Toro 133-6318 Installation Instructions

Installation

LooseParts

FormNo.3406-717RevA

RotationMotorHydraulicKit

4045DirectionalDrill

ModelNo.133-6318

InstallationInstructions

WARNING

CALIFORNIA

Proposition65Warning

ThisproductcontainsachemicalorchemicalsknowntotheStateofCaliforniato

causecancer,birthdefects,orreproductiveharm.

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Nopartsrequired

Latch1

Bulkheadplate1

Check-clipper-manifoldvalve

Smallstraighttting

Largestraighttting

Bolts(M8)

Nuts(M8)

Hose–65cm(25-1/2inches)

O-rings(large)

Bulkheadunion4

Locknut4

Spikeclippermanifold

Large90-degreetting

Smallstraighttting

O-ring(small)

Bolt(7/16x5-1/2inch)

Washer8

Qty.

Use

–

1

2

4

3

3

1

2

1

2

2

4

8

Preparethemachine.

Installthefront-hoodlatch.

Installthebulkheadplateandvalve.

Installthebulkheadunionandspike

clippermanifold.

©2016—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

*3406-717*A

ProcedureDescription

5

6

Hose–28cm(50-1/2inch)

Hose–139cm(55inch)

Hose–5M(16-1/4ft)

Hose–66cm(26inch)

Hose–67cm(26-13/32inch)

Straighttting

Bulkheadnut2

Hose–89cm(35inch)

Hose–86cm(34inch)

Handheldtransmitter1

Qty.

Use

1

1

2

1

1

2

1

1

Installthehydraulichoses.

Associatethehandheldtransmitterwith

thebaseunit.

1

PreparingtheMachine

NoPartsRequired

Procedure

Parkthemachineonalevelsurface,shutofftheengine,set

thebattery-disconnectswitchtooff,andremovetheignition

key.

Drainthehydraulicoilreservoir;refertothemachine

Operator’sManual.

2

InstallingtheFront-Hood

Latch

Partsneededforthisprocedure:

1Latch

Procedure

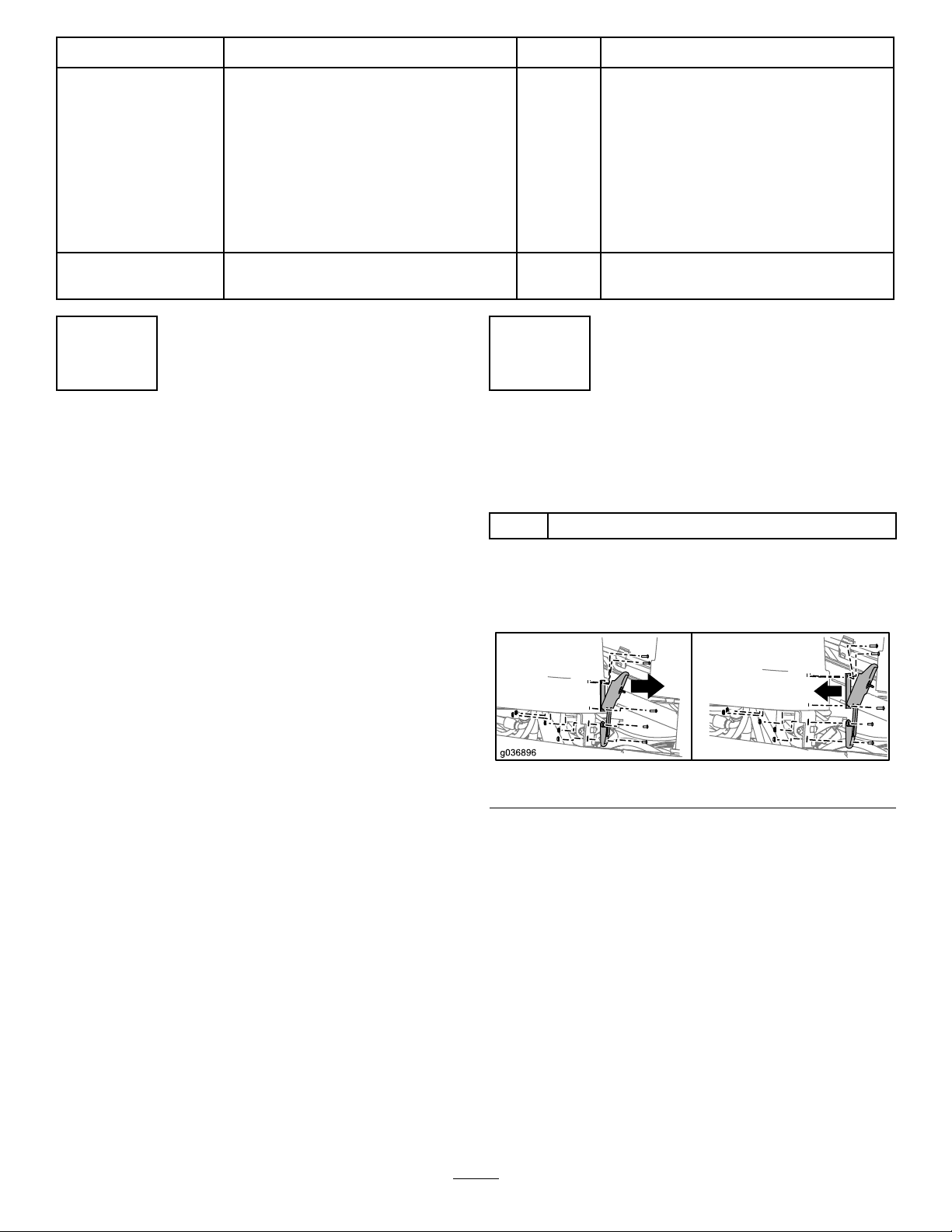

Removethecurrenthoodlatchandinstallthenewhoodlatch.

Figure1

2

4.Removethe2hosesthatgofromthebulkheadplateto

therotarypump(BoxAofFigure3).

3

InstallingtheBulkheadPlate

andValve

Partsneededforthisprocedure:

1Bulkheadplate

1

Check-clipper-manifoldvalve

2

Smallstraighttting

4

Largestraighttting

3

Bolts(M8)

3

Nuts(M8)

1

Hose–65cm(25-1/2inches)

2

O-rings(large)

InstallingtheBulkheadPlate

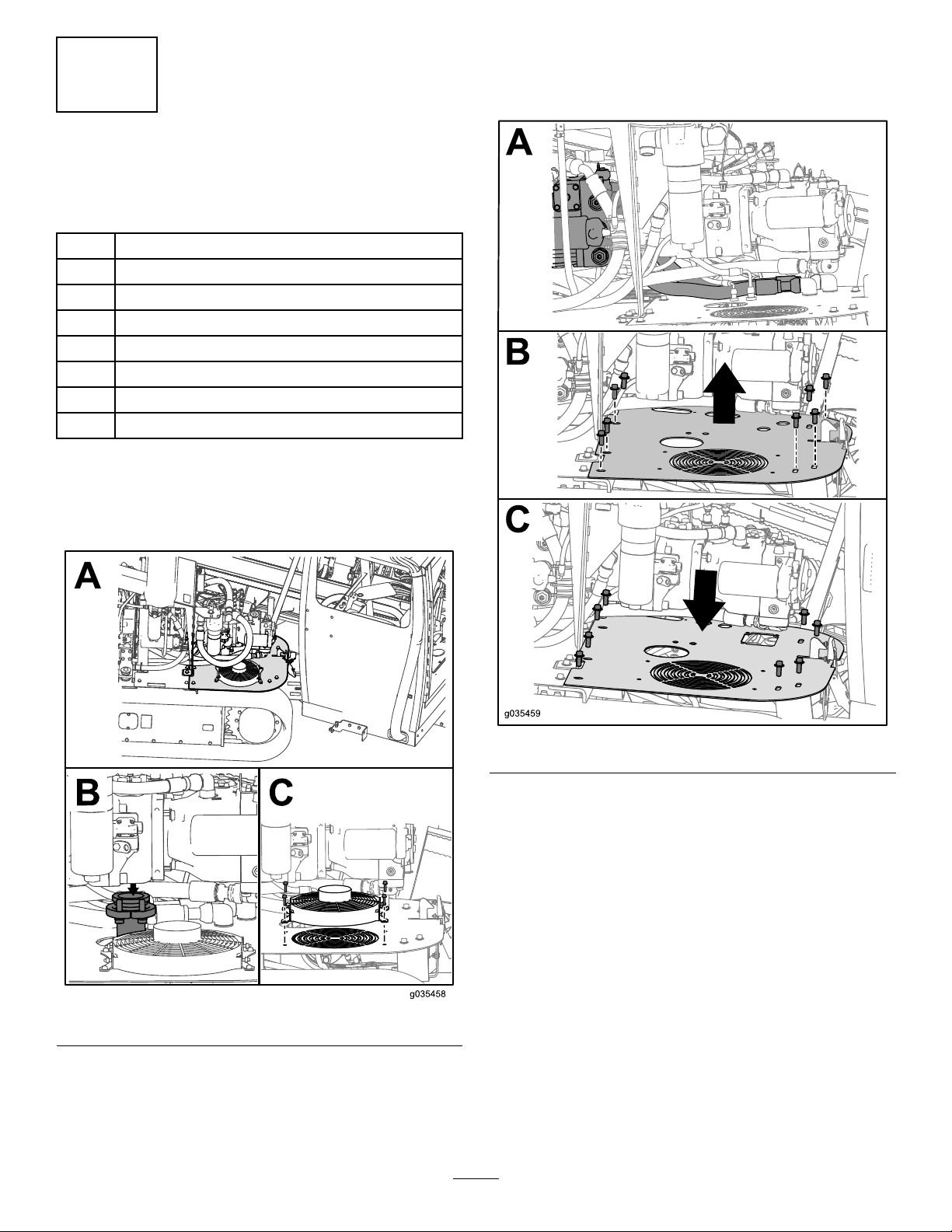

1.Locatethebulkheadplateunderthefronthood(Box

AofFigure2).

Note:Retainthe61cm(24inch)hose.

Figure2

2.Disconnectandlowertubeconnectedtotheload

pumpassembly(BoxBofFigure2).

3.Removethefanassemblyfromthebulkheadplate(Box

CofFigure2).

Figure3

5.Removethehosesandwiringharnessthatare

connectedthroughthebulkheadplate.

6.Removethe8boltsandthebulkheadplatefromthe

machine(BoxBofFigure3).

7.Installthenewbulkheadplateusingthe8boltsfrom

thepreviousstep(BoxCofFigure3).

8.Torquetheboltsto80to100N∙m(59to73ft-lb).

3

InstallingtheBulkheadValve

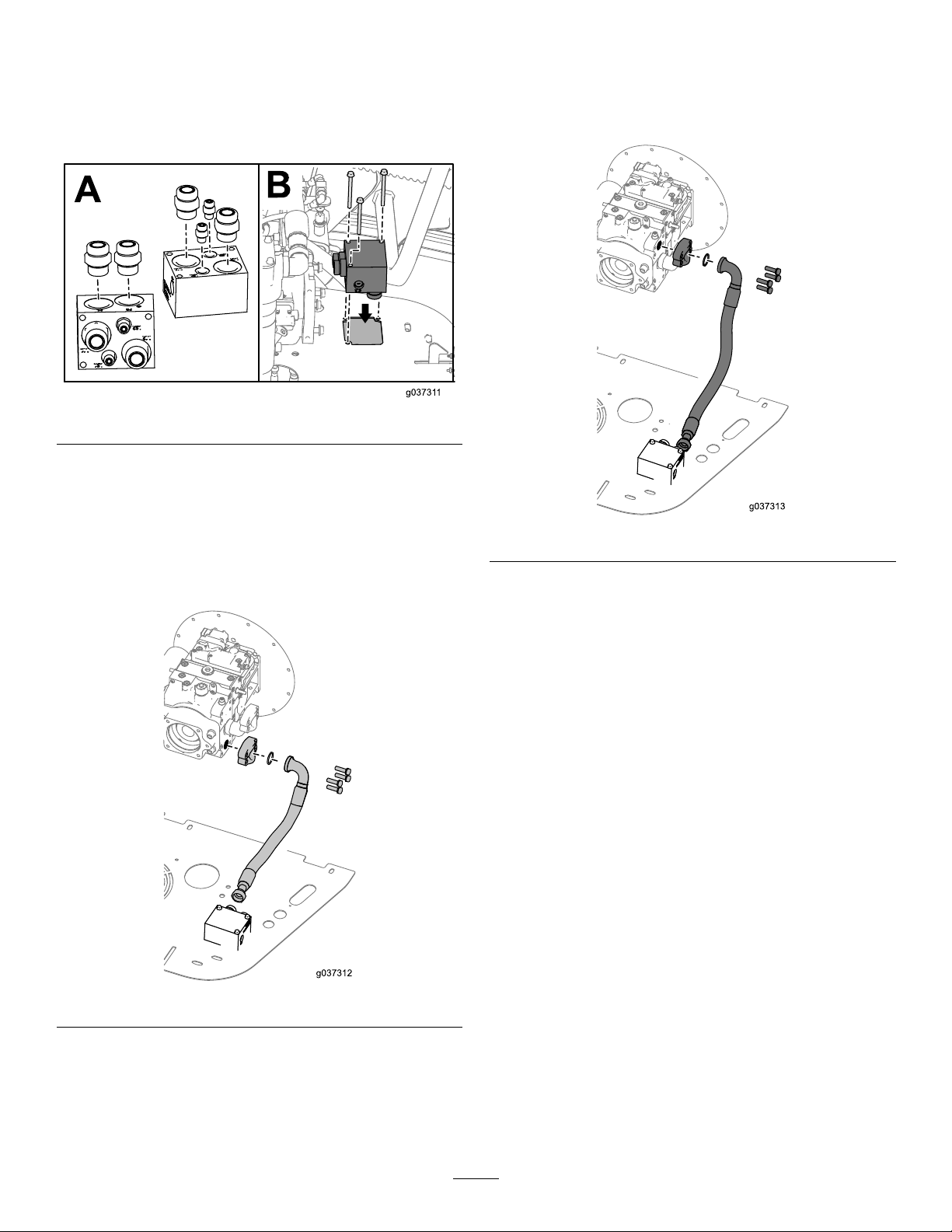

1.Installthettingsontothecheckclippermanifold

valveasshowninBoxAofFigure4.

2.Securethevalvetothebulkheadplateusing3bolts

(M8)and3nuts(M8)(BoxBofFigure4).

Figure4

3.Torquetheboltsto23to29N∙m(17to21ft-lb).

4.Routethe61cm(24inch)hose,previously

disconnectedinstep4,fromthettingonthecheck

clippermanifold,ontheenginesideofthemachine,to

thebottomportontherotarypump(Figure5)using

anO-ringfromthekitandthehardwarefromthe

previouslyconnectedhose.

5.Connectthe65cm(251/2inch)hosefromthetop

ttingonthecheckclippermanifold,ontherod-box

sideofthemachine,tothetopportontherotary

pump(Figure6)usinganO-ringfromthekitandthe

hardwarefromthepreviouslyconnectedhose.

Figure6

Figure5

4

Loading...

Loading...