Page 1

SERVICE MANUAL

REVISED.01

DOCUMENT CREATED IN JAPAN, SEPT., 2006

DVD VIDEO RECORDER

FILE NO. 810-200602GR

DIGITAL VIDEO

D-R5SC

D-R5SU

The above models are classified as green products (*1), as indicated by the underlined serial

numbers. This Service Manual describes replacement parts for the green products. When

repairing these green product(s), use the part(s) described in this manual and lead-free solder (*2).

For (*1) and (*2), see the next page.

Mar.,2006 GREEN

Page 2

(*1) GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for recycling

and reuse of Waste Electrical and Electronic Equipment and for the Restriction of the use of

certain Hazardous Substances. From July 1, 2006, the RoHS Directive will prohibit any

marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba Corporation

recognizes environmental protection as a key management tasks, and is doing its utmost to

enhance and improve the quality and scope of its environmental activities. In line with this,

Toshiba proactively promotes Green Procurement, and seeks to purchase and use products,

parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts used in

manufacture must also be used as replacement parts.

(*2) LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the consumer

products industry at large to be environmentally responsible. Lead-free solder must be used in

the servicing and repair of this product.

WARNING

This product is manufactured using lead free solder .

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT !

The melting temperature of lead-free solder is higher than that of leaded solder by 86°F to 104°F

(30°C to 40°C). Use of a soldering iron designed for lead-based solders to repair product made

with lead-free solder may result in damage to the component and or PCB being soldered. Great

care should be made to ensure high-quality soldering when servicing this product especially

when soldering large components, through-hole pins, and on PCBs as the level of heat

required to melt lead-free solder is high.

Page 3

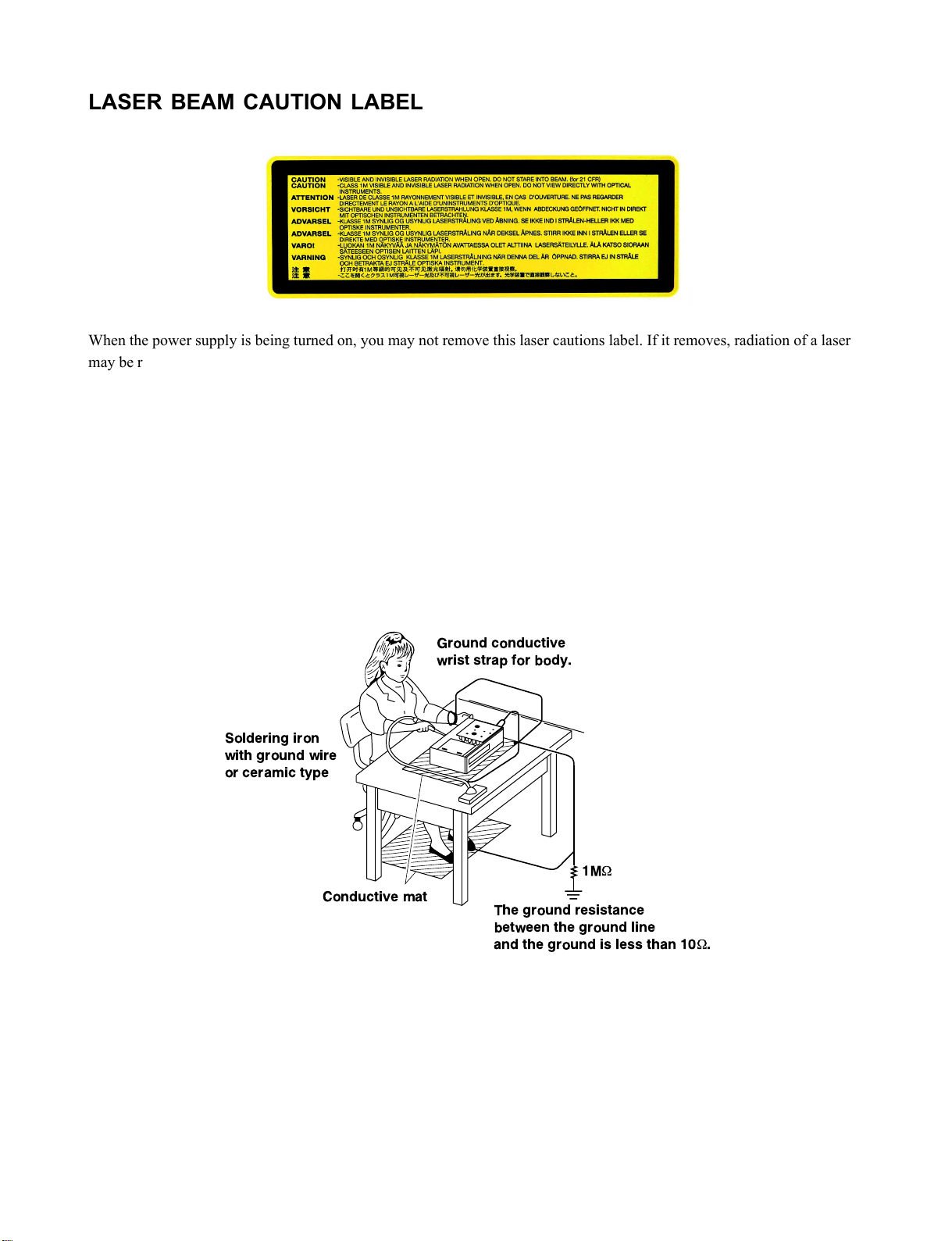

LASER BEAM CAUTION LABEL

When the power supply is being turned on, you may not remove this laser cautions label. If it removes, radiation of a laser

may be received.

PREPARATION OF SERVICING

Pickup Head consists of a laser diode that is very susceptible to external static electricity.

Although it operates properly after replacement, if it was subject to electrostatic discharge during replacement, its

life might be shortened. When replacing, use a conductive mat, soldering iron with ground wire, etc. to protect the

laser diode from damage by static electricity.

And also, the LSI and IC are same as above.

Ground conductive

wrist strap for body.

Soldering iron

with ground wire

or ceramic type

1M

W

Conductive mat

Manufactured under license from Dolby Laboratories. “Dolby” and the double-D symbol are trademarks of Dolby Laboratories.

·

“DTS” and “DTS Digital Out” are trademarks of Digital Theater Systems, Inc.

·

HDMI, the HDMI logo and Hight-Definition Multimedia Interface are trademarks or registered trademarks of HDMI Licensing LLC.

·

Manufactured under license from QSound Labs, Inc. U.S. patent Nos. 5,105,462, 5,208,860 and 5,440,638 and various foreign counterpart.

·

Copyright QSound Labs, Inc. 1998-2002. QXpanderTM is a trademark of QSound Labs, Inc. All rights reserved.

The ground resistance

between the ground line

and the ground is less than 10W.

Page 4

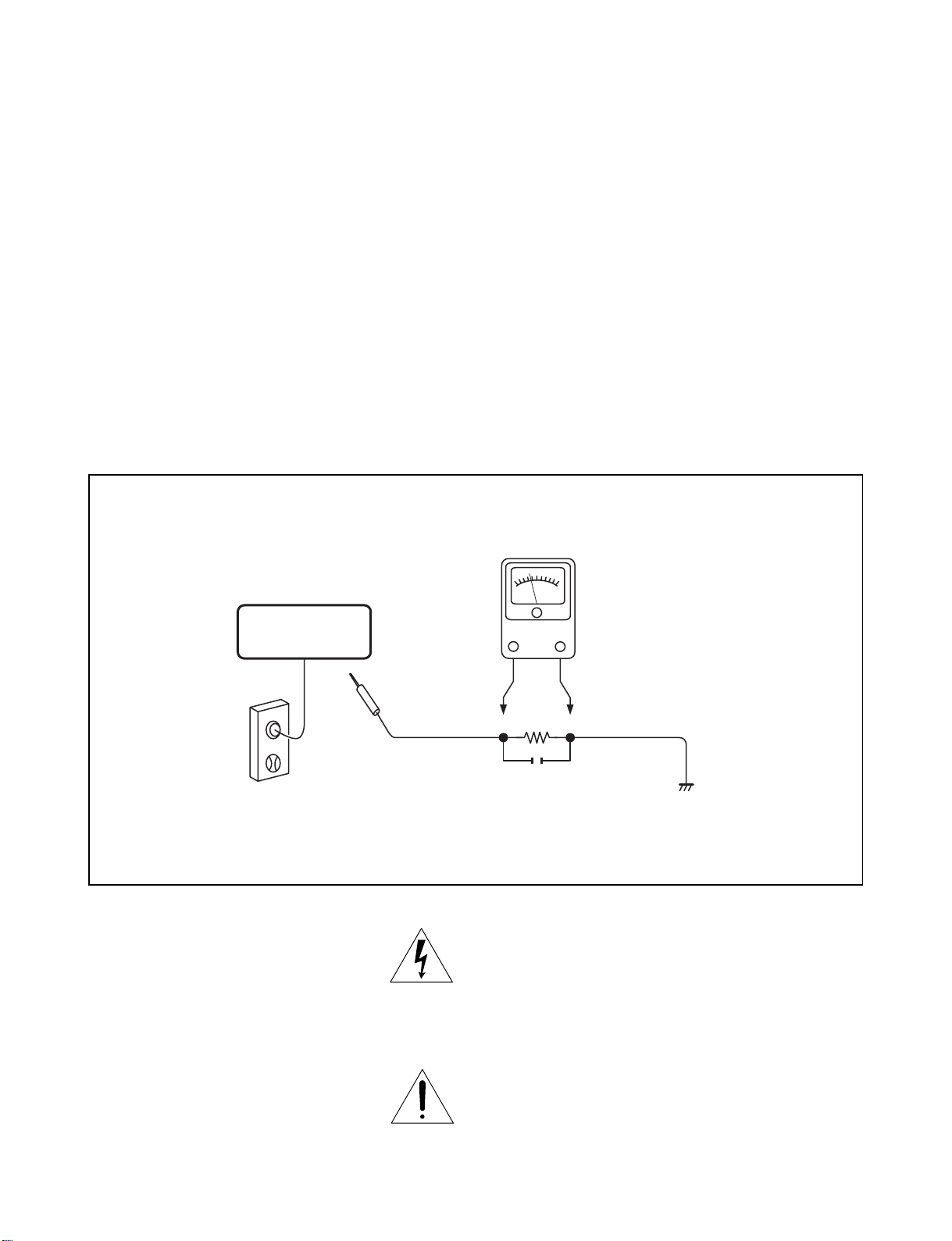

SAFETY NOTICE

SAFETY PRECAUTIONS

LEAKAGE CURRENT CHECK

Plug the AC line cord directly into a 120V AC outlet (do

not use an isolation transformer for this check). Use an

AC voltmeter, having 5000 Ω per volt or more sensitivity.

Connect a 1500 Ω 10 W resistor, paralleled by a 0.15 µF

150V AC capacitor between a known good earth ground

(water pipe, conduit, etc.) and all exposed metal parts of

cabinet (antennas, handle bracket, metal cabinet

screwheads, metal overlays, control shafts, etc.).

READING SHOULD NOT EXCEED 0.3V

Measure the AC voltage across the 1500 Ω resistor.

The test must be conducted with the AC switch on and

then repeated with the AC switch off. The AC voltage

indicated by the meter may not exceed 0.3 V. A reading

exceeding 0.3 V indicates that a dangerous potential

exists, the fault must be located and corrected.

Repeat the above test with the DVD VIDEO RECORDER

power plug reversed.

NEVER RETURN A DVD VIDEO RECORDER TO

THE CUSTOMER WITHOUT TAKING NECESSARY

CORRECTIVE ACTION.

DVD VIDEO RECORDER

AC OUTLET

Test all exposed metal.

Voltmeter Hook-up for Leakage Current Check

AC VOLTMETER

(5000 Ω per volt

or more sensitivity)

Good earth ground

such as a water pipe,

1500 Ω

10 W

0.15 µF 150V AC

conduit, etc.

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufficient magnitude to

constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

Page 5

CONTENTS

1. LOCATION OF MAIN PARTS

1-1. Location of Main Parts

1-2. Location of PC Boards

2. WIRING CONNECTION DIAGRAM

3. PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

4. BLOCK DIAGRAMS

4-1. MPEG & SYSTEM Block Diagram

4-2. Power Supply Block Diagram

5. CIRCUIT DIAGRAMS

5-1. Power Supply Circuit Diagram

5-2. Front Display & Power Switch Circuit Diagram

5-3. Audio & Video Tuner Circuit Diagram

5-4. Digital Circuit Diagram

5-4-1. Audio Output Circuit Diagram

5-4-2. Decorder & SDRAM Circuit Diagram

5-4-3. HDMI Circuit Diagram

5-4-4. Audio & Video Input Circuit Diagram

5-4-5. 1394 Circuit Diagram

5-4-6. Encoder & SDRAM Circuit Diagram

5-4-7. ATAPI Interface Circuit Diagram

5-4-8. Power Supply Circuit Diagram

5-4-9. Video Output Circuit Diagram

6. PC BOARDS

6-1. DV/AV Input PC Board

6-2. Power Switch PC Board

6-3. Front Display PC Board

6-4. AV Tuner Unit PC Board

6-5. Digital PC Board

7. EXPLODED VIEWS

7-1. Packing Assembly

7-2. Chassis Assembly

8. PARTS LIST

Page 6

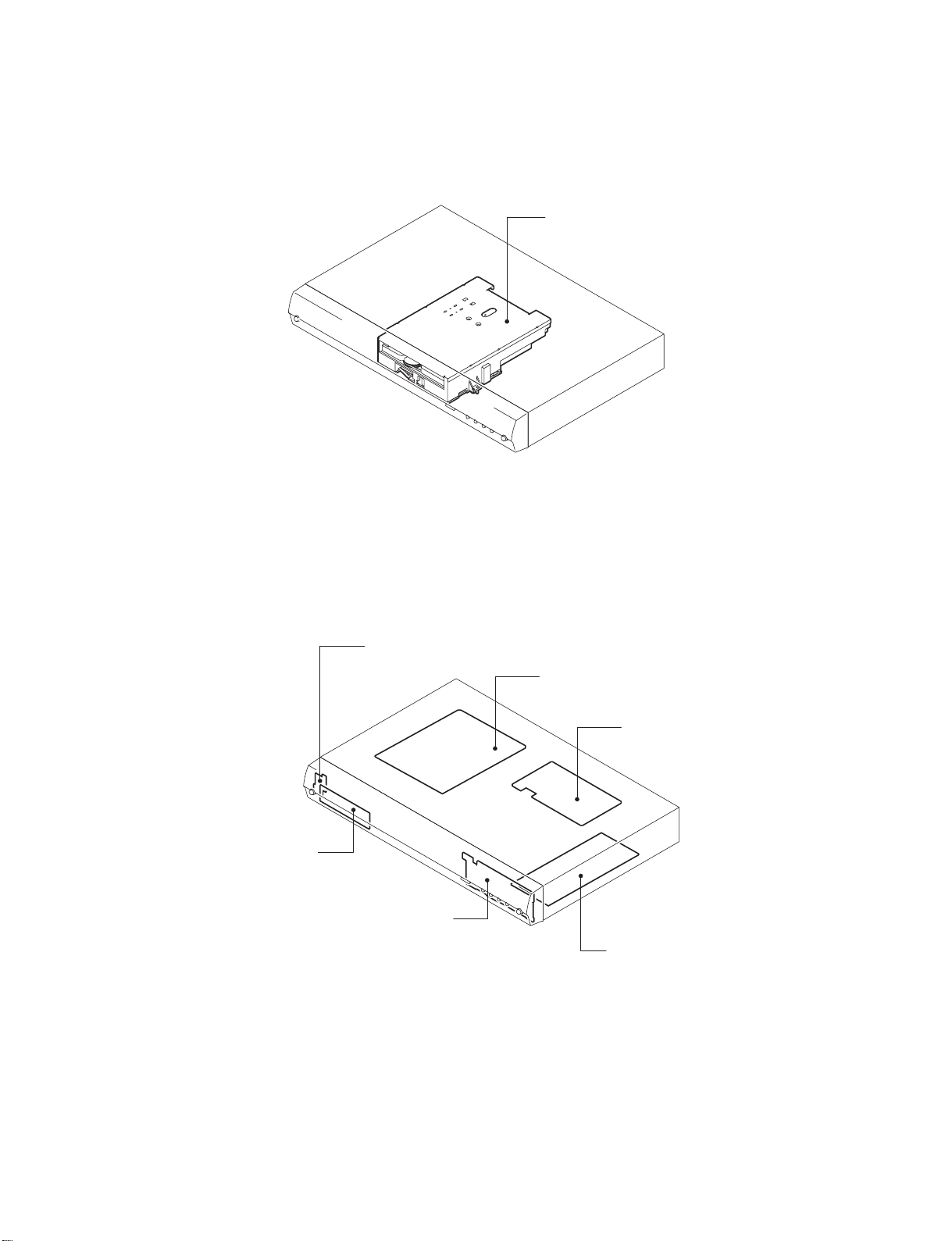

1. LOCATION OF MAIN PARTS

1-1. Location of Main Parts

RAM DRIVE

Fig. 1-1-1

1-2. Location of PC Boards

DV/AV Input PC board

Front Display PC board

Power Switch PC board

Digital PC board

AV Tuner Unit PC board

Power PC board

Fig. 1-1-2

Page 7

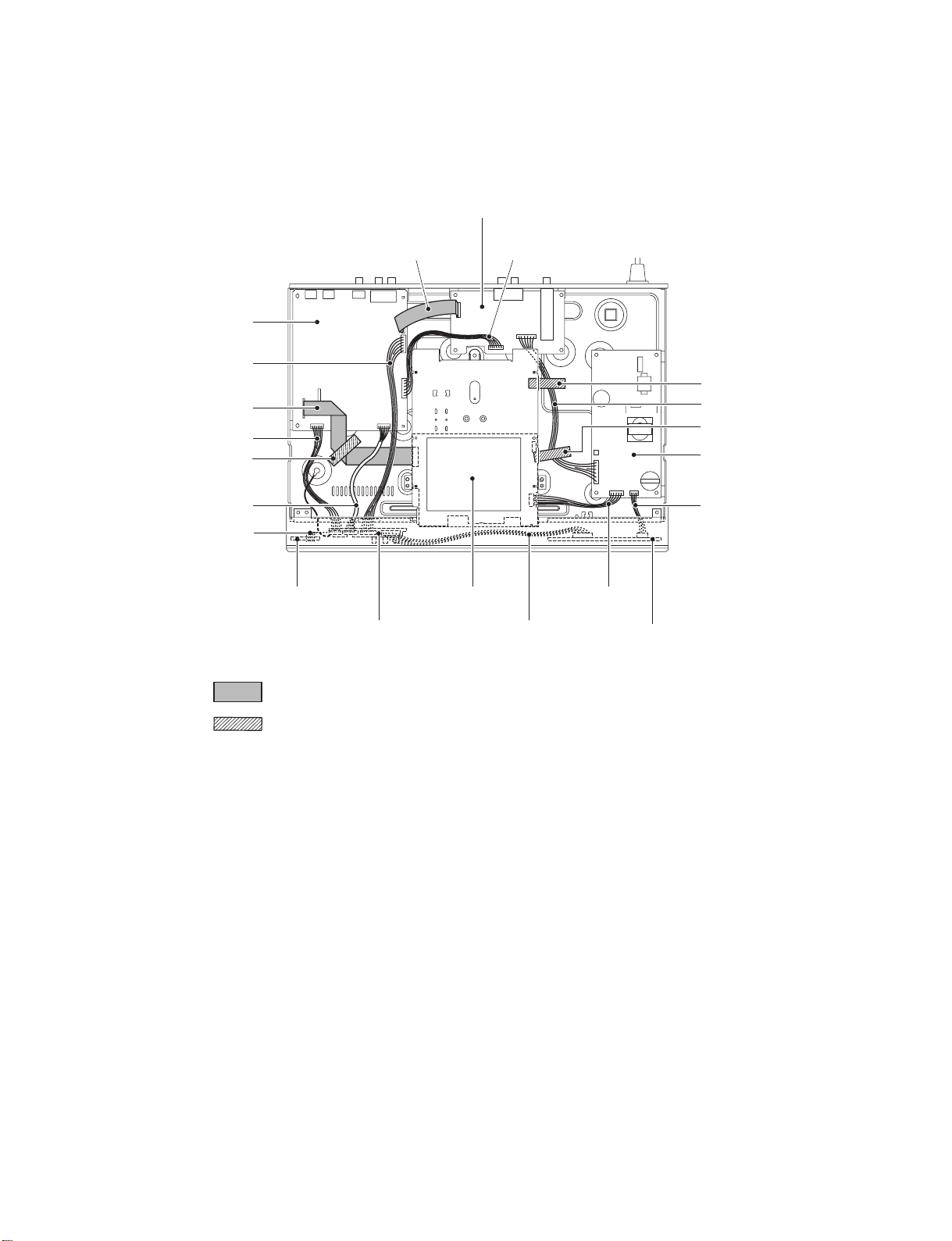

2. WIRING CONNECTION DIAGRAM

After the servicing is complete, return the wiring to its original state by using the diagram below as a reference.

AV Tuner Unit PC board

W301 W303

Digital PC board

W104

Ta pe

W501

W106

Ta pe

W802

Ta pe

Power PC board

W105

W107

Power Switch PC board

DV/AV Input PC board

: Flexible cable

: Tape

RAM Drive

Fig. 2-2-1

W101

W804

W803

Front Display PC board

Page 8

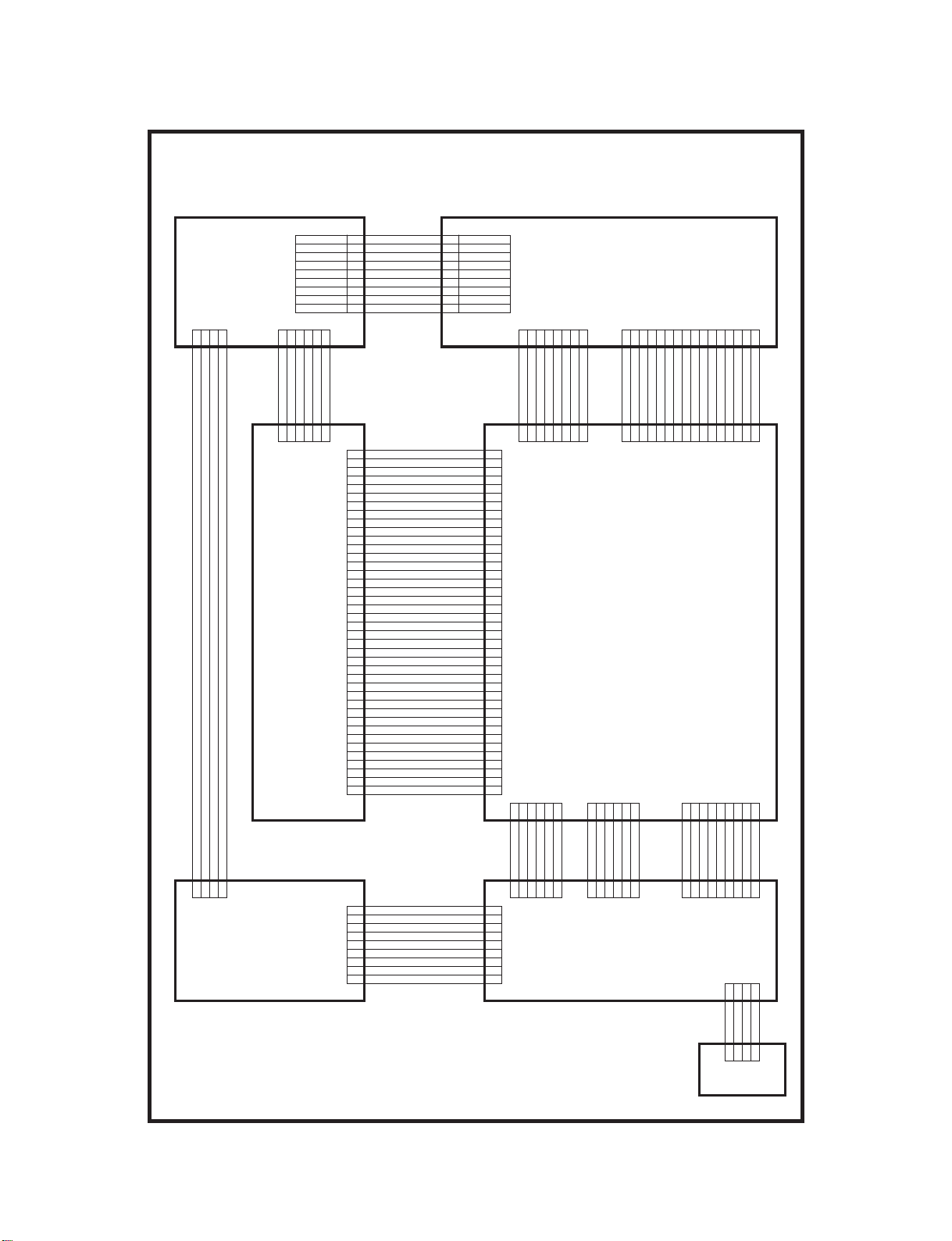

3. PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM

W802

FLAT WIRE 2.54 9P

9

8

7

6

5

4

3

2

1

6

9

8

7

6

5

4

3

2

1

CN302

ON/OFF 5V

+3.3 V

+3.3 V

GND

ON/OFF 5V

AP+12 V

AN-12 V

GND

+33 V

CN303

8765432

AV-TUNER

1

123456789

CN301

Power

CN804

123

4

ON/OFF 5V

ON/OFF 5V

CN803

12345

CN802

+3.3 V

+3.3 V

GND

AP+12 V

AN-12 V

GND

+33 V

01

1121314151

61

GND

Back up

P-ON

EVER+5 V

FLAT WIRE 2mm 4P

W804

M+12 V

M+12 V

M+5 V

M+5 V

GND

GND

12345

6

Mechanism

W803

FLAT WIRE 2mm 6P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

W501

FLAT WIRE 0.5mm 40P

DRVRSTGND

ATCDD7

ATCDD8

ATCDD6

ATCDD9

ATCDD5

ATCDD10

ATCDD4

ATCDD11

ATCDD3

ATCDD12

ATCDD2

ATCDD13

ATCDD1

ATCDD14

ATCDD0

ATCDD15

GND

NC

ATCD MARQ

GND

ATCD IOWGND

ATCD IORGND

ACTIOR DY

GND

ATCD MACK-

GND

ACTINITRQ

NC

ATCDA1

NC

ATCDA0

ATCDA2

ATCCSOATCCSNC

GND

W303

FLAT WIRE 2.54 8P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

CN504

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

ON/OFF 5V

AP+12 V

AP-12 V

1234567

CN509

CN508

12345

ON/OFF 5V

GND

6

+3.3 V

+3.3 V

GND

8

65432

W301

A IN L

A IN R

FLAT WIRE 1mm 16P

123456789

Digital

CN501

1

GND

SC IN

GND

CVBS IN

V-GND

SY IN

CN503

987654321

SCL

SDA

01

SAP MUTE

AFC OUT

11

213141

CN507

VFV

GND

A L TV

51

A R TV

61

432

1

CN102

Front Display

CN101

1

2

3

4

5

6

7

8

9

W101

FLAT WIRE 2mm 9P

STB

CLK

DATA

GND

IR

HOST-RESET

KEY2

KEY4

POWER LED+

W106

FLAT WIRE 2mm 6P

1

2

3

4

5

CN103

6

7

8

9

STB

CLK

DATA

12345

CN106

GND

W105

GNDIRHOST RESET

FLAT WIRE 2mm 6P

6

12345

DV/AV INPUT

TPBI-

TPBI+

TPAI-

TPAI+

GND

6

W104

Y-F

GND

C-F

FLAT WIRE 2mm 9P

123456789

CN104CN105

W107

FLAT WIRE 2mm 4P

Power Switch

GND

CVBS-F

GND

AR-F

CN107

123

GND

KS3

123

CN108

GND

KEY2

AL-F

4

LED+

4

Fig. 3-3-1

Page 9

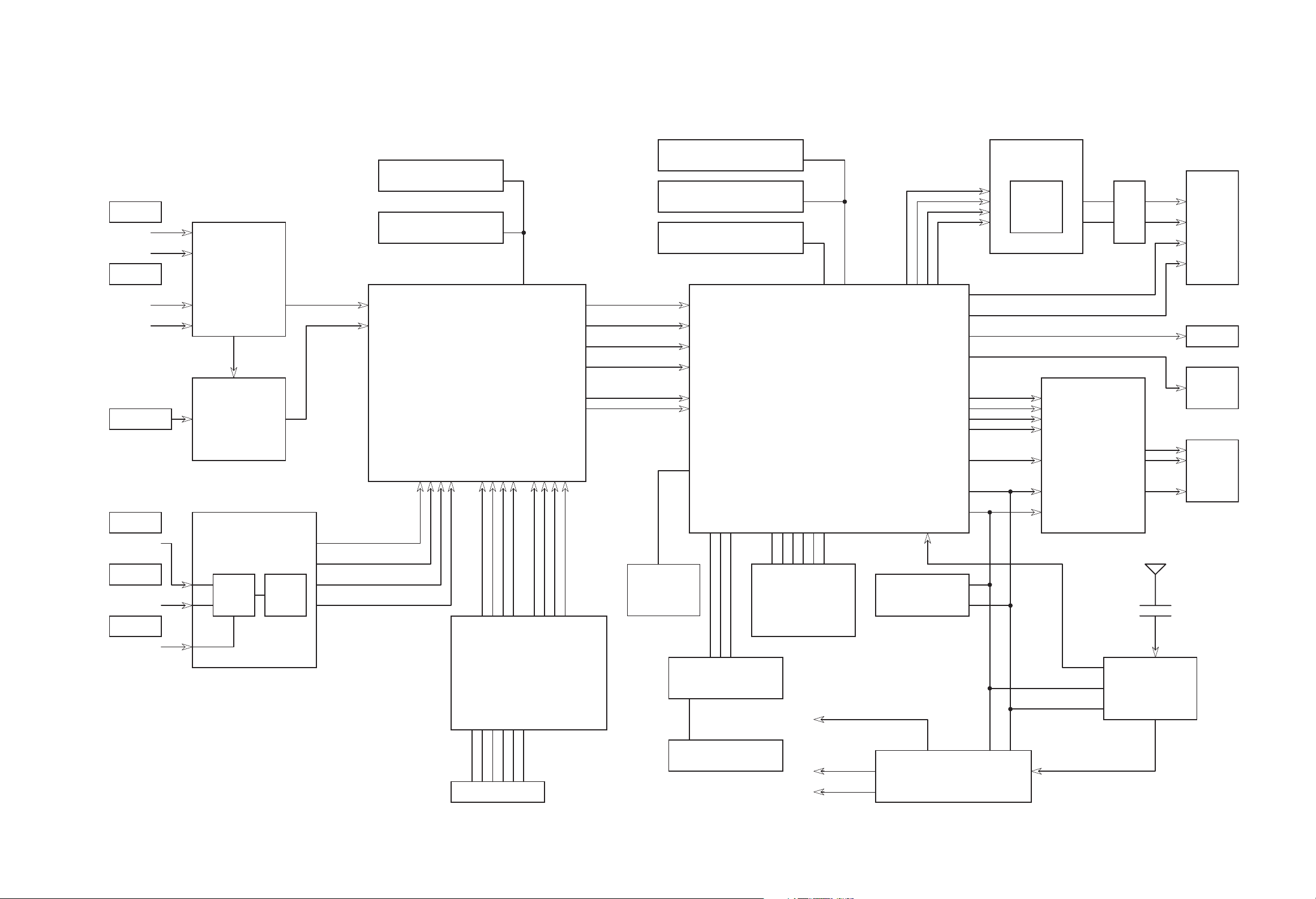

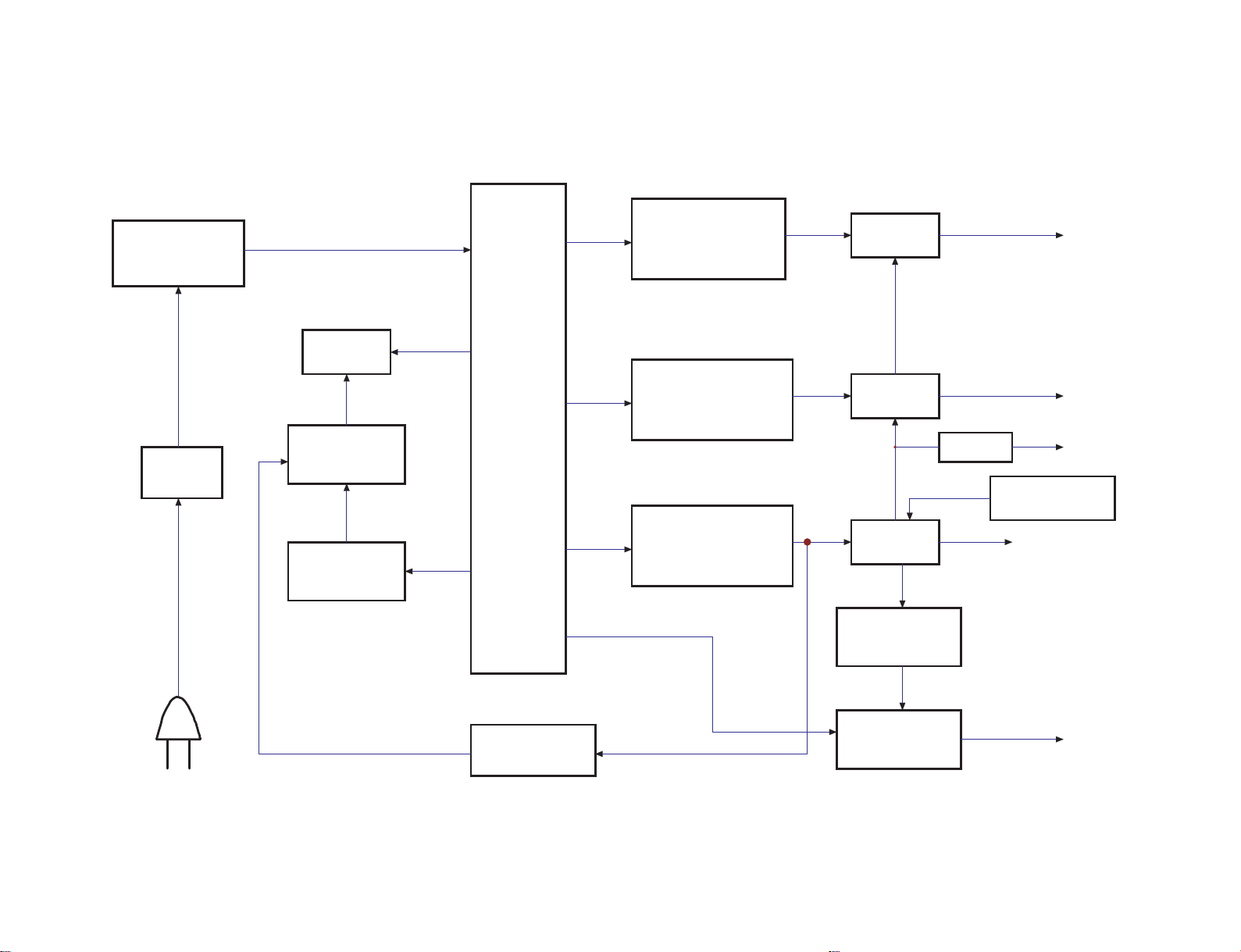

4. BLOCK DIAGRAM

32M CLOCK

4-1. MPEG & SYSTEM Block Diagram

FRONT

Video

Y/C

REAR

Video

Y/C

TV-CVBS

Video

BA7607

IC517

CVBS

BA7653

IC518

IC502

IC503

FR .Y/C IN

CVBS IN

128M SDRAM

128M SDRAM

ZR35100-PQCG

ENCORDER

IC506

IC504

IC507

IC511

128M SDRAM

128M SDRAM

32M FLASH

SERIAL BITSTREAM OUTPUT

SBCLK

SBVALID

SBDAT

SBREQ

Digital Video Output

: : :

ZR36750-BGCG-V

Main Cpu(Decorder)

<BGA>

Digital Audio Out

WM8776

DAC

IC513 2/2

Digital Video I/F

SPD IF

IC514

CV BS Out

Y/C Out

SPDIF-OPTICAL

Y/U/V Out

HDMI

ZR35162

4558

J502

L OUT

R OUT

CV BS

Y/C

J504

J501

Y/U/V OUT

J503

HDMI Out

FRONT

L/R IN

REAR

L/R IN

TV

L/R IN

Audio

WM8776

SW

ADC

IC513 1/2

Digital Audio I/F

ADCMCLK

ADCBLCK

ADCLRCK

DOUT

ISO I/F HOST I/F

ZR35162-BGCG

1394

<BGA>

IC505

DV INPUT

JC101

27MHZ

IC509

SPI

32M CLOCK

FRONT

Driver

DAV-WR532

TV CVBS

TV

TV

EEPROM

L

R

IC510

U24

AN5832

U301

AFC OUT

2

I C

IC516

RF In

TUNER

SIF

Fig. 4-4-1

Page 10

4-2. Power Supply Block Diagram

D101-D104 C105

RECTIFIER

SMOOTHING

L101

AC FILTER

Q101

SW IC

CONTROL IC

3-

RECTIFIER

SMOOTHING

D107 C109

IC101

T101

TRANS

D301 C301

RECTIFIER

SMOOTHING

D201 C201

RECTIFIER

SMOOTHING

D401 C404

RECTIFIER

SMOOTHING

12V SW

32V SW

5V SW

PHOTO

COUPLER

D403 D404

ADJUST

POWER ON SIG

AP+12V

+32V

3.3V

ON/OFF A+5V

AC 100-120V

50/60Hz

PC101

PHOTO

COUPLER

RECTIFIER

SMOOTHING

D601 C601

AN-12V

Fig. 4-4-2

Page 11

5. CIRCUIT DIAGRAMS

5-1. Power Supply Circuit Diagram

201D101D

401D

301D

5004N1

201R

K01

101F

V521/A51.3

301R

K01

101L

03250V11SS

101C

V572/Fu1.0

13NC

NL

511C

112C

FP0022

181T

501R

701C

501C

V002/Fu022

311R

0.1

411R

0.1

511R

0.1

611R

0.1

011R

K7.2

111C

Fn7.4

211C

Fu10.0

101CP

601D

5004N1

711R

001

101CI

4

5

3

6

2

7

1

8

8155AF

011C

V01/Fu22.0

VK1/FP0001

0

801R

K01

901D

331SS1

901C

V53/Fu74

K001

601R

101Q

701D

501D

L5001RP

D

Z05KN01FTSH

G

S

701R

74

111R

001

901R

22

L3001RP

801C

VK1/FP022

102R

0

103D

U02L3S

103C

K1/FP0001

104D

64KR

204D

64KR

104C

106D

K1/FP0001

102Q

102D

202R

K2.2

5001RP

102C

103L

Hu01

303C

V53/Fu074

K1/FP0001

204C

V53/Fu074

106C

V53/Fu74

106R

K7.2

206R

0

202D

V001/Fu3.6

403C

V53/Fu74

022

604C

V53/Fu074

104CI

134LT

103R

K22

103Q

30FN22PTS

203R

K1

103CI

134LT

204R

104R

K1

101-CP

304R

001

106CP

7301AS2

202Q

AKE411CTD

302R

K022

304C

V05/Fu1.0

402R

K33

603C

K2.8

303R

K93

V05/FP001

503C

V53/Fu74

403R

K01

104L

104RV

K7.4

404R

504R

K01

604R

K01

704C

V01/Fu1

404C

V53/Fu74

306D

104Q

106JS2

704R

K1

204Q

K2142CS2

202C

V53/Fu74

208NC

1

V33+

DNG

2

3

V21 NA

4

V21 PA

5

V5-A

DNG

6

7

V3.3-33VP

8

V3.3-33VP

BS5P

9

408NC

4

pukcab

NO-P

3

2

304D

904R

K1

804R

K74

106CP

404D

)504D(

)014R(

XXX

)102TAB(

306R

033

DNG

V5 BTS

DNG

1

108NC

DNG

1

V21+

2

208NC

SV21+

1

SV21+

2

DNG

3

DNG

4

V5+

5

V5+

6

Fig. 5-5-1

Page 12

5-2. Front Display & Power Switch Circuit Diagram

5SB

R128

R126

K

10

1

R127

2.2K

KEY0

VDD

R125

470K

C12

1uF

R130

K

K

10

10

PWR_DECT

3

2N3904

2N3904

1

Q107

Q108

2 3

2

R129

10R

KS1

KS2

KS3

KS4

GR1

GR2

GR3

GR4

GR5

GR6

/RESET

R33

R

R33

R33

33

291R

391R

491R R33

591R R33

191R

091R

C110

220pF

22

52

62

91

02

12

51

71

81

42

32

61

81GS/11RG

71GS/21RG

4

61GS/31RG

31GS/61RG

51GS/41RG

02GS

91GS

21S

11SK/11GS/81RG

8RG

1GS/51RG

K/21GS/71RG

27

GR19/SG10/KS10

28

SG9/KS9

29

SG8/KS8

30

SG7/KS7

31

SG6/KS6

32

SG5/KS5

33

SG4/KS4

34

SG3/KS3

35

SG2/KS2

36

SG1/KS1

37

VEE

38

/RESET

39

GPIO90

PWR_DECT

IR

GPIOC7/DIN

GPIOC6/DOUT

2COIPG

1COIPG

0COIPG

3COIPG

59OIPG

49OIPG

19OIPG

7

69OIPG

39OIPG

29OIPG

9OIPG

24

74

05

14

44

34

64

54

84

04

15

94

TESE

1YEK

0YEK

R_TSOH

2YEK

LRTC

IR101

SENSOR

IR

DNG

C

R109

C

RI

V

100R

1

2

3

C130

47uF/16V

C105

102

CN102

FROM POWER

CN101

TO FRONT AV BOARD

1

2

3

4

1

2

3

4

5

6

7

8

9

OPEN/CLOSE

STOP

BATTERY

STB 5V

GND

STB

K

CL

DATA

IR

HOST_ESET

2

KEY

KS4

LED+

SW101

SW104

SW102

CH+

SW105

PLAY

SW108

KEY2

5SB_IN

CTRL

0805 100 oh

L103

FB-DIP-80

SW103

KS1

CH-

SW106

KS2

REC

TRAY

R131

1 2

10K

R132

1 2

10K

R133

1 2

10K

5SB

D10

3

m

1 2

1N5819

C111

47uF/16V

C108

220uF/16V

KS3

KEY1

VDD

C109

0.01uF

5S

R134

4.7k

STB

R135 33R

CLK

R136 33R

DATA

R137 33R

IR

HOST_RESET

KEY2

KS4

POWER LED1+

JC102

Fp022

K0

22

K

0

01

0

1

741R

021

651R

U102

1

PE

2

PC

3

NC

4

PG

5

PD.

6

PDHMS

7

GR5#

5G

8

GR6#

6G

9

PA

10

R33

691R

R197

R198

33R

33R

IC101

41

EPV6200

6RG

7RG

13

GR5

12

GR4

11

GP3

10

GR2

9

GR1

8

VDD

7

VDD

6

VSS

5

OSCO

4

OSCI

3

PLLC

KLC/5COIPG

2

BTS/4COIPG

1

25

R103

POWER LED1+

100

R

R144

R

100

R105

100R

R106

100R

R107

100R

VDD

C101

0.1uF

PLLC

C102

0.01uF

DATA

STB

LED2

REC

LED3

480P

LED4

720P

LED5

1080I

R101

100R

Y1

2 1

Z

32.768KH

C103

C104

27pF

27pF

CLK

PF

11

GR4#

4G

12

PB

13

GR3#

3G

14

PD

15

GR2#

2G

16

GR1#

1G

R113

GR1

330

R114

GR2

330

R115

GR3

330

R116

GR4

330

R117

GR5

33

0

R118

GR6

0

33

TO DIGITA

GR1#

2N3904

1

Q101

2 3

GR2#

3

2N3904

1

Q102

2

GR3#

3

2N3904

1

Q103

2

GR4#

3

2N3904

1

Q104

2

GR5#

3

2N3904

1

Q105

2

GR6#

3

2N3904

1

Q106

2

C

CN

CN

CN

CN

CN104

AL_F

9

8

AR_F

7

6

CVBS_F

5

4

C_

F

3

2

Y_F

1

L

POWER SWITCH

171R K001

351R K001

321C

951R K001

121C Fp022

221C

CN

CN

CNCNCN

CN108

LED1

POWER

2

421C Fp02

CN

1

2

3

4

SW107

STBA

FRONT POWER SW

12

12

JC101

DV INPUT

TO FRONT DISPLAY

5

5

4

4

3

3

2

2

1

1

6

6

CN103

STB

1

K

CL

2

DATA

3

4

IR

5

HOST_RESET

6

Y2

KE

7

KS3

8

LED+

9

1 2

1 2

1 2

1 2

3

4

2

CN107

L108

L109

L101

L108

L109

L102

D102 1N5819

CN105

6

5

4

3

2

1

TO DIGITAL DV IN

CN106

STB

1

CLK

2

DATA

3

GNDGND

4

12

HOST_RESET

IR

5

6

TO DIGITAL

1

11

11

10

10

9

9

8

8

7

7

1

1

5

5

4

2

3

3

4

2

Y

AV & DV INPUT UNIT

Fp022

Fp0

5SB

R110

4.7K

C106

0.1uF

FRONT DISPLAY UNIT

Fig. 5-5-2

Page 13

5-3. Audio & Video Tuner Circuit Diagram

1RENUT

81

DNG

91

DNG

1

CN

2

CN

3

B+

4

CN

5

CN

6

CN

7

PT-CGA FR

8

CN

9

SSERDDA

01

KCOLC

11

ATAD

21

TUO TFA

31

TUO OIDUA

41

TUO FIS

51

TB

61

CN

71

TUO OEDIV

GND

GND

20

21

L_NI_A 0NISBVC

R_NI_A

303W

GNISUOH + NIP8

8

7

6

5

4

3

2

1

TA50AR-V-511

3BF

Fp06552C

6BF

Fp06562C

31PT

41PT

81PT

51PT

61PT

71PT

2C

1C

Fn01

R052R .C.N

CFA

11R

K01

.C.N

#R_NI_OIDUA

BS5-P

V21PA

V21NA

CCV-P

33V-P

1BF .C.N

V61 Fu01

9BF

92C

.C.N

Fn01

R05R

R06R

VT_LA

R08R .C.N

R001R .C.N

VT_RA

4C

3C

Fn01

OEDIVS/ACR-NC

DNGV

208W

9

8

7

6

5

4

3

2

1

33R

V05/Fu01

K74

103J

#NI_SBVC#L_NI_OIDUA

#NI_Y

GNISUOH + NIP9

V33+

VT_LA

VT_RA

7C

5C

6C

+

+

103CI

1

CN

2

BS5-P

V5A

LCS

ADS

FIS

K123R

V33+

2BF

01C

V61/Fu33.0

+

9C

+

%01/V61/Fu01

V5A

61R

K7.4

.C.N

ETUM_PAS

21C

+

11C

71R

81R

K7.4

K7.4

.C.N

22R

K7.4

31C

Fu1.0

%01/V61/Fu3.3

91R

02R

K7.4

K7.4

.C.N

32R

42R

K7.4

K7.4

.C.N

%01/Fu220.0

12R

K7.4

71C

61C

Fu330.0

Fu1.0

V5A

VFV

4BF

5BF

7BF

BS5-P

33V-P

CCV-P

V21PA

V21NA

0NIYS

0NICS#NI_C

CFA

R3382R

8BF

V5A

82C

72C

V61 Fu01

Fn01

V5A

72R

1Q

92R

03R

K01

EMIT/BW

3

TED/BW

4

EMIT/EPS

5

TED/EPS

6

LIF/EPS

7

ARAP/C2I

8

WSCGA

9

EDOM

01

OMOF

11

ETUM

21

BB/FIS

31

41

TED/PAS

51

FER/R+L

61

51C

+

V61/Fu2.2

6PT

9PT

R001

0701N2

3D

R001

1

3

2

S45TAB

23

FER/R-L

13

CN

03

TUOL

92

TUOR

82

TED/CGA

72

LCS

62

EP

52

DNG

42

ADS

32

FER/OERETS

22

FERFIS

12

TUPNI

02

TED/ESION

CN

91

CCV

81

LLP

71

TED/TOLIPCN

AS2385NA

81C

1PT

4PT

5PT

0NIYS

LCS

VFV

VT_LA

01PT

11PT

TUO_CFA

13R

K7.4

V61/Fu2.2

91C

+

+

V61/Fu7.4

L_NI_A

0NISBVC

TUO_CFA

8C

+

+

V61/Fu2.2

V61/Fu2.2

V61/Fu2.2

LCS

ADS

Fp000141C

32C

+

12C

V61/Fu2.2

V61/Fu33.0

103NC

21

43

65

87

019

2111

4131

6151

2X8 REDAEH

V5A

21R

31R

K01

41R

K081

FIS

Fu1.0

DNGV

K01

V5A

K3.351R

02C

22C

+

42C

V61/Fu74

Fu22.0

R_NI_A

0NICS

ADS

ETUM_PAS

VT_RA

1TM

1

Fu1.0

2PT

3PT

7PT

8PT

21PT

2TM

4TM

3TM

1

1

1

Fig. 5-5-3

Page 14

5-4. Digital Circuit Diagram

Digital Circuit System Diagram

ATAPI INTERFACE

I55_RESETRESET-

+1.5V

+3.3V

1394

I55_RESET- GB_ACK#

1394

RESET-

+1.5V

+3.3V

GND

GBADR[9:0]

GBDAT[15:0]

H_STROBE-

LINK_CSLINK_IRQ

ISOD[7:0]

ISORDY

ISOSTART

ISODIR

ISOCLK

ISOVALRX

ISOVALTX

GBADR[9:0]

GBDAT[15:0]

H_STROBEH_WR-

H_WR-

LINK_CSLINK_IRQ

GB_ACK#

ISOD[7:0] VIDCLK

ISORDY

ISOSTART

ISODIR

ISOCLK

ISOVALRX

ISOVALTX

D5V

+3.3V

+1.8V

Activa100

GBADR[9:0]

GBDAT[15:0]

H_STROBEH_WR-

LINK_CSLINK_IRQ

GB_ACK#

ISOD[7:0]

ISORDY

ISOSTART

ISODIR

ISOCLK

ISOVALRX

ISOVALTX

Activa100

D5V

+3.3V

+1.8V

GND

VGND

VGND

I55_CVBSIN

I55_YIN

I55_CIN

I55_ABCLK

I55_ALRCLK

I55_AMCLK

I55_AODAT

I55_CIN

I55_YIN

I55_CVBSIN

ADC_ADAT

CN508

6 PIN

1

2

3

4

5

6

C36

1nF

RDY_FM

SCK

DATA

IR

HOST_RST

C76

100pF

+3.3V

V_GND

RESET-

HDMI_27MHZ_OSC

A150_VIDO_HS

A150_VIDO_VS

A150_VCLKOx2

A150_VIDO_[0..7]

SPDIF

SCL

SDA

HD_SCL

HD_SDA

Video Output

C

VIDEO OUTPUT_1

Y

G_Y

CVBS

R_V

B_U

+3.3V

V_GND

AGND

AUDIO OUTPUT

MUTE-

ML

MC

MD

AUDIO OUTPUT_1

AOUT0

SPDIF

ABCLKO

ALRCLKO

VADDIS_AMCLK

ADC_ADAT

I55_ABCLK

I55_ALRCLK

AL_REAL

AR_REAL

AL_TV

AR_TV

AR_FRONT

AL_FRONT

I55_AMCLK

Audio & Video Input_1

AL_TV

AR_TV

AL_REAL

AR_REAL

AL_FRONT

AR_FRONT

AFC_OUT

SDA

SDA

SCL

SCL

VIDEO_IN_SEL2

VIDEO_IN_SEL2

VIDEO_IN_SEL

VIDEO_IN_SEL

SAP_MUTE

SAP_MUTE

I55_CIN

I55_CIN

I55_YIN

I55_YIN

I55_CVBSIN

I55_CVBSIN

Audio & Video Input

HDMI

RESETHDMI_27MHZ_OSC

+3.3VA150_VIDO_HS

+1.8V

A150_VIDO_VS

A150_VCLKOx2

A12V

A150_VIDO_[0..7]

A150_SPDIFO

SCL

VDIFGND

SDA

VOGND

HD_SCL GND

HD_SDA

HDMI

AUDIO_OUT_R

AUDIO_OUT_L

AUDIO_OUT_L

AUDIO_OUT_R

A12V

A-12V

5SB

A5V

+3.3V

GND

AGND

+3.3V

+1.8V

A12V

AUDIO_OUT_R

AUDIO_OUT_L

VOGND VDIFGND

A12V

A-12V

5SB

A5V

+3.3V

R24

0R(0805)

VGND

A5V

A5V

VGND

AGND

VGND

C

ATAPI INTERFACE

D5V

D5V

GND

ATIORDY

ATIOW-

ATDMACK-

ATDMARQ

ATIOW-

ATIORDY

ATDMARQ

ATDMACK-

Vaddis V

SBREQ

SBVALID

SBCLK

SBDAT

VID[7:0]

VIDVS

VIDHS

VIDCLK

VIDVLD

I55_TX0

I55_RX0

I55_GPIO0

I55_GPIO2

I55_RESET-

27MHZ_OSC

C77

C78

C79

100pF

100pF

100pF

SBREQ

SBVAILD

SBCLK

SBDAT

VID[7..0]

VIDVS

VIDHS

VIDVLD

I55_GPIO0

I55_GPIO2

I55_RESET-

27MHZ_OSC

HDMI_27MHZ_OSC

SAP_MUTE

VIDEO_IN_SEL

SCL

SDA

A150_VIDO_[0..7]

A150_VIDO_VS

A150_VIDO_HS

A150_VCLKOx2

HD_SCL

HD_SDA

lenaP tnorF

TP34

TP35

R132 33R

R134 33R

R135 33R

R136 33R

TP36

R137 33R

R138 33R

TP37

TP38

VDD_DAC

SBREQ

ATIOW-

SBVALID

ATIORDY

ATDMARQ

SBCLK

ATDMACK-

SBDAT

VID[7..0]

VIDVS

VIDHS

VIDCLK

VIDVLD

I54_DUPRD

I54_DUPTD

I55_GPIO0

I55_GPIO2

I55_RESET-

27MHZ_OSC

HDMI_27MHZ_OSC

SAP_MUTE

VIDEO_IN_SEL

SCL

SDA

VDD_DAC

D5V

D5V

+3.3V

+3.3V

+1.8V

+1.8V

A150_VIDO_[0..7]

A150_VIDO_VS

A150_VIDO_HS

A150_VCLKOx2

HD_SCL

HD_SDA

GND

I55_AMCLK

I55_ALRCLK

I55_ABCLK

I55_AODAT

ADC_ADAT

ecafretnI

FPCSTB

FPCCLK

FPCDIN

FPCDOUT

IRRCV

RESET-

D5V

+3.3V

+1.8V

+1.5V

ATDA0

ATDA1

ATIOR-

ATDA2

ATCS0-

ATDD[0..15]

ATINTRQ

ATCS1-

ATCS0-

ATDA1

ATDD[0..15]

ATDA2

ATDA0

ATIOR-

ATCS1-

ATINTRQ

ATDA0

ATDA1

ATDA2

ATIOR-

ATCS0-

ATCS1-

ATINTRQ

ATDD[0..15]

Vaddis V

DRVRST-

DRVRST-

DRVRST-

FPCDOUT

FPCDIN

FPCCLK

FPCSTB

IRRCV

AFC_OUT

MUTE-

RESET-

VIDEO_IN_SEL2

AOUT0

ABCLKO

ALRCLKO

VADDIS_AMCLK

ADC_ADAT

I55_AODAT

I55_ABCLK

I55_ALRCLK

I55_AMCLK

CVBS

SPDIF

C

Y

G_Y

R_V

B_U

ML

MC

MD

POWER

R12

0R(0805)

POWER

D5V

+3.3V

+1.8V

+1.5V

V_GND

C

Y

G_Y

CVBS

R_V

B_U

FPCDOUT

FPCDIN

FPCCLK

FPCSTB

IRRCV

AFC_OUT

MUTERESET-

VIDEO_IN_SEL2

ML

MC

MD

AOUT0

SPDIF

ABCLKO

ALRCLKO

VADDIS_AMCLK

VDD_DAC

V_GND

5SB

A12V

A-12V

A5V

GND

R49

75R/1%

R48

75R/1%

5SB

A12V

A-12V

A5V

VDD_DAC

C

Y

G_Y

CVBS

R_V

B_U

R47

R45

75R/1%

75R/1%

R44

75R/1%

R46

75R/1%

tuptuo oediv lennahc 6

ecafretni lenap tnorF

lortnoc tceles ni oediV

tuo oiduA

CAD oidua rof kcolC

emaN

1PJ

02NIP

-ETUM

22NIP

32NIP

CM

52NIP

LM

62NIP

DM

72NIP

13NIP

23NIP

74NIP

94NIP

05NIP

Y

G_Y

CVBS

R_V

B_U

MUTE-

ML

MC

MD

AOUT0

SPDIF

ABCLKO

ALRCLKO

VADDIS_AMCLK

ADC_ADAT

I55_ABCLK

I55_ALRCLK

I55_AMCLK

AFC_OUT

OICPG

TESER_PSM

0_OICPG

NO_CIM

41_OICPG

31_OICPG

71_OICPG

61_OICPG

81_OICPG

1SF_TRACS

11_OICPG

21_OICPG

0SF_TRACS

_NI_OEDIV 2LES

51_OICPG

11_OICPG84NIP

TED_SPV

_NI_OEDIV 3LES

02_OICPG

NI_OEDIV LES_

23_OICPG

Fig. 5-5-4

Page 15

5-4-1. Audio Output Circuit Diagram

AL_TV

AL_REAL

AL_FRONT

AR_TV

AR_REAL

AR_FRONT

VADDIS_AMCLK

I55_AMCLK

I55_ABCLK

I55_ALRCLK

ADC_ADAT

A12V

A-12V

5SB

A5V

+3.3V

GND

AGND

ETUM_TUO

A12V

84

+

-

A-12V

R308 5.1K

A12V

84

+

-

A-12V

R324 5.1K

R285

0R

N.C.

AZ4558AM

AZ4558AM

A12V

1

7

IC514A

IC514B

5SB

1

5SB

3

R280 10K

2

1

D15 BAT54S

R287 0R

R286

0R

D17

BAT54S

2

C164

10uF/16V

C165

10uF/16V

D18 BAT54S

3

stiucric etuM

C320

10uF/16V

C332

10uF/16V

R288

2K

R305

10K

R319

10K

5SB

2

1

D16BAT54S

A-12V

D20 BAT54S

R290

1

100K

Q16

2N3906

R3021.8K

R3151.8K

R295

100K

C323

1nF

C334

1nF

3

2

R3037.5K

R3167.5K

C324

680pF

R307 4.7K

C335

680pF

R323 4.7K

3

2

5

6

tuo FIDP/S

J504

C307

0.1uF

LACITPO_FIDPS

15

14

16

17

18

19

11

10

13

12

41

40

47

45

43

39

38

48

46

44

42

32

31

+3.3V

5

4

7

6

3

1

2

1

2

3

IC513

WM8787

DVDD

DGND

MODE

CE

DI

CL

DACMCLK

DACBCLK

DACLRC

DIN

ADCMCLK

ADCBCLK

ADCLRC

DOUT

AINOPL

AINVGL

AIN1L

AIN2L

AIN3L

AIN4L

AIN5L

AINOPR

AINVGR

AIN1R

AIN2R

AIN3R

AIN4R

AIN5R

AUXL

AUXR

GP1FAV51TK0F

DIN

VCC

GND

A5V

DACREFP

DACREFN

ADCREFP

ADCREFGND

VMIDDAC

VMIDADC

AVDD

HPVDD

AGND

HPGND

VOUTL

VOUTR

HPOUTL

HPOUTR

ZFLAGL

ZFLAGR

4

5

6

-ETUM

+

+3.3V

47uF/16V

+

47uF/16V

R328

10K

FB20

C315

C330

R329

33R N.C.

R292 4.7K

A5V

ETUM_TUO

MUTE-

36

22

37

21

30

29

35

34

28

33

26

27

20

23

9

8

25

NC2

24

NC1

C316

0.1uF

C318

0.1uF

C321

0.1uF

C327

0.1uF

C317

0.1uF

+

+

+

47uF/16V

47uF/16V

47uF/16V

C328

L_MW

R_MW

R301

240R

C319

C322

C329

0.1uF

GALFZ

R281 33R

FIDPS

R296

R297

4.7K

4.7K

R299

4.7K

C32510uF/16V

C32610uF/16V R312 2K

C33110uF/16V

C33310uF/16V

C33610uF/16V

C33910uF/16V

R309 10K

R313 10K

R314 10K

R320 10K

R325 10K

R326 10K

A12V

A-12V

5SB

A5V

+3.3V

C440

1uF

ABCLKO

ALRCLKO

AOUT0

SPDIF

ML

MD

MC

FB9

SP5V

C102

R279

C19

+

100pF

10K

47uF/16V

FB19

R298

4.7K

C438

1uF

C314

0.1uF

+3.3V

C439

1uF

CAD OIDUA

GNILPUOC-ED

C313

+

47uF/16V

R300 4.7K

N.C.

R3105.1K

R3215.1K

C340

C341

C441

1uF

1uF

1uF

A5V 5SB

Q15

2N3906

R294

470R

C312

47uF/16V

ETUM_TUO

.etum ffO-rewoP

ETUM_TUO

3

2N3906

Q13

C308

220uF/16V

1

3

2

C311

220uF/16V

R293

91K

.etum ffO/nO-rewoP

C169

47uF/16V

ETUM_TUO

+

R304

680R

R306 2K

R318

680R

A12V

0.1uF

C337

A-12V

0.1uF

C338

C170

+

47uF/16V

2N3904

Q17

Q18

2N3904

R_TUO_OIDUA

AUDIO_OUT_R

L_TUO_OIDUA

AUDIO_OUT_L

C348

47uF/16V

C351

+

47uF/16V

0.1uF

C349

C352

+

47uF/16V

0.1uF

C350

C353

+

0.1uF

Fig. 5-5-5

Page 16

5-4-2. Decorder & SDRAM Circuit Diagram

RESET-

SW3

1

2

JUMPER

N.C.

C142

C152

0.1uF

0.1uF

C433

C432

0.1uF

0.1uF

RP7 47RX4

1

2

3

4 5

RP8 47RX4

1

2

3

4 5

RP9 47RX4

1

2

3

4 5

1

2

3

4 5

RP10 47RX4

RP12 47RX4

1

2

3

4 5

RP11 47RX4

1

2

3

4 5

RP14 47RX4

1

2

3

4 5

1

2

3

4 5

K8D6x16

AM29DL640

R105 51R

R98 51R

R116 51R

RESET CIRCUIT

TP6

C187

R50

3.3nF

100K

N.C.

N.C.

+3.3V

R153 330R

R150

R152

4.7K

4.7K

2N3904

Q1

R151

2K

C139

C178

0.1uF

0.1uF

C435

C434

C33

0.1uF

0.1uF

0.1uF

SDRAM 3.3V DECUPS

FRAMDAT9

8

FRAMDAT8

7

FRAMADD5

6

FRAMADD8

FRAMDAT5RAMDAT5

8

FRAMDAT6

7

FRAMDAT7

6

FRAMADD6

8

FRAMADD11

7

FRAMADD9

6

FRAMADD10

8

FRAMADD0

7

FRAMADD1

6

FRAMDAT24RAMDAT24

RAMBA0

8

RAMDAT31

7

RAMDAT30

6

RAMDAT29

RAMDAT28

8

RAMDAT27

7

RAMDAT26

6

RAMDAT25

RAMDAT16

8

RAMDAT17

7

RAMDAT18

6

RAMDAT19

RAMDAT20

8

RAMDAT21

7

RAMDAT22

6

RAMDAT23

D5V

+3.3V

+1.8V

VDD_DAC

RAMDAT12

RAMDAT4

RESET-

2N3904

Q12

RAMADD0

RAMADD1

RAMADD2

RAMADD3

RAMADD4

RAMADD5

RAMADD6

RAMADD7

RAMADD8

RAMADD9

SD1_+3.3V

C38

C144

C168

0.1uF

C146

0.1uF

C143

0.1uF

0.1uF

0.1uF

C157

C44

C158

C37

1nF

1nF

10nF

10nF

RAMADD10

RAMADD11

RAMADD12

RAMBA0

RAMBA1

RAMWERAMCSPCLK

RAMCKE

RAMCASRAMRAS-

RAMDQM

RAMADD0

RAMADD1

RAMADD2

RAMADD3 RAMDAT19

RAMADD4

RAMADD5

RAMADD6

RAMADD7

RAMADD8

RAMADD9

RAMADD10

RAMADD11

RAMADD12

RAMBA0

RAMBA1

RAMWERAMCSPCLK

RAMCKE

RAMCASRAMRAS-

RAMDQM

2x 64MBit(-16bit) SDRAM

SD1_+3.3V

37

47

IC511

FRAMADD5

25

A0

FRAMADD6

24

A1

VCC

23

VCCO

A2

22

A3

21

A4

DQ0

20

A5

DQ1

19

A6

DQ2

18

A7

DQ3

DQ4

DQ5

8

A8

DQ6

7

A9

DQ7

6

A10

5

A11

4

A12

DQ8

3

A13

DQ9

2

A14

DQ10

1

A15

DQ11

DQ12

DQ13

48

A16

DQ14

17

DQ15/A_1

A17

16

A18

FLASH MEMORY SOCKET

15

A19

10

A20

9

A21

12

RP

11

WE

14

WP

26

CE

28

OE

13

VPP

GND

GND

46

27

RAMADD2

RESETRAMADD4

RAMADD3

RAMDAT10

RAMDAT11

RAMDAT3

SD1_+3.3V

PNVMCE-

FRAMADD7

FRAMADD8

FRAMADD9

FRAMADD11

FRAMDAT8

FRAMDAT9

FRAMDAT5

FRAMDAT6

FRAMDAT7

FRAMBA0

FRAMBA1

FRAMADD10

FRAMADD0

FRAMADD1

R91 51R

R95 51R

R94 51R

R96 51R

R99 51R

R108 51R

R100 51R

MX29LV160BBTC-70

RESET-

+3.3V

FB5

C43

C48

+

+

47uF/16V

47uF/16V

RAMDAT9

RAMDAT8

RAMADD5

RAMADD8

RAMDAT6

RAMDAT7

RAMADD7 FRAMADD7

RAMADD6

RAMADD11

RAMADD9

RAMBA1 FRAMBA1

RAMADD10

RAMADD0

RAMADD1

FRAMBA0

FRAMDAT31

FRAMDAT30

FRAMDAT29

FRAMDAT28

FRAMDAT27

FRAMDAT26

FRAMDAT25

FRAMDAT16

FRAMDAT17

FRAMDAT18

FRAMDAT19

RP13 47RX4

FRAMDAT20

FRAMDAT21

FRAMDAT22

FRAMDAT23

D5V

+3.3V

+1.8V

VDD_DAC

GND

INTEL28F640

AM29LV641

R97 51R

PNVMR_B

R93 51R

R117 0R N.C.

SD1_+3.3V

SD1_+3.3V

1427394943128

IC504

29

31

33

35

38

40

42

44

30

32

34

36

39

41

43

45

23

24

25

26

29

30

31

32

33

34

22

35

36

20

21

16

19

38

37

17

18

15

39

23

24

25

26

29

30

31

32

33

34

22

35

36

20

21

16

19

38

37

17

18

15

39

FRAMDAT31

FRAMDAT29

FRAMDAT27

FRAMDAT25

FRAMDAT23

FRAMDAT21

FRAMDAT19

FRAMDAT17

FRAMDAT30

FRAMDAT28

FRAMDAT26

FRAMDAT24

FRAMDAT22

FRAMDAT20

FRAMDAT18

FRAMDAT16

D0

A0

A1

D1

VDD

VDD

VDDVSS

VDDQ

VDDQ

VDDQ

VDDQ

A2

D2

A3

D3

A4

D4

A5

D5

A6

D6

A7

D7

A8

D8

A9

D9

A10

D10

A11

D11

D12

A12

D13

BA0

D14

BA1

D15

WE

CS

CLK

CKE

N.C

CAS

RAS

LDQM

UDQM

VSS

VSS

VSSQ

VSSQ

VSSQ

VSSQ

K4S641632H-TC/L60

415461246

52

SD1_+3.3V

1427394943128

IC507

D0

A0

A1

D1

VDD

VDD

VDDVSS

VDDQ

VDDQ

VDDQ

VDDQ

A2

D2

A3

D3

A4

D4

A5

D5

A6

D6

A7

D7

A8

D8

A9

D9

A10

D10

A11

D11

D12

A12

D13

BA0

D14

BA1

D15

WE

CS

CLK

CKE

N.C

CAS

RAS

LDQM

UDQM

VSS

VSS

VSSQ

VSSQ

VSSQ

VSSQ

K4S641632H-TC/L60

415461246

52

27MHZ_OSC

HDMI_27MHZ_OSC

1) If using AM29LV641 / Intel

28F640/AT49BV320At ,install R93,R97,R117 ,

not install R98,R105,R116;

2) if using K8D6X16 / AM29DL640 /

SST39VF320 / SST39VF3202 / MBM29PL32 /

MBM29DL32 /AT49BV322AT, install

R98,R105,R116, not install R93,R97,R117.

3).M29KW032E: Almost same to 2). But Pin14

connect to 12V, install R160.

VDD_DAC

+1.8V

+3.3V

FRONT PANEL I/F

+3.3V

EEPROM

8

VCC

7

WP

6

SCL

GNDSDA

AT24C08A

RP15

4.7KX4

TP106

TP108

1

TP110

1

1

ICEMODE

1

1

1

1

TP114

TP113

TP115

+3.3V

IC512

1

A0

2

A1

3

A2

45

CN506

12

34

56

78

910

11 12

13 14

15 16

HEADER 8X2

N.C.

FPCDIN

IRRCV

FPCSTB

0.1uF

R159 4.7K

C39

TP104

TP105

1

SDA

SCL

TP107

TP109

TP111

1

1

1

ICETDO

1

AUDIO ICE CONNECTOR

ICETCK

SERIAL DEBUG I/F

DUPRD

EJTDI

EJTMSEJTDO

+3.3V

EJTAG DEBUG CONNECTOR

I2C I/F

C65

C17

C16

+

C10

47uF/16V

+3.3V

E5F5H5

K5N5R5E7T7U7T9

E10

T11

IC510

N3

NVMDA0

P4

NVMDA1

P3

NVMDA2

R3

NVMDA3

R4

NVMDA4

P1

NVMDA5

P2

NVMDA6

N4

NVMDA7

N1

NVMR/B

L4

NVMCE

M3

NVMR/B1

L3

NVMCE1

M1

NVMRE

N2

NVMWP

M2

NVMWE

L1

NVMALE

L2

NVMCLE

M4

RAMADD12

RAMADD11

RAMADD10

RAMADD9

RAMADD8

RAMADD7

RAMADD6

RAMADD5

RAMADD4

RAMADD3

RAMADD2

RAMADD1

RAMADD0

D5V

C56

0.1uF

C88

0.1uF

RAMCKE

RAMWERAMCASRAMRASRAMCSRAMDQM

RAMBA1

RAMBA0

RAMDAT0

RAMDAT1

RAMDAT2

RAMDAT3

RAMDAT4

RAMDAT5

RAMDAT6

RAMDAT7

RAMDAT8

RAMDAT9

RAMDAT10

RAMDAT11

RAMDAT12

RAMDAT13

RAMDAT14

RAMDAT15

RAMDAT16

RAMDAT17

RAMDAT18

RAMDAT19

RAMDAT20

RAMDAT21

RAMDAT22

RAMDAT23

RAMDAT24

RAMDAT25

RAMDAT26

RAMDAT27

RAMDAT28

RAMDAT29

RAMDAT30

RAMDAT31

PNVMCEPNVMR_B

ATDD0

ATDD1

ATDD2

ATDD3

ATDD4

ATDD5

ATDD6

ATDD7

ATDD8

ATDD9

ATDD10

ATDD11

ATDD12

ATDD13

ATDD14

ATDD15

ATIOWATIORATIORDY

ATDMACKATINTRQ

ATDA0

ATDA1

ATDA2

ATCS0ATCS1-

XO

GCLKP

GCLKA

RESET-

NVMCD

U12

PCLK

V11

RAMCKE

Y14

RAMWE

W13

RAMCAS

Y13

RAMRAS

Y12

RAMCS

W14

RAMDQM

Y11

RAMBA1

W11

RAMBA0

T4

RAMADD12

U10

RAMADD11

W9

RAMADD10

V10

RAMADD9

U9

RAMADD8

V9

RAMADD7

U8

RAMADD6

V8

RAMADD5

W7

RAMADD4

Y7

RAMADD3

Y8

RAMADD2

W8

RAMADD1

Y9

RAMADD0

W18

RAMDAT0

Y18

RAMDAT1

W17

RAMDAT2

Y17

RAMDAT3

W16

RAMDAT4

Y16

RAMDAT5

W15

RAMDAT6

Y15

RAMDAT7

V14

RAMDAT8

U14

RAMDAT9

V15

RAMDAT10

V16

RAMDAT11

V17

RAMDAT12

U17

RAMDAT13

V18

RAMDAT14

U18

RAMDAT15

W6

RAMDAT16

Y6

RAMDAT17

W5

RAMDAT18

Y5

RAMDAT19

W4

RAMDAT20

Y4

RAMDAT21

Y3

RAMDAT22

Y2

RAMDAT23

W2

RAMDAT24

W3

RAMDAT25

V4

RAMDAT26

U4

RAMDAT27

V5

RAMDAT28

V6

RAMDAT29

U6

RAMDAT30

V7

RAMDAT31

Y1

PNVMCE

W1

PNVMR/B

D2

ATDD0

C2

ATDD1

A1

ATDD2

B2

ATDD3

D3

ATDD4

C3

ATDD5

D4

ATDD6

C4

ATDD7

A4

ATDD8

B4

ATDD9

A3

ATDD10

B3

ATDD11

A2

ATDD12

E4

ATDD13

E3

ATDD14

F4

ATDD15

B1

ATDMARQ

C1

ATIOW

D1

ATIOR

F3

ATIORDY

E2

ATDMACK

E1

ATINTRQ

G3

ATDA0

F1

ATDA1

F2

ATDA2

G1

ATCS0

G2

ATCS1

B7

HD0

A7

HD1

B8

HD2

A8

HD3

B9

HD4

A9

HD5

B10

HD6

A10

HD7

B5

HA0

A5

HA1

B6

HA2

A6

HA3

C6

HWR

D6

HRD

D7

HCS

C7

HIRQ

C5

HACK

D8

HCS1

C8

HIRQ1

D5

HACK1

C14

XO

A14

GCLKP

B15

GCLKA

B14

RESET

VSSP

T5T6T8

+1.8V

C116

C112

C93

0.1uF

C101

0.1uF

0.1uF

0.1uF

R235 0R

PCLK

RAMDAT0

2

RAMDAT1

4

RAMDAT2

5

RAMDAT3

7

RAMDAT4

8

RAMDAT5

10

RAMDAT6

11

RAMDAT7

13

RAMDAT8

42

RAMDAT9

44

RAMDAT10

45

RAMDAT11

47

RAMDAT12

48

RAMDAT13

50

RAMDAT14

51

RAMDAT15

53

40

RAMDAT16

2

RAMDAT17

4

RAMDAT18

5

7

RAMDAT20

8

RAMDAT21

10

RAMDAT22

11

RAMDAT23

13

RAMDAT24

42

RAMDAT25

44

RAMDAT26

45

RAMDAT27

47

RAMDAT28

48

RAMDAT29

50

RAMDAT30

51

RAMDAT31

53

40

R64 0R

R330 0R

PCLK1

RAMADD[12..0]

ATDD[0..15]

ATDD[0..15]

ATDMARQ

ATIOWATIORATIORDY

ATDMACKATINTRQ

ATDA0

ATDA1

ATDA2

ATAPI AND AV DRIVE I/F

ATCS0-

ATCS0-

ATCS1-

ATCS1-

CLK_OUT

3

2

C91

1nF

1nF

RAMDAT[31..0]

TP8

OUT

GND

27MHz

C115

R62

4.7K

IC509

VCC

N/C

C104

10nF

R61

4.7K

1

R6 0R

R3 0R

+3.3V

4

1

C103

10nF

VADDIS 1.8V DECUPS

U11

VDDP

VDDP

VDDP

VDDP

VDDP

VDDP

VDDP

VDDP

VDDP

VDDP

VDDP

VDDP

VDDP

ZR36750-BGCG-V

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

T10

T12

T13

V13

T14

U15

T16J9K9L9M9

C28

+

C22

47uF/16V

+1.8V

K16

E12

U13

E15

M16

R16

U16

T15

VDDP

VDDP

VDDP

VSSP

VSSP

VSSP

L10

K11

K12

J11

C30

+

47uF/16V

E13

L17

V12

W10L5A18

D12

U5

E9

A19

VDDC

VSSC

VSSC

E14

E8

C145

0.1uF

C27

0.1uF

VDDC

VDDC

VDDC

VDDC

VSSC

VSSC

VSSC

VSSC

L16

W12

Y10M5A12

C61

0.1uF

C160

0.1uF

VADDIS 3.3V DECUPS

A20

VDDC

VDD_DAC

VDD_DAC

VDD_DAC

VSSA_PLL

VSSA_AMCLK

VSSA_PLL

H16

A11

C87

C75

0.1uF

0.1uF

C66

C127

0.1uF

0.1uF

VDDP

VDDP

VDDP

VDDP

VDDP

VDD_IP

VDD_IP

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

VSSP

J12

J10

K10

L11

L12

M10

M11

M12

C29

0.1uF

+

47uF/16V

10nF

A13

A16

G16

DAC_BU

DAC_RV

DAC_GY

DAC_CVBS

VDDA_DC

VDDA_PLL

DAC_Y

DAC_C

VDDA_AMCLK

COSYNC

RSET

VREF

VIDO_0

VIDO_1

VIDO_2

VIDO_3

VIDO_4

VIDO_5

VIDO_6

VIDO_7

VSYNC

HSYNC

VCLK

VCLKx2

VIDI_0

VIDI_1

VIDI_2

VIDI_3

VIDI_4

VIDI_5

VIDI_6

VIDI_7

VIDIVS

VIDIHS

VIDICLK

VIDIVALID

SBCLK

SBREQ

SBDAT

SBVALID

SBSOS

AMCLK

ALRCLKI

ABCLKI

ALRCLKO

ABCLKO

AIN0

AIN1

AOUT0

AOUT1

AOUT2

AOUT3

AOUT4

SPDIF

FPCDOUT

FPCDIN

FPCCLK

FPCSTB

IRRCV

DUPRD

DUPTD

MODRI

MODDCD

MODDSR

MODCTS

MODDTR

MODRTS

MODRD

MODTD

SPIDATI

SPIDATO

SPICLK

I2CDAT

I2CCLK

PWM

SERADC0

SERADC1

SERADC2

ICETDI

ICETDO

ICETMS

ICETCK

EJTRST

EJTDI

EJTDO

EJTMS

EJTCK

GPCIO6

GPCIO7

GPCIO8

GPCIO9

GPCIO10

GPCIO11

GPCIO12

GPCIO13

GPCIO14

GPCIO15

GPCIO16

GPCIO17

GPCIO18

GPCIO19

GPCIO20

GPAIO0

BOOTSEL0

BOOTSEL1

BOOTSEL2

TESTMODE

PLLSEL

PLLCFGP

PLLCFGA

VSS_DACD

VSS_DACD

VSSA_DC

VSS_DACP

VSS_DACB

VSS_DACD

A15

C19

B19

B20

C20

D20

C99

C114

C107

0.1uF

0.1uF

0.1uF

C89

C90

C100

10nF

10nF

10nF

10nF

0.1uF

B_UB_U

E17

R_VR_V

F17

G_YG_Y

F18

CVBSCVBS

G17

YY

G18

CC

H17

COSYNC

K17

1

RSET

D16

D17

A150_VIDO_0

K19

A150_VIDO_1

K20

A150_VIDO_2

L19

A150_VIDO_3

L20

A150_VIDO_4

L18

A150_VIDO_5

M19

A150_VIDO_6

M20

A150_VIDO_7

M18

A150_VIDO_VS

R17

A150_VIDO_HS

T20

VCLK

T19

1

A150_VCLKOx2

K18

VID0

M17

VID1

N20

VID2

N19

VID3

N18

VID4

N17

VID5

P20

VID6

P19

VID7

P18

VIDVS

R18

VIDHS

R19

VIDCLK

P17

VIDVALID

R20

SBCLK

J18

SBREQ

H18

SBDAT

E18

SBVALID

D19

SBSOS

D18

PAMCLK

E19

I55_ALRCLK

E20

I55_ABCLK

F20

PALRCLKO

F19

PABCLKO

G19

I55_AODAT

C17

ADC_ADAT

C16

AOUT0

J17

J19

H20

H19

G20

SPDIF

J20

FPCDOUT

G4

FPCDIN

H4

FPCCLK

H3

FPCSTB

H1

IRRCV

H2

DUPRD

T3

DUPTD

U3

W19

U20

V20

V19

U19

Y20

I54_DUPRD

Y19

I54_DUPTD

W20

B13

C13

D13

B17

A17

C9

C15

B16

D15

ICETDI

E11

ICETDO

T17

ICETMS

J5

ICETCK

T18

EJTRST

K3

EJTDI

K4

EJTDO

K2

EJTMS

K1

EJTCK

J1

I55_GPIO0

J4

AFC_OUT

B18

I55_RESET-

C18

V1

I55_GPIO2

V2

HD_SCL

U2

HD_SDA

U1

T1

MUTE-

T2

VIDEO_IN_SEL2

R1

ML

R2

MC

B11

MD

C11

DRVRST-

C12

V3

B12

BOOTSEL0

C10

BOOTSEL1

D10

ICEMODE

D11

TESTMODE

D14

PLLSEL

D9

PLLCFGP

J2

PLLCFGA

J3

RP18

470RX4

+3.3V

C113

C118

0.1uF

0.1uF

C117

C106

C92

1nF

1nF

1nF

C86

C640.1uF

R9 33R

R5 33R

R8 33R

I55_AMCLK

C980.1uF

+

C13

47uF/16V

10nF

TP12

R79 392R/1%

TP2

VID[7..0]

R13 0R

R14 1K

R70 1K

VADDIS_AMCLK

ALRCLKO

ABCLKO

FPCDOUT

FPCDIN

FPCCLK

FPCSTB

IRRCV

R101

A150_VIDO_VS

0R N.C.

SAP_MUTE

FP_CTRL2

VIDEO_IN_SEL

SW2

CN2.54MM2X2-M

R19

678

470R

R20

R143 0R

470R

123

4 5

1) Work mode

short pin2 to pin4 of SW2,open pin1 to pin3 of SW2;

or solder R143 and not solder R142;

2) Download & Debug mode

short pin1 to pin3 of SW2,short pin2 to pin4 of SW2.

or solder R142 and not solder R143.

C320.1uF

+

C24

47uF/16V

R142

0R

Sel0

Sel1

2

BOOT SELECT

+

C31

C120

47uF/16V

10nF

B_U

R_V

G_Y

ANALOG VIDEO OUTPUTS

CVBS

Y

C

A150_VIDO_[7..0]

A150_VIDO_VS

A150_VIDO_HS

A150_VCLKOx2

FPCCLK

VID[7..0]

VIDVS

VIDHS

DIGITAL VIDEO INPUT

VIDCLK

VIDVLD

SBCLK

SBREQ

SBDAT

ENCODER SERIAL BITSTREAM I/F

SBVALID

I55_ALRCLK

I55_ABCLK

ALRCLKO

ABCLKO

I55_AODAT

ADC_ADAT

DIGITAL AUDIO I/F

AOUT0

SPDIF

I54-I55 UART

INTERFACE

I54_DUPRD

I54_DUPTD

SDA

SCL

RP16

1

8

2

7

3

6

R86

4 5

4.7K

4.7KX4

I55_GPIO0

AFC_OUT

I55_RESET-

MUTEMC

I55_GPIO2

ML

HD_SCL

MD

HD_SDA

HD_SCL

HD_SDA

MUTE-

VIDEO_IN_SEL2

VIDEO_IN_SEL2

VIDEO_IN_SEL

ML

DRVRST-

MC

VIDEO_IN_SEL GPCIO_32

MD

DRVRST-

RP2

4 5

3

6

2

7

1

8

4.7KX4

341

N.C.

SEL1 SEL0 BOOT DEVICE

0 0 NAND

0 1 NOR

1 0 UART

1 1 VMI A

R1 100R

VADDIS_AMCLK

D5V

678

RP21

4.7KX4

123

4 5

+3.3V

4.7K

4.7K

R18

R17

+3.3V

678

123

4 5

GPCIOName

GPCIO_14

GPCIO_17

GPCIO_16

GPCIO_18

GPCIO_11

GPCIO_12

GPCIO_15

GPCIO_32

GPCIO_19

ICETDI

ICETMS

D5V

DUPTD

EJTRST

R22 33R

EJTCK

+3.3V

TP112

VADDIS_AMCLK

Fig. 5-5-6

Page 17

5-4-3. HDMI Circuit Diagram

+3.3V

+1.8V

FB25

FB26

A12V

A12V

+3.3V

+1.8V

GND

VOGND

VDIFGND

HD_3.3V

HD_1.8V

VDIFGND

+3.3V +1.8V

VOGND

IC515

L78L05/TO92

3 1

IN OUT

C354

+

10uF/16V

J503

GULPTOH

VDIFGND

HDMI_TYPE_A

1

TDMS_D2+

2

TDMS_D2_SHIELD

3

TDMS_D2-

4

TDMS_D1+

5

TDMS_D1_SHIELD

6

TDMS_D1-

7

TDMS_D0+

8

TDMS_D0_SHIELD

9

TDMS_D0-

10

TDMS_CLK+

11

TDMS_CLK_SHIELD

12

TDMS_CLK-

13

CEC

14

NC

15

SCL

16

SDA

17

DDC/CEC_GND

18

+5V

19

HOTPLUG

GND

202122

TUO IMDH

GND

GND

GND

23

+2D_SDMT

-2D_SDMT

+1D_SDMT

-1D_SDMT

+0D_SDMT

-0D_SDMT

HD_+5V

+KLC_SDMT

-KLC_SDMT

HD_+5VA12V

Q21

LCS_DH

R340 1.8K

GND

2

C355

+

10uF/16V

C163

0.1uF

HD_+5V

A12V

HD_+5V

R342 1.8K

ADS_DH

2

Q22

2

31

2N7002

31

2N7002

OEDIV

F/I

ROF C2I

YLNO DH

HD_SCL

HD_SDA

SCL

SDA

HDMI_27MHZ_OSC

RESET-

LATIGID

A150_VIDO_[0..7]

A150_VIDO_HS

A150_VIDO_VS

A150_VCLKOx2

A150_SPDIFO

R337 4.7K

R338 4.7K

R339 4.7K

+0D_SDMT

-0D_SDMT

+KLC_SDMT

-KLC_SDMT-2D_SDMT

HD_3.3V

+1.8V

HD_1.8V

+3.3V

HD_AVDDT_3.3V

+1.8V

Q19

FB28

2SA1955F

R331

2.7K

R333

1K

R332

1K

2N3904

Q20

A_77I rof rewoP V3.3TDDV

RDDA C2I GIFNOC

SH_ODIV_051A

SV_ODIV_051A

OFIDPS_051A

A8X0 = RDDA

LCS_DH

ADS_DH

R345 0R

C34

1nF

N.C.

HD_AVDDT_3.3V+3.3V

R336 4.7K

V3.3TDDVA_77I ROF REWOP

C357

C356

+

0.1uF

100uF/25V

9

16

IC516

1

VIN[0]

2

VIN[1]

3

VIN[2]

4

VIN[3]

5

VIN[4]

6

VIN[5]

7

VIN[6]

8

VIN[7]

14

HSYNC/I2C_CFG0

15

FIELD/I2C_CFG1

11

VCLKx2

22

SPDIF/I2C_CFG2

38

GPIO[17]

37

GPIO[16]

23

GPIO[15]

75

GPIO[14]

77

GPIO[13]

78

GPIO[12]

79

GPIO[11]

80

GPIO[10]

17

GPIO[9]

18

GPIO[8]

19

GPIO[7]

20

GPIO[6]

21

GPIO[5]

25

GPIO[4]

35

SCL

36

SDA

43

REFCLK

RESET-

VDDIP

GNDPLL

44

0_ODIV_051A

1_ODIV_051A

2_ODIV_051A

3_ODIV_051A

4_ODIV_051A

5_ODIV_051A

6_ODIV_051A

7_ODIV_051A

SH_ODIV_051A

SV_ODIV_051A

2xOKLCV_051A

OFIDPS_051A

26

VDDP

13

404142

76

VDDP

VDDP

VDDP

GNDP

GNDP

GNDP

24

34

74

GNDP

VDDPLL

GNDC

12

10

31

48

54

65

72

VDDC

VDDC

VDDC

VDDDAC

AVDDT33

AVDDT33

CSET

VREF

RSET

Y/G

Pr/R

Pb/B

V_SYNC

H_SYNC

TXDP2

TXDN2

TXDP1

TXDN1

TXDP0

TXDN0

TXCP

TXCN

CEC

HOTPLUG

GPIO[0]

GPIO[1]

GPIO[2]

GPIO[3]

GNDC

GNDC

33

70

69

VOGND

GNDDACP

GNDDAC

62

63

GNDDACBS

45

VDIFGND

AGNDT33

AGNDT33

AGNDT33

AGNDT1_8 AVDDT1_8

51

57

59 60

58

61

64

66

67

68

73

71

56

55

53

52

50

49

47

46

39

32

30

29

28

27

R334 430R_1%

R335 392R_1%

1

1

1

TP28

1

TP29

TP30

TP31

HD_3.3V

C359

+

100uF/16V

VDIFGND

VOGND

CNYSV_DH

TP32

1

CNYSH_DH

TP33

1

+2D_SDMT

-2D_SDMT

+1D_SDMT

-1D_SDMT

+0D_SDMT

-0D_SDMT

+KLC_SDMT

-KLC_SDMT

TUO_GULPTOH GULPTOH

R341 0R

R343

10K

C371

C373

+

100uF/16V

0.1uF

V8.1_LLP_DH

V3.3_CAD_DH

V3.3_TDDVA_DH

V8.1_FIDV_DH

C361

C360

0.1uF

0.1uF

VDIFGND

FERV_DH

FB32

4

C362

+

100uF/16V

C368

+

47uF/16V

N.C.

123

VOGND

VOGND

C363

0.1uF

C369

0.1uF

FB31

+2D_SDMT

ACM2012

FB34

N.C.

+1D_SDMT

123

4

-1D_SDMT

ACM2012

HD_1.8V

C377

C376

C375

C374

0.1uF

0.1uF

0.1uF

0.1uF

C372

+

47uF/16V

C378

0.1uF

C365

+

100uF/25V

ACM2012

ACM2012

4

4

+3.3V

FB33

FB35

C379

0.1uF

FB27

FB29

FB30

C366

0.1uF

N.C.

123

N.C.

123

C380

0.1uF

Fig. 5-5-7

Page 18

5-4-4. Audio & Video Input Circuit Diagram

A5V

A5V

TP85

CN507

9PIN + HOUSING

SCL

C383 10nF

C384 10nF

C385 10nF

R370 0R

R371 0R

R372 0R

TP95

C390 1uF

C391 1uF

C392 1uF

C395 1uF

R373 0R

VGND

NI_OEDIV_VT

R_F_SBVC

R356

75R/1%

VGND

F_Y

R_SBVC

F_SBVC

F_C

R_C

R_SBVC

NI_OEDIV_VT

VGND

AGND

TP72

TP73

9

F_LA

8

7

F_RA

6

5

F_SBVC

4

3

F_C

F_Y

TP76

R362

75R/1%

TP81

C35

1nF

TP87

LCS

VGND

TP74

TP75

R363

75R/1%

L_NI_A

NIYS

NISBVC

TUO_CFA

VFV

2

1

VGND

TP82

TP83

R352 330R

TP77

R367

R364 330R

75R/1%

TP78

CN503

12

34

56

78

910

11 12

VT_LA

13 14

15 16

HEADER 8X2

AL_FRONT

AR_FRONT

R368 330R

R369 330R

TP79

R_NI_A

NICS

TP84

ADS

ETUM_PAS

VT_RA

TP88

TP80

TP86

TP89

I55_CVBSIN

I55_YIN

I55_CIN

VIDEO_IN_SEL

SDA

SAP_MUTEAFC_OUT

AR_TV

AL_TV

AL_REAL

AR_REAL

R349 0R

A5V

+

VGND

VIDEO_IN_SEL2

VIDEO_IN_SEL

R_Y

R_F_SBVC

R_C

C386

47uF/16V

LES_NI_OEDIV

C387

0.1uF

C389 1uF

C394 1uF

IC518

OUT

VCC

GND

BA7653AFV

1

2

3

4

5

6

7

8

CTLA

CTLB

2LES_NI_OEDIV

LES_NI_OEDIV

IC517

BA7607F

IN2A

CTLA

OUTA

GND

OUTB

OUTC

CTLC

IN2C

1

IN1

3

IN2

5

IN3

2

4

16

IN1A

15

GND

14

IN2B

13

VCC

12

CTLB

11

IN1B

10

GND

9

IN1C

LES NI OEDIV

S TNORF : H OEDIV

S LAER : L OEDIV

7

6

8

NICS

NIYS R_Y

NISBVC

VFV

+

VGND

C393

47uF/16V

I_OEDIV LES_NI_OEDIV TUPTUO 2LES_N

23OICPG LES_NI_OEDIV

OICPG 2LES_NI_OEDIV

A5V

C396

0.1uF

NI_OEDIV_VT L L

NI_TRACS L H

R_SBVC H L

F_SBVC H H

VGND

R377

75R 1%

R378

75R 1%

R379

75R 1%

R380

75R 1%

N.C

Fig. 5-5-8

Page 19

5-4-5. 1394 Circuit Diagram

GBADR[9:0]

GBDAT[15:0]

H_WRH_STROBELINK_CSGB_ACK#

LINK_IRQ

RESET-

+3.3V

FB11

FB10

+3.3V

+1.5V

GND

PHY_VCC

PHY_PLL_VCC

+3.3V

+1.5V

+3.3V

+1.5V

GND

RESET-

I55_RESET-

+1.5V

GBADR[9:0]

GBDAT[15:0]

H_WRH_STROBELINK_CSGB_ACK#

LINK_IRQ

R211 0R N.C.

R227 0R

0 : NO BYTE SWAP

+3.3V

R229

4.7K

RP23 4.7KX4

1

8

2

7

3456

RP24 4.7KX4

1

8

2

7

3456

RP22 4.7KX4

1

8

2

7

3456

DV_RESET-

CONFIGURE THE

MICROCONTROLLER

INTERFACE TO

68K-LIKE

+1.5V

PHY_VCC

PHY_PLL_VCC

IC505

D1D2D7C6A5F3J5L2K5M9P14

AVDD

AVDD

VDD_PLL

F5

PCI_AD31

G3

PCI_AD30

G1

PCI_AD29

H3

PCI_AD28

H1

PCI_AD27

H5

PCI_AD26

GBADR9

H2

PCI_AD25/MCIF_A11

GBADR8

J4

PCI_AD24/MCIF_A10

GBADR7

J1

PCI_AD23/MCIF_A9

GBADR5

K4

PCI_AD22/MCIF_A7

GBADR6

J2

PCI_AD21/MCIF_A8

GBADR3

PCI_AD20/MCIF_A5

GBADR4

K3

PCI_AD19/MCIF_A6

GBADR2

K2

PCI_AD18/MCIF_A4

GBADR1

L1

PCI_AD17/MCIF_A3

GBADR0

L3

GBDAT11

GBDAT12

GBDAT9

GBDAT10

GBDAT6

GBDAT7

R232

10K

PCI_AD16/MCIF_A2

P3

PCI_AD15/MCIF_D15

M5

PCI_AD14/MCIF_D14

P5

PCI_AD13/MCIF_D13

N6

PCI_AD12/MCIF_D11

P6

PCI_AD11/MCIF_D12

PCI_AD10/MCIF_D9

PCI_AD9/MCIF_D10

N7

PCI_AD8/MCIF_D8

P7

PCI_AD7/MICF_D6

L7

PCI_AD6/MICF_D7

M8

PCI_AD5/MICF_D5

K7

PIC_AD4/MICF_D4

P8

PIC_AD3/MICF_D3

L8

PCI_AD2/MICF_D2

N8

PCI_AD1/MICF_D1

K8

PIC_AD0/MICF_D0

M4

PCI_PAR/MICF_LITTLE_ENDIAN

H4

PCI_C/BE3#

M1

PCI_C/BE2#

L5

PCI_C/BE1#

K6

PCI_C/BE0#

M2

PCI_FRAME#/MCIF_REZ/MCIF_RW

N5

PCI_PERR#

M3

PCI_TRDY#/MCIF_WEZ/MCIF_STRBZ

N1

PCI_IRDY#

P2

PCI_STOP#/MCIF_CSZ

P1

PCI_DEVSEL#/MCIF_ACKZ

P4

PCI_SERR#

J3

PCI_IDSEL

F2

PCI_INTA#/MCIF_INTZ

F1

PCI_REQ#

G2

PCI_GNT#

F4

PCI_CLK

G4

PCI_RST#/RESET_HOSTZ

K9

TDI

L10

TDO

P9

TCK

N9

TRST#

L9

TMS

N10

RESETZ

C8

RESET_LINKZ

P10

GPIO0

L11

GPIO1/HDSI0_AV

M13

GPIO2

N14

GPIO3/HDSI1_AV

M14

GPIO4

B11

GPIO5/HDSI2_AV

A10

GPIO6

A11

GPIO7

E10

GPIO8

B9

GPIO9

C7

GPIO10

B10

EXDMA_REAZ_CH0

A13

EXDMA_ACKZ_CH0

D10

EXDMA_REQZ_CH1

C9

EXDMA_ACKZ_CH2

A14

MCIF_SEL1

E9

MCIF_SEL0

D9

TEST_MODE

VSS

VSS

VSS

VSS

VSS

P11

N4

G5

M7M6C10

L4

VSS

VSS

K13

F13

H14

GBDAT15

GBDAT14

GBDAT13

GBDAT8

GBDAT5

GBDAT4

GBDAT3

GBDAT2

GBDAT1

GBDAT0

H_WR-

GB_ACK#

+3.3V

+3.3V

H_STROBE-

LINK_CSGB_ACK#

LINK_IRQ

R224 4.7K R225

ISORDY

ISOVALRX

ISODIR

R219

4.7K

MCIF_SEL1

MCIF_SEL0

R223

4.7K

+3.3V

K11

C14B8E3E4N2N3M12

AVDD

AVDD

VDD_IO

VDD_IO

VDD_IO

VDD_IO

VDD_IO

VDD_IO

VDD_IO

VDD_IO

VDD_IO

ZR35162-BGCG

PRELIMINARY-V1.97

SLLS560-Jan-2004

VSS_PLL

VSS

VSS

B12

TB1

AVSS

AVSS

AVSS

VSS

TB2

AVSS

B2

J7

D6K1D4

J8

B5

C1

J9

1.5V

1.5V

1.5V

1.5V

TB6

TB3

TB5

TB4

H8

H9

J6

N13

C13

C12G8

1.5V

1.5V

1.5V

1.5VTB10

HSDIO_SYNC

HSDIO_DVALID/HSDIO_EN

HSDIO_ERROR

HSDI1_DVALID/HSDI1_EN

HSDI1_ERROR

HSDI2_SYNCz

HSDI2_DVALIDz

HSDI2_ERRORz

AUDIO_MUTE

PHY_TEST_MODE

TB11

TB12

TB13

TB14

TB8

TB7

TB9

H6

H7L6G9

G7G6F9F8F7F6E5

HSDIO_CLK

DSSCLK27

HADIO_D0

HADIO_D1

HADIO_D2

HADIO_D3

HSDIO_D4

HSDIO_D5

HSDIO_D6

HSDIO_D7

HSDI1_CLKZ

HSDI1_SYNC

HSDI1_D0

HSDI1_D1

HSDI1_D2

HSDI1_D3

HSDI1_D4

HSDI1_D5

HSDI1_D6

HSDI1_D7

HSDI2_CLK

HSDI2_D0

60958_IN

60958_OUT

DAC_MCK

DAC_BCK

DAC_LRCK

DAC_DATA

AUDIO_ERR

VCO_CLK

REF_SYT

DIV_VCO

TPBIAS0

TPA0P

TPA0N

TPB0P

TPB0N

TPBIAS1

TPA1P

TPA1N

TPB1P

TPB1N

WAKEUP

BIASDIS

PHYHCLK

PHY8CLK

TB15

TB16

TB17

G13

G10

G11

G14

M10

D14

E13

E14

E12

E11

F10

F12

F11

L12

K12

L14

L13

H12

H13

H11

J10

J14

J13

J12

K14

M11

N11

P13

N12

P12

G12

H10

B13

D12

D11

D13

A12

B14

F14

K10

J11

D5

B6

A6

E6

E7

A3

B3

C4

B4

C5

A1

R1

B1

R0

C2

NC1

D3

NC2

E1

XI

E2

XO

B7

CPS

A7

CNA

E8

D8

C11

A8

A9

A2

NC3

A4

NC4

C3

NC5

ZR35162-BGCG

ERROR

ISOD0

ISOD1

ISOD2

ISOD3

ISOD4

ISOD5

ISOD6

ISOD7

8

7

R218 6K34 1%

1

1

R217 1K

1

1

R214 10K

R215 10K

R213 10K

R212 10K