Page 1

INSTRUCTION MANUAL

ROTATING LASER

RL-100 2S

31485 90050

ESC

MENU

ENT

RL-100 2

S

X/Y

Page 2

FCC WARNING

Changes or modifications not expressly approved by the manufacturer for compliance could void the user’s

authority to operate the equipment.

In order to comply with FCC radio-frequency radiation exposure guidelines for an uncontrolled exposure, this

device and its antenna must not be co-located or operating in conjunction with any other antenna or transmitter.

The term “IC:” before the radio certification number only signifies that Industry Canada technical specifications

were met.

“Operation of this device is subject to the following two conditions: (1) this device may not cause interference,

and (2) this device must accept any interference, including interference that may cause undesired operation of

the device.”

“The installer of this radio equipment must ensure that the antenna is located or pointed such that it does not

emit RF field in excess of Health Canada limits for the general population; consult Safety Code 6, obtainable

from Health Canada’s website www.hc-sc.gc.ca/rpb”.

Declaration of Conformity

Model Number: RL-100 2S/RC-400

Trade Name: TOPCON CORPORATION

Responsible party: TOPCON POSITIONING SYSTEMS,Inc.

Address: 7400 National Drive, Livermore, CA 94550, U.S.A.

Telephone number: 925-245-8300

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Page 3

1

Foreword

Thank you for purchasing the Topcon RL-100 2S Rotating Laser.

It is one the world’s most advanced and accurate grade-setting lasers. To quickly and effectively use

the RL-100 2S, please read these brief instructions carefully, and keep them in a convenient location

for future reference.

Handling Precautions

Guarding the instrument against shock

When transporting the instrument, provide some protection to minimize risk of shock. Heavy

shocks may affect beam accuracy.

Sudden changes of temperature

A sudden change in temperature may cause water condensation on the glass used for the laser

emission part.

In such a case, let the instrument stand for a while to allow it to adjust to the temperature prior to

actual use.

Caution:

Use of adjustment controls or performance procedures other than those specified herein may

results in hazardous radiation exposure.

Page 4

2

Safety Information

In order to encourage the safe use of products and prevent any danger to the operator and others or

damage to properties, important warnings are put on the products and inserted in the instruction

manuals.

We suggest that everyone understand the meaning of the following displays and icons before

reading the “Safety Cautions” and text.

• Injury refers to hurt, burn, electric shock, etc.

• Physical damage refers to extensive damage to buildings or equipment and furniture.

Display Meaning

WARNING

Ignoring or disregard of this display may lead to death or serious injury.

CAUTION

Ignoring or disregard of this display may lead to personal injury or physical damage

to the instrument.

The user of this product is expected to follow all operating instructions and make periodic checks

of the product’s performance. The manufacturer or its representatives assume no responsibility

for results of the use of this product including any direct, indirect, consequential damage, and loss

of profits.

Page 5

3

Safety Cautions

WARNING

There is a risk of fire, electric shock or physical harm if you attempt to disassemble or repair the instrument

yourself.

This is only to be carried out by TOPCON or an authorized dealer, only!

Laser beams can be dangerous, and can cause eye injury if used incorrectly .

Never attempt to repair the instrument yourself.

Laser beams can be dangerous. They can cause eye injury.

Do not stare into beam or view directly with optical instruments.

High temperature may cause fire.

Do not cover the charger while it is charging.

Risk of fire or electric shock.

Do not use damaged power cable, plug and socket.

Risk of fire or electric shock.

Do not use a wet battery or charger.

Cause eye injury or blindness.

Do not look at the sun through a telescope.

May ignite explosively.

Never use an instrument near flammable gas, liquid matter, and do not use in a coal mine.

Battery can cause explosion or injury.

Do not dispose in fire or heat.

Risk of fire or electric shock.

Do not use any power voltage except the one given on manufacturers instructions.

Battery can cause outbreak of fire.

Do not use any other type of charger other than the one specified.

The short circuit of a battery can cause a fire.

Do not short circuit battery when storing it.

Page 6

4

CAUTION

Use of controls or adjustment or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

Do not connect or disconnect equipment with wet hands, you are at risk of electric shocks if you do!

Risk of injury by overturn the carrying case.

Do not stand or sit on the carrying cases.

Please note that the tips of tripod can be hazardous, be aware of this when setting up or carrying the tripod.

Risk of injury by falling down the instrument or case.

Do not use a carrying case with a damaged which belts, grips or latches.

Do not allow skin or clothing to come into contact with acid from the batteries, if this does occur then wash off

with copious amounts of water and seek medical advice.

It could be dangerous if the instrument falls over, please check that you fix the instrument to the tripod

correctly.

Risk of injury by falling down a tripod and an instrument.

Always check that the screws of tripod are tightened.

Let the laser beam reach the aimed object or the target without anybody else in the laser beam path. When

operating in an open area, avoid radiating laser beam at eye level. It is quite possible for the beam to enter into

one's eyes, and it is possible to lose visual sight temporarily, and lose one's caution and awareness of other

dangers - avoid glaring beam.

Please note that the tips of tripod can be hazardous, be aware of this when setting up or carrying the tripod.

Risk of injury by overturn the carrying case.

Do not stand or sit on the carrying cases.

Page 7

5

EXCEPTIONS FROM RESPONSIBILITY

1) The user of this product is expected to follow all operating instructions and make periodic checks of the product’s

performance.

2) The manufacturer, or its representatives, assumes no responsibility for results of a faulty or intentional usage or

misuse including any direct, indirect, consequential damage, and loss of profits.

3) The manufacturer, or its representatives, assumes no responsibility for consequential damage, and loss of profits by

any disaster, (an earthquake, storms, floods etc.).

A fire, accident, or an act of a third party and/or a usage any other usual conditions.

4) The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of profits due to a

change of data, loss of data, an interruption of business etc., caused by using the product or an unusable product.

5) The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of profits caused by

usage except for explained in the user manual.

6) The manufacturer, or its representatives, assumes no responsibility for damage caused by wrong movement, or

action due to connecting with other products.

Page 8

6

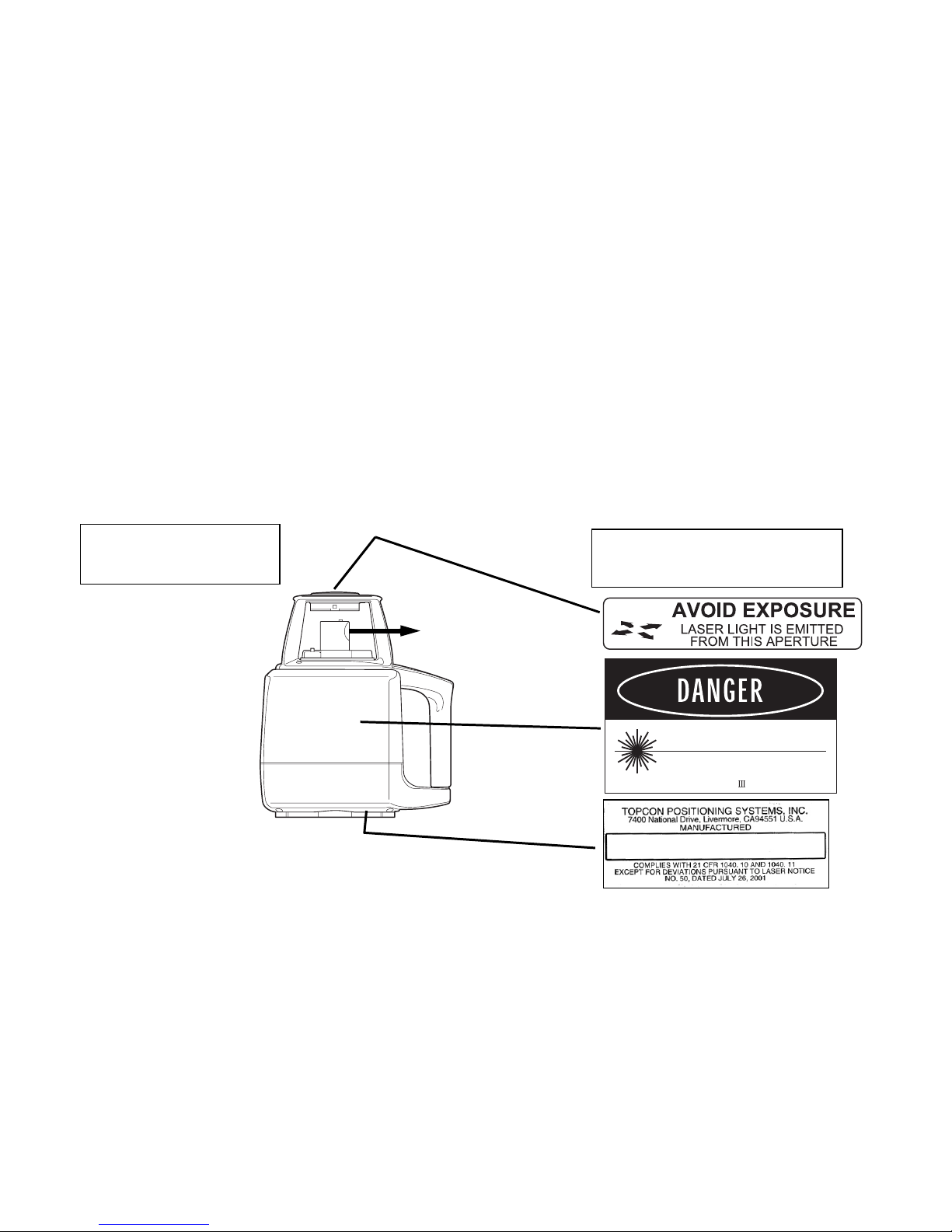

Laser Safety

Safety Information

This laser complies with all applicable portions of title 21 of the Code of Federal Regulations, Dept. of Health,

Education, and Welfare: Food and Drug Administration: Center for Devices: Bureau of Radiological Health.

Do not stare into the laser beam or view directly with optical instruments.

Do not disassemble the instrument or attempt to perform any internal servicing.

Repair and servicing of this laser are to be performed by TOPCON or its authorized dealer.

Caution : Use of adjustment controls or performance procedures other than those specified herein may result

in hazardous radiation exposure.

CLASS a LASER PRODUCT

AVOID DIRECT EYE EXPOSURE

LASER RADIATION

WAVE LENGTH 685nm

5mW MAXIMUM OUTPUT

Visible laser

Laser output: 2.5mW

CLASS IIIa LASER PRODUCT

VISIBLE LASER BEAM

Beam Aperture

Page 9

7

Contents

Foreword .......................................................................................................................... 1

Handling Precautions................................................................................................. 1

Safety Information...................................................................................................... 2

Safety Cautions ........................................................................................................ 3

Laser Safety............................................................................................................... 6

Contents .................................................................................................................... 7

Standard System Components.................................................................................. 9

Nomenclature................................................................................................................. 10

Sample Display........................................................................................................ 12

Key Functions .......................................................................................................... 13

RL-100 2S LED Display........................................................................................... 13

Basic Operation.............................................................................................................. 14

Preparation and Functions ............................................................................................. 15

Power Source .......................................................................................................... 15

Setting Up Instrument .............................................................................................. 15

RC-400 Remote Controller ...................................................................................... 16

Power Switch ........................................................................................................... 18

Battery Status Display ............................................................................................. 20

Setting Grades......................................................................................................... 21

Aligning Direction of Grade...................................................................................... 22

How to Enter Grade ................................................................................................. 23

Menu .............................................................................................................................. 24

How to Set the Menu ............................................................................................... 24

Switching Masking Mode ......................................................................................... 26

Page 10

8

Maintaining Power Sources ........................................................................................... 33

How to Change Batteries on the Instrument ............................................................ 33

How to Replace the RC-400 Batteries..................................................................... 37

Check and Adjusting ...................................................................................................... 38

Horizontal Calibration .............................................................................................. 38

Horizontal Rotation Cone Error................................................................................ 42

Grade Setting Error.................................................................................................. 43

Storage Precautions....................................................................................................... 45

Standard/Optional Accessories...................................................................................... 46

Specifications ................................................................................................................. 51

Error Display .................................................................................................................. 53

FCC WARNING ............................................................................................................. 55

IC WARNING ................................................................................................................. 56

Page 11

9

Standard System Components

1) Instrument ...............................................................1pc.

2) Level sensor LS-80B ...............................................1pc.

3) Remote controller RC-400.......................................1pc.

4) Level sensor holder model 6 ...................................1pc.

5) Carrying case ..........................................................1pc.

6) AA Manganese battery (To confirm operation)*.....5pcs.

7) Instruction manual ..................................................1vol.

8) Battery holder DB-67C ............................................1pc.

9) Ni-MH battery pack BT-67Q ....................................1pc.

10) AC/DC converter AD-11 ..........................................1pc.

• Please make sure that all of above items are in the box when you unpack.

* Batteries included in the package are to confirm the initial operation.

Please replace the batteries provided with new batteries as soon as possible.

Page 12

10

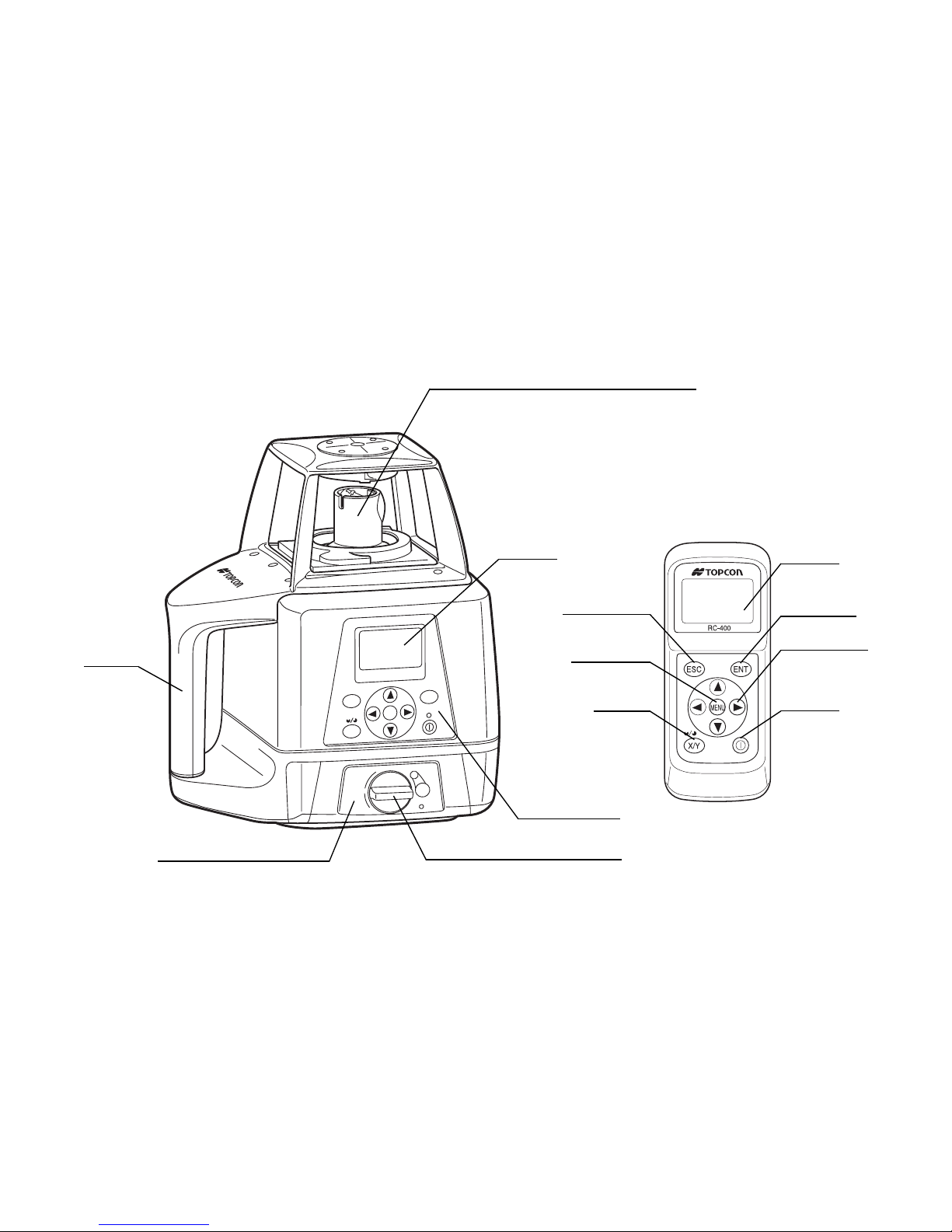

Nomenclature

ESC

MENU

ENT

RL-1

00 2S

X/Y

Rotary head/Laser emitting window

Beam aperture

RC-400 Remote Controller

Handle

Battery holder DB-67C

Control panel

Battery compartment lock

Display

Escape key

Enter key

X/Y key

Power

switch

Arrow keys

MENU key

Display

Page 13

11

ESC

MENU

ENT

RL-100 2S

X/Y

Escape key

Enter key

X/Y key

Power switch

Arrow keys

MENU key

Control panel

Automatic leveling indicator

Page 14

12

Sample Display

Normal display

X axis grade

(Blinks digit by digit

during leveling)

Leveling indicator

(Blinks during leveling)

Transmission and

reception display

(On remote controller only)

Battery remaining

Rotating laser display: RL

Remote controller display: RC

Transmitting

Complete

Incomplete

Channel

Y axis grade

(Blinks digit by digit

during leveling)

Rotation speed (rpm)

Menu screen display

See “Menu” on page 24.

Page 15

13

Key Functions

RL-100 2S LED Display

There is an LED that signals automatic alignment of the control panel screen of the main

instrument.

Flashing : Auto-leveling or grade setting is in process.

The rotary head is not rotating.

ON solid : Auto-leveling grade setting is complete.

The rotary head is active and emits the laser beam.

Enter key End Operation of Data Input and Sends data to the instrument.

Escape key Cancels input or escape to previous status.

X/Y key Sets each grade axis.

Menu and arrow keys Selects menu items.

Inputs the grades of X Y axis.

Sets the masking direction.

Power switch On/Off of the RL-100 2S and RC-400.

(RC-400 has auto-cut off 60 seconds function)

You can stop the auto-levelling function. Refer to “Menu” on page 24 to stop the

function.

Page 16

14

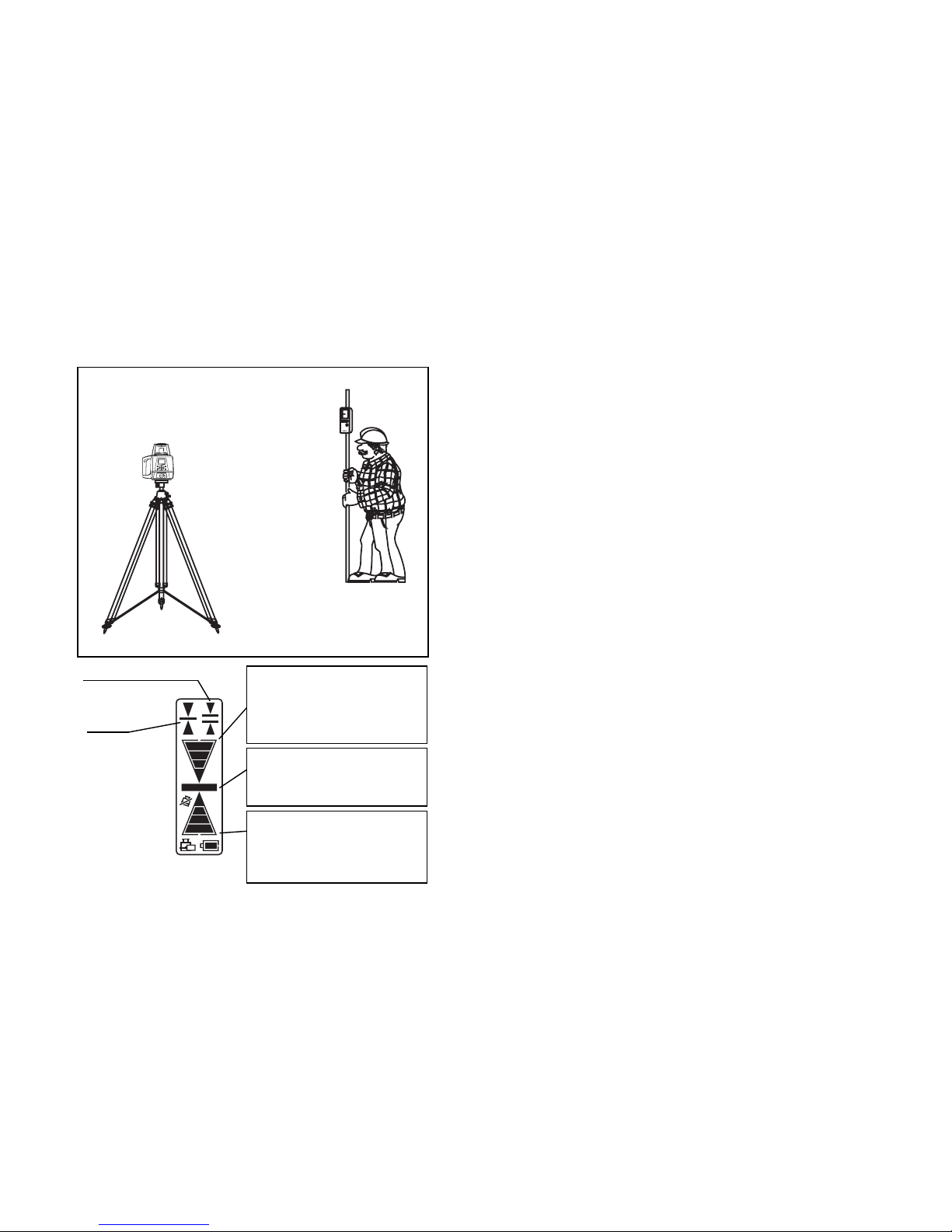

Basic Operation

1 Set the instrument on a tripod or smooth surface

and turn on the power.

When using the remote controller, turn on the power for

the instrument, and then the power for the remote

controller.

2 Set X and/or Y axis grades.

3 Turn on the level sensor. Check the operation

surface by using the level sensor. If high-precision

detection is desired, select that setting on the

level sensor.

4 Check the rotating beam elevation using the level

sensor.

Normal precision mode

High precision

mode

Level sensor

Higher than datum position

(Buzzer sound: High frequent

beep sound)

Move the sensor downward.

Datum position

(Buzzer sound: Continuous

beep sound)

Lower than datum position

(Buzzer sound: Low frequent

beep sound)

Move the sensor upward.

(For more information about level sensor refer to

“Standard/Optional Accessories” section.)

Page 17

15

Preparation and Functions

Power Source

Connect the battery according to the battery type purchased.

For charging and battery replacement instructions, see the “Maintaining Power sources” section.

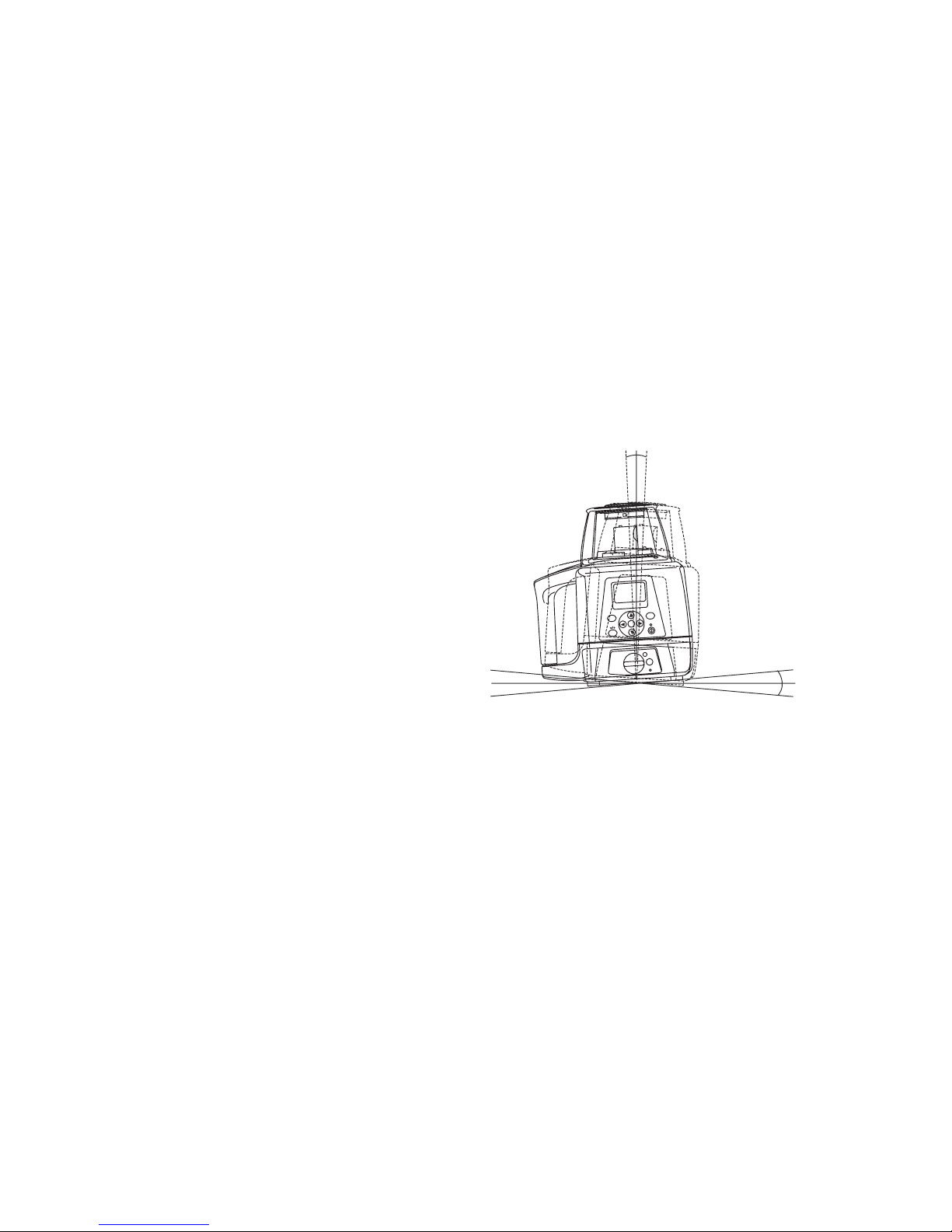

Setting Up Instrument

Set the instrument on a tripod or smooth

surface.

The instrument must be within horizontal ±5

degrees of true level for auto-leveling to

operate.

ES

C

MENU

ENT

R

L-100

2S

X/Y

±5°

Page 18

16

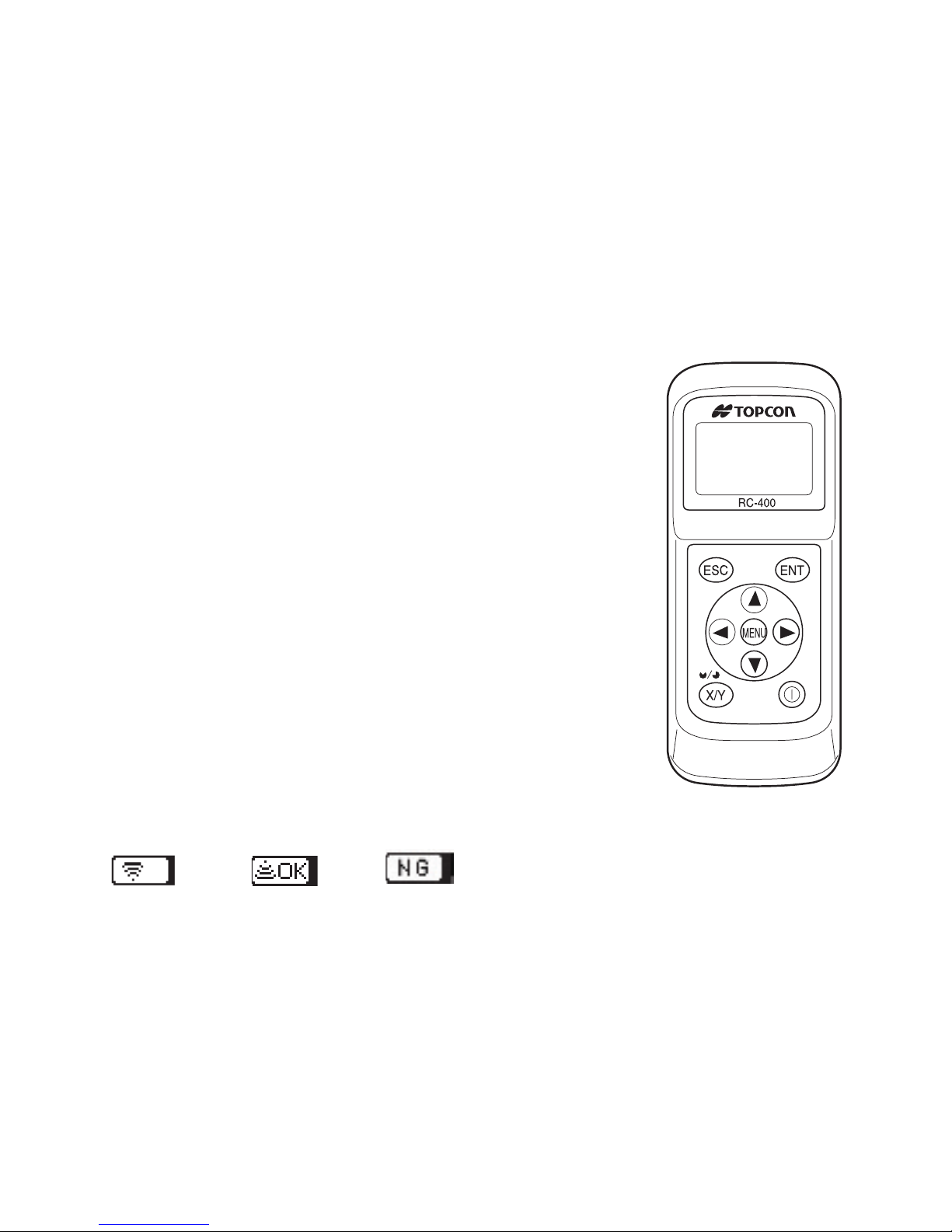

RC-400 Remote Controller

When using the remote controller, turn on the power for the

instrument, and then the power for the remote controller.

Key operation

Press the [ENT] key after each key operation to lock the entry.

There will be interactive transmission between the instrument and

the remote controller.

When the [ENT] key is pressed, entered information is transmitted

from the remote controller to the instrument. When information is

received by the instrument, it sends out signal of its confirmation to

the remote controller.

Please check the display to make sure that the entry is correctly

performed. (It will not be displayed on the display screen of the

instrument.)

Transmission and reception display

Transmitting Complete Incomplete

Page 19

17

1) The working range of the remote controller is up to a distance of about 300 m from

the instrument.

2) It is necessary to install batteries when using the remote controller. Install the

batteries by referring to “Maintaining Power Sources” on page 33.

3) The power of the remote controller shuts off automatically after about 60 seconds

when key or leveling operations have been completed (Auto Shutoff Function).

When using it in the temperature -10°C or lower, warm up function will activate and

the power for the remote controller shuts off automatically in about 5 minutes after

warm up is completed.

Press the power switch once to restore power to the remote controller after the auto

shutoff function has been activated.

Common use of RC-400 remote controller

RC-400 remote controller can control plural RL-100 2S. When you are using plural RL-100 2S

at your job site, you can use your RC-400 for the other RL-100 2S unit. Change the channel to

receive the internal data of each RL-100 2S to the RC-400 by operating the RC-400.

This function enables operating of each RL-100 2S, by transmitting and displaying the data of

each unit to the remote controller before operation.

See page 28 for the operation “3) Setting channel”.

Page 20

18

Power Switch

When the power switch on the instrument is turned on, automatic alignment and automatic grade

setting will activate.

When using the RC-400 for wireless remote control, also turn the instrument ON or OFF by

pressing the power switch on the RC-400.

When transmission had not been correctly performed, “NG” will appear at the lower left of the

screen. In such case, please turn the power on once again.

Always turn off the power for the RC-400 before turning off the power for the instrument after the

operation. If you forget to turn off the power for the instrument before one for RC-400, the

instrument will go into standby mode and the power will not turn off completely.

When the power is not turned off for the instrument.

Standby mode

Instrument will go into standby mode when turning

off the power by remote controller.

The power of instrument will turn off completely after

keeping standby mode 3 hours.

Page 21

19

The channel on the RL-100 2S is not same as one on the RC-400 (Remote mode).

1 If the channel on the main unit is different from that on the remote control when the power

switch is turned ON, the channel on the main unit will be automatically searched for.

[SEARCHING...] will be displayed.

2 When the search is finished, the available channel and serial number of the instrument will be

displayed. If more than one channel is displayed, use the arrow key (up/down) to position the

cursor on the channel you want to select. Press the [ENT] key to select that channel.

If the message shown left appears, it may indicate that the

radio transmission fails. Please turn on the power for the

instrument and the remote controller once again.

Page 22

20

Battery Status Display

Remaining battery level is displayed at the lower bar in the display area.

For handling batteries, see the “Maintaining Power Sources” on page 33.

If an AC/DC converter is connected to the

main instrument when the main

instrument is displaying “RL-100

BATTERY LOW”, the remaining battery

level display will not change.

Once the power is turned off, the battery

remaining display will reset.

Battery remaining display

Rotating laser display: RL

Remote controller display: RC

RL-100 BATTERY Low

or

RC-400 BATTERY Low

(Displayed on the RC-400 only)

Battery is sufficient.

Battery is sufficient.

Battery is sufficient.

The power is low, but laser is still usable. (Indication

continues until batteries are dead.)

Dead batteries of RL-100 2S or RC-400. Recharge

the battery or replace the dry batteries with new ones.

Page 23

21

Setting Grades

Grade can be set in both axes, X and Y, as shown below.

Grades can be set in the range indicated below.

X: –10% to +10%

Y: –5% to +25%

Grade axes and axis symbols are as shown in the diagram below.

+10%

X axis

Y axis

–10%

+25%

–5%

Panel side

Plus

Minus

Plus

Minus

Page 24

22

Aligning Direction of Grade

When using the laser with a percent of grade entered, the laser

must be properly aligned so the slope of the laser beam is

parallel to the desired direction of grade.

The sighting collimator on top of the instrument is calibrated to

the grade axis of the laser beam. Follow the steps below to align

the laser to the desired direction of grade:

1 Establish a target line parallel to desired direction of grade.

2 Set up the laser over this line (drop a plumb bob from the

tripod mounting screw).

3 Rough align the instrument to the direction of grade. Make

sure it is properly oriented for the grade to be entered,

positive or negative. (See page 21)

4 Place a rod or other target down range on the target line.

5 While sighting through

the collimator, adjust the

instrument until the sight

is aligned with the target.

(See the figures on the

right.)

E

S

C

M

E

N

U

E

N

T

R

L

1

0

0

X

/

Y

Target

Plus direction

Minus direction

Page 25

23

How to Enter Grade

1 Press the X/Y key to begin grade input.

The axis symbol will flash and it will go into grade entry

status.

(The X and Y axis displays will switch with each push.)

2 Select positive or negative grade by pressing arrow

keys (Up or Down).

3 Move the cursor by pressing the arrow keys (Right or Left).

4 Increase or decrease the number by pressing the arrow keys (Up or Down).

5 Press the [ENT] key to finish input.

When setting up using the remote controller

Confirm the [OK].

If the [NG] mark is displayed, press the [ENT] key.

When holding down the [X] or [Y] key while the X or Y symbol is flashing, the flashing

axis will reset to 00.000%.

Single axis Dual axes

Grade range:

X: –10% to +10%

or

Y: – 5% to +2 5 %

Grade range:

X: –10% to +10%

Y: –5% to +25%

X axis

Y axis

X axis

Y axis

Page 26

24

Menu

How to Set the Menu

As indicated by arrows in the figure, there are 6 setting categories in the menu and selection and

changes of the settings are performed using the arrow keys and [ENT] key.

1 Press the menu key to display the menu screen. As

you can see, the mask setting is framed with the

curser.

2 Move the curser to the item you would like to set up

using the arrow keys and press the [ENT] key. The

selected item will start flashing.

3 Select the setting details using the arrow keys.

4 Press the [ENT] key to lock the setting.

When setting up using the remote controller, make

sure that “OK” is displayed on the transmission and

reception display. If “NG” is displayed, press the

[ENT] key once again.

5 In the same manner, select and change the next

setting.

Changing Masking Mode

Changing rotary head speed

Setting channel

Sensitivity Level (LEVEL)

Safety Lock System

(Height Alert)

Alarm Signal (COM)

Page 27

25

The menu allows setting of the following functions.

1) Changing Masking Mode

Sets up masking (laser beam shut off) and change shut off directions.

Masking (Laser beam shutter) setting

Depending on the status of the location where the instruments are used, laser beam emission to

unnecessary direction can be shut off.

1 Press menu key to display the menu

screen.

The mask setting will be displayed on the

right in the upper side of the screen.

2 Use the arrow keys to position on the

Mask display and press the [ENT] key.

3 Select the direction you desire to mask

using the arrow keys.

Each press repeats mask activating/

releasing.

4 When desired masking is displayed, press the [ENT] key to finish.

Confirm the [OK] mark on the display

1) Changing Masking Mode 2) Changing rotary head speed

3) Setting channel 4) Sensitivity Level (LEVEL)

5) Safety Lock System (Height Alert) 6) Alarm Signal (COM)

The state when masking is not activated

(Laser beams are emitted to all directions.)

Page 28

26

When setting up using the remote

controller

After completing 1 through 4 of the above

setting procedures, check that the transmission

and reception display is showing “OK”.

If the [NG] mark is displayed, press [ENT]

again. (“OK” and “NG” will be displayed only on

the remote controller screen.)

Switching Masking Mode

The status in which the X+ direction is masked.

(Laser beam is shut off in the X+ direction.)

Displays the direction that

laser beam is emitted.

Displays the masking direction

Mode 1 Mode 2

As seen

from above

As seen

from above

You can select either Mode 1 or Mode 2 for the masking mode (split-masking direction).

The relationship between the arrow keys and masking directions are shown in the above figure.

X axis

Y axis

Page 29

27

Masking Mode Setting

1 Follow steps 1-2 for the masking setting.

2 Each press of the [X] or [Y] key toggles Mask Mode 1 and Mask Mode 2.

3 Press the [ENT] key to lock the entry. When setting up with the remote controller, make sure

that “OK” is displayed on the transmission and reception display. If “NG” is displayed, press the

[ENT] key once again.

Sample display

2) How to change the rotary head speed (300, 600, 900 R.P.M.)

The rotary head speed can be set to 300, 600 or 900

R.P.M.

Press the menu key to display the menu screen. Use

the arrow keys to select the rotary head speed and

press the [ENT] key. When the head speed starts

flashing, select the desired speed using the arrow

keys and press the [ENT] key.

Mode 1 Mode 2

Rotation speed

Page 30

28

3) Setting channel

[Setting from the control panel of the instrument]

Only channel on the instrument can be changed.

[Setting from the remote controller]

Only channel on the remote controller can be changed.

[Changing a channel setting by searching] *RC-400 only

1 Set channel display to “SEARCH” as later described in

the “How to set the menu”, press the [ENT] key to lock

entry.

2 Search for the channels available on active or standby

RL-100 2S.

When the search is completed, searched channels will be

displayed.

3 Use the arrow keys (up and down) to position the curser

on the channel you want to select and then press the

[ENT] key.

When using more than one units, do not

use the same channel at the same time.

You may set the channel from 1 to 9.

[Setting Channel]

[Channel setting by searching]

Page 31

29

4) Sensitivity Level (LEVEL)

The sensitivity level allows the user to select the vibration level that is permitted during

automatic alignment or grade setting. Set a sensitivity level to suit the location where the

instrument is used such as places that undergo many vibrations, and also in consideration of

the operational precision.

Two sensitivity levels can be set: large and small vibrations.

Manual setting will stop the automatic alignment function.

Do not use the manual setting for sensitivity level except in special

circumstances. If the manual setting is selected, the automatic alignment function

will not operate, so the grading setting precision will not be assured at all. The

manual setting will also deactivate the settings for X- and Y-grades.

Large vibration

Small vibration

Manual

Page 32

30

5) Safety Lock System (Height Alert)

In case the [ALERT] setting is ON. Safety Lock System will active. (This will be active around

10 minutes after turning on the power.)

Should the installed status of the instrument suddenly change when automatic alignment is

functioning and laser beam is being emitted, through, for example, unnecessary contact by the

user, the automatic alignment function will automatically stop to protect operational precision.

In such a case, the rotary head will act as below:

When [6) Warning transmission] is activated: it will rotate slowly

When [6) Warning transmission] in not activated: the rotation will stop

How to reactivate

Turning off the power for the instrument, and then turning it back on will activate the automatic

alignment function.

Active

Inactive

Error : Blinks alternately

Page 33

31

6) Alarm Signal (COM)

When used with the Topcon laser sensor, the RL-100 2S can communicate alarm signals

directly to the sensor. This helps enable the user to be completely aware of potential

problems before they can become serious.

Active

Inactive

Page 34

32

Concerning initial operation in a low temperature

When the instrument and remote controller is used in a temperature below -10°C, a warm up

operation of approximately 4 minutes is necessary for the LCD after the power is turned on.

During the warm up operation, no operation is possible except turning the power switch on/off.

The instrument will perform automatic alignment; however, when the automatic alignment has

been completed, the instrument will go into a standby state until the warm up operation is

completed (the rotary head is in a resting state).

After the warm up operation is completed, the instrument and remote controller will function

normally.

During the warm up operation, the instrument will continue the operation even if the

power of the remote controller is turned off. (The instrument will not go into a

standby state.)

When the power is turned off after the warm up operation is completed, the

instrument will begin warm up operation again when the power is back on.

Warm up screen

Approximately

4 minutes later

Page 35

33

Maintaining Power Sources

How to Change Batteries on the Instrument

Dry battery

How to replace dry batteries

1 Remove the battery cover by turning the battery

cover knob to “OPEN”.

2 Remove the old batteries and replace with new

batteries (four D batteries) matching [+] and [-] as

shown in the figure.

3 Replace the battery cover and turn the knob to

“LOCK”.

Replace all 4 batteries with new ones.

Do not mix old batteries and new ones.

Page 36

34

Rechargeable battery

Installing

1 Insert Ni-MH BT-67Q battery pack into the DB-67C battery holder.

2 Insert the battery pack into the instrument and turn the battery cover knob to “LOCK”.

Charging

1 Plug the AC/DC converter AD-11 into the DB-67C

battery holder.

2 Plug the converter power cord into the appropriate

AC outlet.

3 When charging is complete (after approximately

seven hours), unplug the converter from the

connector on the DB-67C battery holder.

4 Unplug the converter power cord from the AC

receptacle.

AC/DC

converter AD-11

DB-67C

LED

Page 37

35

The LED of DB-67C will indicate charging status:

Red ON : Charging.

Green ON : Charging completed.

Green flashing : Ni-MH BT-67Q battery pack is not installed correctly.

Red flashing : Ni-MH BT-67Q battery pack protection feature is working automatically.

RL-100 2S can be used in this state.

The instrument has a protection feature which works when nickel hydride batteries are

overcharged or when the batteries are under a high or low temperature (+70°C or higher, or 0°C or

lower) state. In such a case, charging will stop automatically to protect nickel hydride batteries.

Recharging should be performed in a room temperature ranging from +10°C to +40°C.

Always use the AC/DC converter provided with the product.

1) The Ni-MH BT-67Q rechargeable battery can be charged while using the laser.

2) The Ni-MH BT-67Q rechargeable battery can be charged when the battery holder is

removed from the instrument. This allows the option of alternately using two battery

packs to always maintain a fully charged pack.

3) The Ni-MH BT-67Q rechargeable battery can be removed from the DB-67C battery

holder and four “D” cell alkaline batteries can be installed.

4)The DB-67 dry cell battery holder cannot be used to charge the BT-67Q Ni-MH battery

pack. Use the DB-67C charging battery holder instead.

BT-67Q

DB-67C

Page 38

36

1) For longer battery life, conform to the suggested charging time to the extent possible.

2) The battery source will discharge when stored and should be checked before using

with instrument.

3) Be sure to charge stored battery source every 3 or 6 months and store in a place at

30 °C or below.

If you allow the battery to become completely discharged, it will have an effect on

future charging.

Page 39

37

How to Replace the RC-400 Batteries

1 Keep pushing the battery cover in [1] direction,

and then try to slide the cover in [2] direction. The

cover does not move but it will be open.

2 Remove the old batteries and replace with new

batteries (three AA batteries), matching [+] and [-]

as shown in the figure.

3 Replace the battery cover.

Replace all 3 batteries with new ones.

Do not mix old batteries and new ones.

[1]

[2]

Page 40

38

Check and Adjusting

Horizontal Calibration

(1) Checking Calibration

1 Steadily set up a tripod approximately 50m from a

staff member or wall and adjust so that the head

of the tripod is horizontal.

Mount the instrument on the tripod in the

direction shown in the right figure (Y-axis facing

the wall).

2 While pressing the [X] or [Y] key, turn on the

power switch.

3 The flashing axis is the selected one.

Select the axis to check using the arrow keys

(right and left) and press the [ENT] key to lock.

50m (164feet)

Turn on the power while pressing the [X] or [Y] key.

Select the axis using the arrow keys (right and left)

and press the [ENT] key.

XY

WX

Level sensor

Staff or Wall

Page 41

39

(Example: Y axis)

4 Select Y axis by pressing the right arrow key.

Press the [ENT] key to lock.

5 “POSITION 1” display will flash and the instrument

will begin automatic alignment. After the automatic

alignment is completed, the “POSITION 1” light will

turn on, then, the rotary head rotates and emits

laser beam. (Y-).

6 Turn on the power for the level sensor, and press

the detective precision switch to select the high

detection mode.

7 Check the position of the laser beam (Y-) on the

wall.

Move the sensor up or down until the LCD indicator

identifies the center of the laser beam.

8 After fixing the beam, press the [ENT] key.

The display will change to flashing “POSITION 2”.

Check the laser beam on the wall.

Fix the laser sensor in the position where

the LCD indicator identifies the center of

the laser beam.

Press the [ENT] key after check.

POSITION 1

POSITION 2

Page 42

40

9 Loosen the tripod and rotate the instrument 180°

and retighten to fix. The Y+ side of the instrument

should be facing the wall. After the automatic

alignment is completed, the display will change to

[S][T], then, the rotary head rotates and emits

laser beam.

10 Following step 7, mark the laser beam position for

(Y+).

If the two lasers being marked are misaligned for

less than 5mm, adjustment is not necessary. Turn

off the power for the instrument. If adjustment is

required, move on to (2) How to adjust.

(2) How to adjust

After completing the checking in step 10, go on to

the adjustment specified below.

1 Using the arrow keys (up and down), adjust the

(Y+) laser beam to the center of (Y+) and (Y-).

2 Press the [ENT] key when the laser beam is

correctly positioned in the center.

Check the misalignment of laser

beam of (Y+) and (Y-) on the wall.

If one of the 3 center indicators is lit,

calibration is normal.

Misalignment of (Y-) and (Y+) laser

beam within 5mm is considered

normal.

Turn off the power to complete the checking.

When rotating the instrument

180º, ensure that the height of the

instrument is aligned.

By using the up and down arrow keys of the remote

controller, adjust the (Y+) laser beam to the center of

the (Y-) and (Y+).

Y+ rotating laser beam

center

S

T

Page 43

41

3 “CALCULATING” will flash indicating that the

calibration value is being calculated by the

instrument. Do not touch the instrument until “END”

is displayed to signify operation completed. (If you

touch the instrument, you will need to recalibrate.)

4 When “END” is displayed, press the [ENT] key.

The screen will return to the axis selection screen.

If you wish to continue with checking the X axis, go

back to step 3 for calibration check.

5 When you have completed the adjustment, turn off

the power.

After adjustment is completed, go through the

checking procedure to check if the adjustment was

done accurately.

If the correction value calculated exceeds the allowable range, the RL-100 2S will

display error code [CALIBRATION OVER ERR]. Check the procedure again and

perform any inspections and adjustments.

After positioning the laser beam, press the [ENT] key.

After calibration value is fixed, press the [ENT] key.

The screen goes back to the axis selection screen.

CALCULATING

END

XY

WX

Page 44

42

Horizontal Rotation Cone Error

Perform the following check after completing “Horizontal Calibration” on the previous

page.

1 Set up the laser centered between two walls approximately 50 m (164 ft) apart. Orient the

instrument so one axis, either X or Y, is facing the walls. Grade should be set to 0.00% in both

axes.

2 Locate and mark the position of the rotating laser beam on both walls using the level sensor.

3 Turn off the instrument and move the instrument closer to wall A (1 m to 2 m /3 ft to 6 ft).

Do not change the axis orientation of the instrument. Turn the instrument on.

4 Again locate and mark the position of the rotating laser beam on both walls using the level

sensor.

5 Measure the distance between the first and second marks on each wall.

6 If the difference between each set of marks is less than ±5 mm (±7/32 of an inch), no error

exists.

If the difference between [wall A]-side and [wall B]-side exceeds ±5 mm (±7/32 of an

inch), contact your dealer or Topcon.

Minimum about 50 m/164 ft

Cone error

Datum position

Wall

A

Wall

A

Wall

B

Wall

B

Page 45

43

Grade Setting Error

Perform the following check only after completing “Horizontal Calibration” and

“Horizontal Rotation Cone Error”.

(1) Checking

1 Setup the Y+ side facing the staff as shown in the figure.

Securely position Nail 1 and Nail 2 exactly 30m apart.

2 Turn on power for the instrument and verify the staff height of Nail 1 and Nail 2 at grade setting

of 0% with laser sensor and record.

At this time the staff height for Nail 1 and Nail 2 should recorded as h1 and h2 (mm). Check the

laser sensor is set at high precision.

Level

sensor

Staff

Nail 1 Nail 2

Page 46

44

3 Set Y axis grade to 1.00%.

Align read the elevation of the laser beam in millimeters at Nail 1 and Nail 2.

Designate these elevations as “h3” at Nail 1, and “h4” at Nail 2.

4 Using the elevation readings for h1, h2, h3 and h4, complete the equation below.

If the calculated result is the range of 0.990% - 1.010%, the instrument is normal.

If the calculated result for either axis is out of the range, contact your dealer or Topcon.

Repeat the procedure aligning the “X” axis on the line created by Nail 1 and Nail 2.

Nail 1 Nail 2

Page 47

45

Storage Precautions

(1) Always clean the instrument after use.

1) If the instrument got wet with rain, wipe it well before storing in the storage case.

2) Wipe away stain or dirt with soft cloth after dusting.

(2) Clean storage case using cloth moistened with neutral detergent or water. Do not use ether,

benzene, thinner or other solvents.

(3) Store with the batteries removed, when operation is halted for more than a month.

Page 48

46

Standard/Optional Accessories

Level sensor holder model 6

154

152

150

153

151

138

136

134

132

139

137

135

133

131

131

149

147

148

146

HOLDER-6

Clamp knob

Level sensor

holder model 6

Level sensor

Page 49

47

Level Sensor LS-80A / 80B

Beam receiving

window

Buzzer sound

switch

(Quiet/Loud/OFF)

Display

Index

Detective

precision switch

Two leveling precision

options are available, normal

precision and high precision.

By pressing this switch, the

precision options are

switched alternately. Confirm

the precision choice by the

indicator. (Normal precision

is set when turning on the

power switch.)

Power switch

Buzzer speaker

Display

(Only LS-80A)

Auto-cut off function

The power will be turned off automatically if no laser beam is detected within

approximately 30 minutes. (To turn the sensor on again, press the power switch.)

Page 50

48

Display

The warning signal *1 and *2 will function only if RL-100 2S Alert Signal function [COM]

is active.

Alarm detection at the level sensor can be canceled by turning off the level sensor

switch while pressing the buzzer sound switch. When the switch is turned back on

again, alarm detection functions as usual.

High precision mode

Normal precision mode

RL-100 2S Height Alert warning

*1

When the Alert Signal function [COM] is active

on the RL-100 2S, the sensor will signal if the

laser has been disturbed so the height of the

instrument can be checked.

The buzzer will sound for about five seconds

and the height alert warning symbol will flash

until the sensor detects normal beam rotation

from the laser. To obtain normal beam rotation,

the RL-100 2S must be turned off then back on.

Then check that beam height has not changed.

RL-100 2S battery warning

*2

When the Alert Signal function [COM] is active

on the RL-100 2S, the sensor will signal if the

battery of the RL-100 2S is low. The laser low

battery warning symbol will flash on the level

sensor display. No audio signal is generated for

this warning.

Higher than datum position

Move the sensor down, The arrow will become shorter

as the datum position is approached.

Audio signal: High- pitch, frequent beep.

Datum position

(Audio signal: Continuous beep sound)

Lower than datum position

Move the sensor up. The arrow will become shorter as

the datum position is approached.

Audio signal: Low- pitch, frequent beep.

Battery remaining display

Indicates the battery remaining of level sensor

as follows.

Battery is sufficient.

The power is low, but laser is still usable.

Dead battery. Replace the 9v alkaline battery.

Page 51

49

Detective

range

Mode

Display

HIGH NORMAL

Replacing Battery

1 Keep pushing the battery lid in [1] direction,

and then try to slide the lid in [2] direction to

lift.

2 Remove the batteries from the battery box

and insert new batteries (two AA dry

batteries).

3 Press the lid down and click to close.

±1 mm/±.0032 ft

(2 mm/.0064 ft width)

±2 mm/±.0064 ft

(4 mm/.013 ft width)

±5 mm/±.016 ft

(10 mm/.032 ft width)

±10 mm/±.033 ft

(20 mm/.066 ft width)

±15 mm/±.005 ft

(30 mm/.010 ft width)

More than ±15 mm/.05 ft

Laser sensor has been moved above or

below the laser beam.

Move sensor in direction of arrow to

receive laser.

[1]

[2]

Page 52

50

Scope Model 4

The optional scope replaces the sighting collimator (see page 22) on top of the instrument and

provides greater accuracy in aligning the laser to the direction of grade. The scope can be

swiveled and locked in place so its aimed toward any of the four beam axes. Using the scope,

follow the steps on page 22 to align the instrument.

Page 53

51

Specifications

RL-100 2S

Accuracy (reproducibility) : ±10"

Auto-leveling range :±5°

Measuring range (Diameter) : Approx. 2 – 800 m (6 - 2624.7 ft) with level sensor

Rotation speeds : 300/600/900 rpm (Changeable)

Light source : L.D (Visible laser)

Power supply : 4D-CELL dry batteries (DC6V)

Ni-MH battery pack BT-67Q (It can be charged while using it.)

Continuous operating time Alkaline manganese dry battery

: Approx. 85 hours

Ni-MH battery pack BT-67Q

: Approx. 80 hours

Tripod screw : Flat and dome head type, 5"/8X11threads

Waterproof property/dust resistance : JIS protection grade IP66

Water proof construction : IP66 (Based on the standard IEC60529)

Operating temperature : –20 °C to +50 °C (–4 °F to +122 °F)

Dimensions : 174 (L) × 218 (W) × 253 (H) mm [6.9 (L) × 8.6 (W) × 10.0 (H) in]

Weight : 3.4kg (7.5lbs) (Dry battery type: Including dry batteries)

3.6kg (7.9lbs) (Ni-MH battery type: Including BT-67Q)

RC-400

Power source :Three “AAA” cell batteries

Operating distance : Approx. 300m

Continuous operating time : Approx. 3 months (Alkaline manganese dry battery)

(Life of battery may significantly shorten in the cold region.)

Operating temperature : –20 °C to +50 °C (–4 °F to +122 °F)

Dimensions : 157 (L) × 64 (W) × 37 (H) mm [6.8 (L) × 2.5 (W) × 1.4 (H) in]

Weight : 0.25kg (0.5lbs) (Including dry batteries)

Page 54

52

LS-80A (Back side display area)

Detective range : 50 mm (2.0 in)

Detective precision

High precision : ±1 mm (±0.04 in)

Normal precision : ±2 mm (±0.08 in)

Detective beam indication

: Liquid crystal and buzzer

Power source : Two AA dry batteries

Power voltage : 3VDC

Continuous operating time

Alkaline manganese dry battery

: Approx. 120 hours

The time for auto-cut off

: Approx. 30 min.

Waterproof property/dust resistance

: JIS protection grade IP66

Operating temperature

: –20 °C to +50 °C (–4 °F to +122 °F)

Dimensions : 146 (l) × 76 (w) × 26 (h) mm

: (5.7 (l) × 3.0 (w) × 1.0 (h) in)

Weight : 0.19 kg (0.42 lbs)

: (including a dry battery)

LS-80B

Detective range : 50 mm (2.0 in)

Detective precision

High precision : ±1 mm (±0.04 in)

Normal precision : ±2 mm (±0.08 in)

Detective beam indication

: Liquid crystal and buzzer

Power source : Two AA dry batteries

Power voltage : 3VDC

Continuous operating time

Alkaline manganese dry battery

: Approx. 120 hours

The time for auto-cut off

: Approx. 30 min.

Waterproof property/dust resistance

: JIS protection grade IP66

Operating temperature

: –20 °C to +50 °C (–4 °F to +122 °F)

Dimensions : 146 (l) × 76 (w) × 26 (h) mm

: (5.7 (l) × 3.0 (w) × 1.0 (h) in)

Weight : 0.19 kg (0.42 lbs)

: (including a dry battery)

Page 55

53

Error Display

Error Code Description Countermeasure

Batteries of the instrument are

dead.

Replace the batteries of the instrument.

Batteries of the remote controller

are dead.

Replace the batteries of the remote controller.

Safety lock system is activated.

Turn the power for the instrument off, and then turn it

back on to activate automatic alignment function.

The instrument is set up

exceeding the alignment range.

Reposition the instrument to fit into the alignment

range in the direction specified.

CALIBRATION OVER

ERR

Checking mode identified as

being exceeding calibration

range.

Turn the power for the instrument; turn it back on and

start over from the beginning.

RL-100 BATTERY LOW

RC-400 BATTERY LOW

Page 56

54

If errors still persist after attempting to clear them, contact Topcon or your dealer.

E-05

The rotary head is not rotating

Turn the power for the instrument off, and then turn it

back on.

E-51

Internal memory error for the

remote controller

Turn the power for the remote controller off, and then

turn it back on.

E-60’s

Encoder system error for the

instrument

Turn the power for the instrument off, and then turn it

back on.

E-80’s

Alignment is not completed

Turn the power for the instrument off, and then turn it

back on.

E-99

Internal memory error for the

instrument

Turn the power for the instrument off, and then turn it

back on.

LCD backlight is

flashing

Cannot be displayed

Turn the power for the instrument off, and then turn it

back on.

Error Code Description Countermeasure

Page 57

55

FCC WARNING

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause

undesired operation.

CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY THE MANUFACTURER

FOR COMPLIANCE COULD VOID THE USER’S AUTHORITY TO OPERATE THE EQUIPMENT

CAUTION: This device and its antenna(s) must not be co-located or operating in conjunction with

any other antenna or transmitter. End user cannot modify this transmitter device. Any

unauthorized modification made on the device could avoid the user's authority to

operate this device.

The following sentence has to be displayed on the outside of the device in which the transmitter

module is installed:

“Contains FCC ID: PH3XE972

Page 58

56

IC WARNING

The term “IC:” before the radio certification number only signifies that Industry Canada technical

specifications were met.

“Operation is subject to the following two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired

operation of the device.”

“The installer of this radio equipment must ensure that the antenna is located or pointed such that

it does not emit RF field in excess of Health Canada limits for the general population; consult

Safety Code 6, obtainable from Health Canada’s website www.hc-sc.gc.ca/rpb”

The following sentence has to be displayed on the outside of the device in which the transmitter

module is installed:

“Contains IC: 3070C-XE972

“This device has been designed to operate with the antennas listed below, and having a maximum

gain of 0.61 dB. Antennas not included in this list or having a gain greater than 0.61 dB are strictly

prohibited for use with this device. The required antenna impedance is 50 ohms.”

“To reduce potential radio interference to other users, the antenna type and its gain should be so

chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that permitted for

successful communication.”

Page 59

Page 60

75-1 Hasunuma-cho, Itabashi-ku, Tokyo 174-8580, Japan

www.topcon.co.jp

7400 National Drive, Livermore, CA 94550, U.S.A.

Phone: 925-245-8300 Fax: 925-245-8599 www.topcon.com

3380 Industrial Blvd, Suite 105, West Sacramento, CA 95691, U.S.A.

Phone: 916-374-8575 Fax: 916-374-8329

Essebaan 11, 2908 LJ Capelle a/d IJssel, The Netherlands.

Phone: 010-458-5077 Fax: 010-284-4941 www.topconeurope.com

Giesserallee 31, 47877 Willich, GERMANY

Phone: 02154-885-100 Fax: 02154-885-111 info@topcon.de

www.topcon.de

89, Rue de Paris, 92585 Clichy, Cedex, France.

Phone: 33-1-41069490 Fax: 33-1-47390251 topcon@topcon.fr

Neongatan 2 S-43151 Mölndal, SWEDEN

Phone: 031-7109200 Fax: 031-7109249

Topcon House Kennet Side, Bone Lane, Newbury, Berkshire RG14 5PX U.K.

Phone: 44-1635-551120 Fax: 44-1635-551170

survey.sales@topcon.co.uk laser.sales@topcon.co.uk

Blk 192 Pandan Loop, #07-01 Pantech Industrial Complex, Singapore 128381

Phone: 65-62780222 Fax: 65-62733540 www.topcon.com.sg

77/162 Sinn Sathorn Tower, 37th Fl.,

Krungdhonburi Rd., Klongtonsai, Klongsarn, Bangkok 10600 Thailand.

Phone: 66-2-4401152~7 Fax: 66-2-4401158

Excella Business Park Block C, Ground & 1st Floor, Jalan Ampang Putra,

Taman Ampang Hilir, 55100 Kuala Lumpur, MALAYSIA

Phone: 60-3-42701192 Fax: 60-3-42704508

2F Yooseoung Bldg., 1595-3, Seocho-Dong, Seocho-gu, Seoul, 137-876, Korea.

Phone: 82-2-2055-0321 Fax: 82-2-2055-0319 www.topcon.co.kr

Block No.9, Kangding Street

Beijing Economic Technological Development Area, Beijing, China 100176

Phone: 86-10-6780-2799 Fax: 86-10-6780-2790

P. O Box293705, Office C-25(row C-2), Dubai Airport Free Zone, Dubai, UAE

Phone: 971-4-2995900 Fax: 971-4-2995901

Unit 69 Western Parkway Business Center

Phone: 01460-0021 Fax: 01460-0129

Lower Ballymount Road, Dublin 12, Lreland

5E

Loading...

Loading...