Page 1

INSTRUCTION MANUAL

AUTO TRACKING TOTAL STATION

GTS-820A

SERIES

GTS-821A

GTS-822A

GTS-823A

GTS-825A

Page 2

Page 3

FOREWORD

Thank you for purchasing the TOPCON Auto Tracking Total Station, GTS-82 0A

series. For the best performance of the instruments, please carefully read these

instructions and keep them in a convenient location for future reference.

General Hand l ing Prec autions

Before starting work or operation, be sure to check that the instrument is functioning

correctly with normal performance.

Do not submerge the instrument into water.

The instrument can not be submerged underwater.

The instrument is designed based on the International Standard IP54, therefore it is protected from

the normal rainfall.

Setting the instrument on a tripod

When mounting the instrument on a tripod, use a wooden tripod when possible. The vibrations that

may occur when using a metallic trip od can effect the measuring precision.

Installing the tribrach

If the tribra ch is ins talle d inco rrec tly, the measuring pr ecis ion coul d be effec ted . Occasional ly check the

adjusting screws on the tr i brach. Make s ur e the base fix ing lever is locked and the base fixing screws

are tightened.

TR-5 or TR-5P tribrach should be used for prism side when the traverse s urveys is perfor med .

FORE W ORD

Guarding the instrument against shocks

When tr anspo r ting t he instrum ent, p ro vide some pr otection t o m in imize risk of shocks. Heavy shocks

may cause the measurement to be faulty.

Carrying the instrument

Always carry the instrument by its handgrip.

Exposing the instrument to extreme heat.

Do not leave the instrument in extreme heat for longer than necessary. It could adversely affect its

performance.

Sudden changes of temperature

Any sudden change of temperature to the instrument or prism may result in a reduction of measuring

distance range, i.e when taking the instrument out from a heated vehicle. Let instrument acclimate

itself to ambient temperature.

Battery level check

Confirm battery level remaining before operating.

Memory back up

The instrument has a built in battery for memory back up. If the battery power is low, “Back up battery

empty” will display. It is still possible to measure the distance and the angle , but t h e measured data

and the parameter setting can be lost . Cont act your dealer, to replace the battery.

Taking the battery out

It is recommended not to take the battery out during the power is on. All the data stored is possible

gone at th at t i me. So please do your assembling or ta ki ng the bat ter y out after the pow er i s off .

No responsibility

TOPCON Corporation has no responsibility for loss of data stored in the memory in case unexpected

accidents.

1

Page 4

FORE W ORD

Rotating the instrument and telescope

Rota t i on of t he inst rum ent or tel escope is driven electronically in normal operation.

Do not disturb the rotation.

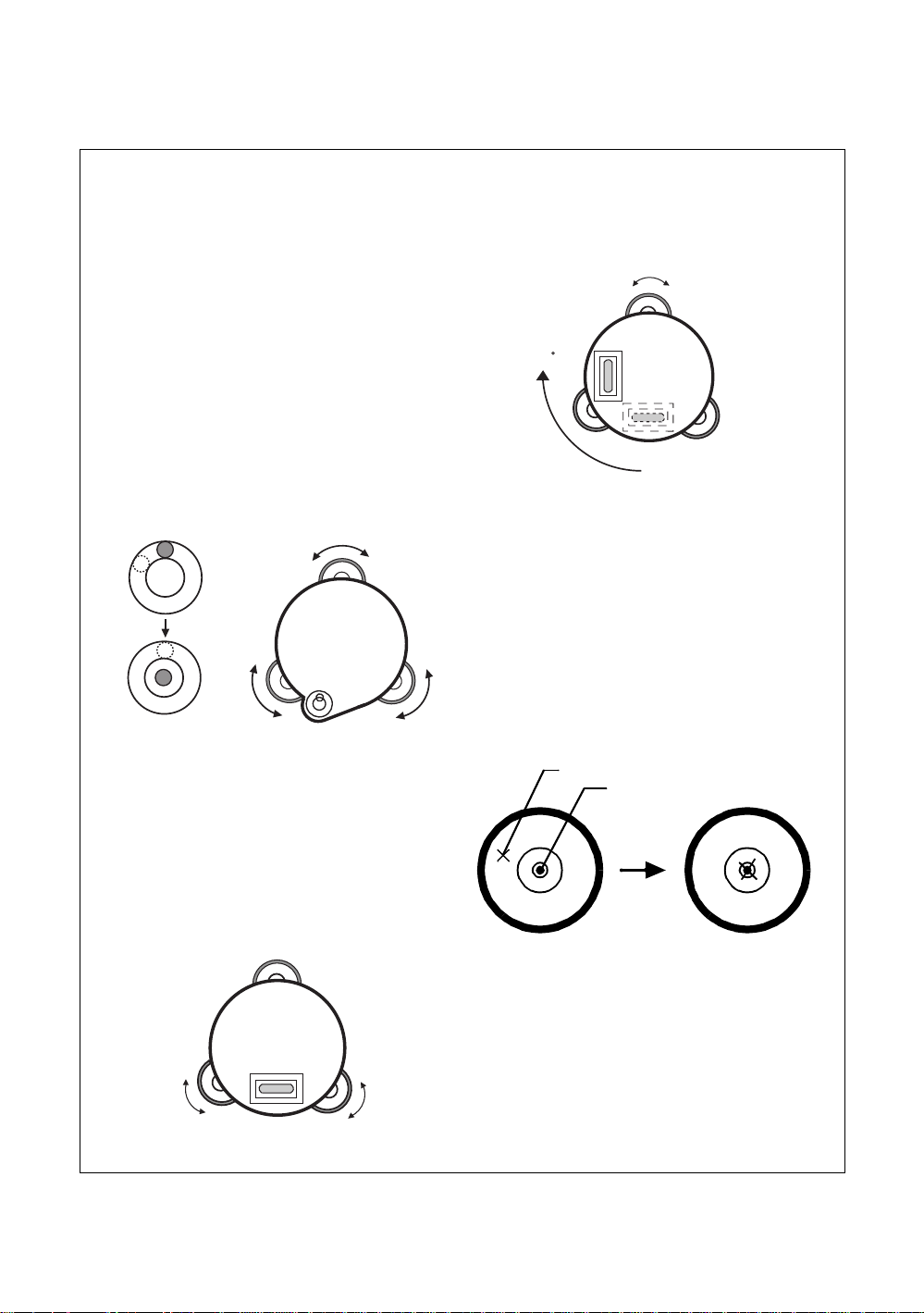

Storage in the case

Keep the telescope horizontally and turn the instrument to align its mark with the lower base mark

(Storage mark). Keep its objective lens si de downward . Sto r ing it in the case in any other way may

cause damage. Hold the hand grips and base with both hands, when taking the instrument out of the

case, or putting the equ i pm ent i n th e case.

Maintenance for driving parts.

Every 4,000~5, 000 hours operation in total, cha nge grease of driving parts.

Contact your dealer or TOPCON Head Office for the maintenance.

2

Page 5

FORE W ORD

G

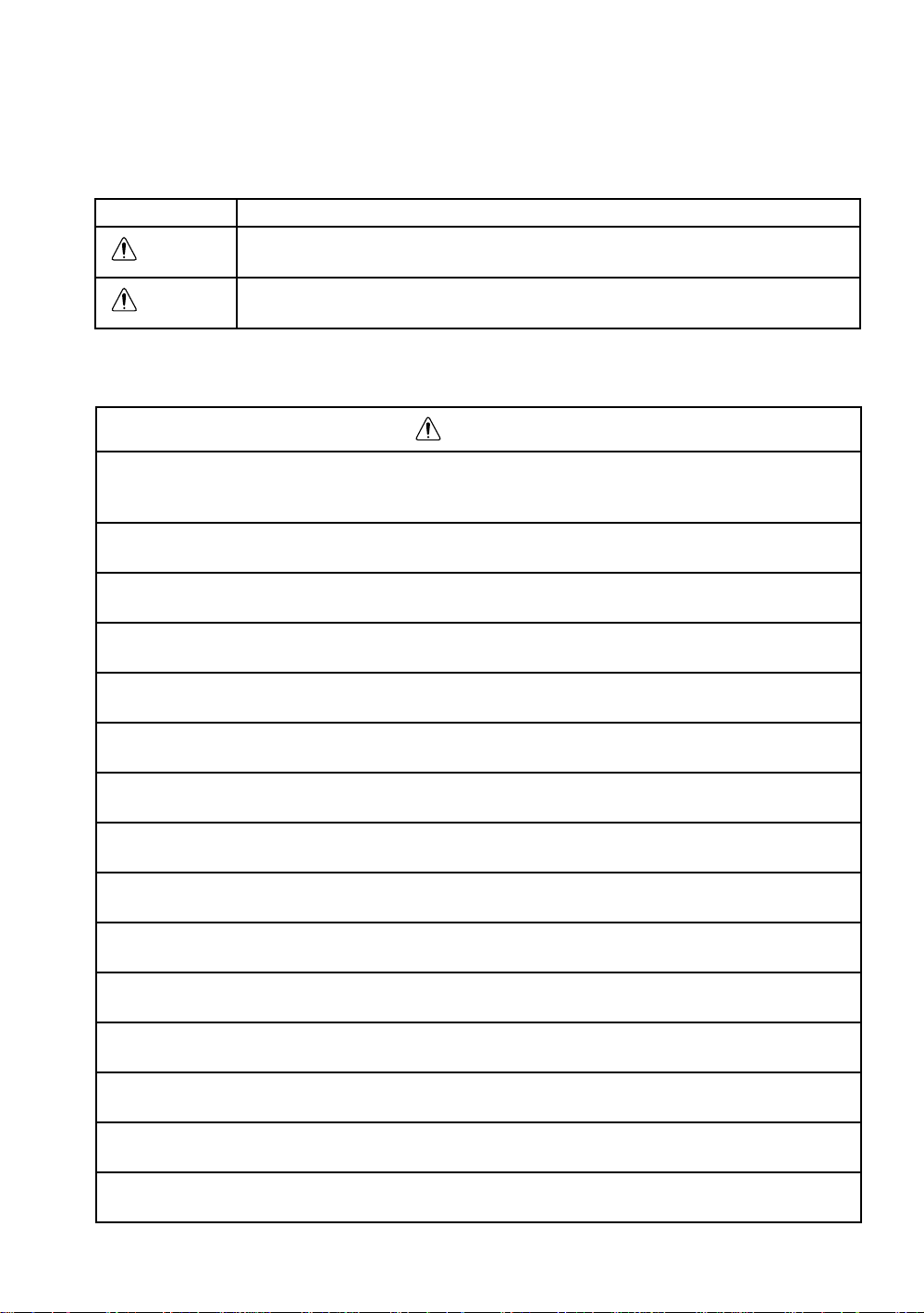

Display for Safe Use

In order to encourage the safe use of products and prevent any danger to the operator and others or

damage to properties, important warnings are put on the products and inserted in the instruction

manuals.

We suggest that everyone understand the meaning of the following displays and icons before reading

the “Safety Cautions” and text

Display Meaning

WARNIN

CAUTION

•Injury refers to hurt, burn, electric shock, etc.

•Physical damage refers to extensive damage to buildings or equipment and furniture.

Ignoring or disregard of this display may lead to t he danger of death or

serious injury.

Ignoring or disregard of this display may lead to personal injury or physical damage.

Safety Caut ions

WARNING

•There is a risk of fire, electric shock or physical harm if you attempt to disassemble or

repair the instrument yourself.

This is only to be carried out by TOPCON or an authorized dealer, only!

•Cause eye injury or blindness.

Do not look at the sun through a telescope.

•Laser beams can be dangerous, and can cause eye injury's if used incorrectly.

Never attempt to repair the instrument yourself.

•Cause eye injury or blindness.

Do not stare into beam.

•High temperature may cause fire.

Do not cover the charger while it is charging.

•High temperature may cause fire.

Do not connect the battery to an instrument while it is charging.

•Risk of fire or electric shock.

Do not use damaged power cable, plug and socket.

•Risk of fire or electric shock.

Do not use a wet battery or charger.

•May ignite explosively.

Never use an instrument near flammable gas, liquid matter, and do not use in a coal mine.

•Battery can cause explosion or injury.

Do not dispose in fire or heat.

•Risk of fire or electric shock.

Do not use any power voltage except the one given on manufacturers instructions.

•Battery can cause outbreak of fire.

Do not use any other type of charger other than the one specified.

•Risk of fire.

Do not use any other power cable other than the one specified.

•Battery can cause outbreak of fire.

Do not block up the vent of the battery.

•The short circuit of a battery can cause a fire.

Do not short circuit battery when storing it.

3

Page 6

FORE W ORD

CAUTION

Use of controls or adjustment or performance of procedures other than those specified herein

may result in hazardous radiation exposure.

Let the laser beam reach the aimed object or the target without anybody else in the laser beam

path. In case you operate laser beam open, avoid radiating laser beam to the height of man's

head. It is quite possible for the beam to enter into one's eyes, and it is possible to lose visual

sight temporarily, and lose one's caution and awareness of other dangers - avoid glaring beam.

Do not connect or disconnect equipment with wet hands, you are at risk of electric shocks if you

do!

Risk of injury by overturn the carrying case.

Do not stand or sit on th e carrying cases.

Please note that the tips of tripod can be hazardous, be aware of this when setting up or carrying

the tripod.

Risk of injury by falling down the instrument or case.

Do not use a carrying case with a damaged which belts, grips or latches.

Do not allow skin or clothing to come into contact with acid from the batteries, if this does occur

then wash off with copious amounts of water and seek medical advice.

A plumb bob can cause an injury to a person if used incorrectly.

It could be dangerous if the instrument falls over, please ensure you attach a handle battery to

the instrument securely.

Ensure that you mount the Tribrach correctly, failing to do so may result in injury if the tribrach

were to fall over.

It could be dangerous if the instrument falls over, please check that you fix the instrument to the

tripod correctly.

Risk of injury by falling down a tripod and an instrument.

Always check that the screws of tripod are tightened.

User

1)This product is for professional use only!

The user is required to be a qualified surveyor or have a good knowledge of surveying, in order to

understand the user and safety instructions, before operating, inspecting or adjusting.

2)Wear the required protectors (safety shoes, helmet, e tc.) when operating.

Exceptions fr om Respo ns ibility

1)The user of this product is expected to follow all operating instructions and make periodic checks of the

product’s performance.

2)The manufacturer, or its representatives, assumes no responsibility for results of a faulty or intentional

usage or misuse including any direct, indirect, consequential damage, and loss of profits.

3)The manufacturer, or its representative s, assumes no responsibility for co ns equential damage, and

loss of profits by any disaster, (an earthquake, storms, floods etc.).

A fire, accident, or an act of a third party and/or a usage any other usual conditions.

4)The manufactur er , or its represent ativ es, assumes no respon si bility for any damage, and loss of pr ofits

due to a change of data, loss of data, an in terruption of business etc., caused by using the product or

an unusable product.

5)The manufactur er , or its represent ativ es, assumes no respon si bility for any damage, and loss of pr ofits

caused by usage except for explained in the user manual.

6)The manufacturer, or its representative s, assumes no responsibility for damage c aused b y wrong

movemen t , or ac t i o n due to connecti n g with o th er products.

4

Page 7

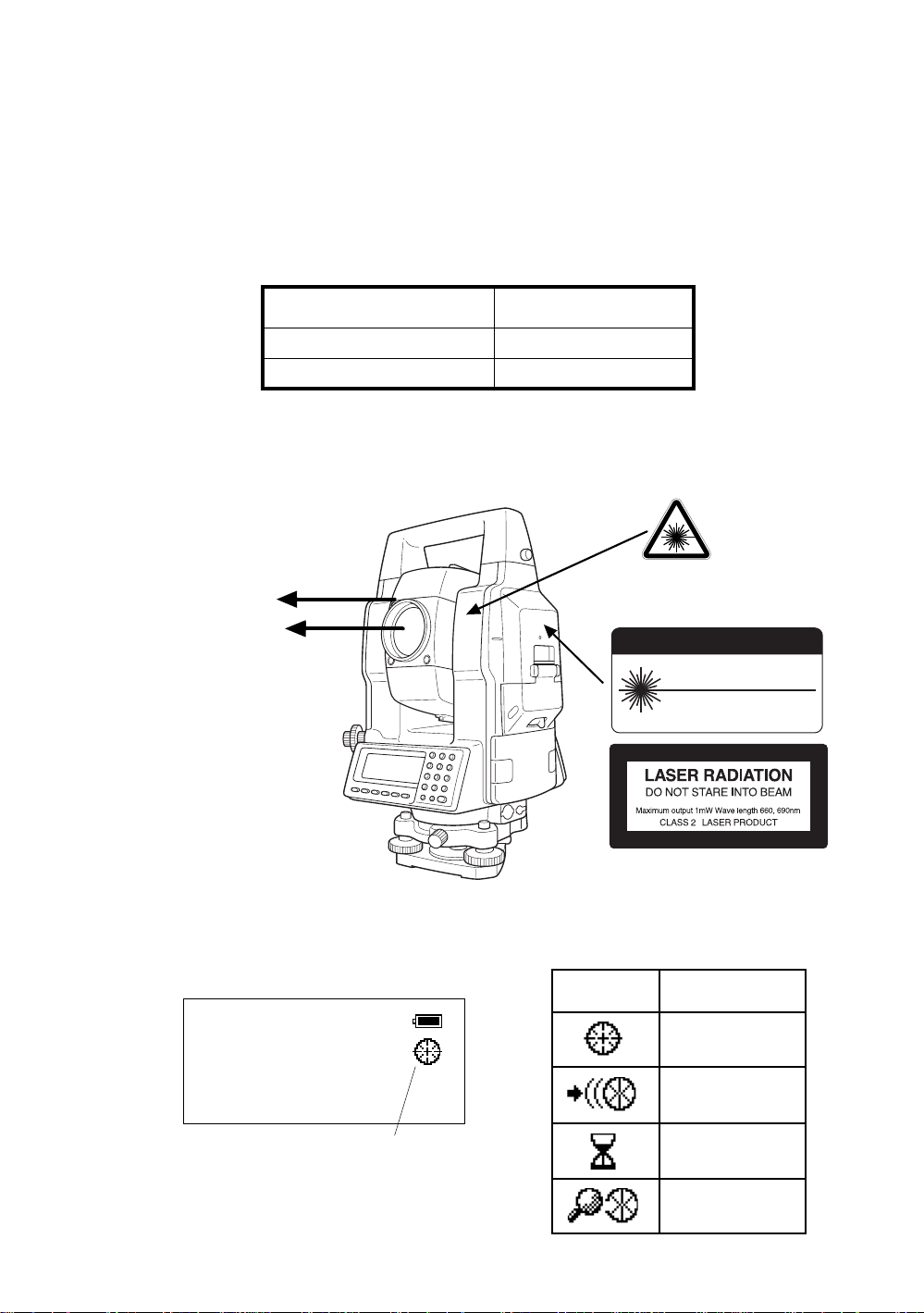

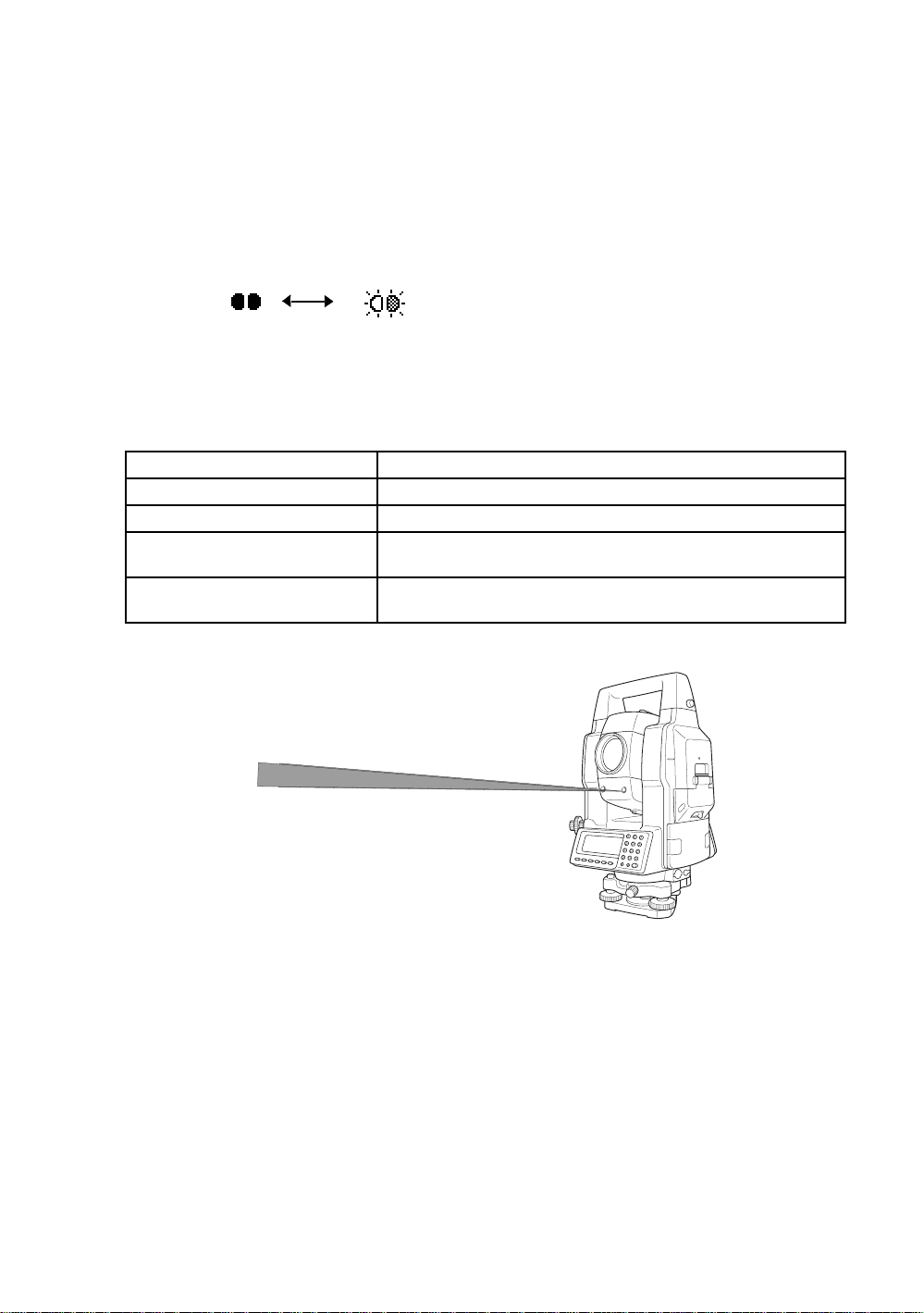

Laser Safety

GTS-820A series uses the visible laser beam for auto tracking, optical communication. The

GTS-820A series products are manufactured and sold in accordance with “Radiation Safety of Laser

Products, Equip men t Classificati on, Require me nts and Use r‘s Guid e” (I EC Pub li cation 60825-1 ) or

“Performance Standards for Light-Emitting Products” (FDA/BRH 21 CFR 1040) provided on the safety

standards for laser beam.

As per the said standards, GTS-820A series is classified as “Class 2 (CLASS II) Laser Products”.

The laser beam belongs not very dangerous type but we request you to keep and understand “Safety

standard for users” as mentione d in the manual inst ruction.

In case of any failure, do not disassemble the instrument. Contact TOPCON or your TOPCON dealer.

Laser class of each mode is as foll o ws.

Mode Laser class

Autotracking Class 1 (CLASS II)

Optical communication Class 2 (CLASS II)

Labels

Find the labels which describes the caution and safety about the laser beam as follows in GTS-820A

series.

We request you to replace it one anytime the caution labels are damaged or lost and paste a new one

at the same place. You can get the labels from Topcon or your dealer.

Warning Label

Beam ap ertur e

Explanatory Label

Beam ap ertur e

CAUTION

LASER RADIATION-DO NOT

STARE INTO BEAM

WAVE LENGTH 660, 690nm

1mW MAXIMUM OUTPUT

DIODE LASER

CLASS II LASER PRODUCT

FORE W ORD

Each label is differed by the market.

GTS-820A series

Symbol marks while the laser is emitting.

The following symbol marks of instrument status will indicate that the laser is emitting.

Marks

V : 87°55'45"

HR: 180°44'12"

SD HD NEZ 0SET HOLD P1↓

The symbol mark

Status of

instrument

Auto-collimating

Auto-tracking

Waiting

Searching

5

Page 8

Contents

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Handling Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Display for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Exceptions from Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Laser Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Standard Set Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 NOMENCLATURE AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 Operating Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.4 Function Key (Soft Key) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.5 Star key (*key) mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.6 Auto Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.7 Data Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

1.8 Rotating Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.8.1 Rotating by H/V Shuttle and H/V Jog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.8.2 Auto Inversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

1.8.3 Rotating automatically to a required Horizontal and Vertical angle . . . . . . . . . . 1-11

1.9 Using together with RC-2II Remote Control System. . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

1.10 Using connecting with Personal Computer (PC). . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

2 PREPARATION FOR MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Power Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Setting Instrument Up For Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Power Switch Key ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 Battery Level Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5 Main Menu Icons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6 Vertical and Horizontal Angle Tilt Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.7 Compensation of Systematic Error of Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.8 Resume Mode ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.9 How to Enter Numerals and Alphabet Letters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.10 Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.11 Inclination of Prism and Measuring Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3 AUTOMATIC TRACKING / AUTOMATIC COLLIMATION . . . . . . . . . . 3-1

3.1 Automatic Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Automatic Collimation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3 Range of Laser for Auto-tracking and Auto-collimating . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Setting Parameters for Auto-Tracking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.1 Setting Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.2 How to set the parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

4 STANDARD MEASUREMENT MODE . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Angle Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Measuring Horizontal Angle Right and Vertical Angle . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.2 Switching Horizontal Angle Right/Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.3 Measuring from the Required Horizontal Angle. . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.4 Vertical Angle Percent Grade(%) Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.1.5 Automatic Rotation to a Required Horizontal and Vertical Absolute Angle . . . . .4-4

4.2 Distance Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.1 Setting of the Atmospheric Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.2 Setting of the Correction for Prism Constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.3 Distance Measurement (Continuous Measurement) . . . . . . . . . . . . . . . . . . . . . . 4-5

4.2.4 Distance Measurement (Single/N-times Measurement) . . . . . . . . . . . . . . . . . . . . 4-6

4.2.5 Fine / Coarse Measuring Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2.6 Stake Out (S-O) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.3 COORDINATE MEASUREMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.3.1 Setting Coordinate Values of Occupied Point . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.3.2 Setting of the Instrument Height / Prism Height . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4.3.3 Execution of Coordinate Measuring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

6

FORE W ORD

Page 9

FORE W ORD

4.4 DATA OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

5 PROGRAM MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Se tt ing a D i rection Angle for B acksight Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Retaining a Coordinate (STORE- NEZ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3 Remote Elevation measurement (REM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4 Missing Line Measurement (MLM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.5 Line Measurement (LINE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.6 Offset measurement (OFFSET) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

5.6.1 Angle Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.6.2 Distance Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.6.3 Plane Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

5.6.4 Column Offset Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

5.7 External Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.7.1 Starting compatible communication program of AP-L1A . . . . . . . . . . . . . . . . . . 5-23

5.7.2 Setting for the communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

5.7.3 Carrying out Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

6 MEMORY MANAGE MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 View Internal Memory and Card Memory Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Protect a File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 Rename a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.4 Deleting a File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.5 Copy a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.6 Initializing Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

7 COMMUNICATION MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Setting of PROTOCOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Data File In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7.3 Data File Out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

8 PARAMETERS SETTING MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 Parameter Setting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.1 Parameters for Measurement and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1.2 Parameters for communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.2 Setting Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.2.1 Parameters for Measurement and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.2.2 Parameters for Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.2.3 Password Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

9 CHECK AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Checking and Adjusting of Instrument Constant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.2 Checking the Optical Axis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.3 Checking/Adjusting the Theodolite Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.3.1 Checking /Adjusting the Plate Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.3.2 Checking /Adjusting the Circular Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.3.3 Adjustment of the Vertical Cross-hair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.3.4 Collimation of the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

9.3.5 Checking / Adjusting the Optical Plummet Telescope . . . . . . . . . . . . . . . . . . . . . 9-8

9.4 Adjustment of Compensation Systematic Error of Instrument . . . . . . . . . . . . . . . . . . . 9-9

9.5 Showing Constant List and Switch ON/OFF

Compensation Systematic Error of Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.6 How to adjust the date and time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.7 How to Set the Instrument Constant Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

9.8 Reference Frequency Checking Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

9.9 Inspection and Adjustment of Optic Axis for Auto -Tracking. . . . . . . . . . . . . . . . . . . . 9-15

10 SETTING THE PRISM CONSTANT VALUE. . . . . . . . . . . . . . . . . . . . 10-1

11 SETTING ATMOSPHERIC CORRECTION . . . . . . . . . . . . . . . . . . . . 11-1

11.1 Calculation of Atmospheric Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

11.2 Setting of Atmospheric Correction Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

12 CORRECTION FOR REFRACTION AND EARTH CURVATURE . . . 12-1

12.1 Distance Calculation Formula. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

13 POWER SOURCE AND CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

13.1 Rechargeable Battery BT-56Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

7

Page 10

FORE W ORD

14 DETACH/ATTACH OF TRIBRACH. . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

15 BATTERY SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

16 PRISM SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

17 PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-1

18 ERROR DISPLAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

19 SPECIAL ACCESSORIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-1

20 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . APPENDIX-1

Dual Axis Compensation...... ............ ............ .. ............ ............ ............................. APPENDIX-1

Precaution when Charging or Storing Batteries.................................................. APPENDIX-3

8

Page 11

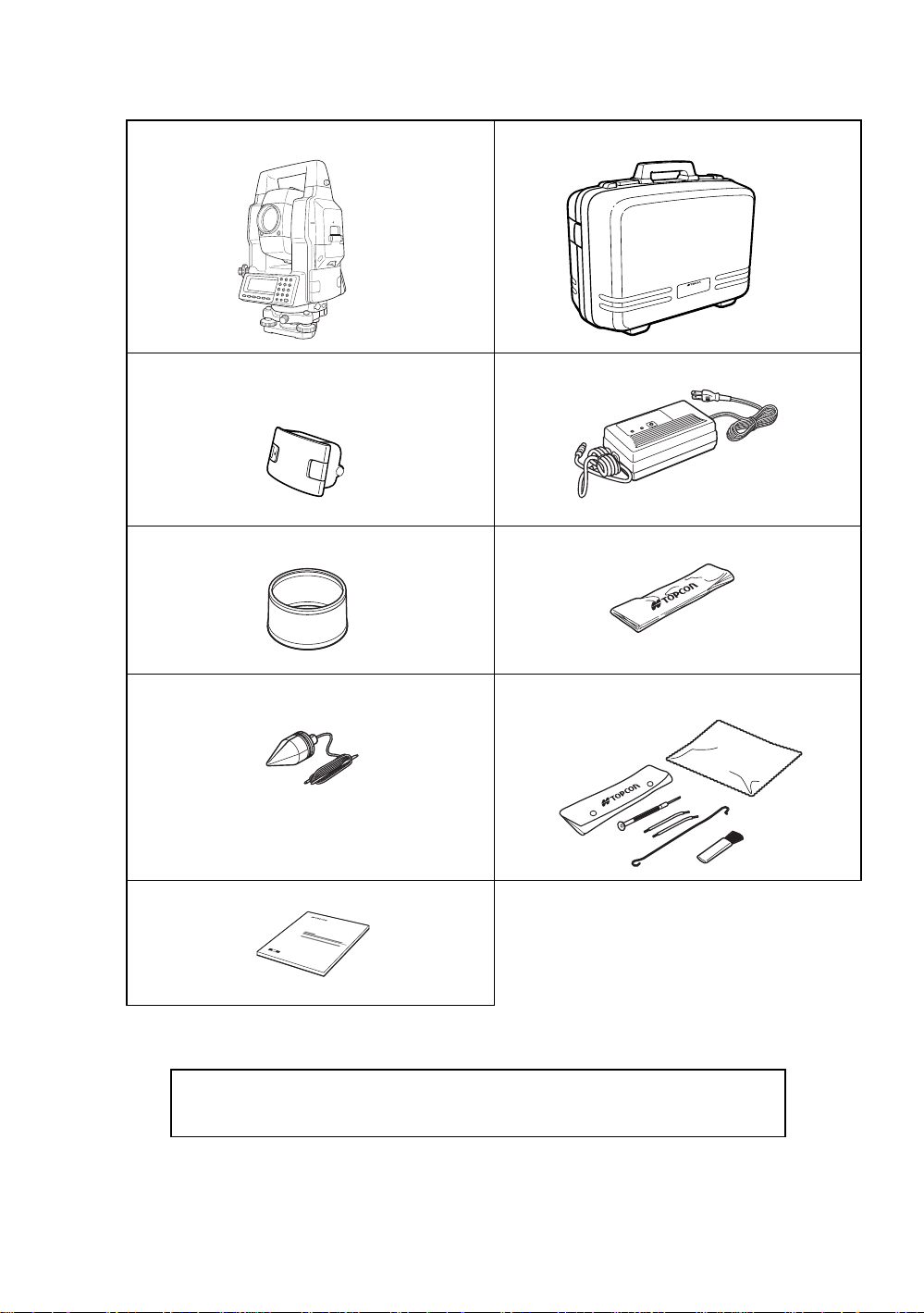

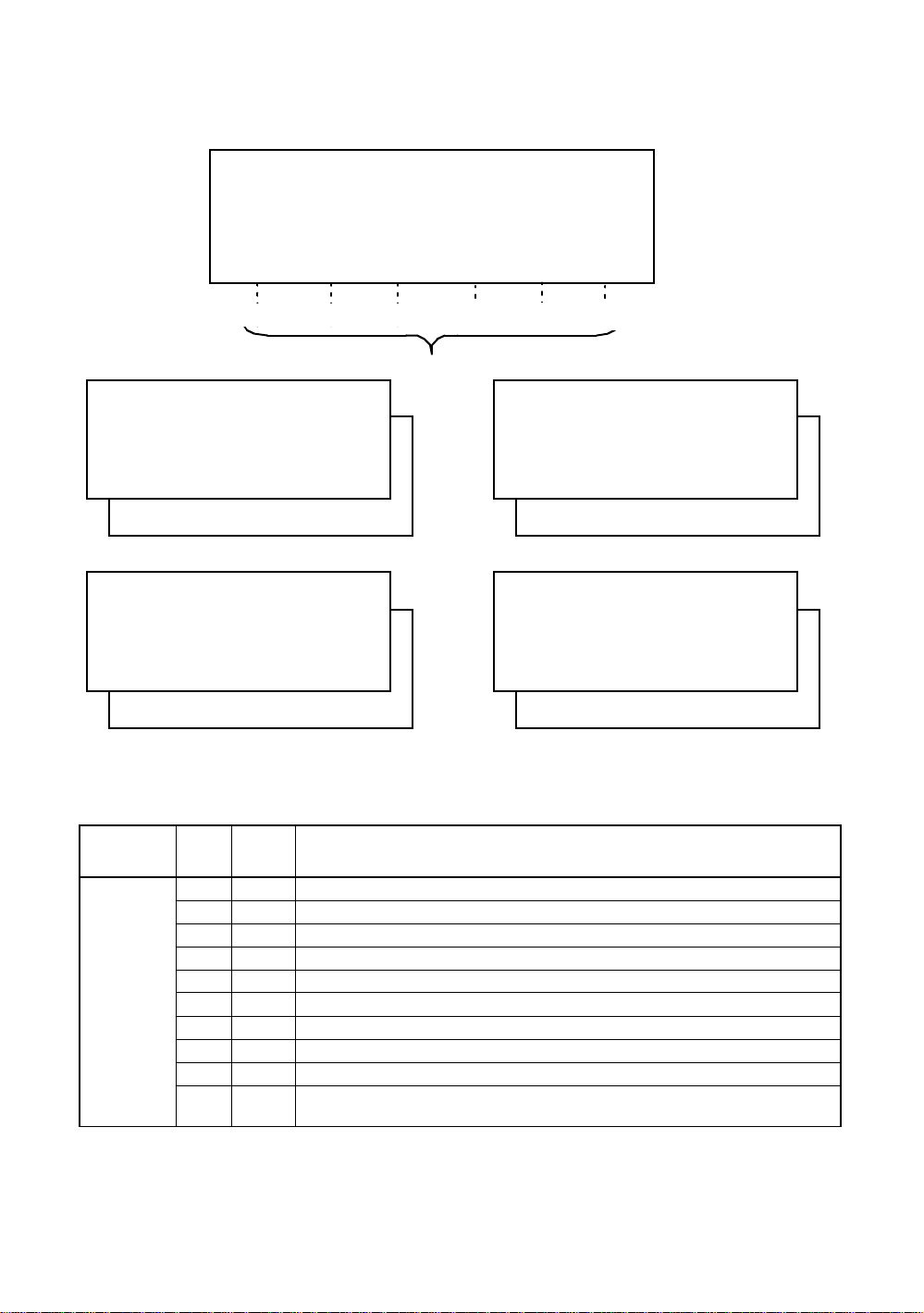

Standard Set Composition

The numeric al v alue in parentheses shows t he quantity.

GTS-820A series (with lens cap) (1) Plastic carrying case (1)

Battery BT-56Q (2) Battery charger BC-27BR or BC-27CR (1)

Sun shade (1) Plastic rain cove r (1)

FORE W ORD

Plumb bo b se t (1) Tool kit with c a se [ rod pi ns , Plum b bob hook, scre w -

Plumb bob hook is included

in the tool kit case.

Instruction manual (1)

(Make sure that all of the above items are with the instrument when purchased.)

Remarks:

1) Battery char ger BC- 27C R is for AC 230V us e and BC-27B R is for AC 120V use.

2) Plumb bob set and plumb bob hook are supplied for certain markets.

driver, cleaning brush ] (1)

9

Page 12

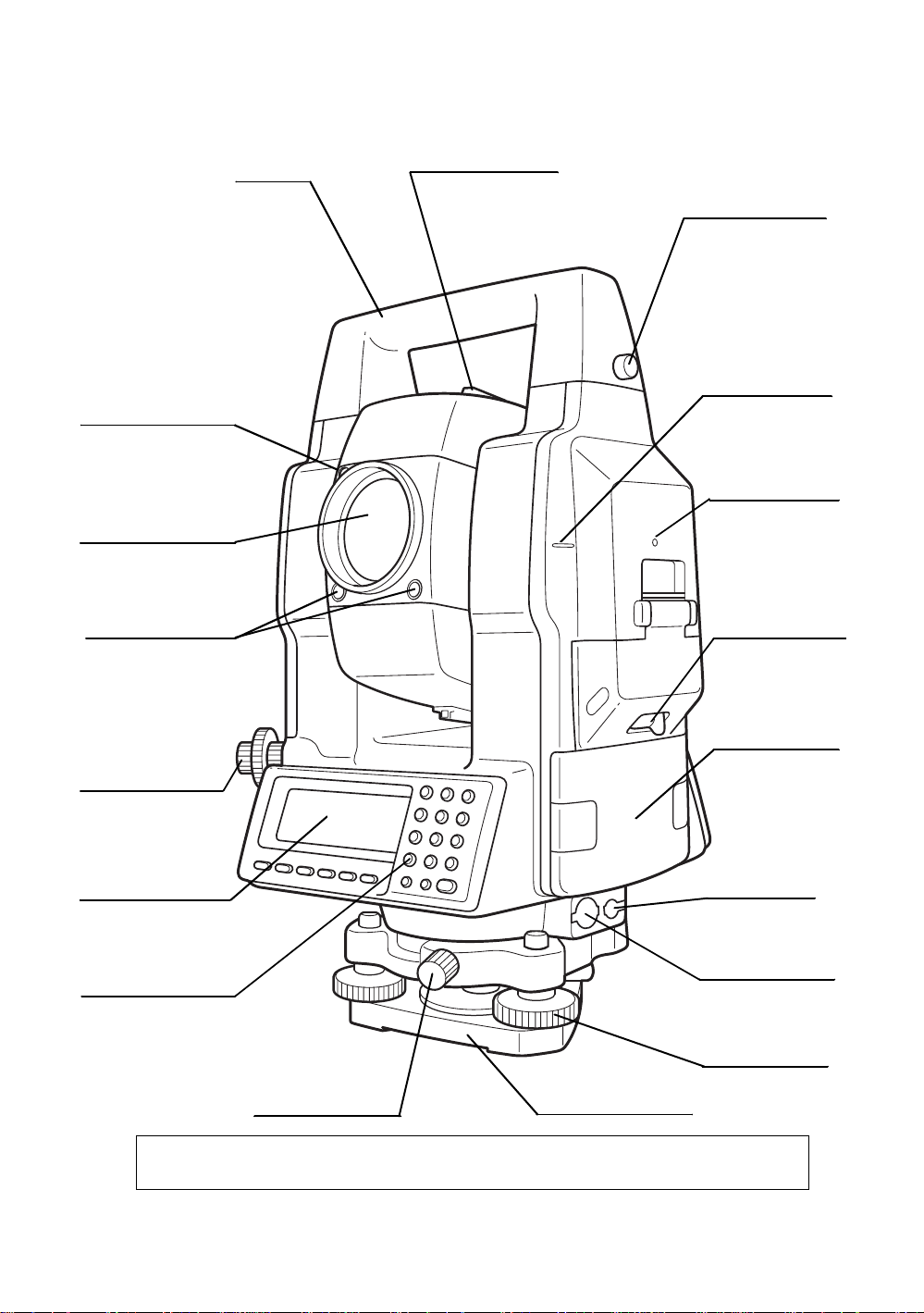

1 NOMENCLATURE AND FUNCTIONS

O

L

(

T

L

(

c

(

1 NOMENCLATURE AND FUNCTIONS

1.1 Nomenclature

Handle

aser aperture

for optical

ommunication)

bjective lens

aser aperture

for auto-tracking)

racking indicator

Sighting collimator

Handle fixing knob

Instrument height

mark

Instrument center

mark

Card cover lever

Battery BT-56 Q

Optical plummet

telescope

Display window

Only for GTS - 821A)

Operation keys

(Only for GTS-821A)

The caution labels are pasted up GTS-820A series which describe the warning of laser beam.

Refer to "Laser Safety" about label positions and their shapes.

Base fixing screw

Base (Model TR-5)

Power sup p ly

connector

Serial Signal

Connector-1(6pin)

Leveling screw

1-1

Page 13

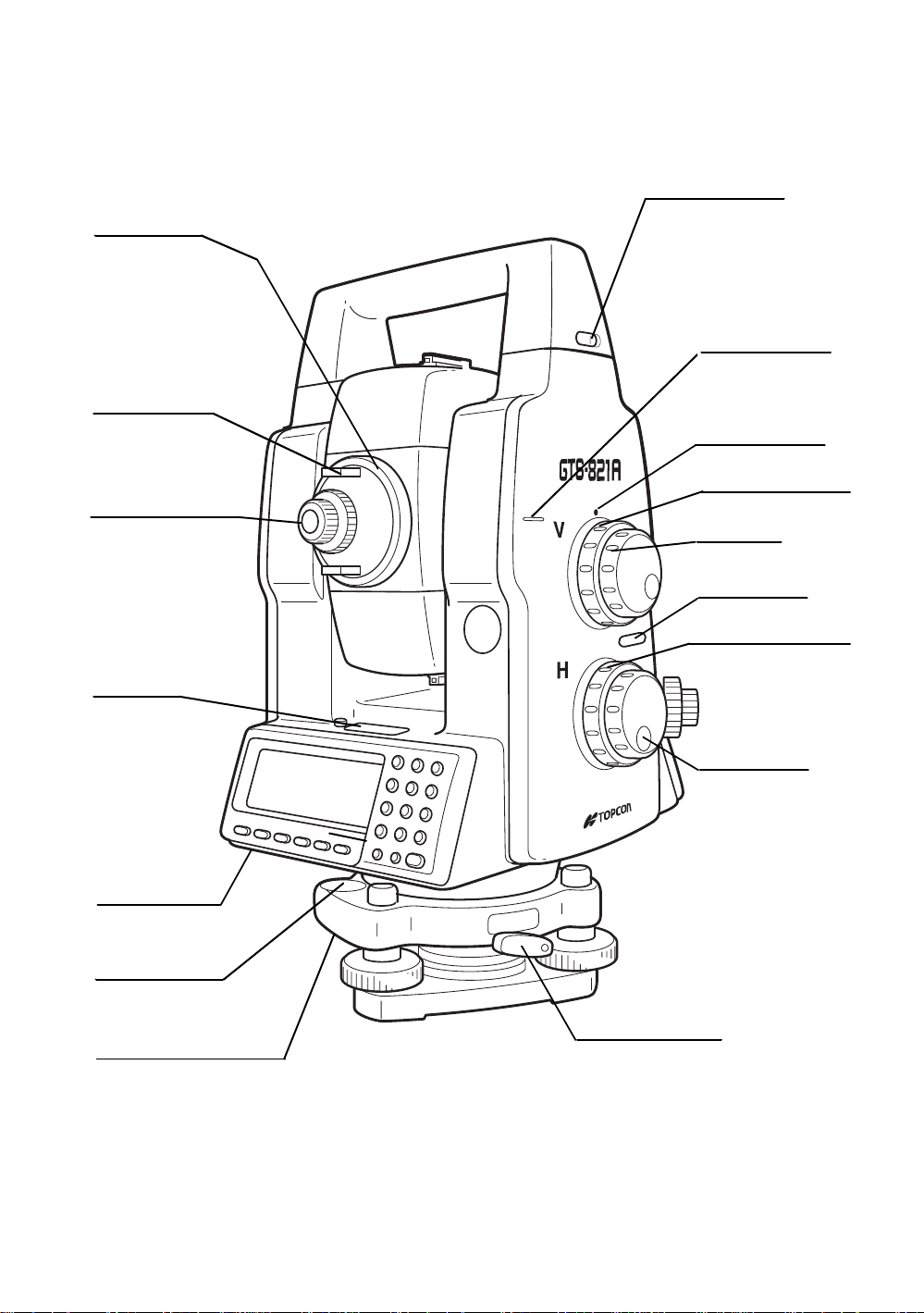

Telescope

focusing knob

1 NOMENCLATURE AND FUNCTIONS

Handle fixing knob

Instrument height

mark

Telescope grip

Telescope eyepiece

Plate level

Centronics

connector

Instrument center

mark

Vertical shuttle

Vertical jog

Power swi t ch

Horizontal shuttle

Horizontal jog

Circular level

Adjusting screws for

circular level

Tribrach fixing lever

1-2

Page 14

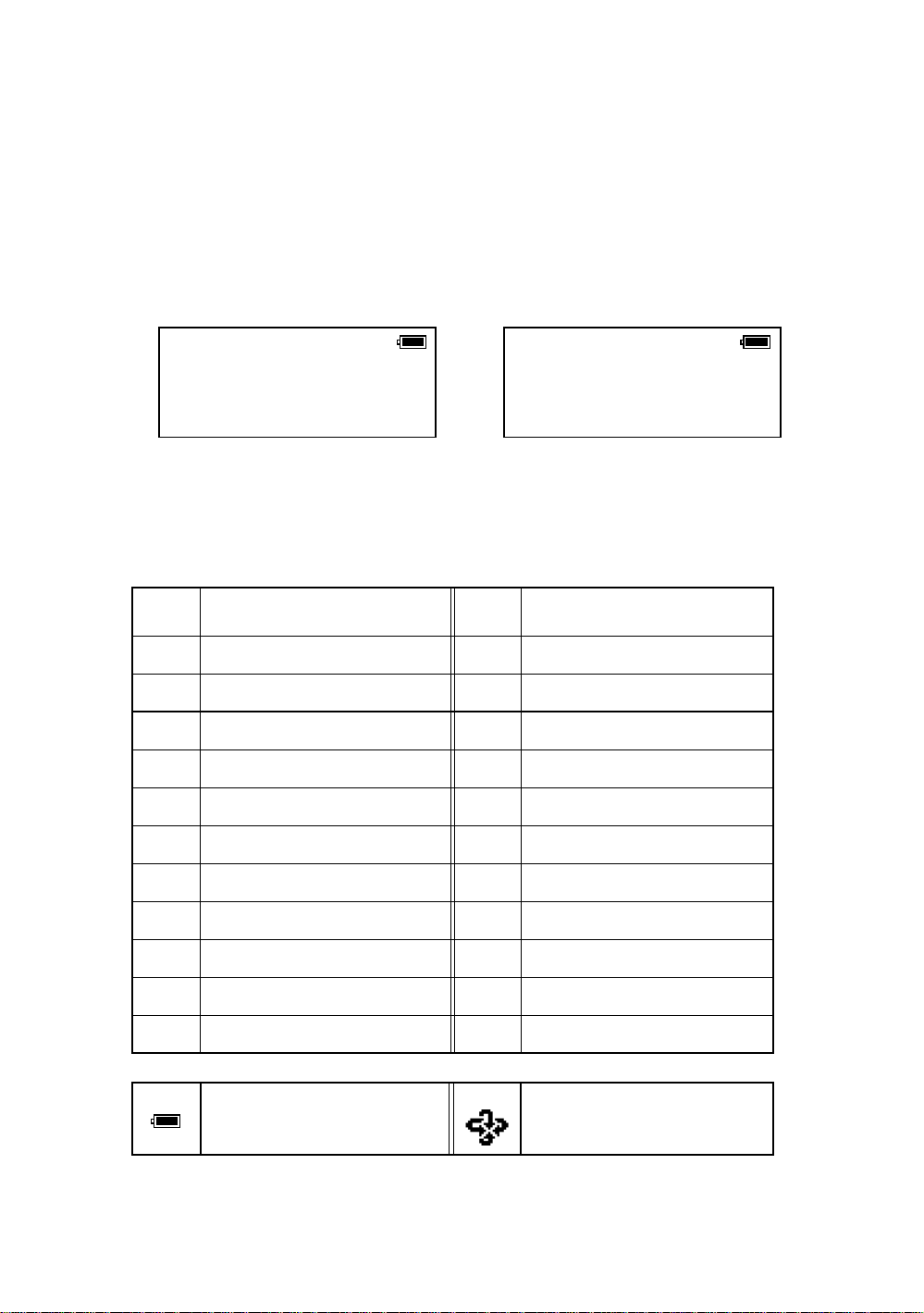

1.2 Display

Display

•

In general upper fo ur lines displ ay the mea suring data, and the

bottom line displays the soft key function which is changed by the measuring mode.

Contrast

•

The c ontras t and i ll umination of display w i ndow are ad justed by st a r (H) key.

Heater (Au t om atic)

•

The built-in heater keeps the display functional when the temperature goes below 0°C (32 °F). To

switch the heater ON or OFF, refer to Chapter 8 “PARAMETERS SETTING MODE”.

When the he ater i s ON a nd the temperat ure g o es belo w 0 ° C .(32 °F), the heater automatical ly

adjust the temperature to the display to keep it operating.

Example

•

1 NOMENCLATURE AND FUNCTIONS

V : 87°55'45"

HR: 180°44'12"

SD HD NEZ 0SET HOLD P1

Angle measure me nt mode

V-angle : 87°55’20”

H-angle : 180°44’12”

↓

V : 87°55'40"

HR: 180°44'12" PSM 0.0

SD: 12.345 PPM 0.0

(m) *F.R

MEAS MODE VH HD NEZ P1

Distance measurement mode

Horizontal-angle : 87°55’40”

Horizontal distance : 180°44’12”

Relative elevation :12.345m

Display marks

•

Display Contents Display Content

V V-angle * EDM working

V% Percent grade (m) Meter unit

HR H-angle right (f) Feet unit

HL H-angle l ef t F Fine mode

HD Horizontal dis t ance C Coarse mode (1mm)

VD Relative elevation T Tracking mode (10mm)

↓

SD Slope distance R Repeat meas ur ement

N N coordinate S Single measurement

E E coordinate N N-ti m es me as urem ent

Z Z coordinate ppm Atmospheric correction value

psm Prism constant value

Battery Level Indicator

Refer to Section 2.4 “B attery Level

Indicator” for further information.

Rotation Indicator

Refer to Section 1.8 “Rotating

Method” for further information.

1-3

Page 15

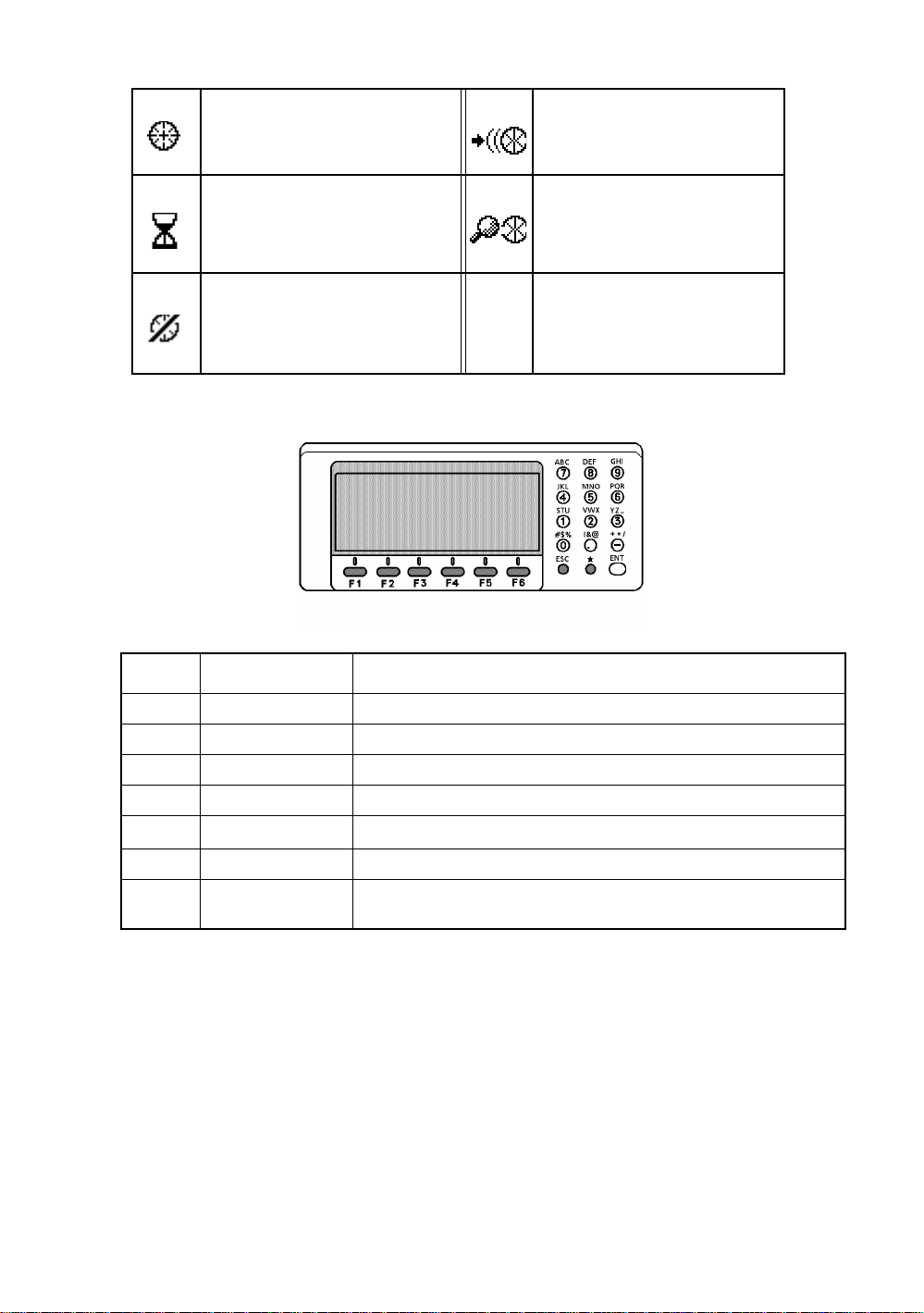

l The symbol marks for Auto-tracking and Auto-collimating

1 NOMENCLATURE AND FUNCTIONS

Auto-collimating

Laser is emit ting

(

GTS-820A serie s is i n autocollimat ing stat u s.

Waiting (

GTS-820A serie s is i n waiting

status.

Failure in auto-collimating.

Laser is off

(

GTS-820A serie s could not find

the target prism dur ing aut o collimating.

Laser is emitting

1.3 Operat ing Key

Auto-tracking

)

)

)

Laser is emitting

(

GTS-820A series is in autotracking status.

Searching (

GTS-820A series is searching a

prism.

)

Laser is emitting

)

KEY NAME FUNCTION

F1~F6 Soft key Functions are according to the displayed message.

0~9 . - Numeric key Numeric Character Entry for Preset Data

A ~/ Alpha key Alpha Character Entry

ESC Escape key Escape to Previous Display or Menu

*

ENT Enter key End operation of data input and accepts data

POWER Power key

Star key Option al ins tr ume nt funct i ons

ON/OFF of power source.

(Power key is located on the side of the instrument.)

1-4

Page 16

1 NOMENCLATURE AND FUNCTIONS

1.4 Function Key (So ft K ey)

The Soft Key Functions are labeled on the bottom of display. Soft Key functions are different for each

measurement.

V : 87°55'45"5

HR: 180°44'12"5

SD HD NEZ 0SET HOLD

P1

↓

[F1] [F2] [F3] [F4]

V : 87°55'45"5

HR: 180°44'12"5

SD HD NEZ 0SET HOLD P1

TURN HSET R/L V/% TILT P2

Angle measuring

V : 90 10'20"5

HR: 120 30'40"5 PSM 0.0

HD: PPM 0.0

VD: (m) F.R

MEAS MODE VH SD NEZ P1

REC SO MEAN P2

Horizontal distance measuring

Page Display

Angle

measuring

SD F1 Slope distance measur ing mode.

HD F2 Horizontal distance measuring mode.

NEZ F3 Coordinate distance measuring mode.

0SET F4 Set horizontal angle to 0°00'00".

HOLD F5 Horizontal angle hold.

TURN F1 Turns the instrument to required angle automatically.

HSET F2 Preset a horizontal angle.

R/L F3 Changes hori zontal angle ri gh t or lef t.

V/% F4 Changes the disp l ay to vertical angle or percent of grade.

TILT F5

Soft

key

Sets the tilt function, ON/OFF.

If ON, the display shows tilt correction value.

Soft keys

↓

↓

↓

↓

[F5]

[F6]

V : 90°10'20"5

HR: 120°30'40"5 PSM 0.0

SD: PPM 0.0

(m) F.R

MEAS MODE VH HD NEZ P1

TURN SO MEAN m/ft P2

Slope distance measur ing

N : 12345.6789

E : -12345.6789 PSM 0.0

Z : 10.1234 PPM 0.0

(m) F.R

MEAS MODE VH SD HD P1

↓

TURN HT MEAN P2

Coordinate measuring

Function

↓

↓

↓

1-5

Page 17

1 NOMENCLATURE AND FUNCTIONS

Page Display

Slope

distance

measuring

Horizontal

distance

measuring

Coordinate

measuring

Soft

key

MEAS F1

Starts sl ope distance mea surement mode.

Changes Continuous/ N-times (single) measurement mode.

Function

MODE F2 Chang es Fine / Coarse(1mm) /Co arse(10 mm) m ode.

VH F3 Angle me asurement mode.

HD F4

NEZ F5

Horizontal distance measurement mode. Displays the horizontal distance

data after N-times or single measurement.

Coordinate measurement mode.

Displays the coordinate after N-times or single measurement.

TURN F1 Turns the instrument to required angle automatically.

SO F2 Stake out measurement mode.

MEAN F3 Sets the number of N-time measurement.

m/ft F4 Changes distance measurement unit to meter or feet.

MEAS F1

Starts horizontal d i stance measurement mode.

Changes continuous/ N-times (single) measurement mode.

MODE F2 Chang es Fine / Coarse(1mm) /Co arse(10 mm) m ode.

VH F3 Angle me asurement mode.

SD F4

NEZ F5

Slope distance measuri ng mode.

Display the sl ope distance af ter N-times or si ngl e measureme nt.

Coordinate measurement mode.

Displays the coordinate after N-times or single measurement.

TURN F1 Turns the instrument to required angle automatically.

SO F2 Stake out measurement mode.

MEAN F3 Sets the number of N-time measurement.

m/ft F4 Switches meter or feet unit.

MEAS F1

Starts coordinate measurement mode.

Changes continuous/ N-times (single) measurement mode.

MODE F2 Chang es Fine / Coarse(1mm) /Co arse(10 mm) m ode.

VH F3 Angle me asurement mode.

SD F4

HD F5

Slope distance measuri ng mode.

Display the sl ope distance af ter N-times or si ngl e measureme nt.

Horizontal distance measurement mode. Displays the horizontal distance

data after N-times or single measurement.

TURN F1 Turns the instrument to required angle automatically.

HT F2 Input Instrument / prism height values.

MEAN F3 Sets the number of N-time measurement.

m/ft F4 Switches meter or feet unit.

SET F5 Pre-set instrument coordinate values.

1-6

Page 18

1 NOMENCLATURE AND FUNCTIONS

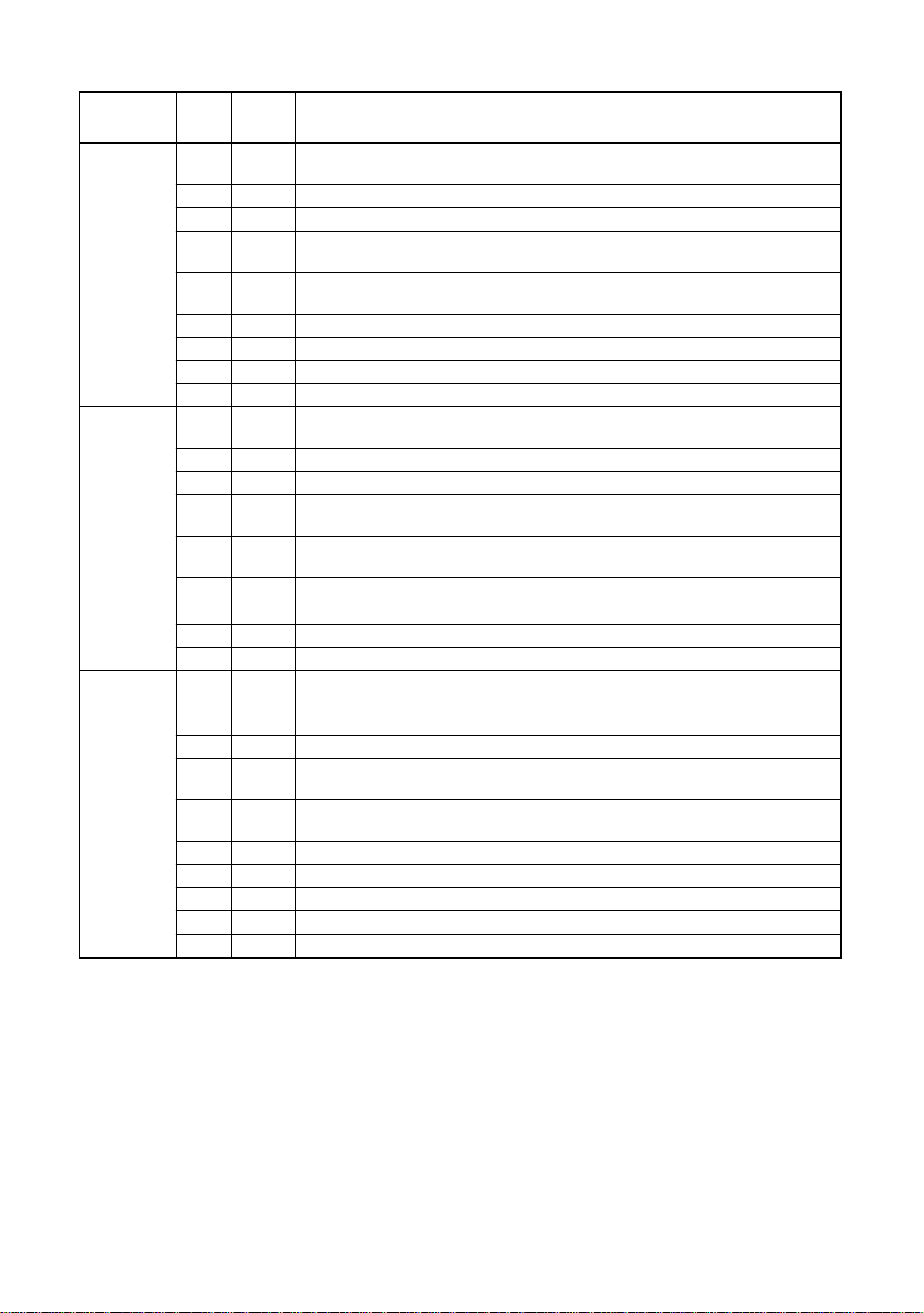

1.5 Star key (*key) mode

Press the (H) key to view the instrument options. Since there are three screens of options, press

[F6](1↓) soft key to view the next screen.

The following instrument options can be selected from the (H):

Screen One

•

1)View Dat e & Time

2)Auto-tracking [F1]

3)Auto-collimating [F2]

4)Set the parameters for Auto-tracking.[F3]

5)Auto- inversio n [F4]

6)Electric circular graphic display[F5]

Screen Two

•

7)Adjustment the co ntrast of the displa y [F1 & F2]

8)Turn the back light of the display ON/OFF [F3]

9)Reticle illumination---Off / Low / Medium / High [F4]

10) View free memory for internal and card memory [F5 ]

Screen Th ree

•

11) The light acceptance quantity level (signal level) is displayed.[F1]

12)Set the Temperature, Pressure, Atmospheric Correction Value (ppm), and Prism Constant

Va lue ( PSM ) [F2]

13)Turn the Tracking Indicator option ON/OFF [F3]

Auto-tracking

Auto-collimating

Set parameter for Auto-trackin g

Auto- inversion

Electric circular graphic display

Date & Time

Cont rast adjustment

Displaying

Signal Level

2003-10-10 14:30:40

1

↓

View free memory for Card/Internal Memory

Back Li ght of Displ ay

Reticle illumination

2003-10-10 14:30:40

2

↓

Set the Temperature, Pressure, Atmospheric Correction

Value (PPM), and Prism Constant Value (PSM)

Trac ki ng indicator

2003-10-10 14:30:40

3

↓

Screen 1

Screen 2

Screen 3

1-7

Page 19

1 NOMENCLATURE AND FUNCTIONS

1) View Date & Time

The date and time can be viewed on both screens. To change the displayed order of the date, (Date/

Month/Year), (Month / Date / Ye ar) or (Year/Month/Date), see Chapter 8 “PARAMETERS SETTI NG

MODE” .

To set the date a nd time, see Chapter 9 “CHECK AND ADJUSTMENT”.

2) Turn the auto-trackin g ON/OFF

Press the [F1] key to start auto-tracking. See Section 3.1 “Automatic Tracking” .

3) Turn the auto-collima tin g ON/OFF

Press the [F2] key to start auto-col lima ting. See Section 3.2 “Automatic Collimation” .

4) Set the parameters for the auto-tracking

A proper setting for each parameter such as tracking pattern, tracking range, waiting time, tracking

speed and trac ki ng se nsit ivity. See Section 3.4 “Set ting Par a me ter s for Aut o -Tracking” .

5) Auto Inversion

Pressing the [F4] key causes the instrument to reverse and turn the telescope and instrument

automatically.

l To stop auto rotating in case of emergency, press any keys except POWER key.

l During auto rotation, do not disturb the instrument.(Stopping the rotation with a touch of the hand).

Such action may cause trouble or harm to instrument or operator.

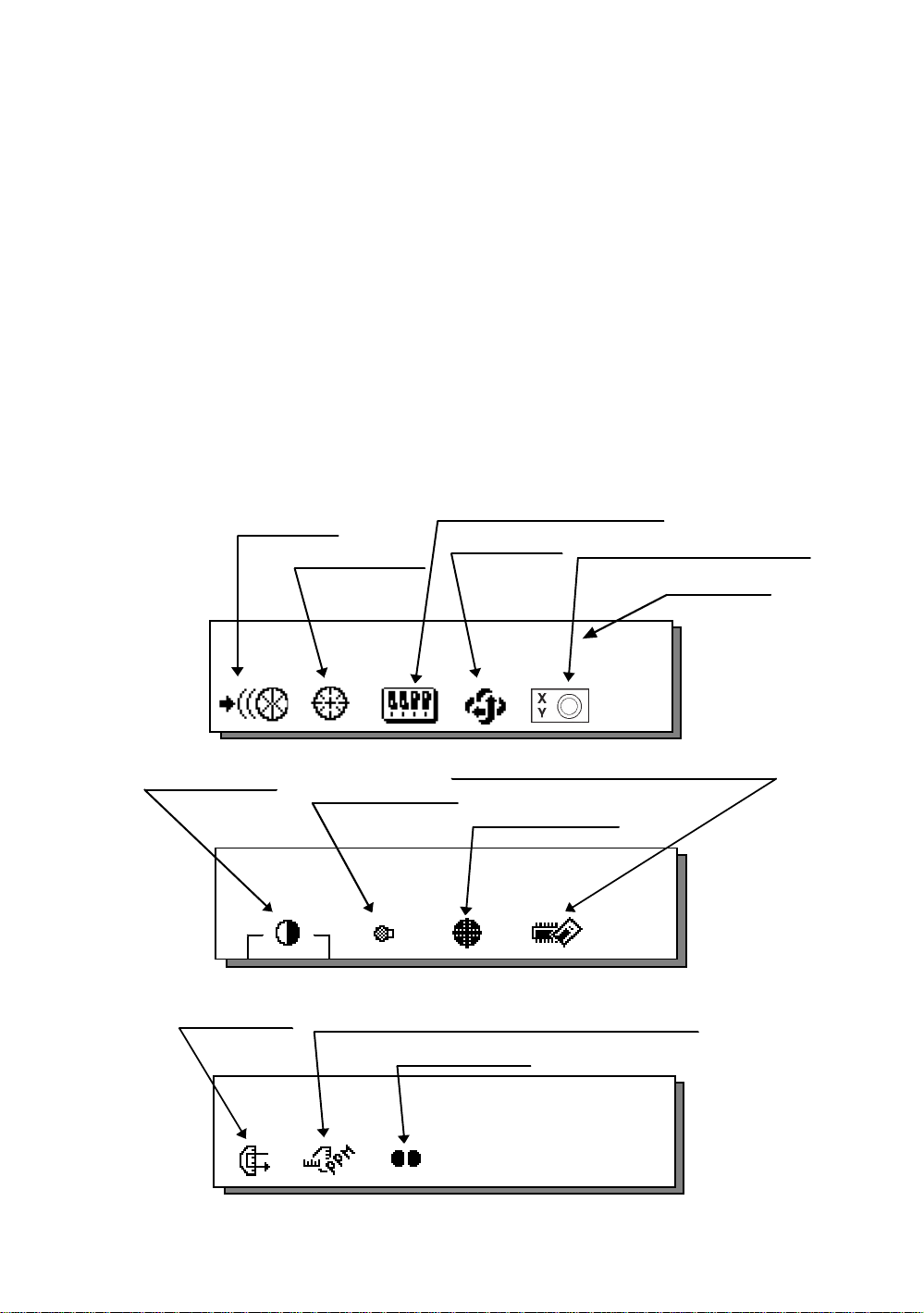

6) Electr ic circular level graphic display

Electric circular level can be displayed by graphic. This function is good for level the instrument when

the circular level is difficult to see directly.

Press the [F5] key to display the graphic.

In the displays of reverse side, the graphic bub ble mov es in reverse.

X:------------Y:-------------

Rotate the leveling screws while observing the display.

After leve ling, press [F1]. The display cha nge s to the prev ious mode.

7) Adjustme nt the contrast of the dis p lay

This enable you to adjust the contrast of the display.

Press the [F6] key to get to Screen 2 on the display.

Press the [F1] or [F2] key to brighten or dim the display.

8) Turn the display back light ON/OFF

When the back light is OFF, the light bulb icon is dark.

Press the [F6] key to get to Screen 2 on the display.

To turn the back light ON, press the [F3] key. Press [F3] again to turn the back light OFF.

OFF ON

X:+0°00'00"

Y:+0°00'00"

1-8

Page 20

1 NOMENCLATURE AND FUNCTIONS

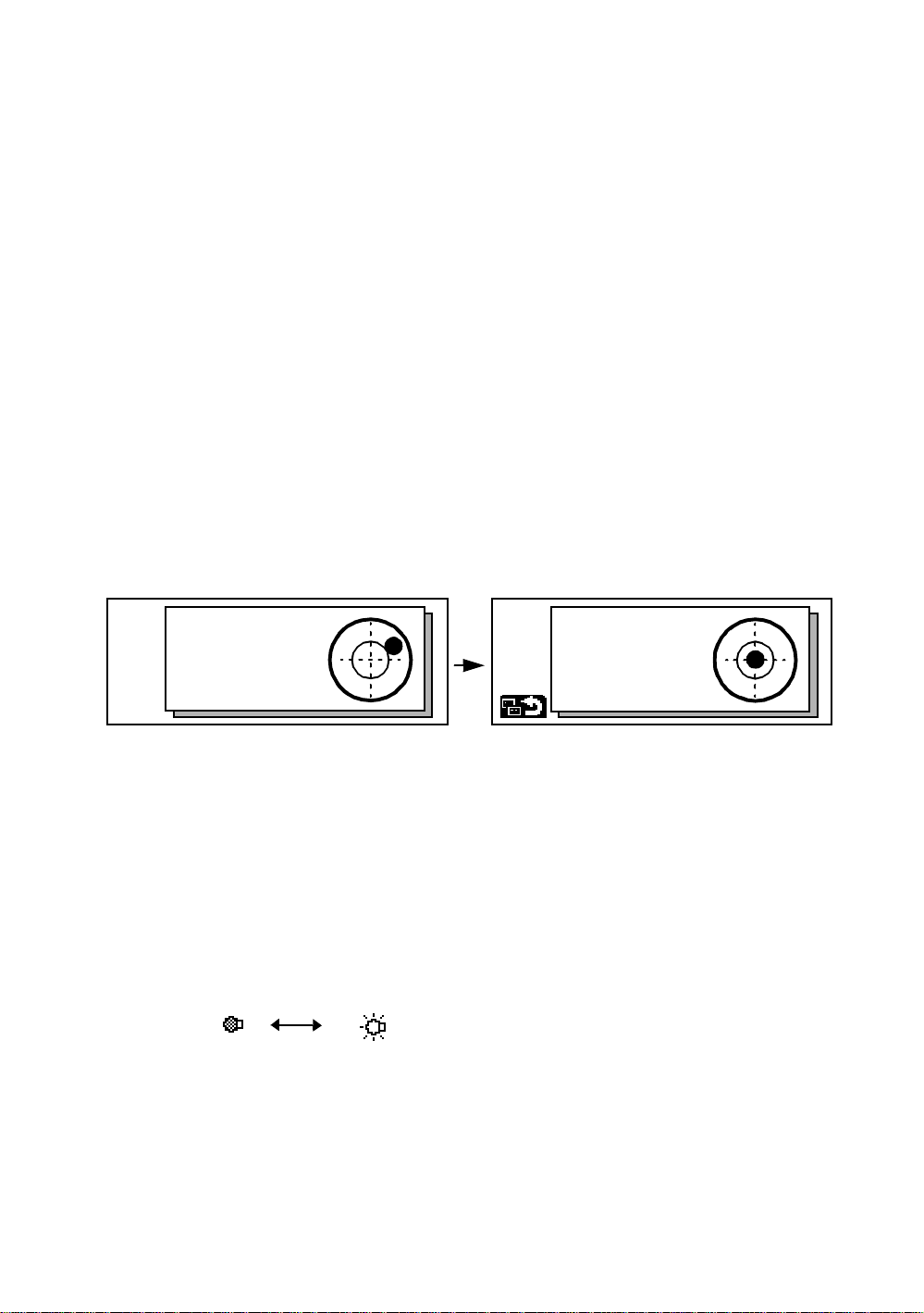

9) Reticle illumination (OFF/Low/Middle/High)

Press the [F6] key to get to Screen 2 on the display. Press the [F4] key to turn the reticle illumination

ON. Continuing to press [F4] will change the intensity options.

OFF

10) View free memory

The amount of free memory for the card or internal memory can be displayed.

Press the [F6] key to get to Screen 2 on the display.

Press the [F5] key to view free memory.

The card memory icon (top left side of the display) shows the size of the card and the amount of free

memory. The second icon shows the amount of free internal memory.

Card Memo r y

Internal Memory

See Chapter 6 “MEMORY MANAGE MODES”, for further options and instructions.

11) Set audio mode

The light acceptance quantity level (Signal level) is displayed in this mode.

When reflected light from the prism is rece i ved , a buzzer soun ds. This function is good for easy

collimation when the target is difficult to find.

Press the [F1] key on scre en 3.

The received return signal level is displayed with bar graph as follows.

Low

Middle

512KB

High

315KByte

1882KByte

No light acceptance

(1) To stop the buzzer, see Chapter 8 “PARAMETERS SETTING MODE”.

(2) Also, it is possible to display the signal level in Distance Measuring Mode.

12)Setting Temperature, Pressure, Atmospheric correction value (ppm), Prism constant value

(PSM)

The temperature, pressure, PPM, and PSM can be viewed by pressing the [F2] key on screen 3 .

The received return signal level is displayed with bar graph as follows.

Refer to Chapter 10 “SETTING THE PRISM CONSTANT VALUE” and Chapter 11 “SETTING

ATMOSPHERIC CORRECTION”, for further instructions.

Minimum quantity level

Maximum quantity l evel

1-9

Page 21

1 NOMENCLATURE AND FUNCTIONS

13)Tracking Indicator

A man who is staying on line with t he direc t ion of GTS-820A series or automatic tracking status by

emitted LED light (orange color) from GTS-820A series.

Operation

•

Pressing [F3] key on screen three functions Tracking Indicator. The tracking indicator status will be

changed a cco rding to the typ e of auto tra cki n g m ode an d i ts co ndi tions. A man from the prism side can

recognize t he status of instrument.

When angle measuring value turns stable during track ing still object, the tracking indicator changes

from quick con tinu ous fla shing to qu ick inte rm itten t flashing. S o you can dec ide fro m the sign of fla shing

for recording data timing at one person surveying.

OFF ON

Meaning of Tracking Indicator ON or Flashing

Trac ki ng Indicator Tracking status of instrument

Continuous ON Wait status

Slow flashing Manual mode

Quick continuous flashing

Quick intermittent flashing

In case angle measuring value is instable during auto tracking

mode.

In case angle measuring value is stable during auto tracking

mode.

l The function of the Tracking Indicator will be used as a guide to know the status of GTS-820A

series from the prism side. This is not a function to determine precise collimating for measuring.

l The quality of its results will depend on the weather conditions and the use's eyesight.

l Sometimes happens d i fficult y of seeing t he t r ack i ng ind i cator becaus e too mu ch bright of the beam

for tracking.

l Using Tracking Indicator mode will result shorter in reduced time out of the battery.

1-10

Page 22

1 NOMENCLATURE AND FUNCTIONS

1.6 Auto Power Off

The Auto Power OFF feature can be set from 1 to 99 minutes. If no keys are pressed within the set

time, the Auto Power OFF will automatically turn the instrument OFF in order to save the battery time.

See Chapter 8 “PARAMETERS SETTIN G MODE”, for furth e r inst ru ct ions.

1.7 Data Output

When GTS-820A series receives data output command from an external connected

device, the measured data will be output by GTS-820A series. Select from the following

2 ways for the output. (For setting, see Chapter 8 “PARAMETERS SETTING MODE” .)

REC-A : The measurement is started and new data is output.

REC-B : The data being displayed is output.

1.8 Rotating Method

1.8.1 Rotating by H/V Shuttle and H/V Jog

H/V shuttle or H/V jog can be used to rotate the instrument manually. The shuttle movement or

displacement is proportional in speed and size of angle desired. A small, slow turn of the shuttle will

result in a slow sma ll angl e displaced. L i kew ise, a larger abr up t turn of the shuttle will result in a coarse

angle displacement. H/V jog can be used for accurate collimating of the target much like a standard

tangent screw.

1.8.2 Auto Inversion

Pressing the [F4] key in Star Key mode causes the instrument to reverse and turn the telescope and

instrument automa tically.

l To stop auto rotating by auto inversion key in case of emergency, press any keys except POWER

key.

l During auto rotation, don't disturb the instrument.(Stopping the rotation with a touch of the hand).

Such action may cause trouble or harm to instrument or operator.

See Section 1.5 “Star key (*key) mode” for further instructions.

1.8.3 Rotating automatically to a required Horizontal and Vertical angle

In Standard Measu rem ent Modes, the instrument can be rot ate d autom at ically by inpu t a required

horizontal and/or vertical angle.

For further instructions, see Section 4.1.5 “Automatic Rotation to a Required Horizontal and Verti cal

Absolute Angle” .

V : 87°55'45"5

This mark will appear while the

instrument is rotating automatically.

HR: 180°44'12"5

SD HD NEZ 0SET HOLD P1

↓

1-11

Page 23

1 NOMENCLATURE AND FUNCTIONS

1.9 Using together with RC-2II Remote Control System

Using together with RC-2II Remot e Con tr ol System makes it possibl e to opti c al communi cat e betwe en

the inst rument and rem ot e controller RC-2RII, the pris m side. This gi ves easy operat ion by one man

surveying in applying programs.

Also connecting data collector to remote con troller, you can manage communication reciprocally

between the instrument and direct to data collector.

Turn-round function

You can turn the GTS-820A series round to the remote controller RC-2RII side easily by [Turn-round]

key of the remote controller RC-2RII. This function helps to increase one man surveying efficiency.

RC-2RII

See to Section 5.7 “External Link” and Chapter 8 “PARAMETERS SETTING MODE” for further

information.

l Set the transmit path to " RC".

l Set the transmit channel same as RC-2RII side.

l To execute transmission, set the remote in Programs mode to [Remote].

1-12

Page 24

1 NOMENCLATURE AND FUNCTIONS

1.10 Using connectin g with Personal C om pu ter (P C )

The auto-tracking function or auto collimating function makes easy remote control of the instrument

from PC. The followings are the main communication commands and explanations. How to

communicat e or more information s of communica ti on com ma nd, you can see the i nterface manua l

which provided optiona ll y.

Commands Action of GTS-820A series

Transmit

command

Mode setting

Transmit command for measured data

Transmit command for tracking mode

Transmit command for battery level The battery level will be out put.

Transmit command for coordinate of

instrument point

Transmit command for tracking

parameter

Setting of angle me asurement

Setting of distance measuremen t

Setting coor dinate of instrument point Setting the coo rdinate of instru me nt poi nt .

Setting the track i ng para me t er

Each measured data will be out put

according to t he command type.

The status of Aut om at ic Tr acking mode

will be out put.

Setting coordinate of instrument point will

be ou t put.

Each setting tracking parameter of

instrument will be out put according to the

command type.

Each selecting mode in horizontal angle

or angle measurement can be decided

according to t he purpose of comman d.

Setting the measurement mode for

distance me asurement.

Setting each tracking parameter

according to t he command.

Action

T.I. ON / OFF ON / OFF of Tracking indicator.

Rotating command Rotating of setting angle.

Inversion Inversion movement.

Setting trac ki ng mo de

Setting from automatic tracking mode to

each command mode.

1-13

Page 25

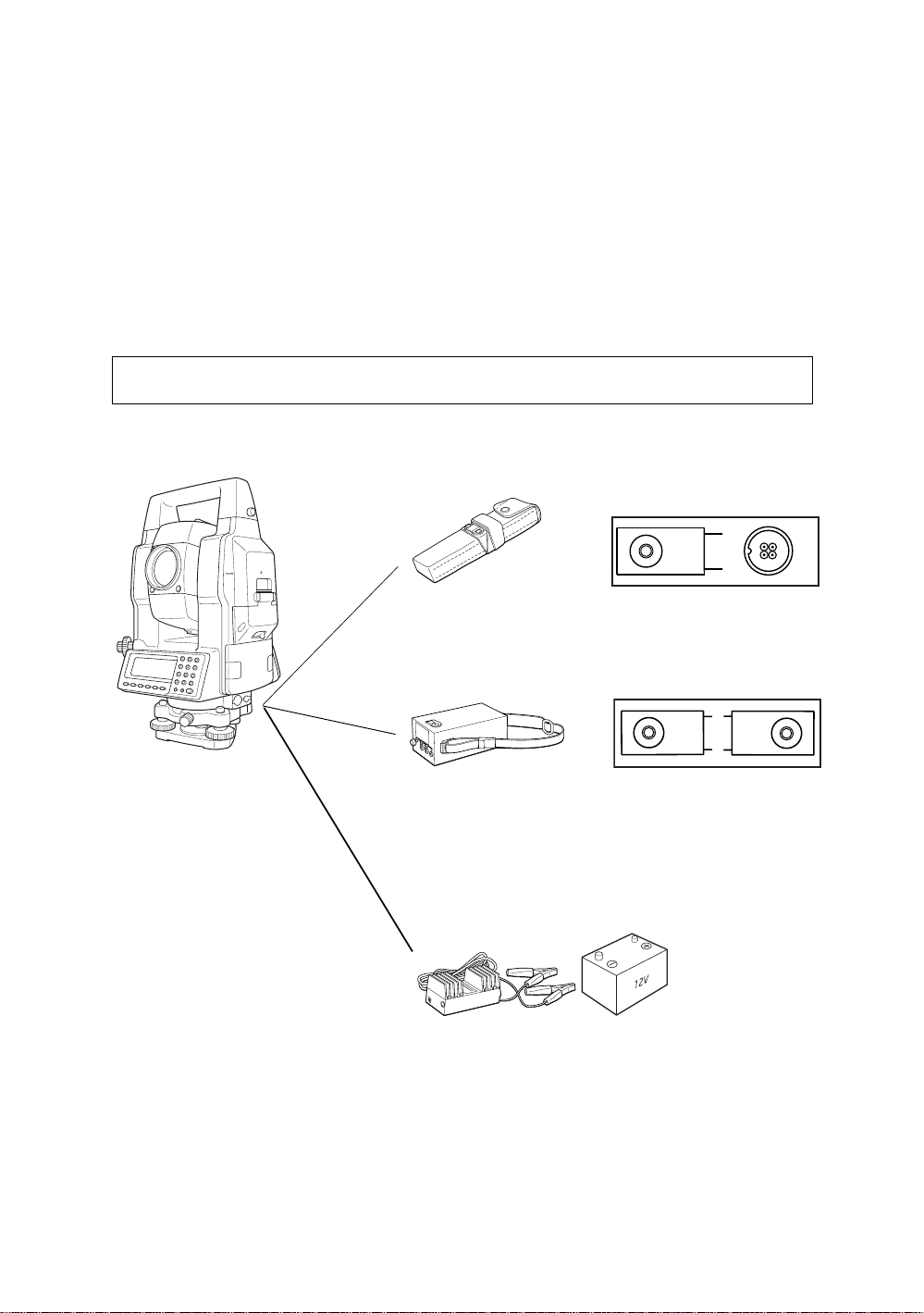

2 PREPARATION FOR MEASUREMENT

2 PREPARATION FOR MEASUREMENT

2.1 Power Connectio n

(unnecessary if on-board Ni-MH battery BT-56Q is used)

See below for connecting the external battery pack.

Battery pack BT-3Q

l

Power cord , PC-5 is used.

Large capacity battery pack BT-3L

l

Power cord PC-6 is used.

l When using a external battery, the rechargeable battery BT-56Q should be attached

(The instrument will lack in balance if the internal battery BT-56Q is removed.)

The external batter y and th e inter nal ba ttery can be used at the same time. The GTS- 820 A seri es

will select a battery due to the battery remaining automatically.

PC-5

Connector ends

BT-3Q

PC-5

PC-6

PC-5 or PC-6

BT-3L

2-1

AC-6

PC-6

External 12V Battery

Page 26

2 PREPARATION FOR MEASUREMENT

Leveling screw C

9

2.2 Setting Instrument Up For Measurement

Mount the instrument to the tripod. Level and cente r the instr um en t pre cise l y to ins ur e the best

performance. Use tripods with a tripod screw of 5/8 in. diameter and 11 threads per inch, such as the

Type E TOPCON wide- frame wooden tripod.

Reference: Leveling and Centering the Instrument

1. Setting up the Tripod

First, e xtend t he ex tens ion legs to s uita ble l engths

and tighten t he screws on thei r midsec ti ons.

2. Attaching the Instrument on the Tripod

Head

Place the instrument carefully on the tripod head

and slide the instrument by loosening the tripod

screw. If the plumb bob is p osit ioned right over the

center of th e point, slightl y ti gh t en the tri po d

screw.

3.

Roughly Leveling the Instrument by Using the Circular

Level

1 Turn the leveling screws A and B to move the

bubble i n t he c i rcular level. The bub ble is now

located on a line perpendicular to a line

running thr oug h the cen ters of t he two l evel ing

screws be i ng adjusted.

Leveling

screw A

2 Turn the leveling scre w C to bring the bubble

to the center of the cir c ular level.

4. Centering by Using the Plate Level

1 Ro tat e the instrument horizontally by using

the Horizontal motion/c l am p scr ew and place

the plate level parallel with the line connecting

levelin g screw s A and B, and then brin g the

bubble to the center of the plate level by

turning leveling screws A and B.

Leveling screw B

2 Ro t ate the instrument 90° (100g) around its

vertical axis and turn the remaining leveling

screw or C to center the bubble once more.

Leveling screw C

0

3 Repeat the procedures 1 and 2 for each 90°

(100g) rotation of the instrument and check

whether the bubble is corr ectly centere d for all

four points.

5. Centering by Using the Optical Plummet

Telescope

Adjust the eyepiece of the optical plummet

telescope t o your eyes ight.

Slide the instrument by loosening the tripod

screw, place the point on the center mark, and

then tighten the tripod screw. Sliding the

instrument carefully not to rotate that allows you

to get the least dislocation of the bubble.

Point

Center mark

6. Completely Leveling the Instrument

Leveling the instrument precisely in a similar way

to 4. Rotate the ins trum ent and check to see that

the bubble is in the center of the plate level

regardless of telescope direction, then tighten the

Leveling

screw A

Leveling

screw B

tripod screw hard.

2-2

Page 27

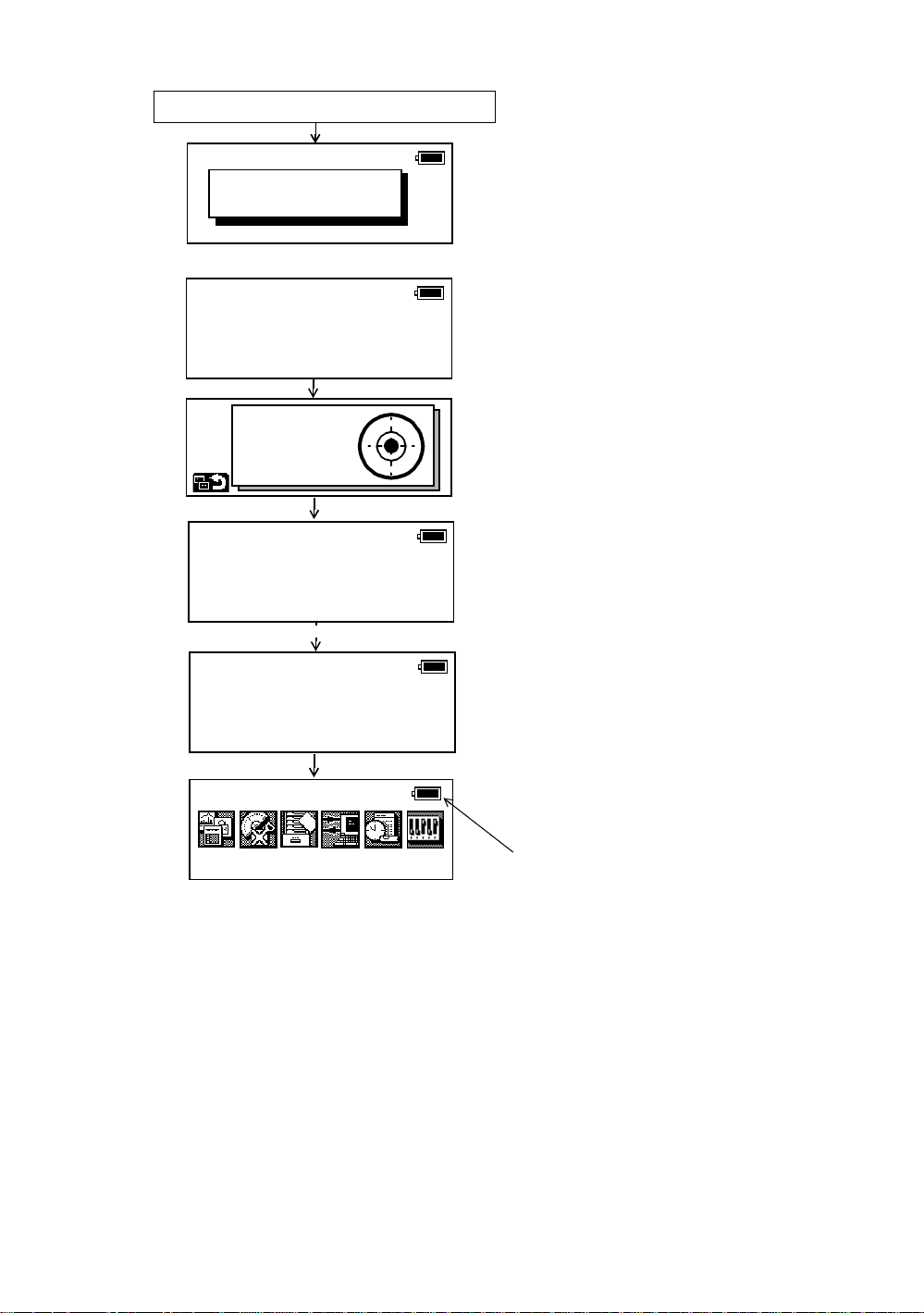

2.3 Power Switch Key ON

)

g

d

e

Power ON

2 PREPARATION FOR MEASUREMENT

1) Confirm the instrument is leveled.

2) Turn the power switch ON.

Input a password

[ ]

Self check mode

ESC

X:+0°00'00"

Y:+0°00'00"

Self checking ...

[ 1/6 ]

Self checking ...

[ 6/6 ]

3) Type your password.

Self checki n g mode will disp lay.

To skip the self checking , pr ess [F1 ] (ES C

key.

Level the ins trumen t by turning t he leveli n

screws.

When the leveling is within ±30" and

stable, the self checking will start.

The instrument will turn automatically and

the tilt sensor offset value will be measure

and me mo rized.

2003-10-10 14:30

Prog

Std Mem

Main menu icons

Self checking option

l

The self checking f unc ti on is to che ck i nternal communicat ion and ti lt sens or of f set value.

When ambient tem per at ur e is cha nged or the i nstrument is not balanc ed by its int e rnal battery is

attached or detach ed, the self che cki n g is reco mm end ed.

Password option

l

Setting a password (Maximum 10 digits number) and activating ON of password option can be helpful

to avoid miss operation by unauthorized operator.

Setting password option is necessary to use this function.

To set password option, see Chapter 8 “PARAMETERS SETTING MODE” .

Choosing the first mode when turning on the instrum ent

l

You can choose the first mode from the following modes when turning on the instrument.

1. Main Menu 2. Standard Measurement Mode 3. External Link

See Chapter 8 “PARAMETERS SETTING MODE” .

ON/OFF of a self check function can also be chosen.

l

See Chapter 8 “PARAMETERS SETTING MODE” .

l Confirm the battery power remaining on the display. Replace with charged battery or charge when

battery level is low. Refer to Section 2.4 “Battery Level Indicator” .

Comm

Adj

Para

After checki ng, the mai n me nu icon s wi ll b

shown.

Battery Power Remaining Display

2-3

Page 28

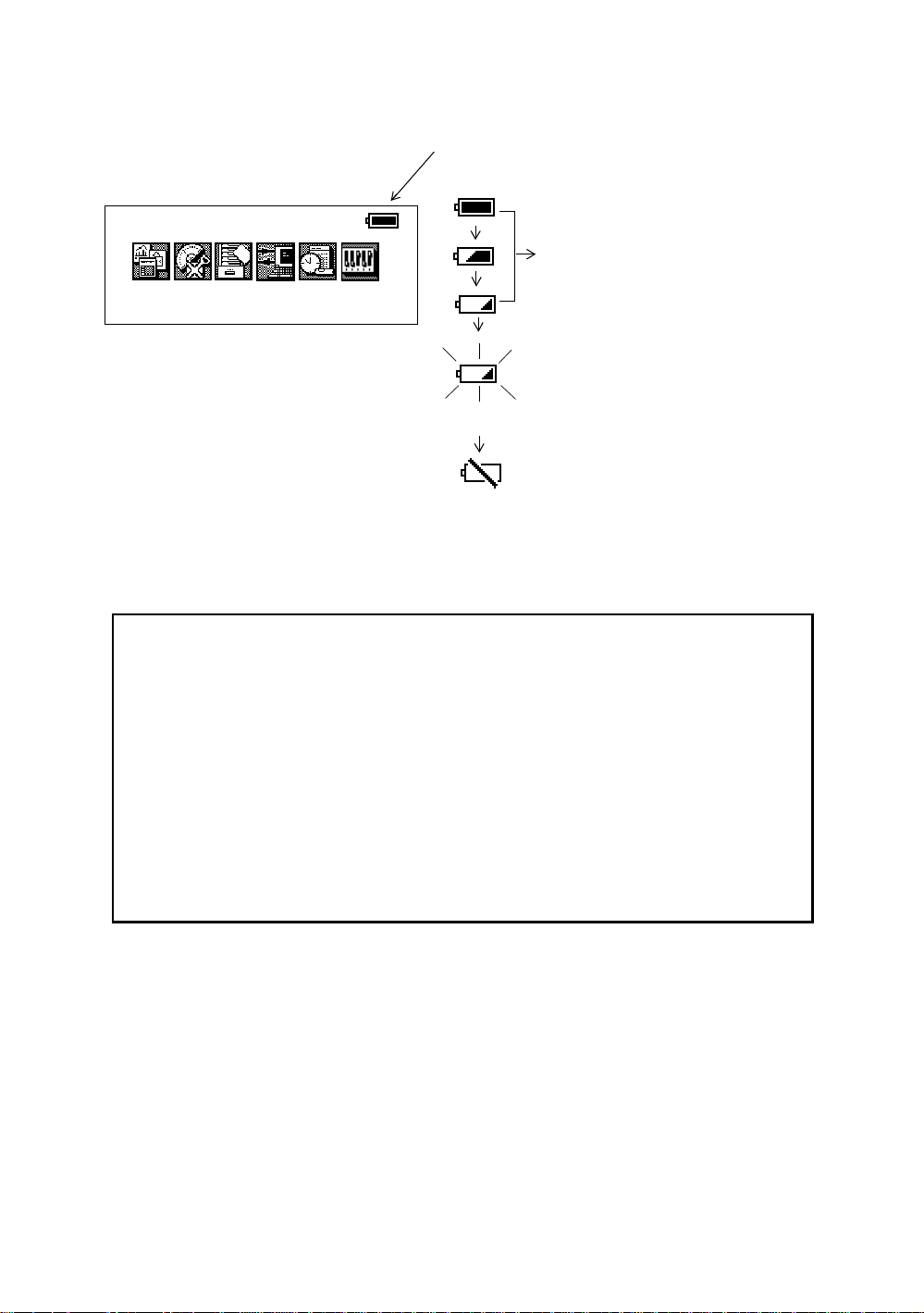

2.4 Batter y Level Indicator

The battery power indicator shows the level of battery strength.

Indicates Battery Power Remaining

2003-10-10 15:30:40

2 PREPARATION FOR MEASUREMENT

Measurement is possible.

Prog

Note:

1) The battery operating time will vary depending on the environmental conditions, such as

ambi ent temper ature, chargin g time, and t he number of tim es charging and discharging the

battery.

2) In low temperature (especially while the heater of display is working), the battery operating

time will shorten to one-half of normal temperature use.

3) The indicator for battery power remaining shows the power level during each measurement

mode. The condition indicated for the battery power remaining in the angle measurement

mode may not be adequate to measure a distance. Changing from angle mode to distance

mode during a poor battery condition may cause the EDM not to measure a distance.

We recommend that you check the battery condition before going into the field.

4) Also note, when changing from one measurement mode to another, the battery indicator may

not show a decr eas e or an i ncr ease i mm ediately. The batt ery i ndicator syste m was desi gne d

to show the general condition for the battery strength. It does not respond instantly.

5) For more information on battery usage, refer to Chapter 13 “POWER SOURCE AND

CHARGING” .

Mem Comm

Std

* Battery power remaining display is omitted in this manual.

Adj

Para

Blinking

The power is p oor. The batter y sho ul d be

recharged or replace the battery.

(Angle me asurent can only be possi ble,

the auto-collimating, auto-tracking and

distance maesurenat can not be

possible.)

Measurement is impossible. Need to

recharge or replace the battery.

2-4

Page 29

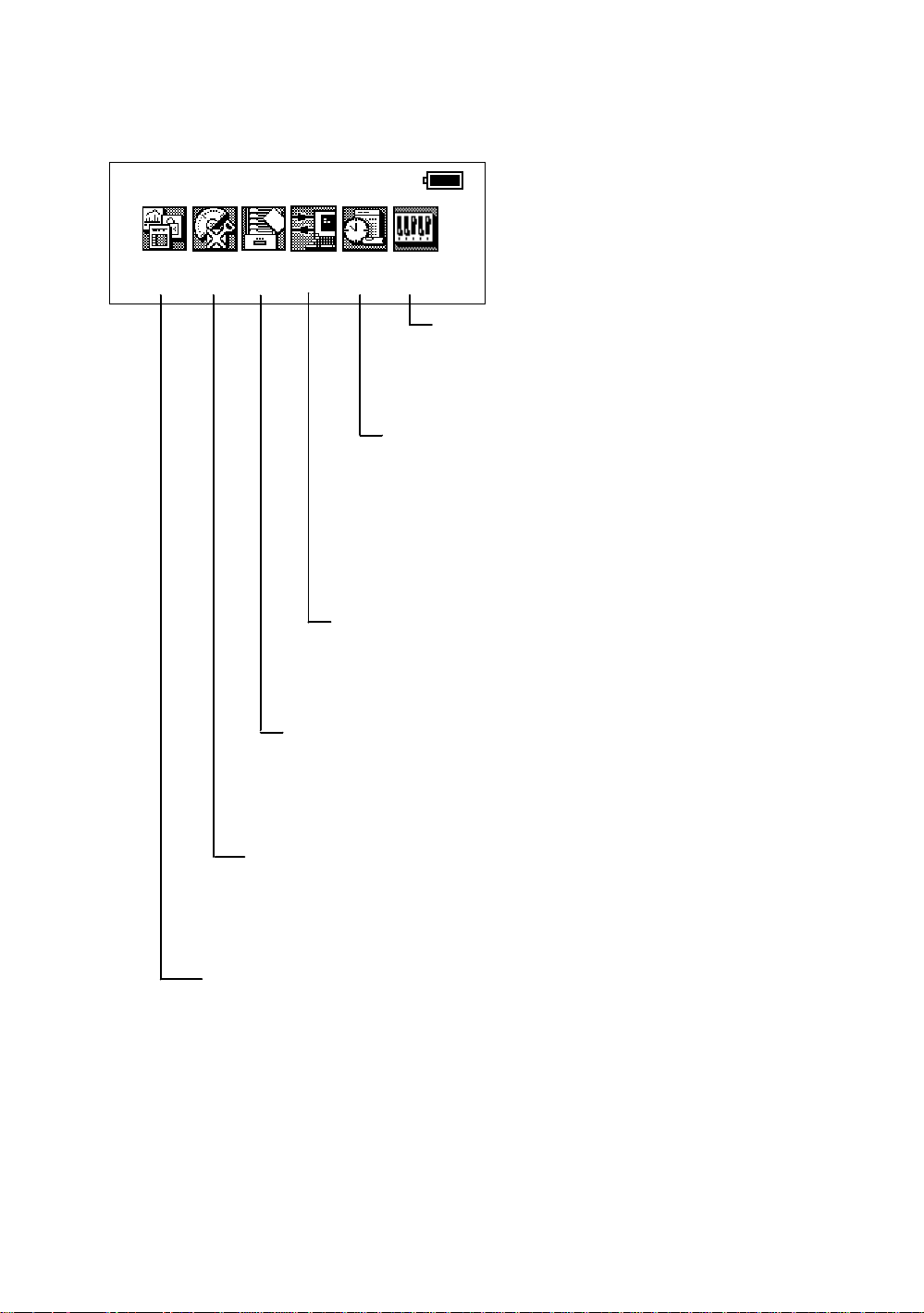

2.5 Main Menu Icons

The main menu icons are as follow s.

Select t he men u by pressi ng soft k eys ([F1]~[F6]).

2003-07-10 15:30:40

2 PREPARATION FOR MEASUREMENT

Prog

Std

Mem Comm

Adj

Para

PARAMETERS SETTING MODES

The PARAMETE RS SETTING MODES are

stored in memory once the instrument is OFF.

(See Chapter 8 “PARAMETERS SETTING

MODE”.)

ADJUSTMENT MODES

Used for checki ng and adjust m ent.

l Systematic errors adjust m ent for com pensa tion.

l Show compensation value s of systemati c erro rs of

instrument

l Set Date & Time

l Set instrument constant value

l Reference frequency of EDM

l Optic Axis for Auto-tracking

(See Chapter 9 “CHECK AND ADJUSTMENT”.)

COMMUNICATION MODES

l Set communica ti on with external instrument

l Input/Output a data file

l Load application program.

(See Chapter 7 “COMMUNICATION MODES”.)

MEMORY MANAGE MODES

l Display memory status

l Pro tect/ Er as/Renam e/Copy File s,

l Initialize a card or internal memory.

(See Chapter 6 “MEMORY MANAGE MO DES” .)

STANDARD MEASUREMENT MODES

l Angle measurement

l Distance measurement

l Coordinate measurement

(See Chapter 4 “STANDARD MEASUREMENT MO DE ” .)

PROGRAM MODES ( APPLICATION MEASUREMENT)

l Set a direction angle for h orizontal orientation

l Retain Coordinate (STORE-NEZ)

l Remote elevation measuremen t

l Missing line me asurement

l Line measurement

l External link

l Off set measurement

(See Chapter 5 “PROGRAM MODES” .)

2-5

Page 30

2 PREPARATION FOR MEASUREMENT

V

W

X

S

P

O

T

Q

D

U

R

|

2.6 Vertical and Horizontal Angle Tilt Correction

When the tilt sensors are activated, automatic correction of vertical and horizontal angle for

mislevelment is displayed.

To ensure a precise angle measurement, tilt sensors must be turned on. The display can also be used

to fine level the instrument. If the (TILT OVER) display appears the instrument is out of automatic

compensation range and must be leveled manually.

Zenith

Standing axis

Standing axis

Inclination of the standing

axis in the X direction

Zenith

Inclinati on of the standing

axis in the Y direction

X

U

R

|

Trunnion axis

Horizontal

W

V

T

S

Q

P

D

O

l GTS-820A seri es compensates bot h th e vert i cal angle and the hor i zontal angle r eadings due to

inclination of the standing axis in the X and Y directions.

l For more information about dual axis compensation, see Chapter “APPENDIX” “Dual Axis

Compensation”.

When the instrume nt t il ted ove r correc t ion

range.

X:

Y:

Rotate the leveling screws and level the

instrument.

After leveling (when each axis is within ±1'30 "),

the display returns to the previous mode

automatically.

X:+0°00'00"

Y:+0°00'00"

X,Y tilt correction range : within ±4'

l The display of Vertical or Horizontal angle i s unst able when i nst ru me nt is on an uns ta ble stage or a

windy day. You can turn off the auto tilt correction function of V/H angle in this case. To set TILT

correct ion mod e ON/O FF, refer to next page or Chapter 8 “P AR AME TE RS SETTI N G MODE ”.

2-6

Page 31

Setting Tilt Correction by Soft Key

l

Enable you to select tilt ON/OFF function on page 2.

The setting performed here will be me morized after powering OFF.

[Example] Setting X,Y Tilt ON

Operating procedure Option Display

1

Press [F6] key to get the function page 2.

2 PREPARATION FOR MEASUREMENT

V : 87°55'45"

HR: 180°44'12"

[F6]

2

Press [F5](TI LT) key.

Current setting is displayed. *1

3

Press [F2]( ON- 2) key.

The display sh ow s t ilt cor r ection value .

4

Press [F1] key.

The display returns previous mode.

*1) Pressing [F6](ESC) key, the display returns previous mode.

l The tilt sensor setting will be stored in memory when the instrument is turned OFF.

The tilt sensor option can al so be changed in t he Parameter Setting Modes. When you change t he tilt

sensor option in the angle measurement mode, it will change in the Parameter Setting Modes and visa

verse.

[F5]

[F2]

[F1]

SD HD NEZ 0SET HOLD P1

REC HSET R/L V/% TILT P2

TILT ON (V)

ON-1 ON-2 OFF ESC

X:+0°00'00"

Y:+0°00'00"

2.7 Compensat ion of Systematic Error of Instrument

1) Error of vertical axis (X,Y tilt sensor of f se t )

2) Collimat ion err o r

3) Erro r of ve r tical angle 0 datum

4) Error of horizontal axis

The above mentioned errors can be compensated by software, which calculated internally

according to each compensation value.

Also these er rors can be compensat ed by software collima t ing one sid e o f the telescope t hat i s

carried out to delete the error by turning in normal and reverse both sides of telescope so far.

↓

↓

l To adjust or reset the above compensation value, see Chapter 9 “CHECK AND ADJUSTMENT” .

l Enable you to st op this function, se e Chapter 8 “PARAMETERS SETTING MODE” or Chapter 9

“CHECK AND ADJ U STMEN T” .

2-7

Page 32

2 PREPARATION FOR MEASUREMENT

2.8 Resume Mode ON/OFF

The Resume mode will memorize the last display or mode when the power is turned OFF.

When the power is turned bac k ON, the last display or mode will be shown.

The Resume mode option only appears when the power is OFF.

Power switch key OFF

Power off

Resume mode

OFF ON ESC

[F1] [F2]

Pressing [F1](OFF) key or [F2](ON) key, select the resume mode.

2.9 How to Enter Numerals and Alphabet Letters

Alpha and numeri c charact er k ey entr y is simple and quick from the key board.

[Example] Renaming a file in the Memory Manager Modes.

Operating procedure Option Display

Rename

Old name [TOPCON .DAT]

New name [

1

Press [F1](Alpha) key to be entering alphabet

letter mode.

2

Enter Alphabets. *1)

Type “H”

Move cursor

Type “I”

Type “L”

Type “

”

3

Press [F1](Num) key to be entering numeric

mode.

Input “104”

[F1]

[9][9]

[F4]

[9][9][9]

[4][4][4]

[3][3][3]

[F1]

[1][0][4]

Alpha SPC ← →

Rename

Old name [TOPCON .DAT]

New name [HIL

Num SPC ← →

Rename

Old name [TOPCON .DAT]

New name [HIL

]

]

104 ]

Alpha SPC ← →

4

Press [ENT] when complete.

*1) When the same alpha key is to be typed two or more times consecutively, press [F4](→) key between

characters. This moves the cursor to the right.

*2) Extensions can not be changed.

[ENT]

2-8

Page 33

2.10 Memory Card

How to i n sert a memor y card

2 PREPARATION FOR MEASUREMENT

1) Pull the ca rd c over lever to open the

card cover.

2) Insert a memory card until the card

guide is up.

3) Close the card cov er.

Card cover lever

Card guide

Memory card

How to extract a memory card

1) Pull the card cover lever to open the card

cover.

2) Pull down the card guide.

3) Extract the memory card.

Card guide

2-9

Page 34

2 PREPARATION FOR MEASUREMENT

2.11 Inclination of Prism and Measuring Error

For the best results, aim or point prism s in the di recti on of the GTS-820 A series so t hat maximum signal

can be returned to the instrument. Sighting prism obliquely because of inclined settings, may result in

measuring errors. These errors will be proportional to the misalignment as showing in following graphs.

The more misali gnment of the prism, the more error in me asurement.

Measured data can be different according to the prism constant value. This can occur when a prism is

moving. Pin- pole prism set L1 ( for one-person surveying) and pin-pole pris m holder L1 (for fixed point

observation) are designed to minimize measuring error in such case. Make the best use of them. In

case you are forced to use the normal prism in inclined state because there is no other way possible,

we recommend to use switching holder, prism constant value (0 or 30mm), and set to 30mm

(Compensation value of -30mm).

Prism constant value : 0mm

Prism

Inclined angle

Measuring

point

Instrument

point

Prism constant value : 30mm

Inclined angle

2-10

Page 35

Prism type-2 (Normal prism)

l

2 PREPARATION FOR MEASUREMENT

Increasing

distance

range

( mm )

l

Increasing

distance

range

( mm)

-1

Distance Measuring er ror

6

5

4

3

C=0

2

C=30

1

0

-1

0

10

20

Inclined angle (degree)

Prism type - 3 or 5 (Prism unit A2/A3)

Distance Measuring er ror

4

3

2

C=0

1

C=20

0

C=30

0

10 20 30

Incli ned angle (degree)

C=40

Angle error

range

( mm )

30

12

8

Angle error

range

4

( mm

0

-4

-2

22

14

18

0

Angle measuring error

C=0

6

2

C=30

C=40

0

0

10

20

30

Inclined angle (degree)

Angle me asuring error

C=0

C=20

C=30

10

20 30

Incli ned angle (degree)

(Example)

In case Prism constan t value (C) = 0mm, Prism inclinati on = 20°, Measuring distance = 100m by Prism

type-2 :

Distance error is :

l

From the graph prism type-2, the distance error shows in increasing range quantity 2.5mm along

curved li ne of C=0 when prism inclinati on i s 20° .

Angle error is :

l

From the graph prism type-2, along curved line of C=0 with prism inclination of 20°, find angle error

quantit y (14. 2m m) and cal cul ate angle error by the following formula.

-1

Angleerror range

Angle error =

------------------------------------------------------

tan

Measuring dis cetan

-1

14.2

=

--------------------

tan

100x10

3

=29″

2-11

Page 36

3 AUTOMATIC TR ACKING / AUT OMATIC COLLIMATION

3 AUTOMATI C TRACKING / AUTOMATIC

COLLIMATION

WARNING

l Cause eye injury or blindness.

Do not stare into beam.

CAUTION

l Let the laser beam reach the aimed object or the target without anybody else in the laser beam path. In

case you operate laser beam open, avoid rad i ating laser beam to the heig ht of man's head. It is quite

possible for the beam to enter into one's eyes, and it is possible to lose visual sight temporarily, and

lose one's caution and awareness of other dangers - avoid glaring beam.

3.1 Automatic Tracking

Measuring t he moving tar get in autom at ic t racking mode.

l The Coarse (10mm) mode is used for t he mov ing t arg et .

l Use a keyboard on the eyepiece side. When the keyboard on the opposition side is used an error

will be displayed to protect a worker from the radiation of the laser.

Operating procedure Option Display

1

Manually collimate the target prism using V/H

jog/shuttle.

2

Press the star [*] key to show the star key

options.

3

Press the [F1] key. The mode will be

automatic tr ac king mode.

The instrument search es the prism a nd t r ack s

automatically.

[

*

[F1]

]

V : 87°55'45"

HR: 180°44'12"

SD HD NEZ 0SET HOLD P1↓

V : 87°55'45"

HR: 180°44'12"

SD HD NEZ 0SET HOLD P1↓

2003-10-10 14:30:40

1

↓

3-1

Page 37

3 AUTOMATIC TR ACKING / AUT OMATIC COLLIMATION

4

Choose measuring modes by pressing the

soft keys.

Measuring starts.

Sample: Horizontal distance measuring

l If the target prism is lost during auto tracking status, the instrument will automatically change to Wait i ng

status and symbol mark will be switched. If the target is found during Waiting status, tracking resumes,

and if not, status changes to Searching status. When the target prism is found, tra cking will resume.

[F2]

V : 90°10'20"

HR: 120°30'40" PSM 0.0

HD: < PPM 0.0

VD: (m) *c.R

MEAS MODE VH SD NEZ P1↓

Automatic tracking

Tracking

status

Normal

Star key

mode

F1

mode

The target prism is lost

Waiting status

The target prism is not found

for some time

Searching status

l The following symbol marks are indicated at the right side of the display.

In all these sta tus, laser beam is emitt ing.

Track ing st at us

The target pr ism

is found

Waiting status

Searching status

l Aut o tracking stat us sometimes can be unst able fo r a few second s af t er the o pt ical p at h is disturbed.

l If the center of reticle and the center of the prism is not coincided, you should adjust optical axis for

auto-tr ack ing, refer to chapter 9"C hec k and adjus t me nt".

l In the not suitable operati n g condition in such the atmosph eri c con dit ion is not good by the heat

shimmer, or other bad weather condition, in the long distance of the auto-tracking limit, can be

happened not certain tracking or not tracking at the center of the prism.

3-2

Page 38

3 AUTOMATIC TR ACKING / AUT OMATIC COLLIMATION

3.2 Automatic Collimation

The function enables to collimate automatically so that the instrument searches for the cent er of th e

prism when t he tele scop i c is aimed a pr i s m roughly.

Use this mode for the obje ct which is stable.

l You can select Fine or Course mode for the distance measurement in auto-collimation.

Operating procedure Option Display

1

Manually collimate the target prism roughly

using V/H jog/ shuttle.

2

Press the star [*] key.

3

Press the [F2] key.

The instrument begins to collimate When it

searches the prism.

4

Choose measuring modes by pressing the

soft keys.

Measuring starts.

Sample: Horizontal distance measuring

[

]

*

[F2]

[F2]

V : 87°55'45"

HR: 180°44'12"

SD HD NEZ 0SET HOLD P1↓

V : 87°55'45"

HR: 180°44'12"

SD HD NEZ 0SET HOLD P1↓

V : 90°10'20"

HR: 120°30'40" PSM 0.0

HD: < PPM 0.0

VD: (m) *c.R

MEAS MODE VH SD NEZ P1↓

2003-10-10 14:30:40

1

↓

l In case the instrument could not find the prism during auto-collimating, the auto-collimating mode

returns to normal mode after displaying the mark as follows.

l If any key is pressed during auto-collimating, the auto-collimating mode returns to normal mode.

l After auto-collimating is finished, the instrument does not track the prism even if the prism is moved.

l The auto-tracking can be done correctly in the time of shaking prism, or in bad weather condition is not

good by the heat sh immer. Th e above cau tio n mark will be displayed after 10 seconds and the autotracking will be finished.

3-3

Page 39

3 AUTOMATIC TR ACKING / AUT OMATIC COLLIMATION

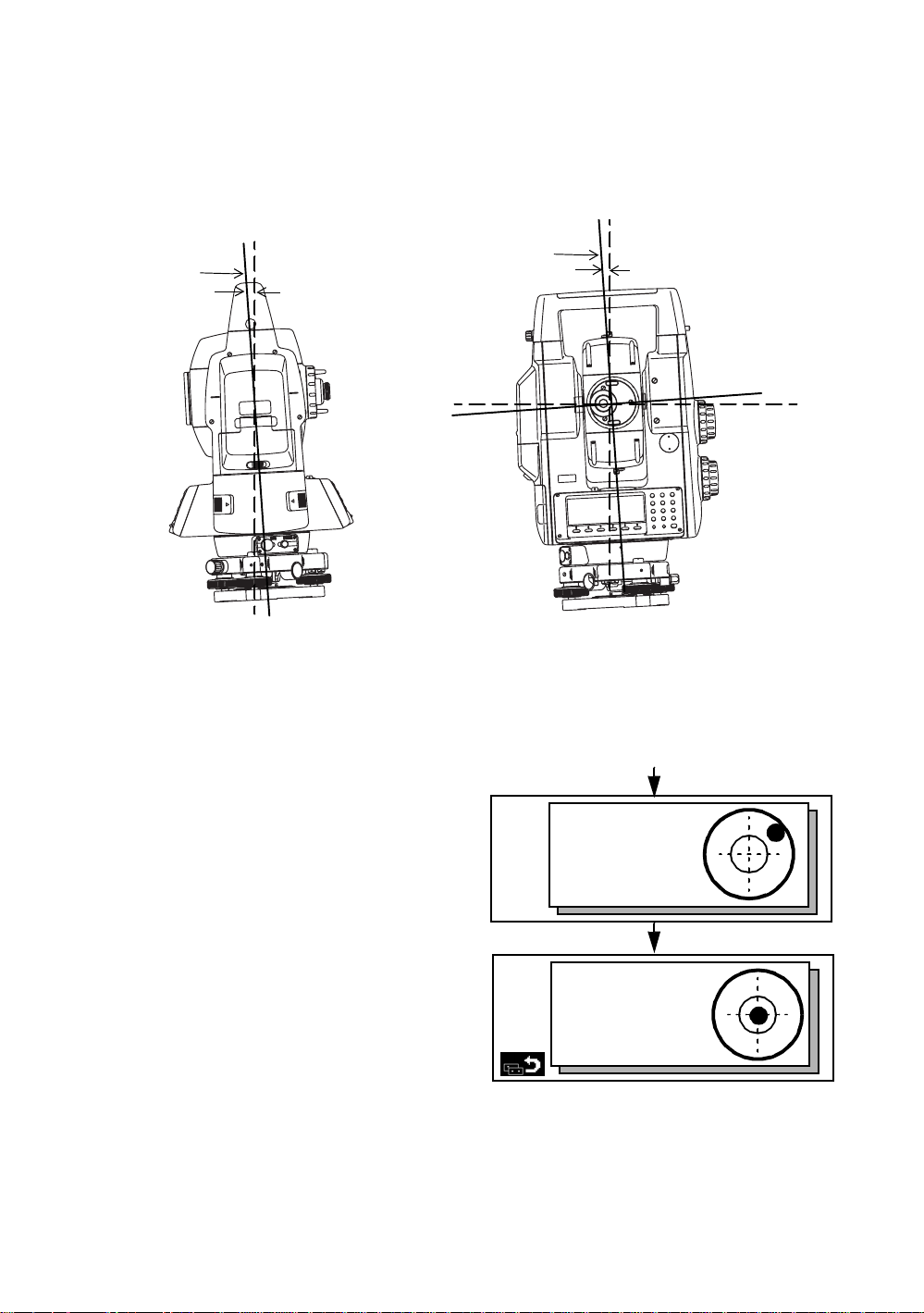

3.3 Range of Laser for Auto-tracking and Auto-collimating

The range of laser at the long di s tance is wi thin ±30' as shown i n following. So you had better collimate

the prism so that the prism may be located within this range of laser in the first step. As for it, rapid

automatic collimating and automatic tracking becomes possible. If the target prism is out of this range,

time for searching mode will be necessary.

Field of view

about ±30'

Range of laser

about ±30'

The range of the laser beam for auto-tracking in a short distance is same as a telescopic filed of view.

Therefore, quick starting of auto-tracking and auto-collimating are possible if the prism is contained in

the telescopic field of v iew.

3-4

Page 40

3 AUTOMATIC TR ACKING / AUT OMATIC COLLIMATION

3.4 Setting Parameters fo r Auto-Trackin g

A proper setting for each parameter are necessary for custom use.

The setting of the parameters can be done in the star key mode.

3.4.1 Setting Items

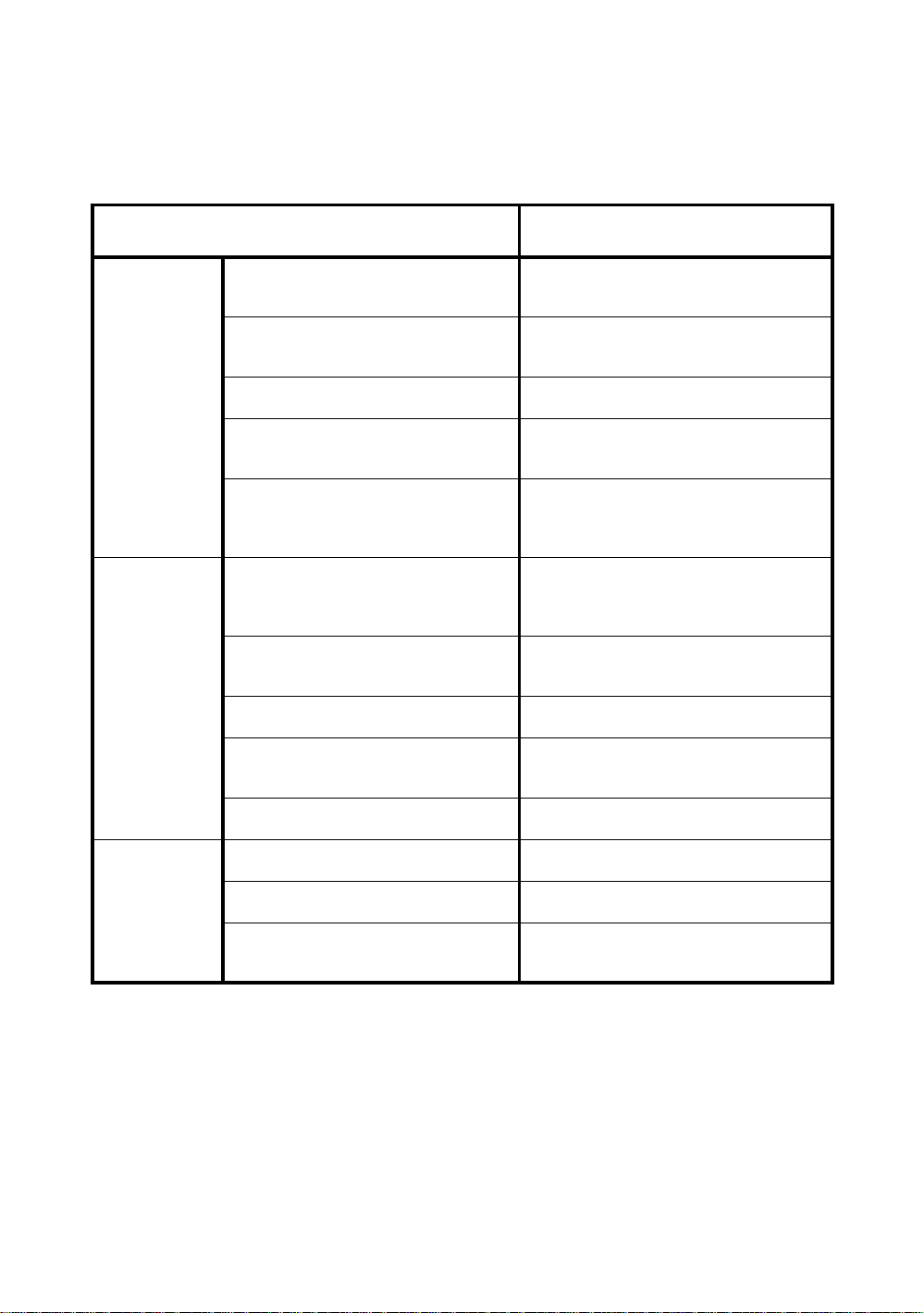

Items Selecting item Contents

SEARCH

PATTERN

SEARCH

RANGE

WAIT TI ME 0:00 to1:00:00

TRACKING

SPEED

REFLECTOR

TYPE

PREDICTION

CTRL TIME

PATTERN 1 The search range is the area to searche d fo r the pr ism by rotating

PATTERN 2

V:0° to 90°

H:0° to180°

(1sec. step)

HOLD

SURVEY Select your purpose.

MACHINE

CONTROL

PRISM The type of the reflector can be selected.

REFLECTOR

TAPE

0.5sec./ 1sec. /

2sec. /3sec. / 4sec

/ 5sec.

the telesc ope and body in sea rching.

The search range is the area to searche d fo r the pr ism by rotating

the telesc ope and body in sea r ching. The SEARC H range is

decided from the point where the prism lost, and the values will be

set to plus and mi nus di re ct ions in horizon tal and vertical. Al s o it is

enable to set each search pattern separately.

The time the prism is lost be for e GTS-820A series starts the

searching. If the mode is set to [HOLD], mode will not change to

searching.

After the instrument loses a prism, the time (prediction operation

time) for the instrument to continue moving operation can be set up.

1) Search Patterns

The search p att e rn i s the rotating method of teles cope and instru men t to f i nd the t arg e t prism in s ea rc h

mode. Search pattern includes the following 2 ways that can be selected.

This patter n can be selected to search the pr ism at the point where the prism is lost.

Instrument searches in up down direction gradually from the point whe re the prism is los t.

PATTERN 1

PATTERN 2

1) Things like hea t haze m ight interfer e w it h th e t r acking syste m in the long di s t anc e, near li mi t of auto

2) Reaction by rotating of inst r ume nt in search mode is se rious. Be sure of each connect io n part of the

The searching is arranged to 2 times until the prism is found.

The au t o tr acking mode changes to manual mode w hen the refl ec tor co ul d not found out

within 2 times searching, and returns to the point where the reflector is lost.

This patt ern can be selected to search for the prism. The search patt er n tri es to locate the

prism in a very short time.

The searching is arranged to 2 times until the reflector is found.

The au t o tr acking mode changes to manual mode w hen the refl ec tor co ul d not found out

within 2 times searching, and returns to the point where the reflector is lost.

tracking range, in search mode.

tribrach or tri pod are firmly.

2) Search Range

The search range is the area to searched for the prism by rotating the telescope and body in Searching.

The Search ran ge is decided fr om the point wher e the prism lost, and the values will be set to plus an d

minus directions in horizontal and vertical.

Select search pattern f ir st, and set the sea r ch r ange to the selected sear ch pattern . Als o it is enabl e to

set each search pattern separately.

3-5

Page 41

3 AUTOMATIC TR ACKING / AUT OMATIC COLLIMATION

[Examp le] SEARC H RANG E : 10° in horizontal, 5° in vertical

Search range

+5°

10°

Point where prism lost

-10° +10°

20°

Setting Sea rch ra nge requi res considera ti on . The items to think about: opti ca l path interrupted by other

objects; collimated point from GTS-820A series to prism is shifted a fter Turning and Searching

Command; possible other prisms, targets, or other objects to interfere with tracking the desired prism;