ZMaster

®

RidingMower

For3000Through7000SeriesModels

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

FormNo.3434-244RevB

SetupInstructions

ProcedureDescription

1

2

3

4

5

6

7

8

9

10

11

12

13

Rearwheels(woodencrateonly)

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

J-bolt2

Wingnut2

Hold-downclamp1

Clamp

Wingnut(1/4inch)

Batteryhold-down2

Nopartsrequired

Seat

Seatplate(xedseatsonly)

Flangenuts(3/8inch)—xedseatsonly

Spacers(3/8inch)—xedseatsonly

Flangenuts(3/8inch)—tiltingseatsonly

Longspacers(tilting,deluxeseatsonly)

Shortspacers(tilting,deluxeseatsonly)

Nopartsrequired

Rightcontrollever1

Leftcontrollever

Bolt(3/8x1inch)—2areassembled

Nut(3/8inch)—2areassembled

Carriagebolt(3/8x1-1/2inches)

Flangelocknut(3/8inch)

Qty.

Use

2

–

–

–

–

–

1

2

–

1

1

8

4

4

2

4

–

1

4

4

1

1

Removethemachinefromacrate.

Addfueltothemachine.

Checktheengine-oillevel.

Checkthetirepressure.

Checkthewheellugnuttorque.

Checkthegrassdeector .

Installabattery(dieselmachinesonly).

Installabattery(gasolinemachines

only).

Chargethebattery.

Installtheseat(internationalmachines

usinggasolineonly).

Checktheseatbelt(international

machinesusinggasolineonly).

Installthemotion-controllevers

(internationalmachinesusinggasoline

only).

Installthelift-assistpedal(international

machinesusinggasolineonly).

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

*3434-244*

ProcedureDescription

14

15

16

17

18

Air-cleanercap1

Hoseclamp1

RolloverProtectionSystem(ROPS)Kit

Rollbar,rightsection1

Rollbar,leftsection

Rollbar,centersection1

Bolt(3/8x1inch)

Curvedwasher

Flangenut(3/8inch)

Bolt(1/2x3-1/4inches)

Flangenut(1/2inch)

No.2lithiumormolybdenumgrease.

(Purchaseseparately.)

Nopartsrequired

1tube

Qty.

Use

Installtheair-cleanercap(international

machinesusinggasolineonly).

1

1

8

8

8

2

2

–

InstalltheROPS(internationalmachines

usinggasolineonly).

InstalltheROPS(dieselmachinesonly).

Checkthemachineforgrease.

Removetheshippingstraps(for

machineswithMyRide™suspension

systemonly).

19

20

Nopartsrequired

Operator'sManual

EngineOwner'sManual

Registrationcard1

Operatortrainingmaterial

Key2

1

RemovingtheMachine

fromaCrate

Partsneededforthisprocedure:

2

Rearwheels(woodencrateonly)

RemovingaMachinefromaMetal

–

1

1

1

Checkthemachinebeforedeliveryto

thecustomer(allmachines).

Deliverthemachinetothecustomer(all

machines).

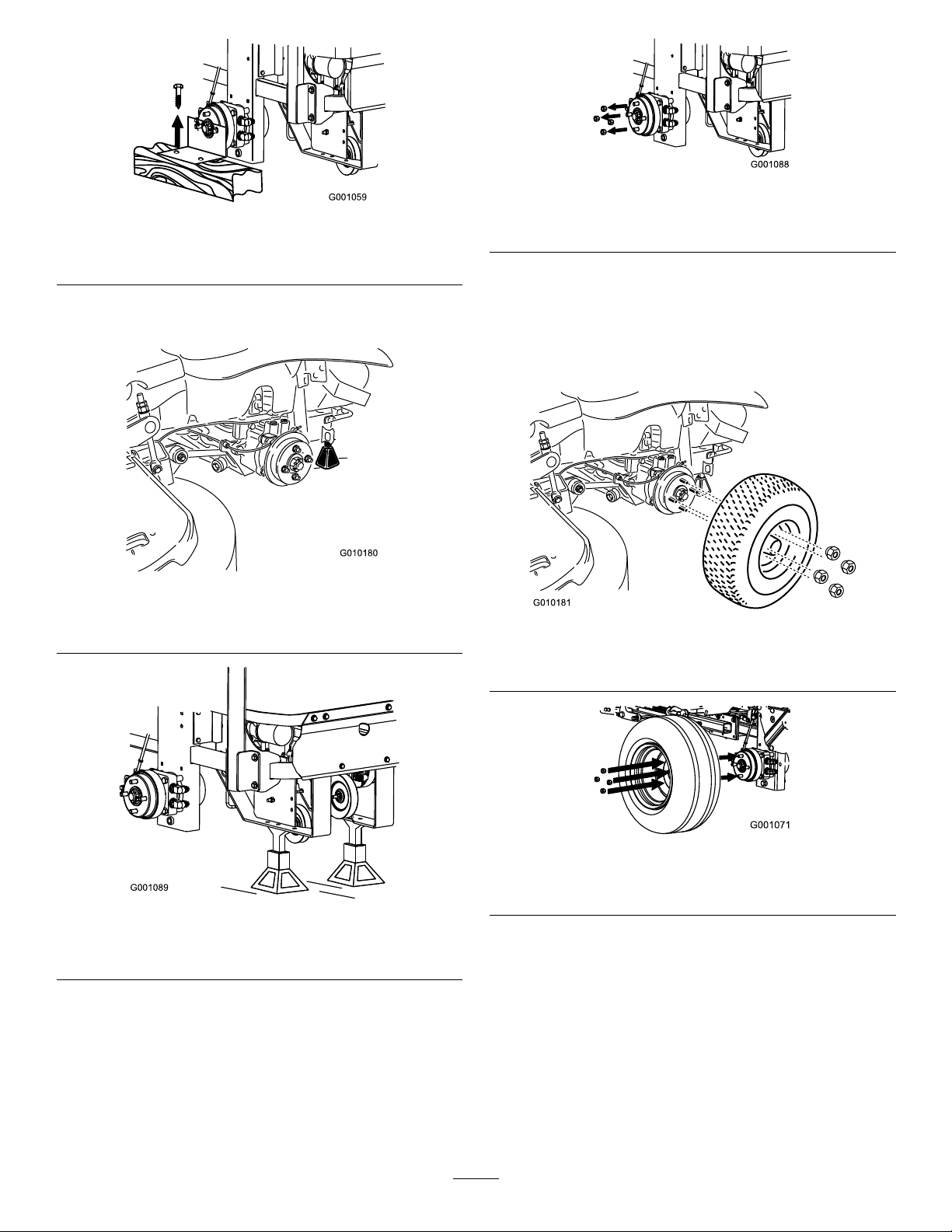

g010179

Figure1

GasolineMachineShown

Crate

Ifyouareremovingthemachinefromametalcrate,

refertotheDealer/DistributorPortalforfurther

information.

RemovingtheMachinefroma

WoodenCrate

1.Removethescrewsholdingtherightangle

retainingplatetothecrate.

2

Figure2

DieselMachineShown

2.Raisetherearofthemachineandsupportit

withjackstands.

Figure3

GasolineMachineShown

g001088

Figure5

g001059

DieselMachineShown

4.Mountthewheelswiththevalvestemtothe

outsideandsecurethemwiththewheelnuts

previouslyremoved.

5.Torquethewheelnutsto128N∙m(95ft-lb).

6.Removethejackstands.

g010180

g010181

Figure6

GasolineMachineShown

Figure4

DieselMachineShown

3.Removethewheelnutsfrombothsidesofthe

machineandremovetherightangleretaining

plate.Discardthescrewsandretainingplate.

g001071

Figure7

DieselMachineShown

g001089

3

2

5

AddingFueltotheMachine

NoPartsRequired

Procedure

Addfueltothemachinebeforestartingit.Refer

toyourOperator’sManualforthecorrectfueland

procedure.

3

CheckingtheEngine-Oil

Level

NoPartsRequired

Procedure

CheckingtheWheelLug

NutTorque

NoPartsRequired

Procedure

Beforeyoustarttheengineandusethemachine,

checkthewheellugnuttorque;refertoCheckingthe

WheelLugNutsintheOperator'sManual

6

CheckingtheGrass

Deector

NoPartsRequired

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

theOperator'sManual.

4

CheckingtheTirePressure

NoPartsRequired

Procedure

Airpressurespecication:90kPa(13psi)

Note:Checkthetirepressurebeforestartingthe

machine.RefertoyourOperator’sManualforthe

correcttiretype,correctairpressureneeded,and

procedure.

Procedure

Ifthereareplastictiesholdingthegrassdeectorup,

removethemandlowerthedeectorintoplace.

WARNING

Anuncovereddischargeopeningcouldallow

themachinetothrowobjectsintheoperator's

orbystander'sdirectionandresultinserious

injuryordeath.Also,contactwiththeblade

couldoccur.

Neveroperatethelawnmowerunlessyou

installacoverplate,amulchplate,grass

deectororbagger.

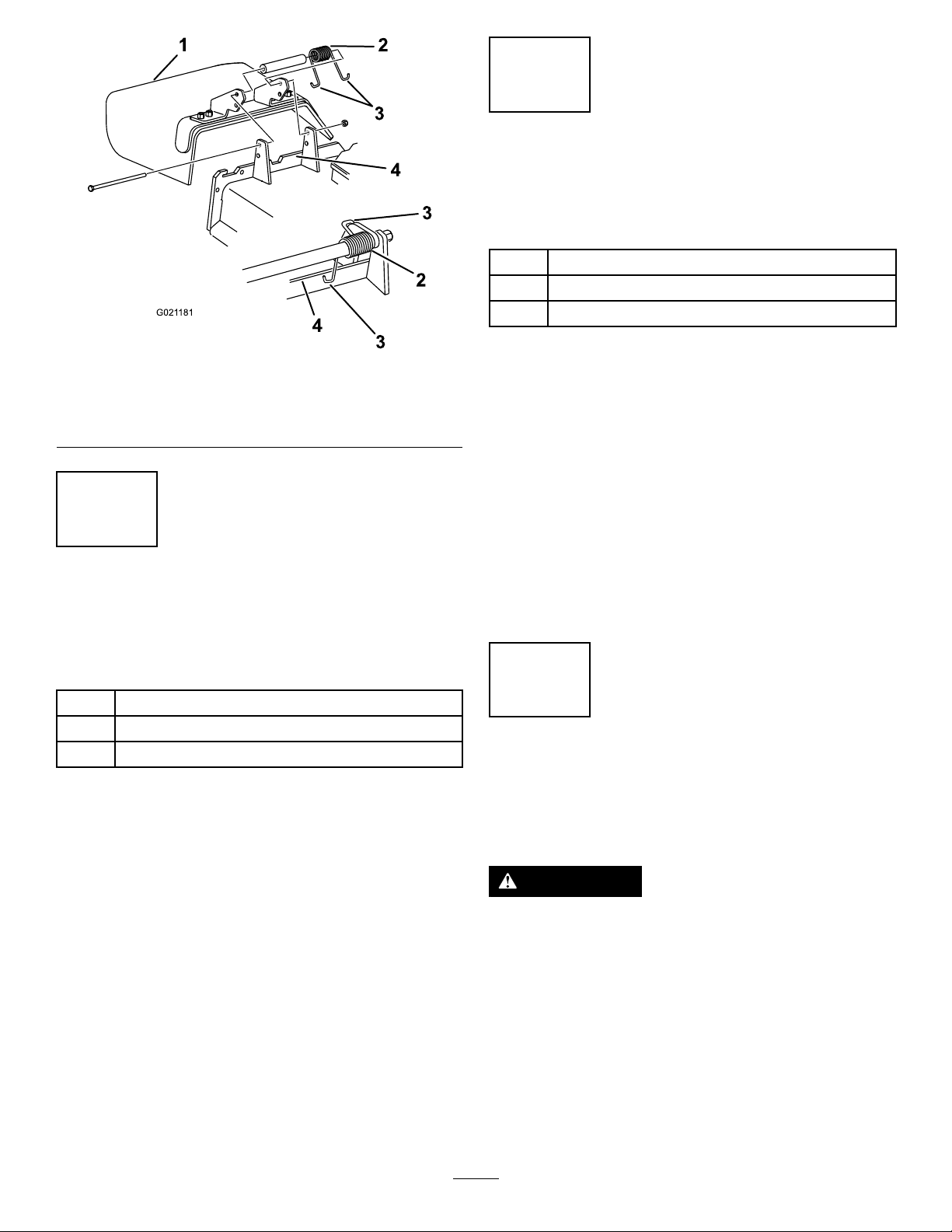

1.Ensurethat1endofthespringisinstalled

behindthedeckedgebeforeinstallingthebolt

asshowninFigure8.

2.Placetheotherendofthespringaroundthe

grassdeector(Figure8).

Important:Thegrassdeectormustbefree

torotatewithdownwardtension.Liftthe

deectoruptothefullyopenpositionand

ensurethatitrotatesfreely,withoutbinding

intothefullydownposition.

4

Figure8

8

InstallingaBattery

GasolineMachinesOnly

Partsneededforthisprocedure:

1

Clamp

2

Wingnut(1/4inch)

2Batteryhold-down

g021181

Procedure

1.Grassdeector3.Endofthespring

2.Spring

4.Deckedge

7

InstallingaBattery

DieselMachinesOnly

Partsneededforthisprocedure:

2J-bolt

2Wingnut

1Hold-downclamp

Procedure

Important:Thisprocedureonlyappliesto

machinesthatdonotcomewithabattery

installed.

Important:Thisprocedureappliesonlyto

machinesthatdonotcomewithabattery

installed.

1.Purchasea12Vbattery.

Modelswitha29hpengineandbelowrequirea

batterywithaminimumof260CCA.

Modelswitha30hpengineandhigherrequirea

batterywithaminimumof340CCA.

2.Locatethebattery-mountinghardwareand

installitintothemachine.RefertoInstallingthe

BatteryintheOperator'sManual.

9

ChargingtheBattery

NoPartsRequired

Procedure

WARNING

Purchasea12Vbatteryandinstallitintothemachine.

Theenginerequiresaminimumof540CCA.

Usethehardwareincludedtoinstallthenewbattery.

RefertoInstallingtheBatteryintheOperator's

Manual.

Chargingthebatteryproducesgassesthat

canexplodeandcauseseriousinjury.

•Keepcigarettes,sparksandamesaway

fromthebattery.

•Makesuretheignitionswitchisoff.

•Ventilatewhenchargingorusingthe

batteryinanenclosedspace.

Important:Donotrunthemachinewiththe

batterydisconnected;electricaldamagemay

occurtotheengine.

5

Loading...

Loading...