Page 1

INSTRUCTION MANUAL

LUMINANCE METER

Rev 1.1

Page 2

2 3

Page 3

INTRODUCTION

Thank you so much for your purchasing our TOPCON TECHNOHOUSE Luminance Meter IM-1000.

IM-1000 is a handy type luminance meter that can measure a wide range with high accuracy. This

manual describes the outline, basic operation procedure, specifications and the communication

specifications required for developing the software regarding the Luminance Meter IM-1000. Read

this manual carefully before putting the instrument into operation in a proper manner.

Page 4

DISPLAY FOR SAFE USE

Display

Meaning

DANGER

Ignoring or disregarding this display may result in serious injury

or cause the death of human beings.

WARNING

Ignoring or disregarding this display may result in serious injury

or lead to life threatening situations.

CAUTION

Ignoring or disregarding this display may lead to personal injury

or damage of facilities.

Icon

Meaning

This icon indicates Caution.

Specific content is expressed with words or an image located close to

the icon.

(Example

: Be careful for an electric shock.)

This icon indicates Prohibition.

Specific content is expressed with words or an image located close to

the icon.

(Example : Don’t touch the operating units.)

This icon indicates Mandatory Action.

Specific content is expressed with words or an image located close to

the icon.

(Example : Install the grounding.)

In order to encourage the safe use of products and prevent any danger to the operator and others or

damage to existing facilities, important warnings are put on the products and inserted into the

instruction manuals.

We suggest that everyone understand the meaning of the following displays and icons before reading

the "SAFETY CAUTIONS" and text.

DISPLAYS

• "Personal injury" means an injury, burn or electric shock which does not requir entering or going to

hospital.

• "Damage of facilities" refers to extensive damage to buildings, household belongings, livestock or

pets.

ICONS

4

Page 5

Icons

Prevention Item

Prohibition

Don't use this instrument where combustible steam (for example

gasoline) occurs.

It may cause a fire.

Prohibition

Don't disassemble or modify this instrument.

A fire or electric shock may occur.

Mandatory Action

Use the AC adapter which is an accessory sold separatery.

If not, the AC adapter malfunctions to cause a fire or electric shock.

Prohibition

Don't disassemble the AC adapter.

It may cause a fire or electric shock.

Mandatory Action

Remove dust or water from the outlet of the AC adapter.

If not, a fire may occur.

Mandatory Action

If an abnormal noise, smell or smoke comes in this instrument, turn

off the power and remove the AC adapter from the outlet at once.

A fire will occur if using the instrument without repairing the

troublepoint. Consult with your dealer or TOPCON TECHNOHOUSE.

Icons

Prevention Item

Prohibition

Install the battery to be fit to the specified polarity.

The leakage may cause an injury or malfunction.

Prohibition

Don’t put the instrument on an unstable place (e.g., on an

unsteady table or a sloped surface).

The instrument may fall off or turn over to cause an injury.

Prohibition

Don't pull out or insert the plug by a moistened hand.

It may cause an electric shock.

WARNING

CAUTION

5

Page 6

ESCAPE CLAUSE

• TOPCON shall not take any responsibility for damage due to fire, earthquake, actions by third

persons and other accidents, or the negligence and misuse of the user and use under unusual

conditions.

• TOPCON shall not take any responsibility for damage derived from the inability to use this equipment,

such as a loss of business profit and suspension of business.

• TOPCON shall not take any responsibility for damage caused by operations other than those

described in this Instruction Manual.

• TOPCON shall not take any responsibility for damage caused by operation failures due to

combination with other devices.

CAUTIONS FOR USE

• Be sure to use the standard accessory, nickel hydride battery (charging type) for the instrument. If

you use others except the standard accessory, the instrument may operate irregularly.

• Be sure to use the specified AC adapter for the instrument. Any other AC adapter will cause a

malfunction. The input voltage is AC100 - AC240 and the power supply frequency is 50Hz - 60Hz.

• Be sure to turn off the power switch before connecting/disconnecting an external plug such as the AC

adapter or RS-232C connector.

• When the instrument is not in use for a long time, disconnect the power plug to save the energy.

• Take out the battery to avoid leakage and store the instrument when it is expected to be disused for

a month or more.

• The instrument does not have a waterproof structure. Don’t use or store the instrument where it is

splashed with water or other liquids.

• Don’t measure a bright thing that is beyond the measuring range. The photo detector may be

damaged to hinder the accurate measurement.

• Don’t use the instrument in the place with much dust, high humidity or corrosive gas.

• Don’t use the instrument where the temperature is sharply changed. The instrument has the built-in

temperature compensation circuit. However, it cannot perform measurement precisely in the

environment where the temperature is sharply changed.

• Don’t use or store the instrument where a strong shock (e.g., falling off) or constant vibration is given.

Because the instrument has the precise optical parts, a shock or vibration will cause a malfunction.

When carrying the instrument, do not give a vibration or shock to it directly.

• Store the instrument under the normal temperature condition. Don’t store it under the high

temperature and humidity condition (e.g., in a vehicle).

• The instrument case is made of plastic. Don’t wipe it, using any chemicals (acetone or thinner).

Don’t bring it near any place whose temperature is 50°C or more.

• Make a calibration regarding the instrument about once a year to keep the measurement accuracy.

For the request of calibration, contact your dealer or TOPCON TECHNOHOUSE.

• The data stored in the built-in memory are erased in the calibration of the instrument. Make a

backup file of the necessary data before requesting the calibration.

6

Page 7

USER MAINTENANCE

Unless specified in this manual, the maintenance work shall be conducted only by a trained service

engineer, to ensure the safety and performance of the instrument. The following maintenance work,

however, may be executed by the operator. Regarding the maintenance method, read the applicable

text in this manual.

n Cleaning the instrument cover and beam detector

If the instrument case and beam detector are stained, moisten a soft cloth with the diluted neutral

detergent and, with this cloth, remove the stain. Then, wipe the case and beam detector with a dry,

soft cloth.

The stain, fingerprint or oil on the beam detector sometimes causes a measurement error. Carefully

clean the beam detector. Don’t use acetone, thinner, benzine or other solvents.

7

Page 8

CONTENTS

INTRODUCTION ...................................................................................................................... 3

DISPLAY FOR SAFE USE ........................................................................................................ 4

1.PREPARATION BEFORE USE .................................................................................. 12

1.1. CHECKING THE INSTRUMENT AND ACCESSORIES ................................................... 12

1.2. NAMES AND FUNCTIONS OF COMPONENTS .............................................................. 13

1.2.1. Names and functions of switches on keyboard ......................................................................................... 15

1.2.2. Names and contents of data on the display screen ................................................................................... 17

1.3. PREPARATION................................................................................................................ 18

1.3.1. Connecting the AC adapter ....................................................................................................................... 18

1.3.2. Installing the batteries ............................................................................................................................... 20

1.3.3. Installing personal computer ..................................................................................................................... 21

1.3.4. Turning ON/OFF the power ....................................................................................................................... 22

2.OPERATION OF THE MEASURED VALUE .............................................................. 23

2.1. DISPLAY OF THE MEASURED VALUE ........................................................................... 23

3. SETTING OPERATION............................................................................................... 24

3.1. FUNCTION MODE........................................................................................................... 24

3.1.1. Shifting to function mode/returning to measurement mode ....................................................................... 24

3.1.2. Set item/Data display ................................................................................................................................ 25

3.2. DETAILS OF FUNCTION MODE ..................................................................................... 26

3.2.1. Setting the averaging count ...................................................................................................................... 26

3.2.2. Setting the interval mode .......................................................................................................................... 26

3.2.3. Setting the interval measurement conditions ............................................................................................ 27

3.2.4. Setting the manual measurement conditions ............................................................................................ 27

3.2.5. Setting continuous measurement .............................................................................................................. 27

3.2.6. Setting the reference light source.............................................................................................................. 28

3.2.7. Setting the sample light source ................................................................................................................. 28

3.2.8. Setting the reference value ....................................................................................................................... 28

3.2.9. Setting the spectral correction ................................................................................................................... 29

3.2.10. Setting the tristimulus values correction .................................................................................................. 29

3.2.11. Setting the wireless LAN ......................................................................................................................... 30

3.2.12. Setting the wireless LAN IP address ....................................................................................................... 30

3.2.13. Setting the wireless LAN subnet mask .................................................................................................... 31

3.2.14. Setting the wireless LAN port number ..................................................................................................... 31

3.2.15. Setting the wireless LAN access point .................................................................................................... 32

3.2.16. Setting the wireless LAN WEP ................................................................................................................ 32

3.2.17. Setting the wireless LAN PASS PHRASE ............................................................................................... 33

3.2.18. Setting the RS-232C baud rate ............................................................................................................... 33

8

Page 9

3.2.19. Setting the back light ............................................................................................................................... 34

3.2.20. Setting the measurement data automatic saving function ................................................................................ 34

3.2.21. Setting the measurement data history clearing function .................................................................................. 34

4. COMMUNICATION WITH PERSONAL COMPUTER ................................................ 35

4.1. COMMUNICATION COMMAND ...................................................................................... 35

4.2. COMMAND LIST ............................................................................................................. 35

4.3. COMMUNICATION PROTOCOL ..................................................................................... 38

4.3.1. RM command ............................................................................................................................................ 38

4.3.2. LM command............................................................................................................................................. 38

4.3.3. WHO command ......................................................................................................................................... 38

4.3.4. VER command .......................................................................................................................................... 39

4.3.5. SRL command ........................................................................................................................................... 39

4.3.6. ST command ............................................................................................................................................. 40

4.3.7. ST2 command ........................................................................................................................................... 41

4.3.8. ST3 command ........................................................................................................................................... 41

4.3.9. CST command .......................................................................................................................................... 42

4.3.10. STP command ......................................................................................................................................... 42

4.3.11. STR_# command ..................................................................................................................................... 43

4.3.12. STR2_# command .................................................................................................................................. 44

4.3.13. STR3_# command .................................................................................................................................. 45

4.3.14. MG_# command ...................................................................................................................................... 45

3.3.15. MRW_# command ................................................................................................................................... 45

4.3.16. MRR command ....................................................................................................................................... 46

4.3.17. MTW_## command ................................................................................................................................. 46

4.3.18. MTR command ........................................................................................................................................ 46

4.3.19. FO_# command ....................................................................................................................................... 46

4.3.20. FOR command ........................................................................................................................................ 47

4.3.21. FW_##_#### command .......................................................................................................................... 47

4.3.22. FR_## command ..................................................................................................................................... 47

4.3.23. TRW_# command.................................................................................................................................... 47

4.3.24. TRR command ........................................................................................................................................ 48

4.3.25. XW, YW, ZW_##_#### command ........................................................................................................... 48

4.3.26. XR, YR, ZR command ............................................................................................................................. 48

4.3.27. BRW _# command .................................................................................................................................. 48

4.3.28. BRR command ........................................................................................................................................ 49

4.3.29. ACW_## command ................................................................................................................................. 49

4.3.30. ACR command ........................................................................................................................................ 49

4.3.31. ERR command ........................................................................................................................................ 49

4.4. MEASUREMENT DATA OUTPUT FORMAT .................................................................... 50

4.5. WIRELESS LAN CONNECTION ..................................................................................... 53

5. ERROR CODE ........................................................................................................... 56

9

Page 10

5.1. ERROR CODE LIST ........................................................................................................ 56

APPENDICES ................................................................................................................. 58

SPECIFICATIONS & PERFORMANCE .................................................................................. 58

BLOCK DIAGRAM .................................................................................................................. 61

EXTERNAL DIMENSIONS DIAGRAM .................................................................................... 62

GRAPH ................................................................................................................................... 63

10

Page 11

RULES OF SYMBOLS IN THIS MANUAL

Symbol

Description

☞

“ ”

Shows the section to which you should make reference in this manual.

☞

< >

Shows other manuals to which you should make reference.

NOTICE

Explains the points that you should understand and pay attention to.

MEMO

Explains the knowledge that you should refer to or that will be useful.

This manual has the rules about symbols as shown below.

11

Page 12

1.PREPARATION BEFORE USE

1.1. CHECKING THE INSTRUMENT AND ACCESSORIES

Make sure that you have the instrument and accessories shown below.

If one of them is missing, contact your dealer or TOPCON TECHNOHOUSE.

n IM-1000 instrument body 1

n CD-ROM 1

(Instruction manual/colorimetry program CS-900A)

n Soft case 1

n Hand strap 1

n Beam detector cap 1

n RS-232C cable 1

n Nickel hydride battery charger set 1

(with four nickel hydride batteries)

12

Page 13

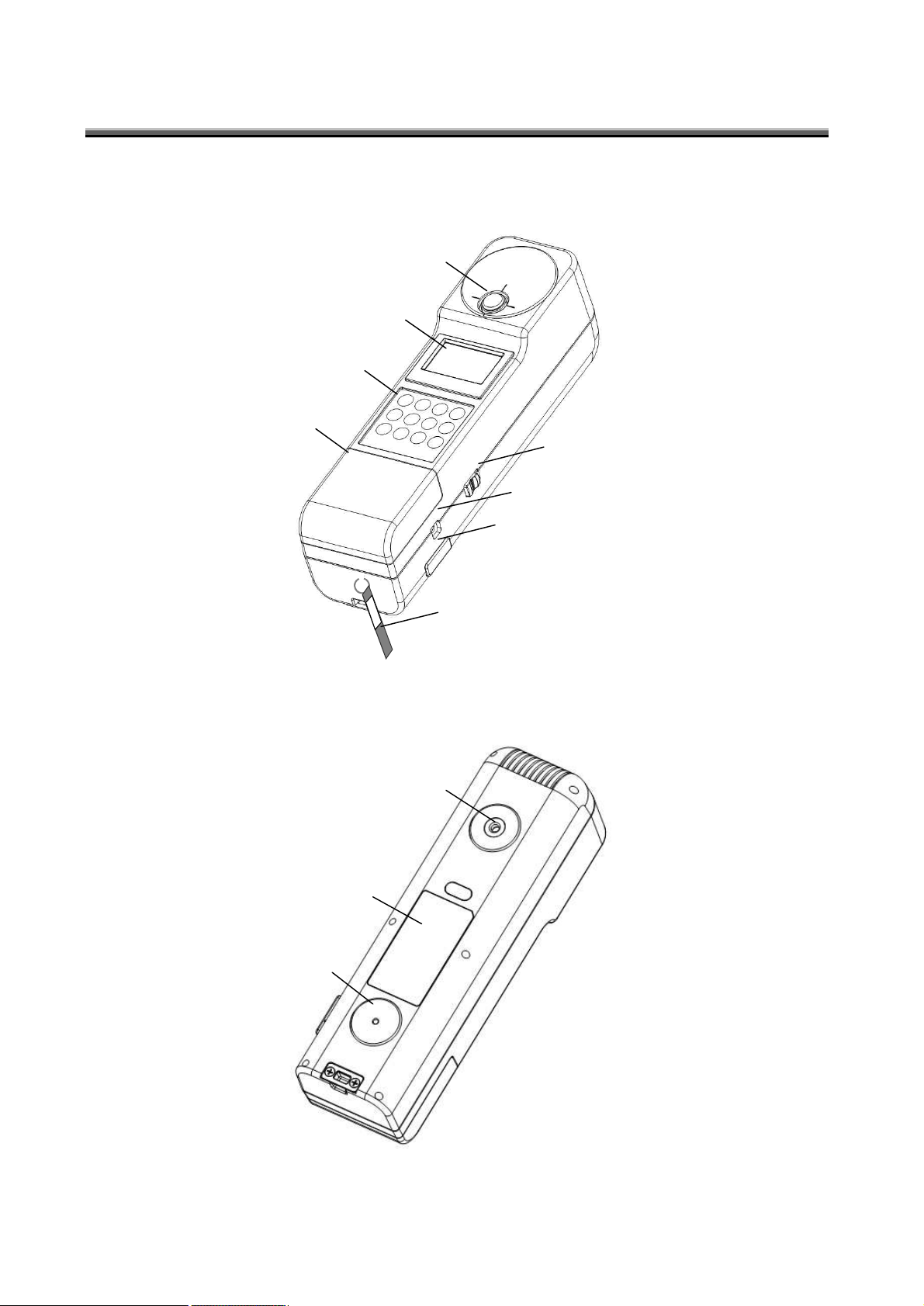

1.2. NAMES AND FUNCTIONS OF COMPONENTS

○1 Beam detector

○2 Display unit

○3 Keyboard

○5 External power supply connector

○4 Power switch

○6 RS-232C connector

○7 Hand strap

Battery cover

○8 Tripod screw

Rating name plate

○9 Tool screw

This chapter will explain the names and functions of the components with the illustrations about the

instrument.

13

Page 14

○1 Beam detector:

Receives the light. Make the whole beam detector receive the light to measure the illuminance.

○2 Display unit:

This is the liquid crystal display unit to indicate a variety of information such as the measured

value or measurement condition.

○3 Keyboard:

These switches are used to start/stop measurement, set the measurement conditions and

perform other operations.

○4 Power switch:

This switch is used to turn on/off the instrument.

○5 External power supply connector:

Insert the output plug of the AC adapter (optional accessory) exclusively for the instrument into

this connector.

○6 RS-232C connector:

Connect the RS-232C cable (standard accessory) exclusively for the instrument to this

connector.

○7 Hand strap:

The falling-off prevention hand strap is attached here.

○8 Tripod screw:

This screw is used to mount the instrument on the tripod.

TOPCON TECHNOHOUSE has adopted the screw for mounting the 1/4-20UNC (depth: 5mm)

camera.

○9 Tool screw:

This screw is used to mount the instrument on a system or others.

The size is “M3×0.5, depth: 6mm”.

14

Page 15

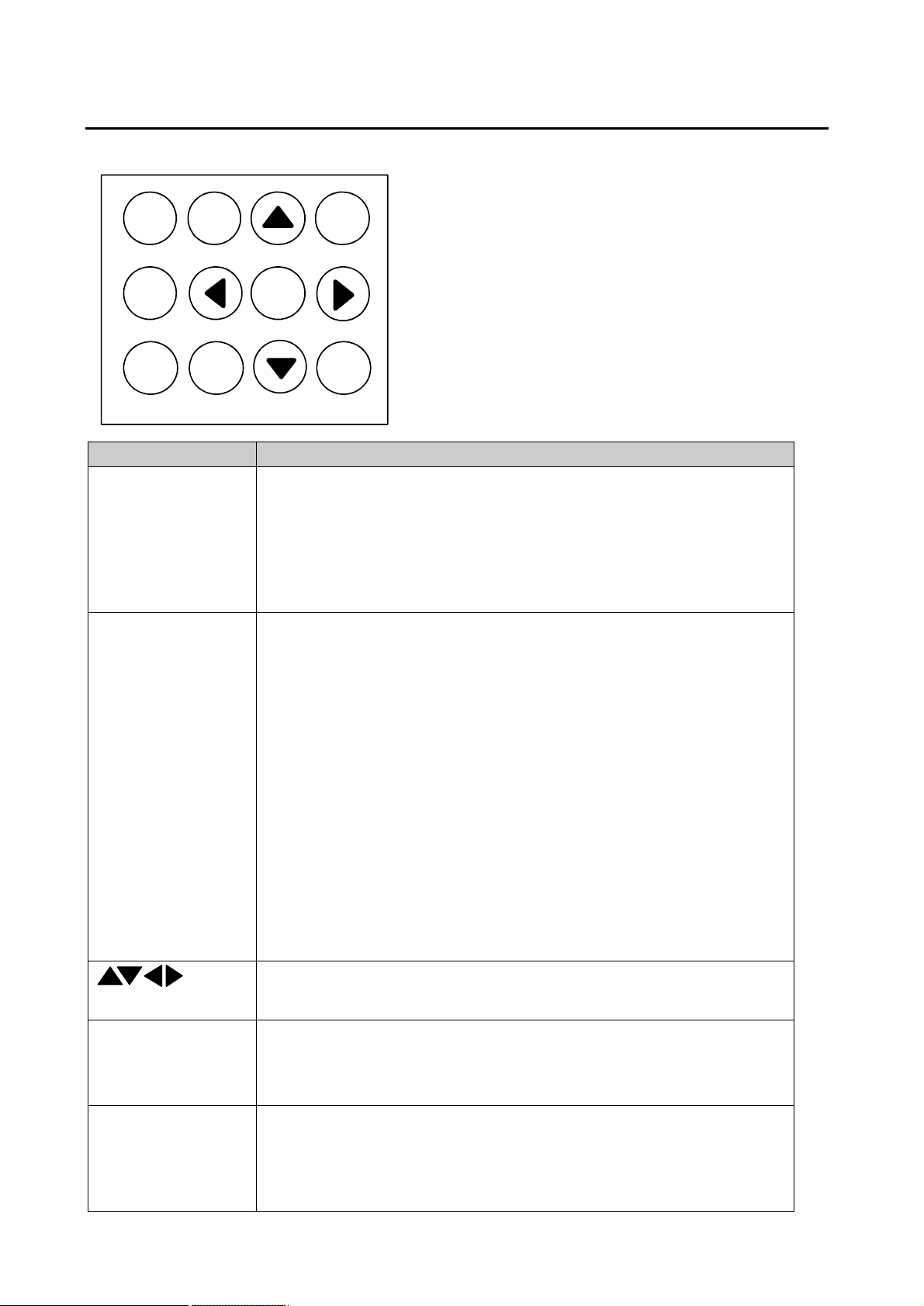

1.2.1. Names and functions of switches on keyboard

Name

Function

MEAS. switch

Starts/stops measurement.

When continuous measurement is valid, measurement starts by

pressing this switch once and stops by pressing it again. To stop

measurement, sometimes the pressing time is longer than usual due to

the integral time.

When continuous measurement is invalid, measurement is performed

once by pressing this switch once.

AUTO/MANU.

switch

Select the measurement range mode.

Each time you press this switch, the mode is changed.

AUTO FULL (FL):

At every measurement, the optimal measurement range and the

integral time are set.

AUTO FIRST (FS):

Only at first measurement, the optimal measurement range and the

integral time are set. The set range and time are kept until the

measurement stops.

AUTO ADJUST (AJ):

When first measurement is done and when “over range” and “under

range” are detected, the optimal measurement range and the integral

time are set.

MANUAL RANGE (ML):

Measurement is done with the measurement range and integral time

set for the “MANUAL” mode.

One of “FL”, “FS”, “AJ” and “ML” is indicated on the display unit.

switches

Used to display the items, the value increment/decrement, the digit shift

and the measurement data history in the function mode.

INV. switch

Used to effectuate the [CALL], [CAL], [WPS] and [W-LAN] functions that

are indicated at the bottom.

When any of these functions is valid, “INV” is indicated on the display

unit.

SAVE. switch

Saves the measurement data of the instrument (up to 50) in the internal

memory. The saved data are not erased even if the power is OFF.

When the measurement data history is saved, the startup time with

“Power: ON” is delayed because the measurement data are read and

internally calculated.

MEAS.

AUTO/

MANU.

INV.

SAVE.

ENTER

MODE

FUNC.

⊿

INV.

CALL

CAL

WPS

W-LAN

The names and functions of switches on the keyboard are mentioned below.

15

Page 16

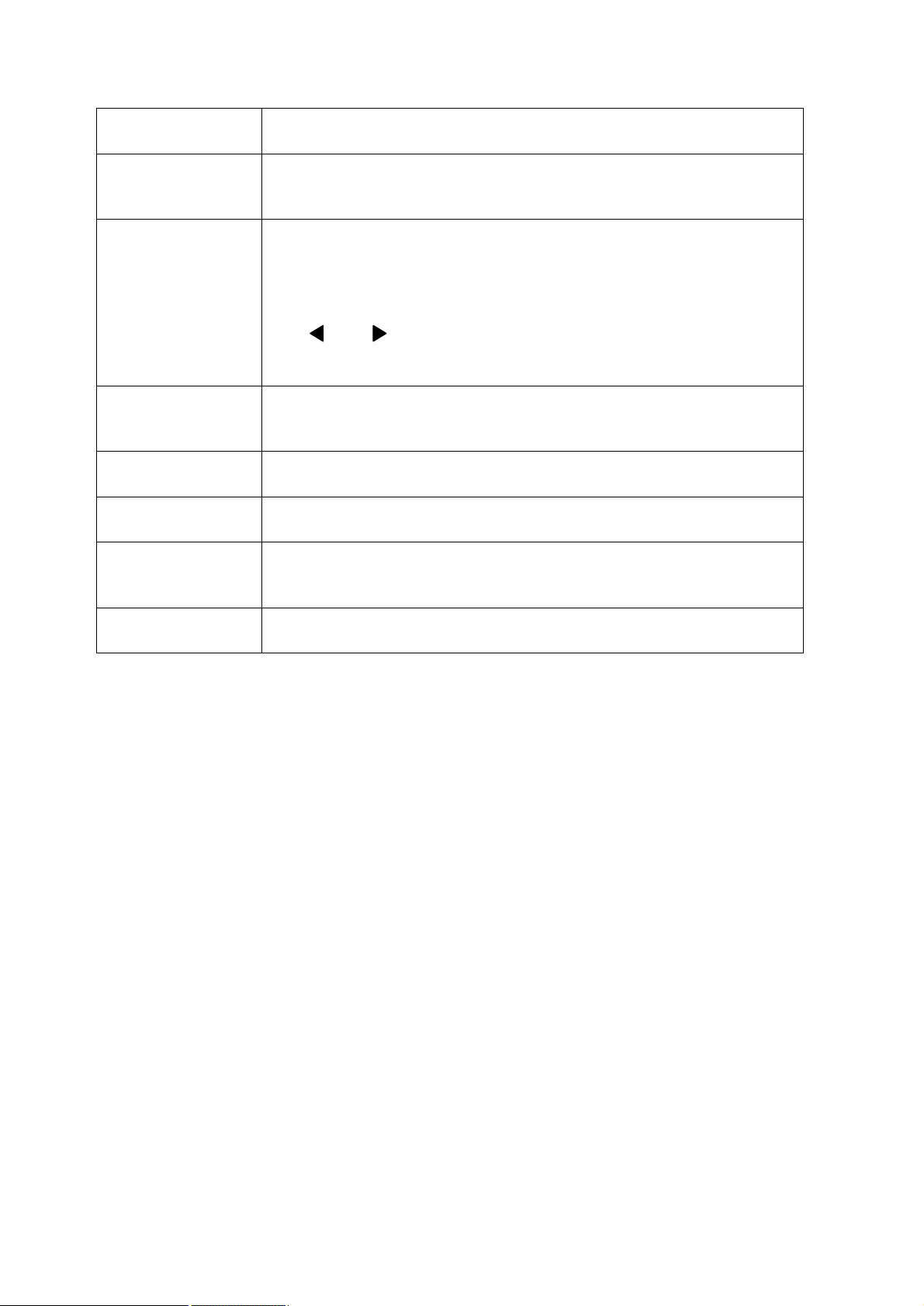

ENTER switch

This is used to decide the item, value, digit position, etc. in the function

mode.

∆ switch

Measurement is done in the difference mode.

The difference against the reference value is indicated as the

measurement data.

MODE. switch

Select the display mode.

Select one of [Ev/x/y], [Ev/u’/v’], [X/Y/Z], [Ev/Tcp/duv], [Ev/Ra/Tcp],

[Ev/λd/Pe] and [Spectral radiation graph].

You can change “Tcp” of [Ev/Ra/Tcp] to “color rendering property

evaluation” and “special color rendering property evaluation R1-R15”

with [ ] and [ ] switches.

In the color rendering property evaluation mode, the display update is

slower than other modes due to the internal calculation time.

FUNC. switch

The system shifts to the function mode.

In the function mode, set the measurement conditions, the

communication conditions, the correction factor application, etc.

CALL switch

(INV)

Indicates the reference value to be applied to the difference mode.

To return to the normal mode, press [INV.] and then [CALL] again.

CAL switch

(INV)

Unused.

WPS switch

(INV)

You can set and connect the wireless LAN to the WPS device easily.

For applying the WPS function, please read the instruction manual of the

connected device together with this manual.

W-LAN switch

(INV)

Connect the wireless LAN according to the setting conditions.

To disconnect the wireless LAN, press [INV.] and then [W-LAN] again.

16

Page 17

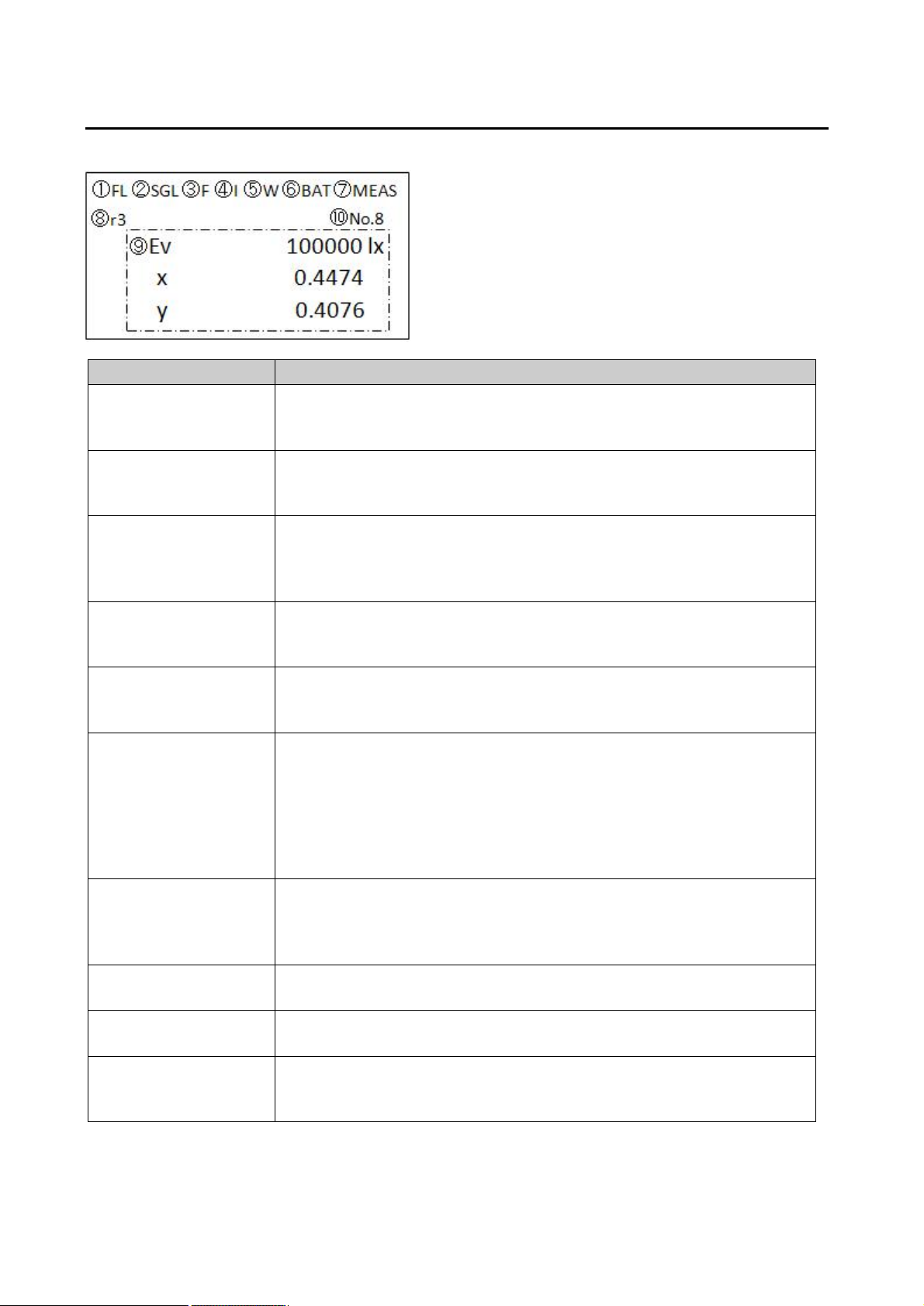

1.2.2. Names and contents of data on the display screen

Name

Contents

○1 Measurement

range mode

Indicates the measurement range mode which is currently set.

FL/FS/AJ/ML

☞

“1.2.1. Names and functions of switches on keyboard”

○2 Average

measurement

Indicates whether average measurement should be done.

SGL : One measurement

AVE : Average measurement

○3 Correction

Indicates whether the correction factor should be applied.

No indication : Correction factor is not applied.

F : Correction factor of spectrum or tristimulus values is

applied.

○4 Interval

measurement

Indicates whether interval measurement should be done.

No indication : Normal measurement

I : Interval measurement

○5 Wireless LAN

Indicates the wireless LAN connection.

No indication : Not connected.

W : Connected.

○6 Battery power

Indicates the remaining power of the driven batteries.

No indication : Power is sufficient.

BAT : Power is not sufficient. (Replace the batteries within 10

minutes.)

Be sure to use the standard accessory, nickel hydride battery. If any

other battery is used, the indication is sometimes different from the

above.

○7 Measurement

status/INV

Indicates the measurement status and the [INV.] ON/OFF status.

No indication: Measurement stops/INV is OFF.

MEAS : Measurement is being performed.

INV : INV is ON.

○8 Measurement

range

Indicates the measurement range.

r1 - r4 : Range 1 to Range 4

○9 Measurement data

Indicates the measurement data according to the display mode.

☞

“1.2.1. Names and functions of switches on keyboard”

○10 Measurement data

history number

Indicates the measurement data history number.

No. 1 - No. 50 (The number of the newest data is No. 1 and the

sequential numbers are given.)

The names and contents of data on the display screen are mentioned below.

17

Page 18

1.3. PREPARATION

WARNING

WARNING

CAUTION

This chapter will explain the preparation before starting measurement.

1.3.1. Connecting the AC adapter

How to connect the AC adapter to the instrument is mentioned below.

Use the AC adapter which is an accessory sold separately.

If not, the AC adapter malfunctions to cause a fire or electric shock.

Remove dust or water from the outlet of the AC adapter.

If not, a fire may occur.

Don’t pull out or insert the plug by a moistened hand.

It may cause an electric shock.

1. Make sure that the instrument is OFF.

18

Page 19

2. Insert the output connector of the AC adapter into the external power supply connector of the

instrument.

3. Insert the AC adapter plug into the outlet.

19

Page 20

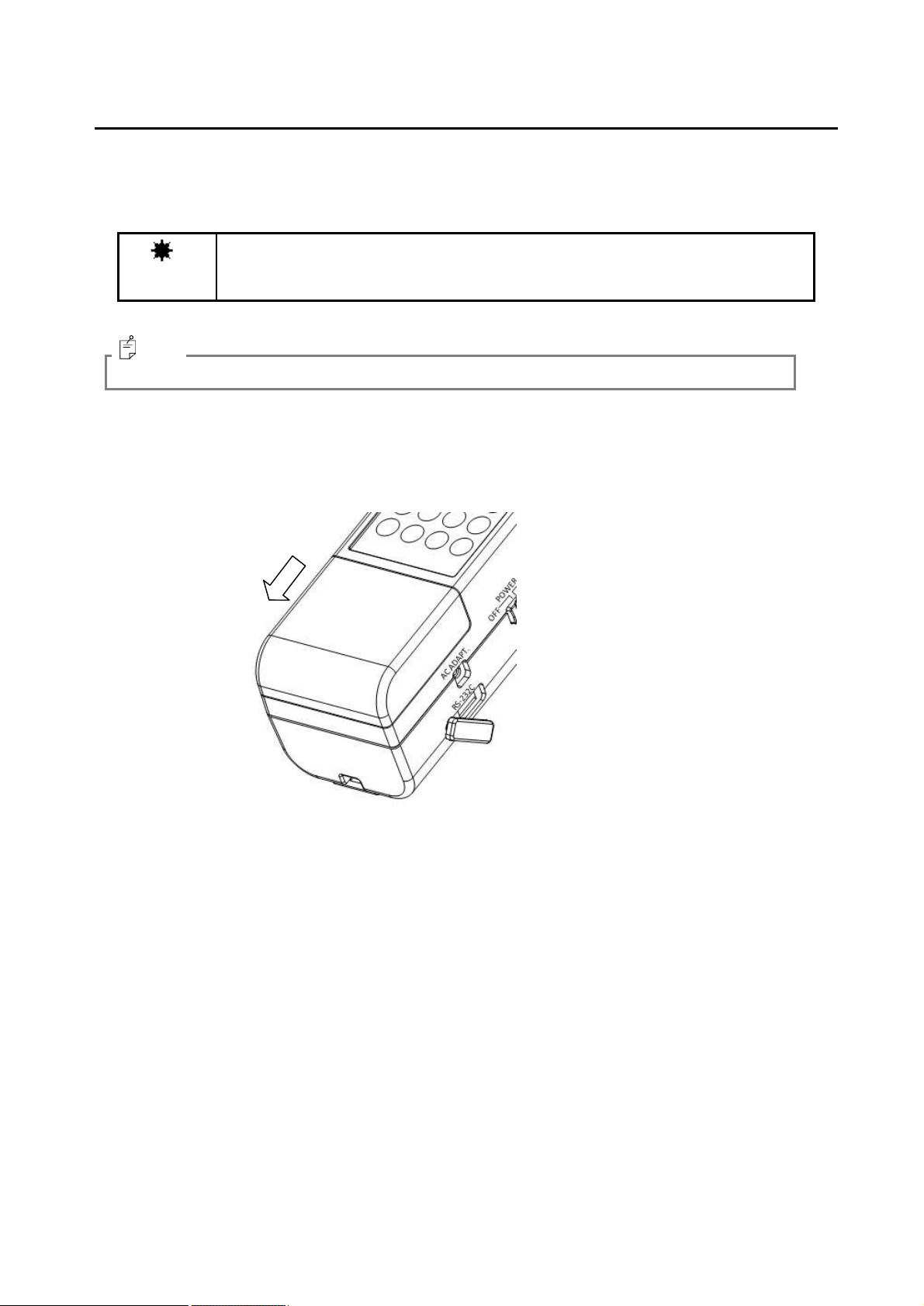

1.3.2. Installing the batteries

NOTICE

Use the standard accessory, nickel hydride battery (charging type). If you use

others except the standard accessory, the instrument may operate irregularly.

MEMO

How to install the batteries is mentioned below.

Use the standard accessory, nickel hydride battery (charging type: 4 pieces).

For charging the nickel hydride battery, refer to the instruction manual of the charger.

1. Make sure that the instrument is OFF.

2. Install the batteries according to the polarity indication in the battery chamber.

3. Attach the battery cover securely.

20

Page 21

1.3.3. Installing personal computer

NOTICE

Don’t connect and disconnect the connectors on condition that the instrument is ON.

NOTICE

The frequency 2.4GHz band, which is used by the instrument, is also used by

electronic ovens, medical instruments and other wireless stations.

1. When using the instrument, check if any other wireless station or wireless

equipment is used in its periphery.

2. If radio wave interference has occurred, change the location of the instrument or

stop using the wireless LAN for the instrument.

3. The wireless LAN module, which conforms to the Japanese technical standards, is

built in the instrument. It is not possible to use the wireless LAN in any other

country or area except Japan.

4. If you use the instrument out of Japan, turn off the wireless LAN function.

☞

“3.2.11. Setting the wireless LAN”

MEMO

MEMO

To connect a personal computer with the instrument, use the RS-232C cable exclusively for the

instrument or the wireless LAN. The RS-232C signal line of the instrument is arranged according to

the 9-pin D-SUB that is used in the DOS/V personal computer and others. When connecting with a

personal computer through the extension cable, use the straight wiring cable.

For the connection on the personal computer, refer to your computer’s manual at the same time.

The RS-232C specifications are shown below. Others except the baud rate are fixed.

• Communication method : Full duplex

• Synchronization : Start-stop transmission

• Baud rate : 9600/19200/38400 bps (Bits Per second)

• Data length : 7 bits

• Parity : Odd number (ODD)

• Stop bit : 1 bit

• Communication type : Text (ASCII)

• Delimite : CR + LF (This is added to the last of a communication data line and

then the data is sent.)

The wireless LAN specifications are shown below. (Exclusively for Japan)

• Standard to be observed : IEEE802.11b infrastructure/ad hoc mode

• Frequency range : 2.4GHz band (1-13ch)

• Communication distance : Indoors 10m/Outdoors 15m typ

• Baud rate : 38400 bps

• Security : WEP/WPA/WPA2

The communication distance and speed are changed due to the radio wave, obstacles,

installation environment, etc. We cannot guarantee the communication speed and distance.

Please understand this.

21

Page 22

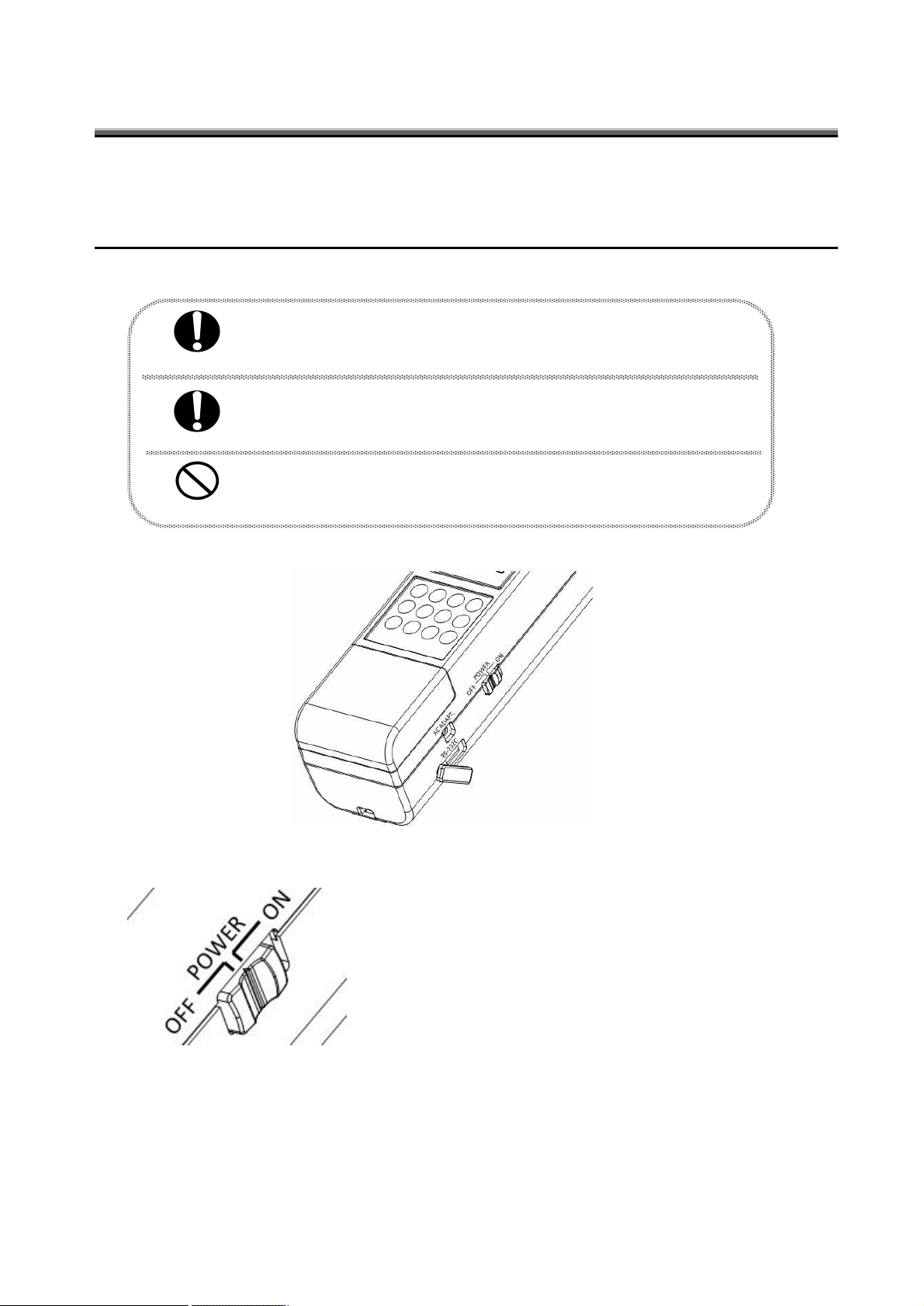

1.3.4. Turning ON/OFF the power

How to turn on/off the power is mentioned below.

n When turning on the power

Slide the power switch to “ON”.

When the power is turned on, initialization starts. If an error occurs during the initialization, the

error message is indicated on the display unit.

n When turning off the power

Slide the power switch to “OFF”.

22

Page 23

Illuminance Ev/Average color rendering property

evaluation Ra/Correlated color temperature mode

Illuminace Ev/Dominant wavelength

λd/Excitation purity Pe mode

MEMO

2.OPERATION OF THE MEASURED VALUE

2.1. DISPLAY OF THE MEASURED VALUE

You can change the measured value display mode by pressing the [MODE] switch when

measurement stops. The changeable display modes are shown below.

Illuminance Ev/Chromaticity xy mode Illuminance Ev/Chromaticity u’v’ mode

Tristimulus values XYZ mode Illuminance Ev/Correlated color temperature

Tcp/Deviation duv mode

Spectral radiation illuminance graph/Peak wavelength

spectral radiation illuminance/Illuminance Ev mode

• [Tcp] can be changed to “Color rendering property evaluation R1-R15”.

• In the difference mode, only illuminance is updated.

23

Page 24

3. SETTING OPERATION

3.1. FUNCTION MODE

Function mode is used to check and change a lot of data and items stored in the built-in memory of the

instrument.

3.1.1. Shifting to function mode/returning to measurement

mode

Use the [FUNC.] switch to shift to the function mode and return to the measurement mode. Press the

[FUNC.] switch once, and the system shifts to the function mode. Press the switch again, and the

system returns to the measurement mode (function mode is canceled).

n Shifting to function mode

1. Make sure that the instrument is in the standby status.

2. Press the [FUNC.] switch to access the function mode.

“3.1.2. Set item/Data display”

☞

n Returning to the measurement mode

Press the [FUNC.] mode again in the function mode. The system exits from the function mode

and returns to the measurement mode.

24

Page 25

3.1.2. Set item/Data display

In the function mode, the displayed items and data are changed by pressing the [ ] and [ ] switches.

The set items and data are shown below.

• Setting the averaging count

• Setting ON/OFF of interval mode

• Setting the interval measurement conditions

• Setting the manual measurement conditions

☞

• Setting ON/OFF of continuous measurement

• Setting the reference light source

• Setting the sample light source

• Setting the reference value

• Setting ON/OFF of the spectral correction factor

• Setting ON/OFF of the tristimulus values correction factor

• Setting ON/OFF of the wireless LAN

• Setting the wireless LAN IP address

• Setting the wireless LAN subnet mask

• Setting the wireless LAN port number

• Setting the wireless LAN access point

• Setting the wireless LAN WEP

• Setting the wireless LAN PASS PHRASE

• Setting the RS-232C baud rate

• Setting the back light

• Setting the measurement data automatic saving function

• Setting the measurement data history clearing function

“3.2.1. Setting the averaging count”

☞

“3.2.2. Setting the interval mode”

☞

“3.2.3. Setting the interval measurement conditions”

☞

“3.2.4. Setting the manual measurement conditions”

“3.2.5. Setting continuous measurement”

☞

“3.2.6. Setting the reference light source”

☞

“3.2.7. Setting the sample light source”

☞

“3.2.8. Setting the reference value”

☞

“3.2.9. Setting the spectral correction”

☞

“3.2.10. Setting the tristimulus values correction”

☞

“3.2.11. Setting the wireless LAN”

☞

“3.2.12. Setting the wireless LAN IP address”

☞

“3.2.13. Setting the wireless LAN subnet mask”

☞

“3.2.14. Setting the wireless LAN port number”

☞

“3.2.15. Setting the wireless LAN access point”

☞

“3.2.16. Setting the wireless LAN WEP”

☞

“3.2.17. Setting the wireless LAN PASS PHRASE”

☞

“3.2.18. Setting the RS-232C baud rate”

☞

“3.2.19. Setting the back light”

☞

“3.2.20. Setting the measurement data automatic saving function”

☞

“3.2.21. Setting the measurement data history clearing function”

☞

25

Page 26

3.2. DETAILS OF FUNCTION MODE

To select a proper item, use the [ ] and [ ] switches. To enter a numerical value, specify the digit

position with the [ ] and [ ] switches and set a value with the [ ] and [ ] switches.

3.2.1. Setting the averaging count

Set the averaging count.

Settable range: 1 - 20

* When “1” is set, the average measurement is invalid.

3.2.2. Setting the interval mode

Set ON/OFF of the interval measurement and the system operation if the interval time is exceeded.

MODE : Set ON/OFF of the interval measurement.

OFF : Invalid

ON : Valid

ERROR STOP : Set whether measurement should continue or stop when the interval time is

exceeded.

OFF : Measurement continues.

ON : Measurement stops.

26

Page 27

3.2.3. Setting the interval measurement conditions

Set the start delay time, the count and the interval time for interval measurement.

START : Set the time until measurement starts since you pressed the [MEAS.] switch.

Settable range: 1 - 180s

COUNT : Set the interval measurement count.

Settable range: 1 - 50

TIME : Set the interval time.

Settable range: 1 - 99s

3.2.4. Setting the manual measurement conditions

Set the measurement range and the integral time for manual measurement.

RANGE : Set the measurement range.

Settable range: 1 - 4

TIME : Set the integral time.

Settable range: 10 - 20000ms

3.2.5. Setting continuous measurement

Set ON/OFF of continuous measurement.

OFF : Measurement is done once and is finished.

ON : Measurement continues until the [MEAS.] switch is pressed again.

27

Page 28

3.2.6. Setting the reference light source

MEMO

Set the type of the reference light that will be applied to the calculation of color rendering property

evaluation.

Settable range : JIS Z 8726/Illuminant A/Illuminant D65/Illuminant D50/Illuminant D55/Illuminant

D75/Illuminant C

3.2.7. Setting the sample light source

Set the sample light source that will be applied to the calculation of color rendering property evaluation.

Daylight : Daylight fluorescent lamp

Other Lamp : Others except daylight fluorescent lamp

3.2.8. Setting the reference value

Set the reference value that will be applied to the difference mode.

STD SELECT : Set the reference value registration number.

Settable range: 1 - 3

The setting procedure is shown below.

1. Press the [ENTER] switch and select a registration number with the [ ] and [ ] switches.

2. After selecting, press the [MEAS.] switch to perform measurement.

3. After the measurement, its result is indicated. Press the [ENTER] switch to register the result.

The reference value of the indicated number is applied.

28

Page 29

3.2.9. Setting the spectral correction

MEMO

Set whether the correction factor of each wavelength should be applied to the spectral radiation

illuminance.

Enter the correction factor directly or set it within 380nm - 780nm at intervals of 1nm through the

remote mode.

OFF : Spectral correction is not applied.

ON : Spectral correction is applied.

Shift to the direct entry screen for the correction factor of each wavelength. You can

change the wavelength with the [ ] and [ ] switches. If you do not enter the correction

factor directly, press the [FUNC.] switch.

Settable range: 0.0001 - 100.0

You can set the correction factor from the colorimetry program CS-900A.

3.2.10. Setting the tristimulus values correction

Set the correction factor and whether it should be applied to the tristimulus values.

OFF : Tristimulus values correction is not applied.

ON : Tristimulus values correction is applied.

Settable range: 0.0001 - 100.0

29

Page 30

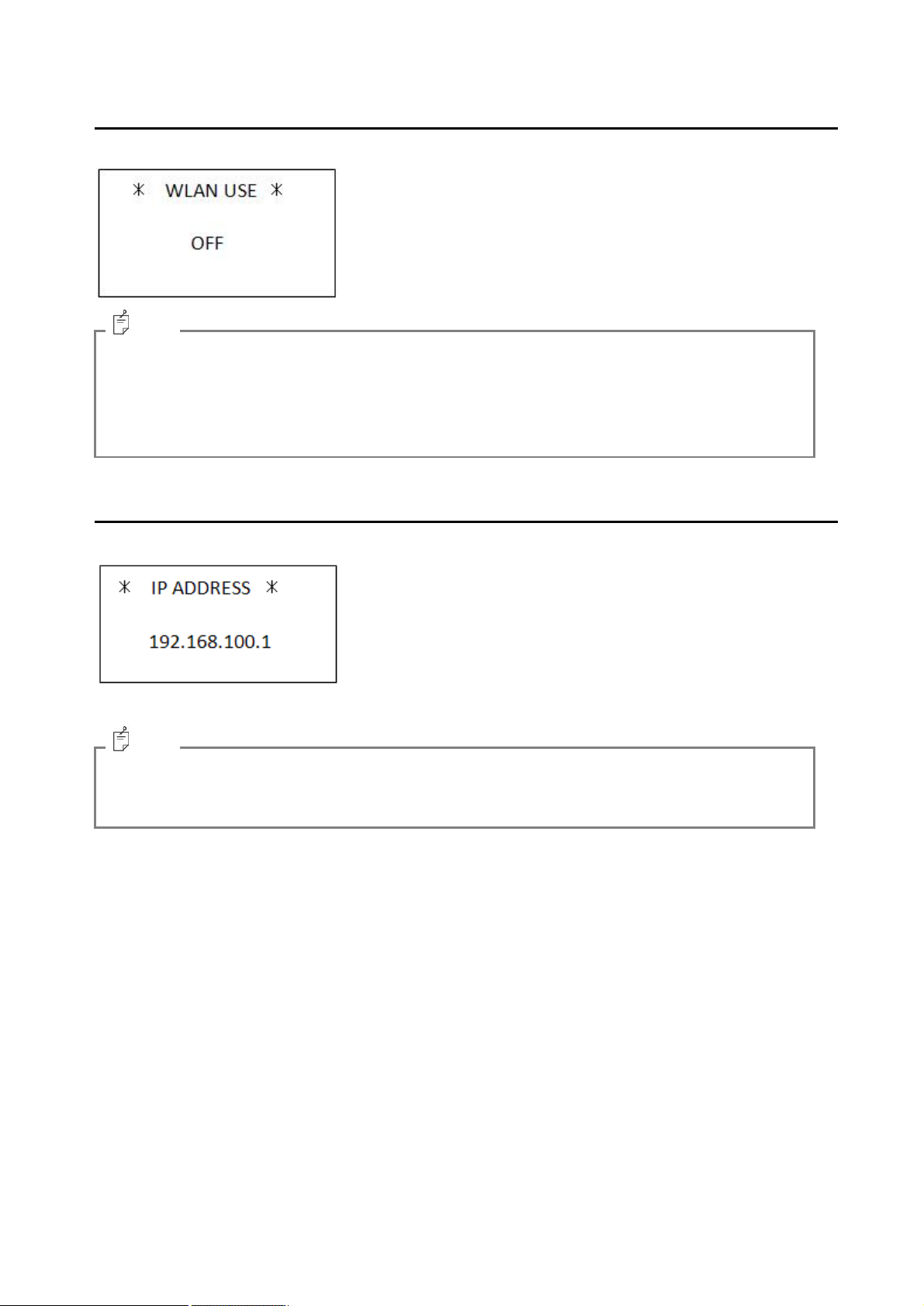

3.2.11. Setting the wireless LAN

MEMO

MEMO

Set ON/OFF of the wireless LAN function.

• This menu is indicated only in the model having the wireless LAN function.

• After changing the setting, turn on/off the power of the instrument. By turning it on/off, the set

data is applied.

• If the instrument is used in other countries except Japan, be sure to set “OFF” for wireless

LAN function.

3.2.12. Setting the wireless LAN IP address

Set the instrument’s IP address that will be applied to the wireless LAN communication.

Settable range : 192.168.0.0 - 192.168.255.255

• This menu is indicated only in the model having the wireless LAN function.

• After changing the setting, turn on/off the power of the instrument. By turning it on/off, the set

data is applied.

30

Page 31

3.2.13. Setting the wireless LAN subnet mask

MEMO

MEMO

Set the instrument’s subnet mask that will be applied to the wireless LAN communication.

Settable range : 255.255.0.0. - 255.255.255.255

• This menu is indicated only in the model having the wireless LAN function.

• After changing the setting, turn on/off the power of the instrument. By turning it on/off, the set

data is applied.

3.2.14. Setting the wireless LAN port number

Set the instrument’s port number that will be applied to the wireless LAN communication.

Settable range : 49152 - 65535

• This menu is indicated only in the model having the wireless LAN function.

• After changing the setting, turn on/off the power of the instrument. By turning it on/off, the set

data is applied.

31

Page 32

3.2.15. Setting the wireless LAN access point

MEMO

MEMO

Set the access point (SSID) that will be applied to the wireless LAN communication.

Press the [ENTER] switch, and the access points, which can be connected currently, are indicated.

Select and decide a proper access point.

• For setting the access point, read the instruction manual of the connected device at the same

time.

• If the access point is not changed, it is not necessary to set it at each measurement. Set the

access point only when it must be changed.

• This menu is indicated only in the model having the wireless LAN function.

• After changing the setting, turn on/off the power of the instrument. By turning it on/off, the set

data is applied.

3.2.16. Setting the wireless LAN WEP

Set WEP (Wired Equivalent Privacy Key) that will be applied to the wireless LAN communication.

• For setting WEP, read the instruction manual of the connected device at the same time.

• This menu is indicated only in the model having the wireless LAN function.

• After changing the setting, turn on/off the power of the instrument. By turning it on/off, the set

data is applied.

32

Page 33

3.2.17. Setting the wireless LAN PASS PHRASE

MEMO

MEMO

Set PASS PHRASE that will be applied to the wireless LAN communication.

Settable range : 63 letters or less

• For setting PASS PHRASE, read the instruction manual of the connected device at the same

time.

• This menu is indicated only in the model having the wireless LAN function.

• After changing the setting, turn on/off the power of the instrument. By turning it on/off, the set

data is applied.

3.2.18. Setting the RS-232C baud rate

Set the baud rate that will be applied to the RS-232C communication.

Settable range: 38400/19200/9600

After changing the setting, turn on/off the power of the instrument. By turning it on/off, the set

data is applied.

33

Page 34

3.2.19. Setting the back light

MEMO

MEMO

Set ON/OFF of the back light in the liquid crystal display unit.

OFF : The back light is always OFF.

ON : The back light is always ON.

ECO : When measurement is being done and when the instrument is not operated for 1 minute or

more, the back light is OFF.

Right after measurement has been finished and when any switch is pressed, the back light

is ON.

If turning on the back light only is necessary in the [ECO] mode, press the [ENTER] switch.

3.2.20. Setting the measurement data automatic saving function

Set ON/OFF of the measurement data automatic saving function.

OFF : The data is not automatically saved.

ON : The data is automatically saved at each measurement.

When the automatic saving function is ON, the data is written in the internal memory at each

measurement. So it takes longer time until the measurement is finished.

3.2.21. Setting the measurement data history clearing function

Clear the history of all the measurement data that are saved in the instrument’s internal memory.

YES : Clear the history of all the measurement data.

BACK : Cancels the function mode.

34

Page 35

Communication command

Function

RM

Set the remote mode.

LM

Set the local mode. (The remote mode is canceled.)

WHO

Obtain the model name.

VER

Obtain the software version.

SRL

Obtain the serial number.

ST

Execute measurement.

When measurement is finished, the measurement data is sent

back.

All the measurement data are sent back.

☞

“4.4 MEASUREMENT DATA OUTPUT FORMAT”

ST2

Execute measurement.

When measurement is finished, the measurement data is sent

back.

Only colorimetry data is sent back.

☞

“4.4 MEASUREMENT DATA OUTPUT FORMAT”

ST3

Execute measurement.

When measurement is finished, the measurement data is sent

back.

Only the colorimetry data and color rendering property evaluation

are sent back.

☞

“4.4 MEASUREMENT DATA OUTPUT FORMAT”

4. COMMUNICATION WITH PERSONAL

COMPUTER

4.1. COMMUNICATION COMMAND

The instrument (IM-1000) can communicate with a personal computer by using RS-232C and wireless

LAN.

This chapter will explain the commands that will be used when the customer makes a peculiar

program for the communication with the instrument.

* The values are fixed for the following items.

Data bit: 7

Stop bit: 1

Parity: Odd number (ODD)

Delimiter: CR: 0x0d, LF: 0x0a

Use the RS-232C communication cable exclusively for the instrument.

4.2. COMMAND LIST

The communication commands and their functions are shown below. “_” means a space and “#”

means a numerical value.

35

Page 36

Communication command

Function

CST

Start continuous measurement.

The data of each measurement is not sent back. Obtain the

measurement data with the “STR*” command.

If you send this command during continuous measurement, “NO” is

returned.

STP

Stop continuous measurement.

If you send this command during continuous measurement,

continuous measurement stops.

STR_#

- Obtain the data of the specified number from the measurement

history while measurement is in the stop status.

Settable range: 1 - 50 (“1” is the newest data.)

- Obtain the newest data during continuous measurement. It is

not necessary to specify the measurement history number.

Send the “STR” command only.

Obtain all the measurement data.

☞

“4.4 MEASUREMENT DATA OUTPUT FORMAT”

STR2_#

- Obtain the data of the specified number from the measurement

history while measurement is in the stop status.

Settable range: 1 - 50 (“1” is the newest data.)

- Obtain the newest data during continuous measurement. It is

not necessary to specify the measurement history number.

Send the “STR2” command only.

Obtain the colorimetry data only. You cannot obtain the spectral

radiation illuminance and color rendering property evaluation.

☞

“4.4 MEASUREMENT DATA OUTPUT FORMAT”

STR3_#

- Obtain the data of the specified number from the measurement

history while measurement is in the stop status.

Settable range: 1 - 50 (“1” is the newest data.)

- Obtain the newest data during continuous measurement. It is

not necessary to specify the measurement history number.

Send the “STR3” command only.

Obtain the colorimetry data and color rendering property evaluation.

You cannot obtain the spectral radiation illuminance.

☞

“4.4 MEASUREMENT DATA OUTPUT FORMAT”

MG_#

Set the measurement range mode.

0: AUTO FULL (FL) 1: AUTO FIRST (FS)

2: AUTO ADJUST (AJ) 3: MANUAL RANGE (ML)

☞

“1.2.1. Names and functions of switches on keyboard”

MRW_#

Set the measurement range when [MANUAL RANGE] is set.

1: Range 1 2: Range 2 3: Range 3 4: Range 4

MRR

Obtain the measurement range when [MANUAL RANGE] is set.

MTW_##

Set the integral time when [MANUAL RANGE] is set.

Settable range: 10 - 20000ms

MTR

Obtain the integral time when [MANUAL RANGE] is set.

FO_#

Set ON/OFF of spectral correction.

0: OFF 1: ON

FOR

Obtain the ON/OFF data of spectral correction.

36

Page 37

Communication command

Function

FW_#_#######

Set the spectral correction factor (within 380 - 780nm at intervals of

1nm).

0: 380nm - 400: 780nm

Settable range: 0.0001 - 100.0

FR_#

Obtain the spectral correction factor (within 380 - 780nm at

intervals of 1nm).

0: 380nm - 400: 780nm

TRW_#

Set ON/OFF of the tristimulus values.

0: OFF 1: ON

TRR

Obtain the ON/OFF data of tristimulus values.

XW_#######

Set the correction factor of the tristimulus value X.

Settable range: 0.0001 - 100.0

XR

Obtain the correction factor of the tristimulus value X.

YW_#######

Set the correction factor of the tristimulus value Y.

Settable range: 0.0001 - 100.0

YR

Obtain the correction factor of the tristimulus value Y.

ZW_#######

Set the correction factor of the tristimulus value Z.

Settable range: 0.0001 - 100.0

ZR

Obtain the correction factor of the tristimulus value Z.

BRW_#

Set the baud rate of RS-232C.

0: 9600 1: 19200 2: 38400

BRR

Obtain the baud rate of RS-232C.

ACW_##

Set the averaging count.

Settable range: 1 - 20

When “1” is set, the average measurement is invalid.

ACR

Obtain the averaging count in average measurement.

ERR

Obtain the newest error number and message.

37

Page 38

4.3. COMMUNICATION PROTOCOL

MEMO

The protocols for the RS-232C/wireless LAN communication are shown below.

The instrument (IM-1000) sends the following answers as the responses to all the commands.

• “OK” when the command is normally received

• “NO” when the command cannot be analyzed

• “NG” when the command is normally received but the processing is not normal

“_” means a space and “#” means a numerical value.

When sending the commands continuously, set an interval of at least 3ms between the

sending actions.

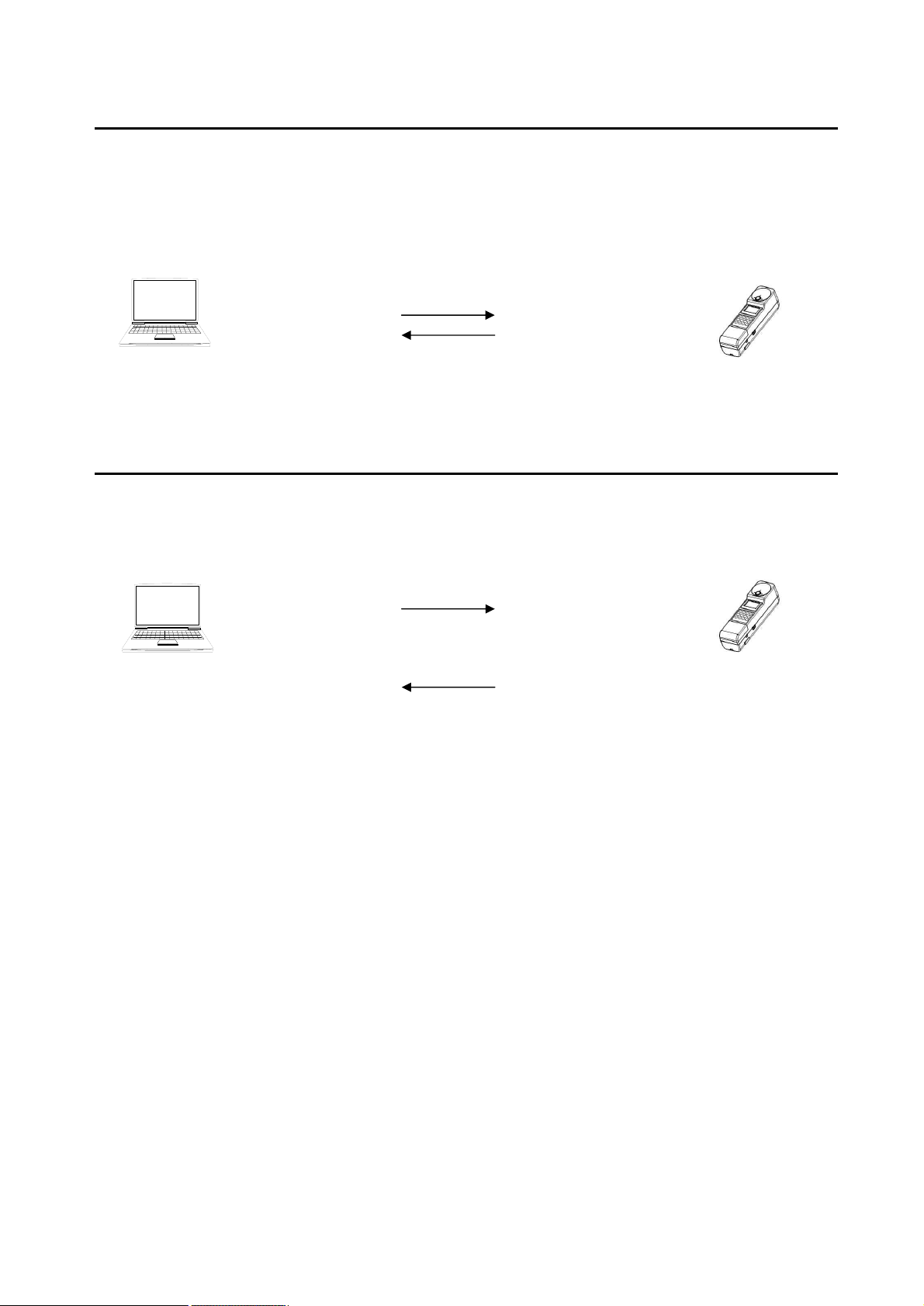

4.3.1. RM command

Set the remote mode.

External control device

“RM”+CR+LF

Command IM-1000

“OK”+CR+LF

4.3.2. LM command

Set the local mode.

When the instrument receives this command while the local mode is set, it sends back “NO”.

External control device Command IM -1000

“LM”+CR+LF

“OK”+CR+LF

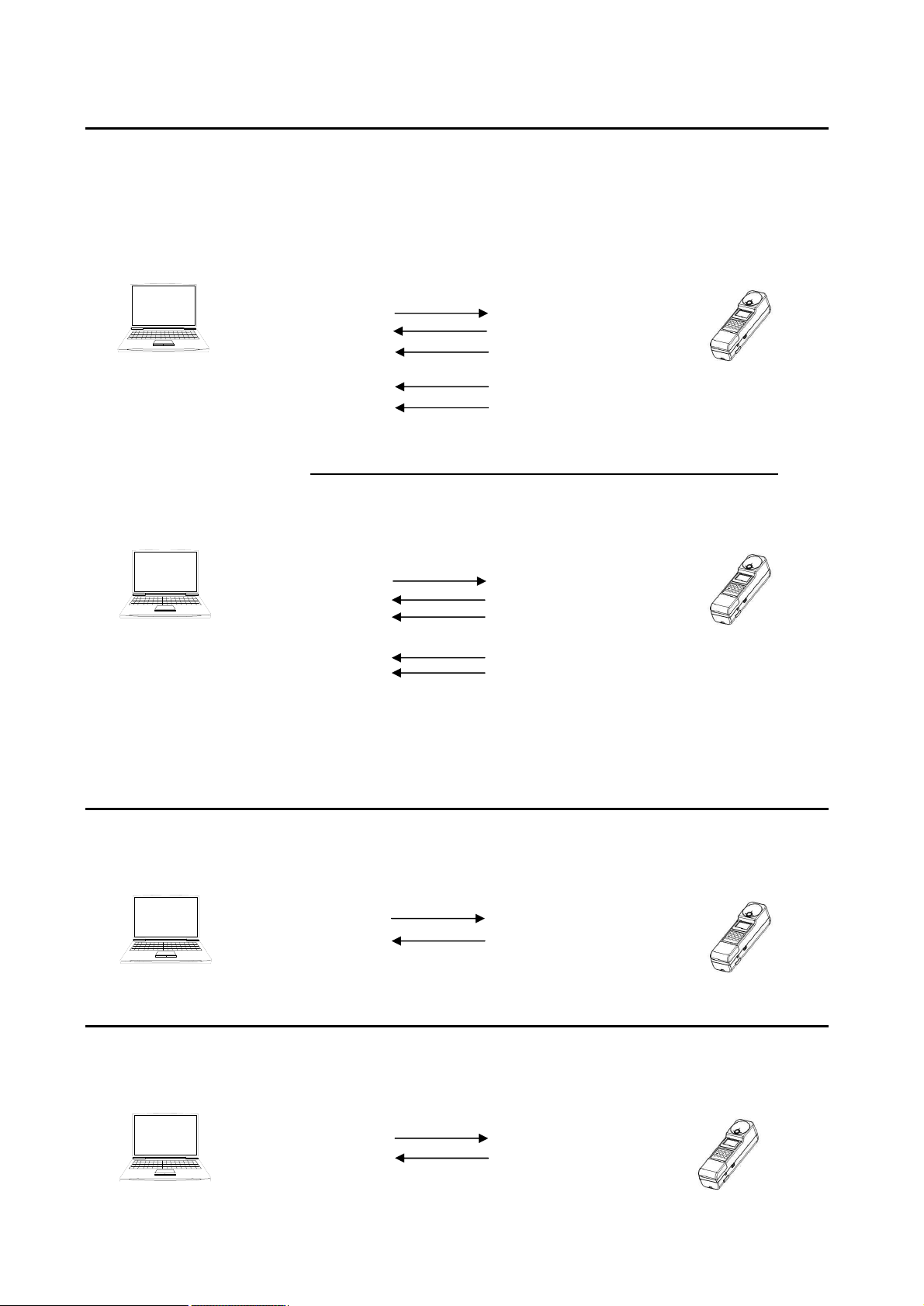

4.3.3. WHO command

Obtain a model name.

External control device Command IM -1000

“WHO”+CR+LF

“OK”+CR+LF

“IM-1000”+CR+LF

“END”+CR+LF

38

Page 39

4.3.4. VER command

Obtain the software version.

Obtainable range: 1.00 - 99.99

External con trol device Command IM -1000

“VER”+CR+LF

4.3.5. SRL command

Obtain the serial number.

Obtainable range: 00000000 - 99999999

External control device Command IM -1000

“SRL”+CR+LF

“OK”+CR+LF

“1.00”+CR+LF

“END”+CR+LF

“OK”+CR+LF

“12345678”+CR+LF

“END”+CR+LF

39

Page 40

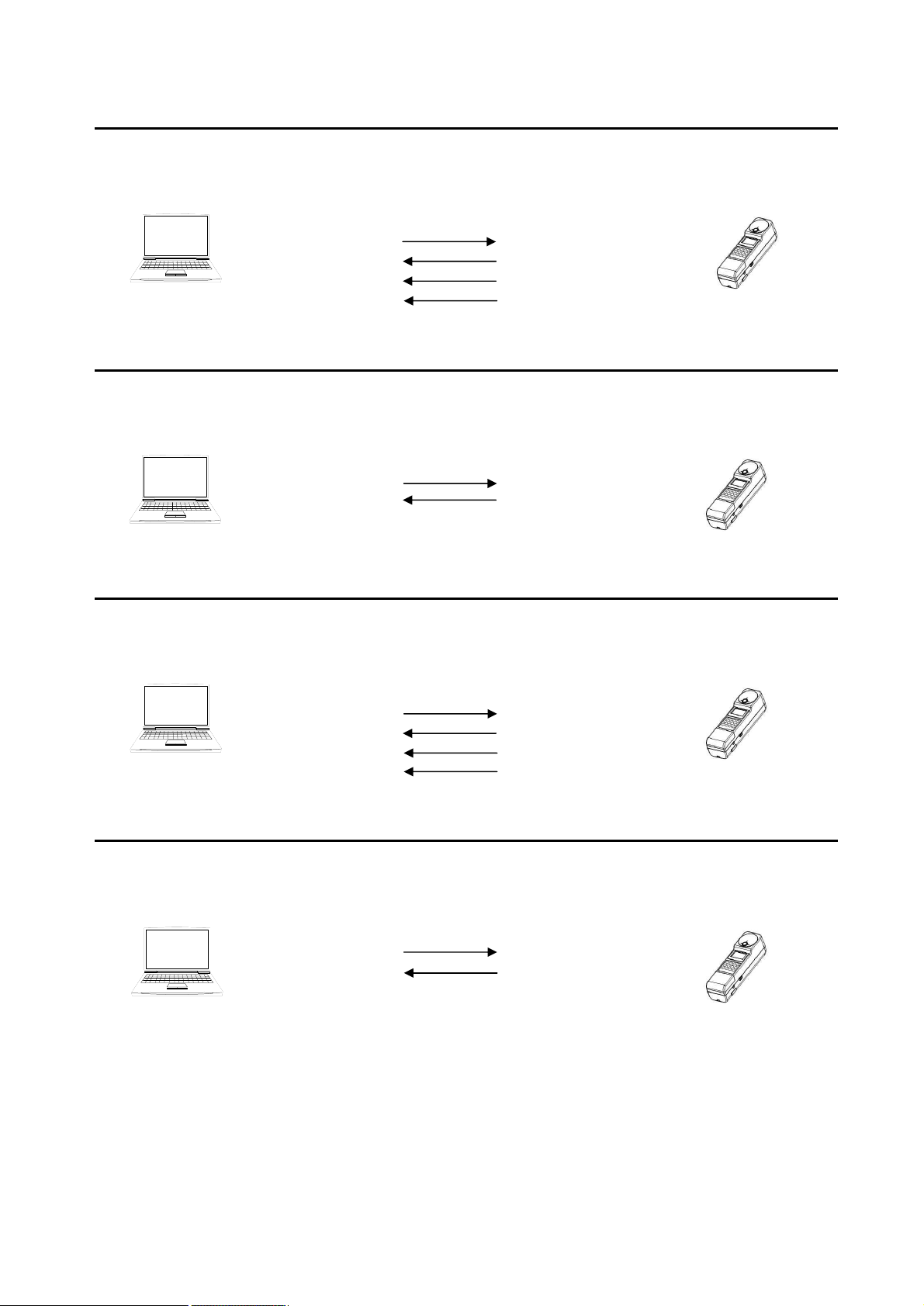

4.3.6. ST command

As soon as the instrument receives this command, it starts measurement according to the

measurement conditions already set. When the measurement is finished, the measurement data is

sent according to “4.4. MEASUREMENT DATA OUTPUT FORMAT”.

- Sending from the external control device to the instrument

The external control device (PC or PLC, etc.) sends the character line “ST” (0x53/0x54) with CR

(0x0d) and LF (0X0a) via RS-232C or wireless LAN.

- Sending from the instrument to the external control device

The instrument recognizes “ST” and sends back “OK” with CR and LF as the command recognition

normal response. At the same time measurement starts.

When the measurement is normally finished, the measurement data is sent back according to “n ST,

STR command measurement data format” of “4.4 MEASUREMENT DATA OUTPUT FORMAT”. If an

error occurs during measurement, “NG” with CR and LF is sent back. When the external control

device receives “NG”, it sends “ERR” with CR and LF and you can check the contents of the error.

External control device Command IM -1000

“ST”+CR+LF

“OK”+CR+LF

Measurement starts.

・ ・ ・ ・ ・

Measurement is finished.

DATA1+CR+LF

・ ・ ・ ・ ・

DATA433+CR+LF

“END”+CR+LF

n When the command cannot be recognized

“ST”+CR+LF

“NO”+CR+LF

n When a measurement error occurs

“ST”+CR+LF

“OK”+CR+LF

Measurement starts.

・ ・ ・ ・ ・

“NG”+CR+LF

* All the data (colorimetry, spectral radiation illuminance and color rendering property evaluation) are

output.

40

Page 41

4.3.7. ST2 command

As soon as the instrument receives this command, it starts measurement according to the

measurement conditions already set. When the measurement is finished, the measurement data is

sent back according to “n ST2, STR2 command measurement data format” of “4.4. MEASUREMENT

DATA OUTPUT FORMAT”.

External control device Command IM -1000

“ST2”+CR+LF

“OK”+CR+LF

Measurement starts.

・ ・ ・ ・ ・

Measurement is finished.

DATA1+CR+LF

・ ・ ・ ・ ・

DATA16+CR+LF

* Only the colorimetry is output. The spectral radiation illuminance and color rendering property

evaluation are not output.

“END”+CR+LF

4.3.8. ST3 command

As soon as the instrument receives this command, it starts measurement according to the

measurement conditions already set. When the measurement is normally finished, the measurement

data is sent back according to “n ST3, STR3 command measurement data format” of “4.4.

MEASUREMENT DATA OUTPUT FORMAT”.

External control device Command IM -1000

“ST3”+CR+LF

“OK”+CR+LF

Measurement starts.

・ ・ ・ ・ ・

Measurement is finished.

DATA1+CR+LF

・ ・ ・ ・ ・

DATA32+CR+LF

* Only the colorimetry and color rendering property evaluation are output. The spectral radiation

illuminance is not output.

“END”+CR+LF

41

Page 42

4.3.9. CST command

When the instrument receives this command while measurement is in the stop status, it starts

continuous measurement at once according to the measurement conditions already set. The data of

each measurement is not sent back. Obtain the measurement data with the “STR”, “STR2” and

“STR3” commands.

When the instrument receives this command during continuous measurement, it sends back “NO”.

External control device Command IM -1000

“CST”+CR+LF

“OK”+CR+LF

Continuous

measurement starts.

・ ・ ・ ・ ・

4.3.10. STP command

When the instrument receives this command during continuous measurement, it stops the continuous

measurement. Sometimes it takes long time until the measurement stops due to the receiving time

status.

External control de vice Command IM -1000

“STP”+CR+LF

Continuous

measurement stops.

・ ・ ・ ・ ・

“OK”+CR+LF

42

Page 43

4.3.11. STR_# command

When the instrument receives this command while measurement is in the stop status, the specified

number data saved in the instrument is output. The measurement data number is “No.1” (newest) to

“No.50”.

Obtainable range: 1 (newest) - 50

n When measurement is in the stop status

External control device Command IM -1000

“STR_#”+CR+LF

“OK”+CR+LF

DATA1+CR+LF

・ ・ ・ ・ ・

DATA433+CR+LF

“END”+CR+LF

When the instrument receives this command during continuous measurement, the newest

measurement data is output. It is not necessary to specify the measurement data number.

n When the instrument is performing measurement continuously

External contr ol device Command IM -1000

“STR”+CR+LF

“OK”+CR+LF

DATA1+CR+LF

・ ・ ・ ・ ・

DATA433+CR+LF

“END”+CR+LF

* All the data (colorimetry, spectral radiation illuminance and color rendering property evaluation) are

output.

43

Page 44

4.3.12. STR2_# command

When the instrument receives this command while measurement is in the stop status, the specified

number data saved in the instrument is output. The measurement data number is “No.1” (newest) to

“No.50”.

Obtainable range: 1 (newest) - 50

n When measurement is in the stop status

External control device Command IM -1000

“STR2_#”+CR+LF

“OK”+CR+LF

DATA1+CR+LF

・ ・ ・ ・ ・

DATA16+CR+LF

“END”+CR+LF

When the instrument receives this command during continuous measurement, the newest

measurement data is output. It is not necessary to specify the measurement data number.

n When the instrument is performing measurement continuously

External control device Command IM -1000

“STR2”+CR+LF

“OK”+CR+LF

DATA1+CR+LF

・ ・ ・ ・ ・

DATA16+CR+LF

“END”+CR+LF

* Only the colorimetry is output. The spectral radiation illuminance and color rendering property

evaluation are not output.

44

Page 45

4.3.13. STR3_# command

When the instrument receives this command while measurement is in the stop status, the specified

number data saved in the instrument is output. The measurement data number is “No.1” (newest) to

“No.50”.

Obtainable range: 1 (newest) - 50

n When measurement is in the stop status

External control device Command IM -1000

“STR3_#”+CR+LF

“OK”+CR+LF

DATA1+CR+LF

・ ・ ・ ・ ・

DATA32+CR+LF

When the instrument receives this command during continuous measurement, the newest

measurement data is output. It is not necessary to specify the measurement data number.

n When the instrument is performing measurement continuously

External control device Command IM -1000

“STR3”+CR+LF

* Only the colorimetry and color rendering property evaluation are output. The spectral radiation

illuminance is not output.

“END”+CR+LF

“OK”+CR+LF

DATA1+CR+LF

・ ・ ・ ・ ・

DATA32+CR+LF

“END”+CR+LF

4.3.14. MG_# command

Set the measurement range mode.

Settable range 0: AUTO FULL 1: AUTO FIRST 2: AUTO ADJUST 3: MANUAL RANGE

External control device Command IM -1000

“MG_#”+CR+LF

“OK”+CR+LF

3.3.15. MRW_# command

Set the measurement range for the “MANUAL RANGE” measurement.

Settable range 1: Range 1 2: Range 2 3: Range 3 4: Range 4

External control device Command IM -1000

“MRW_####”+CR+LF

“OK”+CR+LF

45

Page 46

4.3.16. MRR command

Obtain the measurement range for the “MANUAL RANGE” measurement.

Obtainable range 1: Range 1 2: Range 2 3: Range 3 4: Range 4

External control device Command IM -1000

“MRR”+CR+LF

“OK”+CR+LF

“1”+CR+LF

“END”+CR+LF

4.3.17. MTW_## command

Set the integral time for the “MANUAL RANGE” measurement.

Settable range: 10 - 20000ms

External control device Command IM -1000

“MTW_##”+CR+LF

“OK”+CR+LF

4.3.18. MTR command

Obtain the integral time for the “MANUAL RANGE” measurement.

Obtainable range: 10 - 20000ms

External control device Command IM -1000

“MTR”+CR+LF

“OK”+CR+LF

“####”+CR+LF

“END”+CR+LF

4.3.19. FO_# command

Set ON/OFF of the spectral correction factor.

Settable range 0: OFF 1: ON

External control device Command IM -1000

“FO_#”+CR+LF

“OK”+CR+LF

46

Page 47

4.3.20. FOR command

Obtain the ON/OFF data of the spectral correction factor.

Obtainable range 0: OFF 1: ON

External control device Command IM -1000

“FOR”+CR+LF

4.3.21. FW_##_#### command

Set the spectral correction factor at intervals of 1nm.

Settable range 1: 0:380nm - 400:780nm

Settable range 2: 0.0001 - 100.0

External control device Command IM -1000

“FW_##_####”+CR+LF

“OK”+CR+LF

“#”+CR+LF

“END”+CR+LF

“OK”+CR+LF

4.3.22. FR_## command

Obtain the spectral correction factor at intervals of 1nm.

Obtainable range: 0:380nm - 400:780nm

External control device Command IM -1000

“FR_##”+CR+LF

4.3.23. TRW_# command

Set ON/OFF of the tristimulus values correction factor.

Settable range 0: OFF 1: ON

External control device Command IM -1000

“TRW_#”+CR+LF

“OK”+CR+LF

“####”+CR+LF

“END”+CR+LF

“OK”+CR+LF

47

Page 48

4.3.24. TRR command

Obtain the ON/OFF data of the tristimulus values correction factor.

Obtainable range 0: OFF 1: ON

External control device Command IM -1000

“TRR”+CR+LF

“OK”+CR+LF

“#”+CR+LF

“END”+CR+LF

4.3.25. XW, YW, ZW_##_#### command

Set the correction factors of the tristimulus values XYZ.

Settable range: 0.0001 - 100.0

External control device Command IM -1000

“FY_####”+CR+LF

“OK”+CR+LF

4.3.26. XR, YR, ZR command

Obtain the correction factors of the tristimulus values XYZ.

Obtainable range: 0.0001 - 100.0

External control device Command IM -1000

“XR”+CR+LF

4.3.27. BRW _# command

Set the baud rate for the RS-232C communication.

Settable range 0: 9600 1: 19200 2: 38400

External control device Command IM -1000

“BRW_#”+CR+LF

“OK”+CR+LF

“####”+CR+LF

“END”+CR+LF

“OK”+CR+LF

48

Page 49

4.3.28. BRR command

Obtain the baud rate for the RS-232C communication.

Obtainable range 0: 9600 1: 19200 2: 38400

External control device Command IM -100 0

“BRR”+CR+LF

4.3.29. ACW_## command

Set the averaging count.

Settable range: 1 - 20

External control device Command IM -1000

“ACW_##”+CR+LF

“OK”+CR+LF

“#”+CR+LF

“END”+CR+LF

“OK”+CR+LF

4.3.30. ACR command

Obtain the averaging count.

Obtainable range: 1 - 20

External control device Command IM -1000

“ACR”+CR+LF

4.3.31. ERR command

Obtain the newest error number and message.

Obtainable range 1: 0 - 999

Obtainable range 2: Maximum 20 bytes

External con trol device Command IM -1000

“ERR”+CR+LF

“OK”+CR+LF

“##”+CR+LF

“END”+CR+LF

“OK”+CR+LF

“12”+CR+LF

“over range error”+CR+LF

“END”+CR+LF

49

Page 50

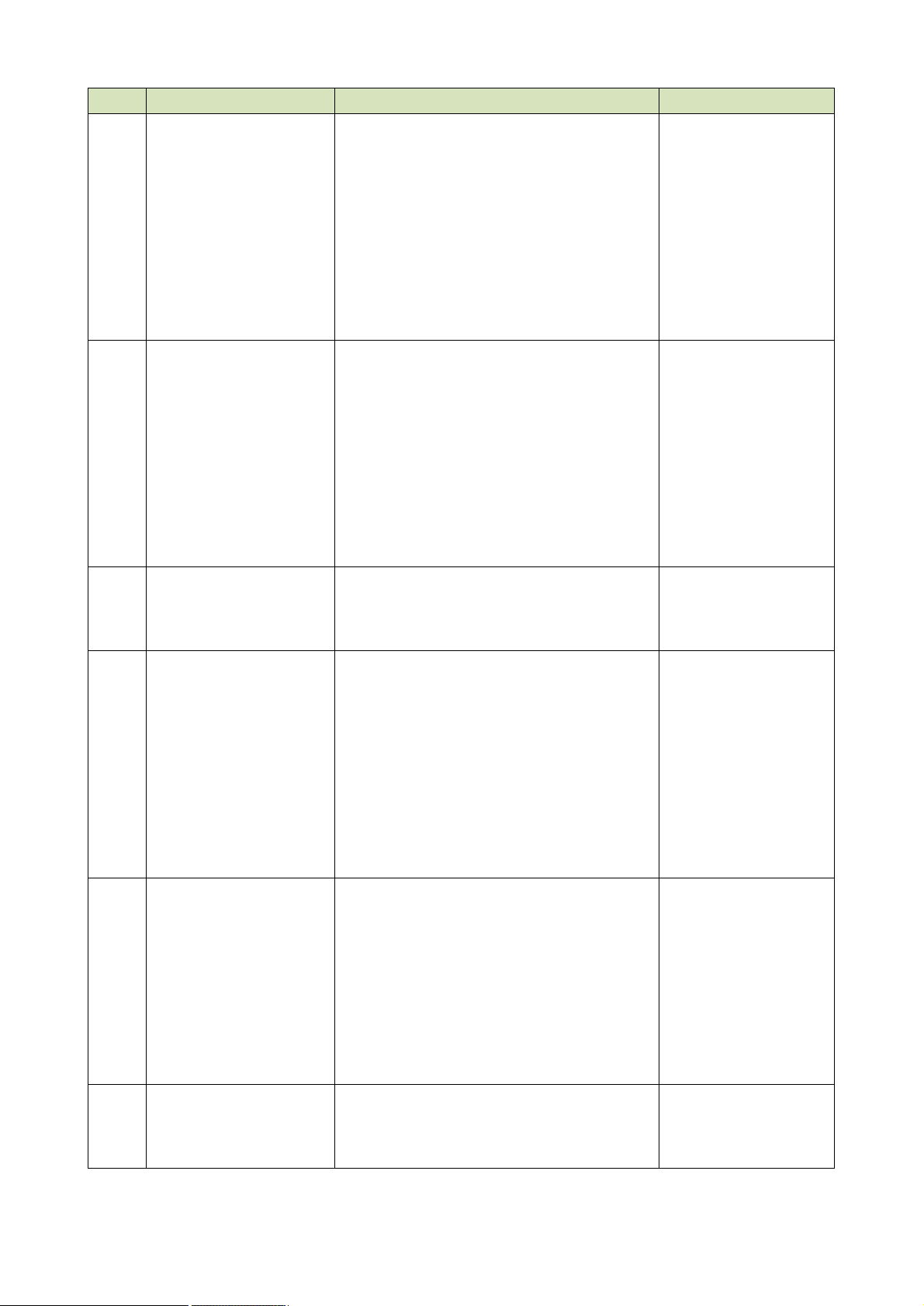

4.4. MEASUREMENT DATA OUTPUT FORMAT

No.

Item

Unit

Example of output

Remarks

1

Measurement range

- 1

2

Integral time

ms

150

Unit: 1ms

3

Radiant illuminance

W/m2

2.495E-05

Valid digit of index: 4 digits

4

Illuminance

lx

143.5

Valid digit: Upper 4 digits

In the case of 999 or less, the

numeral at the first decimal

place is indicated.

5

Tristimulus value X

-

144.1

¯

6

Tristimulus value Y

-

143.5

¯

7

Tristimulus value Z

-

83.1

¯

8

Chromaticity x

-

0.3885

To the fourth decimal place

9

Chromaticity y

-

0.3872

¯

10

Chromaticity u’

-

0.2262

¯

11

Chromaticity v’

-

0.5073

¯

12

Correlated color

temperature

K

3868

13

Deviation

-

0.0026

To the fourth decimal place

14

Dominant wavelength

nm

578.3

To the first decimal place

15

Excitation purity

-

0.3281

To the fourth decimal place

16

Peak wavelength

nm

555

17

Spectral radiation

illuminance 380nm

W/m3

2.495E-04

Valid digit of index: 4 digits

¯

¯

¯

¯

¯

417

Spectral radiation

illuminance 780nm

W/m3

1.736E-02

¯

418

Average color rendering

property evaluation Ra

-

89

419

Color rendering property

evaluation R1

-

76

¯

¯

¯

¯

¯

Color rendering property

evaluation R8

-

98

¯

Special color rendering

property evaluation R9

-

84

¯

¯

¯

¯

433

Special color rendering

property evaluation R15

-

64

434

Data end

-

“END”

End command

The formats to output the measurement data from the instrument are shown below.

The measurement data format is changed according to the measurement commands and the

measurement data obtaining commands.

n ST, STR command measurement data format

* 434 items are fixed for output. If the measured value is not normal, “****” is output for the item.

50

Page 51

n ST2, STR2 command measurement data format

No.

Item

Unit

Example of output

Remarks

1

Measurement range

- 1

2

Integral time

ms

150

Unit: 1ms

3

Radiant illuminance

W/m2

2.495E-05

Valid digit of index: 4 digits

4

Illuminance

lx

143.5

Valid digit: Upper 4 digits

In the case of 999 or less, the

numeral at the first decimal

place is indicated.

5

Tristimulus value X

-

144.1

¯

6

Tristimulus value Y

-

143.5

¯

7

Tristimulus value Z

-

83.1

¯

8

Chromaticity x

-

0.3885

To the fourth decimal place

9

Chromaticity y

-

0.3872

¯

10

Chromaticity u’

-

0.2262

¯

11

Chromaticity v’

-

0.5073

¯

12

Correlated color

temperature

K

3868

13

Deviation

-

0.0026

To the fourth decimal place

14

Dominant wavelength

nm

578.3

To the first decimal place

15

Excitation purity

-

0.3281

To the fourth decimal place

16

Peak wavelength

nm

555

17

Data end

-

“END”

End command

* 17 items are fixed for output. If the measured value is not normal, “****” is output for the item.

51

Page 52

n ST3, STR3 command measurement data format

No.

Item

Unit

Example of output

Remarks

1

Measurement range

- 1

2

Integral time

ms

150

Unit: 1ms

3

Radiant illuminance

W/m2

2.495E-05

Valid digit of index: 4 digits

4

Illuminance

lx

143.5

Valid digit: Upper 4 digits

In the case of 999 or less, the

numeral at the first decimal

place is indicated.

5

Tristimulus value X

-

144.1

¯

6

Tristimulus value Y

-

143.5

¯

7

Tristimulus value Z

-

83.1

¯

8

Chromaticity x

-

0.3885

To the fourth decimal place

9

Chromaticity y

-

0.3872

¯

10

Chromaticity u’

-

0.2262

¯

11

Chromaticity v’

-

0.5073

¯

12

Correlated color

temperature

K

3868

13

Deviation

-

0.0026

To the fourth decimal place

14

Dominant wavelength

nm

578.3

To the first decimal place

15

Excitation purity

-

0.3281

To the fourth decimal place

16

Peak wavelength

nm

555

17

Average color

rendering property

evaluation Ra

-

89

18

Color rendering

property evaluation R1

-

76

¯

¯

¯

¯

¯

Color rendering

property evaluation R8

-

98

¯

Special color rendering

property evaluation R9

-

84

¯

¯

¯

¯

32

Special color rendering

property evaluation

R15

-

64

33

Data end

-

“END”

End command

* 33 items are fixed for output. If the measured value is not normal, “****” is output for the item.

52

Page 53

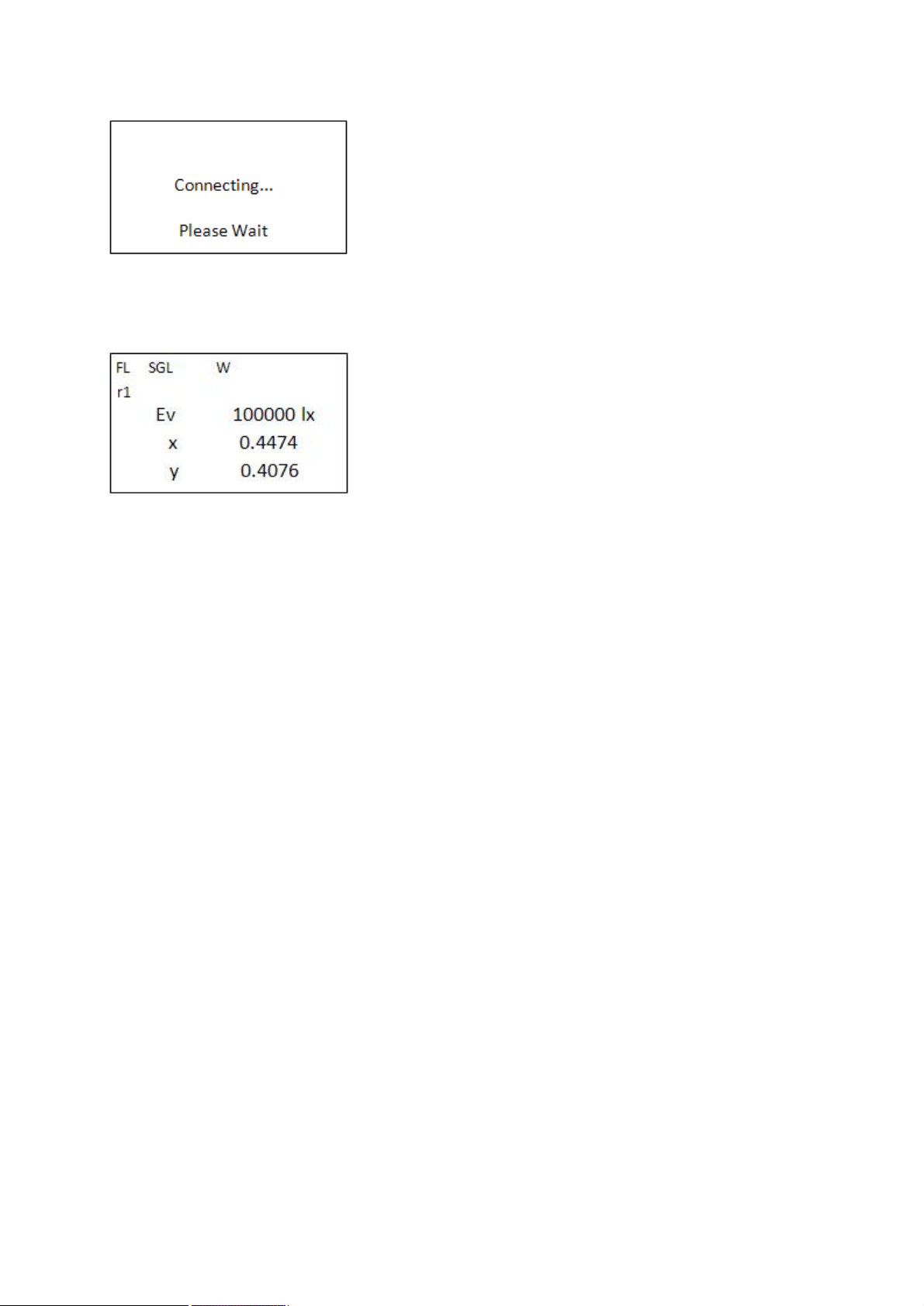

4.5. WIRELESS LAN CONNECTION

NOTICE

The frequency 2.4GHz band, which is used by the instrument, is also used by

electronic ovens, medical instruments and other wireless stations.

1. When using the instrument, check if any other wireless station or wireless

equipment is used in its periphery.

2. If radio wave interference has occurred, change the location of the instrument or

stop using the wireless LAN for the instrument.

3. The wireless LAN module, which conforms to the Japanese technical standards, is

built in the instrument. It is not possible to use the wireless LAN in any other

country or area except Japan.

4. If you use the instrument out of Japan, turn off the wireless LAN function.

☞

“3.2.11. Setting the wireless LAN”

MEMO

This chapter will explain how to connect the instrument with the wireless LAN access point (hereinafter,

access point).

• The explanation in this chapter will be done on the assumption that setting the access point has

already been finished.

• For setting and operating the access point, check the instruction manual of the access point.

• The procedure in this chapter is one example. It cannot be applied to some access points.

n Connection (when the access point has the easy connection AOSS function)

1. Set the IP address, subnet mask and port number of the instrument in the function mode. The IP

address must be fit to that on the access point.

2. Turn on the power of the access point and enable it to be connected.

3. Retrieve and set the access point in the function mode. After setting, cancel the function mode.

4. Press the [INV.] switch and then the [WPS] switch to connect with the access point.

53

Page 54

5. Press the [AOSS] button of the access point until the corresponding LED blinks twice.

6. When the connection is finished normally, “W” is indicated as the status display.

If the connection has failed several times, check the setting of the instrument and access point.

Then, wait for 3 minutes or more and start the connection again.

n Connection (when the access point does not have the easy connection function)

1. Set the IP address, subnet mask and port number of the instrument in the function mode. The IP

address must be fit to that on the access point.

2. Set “WEP” and “PASS PHRASE”, which are set for the access point, into the instrument.

3. Turn on the power of the access point and enable it to be connected.

4. Retrieve and set the access point in the function mode. After setting, cancel the function mode.

54

Page 55

5. Press the [INV.] switch and then [W-LAN] switch to connect with the access point.

6. When the connection is finished normally, “W” is indicated as the status display.

If the connection has failed several times, check the setting of the instrument and access point.

Then, wait for 3 minutes or more and start the connection again.

55

Page 56

Code

Contents

Remedial measure

Message

0

The instrument is

normal.

A remedial measure is not necessary.

1

13

A system error has

occurred.

Contact TOPCON TECHNOHOUSE.

When contacting our company, inform us

of the error code, the occurrence

frequency, the power supply status (AC

adapter or batteries) and the occurrence

status as detailedly as possible.

system error

mode change error

2 3 A trouble has occurred

in the internal memory.

It is probable that the internal memory is

damaged.

Restart the instrument by turning OFF and

then ON. Then, contact TOPCON

TECHNOHOUSE. When contacting our

company, inform us of the error code, the

occurrence frequency, the power supply

status (AC adapter or batteries), the

occurrence status and the condition at

restart as detailedly as possible.

memory init error

memory access error

5

The correction factor

calculation has failed.

Check the following points.

- Does an error occur when measurement

is performed?

- Is the measured value abnormal?

calculation error

6

The parameters are not

normal.

Check the following points.

- Are the parameters for sending within

the allowable setting range?

- Is the quantity of the parameters for

sending correct?

parameter error

7 9 Initialization of RS232C has failed.

Initialization of the

wireless LAN has

failed.

It is probable that the internal device is

damaged.

Restart the instrument by turning OFF and

then ON. Then, contact TOPCON

TECHNOHOUSE. When contacting our

company, inform us of the error code, the

occurrence frequency, the power supply

status (AC adapter or batteries), the

occurrence status and the condition at

restart as detailedly as possible.

RS-232C init error

LAN init error

5. ERROR CODE

5.1. ERROR CODE LIST

This chapter will explain the error messages and error codes that will be displayed on the instrument

and be obtained by the “ERR” command.

56

Page 57

Code

Contents

Remedial measure

Message

8

10

32

33

34

A trouble has occurred

in the RS-232C

communication.

A trouble has occurred

in the wireless LAN

communication.

Check the following points.

- Is the communication data (of wireless

LAN access point) set correctly in both

the external control device and the

instrument?

- Is the exclusive RS-232C cable

connected to both the external control

device and the instrument normally?

- Is the straight wiring cable used when

the RS-232C extension cable is used?

RS-232C trans error

LAN trans error

over run error

flamig error

parity error

11

12

Under range error has

occurred.

Over range error has

occurred.

Check the following points.

- Is the measured brightness within the

allowable measurement range?

- Is the measurement range mode set to

[AUTO FIRST] or [MANUAL RANGE]?

Is measurement performed where

brightness is sharply changed?

- Does the error occur though the

measurement range mode is set to

[AUTO FULL]?

under range error

over range error

14

The set value is beyond

the allowable range.