Page 1

SURVEYING INSTRUMENTS

IP-S3 HD1

Mobile Mapping System

72008 92080

INSTALLATION MANUAL

For more information contact Synergy Positioning Systems or

visit the Synergy Positioning Systems website at www.synergypositioning.co.nz

All branches: Phone 0800 867 266 Email: info@synergypositioning.co.nz

Page 2

i

HOW TO READ THIS MANUAL

Thank you for selecting the IP-S3.

• Please read this Instruction manual carefully, before using this product.

• The specifications and general appearance of the instrument are subject to change without prior

notice and without obligation by TOPCON CORPORATION and may differ from those appearing in

this manual.

• The content of this manual is subject to change without notice.

• Some of the diagrams shown in this manual may be simplified for easier understanding.

• This manual is protected by copyright and all rights are reserved by TOPCON CORPORATION.

• Except as permitted by Copyright law, this manual may not be copied, and no part of this manual

may be reproduced in any form or by any means.

• This manual may not be modified, adapted or otherwise used for the production of derivative works.

Symbols

The following conventions are used in this manual.

: Indicates precautions and important items which should be read before

operations.

: Indicates the chapter title to refer to for additional information.

: Indicates supplementary explanation.

Notes regarding manual style

• All other company and product names featured in this manual are trademarks or registered

trademarks of each respective organization.

Page 3

ii

CONTENTS

1. PRECAUTIONS FOR SAFE OPERATION ................................................ 1

2. PRECAUTIONS ......................................................................................... 3

3. LASER SAFETY INFORMATION .............................................................. 6

4. SYSTEM CONFIGURATION ..................................................................... 7

4.1 Standard Package Components ........................................................ 7

IP-S3 Cube ...............................................................................................7

4.2 Optional Accessories ......................................................................... 7

Mount kit ...................................................................................................7

Wheel encoder .........................................................................................7

Gasket ......................................................................................................7

Car ...........................................................................................................8

Roof carrier ..............................................................................................8

Overfender ...............................................................................................8

Personal computer ...................................................................................8

AC/DC inverter .........................................................................................8

Tools ........................................................................................................8

4.3 Vehicle Preparation ............................................................................ 8

5. INSTALLING AND ARRANGING CABLES ............................................... 9

6. IP-S3 CUBE DIAGRAM ........................................................................... 10

7. OPERATION FLOW OF IP-S3 SYSTEM................................................. 11

8. PREPARE THE VEHICLE ....................................................................... 12

8.1 Install the Roof Carrier ..................................................................... 12

8.2 Install the Mount Kit ......................................................................... 12

8.3 Install the Wheel Encoder ................................................................ 16

Required Parts .......................................................................................16

Installing the wheel encoder ...................................................................16

Installing the wheel encoder cable .........................................................17

8.4 Install the Gasket ............................................................................. 18

9. INSTALLING THE IP-S3 CUBE............................................................... 19

9.1 Install the IP-S3 Cube ...................................................................... 19

9.2 Connect the Cables ......................................................................... 23

Fixing the timing box ..............................................................................23

Connecting the power cable ...................................................................23

Connecting the power cable (battery side) .............................................24

Preparing a personal computer ..............................................................25

Connect the Computer Cable .................................................................25

Connect the Timing Box Ethernet Cable ................................................26

Connect the Indicator Box Cable ...........................................................27

Connect the Wheel Encoder Cable to the Box .......................................27

Connect the IP-S3 Cube Cables ............................................................28

Fixing the Cables ..................................................................................29

Page 4

iii

9.3 Indicator Box .................................................................................... 30

Status LED .............................................................................................30

GNSS LED .............................................................................................30

LED display ............................................................................................31

Resetting the timing box .........................................................................31

Clearing NVRAM (Initializing GNSS) ......................................................31

9.4 Removing of IP-S3 Cube ................................................................. 32

10. SPECIFICATIONS ................................................................................... 33

11. REGULATIONS ....................................................................................... 35

Page 5

1

1. PRECAUTIONS FOR SAFE OPERATION

For the safe use of the product and prevention of injury to operators and other persons as well as

prevention of property damage, items which should be observed are indicated by an exclamation point

within a triangle used with WARNING and CAUTION statements in this operator’s manual.

The definitions of the indications are listed below. Be sure you understand them before reading the

manual’s main text.

Definition of Indication

General

WARNING

Ignoring this indication and making an operation error could possibly

result in death or serious injury to the operator.

CAUTION

Ignoring this indication and making an operation error could possibly

result in personal injury or property damage.

This symbol indicates items for which caution (hazard warnings inclusive) is urged.

Specific details are printed in or near the symbol.

This symbol indicates items which are prohibited. Specific details are printed in or near

the symbol.

This symbol indicates items which must always be performed. Specific details are printed

in or near the symbol.

Warning

Do not use the unit in areas exposed to high amounts of dust or ash, in areas where there

is inadequate ventilation, or near combustible materials. An explosion could occur.

Do not perform disassembly or rebuilding. Fire, electric shock, burns, or hazardous

radiation exposure could result.

Carefully attach the IP-S3 cube to the mount kit. Damage to the instrument or serious

injury can occur.

To avoid injury, stop the car engine and apply the emergency brake before mounting or

removing the device.

Before approaching the extended slide bar, look around carefully. The slide bar may hit

your head or face to cause injury.

When securing the instrument in the carrying case make sure to set all the locks. Failure

to do so could result in the instrument falling out while being carried, causing injury.

Caution

Do not use the carrying case as a footstool. The case is slippery and unstable so a

person could slip and fall off it.

Page 6

2

1. PRECAUTIONS FOR SAFE OPERATION

Power Supply

Do not place the instrument in a damaged case. The instrument could be dropped

and cause injury.

Carefully carry this instrument. Dropping it will cause injury of persons or trouble/wrong

operation of the instrument.

Warning

Do not use voltage other than the specified power supply voltage. Fire or electrical shock

could result.

Do not use damaged power cords or plugs. Fire or electric shock could result.

Do not use power cords other than those designated. Fire could result.

Do not connect or disconnect power supply plugs with wet hands. Electric shock could

result.

To avoid fire and electric shock in the event of an instrument malfunction, immediately

turn off the power if you notice heat, smoke or smell coming from the instrument or if you

detect other problems.

To avoid electric shock, turn off the power of the car before connecting the power cable.

Page 7

3

2. PRECAUTIONS

Shock to the instrument

When carrying or transporting this instrument, put it into the special shipping case (Optional). If the

instrument is exposed to extreme shock, it may malfunction or be operated wrongly.

Dew condensation

After operating the instrument in a place with much rain/moisture, dry the instrument completely and

then store it into the case. If the instrument is stored with water, dew condensation will occur in the

instrument to cause malfunction or wrong operation.

Extreme temperature change

If this instrument is subject to extreme temperature change (for example, carrying it from a warm room

to the cold outdoors), the survey accuracy is temporarily changed. Accustom the instrument to the

use environment before using it.

Mounting to a car

Before mounting/removing this instrument, put the car on a flat and stable place with enough extent

and brightness, and turn off the engine. Mount the roof carrier securely according to the roof carrier's

instruction manual. Unless you observe this caution, serious injury may occur.

Stain

When the window unit in the laser scanner is dirty, moisten a soft, clean lint-free cloth with water and

wipe off the window unit with the cloth. If the instrument with the dirty window unit is used, the

accuracy is sometimes affected adversely.

Influence by electric wave

When using this instrument in a place with the strong electric waves mentioned below, it does not

operate normally from time to time.

• Near a transceiver or other devices generating strong electric waves

• Near an electric wave source such as television or radio

Driving

Drive the vehicle at legal speed.

Follow all driving laws for your area while driving the vehicle. When starting, steering or braking

suddenly, check the mounting status of the device.

When this instrument has been mounted on the car, the car height increases to approximately 2.3m

for sedans. Drive the car carefully where the height is limited.

Survey in rainy weather

Do not perform survey in rainy weather. Sometimes the instrument cannot survey the object

accurately.

Page 8

4

2. PRECAUTIONS

Mounting the wheel encoder

To mount the wheel encoder, install the overfender according to the vehicle laws in your area, and

obtain the automobile inspection certificate again.

Privacy

The data collected with this device can include images that violate privacy laws. Delete or alter images

that violate privacy rights before making the data publicly available.

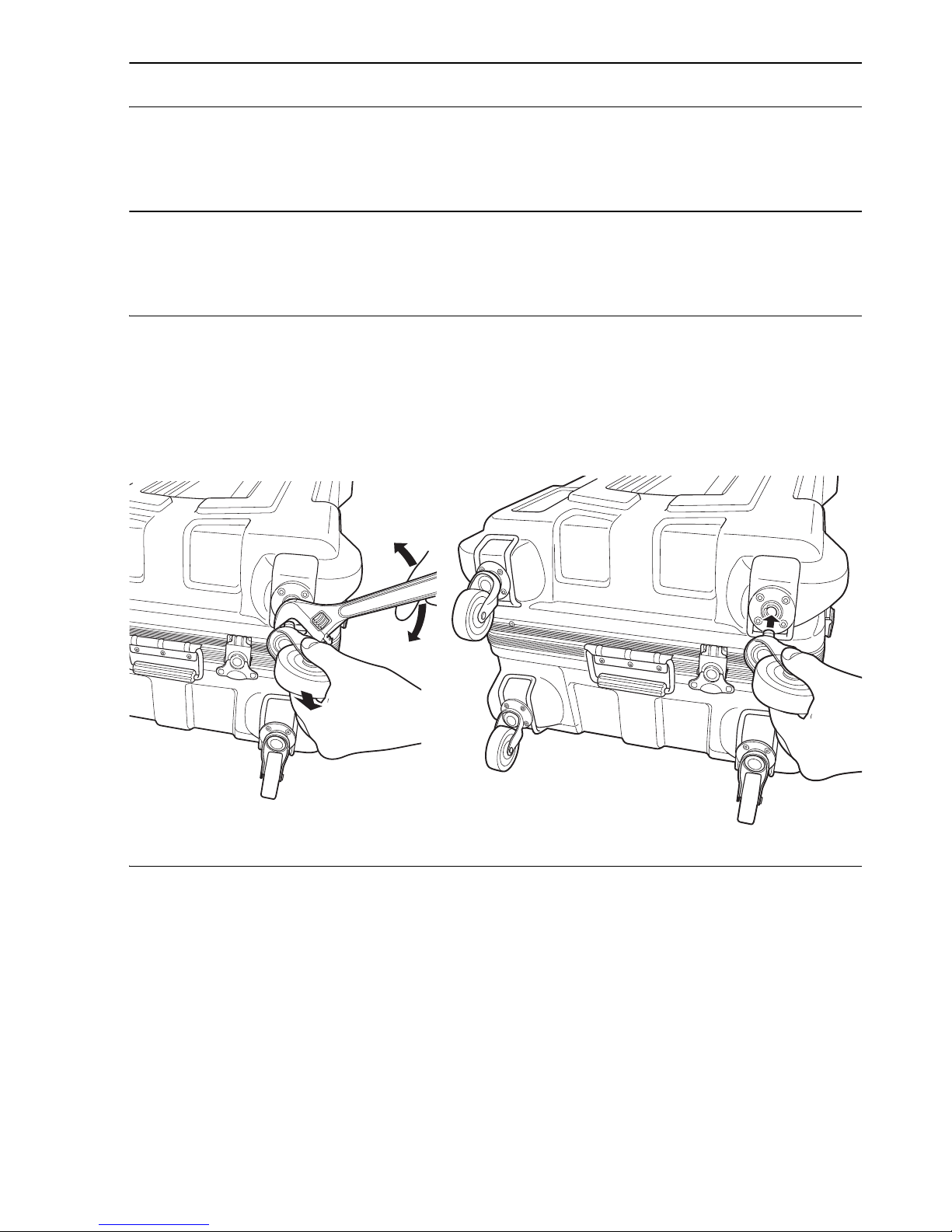

Removing/attaching casters on the carrying case(Optional)

Remove casters from the case as needed.

Maintenance

• Wipe off moisture completely if the instrument gets wet during survey work.

• Always clean the instrument before returning it to the case.

• Store the instrument in a dry room where the temperature remains fairly constant.

• Even when the instrument is not used for a long time, check its operation at least every 3 months.

• When removing the instrument from the carrying case, never pull it out by force. The empty carrying

case should be closed to protect it from moisture.

• Check the instrument for proper adjustment periodically to maintain the instrument accuracy.

Attachment

Removal

If you cannot remove casters by pulling

them with your hand, use commercially

available tools sold in stores.

Page 9

5

2. PRECAUTIONS

Exporting this product (Relating EAR)

• This product is equipped with the parts/units, and contains software/technology, which are subject

to the EAR (Export Administration Regulations). Depending on countries you wish to export or bring

the product to, a US export license may be required. In such a case, it is your responsibility to obtain

the license. The countries requiring the license as of May 2013 are shown below. Please consult

the Export Administration Regulations as they are subject to change.

North Korea

Iran

Syria

Sudan

Cuba

URL for the EAR of the US: http://www.bis.doc.gov/policiesandregulations/ear/index.htm

Exceptions from responsibility

• The user of this product is expected to follow all operating instructions and make periodic checks

(hardware only) of the product’s performance.

• The manufacturer, or its representatives, assumes no responsibility for results of faulty or intentional

usage or misuse including any direct, indirect, consequential damage, or loss of profits.

• The manufacturer, or its representatives, assumes no responsibility for consequential damage, or

loss of profits due to any natural disaster, (earthquake, storms, floods etc.), fire, accident, or an act

of a third party and/or usage under unusual conditions.

• The manufacturer, or its representatives, assumes no responsibility for any damage (change of

data, loss of data, loss of profits, an interruption of business etc.) caused by use of the product or

an unusable product.

• The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of

profits caused by usage different to that explained in the operator’s manual.

• The manufacturer, or its representatives, assumes no responsibility for damage caused by incorrect

operation, or action resulting from connecting to other products.

Page 10

6

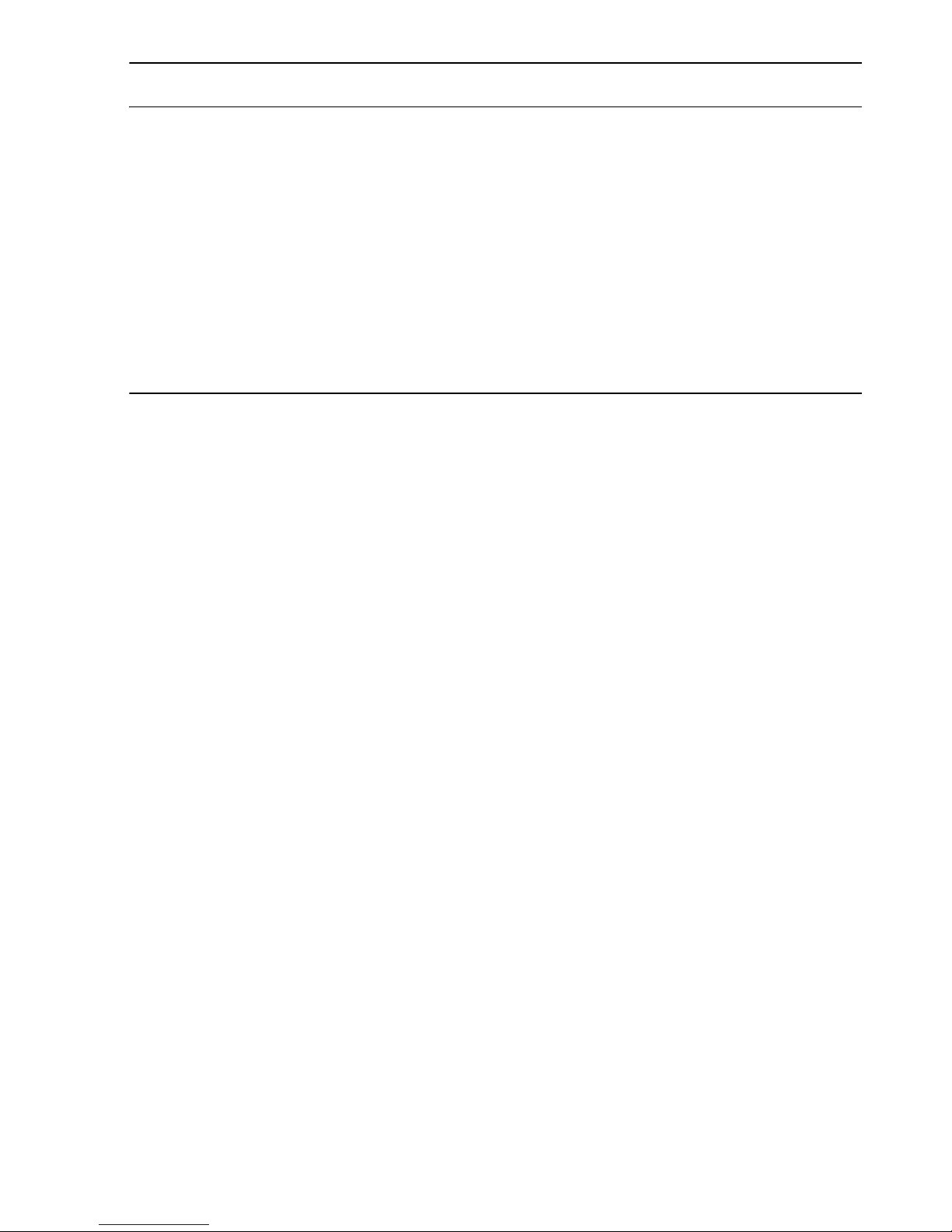

3. LASER SAFETY INFORMATION

The instrument is classified as the following class of Laser Product according to IEC Standard

Publication 60825-1 Ed.2.0: 2007 and United States Government Code of Federal Regulation FDA

CDRH 21CFR Part 1040.10 and 1040.11 (Complies with FDA performance standards for laser

products except for deviations pursuant to Laser Notice No.50, dated June 24, 2007.)

Please read the following safety instructions carefully before using the IP-S3.

Warning

• Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

• Never intentionally point the laser beam at another person. The laser beam is injurious to the eyes

and skin. If an eye injury is caused by exposure to the laser beam, seek immediate medical attention

from a licensed ophthalmologist.

Caution

• Perform checks at start of work and periodic checks and adjustments with the laser beam emitted

under normal conditions.

• When the instrument is not being used, turn off the power.

• When disposing of the instrument, destroy the battery connector so that the laser beam cannot be

emitted.

Laser beam is emitted

from here. (360° rotation)

Class 1 Laser Product

Page 11

7

4. SYSTEM CONFIGURATION

IP-S3 Cube

Refer to "STANDARD PACKAGE COMPONENTS" (enclosed paper).

IP-S3 cube has already been assembled. Because it has already been adjusted, do not disassemble

it.

Mount kit

Slide bar (with clamp lever) : 1 set

Carrier plate : 2 pcs.

Slide base : 2 pcs.

Step screw (M6) : 2 pcs.

Cable tie :20 pcs.

Carrier base A : 8 pcs.

Carrier base B : 8 pcs.

Hexagonal socket head cap screw

(M10×55mm) :16 pcs.

Spare hexagonal socket head cap screw : 4 pcs.

Washer assembled hexagonal socket head cap screw

(M10×20mm) : 1 pc.

Spare washer assembled hexagonal socket head cap screw : 1 pc.

Plain washer (M10) :16 pcs.

Spare plain washer : 4 pcs.

Spring washer (M10) :16 pcs.

Spare spring washer : 4 pcs.

Wheel encoder

Wheel encoder : 1 pc.

Nut : Size and quantity depend on the car model.

Tire nut quantities and wheel encoder shape are different between vehicles. Contact your local dealer

for more information.

Gasket

When cables are arranged in the car, a gasket is used to minimize the clearance of the window glass.

4.1 Standard Package Components

4.2 Optional Accessories

Page 12

8

4. SYSTEM CONFIGURATION

Car

Wheel encoder types are determined by the car model. Contact your local dealer. To prevent the car

from being reflected within the scan range of scanner, select a car model where you can mount the

instrument at the rear.

Roof carrier

Mount the roof carrier onto the car securely.

Overfender

When using the wheel encoder, an overfender is required for most of the car models. To mount the

overfender, obtain the automobile inspection certificate again. Contact your dealer both when

selecting a car model and when mounting the overfender.

Personal computer

For the recommended specifications, refer to the Mobile Master Office and Mobile Master Field

instruction manuals.

AC/DC inverter

This inverter is necessary to activate a personal computer. Prepare an AC/DC inverter according to

the power consumption of your personal computer.

Tools

When installing the mount kit, the following tools are necessary.

• Allen wrench 8mm (for hexagonal socket head cap screw)

• Allen wrench 4mm (for step screw)

4.3 Vehicle Preparation

Page 13

9

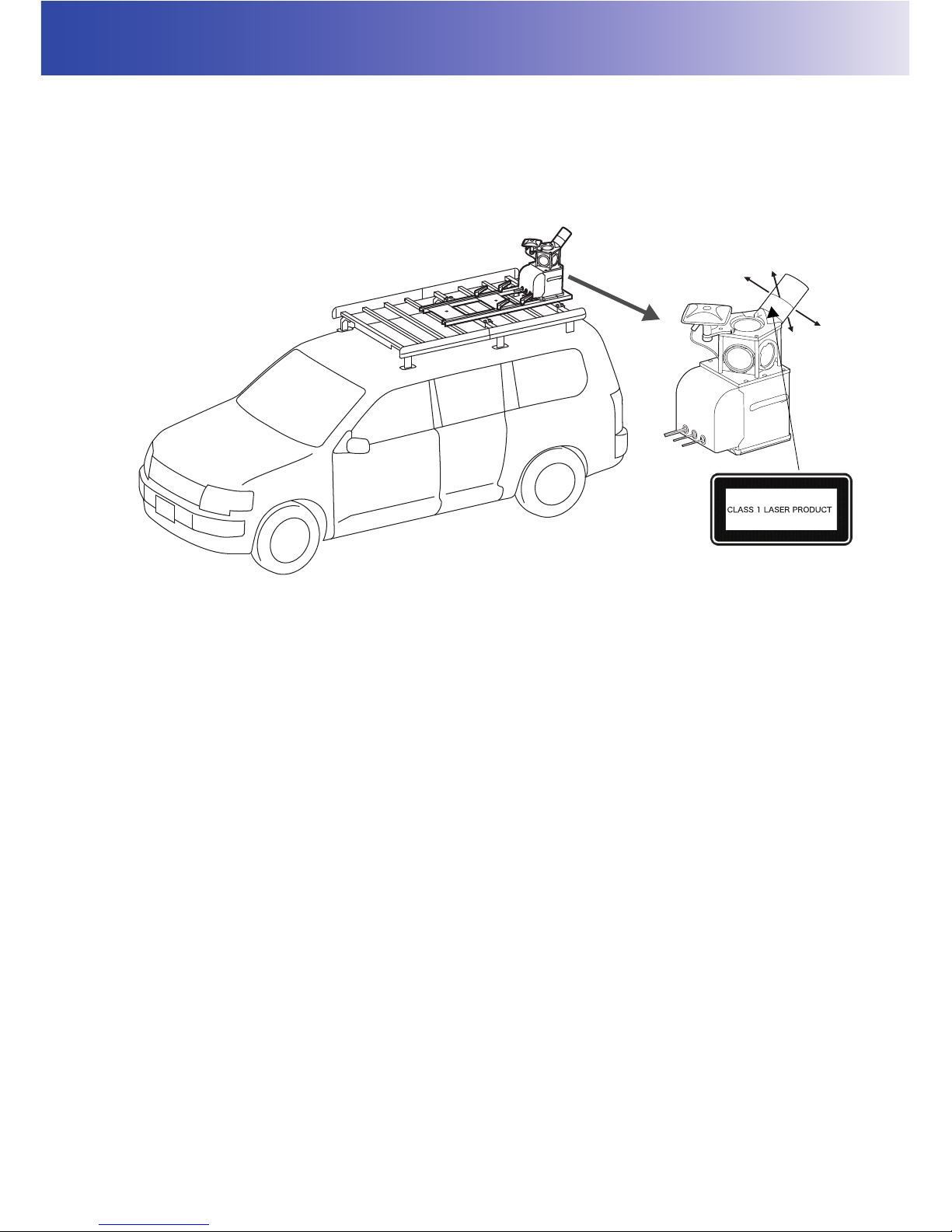

5. INSTALLING AND ARRANGING CABLES

The outline for installing the devices is shown below.

The cables from the IP-S3 cube are connected to the devices from the inside of the vehicle through

the windows.

Roof carrier

Mount kit

IP-S3 cube

Gasket

Car battery

Personal computer

(for collecting data/setting

devices)

Wheel encoder

Overfender

Cable

Timing box

Indicator box

Fuse (30A)

AC/DC inverter

USB3.0

repeater

Relay connector

Page 14

10

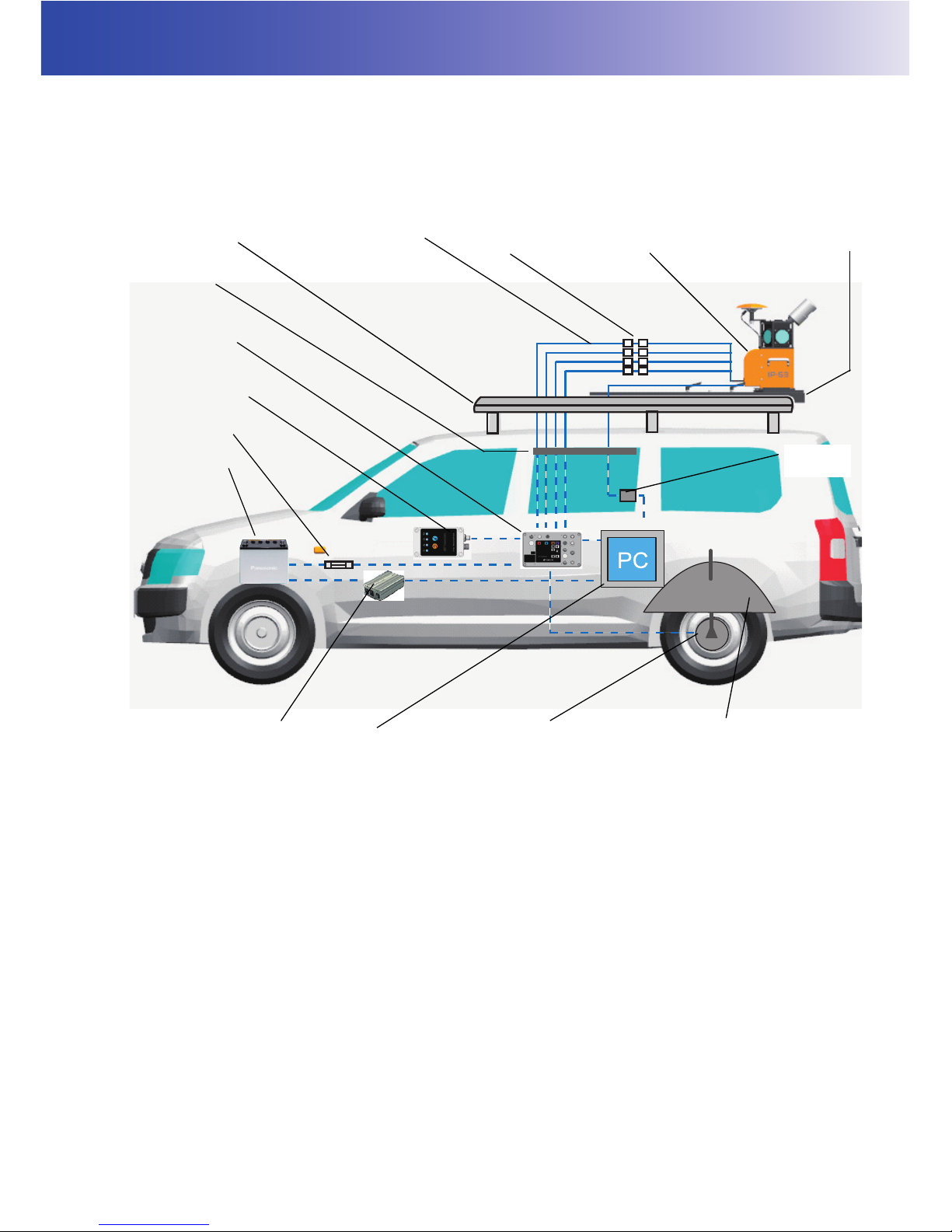

6. IP-S3 CUBE DIAGRAM

The IP-S3 cube has already been assembled. Because it has already been adjusted, do not

disassemble it.

Scanner

GNSS antenna

Spherical

camera

IMU

(in the case)

Handle

IMU cable

Scanner cable

GNSS cable

USB 3.0 cable (long)

Camera cable

Page 15

11

7. OPERATION FLOW OF IP-S3 SYSTEM

The operation outline and the relevant instruction manuals are shown below.

Collect data

Install the IP-S3 cube when surveying (parts that are removed from the car)

• Installing the roof carrier

• Installing the mount kit

• Installing the wheel encoder

• Installing the gasket

Advance preparation (parts that are not removed from the car)

Remove the devices

IP-S3 HD1 Installation Manual (this manual)

• Installing the IP-S3 cube to the mount kit

• Connecting the cables

• Checking the operation

• Preparing the personal computer

IP-S3 HD1 Installation manual (this manual)

• Collecting the base station (known point) data

• Checking the operation of sensors

• Collecting the IP-S3 data

Mobile Master Field Instruction Manual

Post-processing

Subsequent work

• Post-processing

• Making the point cloud data (Coloring the point cloud)

Mobile Master Office Instruction Manual

Page 16

12

8. PREPARE THE VEHICLE

When preparing the vehicle, install the following devices.

1. Mount the roof carrier onto the car. For details, refer to the roof carrier's instruction manual.

Mount the carrier plate onto the roof carrier bar using the following procedure. (The carrier plate has

the binding band to clamp the cables.)

1. Put the carrier base A on the roof carrier bar and align the hole position. (4 places)

2. Put one carrier plate on the carrier base A.

3. Mount the carrier plate to carrier base using the 4 hexagonal socket head cap screws on both

ends of the plate.

4. Repeat step 3 for the other carrier plate.

8.1 Install the Roof Carrier

8.2 Install the Mount Kit

Roof carrier

Carrier base A

Carrier base B

Carrier plate

Roof carrier

Roof carrier bar

Hexagonal socket

head cap screw

Carrier plate

Spring washer

Plain washer

Page 17

13

8. PREPARE THE VEHICLE

5. Mount the side base to the carrier plate using carrier base B and the 8 hexagonal head cap

screws. The side base must be pointed in the direction shown below.

When the instrument is shipped, the slide bases are secured to the slide bar with 4 clamp levers.

Detach the clamp levers from the slide bar before using the slide bases.

Slide base

Hexagonal socket head cap screw(8pcs.)

Carrier plate

Slide base

(Pay attention to the

mounting direction.)

Long hole

Hexagonal socket

head cap screw

Spring washer

Plain washer

Car traveling direction

Clamp lever

Slide bar

Page 18

14

8. PREPARE THE VEHICLE

6. Remove the 4 clamp levers, spring washers, and plain washers from the side bar.

7. Put the slide bar on the slide base.

8. As shown in the illustration below, locate where the sidebar is fully extended and securely tighten

the clamp lever and step screw.

Torque the step screw to 5N-m.

9. Adjust the slide base to be parallel to the slide bar, making sure clearances are the same.

10. Tighten the 8 hexagonal head cap screws, and torque to 24.4N-m.

Clamp lever

Step screw

Slide bar

Slide base

Slide bar

Clamp lever

Step screw

Slide base

Extend fully.

Spring washer

Plain washer

Page 19

15

8. PREPARE THE VEHICLE

11. Loosen the 4 clamp levers, retract the slide bar, and place it in the the center of the roof carrier.

12. Securely tighten the 4 clamp levers by hand.

The knob parts of all clamp levers used for this product can be rotated by pulling them in the direction

indicated by the arrow in the diagram below. When tightening the clamp levers, rotate the knobs so

that you can easily apply your force.

Clamp lever

Slide bar

Retract.

Clamp lever(knob)

Page 20

16

8. PREPARE THE VEHICLE

Required Parts

The number in parentheses is quantity.

Installing the wheel encoder

1. Remove the wheel nuts from one of the right and left tires.

2. Attach the wheel encoder nuts.

8.3 Install the Wheel Encoder

Wheel encoder (1) Wheel encoder cable (1)

Wheel encoder nut and bolt

(Size and quantity are different between car

models.)

Genuine nut

Special nut

Page 21

17

8. PREPARE THE VEHICLE

3. Make a hole on the overfender of the rear tire to fix the wheel encoder bar.

4. Pass the wheel encoder bar through the hole on the overfender of the rear tire.

5. Align the hole of wheel encoder with the nut of the rear tire.

6. Attach the wheel encoder bolt.

Installing the wheel encoder cable

1. Connect the cable of rear tire to the wheel encoder. (The connection for the IP-S3 cube will be

mentioned later.)

Wheel encoder bar

Hole

Overfender

Wheel encoder

Special bolt

Wheel encoder

Wheel encoder cable

[Sensor Side] is written on the tag

of this part.

Page 22

18

8. PREPARE THE VEHICLE

• Arrange the wheel encoder cable so that it stays within the vehicle width.

• The quantity of wheel encoder parts is different from vehicle to vehicle. Contact your local dealer for

more information.

After mounting the IP-S3 cube on the roof of the vehicle, connect it to the timing box using the included

cables. Keep the rear window slightly open to route the cables to the timing box. Use a gasket to

decrease the gap in the open window.

1. Trim the gasket to fit the rear window.

2. Slightly lower the window, and attach the gasket.

8.4 Install the Gasket

Gasket

Window glass of rear seat

Page 23

19

9. INSTALLING THE IP-S3 CUBE

To prevent theft, only install the IP-S3 cube to the mount kit when surveying.

The IP-S3 cube has already been calibrated. Do not disassemble it.

1. Loosen the 4 clamp levers of the slide bar.

2. Extend the slide bar in the direction shown in the diagram below.

3. Tighten the 4 clamp levers.

9.1 Install the IP-S3 Cube

Warning

Carefully attach the IP-S3 cube to the mount kit. Damage to the instrument or serious

injury can occur.

Before approaching the extended slide bar, look around carefully. The slide bar may hit

your head or face to cause injury.

Clamp lever

Slide bar

Extend.

Page 24

20

9. INSTALLING THE IP-S3 CUBE

4. Make sure that the four quick shoe lock pins are lowered.

5. Loosen the 2 clamp levers of the quick shoe.

6. Hold both handles of the IP-S3 cube, and place it on the quick shoe as shown in the image

below.

Be careful not to catch the cable.

Lock pin

Clamp lever

Quick shoe

Lock pin

Handle

Quick shoe

Page 25

21

9. INSTALLING THE IP-S3 CUBE

7. Place the IP-S3 cube against the fixing pins of the quick shoe. Then, raise the lock pins to make

sure that the IP-S3 cube is secured.

8. Tighten the two clamp levers.

9. Tighten the hexagonal socket head cap screw with washer (M10Å~20mm) from the bottom of the

quick shoe.

The IP-S3 cube is now installed.

Fixing pin

Lock pin

Lock pin

Clamp lever

Handle

Washer assembled hexagonal

socket head cap screw

Page 26

22

9. INSTALLING THE IP-S3 CUBE

10. Loosen the clamp lever of the slide bar, and retract the slide bar as shown in the image below.

11. Tighten the clamp lever of slide bar.

• When surveying, extend and use the slide bar.

• If you open the hatchback while the slide bar is extended, the hatchback may be damaged.

Before opening the hatchback, retract the slide bar.

Page 27

23

9. INSTALLING THE IP-S3 CUBE

After mounting the IP-S3 cube on the roof of the vehicle, connect it to the timing box using the included

cables. Keep the rear window slightly open to route the cables to the timing box. Do not allow any slack

in the cables.

Fixing the timing box

To prevent the timing box from moving while the car is running, adhere Velcro tape to the rear surface

of timing box as shown below.

Connecting the power cable

1. Connect the IP-S3 side connector ([Timing Box Side] is written on the tag) of the power cable to

the power supply port (POWER) of timing box. Do not supply power to the timing box.

• If power is supplied to the box at this point, it may draw too much power and cause the connector

to fail.

• The above illustration shows the position of each connector.

• Do not connect the cables incorrectly.

• The color sheet on the timing box shows the color of each cable tag.

9.2 Connect the Cables

Warning

To avoid electric shock, turn off the car engine before connecting the power cables.

Timing box

Velcro tape

Page 28

24

9. INSTALLING THE IP-S3 CUBE

Connecting the power cable (battery side)

1. Connect the power cable to the car battery.

The wire on the battery side of the power cable is exposed. Topcon recommends placing the

exposed wire inside a connector. For safety and ease of use, connect the red cable to the

positive (+) terminal, and the black cable to the negative (-) terminal.

Timing box

Power cable

Sheet

Timing box switch

Example of the connection unit

Power cable

[+] terminal

[-] terminal

Car battery

Page 29

25

9. INSTALLING THE IP-S3 CUBE

• Power is supplied to IP-S3 from the car battery directly. Even if the car engine is turned off, IP-S3

operates and the car battery discharges power. Whenever the car engine stops, turn off the timing

box switch.

• When connecting the power cable, turn off the timing box switch.

• When connecting all cables, turn off the timing box switch.

Preparing a personal computer

A computer running Microsoft Windows is required to set up the IP-S3 cube, check the settings, and

collect data. An AC power supply is required for the computer.

Set up your computer away from heat and moisture and direct sunlight.

Connect the Computer Cable

1. Connect the Ethernet cable to the Ethernet port on the computer.

2. Connect the USB 3.0 cable to the USB jack of the computer.

Do not connect the USB 3.0 cable to the computer while Windows is starting. The camera does not

operate normally from time to time. In such a case, start Windows correctly, then connect the cable.

Ethernet cable

[PC Side] is written on the tag of this part.

USB3.0 cable

[PC Side] is written on the tag of this part.

Page 30

26

9. INSTALLING THE IP-S3 CUBE

Connect the Timing Box Ethernet Cable

1. Remove the cap from the timing box Ethernet cable.

2. Connect the IP-S3 side of the Ethernet cable to the Ethernet port of the IP-S3 cube.

Ethernet cable

[Timing Box Side] is written on the

tag of this part.

Ethernet port(Blue)

Page 31

27

9. INSTALLING THE IP-S3 CUBE

Connect the Indicator Box Cable

1. Remove the cap from the indicator box port.

2. Using the indicator box cable, connect the timing box to the indicator box as shown below.

Connect the Wheel Encoder Cable to the Box

1. Remove the cap from the timing box Encoder port.

2. Connect the wheel encoder cable to the Encoder port on the timing box. The encoder port is

located next to the wheel encoder port. See "8.3 Install the Wheel Encoder" on page 16 for more

information.

Indicator box cable

[Timing Box Side] is written

on the tag of this part.

[Indicator Side] is

written on the tag of

this part.

Wheel encoder cable

[Timing Box Side] is written on

the tag of this part.

Encoder port (white)

Page 32

28

9. INSTALLING THE IP-S3 CUBE

Connect the IP-S3 Cube Cables

1. Connect all cables from the timing box to the IP-S3 cube, and ty-wrap them for easy storage.

Cube side

IMU (Tag: brown)

Camera (Tag: purple)

Scanner (Tag: red)

GNSS (Tag: white)

Timing Box side

[1]IMU

(Tag: brown)

[2]Camera

(Tag: purple)

[3]Scanner

(Tag: red)

[4]GNSS

(Tag: white)

[Joint Side] is written on

the tag of this part.

[Joint Side] is written on

the tag of this part.

Connect the cables on the timing box side to the ports shown below.

Timing Box

[1]IMU

[2]Camera

[3]Scanner

[4]GNSS

Page 33

29

9. INSTALLING THE IP-S3 CUBE

Fixing the Cables

• After connecting all cables, attach them to the binding band of the carrier plate.

• Fix the cables without excessive tension.

Carrier plate

Connector

Binding band

(Detachable)

Page 34

30

9. INSTALLING THE IP-S3 CUBE

Using the LEDs of the IP-S3 indicator box, check if the IP-S3 system operates properly.

Status LED

After turning the power on, if the Status LED blinks red some part of the IP-S3 system is not operating

correctly.

If the Status LED blinks green, the IP-S3 system is operating correctly and the system can collect data.

It takes approximately 1 minute for the Status LED to register green from turning the power on.

GNSS LED

This LED blinks a different color according to the number of satellites currently being tracked in GPS

and GLONASS. Green indicates GPS and orange indicates GLONASS. Right after the power is ON,

this LED blinks red. A Red blinking LED indicates that the instrument is not surveying. When the single

system is surveying, the LED does not blink red.

For more information on device operation, see the Mobile Master Field Instruction Manual.

9.3 Indicator Box

Status LED

LAN LED

Switch LED

GNSS LED

NVRAM Clear button

System reset

button

Indicator box

Page 35

31

9. INSTALLING THE IP-S3 CUBE

LED display

LED status is described in the table below.

For all errors, except GNSS initialization, follow the steps in "Resetting the Timing Box" below.

For descriptions of errors, see the Mobile Master Field Instruction Manual.

Resetting the timing box

1. Continuously press the System Reset button until the Switch LED blinks slowly.

2. Release the system reset button. The Switch LED blinks rapidly until the timing box is reset.

After resetting is finished, the timing box restarts.

Clearing NVRAM (Initializing GNSS)

1. Continuously press the NAVRAM Clear button until the Switch LED blinks slowly.

2. Release the NVRAM Clear button. The Switch LED blinks rapidly until NVRAM is cleared.

After NVRAM is cleared, the timing box restarts.

LED Indication Contents

Status

Solid red

Startup

Solid orange

Sensor is being initialized.

Solid green

Operating properly

Green blink

Collecting data

Blinks red two times

System error

Blinks red three times GNSS initialization error (Clear NVRAM.)

Blinks red four times

IMU error

Blinks red five times

Scanner data error

Blinks red six times

Scanner synchronization error

LAN

Solid green During Ethernet connection to timing box from

each sensor

Switch

Solid green Within 4 seconds after the switch is pressed

Blinks green slowly Within 4 - 8 seconds after the switch is pressed

Blinks green rapidly Instrument reset or NAVRAM is clearing

GNSS

Blinks red Surveying is not performed

Blinks green

Tracking GPS satellites:

The blinking times indicate the number of

satellites being tracked.

Blinks orange

Tracking GLONASS satellites:

The blinking times indicate the number of

satellites being tracked.

Page 36

32

9. INSTALLING THE IP-S3 CUBE

After surveying, follow the steps below to remove the IP-S3 cube.

1. Disconnect the cables.

2. Loosen the clamp lever of slide bar and extend the slide bar.

3. Loosen the clamp lever of the quick shoe.

4. Pull down the 4 lock pins.

5. Holding both handles, remove the IP-S3 cube as shown in the diagram below.

9.4 Removing of IP-S3 Cube

Lock pin

Clamp lever

Page 37

33

10.SPECIFICATIONS

IP-S3 Timing box

Dimensions 260 (W) × 160 (D) × 121 (H) mm

Weight 3.0kg(6.6lb)

Operating temperature range -20°C to 50°C (-4° to 122°F)

Storage temperature range -30°C to 60°C (-22° to 140°F)

Dustproof/Waterproof IP65 (JIS C0920:2003)

Input/Output port Power supply, Ethernet, scanner, spherical camera,

wheel encoder, IMU, GNSS antenna

Time resolution 10 nsec

Input voltage 9V to 36V

Power consumption 60W (when cube is connected)

GNSS receiver Built-in

Indicator Box

Dimensions 75 (W) × 125 (D) × 34 (H) mm

Weight 0.2kg(4.4lb)

Operating temperature range -20°C to 50°C (-4° to 122°F)

Storage temperature range -30°C to 60°C (-22° to 140°F)

Dustproof/Waterproof IP65 (JIS C0920:2003)

LED Status, LAN, Switch, GNSS

Cube

Dimensions 300 (W) × 500 (D) × 600 (H) mm

Weight 18kg(39.6lb)

Sensors installed in Cube GNSS antenna, IMU, Laser scanner, Spherical camera

Sensors

GNSS receiver

Number of channel 226 channels

GPS L1/L2 carrier, L1CA, L1P, L2P

GLONASS L1/L2 carrier, L1CA, L1P, L2P

Data update 10 Hz

Static survey accuracy H: ±3.0mm + 0.5ppm

V: ±5.0mm + 0.5ppm

Kinematic survey accuracy H: ±10mm + 1ppm

V: ±15mm + 1ppm

Operating temperature range -40°C to 85°C (-40° to 185°F)

Storage temperature range -40°C to 60°C (-40° to 140°F)

Vibration 4G (sine wave), 7.7G (Random vibration)

Shock 30G

GNSS antenna

Operating Frequency Range L1 GPS/GLONASS 1586.5 ± 25MHz

L2 GPS/GLONASS 1236 ± 20 MHz

L-Band 1535 ± 10 MHz

Operating temperature range -50°C to 85°C (-58° to 185°F)

Storage temperature range -55°C to 50°C (-67° to 122°F)

Dustproof/Waterproof IP67 (JIS C0920:2003)

Vibration Random Vibration : IEC 60068-2-34, Test Fd

Sinusoidal vibration : IEC 60068-2-6, Test Fc

Shock Shock : IEC 60068-2-29 Test Ea

Bump : IEC 60068-2-29 Test Eb

Drop : 2m pole drop to concrete

IMU

Gyro bias stability 1°/hr

Page 38

34

10. SPECIFICATIONS

Acceleration bias stability 7.5 mg

Operating temperature range -40°C to 65°C (-40° to 149°F)

Storage temperature range -50°C to 80°C (-58° to 176°F)

Dustproof/Waterproof IP67 (JIS C0920:2003)

Vibration 6Grms(20Hz to 2000Hz)

Shock 7G(6 to 10msec 1/2Sine)

Laser scanner

Point density 700000 points/sec

Valid range 100m

Operating temperature range -10°C to 60°C (-14° to 140°F)

Storage temperature range -40°C to 105°C (-40° to 221°F)

Dustproof/Waterproof IP67 (JIS C0920:2003)

Vibration 3Grms(5Hz to 200Hz)

Shock 500m/s

2

(11msec)

Spherical camera

Camera unit CCD camera (6 pcs.)

Maximum resolution 8000 × 4000 pixels

Operating temperature range 0°C to 45°C (32° to 113°F)

Storage temperature range -30°C to 60°C (-22° to 140°F)

Maximum image capturing

speed 10fps

Wheel encoder

Pulse rate 2500 PPR

Operating temperature range -40°C to 85°C (-40° to 185°F)

Dustproof/Waterproof IP67 (JIS C0920: 2003)

Vibration 100m/s

2

(10Hz to 2000Hz)

Shock 2500m/s

2

(6msec)

General

Absolute coordinates accuracy*1) 50mm@10m distance (1 sigma)

*1) Comparison to 10 known points in 30 times by 30km/h

Surface accuracy*2) 10mm on road surface (1 sigma)

*2) Plane fitting results on flat road surface

Continuous surveying time 4 hours

Page 39

35

11.REGULATIONS

Region/

Country

Directives/

Regulations

Labels/Declarations

U.S.A. FCC

-Class A

FCC Compliance

WARNING:

Changes or modifications to this unit not expressly approved by the

party responsible for compliance could void the user's authority to

operate the equipment.

NOTE:

This equipment has been tested and found to comply with the limits

for a Class A digital device pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful inter-ference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the operator’s manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own

expense.

California,

U.S.A

Proposition

65

California,

U.S.A

Perchlorate

Material

(CR Lithium

Battery)

Canada ICES

-Class A

This Class A digital apparatus meets all requirements of Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la Class A respecte toutes les

exigences du Règlement sur le matériel brouilleur du Canada.

This class A digital apparatus complies with Canadian ICES-003.

Cet appareil numerique de la classe A est conforme a la norme

NMB-003 du Canada.

Page 40

36

11. REGULATIONS

EU

EMC-Class A

EMC NOTICE

In industrial locations or in proximity to industrial power

installations, this instrument might be affected by electromagnetic

noise. Under such conditions, please test the instrument

performance before use.

This is a CLASS A product. In a domestic environment this product

may cause radio interference in which case the user may be

required to take adequate measures.

Model: Mobile Mapping System IP-S3 HD1

Manufacturer

Name: TOPCON CORPORATION

Address: 75-1, Hasunuma-cho, Itabashi-ku, Tokyo, 174-

8580 JAPAN

Europe Representative

Name: Topcon Europe Positioning B.V.

Representative Director:

Jim Paetz

Address: Essebaan 11, 2908 LJ Capelle a/d IJssel, The

Netherlands

EU WEEE

Directive

Region/

Country

Directives/

Regulations

Labels/Declarations

Page 41

http://www.topcon.co.jp

GLOBAL GATEWAY http://global.topcon.com/

Please see the attached address list or the following website for contact addresses.

©2015 TOPCON CORPORATION

ALL RIGHTS RESERVED

Loading...

Loading...