Texas Instruments UCC3957MTR-3, UCC3957MTR-2, UCC3957MTR-1, UCC3957M-3, UCC3957M-2 Datasheet

...

UCC3957 -1/-2/-3/-4

PRELIMINARY

SLUS236 - JANUARY 1999

FEATURES

• Three or Four Cell Operation

• Two Tier Overcurrent Limiting

• 30µA Typical Supply Current

Consumption

• 3.5µA Typical Supply Current in Sleep

Mode

• Smart Discharge Minimizes Losses in

Overcharge Mode

• 6.5V to 20V VDD Supply Range

• Highly Accurate Internal Voltage

Reference

• Externally Adjustable Delays in

Overcurrent Controller

• Detection of Loss of Cell Sense

Connections

Three - Four Cell Lithium-Ion Protector Circuit

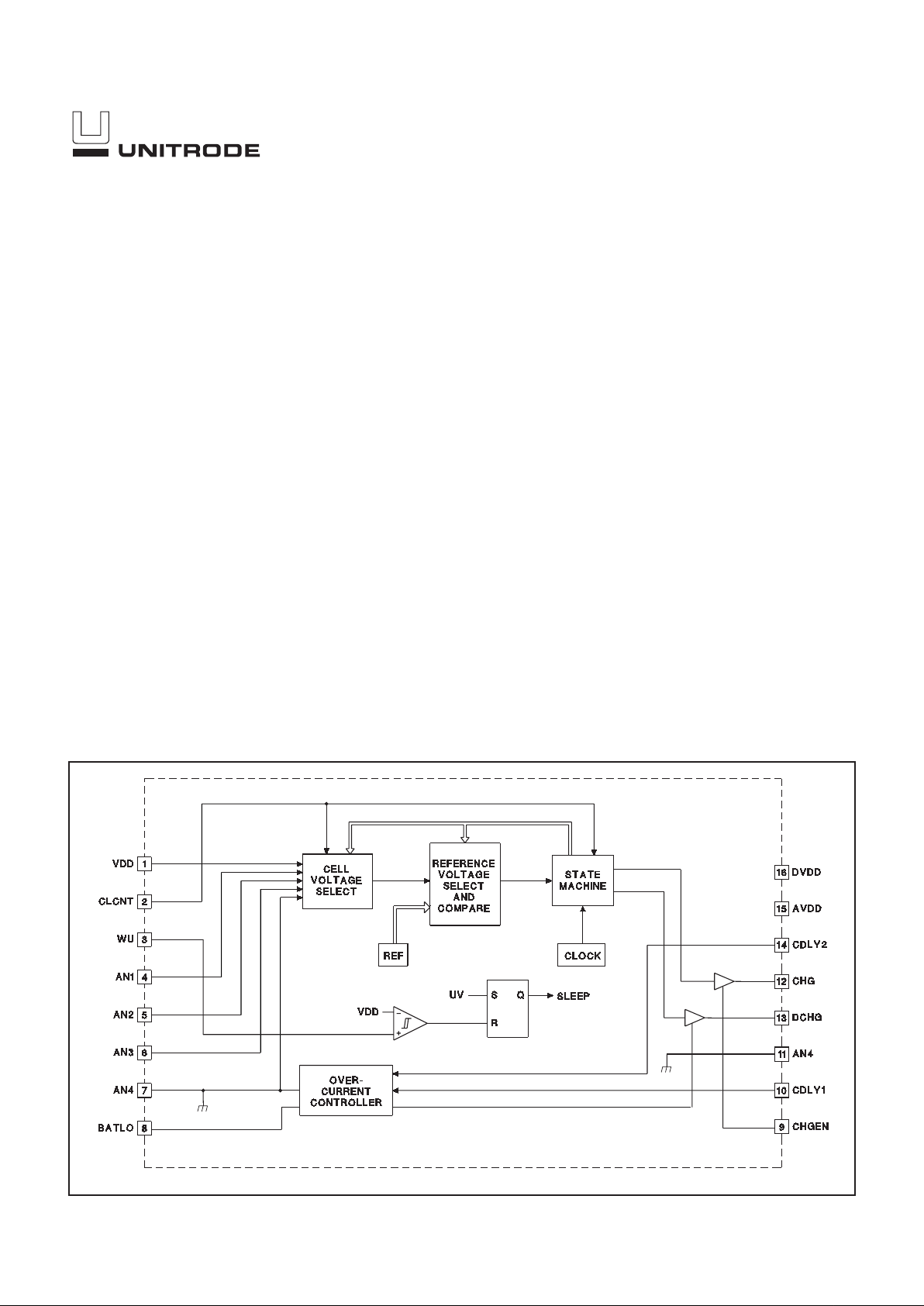

BLOCK DIAGRAM

UDG-97060

DESCRIPTION

The UCC3957 is a BiCMOS three or four cell lithium-ion battery pack

protector designed to operate with external P-channel MOSFETs. Utilizing external P-channel MOSFETs provides the benefits of no loss of

system ground in an overdischarge state, and protects the IC as well as

battery cells from damage during an overcharge state. An internal state

machine runs continuously to protect each lithium-ion cell from overcharge and overdischarge. A separate overcurrent protection block protects the battery pack from excessive discharge currents.

If any cell voltage exceeds the overvoltage threshold, the appropriate external P-channel MOSFET is turned off, preventing further charge current. An external N-channel MOSFET is required to level shift to this high

side P-channel MOSFET. Discharge current can still flow through the

second PFET. Likewise, if any cell voltage falls below the undervoltage

limit, the second P-channel MOSFET is turned off and only charge current is allowed. Such a cell voltage condition will cause the chip to go

into low power sleep mode. Attempting to charge the battery pack will

wake up the chip. A cell count pin (CLCNT) is provided to program the IC

for three or four cell operations.

A two tiered overcurrent controller and external current shunt protect the

battery pack from excessive discharge currents. If the first overcurrent

threshold level is exceeded, an internal timing circuit charges an external

capacitor to provide a user programmable blanking time.

(continued)

2

UCC3957 -1/-2/-3/-4

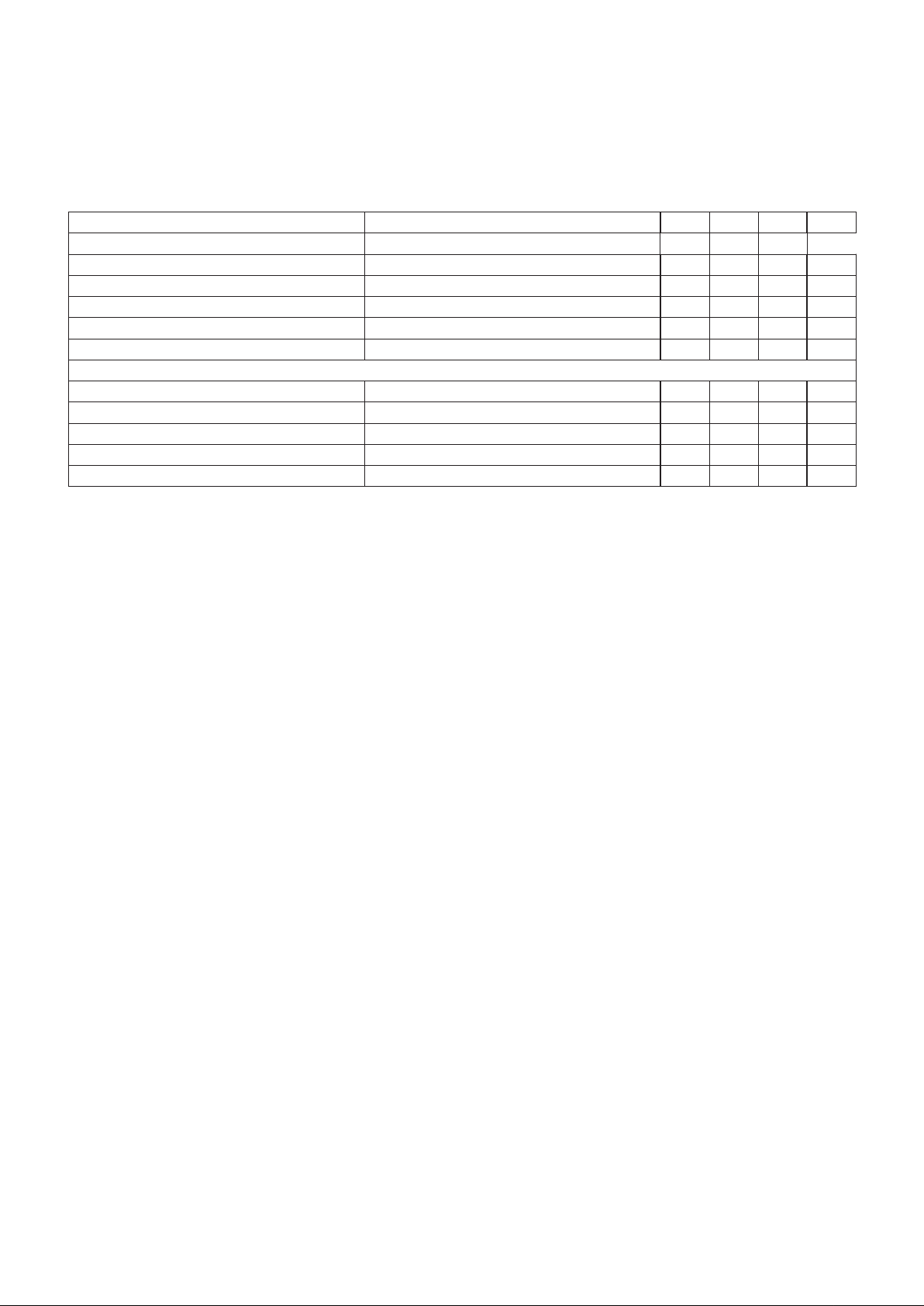

ELECTRICAL CHARACTERISTICS:

Unless otherwise specified, VDD = 16V and –20°C < TA< 70°C, TA= TJ.

All voltages measured with respect to the AN4 terminal.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Supply Section

Minimum V

DD

5.0 5.5 V

Supply Current 30 40 µA

Sleep Mode Supply Current VDD= 10.4V 3.5 7.5 µA

Output Section

DCHG Output Current Driving Logic Low and V

O

= 1V 40 70 100 µA

Driving Logic High and VO= VDD – 1 –20 –7 –3 mA

CHG Ouput Current Driving Logic Low and VO= 1V 40 70 100 µA

Driving Logic High and VO= VDD – 1V –20 –7 –3 mA

State Transitions

Normal to Overcharge UCC3957-1 4.15 4.20 4.25 V

Overcharge to Normal UCC3957-1 3.95 4.00 4.05 V

Normal to Overcharge UCC3957-2 4.20 4.25 4.30 V

Overcharge to Normal UCC3957-2 4.00 4.05 4.10 V

Normal to Overcharge UCC3957-3 4.25 4.30 4.35 V

Overcharge to Normal UCC3957-3 4.05 4.10 4.15 V

Normal to Overcharge UCC3957-4 4.30 4.35 4.40 V

Overcharge to Normal UCC3957-4 4.10 4.15 4.20 V

Undercharge to Normal 2.5 2.6 2.7 V

Normal to Undercharge 2.2 2.3 2.4 V

OV to CHG Delay (Note 1) 10 17 23 ms

ABSOLUTE MAXIMUM RATINGS

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20V

Supply Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25mA

Output Current (CHG, DCHG) . . . . . . . . . . . . . . . . . . . . . 25mA

WU Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28V

BATLO Input Voltage. . . . . . . . . . . . . . . . . . . . . . –0.3V to 2.5V

AN1 and AN3 Input Voltage . . . . . . . . . . . . . . . . . VAN4 – VDD

CLCNT and CHGEN. . . . . . . . . . . . . . . . . . . . . . . VAN4 – VDD

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.). . . . . . . . . . . . . +300°C

Unless otherwise indicated, voltages are referenced to AN4.

Currents are positive into, negative out of the specified terminal.

Consult Packaging Section of Databook for thermal limitations

and considerations of packages.

DESCRIPTION (continued)

If at the end of the blanking time the overcurrent condition still exists, the external discharge FET is turned off

for a period 17 times longer than the first blanking period, and then the discharge FET is turned back on. If at

any time a second higher overcurrent threshold is ex-

ceeded for more than a user programmable time, the discharge FET is turned off, and will remain off for the same

period as the first tier off time. This two tiered overcurrent

protection scheme allows for charging capacitive loads

while retaining effective short circuit protection.

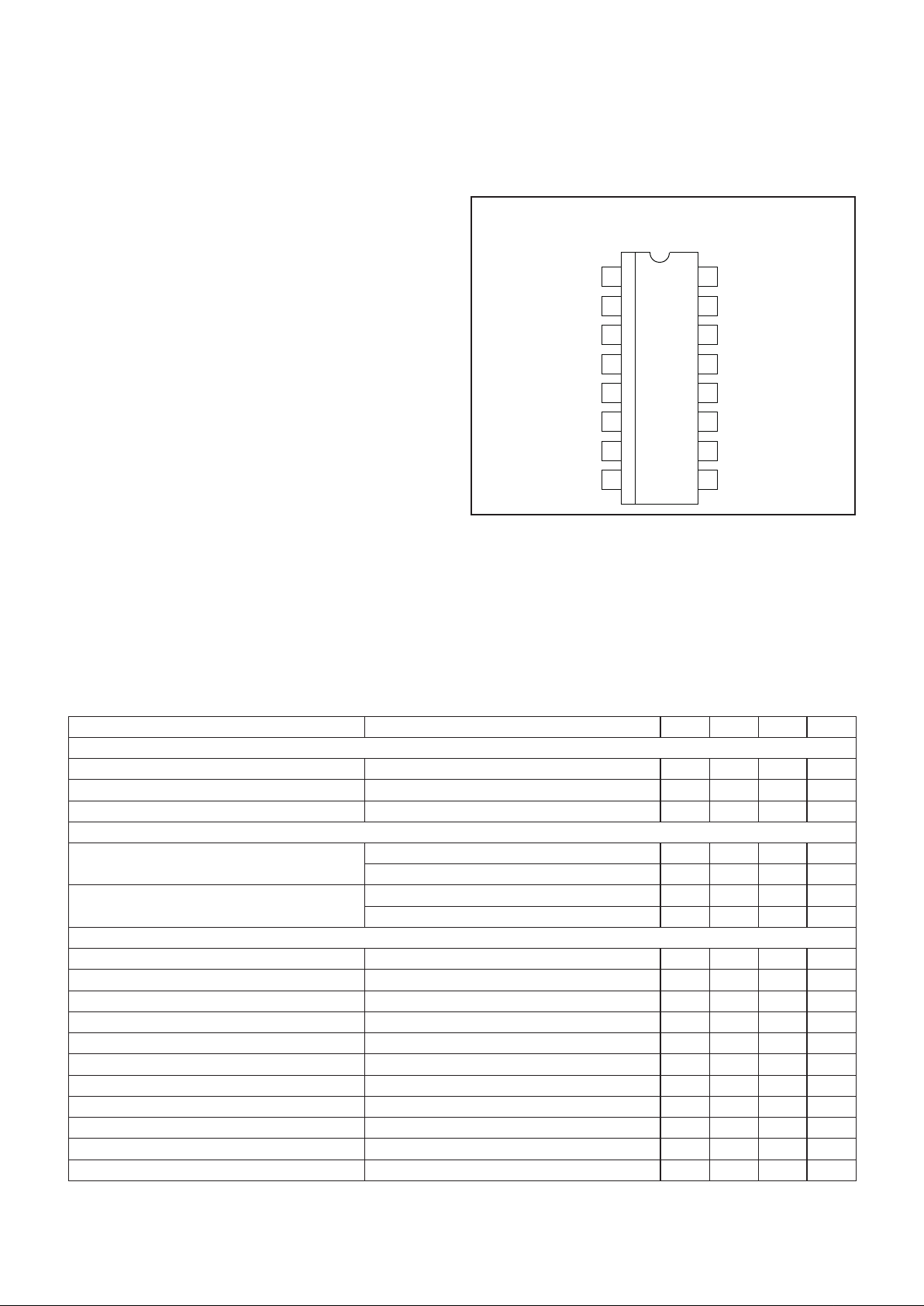

CDLY2

AVDD

DVDD

DCHG

CHG

CDLY1

AN4

CHGEN

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

CLCNT

VDD

BATLO

AN3

AN4

WU

AN1

AN2

CONNECTION DIAGRAM

SSOP-16 (Top View)

M Package

3

UCC3957 -1/-2/-3/-4

PIN DESCRIPTIONS

AN1: Connects to the negative terminal of the top battery

cell and the positive terminal of the second battery cell.

AN2: Connects to the bottom terminal of the second

battery cell and the top terminal of the third battery cell.

AN3: Connects to the bottom terminal of the third battery

cell and the top terminal of the fourth battery cell in a four

cell stack. In a three cell pack it connects to the bottom

terminal of the third battery and to AN4.

AN4: Connects to the bottom terminal of the battery

stack and the top of the current sense resistor.

AVDD: Internal analog supply bypass cap pin. Connect a

0.1µF capacitor between this pin and AN4. This pin is

nominally 7.3V.

BATLO: Connects to the bottom of the current sense

resistor and the negative terminal of the battery pack.

CHGEN: The charge enable input for the protection IC.

This point must be driven high to allow charging of the

battery pack. This pin has a very weak pulldown.

CDLY1: Delay control pin for the short circuit protection

feature. A capacitor connected between this point and

AN4 will determine the time delay from when an

overcurrent situation is detected to when the FET is

turned off. This capacitor also controls the hiccup mode

timeout period.

CDLY2: An external cap can be tied between this pin

and AN4 to extend the blanking time on the second current limit tier.

CLCNT: This pin programs the IC for three or four cell

operation. Tying this pin low (to AN4) sets four cell operation, w`hile tying it high (to VDD or the preferred DSPLY

or ASPLY) sets three cell operation. This pin is internally

pulled low, so open circuit conditions will always result in

four cell mode.

DCHG: This pin is used to prevent overdischarge. If the

state machine indicates that any cell is undervoltage, this

pin will be driven high with respect to chip substrate so

that the external P-channel MOSFET will prevent further

discharge. If all cell voltages are above the minimum

threshold, this pin will be driven low.

CHG: This pin is used to control an external N-channel

MOSFET, which in turn drives a P-channel MOSFET. If at

least one cell voltage is over the OV threshold, this pin

will be driven low with respect to AN4. If all cell voltages

are below this threshold, this pin will be driven high.

DVDD: Internal digital supply bypass capacitor pin. Connect a 0.1µF capacitor between this pin and AN4. This

pin is nominally 7.3V.

VDD: Supply voltage to the IC. Connect this point to the

top of the lithium-ion battery stack.

WU: This pin is used to provide a wake up signal to the

IC during sleep mode. Connect this pin to the drain of the

N-channel level shift MOSFET.

ELECTRICAL CHARACTERISTICS: Unless otherwise specified, VDD = 16V and –20°C < T

A

< 70°C, TA= TJ.

All voltages measured with respect to the AN4 terminal.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

State Transitions (continued)

UV to DCHG Delay (Note 1) 10 17 23 ms

Cell Sample Rate (Note 1) 5 8.5 11.5 ms

Smart Discharge Threshold BATLO Voltage 12 15 20 mV

Wakeup Input Threshold With Respect to V

DD 50 mV

Charge Enable Input Threshold 0.8 1.3 2.6 V

Short Circuit Protection

First Tier Threshold Level V

BATLO

120 150 180 mV

Second Tier Threshold Level V

BATLO

300 375 450 mV

First Tier Blanking Time CDLY1 = 0.1µF 305070ms

Restart Time CDLY1 = 0.1µF 300 500 700 ms

Second Tier Blanking Time CDLY2 = 10pF 200 400 550 µs

Note 1: Tested at probe only.

Note 2: Other OV/UV thresholds are available. Please consult the factory.

Loading...

Loading...