Page 1

Using the UCC25630-1EVM-291

User's Guide

Literature Number: SLUUBQ8B

August 2017–Revised January 2017

Page 2

Contents

1 Introduction......................................................................................................................... 5

2 Description.......................................................................................................................... 5

2.1 Typical Applications...................................................................................................... 5

2.2 Features................................................................................................................... 5

2.3 Using the EVM with UCC256302 ...................................................................................... 6

2.4 Using the EVM with UCC256303 ...................................................................................... 6

2.5 Using the EVM with UCC256304 ...................................................................................... 6

3 Performance Specifications................................................................................................... 7

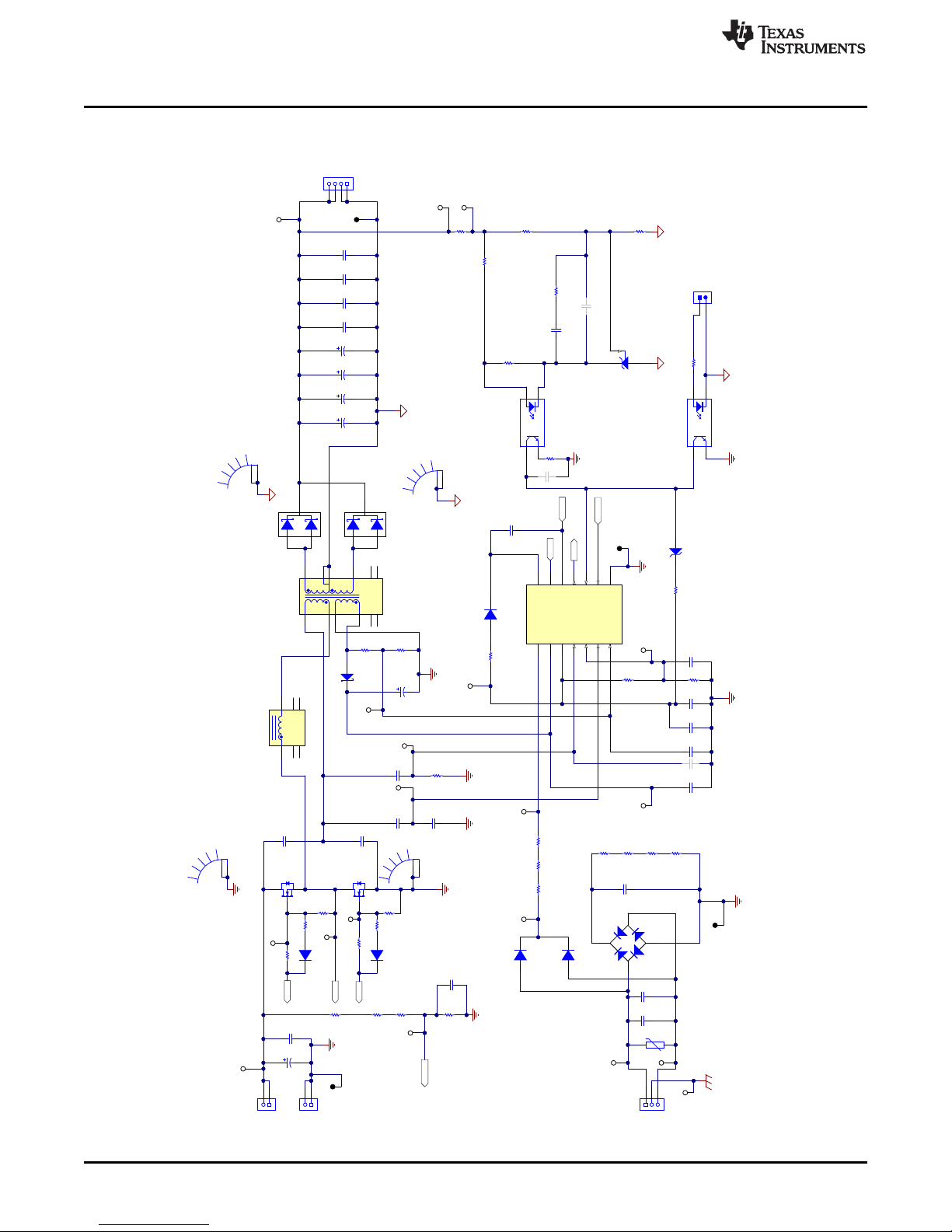

4 UCC25630-1EVM-291 Schematic ............................................................................................ 8

5 Test Setup........................................................................................................................... 9

5.1 Test Equipment........................................................................................................... 9

5.2 Recommended Test Setup at No Load.............................................................................. 10

5.3 Recommended Test Setup With Load............................................................................... 11

6 List of Test Points .............................................................................................................. 11

7 List of Terminals ................................................................................................................ 12

8 Test Procedure................................................................................................................... 12

8.1 Equipment Shutdown .................................................................................................. 12

9 Performance Data and Typical Characteristic Curves ............................................................. 13

9.1 Efficiency................................................................................................................. 13

9.2 Load Regulation ........................................................................................................ 13

9.3 Output Turn On ......................................................................................................... 14

9.4 Load Transient ......................................................................................................... 15

9.5 Output Voltage Ripple.................................................................................................. 16

9.6 Burst Mode at Light Load.............................................................................................. 16

9.7 Voltage on Resonant Capacitor....................................................................................... 17

9.8 X-Cap Discharge........................................................................................................ 17

9.9 Bode Plot ................................................................................................................ 18

9.10 Switching Frequency vs. Load........................................................................................ 18

10 EVM Assembly Drawing and PCB Layout.............................................................................. 18

11 List of Materials ................................................................................................................. 21

Revision History.......................................................................................................................... 23

2

Table of Contents

Copyright © 2017, Texas Instruments Incorporated

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Page 3

www.ti.com

1 UCC25630-1EVM-291 Schematic......................................................................................... 8

2 UCC25630-1EVM-291 Recommended Test Setup for No Load..................................................... 10

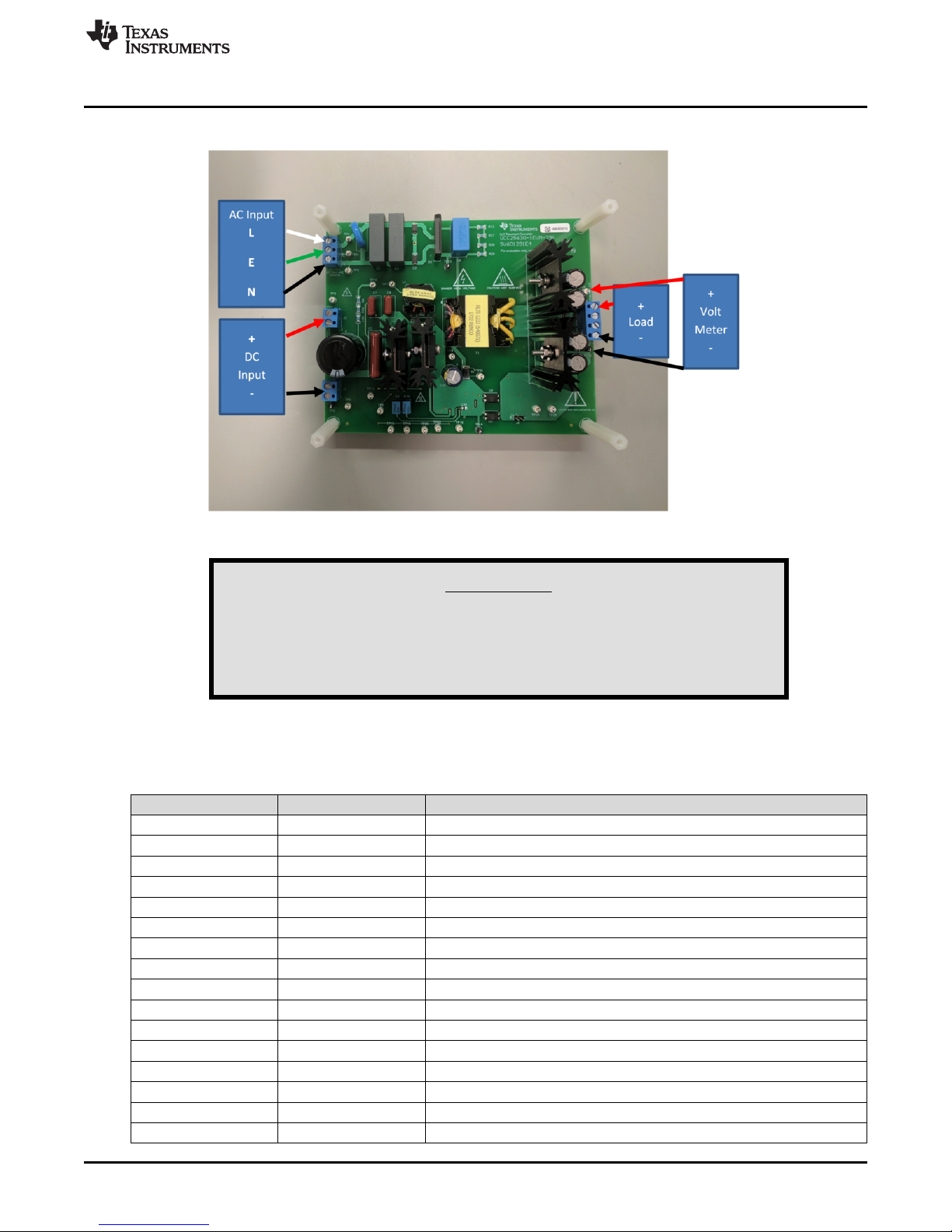

3 UCC25630-1EVM-291 Recommended Test Setup With Load....................................................... 11

4 UCC25630-1EVM-291 Efficiency ........................................................................................ 13

5 UCC25630-1EVM-291 Load Regulation ................................................................................ 13

6 Output Turn On at 390 VDC with Full Load (10 A) .................................................................... 14

7 Output Turn On at 390 VDC with No Load ............................................................................. 14

8 No Load (0 A) to Full Load (10 A) Transient (Ch1 = I

9 Full Load (10 A) to No Load (0 A) Transient (Ch1 = I

10 Output Voltage Ripple at V

11 Burst Mode at Vin= 390-V and 100-mA Load (Ch3 = V

12 Voltage on Resonant Capacitor (Vin= 390-V and 10-A Load, Ch1 = V

13 X-Cap Discharge ........................................................................................................... 17

14 Bode Plot at V

15 Switching Frequency vs. Load (V

16 UCC25630-1EVM-291 Top Layer Assembly Drawing (Top View)................................................... 19

17 UCC25630-1EVM-291 Bottom Layer Assembly Drawing (Bottom View)........................................... 19

18 UCC25630-1EVM-291 Top Copper (Top View)........................................................................ 20

19 UCC25630-1EVM-291 Bottom Copper (Top View).................................................................... 20

List of Figures

; Ch3 = V

out

; Ch3 = V

out

= 390-V and 10-A Load ................................................................. 16

in

; Ch4 = LO).............................................. 16

out

= 390 V and 10 A Load ................................................................................ 18

in

= 390 V)............................................................................ 18

in

)................................................ 15

out

)................................................ 15

out

; Ch4 = LO)........................... 17

RES

List of Tables

1 UCC25630-1EVM-291 Specifications..................................................................................... 7

2 UCC25630-1EVM-291 Typical No Load and Standby Power ......................................................... 7

3 Test Points .................................................................................................................. 11

4 Terminals.................................................................................................................... 12

5 UCC25630-1EVM-291 List of Materials ................................................................................. 21

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

List of Figures

3

Page 4

WARNING

General Texas Instruments High Voltage Evaluation (TI HV EVM) User Safety Guidelines

Always follow TI’s setup and application instructions, including use of all interface components within their

recommended electrical rated voltage and power limits. Always use electrical safety precautions to help

ensure your personal safety and those working around you. Contact TI's Product Information Center

http://support/ti./com for further information.

Save all warnings and instructions for future reference.

Failure to follow warnings and instructions may result in personal injury, property damage, or

death due to electrical shock and burn hazards.

The term TI HV EVM refers to an electronic device typically provided as an open framed, unenclosed

printed circuit board assembly. It is intended strictly for use in development laboratory environments,

solely for qualified professional users having training, expertise and knowledge of electrical safety

risks in development and application of high voltage electrical circuits. Any other use and/or

application are strictly prohibited by Texas Instruments. If you are not suitable qualified, you should

immediately stop from further use of the HV EVM.

1. Work Area Safety

1. Keep work area clean and orderly.

2. Qualified observer(s) must be present anytime circuits are energized.

3. Effective barriers and signage must be present in the area where the TI HV EVM and its interface

electronics are energized, indicating operation of accessible high voltages may be present, for the

purpose of protecting inadvertent access.

4. All interface circuits, power supplies, evaluation modules, instruments, meters, scopes and other

related apparatus used in a development environment exceeding 50Vrms/75VDC must be

electrically located within a protected Emergency Power Off EPO protected power strip.

5. Use stable and nonconductive work surface.

6. Use adequately insulated clamps and wires to attach measurement probes and instruments. No

freehand testing whenever possible.

2. Electrical Safety

As a precautionary measure, it is always a good engineering practice to assume that the entire EVM

may have fully accessible and active high voltages.

1. De-energize the TI HV EVM and all its inputs, outputs and electrical loads before performing any

electrical or other diagnostic measurements. Revalidate that TI HV EVM power has been safely

de-energized.

2. With the EVM confirmed de-energized, proceed with required electrical circuit configurations,

wiring, measurement equipment connection, and other application needs, while still assuming the

EVM circuit and measuring instruments are electrically live.

3. After EVM readiness is complete, energize the EVM as intended.

WARNING: WHILE THE EVM IS ENERGIZED, NEVER TOUCH THE EVM OR ITS ELECTRICAL

CIRCUITS AS THEY COULD BE AT HIGH VOLTAGES CAPABLE OF CAUSING ELECTRICAL

SHOCK HAZARD.

3. Personal Safety

1. Wear personal protective equipment (for example, latex gloves or safety glasses with side shields)

or protect EVM in an adequate lucent plastic box with interlocks to protect from accidental touch.

Limitation for safe use:

EVMs are not to be used as all or part of a production unit.

www.ti.com

4

List of Tables

Copyright © 2017, Texas Instruments Incorporated

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Page 5

1 Introduction

This EVM, UCC25630-1EVM-291, is used to help evaluate the UCC256301 LLC control device in digital

TV SMPS, AC-DC power adapter, LED lighting, etc. applications and then to aid their design. The EVM is

a standalone LLC resonant half-bridge DC-DC power converter. The EVM, UCC25630-1EVM-291, can be

used as it is delivered without additional work to evaluate an LLC resonant half-bridge DC-DC converter.

This user’s guide provides basic evaluation instruction from a viewpoint of system operation in standalone

LLC resonant half-bridge DC-DC power converter.

2 Description

UCC25630-1EVM-291 is an EVM for an LLC resonant half-bridge DC-DC power converter with LLC

controller UCC256301. UCC25630-1EVM-291 accepts DC line input from 340 VDC to 410 VDC, AC input

voltage from 85 VAC to 264 VAC, and a nominal output of 12 VDC with a full-load output power of 120 W,

or a full output current of 10 A.

NOTE: This EVM does not have an input fuse, and relies on an input current limit from its input

voltage source.

User's Guide

SLUUBQ8B–August 2017–Revised January 2017

Using the UCC25630-1EVM-291

2.1 Typical Applications

• Digital TV SMPS

• AC-DC Power Adapters

• Enterprise Server Applications

• LED Lighting Applications

2.2 Features

• Hybrid Hysteretic Controlled LLC Resonant Half-Bridge DC-DC Power Conversion

• DC Line Input from 340 VDC to 410 VDC

• AC Input Voltage from 85 VDC to 264 VAC

• Regulated 12-VDC Output, from No-Load to Full-Load

• Full-Load Power of 120 W, or Full-Load Current of 10 A

• High Efficiency

• Optimized Low Power Features Enable Extremely Low Standby Power

• Advanced Burst Mode with Adaptive Threshold

• Improved Capacitive Region Avoidance Scheme

• Adaptive Dead-Time

• X-Capacitor Discharge

• Over Temperature, Output Over Voltage, and Three Level Over Current Protections

• Test Points to Facilitate Device and Topology Evaluation

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Using the UCC25630-1EVM-291

5

Page 6

Description

2.3 Using the EVM with UCC256302

To use this EVM with UCC256302:

• Replace U1 with UCC256302

• Remove D1, D2

• Connect TP10 to TP5

2.4 Using the EVM with UCC256303

UCC25630-1EVM-291 is designed for UCC256301. With a slightly modification, this EVM can be used for

UCC256303. To use this EVM with UCC256303:

• Replace U1 with UCC256303

• Remove R11, D4

• Connect pin1 (HV) of U1 to PGND

• Connect external bias (11.25V - 26V) to TP21

2.5 Using the EVM with UCC256304

To use this EVM with UCC256304:

• Replace U1 with UCC256304

• Change R4 to 44.2 kΩ

www.ti.com

6

Using the UCC25630-1EVM-291

Copyright © 2017, Texas Instruments Incorporated

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Page 7

www.ti.com

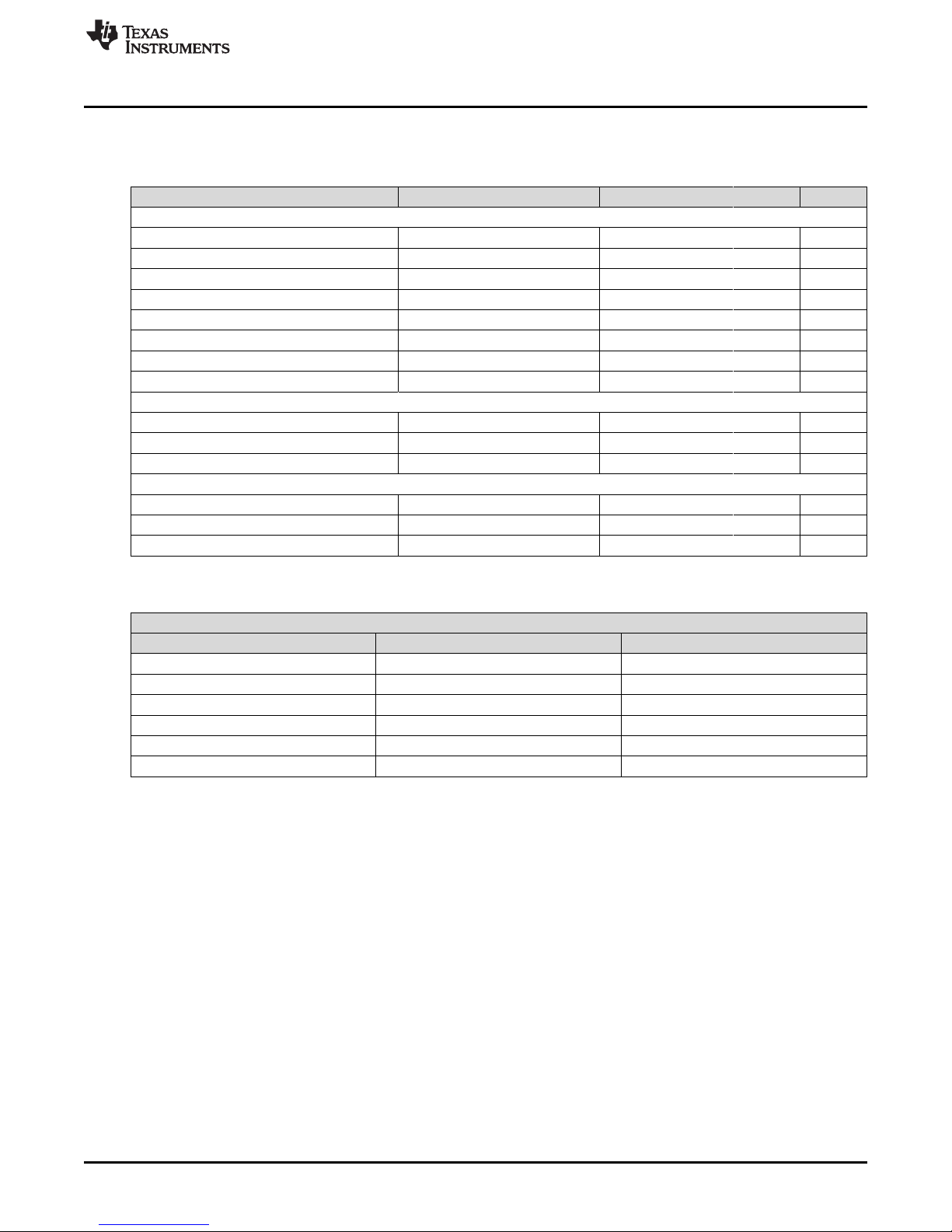

3 Performance Specifications

Table 1. UCC25630-1EVM-291 Specifications

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

INPUT CHARACTERISTICS

DC voltage range 340 390 410 VDC

AC voltage range 85 264 VAC

AC voltage frequency 47 63 Hz

Input DC UVLO On 320 VDC

Input DC UVLO Off 140 VDC

Input DC current Input = 340 VDC, full load = 10 A 0.383 A

Input DC current Input = 390 VDC, full load = 10 A 0.331 A

Input DC current Input = 410 VDC, full load = 10 A 0.315 A

OUTPUT CHARACTERISTICS

V

I

OUT

OUT

Output voltage No load to full load = 10 A 12 VDC

Output load current 340 to 410 VDC 10 A

Output voltage ripple 390 VDC and full load = 10 A 130 mVpp

SYSTEM CHARACTERISTICS

Switching frequency 53 160 kHz

Peak efficiency 390 VDC, load = 8 A 92.9%

Operating temperature Natural convection 25 ºC

Performance Specifications

Table 2. UCC25630-1EVM-291 Typical No Load and Standby Power

VIN= 390 V

INPUT POWER (mW) OUTPUT POWER (mW) POWER LOSS (mW)

39.7 0 39.7

163.7 103.0 60.6

295.0 201.2 93.8

421.7 299.0 122.7

548.0 401.6 146.4

674.0 498.6 175.4

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Using the UCC25630-1EVM-291

7

Page 8

~

3

+

1

~

2

4

D3

GBU8J-BP

1uF

C3

1uF

C4

MURA160T3G

D1

MURA160T3G

D2

0.47µF

C6

HV1VCC

3

BLK

4

FB

5

ISNS6VCR7BW8LL/SS

9

LO

10

GND

11

RVCC

12

HB

14

HO

15

HS

16

U1

UCC25630-1DDB

470µF

C20

470µF

C21

470µF

C22

470µF

C23

TP4

TP1

TP3

TP5

TP2

TP10

TP7

TP12

TP11

TP23

HS2

HS1

PGND

SGND

PGND

PGND

EARTH

PGND

HS3

HS4

SGND

SGND

Q1

SPW20N60CFD

Q2

SPW20N60CFD

10pF

C29

DNP

0.047µF

C28

10.0k

R22

SGND

PGND

147k

R25

16.9k

R26

SGND

1

2 3

U4

TLVH431AQPK

6.04k

R20

2.2

R16

2.2µF

C18

LO

HO

HO

LO

HS

HS

1

2

4

3

U2

VO618A-3

42.2k

R17

10.0k

R18

PGND

3.9pF

C13

2.2µF

C12

4.7µF

C15

4.99M

R1

4.99MR24.99M

R3

140k

R4

PGND

BLK

BLK

PGND

0.022µF

C7

PGND

TP19

120µF

C16

0.15µF

C17

220pF

C5

TP6

RV1

MOV-14D621K

12V Vout

85V - 264V AC Input

TP8

TP9

22µF

C24

0.022µF

C8

1.5 µF

C2

402k

R15

732k

R14

357

R13

PGND

PGND

1.65k

R10

1.65k

R9

0

R24

TP17

TP18

10.0

R5

10.0

R6

5.11k

R7

5.11k

R8

10.0M

R28

TP13

60V

D4

6.04k

R23

NC8NC

11

5

1103

1279

6

NC2NC

4

T1

J2

J3

+

-

+

-

150pF

C11

TP20

TP16

TP15

1

2

4

3

U3

VO618A-3

PGND

2.00k

R19

SGND

J4

External disable

22µF

C25

22µF

C26

22µF

C27

123

D6

STPS41H100CTY

123

D7

STPS41H100CTY

D5

ES1JAF

47µF

C1

J1

10.0M

R27

10.0M

R12

10.0M

R29

TP22

1.65k

R11

J5

3300pF

C30

DNP

1.00

R30

D8

1N4148W-7-F

D9

1N4148W-7-F

TP14

TP21

4.7µF

C14

0

R32

10pF

C19

DNP

10.0k

R21

D10

MMSZ5234B-7-F

0.015µF

C10

150pF

C9

1.00

R31

3

4

NC1NC

2

NC5NC

6

50µHL1

Copyright © 2017, Texas Instruments Incorporated

UCC25630-1EVM-291 Schematic

4 UCC25630-1EVM-291 Schematic

www.ti.com

8

Using the UCC25630-1EVM-291

Figure 1. UCC25630-1EVM-291 Schematic

Copyright © 2017, Texas Instruments Incorporated

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Page 9

www.ti.com

5 Test Setup

5.1 Test Equipment

DC Voltage Source: capable of 340 VDC to 410 VDC, adjustable, with minimum power rating 200 W, or

current rating not less than 1 A, with current limit function. The DC voltage source to be used should meet

IEC60950 reinforced insulation requirement.

AC Voltage Source: capable of single-phase output AC voltage 85 VAC to 264 VAC, 47 Hz to 63 Hz,

adjustable with minimum power rating 100 W. The AC voltage source to be used should meet IEC60950

reinforced insulation requirement.

DC Digital Multimeter: One unit capable of 0-VDC to 450-VDC input range, four digit display preferred;

and one unit capable of 0-VDC to 20-VDC input range, four digit display preferred.

Output Load: DC load capable of receiving 0 VDC to 20 VDC, 0 A to 15 A, and 0 W to 200 W or greater,

with the capability to display things such as load current and load power.

Current Meter: DC, optional in case the load has no display, one unit, capable of 0 A to 15 A. If you want

to measure standby power, the current meter needs to have a time averaging function.

Oscilloscope: capable of 500-MHz full bandwidth, digital or analog, if digital, 5 Gs/s or better.

Fan: 200-LFM to 400-LFM forced air cooling is recommended, but not required.

Recommended Wire Gauge: capable of 15 A, or better than #14 AWG, with the total length of wire less

than 8 feet (4 feet input and 4 feet return).

Test Setup

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Using the UCC25630-1EVM-291

9

Page 10

Test Setup

5.2 Recommended Test Setup at No Load

Figure 2 shows the equipment setup for testing at no load. It is important to note that in this setup, current

drawn by the voltage meter does not flow through the current meter.

Also, do not connect oscilloscope probes or any other sensing devices to the unit while measuring no-load

power, as these can provide a path for common mode current to flow. This causes an error in the

measurements.

During the no-load test, the current meter should be set to long-averaging mode and a few minutes should

be allowed for the reading to be accurate. Additionally, an appropriate current scale factor should be used.

www.ti.com

Figure 2. UCC25630-1EVM-291 Recommended Test Setup for No Load

10

Using the UCC25630-1EVM-291

Copyright © 2017, Texas Instruments Incorporated

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Page 11

www.ti.com

5.3 Recommended Test Setup With Load

Figure 3. UCC25630-1EVM-291 Recommended Test Setup With Load

Test Setup

High voltages that may cause injury exist on this evaluation

module (EVM). Please ensure all safety procedures are followed

when working on this EVM. Never leave a powered EVM

unattended.

6 List of Test Points

TEST POINTS NAME DESCRIPTION

TP1 EARTH AC earth

TP2 VIN_N Input voltage return terminal

TP3 AC_N AC neutral

TP4 AC_L AC line

TP5 VIN_P Input voltage positive terminal

TP6 BLK Input voltage sensing

TP7 HS Primary-side switch node, or the intersection of Q1 and Q2

TP8 HO Primary-side high side MOSFET gate, Q1

TP9 LO Primary-side low side MOSFET gate, Q2

TP10 AC_R AC rectifier output

TP11 VOUT_P Output voltage positive terminal

TP12 HV High-voltage start pin

TP13 PGND Primary-side ground

TP14 PGND Primary-side ground

TP15 VCR Resonant capacitor voltage sense

TP16 ISNS Resonant current sense

WARNING

Table 3. Test Points

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Using the UCC25630-1EVM-291

11

Page 12

List of Terminals

TEST POINTS NAME DESCRIPTION

TP17 INJECT1 Small signal injection terminal

TP18 INJECT2 Small signal injection terminal

TP19 BW Bias winding voltage sense

TP20 RVCC Regulated 12-V supply

TP21 VCC Supply input

TP22 LL/SS Soft-start and light-load burst mode threshold

TP23 VOUT_N Output voltage return terminal

7 List of Terminals

TERMINAL NAME DESCRIPTION

J1 AC Input 3-pin, AC power input, 85 V to 265 V

J2 VIN_P Input voltage positive terminal

J3 VIN_N Input voltage return terminal

J4 DISABLE External disable terminal

J5 VOUT Output voltage terminal, 4-pin

www.ti.com

Table 3. Test Points (continued)

Table 4. Terminals

8 Test Procedure

1. Refer to Figure 3 for basic setup. The required equipment for this measurement is listed in Section 5.1.

2. Before making electrical connections, visually check the board to make sure there are no suspected

spots of damage.

3. Keep the DC voltage source output off, connect it to J2 (+) and J3 (-). The DC voltage source should

be isolated and meet the IEC60950 requirement. Set the DC output voltage within the range specified

in Table 1, between 340 VDC and 410 VDC; set the DC source current limit to 1 A.

NOTE: The board has no fuse installed and relies on the external voltage source current limit to

ensure circuit protection.

4. Connect an electronic load set to either constant current mode or constant resistance mode. The load

current range is from 0 A to 10 A.

5. Keep the AC voltage source output off, connect it to J1 with AC_line to J1-1, AC_earth to J1-2,

AC_neutral to J1-3. The AC voltage source should be isolated and meet the IEC60950 requirement.

Set the AC output voltage in the range specified in Table 1, between 85 VAC and 264 VAC; set the AC

source current limit to 200 mA.

6. If the load does not have a current or a power display, a current meter needs to be inserted between

the load and the board.

7. Connect a voltage meter across the load and set the meter’s scale to 20 VDC.

8. Turn on the AC voltage source output.

9. Turn on the DC voltage source output. Then the measurements can be made.

8.1 Equipment Shutdown

1. Shut down AC voltage source.

2. Shut down DC voltage source.

3. Shut down electronic load.

12

Using the UCC25630-1EVM-291

Copyright © 2017, Texas Instruments Incorporated

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Page 13

I

out

(A)

V

out

(V)

0 1 2 3 4 5 6 7 8 9 10

12.012

12.014

12.016

12.018

12.02

12.022

12.024

D002

I

out

(A)

Efficiency (%)

0 1 2 3 4 5 6 7 8 9 10

77

79

81

83

85

87

89

91

93

95

D001

www.ti.com

Performance Data and Typical Characteristic Curves

9 Performance Data and Typical Characteristic Curves

Figure 4 through Figure 15 present typical performance curves for UCC25630-1EVM-291.

9.1 Efficiency

Figure 4. UCC25630-1EVM-291 Efficiency

9.2 Load Regulation

Figure 5. UCC25630-1EVM-291 Load Regulation

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Using the UCC25630-1EVM-291

13

Page 14

Performance Data and Typical Characteristic Curves

9.3 Output Turn On

www.ti.com

Figure 6. Output Turn On at 390 VDC with Full Load (10 A)

Figure 7. Output Turn On at 390 VDC with No Load

14

Using the UCC25630-1EVM-291

Copyright © 2017, Texas Instruments Incorporated

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Page 15

www.ti.com

9.4 Load Transient

Performance Data and Typical Characteristic Curves

Figure 8. No Load (0 A) to Full Load (10 A) Transient (Ch1 = I

; Ch3 = V

out

out

)

Figure 9. Full Load (10 A) to No Load (0 A) Transient (Ch1 = I

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

; Ch3 = V

out

Using the UCC25630-1EVM-291

out

)

15

Page 16

Performance Data and Typical Characteristic Curves

9.5 Output Voltage Ripple

www.ti.com

Figure 10. Output Voltage Ripple at Vin= 390-V and 10-A Load

9.6 Burst Mode at Light Load

Figure 11. Burst Mode at Vin= 390-V and 100-mA Load (Ch3 = V

16

Using the UCC25630-1EVM-291

Copyright © 2017, Texas Instruments Incorporated

; Ch4 = LO)

out

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Page 17

www.ti.com

9.7 Voltage on Resonant Capacitor

Performance Data and Typical Characteristic Curves

Figure 12. Voltage on Resonant Capacitor (Vin= 390-V and 10-A Load, Ch1 = V

9.8 X-Cap Discharge

; Ch4 = LO)

RES

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Figure 13. X-Cap Discharge

Copyright © 2017, Texas Instruments Incorporated

Using the UCC25630-1EVM-291

17

Page 18

Load Current (A)

Frequency (kHz)

1 2 3 4 5 6 7 8 9 10

82.5

85

87.5

90

92.5

95

97.5

D003

Performance Data and Typical Characteristic Curves

www.ti.com

(Test condition: VAC= 264 V

, disconnected AC randomly, discharge time from 373 VAC to below 30 V:

RMS

700 ms)

9.9 Bode Plot

Figure 14. Bode Plot at Vin= 390 V and 10 A Load

9.10 Switching Frequency vs. Load

Figure 15. Switching Frequency vs. Load (Vin= 390 V)

10 EVM Assembly Drawing and PCB Layout

Figure 16 through Figure 19 show the design of the UCC25630-1EVM-291 printed circuit board. PCB

dimensions: L x W = 5.9 x 4.8 in, PCB material: FR4 or compatible, two layers and 2 oz copper on each

layer.

18

Using the UCC25630-1EVM-291

Copyright © 2017, Texas Instruments Incorporated

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Page 19

www.ti.com

EVM Assembly Drawing and PCB Layout

Figure 16. UCC25630-1EVM-291 Top Layer Assembly Drawing (Top View)

Figure 17. UCC25630-1EVM-291 Bottom Layer Assembly Drawing (Bottom View)

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Using the UCC25630-1EVM-291

19

Page 20

EVM Assembly Drawing and PCB Layout

www.ti.com

Figure 18. UCC25630-1EVM-291 Top Copper (Top View)

Figure 19. UCC25630-1EVM-291 Bottom Copper (Top View)

20

Using the UCC25630-1EVM-291

Copyright © 2017, Texas Instruments Incorporated

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Page 21

www.ti.com

11 List of Materials

DES QTY DESCRIPTION PART NUMBER MANUFACTURER

PCB1 1 Printed Circuit Board SV601291 Any

C1 1 Capacitor, aluminum, 47 µF, 450 V, ±20%, 2.82 ohm, TH B43501A5476M000 TDK

C2 1 Capacitor, film, 1.5uF, 450V, ±10%, TH ECQ-E2W155KH Panasonic

C3, C4 2 Capacitor, film, 1uF, 275V, ±20%, TH R46KN410000P0M Kemet

C5 1 Capacitor, ceramic, 220 pF, 50 V, ±10%, X7R, 0603 GRM188R71H221KA

C6 1 Capacitor, film, 0.47 µF, 630 V, ±10%, TH B32922C3474K TDK

C7, C8 2 Capacitor, film, 0.022 µF, 630 V, ±5%, TH ECWF6223JL Panasonic

C9, C11 2 Capacitor, film, 150 pF, 630 V, ±5%, TH PFR5151J630J11L4B

C10 1 Capacitor, ceramic, 0.015 µF, 25 V, ±5%, C0G/NP0, 0603 C0603C153J3GACTU Kemet

C12 1 Capacitor, ceramic, 2.2 µF, 35 V, ±10%, X5R, 0603 GRM188R6YA225KA

C13 1 Capacitor, ceramic, 3.9 pF, 50 V, ±6%, C0G/NP0, 0603 06035A3R9CAT2A AVX

C14, C15 2 Capacitor, ceramic, 4.7 µF, 16 V, ±10%, X5R, 0603 GRM188R61C475KAAJMuRata

List of Materials

Table 5. UCC25630-1EVM-291 List of Materials

MuRata

01D

Kemet

ULK

MuRata

12D

C16 1 Capacitor, aluminum, 120 µF, 63 V, ± 20%, 0.194 ohm,

C17 1 Capacitor, ceramic, 0.15 µF, 16 V, ±20%, Y5V, 0603 C0603C154Z4VACTU Kemet

C18 1 Capacitor, ceramic, 2.2 µF, 16 V, ±10%, X7R, 1206 C1206C225K4RACTU Kemet

C19 0 Capacitor, ceramic, 10 pF, 50 V, ±5%, C0G/NP0, 0603 06035A100JAT2A AVX

C20, C21,

C22, C23

C24, C25,

C26, C27

C28 1 Capacitor, ceramic, 0.047 µF, 16 V, ±10%, X7R, 0603 GRM188R71C473KA

C29 0 Capacitor, ceramic, 10 pF, 50 V, ±5%, C0G/NP0, 0603 06035A100JAT2A AVX

C30 0 Capacitor, ceramic, 3300 pF, 50 V, ±5%, C0G/NP0, 0603 GRM1885C1H332JA01DMuRata

D1, D2 2 Diode, Ultrafast, 600 V, 1 A, SMA MURA160T3G ON Semiconductor

D3 1 Diode, Switching-Bridge, 420 V, 8 A, TH GBU8J-BP Micro Commercial

D4 1 Diode, Schottky, 60 V, 1 A, AEC-Q101, SMB STPS160UY STMicroelectronics

D5 1 Diode, Ultrafast, 600 V, 1 A, AEC-Q101, SMAF ES1JAF Fairchild

D6, D7 2 Diode, Schottky, 100 V, 20 A, AEC-Q101, TH STPS41H100CTY STMicroelectronics

D8, D9 2 Diode, Ultrafast, 100 V, 0.15 A, SOD-123 1N4148W-7-F Diodes Inc.

D10 1 Diode, Zener, 6.2 V, 500 mW, SOD-123 MMSZ5234B-7-F Diodes Inc.

H1, H3,

H5, H7

H2, H4,

H6, H8

H9, H11 2 TO-220 mounting kit 4880SG Aavid Thermalloy

H10, H12 2 TO-247 mounting kit 4880SG Aavid Thermalloy

H13, H14 2 Large thermal pad to substitute for the smaller one in the

HS1,

HS2,

HS3, HS4

J1 1 Terminal block, 5.08 mm, 3x1, brass, TH ED120/3DS On-Shore Technology

AEC-Q200 Grade 2, TH

4 Capacitor, aluminum, 470 µF, 35 V, ±20%, TH 35ZL470MEFC10X20 Rubycon

4 Capacitor, ceramic, 22 µF, 35 V, ± 20%, X5R, 0805 C2012X5R1V226M12

4 Hex standoff 1-1/2" L #6-32 nylon 4824 Keystone

4 Hex standoff 0.5"L #6-32 nylon 1903C Keystone

TO-247 Mounting Kit

4 Heatsink TO-220 w/pins 1.5" tall 531102B02500G Aavid

EEU-FC1J121 Panasonic

TDK

5AC

MuRata

01D

Components

Semiconductor

SP900S-0.009-00-104 Bergquist

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Using the UCC25630-1EVM-291

21

Page 22

List of Materials

DES QTY DESCRIPTION PART NUMBER MANUFACTURER

J2, J3 2 Terminal block, 5.08 mm, 2x1, brass, TH ED120/2DS On-Shore Technology

J4 1 Header, 100 mil, 2 x 1, tin, TH PEC02SAAN Sullins Connector

J5 1 Terminal block, 5.08 mm, 4x1, brass, TH ED120/4DS On-Shore Technology

L1 1 Inductor, 50 µH, 0.023 Ω, TH RLTI-1234 Renco Electronics

Q1, Q2 2 MOSFET, N-channel, 650 V, 20.7 A, TO-247 SPW20N60CFD Infineon Technologies

R1, R2,

R3

R4 1 Resistor, 140 kΩ, 1%, 0.1 W, 0603 CRCW0603140KFKEAVishay-Dale

R5, R6 2 Resistor, 10.0 Ω, 1%, 0.125 W, 0805 CRCW080510R0FKEAVishay-Dale

R7, R8 2 Resistor, 5.11 kΩ, 1%, 0.1W, 0603 CRCW06035K11FKEAVishay-Dale

www.ti.com

Table 5. UCC25630-1EVM-291 List of Materials (continued)

Solutions

3 Resistor, 4.99 MΩ, 1%, 0.25 W, 1206 CRCW12064M99FKEAVishay-Dale

R9, R10,

R11

R12, R27,

R28, R29

R13 1 Resistor, 357 Ω, 1%, 0.25 W, 1206 CRCW1206357RFKEAVishay-Dale

R14 1 Resistor, 732 kΩ, 1%, 0.1 W, 0603 CRCW0603732KFKEAVishay-Dale

R15 1 Resistor, 402 kΩ, 1%, 0.1 W, 0603 CRCW0603402KFKEAVishay-Dale

R16 1 Resistor, 2.2 Ω, 5%, 0.1 W, 0603 CRCW06032R20JNEAVishay-Dale

R17 1 Resistor, 42.2 kΩ, 1%, 0.1 W, 0603 CRCW060342K2FKEAVishay-Dale

R18, R21,

R22

R19 1 Resistor, 2.00 kΩ, 1%, 0.1 W, 0603 CRCW06032K00FKEAVishay-Dale

R20, R23 2 Resistor, 6.04 kΩ, 1%, 0.1 W, 0603 CRCW06036K04FKEAVishay-Dale

R24, R32 2 Resistor, 0 Ω, 5%, 0.1 W, 0603 CRCW06030000Z0EAVishay-Dale

R25 1 Resistor, 147 kΩ, 1%, 0.1 W, 0603 CRCW0603147KFKEAVishay-Dale

R26 1 Resistor, 16.9 kΩ, 1%, 0.1 W, 0603 CRCW060316K9FKEAVishay-Dale

R30, R31 2 Resistor, 1.00 Ω, 1%, 0.125 W, 0805 CRCW08051R00FKEAVishay-Dale

3 Resistor, 1.65 kΩ, 1%, 0.25 W, 1206 CRCW12061K65FKEAVishay-Dale

4 Resistor, 10.0 MΩ, 1%, 0.25 W, 1206 CRCW120610M0FKEAVishay-Dale

3 Resistor, 10.0 kΩ, 1%, 0.1 W, 0603 CRCW060310K0FKEAVishay-Dale

RV1 1 Varistor 558 V 4.5KA, TH MOV-14D621K Bourns

T1 1 Transformer, 840 µH, TH RLTI-1233 Renco Electronics

22

Using the UCC25630-1EVM-291

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Page 23

www.ti.com

Revision History

Table 5. UCC25630-1EVM-291 List of Materials (continued)

DES QTY DESCRIPTION PART NUMBER MANUFACTURER

TP1, TP3,

TP4, TP5,

TP6, TP7,

TP8, TP9,

TP10,

TP11,

TP12,

TP15,

TP16,

TP17,

TP18,

TP19,

TP20,

TP21,

TP22

TP2,

TP13,

TP14,

TP23

U1 1 Enhanced LLC Resonant Controller with Driver,

U2, U3 2 Optocoupler, 5.3 kV, 50-600% CTR, TH VO618A-3 Vishay-Semiconductor

U4 1 Low-Voltage Adjustable Precision Shunt Regulator, 80

FID1,

FID2,

FID3,

FID4,

FID5,

FID6

19 Test point, multipurpose, white, TH 5012 Keystone

4 Test point, multipurpose, black, TH 5011 Keystone

UCC256301DDB Texas Instruments

DDB0014A

TLVH431AQPK Texas Instruments

mA, -40 to 125 degC, 3-pin SOT-89 (PK), Green (RoHS &

no Sb/Br)

0 Fiducial mark. There is nothing to buy or mount. N/A N/A

Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from A Revision (September 2017) to B Revision .......................................................................................... Page

• Added Using the EVM with UCC256302 section 2.3................................................................................. 6

Changes from Original (August 2017) to A Revision ..................................................................................................... Page

• Added Using the EVM with UCC256303 section 2.4................................................................................. 6

• Added Using the EVM with UCC256304 section 2.5................................................................................. 6

SLUUBQ8B–August 2017–Revised January 2017

Submit Documentation Feedback

Copyright © 2017, Texas Instruments Incorporated

Revision History

23

Page 24

IMPORTANT NOTICE FOR TI DESIGN INFORMATION AND RESOURCES

Texas Instruments Incorporated (‘TI”) technical, application or other design advice, services or information, including, but not limited to,

reference designs and materials relating to evaluation modules, (collectively, “TI Resources”) are intended to assist designers who are

developing applications that incorporate TI products; by downloading, accessing or using any particular TI Resource in any way, you

(individually or, if you are acting on behalf of a company, your company) agree to use it solely for this purpose and subject to the terms of

this Notice.

TI’s provision of TI Resources does not expand or otherwise alter TI’s applicable published warranties or warranty disclaimers for TI

products, and no additional obligations or liabilities arise from TI providing such TI Resources. TI reserves the right to make corrections,

enhancements, improvements and other changes to its TI Resources.

You understand and agree that you remain responsible for using your independent analysis, evaluation and judgment in designing your

applications and that you have full and exclusive responsibility to assure the safety of your applications and compliance of your applications

(and of all TI products used in or for your applications) with all applicable regulations, laws and other applicable requirements. You

represent that, with respect to your applications, you have all the necessary expertise to create and implement safeguards that (1)

anticipate dangerous consequences of failures, (2) monitor failures and their consequences, and (3) lessen the likelihood of failures that

might cause harm and take appropriate actions. You agree that prior to using or distributing any applications that include TI products, you

will thoroughly test such applications and the functionality of such TI products as used in such applications. TI has not conducted any

testing other than that specifically described in the published documentation for a particular TI Resource.

You are authorized to use, copy and modify any individual TI Resource only in connection with the development of applications that include

the TI product(s) identified in such TI Resource. NO OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO

ANY OTHER TI INTELLECTUAL PROPERTY RIGHT, AND NO LICENSE TO ANY TECHNOLOGY OR INTELLECTUAL PROPERTY

RIGHT OF TI OR ANY THIRD PARTY IS GRANTED HEREIN, including but not limited to any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

regarding or referencing third-party products or services does not constitute a license to use such products or services, or a warranty or

endorsement thereof. Use of TI Resources may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

TI RESOURCES ARE PROVIDED “AS IS” AND WITH ALL FAULTS. TI DISCLAIMS ALL OTHER WARRANTIES OR

REPRESENTATIONS, EXPRESS OR IMPLIED, REGARDING TI RESOURCES OR USE THEREOF, INCLUDING BUT NOT LIMITED TO

ACCURACY OR COMPLETENESS, TITLE, ANY EPIDEMIC FAILURE WARRANTY AND ANY IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF ANY THIRD PARTY INTELLECTUAL

PROPERTY RIGHTS.

TI SHALL NOT BE LIABLE FOR AND SHALL NOT DEFEND OR INDEMNIFY YOU AGAINST ANY CLAIM, INCLUDING BUT NOT

LIMITED TO ANY INFRINGEMENT CLAIM THAT RELATES TO OR IS BASED ON ANY COMBINATION OF PRODUCTS EVEN IF

DESCRIBED IN TI RESOURCES OR OTHERWISE. IN NO EVENT SHALL TI BE LIABLE FOR ANY ACTUAL, DIRECT, SPECIAL,

COLLATERAL, INDIRECT, PUNITIVE, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES IN CONNECTION WITH OR

ARISING OUT OF TI RESOURCES OR USE THEREOF, AND REGARDLESS OF WHETHER TI HAS BEEN ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES.

You agree to fully indemnify TI and its representatives against any damages, costs, losses, and/or liabilities arising out of your noncompliance with the terms and provisions of this Notice.

This Notice applies to TI Resources. Additional terms apply to the use and purchase of certain types of materials, TI products and services.

These include; without limitation, TI’s standard terms for semiconductor products http://www.ti.com/sc/docs/stdterms.htm), evaluation

modules, and samples (http://www.ti.com/sc/docs/sampterms.htm).

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2018, Texas Instruments Incorporated

Loading...

Loading...