Page 1

WARRANTY..... Top Flite Models guarantees this kit to be

free from defects in both material and workmanship at the date of

purchase. This warranty does not cover any component parts

damaged by use or modification. In no case shall Top Flite’s

liability exceed the original cost of the purchased kit. Further, Top

Flite reserves the right to change or modify this warranty without

notice. In that Top Flite has no control over the final assembly or

material used for final assembly, no liability shall be assumed nor

accepted for any damage resulting from the use by the user of the

final user-assembled product. By the act of using the userassembled product, the user accepts all resulting liability.

If the buyers are not prepared to accept the liability associated with

the use of this product, they are advised to return this kit

immediately in new and unused condition to the place of purchase.

TopFlite Models

P.O. Box 788

Urbana, IL 61803

Technical Assistance - Call (217) 398-8970

Entire Contents © Copyright 2001

CESCP01 5/01 V1.1

READ THROUGH THIS INSTRUCTION BOOK

FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS

CONCERNINGTHE ASSEMBLY OF THIS MODEL.

Congratulations for deciding to install a fully detailed, scale looking interior in your Top Flite Cessna 182 Skylane. This is a

project that can be as detailed or as straightforward as you care to make it – the choice is yours.We have provided the basic

kit that can be assembled and painted in a few hours. It represents a stock Cessna interior as delivered from the factory.The

color scheme and minor surface details change from plane to plane, so you may need to add extra goodies like headrests or

shoulder harnesses depending on the full-scale plane you modeled. By using this kit, some imagination and your modeling

experience, you can create a great looking interior that will “wow” them at the flying field.

DETAILINGHINTS

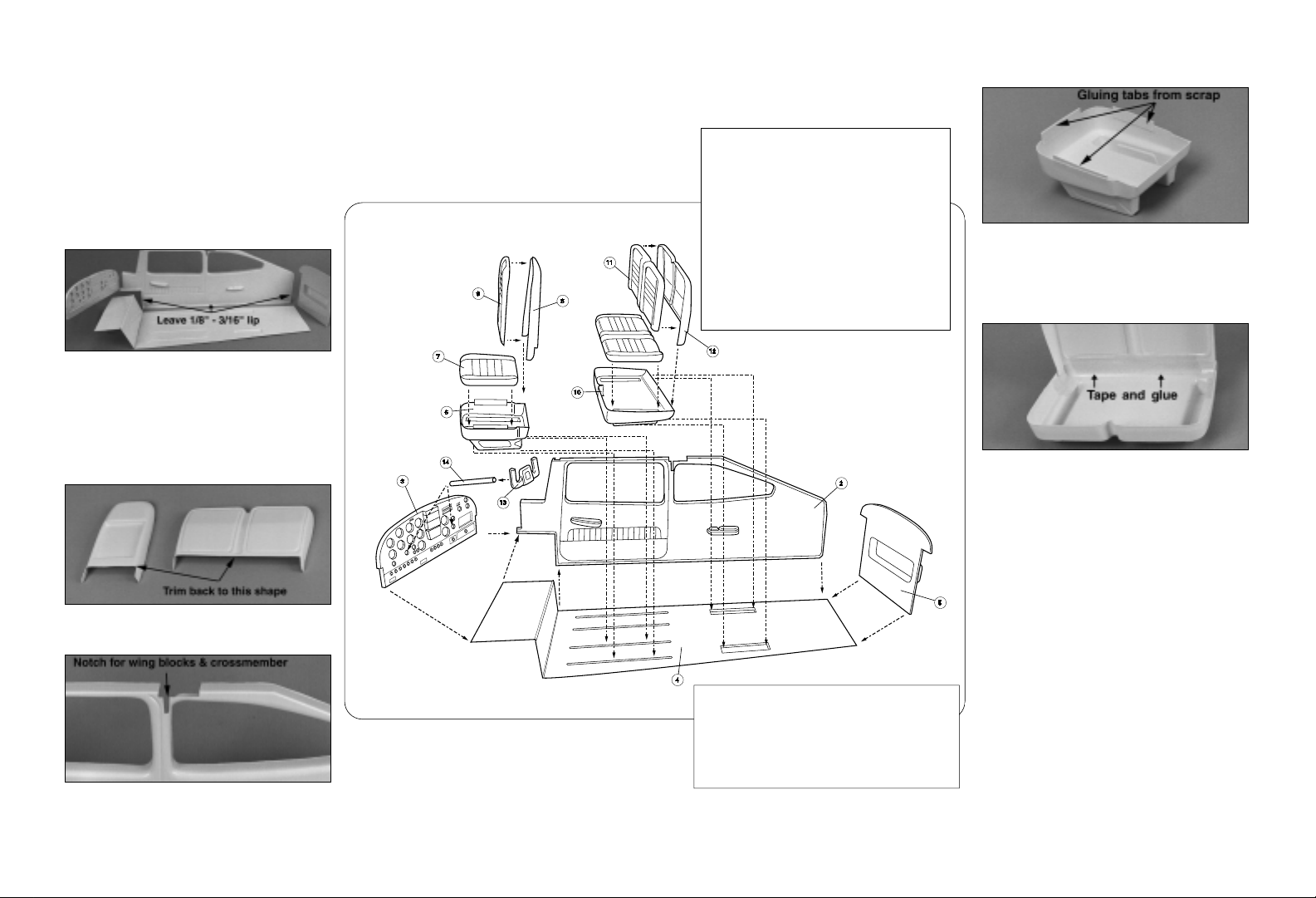

❏ 1. Carefully cut the radios and fuel gauges from the

instrument decal included in your Top Flite Cessna kit and attach

them to the front of the plastic instrument panel. Attach the

remaining instrument decal pieces to scrap balsa or thin

cardboard, then glue it to the back of the molded panel.

The numbers on this photo apply to the following steps

❏ 2. Carpet may be attached to the floor with 3M #77 spray

adhesive. Glue the carpet in position, then cut around the front

seat tracks to expose them.Trim the carpet edges to size.

❏ 3. Seat and door beading can be made from embroidery

“

floss” or string. Tack glue a short piece at one end with thin CA,

then stretch it to the end of its run. Hold it with tweezers while you

CA the floss or string in place.

❏ 4. Seatbelts are cut from 1/4" dressmakers’ elastic (included in

this kit). One end is threaded through the eye of a large T-pinand

spot glued to itself. The pin is inserted through the floor, bent 90

degrees and glued to the underside of the floor. The buckles are

cut from chrome trim tape or could be made from aluminum foil.

❏ 5. Maps and magazines are made from small pieces of the

real thing.

❏ 6. The cavity on the back side of the control yokes is filled with

automotive body filler or epoxy. Before the filler sets-up, insert a

1/8" x 1-1/4" dowel into the center of the yoke. Secure it in

position until the filler cures. The dowels are mounted by drilling

1/8" holes through the instrument panel and glued to small scrap

wood blocks on the back side.

❏ 7. All knobs and buttons are made from large and small

quilters pins. Insert them through the instrument panel, then bend

them 90° on the back side. Cut off the excess close to where the

pins are bent, then glue them in position on the

back side.

❏ 8. The pull straps on the doors are made from short pieces of

scrap plastic glued in position with CA.

Many more details can be added. It’s up to you. A little

imagination and craftsmanship is all it takes. Have fun with this

project.The results will be well worth the effort.

FINAL INSTALLATION

❏ 1. Glue the left and right cabin sides in position. We suggest

using clear silicone sealer as the adhesive because it provides a

good bond between wood and plastic.

❏ 2. Slide the floor into position between the sides followed by

the aft bulkhead. The floor and aft bulkhead may be glued in

position with CA. Glue the seats to the floor with CA after

scraping off any paint from the points of contact.

❏ 3. Install the instrument panel using your chosen method.

When you take your Cessna 182 to the field, try to be

gracious in accepting all the praise you will undoubtedly get.

Happy flying!

PRINTED IN USA.

™

SCALE INTERIOR KIT FOR THE GOLD EDITION CESSNA 182 SKYLANE

TOOLS AND SUPPLIES:

❏Thin CA – (Top Flite

®

Supreme

™

recommended)

❏Hobby knife and # 11 blades

❏Scissors or Lexan

®

shears

❏Round file

❏100, 220,340 and 400-grit wet or

dry sandpaper

❏Sanding block - (Great Planes Easy-

Touch

™

Bar Sander recommended –

#GPMR6170)

❏Selection of small paint brushes

❏Paint compatible with styrene plastic

❏Model Enamel paint – (Testors

Enamel Recommended)

❏Plastic model seam putty (Testors),

or automotive body filler (Bondo

®

)

❏Needle nose pliers

❏Spray adhesive – 3M #77

(MMMR2000)

❏Tweezers

❏Silicone sealer adhesive

Page 2

SCRAPS FROM AROUNDYOURWORKSHOP

❏ Stiff paper or index card – for seat pockets

❏ Chrome trim tape – for seatbelt buckles

❏ Large T-pins – for seatbelt attachment

GETTING STARTED

Assembling and installing your scale cockpit will probably require

minor adjustments and “tweaking” to fit your particular model.

This is because of variations in building technique, par ts

alignment and glue fillets that may interfere with proper

positioning of the parts. A little patience is all that is required to

obtain a good looking installation. Trim par ts a little at a time,

checking the fit after each adjustment. Remember, you can

always remove material, but it’s hard to put it back.

❏ 1. Start by trimming all parts to the embossed “trim lines.” Be

sure to leave a 1/8" - 3/16" lip around the fuse side panels to

provide a gluing surface for the floor and aft bulkhead. Use a

hobby knife or scissors to

“

rough cut”the parts, then sand the

parts with a sanding block to straighten the edges.You can evenly

sand the edges by simply taping a sheet of 240-grit sandpaper to

your workbench. Then work the part in a circular motion while

pressing down gently. Cut out the center of each instr ument

cavity and smooth the edges with sandpaper. NOTE: Save all

scraps of smooth plastic (especially from inside the window

openings) for later use.

❏ 2. Carefully remove the bottom portions of the front and rear

seat backs as shown in the photo.The side “tabs” will be used to

attach the seat backs to the lower sections.

❏ 3. Refer to the exploded drawing on the following page to see

how the parts will fit together. Without using glue, (and in the

following order), fit the sides, floor, aft bulkhead and instrument

panel into the fuselage cavity.Youwill need to cut the top edge of

the sides to fit around the wing blocks and top cabin crossmember as shown in the photo. Use the underside of the rear

window frame and also the side windows for reference when

trimming the side panels to size.

NOTE: We recommend that once the sides are in position, you

glue three or four strips of 1/4" x 1/2" balsa across the width of

the fuse at the bottom edge of the plastic side panels to provide

additional support for the floor.

❏ 4. Decide how you are going to attach the forward floor section

(the part that covers the servos and battery compartment) and the

instrument panel. Some strategically positioned spots of Velcro

®

Hook and Loop Material (Great Planes #GPMQ4480 recommended)

may be used for this purpose or you could use #2 sheet metal

screws and small mounting blocks made from scrap plywood or

hard balsa. The servo cover could be folded back for access to the

servos or it could be made completely removable – your option.

❏ 5. When you are satisfied with the fit of the primary cabin

parts, remove them from the model and set them aside until it’s

time to paint.

ASSEMBLETHE SEATS

❏ 1. Cut several 1/4" x 1" strips of plastic from the flat scrap

material you saved earlier. These will be used to create gluing

tabs for the seats. Glue three strips inside the bottom halves of

both front seats (protruding half way over the edge) as shown.

Glue four strips inside the bottom of the rear seat.

❏ 2. Glue two or three strips to the inside of the three seat

back cushions.

❏ 3. Insert the tabs of the rear seat back into the bottom half of

the seat, then apply a piece of masking tape to the joint.The seat

back should angle toward the rear of the cabin by a few degrees.

Glue the seat back in position by “wicking” a few drops of thin CA

into the joint from the back side. Remove the tape after the CA

has cured.

❏ 4. Tape the rear seat cushions to the bottom half of the seat at

a couple of places. When the two halves are aligned, use thin CA

to glue the parts together. Use the same technique to add the

seat back cushions.

❏ 5. Assemble the two front seats the same way as the rear seat.

❏ 6. Use plastic model seam putty or automotive body filler to

cover all of the joints. When the filler has cured, wet sand it

smooth with 340 or 400-grit sandpaper.

❏ 7. Seat back pockets can be made from index cards or stiff

paper glued into position with thin CA.

PAINTINGAND DETAILING

❏ 1. Before painting, thoroughly clean the parts with rubbing

alcohol, then allow them to dry completely.

❏ 2. Paint the parts with paint compatible with styrene. For the

best results, use spray paint. Do not use Top Flite LustreKote

™

as

it is not compatible with styrene. If adding “carpeting,” paint only

the embossed seat tracks before installing the fabric.

PLASTIC PARTS LIST

1...........1............Side panel – left (Not Shown)

2...........1............Side panel – right

3...........1............Instrument panel

4...........1............Floor

5...........1............Aft bulkhead

6...........2 ea.......Lower front seats

7...........2 ea.......Front seat cushions

8...........2 ea.......Front seat back – rear half

9...........2 ea.......Front seat back – front half

10.........1............Lower rear seat

11.........2 ea.......Rear seat cushions (bottom & back)

12.........1 ea.......Rear seat back – rear half

13.........2 ea.......Control yokes

14.........2 ea. .....1/8" x 1-1/4" Dowel

DETAILINGPARTS LIST

–NotShown–

1 yd. ............Dressmakers’ elastic – Seat belts

12 ea. ..........Small head pins – Dash knobs and buttons

4 ea. ............Large head pins – Throttle/Mixture knobs

1 ea. ............9" x 18" Carpeting

Loading...

Loading...