Page 1

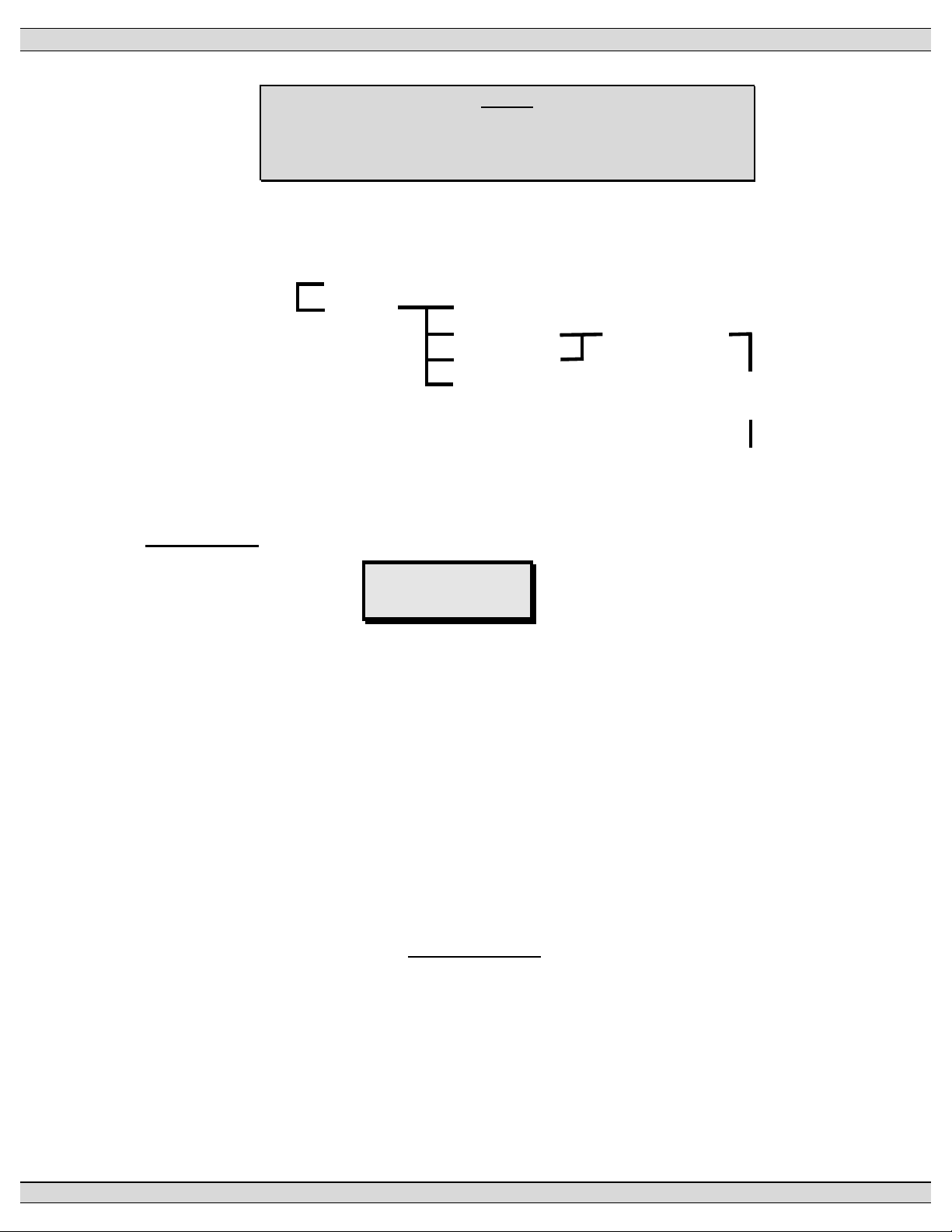

TSC 800

TRANSFER SWITCH CONTROLLER

INSTALLATION, OPERATING &

SERVICE MANUAL

Software Version 2.2

PM049 REV 10 08/09/25

9087A – 198th Street, Langley, BC Canada V1M 3B1 Telephone (604) 888-0110

Telefax (604) 888-3381 E-Mail: info@thomsontechnology.com www.thomsontechnology.com

Page 2

9087A – 198th Street, Langley, BC Canada V1M 3B1 Telephone (604) 888-0110

Telefax (604) 888-3381 E-Mail: info@thomsontechnology.com www.thomsontechnology.com

Page 3

TSC 800 TRANSFER SWITCH CONTROLLER

TABLE OF CONTENTS

1. INTRODUCTION 1

1.1. PRODUCT REVISION HISTORY 1

1.2. GENERAL DESCRIPTION 2

2. INSTALLATION 2

2.1. GENERAL INFORMATION 2

2.2. NOTES TO INSTALLER 3

2.3. AC VOLTAGE SENSING INPUT 3

2.4. AC CONTROL POWER INPUT 3

2.5. OUTPUTS 5

2.6. SYSTEM PHASING-HIGH LEG DELTA SYSTEMS 5

2.7. EXTERNAL PANEL CONTROL WIRING 8

2.8. REMOTE START CONTACT FIELD WIRING 8

2.9. COMMMUNICATION CABLE 9

2.10. DIELECTRIC TESTING 10

3. DESCRIPTION 10

3.1. LEXAN FACEPLATE 10

3.2. PRINTED CIRCUIT BOARD 12

3.2.1. POWER SUPPLY INPUT VOLTAGE SELECTION 12

3.2.2. TERMINAL BLOCKS 13

3.2.3. DIAGNOSTIC LEDs 13

3.2.4. COMMUNICATION PORT 14

3.2.5. CONTRAST ADJUSTMENT 14

4. REMOTE COMMUNICATION 14

5. TSC 800 DISPLAY MENUS 17

5.1. SYSTEM TIME MENU 18

5.2. ATS MODE MENU 18

5.3. TSC 800 PROGRAM MENU 22

5.4. SYSTEM OPERATION MENU 22

5.5. TIMER COUNTDOWN MENUS 24

PM 049 REV 10 08/09/25 Thomson Technology

Page 4

TSC 800 TRANSFER SWITCH CONTROLLER

5.6. UTILITY SUPPLY MENU 25

5.7. GENERATOR SUPPLY MENU 26

5.8. STATS MENU 27

6. OPERATING INSTRUCTIONS 28

6.1. AUTOMATIC SEQUENCE OF OPERATION 28

6.1.1. NORMAL SEQUENCE OF OPERATION (OPEN TRANSITION TRANSFER) 28

6.1.2. NORMAL SEQUENCE OF OPERATION (CLOSED TRANSITION TRANSFER) 29

6.1.3. TEST MODE SEQUENCE OF OPERATION 30

6.1.4. ABNORMAL SEQUENCE OF OPERATION 32

6.2. LCD DISPLAY OPERATION 32

6.4.1 OPERATOR INITIATED UTILITY POWER FAIL SIMULATION (LOAD TEST) 34

6.4.2 AUTOMATIC PLANT EXERCISE TEST 35

6.4.3 FOUR FUNCTION REMOTE TEST (FTS4 OPTION) 35

6.5 TRANSFER FAIL FAULT RESET 37

6.6 LAMP TEST 37

6.7 TIMER BYPASS 37

6.8 MANUAL UTILITY RE-TRANSFER 38

6.9 SERVICE ENTRANCE ATS MODE 38

6.10 PHASE BALANCE PROTECTION ALARM 38

7. PROGRAMMING INSTRUCTIONS 39

7.1. PASSWORDS 39

7.1.1. READ ONLY MODE 39

7.1.2. READ / WRITE MODE 39

7.1.3. MASTER READ / WRITE MODE 40

7.2. EXERCISE TIMER 41

7.2.1. SYSTEM TIME ROLLOVER 41

7.2.2. AUTO TEST START DAY/WEEK NUMBER 42

7.2.3. AUTO TEST START HOUR 42

7.2.4. AUTO TEST START MINUTE 42

7.2.5. AUTO TEST STOP DAY/WEEK NUMBER 42

7.2.6. AUTO TEST STOP HOUR 42

7.2.7. AUTO TEST STOP MINUTE 43

7.2.8. AUTO TEST MODE 43

7.3. SYSTEM CONFIGURATION 43

7.3.1. FIRMWARE VERSION 43

7.3.2. ATS MODE MENU PASSWORD (PW) 43

7.3.3. UTILITY FAIL CALLOUT 44

7.3.4. LOAD ON GENERATOR CALLOUT 44

7.3.5. TRANSFER FAIL CALLOUT 44

7.3.6. AUTO TEST CALLOUT 44

7.3.7. MAN TEST CALLOUT 45

7.3.8. SWITCH NOT IN AUTO CALLOUT 45

7.3.9. NODE ADDRESS 45

PM 049 REV 10 08/09/25 Thomson Technology

Page 5

TSC 800 TRANSFER SWITCH CONTROLLER

7.3.10. SYSTEM VOLTAGE 45

7.3.11. VOLTAGE SENSING RATIO 45

7.3.12. SYSTEM FREQUENCY 46

7.3.13. SYSTEM PHASES 46

7.3.14. LOAD SENSING PHASES 46

7.3.15. PHASE BALANCE 46

7.3.16. PHASE BALANCE DELAY 47

7.3.17. PHASE BALANCE RETRANSFER 47

7.4. VOLTAGE SENSING 47

7.4.1. UTILITY UNDER VOLTAGE SENSOR PICKUP 48

7.4.2. UTILITY UNDER VOLTAGE SENSOR DROPOUT 48

7.4.3. UTILITY UNDER VOLTAGE SENSOR TIME DELAY (DROPOUT) 48

7.4.4. UTILITY OVER VOLTAGE SENSOR PICKUP 48

7.4.5. UTILITY OVER VOLTAGE SENSOR DROPOUT 49

7.4.6. UTILITY OVER VOLTAGE SENSOR TIME DELAY (PICKUP) 49

7.4.7. UTILITY UNDER FREQUENCY SENSOR 49

7.4.8. UTILITY UNDER FREQUENCY SENSOR TIME DELAY (DROPOUT) 49

7.4.9. UTILITY OVER FREQUENCY SENSOR 49

7.4.10. UTILITY OVER FREQUENCY SENSOR TIME DELAY (PICKUP) 49

7.4.11. GENERATOR UNDER VOLTAGE SENSOR PICKUP 49

7.4.12. GENERATOR UNDER VOLTAGE SENSOR DROPOUT 50

7.4.13. GENERATOR UNDER VOLTAGE SENSOR TIME DELAY (DROPOUT) 50

7.4.14. GENERATOR OVER VOLTAGE SENSOR PICKUP 50

7.4.15. GENERATOR OVER VOLTAGE SENSOR DROPOUT 50

7.4.16. GENERATOR OVER VOLTAGE SENSOR TIME DELAY (PICKUP) 51

7.4.17. GENERATOR UNDER FREQUENCY SENSOR 51

7.4.18. GENERATOR UNDER FREQUENCY SENSOR TIME DELAY (DROPOUT) 51

7.4.19. GENERATOR OVER FREQUENCY SENSOR 51

7.4.20. GENERATOR OVER FREQUENCY SENSOR TIME DELAY (PICKUP) 51

7.5. GENERATOR CONTROL LOGIC 51

7.5.1. COMMIT TO TRANSFER LOGIC 51

7.5.2. GENERATOR START DELAY 52

7.5.3. GENERATOR WARMUP DELAY 52

7.5.4. GENERATOR COOLDOWN DELAY 52

7.5.5. PRE-TRANSFER DELAY (LDC) 52

7.5.6. POST-TRANSFER DELAY (LDC) 53

7.5.7. TRANSFER LOGIC 53

7.5.8. LOAD ON UTILITY PROGRAMMABLE OUTPUT 54

7.5.9. LOAD ON GENERATOR PROGRAMMABLE OUTPUT 55

7.5.10. MAXIMUM FIND NEUTRAL DELAY 55

7.5.11. NEUTRAL DELAY TIMER (NDT) 56

7.5.12. NEUTRAL DELAY BYPASS 57

7.5.13. MAXIMUM TRANSFER TIME 57

7.5.14. TRANSFER FAIL 57

7.5.15. MANUAL UTILITY TRANSFER RETURN 58

7.5.16. UTILITY RETURN DELAY 58

7.5.17. MAX SYNC TIME 59

7.5.18. MAX POWER SWITCHING DEVICE OPEN TIME 59

7.5.19. PROGRAMMABLE OUTPUT 59

7.6. VOLTAGE SENSING CALIBRATION 60

7.6.1. GENERAL 61

7.6.2. UTILITY VOLTAGE CALIBRATION 62

7.6.3. GENERATOR VOLTAGE CALIBRATION 65

7.6.4. LOAD VOLTAGE CALIBRATION 67

8. TSC 800 PROGRAMMING DATA SHEETS 70

PM 049 REV 10 08/09/25 Thomson Technology

Page 6

TSC 800 TRANSFER SWITCH CONTROLLER

9. TSC 800 TYPICAL CONNECTION DIAGRAM 75

10. TSC 800 SPECIFICATIONS 76

11. TROUBLESHOOTING 77

12. REPLACEMENT PARTS 81

13. PRODUCT RETURN POLICY 81

14. NOTES 82

PM 049 REV 10 08/09/25 Thomson Technology

Page 7

1. INTRODUCTION

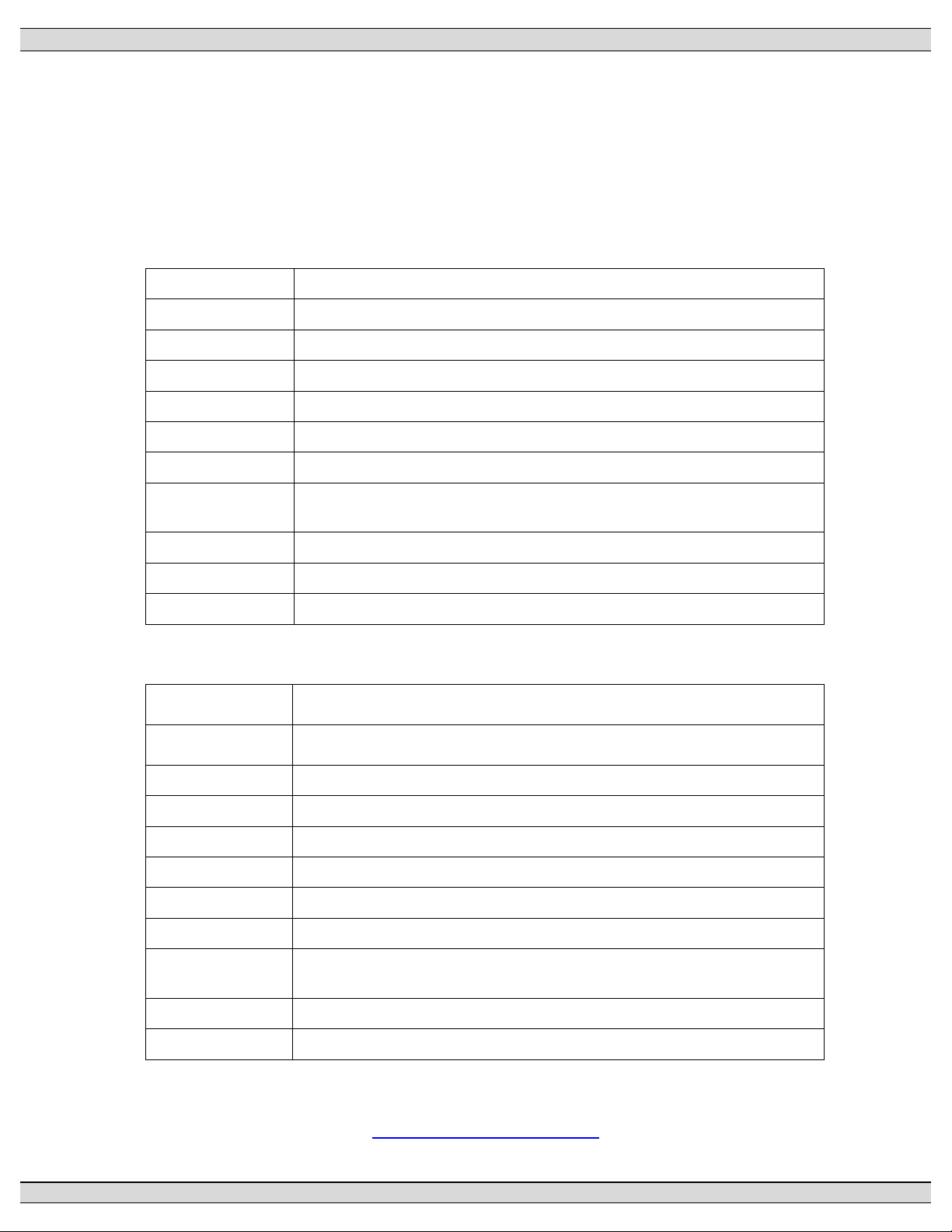

1.1. PRODUCT REVISION HISTORY

The following information provides an historical summary of changes made to this product

since the original release.

Software Version

TSC 800 TRANSFER SWITCH CONTROLLER

2.2 08/08/01

2.1 06/03/27

2.0 04/12/14

1.7 02/04/01

1.6 98/12/15

1.5 N/A

1.4 98/06/15

1.3 98/01/19

Enabled Clock Time Save Feature

Enhanced Phase Balance Features

New Features (Refer to Section 1.2)

Revised Transfer Fail Features and functionality

Added Remote Communication

Unreleased version

Updated Transfer Fail operation

Updated default under/over frequency setpoints, transfer fail

programmability, minor logic revisions

1.2 97/10/10

1.1 97/01/30

1.0 96/06/30

Changed Transfer Switch fail timer to 30 seconds

Upgraded Frequency setting range

Original version

Operating & Service Manual Version

Rev 10 08/09/25

Changes for Version 2.2 TSC 800 Software. Added Information for

ICS ATS Neutral delay time

Rev 9 06/04/24

Minor manual revisions for Version 2.1 TSC 800 Software

Production Release

Rev 8 06/03/27

Enhanced phase balance features

Rev 7 04/12/16

Rev 6 02/04/15

Rev 5 00/07/31

Rev 4 00/03/01

Rev 3 99/02/12

Rev 2 98/12/01

New Features (Refer to Section 1.2)

Changes for Version 1.7 TSC 800 Software

Added Four Position Test Switch Information

General revisions

Added Multi-tap information.

Added Remote Communication features per version 1.6 TSC 800

Software

Rev 1 98/01/21

Rev 0 97/06/04

General Revisions for upgraded TSC 800 software

Original release

Contact Thomson Technology, to obtain applicable instruction manuals. Soft copy of most

current version is available at www.thomsontechnology.com.

PM 049 REV 10 08/09/25 Thomson Technology

1

Page 8

1.2. GENERAL DESCRIPTION

The TSC 800 controller utilizes microprocessor-based design technology, which provides high

accuracy for all voltage sensing and timing functions. The TSC 800 is factory configured to

control all the operational functions and display features of the automatic transfer switch. All

features of the TSC 800 are fully programmable from the front panel LCD display and are

security password protected. The LCD display screen prompts are in plain English, providing

a user-friendly operator interface with many display options available. The microprocessor

design provides many standard features, which were previously only available as add-on

optional features.

2. INSTALLATION

TSC 800 TRANSFER SWITCH CONTROLLER

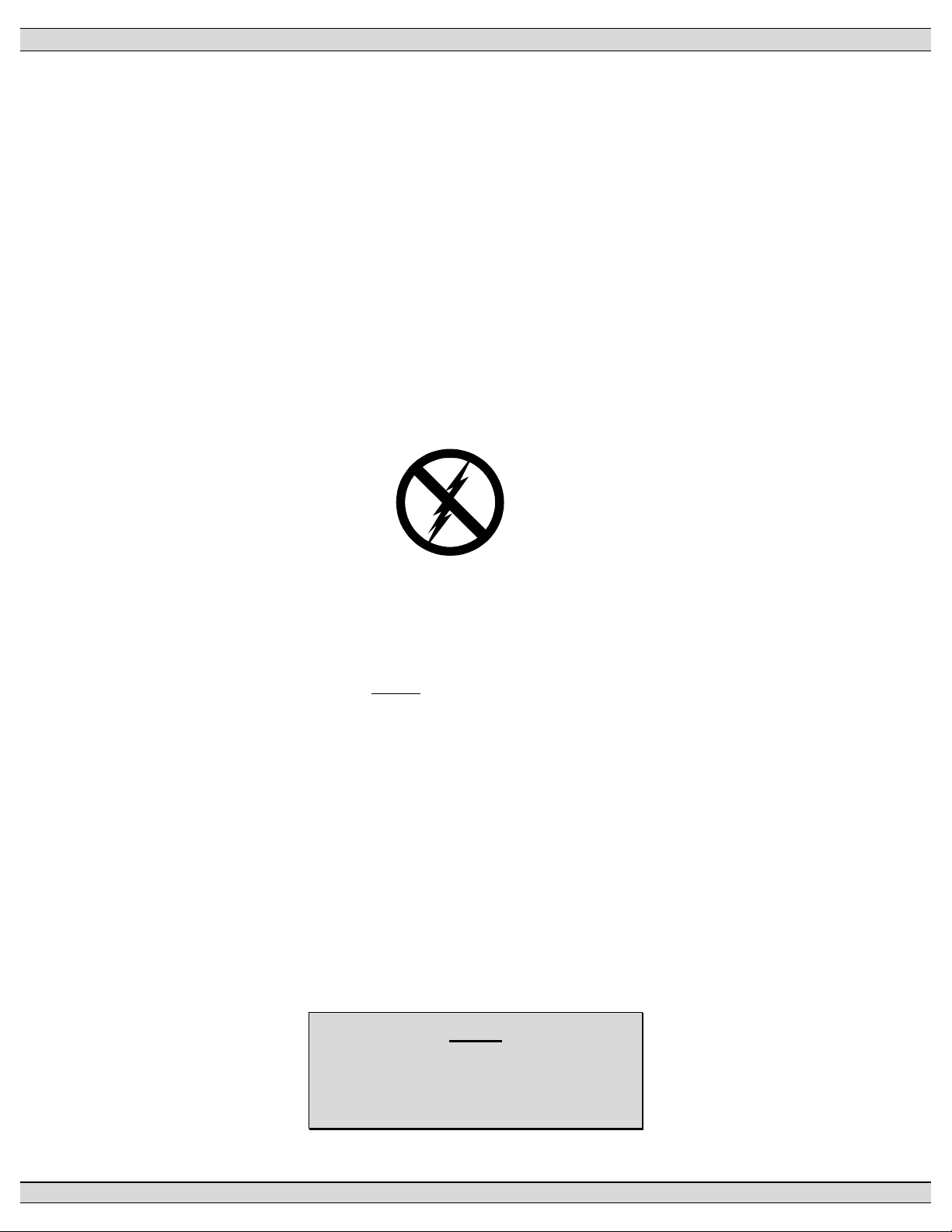

CAUTION

contents subject to damage by

STATIC ELECTRICITY

This equipment contains static-sensitive parts. Please observe the following anti-static precautions at

all times when handling this equipment. Failure to observe these precautions may cause equipment

failure and/or damage.

• Discharge body static charge before handling the equipment (maintain exposed body contact

with a properly grounded surface while handling the equipment, a grounding wrist strap

can/should also be utilized).

• Do not touch any components on the printed circuit board with your hands or any other

conductive equipment.

Do not place the equipment on or near materials such as Styrofoam, plastic and vinyl. Place the

equipment on properly grounded surfaces and only use an anti-static bag for transporting the

equipment.

2.1. GENERAL INFORMATION

NOTE:

Installations should be done in accordance

with all applicable electrical regulation

codes as required.

PM 049 REV 10 08/09/25 Thomson Technology

2

Page 9

TSC 800 TRANSFER SWITCH CONTROLLER

The following installation guidelines are provided for general information only pertaining to

typical site installations. For specific site installation information, consult Thomson

Technology as required. NOTE: Factory installations of THOMSON TECHNOLOGY supplied

transfer switches that have been tested and proven may deviate from these

recommendations.

2.2. NOTES TO INSTALLER

If the transfer switch has programmable/multi-tap system voltage capability (refer to electrical

schematic), confirm the transfer switch has been configured for the system voltage.

WARNING

Failure to confirm and match transfer

switch voltage with the system voltage

could cause serious equipment damage.

If the transfer switch requires reconfiguring, the TSC 800 controller will also require

reprogramming.

CAUTION!!!

Qualified personnel must complete all installation and/or service work

performed only. Failure to do so may cause personal injury or death.

2.3. AC VOLTAGE SENSING INPUT

The TSC 800 can accept direct AC voltage sensing inputs on the generator and utility supplies

from 120-600VAC (nominal). NOTE: Direct input voltage sensing can only be used when the

system utilizes a 3 phase, 4 wire distribution system which has the neutral conductor solidly

grounded. For 3 phase, 3 wire systems (i.e. no neutral) or high voltage systems, potential

transformers must be used (this is also the case where only 1 of the 2 supplies are 3 ph 3 w).

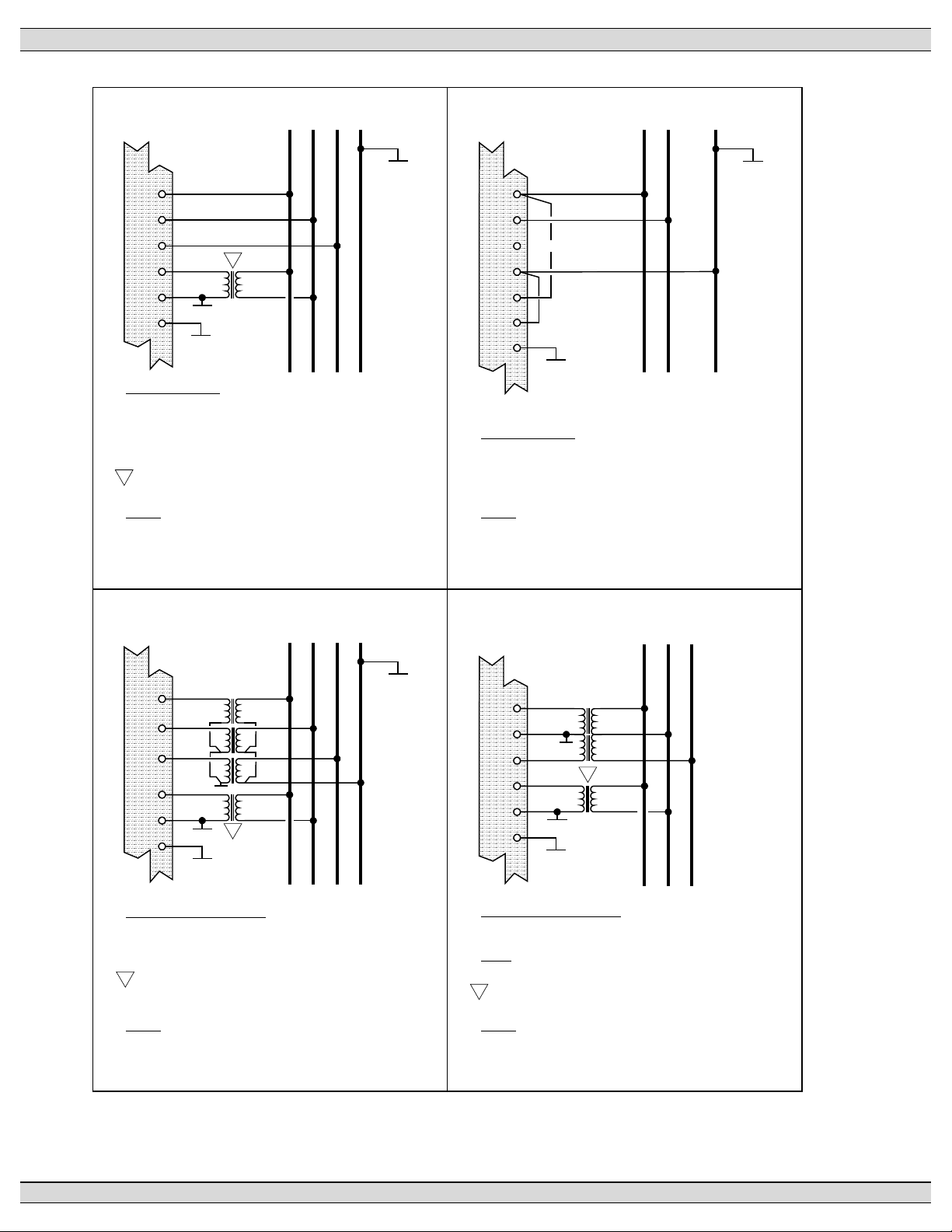

Refer to FIGURES 1-4 for voltage sensing connections.

2.4. AC CONTROL POWER INPUT

The TSC 800 is factory supplied for either 115VAC or 230VAC (nominal) control power input

voltage. Independent AC control power is required from both utility and generator supplies.

AC control power is utilized for internal TSC 800 control circuits and external control device

loads. The TSC 800 requires approximately 12VA AC power for internal control circuits. The

PM 049 REV 10 08/09/25 Thomson Technology

3

Page 10

TSC 800 TRANSFER SWITCH CONTROLLER

maximum external load is limited by output contact ratings (i.e. 10A resistive, 120/250VAC).

Total AC control power requirements for each supply must be determined by adding both

internal and external load requirements.

PM 049 REV 10 08/09/25 Thomson Technology

4

Page 11

TSC 800 TRANSFER SWITCH CONTROLLER

2.5. OUTPUTS

The TSC 800 provides the following types of output circuits:

Engine Start Contact Isolated Form C contact (10A, 250VAC Resistive)

Programmable Output Contact Isolated Form C contact (10A, 250VAC Resistive)

Transfer to Utility Output 250VAC1, 10A (Resistive) powered output contact

Transfer to Generator output 250VAC1, 10A (Resistive) powered output contact

Pre/post-transfer to utility 250VAC1, 3A (Resistive) powered output contact

Pre/post-transfer to generator 250VAC1, 3A (Resistive) powered output contact

Load on utility 250VAC1, 3A (Resistive) powered output contact

Load on generator 250VAC1, 3A (Resistive) powered output contact

1

NOTE: Output voltage is dependent upon AC control power input voltage (i.e. 120VAC or 230VAC

nominal).

Interposing relays are required between the TSC 800 outputs and the end device if loads

exceed the output current rating.

Transient suppression devices are required for all inductive devices sharing wiring or if

physically located near the transfer switch controller.

For AC operated relays or solenoids, use a suitably rated metal oxide varistor (MOV) or

capacitor/resistor suppressor. MOV selection should typically be equal to or slightly greater

than 1.3 times the nominal RMS voltage being applied to the inductive device.

NOTE: Selecting an MOV of too low a value can/will result in a sustained short circuit and

ultimately result in equipment failure.

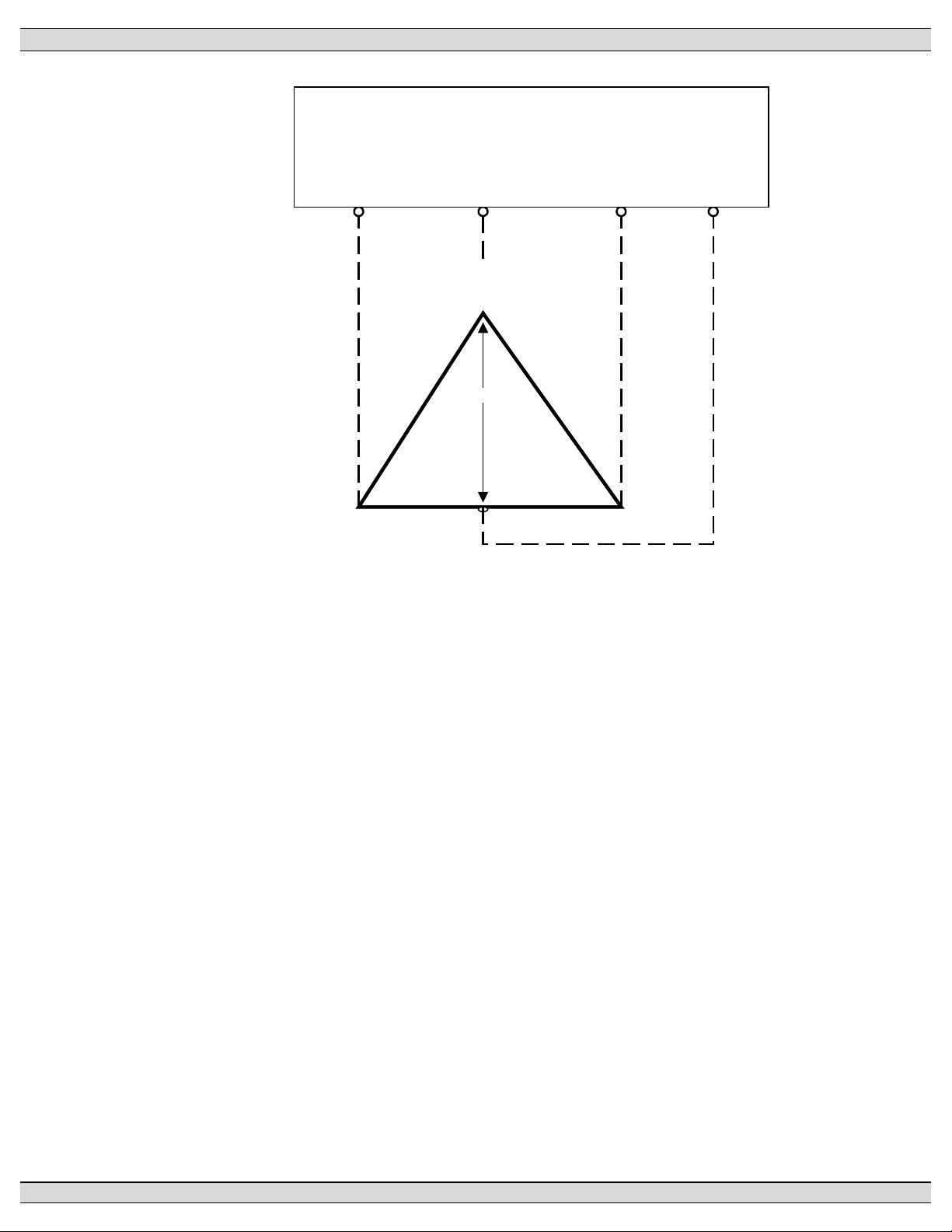

2.6. SYSTEM PHASING-HIGH LEG DELTA SYSTEMS

When the transfer switch is connected to 3 phase 4 wire delta systems and no multi tap

power supply transformers supplied with the ATS, the “High” leg, must be connected to

Phase B of the Utility and/or Generator supply inputs to the ATS (Phase B, colored Orange

per “NEC 384-3(e)” identified as the leg with highest potential with reference to ground). This

will ensure the ATS control power that is internally connected between phase A and neutral is

maintained at 120VAC. Refer to figure below for further details.

WARNING

Failure to match correct system phasing

will result in serious damage to the

TSC 800 controller.

PM 049 REV 10 08/09/25 Thomson Technology

5

Page 12

TSC 800 TRANSFER SWITCH CONTROLLER

Auto matic Tra nsfer

Switch (Utility Supply)

A

(Re d)

PH A

(U A)

PH B

(U B)

B

(O ra ng e)

(High Le g)

240V 240 V

120V 12 0V

208V

N

(W hite )

PH C

(U C )

Neural

(N )

C

(Ye llow)

PM 049 REV 10 08/09/25 Thomson Technology

6

Page 13

TSC 800 TRANSFER SWITCH CONTROLLER

TSC 800

TB1-1

TB1-2

TB1-3

TB3-1

TB3-5

TB2-18

1

120

GRD

GRD

BA C N

VOLTAGE INPUTS

600VAC L-L, 347VAC L-N

480VAC L-L, 277VAC L-N

380VAC L-L, 220VAC L-N

208VAC L-L, 120VAC L-N

PT REQUIRED FOR TRANSFER SWITCH M ECHANISM POWER

1

(MUST BE SIZED TO SUIT POWER REQUIREMENTS).

FIG:1

3Ø, 4W 208/380/480/600VAC DIRECT SENSING

NOTE:

UTILITY VOLTAGE SENSING AND

CONTROL POWER SHOWN ONLY.

GRD

TSC 800

TB1-1

TB1-2

TB1-3

TB1-10

TB3-1

TB3-5

TB2-18

NO CONNECTION

GRD

L2L1 N

VOLTAGE INPUTS

240VAC L-L, 120VAC L-N

FIG:2

1Ø, 3W 120/240VAC DIRECT SENSING

NOTE:

UTILITY VOLTAGE SENSING SHOWN ONLY.

GRD

TSC 800

TB1-1

TB1-2

TB1-3

TB3-1

TB3-5

TB2-18

120

120

120

120

GRD

GRD

GRD

1

BA C N

SECONDARY PT VOLTAGE

208VAC L-L, 120VAC L-N

120VAC L-L, 69VAC L-N

PT REQUIRED FOR TRANSFER SWITCH M ECHANISM POWER

1

(MUST BE SIZED TO SUIT POWER REQUIREMENTS).

FIG:3

3Ø, 4W WYE PT's

NOTE:

UTILITY VOLTAGE SENSING SHOWN ONLY.

GRD

TSC 800

TB1-1

TB1-2

TB1-3

TB3-1

TB3-5

TB2-18

120

120

GRD

1

120

GRD

GRD

BA C

SECONDARY PT VOLTAGE

120VAC L-L [NO NEUTRAL]

NOTE

: ØB IS GROUNDED

PT REQUIRED FOR TRANSFER SWITCH M ECHANISM POWER

1

(MUST BE SIZED TO SUIT POWER REQUIREMENTS).

FIG:4

3Ø, 3W DELTA PT's

NOTE:

UTILITY VOLTAGE SENSING SHOWN ONLY.

REVISED

G:\ENGINEER\PRODUCTS\TSC800\852619.VSD

PM 049 REV 10 08/09/25 Thomson Technology

7

97/06/27 09:12 AM

Page 14

TSC 800 TRANSFER SWITCH CONTROLLER

2.7. EXTERNAL PANEL CONTROL WIRING

As a minimum, all control wiring shall conform to the local regulatory authority on electrical

installations. Specific wire sizes listed below are for typical circuits of distances up to 500ft

(150m)1, are as follows:

Utility or Generator Voltage Sensing #14 AWG (2.5mm2)

Transfer output signals #14 AWG (2.5mm2)

Remote Start Contact for Engine Controls #14 AWG (2.5mm2)

NOTE: For long control wire runs or noisy electrical environments the control wires

should be twisted & shielded with a suitable drain wire. The shielded cable drain wire

must be grounded at one end only. The drain wire grounding location may vary as

micro-processor controllers generally exist at both ends (engine generator set &

transfer switch) and one may be more susceptible depending on the level of induced

noise. The most susceptible controller will requiring the shield ground point as close

as possible to the controller. Wire runs from 500ft to 1000ft should be twisted and

shielded and increased to #12 AWG where total loop resistance is greater than 5

ohms.

1

For distances exceeding 1000ft. (300m) consult Thomson Technology

2.8. REMOTE START CONTACT FIELD WIRING

Field wiring of a remote start contact from a transfer switch to a control panel should conform

to the following guidelines to avoid possible controller malfunction and/or damage.

2.8.1. Remote start contact wires (2 #14 AWG (2.5mm2)) should be run in a separate

conduit (ferromagnetic type) and in all cases separated from any AC wiring.

2.8.2. Avoid wiring near AC power cables to prevent pick-up of induced voltages.

2.8.3. An interposing relay may be required if field-wiring distance is excessively long

(i.e. greater than 1000 feet (300m)) and/or if a remote contact has a resistance

of greater than 5.0 ohms. In extremely noisy environments, the wire run

lengths indicated may not provide reliable operation and can only be corrected

by the use of an interposing relay. The interposing relay is generally installed

at the engine controls and utilizes DC power. It is strongly suggested that the

ground return wire of the interposing relay be used for the interface to the TSC

800 remote start contact, this will ensure integrity of the DC power supply to the

engine generator set controls in the event of a shorted or grounded wire remote

start interface wire.

PM 049 REV 10 08/09/25 Thomson Technology

8

Page 15

TSC 800 TRANSFER SWITCH CONTROLLER

2.8.4. The remote start contact provided is voltage free (i.e. dry contact). Exposing

the remote start contact to voltage or current levels in excess of its rating will

damage the transfer controller.

2.9. COMMMUNICATION CABLE

Communication cable wiring from the controller’s communication port must be suitably routed

to protect it from sources of electrical interference. Guidelines for protection against possible

electrical interference are as follows:

• Use high quality, 8 conductor shielded cable only with drain wire grounded at the

controller end only.

• Route the communication cable at least 3 M (10’) away from sources of electrical

noise such as variable speed motor drives, high voltage power conductors, UPS

systems, transformers, rectifiers etc.

• Use separate, dedicated conduit runs for all communication cables. Do not tightly

bundle communication cables together in the conduit. Conduit should be

ferromagnetic type near sources of possible electrical interference. The entire

length of conduit should be grounded to building earth ground.

• When communication cables must cross over low or high voltage AC power

conductors, the communication cables must cross at right angles and not in

parallel with the conductors.

For additional information on protection against electrical interference, contact

THOMSON TECHNOLOGY factory.

PM 049 REV 10 08/09/25 Thomson Technology

9

Page 16

TSC 800 TRANSFER SWITCH CONTROLLER

2.10. DIELECTRIC TESTING

Do not perform any high voltage dielectric testing on the transfer switch with the TSC 800

controller connected into the circuit, as serious damage will occur to the controller. All AC

control fuses or control circuit isolation plugs connected to the TSC 800 must be

removed/disconnected if high voltage dielectric testing is performed on the transfer switch.

3. DESCRIPTION

The TSC 800 controller consists of two parts; a Lexan faceplate, which is mounted externally on the

transfer switch door, and a printed circuit board (PCB), which is mounted inside the transfer switch

door.

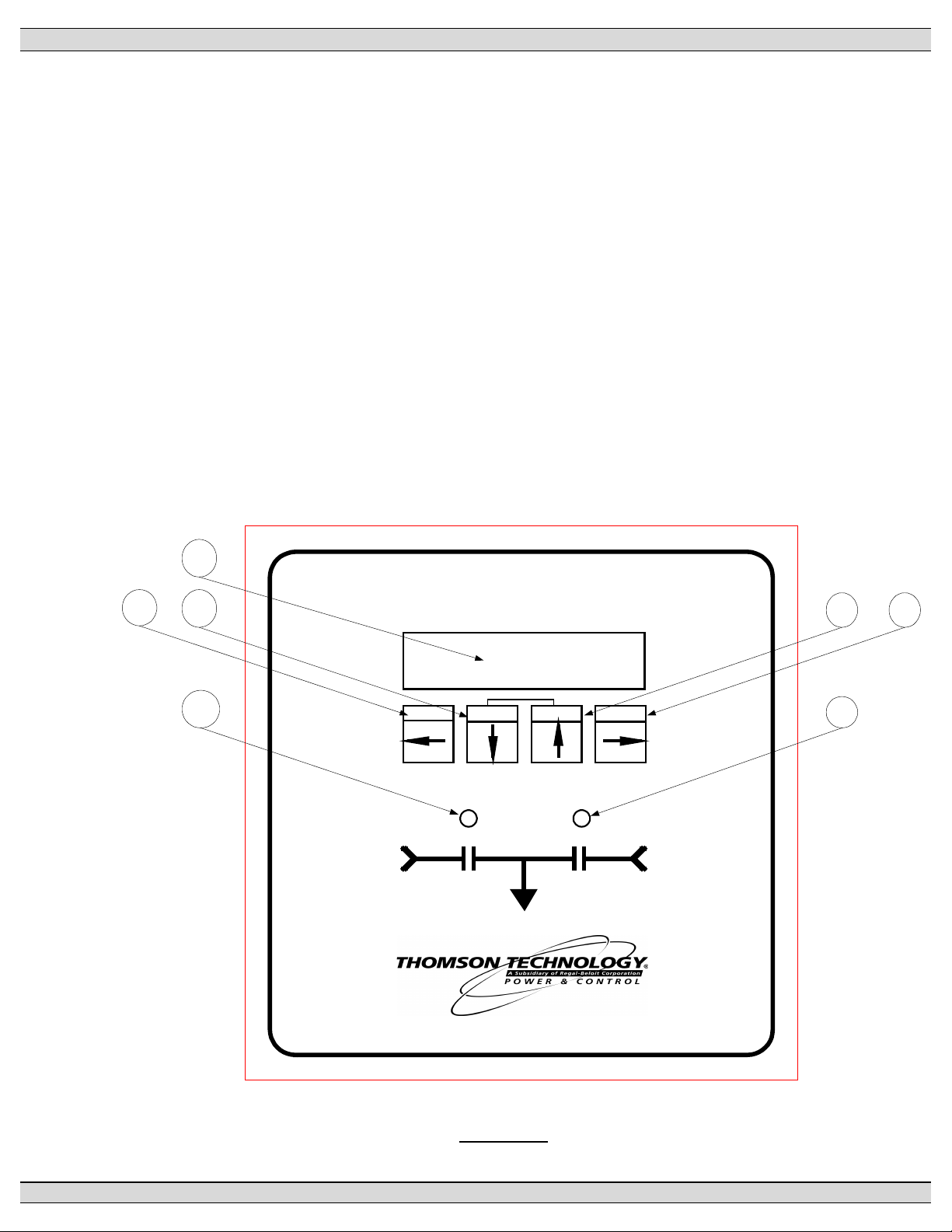

3.1. LEXAN FACEPLATE

The Lexan faceplate is shown as in FIGURE 7. The Lexan pushbuttons are connected to the

main PCB via plug-in ribbon cable. The main features of the Lexan faceplate are described

as follows with reference to FIGURE 7.

1

AUTOMATIC TRANSFER CONTROLLER

2

3

6

UTILITY

SUPPLY

MODEL TSC 800

LAMP TEST

EXIT DECREMENT INCREMENT ENTER

LOAD

54

7

GENERATOR

SUPPLY

FULL FILENAME

DRAWING1

DATE

02/04/04 11:58AM

FIGURE# 7

PM 049 REV 10 08/09/25 Thomson Technology

10

Page 17

TSC 800 TRANSFER SWITCH CONTROLLER

LCD viewing window. The LCD display is mounted on the main PCB which is visible

from the lexan faceplate.

EXIT pushbutton. The EXIT function is used to scroll backwards through the status

menus or programming prompts to the previous item. The EXIT function is used to

“exit” the programming menu by holding this button down for approximately 2 seconds

while in the programming mode.

DECREMENT pushbutton. The DECREMENT function is used to change a

programming value while in the programming mode. When this pushbutton is held

down, the displayed value will be “decremented” to a lower value as desired. NOTE:

The longer the pushbutton is held down, the faster the value will be decremented.

INCREMENT pushbutton. The INCREMENT function is used to change a

programming value while in the programming mode. When this pushbutton is held

down, the displayed value will be “incremented” to a higher value as desired. NOTE:

The longer the pushbutton is held down, the faster the value will be incremented.

ENTER pushbutton. The ENTER function is used to scroll forwards through the status

menus or programming prompts to the next item. The ENTER function is used to

“enter” and accept new programming or operating mode changes after a new value

has been selected (NOTE: Pressing the Exit button instead of the Enter button will

reject the newly selected value and retain the original value). NOTE: In the

programming mode, the longer the ENTER pushbutton is held down, the faster the

next menu prompt will appear.

Load on Utility supply LED light viewing window

Load on Generator supply LED light viewing window

NOTE: A lamp test feature is provided to test all LED lights as well as the LCD display.

To activate the lamp test feature, simultaneously push the INCREMENT and

DECREMENT pushbuttons. All LEDs and LCD display pixels should illuminate for

approximately 2 seconds then return to their original status. The Lamp Test feature is

also used to clear active fault conditions and return the controller to normal operation.

NOTE: An active Timer Bypass feature is provided to allow a manual initiated bypass.

To activate the feature, simultaneously push the DECREMENT and ENTER

pushbuttons. The previously bypassed timer will operate normally during its next

cycle. Refer to Timer Bypass section for related timers.

PM 049 REV 10 08/09/25 Thomson Technology

11

Page 18

TSC 800 TRANSFER SWITCH CONTROLLER

4 3 2 1

HD2

WATCHDOG

ENGINE START

TRANSFER

TO UTILITY

TRANSFER

TO GENERATOR

UTILIT Y SUPPLY

TRANSFORMER

CONTRAST

GENERATOR SUPPLY

TRANSFORMER

HD1

TB3

TB2

1

2

3

4

1

12

1

1

J7

COMM

RJ45

Connector

TB1

5

4

3

2

1

G;\ENGINEER\PRODUCTS\TSC800\852613b.VSD

FIGURE # 8

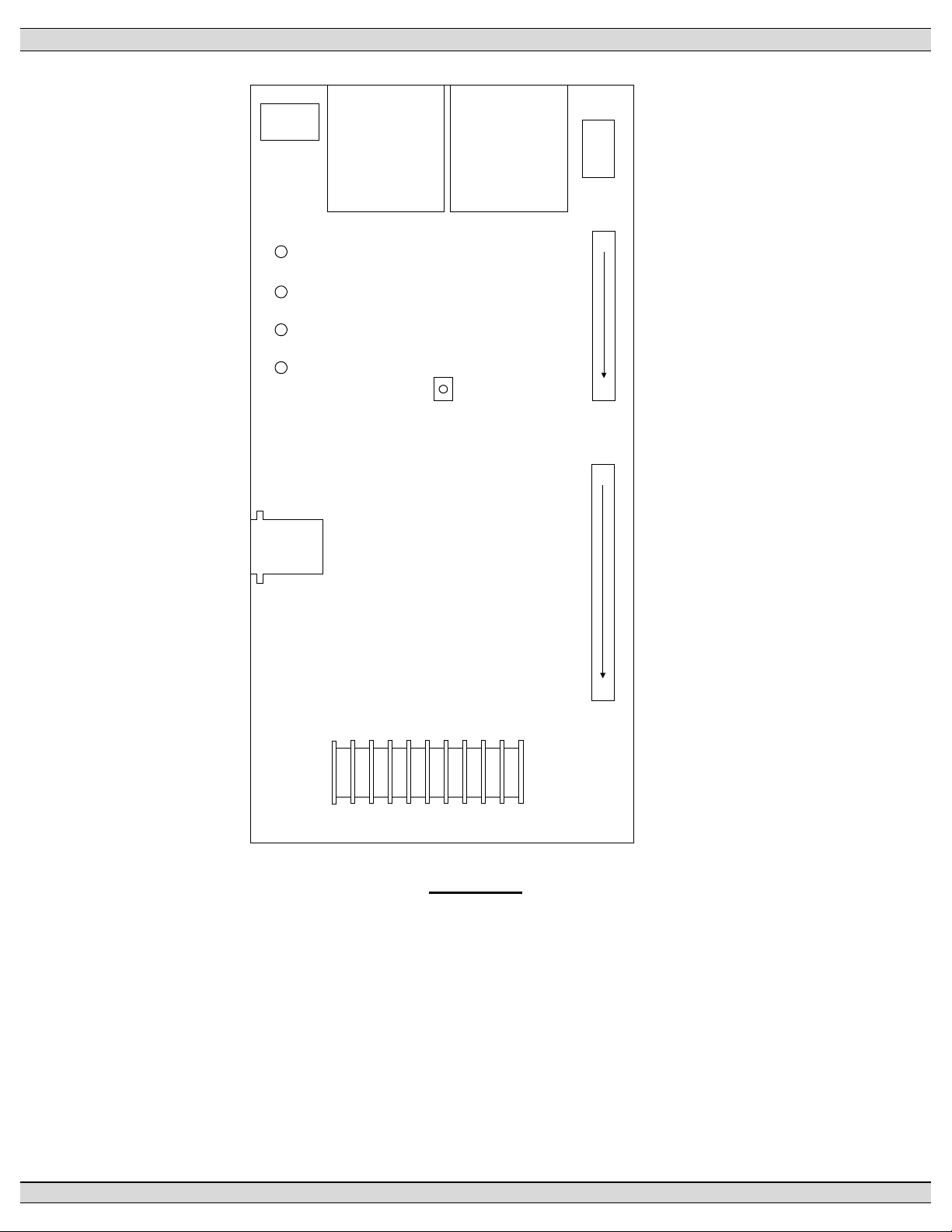

3.2. PRINTED CIRCUIT BOARD

18

9

8

7

6

10

The printed circuit board (PCB) is shown in FIGURE 8. The PCB contains the following user

interface items:

3.2.1. POWER SUPPLY INPUT VOLTAGE SELECTION

The controller power supply input voltage level selection is made via two connector

plugs, which are located on the PCB and are identified as HD1 and HD2. Voltage

selection plug assemblies are unique for each power supply input level voltage

PM 049 REV 10 08/09/25 Thomson Technology

12

Page 19

TSC 800 TRANSFER SWITCH CONTROLLER

arrangement and must match the intended voltage level. Controller failure may result

if incorrectly configured.

The TSC 800 is factory configured for a specific power supply voltage input as

designated by voltage header plugs labeled as follows:

115V - designates a 115V power supply input voltage

230V - designates a 230V power supply input voltage

3.2.2. TERMINAL BLOCKS

Three terminal blocks are located on the PCB as follows:

TB1 High voltage sensing terminal block (120-600VAC)

WARNING

Voltage sensing circuits are capable of lethal voltages while

energized. Standard safety procedures should be followed and

be performed by qualified personnel only. Failure to do so may

cause personnel injury and/or death.

TB2 Transfer control terminal block for output contacts and low voltage inputs

TB3 Transfer control terminal block for 115/230v input and output circuits

3.2.3. DIAGNOSTIC LEDs

The TSC 800 controller provides four diagnostic LED lights that are mounted on the

rear of the printed circuit board as per FIGURE 8. Their functions are described as

follows:

WATCHDOG This LED flashes on and off at irregular intervals that

indicate that the microprocessor is functioning

normally.

ENGINE START This LED is illuminated whenever the TSC 800 is

initiating an Engine Start (except when there is no

power to the TSC 800 controller).

TRANSFER TO UTILITY This LED is illuminated whenever the TSC 800 is

initiating a Transfer to Utility signal.

TRANSFER TO GEN This LED is illuminated whenever the TSC 800 is

initiating a Transfer to Generator signal.

NOTE: All LEDs will be illuminated whenever a lamp test function is performed.

PM 049 REV 10 08/09/25 Thomson Technology

13

Page 20

TSC 800 TRANSFER SWITCH CONTROLLER

3.2.4. COMMUNICATION PORT

A communication port is provided to interconnect to a remote communication system

for remote monitoring and control of the transfer switch. Refer to Section 4 for

additional information.

3.2.5. CONTRAST ADJUSTMENT

A contrast adjustment potentiometer is located on the PCB and is factory set for

ambient temperatures of 15° to 30° Celsius. For different ambient temperatures,

consult the factory for adjustment procedures.

4. REMOTE COMMUNICATION

The TSC 800 transfer switch controller is available with a remote communication feature. The remote

communication feature allows a TSC 800 controller to be monitored and controlled from a remote

location via serial communication link to a personal computer (PC). PC’s may be connected locally

via serial communication cable to the TSC 800 or remotely via modem and telephone systems.

Remote communication can be via customer-supplied equipment or with an external communication

interface module (CIM) as manufactured by Thomson Technology.

NOTE:

The CIM module may be located in the engine control panel

provided the maximum distance between the CIM and TSC 800

controller is not exceeded as per the following information.

Refer to the installation section of this manual for further

information.

The CIM module utilizes an internal modem and contains ModbusTM protocol to interface with different

remote monitoring software programs. Refer to separate literature for detailed information on the

CIM module.

The TSC 800 communication port utilizes a RS422 data transmission signal that is directly

interconnected to the CIM module via an 8 conductor, shielded cable with plug-in RJ45 connectors.

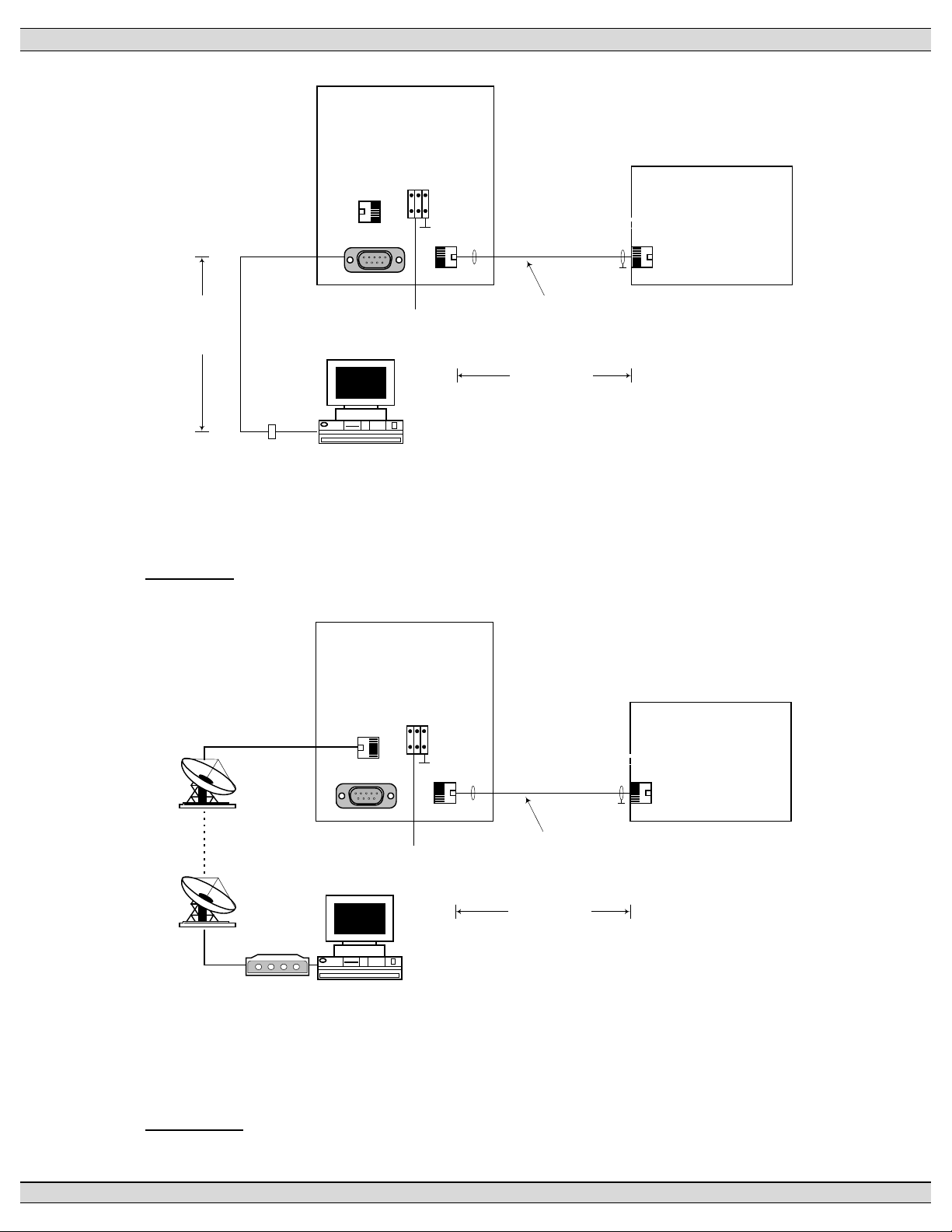

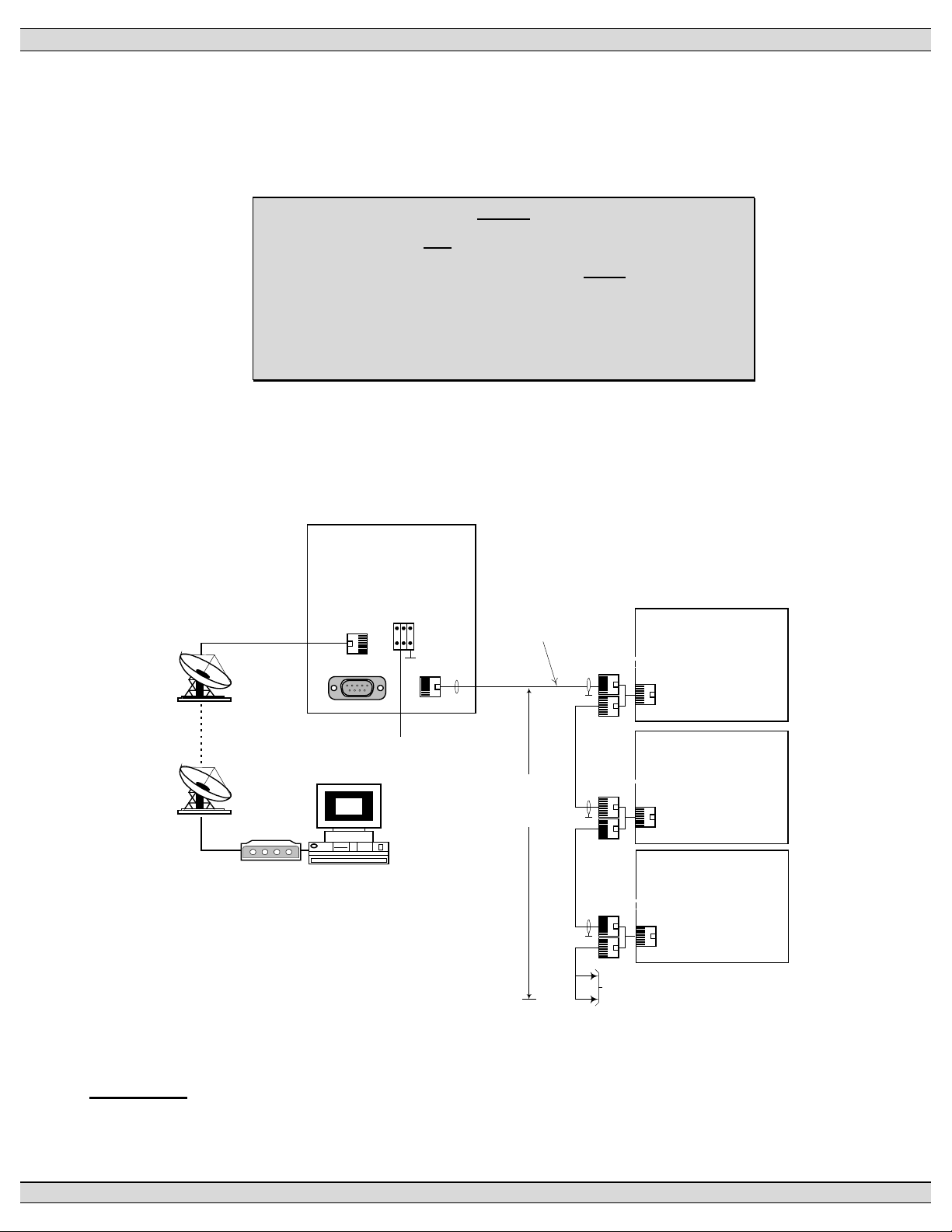

Refer to FIGURES 9 & 10 for detailed information on direct connected or remote connected PC

applications with CIM module.

TM

Trademarks belong to their respective parties.

NOTE: Both phone and serial communications ports cannot be connected at the same time. Doing

so will result in no communication and/or possible CIM failure.

PM 049 REV 10 08/09/25 Thomson Technology

14

Page 21

TSC 800 TRANSFER SWITCH CONTROLLER

CIM

Communication

Interface Module

+-

Phone

no connection

Port 2A

G

GRD

Port 3B

GRD

TSC 800

Transfer

Controller

RS 232 Signal

15M (50ft)**

maximum

cable length

null modem

connector

Personal

Computer

DC Power

8-35Vdc

**Communication cable wiring must be suitably routed to

protect it from sources of electrical interference. Refer to

installation section for further information.

8 conductor

Shielded Cable c/w

RJ45 connectors

305M

(1000ft)**

maximum

cable length

G:\ENGINEER\PRODUCTS\TSC800\852621.VSD

FIGURE #9 TSC 800 WITH CIM MODULE & DIRECT CONNECTED PC (RS232)

CIM

Communication

Interface Module

+-

Phone

Port 2A

no connection

G

GRD

Port 3B

DC Power

8-35Vdc

TSC 800

Transfer

Controller

GRD

8 conductor

Shielded Cable c/w

RJ45 connectors

305M (1000ft)**

maximum

cable length

**Communication cable wiring must be suitably routed to

Modem

Personal

Computer

protect it from sources of electrical interference. Refer to

installation section for further information.

G:\ENGINEER\PRODUCTS\TSC800\852622.VSD

FIGURE #10 TSC 800 WITH CIM MODULE & REMOTE CONNECTED PC

PM 049 REV 10 08/09/25 Thomson Technology

15

Page 22

TSC 800 TRANSFER SWITCH CONTROLLER

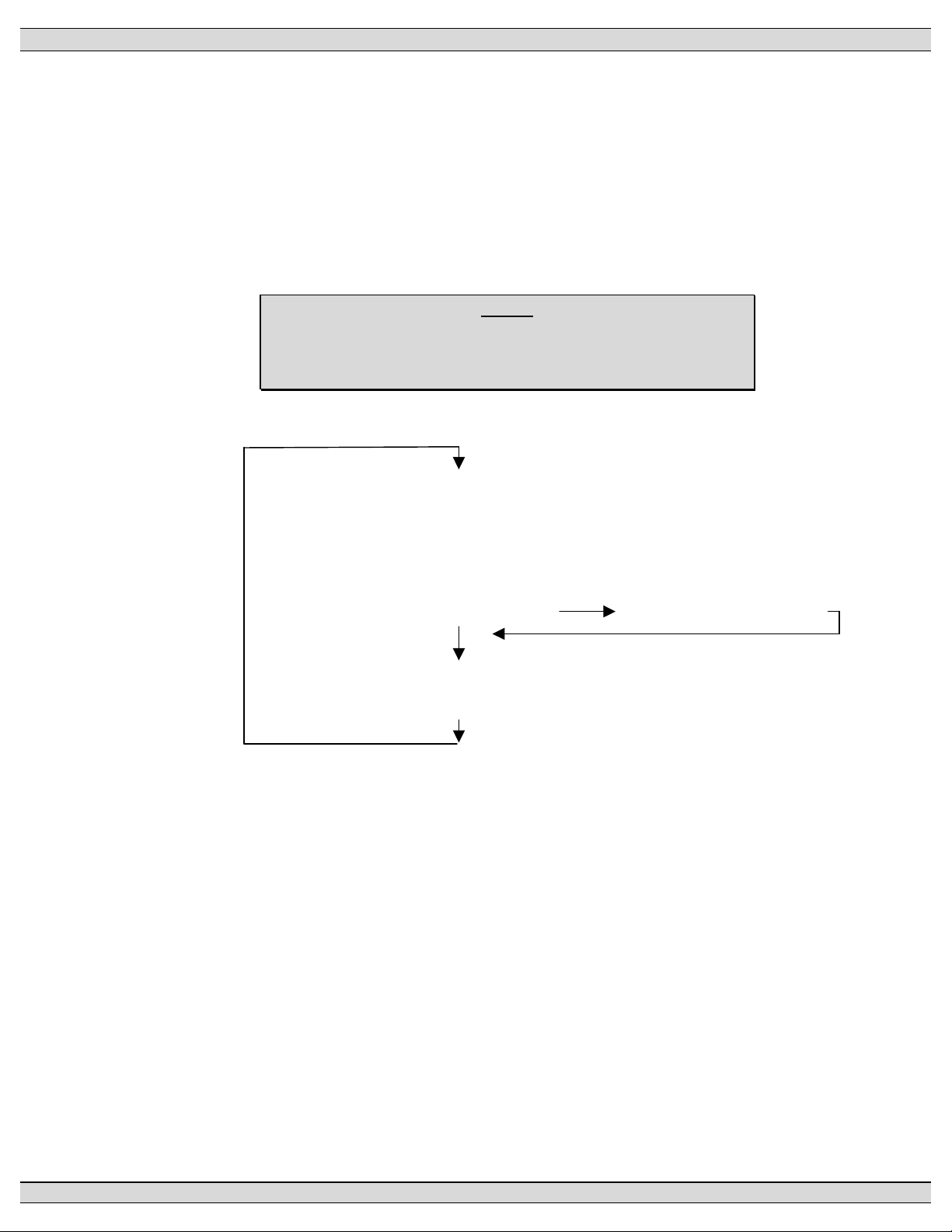

The TSC 800 RS422 communication port allows multiple TSC 800 controllers to be directly

interconnected together to form a single network system. Up to 10 TSC 800 controllers may be

interconnected to a single CIM module.

NOTE:

TSC 800 controllers and MEC 20 engine-generator controllers

may be interconnected together via the same communication

network provided the maximum number of controllers and

interconnection distances are not exceeded. For additional

information, refer to associated product instruction manuals.

Each TSC 800 controller is programmed with a unique communication node address number for the

remote communication system to reference. The network system may be connected to a local PC or

to a remote PC via telephone system and CIM module. Refer to FIGURE #11 for a typical TSC 800

network system with CIM module.

Communication

Interface Module

Phone

Port 2A

no connection

THS

Modem

**Communication cable wiring must be

suitably routed to protect it from sources of

electrical interference. Refer to installation

section for further information.

Personal

Computer

CIM

+-

G

GRD

Port 3B

DC Power

8-35Vdc

8 conductor

Shielded Cable c/w

RJ45 connectors

GRD

305M

(1000ft)**

maximum

cable length

GRD

GRD

TSC 800

Transfer

Controller

#1

TSC 800

Transfer

Controller

#2

TSC 800

Transfer

Controller

#3

To additional TSC 800 controllers

(maximum 10 total per network)

G:\ENGINEER\PRODUCTS\TSC800\852623.VSD

FIGURE #11 NETWORKED TSC 800 INTERCONNECTION DIAGRAM

PM 049 REV 10 08/09/25 Thomson Technology

16

Page 23

TSC 800 TRANSFER SWITCH CONTROLLER

5. TSC 800 DISPLAY MENUS

The TSC 800 contains a Liquid Crystal Display (LCD) that is visible on the front faceplate. The LCD

has pre-programmed display menus which are automatically displayed in an auto-Scrolling mode or

they may be selected manually by pressing the ENTER or EXIT pushbuttons in succession until the

desired menu is displayed. The display menu types and order in which they are programmed are as

follows:

NOTE:

The following display menus are provided in TSC 800 Software

version 2.0 (or higher).

SYSTEM TIME

STATS MENU

ATS MODE MENU

PROGRAM MENU

SYSTEM STATUS TIMER COUNTDOWN

UTILITY SUPPLY MENU

GEN SUPPLY MENU

NOTE: ATS MODE MENU access may be inhibited. Refer to programming instruction

for further details.

PM 049 REV 10 08/09/25 Thomson Technology

17

Page 24

TSC 800 TRANSFER SWITCH CONTROLLER

5.1. SYSTEM TIME MENU

The system time menu is used to show current system time and week number. The TSC 800

controller uses its internal time clock to reference when an automatic exercising operation (if

pre-programmed) is to occur. To change the system time, refer to the “time clock adjustment”

section of this manual. Should control power be lost to the TSC 800 controller for longer than

1-5 minutes, the time clock setting will be saved at the last time value. When the controller is

re-energized, the time setting will indicate the approximate time when the controller lost power

and then will resume keeping system Time. To re-adjust the system time clock, refer to

section 6.3.

NOTE:

The following system Time menu is provided in TSC 800

Software version 2.0 (or higher).

LCD DISPLAY

System Time

Mon

Displays the day of the week (e.g. Monday)

Displays the week number (e.g. 1-4)

Displays the current time in hours (24-hour clock): hour: min: seconds

1

12:24:31

5.2. ATS MODE MENU

The ATS Mode Menu provides manually selectable operating modes which includes

On/Offload testing features (comparable features also available via external inputs utilizing an

optional FTS4 selector switch). The Internal and External ATS Mode inputs operate in a

parallel fashion; the Mode of Operation will be determined by the highest priority selected by

either format. The priority levels are as follows (highest to lowest priority):

1) Off (Controller out of Service, no control logic applied)

2) Onload Test

3) Offload Test

4) Auto

A utility power failure will over ride all but “Off”. In the event of a generator failure and the

utility supply is available and considered normal, the ATS will return to the utility supply except

when “Off” selected.

PM 049 REV 10 08/09/25 Thomson Technology

18

Page 25

TSC 800 TRANSFER SWITCH CONTROLLER

NOTE:

The following test menu is provided in TSC 800 Software

version 2.0 (or higher).

The ATS Mode sub-menus are organized as follows:

ATS Mode Menu No

Yes Auto (Automatic Operation & Programmed Test Mode)

Offload Test Continuous Test

Onload Test

Off (Controller Disabled) Timed Test: Selectable

15 - 240 Min.

Automatic Return to “Auto Mode”

LCD DISPLAY

ATS Mode Menu

No

Displays two messages that may be toggled between YES or NO by pressing the

INCREMENT or DECREMENT pushbuttons. Their functions are described as follows:

No Status message only, a change is required to gain access.

Yes The required variable to be entered to gain access and proceed. If the

password protect feature is enabled a prompt will appear requiring a

level 2 or greater security code be entered to allow a read-write access.

Entering a level 1 password will only permit a read only access.

The following ATS Mode Menu options are provided:

Auto This is the Default Selection and is required to enable all automatic

features of the controller. In this mode the TSC 800 Controller will

automatically transfer the load to the appropriate source based on

availability (the Utility supply is considered the preferred source). The

TSC 800 will provide automatic timed testing if enabled in programming.

Manual testing is disabled when the Auto ATS mode is selected (NOTE:

PM 049 REV 10 08/09/25 Thomson Technology

19

Page 26

TSC 800 TRANSFER SWITCH CONTROLLER

the external mode inputs input will over ride ATS Mode Menu selected

Auto mode).

Offload Test When the Offload Test prompt is selected and entered, the generator

will immediately start and operate offload and will not permit a load

transfer. The test menu will display Continuous Test, to select a timed

test use the INCREMENT or DECREMENT pushbutton to scroll and

select a test duration time, press enter to accept the time (selectable in

15 minutes increments from 15 – 240 min.). The generator will remain

running until a different mode is selected and entered or the timed test

duration expires (selecting Auto will immediately terminate the test). On

expiry of the timed test the operating mode automatically reverts to

Auto.

NOTE: If the Utility supply fails during this test mode, the load will

automatically transfer to the generator if within acceptable limits.

Onload Test When the Onload Test prompt is selected and entered, the generator

will immediately start and transfer on load. The test menu will display

Continuous Test, to select a timed test use the INCREMENT or

DECREMENT pushbutton to scroll and select a test duration time, press

enter to accept the time (selectable in 15 minutes increments from 15 –

240 min.). The generator will remain running until a different mode is

selected and entered or the timed test duration expires (selecting Auto

will terminate the test after the Utility Return Timer has expired). On

expiry of the timed test the operating mode automatically reverts to

Auto.

NOTE: Should the Generator fail during the onload test and the Utility

supply is available and within acceptable limits the load will be

transferred on expiry of the generator under voltage delays.

Off The TSC 800 Controller is considered out of Service. The transfer

mechanism logic outputs are dropped out and disabled. The transfer

switch will remain in its last position and the remote start removed if

previously enabled. Manual and auto test features are disabled. This

selection takes precedence over all other modes.

PM 049 REV 10 08/09/25 Thomson Technology

20

Page 27

TSC 800 TRANSFER SWITCH CONTROLLER

NOTE: When this mode is selected the local generator controls should

also be placed in OFF. Failing to do can result in cyclical engine

starting. On loss of Utility supply in this state (loss of control power to

the TSC 800) the engine start contact will drop out after approximately 4

minutes resulting in generator starting and stopping (the cycle will

repeat approximately every 4 minutes after the control power is

removed).

NOTE: On return to normal service the Engine Start output is inhibited

(held up) for approximately 8 – 10 seconds. Requesting another mode

of operation during this time, which requires the engine start contact to

close, will be ignored.

PM 049 REV 10 08/09/25 Thomson Technology

21

Page 28

TSC 800 TRANSFER SWITCH CONTROLLER

5.3. TSC 800 PROGRAM MENU

The programming menu is used to access the TSC 800’s programmable functions such as

time delays, voltage/frequency setpoints, calibration and time clock adjustments.

Access to the programming sub-menus can only be obtained with a security password

number. The sub menus are organized as follows:

Programming Menu No

Yes Password

LCD DISPLAY

Program Menu

No

Displays two messages that may be toggled between YES or NO by pressing the

INCREMENT or DECREMENT pushbuttons. Their functions are described as follows:

NO Status message only, a change is required to gain access.

YES The required variable to be entered to gain access and proceed. The password

protection prompt will appear requiring a level 2 or greater security code be

entered to provide a read-write access. Entering a level 1 password will permit

a read only access.

5.4. SYSTEM OPERATION MENU

The system operation menu provides the operator with information as to current status of both

the utility and generator supplies.

NOTE:

The system operation menu screen may be momentarily

replaced with a time delay countdown screen when a

transfer sequence is initiated. The display will

automatically return to the previous menu following expiry

of the timing sequence.

PM 049 REV 10 08/09/25 Thomson Technology

22

Page 29

TSC 800 TRANSFER SWITCH CONTROLLER

The system operation sub-menus are organized as follows:

Utility Normal

Failed

Return Delay

Gen ATS In OFF

In Auto

Starting

Failed

Running

Normal

Cooling

Auto Offload Test

Manual Offload Test

Auto Onload Test

Manual Onload Test

Commit To Transfer

LCD DISPLAY

Util Normal

Gen Onload Test

Displays utility supply status conditions. There are three status conditions:

Normal Load is on the utility supply and the utility’s voltage and

frequency is normal.

Failed Utility supply voltage and/or frequency are outside the

nominal programmed limits (e.g. failed condition).

Return Delay Load is on the generator supply and the utility supply is

ready to transfer. This is a temporary condition due to either

a test mode being selected or during a utility return time

delay.

Displays generator supply status conditions. There are twelve status conditions as

follows:

ATS In Off The ATS Mode has been set to OFF via the Internal or

External switch input. The Controller will display the

message “Controller Out of Service”.

In Auto The ATS Mode via the Internal ATS Mode Menu has been

set to Auto.

PM 049 REV 10 08/09/25 Thomson Technology

23

Page 30

TSC 800 TRANSFER SWITCH CONTROLLER

Starting Engine start signal has been initiated, and the TSC 800

sensors are waiting for generator voltage to build up.

Failed Generator is signaled to operate; however its voltage

and/or frequency is outside the nominal programmed limits

(e.g. failed condition).

Running The generator is running (within programmed limits) but

not requested to transfer on load by the controller.

Normal The generator is running due to a failed utility supply.

Cooling The generator is running (within programmed limits) during

the programmed cooldown delay.

Auto Offload Test The generator is running off load due to a

programmed exercise timer mode.

Manual Offload Test The generator is running off load due to manually

initiated off load test mode via the front-panel

pushbuttons or external inputs.

Auto Onload Test The generator is running on load due to a

programmed exercise timer mode.

Manual Onload Test The generator is running on load due to manually

initiated on load test mode via the front-panel

pushbuttons or external inputs.

Commit To Transfer When enabled, the generator will be committed to

transferring onload if the loss of utility is detected

and the engine start issued. The generator will

remain onload for the duration of the power failure

and the transfer return time. If the generator fails

to start within 5 minutes the commit to transfer

request is cancelled.

5.5. TIMER COUNTDOWN MENUS

Timer countdown menus are automatically displayed when a specific time delay function

occurs during a transfer sequence. When a time delay begins, the LCD display will indicate

the time delay function name (e.g. Gen Start Delay) and the current time remaining in the

countdown sequence. When the timing function is complete, the LCD display will

automatically change to either the next timing sequence countdown display or return to auto

scrolling the system status screens.

PM 049 REV 10 08/09/25 Thomson Technology

24

Page 31

TSC 800 TRANSFER SWITCH CONTROLLER

LCD DISPLAY

Gen Start

Delay

Displays specific time delay function currently in operation

Displays current time in seconds that are left in the specific timing sequence.

45 Sec

NOTE:

During a timer countdown sequence, scrolling to

a different display screen is possible by pressing

either the ENTER or EXIT pushbuttons.

The following timer countdown screens are provided and displayed in seconds of time

remaining:

Gen Start Delay Gen Warm up Delay

Gen Cooling Delay Utility Return Delay

PreTransfer Delay PostTransfer Delay

Finding Neutral Neutral Delay

PSD Max Open Time Transferring

Syncing (Close Transition Feature Only)

5.6. UTILITY SUPPLY MENU

The utility supply menu allows the operator to view the utility supply voltage and frequency

values.

LCD DISPLAY

600

Util 60.0Hz

600

600

Displays utility supply frequency in hertz (Hz). The frequency is displayed with a

resolution of 1/10 of a hertz.

Displays utility supply voltage as follows:

• 3-phase system: LINE TO LINE VOLTAGE--Phases A to B

• 1-phase system: LINE TO LINE VOLTAGE--Phases L1 to L2

Displays utility supply voltage as follows:

• 3-phase system: LINE TO LINE VOLTAGE--Phases B to C

• 1-phase system: LINE TO NEUTRAL VOLTAGE--Phases L1 to N

PM 049 REV 10 08/09/25 Thomson Technology

25

Page 32

TSC 800 TRANSFER SWITCH CONTROLLER

Displays utility supply voltage as follows:

• 3-phase system: LINE TO LINE VOLTAGE--Phases C to A

• 1-phase system: LINE TO NEUTRAL VOLTAGE--Phases L2 to N

5.7. GENERATOR SUPPLY MENU

The generator supply menu allows the operator to view the generator supply voltage and

frequency values.

LCD DISPLAY

600

Gen 60.0Hz

600

600

Displays generator supply frequency in hertz (Hz). The frequency is displayed with a

resolution of 1/10 of a hertz.

Displays generator supply voltage as follows:

• 3-phase system: LINE TO LINE VOLTAGE--Phases A to B

• 1-phase system: LINE TO LINE VOLTAGE--Phases L1 to L2

Displays generator supply voltage as follows:

• 3-phase system: LINE TO LINE VOLTAGE--Phases B to C

• 1-phase system: LINE TO NEUTRAL VOLTAGE--Phases L1 to N

Displays generator supply voltage as follows:

• 3-phase system: LINE TO LINE VOLTAGE--Phases C to A

• 1-phase system: LINE TO NEUTRAL VOLTAGE--Phases L2 to N

NOTE: The load bus voltages are viewable only in the Programming Menu. When

selected as 3-phase load sensing it will be displayed as listed above for 3-phase

systems. When selected as 1-phase, only the L1 to L2 voltage will be displayed as a

line-to-line value. 3-phase load sensing can only be selected if all 3 phases of the load

bus are wired to the TSC 800 controller. Most transfer switches manufactured prior to

December 2004 will not have the C phase load bus wiring installed and must be set for

1-phase load sensing.

PM 049 REV 10 08/09/25 Thomson Technology

26

Page 33

TSC 800 TRANSFER SWITCH CONTROLLER

5.8. STATS MENU

The STATS menu displays the recorded data logging for the following events:

NOTE:

The following stats menu is provided in TSC 800 Software

version 2.0 (or higher).

o Total Number of Transfers

o Total Number of Transfers due to source failure

o Number of Hours Controller is energized

o Number of Hours Load is on Utility

o Number of Hours Load is on Generator

The TSC 800 data logging has the maximum number of events memory as follows:

o The limit for the Total Transfers and SRC Fail Transfers is 10,000.

o The limit for the Total Hours, Load On SRC1 Hours, and Load On SRC2 Hours

is 160,000 hours.

LCD DISPLAY

Total Transfers

20

Displays the recorded data

NOTE: Zeroing of the Statistic Records can be accessed by entering the Program Menu with

a master password number. Consult THOMSON TECHNOLOGY factory for master password

number if required.

PM 049 REV 10 08/09/25 Thomson Technology

27

Page 34

TSC 800 TRANSFER SWITCH CONTROLLER

6. OPERATING INSTRUCTIONS

To operate the TSC 800 controller and associated transfer switch using the front faceplate

pushbuttons, refer to the following detailed operating instruction sub-section descriptions.

6.1. AUTOMATIC SEQUENCE OF OPERATION

6.1.1. NORMAL SEQUENCE OF OPERATION (OPEN TRANSITION

TRANSFER)

Under normal operating conditions, the transfer switch operates automatically during a

failure and restoration of utility power and does not require operator intervention.

NOTE:

Refer to sections 6.5 & 6.10 which may require operator

intervention

When utility supply voltage drops below a preset nominal value (70 – 99% of rated

adjustable) on any phase, an engine start delay circuit will be initiated. Following

expiry of the engine start delay period (0 - 60 sec. adjustable) an engine start signal

(contact closure) will be given.

Once the engine starts, the transfer switch controller will monitor the generators

voltage and frequency levels. Once the generator voltage and frequency rises above

preset values (70 – 99% nominal adjustable) a warm up time delay will be initiated.

Once the warm up timer (0 - 3000 Sec adjustable) expires the transfer to utility supply

signal will be removed (i.e. contact opening) and the transfer to generator supply

signal (contact closure) will be given to the transfer switch mechanism. The load will

then transfer from the utility supply (i.e. opening the utility power switching device) to

the generator supply (closing the generator power switching device) to complete a

break-before-make open transition transfer sequence.

The generator will continue to supply the load until the utility supply has returned and

the retransfer sequence is completed as follows: When the utility supply voltage is

restored to above the present values (70 - 99% of rated adjustable) on all phases, a

utility return delay circuit will be initiated. Following expiry of the utility return timer (0 –

50.0 min. adjustable), the transfer to generator supply signal will be removed (contact

PM 049 REV 10 08/09/25 Thomson Technology

28

Page 35

TSC 800 TRANSFER SWITCH CONTROLLER

opening), the transfer to utility supply signal (contact closure) will be given to the

transfer switch mechanism. The load will then be transferred from the generator

supply back to the utility supply. During the utility re-transfer sequence a neutral

position delay circuit can be employed which will cause the transfer mechanism to

pause in the “neutral position (i.e. with both transfer power switching devices open) for

the duration of the neutral delay timer (0 -120 seconds adjustable) setting, once the

time delay expires, the re-transfer sequence will be completed. The Neutral Delay

Bypass feature can also be enabled to detect when all load phases voltages have

dropped below 20% of the nominal system voltage, which will cancel any remaining

Neutral Delay time and complete the transfer.

An engine cooldown timer circuit will be initiated once the load is transferred from the

generator supply and determined to have made position by ensuring the load bus is

energized and the Utility position indication confirmed. Following expiry of the

cooldown delay period (0 – 50.0 min. adjustable) the engine start signal will be

removed (remote start contact opened) to initiate stopping of the generator set.

6.1.2. NORMAL SEQUENCE OF OPERATION (CLOSED TRANSITION

TRANSFER)

For transfer switches equipped with the closed transition transfer option, the TSC 800

is configured to provide additional logic for this application. When the TSC 800

controller receives an input signal for Closed Transition Transfer Mode (contact closing

on TB2-12) the TSC 800 is configured to operate as follows:

Under normal closed transition operating conditions, the transfer switch operates

automatically during a failure and restoration of utility power and does not require

operator intervention.

When utility supply voltage drops below a preset nominal value (70 - 99% of nominal,

adjustable) on any phase, an engine start delay circuit will be initiated. Following

expiry of the engine start delay period (0 - 60 sec. adjustable) an engine start signal

(contact closure) will be given.

Once the engine starts, the transfer switch controller will monitor the generator voltage

and frequency levels. When the generator voltage and frequency rises above preset

values (70 - 99% of nominal, adjustable) a warm up time delay will be initiated. When

the warm up timer (0 – 3000 Sec. adjustable) expires the transfer to utility supply

PM 049 REV 10 08/09/25 Thomson Technology

29

Page 36

TSC 800 TRANSFER SWITCH CONTROLLER

signal will be removed (logic contact(s) opening) and the transfer to generator supply

signal (logic contact(s) closure) will be given to the transfer switch Power Switching

Devices. The load will then transfer from the utility supply (i.e. opening the utility

power switching device) to the generator supply (closing the generator power switching

device) to complete a break-before-make open transition transfer sequence.

The generator will continue to supply the load until the utility supply has returned and

the retransfer sequence is completed as follows: When the utility supply voltage is

restored to above the present values (70 - 99% of rated adjustable) on all phases, a

re-transfer sequence will be initiated once the Utility Return timer expires. The utility

will close its power-switching device when it is in synchronism with the generator

supply via external logic device. If the transfer switch is supplied with a “Momentary”

Closed Transition transfer control option, the generator power switching device will

immediately trip open approximately 50-100 milliseconds after the utility power

switching device closes to complete the “make-before-break” re-transfer sequence. If

the transfer switch is supplied with a “Soft-Load” Closed Transition transfer control

option, the generator power switching device will remain closed for approximately 5-10

seconds to allow a soft-load power transfer sequence to be completed as controlled by

an external device. The generator power switching device will then trip open to

complete the “make-before-break” re-transfer sequence.

An engine cooldown timer circuit will be initiated once the load is transferred from the

generator supply and determined to have made position by ensuring the load bus is

energized and the utility position indication confirmed. Following expiry of the

cooldown delay period (0.0 – 50.0 min. adjustable) the engine start signal will be

removed (remote start contact opened) to initiate stopping of the generator set.

6.1.3. TEST MODE SEQUENCE OF OPERATION

6.1.3.1. TEST CONDITION (OPEN TRANSITION TRANSFER)

When an operator selects a test mode it shall signal a simulated utility power fail signal

to the transfer switch controller. The transfer switch shall operate as per a normal

utility power fail condition. The neutral delay circuit logic will be active during transfer

to and from the generator supply (i.e. when both sources of power are available). (For

definitions and added features refer to Section 7.5.12.)

PM 049 REV 10 08/09/25 Thomson Technology

30

Page 37

TSC 800 TRANSFER SWITCH CONTROLLER

The transfer switch shall remain on generator supply until the test mode is terminated.

It will then re-transfer back to the utility supply and continue to operate the generator

set for its cooldown period then stop.

6.1.3.2. TEST CONDITION (CLOSED TRANSITION TRANSFER)

When a load test is initiated in the closed transition transfer mode, the generator will

start and following its warm up delay, the generator will close its power-switching

device when it is in synchronism with the utility supply via external logic device. If the

transfer switch is supplied with a “Momentary” Closed Transition transfer control

option, the utility power switching device will immediately trip open approximately 50-

100 milliseconds after the generator power switching device closes to complete the

“make-before-break” transfer sequence. If the transfer switch is supplied with a “Soft-

Load” Closed Transition transfer control option, the utility power switching device will

remain closed for approximately 5-10 seconds to allow a soft-load power transfer

sequence to be completed as controlled by an external device. The utility power

switching device will then trip open to complete the “make-before-break” transfer

sequence..

The generator will continue to supply the load until the test mode has been removed

and the re-transfer sequence is completed as follows: The utility power-switching

device will close when it is in synchronism with the generator supply via external logic

device.. If the transfer switch is supplied with a “Momentary” Closed Transition transfer

control option, the generator power switching device will immediately trip open

approximately 50-100 milliseconds after the utility power switching device closes to

complete the “make-before-break” re-transfer sequence. If the transfer switch is

supplied with a “Soft-Load” Closed Transition transfer control option, the generator

power switching device will remain closed for approximately 5-10 seconds to allow a

soft-load power transfer sequence to be completed as controlled by an external device.

The generator power switching device will then trip open to complete the “make-

before-break” re-transfer sequence.

PM 049 REV 10 08/09/25 Thomson Technology

31

Page 38

TSC 800 TRANSFER SWITCH CONTROLLER

6.1.4. ABNORMAL SEQUENCE OF OPERATION

6.1.4.1. GENERATOR FAILURE ON LOAD

Should the generator set fail while on load, the transfer switch shall re-transfer

the load back to the utility supply if within nominal limits. The utility return timer

will be bypassed in this condition.

NOTE:

This operating condition applies to a normal utility failure as well

as any test condition.

6.1.4.2. TRANSFER SWITCH FAIL ALARM LOGIC

The TSC 800 controller contains logic to detect a transfer mechanism failure.

Should a failure be detected, a forced transfer to the alternate supply will be

initiated if the TSC 800 is programmed for force transfer. Refer to the

programming Section 7.5.14 for further information in Force Transfer operation.

6.1.4.3. SERVICE ENTRANCE ATS

For Service Entrance Rated transfer switch applications, the transfer switch

control logic will include external wiring to signal the transfer switch mechanism

to move to the “Service Disconnected” position when Service Disconnect

Operation is required. In this mode the TSC 800’s transfer control outputs and

Transfer Fail feature is disabled. On return to Service the TCS 800 will display

“Resuming Normal Operation” and the Power-Switching Device will be closed

to the utility supply. Should the utility supply be out of limits the generator will

be issued a start command and the load transfer to the generator supply once

its warm-up time has expired. The ATS returns to Auto control and will return

to the utility supply as previously describe for the appropriate ATS design type.

NOTE: On return to Normal Service the Engine Start output is inhibited (held

up) for approximately 8 – 10 seconds. Requesting another mode of operation

requiring the engine start contact to close will be ignored until this timer expires.

6.2. LCD DISPLAY OPERATION

The TSC 800 LCD display will operate in the following modes:

PM 049 REV 10 08/09/25 Thomson Technology

32

Page 39

TSC 800 TRANSFER SWITCH CONTROLLER

NOTE:

The following LCD operation is provided in TSC 800 Software

version 2.0 (or higher).

SLEEP Mode: The LCD display will automatically turn off and go in to a “sleep” mode

to preserve operating life time. The sleep mode will be activated if a faceplate key

press is not activated within a 16 minute time period. Pressing any faceplate key will

automatically reactivate the LCD display.

AUTO SCROLLING Mode: The LCD will automatically scroll through a series of

display menu screens at a rate of 1 screen every 3 seconds. Pressing any faceplate

key while the display is on the desired menu screen will automatically stop the

scrolling feature. The auto-scrolling feature will be re-activated 120 seconds later if no

key presses are made. To view other menus once the auto scrolling has been de-

activated, press the ENTER or EXIT pushbuttons to scroll to the next available menu.

NOTE that the menu list will automatically loop back to the first menu item when the

end of the list is reached.

BACK LIGHT Mode: The LCD incorporates a back light feature. When any keypad is

pressed the back light will illuminate for 120 seconds.

AUTO EXIT PROGRAMMING Mode: The LCD display will automatically exit the

programming menu and return to auto scrolling mode if no keypad is depressed within

5 minutes.

6.3 TIME CLOCK ADJUSTMENT

To adjust the TSC 800 controller’s internal time clock, follow the detailed procedure below.

NOTE: Normal utility or generator control power to the controller must be available to permit

adjustment.

• Using the ENTER or EXIT pushbutton, scroll to the Program Menu.

• Using the INCREMENT pushbutton, select the Yes message and press the

ENTER pushbutton.

• Press the ENTER pushbutton when the Password message is displayed.

• Using the INCREMENT pushbutton, select the current Day of the week message

and week number (1-4) and press the ENTER pushbutton.

PM 049 REV 10 08/09/25 Thomson Technology

33

Page 40

TSC 800 TRANSFER SWITCH CONTROLLER

NOTE:

Week Number is programmable only if the System Time Clock

Rollover period is set longer than 7 days. Refer to Programming

section for further details.

• Using the INCREMENT pushbutton, select the current Hour of the day (e.g. 24

hour clock) and press the ENTER pushbutton.

• Using the INCREMENT pushbutton, select the current Minute of the day (e.g. 60

minute) and press the ENTER pushbutton.

• Press the EXIT pushbutton and hold for 2 seconds to exit the time clock

adjustment mode (Automatic exit if no keypad depressed within 5 minutes).

6.4 TEST MODES

6.4.1 OPERATOR INITIATED UTILITY POWER FAIL SIMULATION (LOAD

TEST)

To perform a testing operation on the transfer switch using the front faceplate

pushbuttons, follow the procedure listed below.

To Initiate the Load Test Mode:

• Using the ENTER pushbutton, scroll to the ATS Mode Menu.

• Using the INCREMENT pushbutton, select the Yes message and press the

ENTER pushbutton.

• Using the INCREMENT pushbutton, select the Onload or Offload test option

as required.

• Press the ENTER pushbutton.

• Continuous Test will be displayed (no time out). Using the INCREMENT

pushbutton, a timed test can be selected if the desired, duration of Test

Mode Time Out is selectable in 15-minute increments from 15 – 240

minutes.

• Press the ENTER pushbutton.

PM 049 REV 10 08/09/25 Thomson Technology

34

Page 41

TSC 800 TRANSFER SWITCH CONTROLLER

To Exit the Test Mode:

• Using the ENTER pushbutton, scroll to the ATS Mode Menu.

• Using the INCREMENT pushbutton, select the Yes message and press the

ENTER pushbutton.

• Using the INCREMENT pushbutton, select Auto.

• Press the ENTER pushbutton. After the Utility Return Timer has expired the

transfer of the load from the generator to the utility supply will be initiated.

6.4.2 AUTOMATIC PLANT EXERCISE TEST

To initiate an automatic plant exercise test mode, the TSC 800 must be pre-

programmed for the desired start/stop times, frequency of the test and type of test (i.e.

Onload, Offload).

Refer to the Programming section for details on programming.

Once the plant exercise timer is programmed, the engine will immediately start at the

selected time and transfer on load (if Onload is selected) once nominal voltage and

frequency levels have been obtained. The engine will remain operating until the stop

time is reached, then the load will re-transfer back to the utility supply after the utility

return timer has expired. The generator will repeat the test sequence as programmed.

6.4.3 FOUR FUNCTION REMOTE TEST (FTS4 OPTION)

The function of the Four Position Test Switch Input is to allow operators to select

various operating scenarios for test or maintenance purposes, in addition to the use of

the faceplate mounted pushbuttons.

NOTE: When an external FTS4 switch is used, the TSC 800 operation will be based

on the highest priority of either the internal ATS Mode or the external FTS4 inputs to

the controller.

Mode Priority: 1 Off, 2 Onload Test, 3 Offload Test & 4 Auto

Off: Disables the engine start output from the transfer switch

(FTS4 only). TSC 800 will display “Controller Out of

Service”. All transfer logic outputs are dropped out

(disabled). The transfer switch will not provide automatic

control in the event of a power failure. Engine start output on

the controller is dropped out. (Place generator controls in

OFF if continuous running of the generator is not desired.)

PM 049 REV 10 08/09/25 Thomson Technology

35

Page 42

TSC 800 TRANSFER SWITCH CONTROLLER

NOTE: Moving FTS4 out of OFF will display “Resuming

Normal Operation” and the ATS will source the

appropriate supply.

NOTE: On return to Normal Service the Engine Start output

is inhibited (held up) for approximately 8 – 10 seconds.

Requesting another mode of operation during this time,

which requires the engine start contact to close, will be

ignored.

Auto: All automatic functions are enabled.

Engine Start: (Offload Test) An engine start signal will be initiated and will

remain on until the FTS4 is placed in another position. The

engine will start if the engine’s auto start controller is in the

”Auto” mode. If the primary source fails in this mode, and the

secondary source is within parameters, the TSC 800 will

initiate a transfer to the secondary source.

Test: (Onload Test) A primary source failure is simulated and an

engine start signal will be initiated. When the secondary

source is within normal limits, the TSC 800 will initiate a

transfer to the secondary source. The system will remain in

this state until the FTS4 is placed in another position or the

secondary supply fails. Upon a secondary supply failure, if

the primary supply is available, the TSC 800 will initiate a

transfer to the primary supply. The Utility Return time

sequence will be initiated when the Onload Test mode is

terminated. Once transfer is complete to the primary source

the engine cooldown time sequence will be initiated, on

expiry, the generator set will stop if no cooldown is included

in its design/programming.

PM 049 REV 10 08/09/25 Thomson Technology

36

Page 43

TSC 800 TRANSFER SWITCH CONTROLLER

6.5 TRANSFER FAIL FAULT RESET

To reset a Transfer Fail condition (i.e. When the LCD Display indicates the applicable fault

condition and the “Press Lamp Test” alarm message), press and hold the DECREMENT &

INCREMENT keys simultaneously.

Once the alarm condition is reset, the load will automatically retransfer back to the original

source if within normal limits.

NOTE:

Refer to section 7.5.14 for further details.

6.6 LAMP TEST

To initiate a Lamp Test, press and hold the DECREMENT & INCREMENT keys

simultaneously until all LEDs & LCD segments illuminate.

6.7 TIMER BYPASS

The following automatic sequencing time delays can be temporarily bypassed when the time

function is active as shown on the TSC 800 LCD display:

NOTE:

Timer Bypass feature is provided in TSC 800 Software version

2.0 (or higher).

Utility Return Timer

Cooldown Timer

Warm up Timer

This feature is typically used when testing to avoid waiting for the complete duration of the

time period.

To activate the bypass function, simultaneously press the DECREMENT and the ENTER keys

during the timer operation.

NOTE: The Time delay functions will return to the normal time settings on the subsequent

automatic operating sequence.

PM 049 REV 10 08/09/25 Thomson Technology

37

Page 44

TSC 800 TRANSFER SWITCH CONTROLLER

6.8 MANUAL UTILITY RE-TRANSFER

If the TSC 800 is programmed to provide a Manual Utility Re-transfer Sequence, an operator

must initiate the re-transfer sequence when the utility supply has returned to normal following

a utility power failure and TSC 800 LCD message “ Util Return” – “Press Lamp Test “.

NOTE:

Manual Re-transfer feature is provided in TSC 800 Software

version 2.0 (or higher). Programmed Utility Return Delay Time

is not included to ensure stable utility supply prior to retransfer.

6.9 SERVICE ENTRANCE ATS MODE

For transfer switches equipped with the Service Entrance Mode option, the TSC 800 is

configured to provide additional logic for the application. When the TSC 800 controller

receives an input signal for Service Entrance Mode (contact closing on TB2-15) the TSC 800

will post an alarm message on the LCD display “ Service Disconnecting” when sourcing

neutral position and when both Load on Generator and Utility inputs are de-energized and the

load bus is de-energized will display “Service Disconnected”. The control logic required to

move the ATS mechanism to the neutral position is controlled by external logic and not by the

TSC 800. When in “Service Disconnect” mode all transfer logic outputs are de-energized.

When “Service Disconnect” mode is removed the controller will display “Returning to Service”

and move to the appropriate source depending on availability within programmed limits.

NOTE: On return to Normal Service the Engine Start output is inhibited (held up) for

approximately 8 – 10 seconds. Requesting another mode of operation during this time, which

requires the engine start contact to close, will be ignored.

NOTE:

Service entrance feature is provided in TSC 800 Software version 2.0

(or higher).

6.10 PHASE BALANCE PROTECTION ALARM

When the TSC 800 is programmed with Phase Balance protection enabled, should a transfer

occur due to an out of limit phase balance condition, an alarm message will be shown on the

TSC 800 LCD display “UTIL (or GEN) UNBALANCED”. The Phase Balance feature may be

user programmed to provide two different re-transfer operating sequences (i.e. AUTO or

MANUAL RETRANSFER).

PM 049 REV 10 08/09/25 Thomson Technology

38

Page 45

TSC 800 TRANSFER SWITCH CONTROLLER

When the “AUTO” retransfer mode is selected, the load will be automatically re-transferred

back to the original source and does not require operator intervention.

When the “MANUAL” retransfer mode is selected, a re-transfer back to the original source will

not occur until the LAMP TEST function is activated and alarm is reset by operator

intervention.

For further details on Phase Balance programming refer to section 7.3.17.

NOTE: When in the MANUAL RETRANSFER mode, if the alternate source fails, the alarm

lockout will not be bypassed inhibiting the load to re-transfer back to the original source even

if within limits. The reason the re-transfer is inhibited is phase unbalance is generally only

detected when load is applied to the source and the condition will appear to clear when the

load is removed, as such allowing a re-transfer to the failed source previously determined to

have a phase balance fault will only result in multiple unnecessary transfers of the load

between sources. Retransfer is set to lockout and requires operator intervention.

Phase balance feature is provided in TSC 800 Software version

2.0 (or higher).

7. PROGRAMMING INSTRUCTIONS

7.1. PASSWORDS

Access to the programmable parameters of the TSC 800 Transfer Controller is via a security

password number. Three levels of security passwords are provided as described below:

7.1.1. READ ONLY MODE

User can view the programmable parameters only and cannot change any values.

The Factory default number for the read-only mode is one (1).

NOTE:

7.1.2. READ / WRITE MODE

User can view and modify any programming parameter as required. The Factory

default number for the read/write mode is two (2).

PM 049 REV 10 08/09/25 Thomson Technology

39

Page 46

TSC 800 TRANSFER SWITCH CONTROLLER

7.1.3. MASTER READ / WRITE MODE

User can view/modify any programming parameter as well as view/modify the security

password level numbers. Consult THOMSON TECHNOLOGY factory for master

password number if required.

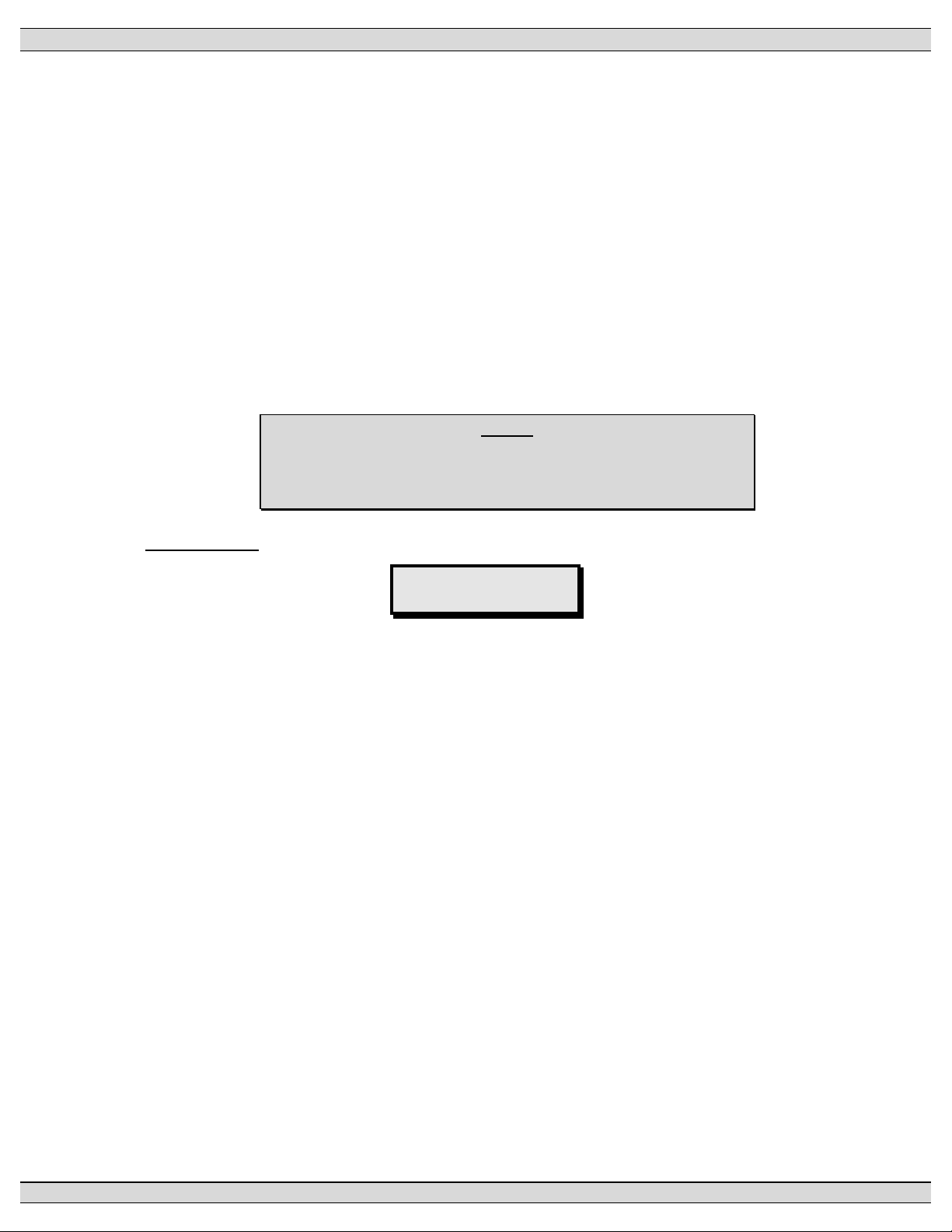

To enter the programming mode, follow the procedure as shown:

Program Menu

Yes

Select the Program Menu by scrolling through the display screens using the ENTER or

EXIT pushbuttons. When displayed, use the INCREMENT pushbutton to select the

YES prompt and push the ENTER button.

Password

0

Use the INCREMENT or DECREMENT pushbuttons to ramp the displayed number up

or down to the desired password access number. Press the ENTER pushbutton when

the correct number is displayed.

NOTE:

If an invalid number is entered, programming access will be

limited to time clock adjustment only. To exit the programming

mode, press the EXIT pushbutton and hold for two seconds

until the display scrolls rapidly.

When the programming mode is accessed, the programming parameters will be

displayed in the same order as the Programming Data Sheet provided with the