TJERNLUND GPAK GAS SIDE WALL VENT SYSTEMS (GPAK-J, 1, JT, 1T DISCONTINUED) 8500370 REV. 4 0198, GPAK-J User Manual

...Page 1

Ideal For Replacing Plastic Pipe On 80-Plus Gas Furnaces

Safety and performance

features time-proven in over

one million installations:

■ All operating components located indoors for weather

protection and easy servicing.

■ Capacities up to 250,000 BTU/hr.

■ Accommodates vent pipe runs up to 100 equivalent feet.

■ Regulated, consistent draft throughout burner cycle.

■ Built-in Fan Proving Switch interlocks with gas valve.

■ Available with 24-volt Relay or Post Purge Timer/Relay.

■ Kit includes everything needed for installation, except

vent pipe. (*GPAK* includes DC-4 Draft Control)

■ Durable, heavy-duty aluminum Vent Hood.

■ AGA design certified for gas furnaces, boilers, pool

heaters, unit heaters and commercial water heaters.

Packaged Side

Wall Vent Systems

Approved for use

with the following

brands of 80-plus

furnaces:

■ Rheem/Ruud/Weatherking

■ Evcon

■

Carrier

■ Amana

■ Heil

■ Arco Air

■

Tempstar

■ Comfortmaker

■

Armstrong

■ Heat Controller/Centur y/

Comfort Air

■ And Other Popular Brands

Page 2

TJERNLUND PRODUCTS, INC.

1601 Ninth Street White Bear Lake, MN 55110-6794

Phone: 612.426.2993 800.255.4208 Fax: 612.426.9547

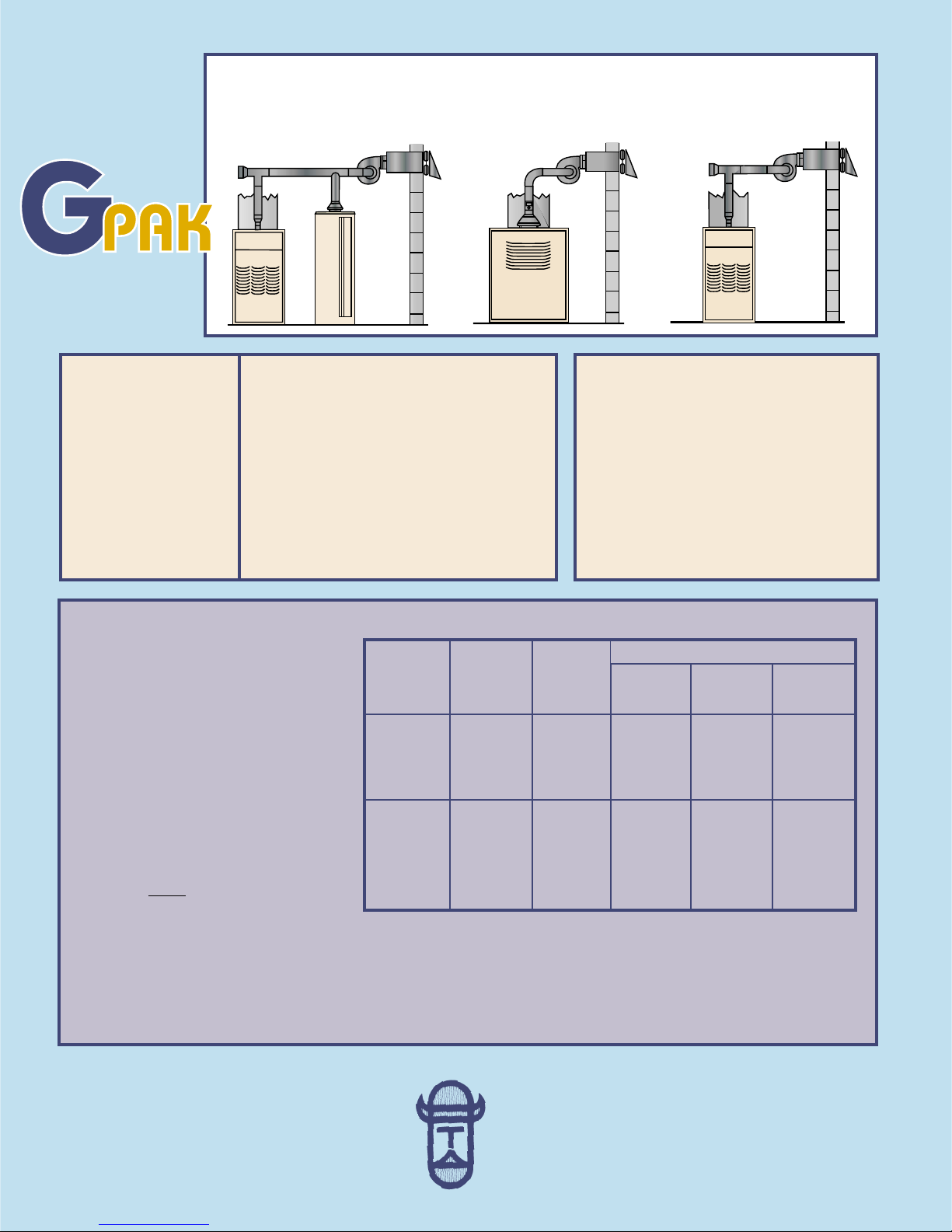

TYPICAL APPLICATIONS

Fan Assisted Furnace

& Water Heater

Commercial Water Heaters

& Residential Boilers

Fan Assisted

Furnaces

NOTES:

1. If the appliance flue outlet is greater than

4'', install a tapered reducer after the

draft hood, draft diverter or barometric

draft control, reducing vent pipe diameter to 4''. All vent pipe from the appliance

to the Power Venter may be 4''.

2.Table is based on straight vent pipe. 90

degree elbows are equivalent to 6 feet of

straight vent pipe.

3.Deter mine maximum pipe length from

type of equipment being vented and

GPAK Model.

Column A pipe runs

over 30 linear feet should use Type

“B” vent. Column B & C pipe runs

over 15 linear feet should use Type

“B” vent.

GPAK

MOTOR

SPECIFICATIONS

ELECTRICAL DATA

COMPONENT DESCRIPTIONS

GPAK-J, 1

Relay — 24/115V Switching Relay

Fan Proving Switch — 3FLA, 18 LRA@120 VAC

GPAK-JT, 1T

Timer/Relay — 24/115V Switching Relay, 45

Second Fixed Delay

Fan Proving Switch — 3FLA, 18 LRA@120 VAC

MODEL SELECTION TABLE

Packaged

Side Wall

Vent Systems

INSTALLATION OVERVIEW

1. Determine point of termination and

install V ent Hood.

2. Attach perforated strap to vibration

isolation mounts on Power Venter and

install adjacent to Vent Hood.

3. Connect outlet flue of heater(s) to inlet

of Power Venter. Connect Power Venter

outlet to Vent Hood.

4. Interlock Relay or Timer/Relay and Fan

Proving Switch with burner.

100'

100'

100'

45'

100'

100'

100'

87'

40'

60'

60'

60'

60'

60'

60'

60'

N/A

N/A

60'

60'

N/A

N/A

60'

60'

60'

N/A

N/A

Maximum Total Vent Pipe Length

Models

GPAK-J

GPAK-JT

*GPAK-JT*

GPAK-1

GPAK-1T

*GPAK-1T*

Vent Pipe

Diameter

4''

4''

BTU/hr

Input

45,000

75,000

100,000

120,000

100,000

120,000

150,000

200,000

250,000

*40,000 ATM

Atmospheric Fan Assisted +Column B

A B C

DISTRIBUTED BY:

Copyright © 1997 Tjernlund Products Inc. All rights reserved P/N: 850-0370 Rev.4, 1/98

Volts

Hertz

RPM

Watts

Amps

Therm. Prot.

115

60

3000

95

1.26

Yes

4. Column C allows for up to a 40,000 BTU/hr. input atmospheric water heater common vented with a fan assisted

appliance from column B.

5. All reducers and vent pipe are to be supplied by the installer and are available from your local heating wholesaler.

6. Models with asterisks, e.g. *GPAK-JT*, include a 4'' draft control and are authorized for use on furnaces eligible for the

HTPV Corrective Action Program.Installations for the HTPV Program must use Type “B” vent.

7. Also available, *GPAK-1TR* for use with Rheem, Ruud, Weatherking and Heat Controller brands.

®

Loading...

Loading...