Page 1

Part No.

35720

Wendy's USA RH36C1W + RH36C7W - English

Toastmaster

Wendy's

Chili

Range

MODELS RH36C1W & RH36C7W

OWNER'S OPERATING

& INSTALLATION

MANUAL

Toastmaster

A Middleby Company

1400 Toastmaster Drive • Elgin, IL 60120 U.S.A. • 847/741-3300 • Fax 847/741-4406

Price: $30.00

R: 11/97

Page 2

WARNING

FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

WARNING

In case of fire, de-energize the Oven Range at its

main disconnect switch / circuit breaker. Switching OFF the

power to the Oven Range allows it to cool, making it easier to

extinguish a fire.

WARNING

ONLY use a CO2 or other fire extinguisher suitable for grease,

oil, and electrical equipment fires. Do NOT try to stop a grease

fire by pointing the fire extinguisher nozzle directly on the

burning grease. Direct the nozzle to the outside of the flames

to prevent them from spreading. Gradually, spray closer to the

center of the flames, to cool and smother them.

CAUTION

DO NOT move the Oven Range while cooking.

Pots of liquid could spill, causing injury.

NOTICE

Contact your local authorized Service Agency to perform maintenance and repairs. A

Service Agency directory is supplied with your oven.

Using any parts other than genuine Toastmaster factory -supplied parts

relieves the manufacturer of all liability.

Toastmaster (Manufacturer) reserves the right to change specifications and product

design without notice. Such revisions do not entitle the buyer to corresponding

changes, improvements, additions or replacements for previously purchased

equipment.

NOTICE

NOTICE

Keep This Manual Available For Future Reference.

ii

Page 3

Toastmaster

NO QUIBBLE LIMITED WARRANTY

TOASTMASTER, HEREINAFTER REFERRED TO AS THE SELLER, WARRANTS

EQUIPMENT MANUFACTURED BY IT TO BE FREE FROM DEFECTS IN MATERIAL

AND WORKMANSHIP FOR WHICH IT IS RESPONSIBLE. THE SELLER'S OBLIGATION

UNDER THIS WARRANTY SHALL BE LIMITED TO REPLACING OR REPAIRING, AT

SELLER'S OPTION, WITHOUT CHARGE, ANY PART FOUND TO BE DEFECTIVE AND

ANY LABOR AND MATERIAL EXPENSE INCURRED BY SELLER IN REPLACING OR

REPAIRING SUCH PART. SUCH WARRANTY SHALL BE LIMITED TO THE ORIGINAL

PURCHASER ONLY AND SHALL BE EFFECTIVE FOR A PERIOD OF ONE YEAR

FROM DATE OF ORIGINAL INSTALLATION, OR 18 MONTHS FROM DATE OF

PURCHASE, WHICHEVER IS EARLIER; PROVIDED THAT TERMS OF PAYMENT HAVE

BEEN FULLY MET.

As part of Toastmaster's "no quibble" warranty, all in-warranty Toastmaster products that require

service, are to be serviced on site.

The warranty period for Accu-Miser griddles shall be 24 months from the date of installation or 30

months from the date of purchase, whichever is earlier.

Normal maintenance functions, including lubrication, cleaning, or customer abuse, are not covered

by this "no quibble" warranty.

Seller shall be responsible only for repairs or replacements of defective parts performed by Seller's

authorized service personnel. Authorized service agencies are located in principal cities throughout

the contiguous United States, Alaska, and Hawaii. This warranty is valid in the 50 United States and

is void elsewhere unless the product is purchased through Middleby International with warranty

included.

The foregoing warranty is exclusive and in lieu of all other warranties, expressed or implied.

There are no implied warranties of merchantability or of fitness for a particular purpose.

The foregoing shall be Seller's sole and exclusive obligation and Buyer's sole and exclusive remedy

for any action including breach of contract or negligence. In no event shall Seller be liable for a sum

in excess of the purchase price of the item. Seller shall not be liable for any prospective or lost profits

of Buyer.

Copyright © 1997 - Toastmaster, A Middleby Company. All rights reserved.

Toastmaster

A Middleby Company

Middleby Corporation 24-Hour Service Hotline: 1-800-238-8444

iii

Page 4

TABLE OF CONTENTS

SECTION 1 - DESCRIPTION

A. OVEN BASE ............................................................................................................................. 1

B. RANGE TOP ............................................................................................................................. 2

C. OVEN RANGE SPECIFICATIONS ........................................................................................... 2

D. DIMENSION DRAWING ............................................................................................................ 3

SECTION 2 - INSTALLATION

A. INSPECT FOR SHIPPING DAMAGE ........................................................................…............ 5

B. MOVING AN OVEN RANGE TO ITS OPERATING SITE ......................................................... 5

C. INSTALLING CASTERS ON AN OVEN RANGE ...................................................................... 5

D. CONNECTING ELECTRIC POWER (ONE 3-0 AND ONE 1-0 POWER SOURCE)................ 7

E. CONNECTING ELECTRIC POWER (ONE 3-0 POWER SOURCE) ........................................ 7

F. CLEANING THE GRIDDLE AND HOT PLATE(S).................................................................... 8

G. TESTING AN OVEN RANGE FOLLOWING INSTALLATION ................................................... 8

SECTION 3 - OPERATION

I. COMPONENT FUNCTION AND LOCATION............................................................................ 9

II. CONTROL FUNCTIONS AND LOCATIONS............................................................................. 10

A. Convection Oven Control Panel ...........................................................................….............

B. Range Top Control Panel......................................................................................….............

III. OVEN OPERATIONS ............................................................................................................... 12

A. Convection Oven Operation ................................................................................…..............

B. End of Shift Operation - Convection Oven.......................................................…..................

IV. RANGE TOP OPERATIONS..................................................................................................... 13

A. Griddle 'Seasoning'........................................................................................…...................

B. Griddle Operating Hints and Safety.............................................................……...................

C. Daily Pre-Operation ....................................................................................…......................

D. End of Shift Operation - Griddle....................................................................…....................

E. 12" x 24" Hot Plate Operation....................................................................….......................

F. 12" x 24" Hot Plate Cleaning .............................................................................................. 14

SECTION 4 - PARTS LIST

Figure 4-1. Oven Range Overall Drawing...................................................………...............................

Oven Range Overall Parts List ..................................................................................................

Figure 4-2. Convection Oven Drawing .....................................................…….....................................

Convection Oven Overall Parts List...........................................................................................

SECTION 5 - SCHEMATICS

RH36C1W Wiring Diagram ("Schematic") 208/240V (USA) ..............................................................

RH36C1W Schematic ("Ladder Diagram") 208/240V (USA).............................................................

RH36C1W Wiring Diagram 480V (USA)............................................................................................

RH36C1W Schematic 480V (USA)................................................................................................... 25

RH36C7W Wiring Diagram 208/240V (USA).....................................................................................

RH36C7W Schematic 208/240V (USA).............................................................................................

RH36C7W Wiring Diagram 480V (USA)............................................................................................

RH36C7W Schematic 480V (USA)....................................................................................................

10

11

12

12

13

13

13

13

14

16

17

18

19

22

23

24

26

27

28

29

iv

Page 5

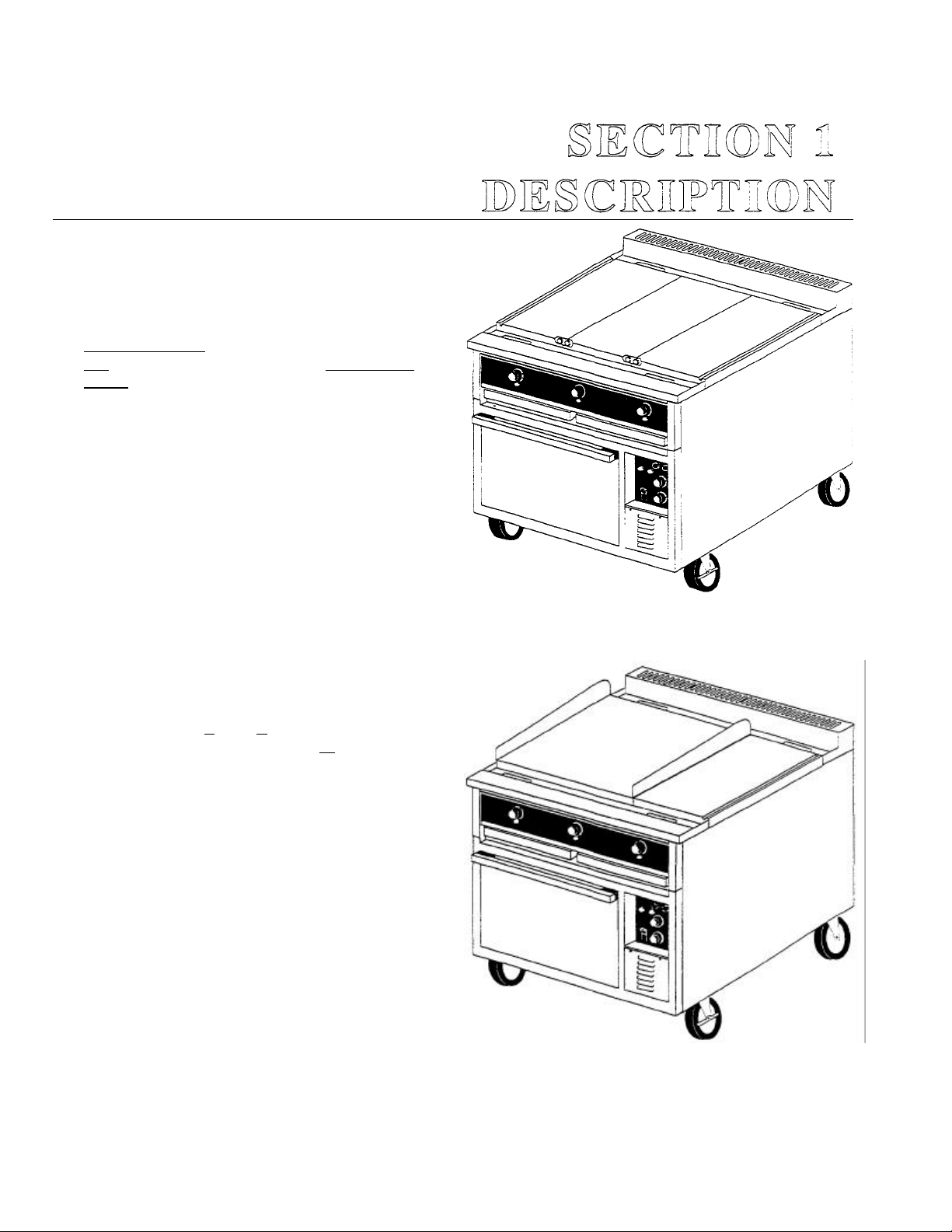

A "Wendy's Chili Range" is a special

Toastmaster

Oven Range that is rated 'heavy-duty for commer-

Figure

1-1. RH36C1W

Ov

en Range

Figure

1-2. RH36C7W

Oven Range

cial use.' This Oven Range consists of a Range Top

(RH36) fastened to an Oven Base (C036), as shown

in Figure 1-1. A terminal block allows electric power

supply connections to an Oven Range from either a

dual power supply (208, 240, or 480 volts, 3-phase

and 1 -phase, 50 or 60 Hertz) OR a single power

supply (208, 240, or 480 volts, 3-phase (only), 50 or

60 Hertz). Refer to electrical supply information,

appearing in Section 1 (paragraph C) and in Section

2, as well as the appropriate 'schematic' (wiring diagram) and 'ladder diagram' (schematic) in Section 5

for the operating site.

Operating power must be supplied via either a fused

disconnect switch or a circuit breaker, sized in compliance with the governing code(s) of the local

statutory authority at the operating site or the NEC

(National Electrical Code).

A. OVEN BASE

The Oven Base houses a convection oven. [This type

of oven is denoted by the letter “C" in the model

designations assigned to the Oven Ranges especially

designed for Wendy's: RH36C1W and RH36C7W.

("RH" designates Range, Heavy-duty; the "W" applies

to a product specially designed for Wendy's.) The "1"

and "7" specify different styles of Range Top units,

respectively depicted in Figures 1-1 and 1-2.]

This convection oven has a stainless-steel oven liner

and a landing shelf-type, oven door. The oven is

insulated on all sides. Removable side racks support

up to four shelf assemblies. Its heating element is

enclosed on the right side of the oven chamber and

encircles the impeller-type blower fan, which draws

the heated air into the baking chamber, moving it

around the chamber to transfer its heat to the food

product being cooked/baked.

The oven has a three-heat (Low-Medium-High) temperature control. The Low setting is approximately

325°F (163°C); Medium is approximately 375°F

(191°C); High is approximately 425°F (218°C). The

oven can preheat to 375°F (191°C) in 10 minutes.

1

Page 6

SECTION 1 - DESCRIPTION

B. RANGE TOP

Griddles and Hot Plates are available in two configu rations

as the main components of the Range Top module of the

Oven Range. Each combination has its own model

number within the Oven Range series. Wendy's selected

models RH36C1W and RH36C7W as their preferred Oven

Ranges.

The RH36C1W Oven Range (shown in Figure 1-1) has

three 12" x 24" Hot Plates covering its Range Top cooking

surface. An RH36C7W Oven Range (Figure 1-2) has a

Range Top cooking surface of one 12" x 24" Hot Plate

(right unit) and one 24" x 24" griddle (left unit).

a. Griddle. The 24" x 24" Griddle has thermostatic control

for each of two 12" x 24" zones. Each griddle zone has a

temperature range of 200°F to 550°F (93°C to 288°C) and

can preheat to 400°F (204°C) in 12 minutes. Figure 1-2

shows an RH36C7W Oven Range with a 24" x 24" Griddle

(left) and one 12" x 24" Hot Plate (right) as its Range Top

cooking surfaces.

b. Hot Plate. The 12" x 24" Hot Plate has thermostatic

control, with a temperature range of 250°F to 850°F

(121°C to 454°C) and can preheat to 400°F (204°C) in 12

minutes. The hot plate is not recommended for griddle-

type cooking; however, it is very useful for stock pot

cooking and other similar heating tasks.

C. OVEN RANGE SPECIFICATIONS

Dimensions:

On Casters

Width

Depth 38-3/4" (98.4 cm)

Height 38-3/8" (97.5 cm)

Weight RH36C1W 569 Ib (258 kg)

36" (91.5 cm)

RH36C7W 545 Ib (247 kg)

Construction: Welded Steel Frame

Finish: Stainless Steel Front, Sides and Top

Aluminized Steel Back

Electrical Requirements: The Oven Range total

power requirement is 24.2 Kilowatt (KW). The

Range Top power requirement is 15.9 KW; the

Oven Base power requirement is 8.3 KW.

Refer to Section 5 for specific ratings of each Oven

Range model. While the total power requirement

remains the same for each Oven Range, the

amperage requirement for the Range Top and

Oven Base modules varies, based on the specific

input voltage and the electric power connection.

Shipping Container Size

Width 40-1/4" (102 cm)

Depth 43" (109 cm)

Height 39-3/4" (101 cm)

Shipping Weight

RH36C1W 533 Ib (242 kg)

RH36C7W 593 Ib (269 kg)

2

Page 7

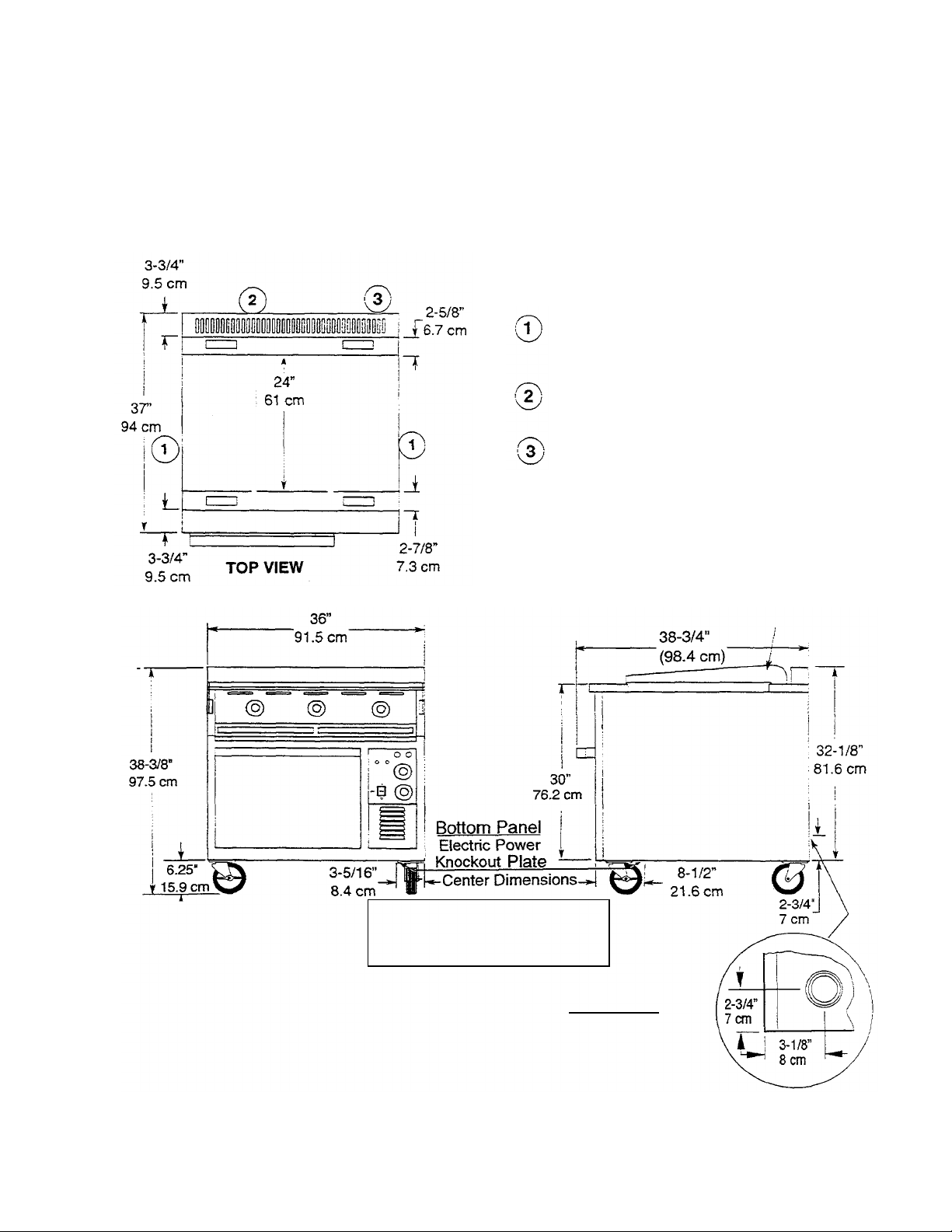

D. DIMENSION DRAWING

REQUIRED CLEARANCES

3"

minimum clearance from Oven Range

FRONT VIEW

SIDE VIEW

Rear Panel

Electric

Splash guard only on range

Figure 1-3 provides dimensional information for both models of

the Wendy's Chili Range.

SECTION 1 - DESCRIPTION

side panel to wall.

6" minimum spacing between appliances

(except Toastmaster Oven Ranges).

0" minimum clearance from Oven Range

rear panel to wall, when using knockout

plate on bottom panel of oven.

4" minimum clearance from Oven Range

rear panel to wall, when using knockout

plate on rear panel.

Knockout Plate Diameters -

Dia.

1-3/8" 1-3/4" 2"

3.5cm 4.5cm 5.1 cm

Power Knockout

Plate Center

Dimensions

equipped with griddle

Figure 1-3. Dimensions, All Models of Wendy's RH36 Oven Ranges

3

Page 8

A. INSPECT FOR SHIPPING DAMAGE

Each Toastmaster product is carefully inspected

and packaged at the factory. The freight carrier

assumes responsibility for safe transport and

delivery. The customer must examine all shipping

containers before, and during, the unloading

process.

If any product is received in damaged condition,

either apparent or concealed, a claim for damages

must be made with the delivering carrier. The carrier

will supply the necessary claim forms.

1. Apparent Damage/Loss - When damage or loss

is apparent, it must be noted on the freight bill or

express receipt at the time of delivery and it must

be signed by the carrier's agent (driver). If this

report is not made, the carrier may refuse the

claim. The carrier will supply the necessary claim

forms.

2. Concealed Damage /Loss - When damage or

loss is NOT apparent until the equipment is

unpacked, a request for inspection of concealed

damage or loss must be made with the carrier

within 15 days. The carrier will make an inspec tion

and will supply the necessary claim forms. Be

certain to retain all containers and their contents,

plus external and internal packaging material for

inspection.

B. MOVING THE OVEN RANGE TO ITS

OPERATING SITE

After unloading the Oven Range shipping container from

the freight carrier's vehicle, simply remove the metal

banding straps and packaging materials.

In a convenient location, attach the casters to the bottom

of the Oven Range, as described in paragraph C. Then,

move the Oven Range to its operat ing site.

C. INSTALLING CASTERS ON AN OVEN RANGE

To install casters on an Oven Range:

1. Raise the Oven Range enough to allow the

attachment of the casters to the bottom panel.

2. Attach a caster near each bottom corner of the Oven

Base, using the hardware supplied (1/4 -20 hex head

bolt and a lockwasher). Locking casters are to be

mounted on the front of the Oven Base; non-locking

casters are to be mounted on the rear.

b. Now, roll the Oven Range to its operating site. Next,

press down on the locking portion of th e casters to

limit movement of the Oven Range.

5

Page 9

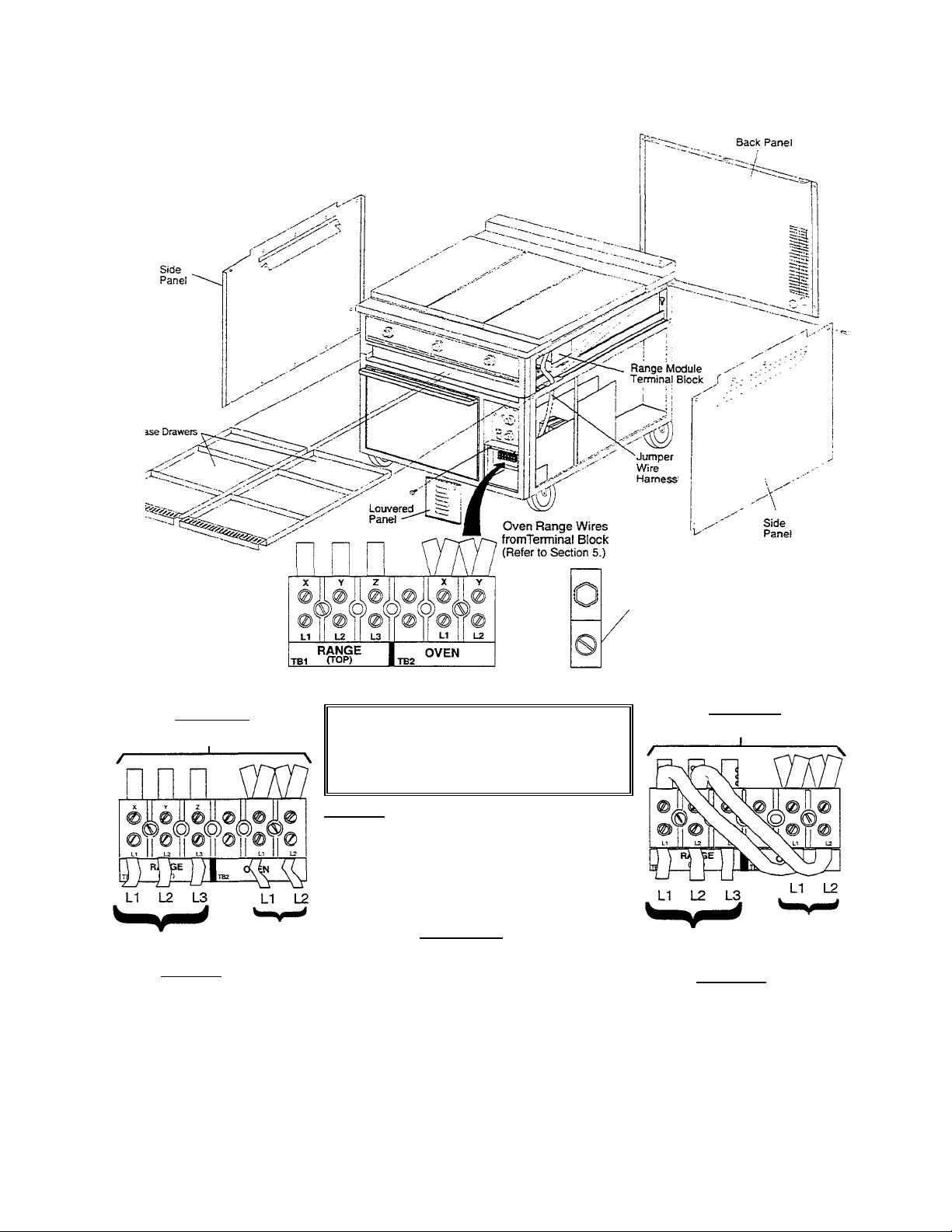

SECTION 2 - INSTALLATION

Connect Electric Supply Ground Wire

Load

-

Side –

Load-Side –

Jumpers from TB1 to

Line-Side - One

Line-Side -

via Two

6

Range Top & Oven Wiring

3-Ø Source

Disconnect Switches/

Circuit Breakers

(One 3-Phase; one 1-Phase)

Figure 2-2. Electric Supply - Oven Range Terminal Block Connections

Figure 2-1. Installation of Range Top and Oven Base Modules

Consult the Diagrams of Section 5 (or the

CAUTION Tag attached to the Terminal Block)

concerning Power and Amperage factors for

the Oven Range.

Left view: Recommended

Electric Supply Connection for

U.S.A. Oven Range Installations,

having two (one 3-Ø and one 1-

Ø) electric supplies.

1-Ø Source

Right View: Optional Electric

Supply Connection for Oven

Range Installations having one

(3- Ø) electric supply.

into Grounding Lug Terminal (located at

right of Terminal Block)

Range Top & Oven Wiring

3-Ø Source

Disconnect Switch/

Circuit Breaker

(One 3-Phase)

TB2 (Added at

Installation)

Page 10

D. CONNECTING ELECTRIC POWER (ONE 3-Ø

AND ONE 1-Ø POWER SOURCE)

SECTION 2 - INSTALLATION

E. CONNECTING ELECTRIC POWER (ONE 3-Ø

POWER SOURCE)

CAUTION

MAKE SURE that the electric supply wiring

connections satisfy the requirements of the

governing electrical code for the locality.

NOTE: Some municipal electrical codes can

require a store to have a separate disconnect

switch (or circuit breaker) for each Oven Range

module;

that is, one switch for the RANGE connections,

and another switch for the OVEN connections,

as shown by the left diagram of Figure 2-2.

1. Measure the diameter of the conduit or cable

conducting the electric power from each main

disconnect switch / circuit breaker.

2. Remove the knockout in the knockout plate

(located either on the bottom panel of the Oven

Base, near the front right leg/caster mounting

area, or on the rear panel near the lower right

comer) that just exceeds the size of the conduit

or cable. Install a strain-relief fitting (not furnished) into the knockout plate hole. Guide the

proper length of conductors into the bottom of

the Oven Range to reach the terminal block

behind the louvered panel (Figure 2-1). Tighten

the strain-relief fitting to prevent accidental

movement of the conduit or cable.

3. Connect the three-phase power wires to their

respective input terminals (L1, L2, and L3) of

the RANGE portion (TB1) of the terminal block,

as shown in Figures 2-1 and 2-2. Connect the

incoming ground wire (where used) to the

grounding lug terminal next to the terminal

block.

NOTE: Also, refer to the Wiring Diagrams of

Section 5 for the wiring scheme that applies.

This depends on the voltage(s) at a particular

store.

4. For a store having both a 3-Ø and a 1-Ø discon-

nect switch (or circuit breaker) for the modules

of an Oven Range: Connect the 1-Ø power

wires to their respective input terminals (L1 and

L2) of the OVEN portion (TB2) of the terminal

block, as shown in Figures 2-1 and 2-2.

Connect the 3-Ø power wires to their respective

input terminals (L1, L2, and L3) of the RANGE

portion (TB1) of the terminal block.

MAKE SURE that the electric supply wiring

CAUTION

connections satisfy the requirements of the

governing electrical code for the locality.

NOTE: Some municipal electrical codes can require a

store to have only one disconnect switch (or circuit

breaker) for the entire Oven Range; the right diagram

of Figure 2-2 shows Oven Range connections meeting

this requirement.

1. Measure the diameter of the conduit or cable

conducting the electric power from the main

disconnect switch(es) / circuit breaker(s).

2. Remove the applicable knockout in the knockout

plate (located either on the bottom panel of the

Oven Base, near the front right leg/caster mount ing area, or on the rear panel near the lower right

corner) matching the size of the conduit or cable.

Install a strain-relief fitting (not furnished) into the

knockout plate hole. Guide the proper length of

conductors into the bottom of the Oven Range to

reach the terminal block behind the louvered

panel (Figure 2-1). Tighten the strain-relief fit-ting

to prevent accidental movement of the conduit or

cable.

3. Connect the three-phase power wires to their

respective input terminals (L1, L2, and L3) of the

RANGE portion (TB1) of the terminal block, as

shown in Figures 2-1 and 2-2. Connect the

incoming ground wire (where used) to the

grounding lug terminal next to the terminal block.

NOTE: Also, refer to the Wiring Diagrams of Section

5 for the wiring scheme that applies. This depends

on the voltage(s) at a particular store.

4. For a store having only one disconnect switch (or

circuit breaker) installed to power the Oven

Range, connect a jumper wire (capable of

handling the current draw of the Oven) from L1 of

the RANGE portion of the terminal block to L1 of

the OVEN portion. Also, connect a second

jumper wire from L2 of the RANGE portion of the

terminal block to L2 of the OVEN portion.

5. Tighten the screw of each terminal block connec tor and the grounding lug terminal to securely

connect each wire (avoiding damage to the wiring

insulation).

5. Tighten the screw of each terminal block

connector and the grounding lug terminal to

securely connect each wire (avoiding damage

to the wiring insulation).

7

Page 11

SECTION 2 - INSTALLATION

F. CLEANING THE GRIDDLE AND HOT PLATE(S)

1. Remove the rust preventive material from the surface

of the Griddle and/or Hot Plate(s), using a

nonflammable grease solvent.

2. Clean the Griddle surface by wiping it with a clean

cloth dampened with warm water and a mild

detergent.

3. Rinse the surface by wiping it with a clean, damp

cloth. Wipe dry.

4. 'Season' the Griddle immediately. Refer to Section 3,

OPERATION, for the 'Season' Procedure.

G TESTING AN OVEN RANGE FOLLOWING

INSTALLATION

1. Switch OFF all Range and Oven controls.

2. Switch ON the main disconnect switch(es) /

circuit breaker(s).

3. Check each Range Top zone (Griddle section or Hot

Plate area) by switching ON one control at a time,

starting at the left side of the Range Control Panel.

Confirm that each Range Top zone begins heating.

Then, switch OFF the control for that zone.

4. Repeat step 3 for each zone of the Range Top.

5. 'Season' the 12" x 24" Hot Plate immediately. Refer to

Section 3, OPERATION, for the 'Season' Procedure.

5. Check the Oven operation, as follows:

a. Set the TEMPERATURE control to LOW.

b. Press the "1" (ON) side of the OVEN POWER

switch.

c. After a few minutes, open the door of the

oven and confirm that the oven is heating.

6. Switch OFF all Range and Oven controls.

8

Page 12

RANGE TOP

Range

Grease

OVEN BASE

Oven Door

Grease Drawers

Oven Control

9

I. COMPONENT FUNCTION AND LOCATION

(Figure 3-1)

A. OVEN BASE Module - Convection Oven,

including heating element, blower fan, and

operating controls.

B. Oven Control Panel - All Oven operating

controls and indicators.

C. Oven Door - "Landing-shelf" door with insulated

handle for access to oven racks.

D. RANGE TOP Module - Location of Hot

Plate(s) and/or Griddle cooking surfaces,

along with the operating controls.

E. Range Control Panel - All Griddle and/or Hot

Plate(s) operating controls.

F. Grease Troughs - In front and behind the

Range Top cooking surfaces. (Grease chutes

provide drainage into the grease drawers.)

G. Grease Drawers - Containers for grease

draining through the grease chutes from

grease troughs.

MODULE

Control

Panel

MODULE

Figure 3-1. Oven Range

Controls & Components

Trough

(Front

and

Back)

Panel

Page 13

SECTION 3 - OPERATION

II. CONTROL FUNCTIONS AND LOCATIONS

A. Convection Oven Control Panel (Figure 3-2)

1. ON Indicator - Indicator glows, when the OVEN

POWER switch is in the ON position.

2. HEATING Indicator - Indicator glows (amber)

whenever electric power is applied to the oven heating

element.

(Low-Medium-High) switch to control oven heating.

The following temperature value is approximate for

each setting:

Low- 325°F(163°C);

Medium- 375°F (19-TC);

High- 425°F(218°C).

5. OVEN POWER - OFF/ON Switch - Off-On (0/1)

rocker switch controlling power application for Oven

operation.

3. FUSES Fuseholders - Containers for 10Ampere fuses (in each power input circuit to the

oven).

4. TEMPERATURE Control - Three-position

6. TIMER Signal - Adjustable timing device for Oven

operation, signaling (via a bell chime) when the

operator-set time setting elapses. Time settings can

range from 6 (lowest mark) to 120 minutes (highest

mark).

10

Figure 3-2. Oven Control Panel

Page 14

II. CONTROL FUNCTIONS AND LOCATIONS

(Continued)

B. Range Top Control Panel (Figures 3-3 and 3-4)

1. Power Indicator - Indicator glows (amber) whenever

power is being applied to the zone controlled by a

Griddle Temperature Control Oust above the indicator).

2. Temperature Control for 12" x 24" Hot Plate -

Control knob allows the operator to adjust the

temperature setting for power applied to the heating

element of a 12" x 24" Hot Plate. NOTE: Temperature

range is 250°F to 850°F (121°Cto454°C).

SECTION 3 - OPERATION

3. Temperature Control for Griddle - Control knob

allows the operator to adjust the temperature setting of

a griddle zone heating element. A 24" x 24" Griddle

has two zones. NOTE: Temperature range is 200°F to

550°F (93°C to 288°C).

4. Power Indicator - Indicator glows (amber) whenever

power is being applied to the Hot Plate controlled by

the Temperature Control (just above the indicator).

Figure 3-3. Range Top Controls - RH36C1W Oven Range

Figure 3-4. Range Top Controls - RH36C7W Oven Range

11

Page 15

SECTION 3 - OPERATION

III. OVEN OPERATIONS

B. End of Shift Operation - Convection Oven

(Continued)

A. Convection Oven Operation

1. Set the TEMPERATURE Control to the desired

setting (Low-Medium-High) for the product.

2. Press the ON (1) portion of the OVEN POWER

Switch. Observe that the ON and HEATING

Indicators both begin glowing.

3. When the HEATING Indicator goes out (becomes

unlighted), place the pans containing the product to

be heated/cooked on the racks of the oven. Position

the pans to avoid blocking air flow on the sides or

back of the baking chamber. Blocking the air flow

can cause uneven, improper heating/cooking.

4. Set the TIMER Control for the desired heating/

cooking time.

NOTE: Opening the oven door often causes uneven

heating/cooking. Keep the oven door CLOSED

except for necessary checking of product being

heated/cooked - very near the end of the

heating/cooking time.

5. Remove the pans containing the product from the

oven, when the TIMER signals (bell chimes) that the

heating/cooking time has elapsed.

5. Detach the baffle surrounding the blower fan by

unscrewing three screws on the forward edge of the

baffle. Pull the baffle forward to free it.

6. Wash all shelf assemblies, side racks, and the blower

fan baffle in warm, soapy water. Rinse the parts in

clear, warm water. Wipe dry.

CAUTION

NEVER use abrasive cleaners because they may

scratch the oven's surface.

7. Use a stiff, plastic-bristle brush to clean the interior of

the cooking chamber. Use a mild detergent on a

damp sponge to wipe down the inside of the oven

and oven door. Rinse these surfaces with a clean,

damp cloth. Wipe dry.

8. Reinstall the baffle surrounding the blower fan,

making sure that the top front edge of the baffle is

very close to the top of the oven liner.

NOTE: Daily, or at least regular, cleaning prevents the

buildup of food particles and stains from spills.

Avoiding these problems aids in better oven

operation.

6. When further heat ing/cooking is not scheduled, set

Oven controls to their OFF positions.

NOTE: Bringing the oven to operating temperature only

requires 10 -15 minutes.

B. End of Shift Operation - Convection Oven

1. Be sure that all oven controls are switched to the

lowest setting or the OFF (0) position.

2. Open the oven door to aid in cooling.

3. After the oven is cool, remove the shelf assemblies.

4. Remove the side racks by lifting them up and away,

to clear the metal loops that position them in the

oven.

12

Page 16

IV. RANGE TOP OPERATIONS

CAUTION

Do NOT cook on a Griddle before

'seasoning' it. Remember that any rust

preventive material MUST be removed

before 'seasoning' the griddle.

SECTION 3 – OPERATION

Griddle Temperature Control(s) to 200°F (93°C)

during idle periods. (Only a few minutes is required to

regain the desired operating temperature when food

orders become more frequent.)

3. Use only one Griddle zone when cooking a small

amount of food.

A. Griddle 'Seasoning'

1. Spread a light film of unsalt ed cooking oil over the

entire Griddle surface with a soft cloth.

2. Set both Temperature Controls to 300°F

(149°C).

3. Operate the Griddle for at least two minutes to allow

the oil to work into the pores of the metal, forming a

smooth coating over the exterior surface of the

Griddle. Use a spatula to spread the oil, if

necessary.

WARNING

NEVER touch a operating griddle. Always

wait until the Temperature Control has

been set to OFF for at least 30 minutes.

4. Set the Griddle Temperature Controls to OFF and

wait at least 30 minutes for the griddle to cool,

before wiping off excess oil with clean cloths.

5. Next, set the Griddle Temperature Controls to

350°F(175°C).

6. Repeat steps 1, 3, and 4. This completes the

Griddle 'seasoning'.

7. Set the Griddle Temperature Controls to the

temperature setting(s) recommended for the type

of food to be heated/cooked.

4. Heat/cook different types of food at the same time by

setting the Temperature Control of each Griddle zone

to the temperature for heating/ cooking each food

type.

5. Hold' (keep warm) food on one zone by decreasing

its temperature setting.

6. Use a spatula to move excess grease or oil into a

grease trough after each load of food is

heated/cooked. This reduces the smoking and

carbonizing of hot grease.

C. Daily Pre-Operation

1. 'Season' the Griddle daily before operation. (Refer to

paragraph A of "Range Top Operations".)

2. Set the Temperature Controls of the Griddle zones to

the desired settings.

3. Wait 15 minutes before loading the Griddle with food

to be sure of heating/cooking the food properly.

4. Observe the indicator below each Temperature Control:

The indicator is lighted when the zone is heating to the

temperature setting. The indicator blinks on and off

while the temperature setting is being held almost

constant by the control.

D. End of Shift Operation - Griddle

B. Griddle Operating Hints and Safety

1. Never leave the Griddle operating without an

attendant.

2. Do not operate the entire Griddle at high temperature, when small amounts of food are being

heated/cooked or during idle periods. Set the

1. Clean the Griddle surface by pushing the grease

and/or oil into the grease troughs. Then, rub the

surface with a pumice stone or a 'griddle stone'. Rub

the Griddle surface in the direction of the metal grain

while the surface is warm (NOT hot).

2. Wipe the Griddle surface clean of residue from the

rubbing stone, using clean cloths.

13

Page 17

SECTION 3 - OPERATION

IV. RANGE TOP OPERATIONS (Continued)

F. 12" x 24" Hot Plate Cleaning

D. End of Shift Operation - Griddle (Continued)

3. Thoroughly clean the grease troughs, grease chutes,

and grease drawers at least once each day (more

often, if necessary).

4. Allow the Griddle to cool. Clean the sides of the

Griddle and all surfaces surrounding the Griddle by

wiping them with a clean cloth dampened in warm

water and a mild detergent.

5. Rinse all washed surfaces, using a clean cloth

dampened with warm, clear water. Wipe dry with a

clean cloth.

6. Empty each grease drawer as often as necessary,

at least once per shift, and at the end of each day.

Wash the grease drawers with hot water and a mild

detergent. Rinse with clear, hot water. Wipe dry.

NOTE: BE SURE to replace the grease drawers after

each cleaning.

E. 12" x 24" Hot Plate Operation

CAUTION

Do NOT cook on a 12" x 24" Hot Plate before

'seasoning' it. Remember that any rust preventive

material MUST be removed before 'seasoning'

the 12" x 24" Hot Plate.

At least once per shift (or day):

WARNING

NEVER touch a operating Hot Plate. Always

wait until the Temperature Control has been

set to OFF for at least 30 minutes.

1. Allow the Hot Plate to cool. Wash the 12" x 24" Hot

Plate surface with warm water and a mild detergent.

Also, clean all surfaces near the Hot Plate.

2. Rinse the Hot Plate (and adjacent surfaces) with

clear, warm water. Wipe dry with clean cloths.

1. 'Season' the 12" x 24" Hot Plate, using the same

procedure as for the Griddle. Refer to paragraph A (earlier

in "Range Top Operations") for this procedure.

2. After 'seasoning', set the Temperature Control to the

desired setting.

3. Wait 15 minutes for the Hot Plate to reach the desired

temperature setting.

4. Place pot(s) (or other cooking vessel(s)) atop the Hot

Plate surface for heating/cooking.

14

Page 18

SECTION 4- PARTS LIST

16

Page 19

Oven Range Overall Parts List

Screw, Hex Washer Head,

1/4 - 20 x

Item

Qty Part No. Description No.

No.

1 1 7600083 12 x 24 Hot Plate Assembly, Complete - Right Drain, 208V 41 4 F706A1013 Clamp, Thermostat Bulb

1 1 7600084 12 x 24 Hot Plate Assembly, Complete - Right Drain, 240V 42 2 F706A8703 Heating Element, 208V, 5200W

1 1 7600086 12 x 24 Hot Plate Assembly, Complete - Right Drain, 480V 42 2 F706A8731 Heating Element, 240V, 5300W

1 1 7600087 12 x 24 Hot Plate Assembly, Complete - Left Drain, 208V 42 2 F706A8729 Heating Element, 480V, 5300W

1 1 7600088 12 x 24 Hot Plate Assembly, Complete - Left Drain, 240V 43 4 20A2G1 Clamp Plate, Healing Element

1 1 7600090 12 x 24 Hot Plate Assembly, Complete - Left Drain, 480V 44 26 B301A8817 Nut, Hex, 1/4 - 20

1 1 7600074 12 x 24 Hot Plate Assembly, Complete - Center, 208V 45 20 F706A8809 Washer, Flat, 11/32" id. x 1-1/4" od

1 1 7600075 12 x 24 Hot Plate Assembly, Complete - Center, 240V 46 8 F706A8811 Spacer

1 1 7600077 12 x 24 Hot Plate Assembly, Complete - Center, 480V 47 16 P706A8805 Lockwasher, Extnl Star, 1/4" id. x 5/8"od

1 1 7601872 12 x 24 Hot Plate Assembly, Complete - Drain Both Sides, 208V 48 4 8500079 Insulation

(Model RH36C7) 49 4 F706A1017 Baffle

1 1 7601873 12 x 24 Hot Plate Assembly, Complete - Drain Both Sides, 240V 50 1 33617 Side Panel, Left

(Model RH36C7) 51 1 33618 Side Panel, Right

1 1 7601875 12 x 24 Hot Plate Assembly, Complete - Drain Both Sides, 480V 52 1 32849 Rear Panel

(Model RH36C7) 53 1 30905 Terminal Block, 3-Pole

2 1 20XA1G1 12 x 24 Hot Plate - Drain Both Sides 53A 1 35986 Terminal Block, 6-Pole (U.S.A. only)

2 1 20A2G8 12 x 24 Hot Plate - Left or Right Drain

2 1 20A2Q9 12 x 24 Hot Plate-Center 53B 1 31589 Ground Lug Terminal

3 1 3004281 Thermostat, Hot Plate [250° F (121° C) -- 850° F (454° C)] 54 1 33616 Cover Plate

1 2100094 Knob, Thermostat [250° F (121° C) -- 850° F (454° C)] 55 1 7007442 Knockout Plate

4 1 F706A8703 Heating Element, 208V, 5200W 56A 2 33519 Caster, Front, 6", Swivel, with Brake

4 1 F706A8731 Heating Element, 240V, 5300W 56B 2 33520 Caster, Rear, 6", Swivel

4 1 F706A8729 Healing Element, 480V, 5300W 56C 16 2000861

5 2 20A2G1 Clamp Plate, Heating Element 56D 16 F707A8805 Lockwasher, Split, 1/4" id.

6 1 8500079 Insulation 57 1 7007992 Louvered Access Panel

7 1 F706A1017 Baffle 58 2 7601840 Grease Drawer & Handle Assembly

8 4 20A2G7 Screw, Latch Plate

9 4 20A2G6 Latch Plate 61 2 33621 Bushing, Door

10

4 20A1G7 Pin, Latch Plate 62 4 7610657 Grease Spout

11

6 34284 Clip, Retaining, 12 x 24 Hot Plate 63 4 2700090 Gasket, Grease Spout

12

1 20A1G8 Key Strip 64 1 33693 Door Assembly, Complete

13

2 F706A1013 Clamp, Thermostat Bulb 67 1 32572 Door Handle Assembly

14

10 F716A8803 Cap Screw, 1/4 - 20 x 3/8" 68 2 3103164 Spacer, Door Handle

15

10 F706A8809 Washer, Flat, 11/32" id. x 1-1/4" od. 69 4 2000320 Screw, Door Handle, 10 - 32 x 3-1/2"

16

4 2001184 Stud, 1/4-20 x 1-5/8" 70 2 3000061 Plug, Handle, Black

17

4 F706A8811 Spacer 71 1 31793 Decal, Range Top Control Panel,

18

10 F706A8805 Lockwasher, Extnl Star, 1/4" id. x 5/8"od.

19

8 F706A8807 Nut, Hex, Brass, 1/4 - 20

38

1 7603538 24 x 24 Griddle Assembly, Complete, 208V

38

1 7603539 24 x 24 Griddle Assembly, Complete, 240V

38

1 7603541 24 x 24 Griddle Assembly, Complete, 480V

39

1 7603536 24 x 24 Griddle Only

40

2 3004238 Thermostat, Griddle [200°F (93°C) — 550°F (287°C)]

2 A710E8739 Knob, Thermostat, [200°F (93°C) — 550°F (287°C)]

Item Qty

Part No. Description

Models RH36C1W, RH36C7W

17

Page 20

SECTION 4- PARTS LIST

Convection Oven

18

Overall Drawing

Figure 4-2

Page 21

No.

1 1 3002453

Heating Element, 240V,

7500W

1 1

3002455

Healing Element, 480V,

7500W

2 4

3027A3083

Support, Healing Element

3 1

30919

Blower Motor Assembly, 208V

- 240V

3A 1

3002761

Blower Motor, 208V

- 240V

4 1

3103902

Wheel, Blower Fan

5 1

7610513

Baffle, Heating Elements

&

Blower Wheel

6 3

3102541

Shel

f Assembly

7 2 3102543

Side Rack, 4

-

Shelf

8 1 35986

Terminal Block, 6

-

Pole (U.S.A. only)

1 35985

Decal, Terminal Block

9 1 28082

-

0010 Transformer, 480V Only

10 1

3000641

Relay, Mercury Contactor, 208V

- 240V

10A 1 33623

Bracket, Mercury Contactor R

elay 11 1 30368

Door Spring

12 1

43685

Eyebolt

13 1

30369

Cable Assembly

14 1

7007809

Pulley

15 1 30359

Axle

16 2 3102937

Retainer Ring

17 1 3003773

Microswitch

1 36180

Bracket

,

Mounting, Microswitch

18 1

32762

Motor Duct

19 1

34404

Seal, Motor

Duct 20 1 30519

Sensor, High

-

Temperature Limit

21

A/R 3004281

Thermostat, Hot Plate [250°F

(121°C)

—

850°F

22 A/R 2100094

Knob, Thermostat (250°F

(121°C)

—

850°F

(454°C)]

23

A/R 33414

Indicator, Amber 250V

23

A/R 33415

Indicator, White, 250

V 23 A/R 35146

Indicator Adapter, 480V Operation

(1

per indicator)

24 1

36115

Switch, 3

-

Heat (Low

-

Medium

-

High) 25 1 33402

Knob, 3

-

Heat Switch

26 1

3004536

Oven Timer,

6-120

minutes

27 1

2100088

Knob, Oven Timer

29 1

33437

Switch, "OVEN POWER," DPDT

30 2

1455A0341

Fuseholder Assembly, 480V

30 2

1455A0339

Fuseholder Assembly, 240V

31 2

1455A8793

Fuse,

10A.,

240V (Slow

-

blow)

31 2

1455A8794

Fuse,

10A.,

480V (Fast

-

blow)

32 1

35710

Panel, Oven Control

1

34111

Decal, Oven Control Panel

33 1

3004261

PC Board, Oven Thermocouple

33A 1 7608145

Thermocouple, Oven

Convection Oven Overall Parts List

Item

Qty Part No. Description

1 1 3002452 Heating Element, 208V, 7500W

SECTION 4- PARTS LIST

19

Page 22

Contents

RH36C1W Wiring Diagram ("Schematic") 208/240V (USA) [33375F, Sheet

1

of

2]……..

22

RH36C1W Schematic ("Ladder Diagram") 208/240V (USA) [33375F, Sheet 2 of 2]……..

RH36C1W Wiring Diagram ("Schematic") 480V (USA) [36093E, Sheet 1 of 2] ...............

RH36C1W Schematic ("Ladder Diagram") 480V (USA) [36093E, Sheet 2 of 2] .............

RH36C7W Wiring Diagram ("Schematic") 208/240V (USA) [33376F, Sheet 1 of 2]……...

RH36C7W Schematic ("Ladder Diagram") 208/240V (USA) [33376F, Sheet 2 of 2]……..

RH36C7W Wiring Diagram ("Schematic") 480V (USA) [33377F, Sheet 1 of 2] ................

RH36C7W Schematic ("Ladder Diagram" ) 480V (USA) [33377F, Sheet 2 of 2]..............

23

24

25

26

27

28

29

21

Page 23

SECTION 5

-

SCHEMATICS

22

Page 24

SECTION 5

-

SCHEMATICS

23

Page 25

SECTION 5

-

SCHEMATICS

24

Page 26

SECTION 5

-

SCHEMATICS

25

Page 27

SECTION 5

-

SCHEMATICS

26

Page 28

SECTION 5- SCHEMATICS

27

Page 29

SECTION 5

-

SCHEMATICS

28

Page 30

SECTION 5

-

SCHEMATICS

29

Loading...

Loading...