Page 1

INSTRUCTION MANUAL

PULSE TOT AL ST A TION

GPT-2000

SERIES

GPT-2003

GPT-2005

GPT-2006

GPT-2009

Page 2

Page 3

FOREWORD

Thank you for purchasing the T OPCON Pulse Total Station, GPT-2000 series. F or

the best performance of the instruments, please carefully read these instructions

and keep them in a convenient location for future reference.

1

Page 4

General Handling Precautions

Before starting work or operation, be sure to check that the instrument is

functioning correctly with normal performance.

Do not submerge the instrument into water.

The instrument can not be submerged underwater.

The instrument is designed based on the International Standard IP66, therefore it is

protected from the normal rainfall.

Setting the instrument on a tripod

When mounting the instrument on a tripod, use a wooden tripod when possible. The

vibrations that may occur when using a metallic tripod can effect the measuring precision.

Installing the tribrach

If the tribrach is installed incorrectly , the measuring precision could be effected.

Occasionally check the adjusting screws on the tribrach. Make sure the base fixing lever is

locked and the base fixing screws are tightened.

Guarding the instrument against shocks

When transporting the instrument, provide some protection to minimize risk of shocks.

Heavy shocks may cause the measurement to be faulty.

Carrying the instrument

Always carry the instrument by its handgrip.

Exposing the instrument to extreme heat.

Do not leave the instrument in extreme heat for longer than necessary. It could adversely

affect its performance.

Sudden changes of temperature

Any sudden change of temperature to the instrument or prism may result in a reduction of

measuring distance range, i.e when taking the instrument out from a heated vehicle. Let

instrument acclimate itself to ambient temperature.

Battery level check

Confirm battery level remaining before operating.

Taking the battery out

It is recommended not to take the battery out during the power is on. All the data stored is

possible gone at that time. So please do your assembling or taking the battery out after the

power is off.

Noise from the inside of instrument

When EDM turns on, the sound of motors from inside the instrument body may be

heard. This is normal and does not effect operation of the instrument.

2

Page 5

Display for Safe Use

WARNING

In order to encourage the safe use of products and prevent any danger to the operator and

others or damage to properties, important warnings are put on the products and inserted in the

instruction manuals.

We suggest that everyone understand the meaning of the following displays and icons before

reading the “Safety Cautions” and text.

Display

Ignoring or disregard of this display may lead to the danger of death or

serious injury.

CAUTION

•Injury refers to hurt, burn, electric shock, etc.

•Physical damage refers to extensive damage to buildings or equipment and furniture.

Ignoring or disregard of this display ma y lead to personal injury or ph ysical damage.

Meaning

Safety Cautions

WARNING

•There is a risk of fire, electric shock or physical harm if you attempt to disassemble or

repair the instrument yourself.

This is only to be carried out by TOPCON or an authorized dealer, only!

•Cause eye injury or blindness.

Do not look at the sun through a telescope.

•Laser beams can be dangerous, and can cause eye injury's if used incorrectly.

Never attempt to repair the instrument yourself.

•Cause eye injury or blindness.

Do not stare into beam.

•High temperature may cause fire.

Do not cover the charger while it is charging.

•Risk of fire or electric shock.

Do not use damaged power cable, plug and socket.

•Risk of fire or electric shock.

Do not use a wet battery or charger.

•May ignite explosively.

Never use an instrument near flammable gas, liquid matter, and do not use in a coal mine.

•Battery can cause explosion or injury.

Do not dispose in fire or heat.

•Risk of fire or electric shock.

Do not use any power voltage except the one given on manufacturers instructions.

•Battery can cause outbreak of fire.

Do not use any other type of charger other than the one specified.

•Risk of fire.

Do not use any other power cable other than the one specified.

•The short circuit of a battery can cause a fire.

Do not short circuit battery when storing it.

(Only for Laser plummet type)

(Only for Laser plummet type)

3

Page 6

CAUTION

•Use of controls or adjustment or performance of procedures other than those specified herein

may result in hazardous radiation exposure.

•Do not connect or disconnect equipment with wet hands, y ou are at risk of electric shocks if you

do!

•Risk of injury by overturn the carrying case.

Do not stand or sit on the carrying cases.

•Please note that the tips of tripod can be hazardous, be aware of this when setting up or carrying the tripod.

•Risk of injury by falling down the instrument or case.

Do not use a carrying case with a damaged which belts, grips or latches .

•Do not allow skin or clothing to come into contact with acid from the batteries, if this does occur

then wash off with copious amounts of water and seek medical advice.

•A plumb bob can cause an injury to a person if used incorrectly.

•It could be dangerous if the instrument falls ov er , please ensure y ou attach a handle battery to

the instrument securely.

•Ensure that you mount the Tribrach correctly, failing to do so may result in injury if the tribrach

were to fall over.

•It could be dangerous if the instrument falls over, please check that you fix the instrument to

the tripod correctly.

•Risk of injury by falling down a tripod and an instrument.

Always check that the screws of tripod are tightened.

User

1)

This product is for professional use only!

The user is required to be a qualified surveyor or have a good knowledge of surveying, in order to

understand the user and safety instructions, before operating, inspecting or adjusting.

2)Wear the required protectors (safety shoes, helmet, etc.) when operating.

Exceptions from Responsibility

1)The user of this product is expected to follo w all operating instructions and make periodic checks of the

product’s performance.

2)The manufacturer, or its representatives, assumes no responsibility for results of a faulty or intentional

usage or misuse including any direct, indirect, consequential damage, and loss of profits.

3)The manufacturer, or its representatives, assumes no responsibility for consequential damage, and

loss of profits by any disaster, (an earthquake, storms, floods etc.).

A fire, accident, or an act of a third party and/or a usage any other usual conditions.

4)The manufacturer , or its representativ es , assumes no responsibility f or an y damage , and loss of profits

due to a change of data, loss of data, an interruption of business etc., caused by using the product or

an unusable product.

5)The manufacturer , or its representativ es , assumes no responsibility f or an y damage , and loss of profits

caused by usage except for explained in the user manual.

6)The manufacturer, or its representatives, assumes no responsibility for damage caused by wrong

movement, or action due to connecting with other products.

4

Page 7

Safety Standard for Laser Beam

GPT-2000 series uses the invisible laser beam. The GPT-2000 series are manufactured and sold in

accordance with "Performance Standards for Light-Emitting Products" (FDA/BRH 21 CFR 1040) or

"Radiation Safety of Laser Products, Equipment Classification, Requirements and User`s Guide" (IEC

Publication 825) provided on the safety standard for laser beam.

As per the said standard, the GPT-2000 series plumb laser type is classified as "Class 1 (l) Laser

Products".

In case of any failure, do not disassemble the instrument. Contact TOPCON or your TOPCON dealer.

Safety Standard for Laser Beam

(Only for GPT-2000 series Plumb Laser Type)

GPT-2000 series plumb laser type uses the visible laser beam. The GPT-2000 series plumb laser type

are manufactured and sold in accordance with "Performance Standards for Light-Emitting Products"

(FDA/BRH 21 CFR 1040) or "Radiation Safety of Laser Products, Equipment Classification,

Requirements and User`s Guide" (IEC Publication 825) provided on the safety standard for laser beam.

As per the said standard, the GPT-2000 series plumb laser type is classified as "Class 2

Products".

In case of any failure, do not disassemble the instrument. Contact TOPCON or your TOPCON dealer.

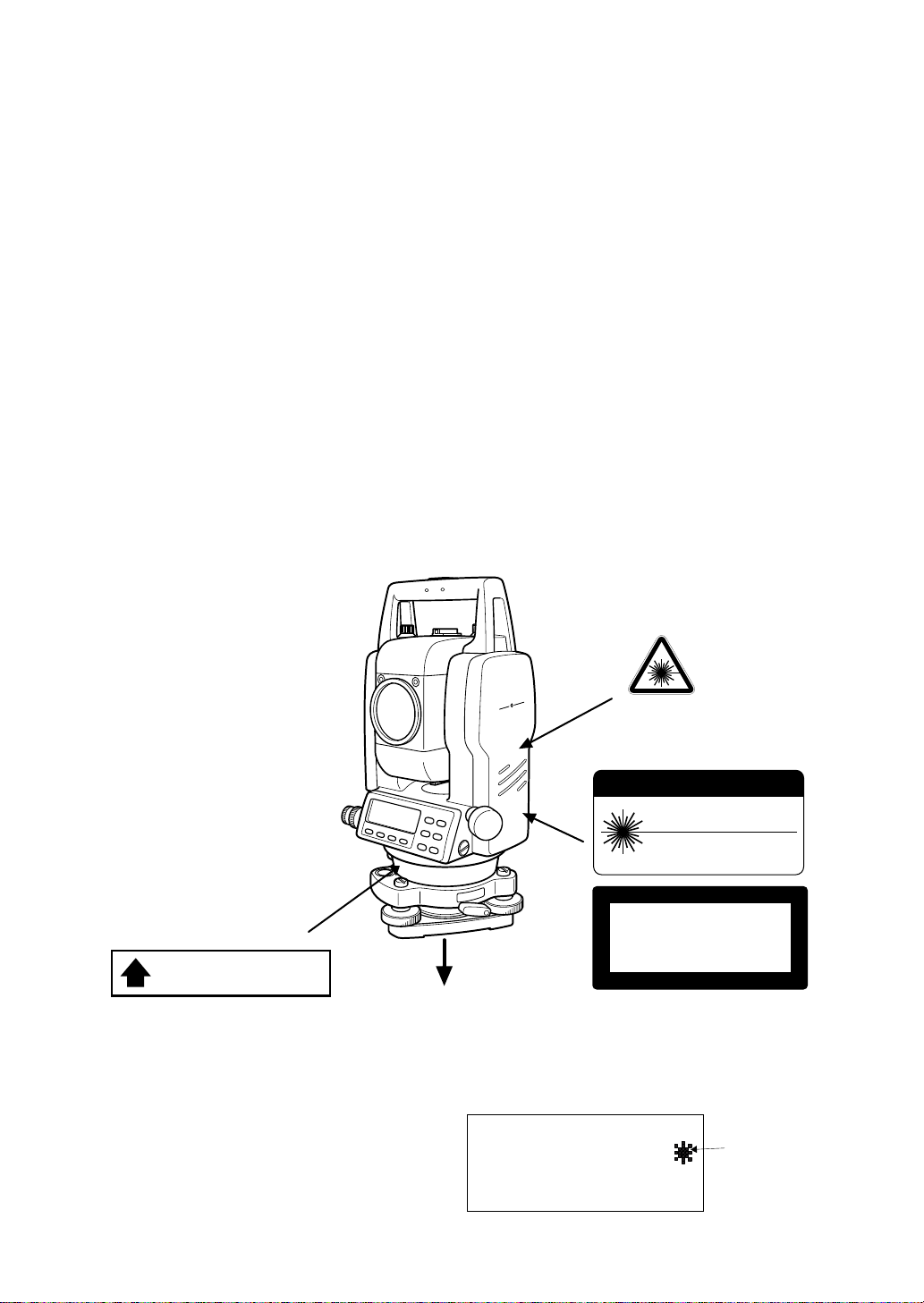

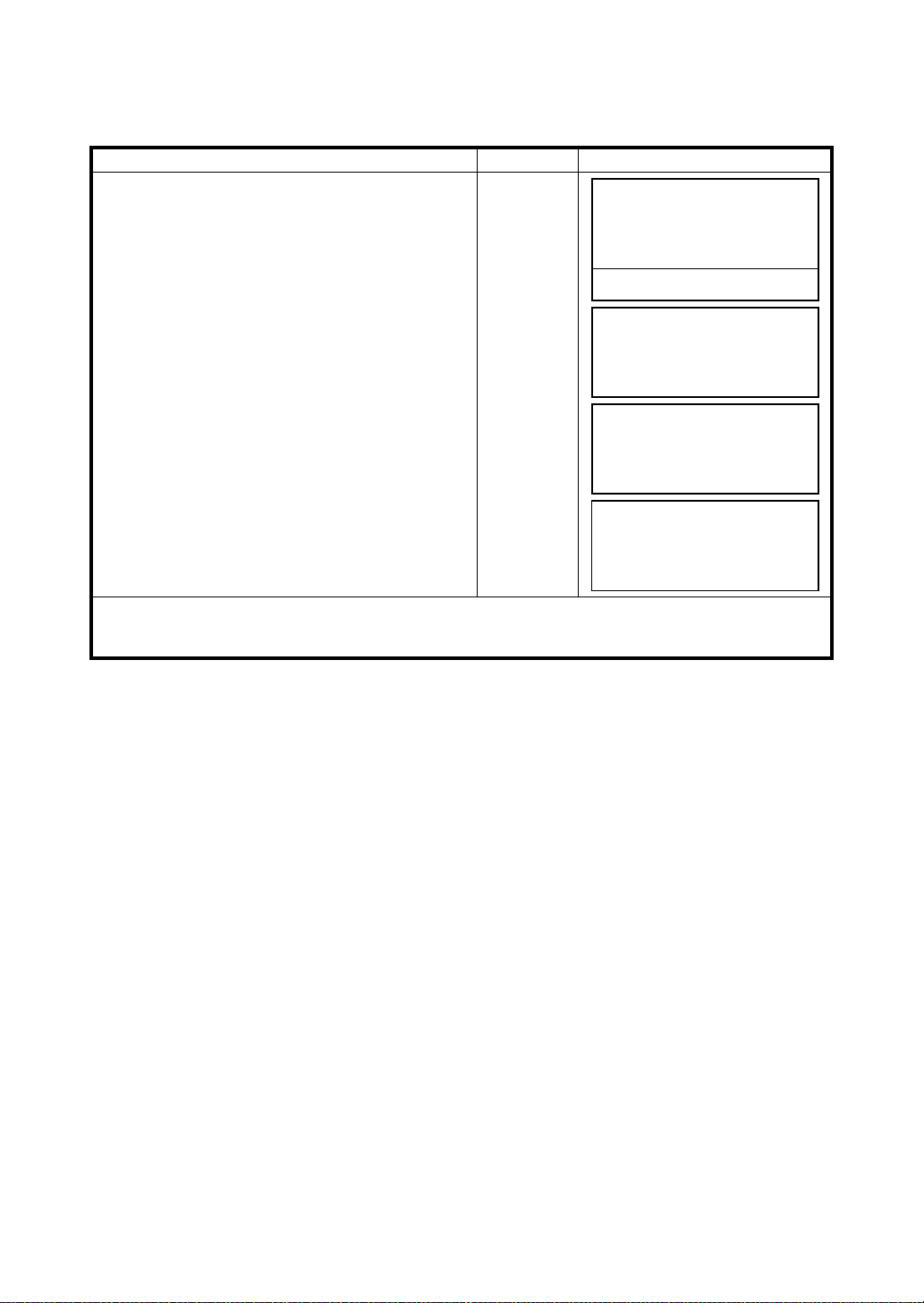

Labels

Find the labels which describes the caution and safety about the laser beam as follows in GPT-2000

series.

We request you to replace it one anytime the caution labels are damaged or lost and paste a new one

at the same place. You can get the labels from Topcon or your dealer.

GPT-2000 series

Laser Plummet type

(

II) Laser

Aperture Label

AVOID EXPOSURE

LASER LIGHT IS EMITTED

FROM THIS APERTURE

Depending on the country where the instrument is sold, either of these labels may be

found on the GPT-2000 series laser plummet type.

Beam aperture

Symbol mark while the laser is emitting.

The following symbol mark will appear at the

right side of the second line.

TILT SENSOR:[XY-ON]

X:-0°00'25"

Y: 0°00'20"

X-ON XY-ON OFF L.PL

Warning Label

Explanatory Label

CAUTION

LASER RADIATION-DO NOT

STARE INTO BEAM

WAVE LENGTH 633nm

1mW MAXIMUM OUTPUT

CLASS II LASER PRODUCT

LASER RADIATION

DO NOT STARE INTO BEAM

Maximum output1mW Wave length 633nm

CLASS2 LASER PRODUCT

Symbol mark

5

Page 8

Contents

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General Handling Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Display for Safe Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety Cautions

User. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Exceptions from Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety Standard for Laser Beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Standard for Laser Beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Symbol mark while the laser is emitting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Standard Set Composition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1 NOMENCLATURE AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 Operating Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.4 Function Key (Soft Key) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 Serial signal RS-232C connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2 PREPARATION FOR MEASUREMENT. . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Setting Instrument Up For Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Power Switch Key ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 Battery Power Remaining Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5 Vertical and Horizontal Angle Tilt Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6 How to Enter Alphanumeric characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.7 Point Guide (Only for Point Guide type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.8 Laser Plummet ON/OFF (Only for Laser Plummet type) . . . . . . . . . . . . . . . . . . . . . . . 2-9

3 ANGLE MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Measuring Horizontal Angle Right and Vertical Angle . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Switching Horizontal Angle Right/Left. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Measuring from the Required Horizontal Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.1 Setting by Holding the Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.2 Setting a Horizontal Angle from the Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.4 Vertical Angle Percent Grade(%) Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.5 Repetition Angle Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.6 Buzzer Sounding for Horizontal Angle 90° Increments . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.7 Compasses ( vertical angle). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

4 DISTANCE MEASUREMENT

4.1 Setting of the Atmospheric Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Setting of the Correction for Prism Constant / Non-prism Constant. . . . . . . . . . . . . . . 4-1

4.3 Distance Measurement (Continuous Measurement) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 Distance Measurement

4.5 Fine Mode/Tracking Mode/Coarse Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.6 Stake Out (S.O) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.7 Offset Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.7.1 Angle Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.7.2 Distance Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

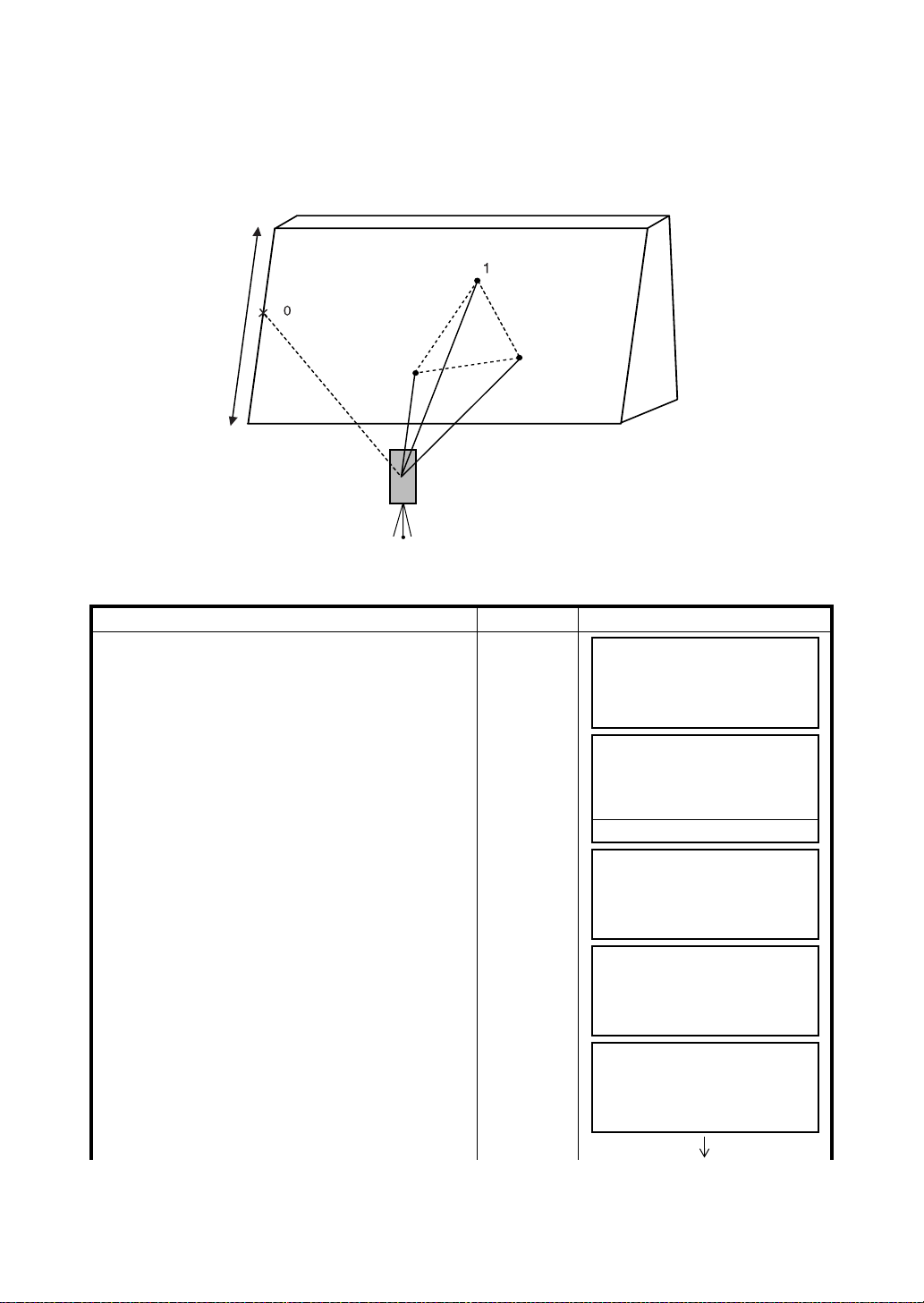

4.7.3 Plane Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.7.4 Column Offset Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

5 COORDINATE MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Setting Coordinate Values of Occupied Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Setting Height of the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 Setting Height of Target (Prism Height) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.4 Execution of Coordinate Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

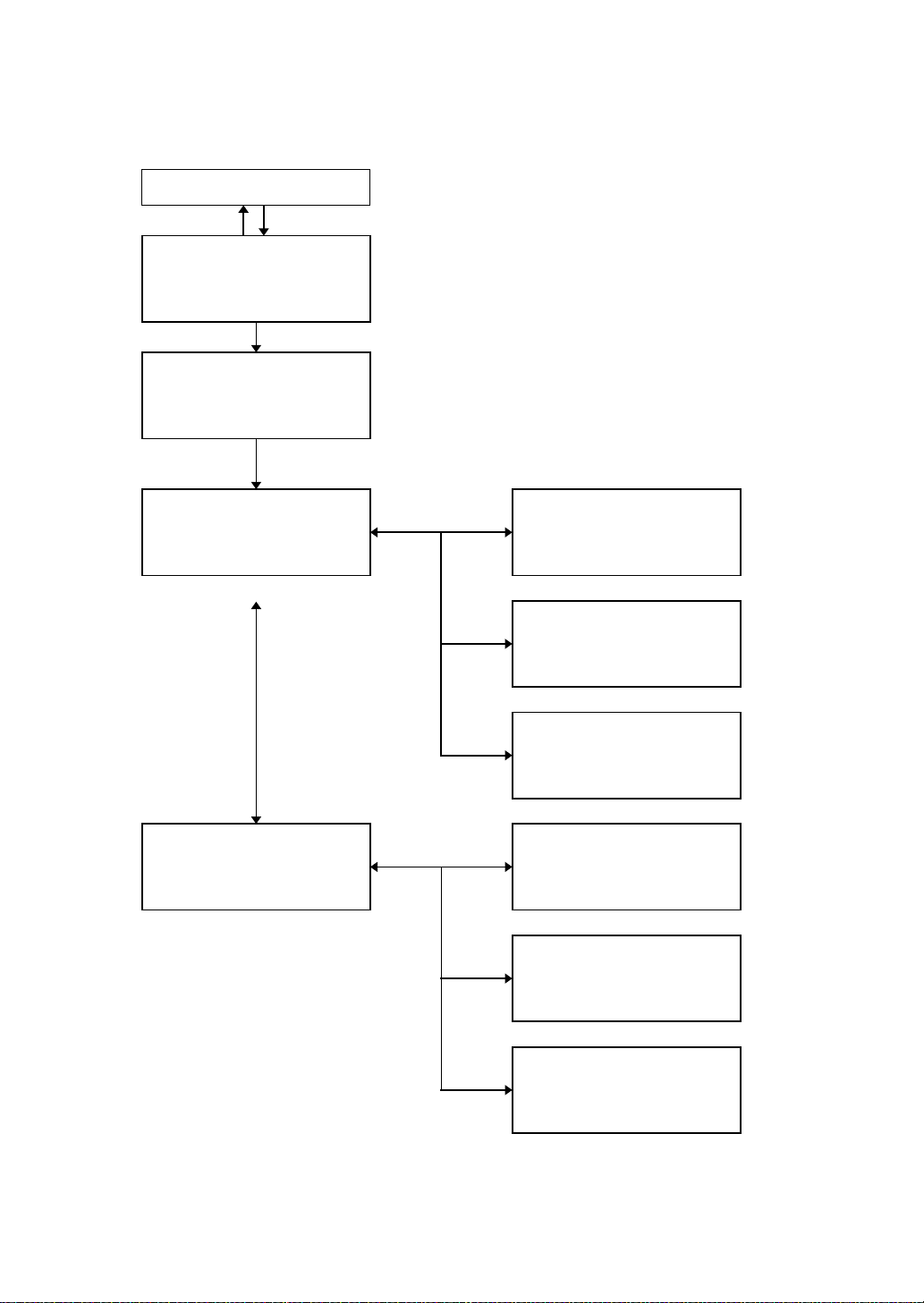

6 SPECIAL MODE (Menu Mode). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

..................................... ............. ...... 3

............................................................................................4-14-1

(N-time Measurement/Single Measurement). . . . . . . . . . . . . . . . . . . 4-3

4-14-1

6

Page 9

6.1 Application Measurement (PROGRAMS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.1.1 Remote Elevation measurement (REM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.1.2 Missing Line Measurement (MLM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.1.3 Setting Z Coordinate of Occupied Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.1.4 Area Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.1.5 Point to Line Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

6.2 Setting the GRID FACTOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

6.3 Setting Illumination of Display and Cross Hairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

6.4 Setting Mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.4.1 Setting Minimum Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.4.2 Auto Power Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.4.3 Vertical and Horizontal Angle Tilt correction ( Tilt ON/OFF) . . . . . . . . . . . . . . . 6-20

6.4.4 Systematic Error of Instrument Correction (only for GPT-2003/2005/2006) . . .6-20

6.4.5 Selecting Battery Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

6.5 Setting Contrast of Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

7 DATA COLLECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.1.1 Selecting a File for Data Collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.1.2 Selecting a Coordinate File for Data Collection . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.1.3 Occupied Point and Backsight Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.2 Operational Procedure of “DATA COLLECT” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.2.1 Searching the recorded data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.2.2 Entering PCODE / ID using PCODE Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.2.3 Entering PCODE / ID from the list of PCODE . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.3 Data Collect Offset Measurement mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7.3.1 Angle Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7.3.2 Distance Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

7.3.3 Plane Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

7.3.4 Column Offset Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

7.4 NEZ Auto Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7.5 Editing PCODE Library [PCODE INPUT] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

7.6 Setting Parameter of Data Collect [CONFIG.]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

8 LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

8.1.1 Setting the GRID FACTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

8.1.2 Selecting Coordinate Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.1.3 Setting Occupied Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.1.4 Setting Backsight Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

8.2 Executing a Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.3 Setting a New Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8.3.1 Side Shot Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

8.3.2 Resection Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-13

9 MEMORY MANAGER MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Display Internal Memory Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

9.2 Searching Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.2.1 Measured Data Searching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.2.2 Coordinate Data Searching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

9.2.3 PCODE LIBRARY Searching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

9.3 FILE MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

9.3.1 Rename a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.3.2 Searching Data in a File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

9.3.3 Deleting a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-9

9.4 Coordinate Data Direct Key Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

9.5 Delete a Coordinate Data from a File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

9.6 Editing PCODE Library. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

9.7 Data Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

9.7.1 Sending Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

7

Page 10

9.7.2 Loading Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

9.7.3 Setting Parameter of Data Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

9.8 Initialization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

10 SET AUDIO MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

11 SETTING THE PRISM / NON-PRISM CONSTANT VALUE . . . . . . . 11-1

12 SETTING ATMOSPHERIC CORRECTION . . . . . . . . . . . . . . . . . . . . 12-1

12.1 Calculation of Atmospheric Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12.2 Setting of Atmospheric Correction Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

13 CORRECTION FOR REFRACTION AND EARTH CURVATURE . . . 13-1

13.1 Distance Calculation Formula. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

14 POWER SOURCE AND CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

14.1 On-board Battery BT-52QA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

15 DETACH/ATTACH OF TRIBRACH. . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

16 SELECTING MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

16.1 Items of the Selecting Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

16.2 How to Set Selecting Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-3

17 CHECK AND ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-1

17.1 Checking and adjusting of instrument constant. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-1

17.1.1 Checking of the accuracy of the non-prism mode . . . . . . . . . . . . . . . . . . . . . . 17-1

17.2 Checking the Optical Axis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-2

17.3 Checking/Adjusting the Theodolite Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-4

17.3.1 Checking /Adjusting the Plate Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-5

17.3.2 Checking /Adjusting the Circular Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-5

17.3.3 Adjustment of the Vertical Cross-hair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-6

17.3.4 Collimation of the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-7

17.3.5 Checking / Adjusting the Optical Plummet Telescope . . . . . . . . . . . . . . . . . . . 17-8

17.3.6 Checking / Adjusting the Laser Plummet (For Laser Plummet type) . . . . . . . . 17-9

17.3.7 Adjustment of Vertical Angle 0 Datum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-10

17.4 How to Set the Instrument Constant Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-11

17.5 Adjustment of Compensation Systematic Error of Instrument . . . . . . . . . . . . . . . . 17-12

18 PRECAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

19 SPECIAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-1

20 BATTERY SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-1

21 PRISM SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-1

22 ERROR DISPLAYS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-1

23 SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-1

APPENDIX ..................................................................................... Appendix-1

Dual Axis Compensation ....................................................................................... Appendix-1

Precaution when Charging or Storing Batteries..................................................... Appendix-3

8

Page 11

Standard Set Composition

1) GPT-2000 series (with lens cap) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

2) On-board Battery BT-52QA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

3) Battery charger BC-27BR or BC-27CR . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

4) Tool kit with case [2 rod pins, screwdriver , hexagonal wrench

cleaning brush, silicon cloth] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 set

5) Plastic carrying case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

6) Sun shade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

7) Plastic rain cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

8) Instruction manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 each

(Make sure that all of the above items are with the instrument when purchased.)

Remarks:

1) Battery charger BC-27CR is for AC 230V use and BC-27BR is for AC 120V use.

2) Plumb bob set and plumb bob hook are supplied for certain markets.

3)

Additional On-board Battery BT-52QA may be included in some markets.

9

Page 12

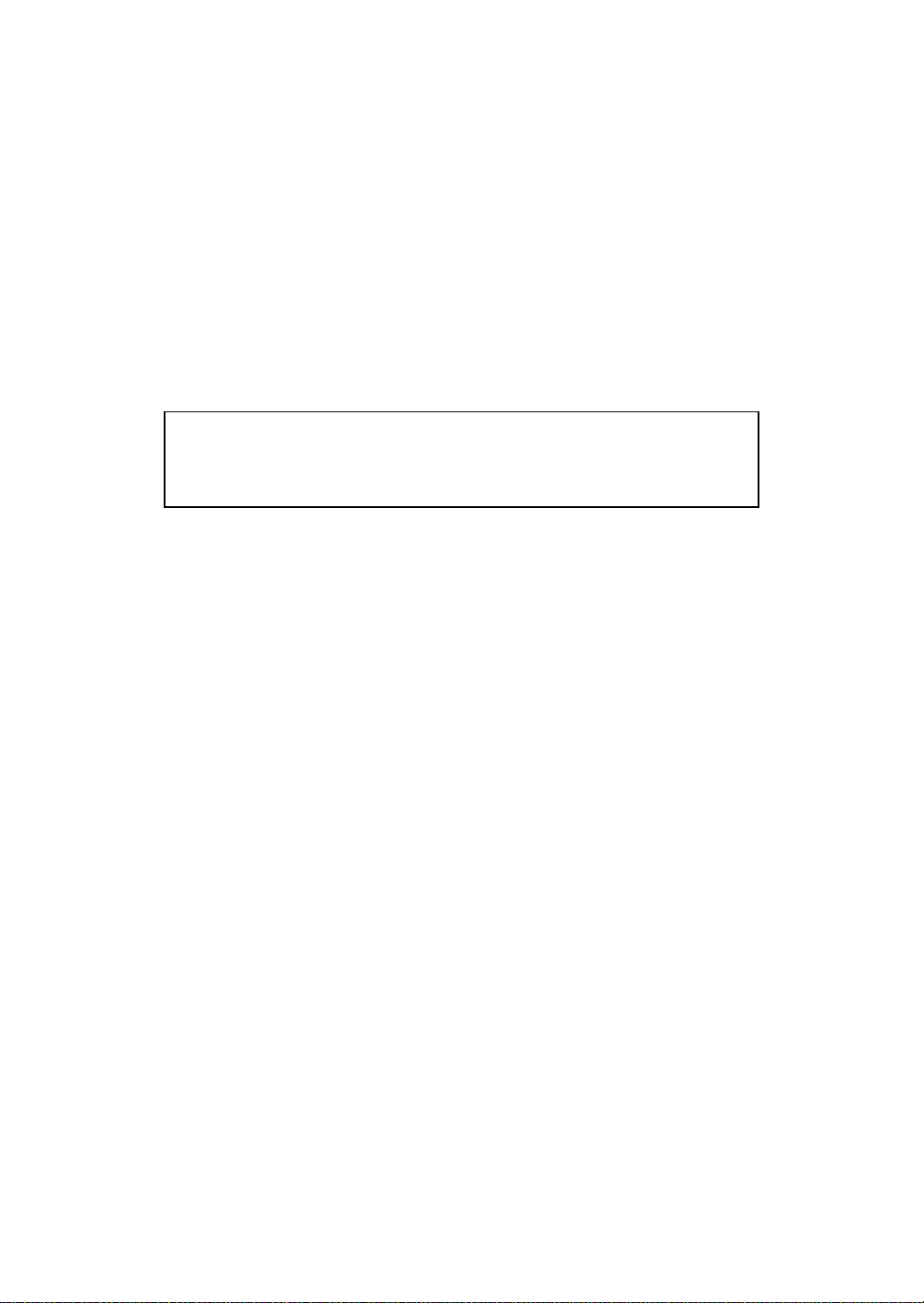

1 NOMENCLATURE AND FUNCTIONS

1 NOMENCLATURE AND FUNCTIONS

1.1 Nomenclature

Handgrip locking screw

Point guide

(Point guide type only)

Handgrip

Objective lens

Display unit

(Only for GPT-2003/

2005)

Circular level

Adjustment screw

for circular level

Tribrach fixing lever

Instrument

center mark

Optical plummet

telescope

(Optical plummet

telescope type only)

Leveling screw

Base

1-1

Page 13

Sighting collimator

1 NOMENCLATURE AND FUNCTIONS

Telescope focusing knob

Telescope grip

Telescope eyepiece

*Vertical motion clamp

*Vertical tangent screw

Plate level

Display unit

Battery locking lever

On-board battery

BT-52QA

Instrument

center mark

Horizontal

tangent screw

Horizontal

motion clamp

Power supply

connector

Serial Signal

connector

*The position of vertical motion clamp and Vertical tangent screw will differ depending on the market.

1-2

Page 14

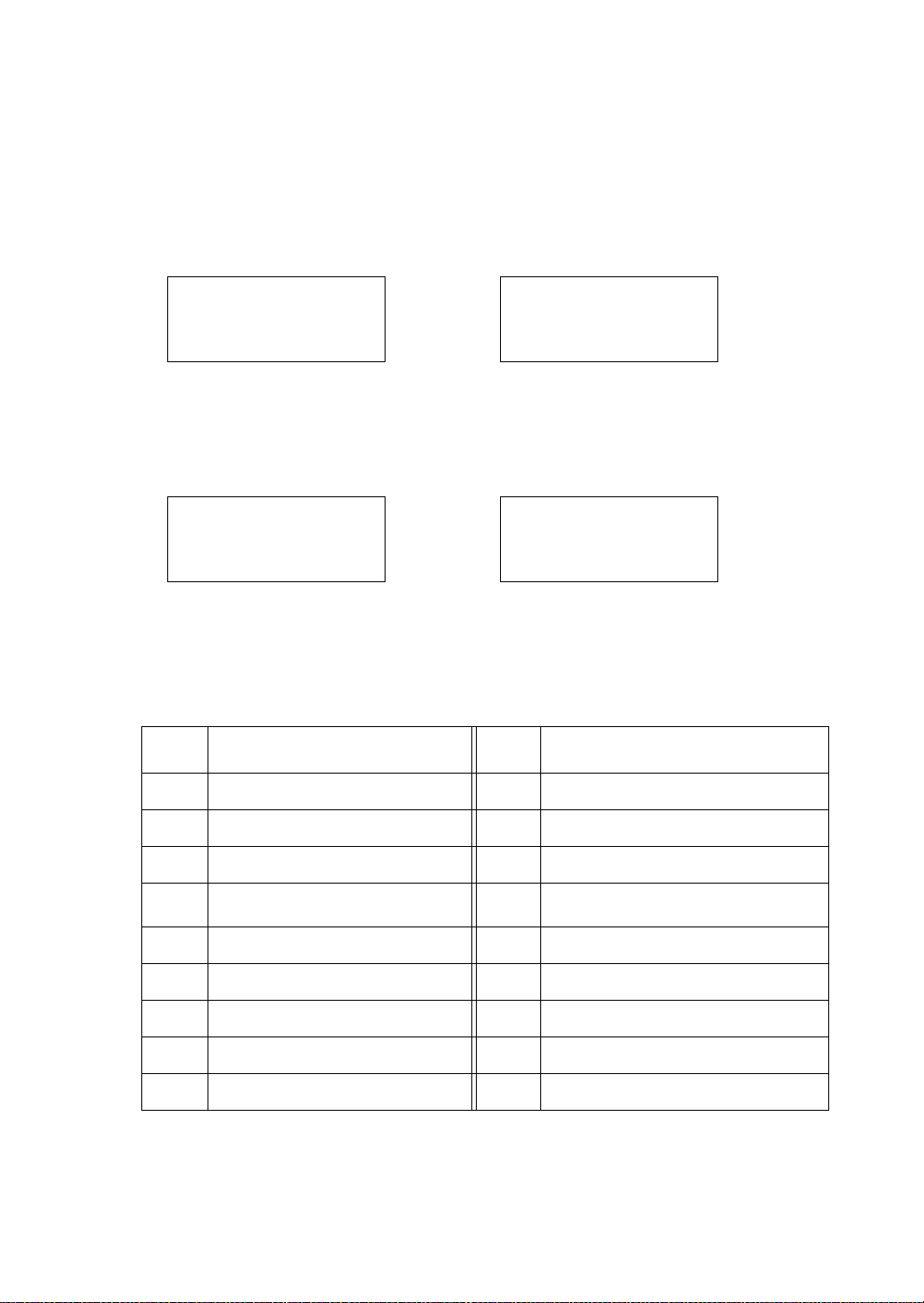

1.2 Display

HR: 120°30'40"

HD* 65.432 m

VD: 12.345 m

MEAS MODE NP/P P1

↓

HR: 120°30'40"

HD* 123.04.6f

VD: 12.03.4f

MEAS MODE NP/P P1

↓

●

Display

The display uses a dot matrix LCD which has 4 lines and 20 characters per line. In general, the

upper three lines display measured data, and the bottom line displays the soft key function which

changes with the measuring mode.

●

Contrast and Illumination

The contrast and illumination of display window are adjusted. See Chapter 6 “SPECIAL MODE

(Menu Mode)”.

●

Example

V : 90°10'20"

HR: 120°30'40"

1 NOMENCLATURE AND FUNCTIONS

0SET HOLD HSET P1

Angle measurement mode

V-angle : 90°10’20”

H-angle : 120°30’40”

Feet unit

↓

Distance measurement mode

Horizontal-angle : 120°30’40”

Horizontal distance : 65.432m

Relative elevation : 12.345m

Feet and inch unit

HR: 120°30'40"

HD* 123.45 f

VD: 12.34 f

MEAS MODE NP/P P1

Horizontal-angle : 120°30’40”

Horizontal distance : 123.45ft

Relative elevation : 12.34ft

●

Display marks

Display Contents Display Content

VV-angle

HR H-angle right m Meter unit

HL H-angle left f Feet unit / Feet and inch unit

↓

Horizontal-angle : 120°30’40”

Horizontal distance : 123ft4in6/8in

Relative elevation : 12ft3in4/8in

✻

EDM working

HD Horizontal distance

VD Relative elevation

SD Slope distance

NN coordinate

EE coordinate

ZZ coordinate

N

Switches non-prism mode or prism mode

P

1-3

Page 15

1 NOMENCLATURE AND FUNCTIONS

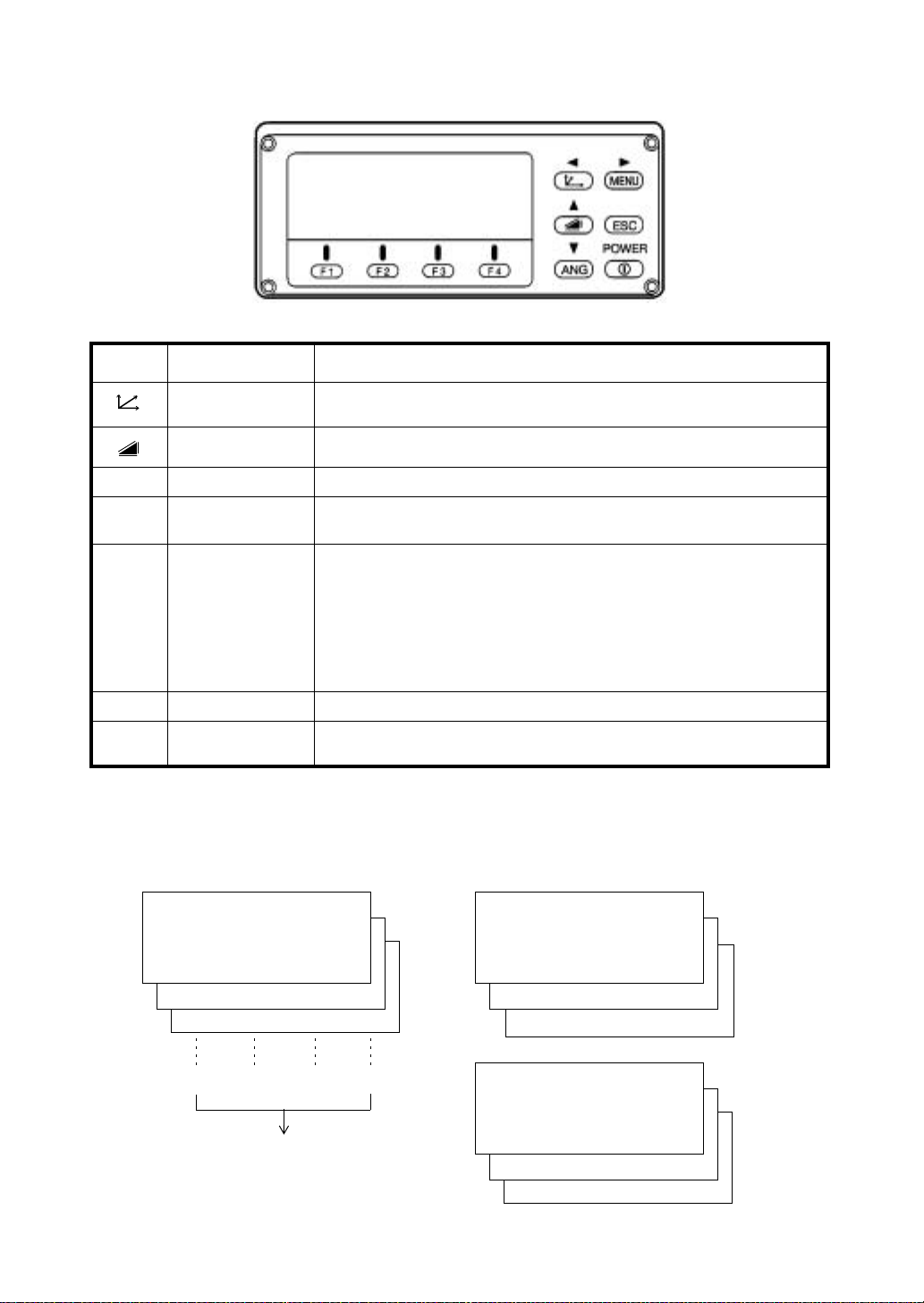

1.3 Operating Key

Keys Name of Key Function

Coordinate

meas.key

Distance meas.key Distance measurement mode.

ANG Angle meas.key Angle measurement mode

MENU Menu key

ESC Escape key

POWER Power source key ON/OFF of power source

F1–F4

Soft key

( Function key)

Coordinate measurement mode

Switches menu mode and normal mode. To set application measurements

and adjust in the menu mode.

● Returning to the measurement mode or previous layer mode from the

mode set.

● To be DATA COLLECTION mode or LAYOUT mode directly from the

normal measurement mode.

● It is also possible to use as Record key in normal measurement mode.

To select function of Escape key, see Chapter 16 “SELECTING MODE”

.

Responds to the message displayed.

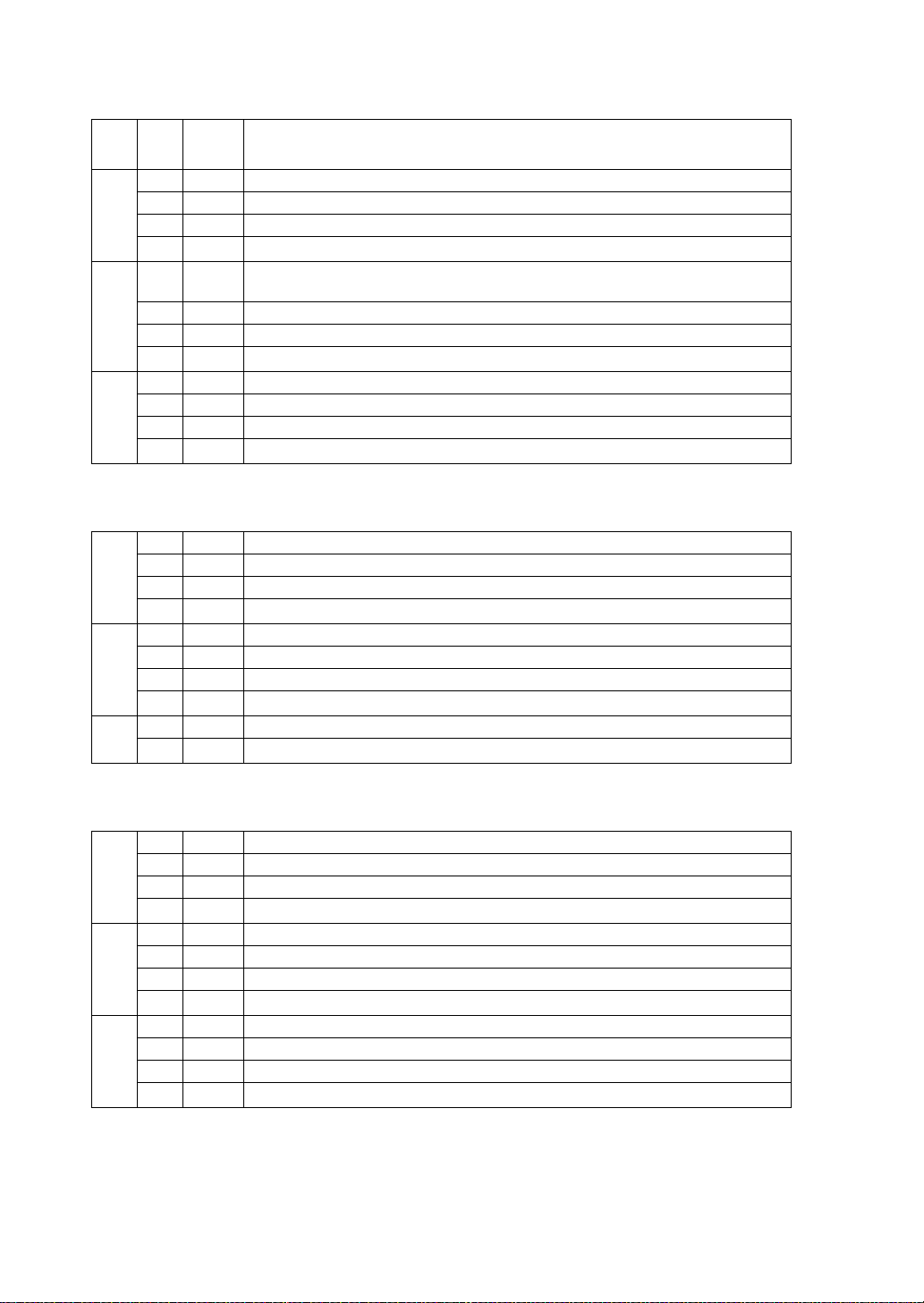

1.4 Function Key (Soft Key)

The Soft Key message is displayed at the bottom line of display. The functions are according to the

displayed message.

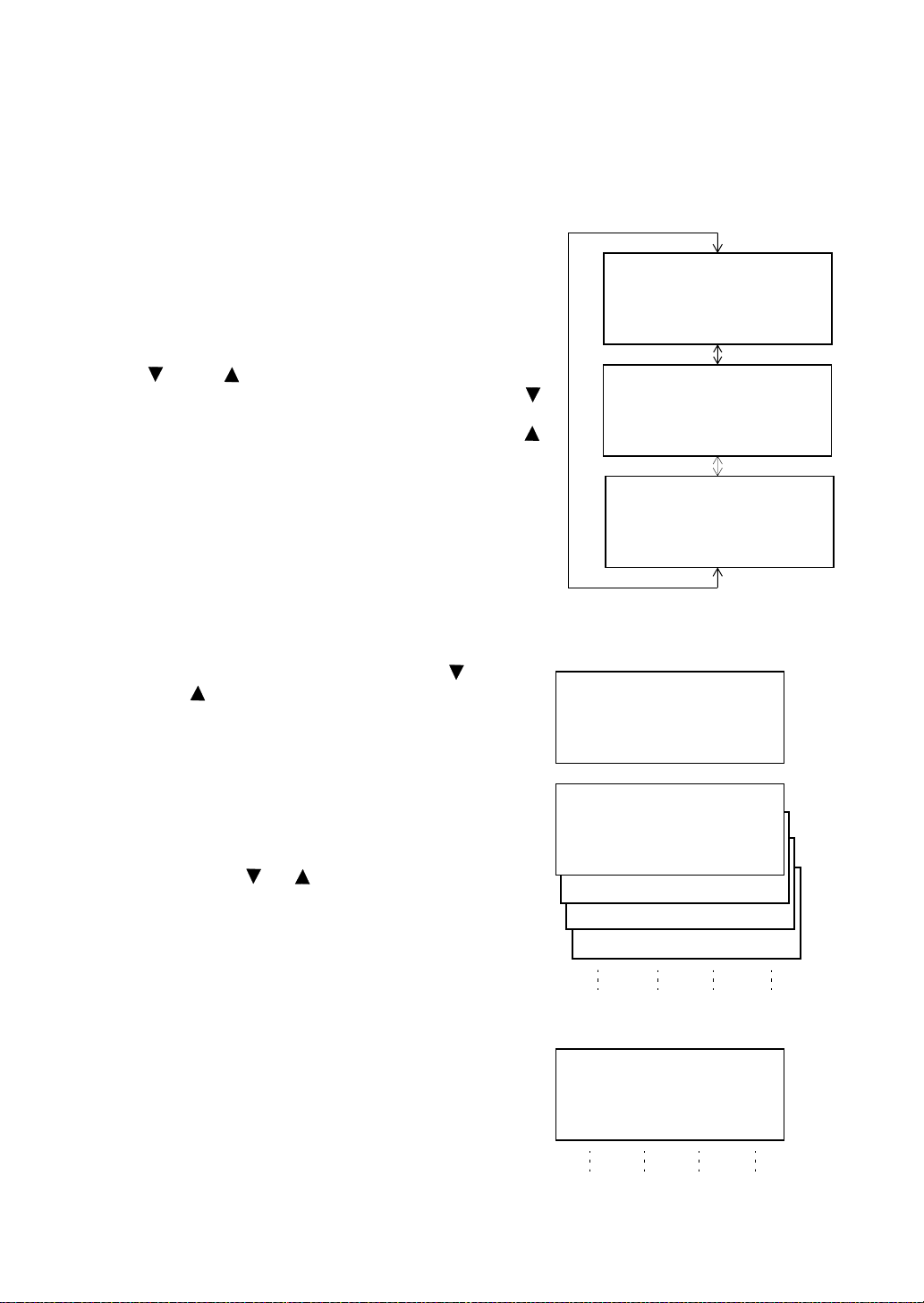

Angle measurement mode Distance measurement mode

V: 90°10'20"

HR:120°30'40"

0SET HOLD HSET P1

TILT REP V% P2

H-BZ R/L CMPS P3

↓

↓

↓

HR:120°30'40"

HD*[r] <<m

VD: m

MEAS MODE NP/P P1

↓

OFSET S.O S/A P2

--- m/f/i --- P3

Coordinates measurement mode

↓

↓

[F1] [F2] [F3] [F4]

Soft keys

N: 123.456 m

E: 34.567 m

Z: 78.912 m

MEAS MODE NP/P P1

R.HT INSHT OCC P2

OFSET m/f/i S/A P3

1-4

↓

↓

↓

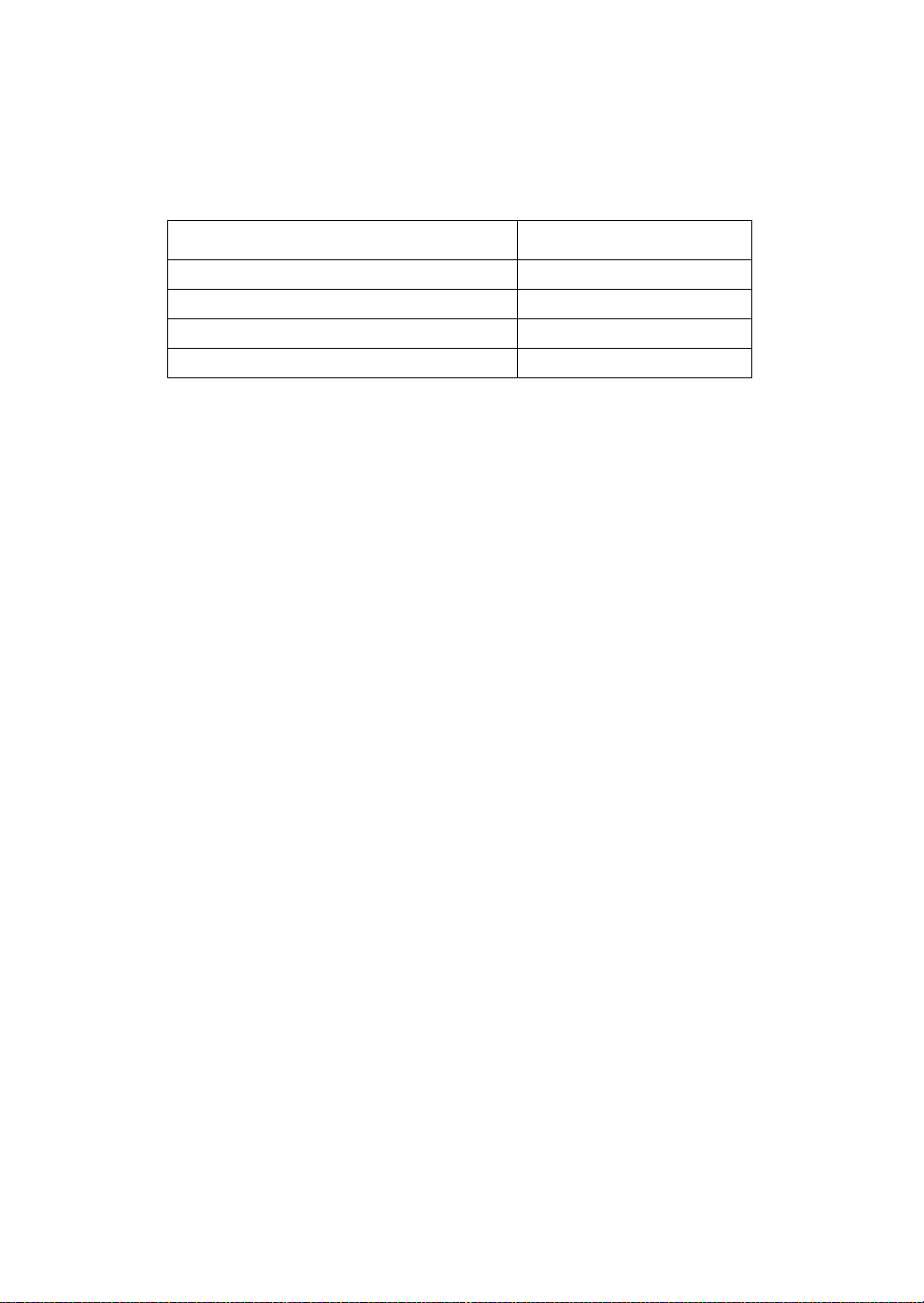

Page 16

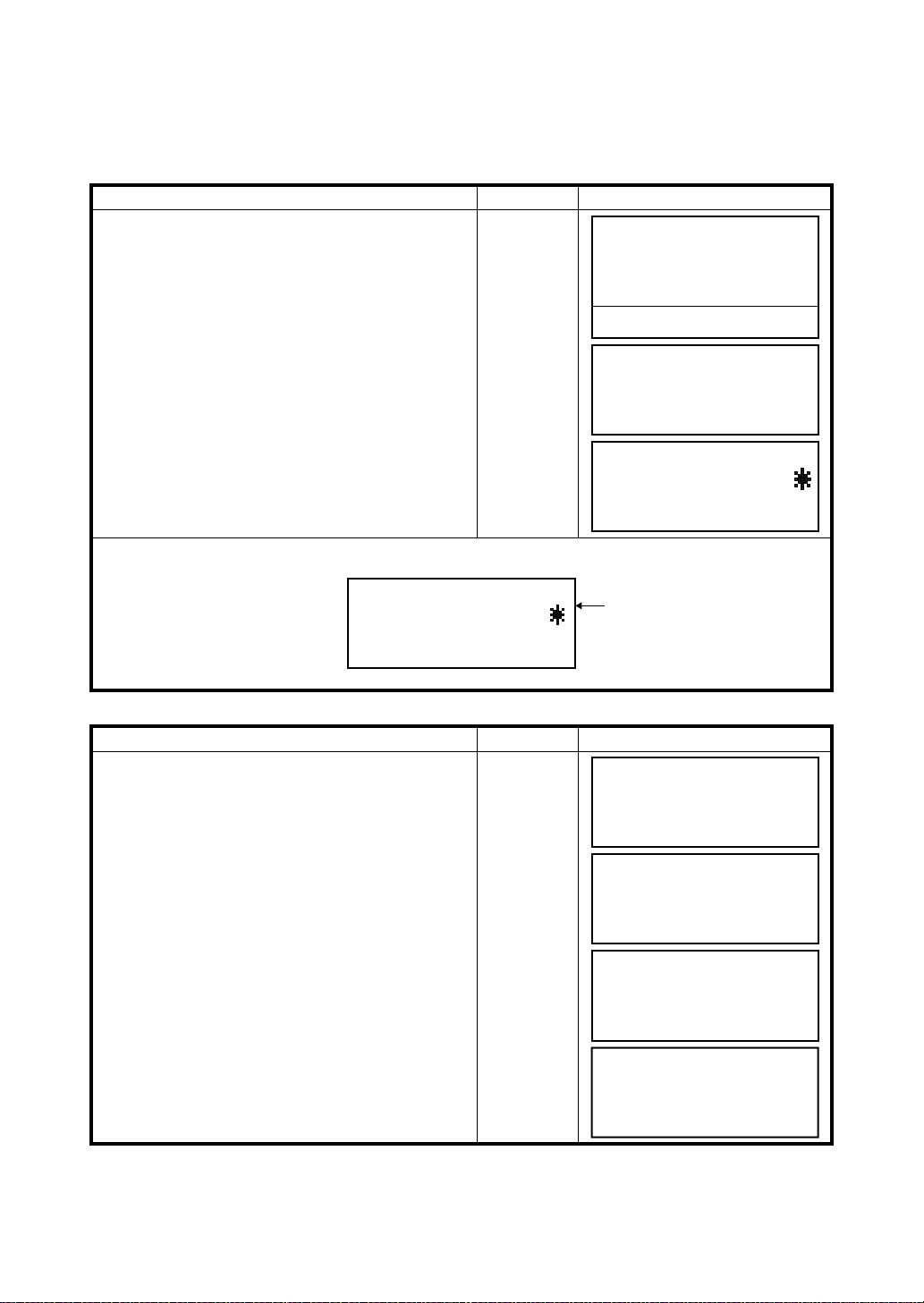

Angle measurement

Soft

Page

1

2

3

Display

key

mark

F1 0SET Angle of Horizontal is set to 0°00'00"

F2 HOLD Hold the horizontal angle

F3 HSET Sets a required horizontal angle by entering numerals.

F4

P1

F1 TILT

F2 REP Repetition angle measurement mode

F3 V% Vertical angle percent grade(%) mode

F4

P2

F1 H-BZ Sets the buzzer sound for every horizontal angle 90°

F2 R/L Switches R/L rotation of horizontal angle.

F3 CMPS Switches the COMPASS ON/OFF of vertical angle.

F4

P3

The function of soft keys is shown on next page (P2).

↓

Setting Tilt Correction

If ON, the display shows tilt correction value.

The function of soft keys is shown on next page (P3).

↓

The function of soft keys is shown on next page (P1).

↓

Distance measurement mode

F1 MEAS Start measuring

F2 MODE Sets a measuring mode, Fine/Coarse/Tracking

1

F3 NP/P Switches non-prism mode or prism mode.

F4

P1

F1 OFSET Select Off-set measurement mode

F2 S.O Select stake out measurement mode

2

F3 S/A Select set audio mode

F4

P2

F2 m/f/i Switches meter, feet or feet and inch unit.

3

F4

P3

The function of soft keys is shown on next page (P2).

↓

The function of soft keys is shown on next page (P3).

↓

The function of soft keys is shown on next page (P1).

↓

1 NOMENCLATURE AND FUNCTIONS

Function

Coordinate measurement mode

F1 MEAS Start measuring

F2 MODE Sets a measuring mode, Fine/Coarse/Tracking

1

F3 NP/P Switches non-prism mode or prism mode.

F4

P1

F1 R.HT Sets a prism height by input values.

F2 INSHT Sets an instrument height by input values.

2

F3 OCC Sets an instrument coordinate point by input values.

F4

P2

F1 OFSET Select Off-set measurement mode

F2 m/f/i Switches meter, feet or feet and inch unit.

3

F3 S/A Select set audio mode

F4

P3

The function of soft keys is shown on next page (P2).

↓

The function of soft keys is shown on next page (P3).

↓

The function of soft keys is shown on next page (P1).

↓

1-5

Page 17

1 NOMENCLATURE AND FUNCTIONS

1.5 Serial signal RS-232C connector

The serial signal connector is used for connecting the GPT-2000 series with a computer or TOPCON

Data Collector, which enables the computer to receive measured data from the GPT-2000 series or to

send preset data of horizontal angle, etc. to it.

● The following data will be output at each mode.

Mode Output

Angle mode ( V,HR or HL) ( V in percent) V,HR (or HL)

Horizontal distance mode (HR, HD, VD) V,HR, HD, VD

Slope distance mode (V, HR,SD) V,HR, SD,HD

Coordinate mode

● The display and the output at the coarse mode are the same as the contents above.

● Output at the tracking mode is displayed as distance data only.

The details necessary for the connection with the GPT-2000 Series are obtained from its Interface

Manual which is optionally available. Please refer to the manual.

N, E, Z, HR (or V,H,SD,N,E,Z)

1-6

Page 18

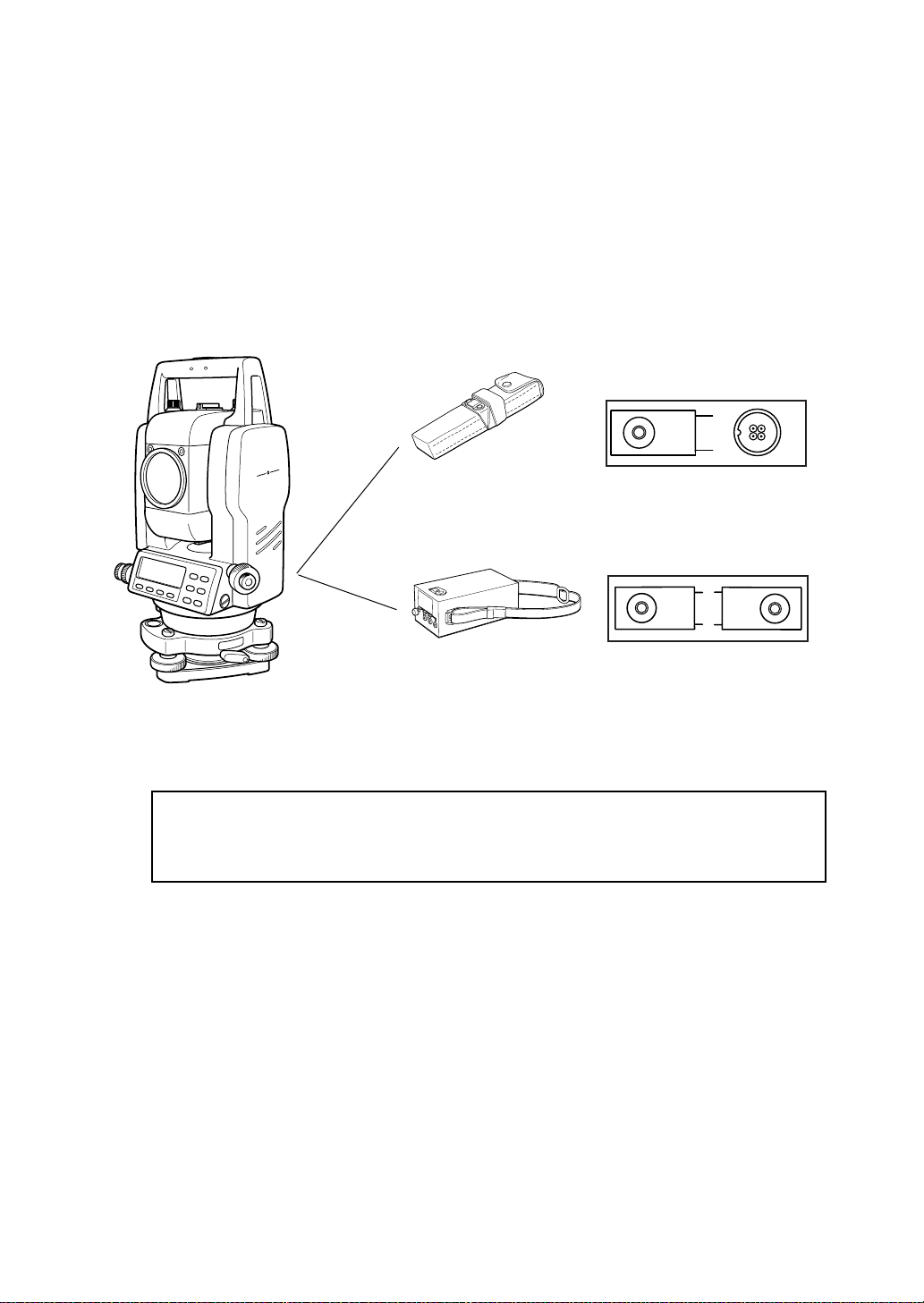

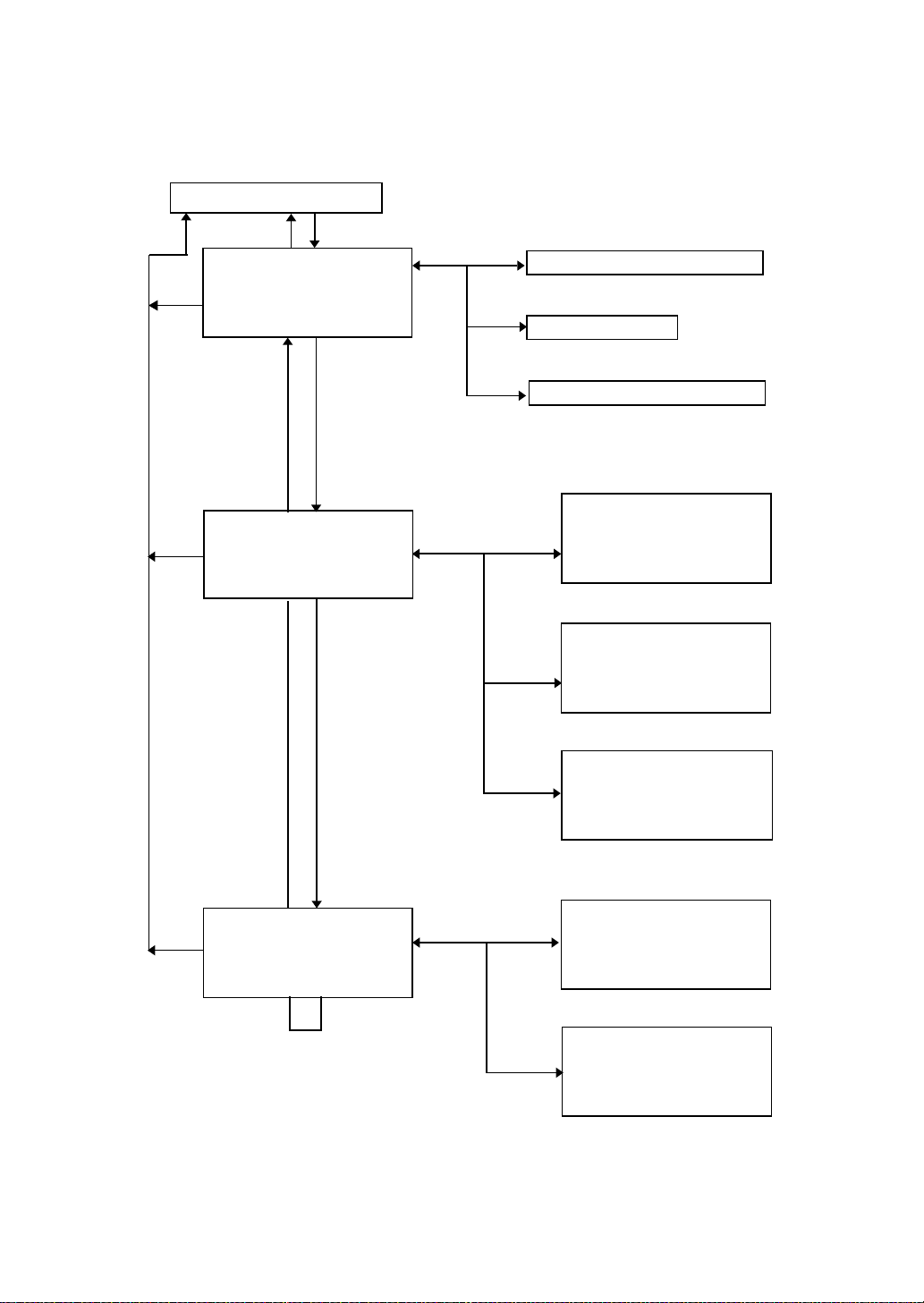

2 PREPARATION FOR MEASUREMENT

2 PREPARATION FOR MEASUREMENT

2.1 Power Connection

(unnecessary if on-board Ni-MH battery BT-52QA is used)

See below for connecting the external battery pack.

● Battery pack BT-3Q

Power cord , PC-5 is used.

● Large capacity battery pack BT-3L

Power cord PC-6 is used.

Cable

PC-5

PC-6

Battery pack

BT-3Q

BT-3L

Connector ends

PC-5

PC-6

Note: BT-32Q on-board (Ni-Cd) battery can be also available.

To use BT -32Q (Ni-Cd) battery, it is required to change battery type in selecting mode, see

Section 6.4.5 “Selecting Battery Type”.

2-1

Page 19

2 PREPARATION FOR MEASUREMENT

2.2 Setting Instrument Up For Measurement

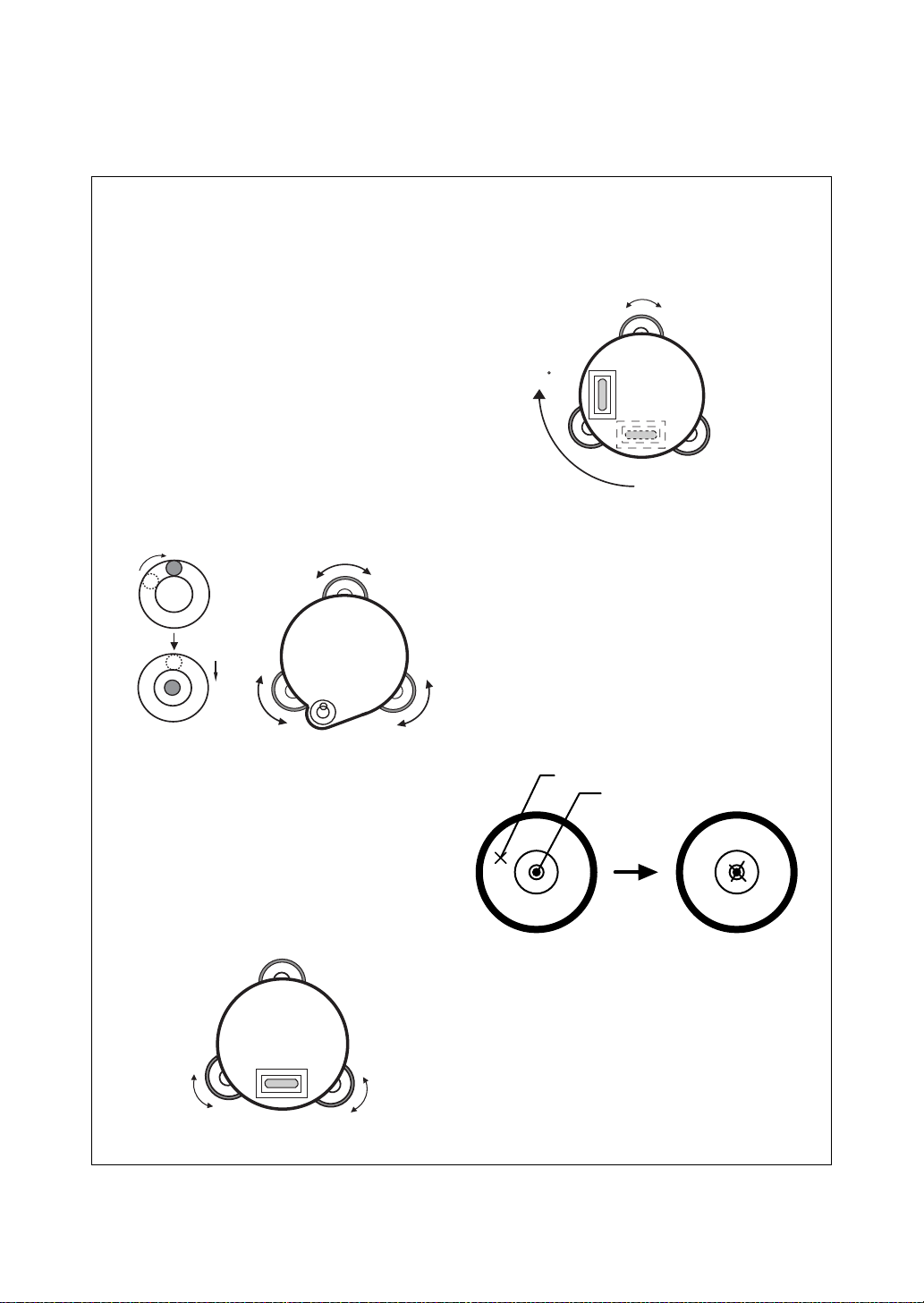

Mount the instrument to the tripod. Level and center the instrument precisely to insure the best

performance. Use tripods with a tripod screw of 5/8 in. diameter and 11 threads per inch, such as the

Type E TOPCON wide- frame wooden tripod.

Reference: Leveling and Centering the Instrument

1. Setting up the Tripod

First, extend the extension legs to suitable lengths

and tighten the screws on their midsections.

2. Attaching the Instrument on the Tripod

Head

Place the instrument carefully on the tripod head

and slide the instrument by loosening the tripod

screw . If the plumb bob is positioned right over the

center of the point, slightly tighten the tripod

screw.

3. Roughly Leveling the Instrument by Using

the Circular Level

1 Turn the leveling screws A and B to move the

bubble in the circular level. The bubble is now

located on a line perpendicular to a line

running through the centers of the two leveling

screws being adjusted.

Leveling screw C

Leveling

screw A

2 Turn the leveling screw C to bring the bubble

to the center of the circular level.

4. Centering by Using the Plate Level

1 Rotate the instrument horizontally by using

the Horizontal motion/clamp screw and place

the plate level parallel with the line connecting

leveling screws A and B, and then bring the

bubble to the center of the plate level by

turning leveling screws A and B.

Leveling screw B

2 Rotate the instrument 90° (100gon) around its

vertical axis and turn the remaining leveling

screw or C to center the bubble once more.

Leveling screw C

90

90°

3 Repeat the procedures 1 and 2 for each 90°

(100gon) rotation of the instrument and check

whether the bubble is correctly centered for all

four points.

5. Centering by Using the Optical Plummet

Telescope

Adjust the eyepiece of the optical plummet

telescope to your eyesight.

Slide the instrument by loosening the tripod

screw, place the point on the center mark, and

then tighten the tripod screw. Sliding the

instrument carefully not to rotate that allows you

to get the least dislocation of the bubble.

Point

Center mark

Leveling

screw A

6. Completely Leveling the Instrument

Leveling the instrument precisely in a similar way

to 4. Rotate the instrument and check to see that

the bubble is in the center of the plate level

regardless of telescope direction, then tighten the

tripod screw hard.

Leveling

screw B

2-2

Page 20

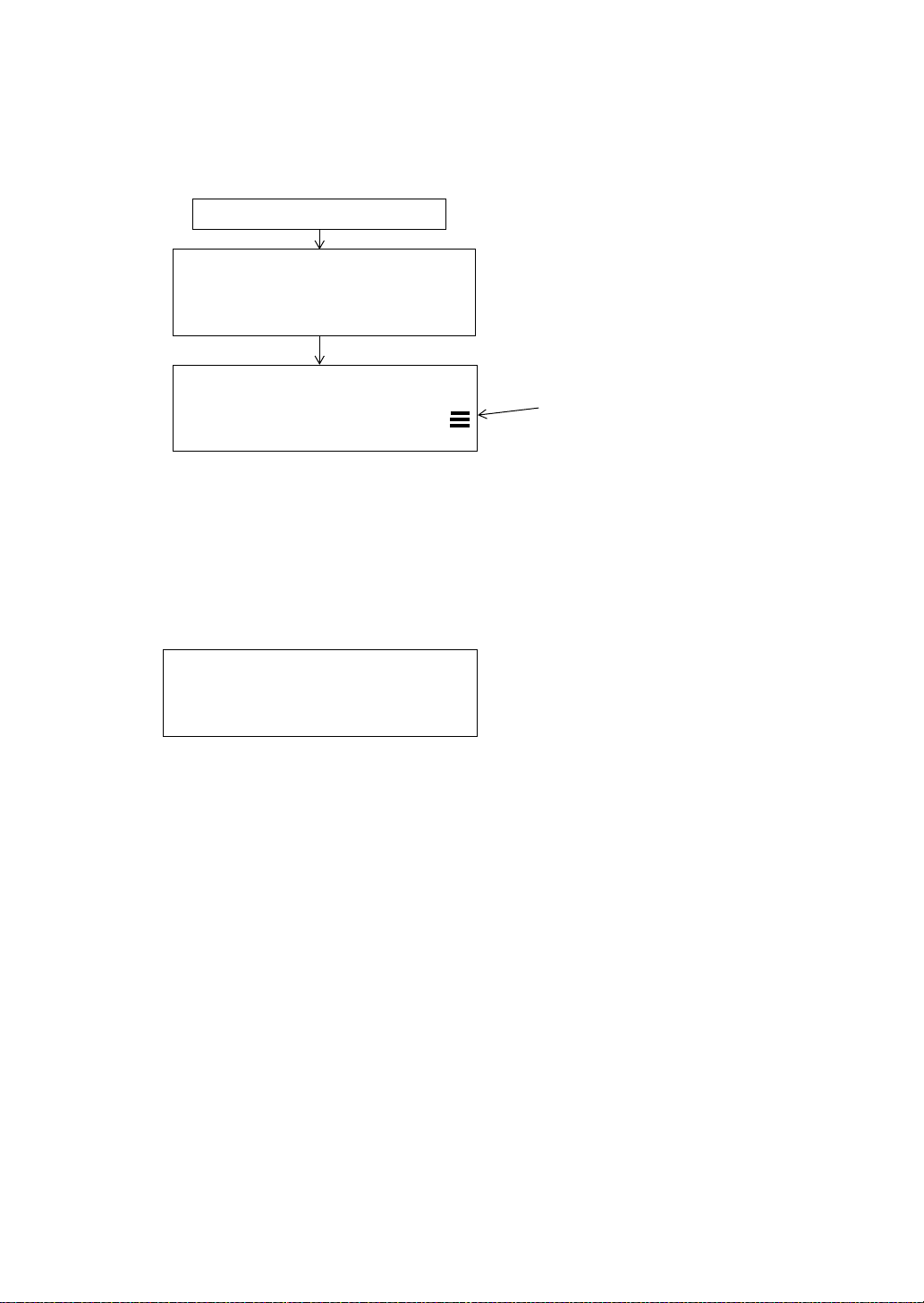

2.3 Power Switch Key ON

1 Confirm the instrument is leveled.

2 Press the power key..

Press the power key

TOPCON GPT-2000

V : 90°10'20"

HR: 0°00'00"

2 PREPARATION FOR MEASUREMENT

Battery Power Remaining Display

0SET HOLD HSET P1

● Confirm the battery power remaining display. Replace with charged battery or charge when battery

level is low or indicates “Battery empty”. see Section 2.4“Battery Power Remaining Display” .

● Contrast adjustment

You can confirm prism constant value (PSM), non-prism constant value (NPM), atmospheric

correction value (PPM) and you can also adjust the contrast of the display when the instrument is

turned on.

To display this screen, see Chapter 16 “SELECTING MODE” .

↓

CONTRAST ADJUSTMENT

PSM: 0.0 PPM 0.0

NPM: 0.0

↓ ↑ - - - ENTER

This enables you to adjust the brightness by pressing the [F1](

To memorize the setting value after powering off, press [F4](ENTER) key.

↓

) or [F2](↑) key.

2-3

Page 21

2.4 Battery Power Remaining Display

Battery power remaining display indicates the power condition.

V : 90°10'20"

HR: 0°00'00"

2 PREPARATION FOR MEASUREMENT

Measurement is possible.

0SET HOLD HSET P1

Battery power remaining display

Note: 1 The battery operating time will vary depending on the environmental conditions such as

ambient temperature, charging time, the number of times of charging and discharging etc.

It is recommended for safety to charge the battery beforehand or to prepare spare full

charged batteries.

2For general usage of the battery, see Chapter 14 “POWER SOURCE AND CHARGING” .

3 The battery power remaining display shows the power level regarding to the

measurement mode now operating.

The safety condition indicated by the battery power remaining display in the angle

measurement mode does not necessarily assure the battery’s ability to be used in the

distance measurement mode.

It may happen that the mode change from the angle mode to the distance mode will stop

the operation because of insufficient battery power for the distance mode which

consumes more power than angle mode.

↓

The power is poor. The battery

should be recharged or replaced.

Blinking

<Battery empty>

Other displays disappear.

Measurement is impossible.

Need to recharge or replace

the battery.

2-4

Page 22

2 PREPARATION FOR MEASUREMENT

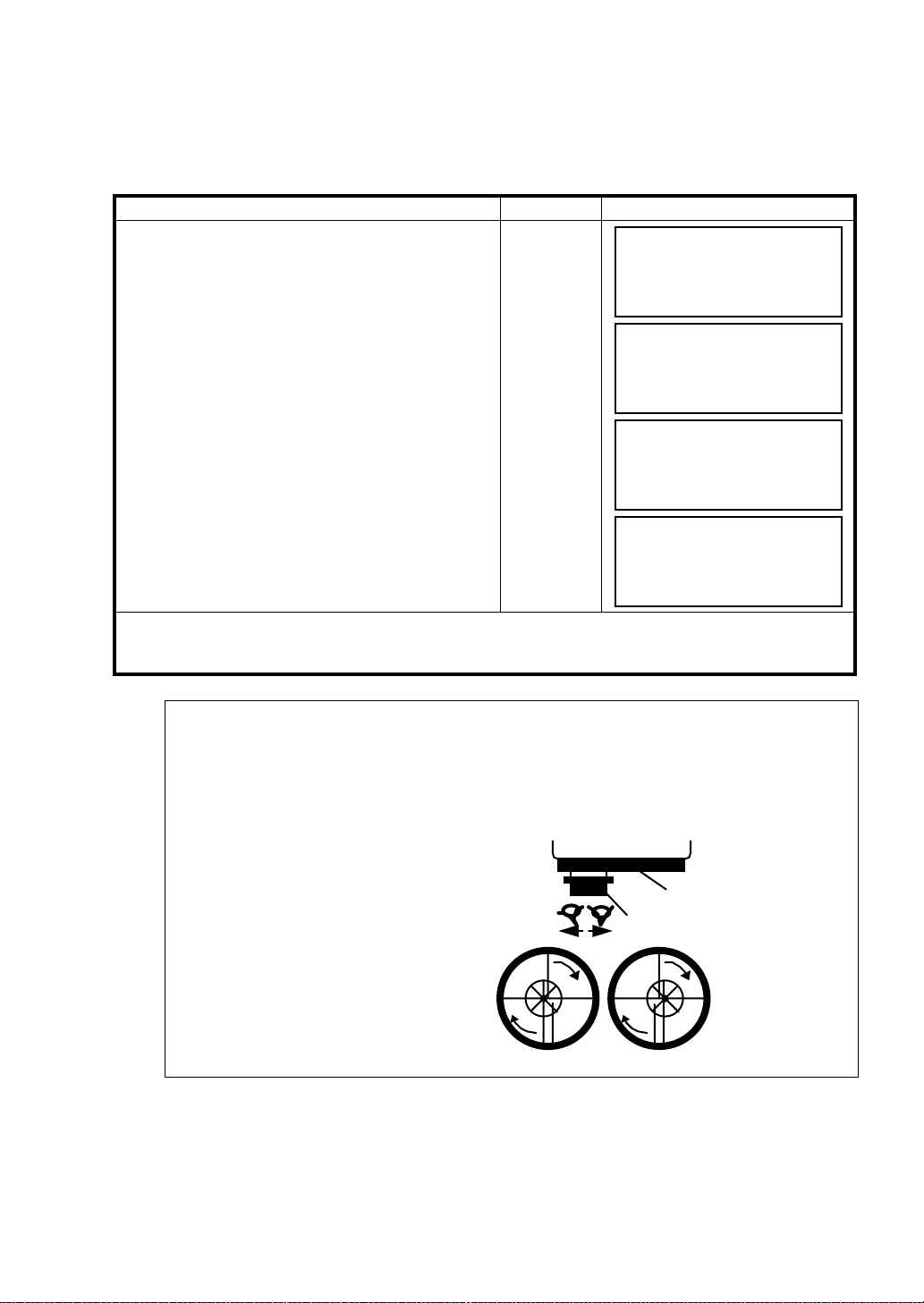

2.5 Vertical and Horizontal Angle Tilt Correction

(GPT-2009 has vertical angle tilt correction only.)

When the tilt sensors are activated, automatic correction of vertical and horizontal angle for

mislevelment is displayed.

To ensure a precise angle measurement, tilt sensors must be turned on. The display can also be used

to fine level the instrument. If the (TILT OVER) display appears the instrument is out of automatic

compensation range and must be leveled manually.

Zenith

Zenith

Standing axis

Standing axis

Inclination of the standing

axis in the X direction

Inclination of the standing

axis in the Y direction

Horizontal

● GPT-2000 compensates both the vertical angle and the horizontal angle readings due to inclination

of the standing axis in the X and Y directions .

● For more information about dual axis compensation, refer to APPENDIX 1 “Dual Axis

Compensation”.

When the instrument is out of compensation. (TILT OVER)

V : ° ' "

HR: ° ' "

<X TILT OVER>

Standing Axis in the X direction

out of range

V : ° ' "

HR: ° ' "

<Y TILT OVER>

Standing Axis in the Y direction

out of range

V : ° ' "

HR: ° ' "

<XY TILT OVER>

Standing Axis in the X and Y

directions out of range

Trunnion axis

● The display of Vertical or Horizontal angle is unstable when instrument is on an unstable stage or a

windy day. You can turn off the auto tilt correction function of V/H angle in this case.

● To set auto tilt correction from the moment that power is on, see Section 6.4.3“Vertical and

Horizontal Angle Tilt correction ( Tilt ON/OFF)” .

2-5

Page 23

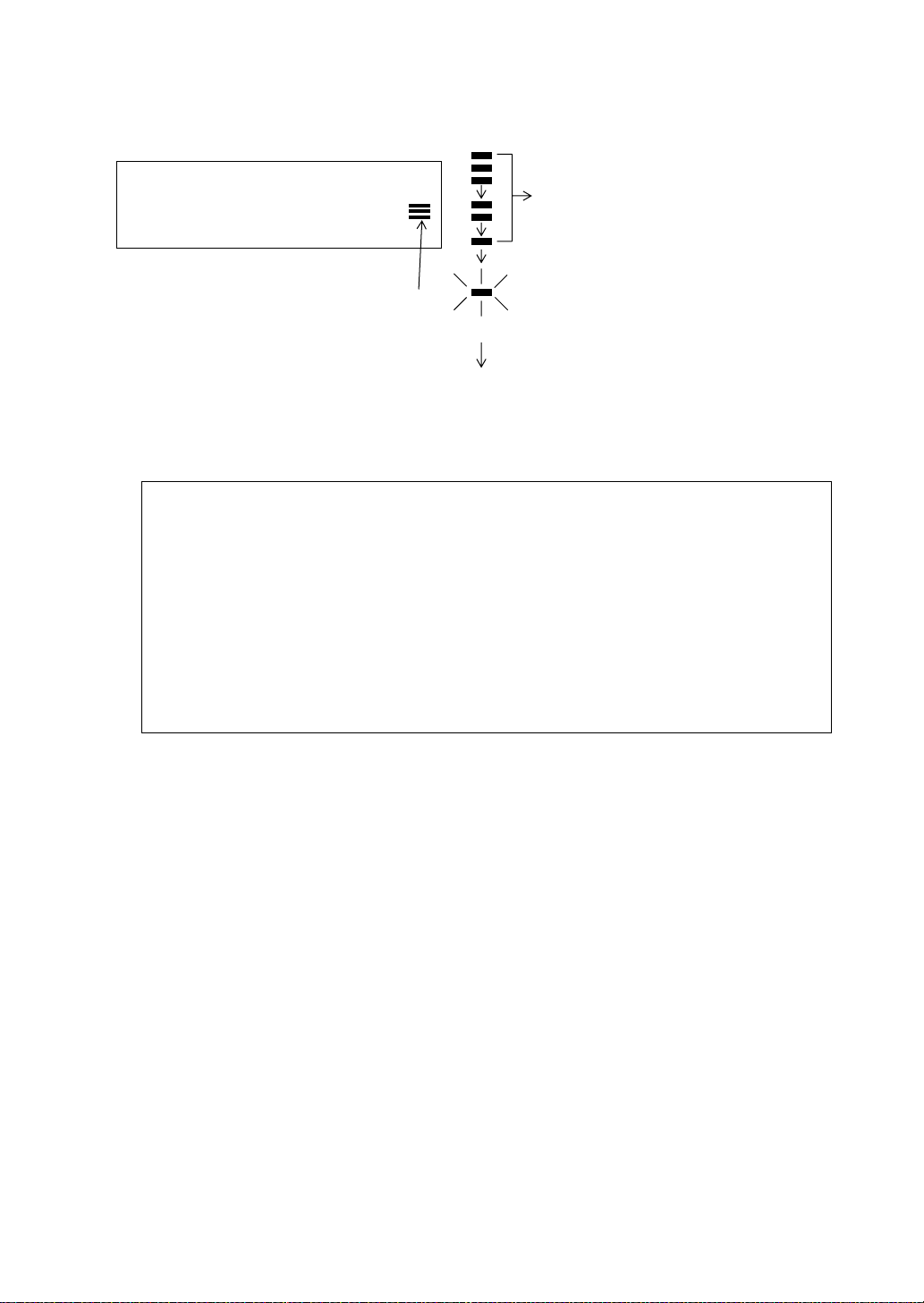

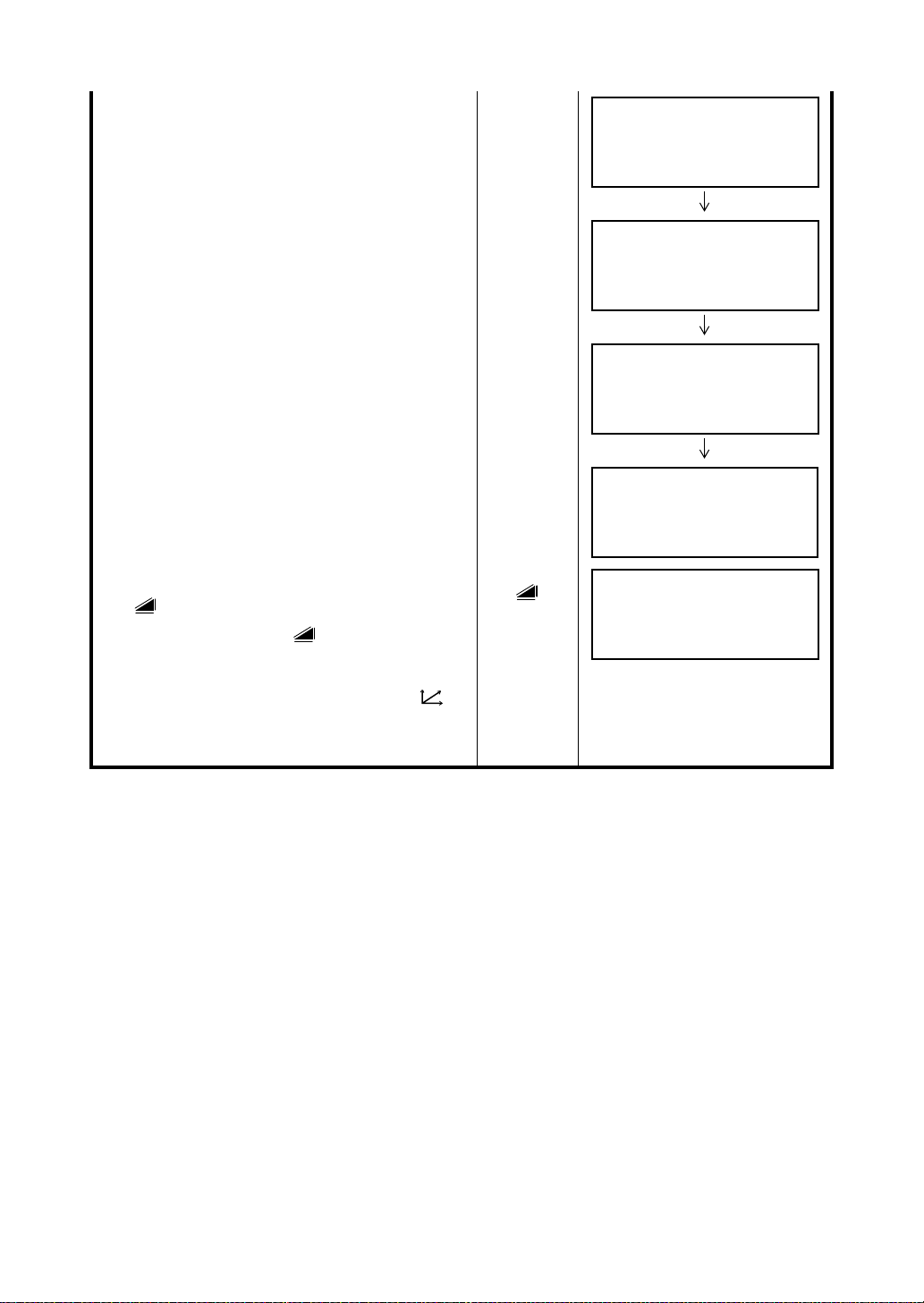

● Setting Tilt Correction by Soft Key

To enable you to select tilt ON/OFF function. setting is not memorized after power is OFF.

[Example] Setting X,Y Tilt OFF

Operating procedure Option Display

1 Press [F4] key to get the function page 2.

2 PREPARATION FOR MEASUREMENT

[F4]

V : 90°10'20"

HR: 120°30'40"

0SET HOLD HSET P1

TILT REP V% P2

2 Press [F1](TILT) key.

In case ON is already selected, the display shows

tilt correction value.

[F1]

TILT SENSOR:[XY-ON]

X:-0°00'25"

Y: 0°00'20"

X-ON XY-ON OFF ---

3 Press [F3](OFF) key.

[F3]

TILT SENSOR: [OFF]

X-ON XY-ON OFF ---

4 Press [ESC] key.

[ESC]

V : 90°10'20"

HR: 120°30'40"

TILT REP V% P2

● The setting mode performed here will not be memorized after powering OFF. To set TILT correction in

the initialized setting ( it is memorized after powering OFF), see Section 6.4.3“Vertical and Horizontal

Angle Tilt correction ( Tilt ON/OFF)” .

↓

↓

↓

2-6

Page 24

2 PREPARATION FOR MEASUREMENT

2.6 How to Enter Alphanumeric characters

This enables you to enter alphanumeric characters such as the instrument height, prism height,

occupied point, backsight point etc..

● How to select a item

[Example setting] Occupied point in the data collection mode.

The arrow indicates a item to enter.

The arrow line moves up or down when the

[] key or [ ] key is pressed.

● How to enter characters

1 Move the arrow to enter a item using the [ ]

or [ ] key.

2 Press the [F1] (INPUT) key.

The arrow changes to the equal (=) .

The characters are displayed on the bottom

line.

3 Press the [ ] or [ ] key to select a page.

PT# →ST-01

ID :

INS.HT: 0.000 m

INPUT SRCH REC OCNEZ

[]

or

[]

PT# :ST-01

ID

→

INS.HT: 0.000 m

INPUT SRCH REC OCNEZ

PT# :ST-01

ID :

INS.HT→ 0.000 m

INPUT SRCH REC OCNEZ

PT#

→

ID :

INS.HT: 0.000 m

INPUT SRCH REC OCNEZ

PT# =

ID :

INS.HT: 0.000 m

1234 5678 90.- [ENT]

ABCD EFGH IJKL [ENT]

4 Press the soft key to select a group of

characters.

Example: [F2](QRST) key is pressed.

MNOP QRST UVWX [ENT]

YZ+#[SPC][CLR][ENT]

[F1] [F2] [F3] [F4]

PT# =

ID :

INS.HT: 0.000 m

(Q) (R) (S) (T)

[F1] [F2] [F3] [F4]

2-7

Page 25

2 PREPARATION FOR MEASUREMENT

5 Press soft key to select a character.

PT# =T

ID :

Example: [F4](T) key is pressed.

Select next character in the same manner.

INS.HT: 0.000 m

MNOP QRST UVWX [ENT]

PT# =TOPCON-1

ID :

INS.HT : 0.000 m

MNOP QRST UVWX [ENT]

6 Press [F4](ENT) key.

The arrow moves to next item.

Select next character in the same manner.

● To correct a character, move the cursor to correct character by pressing [ ] or [ ] key and enter

again.

PT# :TOPCON-1

ID

→

INS.HT : 0.000 m

INPUT SRCH REC OCNEZ

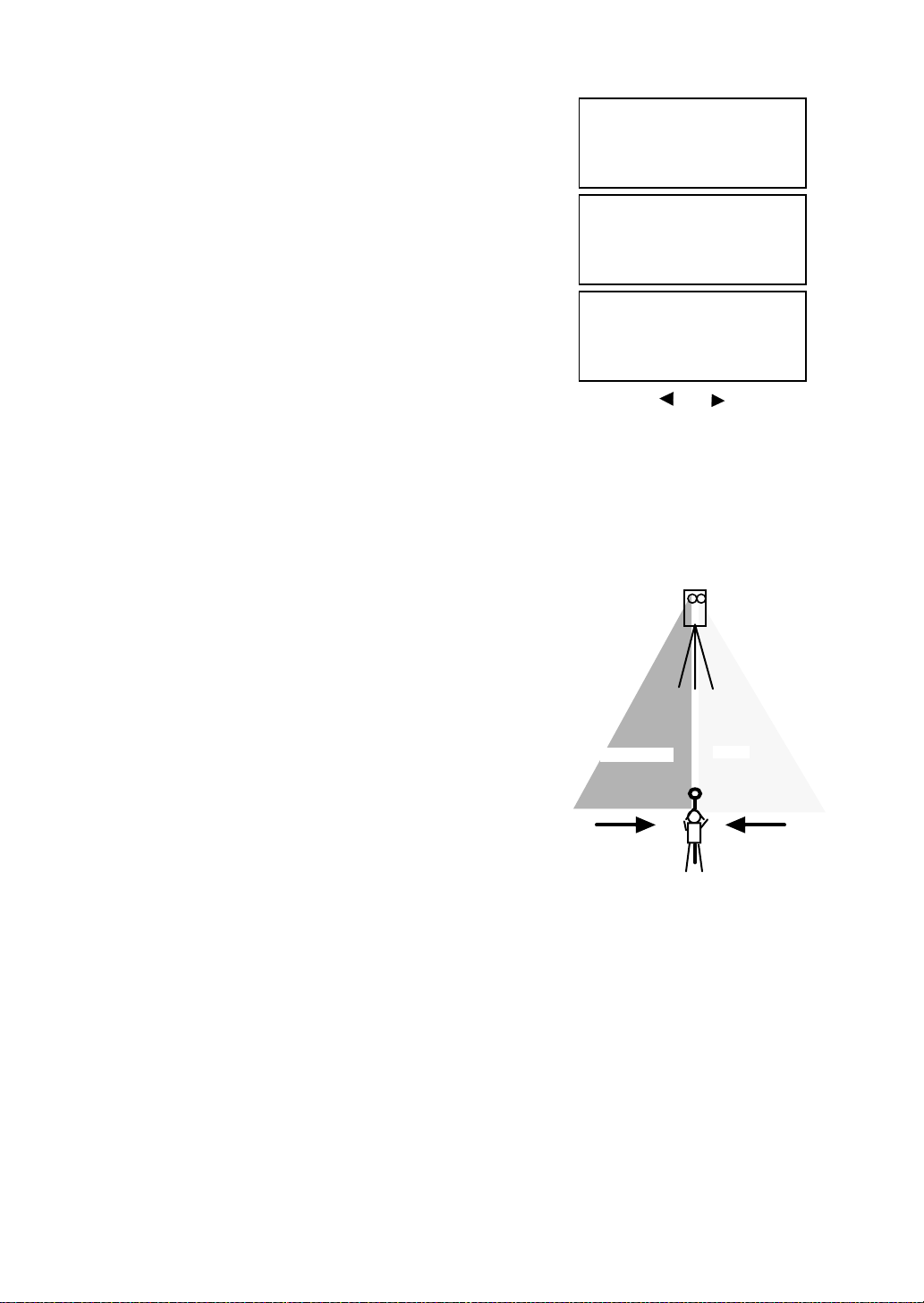

2.7 Point Guide (Only for Point Guide type)

Fast and simple to use, the Point Guide feature is useful when doing stake out work. The LED’s for the

Point Guide System on the instrument telescope assist the rod person to get on-line. When using the

Point Guide System, the battery life will be approximately 8 hours at +20 °C (+68 °F).

Turning the Point Guide ON and Operation:

Press the [MENU] key to get the menu screen and press the

[MENU] key again. Point Guide LED

Looking at the objective lens of the telescope, the right LED

will blink and the left LED will stay lit.

’s will be turned ON.

Instrument

The Point Guide should be used within a distance of 100

meters (328 feet). The quality of its results will depend on the

weather conditions and the user

The goal of the rod person is to look at both LED

instrument and move the prism on-line until both LED

equally bright.

● If the solid LED is brighter, move right.

● If the blinking LED is brighter, move left.

Once you have determined that both of the LED's are equally bright, you are on-line with the

instrument.

Turning the Point Guide OFF:

To turn OFF the Point Guide System, press the [MENU] key again in menu screen.

The point guide function can be available while executing Layout mode. See 8.2 “Executing a Layout”.

’s eyesight.

’s on the

’s are

Illuminate

Blink

Prism

2-8

Page 26

2 PREPARATION FOR MEASUREMENT

2.8 Laser Plummet ON/OFF (Only for Laser Plummet type)

Laser plummet option will help you to center the instrument easily onto the measurement point.

There are two ways to turn on/off of laser plummet option as follows.

● On/Off of laser plummet option by Soft Key in Tilt Correction

Operating procedure Option Display

1 Press the [F4] key to get the function page 2.

[F4]

V : 90°10'20"

HR: 120°30'40"

2 Press the [F1](TILT) key.

In case ON is already selected, the display shows

tilt correction value.

3 Press the [F4](L.PL) key.

By pressing the [F4](L.PL) key, the laser plummet

will be turned On / Off alternately.

● Symbol mark while the laser is emitting.

The following symbol mark will appear at the right side of the second line.

[F1]

[F4]

TILT SENSOR:[XY-ON]

X:-0°00'25"

Y: 0°00'20"

X-ON XY-ON OFF L.PL

● On/Off of laser plummet option from MENU mode

Operating procedure Operation Display

1 Press the [MENU] key.

2 Press the [F4](P

↓

) key to get the menu on page 2.

3 Press the [F3] key.

[MENU]

[F4]

[F3]

0SET HOLD HSET P1

TILT REP V% P2

TILT SENSOR:[XY-ON]

X:-0°00'25"

Y: 0°00'20"

X-ON XY-ON OFF L.PL

TILT SENSOR:[XY-ON]

X:-0°00'25"

Y: 0°00'20"

X-ON XY-ON OFF L.PL

Symbol mark

MENU 1/3

F1:DATA COLLECT

F2:LAYOUT

F3:MEMORY MGR. P

↓

MENU 2/3

F1:PROGRAMS

F2:GRID FACTOR

F3:LASER PLUMMET P

LASER PLUMMET [OFF]

F1:ON

F2:OFF

↓

↓

↓

4 Press the [F1] or [F2] key to turn on or off the laser

plummet option.

[F1] or [F2]

LASER PLUMMET [ON]

F1:ON

F2:OFF

Laser Plummet auto-cut off function

The laser plummet will be turned off automatically after 1 to 99 minutes (Default :3 minutes). It is also

possible to stop the auto-cut off function.

Refer to Chapter 16 “SELECTING MODE” to change the time or to invalidate the function.

2-9

Page 27

3 ANGLE MEASUREMENT

3 ANGLE MEASUREMENT

3.1 Measuring Horizontal Angle Right and Vertical Angle

Make sure the mode is in Angle measurement.

Operating procedure Operation Display

1 Collimate the 1st target (A).

Collimate A

V : 90°10'20"

HR: 120°30'40"

0SET HOLD HSET P1

2 Set horizontal angle of target A at 0° 00' 00".

Press the [F1](0 set) key and press the [F3](YES)

key .

[F1]

H ANGLE 0 SET

> OK?

--- --- [YES][NO]

[F3]

V : 90°10'20"

HR: 0°00'00"

0SET HOLD HSET P1

3 Collimate the 2nd target (B).

The required V/H angle to target B will be

displayed.

Collimate B

V : 98°36'20"

HR: 160°40'20"

0SET HOLD HSET P1

Reference : How to Collimate

1 Point the telescope toward the light. Turn the diopter ring and adjust the diopter so that the cross

hairs are clearly observed.

(Turn the diopter ring toward you first and then backward to focus.)

2 Aim the target at the peak of the triangle mark of the sighting collimator. Allow a certain space

between the sighting collimator and yourself for collimating.

3 Focus the target with the focusing knob.

↓

↓

↓

*If parallax is created between the cross

hairs and the target when viewing

vertically or horizontally while looking

into the telescope, focusing is incorrect

ordiopter adjustment is poor. This

adversely affects precision in

measurement or survey Eliminate the

parallax by carefully focusing

and using diopter adjustment.

3-1

Focusing knob

Telescope eyepiece (Diopter ring)

∞

∞

∞

∞

Page 28

3.2 Switching Horizontal Angle Right/Left

Make sure the mode is Angle measurement.

Operating procedure Operation Display

1

Press the [F4](

on page 3.

↓

) key twice to get the function

twice

[F4]

3 ANGLE MEASUREMENT

V : 90°10'20"

HR: 120°30'40"

0SET HOLD HSET P1

TILT REP V% P2

H-BZ R/L CMPS P3

2

Press the [F2](R/L) key.

The mode Horizontal angle Right (HR)

switches to (HL) mode.

[F2]

V : 90°10'20"

HL: 239°29'20"

H-BZ R/L CMPS P3

3

Measure as HL mode.

Every time pressing the [F2](R/L) key, HR/HL mode switches.

3.3 Measuring from the Required Horizontal Angle

3.3.1 Setting by Holding the Angle

Make sure the mode is angle measurement .

Operating procedure Operation Display

1

Set the required horizontal angle, using

Horizontal tangent screw

Display angle

V : 90°10'20"

HR: 130°40'20"

0SET HOLD HSET P1

↓

↓

↓

↓

↓

2

Press the [F2](HOLD) key.

3

Collimate the target.

4

Press the [F3](YES) key to finish holding the

horizontal angle.*1)

The display turns back to normal angle

measurement mode.

*1) To return to the previous mode, press the [F4](NO) key.

3-2

[F2]

Collimate

[F3]

H ANGLE HOLD

HR= 130°40'20"

> SET ?

--- --- [YES][NO]

V : 90°10'20"

HR: 130°40'20"

0SET HOLD HSET P1

●

↓

Page 29

3.3.2 Setting a Horizontal Angle from the Keys

Make sure the mode is Angle measurement .

Operating procedure Operation Display

1

Collimate the target.

Collimate

3 ANGLE MEASUREMENT

V : 90°10'20"

HR: 170°30'20"

0SET HOLD HSET P1

2

Press the [F3](HSET) key.

[F3]

H ANGLE SET

HR:

INPUT --- --- ENTER

1234 5678 90.-[ENT]

3

Input the required horizontal angle by

using keys. *1)

For example :70°40'20"

When completed, normal measuring from the

required Horizontal angle is possible.

*1) To enter Alphanumeric characters, see Section 2.6 “How to Enter Alphanumeric characters” .

[F1]

70.4020

[F4]

V : 90°10'20"

HR: 70°40'20"

0SET HOLD HSET P1

3.4 Vertical Angle Percent Grade(%) Mode

Make sure the mode is Angle measurement .

Operating procedure Operation Display

1

Press the [F4](↓) key to get the function on page 2.

[F4]

V : 90°10'20"

HR: 170°30'20"

0SET HOLD HSET P1

TILT REP V% P2

↓

↓

↓

↓

2

Press the [F3](V%) key. *1)

[F3]

V : -0.30 %

HR: 170°30'20"

TILT REP V% P2

*1) Every time pressing the [F3](V%) key, the display mode switches.

●

When the measurement is carried out over ±45° (±100%) from the horizontal, the display shows

<OVER>.

3-3

↓

Page 30

3.5 Repetition Angle Measurement

●

Repetition angle measurement can be done by horizontal angle right measurement mode.

Make sure the mode is Horizontal Angle Right measurement.

Operating procedure Operation Display

1

Press the [F4](↓) key to get the function on page 2.

[F4]

3 ANGLE MEASUREMENT

V : 90°10'20"

HR: 170°30'20"

2

Press the [F2](REP)key.

3

Press the [F3](YES) key.

4

Collimate the target A and press the [F1] (0SET)

key .

5

Press the [F3] (YES) key.

6

Collimate the target B using the horizontal clamp

and tangent screw.

Press the [F4](HOLD) key.

[F2]

[F3]

Collimate A

[F1]

[F3]

Collimate B

[F4]

0SET HOLD HSET P1

TILT REP V% P2

↓

↓

REPETITION ANGLE

> OK?

--- --- [YES][NO]

REP-ANGLE COUNT[ 0]

Ht: 0°00'00"

Hm:

0SET V/H REL HOLD

REPETITION ANGLE

INITIALIZE

> OK?

--- --- [YES][NO]

REP-ANGLE COUNT[ 0]

Ht: 0°00'00"

Hm:

0SET V/H REL HOLD

REP-ANGLE COUNT[ 1]

Ht: 45°10'00"

Hm: 45°10'00"

0SET V/H REL HOLD

7

Recollimate target A using the horizontal clamp

and tangent screw, and press the [F3](REL)key.

8

Recollimate target B using the horizontal clamp

and tangent screw, and press the [F4](HOLD) key.

9 Repeat 7 to 8 to measure the desired number of

repetitions.

3-4

Collimate A

[F3]

Collimate B

[F4]

REP-ANGLE COUNT[ 1]

Ht: 45°10'00"

Hm: 45°10'00"

0SET V/H REL HOLD

REP-ANGLE COUNT[ 2]

Ht: 90°20'00"

Hm: 45°10'00"

0SET V/H REL HOLD

REP-ANGLE COUNT[ 4]

Ht: 180°40'00"

Hm: 45°10'00"

0SET V/H REL HOLD

[Example] 4 measurement

Page 31

3 ANGLE MEASUREMENT

10 To return to the normal angle mode, press the

[F2](V/H) key or [ESC] key.

[ESC]

or

[F2]

REPETITION ANGLE

Exit

> OK?

--- --- [YES][NO]

11 Press the [F3](YES) key.

[F3]

V : 90°10'20"

HR: 170°30'20"

0SET HOLD HSET P1

● Horizontal angle can be accumulated up to

(3600°00'00" – minimum reading) (horizontal angle right).

In case of 5 second reading, horizontal angle can be accumulated up to +3599°59'55".

● Error will be displayed when the results differ from first measurement by more than ±30".

3.6 Buzzer Sounding for Horizontal Angle 90° Increments

When the horizontal angle falls in the range of less than ± 1° of 0°, 90°, 180° or 270°, the buzzer

sounds. Buzz er stops only when the horizontal angle is adjusted to 0°00’00”, 90°00’00” , 180°00’00” or

270°00’00”.

This setting is not memorized after powering off. Refer to 16 “SELECTING MODE” to set the initial

setting (memorized after powering off).

Make sure the mode is Angle measurement.

Operating procedure Operation Display

1 Press the [F4](

on page 3.

↓

) key twice to get the function

[F4]

twice

V : 90°10'20"

HR: 170°30'20"

↓

2 Press the [F1](H-BZ) key.

The data previously set is shown.

3 Press the [F1](ON) key or [F2](OFF) key to select

the buzzer ON/OFF.

4 Press the [F4](ENTER) key.

[F1]

[F1] or [F2]

[F4]

0SET HOLD HSET P1

H-BZ R/L CMPS P3

H-ANGLE BUZZER [OFF]

[ON] [OFF] --- ENTER

H-ANGLE BUZZER [ON]

[ON] [OFF] --- ENTER

V : 90°10'20"

HR: 170°30'20"

0SET HOLD HSET P1

↓

↓

↓

3-5

Page 32

3.7 Compasses ( vertical angle)

Vertical angle is displayed as shown below.

3 ANGLE MEASUREMENT

+90°

0°

-90°

Operating procedure Operation Display

1 Press the [F4](

on page 3.

2 Press the [F3](CMPS) key. *1)

*1) Every time pressing the [F3](CMPS) key, the display mode switches.

↓

) key twice to get the function

[F4]

twice

[F3]

0°

V : 98°10'20"

HR: 170°30'20"

0SET HOLD HSET P1

H-BZ R/L CMPS P3

V : - 8°10'20"

HR: 170°30'20"

H-BZ R/L CMPS P3

↓

↓

↓

3-6

Page 33

4 DISTANCE MEASUREMENT

N: 120.456 m

E: 34.567 m

N

P

Z: 12.345 m

MEAS MODE NP/P P1

↓

4 DISTANCE MEASUREMENT

Note: Those distance shorter than 2.5m will not be displayed in Non-prism mode.

● Prism mode and Non-prism mode

In GPT-2000 series, the distance measurement will be done using invisible pulse laser beam emitted

from pulse laser diode. You can select measurement mode between Prism mode which collimating a

prism and Non-prism mode that is collimating a target object except prism.

● Non-prism mode enables all distance measurements such Distance measurement, Coordinate

measurement, Offset measurement and Layout.

● To switch over Prism mode to Non-prism mode or contrary, press the [NP/P] soft key in each

measurement display. [NP] of Non-prism mode indicator will be shown at the right corner of the

display in Non-prism mode measurement.

Changing mode shall be done before measurement.

Example

● It is possible to set Non-prism mode for distance measurement during the power on time. Refer to

● If happened collimating the near distance prism in Non-prism mode, measurement will not be done

Distance measurement mode

HR: 120°30'40"

HD* 65.432 m

N

P

VD: 12.345 m

MEAS MODE NP/P P1

To change the mode, press the [NP/P] soft key in each measurement.

16.SELECTING MODE to set the option.

because of too much light.

↓

Non-prism

mode

indicator

Coordinate measurement mode

4.1 Setting of the Atmospheric Correction

When setting the atmospheric correction, obtain the correction value by measuring the temperature

and pressure. Refer to Section 12.2 “Setting of Atmospheric Correction Value”.

4.2 Setting of the Correction for Prism Constant / Non-prism Constant

Topcon’s prism constant value is 0. Set correction f or prism at 0. If the prism is of another manufacture,

the appropriate constant shall be set beforehand. Refer to Chapter 11 “SETTING THE PRISM / NONPRISM CONSTANT VALUE”. The setting value is kept in the memory even after power is off.

Note: Confirm that Non-prism correction value is set at zero before measurement target such

as a wall in Non-prism mode.

4-1

Page 34

4 DISTANCE MEASUREMENT

4.3 Distance Measurement (Continuous Measurement)

Make sure the mode displays angle measurement.

Operating procedure Operation Display

1 Collimate the center of prism.

Collimate P

V : 90°10'20"

HR: 120°30'40"

2 Press the [ ] key.

Distance measurement starts. *1),2)

[ ]

0SET HOLD HSET P1

HR: 120°30'40"

HD*[r] << m

↓

VD: m

The measured distances are shown. *3)~*5)

MEAS MODE NP/P P1

HR: 120°30'40"

↓

HD* 123.456 m

VD: 5.678 m

MEAS MODE NP/P P1

● Pressing the [ ] key again, the display

changes to horizontal (HR) and vertical (V)angle

and slope distance(SD). *6)

*1) When EDM is working, the "✻ " mark appears in the display.

*2) To change mode from Fine to Coarse or Tracking, refer to section 4.5 “Fine Mode/Tracking Mode/

Coarse Mode”.

To set the distance measurement on when the instrument is powered on, refer to Chapter 16

“SELECTING MODE”.

*3) The distance unit indicator "m" (for meter) , "f" (for feet or feet inch) appears and disappears alternatively

with buzzer sounds at every renewal of distance data.

*4) Measurement may repeat automatically in the instrument if the result is affected by shimmer etc..

*5) To return to the normal measuring angle mode from a distance measuring mode, press the [ANG] key.

*6) It is possible to choose the display order (HR, HD, VD) or (V, HR, SD) for initial measuring distance

mode. Refer to Chapter 16 “SELECTING MODE”.

[ ]

V : 90°10'20"

HR: 120°30'40"

SD* 131.678 m

MEAS MODE NP/P P1

↓

↓

4-2

Page 35

4 DISTANCE MEASUREMENT

4.4 Distance Measurement

When the number of times measurement is preset, the GPT-2000 series measures the distance the set

number of times. The average distance will be displayed.

When presetting the number of times as 1, it does not display the average distance, because of single

measurement. Single measurement is set at the factory.

Make sure the mode displays angle measurement.

Operating procedure Operation Display

1 Collimate the center of prism.

(N-time Measurement/Single Measurement)

V : 90°10'20"

HR: 120°30'40"

0SET HOLD HSET P1

2 Press the [ ] key.

Continuous measuring starts.*1)

[ ]

HR: 120°30'40"

HD*[r] << m

VD: m

MEAS MODE NP/P P1

3 Press [F1](MEAS) key while continuous

measuring is exceeding. *2)

The average value is displayed and "*" mark

disappears.

● While EDM is working, press [F1](MEAS) key

again, the mode will be changed to continuous

measuring mode.

[F1]

HR: 120°30'40"

HD*[n] << m

VD: m

MEAS MODE NP/P P1

HR: 120°30'40"

HD: 123.456 m

VD: 5.678 m

MEAS MODE NP/P P1

↓

↓

↓

↓

*1) It is possible to set the measurement mode for N-times measurement mode or continuous

measurement mode when the power is turned on. Refer to Chapter 16 “SELECTING MODE”.

*2) For setting the number of times (N-times) in the measurement, refer to Chapter 16 “SELECTING

MODE”.

4-3

Page 36

4 DISTANCE MEASUREMENT

● Choose meter /feet / feet+inch unit by soft key

It is possible to change the unit for distance measurement mode by soft key.

This setting is not memorized after power off. Refer to 16 “SELECTING MODE” to set at the initial

setting (memorized after power off).

Operating procedure Operation Display

1 Press the [F4](P1

on page 3.

↓

) key twice to get the function

[F4]

HR: 120°30'40"

HD* 2.000 m

VD: 3.000 m

MEAS MODE NP/P P1

OFSET S.O S/A P2

--- m/f/i --- P3

2 Every time pressing the [F2](m/f/i) key, the display

unit will be changed.

● Every time pressing the [F2](m/f/i) key, the unit

mode switches.

[F2]

HR: 120°30'40"

HD* 6.560 f

VD: 9.845 f

--- m/f/i --- P3

4.5 Fine Mode/Tracking Mode/Coarse Mode

This setting is not memorized after power is off. Refer to Chapter 16”SELECTING MODE” to set at the

initial setting (memorized after power is off).

•Fine Mode : This is a normal distance measuring mode.

•Tracking Mode : This mode measures in shorter time than in fine mode.

•Coarse Mode : This mode measures in shorter time than in fine mode.

The unit to be displayed: 0.2mm or 1mm. (0.001ft or 0.005ft)

Measurement time 0.2mm mode: approx. 3.0 sec.

1mm mode: approx. 1.2 sec.

It is very useful when tailing the moving object or carrying out stake-out work.

The unit to be displayed: 10mm

Measuring time: approx. 0.3 sec.

The unit to be displayed: 10mm or 1mm

Measuring time: approx. 0.5 sec.

↓

↓

↓

↓

Operating procedure Operation Display

1 Press the [F2](MODE) key from the distance

measuring mode.*1)

The initial character (F/T/C) of set mode is

displayed . (F:Fine, T:Tracking, C:Coarse)

2 Press the [F1](FINE) key, [F2](TRACK) key, or

[F3](COARSE) key.

*1) To cancel the setting, press the [ESC] key.

4-4

[F2]

[F1]~[F3]

HR: 120°30'40"

HD* 123.456m

VD: 5.678m

MEAS MODE NP/P P1

HR: 120°30'40"

HD* 123.456m

VD: 5.678m

FINE TRACK COARSE F

HR: 120°30'40"

HD* 123.456m

VD: 5.678m

MEAS MODE NP/P P1

↓

↓

Page 37

4 DISTANCE MEASUREMENT

4.6 Stake Out (S.O)

The difference between the measured distance and the input stake out distance is displayed.

Measured distance — Stake out distance = Displayed value

● In stake out operation, you can select either horizontal distance (HD), relative elevation (VD) and

slope distance (SD)

Operating procedure Operation Display

1 Press the [F4](

mode to get the function on page 2.

↓

) key in the distance measuring

[F4]

HR: 120°30'40"

HD* 123.456 m

VD: 5.678 m

MEAS MODE NP/P P1

OFSET S.O S/A P2

↓

↓

2 Press the [F2](S.O) key.

The data previously set is shown.

3 Select the measuring mode by pressing the [F1] to

[F3] key.

Example : Horizontal distance

4 Enter the distance for stake out. *1)

5 Collimate the target (Prism).

Measuring starts.

The difference between the measured distance

and the stake out distance is displayed.

6 Move the target until the difference becomes 0m.

[F2]

[F1]

[F1]

Enter data

[F4]

Collimate P

STAKE OUT

HD : 0.000 m

HD VD SD ---

STAKE OUT

HD : 0.000 m

INPUT --- --- ENTER

1234 5678 90.-[ENT]

STAKE OUT

HD : 100.000 m

INPUT --- --- ENTER

HR: 120°30'40"

dHD*[r] << m

VD: m

MEAS MODE NP/P P1

HR: 120°30'40"

dHD* 23.456 m

VD: 5.678 m

MEAS MODE NP/P P1

↓

↓

*1) Refer to section 2.6 “How to Enter Alphanumeric characters”.

● To return to normal distance measurement mode, stake out distance to "0" or turn the power off.

4-5

Page 38

4 DISTANCE MEASUREMENT

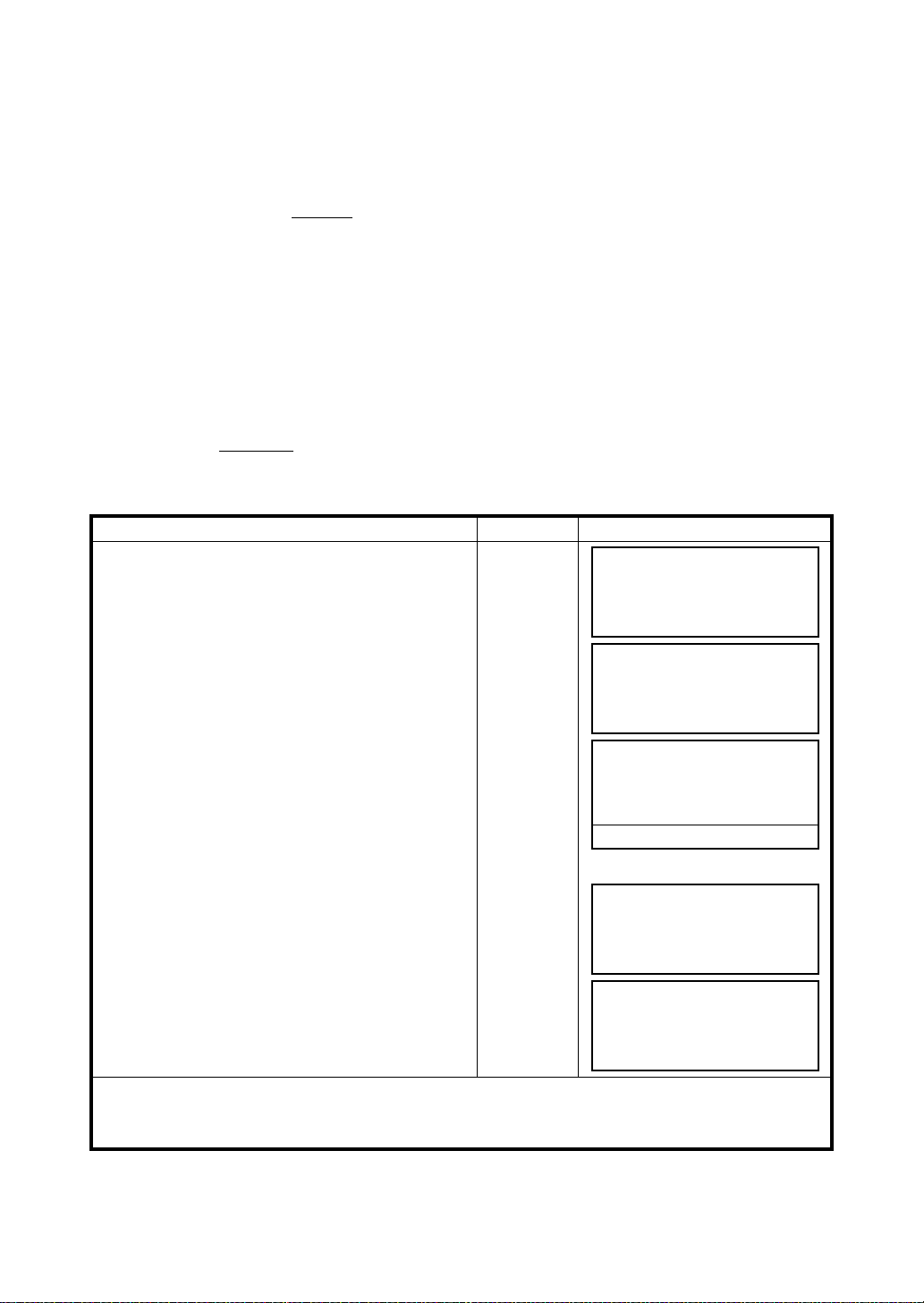

4.7 Offset Measurement

There are four offset measurement modes in the Offset Measurement.

● Angle offset

● Distance offset

● Plane offset

● Column offset

To show the offset measurement menu, press the [OFSET] soft key from distance or coordinate

measurement mode.

Example:

Distance measurement

HR: 120°30'40"

HD: 123.456 m

VD: 5.678 m

MEAS MODE NP/P P1

OFSET S.O S/A P2

Press the [F1](OFSET) key.

↓

↓

Coordinate measurement

N: 123.456 m

E: 34.567 m

Z: 78.912 m

MEAS MODE NP/P P1

R.HT INSHT OCC P2

OFSET m/f/i S/A P3

Press the [F1](OFSET) key.

↓

↓

↓

Offset Measurement Menu

OFFSET 1/2

F1:ANG.OFFSET

F2:DIST.OFFSET

F3:PLANE OFFSET P

[F4]

↓

OFFSET 2/2

F1:COLUMN OFFSET

P

↓

● Outputting the Measurement Data

The results of offset measurement can be output to external device.

Setting the function of the [ESC] key to (REC), the [F3] soft key which assigned (REC) will appear in

measured result display.

Refer to Chapter 16 “SELECTING MODE” to set this option.

OFFSET-MEASUREMENT

HR: 120°30'40"

SD: 123.456 m

NEXT --- REC ---

[F3]

● Distance measurement mode of the offset measurement

Offset measurement will be done by N-time fine measurement mode.

For setting measuring times refer to Chapter 16 “SELECTING MODE”.

4-6

Page 39

4 DISTANCE MEASUREMENT

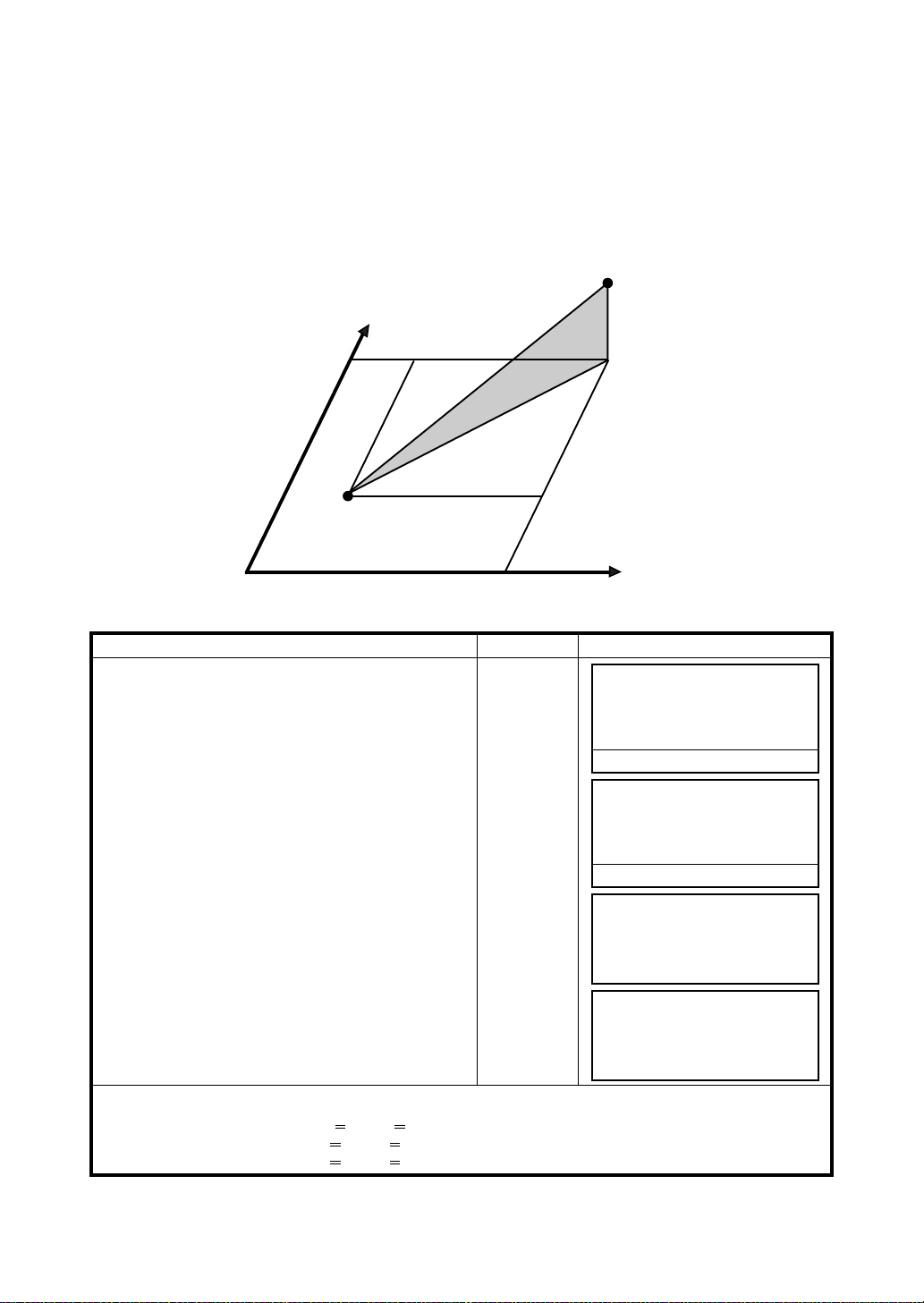

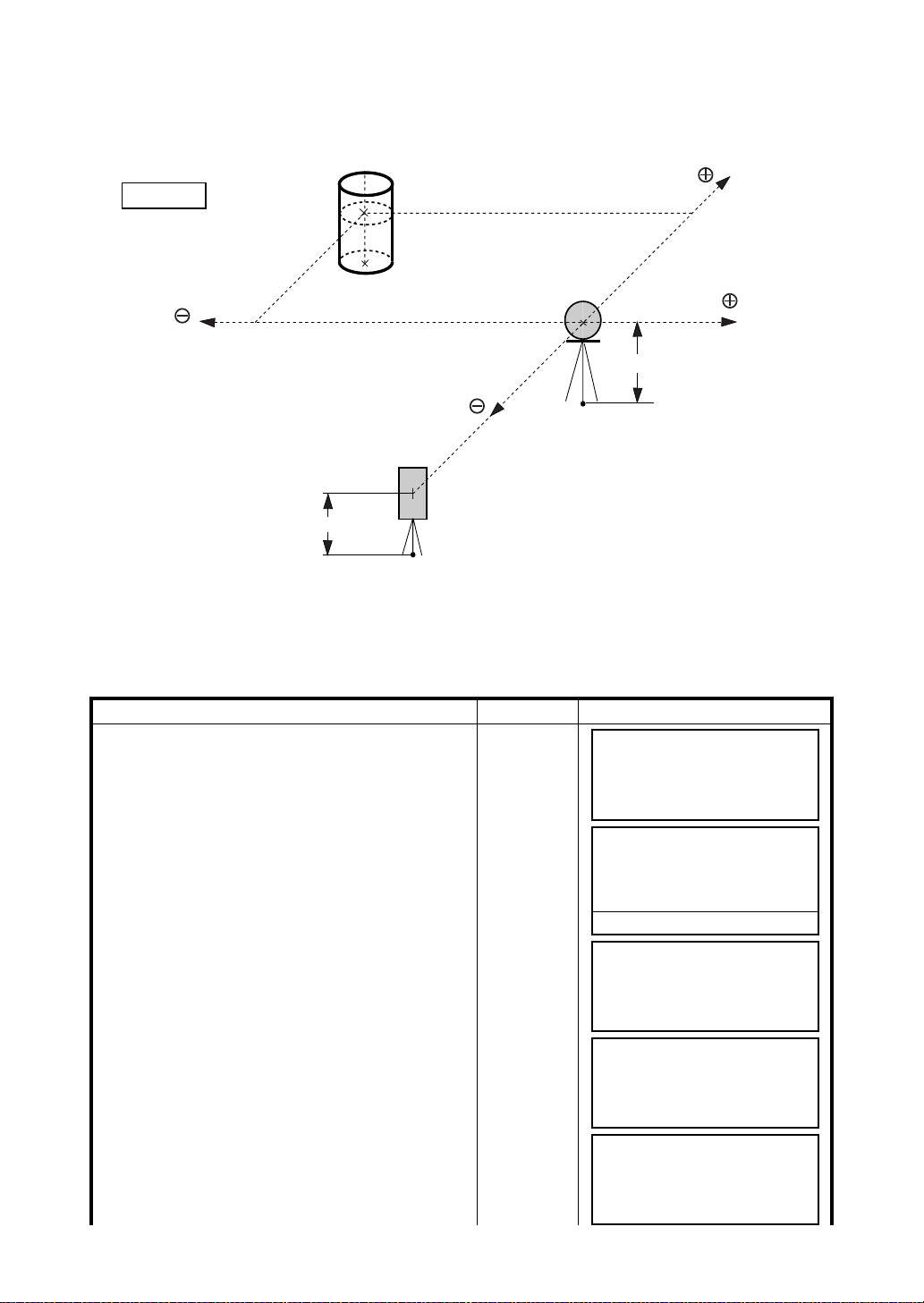

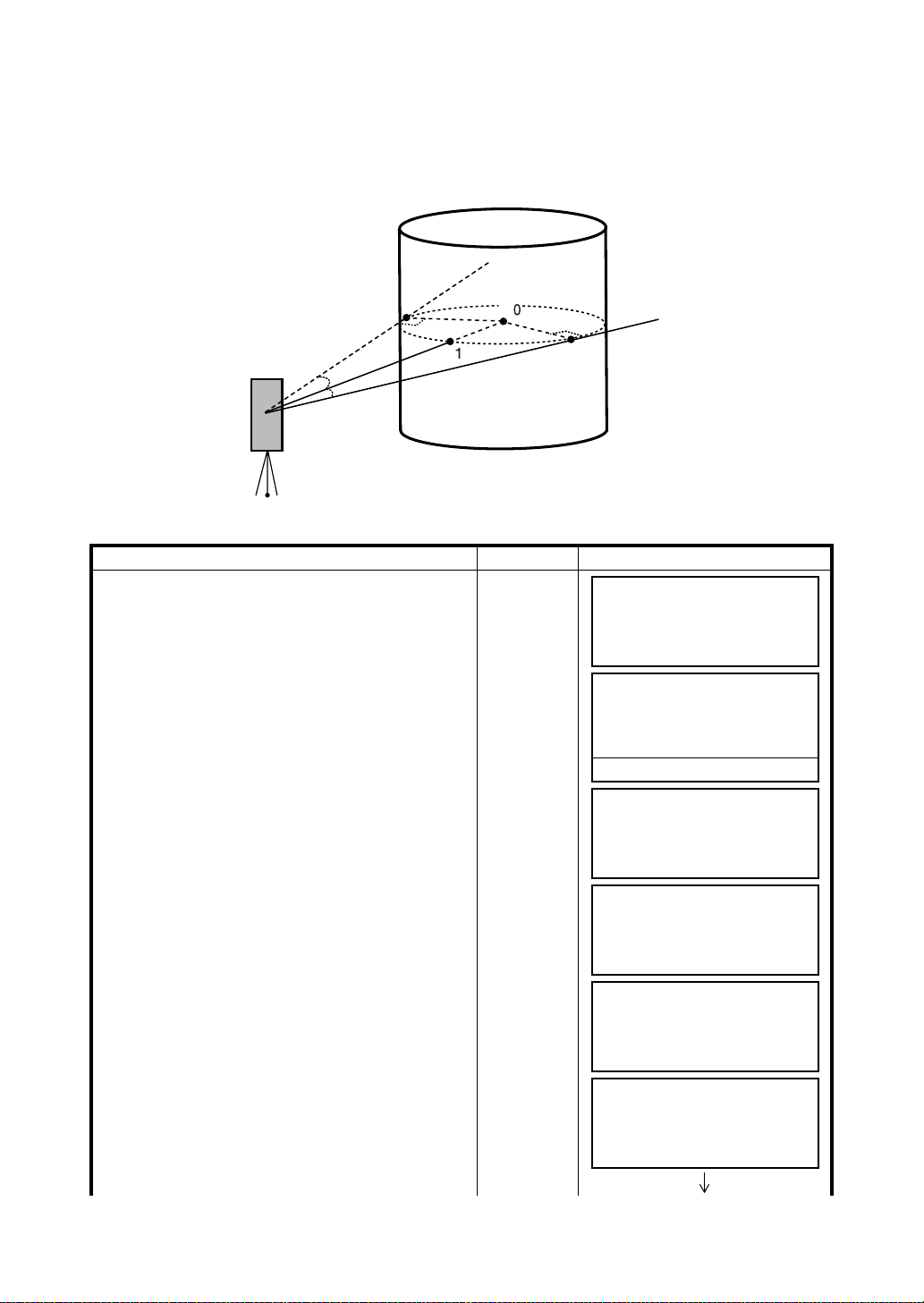

4.7.1 Angle Offset

This mode is useful when it is difficult to set up the prism directly, for example at the center of a tree.

Place the prism at the same horizontal distance from the instrument as that of point A0 to measure.

To measure the coordinates of the center position, operate the offset measurement after setting the

instrument height/prism height.

When measuring coordinates of ground point A

:Set the instrument height/prism height.

When measuring coordinates of point A

Prism P

Prism height

Instrument height

Occ. Point

● Set the instrument height/prism height before proceeding to the offset measurement mode.

● When setting the coordinate value for the occupied station, refer to Section 5.1 “Setting Coordinate

Values of Occupied Point”.

the instrument height only. (Set the prism height

to 0 ).

When sighting to A

ways. One is to fix vertical angle to the prism

position even updown the telescope position, and

the other is to gear vertical angle to the updown of

telescope movement. In case following the

vertical angle to the movement of telescope,

SD(Slope Distance) and VD(Vertical Distance)

will be changed according to the movement of

telescope.

To set this option, refer to Chapter 16

“SELECTING MODE”.

, you can select one of two

0

: Set

0

1

Operating procedure Operation Display

1 Press the [F4](P1

mode to get the function on page 2.

↓

) key from distance measuring

2 Press the [F1](OFSET) key.

3 Press the [F1](ANG. OFFSET) key.

4 Collimate prism P, and press the [F1](MEAS) key.

[F4]

[F1]

[F1]

Collimate P

[F1]

HR: 120°30'40"

HD: 123.456 m

VD: 5.678 m

MEAS MODE NP/P P1

OFSET S.O S/A P2

OFFSET 1/2

F1:ANG.OFFSET

F2:DIST.OFFSET

F3:PLANE OFFSET P1

OFFSET-MEASUREMENT

HR: 120°30'40"

HD: m

MEAS --- NP/P ---

OFFSET-MEASUREMENT

HR: 110°20'30"

HD* [n] << m

>Measuring...

↓

↓

↓

4-7

Page 40

4 DISTANCE MEASUREMENT

The horizontal distance from the instrument to the

prism will be measured.

OFFSET-MEASUREMENT

HR: 110°20'30"

HD: 56.789 m

NEXT --- --- ---

5 Collimate point A

clamp and horizontal tangent screw.

using the horizontal motion

0

Collimate

A

0

OFFSET-MEASUREMENT

HR: 113°30'50"

HD: 56.789 m

NEXT --- --- ---

6 Show the relative elevation of point A

.

0

[ ]

OFFSET-MEASUREMENT

HR: 113°20'30"

VD: 3.456 m

NEXT --- --- ---

7 Show the slope distance of point A

● Each time pressing the [ ] key, horizontal

distance, relative elevation and slope distance are

shown in sequence.

8 Show N coordinate of point A

● Each time pressing [ ] key, N,E and Z

coordinate are shown in sequence.

● To return to procedure

● To return to the previous mode, press the [ESC] key.

● To select the Non-prism or Prism mode, press the [F3](NP/P) key after the step 4.

4, press the [F1](NEXT) key.

or A1.

0

.

0

[ ]

OFFSET-MEASUREMENT

HR: 113°20'30"

SD: 56.894 m

NEXT --- --- ---

[]

OFFSET-MEASUREMENT

HR: 113°20'30"

N : -12.345 m

NEXT --- --- ---

4-8

Page 41

4 DISTANCE MEASUREMENT

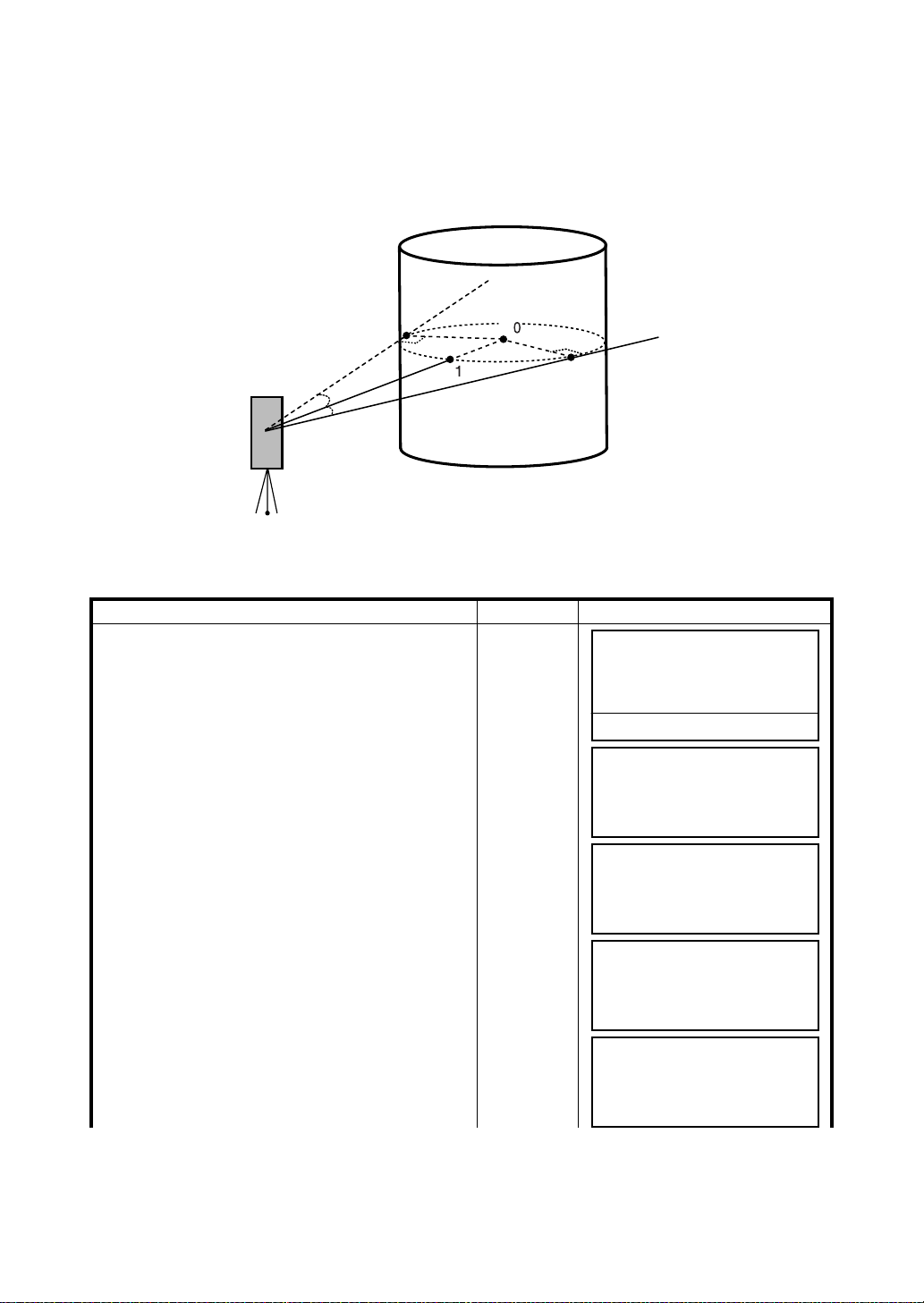

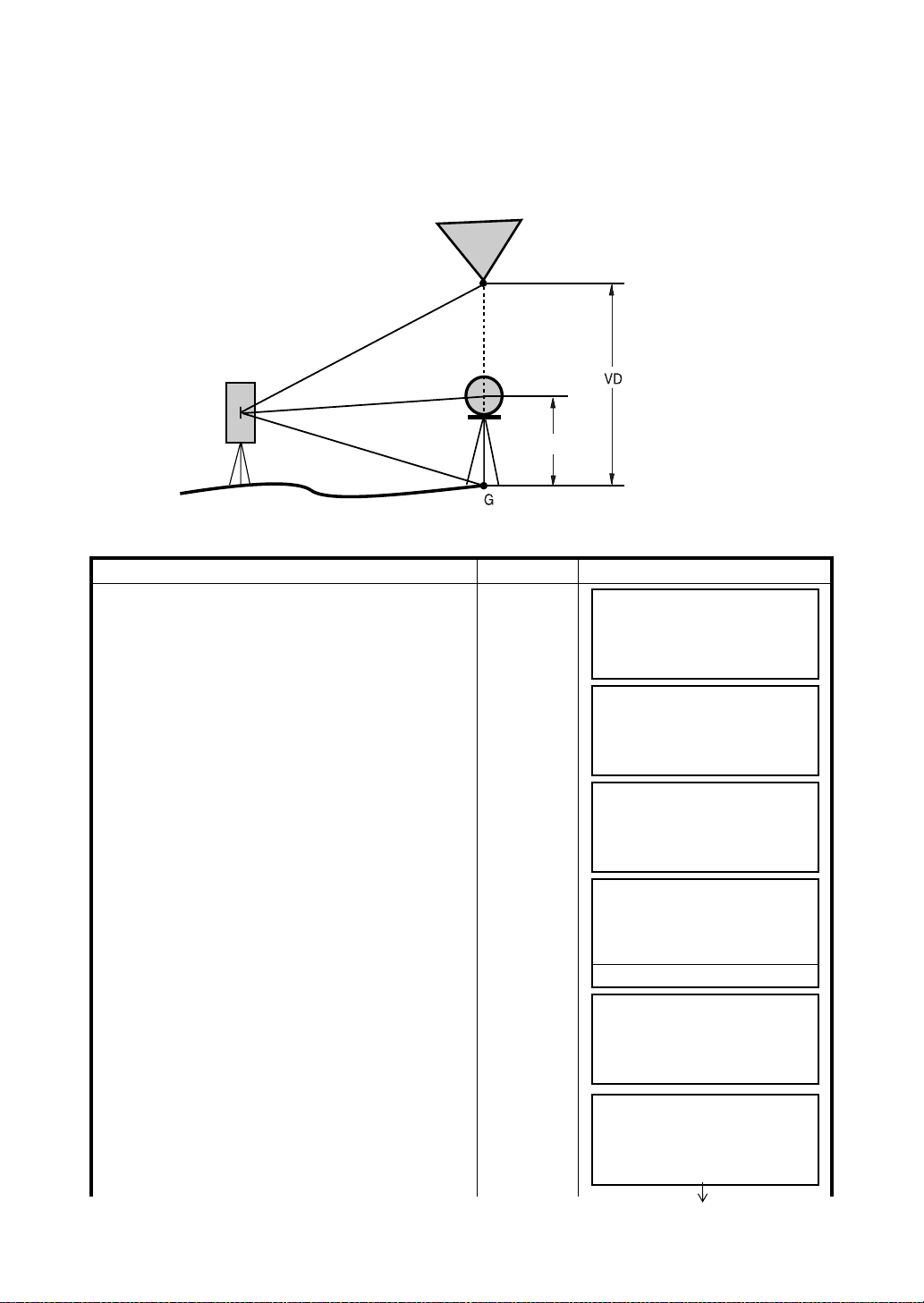

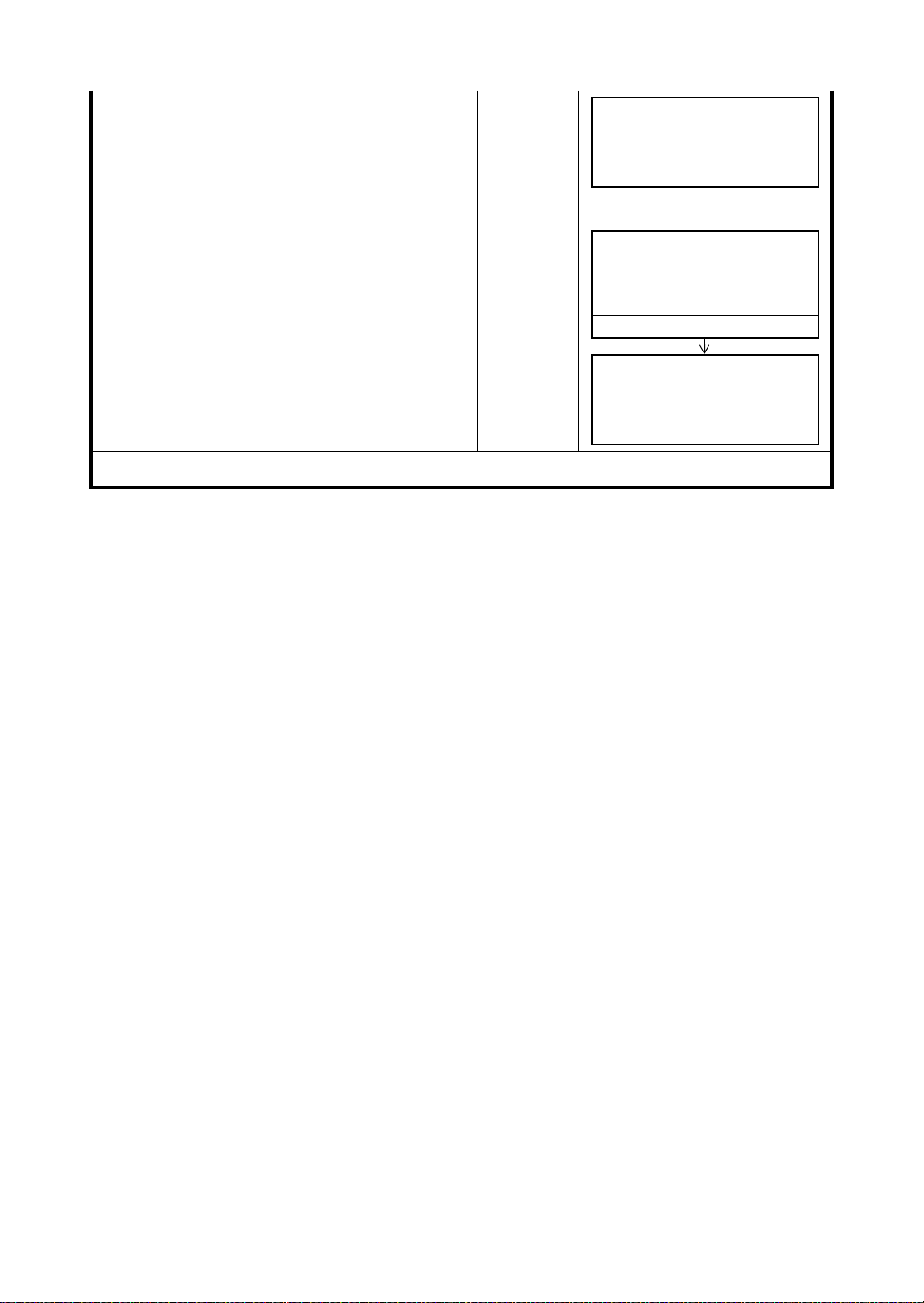

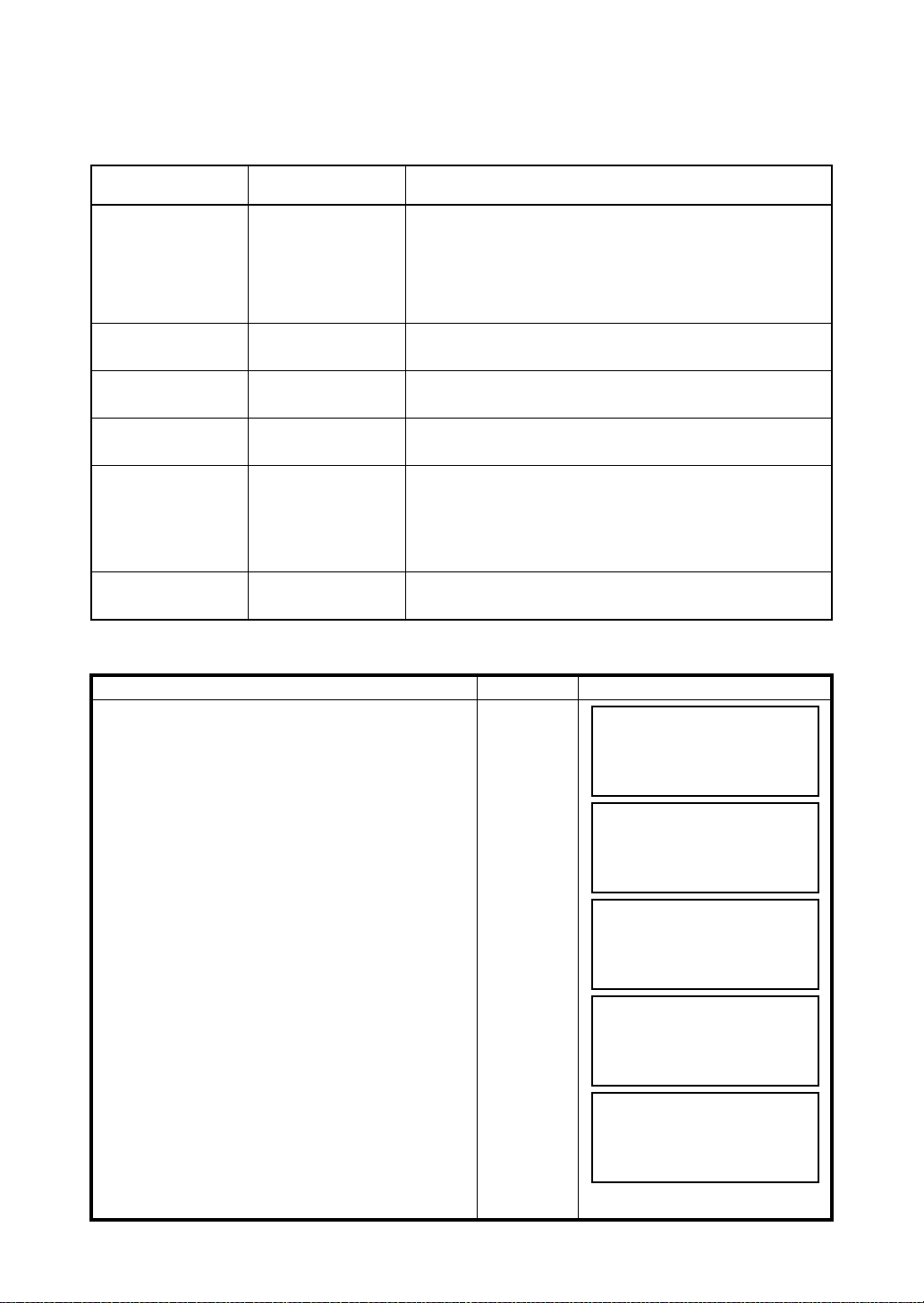

4.7.2 Distance Offset Measurement

Measuring distance and coordinate of the center of a pond or a tree of which the radius is known.

Measuring the distance or coordinate till P0 point, input

point showing as following draw in distance offset measurement. The display shows distance or

coordinate value until P0 point.

P0

oHD value as an offset value and measure P1

P1

P1

oHD >0

In case the measuring point of (P1) is front side than that of requiring

point of (P0), the offset value shall be plus, and if it is rear side, the

offset value shall be minus.

Occ. Point

● When setting the coordinate value for the occupied station, refer to Section 5.1 “Setting Coordinate

Values of Occupied Point”.

Operating procedure Operation Display

1 Press the [F4](P1

mode to get the function on page 2.

↓

) key from distance measuring

[F4]

oHD < 0

HR: 120°30'40"

HD: 123.456 m

VD: 5.678 m

MEAS MODE NP/P P1

OFSET S.O S/A P2

2 Press the [F1](OFSET) key.

[F1]

OFFSET 1/2

F1:ANG.OFFSET

F2:DIST.OFFSET

F3:PLANE OFFSET P

↓

↓

↓

3 Press the [F2](DIST. OFFSET) key.

4 Press the [F1](INPUT) key and enter a offset

value, and press the [F4](ENTER) key.

5 Collimate prism P1, and press the [F1](MEAS)

key .

Measuring will start.

4-9

[F2]

[F1]

Offset

value

[F4]

Collimate

P1

[F1]

DISTANCE OFFSET

INPUT FORWARD HD

oHD: m

INPUT --- --- ENTER

DISTANCE OFFSET

HR: 80°30'40"

HD: m

MEAS --- NP/P ---

DISTANCE OFFSET

HR: 80°30'40"