Tippmann E-TRIGGER, E-GRIP, CUSTOM User Manual

-BACK COVER - BLANKp

TIPPMANN

CUSTOM

KIT PN.205002

Fits: 98 Custom

®

TM

E-TRIGGER

TM

markers with

serial# over

880,000 and all

98 Custom Pro

TM

markers.

INSTALLATION

AND OPERATING

INSTRUCTIONS

TM

TIPPMANN

TM

A-5

E-GRIP

KIT PN. 02-EG

Fits:

TM

A-5

markers

®

TM

E

N

G

L

INSTALLATION

AND OPERATING

INSTRUCTIONS

I

S

H

TIPPMANN

CUSTOMTM DÉTENTE E

®

TM

KIT PN.205002

Convient: les marqueurs de

98 CustomTM avec serial# plus

de 880,000

et tous les

marqueurs de

98 Custom Pro

TM

.

INSTRUCTIONS

D'INSTALLATION

ET D'OPÉRATION

TM

con

®

TM

TM

.

TIPPMANN

CUSTOMTM E-TRIGGER

ESTUCHE PN.205002

Puede Ser Usado con: marcadores

98 Custom

serial# mayor a

880,000 y todos

los marcadores

98 Custom Pro

INSTALACIÓN E

INSTRUCCIONES

DE MANEJO

TIPPMANN

A-5TM POIGNÉE - E

®

TM

Kit PN. 02-EG

Convient:

TM

A-5

marqueurs

INSTRUCTIONS

D'INSTALLATION

ET D'OPÉRATION

E-GRIP

®

TM

TIPPMANN

TM

A-5

ESTUCHE PN.02-EG

Se puede

usar con

marcadores:

TM

A-5

INSTALACIÓN E

INSTRUCCIONES

DE MANEJO

Form# TP04206 Rev 02-08

F

R

A

N

Ç

A

I

S

E

S

P

A

Ñ

O

L

2955 ADAMS CENTER ROAD, FORT WAYNE, IN 46803

E

N

Please take time to read through and follow these Installation and Operating

Instructions thoroughly and become familiar with the Tippmann

G

E-TRIGGERTM or A-5

you attempt to load or fire this marker. If you have a missing or broken

L

part or need assistance, please contact Tippmann

I

at 1-800-533-4831 for fast friendly service.

S

CUSTOM

H

TM

A-5

E-GRIP

260/749-6022 • 800/533-4831 • FAX: 260/749-6619

TM

E-TRIGGERTM KIT PN.205002: Installation ..........1-E Custom

TM

KIT PN. 02-EG: Installation....................................... 4-E A-5

TIPPMANN

INTERNET: www.tippmann.com

TM

TM

E-GRIP

parts, operation, and safety precautions before

TABLE OF CONTENTS

®

®

CUSTOM

®

Consumer Relations

TM

TM

TM

Operating Instructions (CustomTM or A-5TM) ............................................... 7-E

F

R

S’il vous plaît, prenez le temps de lire entièrement ces Instructions

A

D'installation et D'opération et familiarisez – vous avec les parties, l’

opération, et les précautions de sécurité de Tippmann® CUSTOM

N

DÉTENTE E

Ç

marqueur. Si vous avez quelque chose manquante ou quelque chose

cassée ou si vous avez besoin d’ assistance, veuillez contacter Tippmann

A

Consumer Relations à 1-800-533–4831 pour l’assistance amicale et vite.

2955 ADAMS CENTER ROAD, FORT WAYNE, IN 46803

260/749-6022 • 800/533-4831 • FAX: 260/749-6619

TM

ou A-5TM Poignée - ETM avant de charger et de tirer ce

I

CUSTOMTM DÉTENTE ETM KIT PN.205002: D'installation........ 1-F Custom

S

A-5TM Poignée - ETM Kit PN. 02-EG: D'installation ............................. 4-F A-5

TIPPMANN

INTERNET: www.tippmann.com

TABLE DES MATIÈRES

®

TM

®

TM

TM

Instructions D'opération (CustomTM ou A-5TM).............................................7-F

o A-5

®

TM

E-GRIP

TM

. Si alguna de sus

®

al

TM

TM

E

S

Antes de cargar o disparar este marcador por favor tome tiempo para leer

P

completamente estas Instrucciones de Instalaciónes y De Manejo y empezar a

familiarizarse con las partes, operación y todas las precauciones de seguridad

A

del Tippmann® CUSTOMTM E-GATILLO

Ñ

partes no se encuentra, o esta defectuosa y necesita asistencia, por favor

comuníquese con el departamento de Servicio al Cliente de Tippmann

O

teléfono 1-800-533-4831 en donde le daremos un servicio oportuno y amable.

L

CUSTOM

A-5

2955 ADAMS CENTER ROAD • FORT WAYNE, IN 46803

260/749-6022 • 800/533-4831 • FAX: 260/749-6619

TM

E-TRIGGER

TM

E-GRIP

TM

ESTUCHE PN.02-EG: Instalación ........................4-S A-5

TIPPMANN

INTERNET: www.tippmann.com

TM

TABLA DE CONTENIDO

TM

ESTUCHE PN.205002: Instalación ...1-S Custom

Instrucciones De Manejo (CustomTM o A-5TM) ........................................... 7-S

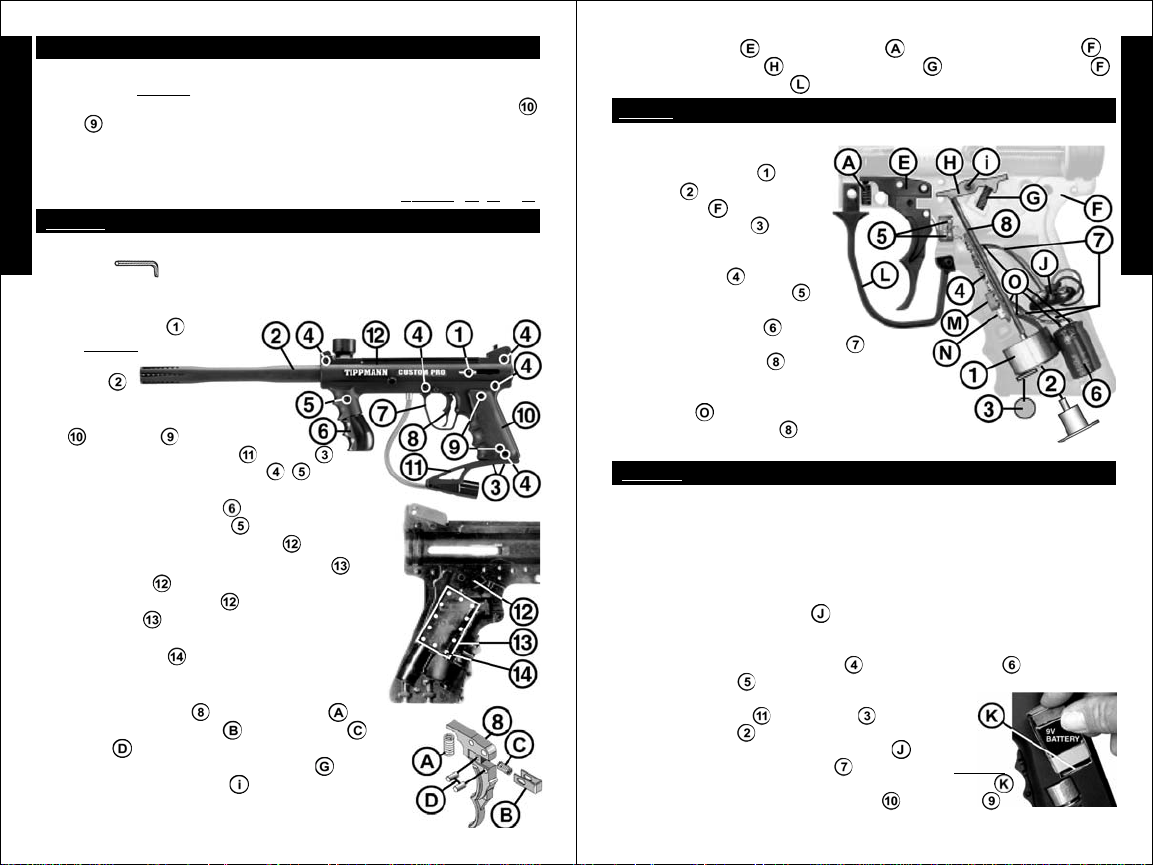

98 CUSTOM

TIPPMANN

Fits: 98 Custom

Custom ProTM markers

CUSTOM

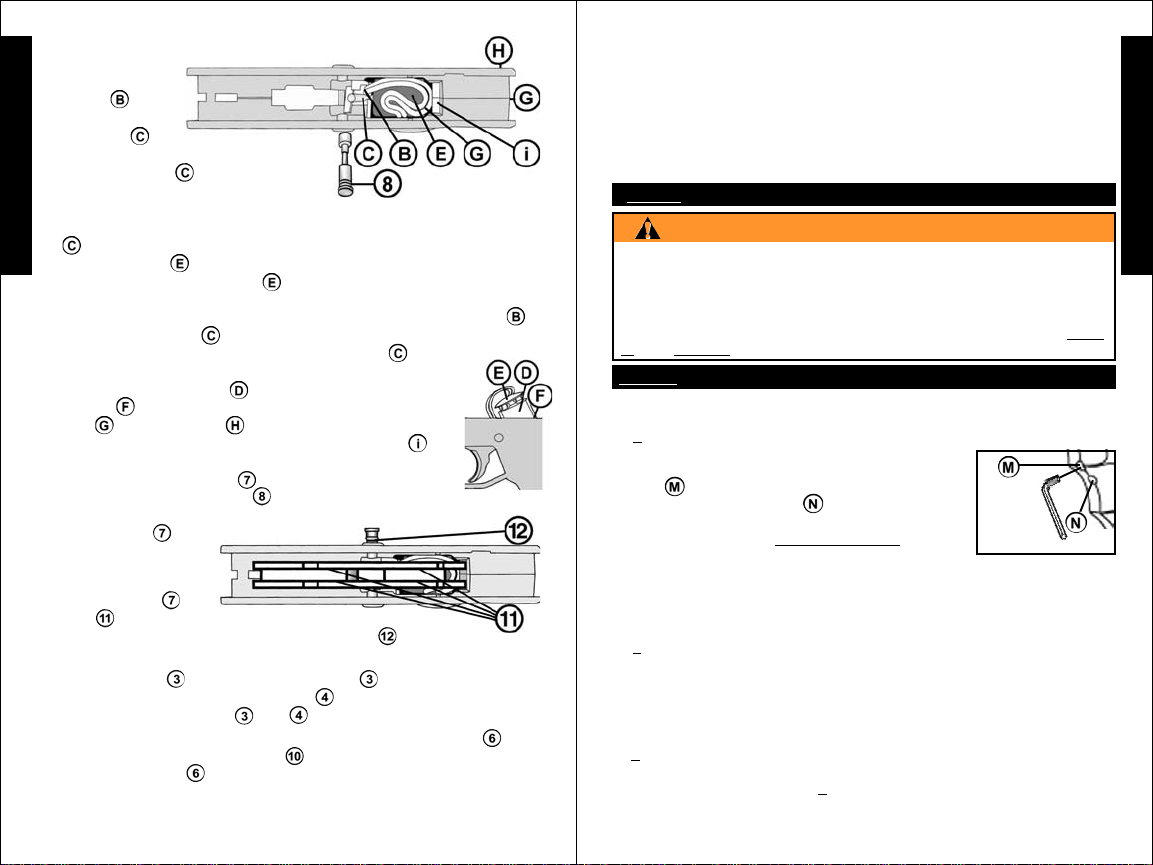

1 - Sear Tripper Assembly

1 - New Sear

1 - Armature Pin

EYE PROTECTION DESIGNED FOR PAINTBALL USE MUST BE WORN AT

ALL TIMES WHEN HANDLING THIS MARKER BY THE USER AND ANY

PERSON WITHIN RANGE. DO NOT DISASSEMBLE THIS MARKER WHILE

IT IS PRESSURIZED WITH AIR. REMOVE AIR SUPPLY CYLINDER OR

CARTRIDGE BEFORE DOING ANY DISASSEMBLY. DISASSEMBLING THE

RECEIVER WHILE UNDER AIR PRESSURE CAN CAUSE PERSONAL

INJURY &/ OR DAMAGE TO THE MARKER. DO NOT OPERATE THIS

MARKER WITH PARTS MISSING OR DAMAGED. IF DURING THE COURSE

OF THIS INSTALLATION, A PART IS LOST OR FOUND TO BE DAMAGED,

OBTAIN A REPLACEMENT PART BEFORE CONTINUING REASSEMBLY.

TM

INSTALLATION INSTRUCTIONS

®

CUSTOM

T M

E-TRIGGER

TM

TM

E-TRIGGERTM KIT

markers with Serial# over 880,000 and all 98

TM

KIT PN.205002 INCLUDES:

PN.TA99007

PN. TA01135 1 - New Sear Spring PN. 02-88

PN. 98-91 1 - Magnet PN. TA05014

WARNING

E

N

G

L

I

S

H

READ EACH STEP COMPLETELY BEFORE PERFORMING STEP.

Keep these instructions with your owner’s manual.

STEP 1: Prepare marker for safe disassembly before

beginning disassembly.

Eye protection designed for paintball use must be worn by the user and

any person within range.

❏

1) Unload your marker: first remove the hopper. Then, point your

marker in a safe direction and fire several times to be sure there are no

balls left in the feeder or lodged in the chamber.

❏

2) Remove air source: To remove a charged air cylinder, turn the

cylinder approximately 3/4 of a turn counterclockwise

or out. This

allows the tank pin valve to close so that no air will enter the marker.

Point the marker in a safe direction and fire the remaining air in the marker

by pulling the trigger until the marker stops firing (This may take 4-5 shots).

• If your marker keeps firing after you have turned the tank 3/4 of a turn,

the tank pin valve has not closed yet and you may have to turn the tank

counterclockwise

a little further.

• If you turn the tank 3/4 of a turn and it begins to leak before you pull the

trigger you have turned it too far and may have damaged the tank o-ring.

❏

3) After air tank is removed, point & fire the marker in a safe direction

until stored air is completely discharged.

❏

4) Put marker in the uncocked position: pull and hold the bolt

cocking handle back, then pull the trigger and slowly release the handle

forward to un-cock the marker.

1-E Custom

TM

(continued on page 2-E CustomTM)

(98 CUSTOM

TM

INSTALLATION INSTRUCTIONS continued from page 1-E CustomTM)

9 VOLT BATTERY REPLACEMENT

❏

1) Prepare Your Marker For Safe Disassembly:

E

instructions in

❏

2) Remove Battery Clip / Battery From Marker:

N

2 bolts .

G

non-connected end out first. As you remove battery from receiver, do not

pull wires off of internal components.

L

battery clip connector.

I

❏

3) Install the New Battery:

S

STEP 2: Prepare Marker for kit installation.

H

❏

Set up a table with plenty of space to work. You will need two allen

wrenches (

STEP 1.

❏

Carefully work the battery out of the receiver cutout bringing

❏

Carefully remove old battery from

❏

Follow instructions in: STEP 4: 6), 7), & 8).

) 1/8" and 5/32", hammer, punch, and a 9 volt battery.

❏

Follow the

❏

Remove left grip

NOTE: Carefully hand start threaded parts, do not over tighten and strip threads.

Disassemble the marker: With Air Source removed & marker in the

uncocked position

as per STEP 1;

❏

1) Remove

the barrel

,

twist counterclockwise.

❏

2) Remove left side receiver

grip

two bolts .

❏

3) Remove tank adapter 2 bolts .

❏

4) Loosen all 6 receiver bolts /

holding marker together with 1/8" Allen

wrench. Note: Front Grip

at reassembly, longest bolt

❏

5) Carefully lift left receiver half off marker.

❏

6) Remove rectangular knockout plate from

left receiver half

❏

Place left receiver half inside up with

knockout plate

❏

Then with a hammer and punch, start in one

for battery insertion.

flush on a flat surface.

corner of the plate

comes off -

goes in front grip.

and carefully tap it loose

by working your way around the plate edge....

until it is removed.

❏

7) Remove trigger & trigger spring .

❏

Remove trigger slider , slider spring and 2

slider pins

❏

8) Remove old sear and sear spring from right

receiver. If black dowel pin

from trigger.

comes out, reinsert it.

TIME SAVER: It is Not necessary to remove additional

parts to install this kit.

2-E Custom

TM

(continued on page 3-E CustomTM)

(98 CUSTOM

❏

❏

❏

STEP 3: Install Sear Tripper Assembly, Magnet & Armature Pin

Do not operate sear tripper assembly uninstalled as solenoid /armature

may pinch you.

❏

armature

right receiver

❏

below armature.

❏

computer board

❏

TM

INSTALLATION INSTRUCTIONS continued from page 2-E CustomTM)

9) Install trigger and trigger spring into the right receiver half .

10) Install new sear and new sear spring into right receiver half .

11) Install trigger guard .

1) Place solenoid /

into position in

.

2) Insert Magnet into slot

3) Carefully align and insert

into slot.

4) Place trigger switch on

E

N

G

L

I

S

H

2 pins of right receiver half.

❏

5) Insert capacitor in slot.

❏

6) Route wires in cutout areas to lay

flat under armature pin

and battery (and not

be pinched when receiver halves are reassembled.

❏

Visually inspect internal wires for disconnected

wire end(s)

❏

7) Insert armature pin into slots so it moves freely.

❏

8) Double check that all parts are in place as shown.

STEP 4: Reassemble Receiver Halves

❏

1) Double check that all other parts: Front Sight, Front Site Pin, Front

Sight Spring, Ball Latch, Front Bolt*, Linkage Arm, Rear Bolt*(+Rear Bolt

Insert on non-A.C.T. markers), Drive Spring* & Guide Pin*, Buffer O-ring,

End Cap, Rear Sight and 2 Tank Adapter Nuts {and for markers with AntiChop Technology: the Spring Cup*, Upper Spring (long)*, Spring Pin*, Upper

Spring (short)*, and Linkarm Pins*(2); are in place /(*=oiled)}.

marker owner's manual for details if needed.

❏

2) Place battery connector through left receiver half ❏ make sure the

magnet fits into left receiver half slot so it does not break and

pinched as you

❏

3) Insert 5 short receiver bolts .

long receiver bolt

over the trigger first, then tighten 5 remaining bolts.

❏

4) Attach adapter with 2 bolts .

❏

5) Install barrel .

❏

6) Attach 9v battery to battery connector and be sure

wires lay flat inside the cutout area

❏

7) Carefully tilt and insert battery (wire attached end first )

into receiver.

Installation is complete, continue on page 7-E Operating Instructions.

or damage.

❏

Refer to the

❏

❏

place left half on right half so the halves fit flush.

to hold grip. For ease of installation tighten the bolt

❏

8) Install left receiver grip with 2 bolts .

3-E Custom

❏

Insert front grip and ❏ insert

of receiver (see STEP 3:).

TM

wires are not

(continued on page 7-E)

TM

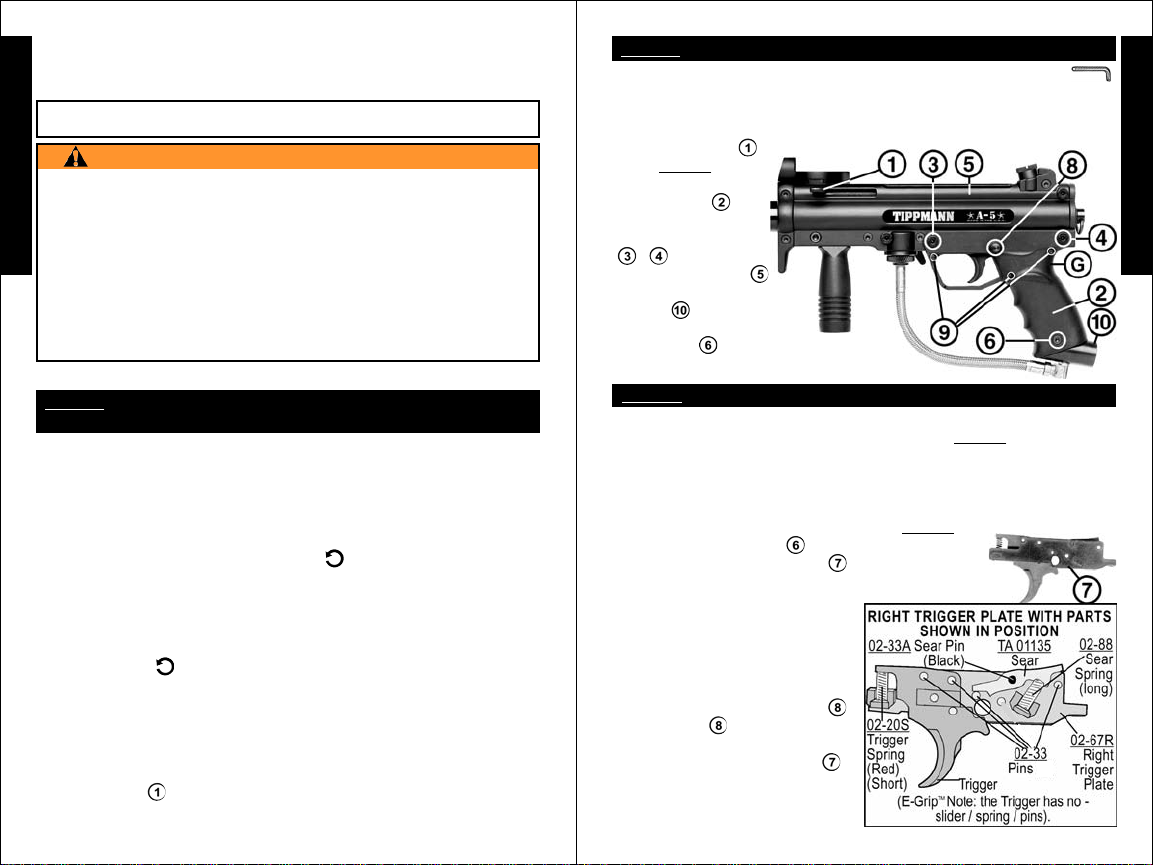

A-5

INSTALLATION INSTRUCTIONS

®

TIPPMANN

E

Fits: A-5TM Markers

N

KIT PN. 02-EG INCLUDES:

(1) 1 - E-GRIPTM Lower Receiver Component

G

A-5

TM

L

EYE PROTECTION DESIGNED FOR P AINTBALL USE MUST BE WORN AT

I

ALL TIMES WHEN HANDLING THIS MARKER BY THE USER AND ANY

S

PERSON WITHIN RANGE. DO NOT DISASSEMBLE THIS MARKER WHILE

IT IS PRESSURIZED WITH AIR. REMOVE AIR SUPPLY CYLINDER OR

H

CARTRIDGE BEFORE DOING ANY DISASSEMBLY. DISASSEMBLING THE

RECEIVER WHILE UNDER AIR PRESSURE WILL CAUSE PERSONAL

INJURY & /OR DAMAGE TO THE MARKER. DO NOT OPERATE THIS

MARKER WITH P ARTS MISSING OR DAMAGED. IF DURING THE COURSE

OF THIS INSTALLATION, A PART IS LOST OR FOUND TO BE DAMAGED,

OBTAIN A REPLACEMENT PART BEFORE CONTINUING REASSEMBLY.

READ EACH STEP COMPLETELY BEFORE PERFORMING STEP

TM

E-GRIP

KIT PN. 02-EG

WARNING

STEP 1: Prepare Marker for SAFE Disassembly before

beginning disassembly.

Eye protection designed for paintball use must be worn by the user and any

person within range.

❏

1) Unload your marker: first remove the hopper. Then, point your marker

in a safe direction and fire several times to be sure there are no balls left in

the feeder or lodged in the chamber .

❏

2) Remove air source: T o remove a charged air cylinder , turn the cylinder

approximately 3/4 of a turn counterclockwise

or out. This allows the tank pin

valve to close so that no air will enter the marker. Point the marker in a safe

direction and fire the remaining air in the marker by pulling the trigger until the

marker stops firing. (This may take 4-5 shots)

• If your marker keeps firing after you have turned the tank 3/4 of a turn, the

tank pin valve has not closed yet and you may have to turn the tank

counterclockwise

a little further.

• If you turn the tank 3/4 of a turn and it begins to leak before you pull the

trigger you have turned it too far and may have damaged the tank o-ring.

❏

3) After air tank is removed, point & fire the marker in a safe direction

until stored air is completely discharged.

❏

4) Put marker in the uncocked position: pull and hold the bolt

cocking handle back, then pull the trigger and slowly release the

handle forward

to un-cock the marker.

4-E A-5

TM

(continued on page 5-E A-5TM) (continued on page 6-E A-5TM)

TM

INSTALLATION INSTRUCTIONS continued from page 4-E A-5TM)

(A-5

STEP 2: Prepare Marker for installation.

Set up a table with plenty of space to work. You Will Need: A ( )

1/8" allen wrench and a 9 volt battery. NOTE: Carefully hand start

threaded parts, do not over tighten and strip threads.

Dissassemble the marker: With Air Source removed & marker in the

uncocked position

as per STEP 1:

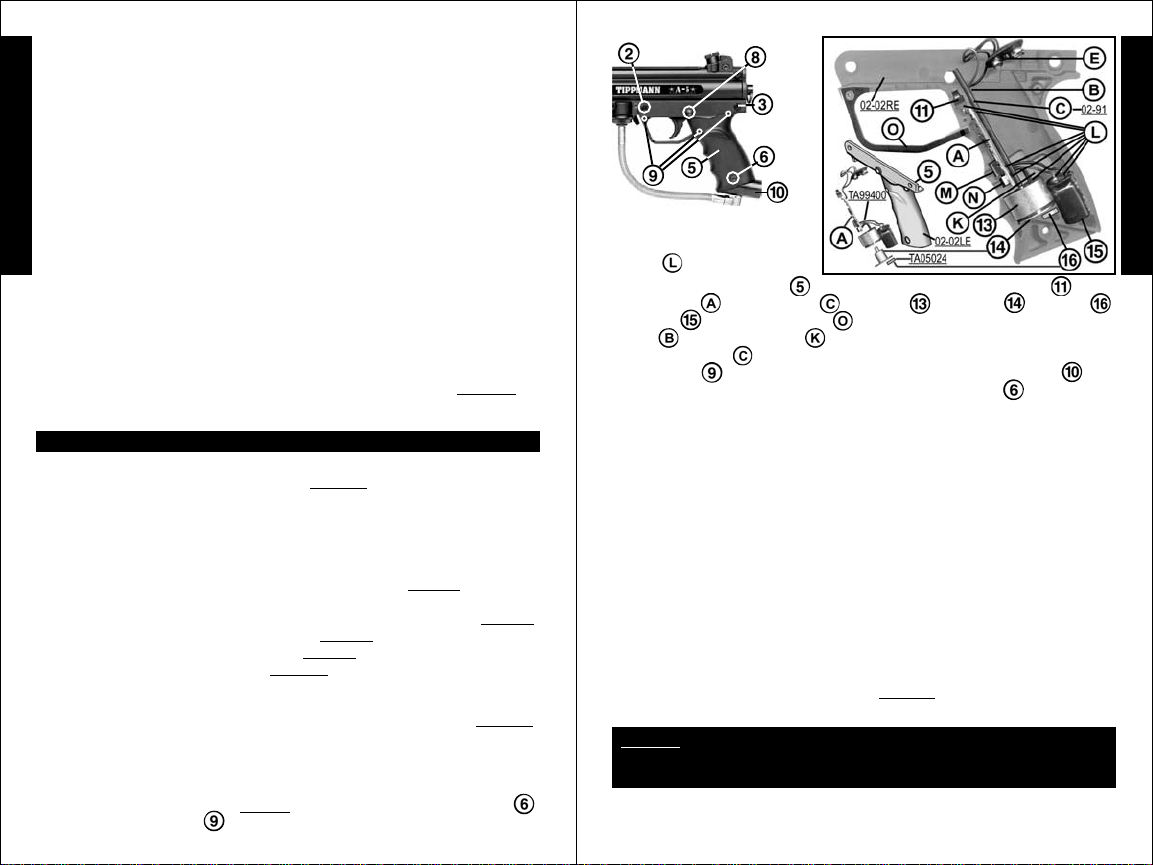

1) ❏ Detach the

lower receiver

:

Remove 2 lower

receiver push pins

& ) to detach

(

from upper receiver

❏

Detach Tank

2)

Adapter

receiver.

from lower

❏

Remove

.

E

N

G

L

I

S

H

receiver bolt

from lower receiver .

STEP 3: Battery Installation / Replacement

E-gripTM lower receiver must be removed to install / replace battery .

❏

1) To do so, you must complete the instructions

“

STEP 1” (unload your

marker / remove air source / discharge stored air / uncock marker) before

further disassembly . – EXAMPLE: If you fail to remove the air source before

removing lower receiver, the marker will fire uncontrollably - possibly

resulting in personal injury and damage to the marker).

❏

2) Remove lower receiver as outlined in “STEP 2” (it is not necessary to

remove tank adapter bolt

❏

3) Remove trigger assembly from lower

to replace battery).

receiver . (NOTE: It is not necessary to disassemble

the trigger assembly to install battery .

Do not replace sear spring with

spring from old trigger assembly,

tensions are specifically designed

for E-GRIP

properly if you do).

TM

and it will not operate

❏

To remove the

trigger assembly , push the safety

out of the left side of the lower

receiver and carefully lift the trigger

assembly out, keeping it intact

.

(4)

NOTE: It is not necessary to

disassemble the lower receiver any

further to install/replace the battery .

5-E A-5

TM

(A-5TM INSTALLATION INSTRUCTIONS continued from page 5-E A-5TM)

❏

4) Notice how

battery wires from

inside lower receiver

E

are in slot

N

beside top of

G

armature pin

and the position

L

of the armature pin

I

❏

To replace the battery, remove

old battery from inside the E-Grip

S

wires, carefully take it out. If you turn the receiver upside down the armature

H

may come out, this is ok, just be sure to replace it.

pin

remove battery clip

❏

5) Carefully attach battery clip to new battery . NOTE: battery

.

TM

lower receiver. Do not jerk it out by the

from old battery .

❏

Carefully

terminals only fit one way in clip.

❏

6) Make sure battery wires coming out of lower receiver are in slot

beside the armature pin .

❏

7) Make sure armature pin is properly positioned in lower receiver

and slides freely up and down.

❏

8) Insert attached battery into lower receiver

bottom first

receiver

with clip wires facing the back of the

and to the right .

NOTE: Make sure battery wires are not sitting on shelf

where the trigger assembly will rest.

❏

9) Insert Trigger Assembly and line up safety holes

❏

insert the safety from the left to hold the trigger assembly in place.

❏

10) Visually inspect E-GRIPTM lower receiver, a top view with the

trigger assembly

and battery installed

should look like this.

❏

Check that the trigger

assembly is intact

no gaps

; and the safety is in the “SAFE”

(pushed to the right and red not showing) position

❏

11) Attach Lower to Upper Receiver ❏ Align the E-GripTM lower receiver

front push pin hole

grip to align upper & lower push pin hole

two lower receiver push pins

❏

12) Attach Tank Adapter to E-Grip

lower receiver.

❏

Insert receiver bolt and tighten.

with

.

with upper receiver hole then gently rock rear of

. ❏ With holes aligned, insert

and to attach.

TM.

❏

❏

Slide tank adapter into lower receiver and align holes;

Remove receiver bolt from

Installation is complete, continue on page 7-E - OPERATING

INSTRUCTIONS.

6-E A-5

TM

OPERA TING INSTRUCTIONS

With the kit installation complete, read and follow these supplemental operating

instructions to the owner's manual FOR TIPPMANN A-5

98 CUSTOM

"EQUALIZER

TM

OR 98 CUSTOM PROTM WITH E-TRIGGERTM marker with the

TM

LED BOARD INST ALLED before attempting to operate this

marker. Keep these instructions with your marker owner's manual. Eye protection

designed for paintball use must be worn by the user and any person within range.

READ EACH STEP COMPLETELY BEFORE PERFORMING STEP:

STEP 1: Prepare the marker for safety before any programming:

WARNING

INSTALL THE AIR SUPPLY AND LOAD THE HOPPER WITH

PAINTBALLS ONLY AFTER YOU:

❏ ❏

❏

HAVE THE BARREL SLEEVE INSTALLED;

❏ ❏

❏ ❏

❏

HAVE THE SAFETY IN THE "SAFE" POSITION;

❏ ❏

❏ ❏

❏

HAVE SUCCESSFULLY INSTALLED THE BATTERY AND

❏ ❏

❏ ❏

❏

ARE FAMILIAR WITH THE E-TRIGGERTM NORMAL OPERATION (STEP

❏ ❏

2: AND STEP 3:).

STEP 2: NORMAL OPERATION:

❏

TOURNAMENT LOCK: Because the E-Trigger board requires a tool to

turn it on and off, no tournament lock is necessary for competition paintball.

❏ ❏

❏

1) To T urn ON the E-Trigger to normal operation - Ready To Fire:

❏ ❏

Without holding the trigger: Use a small object

like an allen wrench to

button

for 1/2 second and then release the

power button. The LED

Orange for 2 seconds, flash once (green in A-5s or

red in 98s) and then

normal operation - “Ready To Fire” mode.

• Y our E-T rigger is now ready to fire in the SEMI-AUT O = 1 pull / release

of the trigger fires 1 time (Factory set Default Firing Mode).

NOTE: If pressing the power button failed to turn on LED light, see

troubleshooting on page 8-E.

❏ ❏

❏

2) T o turn OFF the E-T rigger electronics. ❏ Press and hold the power

❏ ❏

button for 2 seconds as the LED turns solid Red, then release the Power

Button and the LED will turn OFF. NOTE: The trigger electronics are set to

shut-off automatically after a prolonged period of inactivity (120 minutes).

NOTE: The E-Trigger Low Battery Indicator feature: the “Ready T o Fire” solid

Green LED will turn to blinking red when the battery is low and needs replaced.

❏❏

❏

3) To select a new firing mode:

❏❏

❏

1) T urn ON the E-T rigger to normal operation (solid Green LED - Ready

To Fire) as instructed in step

❏

2) Press / hold the power button in one time for more than 1/4 but less

than 2 seconds and release the power button.

❏

press and hold the power

should light solid

light solid Green to show

1) above.

7-E

(CustomTM or A-5TM)

TM

WITH E-GRIPTM ,

Power

Button

LED

❏

Count the LED Orange

(continued on page 8-E)

E

N

G

L

I

S

H

(OPERATING INSTRUCTIONS continued from page 7-E)

flashes to identify your new setting, the LED light will return to solid Green Ready To Fire - in the new firing mode. You can program your marker for

any one of 5 firing modes. The orange flashes = firing mode options are:

E

• 1 orange flash = SEMI-AUTO MODE – 1 pull/release of the trigger fires

N

1 time (default firing mode). (This adheres to the 2005 NPPL rules).

• 2 orange flashes = 3 SHOT RAMPING MODE – 3 trigger pulls are

G

required (semi-auto) and the consecutive trigger pulls will fire 3 shots

L

per pull as long as the trigger is pulled at least 5 times per second.

(This adheres to the 2005 PSP rules).

I

• 3 orange flashes = 3 SHOT FULL AUTO MODE – 3 trigger pulls are

S

required (semi-auto) after which the trigger can he held to achieve full

auto firing. (This adheres to the 2005 NXL rules).

H

• 4 orange flashes = AUTO RESPONSE MODE – Fires one shot for each

pull or release of the trigger. If the trigger is held for more than 1/4 of a

second, when the trigger is released no shot is fired.

• 5 orange flashes = TURBO MODE – Fires one shot for each pull of the

trigger until the time between trigger pulls is less than 1/4 of a second

at which point it will fire on each trigger pull

❏

Repeat step 2) until you have the firing mode you want.

❏

You are now ready to complete the remaining steps in the GETTING

STARTED section of your owner’s manual: beginning with

and

trigger release.

STEP 2: Air

Supply Cylinder Installation. NOTE: If marker will not fire see page 8-E:

E-Trigger - Troubleshooting (below).

E-TRIGGER – TROUBLESHOOTING

❏

PROBLEM: The LED light does not light when you push the power button

and attempt to turn ON the E-Trigger in

1) Battery may be disconnected.

2) Battery may be bad -

❏

Replace battery.

STEP 2: NORMAL OPERATION.

❏

Check battery clip connection.

3) Internal wire may be disconnected. Do NOT disassemble a marker while

it is pressurized with air.

• For 98 Custom

❏

page 1-E: Prepare marker for safe disassembly - STEP 1:

❏

page 2-E: Remove the battery - steps 1) and 2) of Batt ery Replacement;

❏

page 2-E: Disassemble marker - steps 1), 2), 3), 4), and 5 of STEP 2:

❏

page 3-E: Inspect wire connections - STEP 3:

❏

page 3-E: Reassemble Receiver - STEP 4:

Then continue on page 7-E with

problem still exists, call Tippmann

• For A-5

TM

Markers follow A-5

WIRES / ASSEMBLE below. Then continue on page 7-E with

Normal Operation. NOTE: If a problem still exists, call Tippmann

Service Department at 1-800-533-4831.

TM

E-GRIP DISASSEMBL Y / INSPECT WIRES / ASSEMBLE:

A-5

lower receiver and trigger assembly as outlined in Marker/Receiver

Disassembly on page 5-E A-5

❏

Remove 3 grip screws holding the two lower E-GRIPTM halves together.

❏

TM

Inspect wire connections inside the receiver:

Markers follow the instructions on:

STEP 2: Normal Operation. NOTE: If a

®

Service Department at 1-800-533-4831.

TM

E-GRIP DISASSEMBLY / INSPECT

TM

STEP 2. ❏ Remove the tank adapter bolt .

8-E

(CustomTM or A-5TM)

STEP 2:

®

❏

Remove

(continued on page 9-E)

(OPERATING INSTRUCTIONS continued from page 8-E)

E

N

G

L

I

❏

Visually inspect internal

wires for disconnected wire

end(s)

❏

tripper board

capacitor

in slot

the armature pin

grip screws

lower receiver and

❏

8), 9), 10), and 1 1) on page 6-E to reassemble. If a problem still exists,

call Tippmann

❏

or damage.

Replace left grip half , make sure that: (trigger switch ; sear

; armature pin ; solenoid ; armature ; magnet ;

; and trigger guard ) are in place and wires are positioned

and cutout areas so wires are not pinched or sheared and

moves freely . ❏ Secure the E-GripTM halves with 3

. ❏ Attach Tank Adapter: Slide tank adapter into

align holes; ❏ Insert receiver bolt and tighten.

Follow E-GripTM Battery Installation or Replacement steps 5), 6), 7),

®

Service Department at 1-800-533-4831.

PROBLEM: You have successfully installed the battery, turned on the

E-Trigger , installed the air supply and loaded the paintballs and the marker

❏

will not fire.

sure sufficient air supply is hooked up to the marker. If a problem still

exists, call Tippmann

❏

PROBLEM: the “Ready T o Fire” solid Green LED has turned to blinking

❏

red -

Check to be sure safety is in "FIRE" position and

®

Service Department at 1-800-533-4831.

The E-Trigger has a Low Battery Indicator feature: the “Ready

❏

To Fire” solid Green LED will turn to blinking red when the battery is low

❏

and needs replaced.

❏

PROBLEMS WHEN FIRING: You can fine tune how your marker fires

by making adjustments to the Dwell, Debounce

Replace the battery.

TM

and Rate Of Fire Cap

modes. Read and become familiar with detailed descriptions of problems

you may have when firing and instructions for troubleshooting, tuning

and programming to correct them in STEP 3 - Dwell, DebounceTM and

Rate Of Fire sections on pages 9-E, 10-E, 11-E and 12-E.

STEP 3: How to program a new Dwell, Debounce

TM

, Rate Of

Fire Cap or Firing mode setting In the TRIGGER PROGRAMMING

MODE. (Example: Shows how to select a new firing mode).

1) FIRST YOU MUST ENTER INTO THE “TRIGGER PROGRAMMING

❏

MODE:” to access the Trigger Programming Menu:

9-E

(CustomTM or A-5TM)

Make sure the

(continued on page 10-E)

S

H

make

Loading...

Loading...