Page 1

859-UK

ISOBUS Artemis

Seed Drill Controller Calibration

and Operation Manual

Page 2

Page 3

1

Electromagnetic Compatibility (EMC)

This product complies with European Council Directive 2014/30/EU when installed and used in accordance with the relevant instructions.

Preface

This manual provides information about calibrating and operating the RDS “ISOBUS Artemis” system. Correct use and maintenance is important for

safe and reliable operation. Please take time to read this manual and complete appropriate training before use before using the system.

Information in this manual is correct at the time of publication. The system may vary slightly from that described herein. Topcon reserves the right to

redesign and change the system as necessary without notification.

COPYRIGHT: All information contained in this manual is the intellectual property and copyrighted material of Topcon. All rights are reserved. You may

not use, access, copy, store, display, create derivative works of, sell, modify, publish, distribute, or allow any third parties access to, any graphics,

content, information or data in this manual without Topcon’s written consent. And may only use such information for the care and operation of the

product.

Warning

Please read the following important information very carefully.

TERMS AND DEFINITIONS:

Console – The Topcon Agriculture console mounted inside the cab of the tractor used for primary control of the Machine.

Application – Topcon Agriculture mobile application product that allows features of Topcon Console(s) to be monitored and controlled from a Device.

Device – A mobile device (e.g. phones and tablets) on which the Application is installed and operated.

System – The combination of the Device and the Console used to control and monitor the Machine.

Machine – The combination of a tractor and associated farming implements (whether self-propelled, towed by the tractor or mounted to the tractor).

You – The person using the application to control and monitor the Machine.

Device – A mobile device (e.g. phones and tablets) on which the Application is installed and operated.

Documentation – The user documentation and manuals relating the use and operation of the covered Topcon Agriculture product, including, but not

limited to, the Console user manuals/materials and Application end user license agreement.

IMPORTANT: You must read and follow the Documentation and complete appropriate training before use. If You do not operate the System

properly, it may not correctly apply the Application to Your requirements. This can result in damage to property and/or malfunction of the product,

death or serious injury to persons, poor yields and/or crop damage or failure. If You are in any doubt regarding any aspect of operating the System,

then before commencing operation You should obtain further guidance from a suitably qualified source.

WARNING: It is YOUR responsibility to read and understand the safety sections in this book before operating the system. Remember

that YOU are the key to safety.

PRODUCTS/MATERIALS APPLICATION: As limited by the applicable software, You are responsible for accurately entering the information required for

the Machine to apply products/materials to Your requirements, including measurement units (e.g. metric or Imperial), vehicle dimensions, rate of

application, vehicle speed, weight or other required input.

As limited by the applicable software, You are responsible for the calibration of the Machine and ensuring products/materials are applied in

accordance with their specifications (including wind, temperature and moisture conditions, material properties, dilution and withholding periods).

Without prejudice to the generality of the above You hereby acknowledge and agree that the system or application is not designed nor intended to:

▪ originate variable treatment plans; or

▪ achieve or avoid any application rate or other target setting outside application parameters, which in both cases are Your responsibility.

Failure by You to comply with the above may result in incorrect operation of the System, or injury to You or others. You should monitor at all times

that the System is performing as required.

General Safety

DANGER! It is essential that the following information and the product

-

specific safety information is read and understood.

Page 4

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

2

Most incidents arising during operation, maintenance and repair are caused by a failure to observe basic safety rules or precautions. Always be alert

to potential hazards and hazardous situations. Always follow the instructions that accompany a Warning or Caution. The information these provide

aims to minimize risk of injury and/or damage to property. In particular follow instructions presented as Safety Messages.

Safety Messages and Warnings

The safety symbol is used with the relevant word : DANGER, WARNING or CAUTION. Messages marked in this way recommend safety precautions

and practices. LEARN and apply them.

DANGER : Indicates an imminently hazardous situation that, if not avoided, could result in DEATH OR VERY SERIOUS INJURY.

WARNING : Indicates a potentially hazardous situation that, if not avoided, could result in DEATH OR SERIOUS INJURY.

CAUTION : Indicates a potentially hazardous situation that, if not avoided, could result in MINOR INJURY.

Operator Safety

Good safety practices not only protect you, but also the people around you. Study this manual as part of your safety program. This safety information

only relates to Topcon equipment and does not replace other usual safe work practices.

▪ WARNING: Never operate the machine with any panels or safety guards removed. Any illustrations or photos in this manual that show

panels or guards removed are solely for demonstration purposes. If the removal of panels and guards is necessary for calibration or

maintenance, they MUST be replaced before operation.

▪ Always check that any suspended vehicle attachments or load arm(s) are lowered to the ground before beginning repair or

maintenance work on the machine.

▪ Machine and implement parts can become hot during operation and may be under pressure. Refer to the machine/implement

manual(s).

▪ Wear appropriate protective clothing for the task being undertaken.

▪ Check the Machine is correctly setup/configured and ready for the intended use.

▪ Be aware of safety instructions for/on the Machine including hazards such as crush zones.

▪ Prevent the Machine from being accidentally started if working on it e.g. remove the ignition key, place a warning notice in the cab etc.

▪ Check that the area of Machine operation is clear of people, animals, and obstacles and identify any other possible hazards.

▪ Keep other persons required to be in the vicinity of the Machine fully aware of Your immediate intentions.

If a Topcon Agriculture mobile application is used to augment Your ability to perform tasks that are traditionally performed on the Console directly,

then in addition to observing the above warnings and all other pre-determined site safety requirements that apply when operating a Machine from

the Console, You must also observe the following additional requirements when operating the Machine via the Application:

▪ WARNING: The Application must only be operated by You, the single Console operator wholly responsible for the operation of the

Machine.

▪ The Application must only be used when the Machine is not on public roads.

▪ The Device must be affixed to a rigid mount when used inside the cab while the Machine is moving to avoid a temporary loss of control

if the Device is dropped or misplaced.

▪ The Application must only be used outside of the Machine cab when the Machine is stationary.

▪ When operating the Application outside of the cab of the Machine You must remain within a reasonable distance such that You can

return to the cab-mounted Console in a timely manner to resume control of the Machine under any of the following circumstances:

▪ Battery failure on the Device

▪ Wifi signal is lost or signal strength is too weak for proper operation

▪ The Device is redirected to another application (e.g. a phone call is received)

▪ The Device becomes incapacitated (e.g. device is dropped and damaged)

▪ Any other event that causes the Device to no longer be fit for control of the Application and/or Machine.

▪ Stand well clear of any moving parts of the Machine (e.g. hydraulic folding booms, spreader spinners, etc.) and areas of product

application (e.g. Spray Nozzles, NH3 appliers, etc.).

▪ The Device and Machine must be locked when not in use.

Page 5

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

3

1 INTRODUCTION 4

1.1 System Overview 4

1.1.1

System Components......................................................................................................................4

1.2 Artemis Main Functions

5

2. MULTIPLE CHANNELS / PRODUCTS

6

2.1 Linked Channels

6

3. OPERATION

7

3.1 Artemis Primary Screen Pages

7

3.2 The Main Operating screen - Summary

8

3.3 Channel Selection and Status

8 3.3.1

Switching Metering motor(s) On-Off / Manual Override / Half-Width Drilling.............................9

3.4 Work Status 9

3.5 Setting the Application Rate 10

3.5.1

Seed and fertiliser........................................................................................................................10

3.5.2

Pellet/ Small seed Applicator.......................................................................................................10

3.6 Pre-start Sequence 11

3.7 Tramlining 12

3.7.1

Advancing the Bout Number .......................................................................................................12

3.7.2

Holding the Bout Number............................................................................................................13

3.7.3

Setting the Tramline Rhythm.................................................................................................. .....13

3.8 Forward Speed Display 13

3.8.1

Forward Speed Alarm ..................................................................................................................13

3.8.2

Simulated Forward Speed............................................................................................................14

3.9 Fan Speed Display 15

3.9.1

Set Fan Speed Alarms ........................................................................................................ ..........15

3.10

Hopper Level Alarms

15

3.11

Totals

15

4.

BLOCKAGE MONITORING (OPTIONAL)

16

4.1

Blockage sensor status and alarms

16

4.2

Blockage sensor alarm override

17

4.3

Sensor Calibration

17

5.

PRODUCT CALIBRATION

18

5.1

Running the test from the Cab

18

5.2

Running the test using the Priming Switch

19

Page 6

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

4

5.3

Calibrating systems with ‘Accord’ type metering mechanisms.

20

6.

ALARM CODES

21

1 Introduction

This manual provides operator basic instructions for both single-channel and multi-channel generic Isobus “Artemis” Seed

Drill Controller application. It also includes settings in the “Drill Setup” menu accessible by the operator. Information on

Technician and Factory level settings are not included in this manual.

NOTE: Illustrations in this manual are based on a Topcon X25 terminal. The actual Artemis app screen display/button layout and

functions may vary slightly from that shown, depending on the specific implement being controlled, the UT the app is being

run on, its GUI and user-defined settings. If necessary, please refer to the manufacturers user manual for setup and loading

the Artemis app on other UT’s.

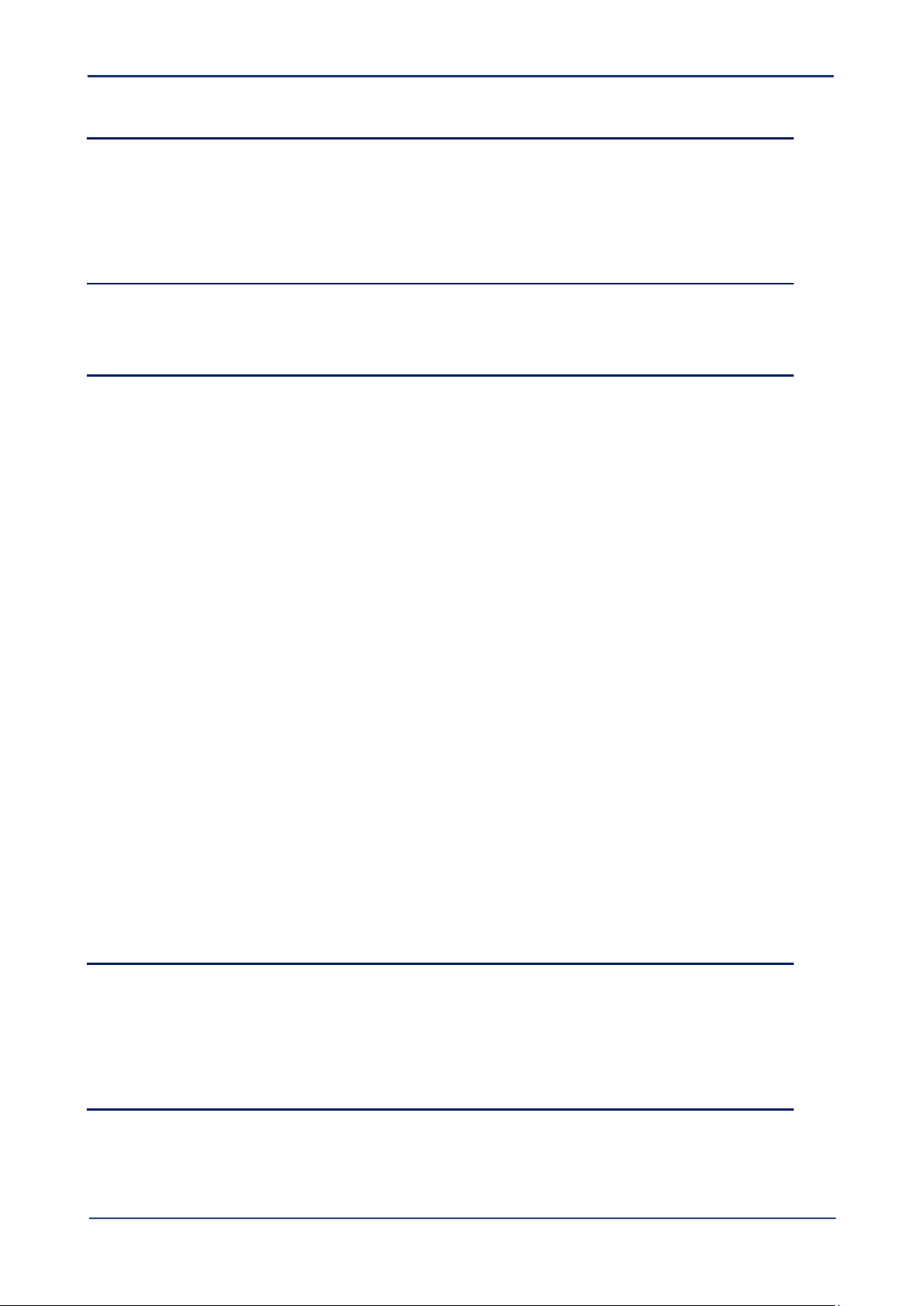

1.1 System Overview

The Artemis is an ISOBUS-compatible, monitoring and application control system for seed drills. It may be configured with

up to 4 control channels. Forward speed measurement and cutout sensing enables full proportional control, to maintain

(within limits) a set application of one or more products irrespective of changes in forward speed.

In its simplest application, the Artemis may be setup in a single-channel configuration to control a single motor as shown in

figure 1. Additional CAN modules enable multi-channel configurations for combined seed/fertiliser/pellet application

(including electro-hydraulic control), to suit a wide range of drill makes and models.

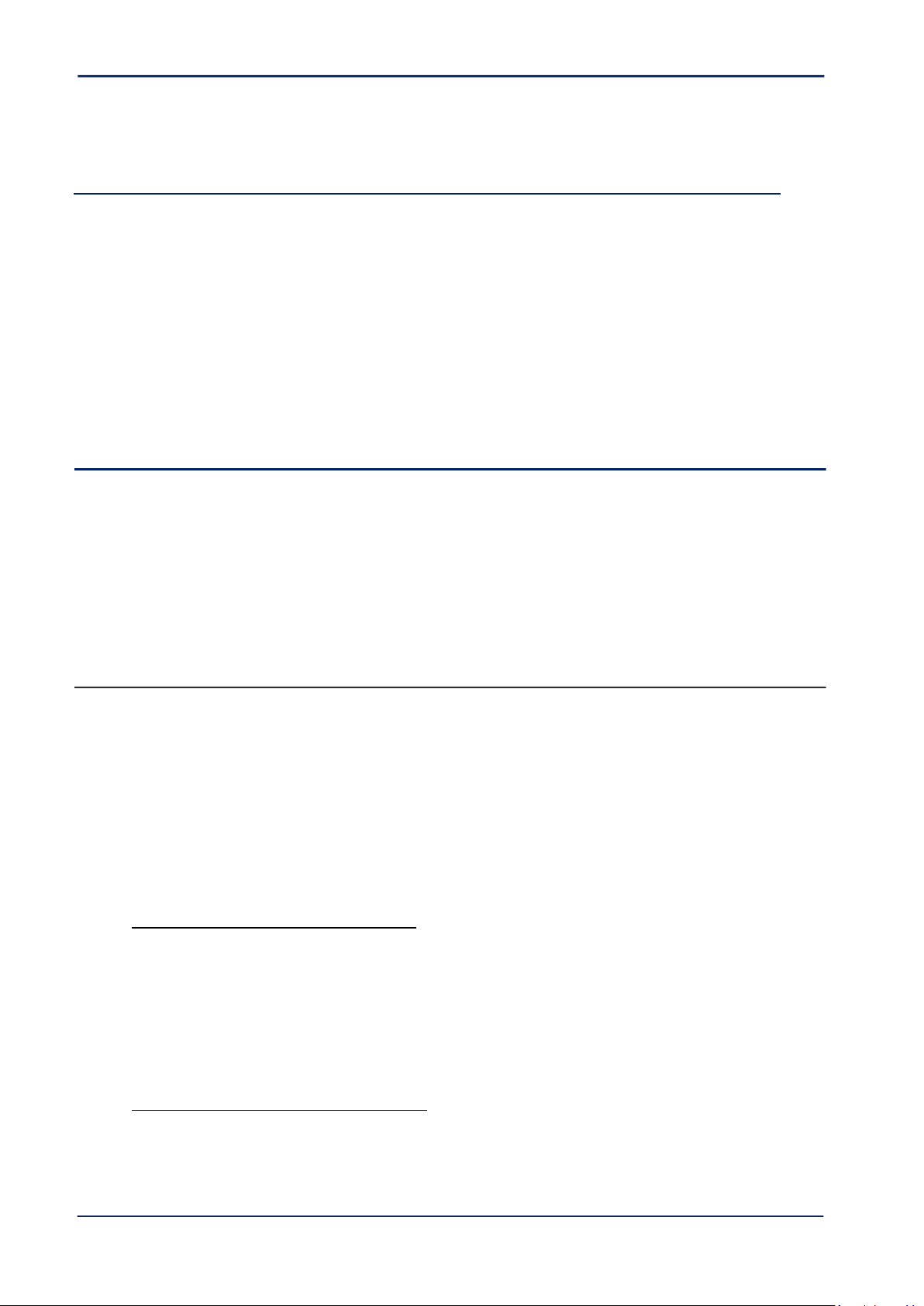

1.1.1 System Components

The system will vary depending on the drill make and model, but will be some combination of one or more of the following,

The main electronic components are,

▪ ISOBUS UT

▪ ISOBUS/CAN Bridge Module – the “brains” of the system, containing the control software. It also contains the graphics

(the ‘Object Pool”), for the GUI to be displayed on any ISOBUS-compliant terminal.

▪ Motor Control (MCM) CAN Module – CANBUS interface for a gearmotor and sensors.

▪ Applicator Control (APM) CAN Module – CANBUS interface for an Applicator system (optional).

▪ I/O (HBM) CAN Module – CANBUS interface for other switches, sensors and actuators.

Connected via the Motor Control Module (‘MCM’)

▪ Gearmotor –driving either single or multiple metering units.

▪ Shaft Speed Confirmation sensor – a magnetic sensor that confirms that the motor is driving the metering unit.

▪ Forward Speed Sensor –Speed signal sent from ISOBUS UT.

▪ Area Cutout Switch(s) - one or two magnetic sensors or finger switch positioned to detect when the drill is lowered/raised

into or out of work. It can be configured to also provide the tramline advance signal.

▪ Priming Switch – manually operates the metering motor to dispense product for calibration purposes.

Connected via the Tramline Control Module (‘HBM’)

▪ Fan Speed Sensor(s) - a magnetic sensor on the fan drive.

Page 7

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

5

▪ Hopper Level Sensor(s) – An upper “pre-level” sensor provides an early-warning alarm, giving the operator advance notice

to refill. A lower sensor provides a second warning when the hopper is about to run out.

▪ Tramline Advance Switch - provides the tramline advance signal (if not a function of the Area Cutout Switch).

▪ Tramline mechanism (existing) – the solenoid or motor-type mechanisms are rewired into the HBM connection box to be

controlled by the Artemis.

▪ Pre-emergence Markers (existing) – re-wired into the HBM connection box to be controlled by the Artemis.

▪ Bout Marker Sensors (optional) – magnetic sensors detect when the Marker arms are lifted/lowered.

Figure 1: Single-motor Artemis System

Area Cutout Shaft Speed (confirmation) Sensors

Sensor

1.2 Artemis Main Functions

The Artemis is designed to allow automatic, variable rate control of any drill. Also it can control an auxilliary Applicator

system e.g. for Slug Pellets etc. You can at any time manually override the predetermined rate as field conditions require.

The basic functions are:

▪ Variable Rate Control

▪ Tramline Control

▪ Forward Speed Alarms

▪ Hopper Level alarm

▪ Fan Speed & alarm

Power

Supply

ISOBUS / CAN

Bridge Module

‘HBM’ CAN

Module

Tramline

mechanisms

(

existing

)

TL Advance Switch

Forward Speed Sensor

(

Radar option

)

‘MCM’ CAN

Module

Metering Drive

Gearmotor/Encoder

Fan Speed Sensor

Hopper Level Sensors

Priming Switch

HBM

Connection

Box

MCM

Connection

Box

Isobus

cable

Page 8

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

6

▪ Information totals

The instrument has a special software routine that makes calibration of the metering unit(s) very easy. In the calibration

mode each metering unit is controlled via a ‘priming switch’ to dispense the product. During normal operation the control

system is started and stopped automatically via magnetic sensor(s) as the drill is put into and taken out of work.

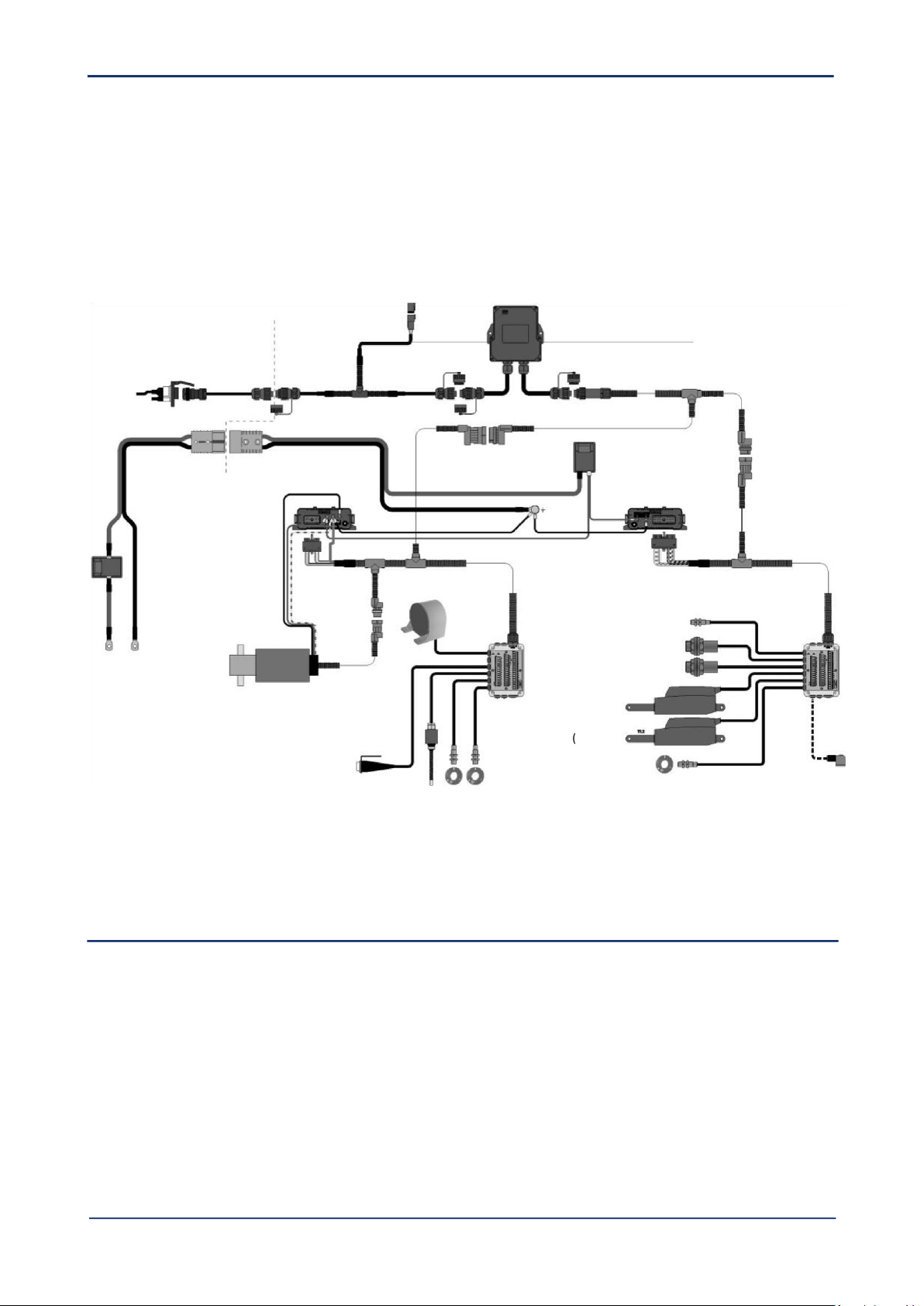

2. Multiple Channels / Products

The Artemis has 4 control channels. Each motor / MCM or APM requires a control channel, therefore the number of

channels used depends on the particular drill configuration. Here are some examples.

PRODUCT

CHANNELS

PRODUCT /MOTOR / METERING UNIT CONFIGURATION

SCREEN

DISPLAY

SEED

1

1 PRODUCT

SINGLE MOTOR / METERING

1+2

1 PRODUCT

2 x SINGLE MOTOR / METERING

1

2

2 PRODUCTS

SINGLE MOTOR / METERING (SEED)

SINGLE MOTOR / METERING (FERT A)

SEED

+

FERTILISER

1+2

3+4

2 PRODUCTS

2 x SINGLE MOTOR / METERING (SEED)

2 x SINGLE MOTOR / METERING (FERT)

SEED

+

FERTILISER

1+2

3

2 PRODUCTS

2 x SINGLE MOTOR / METERING (SEED)

SINGLE MOTOR / METERING (FERT A)

1

2

3

3 PRODUCTS

SINGLE MOTOR / METERING (SEED)

SINGLE MOTOR / METERING (FERT)

SINGLE MOTOR / METERING (APPLICATOR)

EED

+

FERTILISER

+

+PELLETS

1+2

3

4

3 PRODUCTS

2 x SINGLE MOTOR / METERING (SEED)

SINGLE MOTOR / METERING (FERT)

SINGLE MOTOR / METERING (APPLICATOR)

2.1 Linked Channels

When a configuration requires multiple hoppers / metering units to dispense a single product, then the control channels

are linked (via the “Factory Setup” menu).

Two, three or four single, adjacent control channels may be linked in this way, and assigned a product type “Seed”, “Fert

A”, “Fert B or “Pellets”.

Page 9

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

7

Examples:

NOTE: Linked channels are not currently recognized as linked by other software modules outside of the Artemis application. So for

example, if 4 channels are in active use but all are linked for single product application, they will be recognized as 4 channels

instead of effectively one channel.

If starting a Precision Farming job, the VRT (rate instructions) source is uniform across linked channels (ref. section 7.3).

3. Operation

The RDS Artemis application is displayed in the Universal Terminal (UT) window. The Artemis control keys are those within

the UT window.

NOTE: The screens illustrated are as shown on a Topcon UT, and in this case the key locations are configurable. However, the key

layout may be different for other other terminals, and the key layout may or may not be configurable depending on the

terminal. Please refer to the OEM manual for the terminal in question.

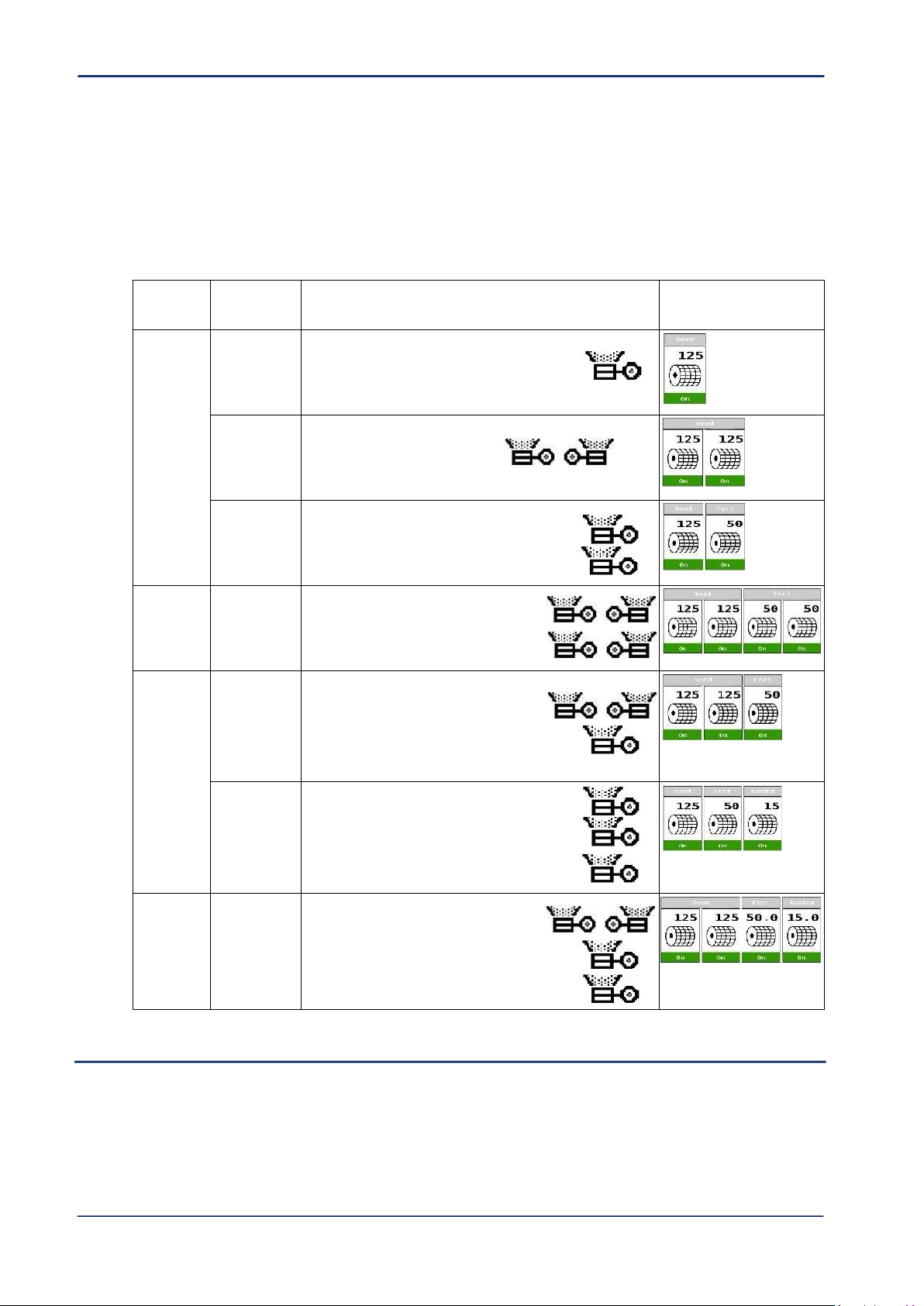

3.1 Artemis Primary Screen Pages

NOTE 1: The hydraulic functions screen is specific to particular drills and is not present unless enabled in the “Factory Setup” menu.

There

are 5 primary screen pages

.

Press to cycle between

the primary screen pages

–

Main,

Totals

,

Seed Blockage

,

Hydraulic Functions

1)

see Note

(

and

Se t tings

.

CAL/SETUP SCREEN (SECT. 5)

SEED BLOCKAGE SCREEN (SECT. 4)

MAIN OPERATING SCREEN (SECT 3)

UK

859 - 0

10

.PNG

UK859 - 030

.PNG

UK

859 - 0

20

.PNG

TOTALS SCREEN (SECT. 3)

UK

859 - 230

.PNG

Page 10

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

8

3.2 The Main Operating screen - Summary

3.3 Channel Selection and Status

The channel icon also indicates the status of the metering motor. The motor speed is proportional to forward speed, and

so when the drill is in work, the icon automatically becomes animated as the metering unit starts to turn. It also is

animated when you select the Prestart sequence, or if you have a simulated forward speed activated.

UK

859 - 0

10

.PNG

Channel Toggle [

3 . 3 ] Select channel. The

selected channel is

highlighted blue

Channel [

3 . 3 ] Shows the status of in

-

use

channels with the target

rate

Target Rate

[ 3 . 5 ]

Shows the current target

rate of the selected

channel

Nudge Rate

[ 3 . 5 ]

preset increments

Set target Rate

[ 3 . 5 ]

Displays a keypad to enter

the target rate for the

selected channel

Cycl e Cycle between the MAIN,

Hydraulic functions, Info

and Setup screens

Prestart

[ 3 . 6 ]

Runs the drill at a simulated

speed for a specified time.

Used whe

n going into work

until the target speed is

reached (e.g. 8km/hr for

) 5 secs

Channel

On/Off

[ 3 . 3 ]

Turn the channel on / off

i.e. start/stop the metering

(

motor)

Tramline Advance

[ 3 . 7 ]

Increases the tramline bout

number by 1

Work Status

[ 3 . 4 ]

Shows the drill in/out of

work status and when o

n a

tramlining bout

Tramline Hold

[ 3 . 7 ]

Hold the current tramline

when the drill is

lifted/lowered

Tramline

Status

[ 3 . 7 ]

Displays Target Bout,

Current Bout and green

ticks when tramlining.

Forward Speed

[ 3 . 8 ]

Displays the live forward

speed, or the simulated

speed when enabled.

Fan Speed

[ 3 . 9 ]

Displays the live fan speed

for 1 or 2 fans.

The currently selected channel is highlighted blue.

Either

press

,

or touch

a

channel icon to select another

channel.

Repeatedly

pressing

cycles through the channels.

The channel icon indicates the product

and

the targ

et application

rate . The target rate can be then set or nudged for the selected channel.

Page 11

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

9

3.3.1 Switching Metering motor(s) On-Off / Manual Override / Half-Width Drilling

The metering motor(s) can be stopped manually as desired, eg:

(i) An area of field needs further cultivation before seeding.

(ii) In the case of a front-mounted hopper, the metering motor is switched off just before the end of the bout to clear the

seed through (the opposite of the ‘pre-start function).

(ii) You want to drill at half-width.

The currently selected channel is highlighted blue.

To switch an individual channel:

Briefly press to switch the currently selected channel On/Off.

Alternatively, briefly touch a channel icon to switch it On/Off.

To switch all channels:

Press and hold for 3 seconds.

Half-width Drilling:

Applicable for drills configured with 2 linked channels, where normally

for full-width drilling the motors are controlled in tandem (indicated

by channel icons 1+2 and/or 3+4 being linked across the top as

shown).

When half-width application is required, either left or right metering

motor may be switched off by briefly touching the appropriate

channel icon(s).

3.4 Work Status

Sensor(s) detect when the drill is raised out of work or lowered into work, and the work status is displayed at the top of

the screen.

Drill is out of work / Metering is stopped / Area totals

accumulation is stopped.

Drill is in work / Normal metering is in progress (unless

being manually overridden – ref. section 3.4) / Area

totals are accumulating.

As above and also indicating a tramlining bout (ref.

section 3.8).

Metering

Motor switched

OFF

Metering Motor switched ON

-

drill raised out of work /

stationary

Metering Motor switched

ON - drill lowered in to work

and moving

Metering Motor switched

ON - drill lowered in to work

but with ASC override

Page 12

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

10

3.5 Setting the Application Rate

3.5.1 Seed and fertiliser

UK859-010.PNG

NOTE: The main screen page will not display or otherwise remind you of an off-target rate set for a channel, unless that channel

remains selected.

NOTE: The fan on/off control operates independently of the metering motor on/off control. Applicator

in Spinner configuration

Set / manually override the target rate as for other seed / fertiliser channels (3.5.1)

The spinner speed may be set between 0 -100% (PWM). It is a

matter of trial and error to establish the % setting to achieve the

desired spread width.

Press , enter the required % speed then touch “OK”.

The drilling rate is metric units only i.e. kgs/ha

.

To set the

Target

r

ate

for a selected channel

:

First select the channel that you want to set the rate

f

or

.

Press

,

enter the required rate the

n

touch

“

OK

”.

The

maximum speed to maintain the application is calculated

and displayed. Press “OK” to return to the main screen.

The system will then automatically maintain this rate

rrespective of forward speed (within limits).

To manually override the

Rat e for a select

ed channel

:

For the selected channel,

at any time

you can

adjust

the

rate up or down in 5% increments

to suit field conditions

,

up to a maximum ±50%

fro m the target rate.

Press

to return to the target rate.

3. 5 .2

Pellet/

S

mall seed

Applicator

Where fitted, a pellet / small seed applicator will be

factory

-

configured for either of two mo

des of operation

– ‘ Fan ’ or

‘

Spinner

’ . The mode is indicated by the or

key.

Applicator in

Fan

configuration

Set

/ manually override the target rate as

for

other

seed / fertiliser

channels

(3. 5 .1)

The fan is normally le

ft on

but should you need to

, press to

s

witch it off

(

indicated by

)

as required.

UK

859 - 400

.PNG

Page 13

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

11

UK859-410.PNG

3.6 Pre-start Sequence

UK859-400.PNG

Particularly useful in the case of a front-mounted hopper, the pre-start function helps to avoid an un-seeded area on

entering work. It starts the metering unit at the calibration speed while the drill is still stationary, and ‘primes’ the drill so

that the seed reaches the coulters just as the drill enters work.

User Settings:

Cycle to the ‘Drill Setup’ screen and touch the tab to view

the ‘Pre-start Duration’ and ‘Pre-start Mode’.

Pre-start Duration:

The pre-start duration is established by trial and error tests when

the system is first set up. The duration can be set from zero to 9.9

seconds.

UK859-040.PNG

Pre-start Mode:

‘AUTO’ mode – the Pre-start function is automatically triggered

when the drill is switched into work.

‘Man’ mode - the pre-start sequence is optional.

As required, simply press the key before moving off.

The metering motor will run at the calibration speed for the set

duration, or until the forward speed exceeds the simulation speed,

when full proportional control then takes over.

While the pre-start duration is active and the forward speed

remains below the simulation speed, the duration counts down

and the Forward Speed display is highlighted yellow.

Once the simulation speed is reached, pre-start is cancelled and

the screen returns to the normal forward speed display.

3.7 Tramlining

The main screen shows the current status of tramlining e.g.

The target no. of bouts can be selected up to 99, with symmetrical, asymmetrical-left or asymmetrical-right rhythm

selectable. A number of special asymmetric rhythms can also be selected to suit the following drill/sprayer width

combinations.

The special tramline sequences (‘L’ – Left, ‘R’ – Right) are as follows:

Bout

8-pass

10-pass

10-pass (2)

14-pass

16-pass

18-pass

22-pass

1

2

R R L

Rhythm:

Symm

etrical

Asymmetrical

-

left

Asymmetrical

-

right

Output Status (On)

Current Bout

Target N

o of Bouts

UK

859 - 0

50

.PNG

Yellow = Pre

-

start active

Countdown

Page 14

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

12

3

L R L

4

L

L

L

5

L R

6

R

7

R

L R R

8

R

L

9

R

L L

10

11

R

12

L R

R

13

14

R

15

16

L

17

18

19

L

20

21 22

3.7.1 Advancing the Bout Number

3.7.2 Holding the Bout Number

On starting up the instrument the tr

amline sequence always

starts at ‘1’.

If

entering work on a bout other than bout 1 of the tramline

sequence

, then you can

press

the

key to select the

correct

,

current bout number.

Page 15

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

13

If it is necessary to take the drill out of work other than the normal headland turn, or depending on the drill setup - lift a

marker to negotiate a field feature, the bout number will still automatically increment by 1.

3.8 Forward Speed Display

3.8.1 Forward Speed Alarm

If while the drill is switched into work and the indicated forward speed is below 0.2 km/hr, the display will flash

continuously and the metering units are stopped.

This is intended to alert the operator in the event that the forward speed signal input has been lost for whatever reason.

In this event however, you can activate a simulated forward speed so that you are able to continue drilling.

The drilling rate is metric units only i.e. km/hr.

The forward speed signal is sourced fro

m either,

▪

RDS Satspeed 2 (

c

onverts

a

GPS NMEA VTG message to a radar

-

compatible speed pulse).

▪

Radar Sensor

You can

however,

press

the

key to

hold the

cur

rent

bout number (e.g. to prevent the bout no. advancing

).

The icon indicates that the bout no. is held.

Press

the

key

again

to resume normal bout advance.

3 . 7

.3

Setting the Tramline Rhythm

Cycle to

the ‘Drill Setup’ screen and touch the tab to

view

/edit

the ‘

Target Bout’

and ‘

Mode

’ (rhythm) settings.

Tramline Number

-

normal advance mode

Tramline Number

held

UK

859 - 0

60

.PNG

Page 16

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

14

3.8.2 Simulated Forward Speed

(ii) Manually in the event of losing the forward speed signal input (in order to continue drilling).

Remember though that your actual forward speed should match the simulated speed as close as

possible, otherwise the drilling rate will not be correct. Drive faster than the simulated speed and

you will under-apply, and vice-versa.

NOTE: The Pre-start mode also uses the simulated speed setting. Pre-start will be de-activated when the

actual forward speed exceeds the simulated speed.

The simulated speed is set and manually activated via the “Drill Setup” menu as follows,

User Settings:

Set Simulated Speed:

Go to “Simulated Speed”. The factory default simulated forward speed is 10 km/hr, however this can be changed to match

your typical forward speed for drilling.

Start / Stop simulated Speed:

Go to “Simulated Speed Status” and check the tickbox to enable.

NOTE: Speed simulation can only be activated when the drill is switched out of work.

3.9 Fan Speed Display

The Artemis can monitor and display the speed of either 1 or 2 fans depending on the drill configuration. If monitoring two

fans, the display will alternate every 6 seconds between fan “1” and fan “2”.

W

hen the forward speed is simulated, the “

Sim

” icon appears on the display

. S peed

simulation is activated

either

,

( i )

Automatically

during product calibration (in order to dispense product whi

le the drill is

stationary).

Cycle to the ‘Drill Setup’ screen and touch the tab

, then

select

“

Forward Speed

”

.

UK

859 - 0

70

.PNG

UK

859 - 0

80

.PNG

Page 17

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

15

3.9.1 Set Fan Speed Alarms

3.10 Hopper Level Alarms

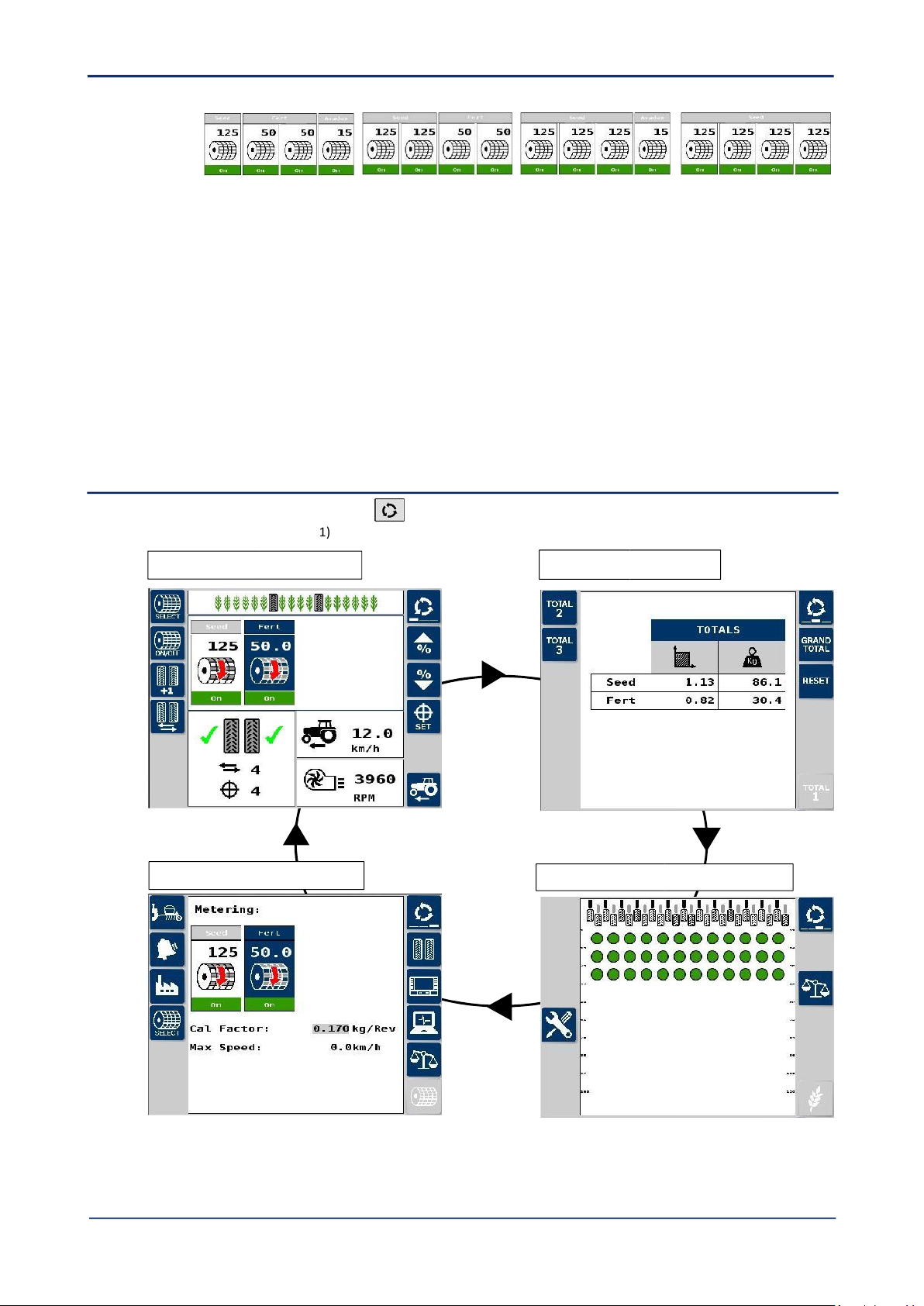

3.11 Totals

The total Area and Weight of each product accumulates to the previously selected memory register, “Total 1”, “Total 2” or

“Total 3” as shown.

The total is the total since last reset.

To reset any of the total registers, first select it and

touch You must then touch again to zero.

The Grand Total memory register cannot be reset.

UK859-020.PNG

There are both low speed and high speed programmable alarms

. T he low and high alarm speed thresholds can be set via the “Drill

Setup” menu as follows,

Cycle to the ‘

Drill Setup’ screen and touch the tab to

view/edit the ‘Fan Low Limit’ and ‘Fan Hi Limit’ settings.

UK

859 - 120

.PNG

Hopper level alarms will alert the operator when the product is

running low and/or has

nearly

run

out. Depending on the drill

configuration,

for each hopper

there is either,

) i (

a single low

-

level sensor

. ( ii ) Both a low

-

level sensor and an upper “Pre

-

Level” level sensor.

The

additional

“pre - level” sensor is positioned

higher up

in the

hopper t

o

provide

the operator a

more

advanced warning

. This

can avoid a possible disruption to drilling a long bout or

unnecessary delay in replenishment.

To view the level sensor configuration

applicable to each

metering unit

, cycle to the ‘Drill Setup’ scre

en and touch the

tab.

Check the r

elevant tickbox to enable a sensor.

UK

859 - 130

.PNG

Page 18

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

16

4. Blockage Monitoring (optional)

Blockage monitoring is an optional feature. When enabled, this screen page appears after the ‘Totals’ screen page.

In the instance of a dual-product setup, select,

to view the sensor status for seed,

to view the sensor status for fertiliser.

The sensors are identified by the row number being monitored.

NOTE: On a dual-metering setup (e.g. Seed Left / Seed Right), when a

channel is switched off, the sensor indicators will turn red, but there

will not be an alarm.

UK859-230.PNG

4.1 Blockage sensor status and alarms

NOTE: Lifting the drill out of work cancels all alarms.

Indication

Status

GREEN

The sensor is operating normally. The required seed flow is detected through the

sensor.

RED

Sensor blocked, either at the coulter or at the distribution head. The alarm message

“Seed Sensor [xx] Row [xx] Blocked” or “Fert Sensor [xx] Row [xx] Blocked” will

appear.

Remove the blockage.

Note: The Sensor No. relates to its position on the distribution head. The Row No.

that the sensor is monitoring may not necessarily be the same as the Sensor No.

ORANGE (FLASHING)

The sensor is detected on the CAN bus, however there is a break in communication

with an adjacent sensor.

The alarm message “Seed Communication Error” or “Fert Communication Error” will

appear.

Check the sensor connectors.

BLACK

A sensor is not being detected on the CANbus, and is breaking communication with

the adjacent sensors.

The alarm message “Seed Communication Error” or “Fert Communication Error” will

appear

Check the sensor connectors, otherwise the sensor may be faulty and need to be

replaced.

Note: A replacement sensor must be configured with the same ID No.

Page 19

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

17

4.2 Blockage sensor alarm override

4.3 Sensor Calibration

It is recommended to calibrate the sensors at the start of each drilling day. Start drilling and make sure everything is up to

full speed and at normal operating condition.

Cycle to the Seed Sensor screen page. If all sensor indicators are showing green, then simply press to automatically

calibrate all the sensors.

Once calibrated, the sensitivity of the sensors is adjusted automatically for varying forward speed / application, e.g for

Variable Rate Treatment from a plan.

5. Product Calibration

There are two ways of running the calibration test, ▪ from the head unit.

▪ via the relevant priming switch on on the drill.

5.1 Running the test from the Cab

1. From the main drilling screen, set the target rate for the channel(s) to be calibrated.

When a blockage occurs, after a pre

-

define

d

delay time, the al

arm screen appears. You can choose to either,

) ( i

press to temporarily cancel the alarm. Until the blockage is cleared, the alarm will re

-

activate after 30 seconds.

(

ii ) press to ignore the alarm. The

sensor icon changes t

o . Press

to revert to the normal alarm function.

UK

859 - 260

.PNG

UK

859 - 250

.PNG

Page 20

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

18

2. Setup the drill in the usual way for a bucket test on the appropriate metering unit.

3.

Cycle to the ‘Drill Setup’ screen.

The

screen displays the channel configuration

as shown on the

main operating screen

.

If multiple channels are configured, the

calibration routine mu

st be repeated for each channel

including

linked channels ( ).

4 . S

elect the chann

el

to calibrate, then

press

.

5 . Press

or ,

(

your

preference)

and e

nter the

weight

that

you wish to meter out for the bucket

test

.

6.

Press

.

The metering unit will then

operate (ba

sed on the simulation

speed

)

to dispense the programmed amount of product, then

stops.

NOTE:

At any time you can touch to curtail the test.

UK

859 - .PNG

160

UK

859 - 175

.PNG

UK

859 - 180

.PNG

Page 21

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

19

The instrument then displays a

weight figure based on the existing,

programmed product calibration

factor.

NOTE: In the case of a single motor / dual

metering configuration

( ) the product

collected, weighed and programmed

is that from BOTH metering units.

So in this case, before going to step 7,

press steps 5 and 6 for the second

metering unit, then total both

weights.

7. Weigh the contents of the container.

Press or and enter the weight

THAT WAS DISPENSED

8. Press .

The new calibration factor (kg/rev), %

error and the maximum forward

speed that is permissible based on

the application rate set for the channel.

9. Press to return to the “Drill Setup” screen.

UK859-200.PNG

5.2 Running the test using the Priming Switch

1. From the main drilling screen, first set the target rate for the channel(s) to be calibrated.

2. Setup the drill in the usual way for a bucket test on the appropriate metering unit.

and repeat

UK 8 59 - 190

.PNG

Page 22

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

20

3. Press the priming switch to meter out the desired amount of

product.

NOTE: Depending on your particular drill configuration, the priming

switch(es) will be setup for either momentary or latching operation.

If set to latching, then press and release the switch to start metering,

then press and release again to stop.

If set to momentary, then press and hold the switch to start

metering, and release to stop.

The displays switches automatically to the calibration screen once

the priming switch is pressed.

When the metering unit is stopped, the instrument then displays a

weight figure based on the existing programmed product calibration

factor.

NOTE: In the case of a single motor / dual metering configuration

( ) the product collected, weighed and programmed is

that from BOTH metering units.

So at this point, press and repeat steps 2 and 3 for the second

metering unit, and total the dispensed weights.

4. Weigh the contents of the container. Press or ,

(your preference) and enter the weight THAT WAS DISPENSED.

5. Press

.

The new calibration factor (kg/rev), % error and the

maximum forward speed that is permissible based on the

application rate

set for the channel.

6. Press

to return to the main operating screen.

UK859-200.PNG

5.3 Calibrating systems with ‘Accord’ type metering mechanisms.

When changing from a low rate to a high rate i.e. 3kg/ha to 100kg/ha

For each channel,

1. Move the metering slide to a position for the higher rate.

2. Perform the calibration test and enter the weight dispensed (as in 5.1 / 5.2).

3. The error will be considerable, but press to accept the error and continue.

4. From the main drilling screen, set the required target rate for the channel.

UK

859 - 180

.PNG

UK

859 - 190

.PNG

Page 23

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

21

5. Perform the product calibration routine again.

6. The error this time will be marginal.

7. Press to accept the error, and begin drilling.

When changing from a high rate to a low rate i.e. 100kg/ha to 3kg/ha :

For each channel,

1. Move the metering slide to a position for the lower rate.

2. Perform the calibration test and enter the weight dispensed (as in 5.1 / 5.2).

NOTE: If using the priming switch simply dispense a small amount of product and enter the weight.

3. The error will be considerable, but press to accept the error and continue.

4. From the main drilling screen, set the required target rate for the channel.

5. Perform the product calibration routine again, this time dispensing a suitable amount of product.

6. The error this time will be marginal.

7. Press to accept the error, and begin drilling.

6. Alarm Codes

No.

Code

Screen

Reason

Check?

1

N/A High forward speed

Forward speed exceeds

the maximum

calculated and

displayed on the RATE

screen

▪ Target application rate is as

required

▪ Calibration factor is realistic

▪ Adjust metering unit and

recalibrate which will increase

kg/rev factor and therefore

increase maximum achievable

forward speed

2

L.1 Low fan speed

Fan speed below the

low alarm value

programmed

▪ Fan is actually operating

▪ Sensor & target functioning and

correct

▪ PPR value programmed correctly

3

L.2

High fan speed

Fan speed is above the

high alarm value

programmed

▪ Sensor & target functioning and

correct

▪ PPR value programmed correctly

4

L.3.1

Low hopper level alarm

Channel with low level

highlighted

▪ Level is actually low

▪ Sensor is functioning correctly

▪ Wiring between sensor and

connection box is correct

▪ Wiring between connection box and

CAN module is correct

Page 24

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

22

5

L.3.2

Pre-Level hopper alarm

Channel with low pre

level highlighted

▪ Level is actually low

▪ Sensor is functioning correctly

▪ Wiring between sensor and

connection box is correct

▪ Wiring between connection box and

CAN module is correct

11

M.3.1

Motor speed signal

from motor not being

received

Motor being operated

and pulses received

from shaft confirmation

sensors but no motor

speed signal

▪ Signs of mechanical damage to

encoder or cabling on motor

▪ 3way connector between motor and

harness is correct

▪ Wiring between 3way connector and

module connector is correct

MCM or APM is offline’

▪ Check wiring between 6way

connector and module connector on

MCM harness

12

M.1

No.

Code

Screen

Reason

Check?

13

M.1.2

Module overload

shutdown

Motor current

requirement exceeded,

so the module is

shutdown and motor

operation is inhibited

▪ The Motor is stalled.

▪ Excessive drag on the metering unit,

requiring motor high current.

14

M.1.3

Motor module

temperature shutdown

Module temperature

has exceeded the value

programmed

▪ The Motor speed is very low.

▪ Excessive load applied to motor

which for a prolonged time, causing

the module high temperature and

shutdown.

▪ Check metering unit for damage /

obstruction.

▪ Re-calibrate to get motor turning

faster.

15

M.2.L

Motor speed low

Error between actual

motor speed and target

motor speed is greater

than 10%

▪ Target motor speed to high

▪ Erratic forward speed signal

▪ Erratic loading on motor via metering

unit

Page 25

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

23

16

M.2.H

Motor speed high

Error between actual

motor speed and target

motor speed is greater

than 10%

▪ Target motor speed to high

▪ Erratic forward speed signal

▪ Erratic loading on motor via metering

unit

17

M.3 Metering unit is not

going around

▪ Is metering unit rotating when motor

rotates

▪ Sensor & target functioning and

correct

▪ PPR value programmed correctly

Wiring between sensor and

connection box is correct

▪ Wiring between connection box and

CAN module is correct

18

- -

-

19

H.1 Tramline module is

‘offline’

▪ Check module has got power from

main battery power cable

▪ Check wiring between 4way

connector and module connector on

HBM harness

No.

Code

Screen

Reason

Check?

20

G.1 GPS signal lost.

▪ Check connections to GPS antenna.

▪ Check GPS coverage for Area

21

B.1 Bridge Module is

‘offline’

22

B.M.1

Blockage monitoring

ECU is ‘offline’

▪ Check power supply to blockage

ECU

▪ Check wiring between power harness

and blockage ECU

▪ Check LEDs are lit and flashing on

blockage ECU

Page 26

ISOBUS ARTEMIS - SEED DRILL CONTROLLER

24

23

B.M.2

Wrong number of

blockage sensors is

detected

▪ The correct number of sensors is

programmed in blockage ECU setup

▪ All sensors are wired correctly and

connected

24

B.M.3

Blocked sensor/row

▪ Row or pipe is actually blocked

25

B.M.4

Communication break

between blockage

sensors

▪ Wiring between blockage sensors

▪ The correct number of sensors is

programmed

26

E.H.1

Electro hydraulic

module offline

▪ Check wiring between 4way

superseal and connection to the

main loom.

Issue Ref. Date Notes

A 14.10.16 1st Draft : Derived from UK805200

B 1.3.17 2

nd

draft : re-formatted

B 23.3.17 3

nd

draft : (Section 1 added note)

Page 27

Page 28

ENGLISH

S/DC/500-10859

Doc. Ref:

UK859-C.DOCX

Doc. Revision:

C : 23.3.17

Software Rev:

IS105002rev43

RDS Technology Ltd

Cirencester Road, Minchinhampton,

Stroud, Gloucestershire, GL6 9BH, UK

Phone:+44 (0)1453 733300

Fax: +44 (0)1453 733311 (General)

+44 (0)1453 733322 (Engineering)

+44 (0)1453 733313 (Repair)

Email:info@rdstec.com

Our policy is one of continuous improvement and the information in this document is subject to change without notice.

Check that the software reference matches that displayed by the instrument.

Please visit our website for technical support or other product information. Replacement user manuals are

www.rdstec.com

available on request.

© Copyright RDS Technology Ltd 201

7

Loading...

Loading...