TPS74301

TPS74301

www.ti.com

R

1

R

5

R

3

R

4

R

2

V

OUT

C

OUT

Optional

PG

OUT

FB

IN

BIAS

TRACK

GND

V

IN

V

BIAS

C

IN

C

BIAS

V

TRACK

V

PG

TPS74301

EN

500mV/div

Time(20ms/div)

V

PG

V

TRACK

I =500mA

OUT

V

OUT

1.5A Ultra-LDO with Programmable Sequencing

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

FEATURES

• Track Pin Allows for Flexible Power-Up

Sequencing

• 1% Accuracy Over Line, Load, and

Temperature

• Supports Input Voltages as Low as 0.9V with

External Bias Supply

• Adjustable Output (0.8V to 3.6V)

• Ultra-Low Dropout: 55mV at 1.5A (typ)

• Stable with Any or No Output Capacitor

• Excellent Transient Response

• Available in 5mm × 5mm × 1mm QFN and

DDPAK-7 Packages

• Open-Drain Power-Good (5 × 5 QFN)

• Active High Enable

APPLICATIONS

• FPGA Applications

• DSP Core and I/O Voltages

• Post-Regulation Applications

• Applications with Special Start-Up Time or

Sequencing Requirements

DESCRIPTION

The TPS74301 low-dropout (LDO) linear regulator

provides an easy-to-use robust power management

solution for a wide variety of applications. The

TRACK pin allows the output to track an external

supply. This feature is useful in minimizing the stress

on ESD structures that are present between the

CORE and I/O power pins of many processors. The

enable input and power-good output allow easy

sequencing with external regulators. This complete

flexibility allows the user to configure a solution that

meets the sequencing requirements of FPGAs,

DSPs, and other applications with special start-up

requirements.

A precision reference and error amplifier deliver 1%

accuracy over load, line, temperature, and process.

Each LDO is stable with low-cost ceramic output

capacitors and the device is fully specified from

–40 ° C to +125 ° C. The TPS74301 is offered in a

small (5mm × 5mm) QFN package, yielding a highly

compact total solution size. For applications that

require additional power dissipation, the DDPAK

(KTW) package is also available.

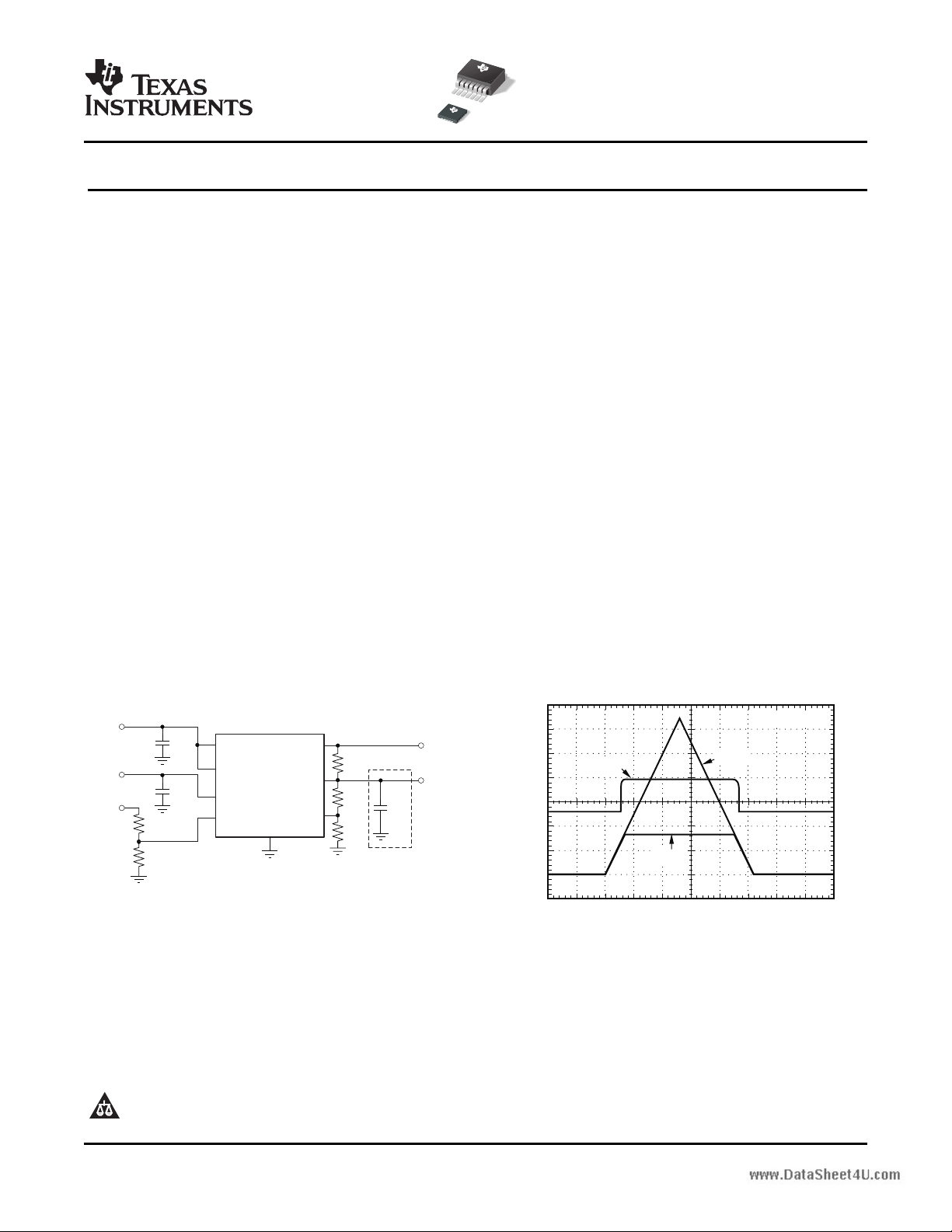

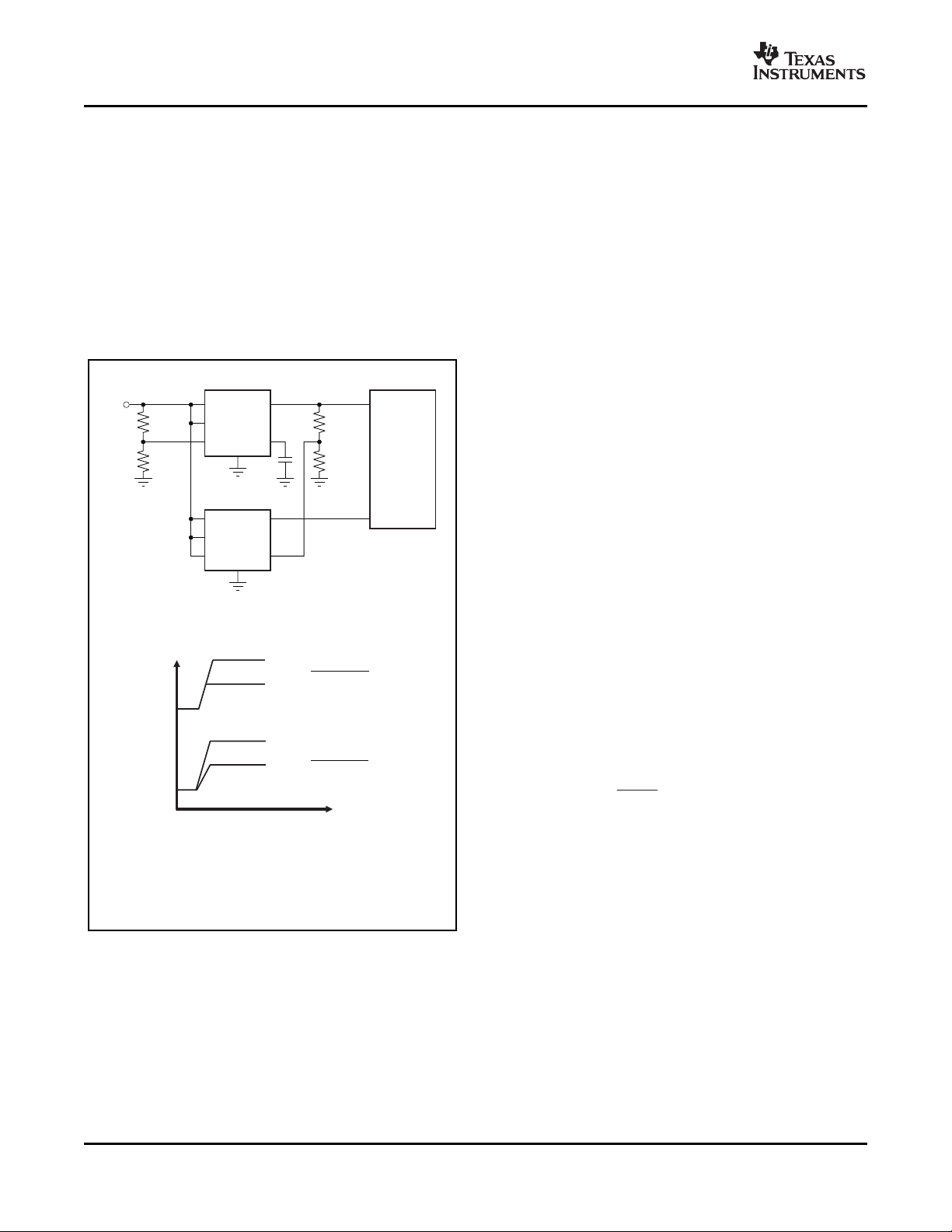

Figure 1. Typical Application Circuit

All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Figure 2. Tracking Response

Copyright © 2005–2007, Texas Instruments Incorporated

www.ti.com

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be

more susceptible to damage because very small parametric changes could cause the device not to meet its published

specifications.

ORDERING INFORMATION

PRODUCT V

TPS743 xxyyyz XX is nominal output voltage (for example, 12 = 1.2V, 15 = 1.5V, 01 = Adjustable).

(1)

(2)

OUT

(3)

YYY is package designator.

Z is package quantity.

(1) For the most current package and ordering information see the Package Option Addendum at the end of this document, or see the TI

website at www.ti.com .

(2) Output voltages from 0.9V to 1.5V in 50mV increments and 1.5V to 3.3V in 100mV increments are available through the use of

innovative factory EEPROM programming; minimum order quantities may apply. Contact factory for details and availability.

(3) For fixed 0.8V operation, tie FB to OUT.

ABSOLUTE MAXIMUM RATINGS

(1)

At TJ= –40 ° C to +125 ° C, unless otherwise noted. All voltages are with respect to GND.

TPS74301 UNIT

VIN, V

V

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only and functional operation of the device at these conditions is not implied. Exposure to absolute-maximum-rated conditions for

extended periods may affect device reliability.

Input voltage range –0.3 to +6 V

BIAS

V

Enable voltage range –0.3 to +6 V

EN

V

Power-good voltage range –0.3 to +6 V

PG

IPGPG sink current 0 to +1.5 mA

Track pin voltage range –0.3 to +6 V

TRACK

V

Feedback pin voltage range –0.3 to +6 V

FB

V

Output voltage range –0.3 to VIN+ 0.3 V

OUT

I

Maximum output current Internally limited

OUT

Output short circuit duration Indefinite

P

Continuous total power dissipation See Dissipation Ratings Table

DISS

TJOperating junction temperature range –40 to +125 ° C

T

Storage junction temperature range –55 to +150 ° C

STG

DISSIPATION RATINGS

PACKAGE θ

RGW (QFN)

KTW (DDPAK)

(1) See Figure 31 for PCB layout description.

(2) See Figure 34 for PCB layout description.

2

(1)

(2)

JA

36.5 ° C/W 4.05 ° C/W 2.74W 27.4mW/ ° C

18.8 ° C/W 2.32 ° C/W 5.32W 53.2mW/ ° C

θ

JC

POWER RATING ABOVE TA= +25 ° C

Submit Documentation Feedback

TA< +25 ° C DERATING FACTOR

www.ti.com

ELECTRICAL CHARACTERISTICS

At V

= 1.1V, V

EN

unless otherwise noted. Typical values are at TJ= +25 ° C.

V

IN

V

BIAS

V

REF

V

OUT

V

/V

OUT

IN

V

/I

OUT

OUT

V

DO

ICLCurrent limit V

I

BIAS

I

SHDN

IFBFeedback pin current

PSRR

Noise Output noise voltage 100Hz to 100kHz, I

V

TRAN

t

STR

T

ACC

ITRTrack pin current V

V

EN, HI

V

EN, LO

V

EN, HYS

V

EN, DG

IENEnable pin current V

V

IT

V

HYS

V

PG, LO

I

PG, LKG

T

J

T

SD

= V

OUT

+ 0.3V, C

IN

= C

IN

BIAS

= 0.1 µ F, C

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Input voltage range V

Bias pin voltage range 2.375 5.25 V

Internal reference (Adj.) TJ= +25 ° C 0.796 0.8 0.804 V

Output voltage range VIN= 5V, I

BIAS

IN

IN

BIAS

dropout voltage

)

to V

OUT

(1)

)

OUT

to V

OUT

droop during load

2.375V ≤ V

V

OUT (NOM)

V

OUT (NOM)

0mA ≤ I

50mA ≤ I

I

= 1.5A, V

(2)

OUT

I

= 1.5A, V

OUT

(2)

I

= 1.5A, VIN= V

OUT

= 80% × V

OUT

= 0mA to 1.5A 2 4 mA

OUT

V

≤ 0.4V 1 100 µ A

EN

(3)

I

= 50mA to 1.5A –250 68 250 nA

OUT

1kHz, I

800kHz, I

1kHz, I

)

800kHz, I

I

= 50mA to 1.5A at 1A/ µ s, C

OUT

TRACK

Accuracy

Line regulation %/V

Load regulation

VINdropout voltage

V

Bias pin current I

Shutdown supply current

(V

Power-supply rejection

(V

Power-supply rejection

(V

%V

transient

Minimum startup time V

Track pin accuracy 0.2V ≤ V

TRACK

= 1.5A, V

OUT

≤ 5.25V, 50mA ≤ I

BIAS

+ 0.3 ≤ VIN≤ 5.5V, QFN 0.0005 0.05

+ 0.3 ≤ VIN≤ 5.5V, DDPAK 0.0005 0.06

≤ 50mA 0.013 %/mA

OUT

≤ 1.5A 0.04 %/A

OUT

BIAS

BIAS

OUT (NOM)

= 1.5A, VIN= 1.8V, V

OUT

= 1.5A, VIN= 1.8V, V

OUT

= 1.5A, VIN= 1.8V, V

OUT

= 1.5A, VIN= 1.8V, V

OUT

> 0.8V 40 µ s

≤ 0.7V, V

TRACK

= 0.4V 0.1 1 µ A

Enable input high level 1.1 5.5 V

Enable input low level 0 0.4 V

Enable pin hysteresis 50 mV

Enable pin deglitch time 20 µ s

= 5V 0.1 1 µ A

EN

PG trip threshold V

decreasing 86.5 90 93.5 %V

OUT

PG trip hysteresis 3 %V

PG output low voltage IPG= 1mA (sinking), V

PG leakage current V

PG

= 5.25V, V

OUT

Operating junction

temperature

Thermal shutdown

temperature

Shutdown, temperature increasing +155

Reset, temperature decreasing +140

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

= 10 µ F, I

OUT

= 5V V

BIAS

– V

OUT (NOM)

– V

OUT (NOM)

BIAS

≥ 1.62V, QFN 55 100

≥ 1.62V, DDPAK 60 120

= 50mA, V

OUT

≤ 1.5A –1 ± 0.2 1 %

OUT

= 5.0V, and TJ= –40 ° C to +125 ° C,

BIAS

+ V

OUT

REF

1.8 4 A

= 1.5V 73

OUT

= 1.5V 42

OUT

= 1.5V 67

OUT

= 1.5V 50

OUT

= 1.5A 25 × V

OUT

= none 3.5 %V

OUT

= 0.8V –60 60 mV

OUT

< V

OUT

IT

> V

IT

–40 +125 ° C

TPS74301

TPS74301

DO

OUT

0.3 1 µ A

5.5 V

3.6 V

1.4 V

0.3 V

mV

dB

dB

µ V

RMS

OUT

OUT

OUT

° C

(1) Adjustable devices tested at 0.8V; external resistor tolerance is not taken into account.

(2) Dropout is defined as the voltage from the input to V

(3) IFBcurrent flow is out of the device.

when V

OUT

OUT

Submit Documentation Feedback

is 2% below nominal.

3

www.ti.com

Thermal

Limit

FB

PG

IN

BIAS

TRACK

EN

Hysteresis

andDe-Glitch

Current

Limit

UVLO

0.8V

Reference

0.9 V´

REF

GND

V <V =1,V >V =0

TRACK REF TRACK REF

V

OUT

R

1

R

2

V =0.8x( )

OUT

1+

R

1

R

2

1

0

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

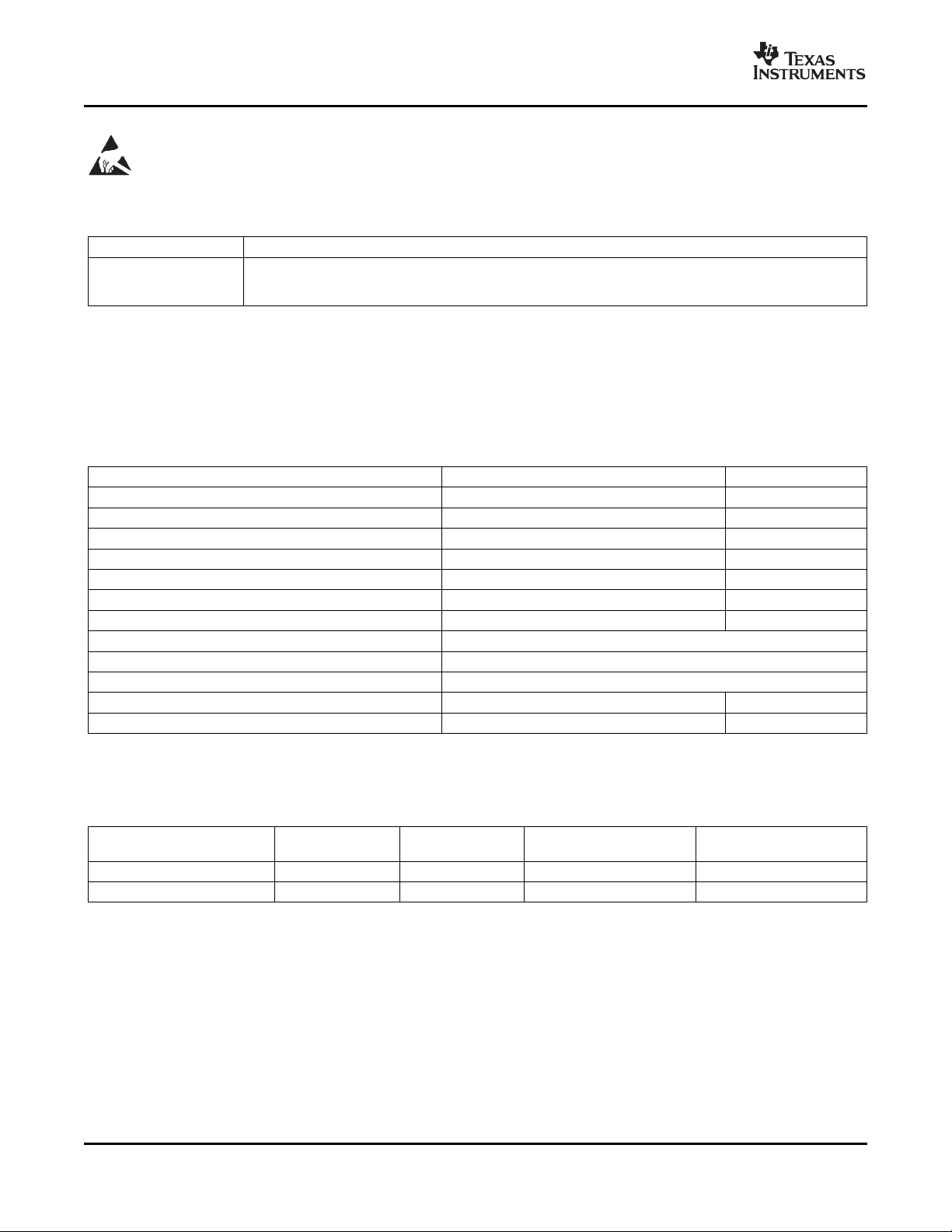

BLOCK DIAGRAM

(1) V

OUT

= 0.8 × (1 + R1/R2)

Table 1. Standard 1% Resistor Values for Programming the Output Voltage

R1(k Ω ) R2(k Ω ) V

Short Open 0.8

0.619 4.99 0.9

1.13 4.53 1.0

1.37 4.42 1.05

1.87 4.99 1.1

2.49 4.99 1.2

4.12 4.75 1.5

3.57 2.87 1.8

3.57 1.69 2.5

3.57 1.15 3.3

(1)

(V)

OUT

4

Submit Documentation Feedback

www.ti.com

IN

IN

IN

PG

BIAS

OUT

OUT

OUT

NC

FB

TPS74301

IN

EN

11

GND

12

NC

13

NC

14

TRACK

15

6

7

8

9

10

20

19

18

17

16

5

NC4

NC3

NC2

OUT1

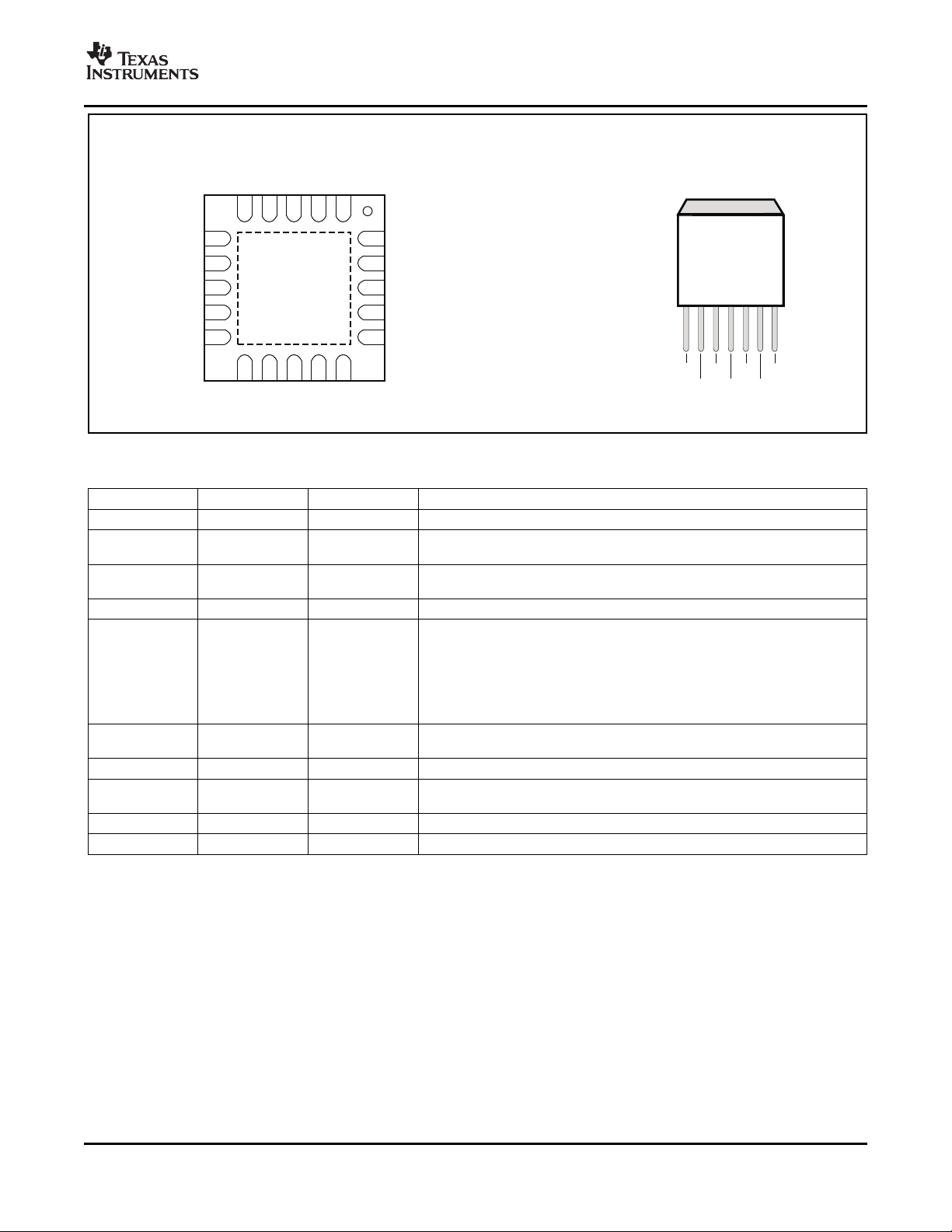

5 5QFN(RGW)´

Package TopView¾

7-Lead

DDPAK(KTW)

Surface-Mount

OUT

GND

BIAS

IN

FB

TRACK

1 2 3 4

5

6

EN

7

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

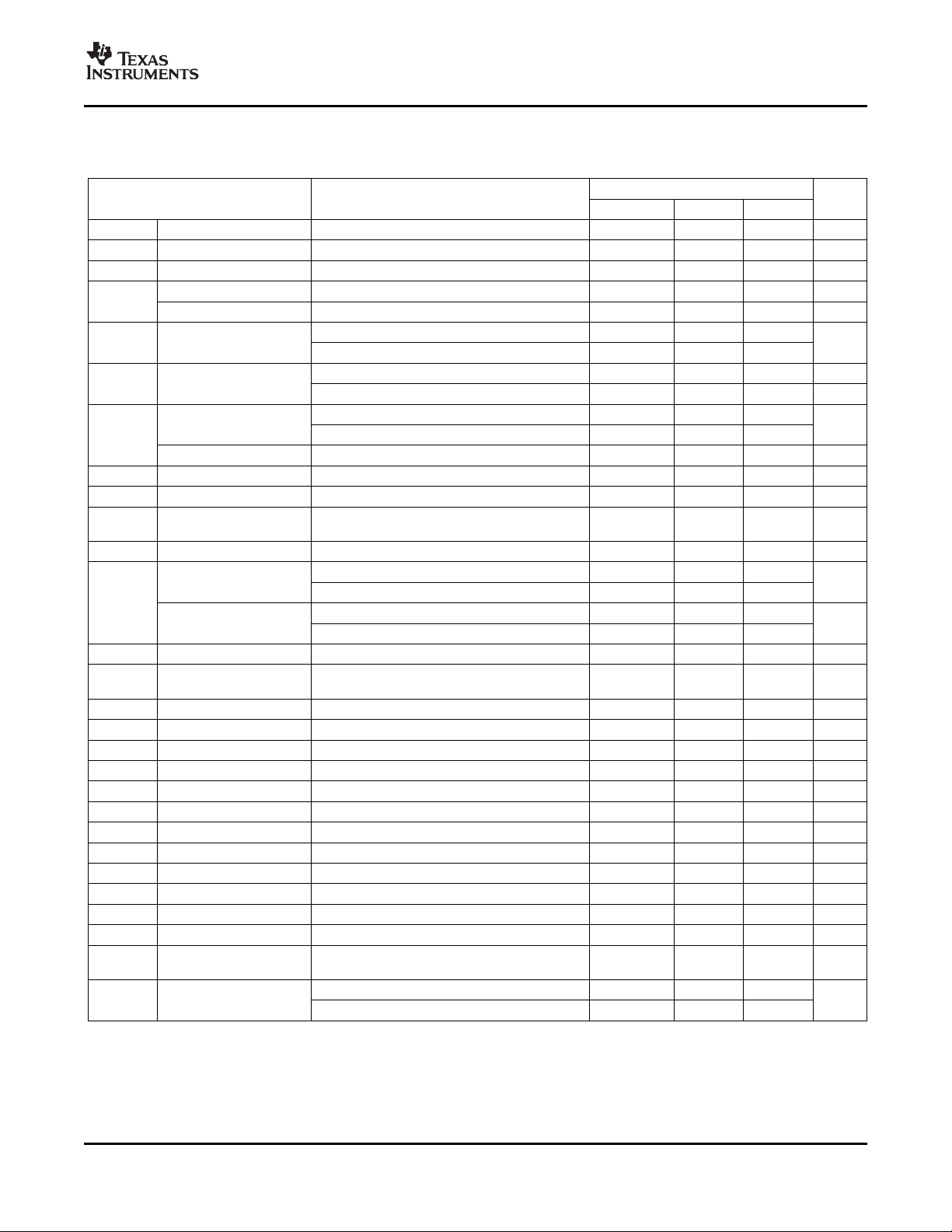

PIN DESCRIPTIONS

NAME KTW (DDPAK) RGW (QFN) DESCRIPTION

IN 5 5–8 Unregulated input to the device.

EN 7 11

TRACK 1 15

Enable pin. Driving this pin high enables the regulator. Driving this pin low puts

the regulator into shutdown mode. This pin must not be left floating.

Tracking pin. Connect this pin to the center tap of a resistor divider off of an

external supply to program the device to track an external supply.

BIAS 6 10 Bias input voltage for error amplifier, reference, and internal control circuits.

Power-Good (PG) is an open-drain, active-high output that indicates the status

of V

. When V

OUT

high-impedance state. When V

PG N/A 9 low-impedance state. A pull-up resistor from 10k Ω to 1M Ω should be

exceeds the PG trip threshold, the PG pin goes into a

OUT

OUT

connected from this pin to a supply up to 5.5V. The supply can be higher than

the input voltage. Alternatively, the PG pin can be left floating if output

monitoring is not necessary.

FB 2 16

This pin is the feedback connection to the center tap of an external resistor

divider network that sets the output voltage. This pin must not be left floating.

OUT 3 1, 18–20 Regulated output voltage. No capacitor is required on this pin for stability.

NC N/A 2–4, 13, 14, 17

No connection. This pin can be left floating or connected to GND to allow better

thermal contact to the top-side plane.

GND 4 12 Ground

PAD/TAB Should be soldered to the ground plane for increased thermal performance.

is below this threshold the pin is driven to a

Submit Documentation Feedback

5

www.ti.com

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

-0.1

0

10 20 30 40

ChangeinV (%)

OUT

I (mA)

OUT

50

+125 C°

+25 C°

-40 C°

ReferredtoI =50mA

OUT

0.050

0.025

0

-0.025

-0.050

-0.075

-0.100

-0.125

-0.150

50

500 1000

ChangeinV (%)

OUT

I (mA)

OUT

1500

+125 C°

+25 C°

- °40 C

ReferredtoI =50mA

OUT

0.05

0.04

0.03

0.02

0.01

0

-0.01

-0.02

-0.03

-0.04

-0.05

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

ChangeinV (%)

OUT

V V-

IN OUT

(V)

4.5

T = 40- °JC

TJ=+25°C

TJ=+125°C

100

75

50

25

0

0

0.5 1.0

DropoutVoltage(mV)

I (A)

OUT

1.5

+125 C°

+25 C°

- °40 C

200

180

160

140

120

100

80

60

40

20

0

0.9

1.4 1.9 2.4 2.9 3.4

DropoutVoltage(mV)

V V-

BIAS OUT

(V)

3.9

+125 C°

+25 C°

-40°C

I =1.5A

OUT

60

50

40

30

20

10

0

0.9

1.4 1.9 2.4 2.9 3.4

DropoutV

oltage(mV)

V -

BIASVOUT

(V)

3.9

+125 C°

+25 C°

-40°C

I =500mA

OUT

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

At TJ= +25 ° C, V

unless otherwise noted.

= 1.5V, VIN= V

OUT

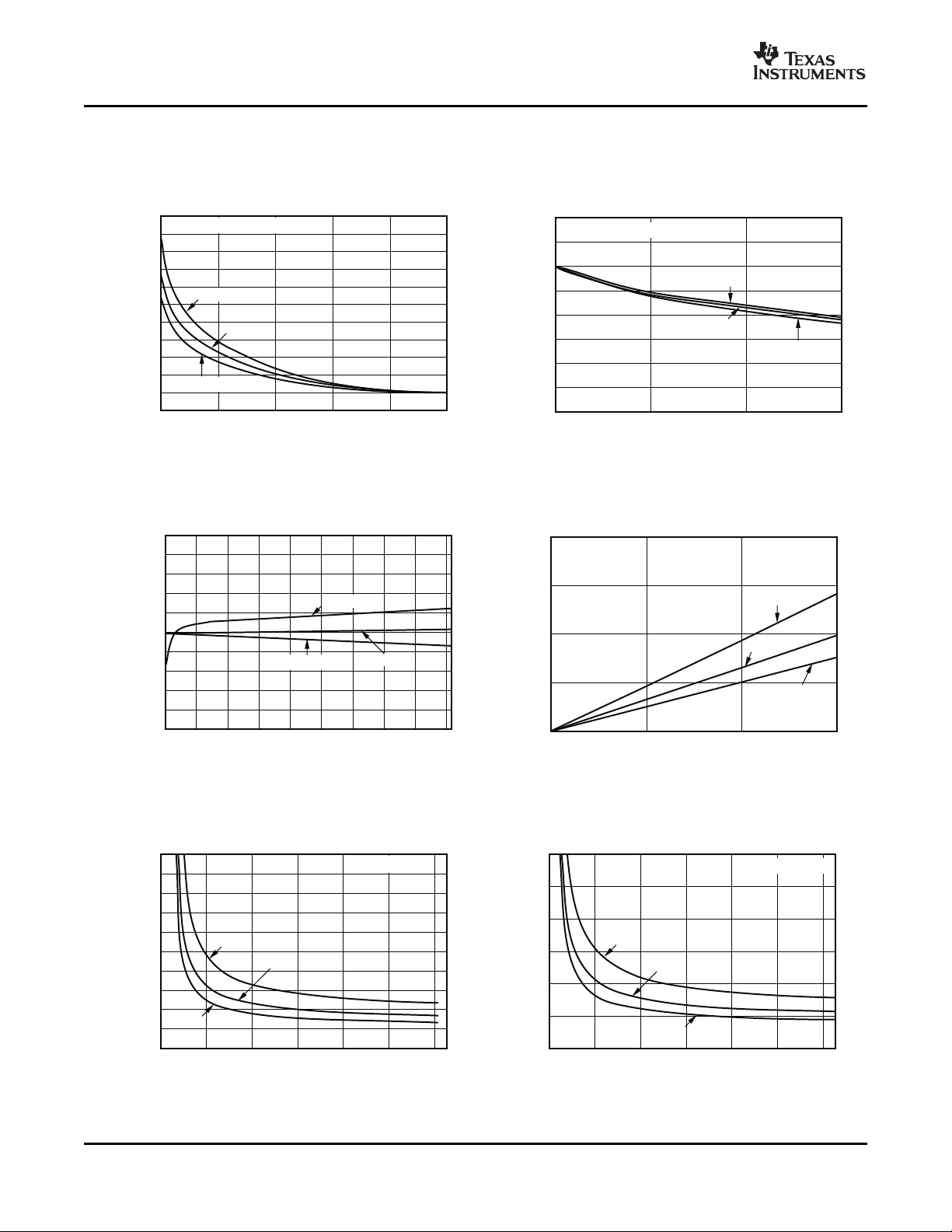

LOAD REGULATION LOAD REGULATION

Figure 3. Figure 4.

TYPICAL CHARACTERISTICS

OUT(TYP)

+ 0.3V, V

BIAS

= 3.3V, I

= 50mA, EN = VIN, CIN= 1 µ F, C

OUT

= 4.7 µ F, and C

BIAS

= 10 µ F,

OUT

LINE REGULATION I

AND TEMPERATURE (TJ)

OUT

Figure 5. Figure 6.

VINDROPOUT VOLTAGE vs VINDROPOUT VOLTAGE vs

V

– V

VINDROPOUT VOLTAGE vs

BIAS

AND TEMPERATURE (TJ) V

OUT

– V

BIAS

AND TEMPERATURE (TJ)

OUT

6

Figure 7. Figure 8.

Submit Documentation Feedback

www.ti.com

1400

1300

1200

1100

1000

900

800

700

600

500

50

500 1000

DropoutVoltage(mV)

I (mA)

OUT

1500

+125 C°

+25 C°

- °40 C

90

80

70

60

50

40

30

20

10

0

P

ower

-SupplyRejection(dB)

10 100

1k

10k 100k

1M

10M

Frequency(Hz)

I =1.5A

OUT

100

90

80

70

60

50

40

30

20

10

0

10

100 1k 10k 100k 1M

Power

-SupplyRejectionRatio(dB)

Frequency(Hz)

10M

V =1.8,V =1.5V

IN OUT OUT

,I =1.5A

C =0 F

OUT

m

C =10 F

OUT

m

C =100 F

OUT

m

100

90

80

70

60

50

40

30

20

10

0

10

100 1k 10k 100k 1M

Power

-SupplyRejectionRatio(dB)

Frequency(Hz)

10M

V =1.8,V =1.5V

IN OUT OUT

,I =100mA

C =10 F

OUT

m

C =100 F

OUT

m

C =0 F

OUT

m

90

80

70

60

50

40

30

20

10

0

0

0.25 0.50 0.75 1.00 1.25 1.50 1.75 2.00 2.25

Power-SupplyRejectionRatio(dB)

V V-

IN OUT

(V)

2.50

1kHz

100kHz

300kHz

700kHz

I =1.5A

OUT

1

0.1

0.01

100

1k 10k

OutputSpectralNoiseDensity(mV/Ö

)

Hz

Frequency(Hz)

100k

I =1.5A

OUT

V =1.1V

OUT

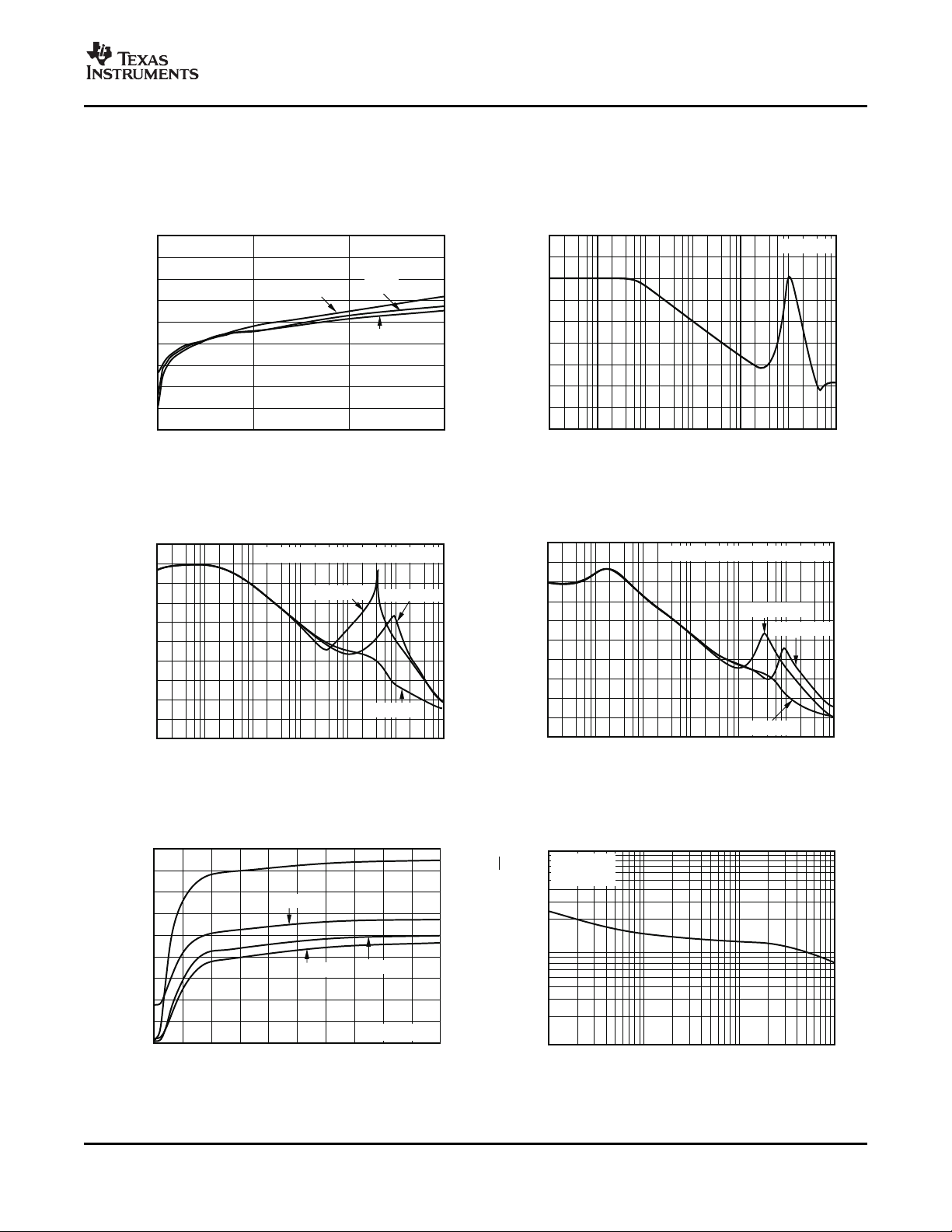

At TJ= +25 ° C, V

unless otherwise noted.

= 1.5V, VIN= V

OUT

V

TYPICAL CHARACTERISTICS (continued)

OUT(TYP)

DROPOUT VOLTAGE vs

BIAS

I

AND TEMPERATURE V

OUT

+ 0.3V, V

BIAS

= 3.3V, I

= 50mA, EN = VIN, CIN= 1 µ F, C

OUT

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

= 4.7 µ F, and C

BIAS

PSRR vs FREQUENCY

BIAS

= 10 µ F,

OUT

Figure 9. Figure 10.

VINPSRR vs FREQUENCY VINPSRR vs FREQUENCY

Figure 11. Figure 12.

VINPSRR vs VIN– V

OUT

NOISE SPECTRAL DENSITY

Figure 13. Figure 14.

Submit Documentation Feedback

7

www.ti.com

20mV/div

20mV/div

20mV/div

20mV/div

1V/div

Time(50 s/div)m

4.3V

C =2x470 F(OSCON)

OUT

m

C =100 F(Cer.)

OUT

m

C =10 F(Cer.)

OUT

m

1V/ sm

3.3V

C =0 F

OUT

m

4.3V

10mV/div

10mV/div

10mV/div

10mV/div

500mV/div

Time(50 s/div)m

C =2x470 F(OSCON)

OUT

m

C =100 F(Cer.)

OUT

m

C =10 F(Cer.)

OUT

m

C =0 F

OUT

m

2.5V

1.5V

V =1.2V

OUT

1V/ sm

50mV/div

50mV/div

50mV/div

50mV/div

1A/div

Time(50 s/div)m

50mA

C =2x470 F(OSCON)

OUT

m

C =100 F(Cer.)

OUT

m

C =10 F(Cer.)

OUT

m

1A/ sm

C =0 F

OUT

m

1.5A

500mV/div

Time(20ms/div)

V

PG

V

TRACK

I =500mA

OUT

V

OUT

1V/div

Time(20ms/div)

V (500mV/div)

PG

V

OUT

V =V

IN BIAS EN

=V

2.85

2.65

2.45

2.25

2.05

1.85

1.65

1.45

1.25

0

0.5 1.0

BiasCurrent(mA)

I (A)

OUT

1.5

+125 C°

+25 C°

- °40 C

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

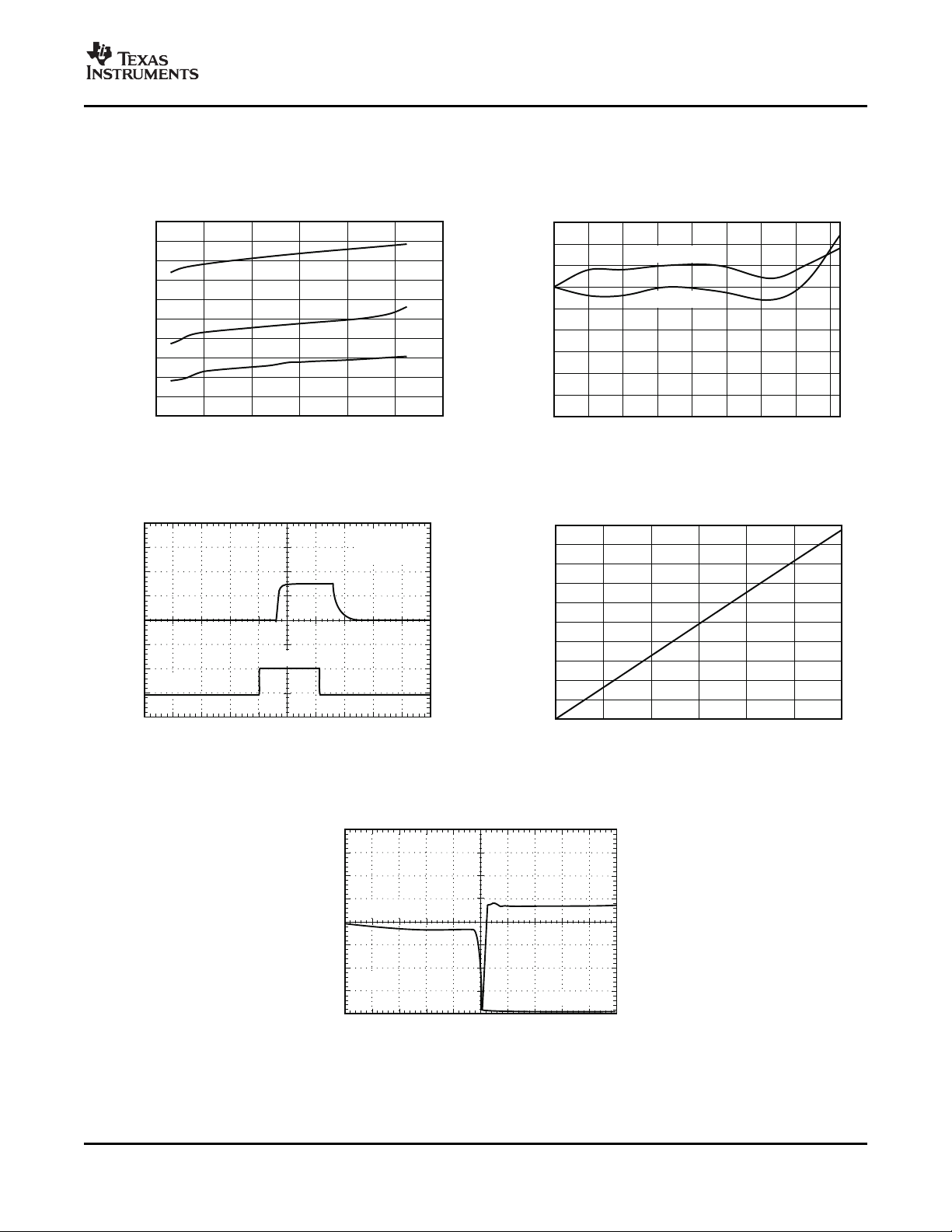

At TJ= +25 ° C, V

unless otherwise noted.

= 1.5V, VIN= V

OUT

V

LINE TRANSIENT VINLINE TRANSIENT (1.5A)

BIAS

Figure 15. Figure 16.

OUTPUT LOAD TRANSIENT RESPONSE TRACKING RESPONSE

TYPICAL CHARACTERISTICS (continued)

OUT(TYP)

+ 0.3V, V

BIAS

= 3.3V, I

= 50mA, EN = VIN, CIN= 1 µ F, C

OUT

= 4.7 µ F, and C

BIAS

= 10 µ F,

OUT

8

Figure 17. Figure 18.

POWER-UP/POWER-DOWN I

Figure 19. Figure 20.

Submit Documentation Feedback

vs I

BIAS

AND TEMPERATURE

OUT

www.ti.com

3.0

2.8

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

2.0

2.5 3.0 3.5 4.0 4.5

BiasCurrent(mA)

V (V)

BIAS

5.0

+125 C°

+25 C°

- °40 C

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0

-40

-20 0 20 40 60 80 100

BiasCurrent( A)m

JunctionTemperature( C)°

120

V =2.375V

BIAS

V =5.5V

BIAS

1V/div

1V/div

Time(50 s/div)m

V

OUT

0V

1.1V

V

EN

V =V

I =1.5A

TRACK IN

OUT

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

V Low-LevelPGVoltage(V)

OL

0

2 4

6 8 10

12

PGCurrent(mA)

Time(20 s/div)m

V

OUT

50mV/div

I

OUT

500mA/div

OutputOpen

OutputShorted

At TJ= +25 ° C, V

unless otherwise noted.

= 1.5V, VIN= V

OUT

TYPICAL CHARACTERISTICS (continued)

AND V

+ 0.3V, V

OUT

OUT(TYP)

I

vs V

BIAS

BIAS

Figure 21. Figure 22.

BIAS

= 3.3V, I

= 50mA, EN = VIN, CIN= 1 µ F, C

OUT

I

BIAS

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

= 4.7 µ F, and C

BIAS

SHUTDOWN vs TEMPERATURE

= 10 µ F,

OUT

TURN-ON RESPONSE–QFN PACKAGE LOW-LEVEL PG VOLTAGE vs PG CURRENT

Figure 23. Figure 24.

OUTPUT SHORT-CIRCUIT RECOVERY

Submit Documentation Feedback

Figure 25.

9

www.ti.com

R

1

R

5

R

3

R

4

R

2

V

OUT

C

OUT

Optional

PG

OUT

FB

IN

BIAS

TRACK

GND

V

IN

V

BIAS

C

IN

C

BIAS

V

TRACK

V

PG

TPS74301

V =0.8

OUT

´ 1+

R

1

R

2

(

)

EN

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

APPLICATION INFORMATION

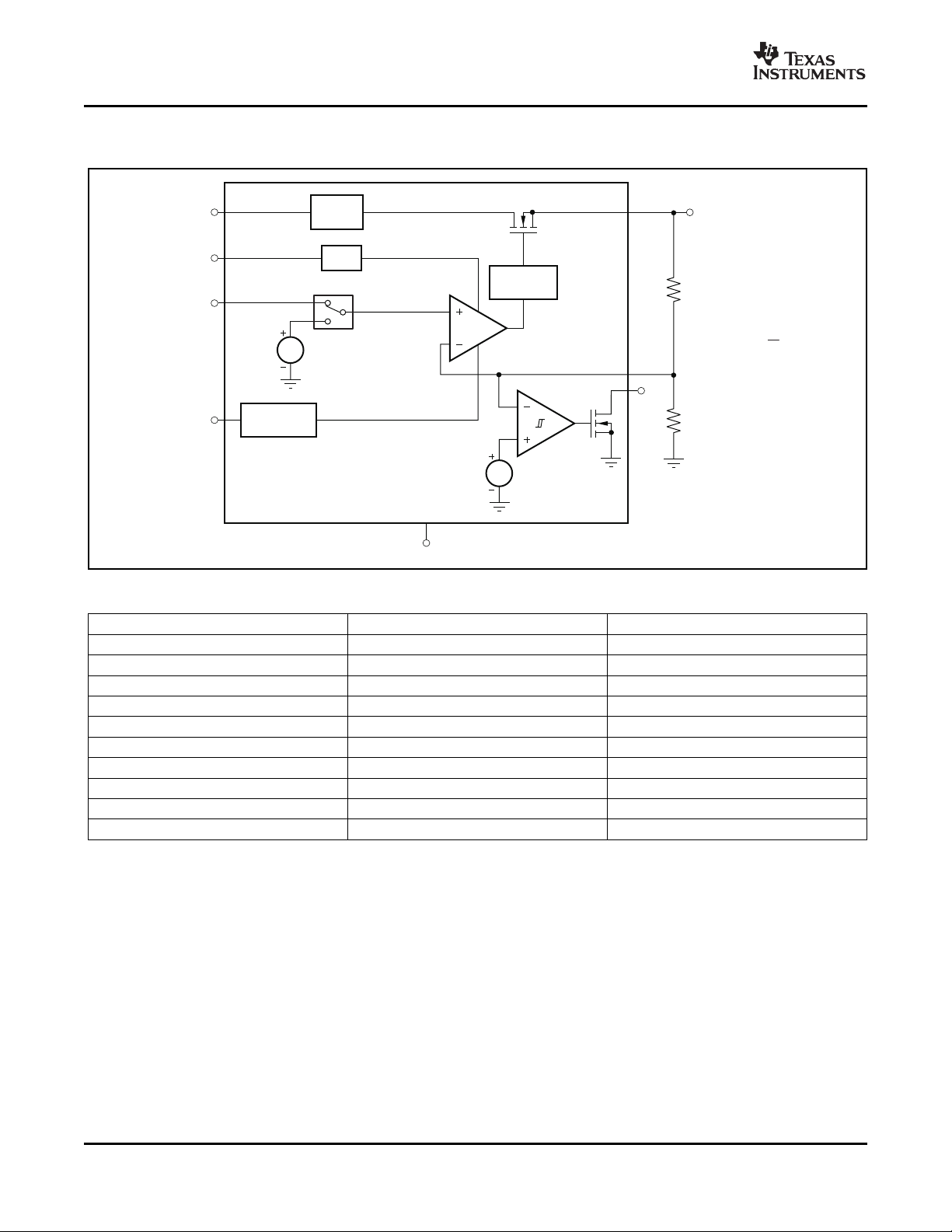

The TPS74301 belongs to a family of new Figure 26 is a typical application circuit for the

generation ultra-low dropout regulators that feature TPS74301 adjustable device.

soft-start and tracking capabilities. These regulators

use a low current bias input to power all internal

control circuitry, allowing the NMOS pass transistor

to regulate very low input and output voltages.

The use of an NMOS-pass FET offers several critical specifications, R

advantages for many applications. Unlike a PMOS

topology device, the output capacitor has little effect

on loop stability. This architecture allows the

TPS74301 to be stable with any or even no output

capacitor. Transient response is also superior to

PMOS topologies, particularly for low V

IN

applications.

The TPS74301 features a TRACK pin that allows the

output to track an external supply. This feature is

useful in minimizing the stress on ESD structures

that are present between the CORE and I/O power

pins of many processors. A power-good (PG) output

is also available to allow supply monitoring and

sequencing of follow-on supplies. To control the

output turn-on, an enable (EN) pin with hysteresis

and deglitch is provided to allow slow-ramping

signals to be utilized for sequencing the device. The

low V

and V

IN

OUT

capability allows for inexpensive,

easy-to-design, and efficient linear regulation

between the multiple supply voltages often present in

processor intensive systems.

R

and R

1

can be calculated for any output voltage

2

using the formula shown in Figure 26 . Refer to

Table 1 for sample resistor values of common output

voltages. In order to achieve the maximum accuracy

should be ≤ 4.99k Ω .

2

INPUT, OUTPUT, AND BIAS CAPACITOR REQUIREMENTS

The device does not require any output capacitor for

stability. If an output capacitor is needed, the device

is designed to be stable for all available types and

values of output capacitance. The device is also

stable with multiple capacitors in parallel, of any type

or value.

The capacitance required on the IN and BIAS pins is

strongly dependent on the input supply source

impedance. To counteract any inductance in the

input, the minimum recommended capacitor for V

and V

the same supply, the recommended minimum

capacitor for V

capacitors should be used on the input; ceramic X5R

and X7R capacitors are preferred. These capacitors

should be placed as close the pins as possible for

optimum performance.

BIAS

is 1 µ F. If V

BIAS

and V

IN

are connected to

BIAS

is 4.7 µ F. Good quality, low ESR

IN

10

Figure 26. Typical Application Circuit for the TPS74301 (Adjustable)

Submit Documentation Feedback

www.ti.com

TRANSIENT RESPONSE

Reference

SimplifiedBlock Diagram

V

OUT

OUT

BIAS

FB

IN

V =5V 5%

BIAS

±

V =1.8V

V =1.5V

I =1.5A

Efficiency=83%

IN

OUT

OUT

Reference

SimplifiedBlock Diagram

BIAS

FB

IN

V

IN

V =3.3V 5%

BIAS

±

V =3.3V 5%

V =1.5V

I =1.5A

Efficiency=45%

IN

OUT

OUT

±

V

OUT

OUT

The TPS74301 was designed to have transient

response within 5% for most applications without any

output capacitor. In some cases, the transient

response may be limited by the transient response of

the input supply. This limitation is especially true in

applications where the difference between the input

and output is less than 300mV. In this case, adding

additional input capacitance improves the transient

response much more than just adding additional

output capacitance would do. With a solid input

supply, adding additional output capacitance reduces

undershoot and overshoot during a transient at the

expense of a slightly longer V

recovery time.

OUT

Refer to Figure 17 in the Typical Characteristics

section. Since the TPS74301 is stable without an

output capacitor, many applications may allow for

little or no capacitance at the LDO output. For these

applications, local bypass capacitance for the device

under power may be sufficient to meet the transient

requirements of the application. This design reduces

the total solution cost by avoiding the need to use

expensive high-value capacitors at the LDO output.

DROPOUT VOLTAGE

The TPS74301 offers industry-leading dropout

performance, making it well-suited for high-current

low V

dropout of the TPS74301 allows the device to be

used instead of a DC/DC converter and still achieve

good efficiencies. This efficiency allows users to

rethink the power architecture for their applications to

find the smallest, simplest, and lowest cost solution.

IN

/low V

applications. The extremely low

OUT

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

Figure 27. Typical Application of the TPS74301

Using an Auxiliary Bias Rail

The second specification (see Figure 28 ), referred to

as V

BIAS together. This option allows the device to be

used in applications where an auxiliary bias voltage

is unavailable or low dropout is not required. Dropout

is limited by BIAS in these applications because

V

BIAS

therefore must be 1.4V above V

Dropout, is for users who wish to tie IN and

BIAS

provides the gate drive to the pass FET, and

.

OUT

There are two different specifications for dropout

voltage with the TPS74301. The first specification (as

shown in Figure 27 ) is referred to as V

is for users wishing to apply an external bias voltage

to achieve low dropout. This specification assumes

that V

case for V

tolerance and with V

than 3.3V × 0.95 or V

dropout is less than specified.

is at least 1.62V above V

BIAS

when powered by a 3.3V rail with 5%

BIAS

= 1.5V. If V

OUT

is less than 1.5V, V

OUT

IN

OUT

Dropout and

, which is the

is higher

BIAS

Submit Documentation Feedback

IN

Figure 28. Typical Application of the TPS74301

Without an Auxiliary Bias

11

www.ti.com

V

N

ǒ

mV

RMS

Ǔ

+ 25

ǒ

mV

RMS

V

Ǔ

V

OUT

(V)

IN

BIAS

EN

OUT

PG

SS

TPS74201LDO1

(1)

DSP

IN

I/O

CORE

BIAS

EN

OUT

PG

TRACK

TPS74301LDO2

(1)

R

3

32.4kW

R

4

10kW

R

1

R

2

5V

3.3V

1.2V

NOTES:(1)CapacitorsonIN,BIAS,andOUTalongwiththeresistors

necessarytosettheoutputvoltagehavebeenomittedforsimplification.

(2)LowestvalueforV andhighestvalueforR shouldbeused

inthiscalculation.R mustbethecloseststandardvaluebelowthe

calculatedvalueforproperratiometricsequencing.

CORE 2

1

I/O

T mei

C REO

V

OUT

SIMU TL A E USSEQUENCINGN O

RATIOMETRICSEQUENCING

(2)

C REO

I/O

xR

2

V CCIO- 0.808

R1=

0.808

xR

2

V CC

CORE

- 0.8

R1=

0.8

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

PROGRAMMABLE SEQUENCING WITH SEQUENCING REQUIREMENTS

TRACK

The TPS74301 features a track pin that allows the sequenced in any order without causing damage to

output to track an external supply at start-up. While the device. However, for the track function to work as

the TRACK input is below 0.8V, the error amplifier intended, certain sequencing rules must be applied.

regulates the FB pin to the TRACK input. Properly V

choosing the resistor divider network (R

shown in Figure 29 enables the regulator output to faster than the external supply being tracked so that

track the external supply to obtain a simultaneous or the tracking signal will not drive the device into V

ratiometric start-up. Once the TRACK input reaches dropout as V

0.8V, the error amplifier regulates the FB pin to the sequence the tracking device is to have V

0.8V internal reference. Further increases to the and V

TRACK input have no effect. before enabling the master supply to initiate the

and R2) as the track signal starts to ramp. V

1

The device can have V

must be present and the device enabled before

BIAS

ramps up. The preferred method to

OUT

above the minimum required voltages

EN

, V

IN

BIAS

, V

, and V

EN

should ramp up

IN

, V

IN

startup sequence. This method is illustrated in

Figure 29 . Resistors R

and R

3

4

disable the master

supply until the input voltage is above 3.52V

(typical).

If the TRACK pin is not needed it should be

connected to VIN. Configured in this way, the device

starts up typically within 40 µ s, which may result in

large inrush current that could cause the input supply

to droop. If soft-start is needed, consider the

TPS74201 or TPS74401 devices.

TRACK

IN

,

BIAS

OUTPUT NOISE

The TPS74301 provides low output noise when a

soft-start capacitor is used. When the device reaches

the end of the soft-start cycle, the soft-start capacitor

serves as a filter for the internal reference. By using

a 0.001 µ F soft-start capacitor, the output noise is

reduced by half and is typically 30 µ V

output (10Hz to 100kHz). Because most of the

output noise is generated by the internal reference,

the noise is a function of the set output voltage. The

RMS noise with a 0.001 µ F soft-start capacitor is

given in Equation 1 .

The low output noise of the TPS74301 makes it a

good choice for powering transceivers, PLLs, or

other noise-sensitive circuitry.

for a 1.2V

RMS

(1)

ENABLE/SHUTDOWN

Figure 29. Various Sequencing Methods Using

the TRACK Pin

The maximum recommended value for R

Once R

the equations given in Figure 29 .

is selected, R

2

1

is 100k Ω .

2

is calculated using one of

The enable (EN) pin is active high and is compatible

with standard digital signaling levels. V

turns the regulator off, while V

EN

above 1.1V turns

below 0.4V

EN

the regulator on. Unlike many regulators, the enable

circuitry has hysteresis and deglitching for use with

relatively slow-ramping analog signals. This

configuration allows the TPS74301 to be enabled by

connecting the output of another supply to the EN

pin. The enable circuitry typically has 50mV of

hysteresis and a deglitch circuit to help avoid on-off

cycling because of small glitches in the V

signal.

EN

12

Submit Documentation Feedback

www.ti.com

P

D

+

ǒ

VIN* V

OUT

Ǔ

I

OUT

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

The enable threshold is typically 0.8V and varies with dissipation, thermal resistance, and ambient

temperature and process variations. Temperature temperature the thermal protection circuit may cycle

variation is approximately –1mV/ ° C; therefore, on and off. This cycling limits the dissipation of the

process variation accounts for most of the variation regulator, protecting it from damage as a result of

in the enable threshold. If precise turn-on timing is overheating.

required, a fast rise-time signal should be used to

enable the TPS74301.

If not used, EN can be connected to either IN or heatsinking. For reliable operation, junction

BIAS. If EN is connected to IN, it should be temperature should be limited to +125 ° C maximum.

connected as close as possible to the largest To estimate the margin of safety in a complete

capacitance on the input to prevent voltage droops design (including heatsink), increase the ambient

on that line from triggering the enable circuit. temperature until thermal protection is triggered; use

POWER-GOOD (QFN Package Only)

The power-good (PG) pin is an open-drain output

and can be connected to any 5.5V or lower rail

through an external pull-up resistor. This pin requires

at least 1.1V on V

The PG output is high-impedance when V

greater than V

V

drops below 1.9V, the open-drain output turns

BIAS

IT

in order to have a valid output.

BIAS

+ V

. If V

HYS

drops below V

OUT

is

OUT

or if

IT

on and pulls the PG output low. The PG pin also

asserts when the device is disabled. The

recommended operating condition of PG pin sink

current is up to 1mA, so the pull-up resistor for PG

should be in the range of 10k Ω to 1M Ω . PG is only

provided on the QFN package. If output voltage DISSIPATION

monitoring is not needed, the PG pin can be left

floating.

INTERNAL CURRENT LIMIT

The TPS74301 features a factory-trimmed, accurate

current limit that is flat over temperature and supply

voltage. The current limit allows the device to supply

surges of up to 1.8A and maintain regulation. The

current limit responds in about 10 µ s to reduce the

current during a short-circuit fault. Recovery from a

short-circuit condition is well-controlled and results in

very little output overshoot when the load is

removed. See Figure 25 in the Typical

Characteristics section for output short-circuit

recovery performance.

The internal current limit protection circuitry of the

TPS74301 is designed to protect against overload

conditions. It is not intended to allow operation above

the rated current of the device. Continuously running

the TPS74301 above the rated current degrades

device reliability.

THERMAL PROTECTION

Thermal protection disables the output when the

junction temperature rises to approximately +155 ° C,

allowing the device to cool. When the junction

temperature cools to approximately +140 ° C, the

output circuitry is enabled. Depending on power

Activation of the thermal protection circuit indicates

excessive power dissipation or inadequate

worst-case loads and signal conditions. For good

reliability, thermal protection should trigger at least

+30 ° C above the maximum expected ambient

condition of the application. This condition produces

a worst-case junction temperature of +125 ° C at the

highest expected ambient temperature and

worst-case load.

The internal protection circuitry of the TPS74301 is

designed to protect against overload conditions. It is

not intended to replace proper heatsinking.

Continuously running the TPS74301 into thermal

shutdown degrades device reliability.

LAYOUT RECOMMENDATIONS AND POWER

An optimal layout can greatly improve transient

performance, PSRR, and noise. To minimize the

voltage droop on the input of the device during load

transients, the capacitance on IN and BIAS should

be connected as close as possible to the device.

This capacitance also minimizes the effects of

parasitic inductance and resistance of the input

source and can therefore improve stability. To

achieve optimal transient performance and accuracy,

the top side of R

as close as possible to the load. If BIAS is connected

to IN, it is recommended to connect BIAS as close to

the sense point of the input supply as possible. This

connection minimizes the voltage droop on BIAS

during transient conditions and can improve the

turn-on response.

Knowing the device power dissipation and proper

sizing of the thermal plane that is connected to the

tab or pad is critical to avoiding thermal shutdown

and ensuring reliable operation. Power dissipation of

the device depends on input voltage and load

conditions, and can be calculated using Equation 2 :

in Figure 26 should be connected

1

(2)

Submit Documentation Feedback

13

www.ti.com

R

qJA

+

(

)125

O

C * T

A

)

P

D

55

50

45

40

35

30

25

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

q

JA

(

°C/W)

Area(in )

2

4.5

0LFM

150LFM

250LFM

T

J

R

qJC

R

qCS

R

qSA

T

C

T

S

T

A

4-layer.0.062” FR4

Viasare0.012” diameter,plated

Top/Bottomlayersare2oz.copper

Innerlayersare1oz.copper

0.062in.

R

qJA

= R +R +R

q q qJC CS SA

PCBCrossSection

PCBTopView

0.5in

2

1.0in

2

2.0in

2

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

Power dissipation can be minimized and greater maximum junction-to-ambient thermal resistance

efficiency can be achieved by using the lowest depends on the maximum ambient temperature,

possible input voltage necessary to achieve the maximum device junction temperature, and power

required output voltage regulation. dissipation of the device, and can be calculated

On both the QFN (RGW) and DDPAK (KTW)

packages, the primary conduction path for heat is

through the exposed pad or tab to the printed circuit

board (PCB). The pad or tab can be connected to

ground or be left floating; however, it should be

attached to an appropriate amount of copper PCB

area to ensure the device does not overheat. The

using Equation 3 :

Knowing the maximum R

and system air flow, the

θ JA

minimum amount of PCB copper area needed for

appropriate heatsinking can be calculated using

Figure 30 through Figure 34 .

(3)

Figure 30. PCB Layout and Corresponding R

14

Data, Buried Thermal Plane, No Vias Under Thermal Pad

θ JA

Submit Documentation Feedback

www.ti.com

T

J

R

qJC

R

qCS

R

qSA

T

C

T

S

T

A

4-layer.0.062” FR4

Viasare0.012” diameter,plated

Top/Bottomlayersare2oz.copper

Innerlayersare1oz.copper

0.062in.

R

qJA

= R +R +R

q q qJC CS SA

50

45

40

35

30

25

20

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5

q

JA

(°C/W)

Area(in )

2

4.0

0LFM

150LFM

250LFM

PCBCrossSection

PCBTopView

0.5in

2

1.0in

2

2.0in

2

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

Figure 31. PCB Layout and Corresponding R

Submit Documentation Feedback

Data, Buried Thermal Plane, Vias Under Thermal Pad

θ JA

15

www.ti.com

4-layer.0.062” FR4

Viasare0.012” diameter,plated

Top/Bottomlayersare2oz.copper

Innerlayersare1oz.copper

T

J

R

qJC

R

qCS

R

qSA

T

C

T

S

T

A

0.062in.

R

qJA

= R +R +R

q q qJC CS SA

90

80

70

60

50

40

30

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5

q

JA

(°C/W)

Area(in )

2

4.0

0LFM

150LFM

250LFM

PCBCrossSection

PCBTopView

0.5in

2

1.0in

2

2.0in

2

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

Figure 32. PCB Layout and Corresponding R

Data, Top Layer Thermal Plane

θ JA

16

Submit Documentation Feedback

www.ti.com

35

30

25

20

15

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5

q

JA

(°C/W)

Area(in )

2

4.0

0LFM

T

J

R

qJC

R

qCS

R

qSA

T

C

T

S

T

A

4-layer.0.062” FR4

Viasare0.012” diameter,plated

Top/Bottomlayersare2oz.copper

Innerlayersare1oz.copper

0.062in.

R

qJA

= R +R +R

q q qJC CS SA

PCBCrossSection

PCBTopView

0.5in

2

1.0in

2

2.0in

2

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

Figure 33. PCB Layout and Corresponding R

Submit Documentation Feedback

θ JA

, Buried Thermal Plane

17

www.ti.com

4-layer.0.062” FR4

Viasare0.012” diameter,plated

Top/Bottomlayersare2oz.copper

Innerlayersare1oz.copper

T

J

R

qJC

R

qCS

R

qSA

T

C

T

S

T

A

0.062in.

R

qJA

= R +R +R

q q qJC CS SA

55

50

45

40

35

30

25

20

15

10

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

q

JA

(°C/W)

Area(in )

2

4.5

0LFM

PCBCrossSection

PCBTopView

0.5in

2

1.0in

2

2.0in

2

TPS74301

SBVS065E – DECEMBER 2005 – REVISED MAY 2007

Figure 34. PCB Layout and Corresponding R

18

Submit Documentation Feedback

, Top Layer Thermal Plane

θ JA

PACKAGE OPTION ADDENDUM

www.ti.com

5-Feb-2007

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TPS74301KTWR ACTIVE DDPAK KTW 7 500 Green (RoHS &

no Sb/Br)

TPS74301KTWRG3 ACTIVE DDPAK KTW 7 500 Green (RoHS &

no Sb/Br)

TPS74301KTWT ACTIVE DDPAK KTW 7 50 Green (RoHS &

no Sb/Br)

TPS74301KTWTG3 ACTIVE DDPAK KTW 7 50 Green (RoHS &

no Sb/Br)

TPS74301RGWR ACTIVE QFN RGW 20 3000 Green (RoHS &

no Sb/Br)

TPS74301RGWRG4 ACTIVE QFN RGW 20 3000 Green (RoHS &

no Sb/Br)

TPS74301RGWT ACTIVE QFN RGW 20 250 Green (RoHS &

no Sb/Br)

TPS74301RGWTG4 ACTIVE QFN RGW 20 250 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU SN Level-3-245C-168 HR

CU SN Level-3-245C-168 HR

CU SN Level-3-245C-168 HR

CU SN Level-3-245C-168 HR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com

17-May-2007

TAPE AND REEL INFORMATION

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com

Device Package Pins Site Reel

Diameter

(mm)

TPS74301RGWR RGW 20 MLA 330 12 5.3 5.3 1.5 8 12 PKGORN

TPS74301RGWT RGW 20 MLA 180 12 5.3 5.3 1.5 8 12 PKGORN

Reel

Width

(mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)W(mm)

17-May-2007

Pin1

Quadrant

T2TR-MS

P

T2TR-MS

P

TAPE AND REEL BOX INFORMATION

Device Package Pins Site Length (mm) Width (mm) Height (mm)

TPS74301RGWR RGW 20 MLA 346.0 346.0 29.0

TPS74301RGWT RGW 20 MLA 190.0 212.7 31.75

Pack Materials-Page 2

PACKAGE MATERIALS INFORMATION

www.ti.com

17-May-2007

Pack Materials-Page 3

MECHANICAL DATA

MPSF015 – AUGUST 2001

KTW (R-PSFM-G7) PLASTIC FLANGE-MOUNT

0.0625 (1,587)

0.0585 (1,485)

H

0.605 (15,37)

0.595 (15,11)

H

0.370 (9,40)

0.330 (8,38)

C

C

0.410 (10,41)

0.385 (9,78)

0.303 (7,70)

0.297 (7,54)

0.050 (1,27)

0.034 (0,86)

F

0.022 (0,57)

0.010 (0,25)

–A–

0.055 (1,40)

0.045 (1,14)

A

0.012 (0,305)

0.000 (0,00)

0.019 (0,48)

0.017 (0,43)

0.026 (0,66)

C

0.014 (0,36)

B

A

M

M

C

M

0.006

–B–

0.104 (2,64)

0.096 (2,44)

0.064 (1,63)

0.056 (1,42)

0.187 (4,75)

0.179 (4,55)

H

0°~3°

0.304 (7,72)

0.296 (7,52)

0.300 (7,62)

0.252 (6,40)

0.183 (4,65)

0.170 (4,32)

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Lead width and height dimensions apply to the

plated lead.

D. Leads are not allowed above the Datum B.

E. Stand–off height is measured from lead tip

with reference to Datum B.

F. Lead width dimension does not include dambar

protrusion. Allowable dambar protrusion shall not

cause the lead width to exceed the maximum

dimension by more than 0.003”.

G. Cross–hatch indicates exposed metal surface.

H. Falls within JEDEC MO–169 with the exception

of the dimensions indicated.

4201284/A 08/01

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements,

improvements, and other changes to its products and services at any time and to discontinue any product or service without notice.

Customers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All products are sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s

standard warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this

warranty. Except where mandated by government requirements, testing of all parameters of each product is not necessarily

performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should

provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask

work right, or other TI intellectual property right relating to any combination, machine, or process in which TI products or services

are used. Information published by TI regarding third-party products or services does not constitute a license from TI to use such

products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under

the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without alteration and is

accompanied by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an

unfair and deceptive business practice. TI is not responsible or liable for such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service

voids all express and any implied warranties for the associated TI product or service and is an unfair and deceptive business

practice. TI is not responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would

reasonably be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement

specifically governing such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications

of their applications, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related

requirements concerning their products and any use of TI products in such safety-critical applications, notwithstanding any

applications-related information or support that may be provided by TI. Further, Buyers must fully indemnify TI and its

representatives against any damages arising out of the use of TI products in such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is

solely at the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in

connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products

are designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any

non-designated products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

Low Power www.ti.com/lpw Video & Imaging www.ti.com/video

Wireless

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2007, Texas Instruments Incorporated

Loading...

Loading...