Page 1

INSTRUCTION MANUAL

LENSMETER

LM

-

8

Page 2

INTRODUCTION

Thank you for your purchase of the TOPCON

LENSMETER LM-8.

To get the best use of the instrument, be sure

to read this Instruction Manual.

By thoroughly familiarizing yourself with the

instrument and its operations, you will surely

be able to obtain the full benefit of a superior

precision optical instrument.

Keep this Manual for future reference.

Precautions

• As this instrument is a precision equipment, always use it under temperature

and humidity conditions of the normal living environment.

• Install this instrument on a level and stable table, and avoid exposure to

direct sunlight.

• Keep clean the ambient conditions, and turn off the power source and apply

the dustcover when not in use.

• To ensure exact measurement values, take care and keep dust and grease

off the lens and other parts that come into contact with the lens.

• We shall not take any responsibility for overhauling and rebuilding without

our permission.

• Note that, if this instrument is used in an manner other than that specified

herein, it may spoil the protections provided by devices.

1

Page 3

DISPLAY FOR SAFE USE

In order to encourage the safe use of this product, important warnings are put on the product and

written in the instruction manual.

We suggest that everyone understand the meaning of the following displays and icons before

reading the “Safety Cautions” and text.

DISPLAY

CAUTION

• Personal

injury refers to hurt, burn, electric shock, etc.

• Property damage refers to extensive damage to building or equipment and furniture.

Ignoring this display may lead to personal

injury or property damage.

MEANING

ICONS MEANING

This icon indicates a Hazard Warning.

Specific content is expressed with words or an icon either

inserted in the icon itself or located close to the icon

SAFETY CAUTIONS

CAUTION

Icons Prevention item Page

To prevent pinching your fingers, pay particular attention in

CAUTION

CAUTION

changing the tilt angle of the machine.

To prevent the machine/component parts from tumbling/falling,

operate the machine gently in changing the tilt angle.

2

9

9

Page 4

USAGE AND MAINTENANCE

Usage:

The Lensmeter is an electric equipment. When using, strictly follow the

instructions in this Manual.

USER MAINTENANCE:

To maintain the safety and performance of the equipment, never attempt to do the

maintenance of parts specified herein, which should be taken care of by our servicemen.

The maintenance items that can be covered by users are the following; for details, follow

the instructions.

Target position adjustment (see page 14)

ESCAPE CLAUSE

• TOPCON shall not take any responsibility for damages due to fire, earthquake,

actions by third person, or the negligence and missuse by the user and used under

unusual conditions.

• TOPCON shall not take any responsibility for damages derived from the inability to

use this equipment, such as a loss of business profit and suspension of business.

• TOPCON shall not take any responsibility for damage caused by operations other

than those described in this Instruction Manual.

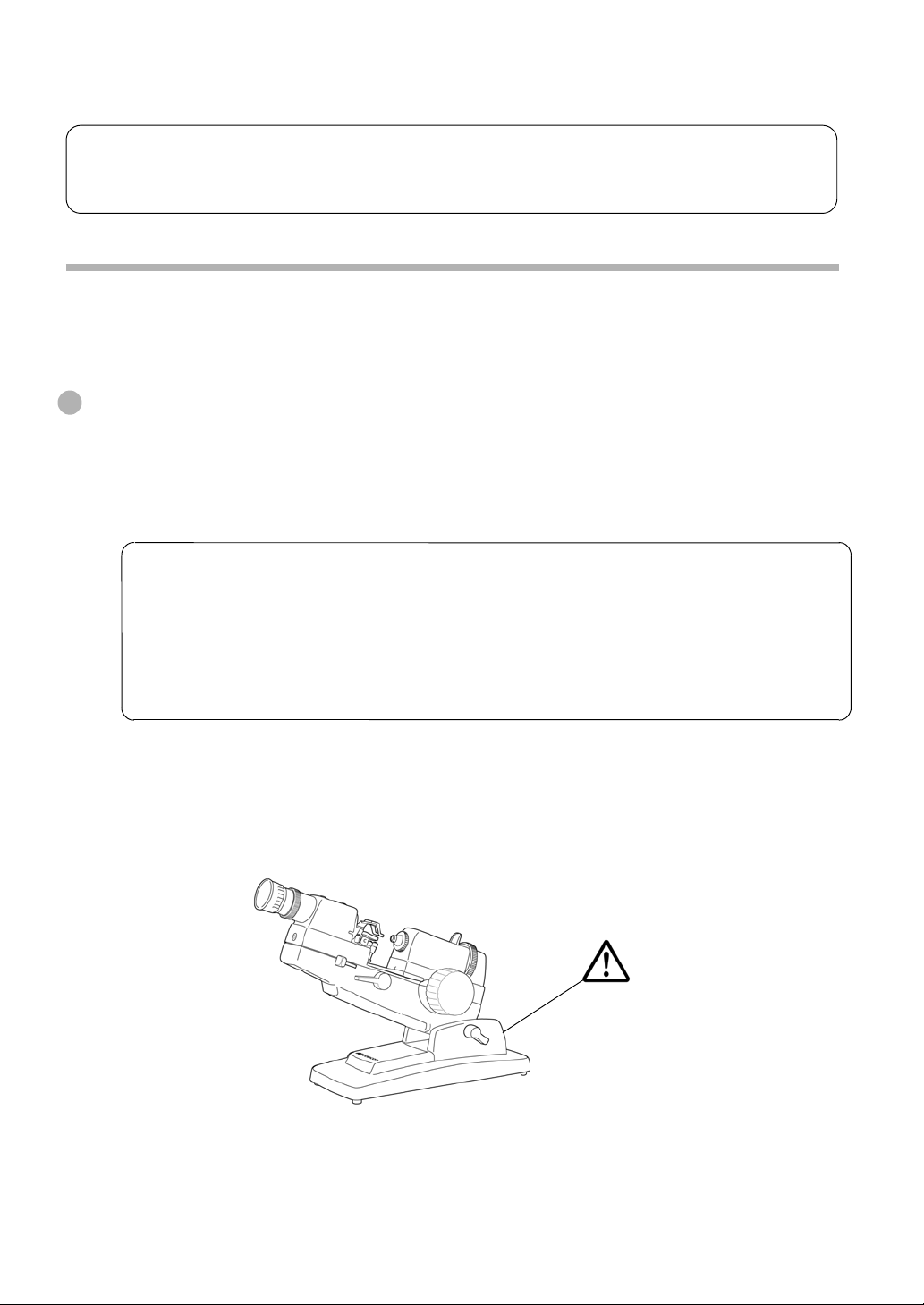

WARNING INDICATIONS AND ITS POSITIONS

To secure the safety of this instrument, warning icons are displayed. To ensure the

correct use, follow the instructions of this Manual.

3

Page 5

CONTENT

INTRODUCTION

DISPLAY FOR SAFE USE

SAFETY PRECAUTIONS

USAGE AND MAINTENANCE

ESCAPE CLAUSE

WARNING INDICATIONS AND

ITS POSITIONS

COMPONENTS

COMPONENT NAME

ACCESSORIES

TARGET IMAGE

TARGET IMAGE

MEASUREMENT PREPARATIONS

1

2

2

3

3

3

5

5

6

MEASUREMENT OF FRAMED

ASTIGMATIC LENS

MEASUREMENT OF CONTACT

LENS

MEASUREMENT OF

PRISMATIC LENS

AXIS MARKING

PRISM COMPENSATOR

PRISM COMPENSATOR

MAINTENANCE

MAINTENANCE

CHECK&ADJUSTMENT

CHECK&ADJUSTMENT

BEFORE REQUESTING

REPAIRING SERVICE

9

9

10

10

11

13

14

MEASUREMENT PREPARATIONS

MEASUREMENT

MEASUREMENT OF

SPHERICAL LENS

MEASUREMENT OF

ASTIGMATIC LENS

4

7

8

8

CHECK ITEMS

SPECIFICATIONS

OPTIONAL ACCESSORIES

15

15

15

Page 6

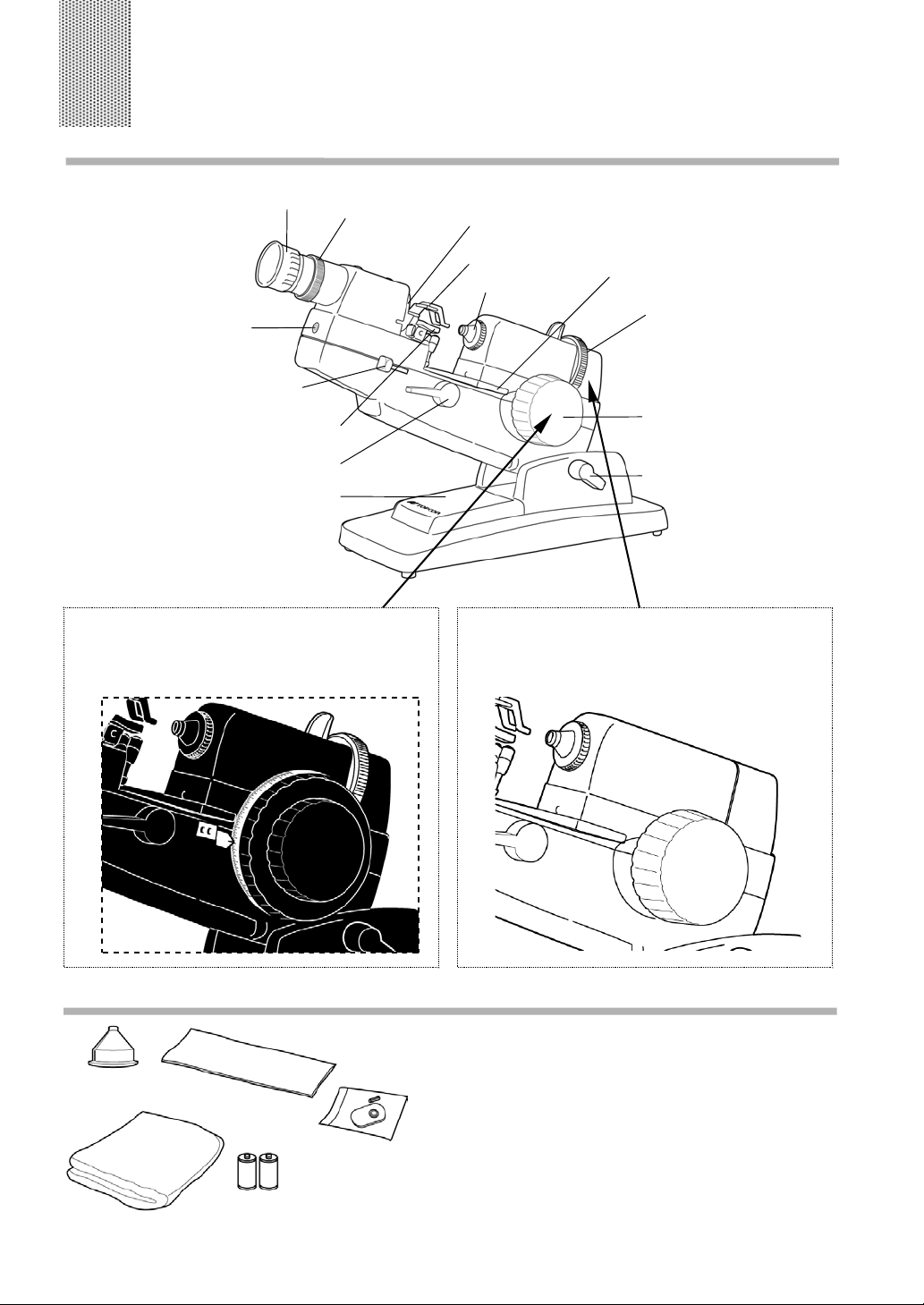

COMPONENTS

COMPONENT NAMES

Eyepiece adjustment ring

Power switch

Lens holder lever

Axis marker lever

Lens table adjustment lever

Cell box

Protractor ring

LM-8E

(Diopter power knob with scale)

LM-8

Prism holder

Lens holder

Lens stop

LM-8C

(without axis wheel)

Lens table

Axis wheel

Diopter power knob

Tilt locking lever

ACCESSORIES

(A)

(B)

(C)

(D)

(E)

(A) Contact lens stop .......................... 1 pc.

(B) Silicon cloth ................................... 1 pc.

(C) Dustcover...................................... 1 pc.

(D) UM1 dry cell .................................. 2 pcs.

(E) Lens protection pad ...................... 1 set

5

COMPONENTS

Page 7

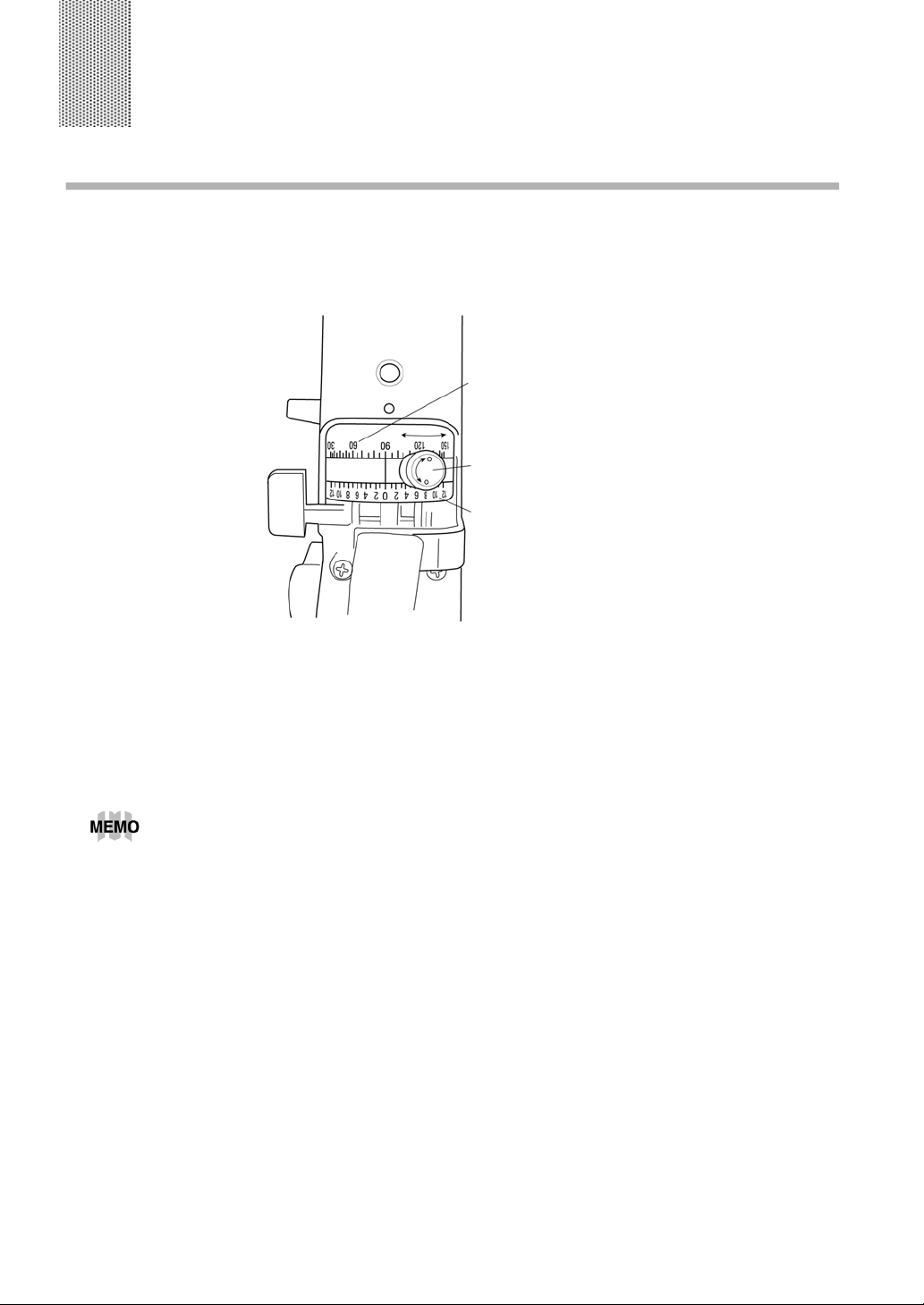

TARGET IMAGE

Pinhole corona

Cross-line

Diopter scale reading window

Cross-line Pinhole Corona

Scale

6

TARGET IMAGE

Pinhole Corona (LM-8C)

Cross-line

LM-8E: Diopter power is

indicated with scale

on the Diopter Power

knob.

A Cross-line Pinhole Corona

Page 8

MEASUREMENT PREPARATIONS

MEASUREMENT PREPARATIONS

Check component parts of the machine.

1

• Remove the adhesive tape from the lens stop.

• Remove the adhesive tape from the marking ink cartridge.

Set dry cells in the cell box. Turn on the power switch; the lamp is lit. The lamp goes

2

off in 5 minutes automatically to save the cell power.

When removing dry cells, remove the (+) side first. If the spring of the (-) side jumps out,

push it into the position.

Contact lens stop

• When using an AC adapter (marketed), insert power connector as illustrated below,

and then turn on the power switch. In this case, the stays on (even after passing 5

minutes).

As for the AC adapter, either purchase one from the market or ask your dealer.

AC adapter specification

For Europe, products are designed

for compliance with the CE standard.

Output: 6V, 100mA and higher

9mm

or longer

To enable measurements in a comfortable position, adjust the tilt angle of the

3

machine by operating the tilt locking lever.

Before starting measurement, properly focus the target (or otherwise an error

4

measurement result occurs).

• Before setting the lens, rotate the eyepiece adjustment ring and stop it where the

scale is clearly visible. Placing a white paper at the lens stop makes the scale clear

to see.

To avoid visual error in

adjustment, rotate it clockwise.

7

MEASUREMENT PREPARATIONS

Page 9

MEASUREMENT

MEASUREMENT OF SPHERICAL LENS

Place the concave surface of the lens on the lens stop and fix it firmly with the lens

1

holder.

Properly focus the target by rotating the diopter power knob.

2

To avoid visual error in adjustment, adjust it in the (+)->(-) direction.

Read the indicator value on the diopter power scale.

3

If the scale center does not align with the target image center, the optical center of lens is

not in proper alignment with the optical axis of lensmeter. Vertical displacement can be

adjusted by pushing the lens toward the lens table by operating the lens table adjustment

lever, and horizontal displacement can be adjusted by moving the lens laterally by hand.

MEASUREMENT OF ASTIGMATIC LENS

Focus the pinhole corona section of the target by rotating the diopter power knob.

1

Align the cross-line with the stronger meridian by rotating the axis wheel. (Not

applicable to LM-8C)

LM-8C : Align the scale with the stronger meridian by rotating the protractor ring.

Meridian direction

Read the diopter power scale and the angle for the meridian direction.

2

Focus the target for the other meridian by rotating the diopter power knob.

3

Meridian direction

8

MEASUREMENT

Page 10

Read the diopter power scale and angle.

Of these 2 measurement values, take the smaller one in absolute value as the S

(spherical) power, and the difference as the C (cylindrical) power. Also, for the axial

angle, take the angle of a measurement value of which the absolute value is the larger.

MEASUREMENT OF FRAMED ASTIGMATIC LENS

Place the glasses on the lens table. Press the frame toward the lens table and align the

lens with the optical axis. The refractive power can be determined in like manner, but for

the direction of astigmatic axis, set the focus for the stronger refractive power.

Focus the target along the stronger meridian. Align the cross-line with the stronger

meridian by rotating the axis wheel. The angle of the indicator ∆ is the astigmatic axis.

LM-8C : Align the scale with the stronger meridian by rotating the protractor ring.

MEASUREMENT OF CONTACT LENS

Remove the lens stop and tilt the lensmeter upright. Place the contact lens stop and put

the contact lens on it.

The contact lens stop can be stored in the dry cell box.

CAUTION

CAUTION

To prevent pinching your fingers between movable parts, pay

particular attention in changing the tilt angle of the machine.

To prevent the machine/component parts from tumbling/falling,

operate the machine gently in changing the tilt angle.

9

MEASUREMENT

Page 11

MEASUREMENT OF PRISMATIC LENS

Non-astigmatic Lens

Place the prismatic lens against the lens

1

stop, and set the diopter power scale to

zero. The target image is displaced from

the scale center.

Rotate the protractor ring and bring the

longer target center line passes through

the scale center. (Not applicable to LM-8C)

In this case, the reading indicates the

direction of the base. When the reading is

2∆, the direction is 30°.

If the target is below the horizontal line,

2

180°must be added to the read angle.

In case of cross-line pinhole corona

Astigmatic Lens

For an astigmatic lens, follow the measurement method of the preceding section.

Measure the astigmatic axis by the axis wheel, and read the prism base by the

protractor ring .

In case of cross-line pinhole corona

AXIS MARKING (Cartridge specification/Steel needle specification)

Using the cartridge, one light touch to the lens can put a clear ink mark.

Non-astigmatic Lens

Set the lens so that the target comes on the scale center.

1

Operate the axis marker lever, raise the three-needle, and print marks on the lens by

2

moving the marker forward.

Astigmatic Lens

Align the cross-line with 180°. (Not applicable to LM-8C)

1

Rotate the diopter power knob for the value S+C of the prescription.

2

Rotate the lens and focus the cross-line in the 180° direction. (Not applicable to LM-

3

8C).

LM-8C : Rotate the lens so that the stronger meridian of pinhole corona comes to

the 180° direction.

Mark the lens by operating the axis marker lever.

4

10

MEASUREMENT

Page 12

PRISM COMPENSATOR

(OPTIONAL ACCESSORY: FOR CERTAIN SPECIFICATIONS, THIS IS

ATTACHED AS STANDARD EQUIPMENT.)

PRISM COMPENSATOR

It is not impossible to measure lenses corrected for phoria over 6 prism diopters, as

1

well as segments in spherical lenses of extreme strength, because the corona target

will be displaced completely out of the field of view of the eyepiece, in this case. For

such lenses, the prism compensator must be put into use.

Base direction scale

Prism knob (Push in to fix.)

Prism diopter scale

Place the lens against the lens stop with the geometric center of the lens coincided to

2

the optical axis of the instrument. Next, rotate the power knob and set the estimated

vertex power to the vertex power scale superimposed on the field of view. Finally,

manipulate the field of view. Then, manipulate the prism knob of the prism

compensator to coincide the centers of the corona target image and the reticle crosshairs.

Rotating the prism knob around its vertical axis produced changes in the prism diopter

power while rotating the prism knob around the optical axis of the instrument produces

changes in the base direction. The prism diopter scale is on the side towards the lens

stop while the protractor scale is on the side towards the eyepiece, with the former scale

color-coded in minus powers and white for plus powers.

Next, rotate the power knob once more to focus the corona target image and then

3

use the prism compensator once more to coincide the centers of the corona image

and cross-hairs.

Read the scales of the prism compensator for the prism diopter and the base

4

direction. (In figure next page, the readings are 8∆ 65° )

11

PRISM COMPENSATOR

Page 13

And, find the vertex power from the vertex power scale

5

superimposed on the field of view.

Cylinders with correction for phoria can be checked in the same manner as simple

cylinders, as explained previously.

If the prism diopter power is indicated in orangecolored figures, the actual base direction

will be the indicated direction plus 180°.

For lenses over 14 prism diopters

For lenses over 14 prism diopters, set the prism compensator to 14∆, by rotating the

prism knob around its vertical axis, and then rotate the compensator, by revolving the

prism knob around the optical axis. Rotating the prism compensator will make the target

image run across the outer edge of the field of view as in figure below. Stop rotation at

the point where the center of the corona target image is nearest to the center of the

reticule cross-hairs and read the prism diopter power from the scale in the field of view.

The actual prism diopter power will be the prism diopter reading thus obtained plus the

prism diopters of the prism compensator. (In figure below, the reading is 2∆+14∆=16∆.)

However, the base direction will be the value

obtained from the protractor scale of the prism

compensator.

The prism diopter scale and protractor scale of the

prism compensator must always be returned to zero

when measurements are completed.

Remove 2 screws from the prism holder and instead attach the prism compensator.

Bring the base angle scale to 0°, and if the target image moves between 0-180° by

rotating the prism handle, fasten 2 screws.

12

PRISM COMPENSATOR

Fitting of prism compensator (in option)

Page 14

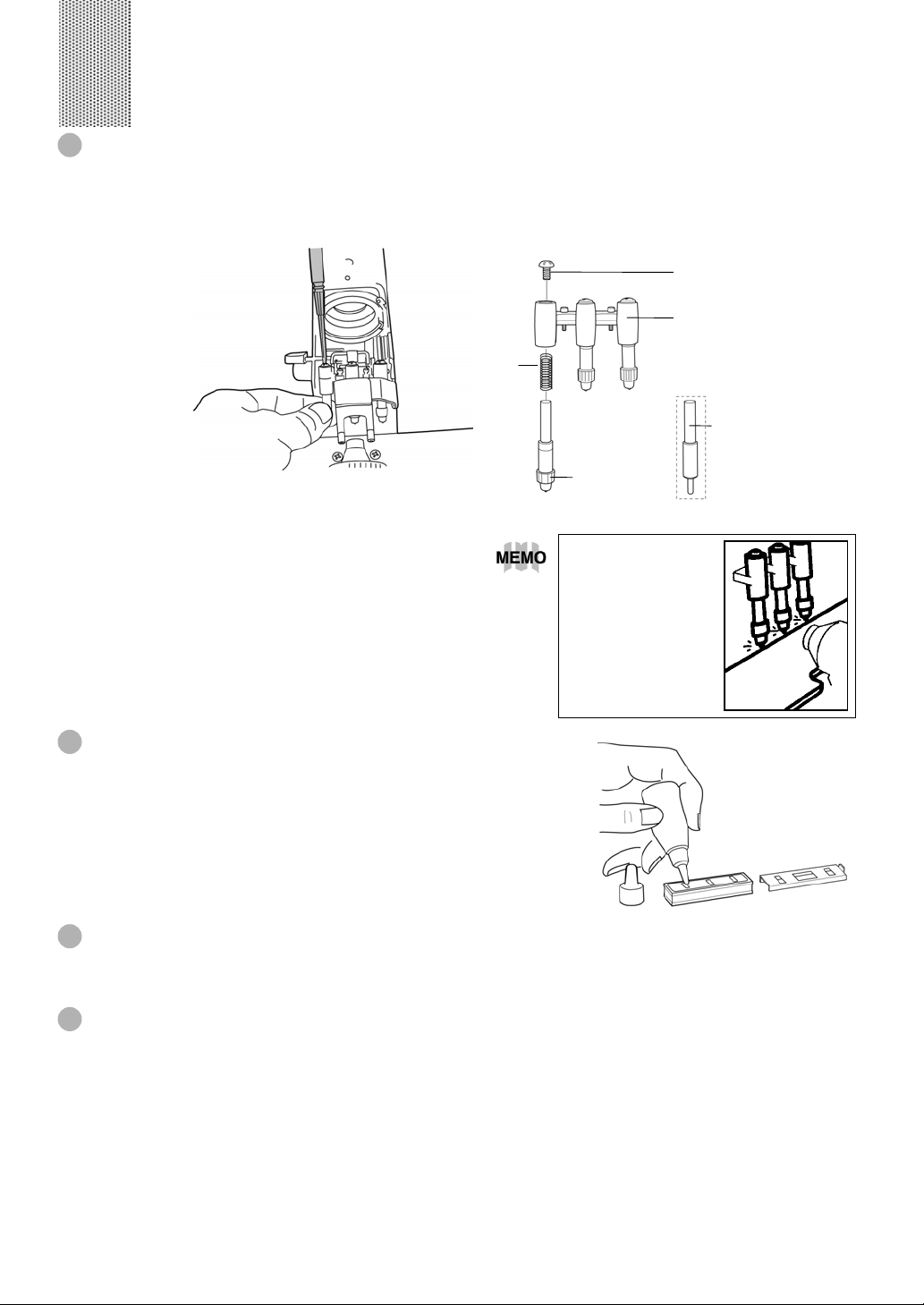

MAINTENANCE

Replacement of Marking Ink Cartridge

To replace the marking ink cartridge, remove the screw from the top. Hold the

1

cartridge when removing so as the spring not to jump out.

Do this operation with the lens holder lowered.

Screw

Marking ink holder

Spring

Steel needle

(optional accessory)

Marking

ink cartridge

Ensure the ink

cartridges do not

interfere with the

lens table

Refilling of ink for steel needle (option)

When ink becomes blurred, refill ink.

1

Slide out the ink pad.

2

Remove the ink pad cover. Pull it in the length

3

direction.

Refill ink. Amply supply ink to the felt.

4

Storage (When not in use)

When the machine is not used for a long period, turn off the power switch and cover the

attached dustcover.

Cleaning

Wipe clean the machine with the attached silicon cloth or a dry, soft cloth.

1

Never use solvents (benzine, thinner, etc.) and chemical dusters.

2

13

MAINTENANCE

Page 15

CHECK AND ADJUSTMENT

Since this machine is a precision optical instrument, use with particular care to keep it

free of shocks and vibrations.

Handling of lens stop (the same for lens holder end)

To protect the lens surface, clean the lens stop end and lens holder end and thoroughly

remove adhering dust.

Lens protection pad is also attached. However, for a highly spherical lens, the

measurement value shifts a little:

Target Position Adjustment

When the target is focused without a lens and when centers of the target and the scale

agree, their positional relations are correct. If the target center rotates at the same

position by rotating the axis wheel, adjust it as follows. (Not applicable to LM-8C)

Adjust 3 screws by a screwdriver. Tighten the screw that faces the direction in which you

want to move the target.

Before adjustment, loosen the screw in the opposite direction. Be sure to loosen the

screw little by little for adjustment. (Eventually, 3 screws must be fastened.)

If the target center is displaced and it moves when the target is moved, experience and

skill is required. In this case ask your dealer for repair.

Diopter power of lens (D) Amount of shift

-20 +0.06

-10 +0.02

+10 +0.02

+20 +0.06

14

CHECK AND ADJUSTMENT

Page 16

BEFORE REQUESTING REPAIRING SERVICE

CHECK ITEMS

Turned on power

switch, but target

image cannot be seen

Measurement value is

incorrect

Ink is blurred • Replace ink cartridge.

Target and scale

centers are displaced

SPECIFICATIONS

Measuring range & minimum

reading

Peak refractive power 0~±25D 0.125D (within ±5D, LM-8E: ±3D)

Prism refractive power

Prism compensator

Axial angle (target) 0~360° 1°

Visibility adjustment +3~ -5D

Eyepiece section 0~180° 1°

Lens diameter 20~90Ømm 2mm

Inclined angle 0~90°

Power supply 3V (UM1 cell x2) 6-V AC adapter (marketed)

Cell life and power consumption 500h and longer by continuous 5-min. ON and 5-min. OFF 0.13VA

Dimensions 310(H)x160(W)x420(D)mm

Weight approx. 4kg

* For product improvements, part of specification and appearance may be changed without prior

notice.

Environmental conditions:

Indoor use, maximum altitude: 2,000m, degree of contamination: II, working temperature

range: 5-40°C, Temperature less than 31°C(40°C): linear drop to max. relative humidity of

80%(50%)

• Aren't dry cells nearly used up?

• Is AC adapter connected properly? (When using AC adapter)

• Lamp goes off in 5min. to save cell power. (When using dry cells)

• Isn't diopter power knob near 0D? (Without lens)

• Isn't diopter power knob far from refractive power of lens. Is optical center measured?

(With lens)

• Prism compensator is 6 prism or higher. (When using prism compensator)

• Is visibility correction done properly?

• Isn't the contact lens holder used for measuring glasses?

• For lens with steep surface curve, use steel needle (optional).

• Is lens set?

• Make sure prism compensator is 0-prism.

• If target center doesn't move by rotating axis wheel, do target position adjustment (p.14).

Measuring range Minimum reading

0~±20D(LM-8E) 0.25D (±5D and higher, LM-8E: ±3D)

0~6∆ 1∆

0~14∆ 1∆(option)

or lower

OPTIONAL ACCESSORIES

• Steel needle marking set (3 steel needles, refill ink, ink pad, holder)

Disposable Items and Spare Supplies

When ordering disposable items and spare supplies, clearly state necessary item name,

item code, quantity and product name.

Item name Item code Remark

Disposable Marking ink cartridge (3 pc/set) 4203699500 Standard accessory

item Lens protection pad 4203656000 Standard accessory

Prism compensator 4203450000 Standard • Optional

Steel needle marking set 4203625100 Optional accessory

Supply ink 4203690060 Optional accessory

BEFORE REQUESTING REPAIRING SERVICE

15

Page 17

LENSMETER

LM

TOPCON AMERICA CORPORATION

CORPORATE OFFICE:37, West Century Road, Paramus, New Jersey 07652, U.S.A. Phone: 201-261-9450 Fax: 201-387-2710

TOPCON OMNI SYSTEMS, INC.

Valley Forge Business Center, 2430 Blvd. of the Generals, Norristown, PA 19403, U.S.A Phone: 610-630-9200 Fax: 610-630-6428

TOPCON EUROPE B.V.

(European Representative)

Esse Baan 11, 2908 LJ Capelle a/d IJssel, The Netherlands. Phone: 010-4585077 Fax: 010-4585045

TOPCON S.A.R.L.

HEAD OFFICE:104/106, Rue Rivay 92300, Levallois-Perret, France. Phone: 01-41069494 Fax: 01-47390251

LYON OFFICE:138, Avenue du 8 Mai 1945, 69100 Villeurbanne, France Phone: 0478688237 Fax: 0478681902

TOPCON DEUTSCHLAND G.m.b.H.

Halskestr. 7, 47877 Willich, Germany. Phone: 02154-9290 Fax: 02154-929-111 Telex: 8531981 TOPC D

TOPCON ESPAÑA S.A.

HEAD OFFICE:Frederic Mompou 5, 08960 Sant Just Desvern Barcelona, Spain. Phone: 03-4734057 Fax: 03-4733932

MADRID OFFICE:Avenida Ciudad de Barcelona 81, 1 Planta 28007, Madrid, Spain. Phone: 01-552-4160 Fax: 01-552-4161

TOPCON SCANDINAVIA A. B.

Industrivägen 4 P. O. Box 2140 43302 Sävedalen Sweden. Phone: 031-261250 Fax: 031-268607

TOPCON (GREAT BRITAIN) LTD.

Topcon House,Kennet Side,Bone Lane,Newbury,Berkshire RG14 5PX United Kingdom Phone:01635-551120 Fax:01635-551170

TOPCON SINGAPORE PTE. LTD.

Alexandra Distripark Block 4, #05-15, Pasir Panjang Road, Singapore 118491 Phone: 2780222 Fax: 2733540 Telex: 61121 TOPSIN

TOPCON INSTRUMENTS (MALAYSIA) SDN. BHD.

Lot 226 Jalan Negara 2, Pusat Bandar Taman Melawati, Taman Melawati, 53100, Kuala Lumpur, Malaysia. Phone: 03-4079801 Fax: 03-4079796

TOPCON INSTRUMENTS (THAILAND) CO., LTD.

77/162 Sinn Sathorn Tower, 37th Fl.,Krungdhonburi Rd.,Klongtonsai, Klongsarn, Bangkok 10600 Phone: 662-440-1152~7 Fax: 662-440-1158

TOPCON AUSTRALIA PTY. LTD.

408 Victoria Road, Gladesville, NSW 2111, Australia Phone: 02-9817-4666 Fax: 02-9817-4654

TOPCON KOREA CORPORATION

Hyobong Bldg., 1-1306, Seocho-Dong, Seocho-Gu, Seoul, Korea. Phone: 02-557-9231~2 Fax: 02-556-1928 Telex: K23231 EXT2264

TOPCON OPTICAL (H.K.) LIMITED

2-4/F Meeco Industrial Bldg, No. 53-55 Au Pui Wan Street, Fo Tan Road,Shatin, N.T., Hong Kong Phone: 26901328 Fax: 26910264

TOPCON CORPORATION BEIJING OFFICE

Room No. 962 Poly Plaza Building, 14 Dongzhimen Nandajie Dongcheng District, Beijing, 100027, China Phone: 10-6501-4191~2 Fax: 10-6501-4190

TOPCON CORPORATION BEIRUT OFFICE

P. O. BOX 70-1002 Antelias, BEIRUT-LEBANON. Phone: 961-1-521119 Fax: 961-1-521119

TOPCON CORPORATION DUBAI OFFICE

Office No.102, KHALAF RASHD AL NAYLI BLDG., Deira, Dubai, UAE Phone: 971-4-696511 Fax: 971-4-695272

-8

TOPCON CORPORATION

75-1 Hasunuma-cho,Itabashi-ku,Tokyo,174-8580 Japan.

Phone:3-3558-2520 Fax:3-3960-4214

Loading...

Loading...