Page 1

SURVEYING INSTRUMENTS

INSTRUCTION MANUAL

LAYOUT NAVIGATOR

LN-100

21313 91070

Page 2

HOW TO READ THIS MANUAL

Thank you for selecting the LN-100 series.

• Please read this Instruction manual carefully, before using this product.

• LN-100 has a function to output data to a connected host computer. Command operations from a

host computer can also be performed. For details, refer to "Communication manual" and ask your

local dealer.

• The specifications and general appearance of the instrument are subject to change without prior

notice and without obligation by TOPCON CORPORATION and may differ from those appearing in

this manual.

• The content of this manual is subject to change without notice.

• Some of the diagrams shown in this manual may be simplified for easier understanding.

• This manual is protected by copyright and all rights are reserved by TOPCON CORPORATION.

• Except as permitted by Copyright law, this manual may not be copied, and no part of this manual

may be reproduced in any form or by any means.

• This manual may not be modified, adapted or otherwise used for the production of derivative works.

Symbols

The following conventions are used in this manual.

: Indicates precautions and important items which should be read before

operations.

: Indicates the chapter title to refer to for additional information.

: Indicates supplementary explanation.

: Indicates an explanation for a particular term or operation.

{Power switch} etc. : Indicates keys on the operation panel.

i

Page 3

CONTENTS

1. PRECAUTIONS FOR SAFE OPERATION ................................................ 1

2. PRECAUTIONS ......................................................................................... 4

3. LASER SAFETY INFORMATION .............................................................. 7

4. NOMENCLATURE AND FUNCTIONS ...................................................... 9

4.1 Parts of the Instrument ....................................................................... 9

4.2 Control Panel ................................................................................... 10

Explanation of the operation panel ......................................................... 10

Displaying battery life .............................................................................11

Laser plummet ON/OFF and brightness adjustment .............................. 11

5. PREPARATION ....................................................................................... 12

5.1 Using the Battery ............................................................................. 12

Battery charging .....................................................................................12

Installing the battery ...............................................................................14

5.2 W-LAN Connection with the Controller ............................................ 15

Mode A connection ................................................................................15

Mode B connection ................................................................................15

Connection setting items ........................................................................16

5.3 Setting Up the Instrument ................................................................ 17

Power ON/OFF ......................................................................................17

Auto leveling ........................................................................................... 18

Centering ................................................................................................19

About the instrument height when setting the instrument point .............20

6. OUTLINE OF SURVEY............................................................................ 21

6.1 Usable Range .................................................................................. 21

6.2 Functions of Guide Light .................................................................. 21

7. CHECK .................................................................................................... 22

Setting Up the Instrument ......................................................................22

Measurement .........................................................................................22

Calculation .............................................................................................24

Assessment ............................................................................................24

8. TROUBLESHOOTING ............................................................................. 25

8.1 LED Display ..................................................................................... 25

8.2 What to Do When ............................................................................. 25

9. SPECIFICATIONS ................................................................................... 26

10. REGULATIONS ....................................................................................... 30

ii

Page 4

1. PRECAUTIONS FOR SAFE OPERATION

For the safe use of the product and prevention of injury to operators and other persons as well as

prevention of property damage, items which should be observed are indicated by an exclamation point

within a triangle used with WARNING and CAUTION statements in this operator’s manual.

The definitions of the indications are listed below. Be sure you understand them before reading the

manual’s main text.

Definition of Indication

General

WARNING

CAUTION

This symbol indicates items for which caution (hazard warnings inclusive) is urged.

Specific details are printed in or near the symbol.

This symbol indicates items which are prohibited. Specific details are printed in or near

the symbol.

This symbol indicates items which must always be performed. Specific details are printed

in or near the symbol.

Warning

Do not use the unit in areas exposed to high amounts of dust or ash, in areas where there

is inadequate ventilation, or near combustible materials. An explosion could occur.

Do not perform disassembly or rebuilding. Fire, electric shock, burns, or hazardous

radiation exposure could result.

When securing the instrument in the carrying case make sure that all catches, including

the side catches, are closed. Failure to do so could result in the instrument falling out

while being carried, causing injury.

Ignoring this indication and making an operation error could possibly

result in death or serious injury to the operator.

Ignoring this indication and making an operation error could possibly

result in personal injury or property damage.

Caution

Do not use the carrying case as a footstool. The case is slippery and unstable so a

person could slip and fall off it.

Do not place the instrument in a case with a damaged catch, belt or handle. The case or

instrument could be dropped and cause injury.

This instrument automatically operates when the power is turned ON or OFF. Do not

touch the instrument during operation. Doing so may cause injury.

1

Page 5

Power Supply

Warning

Do not use batteries other than those designated. An explosion could occur, or abnormal

heat generated, leading to fire.

To prevent shorting of the battery in storage, apply insulating tape or equivalent to the

terminals. Otherwise shorting could occur, resulting in fire or burns.

Do not place articles such as clothing on the battery charger while charging batteries.

Sparks could be induced, leading to fire.

Do not use damaged power cords, plugs or loose outlets. Fire or electric shock could

result.

Do not use power cords other than those designated. Fire could result.

Use only the specified battery charger to recharge batteries. Other chargers may be of

different voltage rating or polarity, causing sparking which could lead to fire or burns.

Do not connect or disconnect power supply plugs with wet hands. Electric shock could

result.

Do not short circuit. Heat or ignition could result.

Do not use voltage other than the specified power supply voltage. Fire or electrical shock

could result.

Do not use the battery or charger for any other equipment or purpose. Fire or burns

caused by ignition could result.

Do not heat or throw batteries or chargers into fire. An explosion could occur, resulting

in injury.

Do not use batteries or the battery charger if wet. Resultant shorting could lead to fire or

burns.

1. PRECAUTIONS FOR SAFE OPERATION

Tripod

Caution

Do not touch liquid leaking from batteries. Harmful chemicals could cause burns or

blisters.

Caution

When mounting the instrument to the tripod, tighten the centering screw securely. Failure

to tighten the screw properly could result in the instrument falling off the tripod, causing

injury.

2

Page 6

Tighten securely the leg fixing screws of the tripod on which the instrument is mounted.

Failure to tighten the screws could result in the tripod collapsing, causing injury.

Do not carry the tripod with the tripod shoes pointed at other persons. A person could be

injured if struck by the tripod shoes.

Keep hands and feet away from the tripod shoes when fixing the tripod in the ground. A

hand or foot stab wound could result.

Tighten the leg fixing screws securely before carrying the tripod. Failure to tighten the

screws could lead to the tripod legs extending, causing injury.

Wireless technology (Wireless LAN)

Warning

Do not use within the vicinity of hospitals. Malfunction of medical equipment could

result.

Use the instrument at a distance of at least 22 cm from anyone with a cardiac

pacemaker. Otherwise, the pacemaker may be adversely affected by the

electromagnetic waves produced and cease to operate as normal.

Do not use onboard aircraft. The aircraft instrumentation may malfunction as a result.

Do not use within the vicinity of automatic doors, fire alarms and other devices with

automatic controls as the electromagnetic waves produced may adversely affect

operation resulting in an accident.

1. PRECAUTIONS FOR SAFE OPERATION

3

Page 7

2. PRECAUTIONS

When the power is turned ON

(Auto leveling)

When the power is turned ON or OFF

(Auto rotation)

Charging Battery

• Be sure to charge the battery within the charging temperature range.

Charging temperature range : 0 to 40°C

Warranty policy for Battery

• Battery is an expendable item. The decline in retained capacity depending on the repeated charging/

discharging cycle is out of warranty.

About operation when the power is turned ON/OFF

This instrument operates as shown below and performs auto leveling/auto rotation when the power of

the instrument is turned ON or OFF. Do not touch the instrument during operation. Doing so may

cause injury.

Precautions concerning water and dust resistance

Dustproof and waterproof performance of the instrument comply with IP65. Please read the following

carefully before using.

• Close the battery cover tightly.

• Make sure that moisture or dust particles do not come in contact with the terminal or connectors.

Operating the instrument with moisture or dust on the terminal or connectors may cause damage to

the instrument.

• Make sure that the inside of the carrying case and the instrument are dry before closing the case. If

moisture is trapped inside the case, it may cause the instrument to rust.

• If there is a crack or deformation in the rubber packing for the battery cover or external interface

hatch, stop using and replace the packing.

• To retain the waterproof property, it is recommended that you replace the rubber packing once every

two years. To replace the packing, contact your local sales representative.

4

Page 8

2. PRECAUTIONS

Other precautions

• Do not insert a foreign object into the instrument during the auto leveling. Doing so will cause a

failure.

• Never place the instrument directly on the ground. Sand or dust may cause damage to the screw

holes or the centering screw on the base plate.

• Protect the instrument from heavy shocks or vibration.

• Protect the instrument from rain or drizzle with an umbrella or waterproof cover.

• Never carry the instrument on the tripod to another site.

• Turn the power off before removing the battery.

• Remove the battery before placing the instrument in its case.

• Make sure that the instrument and the protective lining of the carrying case are dry before closing the

case. The case is hermetically sealed and if moisture is trapped inside, the instrument could rust.

• Consult your local dealer before using the instrument under special conditions such as long periods

of continuous use or high levels of humidity. In general, special conditions are treated as being

outside the scope of the product warranty.

Maintenance

• Wipe off moisture completely if the instrument gets wet during survey work.

• Always clean the instrument before returning it to the case. The lens requires special care. First,

dust it off with the lens brush to remove tiny particles. Then, after providing a little condensation by

breathing on the lens, wipe it with the wiping cloth.

• Store the instrument in a dry room where the temperature remains fairly constant.

• Check the tripod for loose fit and loose screws.

• If any trouble is found on the rotatable portion, screws or optical parts (e.g. lens), contact your local

dealer.

• When the instrument is not used for a long time, check it at least once every 3 months.

• Every 4,000 to 5,000 hours operation in total, change grease of driving parts. Contact your local

dealer for the maintenance.

• When removing the instrument from the carrying case, never pull it out by force. The empty carrying

case should be closed to protect it from moisture.

• Check the instrument for proper adjustment periodically to maintain the instrument accuracy.

Exporting this product (Relating EAR)

• This product is equipped with the parts/units, and contains software/technology, which are subject

to the EAR (Export Administration Regulations). Depending on countries you wish to export or bring

the product to, a US export license may be required. In such a case, it is your responsibility to obtain

the license. The countries requiring the license as of May 2013 are shown below. Please consult

the Export Administration Regulations as they are subject to change.

North Korea

Iran

Syria

Sudan

Cuba

URL for the EAR of the US: http://www.bis.doc.gov/policiesandregulations/ear/index.htm

5

Page 9

2. PRECAUTIONS

Exporting this product (Relating telecommunications regulations)

• Wireless communication module is incorporated in the instrument. Use of this technology must be

compliant with telecommunications regulations of the country where the instrument is being used.

Even exporting the wireless communication module may require conformity with the regulations.

Exceptions from responsibility

• The user of this product is expected to follow all operating instructions and make periodic checks

(hardware only) of the product’s performance.

• The manufacturer, or its representatives, assumes no responsibility for results of faulty or intentional

usage or misuse including any direct, indirect, consequential damage, or loss of profits.

• The manufacturer, or its representatives, assumes no responsibility for consequential damage, or

loss of profits due to any natural disaster, (earthquake, storms, floods etc.), fire, accident, or an act

of a third party and/or usage under unusual conditions.

• The manufacturer, or its representatives, assumes no responsibility for any damage (change of

data, loss of data, loss of profits, an interruption of business etc.) caused by use of the product or

an unusable product.

• The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of

profits caused by usage different to that explained in the operator’s manual.

• The manufacturer, or its representatives, assumes no responsibility for damage caused by incorrect

operation, or action resulting from connecting to other products.

6

Page 10

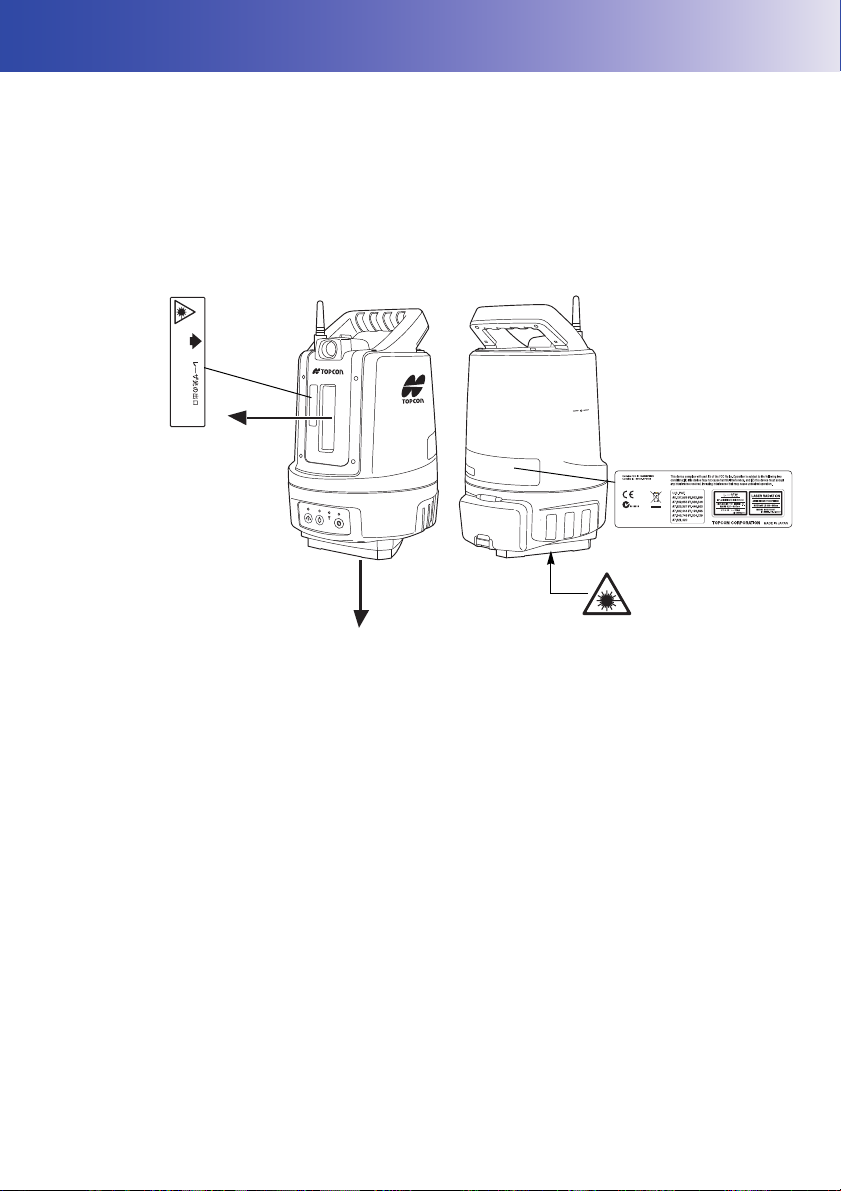

3. LASER SAFETY INFORMATION

A laser beam is emitted

from here

A laser beam is emitted from

here

AVOID EXPOSURE-Laser radiation

is emitted from this aperture.

The instrument is classified as the following class of Laser Product according to IEC Standard

Publication 60825-1 Ed.2.0: 2007 and United States Government Code of Federal Regulation FDA

CDRH 21CFR Part 1040.10 and 1040.11 (Complies with FDA performance standards for laser

products except for deviations pursuant to Laser Notice No.50, dated June 24, 2007.)

• EDM device : Class 3R Laser Product

• Laser pointer : Class 3R Laser Product

• Laser plummet : Class 2 Laser Product

Please read the following safety instructions carefully before using the LN-100.

Warning

• Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

• Never intentionally point the laser beam at another person. The laser beam is injurious to the eyes

and skin. If an eye injury is caused by exposure to the laser beam, seek immediate medical attention

from a licensed ophthalmologist.

• Do not look directly into the laser beam. Doing so could cause permanent eye damage.

• Do not stare at the laser beam. Doing so could cause permanent eye damage.

• Never look at the laser beam through a telescope, binoculars or other optical instruments. Doing so

could cause permanent eye damage.

• Sight targets so that the laser beam does not stray from them.

Caution

• Perform checks at start of work and periodic checks and adjustments with the laser beam emitted

under normal conditions.

• When the instrument is not being used, turn off the power.

• When disposing of the instrument, destroy the battery connector so that the laser beam cannot be

emitted.

7

Page 11

3. LASER SAFETY INFORMATION

• Avoid setting the instrument at heights at which the path of the laser may strike pedestrians or

drivers at head height. Operate the instrument with due caution to avoid injuries that may be caused

by the laser beam unintentionally striking a person in the eye.

• Never point the laser beam at mirrors, windows or surfaces that are highly reflective. The reflected

laser beam could cause serious injury

• Only those who have received training as per the following items shall use this product.

• Read this manual for usage procedures for this product.

• Hazardous protection procedures (read "LASER SAFETY INFORMATION")

• Requisite protective gear (read "LASER SAFETY INFORMATION")

• Accident reporting procedures (stipulate procedures beforehand for transporting the injured and

contacting physicians in case there are laser-induced injuries).

• Persons working within the range of the laser beam are advised to wear eye protection which

corresponds to the laser wavelength of the instrument being used.

• Areas in which the laser is used should be posted with a standard laser warning sign.

• When using the laser-pointer function, be sure to turn OFF the output laser after distance

measurement is completed. Even if distance measurement is canceled, the laser-pointer function is

still operating and the laser beam continues to be emitted.

8

Page 12

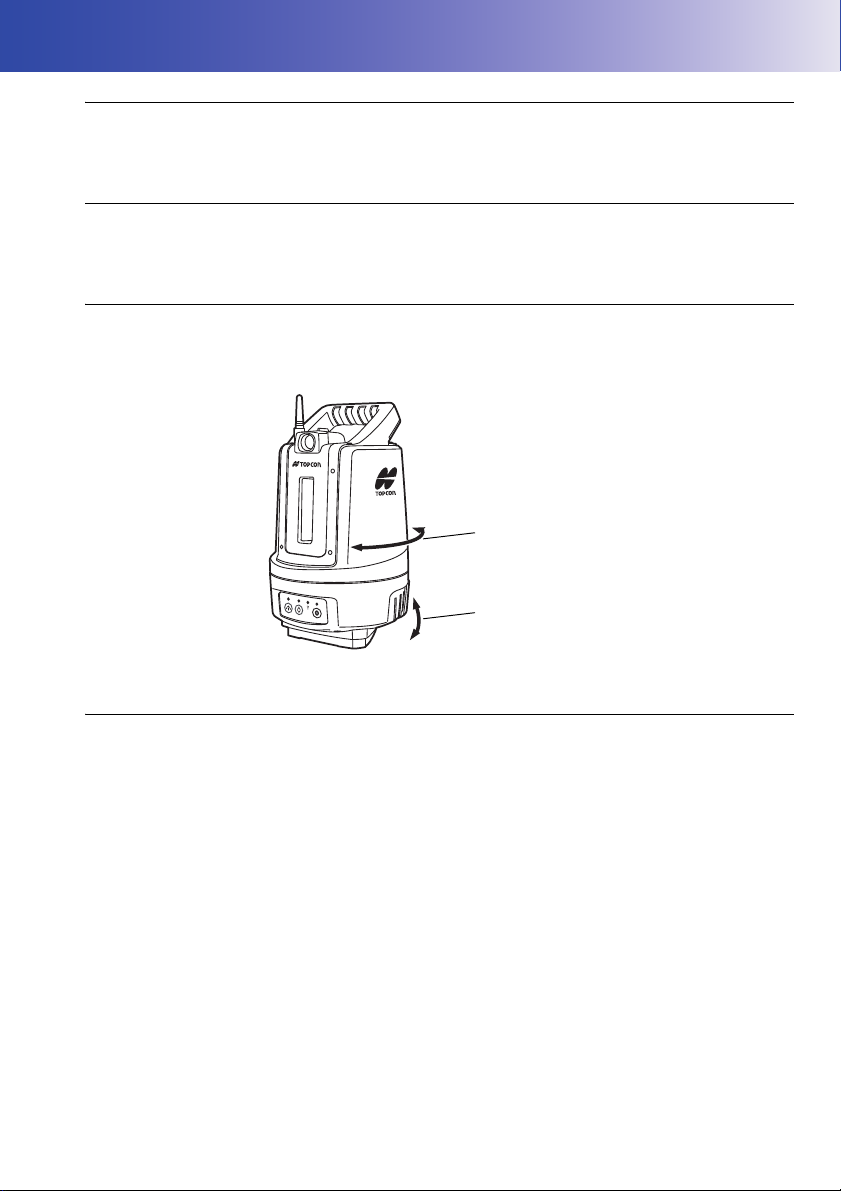

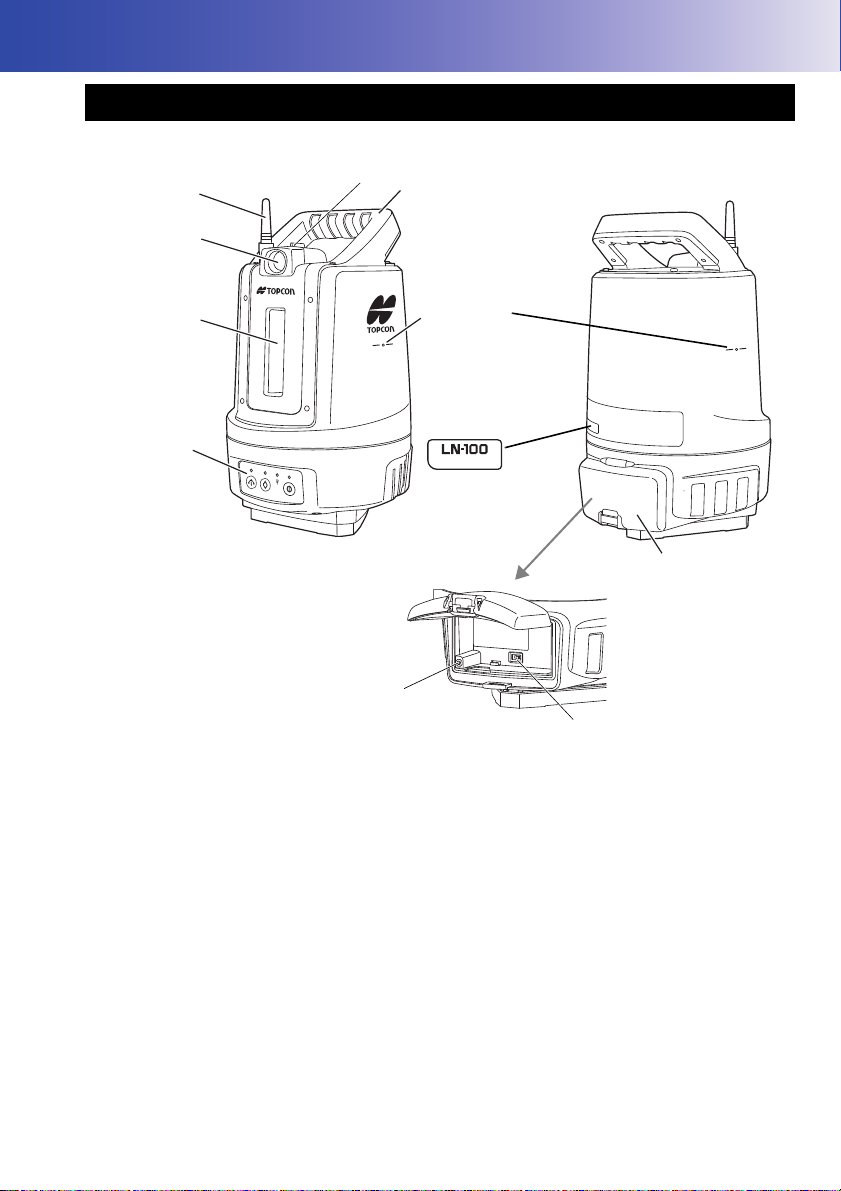

4. NOMENCLATURE AND FUNCTIONS

Wireless

antenna

Guide light

Operation

panel

Battery cover

Handle

Instrument

height mark

W-LAN mode selector

switch

Reset switch

Window

Position where the

serial number is

printed

Sighting collimator

4.1 Parts of the Instrument

Instrument height mark

The height of the instrument is as follows:

176 mm (from the position where a tripod is mounted to the instrument height mark)

“About the instrument height when setting the instrument point” on page 20

Sighting collimator

Use this function to align the direction (horizontal only) of the instrument with the survey point.

Look through the sighting collimator and align the window with the direction of the prism.

Reset switch

This function resets the W-LAN setting to the default factory setting.

"8.2 What to Do When" on page 25

Do not use this switch under normal circumstances.

9

Page 13

4. NOMENCLATURE AND FUNCTIONS

W-LAN LED

Power LED

Auto leveling LED

Laser plummet/

Laser pointer LED

Power switchLaser plummet

switch

Auto leveling switch

Wireless antenna

This antenna may be damaged depending on how it is handled. Be careful not to hit the antenna while

working, as it sticks out from the instrument.

4.2 Control Panel

Explanation of the operation panel

Name Function details

Power switch Power ON: Press it for a short time

Power OFF: Hold down the switch for more than 1 second

Power LED Off: Power OFF

W-LAN mode selector switch

(inside the battery cover)

Lighting up in green: Power is ON

Blinking in green: During Power-OFF-process

Blinking in red: Battery voltage dropped

Mode A: Flip the switch to the right

Mode B: Flip the switch to the left

10

Page 14

4. NOMENCLATURE AND FUNCTIONS

W-LAN LED When it is Mode A

Laser plummet switch Laser plummet ON: Press it

Connection waiting state: Blinking in green every 1 second

(repeating a cycle in which the LED

is on for 1 second and then off for

1 second)

Connecting: Lighting up in green

When it is Mode B

Connection waiting state: Blinking in green quickly

(repeating a cycle of quick on twice,

followed by 2 seconds off)

Connecting: Lighting up in green

When an error is detected in the W-LAN setting item:

Lighting up in red

Laser plummet OFF: Press and hold (More than 1 second).

“Laser plummet ON/OFF and brightness adjustment” on

page 11

Laser plummet/

Laser pointer LED

Auto leveling switch Starts auto leveling: Press it while auto leveling is stopped.

Auto leveling LED Blinking in green: In auto leveling

Off: Laser plummet or laser pointer is OFF

Blinking in green: Laser plummet or laser pointer ON

Stops auto leveling: Press it again while auto leveling is being

Extends the leveling screw:

Lighting up in green: Within the range of inclination

Lighting up in red: Outside the range of inclination

Blinking in red: Outside the range of auto leveling

performed.

Hold it down.

compensation (±6 minutes)

compensation (±6 minutes or over)

“Auto leveling” on page 18

Displaying battery life

The battery life is low when the power LED is blinking in red and a beep sound (repeating beeps) is

heard. Exchange the battery. The battery life of the instrument is displayed on the controller.

Refer to the instruction manual of the controller.

Laser plummet ON/OFF and brightness adjustment

The operation method of the laser plummet is as follows:

Function Description

Turn ON the laser plummet Press the {laser plummet switch} for a short time.

Turn OFF the laser plummet Hold down the {laser plummet switch} for at least 1 second or it

Turn up the brightness Pressing the {laser plummet switch} for a short time while the

The laser plummet lights up with the stored brightness.

turns OFF automatically about five minutes after the laser

plummet is turned ON. The brightness used when the laser

plummet turned OFF is stored.

laser plummet is turned ON turns up the brightness by one level,

up to level 5. After reaching level 5, it goes back to level 1.

11

Page 15

5. PREPARATION

Guides

Slot 1

Slot 2

Charging

lamp

Grooves

5.1 Using the Battery

Battery charging

The battery was not charged at the factory. Charge the battery fully before using the instrument.

• The charger will become rather hot during use. This is normal.

• Do not use to charge batteries other than those specified.

• The charger is for indoor use only. Do not use outdoors.

• Batteries cannot be charged, even when the charging lamp is flashing, when the temperature is

outside the charging temperature range.

• Remove batteries from the charger before putting into storage.

• When not in use, disconnect the power cable plug from the wall outlet.

• Store the battery in a dry room where the temperature is within the following ranges. For long-term

storage, the battery should be charged at least once every six months.

Storage period Temperature range

1 week or less -20 to 50°C

1 week to 1 month -20 to 45°C

1 month to 6 months -20 to 40°C

6 months to 1 year -20 to 35°C

• Batteries generate power using a chemical reaction and as a result have a limited lifetime. Even

when in storage and not used for long periods, battery capacity deteriorates with the passage of

time. This may result in the operating time of the battery shortening despite having been charged

correctly. In this event, a new battery is required.

PROCEDURE

1. Connect the power cable to the charger and

plug the charger into the wall outlet.

2. Mount the battery in the charger by matching

the grooves on the battery with the guides on

the charger.

12

Page 16

5. PREPARATION

3. When charging starts, the lamp starts blinking.

4. The lamp lights when charging is finished.

5. Remove the battery and unplug the charger.

• Slots 1 and 2:

The charger starts charging the battery mounted first. If you place two batteries in the charger, the

battery in slot 1 is charged first, and then the battery in slot 2. (

• Charging lamp:

The charging lamp is off when the charger is outside the charging temperature range or when the

battery is mounted incorrectly. If the lamp is still off after the charger falls within its charging

temperature range and the battery is mounted again, contact your local dealer. (

• Charging time per battery (at 25°C):

BDC70:about 5.5 hours

step 2)

steps 2 and 3)

13

Page 17

5. PREPARATION

Installing the battery

Mount the charged battery.

• Use the attached battery (BDC70).

• When installing/removing the battery, make sure that moisture or dust particles do not come in

contact with the inside of the instrument.

• Be careful not to shut the battery cover on your fingers.

• Before removing the battery, turn off the power to the instrument. If the battery is removed while the

power is switched on, a warm boot may occur. File and folder data may be lost as a result.

• Do not open the battery cover while the power is on.

• Remove batteries from the surveying instrument or charger before putting into storage.

PROCEDURE

1. Push the catch on the battery cover upwards

to open the cover.

2. Check the orientation of the terminal of the

battery, and then insert the battery by sliding it

to the right and pressing against the main unit.

• Do not insert the battery diagonally, as this

may damage the main unit or the battery

terminal.

3. Close the battery cover.

Make sure it clicks.

14

Page 18

5. PREPARATION

Master machine

Slave machine

Master machine

Slave

machine

5.2 W-LAN Connection with the Controller

There are two methods to set up a W-LAN connection between the instrument and the controller:

Mode A connection

This is a one-to-one connection using the instrument as a master machine and the controller as a

slave machine for W-LAN connection. When using the Mode A connection, the instrument performs

as a DHCP server.

For details of the connection method, refer to the instruction manual of W-LAN Config for LN-100.

Mode B connection

Connect via other access point (as the master machine) using the instrument and the controller as

slave machines for W-LAN connection.

For details of the connection method, refer to the instruction manual of W-LAN Config for LN-100.

• The network settings of Mode A and Mode B are saved one each.

15

Page 19

Connection setting items

Item Selection item Default factory setting

SSID Fixed Model name _ serial number

Security None/WEP/WPA/WPA2 WPA2

Password

(Security key)

Mode A

Channel 1 to 11 11

IP address Fixed 192.168.0.1

Subnet mask Fixed 255.255.255.0

DHCP function Fixed DHCP server enabled

DHCP lease address Fixed 192.168.0.10 to

SSID Up to 32 bytes No setting

Security None/WEP/WPA/WPA2 None

Password

(Security key)

Mode B

IP address xxx.xxx.xxx.xxx format No setting

Subnet mask xxx.xxx.xxx.xxx format No setting

DHCP function DHCP client / static IP DHCP client

WEP64:

String of 5 characters

(e.g. RIVER) or

10 hexadecimal characters

(e.g. 12345678AF)

WEP128:

String of 13 characters or

26 hexadecimal characters

WPA/WPA2:

String of 8 to 63 characters or

64 hexadecimal characters

WEP64:

String of 5 characters or

10 hexadecimal characters

WEP128:

String of 13 characters or

26 hexadecimal characters

WPA/WPA2:

String of 8 to 63 characters or

64 hexadecimal characters

5. PREPARATION

(e.g. LN-100_AB1234)

00serial number

(e.g. 00AB1234)

192.168.0.25

No setting

• After purchasing the instrument, change the password for Mode A to other than the serial number.

• If you forget the password, refer to "8.2 What to Do When" on page 25.

16

Page 20

5. PREPARATION

5.3 Setting Up the Instrument

Power ON/OFF

Caution

This instrument automatically operates when the power is turned ON or OFF. Do not

touch the instrument during operation. Doing so may cause injury.

PROCEDURE: Power ON

1. Turn the power ON.

Press the {Power switch} on the operation panel to turn the power ON.

When the power is turned ON, the power LED turns on. After the leveling automatically has

started, the instrument rotates automatically.

• Avoid a W-LAN connection during auto leveling when setting up the instrument.

• After the rotation starts, do not touch the instrument until it stops at the original position.

Refer to “Auto leveling” on page 18 for information on auto leveling.

• Auto Power OFF function:

If no key operation or no data communication has been performed for about 30 minutes, the power

turns OFF automatically.

• If the power cannot be turned ON even when the battery is mounted or if the power turns OFF as

soon as the power turns ON, it is thought that the battery life is gone. Change it for a fully charged

battery.

“Displaying battery life” on page 11

Procedure: Power OFF

1. Hold down the {Power switch} for about 1 second.

17

Page 21

5. PREPARATION

Auto leveling

Caution

Do not touch the instrument during auto leveling. Doing so may cause injury.

• By performing auto leveling, the center of the instrument is automatically leveled within the range

of ±30". After that, if the inclination of the main unit exceeds the range of inclination

compensation (±6'), the red LED will light up. In this case, auto leveling will not automatically

start. Perform auto leveling again.

PROCEDURE

1. Press {Auto leveling switch} while auto leveling is stopped.

The auto leveling LED starts blinking in green and auto leveling starts. After completing auto

leveling, the LED lights up in green.

• If a foreign object gets caught in the auto leveling section, hold down {Auto leveling switch}.

If the leveling screw is extended, remove the foreign object, and restart auto leveling.

The following describes how to press {Auto leveling switch} and its relationship with the

operation of the instrument:

Auto leveling

switch

Short press One beep After the beep sound is heard,

Long press

(1 second)

Hold down Two beeps After the beep sound is heard, the leveling screw starts extending. It

*1)

If a sound other than these beep sound patterns is heard, refer to the instruction manual of TSShield.

*2)

When auto leveling is performed by pressing {Auto leveling switch} for a long time (1 second), the

same auto leveling operation as that performed when {Power switch} is turned ON is performed.

Measurement by rotating the instrument 180° calibrates the inclination sensor.

Beep sound

*1)

Two beeps After the beep sound is heard,

While auto leveling is stopped

auto leveling starts when you

release the switch.

auto leveling starts when you

release the switch. At this time,

the instrument rotates 180°.*2)

stops when you release the switch.

While auto leveling is being

performed

After the beep sound is heard, auto

leveling stops when you release the

switch.

18

Page 22

Centering

Centering screw

Survey point

PROCEDURE

1. Make sure the legs are spaced at equal intervals

and the head is approximately level.

Set the tripod so that the head is positioned over the

survey point.

Make sure the tripod shoes are firmly fixed in the

ground.

2. Place the instrument on the tripod head.

Supporting it with one hand, tighten the centering

screw on the bottom of the unit to make sure it is

secured to the tripod.

5. PREPARATION

3. Aim a laser beam at the survey point.

Turn the {Laser Plummet Switch} ON and loosen the

centering screw.

Fix the centering screw after aiming the laser beam

at the survey point.

• The laser light blinks when the instrument is

performing auto leveling.

19

Page 23

5. PREPARATION

Survey point

Instrument height

About the instrument height when setting the instrument point

The instrument height entered for setting the instrument point is the height from the survey point to the

instrument height mark.

Refer to the instruction manual of the controller for the settings.

20

Page 24

6. OUTLINE OF SURVEY

Center of the instrument

Usable range

Outside the Distance

Measurement Range

Guide light

Green Red

The instrument can perform a stakeout survey and a side shot method.

Use the controller for measurement.

6.1 Usable Range

The following shows the usable range of the instrument.

Do not operate the instrument out of the usable range shown below.

㼻

25

0.9m

22m

100m

0m

• Distance Measurement

The distance measurement limit of the instrument is a radial shape with a radius of 104 m from the

center of the instrument.

Moving the target at the limit of the distance measurement range may result in the target being

located outside the range within which measurement is possible.

5㼻

10m

4m

6.2 Functions of Guide Light

By setting the guide light to “ON,” you can tell from a distance about the state of the instrument and

the direction to move the pole, by reference to the color of the light and the blinking pattern.

The left of the guide light is green and the right is red.

21

Page 25

7. CHECK

µí µí²°í

Йоуфтхнеоф

рпйоф²

Йоуфтхнеоф

рпйоф±

Небухтенеофрпйофв Небухтенеофрпйофб

ATP2 : The 360° Prism should be set up so that a pair of diametrically-opposed hexagonal

points on its rubber flanges are aligned with the sighting direction of the instrument

(see the diagram below).

ATP2S : The 360° Prism should be set up so that a pair of diametrically-opposed marks on

top of the prism are aligned with the sighting direction of the instrument.

: Hexagonal points

: Prism sighting direction

LN-100 is a precision instrument. It must be inspected before use so that it always performs accurate

measurements.

In addition, the instrument should be inspected with special care after it has been stored a long time,

transported, or when it may have been damaged by a strong shock.

Setting Up the Instrument

Perform a setup operation under an environment where the sunlight is weak and not fluctuating

as well as LN-100 and the targets can be set as illustrated below.

• To perform checking efficiently, mark the four points described below using setting-out function

in advance.

• Place the instrument and targets in a straight line when looking from directly above.

• Acceptable range of each point position is ±5cm in all directions.

• Set LN-100 and the targets on a substantially horizontal place (such as a floor, level ground,

tripods of the same height). (The guideline for difference in height at 30 m is about 30 cm)

• Use ATP2 (360° prism) or ATP2S (360° slide prism) for the target.

• To set ATP2S, lower the height of the prism to reduce the setting error.

Measurement

• Sighting can be more accurately performed by facing the ATP2/ATP2S toward the instrument.

22

Page 26

7. CHECK

µí µí²°í

Йоуфтхнеоф

рпйоф²

Йоуфтхнеоф

рпйоф±

Небухтенеофрпйофв Небухтенеофрпйофб

µí µí²°í

Йоуфтхнеоф

рпйоф²

Йоуфтхнеоф

рпйоф±

Небухтенеофрпйофв Небухтенеофрпйофб

µí µí²°í

Йоуфтхнеоф

рпйоф²

Йоуфтхнеоф

рпйоф±

Небухтенеофрпйофв Небухтенеофрпйофб

µí µí²°í

Йоуфтхнеоф

рпйоф²

Йоуфтхнеоф

рпйоф±

Небухтенеофрпйофв Небухтенеофрпйофб

1. Set the instrument at instrument point 1.

2. Measure the target set at measurement point a to record the coordinates.

Because the target is re-measured at measurement point a after shifting to measurement point b,

the position should be marked (positioning accuracy is approximately ±1mm).

3. Set the target at measurement point b.

4. Measure the target set at measurement point b to record the coordinates.

5. Set up the instrument at instrument point 2.

6. Measure the target set at measurement point b to record the coordinates.

7. Set the target at measurement point a.

Return to the measurement position shown in 2. above.

8. Measure the target set at measurement point a to record the coordinates.

23

Page 27

Measurement results recording table:

D

1

X

1 a,

X

1 b,

–()

2

Y

1 a,Y1 b,

–()

2

+=

D

2

X

2 a,

X

2 b,

–()

2

Y

2 a,Y2 b,

–()

2

+=

Z1Z

1 a,Z1 b,

–=

Z

2Z2 a,Z2 b,

–=

ED mm[]

D

1D2

–()

2

------------------------

1000×=

EZ mm[] Z

2Z1

–()1000×=

Instrument point Target X [m] Y [m] Z [m]

1

2

a

b

a

b

X

1,a :

X

1,b :

X

2,a :

X

2,b :

Y

1,a :

Y

1,b :

Y

2,a :

Y

2,b :

Calculation

Obtain the distance error (ED) and the vertical error (EZ) from the following formulas:

Z

Z

Z

Z

7. CHECK

1,a :

1,b :

2,a :

2,b :

Assessment

Confirm that the distance error (ED) and the vertical error (EZ) fall within the following ranges:

• Distance error

• Vertical error

• If the error falls out of the range, contact your local dealer.

-6 (mm) < ED < +6 (mm)

-11.6 (mm) < EZ < +11.6 (mm)

24

Page 28

8. TROUBLESHOOTING

If there is a problem, check the table below and follow the suggestions.

8.1 LED Display

LED display What is happening How to resolve

Auto leveling LED is blinking

in red.

W-LAN LED is blinking in red An error occurred in the

Because the instrument is

inclined excessively, auto

leveling cannot be performed.

hardware.

8.2 What to Do When

Conditions Causes How to resolve

Forgot the password. ---

Signal is weak. Use the instrument in a good

Incorrect security settings Configure the security setting to

Wireless connection to the

controller is disabled.

When the W-LAN mode is set to Mode B

Wireless connection to the

controller is disabled.

*) How to press the reset switch

Set the W-LAN mode to Mode A, and then turn the power ON.

Before being connected to the wireless (while the W-LAN LED is blinking), hold down the reset

switch until it beeps twice.

Incorrect password Enter the correct password.

Another controller is already

communicating.

It takes too long for WPA2

authentication.

Access point cannot be found. The channel of the access point

Attempting to connect with an

access point that cannot be

connected unless the MAC

address is registered in advance.

Perform auto leveling again after

leveling the surface, such as the

flat top surface of the tripod,

where the instrument is installed.

A repair is necessary. Contact

your local dealer.

Press the reset switch*) to reset

to the factory default settings.

Configure the communication

settings again.

signal environment.

the same as that of LN-100.

Check whether it is

communicating with another

controller.

Wait until the authentication

completes.

may be set to 12 or greater (out of

the search range of LN-100).

Change the channel.

MAC address for LN-100 needs

to be registered in advance.

At this time, the W-LAN is configured as follows:

Security: WPA2

Password: 00 serial number

25

Page 29

9. SPECIFICATIONS

282.324

0.294362 p×

1 0.003661 t×+

------------------------------------------

–

0.04127 e×

1 0.003661 t×+

------------------------------------------

+

Atmospheric Correction Factor (ppm) =

Usable range

Altitude angle ±25° (0.9 to 22 m)

Difference of altitude ±10 m (22 to 100 m)

Horizontal angle 360°

Distance 0.9 to 100 m

(

"6.1 Usable Range" on page 21)

General accuracy (While measuring coordinates at 50 m)

Reproducibility

Horizontal positioning 3 mm (2σ)

Altitude positioning 6 mm (2σ)

Absolute positioning

Horizontal positioning ±5 mm

Altitude positioning ±10 mm

Angle measurement section

Method Absolute rotary encoder method

Resolving power 1"

Inclination compensation section

Method Hydraulic dual-axis inclination sensors

Compensation range ±6' 00"

Distance measuring section

Method Retardation survey method (Prism distance measurement only)

Measurable range 0.9 to 100 m

Update rate of distance data 20 Hz

Light source Laser diode

Wavelength 690 nm

Laser class Class 1 equivalent when measuring the distance

Atmospheric correction Entry of the temperature and atmospheric pressure

(Depending on the application)

(Default factory setting : 15°C, 1013hPa)

Atmospheric correction factor (ppm)

Prism constant correction Yes

*1: When using ATP2/ATP2S

Weather conditions for measurement: Other than bad weather, such as rain, dense fog, and

strong heat haze

*1

*2

*2: Atmospheric correction factor (ppm)

The atmospheric correction value is calculated using the following formula and set into the

memory.

t : Air temperature (°C)

p : Pressure (hPa)

e : Water vapor pressure (hPa)

h : Relative humidity (%)

E : Saturated water vapor pressure

26

Page 30

9. SPECIFICATIONS

E6.1110

7.5 t×()

t237.3+()

----------------------------

×=

eh

E

100

--------- -×=

• e (water vapor pressure) can be calculated using the following formula.

Laser pointer section (Availability of the function depends on the application to be used.)

Light source Laser diode

Wavelength 690 nm

Laser class Class 3R

Spot size Width: 7 mm / Length: 8 mm (at a distance of 20 m)

Width 16.9 mm / Length: 19.3 mm (at a distance of 50 m)

Auto tracking section

Method Image sensor method using a coaxial optical system for beam

emission and reception

Auto trackable range

0.9 to 100 m

Light source Laser diode

Wavelength 793 nm

Laser class Class 1

*1: When using ATP2/ATP2S

Weather conditions for measurement: Other than bad weather, such as rain, dense fog, and

strong heat haze

Ranging tracking optical system

Structure Coaxial optical system for tracking a measurement of distance

Objective aperture Ø16.5 mm

Focus distance 50 mm

*1

Motor actuator

Motion range 360° (Horizontal)

Maximum rotation speed 60°/second (10 rpm)

(The time required for 180° rotation: 3.0 seconds)

Minimum feed angle (operated from the external application)

Auto leveling section

Method Main unit integral type

Auto leveling mechanism Dual-axis

Leveling range ±3°

Guide light

Light source Light-emitting diode (LED) (Red 626 nm / Green 524 nm)

Visible range Greater than 8° at horizontal (full length: 7 m at a distance of 50

15" (±3.75 mm equivalent at a distance of 50 m)

m)

27

Page 31

9. SPECIFICATIONS

Laser plummet section

Light source Laser diode

Wavelength 635 nm

Laser class Class 2

Beam accuracy 1.0 mm or less (At the height of the head of a tripod of 1.3 m)

Spot diameter Ø3 mm or less (At the height of the head of a tripod of 1.3 m)

Communication section

W-LAN Supports 802.11 n/b/g

Antenna for W-LAN External

Security (Selection item) None/WEP/WPA/WPA2 (Default factory setting : WPA2)

Communication distance 100 m (Depending on the controller to be used)

Power source section

Standard battery BDC70 lithium-ion battery

Continuous service hour (at 20°C)

About 5 hours

Battery (BDC70)

Nominal voltage 7.2 V

Capacity 5,240 mAh

Dimensions 40 (W) X 70 (D) X 40 (H) mm

Weight About 197 g

Charger (CDC68A)

Input voltage 100 to 240 V AC

Charging time (at 25°C per battery)

BDC70 About 5.5 hours (Charging may take longer than this at low or

Range of charging temperature

Range of storage temperature

Dimensions 94 (W) X 102 (D) X 36 (H) mm

Weight About 170 g

high temperature.)

0 to 40°C

-20 to 65°C

Backup power supply (for the clock)

Power off function Yes (30 minutes)

General

Panel section

Number of keys (types)

Number of LEDs (types)

W-LAN mode switching Mode A/B switching (Inside the battery box)

Self-diagnosis function Yes

Buzzer Beep only

Sighting collimator Yes

Dimensions 185 (W) X 196 (D) X 295 (H) mm

Lithium battery (More than 8 years)

3 types (Power source, laser plummet, auto leveling)

4 types (Power source, laser plummet, auto leveling, W-LAN)

28

Page 32

Instrument height 176 mm

Weight About 4 kg (Including the battery)

Environmental resistance

Operating temperature -20 to 50°C (No condensation)

Storage temperature -30 to 60°C (No condensation)

Dustproof / Waterproof IP65

9. SPECIFICATIONS

29

Page 33

10.REGULATIONS

Region/

Country

U.S.A. FCC

Directives/

Regulations

-Class A

Labels/Declarations

FCC Compliance

WARNING:

Changes or modifications to this unit not expressly approved by the

party responsible for compliance could void the user's authority to

operate the equipment.

NOTE:

This equipment has been tested and found to comply with the limits

for a Class A digital device pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful inter-ference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

operator’s manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Means of conformity

This device complies with part 15 of the FCC Rules, Operation is

subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

This transmitter must not be co-located or operated in conjunction

with any other antenna or transmitter.

This equipment complies with FCC radiation exposure limits set forth

for uncontrolled equipment and meets the FCC radio frequency (RF)

Exposure Guidelines in Supplement C to OET65. This equipment has

very low levels of RF energy that is deemed to comply without

maximum permissive exposure evaluation (MPE). But it is desirable

that it should be installed and operated with at least 20cm and more

between the radiator and person’s body (excluding extremities:

hands, wrists, feet and ankles).

Declaration of Conformity

Model Number: LN-100

Trade Name: TOPCON CORPORATION

Manufacturer

Name: TOPCON CORPORATION

Address: 75-1, Hasunuma-cho, Itabashi-ku, Tokyo,

174-8580 JAPAN

Country:JAPAN

U.S.A. Representative

Responsible party: TOPCON POSITIONING SYSTEMS, INC.

Addr ess 7400 National Drive Livermore, CA94551, U.S.A

Telephone number: 925-245-8300

30

Page 34

10. REGULATIONS

Region/

Country

California,

U.S.A

California,

U.S.A

California

and NY,

U.S.A.

Directives/

Regulations

Proposition

65

Perchlorate

Material

(CR Lithium

Battery)

Recycling

Batteries

Labels/Declarations

31

Page 35

10. REGULATIONS

Region/

Country

Canada ICES

EU

Directives/

Regulations

EMC-Class B

R&TTEClass 2

-Class A

Labels/Declarations

This Class A digital apparatus meets all requirements of Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la Class A respecte toutes les exigences

du Règlement sur le matériel brouilleur du Canada.

This class A digital apparatus complies with Canadian ICES-003.

Cet appareil numerique de la classe A est conforme a la norme

NMB-003 du Canada.

Operation is subject to the following two conditions: (1) this device

may not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired

operation of this device.

This equipment complies with IC radiation exposure limits set forth

for uncontrolled equipment and meets RSS-102 of the IC radio

frequency (RF) Exposure rules. This equipment should be installed

and operated with at least 20cm and more between the radiator and

person’s body (excluding extremities: hands, wrists, feet and ankles).

EU R&TTE-

Class 2

R&TTE Directive

LN-100

Hereby, TOPCON CORP., declares that the above-mentioned

equipment is in compliance with the essential requirements and

other relevant provisions of Directive 1999/5/EC.

Please inquire below if you wish to receive a copy of Topcon's

Declaration of Conformity.

Topcon Europe Positioning B.V.

Essebaan 11, 2908 LJ Capelle a/d IJssel,

The Netherlands

Tel:+31-10-4585077 Fax:+31-10-2844949

http://www.topcon-positioning.eu/index.asp

32

Page 36

10. REGULATIONS

Region/

Country

EU WEEE

EU EU Battery

Australia C-Tick

Directives/

Regulations

Directive

Directive

Labels/Declarations

33

Page 37

http://www.topcon.co.jp

©2013 TOPCON CORPORATION

ALL RIGHTS RESERVED

Please see the attached address list or the following website for contact addresses.

GLOBAL GATEWAY http://global.topcon.com/

Loading...

Loading...