Page 1

User’s Guide

July 2002 PMP Systems Power

SLLU049

Page 2

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty . Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. T o minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third–party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party , or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Page 3

EVM IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation kit being sold by TI is intended for use for ENGINEERING DEVELOPMENT OR EV ALUA TION

PURPOSES ONL Y and is not considered by TI to be fit for commercial use. As such, the goods being provided

may not be complete in terms of required design-, marketing-, and/or manufacturing-related protective

considerations, including product safety measures typically found in the end product incorporating the goods.

As a prototype, this product does not fall within the scope of the European Union directive on electromagnetic

compatibility and therefore may not meet the technical requirements of the directive.

Should this evaluation kit not meet the specifications indicated in the EVM User’s Guide, the kit may be returned

within 30 days from the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE

WARRANTY MADE BY SELLER TO BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED,

IMPLIED, OR ST ATUT ORY, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user

indemnifies TI from all claims arising from the handling or use of the goods. Please be aware that the products

received may not be regulatory compliant or agency certified (FCC, UL, CE, etc.). Due to the open construction

of the product, it is the user’s responsibility to take any and all appropriate precautions with regard to electrostatic

discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER P ARTY SHALL BE LIABLE

TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not

exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or

infringement of patents or services described herein.

Please read the EVM User’s Guide and, specifically, the EVM Warnings and Restrictions notice in the EVM

User’s Guide prior to handling the product. This notice contains important safety information about temperatures

and voltages. For further safety concerns, please contact the TI application engineer.

Persons handling the product must have electronics training and observe good laboratory practice standards.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any

machine, process, or combination in which such TI products or services might be or are used.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Page 4

EVM WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the input and output voltage ranges specified in the

user’s guide.

Exceeding the specified input range may cause unexpected operation and/or irreversible

damage to the EVM. If there are questions concerning the input range, please contact a TI

field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or

possible permanent damage to the EVM. Please consult the EVM User’s Guide prior to

connecting any load to the EVM output. If there is uncertainty as to the load specification,

please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than

60°C. The EVM is designed to operate properly with certain components above 60°C as long

as the input and output ranges are maintained. These components include but are not limited

to linear regulators, switching transistors, pass transistors, and current sense resistors. These

types of devices can be identified using the EVM schematic located in the EVM User’s Guide.

When placing measurement probes near these devices during operation, please be aware

that these devices may be very warm to the touch.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Page 5

About This Manual

Related Documentation From Texas Instruments

Preface

Read This First

This users guide describes the characteristics, operation, and use of the

UCC2977 CCFL backlight converter evaluation module (EVM). The users

guide includes a schematic diagram, bill of materials and test results.

How to Use This Manual

This document contains the following chapters:

- Chapter 1—Hardware

- Chapter 2—Design Procedure

- Chapter 3—Test Results

Related Documentation From Texas Instruments

- Texas Instruments Users Manual, UCC3976/7 Users Manual, TI

Literature Number SLUU108

- Texas Instruments Data Sheet, UCC2977, TI Literature Number

SLUS499A

FCC Warning

This equipment is intended for use in a laboratory test environment only . It generates, uses, and can radiate radio frequency energy , and has not been tested

for compliance with the limits of computing devices pursuant to subpart J of

part 15 of FCC rules, which are designed to provide reasonable protection

against radio frequency interference. Operation of this equipment in other environments may cause interference with radio communications, in which case

the user at his own expense will be required to take whatever measures may

be required to correct this interference.

iii

Page 6

iv

Page 7

Contents

Contents

1 Hardware 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Introduction 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Operating Specifications 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Schematic 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Bill of Materials 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Board Layout 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Design Procedure 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Push-Pull Inductor Selection 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Frequency Range Setting 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Analog Dimming of the Lamp 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Open-Lamp Voltage Programming 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Shutdown 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 No Lock 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Burst Dimming 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Clamp Circuit (Optional) 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Test Results 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Test Setup 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Lighting CCFL 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Analog Dimming Test 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Burst Dimming Test 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Test Results 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Page 8

Contents

Figures

1–1 UCC2977EVM Schematic 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 Top Silk Screen With Top Copper Layer 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–3 Top Layer Copper 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–4 Bottom Layer Copper 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–1 Test Setup 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–2 Test Setup for Analog Dimming 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–3 Test Setup for Burst Dimming 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–4 Efficiency With a Low Profile Sumida Inductor 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–5 Efficiency With a High Profile Toko Inductor 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–6 Transformer Input/Output Voltages at V

3–7 Transformer Input/Output Voltages at VI = 6 V 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–8 Burst Dimming With 50% Duty Cycle 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–9 Burst Dimming With 80% Duty Cycle 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–10 Open Lamp Protection 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

= 3 V 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

Tables

1–1 Operating Specifications 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1–2 Bill of Materials Required for the UCC2977 (SLUP178) 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Page 9

Chapter 1

Hardware

The UCC2977 evaluation module (SLUP178) provides a reference design for

evaluating the performance of a high efficiency CCFL backlight converter

using the UCC2977 (push-pull backlight controller). The device contains all of

the circuitry necessary to control a backlight converter. This chapter contains

the schematic, board layout, and the bill of materials. The evaluation module

(EVM) performance specifications are also given.

Topic Page

1.1 Introduction 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Operating Specifications 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Schematic 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Bill of Materials 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Board Layout 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

Page 10

Introduction

1.1 Introduction

The UCC2977 EVM (SLUP178) is a 1.8-W dc/ac inverter module used to drive

a cold cathode fluorescent lamp (CCFL) with a piezoelectric transformer

(PZT). This EVM consists of a push-pull circuit using the UCC2977 controller.

The principle of operation for the inverter is explained in the application section

of the UCC2977 data sheet.

1.2 Operating Specifications

This section summarizes the performance specifications of the SLUP178

converter. Table 1–1 lists the operating specifications for the SLUP178.

Table 1–1.Operating Specifications

Input voltage (VIN) 3~6 Vdc

Output voltage (Lamp_HV, Lamp LV) 300 V ac, rms

Output current (lamp current) 4.7 mA, rms

Operating frequency (kHz) 100 kHz

Burst dimming (BD )

Analog dimming (AD) 0~3 Vdc

CCFL lamp JKL BF3100–20B (100 mm, 270 V

†

Use a function generator.

†

Square wave, 120 Hz, 0 to 3 V

RMS

)

1-2

Page 11

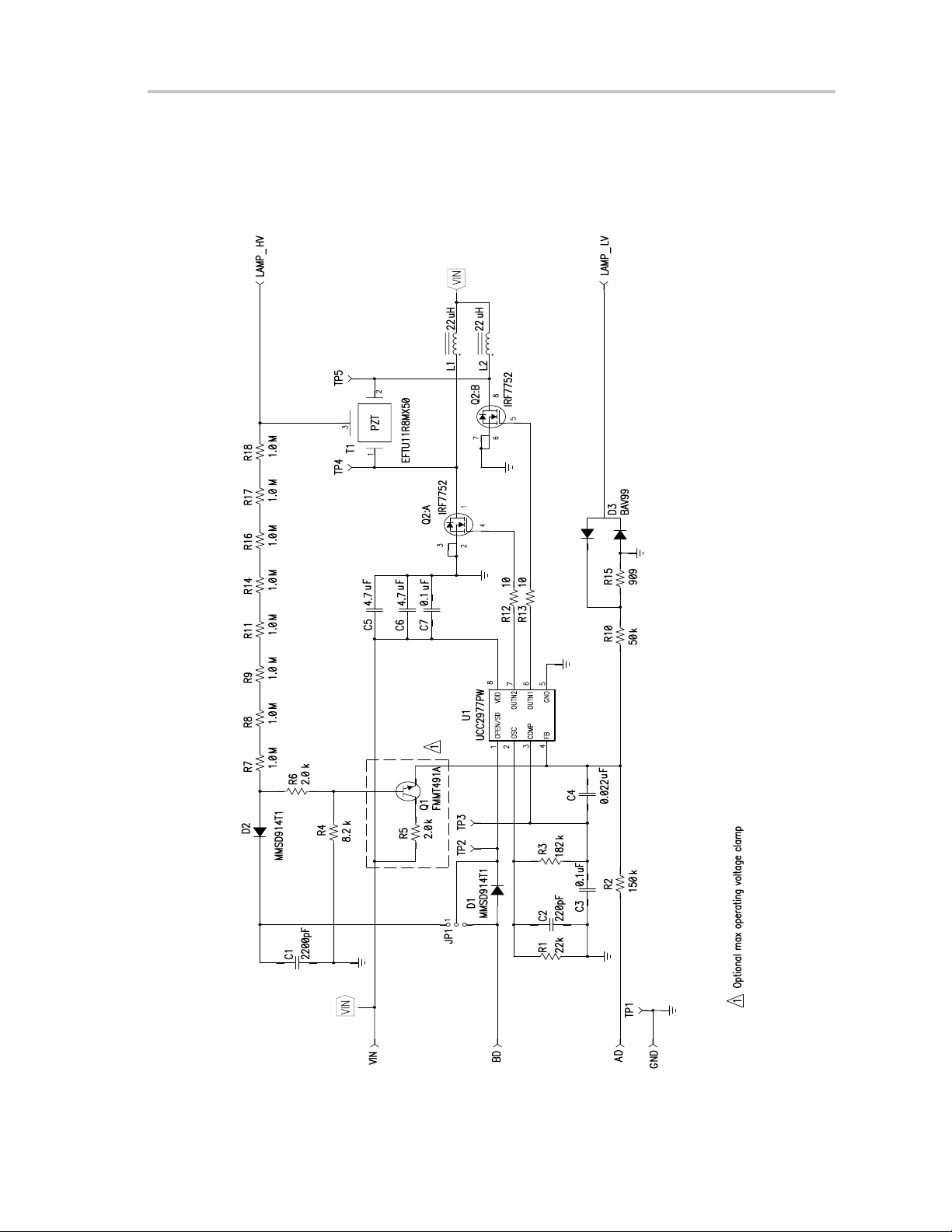

1.3 Schematic

Figure 1–1.UCC2977EVM Schematic

Schematic

Hardware

1-3

Page 12

Bill of Materials

1.4 Bill of Materials

Table 1–2.Bill of Materials Required for the UCC2977 (SLUP178)

Count Ref Des Description Size MFR Part Number

1 C1 Capacitor, ceramic, 2200 pF , 50 V ,

1 C2 Capacitor, ceramic, 220 pF, 50 V,

2 C3, C7 Capacitor, ceramic, 0.1 µF, 25 V,

1 C4 Capacitor, ceramic, 0.022 µF,

2 C5, C6 Capacitor, ceramic, 4.7 µF, 10 V,

2 D1, D2 Diode, switching, 1.0 mA, 75 V SOD123 Motorola MMSD914T1

1 D3 Diode, dual ultra fast, series,

1 JP1 Header, 3 pin, 100 mil spacing,

2 L1, L2 Inductor, SMT, 22 µH, 1.2 A,

1 Q1 Transistor, NPN, high perfor-

1 Q2 XSTR, MOSFET, N-channel,

1 R1 Resistor, chip, 22 kΩ, 1/16 W , 1% 603 Std Std

1 R10 Resistor, chip, 50 kΩ, 1/16 W, 1% 603 Std Std

2 R12, R13 Resistor, chip, 10 Ω, 1/16 W , 1% 603 Std Std

1 R15 Resistor, chip, 909 Ω, 1/16 W , 1% 603 Std Std

1 R2 Resistor, chip, 150 kΩ, 1/16 W , 1% 603 Std Std

1 R3 Resistor, chip, 182 kΩ, 1/16 W , 1% 603 Std Std

1 R4 Resistor, chip, 8.2 kΩ, 1/16 W , 1% 603 Std Std

2 R5, R6 Resistor, chip, 2.0 kΩ, 1/16 W, 1% 603 Std Std

8 R7, R8. R9.

R11, R14,

R16, R17,

R18

1 T1 Transformer , custom,

2 TP1, GND Test point, black, 1 mm 0.038 Farnell 240-333

9 TP2–TP5,

VIN, BD, AD,

LAMP_HV,

LAMP_LV

1 U1 IC, CCFL push-pull driver TSSOP-08 TI UCC2977PW

1 — PCB, 3.55I × 0.905I × 0.62I Any SLUP178

X7R, 20%

X7R, 20%

X7R, 20%

25 V , X7R, 20%

X5R, 20%

200 mA, 70 V

(36-pin strip)

128 mΩ

(or Toko inductor, 22 µH, 115 mΩ 7.6 × 7.6 × 5.1 mm Toko 646CY-220M

mance, 500 mA

30 V, 4.6 A, Rds 35 mΩ

Resistor, chip, 1.0 MΩ, 1/10 W,1%805 Std Std

Piezoelectric, SMT

Test point, red, 1 mm 0.038 Farnell 240-345

603 Murata GRM188R71H222KA01

603 Murata GRM188R7H221KD01

805 Murata GRM21BR71E104KA01

603 Murata GRM188R71E223KA01

1206 Murata GRM31CR61A475KA01

SOT23 Fairchild BAV99

0.100 × 3I Sullins PTC36SAAN

6.7 × 6.7 × 3 mm Sumida CDRH6D28-220NC

SOT23 ZeTek FMMT491A

TSSOP8 IR IRF7752

0.760 × 0.244 Panasonic EFTU11R8MX50

1-4

Page 13

1.5 Board Layout

Figure 1–2.Top Silk Screen With Top Copper Layer

Figure 1–3.Top Layer Copper

Board Layout

Figure 1–4.Bottom Layer Copper

Hardware

1-5

Page 14

1-6

Page 15

Chapter 2

Design Procedure

This chapter describes how to design the UCC2977EVM.

Topic Page

2.1 Push-Pull Inductor Selection 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Frequency Range Setting 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Analog Dimming of the Lamp 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Open-Lamp V oltage Programming 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Shutdown 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 No Lock 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Burst Dimming 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Clamp Circuit (Optional) 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Design Procedure

2-1

Page 16

Push-Pull Inductor Selection

Ȳ

ȴ

2.1 Push-Pull Inductor Selection

The push-pull topology requires a different approach for calculating the

external inductor values. Referring to Figure 1–1, Q2A and Q2B are driven out

of phase at 50% duty cycle. When Q2A is on, current is ramped up in L1.

During the next switch cycle Q2B is turned on, Q2A is turned off, and the

energy stored in L1 is transferred through the piezoelectric transformer. L1

resonates with the piezoelectric primary capacitance forming a half sinusoid

at Q2A’s drain. In order to achieve zero-voltage switching, the drain voltage

must return to ground before the next switching cycle. This dictates that the

LC resonant frequency must be greater than the switching frequency.

L t

In the EVM with a 100 kHz switching frequency and 61.6 nF piezoelectric

transformer, L1 and L2 must be less than 41 µH for zero-voltage switching, so

22-µH inductors are used.

A suitable capacitor must be chosen so that the peak-to-peak output ripple is

within the limits allowable for the application.

4 p

2

2.2 Frequency Range Setting

The VCO frequency range is programmed with external components R1, R3

and C2. The frequency is determined by the voltage decay from 1.7 V to 0.6 V

at the OSC pin. When the voltage reaches 0.6 V, an internal current source

charges OSC back to 1.7 V . The decay time is determined by the value of C2

and the discharge currents generated in R1 and R3. An accurate NPO

capacitor is recommended for C2 and 1% resistors are recommended for R1

and R3. The output frequency range can be calculated by equation 2:

COMP

Ǔ

+

ƒǒV

1

ƒ2 Cp

2 ln

R1 ) R3

ƪ

R1 R3 C2

ȱ

1.7 V (R1 ) R3) * V

ȧ

ǒ

0.6 V * V

COMP

ƫ

R1

COMP

Ǔ

R1 ) 0.6 V R3

(1)

(2)

ȳ

ȧ

With C2 set at 220 pF , R1 at 22 kΩ and R3 at 182 kΩ, the frequency is 100 kHz.

2.3 Analog Dimming of the Lamp

For analog dimming, enable the open-lamp detection by connecting pin 1 to

pin 2 of jumper JP1 and ground BD. Lamp intensity is controlled with the signal

AD.

The RMS lamp current becomes:

ƪ

1.5 V (R2 ) R10) * VAD R10

+

2-2

I

LAMP

Ǹ

2

R2 R15

ƫ

p

(3)

Page 17

Open-Lamp Voltage Programming

Zero volts on VAD commands full current while 3 V commands minimum

current. For the initially configured EVM, maximum current is 4.8 mA. R15 is

selected to be 909 Ω setting V

set to 150 K, R10 is calculated to be 50 K. The control-voltage to lamp-current

equation for the EVM is:

to 0 V and lamp current to 4.8 mA. With R2

AD

I

(mA) + 4.89 * 1.22 V

LAMP

2.4 Open-Lamp Voltage Programming

It is necessary to suspend the power-stage operation if an open lamp occurs

because the piezoelectric transformer has a high gain. The open-lamp

detection circuit is composed of voltage divider R7, R8, R9, R11, R14, R16,

R17, R18, R4, R6, D2, and C1. A 1.5 V comparator at the OPEN pin shuts

down the inverter if an open lamp is triggered. The RMS secondary voltage at

which an open lamp shutdown occurs can be calculated by equation (5).

9

V

OPEN

ǒ

1.5 V ) V

+

With R7~R9, R11, R14, R16~R18 at 1 Meg each, R6 at 2 k and R4 at 8.2 k,

the RMS value of open lamp threshold voltage at the secondary is 1220 V

The value of capacitor C1 should be large enough to filter the sinusoid

waveform into dc. For this board, 2200 pF was chosen. If C5 is too large, it

takes extra time for OPEN/SD to climb to 1.5 V when the output voltage hits

the open-lamp threshold, resulting in a higher output voltage than the set

value.

diode

Ǔ

ǒ

R

S

) R11) R14) S

i

i+7

2Ǹ (R4 ) R6)

AD

18

j+16

R

) R4) R6

j

Ǔ

RMS

(4)

(5)

RMS

.

2.5 Shutdown

2.6 No Lock

The open-lamp level should be set high enough to avoid tripping during normal

operation. Open-lamp detection is disabled for the burst-dimming mode by

connecting pin 3 to pin 2 of JP1. Connect pin 1 to pin 2 of JP1 to enable open

lamp protection.

The OPEN/SD pin is used for both open-lamp detection and commanded

shutdown. When a voltage higher than 2.5 V is applied to OPEN/SD through

D1, the part enters the shutdown or sleep mode where the oscillator is inactive

and both outputs are high. In this mode, the part draws little current at the V

pin and the OPEN/SD pin.

If the part fails to achieve regulation before reaching minimum frequency

(comp >2.2 V), it causes an internal retry counter to increment and then

attempt another start up. If the application does not operate normally after 7

attempts, the controller enters an error-induced shutdown state removing

power to the load.

Design Procedure

DD

2-3

Page 18

Burst Dimming

2.7 Burst Dimming

Burst dimming can be implemented at the OPEN/SD pin at the cost of

open-lamp detection.

Connect pin 2 to pin 3 of JP1 to disable the open-lamp detection circuit during

burst dimming mode.

Since the feedback loop does not need to operate with minimum lamp current

(as with analog dimming), the feedback capacitor, C4, can be reduced to 22

nF to improve the response time when the lamp restrikes.

To implement burst dimming on the EVM, AD should be grounded to set

maximum lamp brightness. A low-frequency 0 V – 4 V square wave applied

to BD will modulate the lamp current between zero and full intensity at the

desired frequency. A low-frequency repetition rate greater than 120 Hz is

recommended to avoid visible flicker. Applying 5 V at BD forces the lamp

current to zero, where 0 V at BD will force maximum lamp current. The duty

cycle of the square wave determines the lamp brightness as a percent of rated

lamp current.

2.8 Clamp Circuit (Optional)

V

CLAMP

There is also a clamp circuit to limit the maximum secondary voltage.

This circuit is typically not needed since the CCFL strikes or the open-lamp

circuit triggers before destructive levels are reached.

If R5 and Q1 are added to the board, the peak clamp voltage for the EVM is

given by equation (6):

Since the feedback loop does not need to operate with minimum lamp current

(as with analog dimming), the feedback capacitor, C4, can be reduced to 22

nF to improve the response time when the lamp restrikes.

(

ǒ

+

1.5 V) V

The peak clamped voltage for the evaluation board is 2200V.

The evaluation board components can be modified depending on the

application requirements. A supply between 3 Vdc and 6 Vdc is required for

this board to operate a 270~450 V cold-cathode fluorescent lamp (CCFL) from

1 mA to 4.8 mA. The input voltage range changes with different voltage lamp.

be

R7)R8)R9)R11)R14)R16)R17)R18)R6)R4

Ǔ

R4

)

PEAK

(6)

2-4

Page 19

Chapter 3

Test Results

This chapter describes how to properly connect and setup the UCC2977EVM.

It also presents the test results, which cover efficiency, burst dimming, and

open-lamp protection.

Topic Page

3.1 Test Setup 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 T est Results 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Results

3-1

Page 20

Test Setup

3.1 Test Setup

3.1.1 Lighting CCFL

Figure 3–1.Test Setup

Power Supply

A power supply with a power capability of 6 V/0.5 A is required for this test.

Figure 3–1 shows the input/output connections to the SLUP178. Connect a

270-V lamp (BF3100–20B). Connect pin 1 to pin 2 of jumper JP1.

CCFL

Lamp

3-2

Page 21

3.1.2 Analog Dimming Test

For analog dimming, enable the open-lamp detection by connecting pin 1 to

pin 2 of jumper JP1. A power supply that has a power capability of 6 V/0.5 A

is required for this test. Figure 3–2 shows the input/output connections to the

SLUP178. The lamp intensity is controlled by V

wire of the lamp is as short as possible and the lamp reflector (if there is one)

is grounded to board ground. Do not let the high voltage wire cross any part

of the board.

Figure 3–2.Test Setup for Analog Dimming

Power Supply

Test Setup

(0~3 Vdc). Make sure the

AD

Power Supply

CCFL

Lamp

Test Results

3-3

Page 22

Test Setup

3.1.3 Burst Dimming Test

Connect pin 2 to pin 3 of JP1 to disable the open-lamp detection circuit during

burst dimming. A low frequency ( >100 Hz) 0~4 V square wave applied to BD

modulates the lamp current.

Figure 3–3.Test Setup for Burst Dimming

Power Supply

CCFL

Lamp

Function

Generator

+ –

3-4

Page 23

Test Results

3.2 Test Results

The test results for the SLUP178 are shown in this section.

Figure 3–4.Efficiency With a Low Profile Sumida Inductor (CDRH6D28; 22 µH, 128 mΩ,

6.7 × 6.7 × 3 mm)

EFFICIENCY

vs

90

85

80

75

70

65

Efficiency – %

60

55

50

3456

INPUT VOLTAGE

4.7 mA

4 mA

3 mA

2 mA

VI – Input Voltage – V

Figure 3–5.Efficiency With a High Profile Toko Inductor (646CY–220M; 22 µH,

115 mΩ, 7.6 × 7.6 × 5.1 mm)

EFFICIENCY

vs

90

85

80

75

70

65

Efficiency – %

60

55

50

3456

INPUT VOLTAGE

4.8 mA

2 mA

3 mA

VI – Input Voltage – V

4 mA

Test Results

3-5

Page 24

Test Results

Figure 3–6.Transformer Input/Output Voltages at VI = 3 V (CH1=Primary 1,

CH4=Primary 2, M1=Transformer Primary Voltage, CH3=Lamp Voltage)

Figure 3–7.Transformer Input/Output Voltages at VI = 6 V (CH1=Primary 1,

CH4=Primary 2, M1=Transformer Primary Voltage, CH3=Lamp Voltage)

Figure 3–8.Burst Dimming With 50% Duty Cycle (CH1=Burst Dimming Control Signal,

CH3=Lamp Voltage)

3-6

Page 25

Test Results

Figure 3–9.Burst Dimming With 80% Duty Cycle (CH1=Burst Dimming Control Signal,

CH3=Lamp Voltage)

Figure 3–10. Open Lamp Protection (CH1=Comp, C2=Open/SD)

Test Results

3-7

Page 26

3-8

Loading...

Loading...