible in the following combinations. (For max. braking rate

applications)

Buift-in braking

resistor

200V systems 2.2kW and smaller

3.7kW

400V systems

When using an optional braking resistor without temperature fuse

b)

3.7kW and smaller 150n

70n

40n

Minimum external resistor

value that can be used with the

built-in braking resistor

70n 3sn

40n 20n

150n

TH-Ry is used as a fire prevention fail-safe.

DBR overload and overcurrent protection

functions are incorporated in the inverter

for protection of the braking resistor, but

TH-Ry operates if those protective

functions are not possible. Select TH-Ry

according to the DBR power rating.

(dynamic braking selection) to 2 (dynamic

braking with overload detection), and set the

braking resistor capacity and resistance value.

(Refer to I Pbc I | PbCP I on page 77.)

Min. total braking

resistance value

75Í1

Note) The step-down transformer does not need to be installed for 200V class inverters.

-17 -

Page 24

6.2 Terminal Functions

Table 6.2.1: Main circuit terminal functions for 3.7kW and smaller units

Main circuit terminal functions for 3.7kW and smaller units are as shown below. The internal circuit

Terminal symbol

G/E

R/L1, S/L2, T/L3

U/T1, V/T2, W/T3

PA, PB

Terminal for external grounding.

Connect to properly-rated power source.

Connect to motor (3-phase induction motor).

When built-in braking resistor is insufficient, connect to external braking

resistor (optional).

Change the settings related to dynamic braking resistor protection.

PC

Minus potential terminal for internal DC circuit

A DC power source can be input between this terminal and the PA

terminal (plus potential).

RO, SO

Control circuit power is input via the shorting bars on the terminal block

(RA-1-R0, S/L2-S0). When using a separate power supply for the control

power, remove the shorting bars before connecting the power supply.

(PR1), (PB1)

Connected to the built-in braking resistor. When not using the built-in

braking resistor, change the wiring from (PB1) to (PR1)i and then

change the settings of the dynamic braking resistor operation

parameters.

(PAD This is an internal connection, so do not remove wires from it or

connect external wires to it. It is connected to the built-in braking

resistor.

(E)

This is for internal connections, so do not remove or connect external

wires. This is wired to the inverter chassis.

Terminal function

Internal

circuit

diagram

A

A

B

Cl

Cl

D1

C1

Cl

A

Table 6.2.2: Main circuit terminal functions for 5.5kW and larger units

Main circuit terminal functions for 5.5kW and larger units are as shown below. The internal circuit

diagrams for each terminal are shown on page 21.

Terminal symbol Terminal function

diagram

G/E Terminal for external grounding.

R/L1, S/L2, T/L3 Connect to properly-rated power source.

U/T1, V/T2, W/T3

PA, PB

Connector to motor (3-phase induction motor).

Connect to the braking resistor (optional) and then set the dynamic

C2,C3,C4

braking resistor operation parameters.

PC

Minus potential terminal for internal DC main circuit.

C2,C3,C4

A DC power source can be input between this terminal and the PA

terminal (plus potentiaO.

PC, PA

Terminals for connecting a DC-link reactor (DCL) (standalone type).

C2,C3,C4

This is short circuited with a shorting bar at shipment.

RO, SO

Control circuit power is input via the shorting bars on the main circuit

terminal block (R0-R/L1, S0-S/L2). When using a separate power supply

for control power, remove the shorting bars before connecting the

power supply.

On 37kW and larger units, these terminals are not connected to the

main circuit terminals at shipment, so connect a power supply for the

control circuit.

R20, S20

Power supply output terminals (190 to 220V - 50Hz, 190 to 230V 60Hz) for operation circuits. Only installed on 400V-class 37kW and

larger units (10VA).

Internal

circuit

A

A

B

D1, D2

D2

-18-

Page 25

Table 6.2.3. Control circuit terminal functions

Control circuit terminal functions are as shown below. The internal circuit diagrams for each terminal

are shown on page 22.

Internal

Terminal symbol

Terminal function

diagram

FLA, FLB, FLC

These are the multifunction programmable relay contact outputs (refer

to page 12). The contact ratings are 250Vac-2A (COS0=1), 30Vdc-1A,

250Vac-1A (COS0=O.4).

The standard function setting detects when the inverter protection

functions have operated.

When a protection function activates, FLA-FLC will close, and FLB-FLC

will open.

P24

RCH

24Vdc power output. (Max. 100mA)

This is a multifunction programmable open-collector output (refer to

page 57). (Max. SOmAdc)

The standard function setting activates this signal when completion of

deceleration or acceleration is detected.

circuit

E

F

G

LOW This is a multifunction programmable open collector output (refer to

page 57). (Max. 50mAdc)

The standard function setting activates this signal when a low speed is

detected.

FP

This is a dedicated open-collector output. (Max. 50mAdc). Pulses that

are 48-, 96- or 360-times the output frequency are output according to

parameter settings.

The standard setting is for 48-times the output frequency.

FM This is a multifunction programmable analog output (refer to page 89.)

The standard setting is the pre-compensation reference frequency.

When connecting a meter, use a ImAdc full-scale ammeter or 7.5Vdc-

1mA full-scale voltmeter.

AM This is a multifunction programmable analog output (refer to page 89.)

The standard setting is the output current. When connecting a meter,

use a ImAdc full-scale ammeter or 7.5Vdc-1mA full-scale voltmeter.

PP This is the power supply for reference frequency setting. (lOVdc)

Connect a 3kft potentiometer (a 1 to lOkQ potentiometer may also be

used).

RR This is a multifunction programmable analog input.

The standard setting is a 0 to lOVdc input corresponding to a 0 to

80Hz frequency setting.

IV

This is a multifunction programmable analog input. Change between 0

to lOVdc (SW at V side) or 4 (0) to 20mAdc (SW at 1 side) via SW,

located under the ROM interface window. The standard setting is a 0 to

lOVdc input conresponding to a 0 to 80Hz frequency setting with the

switch at the V side.

G

H

1

1

J

K

L

RX

Tills is a multifunction programmable +!- analog input. Change

between 0 and ±lOVdc (SW at 10V side) or 0 to ±5Vdc (SW at 5V

side) via SW, located under the ROM interface window. The standard

setting is a 0 to ±10Vdc input corresponding to a 0 to 80Hz

forward/reverse frequency setting with the switch at the 10V side.

CC This is the control circuit common terminal. N

-19-

M

Page 26

Terminal symbol

ST

Terminal function

The standard setting is ‘run ready' with a short circuit between STCC. The motor will coast-stop when opened. This can also be

used for interlocks. (Run ready/ coast-stop terminal)

Internal

circuit

diagram

0

F The standard setting is forward run with a short circuit between F-

R

SI

S2

S3

S4

RES

■ 3

Q.

CC, and decelerated stop when opened. (ST-CC in ON condition)

C

*—•

0

The standard setting is reverse run with a short circuit between R-

ro

CC, and decelerated stop when opened. (ST-CC in ON condition)

c

0

The motor will reverse run when both F-CC and R-CC are short

0

CD

circuited.

JD

CO

The standard setting is preset speed run with a short circuit

e

E

between S1-CC.

CO

O)

The standard setting is preset speed run with a short circuit

0

between S2-CC.

Q.

c

0

The standard setting is preset speed run with a short circuit

0

between S3-CC.

c

3

The standard setting is preset speed run with a short circuit

D

between S4-CC.

The standard setting is that the hold during operation of the

inverter protection functions is reset with a short circuit between

RES-CC.

Even if RES-CC Is short circuited while the inverter is operating

normally, the reset function will not activate.

0

0

0

0

0

0

0

-20-

Page 27

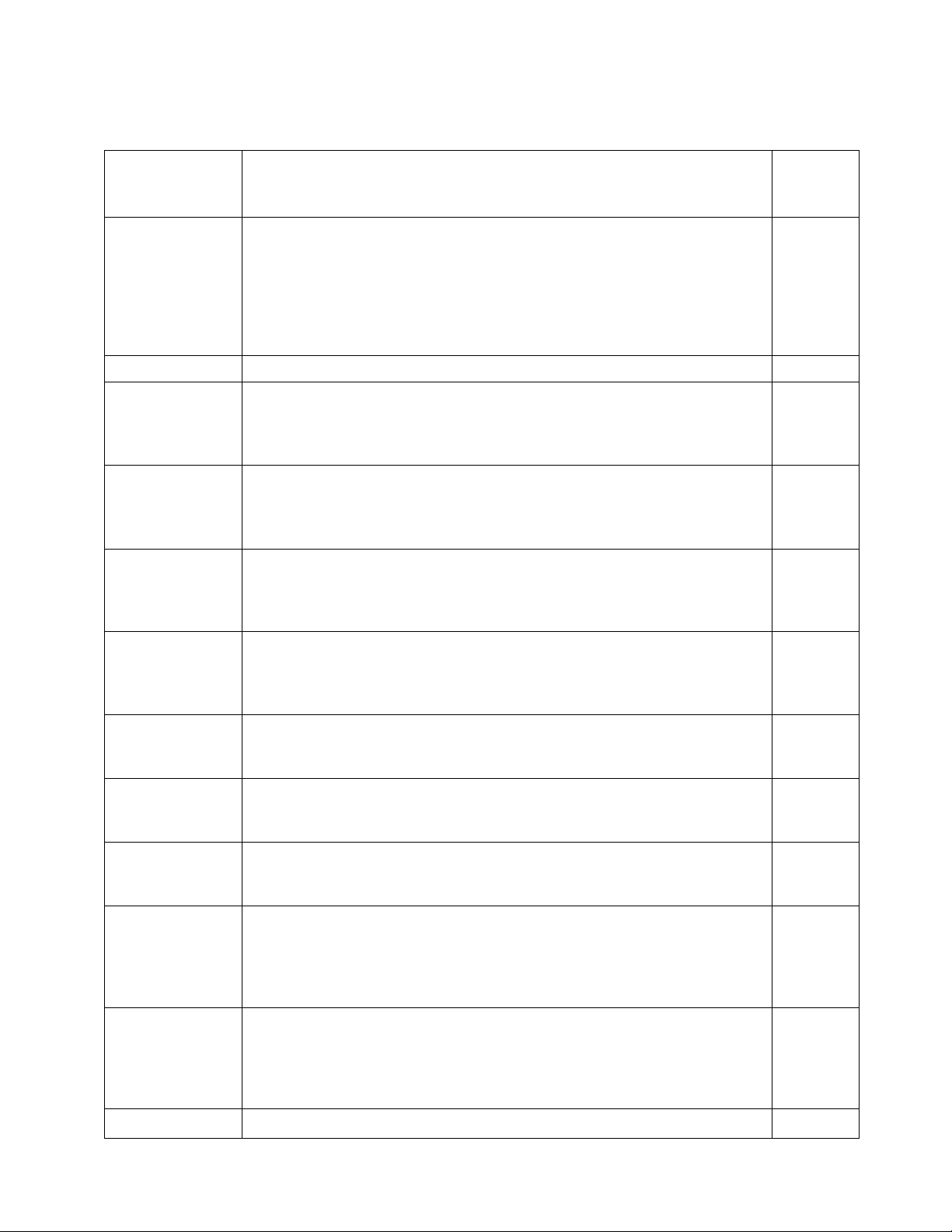

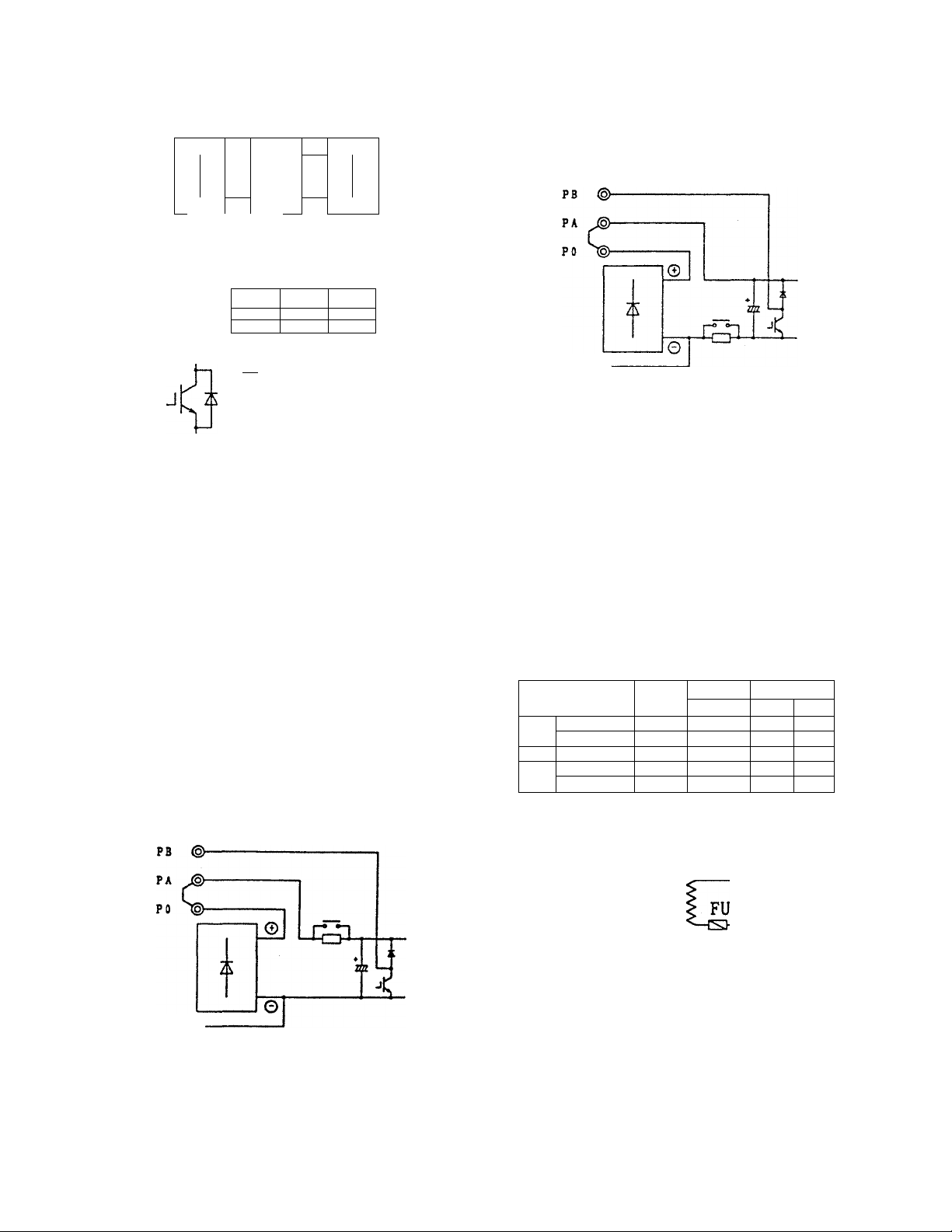

Fig. 6.2.1 Input/output internal circuits (1/2)

Sym

bol

Internal circuit diagram

E/UM

S/lit

T/l><

c/e 0“

Varistor

r

4

MOV

Lightning

L surge

Ad. A absorber

O-

SOOV «yearn •470V aooov

400V tyeam

-tV\ ■

Current detection

circuit

Bultt-in braking r-'*———•

resistor

3.7)Wand smaller

(Ptn

lO-

tfAl)

(Pin ■

"O-

HZ3

PA e-

PB O-

Capacitor

1

T

WrtearMOV

woâageiaang

■AV

‘^fuse

©

2 \

DSAnead

1000V 9000V

tA—@ W/T3

Temperature

U/Tl

V/T2

Sym

bol

Internal circuit diagram

11~18.5kW

PC (§>

22kW and larger

PB (§>—

PA J®

PO t®

PC ®-

„ RlOO

RO®

----

S 0®

-----

-------

--------

<=h-

©

-cm

0

C Bectrolytic capacitor

5.5, 7.5kW

PC ©■

tz

©

InvrtBf cepedty

‘Z/XN

7-5kWand smaller

system

aOkW and smaller

20GV 37kW and larger 60VA lOA-ISmS 33n 200|lF

7JSkWand emaJler

4CeN

system

dOtW and smaller QOVA

400V systam 37-75kW

Max. poDver

Peakinruah Component vatuea

capady

50VA

max. input

50VA

aOA-SmS

SCf^A 20A-7mS lea 220pF

2QA-3mS 320 50|iF

a0A-7mS 32Û IIOpF

RICO

16a lOOpF

c

^ 460:230 150VA

RO©

------=----

S0(§h

R20(§)-

S20©-

-21 -

Page 28

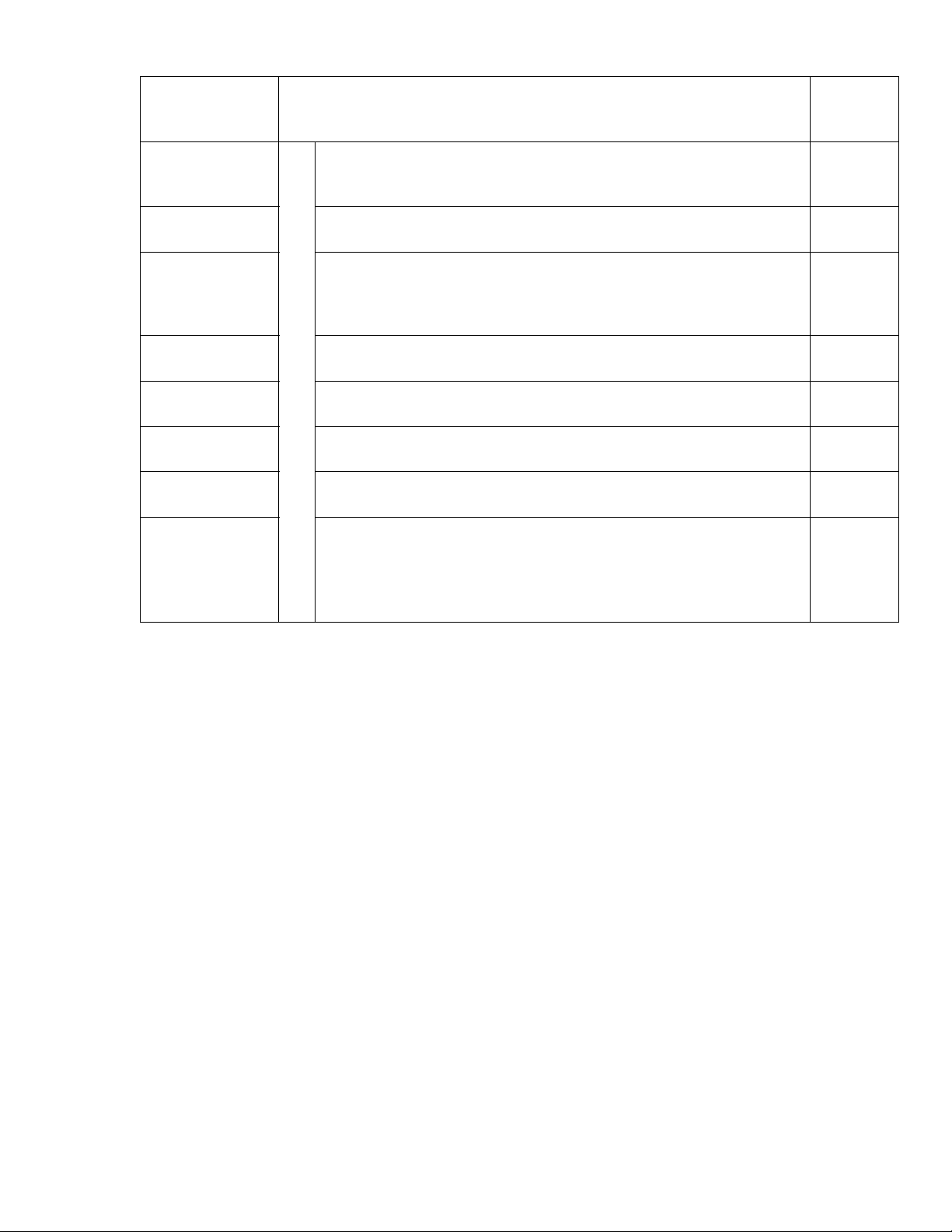

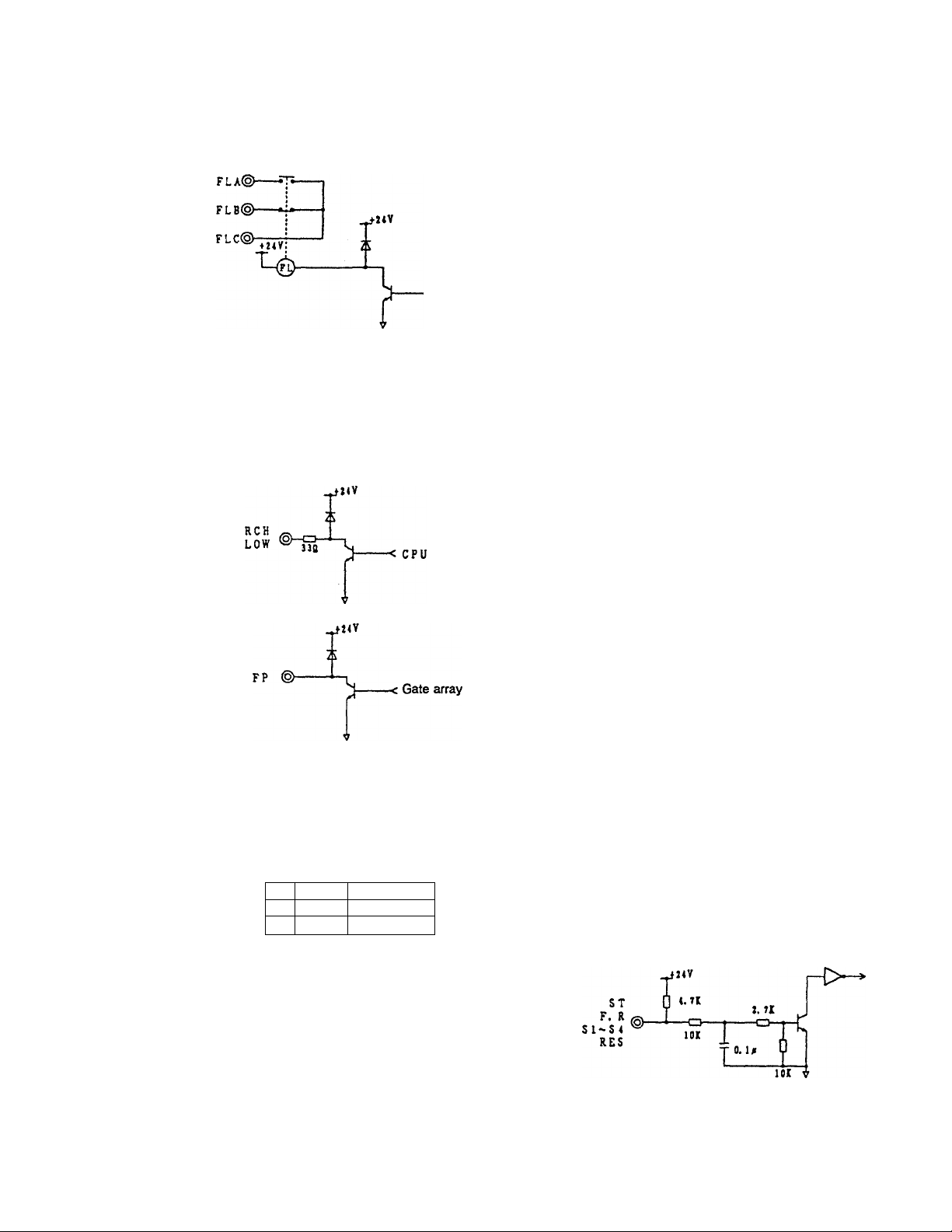

Fig. 6.2.1 Input/output internal circuits (2/2)

Sym

bol

e

©

©

Internal circuit diagram

_a»v

_ t. la T

P2 < ®

----------<z------Fuse resistor

*

< CPU

Sym

bol

©

о

internal circuit diagram

Analog input

(0~10Vdo)

18k

RR ©-

Note 1) Ф

-o-

0. 1a

CC ®------

Analog input

O-'IOVdc, 0~20mAdc)

18k

IY©b

Note 1)

-cu-

hoos

CC ©

------

Cb-IOVdo (switch at V side)

4~20mAdc (swKch at I side)

-F/-Analog input +5V

(o~+/-iovac. (K+/-5Yac)

RX <§>—

Note 1)

CC @—

------

0~6Vdc (switch at 5 side)

0—10Vdc (switch at 10 side)

Voltage converter clrcuft^ ^

Ik 33k 33k

CD- -Oj-CD—

0. iM

+ 5V

2^

A/D converter

SVmax

ll5k 2Í

+ 5V

2^

A/D converter

SVmax

5k 2i

A/D converter

2.5V±2.5V

Analog output

(D

Ф

cc ©—

4.7k

0. u

AM

PM lOOmS

PP ®-

= T

Response

3mS

Low-pass

filter

circuit

1/1024 or better

OOQ

5. lVx2

-< CPU

Resolution

1/256

©

Contact inputs

CC

@-

C/l@-

j.

Grounding

capacitor

22piF

CPU

■jü. lA

CC ©

------

1

Note 1) A capacitor is installed on the analog input terminals (RR, RX, IV), so if an output such as an

operational amplifier is directly connected to these terminals, instability may result. Always pass signals

of this type to these terminals through a lOOft to Ikfi resistor.

-22

Page 29

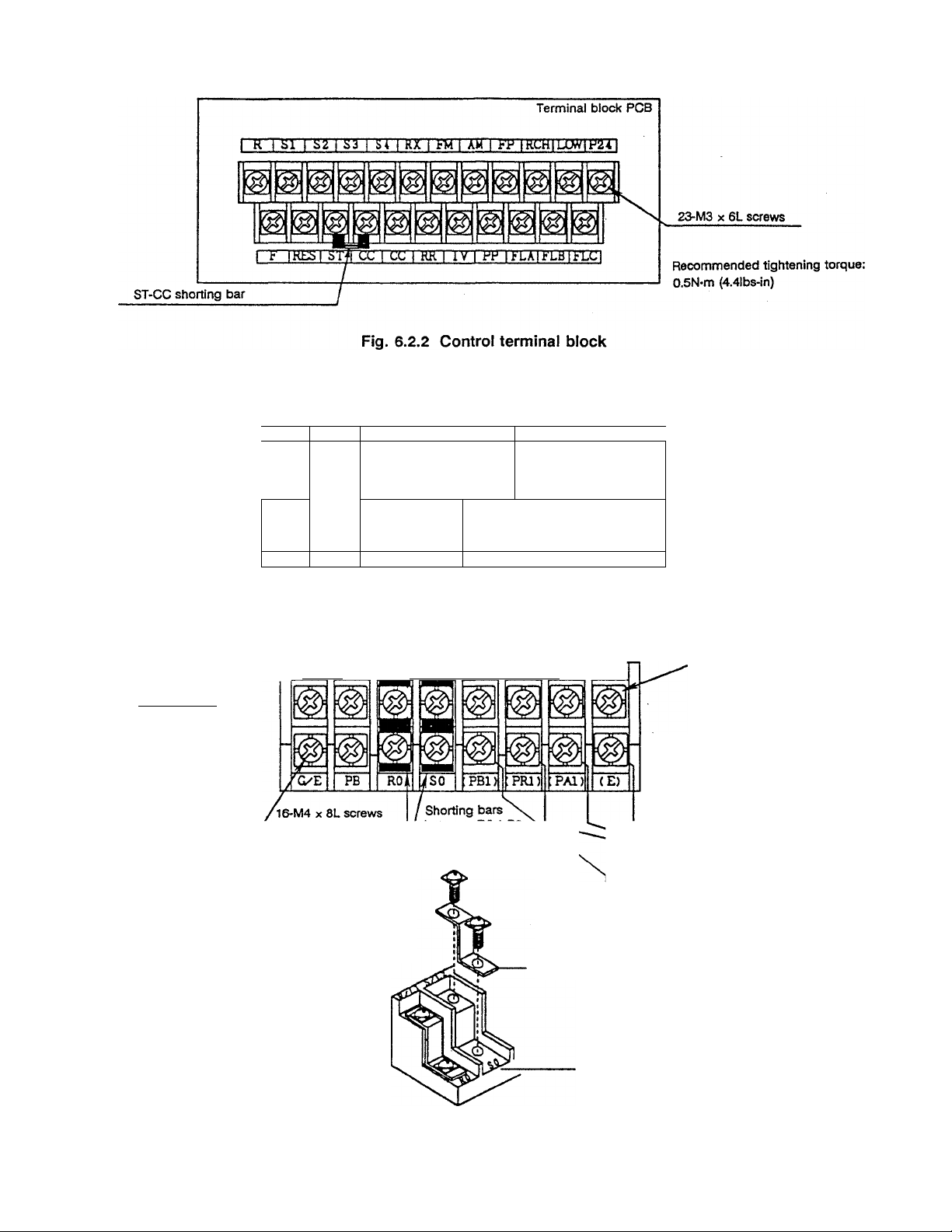

Terminal block cover

FA

R/Ll S/L2 T/L3

U/Tl V/T2 W/T3

Terminal block

CHARGE

o

Charge lamp

(Lights when there is

a charge on the main

circuit capacitors)

3.7kW and smaller units

Removal of shorting bars

Remove the two terminal screws

as shown on the right, and remove

the shorting bar

'e

©

C/E FB

©

POWER SUPPLY

EXT.

RESISTOR

PC PA R/Ll S/L2 TyL3 U/’TL V/T2 W^T3

CONTROL

R SLTPLY

RO SO

MOTOR

INTERNAL RESISTOR

ON , OFF

( PBl)

1 ( PRl) (PAD { E)

Shorting bar

With terminal cover

Recommended tightening torque:

1.2N*m (lllbs-in)

Connected to inverter chassis

Sc-v Connecte

Wired to built-in braking resistor.

When using the buiit-in braking

resistor, change the wiring from

(PR1) to (PB1).

When connecting a separate power

supply to the RO and SO terminals,

always remove the shorting bars,

or the inverter may be damaged.

Fig. 6.2.3 Main circuit terminal block (3.7kW and smaller units)

Terminal block

- 23 -

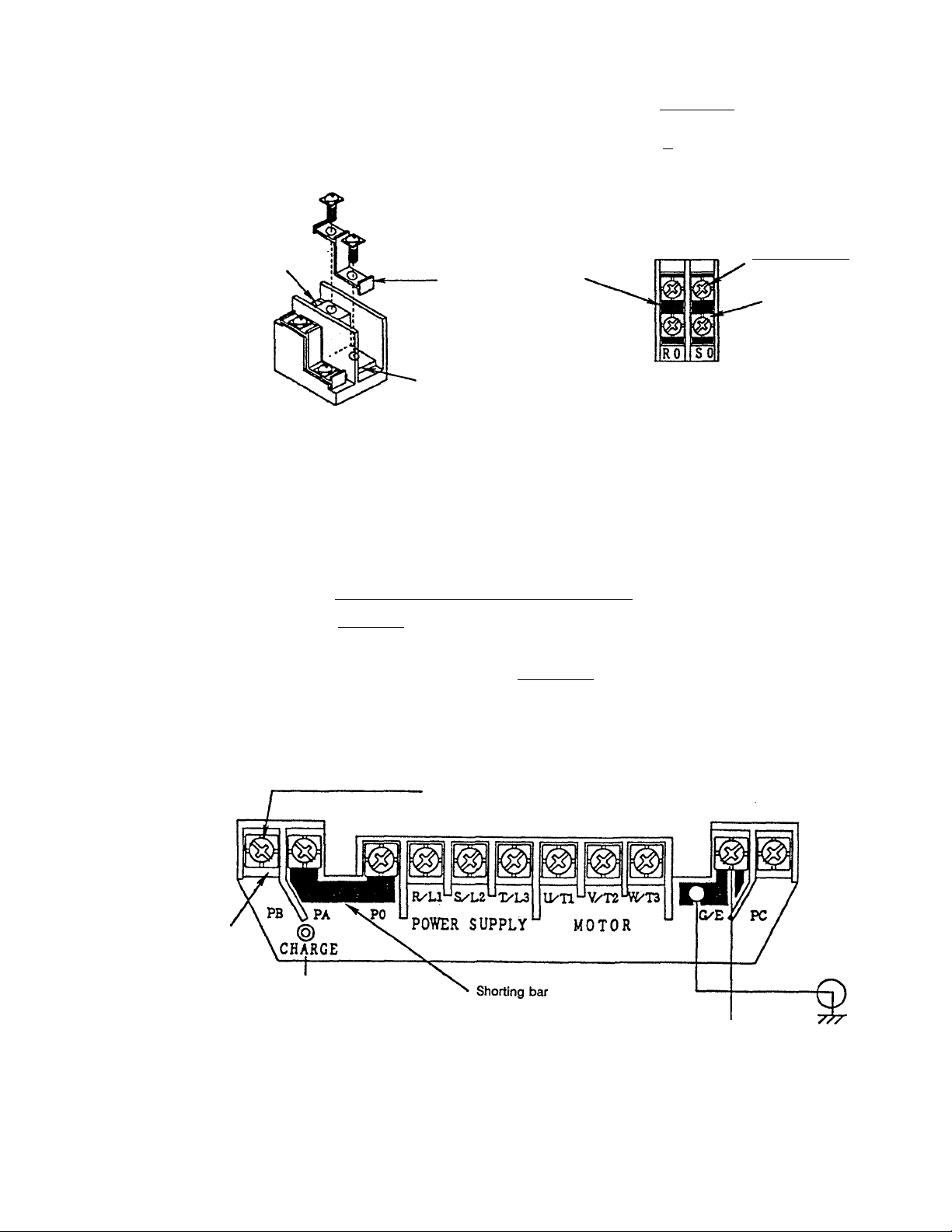

Page 30

5.5kW and larger units

Removal ot RO and SO terminal

shorting bars

Remove the two terminal screws as

shown below, and remove the

shorting bar.

RO, SO terminal block

for external wiring

Terminal block cover

Terminal block cover

^VftRNI^G]

• ttoMtan

t« Hift éfi to

tto to«rt№

ia.toetwnwL

Terminal block

Shorting bar

Connected to the main circuit

terminals. Do not connect

external wiring to the lower

terminals.

Shorting bar

CON-mOL POWER SUPPLY

200V CLASS

Note) 400V systems are indicated as ’400V CLASS“.

Fig. 6.2.4 Control power terminal block (S.SkW to 30kW units)

4-M4 X 8L screws

With terminal cover

Recommended

tightening torque;

1.2N-m (lllbsH'n)

Terminal block

With terminal cover

r

PB ^ PO ^2 ^3, ^2 % %

200V class!POWER SUPPLY MOTOR © ^

Note) 400V systems are indicated as 1400V CLASS

4-M5 X 10L screvtrs

Charge lamp

(Lights when there is

a charge on the main

circuit capacitors)

Recommended tightening torque

2.4N-m (21lbs-in)

Ground

Connected to

inverter chassis

Fig. 6.2.5 Main circuit terminal block (S.SkW to 7.5kW units)

24

Page 31

Main circuit terminal block protective covers

Main circuit terminal block

PA terminal for braking resistor

R/Ll 1 S/L2 1 T/L3

*"----POWER SUPPLY—

U/Tl 1 V/T2 1 W/T3

------

^—MOTOR

IG/E

-------

N-m

lb-«n

2.4

M5

M6 4.0

MS 8.0 71

21

35

Note) The 200V 18.5kW terminal block screw size has been changed from M6 to M8.

Fig. 6.2.6 Main circuit terminal block (IlkW to 18.5kW units)

-25-

Page 32

p (5~p

10-M8 hex. screw

Fig. 6.2.7 Main circuit terminal block (22kW to 30kW units)

,R/U S/L2 VUuUm V/T2 Wn^ PO PA PC PB

POWER SUPPLY MOTOR

DC bus P-N connections

Note) When using a braking resistor

A

with 22kW and iarger units,

the GTR7 (dynamic braking circuit)

option must be installed.

PO, PA, PC terminal block for

200V class 37kW unit

1 j

fî f

© ©

1 OÎ

(External wire connection

caution label)

PO'PA'PC external wire connections:

Install all terminals between the

washers.

Inside I'^®sher,User wiring

1 fl

©

' 1

Inverter

rating

(kW)

37

45 M10 M4

55

75

as.T,u,v.w

M10

M10

200V dass

Control power

suppf/

M4

M4

Main circuit terminal screw size

PA,PC,P0 PB

MS MS

M10 MS

MS

M10

as,T,u,v,w

Main circuit terminal block screw tightening torques

N-m Ib4ns

M4

1.2 11

M5 2.4

MS

MIO 16

M12 32

S.0

21

71

142

283

Fig.6.2.8 Main circuit terminal block (37kW to 45kW units)

400V dass

B0,S0,R20,S20 PA.PC.P0

MS M4

MS M4

MIO M4

MIO M4

-26-

PB

MS MS

MS MS

MIO

MIO

MS

MS

=p=^

G/E

MS

M5

M5

M5

Page 33

7. Operation and Adjustment

7.1 Operation Panel

The operation panel (hereafter, panel) allows the inverter to be operated, and functions and data to be set

and monitored.

LED display

Panel control LED

This LED will light when

•Panel control“ is selected.

The inverter can be operated

from the panel when this

LED is lit, and it will blink

while running.

Panel/remote key

Changes between "Panel

operation' and Terminal

block operation“.

UP key (A) and DOWN key

When a numerical value is

displayed, it can be

incremented/decremented

with these keys. When a

symbol is displayed, the next

item can be displayed by

pressing these keys.

Run key

The LED display normally indicates the operating frequency.

During status monitoring, various conditions can be monitored, and the

frequency command value can be displayed.

During parameter settings, the groups or parameter titles and setting

values can be displayed. During a fault, the cause will be displayed.

0 Lights during operating frequency setting, status monitor mode

displaying, and displaying of a group name, parameter name or

parameter setting value.

© Refer to Appendix 3, Character codes (page 123).

© Lights during option priority operation

(Refer to the Instruction Manual for the option for details.)

® ©

Units LEDs

When a numerical value is

displayed on the LED display, the

LED corresponding to the

numerical value’s units will light.

(No LEDs will be lit when A or V

units are selected.)

Monitor key

Changes between status monitor

mode and frequency display

status.

Initiates running. This key is

valid only when “Panel

control“ is selected.

Stop/reset key

This key functions as the stop key during “Panel control“. In all other

modes, emergency stop is engaged when this key is pressed twice.

During an inverter trip, the tripped state can be reset by pressing this

key twice.

(Refer to section 7.4.7 Fault reset.)

Program key

Changes between settings

monitor mode and frequency

display status.

Enter key

Selects or sets the parameter

name, data or frequency, etc.

27

Page 34

7.2 Basic Operation

Verify the following items before starting operation.

(1) Check that the wiring is correct.

(Refer to Chapter 6, Standard connections, on page 15.)

(2) Check that the power source is the correctly-rated value.

After confirming that there are no mistakes, perform simple operations with the standard settings.

Operate according to the following procedure.

When performing trial operations, run the motor at a low frequency (approx. 10Hz).

(1) Starting and stopping via the panel

Step Operation

1) Power ON

Turn ON the power source’s non-fuse breaker (MCCB).

If the LED display is OFF, all preparation conditions are not established, so

running will not be possible. Terminals ST-CC must be ‘closed*. Running is

possible when the LED display is 0.0 . Remote operation mode from the

control terminal block is automatically entered when power is turned on.

Changeover to "Panel control".

The panel control LED will light, and operation from the panel will be

possible.

(If this key is pressed again, the panel control LED will go out, and remote

operation mode from the control terminal block will once again be entered.)

Set the operating frequency.

The frequency command value can be incremented/decremented with the

UP key (A) or DOWN key (Sy). When one of these keys is pressed, the

LED display will blink, indicating that the value is being changed. When the

desired frequency is displayed, press the

frequency will be alternately displayed on the LED display.

The frequency will increase according to the acceleration time, and the motor

will rotate. The panel control LED will blink while running.

The frequency will decrease according to the deceleration time, and the

motor will decelerate and stop.

ENTER key. F C and the

3)

4)

5)

2)

A

f^ANEU

REMOTE

V

RUN

STOP

RESET

Caution

If the power switch is turned off in the 4) state, the motor will coast-stop. However, this method should

only be used in the case of an emergency.

Avoid frequent starting and stopping of the inverter by turning the power switch on and off, as this will

shorten the life of the inverter.

Page 35

(2) Changing the frequency while running

Step

1)

A

(3) Function setting and adjustment

Use the following procedure to change the "standard settings".

First, refer to the parameter list to find the parameter group where the function to be changed is, and

how the symbol name is displayed.

Blind function

In the standard setting, only groups u, F and U t can be displayed on the panel. The other

groups are blinded via the blind function in group u t ■ Unblind the desired group if necessary.

(Refer to Cr-.L/fc

r-br.U

V

ENTER

The frequency can be changed while running by pressing the UP key (A) or

DOWN key (^. Note that the frequency command value will change and

the operating frequency will chanae.

The operating frequency can be changed even if the ENTER key is not

pressed, but if the power is turned off at this time, the frequency command

value will return to the frequency set before changing.

b L n d Blind function on page 50.)

Operation

dr. U displays only those parameters for which the setting value has been changed by the user,

and the changed setting value differs from the standard default setting. [Auto edit function]

The parameter settings can also be changed in this group.

However, if a parameter setting value that is the same as the default setting is once again input, that

parameter will no longer be displayed in this group.

C i-.U sequentially compares the settings of all parameters to the standard default setting values,

so this process may take several seconds. The 0 t-.U display will blink and may not appear to

immediately react, but the C r.U search can be stopped by pressing a key other thani^,

ENTER

(There is a changed settings memo section on page 142 in which changed setting values may be

recorded.)