FormNo.3435-596RevA

GrandStand

®

MultiForceMower

With52inor60inTURBOFORCE

Unit

ModelNo.72523—SerialNo.400000000andUp

ModelNo.72529—SerialNo.400000000andUp

®

Cutting

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3435-596*A

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

Pleaserefertotheenginemanufacturer’sinformation

includedwiththemachine.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g235457

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Introduction

Thisrotary-blade,stand-onlawnmowerisintended

tobeusedbyprofessional,hiredoperators.Itis

designedprimarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.Using

thisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comformoreinformation,including

safetytips,trainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contactusatwww.Toro.com.

2

g000502

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

ProductOverview.....................................................9

Controls.............................................................9

Specications...................................................11

Attachments/Accessories..................................11

BeforeOperation..................................................11

BeforeOperationSafety....................................11

AddingFuel......................................................12

PerformingDailyMaintenance..........................13

BreakinginaNewMachine..............................13

UsingtheSafety-InterlockSystem....................13

DuringOperation.................................................14

DuringOperationSafety...................................14

OperatingtheParkingBrake.............................15

OperatingthePower-T akeoff(PTO)

Switch...........................................................15

OperatingtheThrottle.......................................16

OperatingtheIgnitionSwitch............................16

StartingtheEngine...........................................17

ShuttingOfftheEngine.....................................17

OperatingthePlatform......................................18

DrivingForwardorBackward............................18

SideDischargingorMulchingthe

Grass............................................................20

AdjustingtheHeight-of-Cut...............................20

AdjustingtheAnti-ScalpRollers........................21

AdjustingtheFlowBafe..................................21

PositioningtheFlowBafe................................21

UsingWeights..................................................22

AfterOperation....................................................22

AfterOperationSafety......................................22

PreventingFreeze-upafterUse........................23

UsingtheFuel-ShutoffValve.............................23

PushingtheMachinebyHand..........................23

TransportingtheMachine.................................24

Maintenance...........................................................26

MaintenanceSafety..........................................26

RecommendedMaintenanceSchedule(s)...........26

Pre-MaintenanceProcedures..............................27

ReleasingtheCushionforRearAccess............27

Lubrication..........................................................28

GreasingtheMachine.......................................28

GreasingtheAccessoryFrame.........................28

GreasingtheT orsionIdler.................................28

GreasingtheFrontCasterPivots......................28

GreasingtheCaster-WheelHubs.....................29

GreasingtheEngineVoltageRegulator............29

GreasingtheBrakeCalipers.............................30

GreasingtheMotionControls...........................30

EngineMaintenance...........................................31

EngineSafety...................................................31

ServicingtheAirCleaner..................................31

ServicingtheEngineOil....................................32

ServicingtheSparkPlug...................................36

CheckingtheSparkArrester.............................37

FuelSystemMaintenance...................................37

DrainingtheFuelT ank......................................37

RemovingtheFuelT ank...................................38

ReplacingtheFuelFilter...................................38

ElectricalSystemMaintenance...........................39

ElectricalSystemSafety...................................39

ServicingtheBattery.........................................39

ServicingtheFuses..........................................41

DriveSystemMaintenance..................................41

AdjustingtheTracking......................................41

CheckingtheTirePressure...............................42

AdjustingtheCaster-PivotBearing...................42

ServicingtheCasterWheelsand

Bearings........................................................43

RemovingtheClutchShim...............................43

CheckingtheWheel-LugNuts..........................45

CoolingSystemMaintenance..............................45

CleaningtheAir-IntakeScreen.........................45

CleaningtheCoolingSystem............................45

BrakeMaintenance.............................................46

TestingtheParkingBrake.................................46

AdjustingtheBrakes.........................................46

BeltMaintenance................................................46

CheckingtheBelts............................................46

ReplacingtheMower-DeckBelt........................46

ReplacingtheTransmissionBelt......................47

ControlsSystemMaintenance.............................48

AdjustingtheMotion-ControlLevers.................48

HydraulicSystemMaintenance...........................49

HydraulicSystemSafety...................................49

HydraulicSystemSpecications.......................49

CheckingtheHydraulicFluid............................49

ReplacingtheHydraulicFluidand

Filters............................................................50

BleedingtheHydraulicSystem.........................51

MowerDeckMaintenance....................................51

BladeSafety.....................................................51

ServicingtheCuttingBlades.............................51

RemovingtheMowerDeck...............................53

InstallingtheMowerDeck.................................55

LevelingtheMowerDeck..................................55

AdjustingtheDeck-LiftSpring...........................57

ReplacingtheGrassDeector..........................58

Cleaning..............................................................58

CleaningundertheMowerDeck.......................58

DisposingofWaste...........................................58

Storage...................................................................59

StorageSafety..................................................59

CleaningandStorage.......................................59

Troubleshooting......................................................60

Schematics.............................................................62

3

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.4-2017.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepclearofthedischargeopening.

SafetyandInstructionalDecals

•Keepbystandersandchildrenoutoftheoperating

area.Donotallowchildrentooperatethemachine.

Allowonlypeoplewhoareresponsible,trained,

familiarwiththeinstructions,andphysically

capabletooperatethemachine.

•Stopthemachine,shutofftheengine,andremove

theignitionkeybeforeservicing,fueling,or

uncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

,which

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard6.Keepbystandersaway

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

fromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

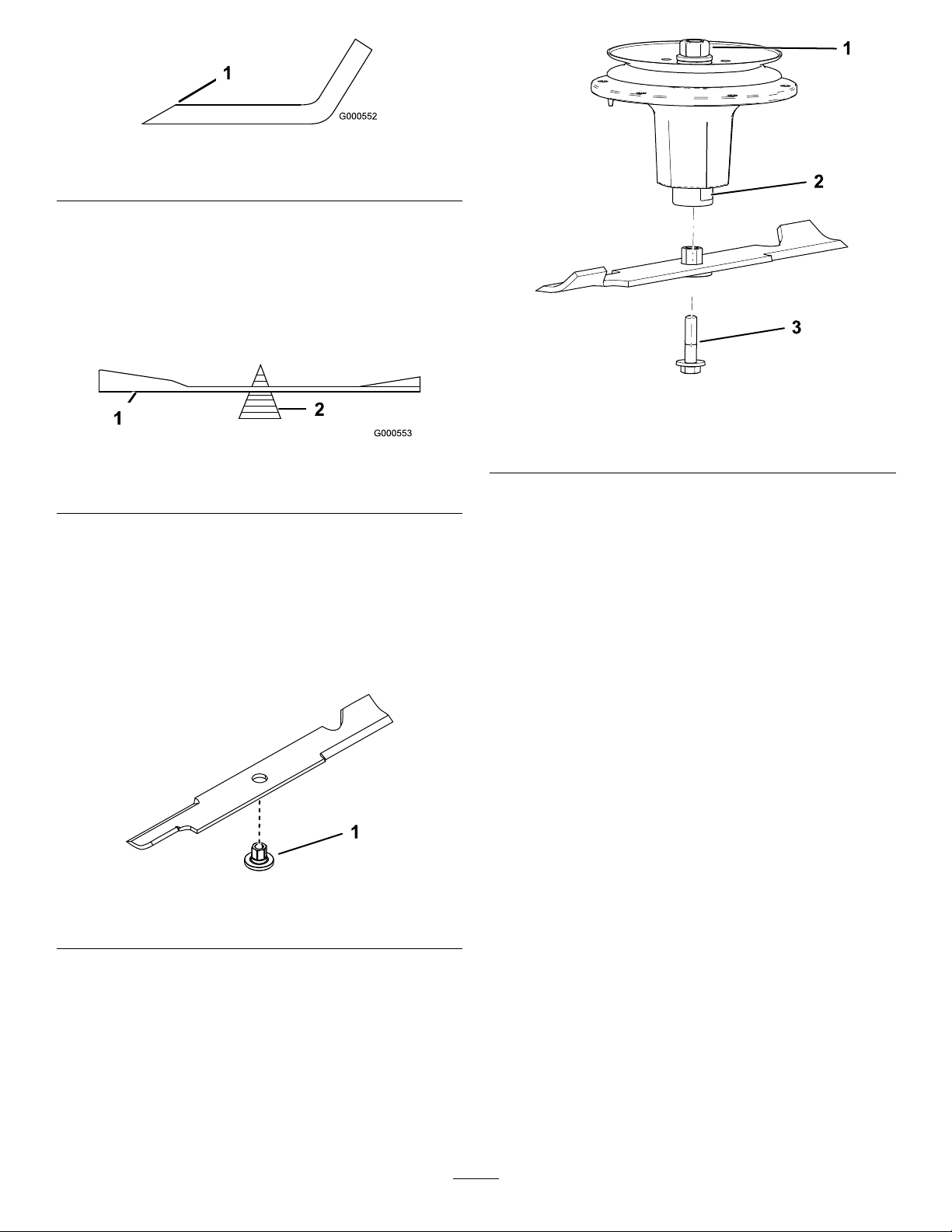

decaloemmarkt

Manufacturer'sMark

1.Thismarkindicatesthatthebladeisidentiedasapart

fromtheoriginalmachinemanufacturer.

decalbatterysymbols

decal106-5517

106-5517

1.Warning—donottouchthehotsurface.

4

Decal112-3858isfor60inmachinesonly.

112-3858

decal112-3858

1.ReadtheOperator's

Manual.

2.ReadtheOperator's

3.Removethekeybefore

adjustingtheheightofcut.

4.Height-of-cutsettings

Manualbeforeperforming

maintenance.

116-8283

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto75to81N∙m(55to60ft-lb).

decal131-1180

131-1180

1.ReadtheOperator's

Manual.

2.Short,lightgrass;dry

conditions

decal116-8283

3.Baggingsetting

4.Tall,densegrass;wet

conditions

1.ReadtheOperator’s

Manual.

116-8775

2.Warning—lltothebottom

ofthellerneck;donot

overllthetank.

decal131-3507

decal116-8775

1.ReadtheOperator's

131-3507

2.Belttensioner

Manual.

5

decal131-3521

131-3528

15A 15A 10A

7.5A

131-3521

1.Heightofcut

1.ReadtheOperator's

Manual.

2.Transmissionuid

131-3524

3.Colduidlevel

decal131-3536

131-3536

1.Battery4.Parkingbrake

2.Time5.Engine—start

3.Powertakeoff(PTO)

6.Engagethehandlebars.

decal133-4604

133-4604

1.Thrownobject

hazard—keepbystanders

decal131-3524

awayfromthemachine.

2.Thrownobjecthazard,

openbafe—onlyoperate

themachinewithabafe

oragrasscollector.

3.Severinghazardofhand

orfoot—keepawayfrom

movingparts.

4.Entanglement

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

1.Keyswitch—15A

2.Accessoryport—15A

131-3528

decal131-3528

3.Powertakeoff(PTO)—10

A

4.Infocenter—7.5A

6

133-4648

1.ReadtheOperator'sManualformoreinformationon

servicingthemachine.

decal133-8062

133-8062

decal133-4648

decal131-3526

131-3526

1.Powertakeoff(PTO)—disengaged

2.Fast6.Tractiondrive

3.Slow

4.Neutral

5.Reverse

7.Engagethehandles.

decal139-2878

139-2878

1.Warning—readtheOperator’sManual.

2.Warning—alloperatorsshouldbetrainedbeforeoperating

themachine.

3.Warning—wearhearingprotection.8.Tippinghazard—donotusedualrampswhenloadingontoa

4.Thrownobjecthazard—lowerthedeectorbeforeoperating

themachine.

5.Cutting/dismembermenthazardofhandorfoot—stayaway

frommovingparts;keepallguardsandshieldsinplace.

6.Thrownobjecthazard—keepbystandersaway .

7.Warning—engagetheparkingbrake,shutofftheengine,and

removethekeybeforeleavingthemachineorperforming

maintenance.

trailer;use1rampwideenoughforthemachine;backup

therampwhenloadingthemachineanddriveforwardoffthe

rampwhenunloading.

9.Tippinghazard—donotusethemachineneardrop-offsor

onslopes;stayatleast2widthsofthemachineawayfrom

drop-offs.

7

140-4260

1.Parkingbrake—disengaged5.Fast

2.Parkingbrake—engaged6.Enginespeed

3.On7.Slow

4.Off

decal140-4260

8

ProductOverview

Figure3

1.Adjustablecaster9.Motion-controllevers

2.Accessory-framelock

3.Anti-scalproller(60-inch

decksonly)

4.Frontcasterwheel

5.Side-dischargechute13.Fuel-shutoffvalve

6.Accessoryframe

7.Engine15.Mowerdeck

8.Controlpanel

10.Hydraulictank

11.Fueltank

12.Platform(downposition)

14.Battery

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure4).

ControlPanel

g306613

g301785

Figure4

1.Fuelcap7.Keyswitch

2.Malfunction-indicatorlight

(MIL)

3.Parking-brakelever

4.Hydraulic-tankcap

5.Hourmeter11.Motion-controllever

6.Power-takeoffswitch

(PTO)

8.Throttlecontrol

9.Height-of-cutlever

10.Height-of-cutpin

12.Referencebar

Electronic-ControlUnit

Malfunction-IndicatorLight

Theelectronic-controlunit(ECU)continuously

monitorstheoperationoftheEFIsystem.

Ifaproblemorfaultwithinthesystemisdetected,the

malfunction-indicatorlight(MIL)isilluminated(Figure

4).

TheMIListheredlightlocatedintheconsolepanel.

WhentheMILilluminates,makeinitialtroubleshooting

checks;refertoTroubleshooting(page60).

Ifthesechecksdonotcorrecttheproblem,further

diagnosisandservicingbyanAuthorizedService

Dealerisnecessary.

Power-TakeoffSwitch(PTO)

Usethepower-takeoffswitch(PTO)toengageand

disengagemowerbladesorstartandstoppowered

attachments(Figure4);refertoOperatingthe

Power-Takeoff(PTO)Switch(page15).

9

HourMeter

Fuel-ShutoffValve

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure5).

Figure5

1.Safety-interlocksymbols

2.Batterylight

3.Hourmeter

Safety-InterlockIndicators

Symbolsonthehourmeterindicatewithablack

trianglethattheinterlockcomponentisinthecorrect

position(Figure5).

Closethefuel-shutoffvalvewhentransportingor

storingthemachine;refertoUsingtheFuel-Shutoff

Valve(page23).

AccessoryFrame

UsetheaccessoryframetoattachonlyToro-approved

accessoriestothemachine(Figure3).Refertothe

Operator’sManualfortheaccessoryforinstallation

instructions.

Accessory-FrameLock

Theaccessory-framelockholdstheframeinplaceon

g216020

themachineusingthelockpin.Alwayslocktheframe

unlessahydraulickitisinstalledwithanaccessory

onthemachine(Figure3).

AdjustableCasters

Whenusingthemachinewithoutanaccessory,place

theadjustablecastersinthemowingposition(front

hole)asshowninFigure6.Whenusingthemachine

withanaccessory,refertotheOperator’sManualfor

thataccessoryforthecorrectcasterposition.

Battery-IndicatorLight

IfyouturnthekeytotheONpositionforafew

seconds,thebatteryvoltagedisplaysinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhenyouturnthekeytothe

ONpositionandwhenthechargeisbelowthecorrect

operatinglevel(Figure5).

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure4).

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andSTART.Referto

OperatingtheIgnitionSwitch(page16).

Motion-ControlLevers

g033081

Figure6

RightCasterShown

1.Mowingposition2.Accessorypositions

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection(Figure4).

10

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

52inMowerDeck60inMowerDeck

Cuttingwidth131cm(52inches)152cm(60inches)

Widthwith

deectordown

Widthwith

deectorraised

Lengthwith

platformdown

Lengthwith

platformup

Height

Weight

173cm(68inches)193cm(76inches)

137cm(54inches)157cm(62inches)

191cm(75inches)201cm(79inches)

155cm(61inches)165cm(65inches)

122cm(48inches)122cm(48inches)

405kg(893lb)420kg(926lb)

Operation

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopletooperate

themachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefor

trainingalloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

•Checkthatoperator-presencecontrols,safety

switches,andguardsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

FuelSafety

•Fuelisextremelyammableandhighlyexplosive.

Areorexplosionfromfuelcanburnyouand

othersandcandamageproperty.

–Topreventastaticchargefromignitingthefuel,

placethecontainerand/ormachinedirectlyon

thegroundbeforelling,notinavehicleoron

anobject.

–Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuelthat

spills.

–Donothandlefuelwhensmokingoraroundan

openameorsparks.

–Donotremovethefuelcaporaddfueltothe

tankwhiletheengineisrunningorhot.

–Ifyouspillfuel,donotattempttostartthe

engine.Avoidcreatingasourceofignitionuntil

thefuelvaporshavedissipated.

11

–Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.

•Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

–Avoidprolongedbreathingofvapors.

–Keepyourhandsandfaceawayfromthe

nozzleandthefuel-tankopening.

–Keepfuelawayfromyoureyesandskin.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromyourvehicle

beforelling.

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

UsingStabilizer/Conditioner

Usefuelstabilizer/conditionerinthemachinetokeep

thefuelfreshlongerwhenusedasdirectedbythe

fuel-stabilizermanufacturer.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addtheamountoffuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizermanufacturer.

FillingtheFuelTank

1.Parkthemachineonalevelsurface,disengage

thePTO,movethemotion-controlleverstothe

NEUTRAL-LOCKposition,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanaroundthefuel-tankcapandremovethe

cap.

4.Fillthefueltanktothebottomofthellerneck.

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

5.Installthefuel-tankcapsecurely.Wipeupany

spilledfuel.

AddingFuel

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

g038312

Figure7

12

PerformingDaily

Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page26).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

UsingtheSafety-Interlock

System

WARNING

Ifsafety-interlockswitchesaredisconnected

ordamaged,themachinecouldoperate

unexpectedly,causingpersonalinjury .

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdaily,andreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtoprevent

PTOfromengagingunlessyoudo1ofthefollowing:

•Moveeithermotion-controllevertothecenter,

unlockedposition.

•PresstheONpositiononthePTOswitch.

Thesafety-interlocksystemisdesignedtostop

theblades/attachmentifyoumoveorrelease

bothmotion-controlleversintotheNEUTRAL-LOCK

position.

Thehourmeterhassymbolstonotifytheuser

wheneachinterlockcomponentisinthecorrect

position.Whenthecomponentisinthecorrect

position,atrianglelightsupinthecorresponding

square(Figure8).

g031282

Figure8

1.Thetriangleslightupwhentheinterlockcomponentsare

inthecorrectposition.

TestingtheSafety-Interlock

System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.

Note:Ifthesafetysystemdoesnotoperateas

describedbelow,haveanAuthorizedServiceDealer

repairthesafetysystemimmediately.

1.Starttheengine;refertoStartingtheEngine

(page17).

2.Movethemotion-controlleverstothecenter,

unlockedposition.

Note:Theblades/attachmentshouldstopand

theengineshouldstoprunning.

3.Starttheengineanddisengagetheparking

brake.

4.Moveeithermotion-controllevertothecenter,

unlockedposition.

5.Continueholdingthemotion-controlleverin

thecenter,unlockedpositionandpresstheON

positiononthePTOswitch.

Note:Theclutchandblades/attachmentshould

engage.

6.Moveorreleasethemotion-controlleversinto

theNEUTRAL-LOCKposition.

Note:Theblades/attachmentshouldstopand

theengineshouldcontinuetorun.

7.PresstheOFFpositiononthePTOswitchand

moveeithermotion-controllevertothecenter,

unlockedposition.

8.Continueholdingthemotion-controlleverin

thecenter,unlockedpositionandpresstheON

positiononthePTOswitch.

13

Note:Theclutchandblades/attachmentshould

engage.

9.PresstheOFFpositiononthePTOswitch.

Note:Theblades/attachmentshouldstop.

10.Withtheenginerunning,presstheONposition

onthePTOswitchwithoutholdingeither

motion-controllevertothecenter,unlocked

position.

Note:Theblades/attachmentshouldnot

engage.

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

•Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblade.Avoidmowingin

wetconditions.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Ensurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.

•Keepyourhandsandfeetawayfromthecutting

units.Keepclearofthedischargeopeningatall

times.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Useextremecarewhenapproachingblind

corners,shrubs,trees,orotherobjectsthatmay

blockyourview.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachine,removetheignitionkey,and

waitforallmovingpartstostopbeforeinspecting

themowerdeckorattachmentafterstrikingan

objectorifthereisanabnormalvibrationinthe

machine.Makeallnecessaryrepairsbefore

resumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Disengagethecuttingunitandshutofftheengine

beforeadjustingtheheightofcut(unlessyoucan

adjustitfromtheoperatingposition).

•Operatetheengineonlyinwell-ventilatedareas.

Exhaustgasescontaincarbonmonoxide,which

islethalifinhaled.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition(including

toemptythecatchersortounclogthechute),do

thefollowing:

–Parkthemachineonalevelsurface.

–Disengagethepowertake-off.

–Engagetheparkingbrake.

–Shutofftheengineandremovetheignitionkey.

–Waitforallmovingpartstostop.

•Shutoffthemachineanddisengagethedriveto

thecuttingunitinthefollowingsituations:

–Beforefueling

–Beforeclearingblockages

–Beforechecking,cleaning,ormaintainingthe

cuttingunit

–Afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthecuttingunitfor

damageandmakerepairsbeforestartingand

operatingthemachine

–Beforeleavingtheoperatingposition

•Donotusethemachineasatowingvehicle.

•Useonlyaccessoriesandattachmentsapproved

byTheT oro®Company.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Youareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.Beforeusingthemachine

onaslope,dothefollowing:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

14

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Operateacrossslopes,neverupanddown.Avoid

operationonexcessivelysteeporwetslopes.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,water,orotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalk-behind

machineorahandheldtooltooperateinthese

areas.

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopesordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocks,orotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

g009465

Figure9

1.Parkingbrake—engaged2.Parking

brake—disengaged

Operatingthe

Power-Takeoff(PTO)

Switch

Usethepower-takeoff(PTO)switchinconjunctionwith

themotion-controlleverstoengageanddisengage

themowerbladesorpowerattachments.

EngagingthePower-Takeoff(PTO)

Switch

•Useextracarewhileoperatingwithaccessoriesor

attachments.Thesecanchangethestabilityof

themachineandcausealossofcontrol.Follow

directionsforcounterweights.

•Ifyoulosecontrolofthemachine,stepoffand

awayfromthedirectionoftravelofthemachine.

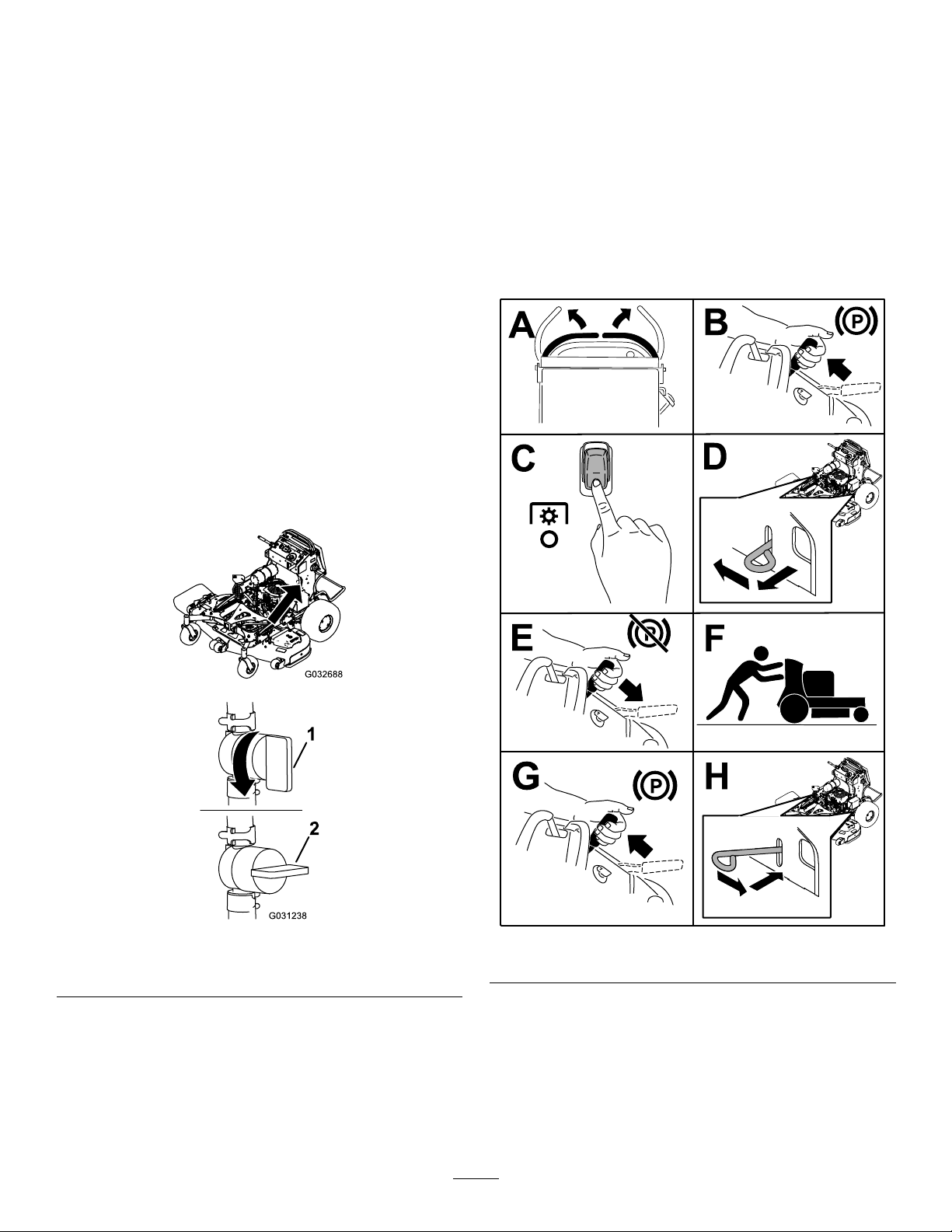

OperatingtheParking

Brake

Alwaysengagetheparkingbrakewhenyoushutoff

themachineorleaveitunattended.Beforeeachuse,

checktheparkingbrakeforproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit;

refertoAdjustingtheBrakes(page46).

Pulltheparking-brakeleverrearwardtoengageit

(Figure9).

Pushtheparking-brakeleverforwardtodisengageit.

g301277

Figure10

15

DisengagingthePower-Takeoff

(PTO)Switch

Figure11andFigure12show2waystodisengage

thePTO.

Figure11

Figure12

OperatingtheThrottle

YoucanmovethethrottlecontrolbetweenFASTand

SLOWpositions(Figure13).

AlwaysusetheFASTpositionwhenengagingthePTO.

g008946

Figure13

g301401

OperatingtheIgnition

Switch

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failure

g031593

tofollowtheseinstructionscanburnoutthe

startermotor.

Note:IfyoudisengagethePTObyreleasingthe

motion-controllevers,youcanengagethePTOagain

bypressingtheONpositionoftheswitchwithout

pressingtheOFFpositionrst.

Note:Y oumayneedtorepeatthecycleforstarting

theenginewhenyoustartitforthersttimeafteryou

havelledacompletelyemptyfuelsystemwithfuel.

g031239

Figure14

g031281

Figure15

16

StartingtheEngine

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failure

tofollowtheseinstructionscanburnoutthe

startermotor.

Note:Y oumayneedtorepeatthecycleforstarting

theenginewhenyoustartitforthersttimeafteryou

havelledacompletelyemptyfuelsystemwithfuel.

Note:Themachinemayhavedifcultystartingunder

severecoldconditions.Whenstartingacoldmachine,

keepthemachineabove-23°C(-10°F).

ShuttingOfftheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

Lettheengineidleatslowthrottle(turtle)for60

secondsbeforeturningthekeyswitchtotheOFF

position.

Important:Startingandshuttingofftheengine

frequentlyincoldconditionscandamagethe

engine.Allowthemachinetoreachnormal

operatingtemperaturebeforeshuttingoffthe

engine.

Figure16

g306776

g301288

Figure17

Important:Makesurethatthefuel-shutoffvalve

isclosedbeforetransportingorstoringthe

machinetopreventafuelleak.Beforestoringthe

machine,disconnectthesparkplug(s)toprevent

thepossibilityofaccidentalstarting.

17

OperatingthePlatform

Youcanusethemachinewiththeplatforminthe

upordownposition.Itisyourpreferenceonwhich

positiontouse.

WARNING

Theoperatorplatformisheavyandmaycause

injurywhenyouraiseorlowerit.Carefully

lowerorraisetheoperatorplatform,as

suddenlydroppingitcouldinjureyou.

•Donotputyourhandsorngersinthe

platform-pivotareawhenloweringor

raisingtheoperatorplatform.

•Makesurethattheplatformissupported

whenyoupullthelatchpinout.

•Makesurethatthelatchsecuresthe

platformwhenfoldingitup.Pushittight

againstthecushionforthelatchpinto

lockintoplace.

•Keepbystandersawayfromthemachine

whenraisingorloweringtheplatform.

1.Platformup

2.Platformdown

g031026

Figure18

3.Pulltheknobouttorelease

theplatform.

OperatingtheMachinewiththe

PlatformUp

Operatethemachinewiththeplatformupforthe

followingconditions:

•Usingthemachineneardrop-offs

•Usingthemachineinsmallareaswherethe

machineistoolarge

•Areaswithlow-hangingbranchesorobstacles

•Loadingthemachinefortransport

•Drivingupslopes

Toraisetheplatform,pullthebackoftheplatformup

sothatthelatchpinandknoblockitintoplace.Push

ittightagainstthecushionforthelatchpintolockit

intoplace.

OperatingtheMachinewiththe

PlatformDown

Operatethemachinewiththeplatformdownforthe

followingconditions:

•Usingthemachineinmostareas

•Drivingacrossslopes

•Drivingdownslopes

DrivingForwardor

Backward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.

Important:Backthemachineovercurbs,1wheel

atatime;drivingitforwardovercurbscould

damagethemachine.

CAUTION

Themachinecanspinveryrapidly,andyou

maylosecontrolofthemachine,causing

personalinjurytoyouanddamagetothe

machine.

Slowdownthemachinebeforemakingsharp

turns.

Tolowertheplatform,pushtheplatformforward

againstthecushiontoreleasepressureonthelatch

pin,thenpulltheknoboutandlowertheplatform

(Figure18).

18

DrivingForward

1.Disengagetheparkingbrake;refertoOperating

theParkingBrake(page15).

2.Movethemotion-controlleverstothecenter,

unlockedposition.

g009473

Figure20

Figure19

1.Frontreferencebar

2.Leftcontrollever

3.Rearreferencebar6.Leftcontrolleverinthe

4.Rightcontrollever

5.Rightcontrolleverinthe

NEUTRAL-LOCKposition

NEUTRAL-LOCKposition

3.Slowlypushthemotion-controlleversforward

(Figure20).

Note:Theengineshutsoffifyoumovea

motion-controlleverwhiletheparkingbrakeis

engaged.

Note:Thefartheryoumovethemotion-control

leversineitherdirection,thefasterthemachine

movesinthatdirection.

Note:T ostop,pullthemotion-controllevers

backtotheNEUTRALposition.

g030983

DrivingBackward

1.Movebothmotion-controlleverstothecenter,

unlockedposition.

2.Slowlypullthemotion-controlleversrearward

(Figure21).

g009474

Figure21

19

SideDischargingor

AdjustingtheHeight-of-Cut

MulchingtheGrass

Thismachinehasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutthegrassdeector,dischargecover,

orcompletegrasscatcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

causeinjuryordeath.

•Donotremovethegrassdeectorfrom

themachine,becausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

machine.

•Nevertrytoclearthedischargeareaor

mowerbladesunlessyoureleasethebail

andthepowertakeoff(PTO)isoff.Rotate

thekeytotheOFFposition.Alsoremove

thekeyanddisconnectthewire(s)from

thesparkplug(s).

Theheight-of-cutcanbeadjustedfrom38to127mm

(1-1/2to5inches)in6mm(1/4inch)increments.

Note:Usingaheight-of-cutunder51mm(2inches)

increasesthewearonthemower-deckbelt.Usea

height-of-cutthatisgreaterthan51mm(2inches)

wheneverpossible.

g267253

Figure22

20

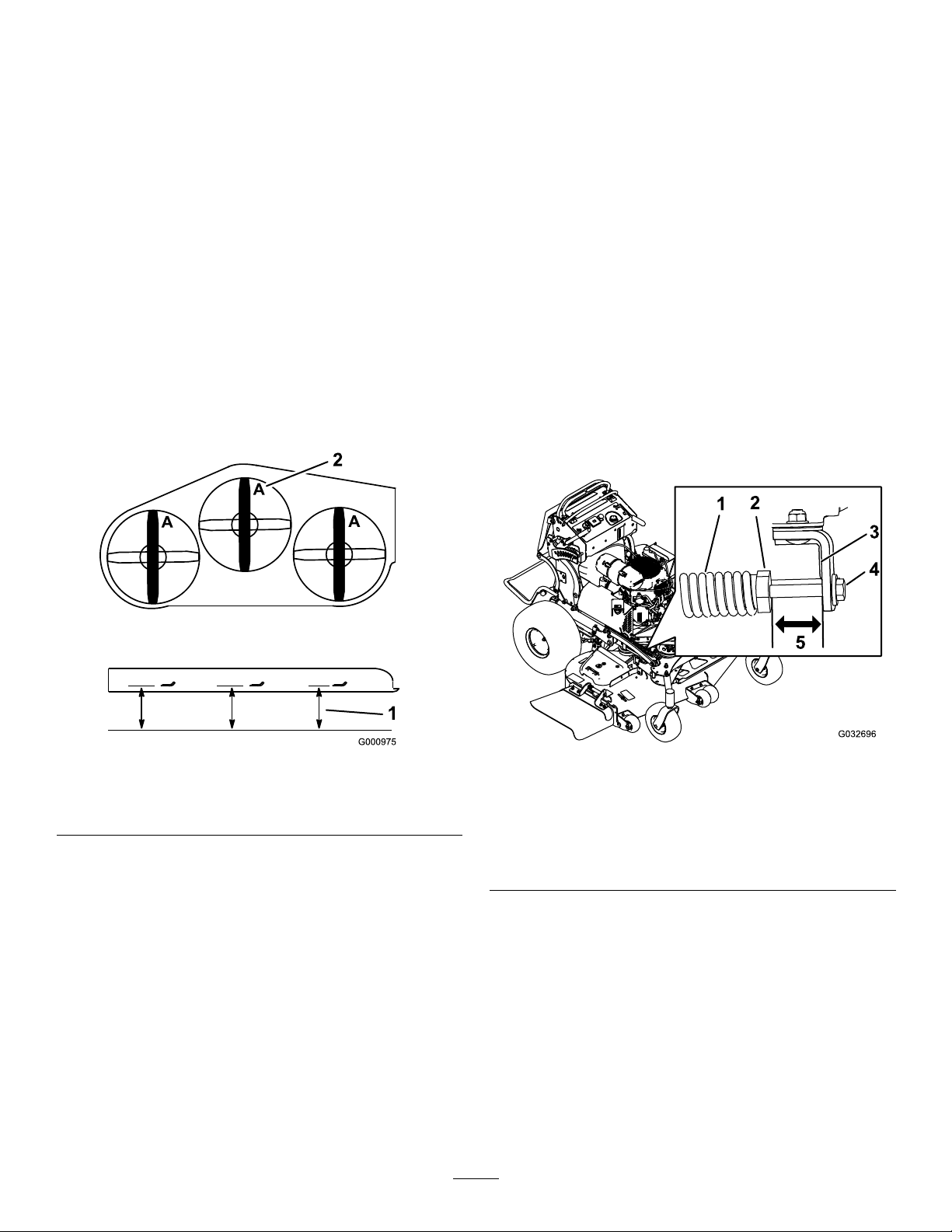

AdjustingtheAnti-Scalp

Rollers

Modelswitha60-InchDeckOnly

Wheneveryouchangetheheight-of-cut,adjustthe

heightoftheanti-scalprollers.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethenutandboltpositiontheanti-scalp

rollersandinstallthenutandbolt.

4.Ensurethatthespacersandbushingsare

installed(Figure23).

Figure24

1.Slot

2.Knob

PositioningtheFlowBafe

Thefollowingguresareforrecommendeduseonly.

Adjustmentsvarybygrasstype,moisturecontent,

andtheheightofthegrass.

g301806

Figure23

1.Bushing4.Bolt

2.Anti-scalproller5.Nut

3.Spacer

AdjustingtheFlowBafe

Youcanadjustthemower-dischargeowfordifferent

typesofmowingconditions.Positionthecamlock

andbafetoprovidethebestqualityofcut.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Toadjustthebafe,loosentheknob(Figure24).

4.Adjustthebafeandknobintheslottothe

desireddischargeowandtightentheknob.

Note:Iftheenginepowerdrawsdownandthe

mowergroundspeedisthesame,openthebafe.

PositionA

Thisisthefull,rearposition(seeFigure25).Usethis

positionforthefollowing:

•Inshort,lightgrassmowingconditions

g018324

•Indryconditions

•Smallergrassclippings

•Propelsgrassclippingsfartherawayfromthe

mower

g012677

Figure25

21

PositionB

UsingWeights

Usethispositionwhenbagging(Figure26).

Figure26

PositionC

Thisisthefull,openposition(Figure27).Usethis

positionforthefollowing:

•Installweightstoimprovebalance.Youcanaddor

removeweightstocreateoptimizedperformance

underdifferentoperatingconditionsandforyour

preference.

•Addorremoveweights1atatimeuntilyou

achievethedesiredhandlingandbalance.

•RefertotheOperator’sManualofattachmentsfor

recommendedweights.

Note:ContactanAuthorizedServiceDealertoorder

aweightkit.

WARNING

Excessiveweightchangescanaffectthe

handlingandoperationofthemachine.

g012678

Thiscouldcauseseriousinjurytoyouor

bystanders.

•Makeweightchangesinsmallincrements

only.

•Evaluatethemachineaftereachweight

changetoensurethatyoucanoperatethe

machinesafely.

•Intall,densegrassmowingconditions

•Inwetconditions

•Lowerstheengine-powerconsumption

•Allowsincreasedgroundspeedinheavyconditions

Figure27

AfterOperation

AfterOperationSafety

GeneralSafety

•Alwaysshutoffthemachine,removetheignition

key,waitforallmovingpartstostop,andallow

themachinetocoolbeforeadjusting,servicing,

cleaning,orstoringit.

•Cleangrassanddebrisfromthecuttingunits,

mufers,andenginecompartmenttohelpprevent

res.Cleanupoilorfuelspills.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•DisengagethePTOwheneveryouaretransporting

ornotusingthemachine.

g012679

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Usefull-widthrampsforloadingthemachineinto

atrailerortruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

22

PreventingFreeze-upafter

PushingtheMachineby

Use

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.

Ifyouhavedifcultyoperatinganycontrolorpart,

starttheengineandletitrunforafewminutes.

Thawfrozenpartsbeforeoperatingthemachine.

•Afterusingthemachine,lettheenginerunfora

fewminutestopreventmovingpartsfromfreezing.

Shutofftheengine,waitforallmovingparts

tostop,andremovealliceandsnowfromthe

machine.

UsingtheFuel-Shutoff

Valve

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage(Figure28).

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

Hand

Thebypassvalvesallowyoutopushthemachineby

handwithouttheenginerunning.

Important:Alwayspushthemachinebyhand.

Donottowthemachine,becausehydraulic

damagemayoccur.

Important:Donotstartoroperatethemachine

withthebypassvalvesopen.Damagetosystem

mayoccur.

Figure28

1.ONposition2.OFFposition

g032688

g031238

Figure29

g306777

23

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Useafull-widthramp.Ensurethatthetrailer

ortruckhasallthenecessarybrakes,lighting,and

markingasrequiredbylaw.Pleasecarefullyreadall

thesafetyinstructions.Knowingthisinformationcould

helpyouorbystandersavoidinjury.Refertoyour

localordinancesfortrailerandtie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

SelectingaTrailer

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure30).

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Ensurethatthelengthoframpisatleast4

timesaslongastheheightofthetraileror

truckbedtotheground.

Figure30

1.Full-widthrampinstowed

position

2.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

3.H=heightofthetraileror

truckbedtotheground

4.Trailer

LoadingtheMachine

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Backthemachineuptherampandwalkit

forwarddowntheramp.

g229507

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakesand

lights.

3.Lowertheramp(Figure30).

4.Raisetheplatform.

Important:Alwayskeeptheplatformup

whenloadingandunloadingthemachine.

5.Backthemachineuptheramp(Figure31).

24

Figure31

g031405

1.Backthemachineupthe

ramp.

2.Walkthemachinedown

theramp.

6.Shutofftheengine,removethekey,andengage

theparkingbrake.

7.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumperwithstraps,chains,

cable,orropes(Figure32).Refertolocal

regulationsfortie-downrequirements.

Figure32

1.Tie-downloops

g032703

25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthespark-plugwiresfromthesparkplugs

beforeyoudoanymaintenance.Setthewiresasidesothattheydonotaccidentallycontact

thesparkplugs.

MaintenanceSafety

•Beforeadjusting,cleaning,servicing,orleaving

themachine,dothefollowing:

–Parkthemachineonalevelsurface.

–Disengagethedrives.

–Engagetheparkingbrake.

–Shutofftheengineandremovetheignitionkey.

–Waitforallmovingpartstostop.

–Allowmachinecomponentstocoolbefore

performingmaintenance.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Checktheparkingbrakeoperationfrequently.

Adjustandservicethebrakeasneeded.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufer,andenginetohelppreventres.

Cleanupoilorfuelspills.

•Checkthegrasscatchercomponentsfrequently

andreplacethemwhentheyarewornordamaged.

•Donotrelyonahydraulicsystemtosupportthe

machine;supportthemachinewithjackstands

wheneveryouraisethemachine.

•Keepallpartsingoodworkingconditionandall

hydraulicttingstight.Replaceallworn,damaged,

ormissingpartsanddecals.Keepallfasteners

tighttoensurethatthemachineisinsafeworking

condition.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every50hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthehydraulic-uidlevel.

•Changethehydraulicltersandhydraulicuid.

•Checkthewheel-lugnuts.

•Checkthesafety-interlocksystem.

•Checktheengine-oillevel.

•Cleantheair-intakescreen(moreoftenindirtyordustyconditions).

•Testtheparkingbrake.

•Inspecttheblades.

•Cleanunderthemowerdeck.

•Washthemachine,especiallyafterwinterapplications.

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Checkthehydraulic-uidlevel.

26

MaintenanceService

Every100hours

Interval

MaintenanceProcedure

•Changetheengineoil.

•Checkthebattery.

•Checktheclutch.

•Checkandcleantheenginecoolingnsandshrouds(moreoftenindirtyordusty

conditions).

•Checkthemower-deckbelt(s).

Every150hours

Every200hours

Every300hours

Every500hours

Every600hours

Every800hours

Every1,000hours

Beforestorage

•Inspecttheprimarylterandtheair-inletscreen.

•Changetheengine-oillter.

•Check,cleanandgapthesparkplug.

•Greasetheenginevoltageregulator.(Moreoftenifgreaseisnotpresent.)

•Replacetheprimaryairlter(moreoftenindirtyordustyconditions).

•Checktheinnerairlter(moreoftenindirtyordustyconditions).

•Adjustthecaster-pivotbearing.

•Changethehydraulicltersandhydraulicuid.

•Replacetheinnerairlter(moreoftenindirtyordustyconditions).

•Replacethefuellter.

•Replacethetransmissionbelt.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Greasethetorsionidler.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Greasethecaster-wheelhubs.

Yearly

•Greasethebrakecalipers.

•Greasethemotioncontrols.

•Applyanti-seizecompoundtothecushionknobs.

•Applydielectricgreasetothebatteryterminals.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

Pre-Maintenance

Procedures

ReleasingtheCushionfor

RearAccess

Youcanreleasethecushionforrearaccesstothe

machineformaintenanceoradjustment.

1.Lowertheplatform.

2.Loosenthetwistknobsoneachsideofthe

machine(Figure33).

1.Twistknob

3.Removethecushionandlowerittotheplatform.

4.Performanymaintenanceoradjustmentonthe

machine.

5.Raisethecushion,andslideitontothepinson

bothsidesofthemachine.

6.Tightenthetwistknobs.

g032556

Figure33

2.Cushion

27

Lubrication

GreasingtheTorsionIdler

ServiceInterval:Yearly

GreasingtheMachine

GreasewithNo.2lithiumormolybdenumgrease.

1.DisengagethePTOandsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.

Note:Makesuretoscrapeanypaintoffthe

frontofthetting(s).

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

GreasingtheAccessory

Frame

Greasethepivotsoftheaccessoryframeatthe

locationsshowninFigure34.

Greasethetorsionidleronthemowerdeckusing

high-temperaturegreaseatthegreasettingshown

inFigure35.

Important:Useonlyhigh-temperaturegrease.

Donotusegeneral-purposegrease.

g268671

Figure35

1.Greasethesepivots.

Figure34

1.Greasetting

GreasingtheFrontCaster

Pivots

ServiceInterval:Yearly

Greasetype:Lithiumormolybdenumgrease

1.Removethedustcapandadjustthecaster

pivots;refertoAdjustingtheCaster-Pivot

g032690

Bearing(page42).

Note:Keepthedustcapoffuntilyouhave

nishedgreasingthecasterpivots.

2.Removethehexplug.

3.Threadagreasetting(1/4inch–28taper

thread)intothehole.

4.Pumpgreaseintothettinguntilitoozesout

aroundthetopbearing.

5.Removethegreasettingfromthehole.

6.Installthehexpluganddustcap.

28

GreasingtheCaster-Wheel

Hubs

ServiceInterval:Yearly

Greasetype:Lithiumormolybdenumgrease

10.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

11.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

general-purposegrease.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethecasterwheelfromthecasterforks.

4.Removethesealguardsfromthewheelhub

(Figure36).

Figure36

1.Sealguard2.Spacernutwithwrench

ats

12.Insertthesecondbearingandthenewsealinto

thewheel.

13.Applyathread-lockingadhesivetothesecond

spacernut,threadingitontotheaxlewiththe

wrenchatsfacingoutward.

14.T orquethenutto8to9N∙m(71to80in-lb),

loosenit,thentorqueitto2to3N∙m(20to25

in-lb).

Note:Makesurethattheaxledoesnotextend

beyondeithernut.

15.Installthesealguardsoverthewheelhuband

insertthewheelintothecasterfork.

16.Installthecasterboltandtightenthenutfully.

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoftenbyspinning

thecasterwheel.Thewheelshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

g006115

play.Ifthewheelspinsfreely,adjustthetorque

onthespacernutuntilthereisaslightamountof

drag,andapplythread-lockingadhesive.

5.Remove1spacernutfromtheaxleassemblyin

thecasterwheel.

Note:Thread-lockingadhesivehasbeen

appliedtolockthespacernutstotheaxle.

Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly.

6.Pryouttheseals,inspectbearingsforwearor

damage,andreplacethemifnecessary.

7.Packthebearingswithageneral-purpose

grease.

8.Insert1bearingand1newsealintothewheel.

Note:Y oumustreplacetheseals.

9.Ifbothspacernutsintheaxleassembly

havebeenremoved(orbrokenloose),apply

athread-lockingadhesiveto1spacernut,

threadingitontotheaxlewiththewrenchats

facingoutward.

Note:Donotthreadthespacernutallof

thewayontotheendoftheaxle.Leave

approximately3mm(1/8inch)fromtheouter

surfaceofthespacernuttotheendoftheaxle

insidethenut.

GreasingtheEngine

VoltageRegulator

ServiceInterval:Every300hours(Moreoftenif

greaseisnotpresent.)

Greasetype:Dielectricgrease

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Disconnectthesparkplugwiresfromthespark

plug.

4.Lightlyapplygreasetothevoltageregulator

blades(Figure37).

Important:T oomuchgreasecancause

watertopoolattheconnectorandshortthe

regulator.

5.Connectthesparkplug.

29

Figure37

1.Voltageregulator2.Regulatorblades

GreasingtheBrakeCalipers

ServiceInterval:Yearly

GreasingtheMotion

Controls

ServiceInterval:Yearly

Greasetheoperator-presence-controlballjointand

themotion-controlbushingforbothlevers.

Note:Useanoildripbetweentheleverbracketsto

greasethebushing,locatedinthepivottube.

g228035

Applyarust-preventativespraytothebrakecalipers

yearly.

Figure38

1.Brakecaliper

g228034

g228033

1.Operator-presencecontrol

balljoint

Figure39

2.Pivottube

30

EngineMaintenance

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Keepyourhands,feet,face,clothing,andother

bodypartsawayfromthemuferandotherhot

surfaces.

ServicingtheAirCleaner

ServiceInterval:Every150hours

Every300hours/Y early(whichevercomes

rst)—Replacetheprimaryairlter(moreoften

indirtyordustyconditions).

Every300hours—Checktheinnerairlter

(moreoftenindirtyordustyconditions).

Every600hours—Replacetheinnerairlter

(moreoftenindirtyordustyconditions).

Note:Checktheltersmorefrequentlyifthe

operatingconditionsareextremelydustyorsandy .

RemovingtheFilters

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

g012996

Figure40

1.Air-inletcover3.Air-cleanerbody

2.Air-inletscreen4.Latch

6.Releasethelatchesontheaircleanerandpull

theair-cleanercoverofftheair-cleanerbody

(Figure41).

7.Cleantheinsideoftheair-cleanercoverwith

compressedair.

8.Gentlyslidetheprimarylteroutofthe

air-cleanerbody(Figure41).

Note:Avoidknockingthelterintothesideof

thebody.

9.Removetheinnerlteronlyifyouintendto

replaceit.

3.Releasethelatchesontheaircleanerand

pulltheair-inletcoverofftheair-cleanerbody

(Figure40).

4.Cleantheair-inletscreenandcover.

5.Installtheair-inletcoverandsecureitwiththe

latches(Figure40).

1.Innerlter

2.Primarylter

3.Air-cleanercover

g012997

Figure41

4.Latch

5.Air-cleanerbody

31

InspectingtheFilters

1.Inspectthesafetylter.Ifitisdirty,replaceboth

thesafetyandprimarylters.

Important:Donotattempttocleanthe

safetylter.Ifthesafetylterisdirty ,then

theprimarylterisdamaged.

2.Inspecttheprimarylterfordamagebylooking

intothelterwhileshiningabrightlightonthe

outsideofthelter.Iftheprimarylterisdirty,

bent,ordamaged,replaceit.

Note:Holesinthelterappearasbrightspots.

Donotcleantheprimarylter.

InstallingtheFilters

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandthe

coverinstalled.

1.Ifyouareinstallingnewlters,checkeachlter

forshippingdamage.

ServicingtheEngineOil

Engine-OilSpecications

OilType:Detergentoil(APIserviceSJorhigher)

OilCapacity:1.65L(56oz)withthelter;1.50L

(51oz)withoutthelter

Viscosity:Seethetablebelow.

Note:Donotuseadamagedlter.

2.Ifyouarereplacingtheinnerlter,carefullyslide

itintothelterbody(Figure41).

3.Carefullyslidetheprimarylteroverthesafety

lter(Figure41).

Note:Ensurethattheprimarylterisfully

seatedbypushingontheouterrimwhile

installingit.

Important:Donotpressonthesoft,inside

areaofthelter.

4.Installtheair-cleanercoverandsecurethe

latches(Figure41).

g012991

Figure42

Note:Useasyntheticoilwith5W-20or5W-30rating,

upto4°C(40°F).

Note:Syntheticoilsprovidebetterstartingwhenthe

temperatureisbelow-23°C(-10°F).

32

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothingand

otherbodypartsawaythemuferandother

hotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowthelowmarkbecause

theenginemaybedamaged.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Checktheengine-oillevelasshownin(Figure

43).

g032691

g307458

Figure43

33

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every100hours

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoil

drainscompletely.

2.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

3.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.ChangetheengineoilasshowninFigure44.

g032710

Figure44

5.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

45).

34

g027734

Figure45

ChangingtheEngine-OilFilter

ServiceInterval:Every200hours

Note:Changetheengine-oilltermorefrequently

whenoperatingconditionsareextremelydustyor

sandy.

1.Draintheoilfromtheengine;refertoChanging

theEngineOil(page34).

2.Changetheengine-oillter(Figure46).

g032710

g194610

6.Starttheengineanddrivetoaatarea.

7.Checktheoillevelagain.

g027477

Figure46

Note:Ensurethattheoil-ltergaskettouches

theengine,thenrotatethelteranextra3/4turn.

3.Fillthecrankcasewiththepropertypeofnew

oil;refertoEngine-OilSpecications(page32).

35

ServicingtheSparkPlug

CheckingtheSparkPlug

ServiceInterval:Every200hours

Makesurethattheairgapbetweenthecenterand

sideelectrodesiscorrectbeforeinstallingthespark

plug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

TypeforallEngines:Kohler2513214-c,Champion

XC12YC,orequivalent

AirGap:0.75mm(0.03inch)

RemovingtheSparkPlug

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.RemovethesparkplugasshowninFigure47.

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

g027479

Figure48

InstallingtheSparkPlug

Figure47

g265991

g027478

Figure49

g028109

36

CheckingtheSpark

FuelSystem

Arrester

ForMachineswithaSpark

Arrester

ServiceInterval:Every50hours

WARNING

Hotexhaust-systemcomponentsmayignite

fuelvaporsevenafteryoushutofftheengine.

Hotparticlesexhaustedduringengine

operationmayigniteammablematerials,

resultinginpersonalinjuryorproperty

damage.

Donotrefuelorruntheengineunlessthe

sparkarresterisinstalled.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Waitforthemufertocool.

4.Ifyouseeanybreaksinthescreenorwelds,

replacethearrester.

5.Ifthescreenisplugged,removethearrester,

shakelooseparticlesoutofthearrester,and

cleanthescreenwithawirebrush(soakthe

screeninsolventifnecessary).

6.Installthearresterontheexhaustoutlet.

Maintenance

DrainingtheFuelTank

Youcandrainthefueltankbyremovingitandpouring

thefueloutofthellneck;refertoRemovingtheFuel

Tank(page38).Youcanalsodrainthefueltankby

usingasiphoninthefollowingprocedure.

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Drainfuelfromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanyfuelthatspills.

•Neversmokewhendrainingfuel,andstay

awayfromanopename,orwhereaspark

mayignitethefuelfumes.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanaroundthefuelcaptopreventdebrisfrom

gettingintothefueltank(Figure50).

4.Removethefuelcap.

5.Insertasyphonpumpintothefueltank.

6.Usingthesyphonpump,drainthefuelintoafuel

container.

7.Wipeupanyspilledfuel.

Figure50

1.Fuelcap

37

g273861

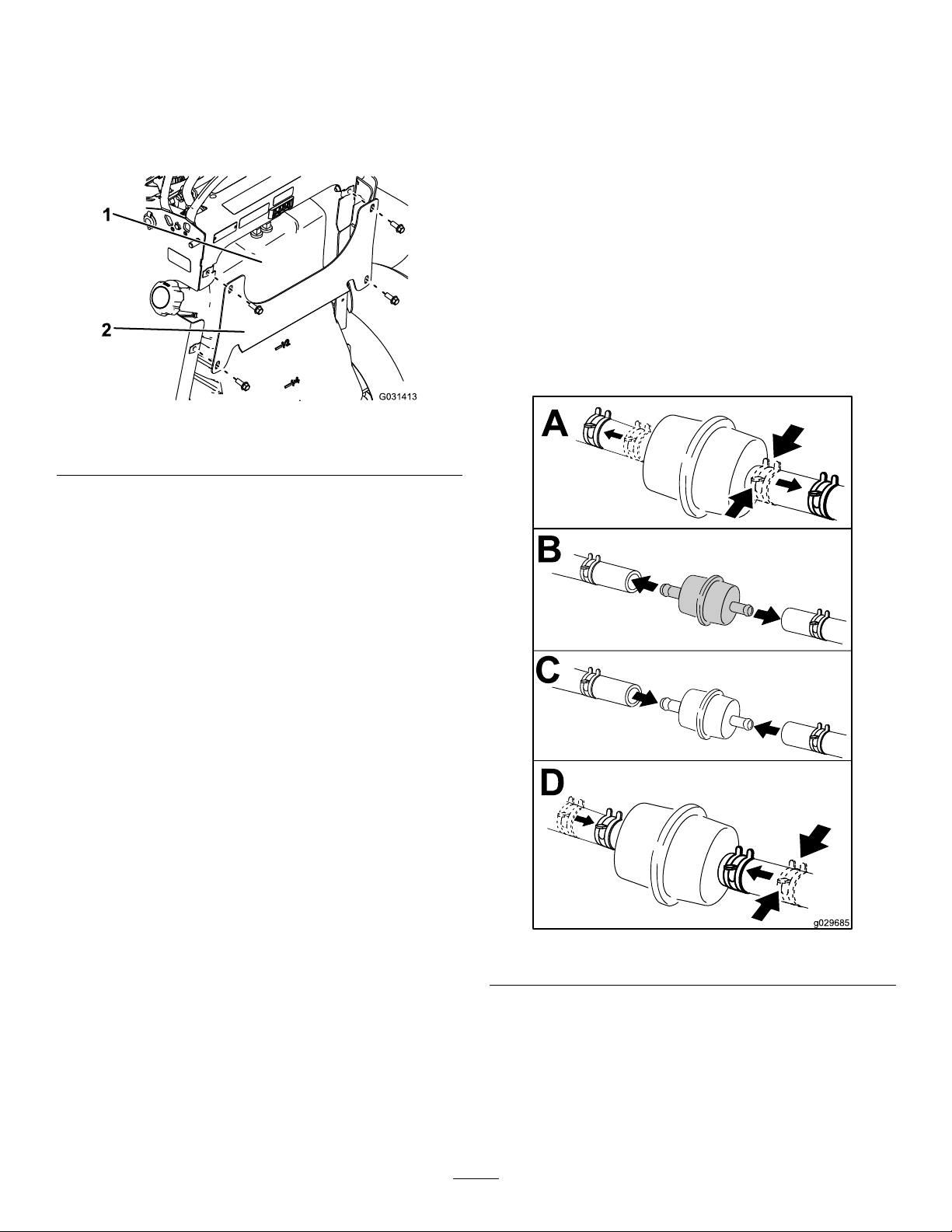

RemovingtheFuelTank

ReplacingtheFuelFilter

1.Lowertheplatform.

2.Releasethecushion;refertoReleasingthe

CushionforRearAccess(page27).

3.Removethecrossbracket.

Figure51

1.Fueltank

4.Removethefueltankandsetitontheoperator

platform.

2.Crossbracket

ServiceInterval:Every800hours/Yearly(whichever

comesrst)

Donotinstalladirtylterifitisremovedfromthefuel

line.

Note:Wipeupanyspilledfuel.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Closethefuel-shutoffvalve;refertoUsingthe

Fuel-ShutoffValve(page23).

4.ReplacethefuellterasshowninFigure52.

g031413

Note:Ifyouwanttomovethefueltankfurther

fromthemachine,removethefuelandvent

linesfromthetopofthetank.

g029685

Figure52

38

ElectricalSystem

Maintenance

ElectricalSystemSafety

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiveterminalrstand

negativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

ServicingtheBattery

ServiceInterval:Every100hours

Yearly

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

4partswaterand1partbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoprevent

corrosion.

Voltage:12V

RemovingtheBattery

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.RemovethebatteryasshowninFigure53.

g030988

Figure53

39

ChargingtheBattery

InstallingtheBattery

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery .

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity)topreventbatterydamage

whenthetemperatureisbelow0°C(32°F).

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page39).

2.Checktheelectrolytelevel.

3.Ensurethatthellercapsareinstalledonthe

battery.

4.Chargethebatteryfor1hourat25to30Aor6

hoursat4to6A.

5.Whenthebatteryisfullycharged,unplugthe

chargerfromtheelectricaloutlet,anddisconnect

thechargerleadsfromthebatteryposts(Figure

54).

InstallthebatteryasshowninFigure55.

6.Installthebatteryontothemachineandconnect

thebatterycables;refertoInstallingtheBattery

(page40).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Figure54

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

g030989

Figure55

g000538

40

ServicingtheFuses

DriveSystem

Theelectricalsystemisprotectedbyfuses.It

requiresnomaintenance.Ifafuseblows,checkthe

componentorcircuitforamalfunctionorshort.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Releasetheoperatorcushionfromtherearof

themachine.

4.Ifyouneedtoaccessthechargefuse,remove

thefueltank;refertoRemovingtheFuelT ank

(page38).

5.Pulloutthefuseandreplaceit(Figure56).

Maintenance

AdjustingtheTracking

Ifyoupushbothmotion-controlleversforwardthe

samedistanceandthemachinepullsto1side,adjust

thetrackingasfollows.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Releasethecushionfromtherearofthe

machine;refertoReleasingtheCushionfor

RearAccess(page27).

Note:Foreasieraccess,youcanalsoremove

thefueltank;refertoRemovingtheFuelT ank

(page38).

4.Rotatetheleftcontrolrodinquarter-turn

incrementsuntilthemachinetracksstraight

(Figure57).

Figure56

1.Keyswitchfuse(15A)4.Hourmeter(7.5A)

2.Accessoryport(15A)5.Chargefuse(20A)

3.Power-takeoff(PTO)fuse

(10A)

6.Installthefueltank,ifremoved;referto

RemovingtheFuelTank(page38).

7.Installtheoperatorcushion.

Note:Ifthemachinepullstotheright,shorten

thecontrolrodbyrotatingittotheright.Ifthe

machinepullstotheleft,lengthentherodby

rotatingittotheleft.

g301335

Note:Adjustonlytheleftcontrolrodtomatch

theleftwheelspeedtotherightwheelspeed.

Donotadjusttherightwheelspeed,asthis

positionstherightmotion-controlleveroutofthe

centerforthecontrolpanelneutral-lockslot.

Important:Donotrotatethecontrolrodtoo

far,asthismaycausethemachinetocreep

inneutral.

g031531

Figure57

1.Rotatelefttolengthenthe

rod.

2.Leftcontrolrod

41

3.Rotaterighttoshortenthe

rod.

5.Checkforpropertracking,andadjusttherod

asnecessary.

Note:Ifyouareunabletoachieveproper

trackingbyadjustingtheleftcontrolrod,contact

yourAuthorizedServiceDealer.

6.Checkthatthemachinedoesnotcreepfrom

theneutralpositionwiththeparkbrakes

disengaged.

7.Installthefueltank,ifyouremovedit.

8.Installthecushion.

CheckingtheTirePressure

AdjustingtheCaster-Pivot

Bearing

ServiceInterval:Every500hours/Yearly(whichever

comesrst)

1.Disengagetheblade-controlswitch(PTO),move

themotioncontrolleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethedustcapfromthecasterandtighten

thelocknut(Figure59).

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat83to97

kPa(12to14psi).

Important:Uneventirepressurecancausean

unevencut.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireair-pressuremaintenance.

Figure58

4.Tightenthelocknutuntilthespringwashersare

at,andthenbackoffa1/4turntoproperlyset

thepreloadonthebearings(Figure59).

Important:Makesurethatthespring

washersareinstalledcorrectlyasshownin

Figure59.

5.Installthedustcap(Figure59).

g001055

g001297

Figure59

1.Springwashers

2.Locknut

42

3.Dustcap

ServicingtheCaster

WheelsandBearings

Thecasterwheelsrotateonarollerbearingsupported

byaspannerbushing.Ifthebearingiskeptwell

lubricated,wearwillbeminimal.Failuretokeepthe

bearingwelllubricatedcausesrapidwear.Awobbly

casterwheelusuallyindicatesawornbearing.

1.Removethelocknutandwheelboltholdingthe

casterwheeltothecasterfork(Figure60).

9.Tightenthelocknutuntilthespannerbushing

bottomsagainsttheinsideofthecasterforks

(Figure60).

10.Greasethettingonthecasterwheel.

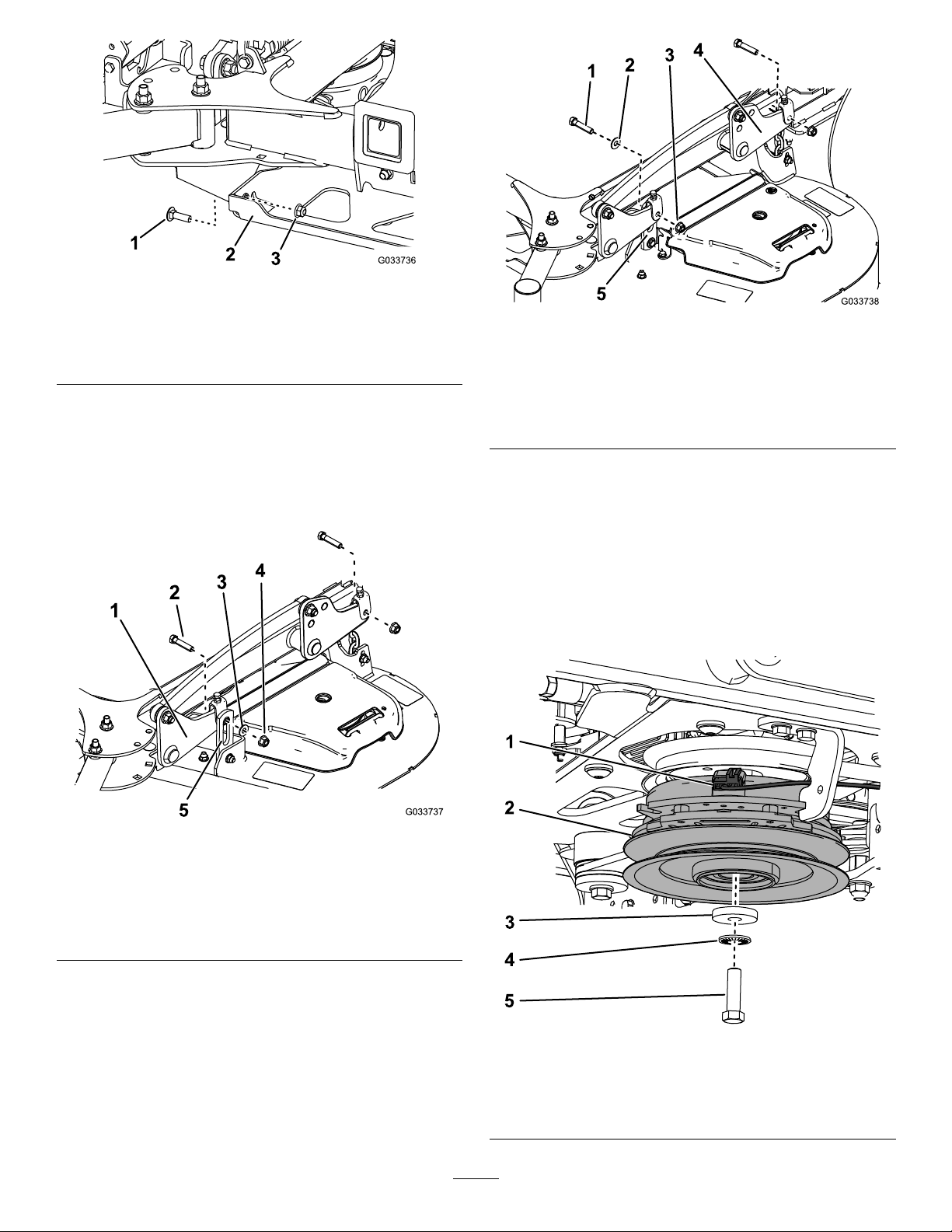

RemovingtheClutchShim

ServiceInterval:Every100hours

Whentheclutchbrakehasworntothepointwhere

theclutchnolongerengagesconsistently,youcan

removetheshimtoextendtheclutchlife(Figure61).

Figure60

1.Locknut4.Rollerbearing

2.Bushing

3.Spannerbushing

5.Casterwheel

6.Wheelbolt

2.Remove1bushing,thenpullthespanner

bushingandrollerbearingoutofthewheelhub

(Figure60).

3.Removetheotherbushingfromthewheelhub

andcleananygreaseanddirtfromthewheel

hub(Figure60).

4.Inspecttherollerbearing,bushings,spanner

bushingandtheinsideofthewheelhubforwear.

Note:Replaceanydamagedorwornparts

(Figure60).

g302539

Figure61

1.Armature5.Brakespacer

2.Fieldshell

g009453

3.Rotor7.Brakepole

4.Brake-mountingbolt

6.Shim.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Usinganaircompressor,blowoutanydebris

underthebrakepoleandaroundthebrake

spacers.

5.Place1bushingintothewheelhub(Figure60).

6.Greasetherollerbearingandspannerbushing,

andslidethemintothewheelhub(Figure60).

7.Placethesecondbushingintothewheelhub

(Figure60).

8.Installthecasterwheelintothecasterforkand

secureitwiththewheelboltandlocknut(Figure

60).

g302534

Figure62

43

4.Checktheconditionofthewire-harnessleads,

connectors,andterminals.Cleanorrepairthem

asnecessary.

5.Verifythat12Vispresentattheclutchconnector

whentheyouengagethePTOswitch.

6.Measurethegapbetweentherotorand

armature.Ifthegapisgreaterthan1mm(0.04

inch),proceedwiththefollowingsteps:

A.Loosenbothbrakemountingbolts1/2to1

fullturnasshowninFigure63.

Note:Donotremovethebrakepolefrom

theeldshell/armature.Thebrakepole

hasworntomatchthearmatureandneeds

tocontinuetomatchafteryouremovethe

shimtoensuretheproperbraketorque.

E.Usinga0.010inchthick-feelergauge,verify

thatagapispresentbetweentherotorand

armaturefaceonbothsidesofthebrake

poleasshowninFigure65andFigure66.

Note:Duetothewaytherotorand

armaturefaceswear(peaksandvalleys),it

issometimesdifculttomeasurethetrue

gap.

g302536

Figure65

1.Feelergauge

Figure63

1.Brake-mountingbolt

B.Usingneedle-nosepliers,orbyhand,

removetheshim.

Note:Donotdiscardtheshimuntilyou

conrmthattheclutchfunctionsproperly.

Figure64

1.Shim

g302537

g302535

Figure66

1.Feelergauge

•Ifthegapislessthan0.010inch,

theninstalltheshimandreferto

Troubleshooting(page60).

•Ifthegapissufcient,proceedtothe

safetycheckinstepF.

g302538

C.Usingapneumaticline,blowoutanydebris

underthebrakepoleandaroundthebrake

spacers.

D.T orqueeachbolt(M6x1)to12.3to13.7

N∙m(9.5to10.5ft-lb).

44

F.Performthefollowingsafetycheck:

i.Starttheenginefromtheoperator’s

position.

ii.Makesurethatthebladesdonot

engagewhenthePTOswitchisin

theOFFpositionandtheclutchis