Page 1

Copyright © 2007, Tjernlund Products, Inc. All rights reserved. P/N 8504143

REV. 9/07

MODEL FV1 PASSIVE FOUNDATION VENT

INSTALLATION INSTRUCTIONS

SUGGESTED TOOLS AND MATERIALS

• Safety glasses with side shields

• Work gloves

• Tape measure

• 7/16" wrench

• Caulk gun

• Silicone caulk

• Level

IF REMOVING OLD VENTS

• Hammer

• Pry bar

• Mason chisel

MATERIALS INCLUDED

Gray vent faceplate

Screen door

White sealer/winter door

Black backer bar

2 - 9” Threaded rods

2 - ¼” Lock nuts

2 - ¼” Brass knurled nuts

2 - ¼” Wing nuts

IMPORTANT: ALWAYS FOLLOW LOCAL BUILDING CODES.

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • ww w.tjernlund.com

Page 2

INSTALLATION

IMPORTANT:

ALWAYS FOLLOW YOUR LOCAL BUILDING CODES.

1. Measure width and height of opening to verify the FV1 faceplate will overlap the opening by at least ¼" or more on all

four sides.

2. If replacing an existing vent, remove the mortar that secures the vent to the foundation using a hammer, flat pry bar

and/or large masonry chisel.

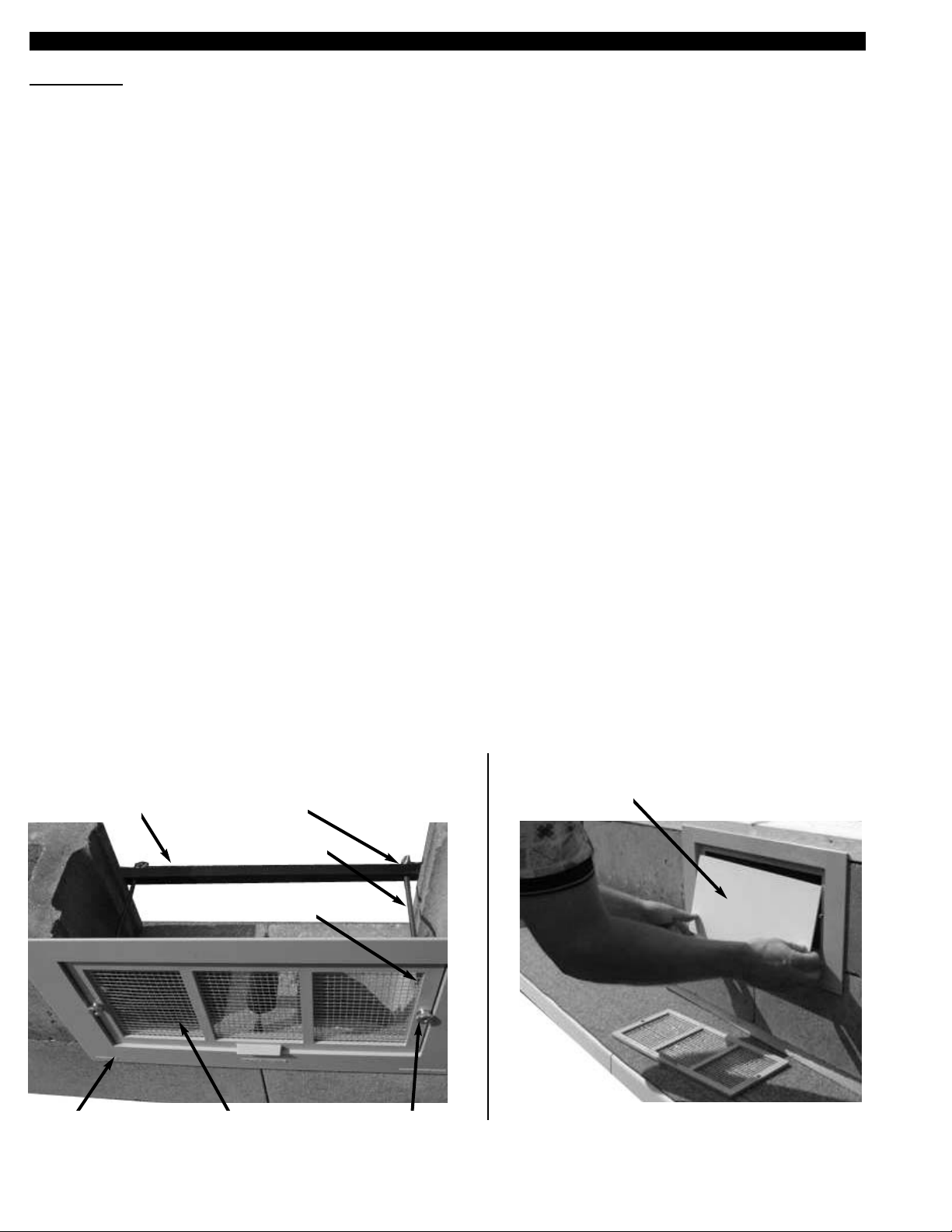

CRAWL SPACE VENT INSTALLATION (DIAGRAM A)

1. Once it is verified that the faceplate fits flush with the sill plate and foundation, caulk the backside of the faceplate

with ample silicone caulk to insure a quality seal.

2. Put one lock nut on each of the threaded rods.

3. Reach inside through the faceplate opening and screw each of the threaded rods through the inserts of the faceplate

toward the outside of the foundation until the rods protrude at least 5/8".

4. Tighten the lock nuts on inside of threaded rod with 7/16" wrench. DO NOT over tighten.

5. Reach through faceplate opening with the backer bar in hand and place backer bar on threaded rods. Install the wing

nuts on each of the threaded rods behind the backer bar and finger tighten until the bar is tight against the inside wall

and begins to bend slightly. This will apply tension to allow for consistent sealing of the caulk that was applied to the

back of the faceplate.

6. Place the screen door on the unit by aligning the screen door holes with the protruding ends of the threaded rods and

hand tighten the knurled nuts to the screen door.

WINTER DOOR INSTALLATION (DIAGRAM B)

Store the winter door in a convenient place for heating season installation. To install the winter door, unscrew the

knurled nuts and place the winter door behind the screen door. Replace the screen door and retighten the knurled

nuts.

Wing nut(s)

Faceplate Screen door

Lock nut(s)

Threaded rod(s)

Backer bar

Knurled nut

Winter door

DIAGRAM A DIAGRAM B

Page 3

DIMENSIONS

TROUBLESHOOTING INSTALLATION PROBLEMS

VENT FACEPLATE DOES NOT FIT UNDER SIDING

OPTION 1: Trim the FV1 faceplate. The backside of the faceplate has pre-scored lines to assist in trimming. This

area can be trimmed using simple tools (utility knife, pliers, hacksaw) to customize the height of the faceplate. Width

trimming is usually not needed, but may be done using cutting tools made to cut ABS materials.

OPTION 2: On some homes the siding needs to be pried away from the sill plate and the foundation by a 1/8” or 1/4”

for the vent faceplate to slide under and up to the sill plate. To do this, one may use a pry bar or shims to pry the siding away from the framing and foundation. Do so with caution. Siding can be very brittle. Always secure all

loosened areas once installation is complete. If the siding is pried away and the vent still will not fit check for nails,

screws, or other obstructions.

SILL PLATE OVERHANGS THE FOUNDATION AND THE VENT DOES NOT FIT FLUSH AGAINST FOUNDATION

If the sill plate overhangs or is recessed from the foundation, use a 1x2, 2x2 or 2x4 piece of lumber cut to the length of

the opening of the foundation and attach the lumber to the sill plate so that it is flush with the foundation. This now

becomes the sill plate to which the faceplate can be mounted.

FACEPLATE IS FLUSH, THREADED RODS ARE IN THE FACEPLATE BUT THE THREADED RODS DO NOT GO

THROUGH THE PRE-DRILLED HOLES IN THE BACKER BAR; THE WING NUTS CANNOT BE ATTACHED

The included threaded rods are 9” long. These will accommodate foundation block wall widths of up to 8”. For buildings

with thicker foundations, substitute the included rod with an 1/4” diameter rod cut to the length necessary for installation.

NOTE: At least 1” of clearance is needed beyond the width of the foundation wall in order for the vent screen, winter

door, and backer bar to fit properly.

VENT OPENING IS BIGGER OR SMALLER THAN THE FV1 FACEPLATE

A frame can be built for openings too large for the faceplate or the faceplate can be cut to size for a smaller

opening.

FACEPLATE INSTALLATION

7"

10"

19 1/2"

14 1/2"

18"

2" 2"

1/2"

1"

9"

8061006 9/5/07

Page 4

COMPANION VENTILATION PRODUCTS

UNDERAIRETMCRAWL SPACE

VENTILTORS

MODEL V1

One fan and small faceplate for

ventilation openings through brick

foundations. (Requires switch or

dehumidistat to activate. Multiple

ventilators may be controlled by a

single switch or dehumidistat).

Includes thermostat.

MODEL V1D

One fan and large faceplate sized

for ventilation openings through

block foundations. Includes thermostat, dehumidistat and

pre-wired 6’ power cord.

MODEL V2D

Two fans and large faceplate sized

for ventilation openings through

block foundations. Includes thermostat, dehumidistat and prewired 6’ power cord.

Fan powered crawl space ventilation quickly reduces

moisture helping to protect both home and occupants.

Loading...

Loading...