Page 1

User's Guide

SLVU347–December 2009

Evaluation Module for UCD90120 and UCD90124

This User’s Guide describes the evaluation modules (EVM) for the UCD90120 (UCD90120EVM) and

UCD90124 (UCD90124EVM). The EVM contains evaluation and reference circuitry for the UCD90120 and

UCD90124. UCD90120 and UCD90124 are advanced power system controllers containing sequencing,

monitoring, fan control and many other power supply system support features.

Contents

1 Description ................................................................................................................... 2

1.1 Features ............................................................................................................. 2

1.2 Applications ......................................................................................................... 2

2 Quick Start ................................................................................................................... 3

2.1 Test Setup .......................................................................................................... 3

2.2 EVM Layout View .................................................................................................. 4

2.3 EVM Block Diagram ............................................................................................... 5

3 UCD90120/4 EVM GUI Setup ............................................................................................. 6

3.1 UCD90120/4 EVM GUI Installation .............................................................................. 6

3.2 UCD90120/4 EVM GUI Operation ............................................................................... 7

4 General Use Features ...................................................................................................... 9

4.1 EVM Input/Output Connectors and Switches .................................................................. 9

4.2 EVM LEDS ........................................................................................................ 10

4.3 EVM Test Points .................................................................................................. 11

4.4 EVM Test Jumpers ............................................................................................... 13

5 Description ................................................................................................................. 15

5.1 Communication Interfaces ....................................................................................... 15

5.2 Power .............................................................................................................. 15

5.3 Test/Debug and Status .......................................................................................... 16

5.4 Digital I/O Terminations .......................................................................................... 16

5.5 Analog Monitor Inputs ............................................................................................ 16

5.6 Local Voltage Rails ............................................................................................... 17

5.7 External Temperature Sensor .................................................................................. 17

5.8 Input Current Monitoring ......................................................................................... 21

5.9 Closed Loop Voltage Margining ................................................................................ 25

5.10 Fan Interface ...................................................................................................... 30

6 Bill of Materials ............................................................................................................. 31

7 Layout Guidelines, EVM Schematic, and Assembly Drawings ...................................................... 37

7.1 Layout Guidelines ................................................................................................ 37

7.2 EVM Schematic ................................................................................................... 37

7.3 Assembly Drawings .............................................................................................. 37

1 Typical Test Setup.......................................................................................................... 3

2 UCD90120/4 EVM View.................................................................................................... 4

3 UCD90120/4 EVM Block Diagram........................................................................................ 5

1 EVM Input/Output Connectors and Switches ........................................................................... 9

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

List of Figures

List of Tables

1

Copyright © 2009, Texas Instruments Incorporated

Page 2

Description

2 EVM LED’s ................................................................................................................. 10

3 EVM Test Points........................................................................................................... 11

4 EVM Jumpers.............................................................................................................. 13

5 Local Rail Nominal Output Voltages .................................................................................... 17

6 UCD90120/4EVM Bill of Materials ..................................................................................... 31

1 Description

The UCD90120 and UCD90124 EVM provides many sophisticated power supply system controller

application capabilities. The EVM allows direct PMBus (power management bus) communication with the

UCD90120 and UCD90124 via an onboard USB interface. This interface allows direct control and

feedback with the UCD90120 and UCD90124 when using the

TI-Fusion-Digital-Power-Designer-Graphical-User-Interface.

1.1 Features

• General features

– Single 12V supply input

– 12 rail sequencing

– 13 analog monitors

– Single fan control interface

– Status LEDs on all GPIOs

– USB-PMBus interface for communication

• Orderable options

– UCD90124EVM 12 channel sequencer and monitor with fan control

– UCD90120EVM 12 channel sequencer and monitor

www.ti.com

1.2 Applications

• Industrial / ATE

• Telecommunications and Networking Equipment

• Servers and Storage Systems

• Any System Requiring Sequencing and Monitoring of Multiple Power Rails

2

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

12V

Power

Supply

UCD90120/4EVM

J1

D56

J2

J3

FAN

- +

J66 J9 J77

J74 J73

J18

U4

UCD90120/

UCD90124

S1 S10

S2

S4

S6

S8

S3

S5

S7

S9

JTAG PMBUS

USB

EXPANSION

FAULT INJECTION

12VINPUT

ADDRESS

RESET LEDENABLE

VR5 - VR12

EVR5 - EVR12

VR1 – VR4

EVR1 – EVR4

PCwithGUI

USBCABLE

FAN

www.ti.com

2 Quick Start

2.1 Test Setup

Figure 1 shows a typical test setup for UCD90120/4EVM. All that is required is a 12V (500mA for

UCD90120EVM or 2000mA for UCD90124EVM running a fan) wall adapter/laptop power supply (see J1

BOM description for receptacle size) and a PC. The USB-EVM cable is provided with the EVM.

Quick Start

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

Figure 1. Typical Test Setup

Copyright © 2009, Texas Instruments Incorporated

3

Page 4

USB

J 3D 56

J 77 EXT

PMBUS

J 74

PWMTEST

ACCESS

J 73

GPIOTEST

ACCESS

R 186

TEMP SIM

POT

RAIL5 -12

FAULT &

CONFIG

RAIL 5 -12

INT/EXTMON

CONFIG

RAIL 3 ,4

INT/EXT/IMON &

MARGINCONFIG

RAIL 1 ,2

INT/EXT/TMON &

MARGINCONFIG

LOCAL 3 .3 V

12 VINPUT

(SCREWJACK)

12 VINPUT

DC ADAPTERJACK)

J9 JTAG

J 66 FAN

S 10 STAT

LEDENABLE

UCD 90120

FAN

CONFIG

PBRST &

ADDRESS

GPICONFIG

Quick Start

2.2 EVM Layout View

www.ti.com

Figure 2. UCD90120/4 EVM View

4

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

UCD 90120

/

UCD 90124

GPIO

PMBUS

MON

V 33

FPWM /GPIO

RESET

PWM / GPI

V 33D

ON

LOCAL

RAILSVR

1- 4

FBx

ENx

5VBUS

ExtENoutputs

ExtMON

1- 4

15 VMax

3 P 3V

USB -

PMBUS

EN 1 - 4

5 VBUS

SUPPLY

CurrentMonitor

MON 3 only

2V/ A

ON

3

1

MON 1 -4

2

1

FPWM 1 - 4

PCB Temp

Monitor

MON 2 only

T(C)=100 *V -50

VR 1

Margin

RAILS

1-4

LOCAL

RAILSVR

5- 12

ENx

5VBUS

ExtENoutputs

ExtMON

5- 12

5VMax .

3 P 3V

EN 5 - 12

ON

MON 5 -12

2

1

RAILS 5 -12

FAULT

INJECTION

UVOV

FANPWM

LEVELSHIFTER

/DRIVER

PULLUP

/

DOWN

SELECT

PWM 1

PULLUP

SELECT

FANTACH

LEVELSHIFTER

FPWM 5

FANINTERFACE

3 P3 V

PWM /GPI

3 P 3V

GPI 1 -4

GPISTATUS

INRUSH

LIMITER

12VBUS

5VBUS

3 .3V

SUPPLY

L3P 3V

3P 3 V

V 33D

12 -3 .3V

SUPPLY

3P 3 V_USB

POWER

V33 FB

FLTR

V 33A

1

2

1

6

V33 D

MON 13

ADDRSENSx

JTAG

USB

USB

HOST

USB

3. 3V

LDO

3P 3V _USB

PWR

MON

BUS

SWITCH

EXP

PMBUS

CTRL

ALRT

USB -PMBUS

JTAG

EXP

GPIO

LED

ENABLE

FPWM

GPIO

12VIN

TACH

IN

PWM

OUT

12 VBUS

FANTEMP SIM

EVR 12 ONLY

www.ti.com

2.3 EVM Block Diagram

Quick Start

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

Figure 3. UCD90120/4 EVM Block Diagram

5

Copyright © 2009, Texas Instruments Incorporated

Page 6

UCD90120/4 EVM GUI Setup

3 UCD90120/4 EVM GUI Setup

3.1 UCD90120/4 EVM GUI Installation

The UCD90120 and UCD90124 EVMs use the Texas Instruments Fusion Digital Power Designer

graphical user interface (GUI) which may be downloaded from the following web site:

http://focus.ti.com/docs/toolsw/folders/print/fusion_digital_power_designer.html

Place the TI-Fusion-Digital-Power-Designer-zip file in a known location on the PC. Unzip the

TI-Fusion-Digital-Power-Designer-zip file.

Double click the unzipped TI-Fusion-Digital-Power-Designer-exe file. Proceed through the installation by

accepting the installer prompts and the license agreement. Accept the GUI suggested default PC

installation locations to complete the install.

Once the GUI completes the installation it will start. The first time the GUI is launched on a particular PC

the user may be prompted to select a device. Choose UCD9xxx. Afterwards, the GUI may be closed.

Note that the TI-Fusion-Digital-Power-Designer v1.6.105 was used for the examples to be shown later in

the document.

www.ti.com

6

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

3.2 UCD90120/4 EVM GUI Operation

The EVM comes pre-loaded with a 12 rail default project that sequences the EVM rails on at power up. It

is a good idea to export the default project to a file on the PC prior to making changes.

3.2.1 Launch TI-Fusion-Digital-Power-Designer

Navigate to the location where the Fusion GUI is installed and (Start, All Programs, Texas Instruments

Fusion Digital Power Designer, Fusion Digital Power Designer) and start it. A window similar to the

following will appear.

UCD90120/4 EVM GUI Setup

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

7

Copyright © 2009, Texas Instruments Incorporated

Page 8

UCD90120/4 EVM GUI Setup

Most of the GUI control features are available from the Configure window. Monitor and Status information

is available from the respective buttons on the GUI lower left. A typical Monitor window is shown below.

www.ti.com

8

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

4 General Use Features

4.1 EVM Input/Output Connectors and Switches

Table 1. EVM Input/Output Connectors and Switches

Connector/Switch Label Description

J1 12V INPUT 12V DC jack

J2 12V INPUT 12V screw jack

J9 JTAG JTAG Connector

J66 FAN Fan interface connector

J73 GPIO TESTACCESS GPIO expansion

J74 PWM TEST ACCESS PWM expansion

J77 PMBUS PMBus expansion

J3 USB IN USB input connector

S1 RESET Push button reset

S10 STAT LED Status LED enable switch

S2 FAULT – MON5 MON5 fault switch

S4 FAULT – MON6 MON6 fault switch

S6 FAULT – MON7 MON7 fault switch

S8 FAULT – MON8 MON8 fault switch

S3 FAULT – MON9 MON9 fault switch

S5 FAULT – MON10 MON10 fault switch

S7 FAULT – MON11 MON11 fault switch

S9 FAULT – MON12 MON12 fault switch

R186 TEMP MON Fan temperature simulator

General Use Features

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

9

Copyright © 2009, Texas Instruments Incorporated

Page 10

General Use Features

4.2 EVM LEDS

LED Color Label Description

D5 RED 5V 5VBUS ON indicator

D9 RED V33D UCD90120/4 power ON

D28 RED ALERT PMBus Alert

D29 GREEN CTRL PMBus Control

D56 GREEN USB ON USB attached

D8 AMBER GPI1 GPI1 input HIGH

D10 AMBER GPI2 GPI2 input HIGH

D12 AMBER GPI3 GPI3 input HIGH

D13 AMBER GPI4 GPI4 input HIGH

D30 GREEN GPIO1 GPIO1 HIGH

D32 GREEN GPIO2 GPIO2 HIGH

D34 GREEN GPIO3 GPIO3 HIGH

D36 GREEN GPIO4 GPIO4 HIGH

D38 GREEN GPIO13 GPIO13 HIGH

D47 GREEN GPIO14 GPIO14 HIGH

D49 GREEN GPIO15 GPIO15 HIGH

D40 GREEN GPIO16 GPIO16 HIGH

D42 GREEN GPIO17 GPIO17 HIGH

D44 GREEN GPIO18 GPIO18 HIGH

D46 GREEN GPIO19 GPIO19 HIGH

D48 GREEN GPIO20 GPIO20 HIGH

D54 GREEN GPIO21 GPIO21 HIGH

D55 GREEN GPIO22 GPIO22 HIGH

D31 AMBER FPWM1 GPIO5 HIGH

D33 AMBER FPWM2 GPIO6 HIGH

D35 AMBER FPWM3 GPIO7 HIGH

D37 AMBER FPWM4 GPIO8 HIGH

D39 AMBER FPWM5 GPIO9 HIGH

D41 AMBER FPWM6 GPIO10 HIGH

D43 AMBER FPWM7 GPIO11 HIGH

D45 AMBER FPWM8 GPIO12 HIGH

D14 RED VR1 VR1 ON

D15 RED VR2 VR2 ON

D16 RED VR3 VR3 ON

D17 RED VR4 VR4 ON

D18 RED VR5 VR5 ON

D19 RED VR6 VR6 ON

D20 RED VR7 VR7 ON

D21 RED VR8 VR8 ON

D22 RED VR9 VR9 ON

D23 RED VR10 VR10 ON

D24 RED VR11 VR11 ON

D25 RED VR12 VR12 ON

www.ti.com

Table 2. EVM LED’s

10

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

4.3 EVM Test Points

TP Color Label

TP1 RED 12VBUS

TP2 RED 5VBUS

TP3 WHT L3P3V

TP4 WHT V33D

TP11 BLK GND

TP17 BLK GND

TP6 WHT ADDRSENS0

TP7 ORG ADDRSENS1

TP37 BLK GND

TP43 BLK GND

TP8 YEL EVR1

TP13 YEL EVR2

TP16 YEL EVR3

TP22 YEL EVR4

TP28 YEL EVR5

TP34 YEL EVR6

TP46 YEL EVR7

TP52 YEL EVR8

TP29 YEL EVR9

TP35 YEL EVR10

TP47 YEL EVR11

TP53 YEL EVR12

TP14 WHT VR1 LOAD TEMP MON

TP18 WHT VR1 CURRENT MON

TP9 WHT VR1

TP12 WHT VR2

TP19 WHT VR3

TP20 WHT VR4

TP36 WHT VR5

TP38 WHT VR6

TP39 WHT VR7

TP40 WHT VR8

TP54 WHT VR9

TP56 WHT VR10

TP61 WHT VR11

TP62 WHT VR12

TP55 BLK GND

TP24 WHT GPIO1

TP25 WHT GPIO2

TP26 WHT GPIO3

TP27 WHT GPIO4

TP32 WHT GPIO13

TP66 WHT GPIO14 (SCI-TX)

TP65 WHT GPIO15 (SCI-RX)

TP44 WHT GPIO16

TP48 WHT GPIO17

General Use Features

Table 3. EVM Test Points

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

11

Copyright © 2009, Texas Instruments Incorporated

Page 12

General Use Features

www.ti.com

Table 3. EVM Test Points (continued)

TP Color Label

TP33 WHT GPIO19

TP57 WHT GPIO18

TP45 WHT GPIO20

TP49 WHT GPIO21

TP58 WHT GPIO22

TP10 YEL MON1

TP15 YEL MON2

TP21 YEL MON3

TP23 YEL MON4

TP30 YEL MON5

TP41 YEL MON6

TP50 YEL MON7

TP59 YEL MON8

TP31 YEL MON9

TP42 YEL MON10

TP51 YEL MON11

TP60 YEL MON12

TP5 YEL MON13

TP63 BLK GND

TP64 YEL TEMP POT WIPER

TP67 WHT LA CLOCK

TP68 SM-SLV GND

TP69 SM-SLV GND

TP70 SM-SLV GND

TP71 SM-SLV GND

TP72 SM-SLV GND

TP73 SM-SLV GND

12

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

4.4 EVM Test Jumpers

The EVM will be equipped with shunts on the jumper positions identified in the Default Pin Position below.

Shunts can be moved and removed as required during use.

Jumper Default Pin Label Description

Position

J8 3.3VUSB 3.3V USB

J78 1-2 EEPROM SCL

J79 1-2 EEPROM SDA

J69 1-2 PWM PU Fan PWM pullup/pulldown select

J70 1-2 Fan PWM select (fast or slow) FPWM5

J67 1-2 Fan tach input or slow PWM output

J72 2-3 TACH PU Fan tach input pullup/pulldown select

J71 EVR12 Fan temperature simulator pot to MON12

J68 2-3 Fan type select (4 or 2/3 wire)

J10 1-2 GPI1 General purpose input #1

J14 1-2 GPI2 General purpose input #2

J16 1-2 GPI3 General purpose input #3

J17 1-2 GPI4 General purpose input #4

J34 2-3 GPIO1 GPIO1 (enable #1) pullup/pulldown

J35 2-3 GPIO2 GPIO2 (enable #2) pullup/pulldown

J36 2-3 GPIO3 GPIO3 (enable #3) pullup/pulldown

J37 2-3 GPIO4 GPIO4 (enable #4) pullup/pulldown

J44 2-3 GPIO13 GPIO13 (enable #5) pullup/pulldown

J45 2-3 GPIO16 GPIO16 (enable #6) pullup/pulldown

J50 2-3 GPIO17 GPIO17 (enable #7) pullup/pulldown

J51 2-3 GPIO18 GPIO18 (enable #8) pullup/pulldown

J56 2-3 GPIO19 GPIO19 (enable #9) pullup/pulldown

J57 2-3 GPIO20 GPIO20 (enable #10) pullup/pulldown

J62 2-3 GPIO21 GPIO21 (enable #11) pullup/pulldown

J63 2-3 GPIO22 GPIO22 (enable #12) pullup/pulldown

J75 2-3 GPIO14 GPIO14 pullup/pulldown

J76 2-3 GPIO15 GPIO15 pullup/pulldown

J18 1-2,7-8 PM ADDR PMBus address

J11 TCK JTAG TCK

J6 TDI JTAG TDI

J12 TDO JTAG TDO

J7 TMS JTAG TMS

J4 1-2 L3.3V LDO 3.3V to board 3.3V

J13 12VB Local 12VBUS-V33D regulator

J5 1-2 Local or LDO 3.3V

J19 HVMON EVR1 monitor scaling

J23 HVMON EVR2 monitor scaling

J27 HVMON EVR3 monitor scaling

J31 HVMON EVR4 monitor scaling

J20 1-2 1L 1E MON1 source select

J24 3-4 E2 L2 T1 MON2 source select

J28 3-4 E3 L3 C1 MON3 source select

J32 1-2 4L 4E MON4 source select

General Use Features

Table 4. EVM Jumpers

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

13

Copyright © 2009, Texas Instruments Incorporated

Page 14

General Use Features

Jumper Default Pin Label Description

J42 1-2 5L 5E MON5 source select

J48 1-2 6L 6E MON6 source select

J54 1-2 7L 7E MON7 source select

J60 1-2 8L 8E MON8 source select

J43 1-2 9L 9E MON9 source select

J49 1-2 10L 10E MON10 source select

J55 1-2 11L 11E MON11 source select

J61 1-2 12L 12E MON12 source select

J15 1-2 MON13 MON 13 source select

J26 1-2 C1 VR1 output load

J22 RC MRG1 VR1 margining feedback

J25 RC MRG2 VR2 margining feedback

J30 RC MRG3 VR3 margining feedback

J33 RC MRG4 VR4 margining feedback

J21 1-2 5V VR1, VR2 5VBUS input

J29 1-2 5V VR3, VR4 5VBUS input

J38 1-2 R1_EN VR1 enable

J39 1-2 R2_EN VR2 enable

J40 1-2 R3_EN VR3 enable

J41 1-2 R4_EN VR4 enable

J46 1-2 R5_EN VR5 enable

J47 1-2 R6_EN VR6 enable

J52 1-2 R7_EN VR7 enable

J53 1-2 R8_EN VR8 enable

J58 1-2 R9_EN VR9 enable

J59 1-2 R10_EN VR10 enable

J64 1-2 R11_EN VR11 enable

J65 1-2 R12_EN VR12 enable

www.ti.com

Table 4. EVM Jumpers (continued)

Position

14

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

www.ti.com

5 Description

The following paragraphs describe the UCD90120/4 EVM functionality and operation.

5.1 Communication Interfaces

Several communication interfaces to the UCD90120/4 are provided on the EVM.

5.1.1 USB Interface

An onboard USB to PMBus interface is provided through the USB Input (J3) connector. D56 provides USB

attach status. The presence of USB power at J3 activates buffer circuitry which gives control of the PMBus

to the on board circuitry. The absence of USB power at J3 gives PMBus control through the Expansion

PMBus (J77) connector.

5.1.2 PMBus

Standard PMBus interface is provided to the UCD90120/4 through the J77 connector when the on EVM

USB-PMBus interface is not used. PMBus addressing is set using the J18 jumper block for ADDRSENS1

and ADDRSENS0 respectively. ADDRx=8 and ADDRx=5 positions for each are provided. The EVM

comes with PMBus address set to 101 decimal.

PMBus Address (decimal) = 12 × ADDR1 + ADDR0 jumper block setting.

5.1.3 JTAG

Standard JTAG programming interface is provided to the UCD90120/4 through the J9 connector. Install

J6, J7, J11, and J12 jumpers and ensure that rail 9-12 enable jumpers (J47, J53, J59, J65) are removed

when using the JTAG interface.

Description

5.2 Power

5.2.1 Input Power

The 12VDC EVM input power is provided through J1 (standard DC jack) or J2 (screw jack). A wall or

laptop adapter with 500mA (UCD90120EVM) or 2000mA (UCD90124EVM running a fan) capability and

2.5mm I.D. x 5.5mm O.D. x 9.5mm DC jack can power the EVM. Reverse voltage protection and inrush

limiting is provided for 12VBUS. The 12VBUS signal is distributed for fan power and Local 3.3V supply.

5.2.2 5VBUS

5VBUS is derived from 12VBUS and provides the input voltage for rails 1-12. D5 will illuminate when

5VBUS is present.

5.2.3 L3P3V

L3P3V is derived from 5VBUS and provides a general purpose 3.3V supply for the common onboard

functions. The L3P3V jumper (J4) is installed to provide a connection to the 3P3V node.

5.2.4 V33D

The V33D node is connected to the UCD90120/4 digital and analog supply pins. V33D can be sourced by

3P3V or Local V33D using the J5 jumper. D9 will illuminate when V33D is present.

5.2.5 Local 3.3V

The UCD90120/4 can be powered from 12VBUS using the local V33D supply. Install J13 (12VB) and

ensure J5 is installed in the LV33D position to use the local regulator.

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

15

Copyright © 2009, Texas Instruments Incorporated

Page 16

Description

5.2.6 Local USB

When the local 12V power supply source is not available, a subset of EVM functionality is available using

only power from the local USB source (3P3V_USB). Install J8 (3.3VUSB) and remove J4 when this

operation is desired. Communication to the UCD90120/4 is possible but power supply sequencing and

operation is not.

5.3 Test/Debug and Status

5.3.1 GPIO Expansion

J73 and J74 provide EVM to system board expansion capability as well as an HP type logic analyzer

interface.

5.3.2 Status LEDs

Visual status information for the GPI, GPIO, and PMBus signals (control and alert) is provided. Logic high

at GPI1-4 or GPIO1-22 will illuminate the associated LED. The GPIO status LEDs can be enabled (EN) or

disabled (EN bar) through the use of S10 to prevent the LED bias from affecting the logic state of the

GPIO signal during device reset.

5.4 Digital I/O Terminations

5.4.1 General Purpose Input/Output Terminations

GPIO1-22 can be pulled up or down with a 10kΩ resistor using jumpers. GPIO14 and GPIO15 can also be

used as voltage margining inputs.

www.ti.com

5.4.2 General Purpose Input Terminations

GPI1-4 can be pulled up or down with a 10kΩ resistor using jumpers.

5.5 Analog Monitor Inputs

The UCD90120/4 monitor inputs MON1-13 can be used to monitor onboard or off board voltages.

Jumpers are used to select the analog source.

5.5.1 MON1 and MON4–MON11

MON1 and MON4-11 can be sourced by the onboard rail (L#) or an external (E#) voltage.

5.5.2 MON2, MON3, MON12 and MON13

MON2 can be sourced by the onboard rail (L2), an external (E2) or the on board temperature sensor (T1)

voltage. MON3 can be sourced by the onboard rail (L3), an external (E3) or the on board current monitor

(C1) voltage. MON12 can be sourced by onboard rail (12L), an external source (12E) or the onboard fan

temperature potentiometer input (TEMP MON) voltage. MON13 can be sourced by the V33D or 12VBUS

voltage.

5.5.3 Monitor Scaling

For the external monitor jumper positions (E1-E4), the external supply can be scaled by a selectable factor

of 2 for monitoring external voltages up to 5V or 6 for monitoring external voltages up to 15V. For MON13,

the scale factor is 6 for the 12VB position and 2 for the V33D position. For all other MON jumper positions,

the scale factor is 2.

5.5.4 Monitor Fault Injection

Under voltage or over voltage faults can be injected on MON 5–MON12 through the use of on board

switches (S2, S4, S6, S8, S3, S5, S7, S9 respectively). The switches provide a fault bias on the nominal

voltage of approximately ±20%

16

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 17

www.ti.com

5.6 Local Voltage Rails

Twelve on board voltages are provided for sequencing and monitoring. Each voltage rail has an output on

LED. The nominal output voltages are listed in Table 5.

Table 5. Local Rail Nominal Output Voltages

Local Rail L1 L2 L3 L4 5L 6L 7L 8L 9L 10L 11L 12L

NominalVoltage 3.5V 3.3V 2.5V 1.8V 3.4V 3.2V 3.0V 2.8V 2.6V 2.4V 2.2V 2.0V

5.7 External Temperature Sensor

An onboard temperature sensor is provided to measure temperature rise of the VR1 output load (R74).

MON2 can be used to monitor the temperature rise caused by heat up of R74 when the shunt on J24 is in

the T1 position. When J26 (C1) is installed, the temperature sensor near R74 records temperature rise

simulating power supply warm up.

• Use TP14 (T1) to measure the temperature sensor output voltage.

• Temperature (in degrees C) = 100 × VT1 – 50 where VT1 is the voltage at TP14.

• The voltage at TP14 is scaled by a factor of 2 prior to sampling at MON2.

• Set the GUI Temp Cal Gain = 200°C/V and the Temp Cal Offset = –50°C.

5.7.1 Basic Process for Adding Temperature Monitoring to a Rail

A basic procedure to add temperature monitoring to rail #1, starting with the EVM default configuration will

follow. Ensure that rail #1 is selected in the upper right corner.

Description

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

17

Copyright © 2009, Texas Instruments Incorporated

Page 18

Description

• While in the Configure section of the GUI, select the Pin Assignment tab

www.ti.com

18

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 19

www.ti.com

• Delete the current pin assignment for MON2, then add a temperature pin assignment to MON1

Description

• Choose MON2 then the GUI will switch back to the Pin Assignment tab.

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

19

Copyright © 2009, Texas Instruments Incorporated

Page 20

Description

• Switch to the Other Config tab then enter Temp Cal Gain (200) and Temp Cal Offset (-50).

www.ti.com

• Press the Write to Hardware Button and OK the window below. Fusion will restart.

• Once Fusion restarts, press the Store RAM to flash and accept the response.

20

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 21

www.ti.com

• Press and release the EVM RESET (S1) button and the on EVM temperature sensor will provide rail

Description

#1 load temperature.

5.8 Input Current Monitoring

An onboard current monitor is provided to measure VR1 load current. MON3 can be used to monitor VR1

output current when the shunt on J28 is in the C1 position. When J26 (C1) is installed, VR1 output load

(R74) is connected causing an increase in current which can be measured by MON3 and at TP18.

• Use TP18 (C1) to measure the current monitor output voltage.

• Current (in amperes) = 0.5 × VC1 where VC1 is the voltage at TP18.

• The voltage at TP18 is scaled by a factor of 2 prior to sampling at MON3.

• Set the GUI Iout Cal Gain = 1000mΩ and the Iout Cal Offset = 0A.

5.8.1 Basic Process for Adding Current Monitoring to a Rail

A basic procedure to add current monitoring to rail #1, starting with the previously modified (adding

temperature) configuration will follow. Ensure that rail #1 is selected in the upper right corner.

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

21

Copyright © 2009, Texas Instruments Incorporated

Page 22

Description

• While in the Configure section of the GUI, select the Pin Assignment tab

www.ti.com

22

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 23

www.ti.com

• Delete the current pin assignment for MON3 and add a current pin assignment to MON1.

Description

• Choose MON3 then the GUI will switch back to the Pin Assignment tab.

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

23

Copyright © 2009, Texas Instruments Incorporated

Page 24

Description

• Switch to the Other Config tab and enter Iout Cal Gain (1000) and Iout Cal Offset (0).

www.ti.com

• Press the Write to Hardware Button and OK the window below. Fusion will restart.

• Once Fusion restarts, press the Store RAM to flash and accept the response.

24

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 25

www.ti.com

• Press and release the EVM RESET (S1) button and the on EVM current monitor will provide rail #1

Description

load current.

5.9 Closed Loop Voltage Margining

The output voltage of VR1-4 can be varied from nominal in a closed loop fashion for voltage margining.

Four duty cycle modulated GPIO signals (FPWM1-4) are filtered to control the rail output voltage. Two

GPIO – feedback node filter configurations are provided; simple R-C-R or R-C-buffer-R. Jumpers provide

selection of either the simple or buffered method. Install J22, J25, J30, or J33 in either the RC (for R-C-R)

or MRGx (for R-C-buffer-R).

5.9.1 Basic Process for Voltage Margining a Rail

A basic procedure to voltage margin rail #1, starting with the EVM default configuration will follow. For

more information on voltage margining please refer to application note (SLVA375). Ensure that rail #1 is

selected in the upper right corner.

NOTE: Ensure that S10 (STAT LED) is in the EN position.

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

25

Copyright © 2009, Texas Instruments Incorporated

Page 26

Description

• While in the Configure section of the GUI, select the Pin Assignment tab

www.ti.com

26

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 27

www.ti.com

• Delete the pin assignment for FPWM1 and select Margin on rail #1

Description

• Choose FPWM1 then the GUI will switch back to the Pin Assignment tab.

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

27

Copyright © 2009, Texas Instruments Incorporated

Page 28

Description

• Click the Configure link for rail #1

www.ti.com

• Enter Duty Cycle in percent and Frequency.

• Press the Write to Hardware button and OK the window below (note that the window below may not

always be present depending on the version of the GUI used.

28

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 29

www.ti.com

• Install a shunt in the RC position of J22. Rail #1 and rail #2 may experience a fault and may turn off.

• Press the Store RAM to flash and accept the response.

• Press and release the EVM RESET (S1) button and rail #1 can now be voltage margined.

• Navigate to the GUI Monitor tab with rail #1 selected and toggle the margin window

Description

none-low-high-none switches. Note that rail #1 voltage margins.

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

29

Copyright © 2009, Texas Instruments Incorporated

Page 30

Description

5.10 Fan Interface

The UCD90124 provides support for up to four fans. The UCD90124EVM provides a single fan interface

from J66. The UCD90124EVM interface can support three fan types including 2-wire, 3-wire, and 4-wire.

The FAN connector has four terminals (12V, GND, Tach, and PWM).

5.10.1 Fan Tach Input

The fan tach signal is an input to the UCD90124 providing an indication of fan speed based on signal

frequency. The EVM Tach input signal is conditioned prior to being connected to the UCD90124 and can

interface with either a 3.3V or 5V signal using J72. Install a shunt in the TACH position of J67 to connect

the conditioned signal to the UCD90124. The TACH signal at J66-2 is inverted by the conditioning circuitry

prior to J67.

5.10.2 Fan PWM Output

The fan PWM signal is an output from the UCD90124 providing fan speed control using a pulse width

modulated signal. The UCD90124 output signal can come from either PWM1 (J67 in the PWM position) or

FPWM5 (J70 in the FPWM5 position). The PWM1 or FPWM5 output signal can directly drive the fan PWM

input (four wire fan with J68 in the 4W position) or be conditioned prior the fan PWM input (two or three

wire fan with J68 in the 2/3W position). When J68 is in the 2/3W position, the PWM signal at J66-3 can

drive or modulate the ground of a two or three wire fan. When J68 is in the 2/3W position, the PWM signal

at J66-3 can provide a 3.3V, 5V, or 12V level PWM signal with appropriately installed shunts on J69 for

use with four wire fans. When J68 is in the 2/3W position, the PWM1 or FPWM5 signal at J70 is inverted

by the conditioning circuitry prior to J66-3.

www.ti.com

5.10.3 Fan Temperature Simulation

An onboard potentiometer (TEMP MON) can be used to simulate analog temperature when used in

conjunction with the fan interface for fan speed control. The potentiometer voltage can be monitored at

TP54 (TEMP MON) through MON12. Install a shunt in the 12E position of J61 and install J71 (EVR12).

The potentiometer voltage can be varied from 0 to approximately 4.2V. This voltage is scaled by 2 before

being sampled at MON12.

30

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Copyright © 2009, Texas Instruments Incorporated

Submit Documentation Feedback

Page 31

www.ti.com

Bill of Materials

6 Bill of Materials

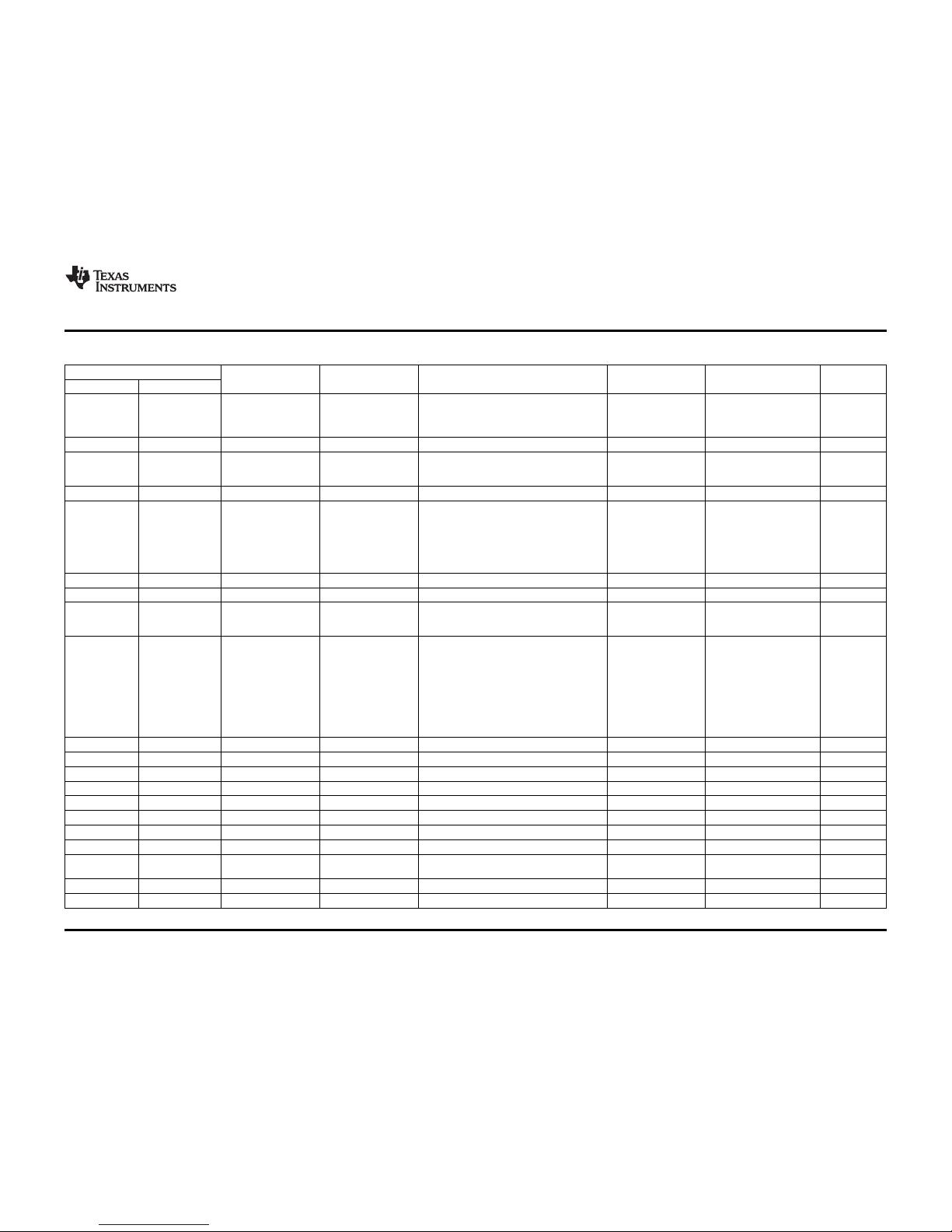

Table 6. UCD90120/4EVM Bill of Materials

Count

RefDes Value Description Size Part Number MFR

UCD90124EVM UCD90120EVM

2 2 C1, C16 330 µF Capacitor, Aluminum, 16V, ±20% 0.328 × 0.328 inch EEE-FK1C331P Panasonic

3 3 C12, C13, C15 4.7 µF Capacitor, Ceramic, 25V, X5R, 20% 0805 ECJ-2FB1E475M Panasonic

3 3 C2, C3, C17 4.7 µF Capacitor, Ceramic, 50V, X5R, 20% 1812 C4532X5R1H475MT TDK

3 3 C25, C59, C65 1000 pF Capacitor, Ceramic, X7R, 16V, 10% 0603 Std Std

8 8 C26, C27, C30, C31, 10 µF Capacitor, Ceramic, 10V, X5R, 10% 0805 C2012X5R1A106K TDK

C33, C34, C43, C44

2 2 C28, C39 33pF Capacitor, Ceramic, 50V, COG, 5% 0603 Std Std

4 4 C32, C35, C41, C46 47 pF Capacitor, Ceramic, X7R, 16V, 10% 0603 Std Std

4 4 C4, C23, C37, C45 0.01 µF Capacitor, Ceramic, 50V, X7R, 10% 0603 C1608X7R1H103K TDK

3 3 C40, C62, C63 22 pF Capacitor, Ceramic, 50V, C0G, 5% 0603 Std. Std

9 9 C42, C48, C49, C50, 1.0 µF Capacitor, Ceramic, X7R, 16V, 10% 0603 Std Std

C51,

C53–C56

1 1 C5 100 µF Capacitor, Tantalum, 10V, 20% 7343(D) TPSD107M010R0080 AVX

1 1 C57 1 µF Capacitor, Ceramic, 25V, X7R, 20% 0805 Std Std

1 1 C6 100 µF Capacitor, Tantalum, 10V, 10% 6032 TAJC107K010R AVX

1 1 C68 1 µF Capacitor, Tantalum, 16V, 20% 3216 293D105X0016A2T Vishay

3 3 C7, C69, C71 10 µF Capacitor, Tantalum, 10V, 20% 3216 293D106X0010A2T Vishay

23 23 C8–C11,C14, 0.1 µF Capacitor, Ceramic, X7R, 16V, 10% 0603 Std Std

C18–C22, C24, C29,

C36, C38, C47, C52,

C58, C60, C61, C64,

C66, C67, C70

2 2 D1, D4 B340A Diode, Schottky, 3A, 40V SMA B340A Diodes Inc

1 1 D11 BZX84B5V1LT1G Diode, Zener, 5.1-V, 2%, 225-mW SOT-23 BZX84B5V1LT1G Diodes

1 1 D2 10BQ015 Diode, Schottky, 1A, 15V SMB 10BQ015 IR

1 1 D26 MMSZ5242BT1G Diode, Zener, 20-mA, 12-V, 0.5W SOD123 MMSZ5242BT1G On Semi

1 1 D27 SMAJ24A Diode, Transient Voltage Suppressor, 400W, SMA SMAJ24A Littlefuse

24V

15 15 D29, D30, D32, D34, LN1371G Diode, LED, Green, 20-mA, 0.9-mcd SMD LN1371G Panasonic

D36, D38, D40, D42,

D44, D46– D49, D54,

D55

1 1 D3 TLV1117-33IDCY IC, Adj., 3.3 V, 800mA LDO Voltage Regulators SOT-223 TLV1117-33CDCY TI

15 15 D5, D9, D14–D25, D28 SML-LXT0805SRW-TR Diode, LED, Red, 100 mA 0805 SML-LXT0805SRW-TR Lumex

4 4 D50– D53 GL05T Diode, TVS, Low Cap., V(RM) = 5 V, 300 W Pk. SOT-23 GL05T Vishay

1 1 D56 SSF-LXH305GD-TR Diode, LED, Green, 20 mA, 30 mcd SMD SSF-LXH305GD-TR Lumex

31

SLVU347– December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

Copyright © 2009, Texas Instruments Incorporated

Page 32

Bill of Materials

www.ti.com

Table 6. UCD90120/4EVM Bill of Materials (continued)

Count

RefDes Value Description Size Part Number MFR

UCD90124EVM UCD90120EVM

1 1 D6 MBRA130 Diode, Schottky, 1A, 30V SMA MBRA130 IR

1 1 D7 1SMB5922BT3G Diode, Zener, 7.5V, 3W SMB 1SMB5922BT3G On Semi

12 12 D8, D10, D12, D13, LN1471Y Diode, LED, Amber, 20-mA, 0.4-mcd 0.114 × 0.049 inch LN1471YTR Panasonic

D31, D33, D35, D37,

D39, D41, D43, D45

3 3 FB1, FB2, FB3 220 Ω Ferrite Bead, 2A, 0.050 mΩ 0805 BLM21P221SN Murata

1 1 J1 RAPC 712 Connector, DC Jack, Pin dia.2.5mm, Shell dia 0.57 × 0.35 inch RAPC 712X Switchcraft

5.5mm

2 2 J18, J69 PEC04DAAN Header, Male 2x4-pin, 100mil spacing 0.20 × 0.40 inch PEC04DAAN Sullins

1 1 J2 ED120/2DS Terminal Block, 2-pin, 15-A, 5.1mm 0.40 × 0.35 inch ED120/2DS OST

2 2 J24, J28 PEC03DAAN Header, Male 2x3-pin, 100mil spacing 0.20 inch × 0.30 PEC03DAAN Sullins

1 1 J3 UX60-MB-5ST Connector,Recpt, USB-B, Mini, 5-pins, SMT 0.354in × 0.303in UX60-MB-5S8 Hirose

29 29 J4, J6, J7, J8, J11, J12, PEC02SAAN Header, Male 2-pin, 100mil spacing, 0.100 inch × 2 PEC02SAAN Sullins

J13, J19, J21, J23, J26,

J27, J29, J31, J38, J39,

J40, J41, J46, J47, J52,

J53, J58, J59, J64, J65,

J71, J78, J79

38 38 J5, J10, J14, J15, J16, PEC03SAAN Header, Male 3-pin, 100mil spacing, 0.100 inch × 3 PEC03SAAN Sullins

J17, J20, J22, J25, J30,

J32, J33, J34, J35, J36,

J37, J42, J43, J44, J45,

J48, J49, J50, J51, J54,

J55, J56, J57, J60, J61,

J62, J63, J67, J68, J70,

J72, J75, J76

1 1 J66 ED120/4DS Terminal Block, 4-pin, 15-A, 5.1mm 0.80 × 0.35 inch ED120/4DS OST

2 2 J73, J74 PEC10DAAN Header, Male 2x10-pin, 100mil spacing 0.100 inch × 10 × 2 PEC10DAAN Sullins

1 1 J77 N2510-6002-RB Connector, Male Straight 2x10 pin, 100mil 0.338 × 0.788 inch N2510-6002-RB 3M

spacing, 4 Wall

1 1 J9 PEC07DAAN Header, Male 2x7 pin, 100mil spacing 0.100 inch × 2×7 PEC07DAAN Sullins

1 1 L1 33 µH Inductor, SMT, 2.2A, 75mΩ 0.484 × 0.484 inch MSS1260-333MLB Coilcraft

2 2 L2, L3 2.2 µH Inductor, SMT, 1.5A, 110mΩ 0.118 × 0.118 inch LPS3015-222MLB Coilcraft

1 1 Q1 MMBT2222A Transistor, NPN, 40 V, 500 mA SOT-23 MMBT2222A Fairchild

1 1 Q2 FCX491A Transistor, NPN, 40V, 2A, 300 hfe SOT89 FCX491A Zetex

4 4 Q3, Q4, Q11, Q12 FDN5630 MOSFET, N-ch, 60-V,1.7-A, 100-mΩ SSOT3 FDN5630 Fairchild

1 1 Q5 MMBT2907ALT1 Transistor, PNP, -60V, -600mA, 225-W SOT23 MMBT2907ALT1 On Semi

5 5 Q6, Q7, Q8, Q9, Q10 BSS84 Transistor, PFET, -50 V, 130 mA, Rds(ON) < 10 SOT-23 BSS84 Fairchild

Ω at V(gs) = 5 V

1 1 R1 590 Resistor, Chip, 1/10W, 1% 0805 Std Std

32

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Submit Documentation Feedback

Copyright © 2009, Texas Instruments Incorporated

Page 33

www.ti.com

Bill of Materials

Table 6. UCD90120/4EVM Bill of Materials (continued)

Count

RefDes Value Description Size Part Number MFR

UCD90124EVM UCD90120EVM

10 10 R11, R110, R111, 15.0K Resistor, Chip, 1/16W, 1% 0603 Std Std

R134, R135, R144,

R145, R166, R167,

R238

1 1 R116 158 Resistor, Chip, 1/10W, 1% 0805 Std Std

8 8 R117, R119, R121, 750 Resistor, Chip, 1/10W, 1% 0805 Std Std

R123, R155, R157,

R159, R161

1 1 R118 191 Resistor, Chip, 1/10W, 1% 0805 Std Std

23 23 R12, R17, R25, R32, 100K Resistor, Chip, 1/16W, 1% 0603 Std Std

R45, R59, R62, R66,

R67, R70, R83, R87,

R90, R91, R94, R177,

R179, R235, R237,

R239, R241, R251,

R252

1 1 R120 232 Resistor, Chip, 1/10W, 1% 0805 Std Std

1 1 R122 280 Resistor, Chip, 1/10W, 1% 0805 Std Std

8 8 R128, R129, R130, 402 Resistor, Chip, 1/10W, 1% 0805 Std Std

R131, R170, R171,

R172, R173

29 29 R15, R23, R30, R42, 332 Resistor, Chip, 1/10W, 1% 0805 Std Std

R154, R195, R203,

R204, R205, R207,

R208, R211, R212,

R216, R217, R218,

R219, R220, R221,

R222, R223, R226,

R227, R230, R231,

R232, R233, R234,

R236

1 1 R156 392 Resistor, Chip, 1/10W, 1% 0805 Std Std

1 1 R158 464 Resistor, Chip, 1/10W, 1% 0805 Std Std

1 1 R160 549 Resistor, Chip, 1/10W, 1% 0805 Std Std

1 1 R186 5K Potentiometer, Multi-Turn, 3/8 Hole 0.375 sq inch 3386P-1-502LF Bourns

2 2 R196, R197 10K Resistor, Chip, 1/16 W, 5% 0603 Std. Std.

2 2 R8, R14 0 Resistor, Chip, 1/16W, 1% 0603 Std Std

0 0 R2, R18 0 Resistor, Chip, 1/16W, 1% 0603 Std Std

2 2 R20, R240 200 Resistor, Chip, 1/16W, 5% 0603 Std Std

5 5 R209, R210, R242, 2.2K Resistor, Chip, 1/16 W, 5% 0603 Std. Std.

R243, R245

1 1 R213 1.00M Resistor, Chip, 1/16 W, 1% 0603 Std. Std.

3 3 R214, R215, R255 1.5K Resistor, Chip, 1/16 W, 5% 0603 Std Std

33

SLVU347– December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

Copyright © 2009, Texas Instruments Incorporated

Page 34

Bill of Materials

www.ti.com

Table 6. UCD90120/4EVM Bill of Materials (continued)

Count

RefDes Value Description Size Part Number MFR

UCD90124EVM UCD90120EVM

2 2 R26, R53 20K Resistor, Chip, 1/16W, 1% 0603 Std Std

2 2 R27, R29 4.02K Resistor, Chip, 1/16W, 1% 0603 Std Std

63 63 R3, R5, R6, R7, R9, 10K Resistor, Chip, 1/16W, 1% 0603 Std Std

R10, R13, R16, R19,

R21, R22, R24, R28,

R31, R33, R44, R96,

R97, R98, R99–R103,

R106–R109, R114,

R115, R124, R125,

R132, R133, R138,

R139, R142, R143,

R148, R149,

R150–R153, R162,

R163, R174–R176,

R180–R182, R185,

R187–R191, R194,

R198, R200, R247,

R248

24 24 R34–R41, R43, 33 Resistor, Chip, 1/16W, 5% 0603 Std Std

R46–R48, R178, R224,

R225, R228, R229,

R249, R250,

R253–R258

1 1 R4 3.24k Resistor, Chip, 1/16W, 1% 0603 Std Std

2 2 R49, R51 84.5K Resistor, Chip, 1/16W, 1% 0603 Std Std

2 2 R50, R52 36.5K Resistor, Chip, 1/16W, 1% 0603 Std Std

11 11 R54, R183, R184, 1K Resistor, Chip, 1/16W, 1% 0603 Std Std

R192, R193, R199,

R201, R202, R206,

R244, R246

6 6 R55, R68, R76, R88, 30.1K Resistor, Chip, 1/16W, 1% 0603 Std Std

R89, R92

1 1 R56 732K Resistor, Chip, 1/16W, 1% 0603 Std Std

1 1 R57 374 Resistor, Chip, 1/16W, 1% 0603 Std Std

24 24 R58, R61, R71, R73, 7.50K Resistor, Chip, 1/16W, 1% 0603 Std Std

R79, R80, R93, R95,

R104, R105, R112,

R113, R126, R127,

R136, R137, R140,

R141, R146, R147,

R164, R165, R168,

R169

2 2 R60, R69 150K Resistor, Chip, 1/16W, 1% 0603 Std Std

2 2 R63, R72 1.20M Resistor, Chip, 1/16 W, 1% 0603 Std. Std.

1 1 R64 681K Resistor, Chip, 1/16W, 1% 0603 Std Std

1 1 R65 316 Resistor, Chip, 1/16W, 1% 0603 Std Std

34

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Submit Documentation Feedback

Copyright © 2009, Texas Instruments Incorporated

Page 35

www.ti.com

Bill of Materials

Table 6. UCD90120/4EVM Bill of Materials (continued)

Count

RefDes Value Description Size Part Number MFR

UCD90124EVM UCD90120EVM

1 1 R74 24 Resistor, Chip, 1W, 5% 2512 STD STD

1 1 R75 0.1 Resistor, Chip, 1/2W, 1% 2010 STD STD

2 2 R77, R78 10 Resistor, Chip, 1/16W, 1% 0603 Std Std

1 1 R81 31.6K Resistor, Chip, 1/16W, 1% 0603 Std Std

1 1 R82 14.3K Resistor, Chip, 1/16W, 1% 0603 Std Std

1 1 R84 243 Resistor, Chip, 1/16W, 1% 0603 Std Std

1 1 R85 49 Resistor, Chip, 1/16W, 5% 0603 Std Std

1 1 R86 162K Resistor, Chip, 1/16W, 1% 0603 Std Std

1 1 RT1 5 Ohms Inrush current limiter, 4.7A, 0.11 Ω 0.180 × 0.550 CL-150 GE Sensing

1 1 S1 KT11P2JM34LFS Switch, SPST, PB Momentary, Sealed 0.245 × 0.251 KT11P2JM34LFS C & K

Washable

1 1 S10 EG1218 Switch, 1P2T, Slide, PC-mount, 200-mA 0.46 × 0.16 EQ1218 E_Switch

8 8 S2, S3, S4, S5, S6, S7, MHS12304 Switch, ON-OFF-ON Miniature Slide 0.268 × 0.630 inch MHS12304 Tyco

S8, S9

2 2 TP1, TP2 5010 Test Point, Red, Thru Hole 0.125 × 0.125 inch 5010 Keystone

6 6 TP11, TP17, TP37, 5011 Test Point, Black, Thru Hole 0.125 × 0.125 inch 5011 Keystone

TP43, TP55, TP63

32 32 TP3, TP4, TP6, TP9, 5012 Test Point, White, Thru Hole 0.125 × 0.125 inch 5012 Keystone

TP12, TP14, TP18,

TP19, TP20,

TP24–TP27, TP32,

TP33, TP36, TP38,

TP39, TP40, TP44,

TP45, TP48, TP49,

TP54, TP56, TP57,

TP58, TP61, TP62,

TP65, TP66, TP67

26 26 TP5, TP8, TP10, TP13, 5014 Test Point, Yellow, Thru Hole 0.125 × 0.125 inch 5014 Keystone

TP15, TP16, TP21,

TP22, TP23, TP28,

TP29, TP30, TP31,

TP34, TP35, TP41,

TP42, TP46, TP47,

TP50, TP51, TP52,

TP53, TP59, TP60,

TP64

6 6 TP68–TP73 5016 Test Point, SM, 0.150 x 0.090" 0.185 × 0.135 5016 Keystone

1 1 TP7 5013 Test Point, Orange, Thru Hole 0.125 × 0.125 inch 5013 Keystone

1 1 U1 TPS5420D IC, Switching Step-Down Regulator, 36V, 2A SO8 TPS5420D TI

2 2 U10, U11 SN74LV126ADBR IC, Quad Bus Buffer with 3-State Outputs VSSOP-14 SN74LV126ADBR TI

1 1 U12 SN74LVC2G125DCU IC, Dual Bus Buffer with 3-State Outputs VSSOP-8 SN74LVC2G125DCU TI

1 1 U13 24LC64-I/SN IC, Serial EEPROM, 64K, 2.5-5.5V, 400 kHz SO-8 24LC64-I/SN Microchip

Max

35

SLVU347– December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

Copyright © 2009, Texas Instruments Incorporated

Page 36

Bill of Materials

www.ti.com

Table 6. UCD90120/4EVM Bill of Materials (continued)

Count

RefDes Value Description Size Part Number MFR

UCD90124EVM UCD90120EVM

1 1 U14 SN74CBTLV3125DBQ IC, Low Voltage Quad FET Bus Switch TSSOP-16 SN74CBTLV3125DBQ TI

1 1 U15 TUSB3210PM IC, USB, General Purpose Device Controller PQFP-64 TUSB3210PM** TI

1 1 U16 TPS76333DBV IC, Micro-Power 100 mA LDO Regulator SOT23-5 TPS76333DBV TI

2 2 U2, U3 SN74LVC2G04DBV IC, Dual Schmitt-Trigger Inverter SOT23-6 SN74LVC2G04DBV TI

0 1 U4 UCD90120RGC IC, Digital PWM System Controller PFC-64 UCD90120RGC TI

1 0 U4 UCD90124RGC IC, Digital PWM System Controller w/Fan PFC-64 UCD90124RGC TI

Control

1 1 U5 TPS62420DRC IC, 2.25 MHz Dual Step Down Converter QFN10 TPS62420DRC TI

1 1 U6 TLC274CD IC, CMOS, Quad Operational Amplifier SO14 TLC274CD TI

1 1 U7 MCP9700T-E IC, Low-Power Voltage output Temperature SC70-5 MCP9700T-E Microchip

Sensor

1 1 U8 INA196AIDBV IC, Current Shunt Monitor, –16V to 80V SOT23-5 INA196AIDBV TI

Common-Mode Range

1 1 U9 TPS71202DRC IC, Dual 250mA Output, Ultralow Noise, High DRC10 TPS71202DRC TI

PSRR, LDO Linear Regulator

1 1 Y1 12MHZ Crystal, 12-MHz, 20 pF, ±50 PPM at 25C 0.185 × 0.532 CY12BPSMD Crystek

57 57 – Shunt, Black 100-mil 929950-00 3M

4 4 SJ-5003 BUMPON HEMISPHERE 0.44×0.20 BLACK SJ-5003 3M

1 1 – PCB, 6 In × 5 In × 0.062 In HPA459 Any

1 1 USB Cable, 5-pin, B-Mini Male to Type A Male, AK672M/2-2-R Assman

2m

36

Evaluation Module for UCD90120 and UCD90124 SLVU347–December 2009

Submit Documentation Feedback

Copyright © 2009, Texas Instruments Incorporated

Page 37

www.ti.com

Layout Guidelines, EVM Schematic, and Assembly Drawings

7 Layout Guidelines, EVM Schematic, and Assembly Drawings

7.1 Layout Guidelines

Thermal pad

The thermal pad provides a thermal and mechanical interface between the device and the printed circuit

board (PCB). While device power dissipation is not of primary concern, a more robust thermal interface

can help the internal temperature sensor provide a better representation of PCB temperature. Connect the

exposed thermal pad of the PCB to the device VSS pins and provide at least a 4 × 4 pattern of PCB vias

to connect the thermal pad and VSS pins to the circuit ground on other PCB layers.

Supply voltage decoupling

Provide power supply pin bypass to the device as follows:

• 0.1µF, X7R ceramic in parallel with 0.01µF, X7R ceramic at pin 47 (BPCAP)

• 0.1µF, X7R ceramic in parallel with 4.7µF, X5R ceramic at pin 44 (V33D)

• 0.1µF, X7R ceramic at pin 7 (V33DIO)

• 0.1µF, X7R ceramic in parallel with 4.7µF, X5R ceramic at pin 46 (V33A)

Digital output signals

Depending on use and application of the various GPIO signals used as digital outputs, some impedance

control may be desired to quiet fast signal edges. For example, when using the FPWM pins for fan control

or voltage margining the pin will be configured as a digital clock signal. Route these signals away from

sensitive analog signals. It is also good design practice to provide a series impedance of 20–33 Ω at the

signal source to slow fast digital edges.

PMBus clock and data

Route PMBUS_CLK and PMBUS_DATA in a careful fashion away from sensitive analog signals. Provide

a series impedance of 20–33 Ω at the signal source.

7.2 EVM Schematic

The searchable PDF of the schematic is appended to this User's Guide.

7.3 Assembly Drawings

The assembly drawings are appended to this User's Guide. The topside and bottomside component

layouts are searchable.

SLVU347–December 2009 Evaluation Module for UCD90120 and UCD90124

Submit Documentation Feedback

37

Copyright © 2009, Texas Instruments Incorporated

Page 38

Evaluation Board/Kit Important Notice

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION

PURPOSES ONLY and is not considered by TI to be a finished end-product fit for general consumer use. Persons handling the

product(s) must have electronics training and observe good engineering practice standards. As such, the goods being provided are

not intended to be complete in terms of required design-, marketing-, and/or manufacturing-related protective considerations,

including product safety and environmental measures typically found in end products that incorporate such semiconductor

components or circuit boards. This evaluation board/kit does not fall within the scope of the European Union directives regarding

electromagnetic compatibility, restricted substances (RoHS), recycling (WEEE), FCC, CE or UL, and therefore may not meet the

technical requirements of these directives or other related directives.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30

days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY

SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all

claims arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to

take any and all appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER

FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or infringement of

patents or services described herein.

Please read the User’s Guide and, specifically, the Warnings and Restrictions notice in the User’s Guide prior to handling the

product. This notice contains important safety information about temperatures and voltages. For additional information on TI’s

environmental and/or safety programs, please contact the TI application engineer or visit www.ti.com/esh.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used.

FCC Warning

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION

PURPOSES ONLY and is not considered by TI to be a finished end-product fit for general consumer use. It generates, uses, and

can radiate radio frequency energy and has not been tested for compliance with the limits of computing devices pursuant to part 15

of FCC rules, which are designed to provide reasonable protection against radio frequency interference. Operation of this

equipment in other environments may cause interference with radio communications, in which case the user at his own expense

will be required to take whatever measures may be required to correct this interference.

EVM Warnings and Restrictions

It is important to operate this EVM within the input voltage range of 0 V to 20 V and the output voltage range of 0 V to 5 V .

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM. If there are

questions concerning the input range, please contact a TI field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible permanent damage to the

EVM. Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the load

specification, please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than 85°C. The EVM is designed to

operate properly with certain components above 85°C as long as the input and output ranges are maintained. These components

include but are not limited to linear regulators, switching transistors, pass transistors, and current sense resistors. These types of

devices can be identified using the EVM schematic located in the EVM User's Guide. When placing measurement probes near

these devices during operation, please be aware that these devices may be very warm to the touch.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2010, Texas Instruments Incorporated

Page 39

PWM4

PWM2

PWM1

PGPI4

PGPI3

PGPI1

33R40

33R34

L3P3V

RESET

SGPIO20

SGPIO19

SGPIO22

SGPIO21

1

2

J17

3P3V

J16

3P3V

R24

10K

R22

10K

3P3V

R16

10K

R13

10K

3P3V

R25

100K

R17

100K

0.1uF

C10

3P3V

3P3V

TP6 TP7

D1

B340A

5 Ohms

RT1

PWM3

12VBUS

33R38

33R36

PGPI2

R29

4.02K

TP5

V33D

C16

330uF

J4

TP1

C17

4.7uF

3P3V

1

R2

0

1000pF

C25

R53

20K

V33D

10K

R21

J8

TP2

0.1uF

C18

0.1uF

C14

0.01uF

C23

C15

4.7uF

5VBUS

200

R20

10BQ015

D2

2

J12

J11

2

J7

J6

L3P3V

10K

R5

1

10K

R7

10K

R6

R8

0

10K

R9

10K

R10

3P3V

R44

10K

R28

10K

R31

10K

R33

10K

J10

R45

100K

R32

100K

0.1uF

C24

D13

LN1471Y

D12

LN1471Y

D10

LN1471Y

D8

LN1471Y

84.5K

R49

84.5K

R51

J15

0.1uF

C8

J13

C3

4.7uF

0.1uF

C21

V33A

C5

100uF

TP4

BPCAP

2

2

C6

100uF

J14

J5

PMBUS_CTRL

PMBUS_ALERT

PMBUS_CLK

SR12_MON

SR10_MON

SR9_MON

SR13_MON SR7_MON

SR6_MON

SR4_MON

SR3_MON

SR1_MON

33R47

33R41

33R35

TRST*

SGPIO22

SGPIO20

SGPIO19

SGPIO17

SGPIO16

SGPIO4

SGPIO3

SGPIO1

SGPIO15

FPWM8

FPWM7

FPWM5

FPWM4

FPWM2

FPWM1

TCK

TDO

TRST*

TMS

PWM4

PWM3

PWM2

PWM1

R42

332

3 4

U3:B

SN74LVC2G04DBV

R30

332

3P3V

R23

332

3P3V

ADDRSENS1

ADDRSENS0 PMBUS_DATA

SR8_MON

SR11_MON

R26

20K

R27

4.02K

SR2_MON

SR5_MON

0.1uF

C20

12VBUS

C4

0.01uF

33R48

33R39

33R37

33R46

33R43

SGPIO21

TRCK

SGPIO18

SGPIO13

SGPIO2

0.1uF

C22

0.1uF

C19

D9

C12

4.7uF

C13

4.7uF

0.1uF

C9

V33D

D5

10K

R3

C7

10uF

5.0 V

21

33uH

L1

SGPIO14

FPWM3

FPWM6

TRCK

TDI

TP3

0R18

10K

R19

0R14

1 6

2

5

U3:A

SN74LVC2G04DBV

R15

332

3 4

U2:B

SN74LVC2G04DBV

1 6

2

5

U2:A

SN74LVC2G04DBV

36.5K

R52

36.5K

R50

J18

2

1

3

J1

330uF

C1

1

2

J2

1K

R54

4

1

3

2

S1

D11

BZX84B5V1LT1G

FCX491A

Q2

3P3V_USB

C2

4.7uF

6

GND5ENA7VIN

1

BOOT

8

PH

2NC3

NC

4

VSNS

TPS5420D

U1

12

220 Ohm

FB1

B340A

D4

R4

3.24k

R1

590

3

1

4

2

D3

TLV1117-33IDCY

J9

VREG33FB

64

AVSS3

46

V33A

26

DVSS2

44

V33DIO2

47

BPCAP

19

FPWM3/GPIO7

60

PMBUS_ADDR127PMBUS_ALERT41PWM4/GPI431PWM1/GPI153NC254MON1263MON9

6

MON6

3

MON3

30

GPIO15

23

FPWM7/GPIO11

20

FPWM4/GPIO817FPWM1/GPIO5

39

TMS/GPIO22

36

TCK/GPIO19

33

GPIO16

13

GPIO3

49

AVSS1

28

PMBUS_CTRL61PMBUS_ADDR0

9

RESET

32

PWM2/GPI215PMBUS_CLK

16

PMBUS_DATA42PWM3/GPI3

56

MON1351NC155NC357NC4

59

MON762MON850MON1052MON11

2

MON21MON1

4

MON45MON5

58

V33FB

65

TPAD

8

DVSS1

43

DVSS3

45

V33D

7

V33DIO1

24

FPWM8/GPIO12

29

GPIO14

18

FPWM2/GPIO621FPWM5/GPIO9

22

FPWM6/GPIO10

40

TRST

10

TRCK

34

GPIO1735GPIO18

37

TDO/GPIO20

11

GPIO112GPIO214GPIO4

25

GPIO13

38

TDI/GPIO21

48

AVSS2

U4

UCD90120/4RGC

Page 40

FPWM4

R2_EN

SGPIO2

CL MRG

CL MRG

CL MRG

OP BYP

R1_EN

R2_EN

R3_EN

SGPIO3

5VBUS

R4_EN

SGPIO4

R100

10K

R96

10K

3P3V

TP24

100KR94

100KR83

100KR70

100KR62

TP25

3P3V

12

220 Ohm

FB2

0.1uF

C29

OP BYP

OP BYP

OP BYP

CL MRG

TP26

R88

30.1K

R82

14.3K

5VBUS

R89

30.1K

R81

31.6K

C39

33pF

R72

1.20M

C31

10uF

R90

100K

C40

22pF

TP27

0.01uF

C45

J29

21

L3

2.2uH

21

L2

2.2uH

1.0uF

C42

C34

10uF

C27

10uF

C44

10uF

TP19

R69

150K

R64

681K

R60

150K

R56

732K

D17

D15

R65

316

VR2

D14

R57

374

VR1

30.1K

R92

30.1K

R76

TP16

J27

TP13

J23

TP8

J19

R93

7.50K

TP23

TP21

R79

7.50K

R73

7.50K

TP15

R71

7.50K

R61

7.50K

J20

5VBUS

TP14

24.0

R74

VR1

3P3V

J34

J38

J21

R63

1.20M

VR3

R85

49

VR4

TP22

J31

30.1K

R68

30.1K

R55

R95

7.50K

R80

7.50K

J32

R58

7.50K

TP10

0.1uF

C38

3

VOUT2GND

4

VDD

5NC1

NC

U7

MCP9700T-E

R77

10

0.1uF

C36

R78

10

R1_EN

SGPIO1

FPWM3

FPWM2

R1_FB

R3_EN

EVR4

EVR3

47pF

C46

47pF

C35

FPWM1

R101

10K

R102

10K

R97

10K

R98

10K

3P3V

R4_FB

J30

R3_FB

J25

R2_FB

J22

5VBUS

R103

10K

R99

10K

3P3V

R91

100K

R4_EN

10uF

C30

R59 100K

C43

10uF

D16

TP17

TP20

C33

10uF

C28

33pF

C26

10uF

TP9

EVR2

EVR1

5

4

123

U8

INA196AIDBV

TP18

0.01uF

C37

0.11/2 W

R75

47pF

C41

47pF

C32

J35 J36

J39

J33

J37

J41

J40

R67

100K

R66

100K

R84

243

TP12

TP11

J28

J24

1 2

220 Ohm

FB3

J26

3

VIN

8

GND

4

FB15DEF_1

1

ADJ22Mde/Data

7

EN1

6

SW1

9

EN2

11

PwPd

10

SW2

U5

TPS62420DRC

100KR87

SR2_MON

SR1_MON

SR4_MON

SR3_MON

162KR86

10

+

9

-

8

3OUT

U6:C

TLC274CD

12+13

-

14

4OUT

U6:D

TLC274CD

7

FB2/NC6NR

9

FB1/NC8EN2

4

OUT2

1

IN

10

EN1

5

GND

2

NC

3

OUT1

11

PwPd

U9

TPS71202DRC

5+6

-

7

20UT

U6:B

TLC274CD

4

3+2

-

1

11

U6:A

TLC274CD

Page 41

2

2

2

2

2/3 Wire

12VBUS

5VBUS

3P3V

VR8

VR7

VR5

EVR12

EVR10

EVR9

VR12

VR11

VR9

FPWM5

PWM1

R174

10K

R162

10K

3P3V

R152

10K

R142

10K

R138

10K

R132

10K

3P3V

J44

3P3V

J58 J52 J46

R175

10K

R163

10K

R153

10K

R143

10K

R139

10K

R133

10K

J45

TP58

J59 J53 J47

TP33

FETPWM1

SFTAC1

4 Wire

J68

TP64

EVR12

R177

100K

10K

R107

10K

R106

3P3V

SFPWM1

D22

1.0uF

C48

R117

750

5VBUS

5VBUS

D23

1.0uF

C49

R119

750

10K

R185

C57

1 uF

D24

R121

750

10K

R109

D25

R173

402

R123

750

R122

280

TP61

VR11

TP54

VR9

TP39

VR7

TP36

VR5

TP63

VR12

TP55

VR10

TP43

VR8

TP37

VR6

TP52

TP34

VR6

TP28

R164

7.50K

TP59

R146

7.50K

J54

R136

7.50K

R126

7.50K

TP41

R104

7.50K

TP30

J42

TP53

EVR11

TP35

TP29

15.0K

R145

VR10

15.0K

R111

TP60

TP42

TP31

SR9_MON

J70

J67

J62

J50

J56

3P3V

R114

10K

R124

10K

J64

J63

J51

J57

R125

10K

R115

10K

J65

TP45

TP49

R183

1K

10K

R148

10K

R149

1.0uF

C53

R155

750

D18

5VBUS

1.0uF

C54

R157

750

D19

R187

10K

J72

J69

312

4

J66

R159

750

D20

10K

R151

R161

750

R160

549

D21

R131

402

TP46

R168

7.50K

R140

7.50K

TP50

R112

7.50K

J48

TP47

15.0K

R167

15.0K

R135

TP51

J60

PWM TO FAN

FETDRN1

PWM TO FAN

TACH FROM FAN

R12_ENR8_EN

SGPIO22SGPIO18

R7_EN R11_EN

SGPIO20SGPIO16

R9_ENR5_EN

SGPIO19SGPIO13

PWM TO FAN

R6_EN

R5_EN

10KR181

FAN GND

FAN TACH

FAN +12V

R11_EN

R12_EN

EVR8

EVR6

EVR5

SR7_MON

SR6_MON

SR11_MON

SR10_MON

FPWM TO FAN

33R178

R179

100K

TP57

3P3V

SGPIO21SGPIO17

R10_ENR6_EN

3P3V

TP32

3P3V

2

1

3

R186

5K

5VBUS

TACH FROM FAN

3P3V

R170

402

R9_EN

R10_EN

0.1uF

C52

R116

158

10KR182

10KR180

1KR184

FAN PWM

12VBUS

R172

402

R171

402

1.0uF

C51

1.0uF

C50

R118

191

R120

232

10K

R108

R7_EN

R8_EN

TP62

TP56

EVR7

TP40

TP38

SR8_MON

15.0K

R144

15.0K

R110

SR5_MON

R165

7.50K

SR12_MON

R147

7.50K

J55

R137

7.50K

R127

7.50K

R105

7.50K

J43

FDN5630

Q4

TP44

TP48

3P3V

J71

FDN5630

Q3

R176

10K

R154

332

R128

402

0.1uF

C47

1.0uF

C56

1.0uF

C55

R156

392

R158

464

10K

R150

R129

402

R130

402

52A2

1A

62B7

GND

1

1OE31B42OE

10

3OE

13

4OE

83B9

3A

12

4A

14

VCC

11

4B

SN74LV126ADBR

U11

52A2

1A

62B7

GND

1

1OE31B42OE

10

3OE

13

4OE

83B9

3A

12

4A

14

VCC

11

4B

SN74LV126ADBR

U10

15.0K

R166

15.0K

R134

R169

7.50K

R141

7.50K

R113

7.50K

J49

J61

D27

SMAJ24A

D26

MMSZ5242BT1G

S7S6

S3S2

S9S8

S5S4

Page 42

33R229

33R224

SGPIO22

SGPIO21

SGPIO19

SGPIO18

SGPIO16

SGPIO13

SGPIO3

SGPIO2

LA1_CLK

CLK

R236 332

332R230

R220 332

332R211

GND

+5V DNC

SCI_RX

GND

CLK

PWM1

PWM3

PWM4

FPWM2

FPWM3

FPWM5

FPWM6

FPWM8

R238

15.0K

3P3V_USB

1000pF

C65

3P3V_USB

1.5K

R255

0.1uF

C64

R214

1.5K

0.1uFC60

R11

15.0K

33

R256

C62

22pF

3P3V_USB

C63

22pF

3P3V_USB

R200

10K

Q7

BSS84

R244

1K

Q10

BSS84

D50

GL05T

ALERT

D28

D51

GL05T

D53

GL05T

R206

1K

3P3V

SGPIO15

SGPIO20

SGPIO17

SGPIO4

SGPIO1

TP69TP68

R232 332

332R222

R216 332

332R204

DNC

TP72TP71

R251

100K

R247

10K

LN1371GD55

LN1371GD46

LN1371GD48

LN1371GD42

LN1371GD40

LN1371GD34

LN1371GD36

LN1371GD30

TP65

TP73

3P3V 3P3V

FPWM1

PWM2

FPWM7

FPWM4

J78

1uF

C68

1A02A13A24

Vss

5

SDA

6

SCL

7WP8

Vcc

24LC64-I/SN

U13

0.1uF

C70

R194

10K

0.1uF

C66

100K

R237

3P3V

0.1uF

C61

R209

2.2K

R195

332

R196

10K

33R228

33R225

J75 J76

332R234

332R218

R226 332

R207 332

LN1371GD54

LN1371GD38

LN1371GD44

LN1371GD32

R201

1K

J74

R202

1K

PMBCTRL1/GPIO3

33R258

33R250

PMBUS_CLK

PMBUS_DATA

CTRL

SGPIO14

FPWM8

FPWM6

FPWM5

FPWM3

FPWM2

SGPIO1

SGPIO3

SGPIO4

SGPIO14

SGPIO15

SGPIO17

SGPIO18

SGPIO20

SGPIO21

SCI_TX

+5V DNC

0.1uF

C67

MBRA130

D6

33

R257

R240

200

R215

1.5K

R213

1.00M

R199

1K

0.1uF

C11

C71

10uF

3P3V_USB

33R254

33R253

33R249

Q6

BSS84

Q8

BSS84

Q9

BSS84

100K

R235

R243

2.2K

R245

2.2K

R242

2.2K

3P3V

R193

1K

3P3V_USB

R246

1K

D52

GL05T

R203

332

0.1uF

C58

R191

10K

R190

10K

SGPIO14

R189

10K

R188

10K

TP70

3P3V

SGPIO15

FPWM7

FPWM4

FPWM1

R192

1K

SGPIO13

SGPIO2

SGPIO19

SGPIO16

TP66

SGPIO22

R252

100K

R248

10K

LN1371GD49

LN1371GD47

LN1471YD41

LN1471YD43

LN1471YD35

LN1471YD37

LN1471YD31

TP67

DNC

100K

R241

J79

SSF-LXH305GD-TR

D56

D7

1SMB5922BT3G

3W

C69

10uF

64

18

61

21

58

24

55

27

52

30

49

15

12

9

6

3

34

43

46

16

17

10

131411

4

587

1

2

63

62

22

60

59

57

56

28

29

53

51

50

33

3639384541

444847

23

54

37

40

25

20

26

19

31

32

35

42

TUSB3210PM

U15

1 2

12MHZ

Y1

3P3V_USB

100K

R12

5

OUT

4

FB

1IN3EN2

GND

U16

TPS76333DBV

100K

R239

Q5

MMBT2907ALT1

R198

10K

D29

LN1371G

R210

2.2K

R197

10K

1

1OE21A32Y4GND

52A61Y7

2OE

8

VCC

U12

SN74LVC2G125DCU

J77

3P3V

FDN5630

Q11

J73

FDN5630

Q12

LN1471YD39

LN1471YD45

LN1471YD33

9

NC

62A3

1A

113A14

4A

72B8

GND41B1NC21OE

103B134B16

VCC

15

4OE

5

2OE

12

3OE