Page 1

User's Guide

SLVUA44–June 2014

TPS25940XEVM-635: Evaluation Module for TPS25940X

This user’s guide describes the evaluation module (EVM) for the Texas instruments TPS25940X devices.

TPS25940X devices are eFuse with true reverse blocking for power mux that operates from 2.7 V to 18 V,

the device has integrated back-to-back FETs with programmable undervoltage, overvoltage, reversevoltage, overcurrent and in-rush current protection features.

Contents

1 Introduction ................................................................................................................... 2

1.1 EVM Features....................................................................................................... 2

1.2 EVM Applications ................................................................................................... 2

2 Description.................................................................................................................... 2

3 Schematic..................................................................................................................... 3

4 General Configurations ..................................................................................................... 4

4.1 Physical Access..................................................................................................... 4

4.2 Test Equipment ..................................................................................................... 5

4.3 Test Setup ........................................................................................................... 6

4.4 Test Procedures .................................................................................................... 7

5 EVM Assembly Drawings and Layout Guidelines...................................................................... 12

6 Bill of Materials (BOM)..................................................................................................... 14

List of Figures

1 TPS25940XEVM Schematic ............................................................................................... 3

2 EVM Test Setup.............................................................................................................. 6

3 V

4 V

5 J4 = LO Current Limit Test Auto Retry (CH1) .......................................................................... 11

6 J9 = “No Jumper” Current Limit Test with Latch (CH2) ............................................................... 11

7 Top Side Placement ....................................................................................................... 12

8 Top Side Routing Layer ................................................................................................... 12

9 Bottom Side Routing Layer ............................................................................................... 13

1 TPS25940X EVM Options and Default Setting .......................................................................... 2

2 Input and Output Connector Functionality................................................................................ 4

3 Test Points Description ..................................................................................................... 4

4 Jumper and LED Descriptions ............................................................................................. 4

5 EVM Configuration Setting ................................................................................................. 5

6 Operational Range Setting for VIN1, VIN2 = 12 V, 5 V and 3.3 V .................................................... 7

7 PWR635 DMM Readings at Different Test Points....................................................................... 7

8 PWR635 Oscilloscope Setting for Ramp Up Voltage Test............................................................. 8

9 PWR635 Oscilloscope Settings for Current Limit Test................................................................ 10

10 PWR635 Jumper Setting for Current Limits ............................................................................ 10

11 TPS25940XEVM-635 Bill of Material ................................................................................... 14

Ramp Up Time for CH1 ............................................................................................... 9

OUT

Ramp Up Time for CH2 ............................................................................................... 9

OUT

List of Tables

SLVUA44–June 2014 TPS25940XEVM-635: Evaluation Module for TPS25940X

Submit Documentation Feedback

1

Copyright © 2014, Texas Instruments Incorporated

Page 2

Introduction

1 Introduction

The TPS25940XEVM allows reference circuit evaluation of TI's TPS25940X devices. The TPS25940X

devices are available with both latched and auto-retry operation.

1.1 EVM Features

• 2.7-V to 18.0-V (TYP) operation

– CH1 rising input voltage turn-on threshold – 10.5 V (TYP)

– CH1 falling input voltage turn-off threshold – 9.7 V (TYP)

– CH2 rising input voltage turn-on threshold – 2.3 V (TYP)

– CH2 falling input voltage turn-off threshold – 2.1 V (TYP)

• 0.6-A to 5.0-A programmable current limit

• Programmable undervoltage lockout, overvoltage

• Programmable V

• Latched-off TPS25940LRUV (CH2)

• Auto-Retry TPS25940ARUV (CH1)

• Pushbutton RESET signal

• On-board transorb for overvoltage input protection

• Schottky diode at output to minimize negative spike when load is removed

1.2 EVM Applications

• Solid state drives and hard disk drives

• PCIe, RAID, and NIC cards

• USB power switch

• Industrial

– PLCs

– Solid-state relays and FAN control

slew rate

OUT

www.ti.com

2 Description

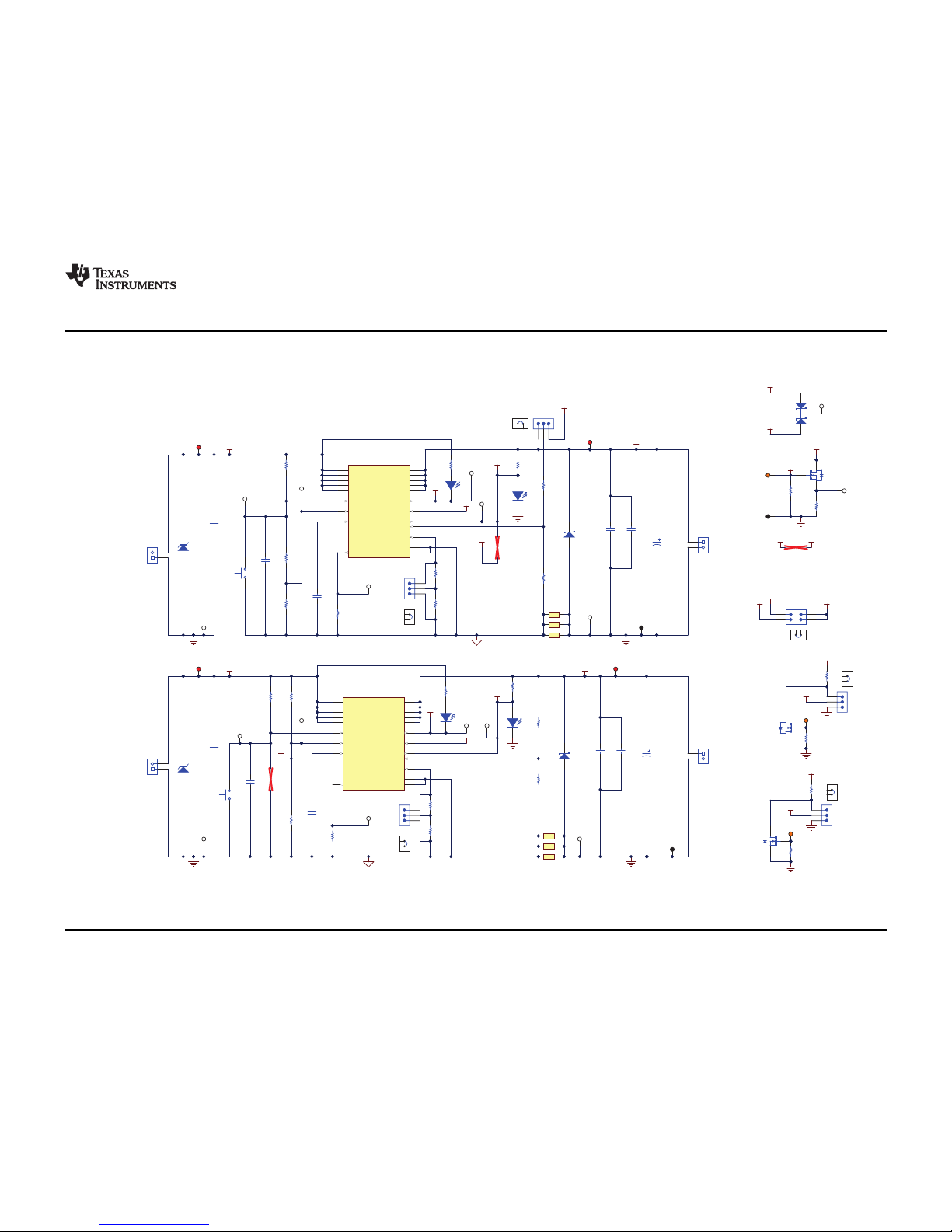

The TPS25940XEVM-635 enables full evaluation of the TPS25940X devices. The EVM supports two

versions (Auto-retry and Latched) of the devices on two Channels (CH1 and CH2, respectively). Input

power is applied at J3 (CH1) and J8 (CH2), while J2 (CH1)/J7 (CH2) provide the output connection to the

load, refer to the schematic in Figure 1, and test setup in Figure 2.

D5/C1 (CH1), D9/C7 (CH2) provides input protection for TPS25940X (U1 and U2, respectively) while

D4/C2/C3/C4 (CH1), D8/C8/C9/C10 (CH2) provides output protection.

Table 1. TPS25940X EVM Options and Default Setting

Part Number EVM Function VINRange UVLO OVP Current Limit Fault Response

TPS25940XEVM-635 Current Limiter with DEVSLP 2.7 V–18 V 10.5 V 2.3 V (internal) 16.5 V 3.6 A 2.1 A 5.3 A Auto-retry Latched

S1 allows U1 and S2 allows U2 to be RESET or disabled. A power good (PG) indicator is provided by D3,

D6 for CH1 and CH2, respectively, and circuit faults can be observed with D2 and D6. Scaled channel

current can be monitored at TP11 and TP22 with a scale factor of 0.842 V/A.

2

TPS25940XEVM-635: Evaluation Module for TPS25940X SLVUA44–June 2014

CH1 CH2 LO setting No Jumper HI Setting CH1 CH2

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

1nf

C12

475k

R20

SH-J9

1

2

3

J9

16.9k

R25

TP26

ILIM LO

ILIM HI

TP17

EN_UV2

TP18

OVP2

TP15

VIN2

TP16

VOUT2

Red

D6

Green

D7

10.0k

R5

TP10

P-LOAD-RTN

TP6

P-LOAD

330pF

C11

VIN2

TP7

I-LOAD

VOUT2

VOUT1

4

7,8

1,2,3

5,6,

30V

Q1

CSD17301Q5A

Pin1_CTRL-2

TP22

IMON2

FLTb-2

P-LOAD

2

1

S2

1nf

C6

475k

R4

SH-J4

1

2

3

J4

TP14

ILIM LO

ILIM HI

TP3

VIN1

TP2

VOUT1

Red

D2

Green

D3

330pF

C5

VIN1

VOUT1

Pin1_CTRL-1

TP11

IMON

FLTb-1

2

1

S1

0.1µF

C1

TP4

FLTb1

TP20

FLTb2

TP21

PG2

1 2

3 4

J5

VOUT1 VOUT2

SH-J5

TP12

TP25

TP24

TP13

VIN=2.7V-18V

IIN=0.6A-5.0A

VIN=2.7V-18V

IIN=0.6A-5.0A

VOUT=2.7V-18V

IOUT=0.6A-5.0A

VOUT=2.7V-18V

IOUT=0.6A-5.0A

1

2

3

Q3

1

2

3

J10

10k

R29

VIN2

100k

R24

SH-J10

Pin1_CTRL-2

1

2

3

Q2

10k

R21

VIN1

100k

R15

SH-J6

Pin1_CTRL-1

PG-1

PG-2

PG-1

PG-1

PG-2

TP1

SYS_PG

TP19

TP23

FLTb-1 Pin1_CTRL-2

VIN1

22k

R8

DNP

OVP-2

OVP-2

SH-J1

24.9k

R12

24.9k

R27

100k

R1

100k

R2

100k

R16

100k

R17

20V

D8

B320A-13-F

20V

D4

B320A-13-F

330µF

C10

16V

D9

16V

D5

4.7µFC24.7µF

C3

4.7µFC84.7µF

C9

DEVSLP

1

PGOOD

2

PGTH

3

OUT

4

OUT

5

OUT

6

OUT

7

OUT

8

IN

9

IN

10

IN

11

IN

12

IN

13

EN/UVLO

14

OVP

15

GND

16

ILIM

17

DVDT

18

IMON

19

FLTB

20

PAD

U1

TPS25940ARVC

DEVSLP

1

PGOOD

2

PGTH

3

OUT

4

OUT

5

OUT

6

OUT

7

OUT

8

IN

9

IN

10

IN

11

IN

12

IN

13

EN/UVLO

14

OVP

15

GND

16

ILIM

17

DVDT

18

IMON

19

FLTB

20

PAD

U2

TPS25940LRVC

0.1

R6

1

2

J3

1

2

J8

1

2

J2

1

2

J7

TP9

PG1

0.003

R7

DNP

TP5

OVP1

TP8

EN_UV1

475k

R3

475k

R18

475k

R19

16.9k

R9

32.4k

R13

48.7k

R22

DNP

32.4k

R26

47k

R11

47k

R23

EN/UVLO-1

OVP-1

DVDT-1

IMON-1

ILIM-1

PGTH-1

DVDT-2

IMON-2

ILIM-2

PGTH-2

EN/UVLO-2

1

2

3

J6

123

J1

SGND1

SGND2

Net-Tie

Net-Tie

Net-Tie

Net-Tie

Net-Tie

IMON-1

330µF

C4

16.9k

R10

16.2k

R14

16.2k

R28

Net-Tie

1µF

C7

1

3

2

D1

BAT54C-7-F

www.ti.com

Schematic

3 Schematic

Figure 1 shows the EVM schematic.

Figure 1. TPS25940XEVM Schematic

3

SLVUA44–June 2014 TPS25940XEVM-635: Evaluation Module for TPS25940X

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 4

General Configurations

4 General Configurations

The following sections describe physical access, test equipment, test setup, and test procedures for the

EVM.

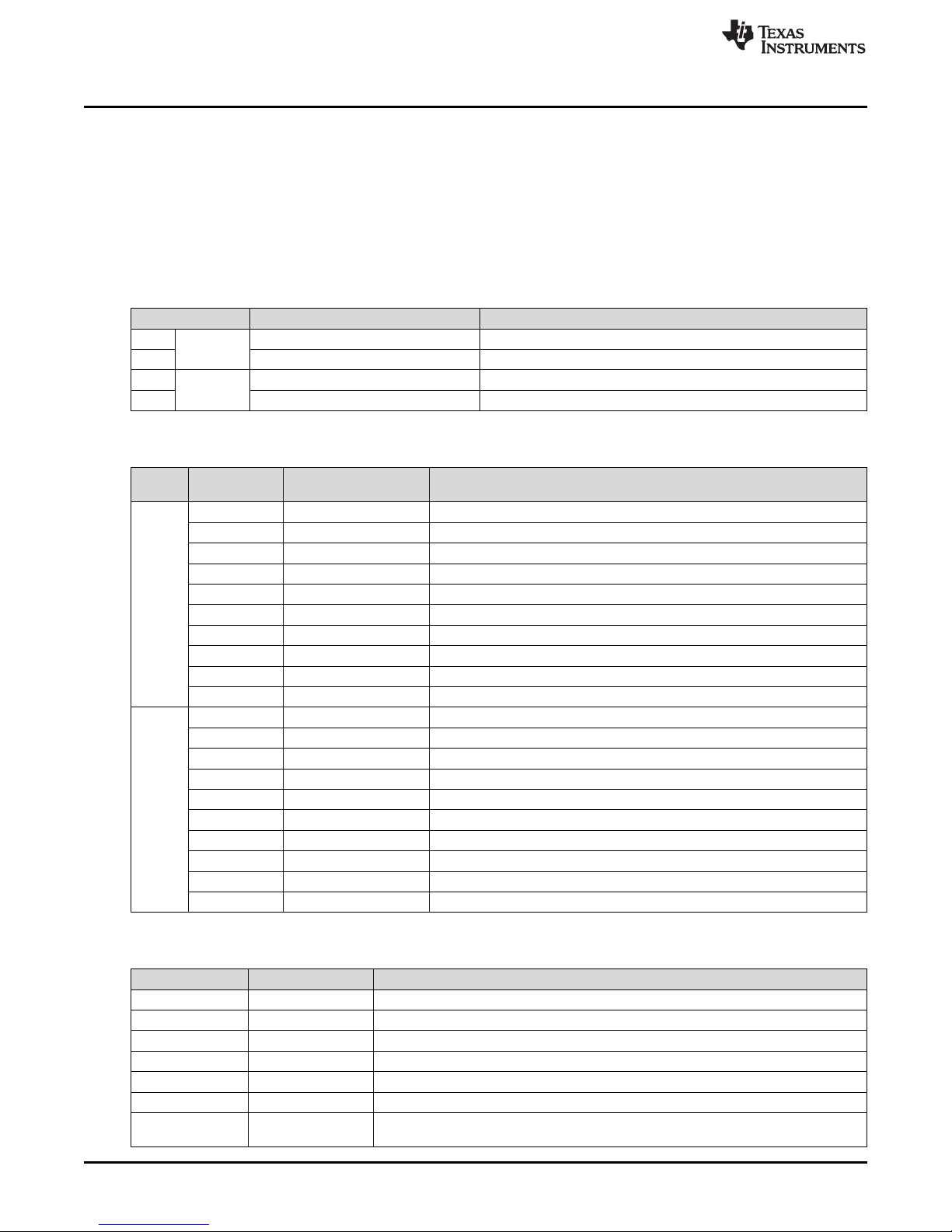

4.1 Physical Access

Table 2 lists the TPS25940XEVM-635 input and output connector functionality. Table 3 describes the test

point availability and Table 4 describes the jumper functionality.

Connector Label Description

J3 CH1 VIN1(+), GND(–) CH1 Input power supply to the EVM

J2 VOUT1(+),GND(–) CH1 Output power from the EVM

J8 CH2 VIN2(+), GND(–) CH2 Input power supply to the EVM

J7 VOUT2(+),GND(–) CH2 Output power from the EVM

Channe Test Points Label Description

l

CH1 TP3 VIN1 CH1 Input power supply to the EVM

TP8 EN_UV1 CH1 Active high enable and under voltage input

TP5 OVP1 CH1, Active high overvoltage input (>16.5V)

TP11 IMON1 CH1 Current monitor. Load current = 1.187 × voltage on TP11

TP2 VOUT1 CH1 Output from the EVM

TP9 PG1 CH1 Power good test point

TP4 FLTb1 CH1, Fault test point

TP12 GND GND

TP13 GND GND

TP14 GND GND

CH2 TP15 VIN2 CH2 Input power supply to the EVM

TP17 EN_UV2 CH2 Active high enable and under voltage input

TP18 OVP2 CH2, Active high overvoltage input

TP22 IMON2 CH2 Current monitor. Load current = 1.187 × voltage on TP22

TP16 VOUT2 CH2 Output from the EVM

TP21 PG2 CH2 Power good test point

TP20 FLTb2 CH2, Fault test point

TP24 GND GND

TP25 GND GND

TP26 GND GND

www.ti.com

Table 2. Input and Output Connector Functionality

Table 3. Test Points Description

Jumper Label Description

J1 J1 Priority Mux Setting (applicable to TPS25942XEVM-635)

J4 LO - HI CH2 Current Setting

J5 J5 PG1 and FLTb1 setting

J6 J6 DEVSLP1 Setting

J9 LO - HI CH2 Current Setting

J10 J10 DEVSLP2 Setting

D2 (Red) D2 CH1 circuit fault indicator. LED turns on when the internal MOSFET is disabled due to

4

TPS25940XEVM-635: Evaluation Module for TPS25940X SLVUA44–June 2014

Table 4. Jumper and LED Descriptions

a fault condition such as over load , short circuit, under voltage etc.

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 5

www.ti.com

Use Table 5 to set the EVM in different configurations in order to achieve the desired functionality from the

TPS25940XEVM-635.

General Configurations

Table 4. Jumper and LED Descriptions (continued)

Jumper Label Description

D3 (Green) D3 CH1 Power good indicator. LED turns on when the voltage at TP2(VOUT1) is more

than 11 V

D6 (Red) D6 CH2 circuit fault indicator. LED turns on when the internal MOSFET is disabled due to

a fault condition such as over load , short circuit, under voltage etc.

D7(Green) D9 CH2 Power good indicator. LED turns on when the voltage at TP2(VOUT1) is more

than 11 V

Table 5. EVM Configuration Setting

Jumper Location E-fuse with DevSleep

J4 1-2 Install jumper at this location for 5.3 A

current Limit for VIN1

2-3 Install jumper at this location for 3.6 A

current Limit for VIN1

OPEN If no jumper is installed default current

limit is 2.1 A for VIN1

J9 1-2 Install jumper at this location for 5.3 A

current Limit for VIN2

2-3 Install jumper at this location for 3.6 A

current Limit for VIN2

OPEN If no jumper is installed default current

limit is 2.1 A for VIN2

J5 1-2 OPEN

3-4

J1 1-2 Install Jumper to get PG1 from VOUT1

2-3 OPEN

J6 1-2 OPEN

2-3

J10 1-2 OPEN

2-3

4.2 Test Equipment

This section describes the power supply, meter, oscilloscope, and loads for testing this EVM.

4.2.1 Power Supplies

One adjustable power supply: 0-V to 20-V output, 0-A to 6-A output current limit.

4.2.2 Meters

One DMM minimum needed and may require more if simultaneous measurements are needed.

4.2.3 Oscilloscope

A DPO2024 or Lecroy 424 oscilloscope or equivalent, three 10X voltage probes, and a DC current probe.

4.2.4 Loads

One resistive load or equivalent which take up to 6 ADC load at 12 V and capable to do the output short.

SLVUA44–June 2014 TPS25940XEVM-635: Evaluation Module for TPS25940X

Submit Documentation Feedback

5

Copyright © 2014, Texas Instruments Incorporated

Page 6

+ -

J2

J7

R7

D9

Positive

Load

Negative

J3

Negative

Power

Supply

Positive

Negative

Power

Supply

Positive

J8

D5

TP

12

TP

13

TP

24

TP

25

U1

U2

DUT

PWR635

Positive

Load

Negative

Voltmeter

PRINT

HELP

ALPHA

SHIFT

ENTER

RUN

DGERF

I

AJBKC

L

7M8N9

O

DGDGD

G

D

G T3U

0V.WX

Y

Z

TAB

% UTILIZATION

HUB/MAU NIC

2

BNC

4Mb/s

Voltmeter

PRINT

HELP

ALPHA

SHIFT

ENTER

RUN

DGERF

I

AJBKC

L

7M8N9

O

DGDGD

G

D

G T3U

0V.WX

Y

Z

TAB

% UTILIZATION

HUB/MAU NIC

2

BNC

4Mb/s

Oscilloscope

Texas

Instruments

S1

S2

D3

D2

D7

D6

General Configurations

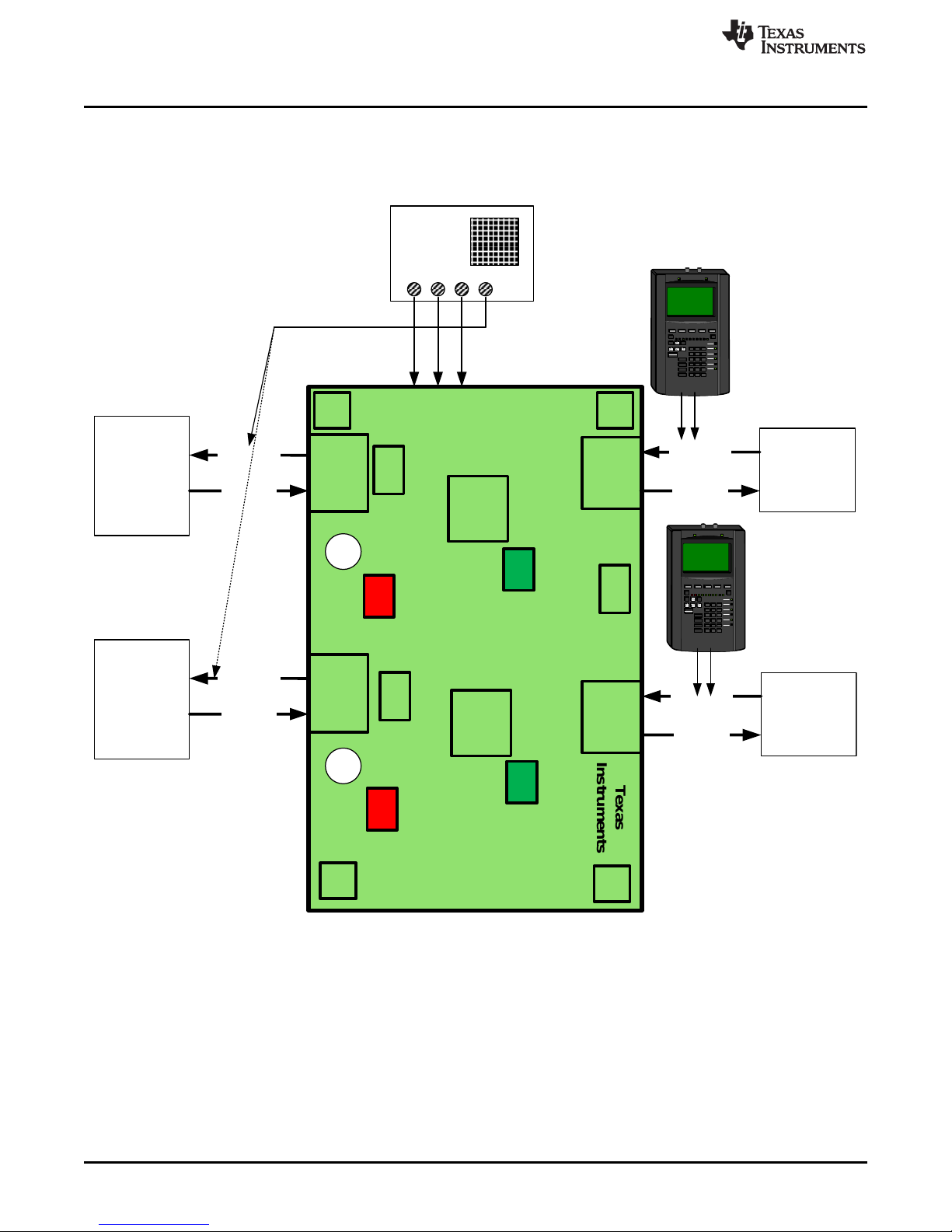

4.3 Test Setup

Figure 2 shows a typical test setup for the TPS25940XEVM. Connect J3/J8 to the power supply and J2/J7

to the load.

www.ti.com

Figure 2. EVM Test Setup

6

TPS25940XEVM-635: Evaluation Module for TPS25940X SLVUA44–June 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

4.4 Test Procedures

Use the following steps for the test procedure:

1. The operational voltage range of the two rails VIN1 and VIN2 can be adjusted by changing a few

resistor settings, as listed in Table 6.

Table 6. Operational Range Setting for VIN1, VIN2 = 12 V, 5 V and 3.3 V

VIN Operational Range Rail: VIN1 or VIN2 R9 R13 R11 R22 R26

12 V: 10.5 V to 16 V VIN1 16.9k 32.4k 47k

(Default)

5 V: 4.6 V to 5.7 V VIN1 23.2k 105k 137k

3.3 V: 3 V to 3.8 V VIN1 48.7k 187k 237k

2.3 V to 15.5 V (Default) VIN2 NoPoP 32.4k

5 V: 4.6 V to 5.7 V VIN2 130k 100k

3.3 V: 3 V to 3.8 V VIN2 237k 169k

2. Turn on the power supply and set the power supply voltage to 12 V.

3. Turn off the power supply. Hook up CH1 and CH2 of the PWR635 assembly as shown in Figure 2.

4. Ensure that the output load is disabled and the power supply is set properly for the design under test

(DUT). Connect the negative probe of DMM to TP12 or TP25 (GND).

5. Turn on the power supply, only 1 channel at a time. Verify that the voltages shown in Table 7 are

obtained.

General Configurations

Table 7. PWR635 DMM Readings at Different Test Points

Voltage test on (CH1) Measured Voltage Reading Voltage tested on (CH2) Measured Voltage Reading

VIN1 (TP3) 12 ±0.3 VDC VIN2 (TP15) 12 ±0.3 VDC

EN_UV1 (TP8) 1.13 ±0.1 VDC EN_UV2 (TP17) 12 ±1 VDC

OVP1 (TP5) 0.742 ±0.1 VDC OVP2 (TP18) 0.742 ±0.1 VDC

IMON1 (TP11) 32.9 mV ±5 mV VDC IMON2 (TP22) 32.6 mV ±5 mV VDC

VOUT1 (TP2) 12 ±0.3 VDC VOUT2 (TP16) 12 ±0.3 VDC

PG1 (TP9) 2.40 ±0.2 VDC PG2 (TP21) 2.4 ±0.2 VDC

FLTb1 (TP4) 10.51 ±0.5 VDC FLTb2 (TP20) 10.5 ±0.5 VDC

SLVUA44–June 2014 TPS25940XEVM-635: Evaluation Module for TPS25940X

Submit Documentation Feedback

7

Copyright © 2014, Texas Instruments Incorporated

Page 8

General Configurations

4.4.1 Preliminary Tests

4.4.1.1 For CH1 (J3-J2)

• With the power supply set to 12 V on CH1, verify that the green PG LED (D3) is on. Press the EVM

RST switch, S1 and verify that the voltage at VOUT1 (TP2) starts falling slowly below 12 V and that the

green PG LED (D3) turns off and FLTb1 red LED (D2) turns ON. Release S1.

• Reduce the input voltage on VIN1 and monitor VOUT1, Verify that VOUT1 (TP2) starts falling and is

fully turned off when VIN1 (TP3) reaches 9.5 V (±0.5 V). Verify that the PG1 green LED (D3) turns off

and FLTb1 red LED (D2) turns ON.

• Increase the input voltage on VIN1 and monitor VOUT1, Verify that VOUT1 (TP2) starts increasing and

is fully turned off when VIN1 (TP3) reaches 16.5 V (±1 V). Verify that the PG1 green LED (D3) turns off

and FLTb1 red LED (D2) turns ON.

4.4.1.2 For CH2 (J8-J7)

• With the power supply set to 12 V on CH2, verify that the green PG LED (D7) is on. Depress the EVM

RST switch, S2 and verify that the voltage at VOUT2 (TP16) starts falling slowly below 12 V and that

the green PG LED (D7) turns off and red FLTb2 LED (D6) turns ON. Release S2.

• Reduce the input voltage on VIN2 and monitor VOUT2, verify that VOUT2 (TP16) starts falling and is

fully turned off when VIN2 (TP15) reaches 2.1 V (±0.3 V). Verify that the PG2 green LED (D7) turns off

and FLTb2 red LED (D6) turns ON.

• Increase the input voltage on VIN2 and monitor VOUT2, verify that VOUT2 (TP16) starts increasing

and is fully turned off when VIN2 (TP15) reaches 15.5 V (±1 V). Verify that the PG2 green LED (D7)

turns off and FLTb2 red LED (D6) turns ON.

• Turn off both the power supplies.

www.ti.com

4.4.1.3 Ramp up Time Test (CH1 and CH2)

• Verify ramp up time (CH1 and CH2, with only 1 channel powered at a time). Set up the oscilloscope

as shown in Table 8.

Table 8. PWR635 Oscilloscope Setting for Ramp Up Voltage Test

Oscilloscope setting CH1 Probe Points CH2 Probe Points

Channel 1 = 5 V/div TP2 = VOUT1 TP16 = VOUT2

Channel 2 = 5 V/div TP3 = VIN1 TP15 = VIN2

Channel 3 = 2 V/div TP8 = EN/UVLO1 TP17 = EN/UVLO2

Trigger source = Channel 1

Trigger level = 6.0 ±0.5 V

Trigger polarity = Positive

Trigger Mode = Single Sequence

Time base = 1 ms/div

8

TPS25940XEVM-635: Evaluation Module for TPS25940X SLVUA44–June 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

• Set the output load at 100 Ω on CH1 and then enable the load. Turn on the power supply, Press the

General Configurations

EVM RST switch, S1 and release verify that VOUT1 (TP2) ramps up as Figure 3 illustrates.

Figure 3. V

Ramp Up Time for CH1

OUT

• Set the output load at 100 Ω on CH2 and then enable the load. Turn on the power supply, Press the

EVM RST switch, S2 and release verify that VOUT2 (TP16) ramps up as Figure 4 shows.

SLVUA44–June 2014 TPS25940XEVM-635: Evaluation Module for TPS25940X

Submit Documentation Feedback

Figure 4. V

Copyright © 2014, Texas Instruments Incorporated

Ramp Up Time for CH2

OUT

9

Page 10

General Configurations

4.4.1.4 Current Limit Tests

• Verify all three current limits (CH1 and CH2, with only 1 channel powered at a time) and verify the

latch and auto-retry feature. Setup the oscilloscope as shown in Table 9.

Table 9. PWR635 Oscilloscope Settings for Current Limit Test

Oscilloscope setting CH1 Probe Points CH2 Probe Points

Channel 1 = 5 V/div TP2 = VOUT1 TP16 = VOUT2

Channel 2 = 5 V/div TP3 = VIN1 TP15 = VIN2

Channel 4 = 2 A/div Input current into J3 +ve wire Input current into J8 +ve wire

Trigger source = Channel 4

Trigger level = 1.0 ±0.2 A

Trigger polarity = +ve

Trigger Mode AUTO Single Sequence

Time base 40 ms/div 100 ms/div

NOTE: If an electronic load is used, ensure that the output load is set to constant resistance mode

and not constant current mode.

NOTE: Measuring Current Limit values on the oscilloscope can easily cause 10% error from

anticipated values listed in Table 10.

www.ti.com

NOTE: Since the pulse width of current can vary significantly with the VIN ramp rate, which varies

from one power supply to another, do not worry about matching the pulse widths of Figure 5

and Figure 6.

• The jumper setting for the different current limit test is shown in Table 10.

Table 10. PWR635 Jumper Setting for Current Limits

Jumper Position Load Current Limit

J4 (CH1) J9 (CH2)

HI HI 5.3

LO LO 3.6

No Jumper No Jumper 2.1

(A)

10

TPS25940XEVM-635: Evaluation Module for TPS25940X SLVUA44–June 2014

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

• Set the output load at 1.0 Ω ±0.1 Ω on CH1 and then enable the load. Turn on the VIN1 power supply.

• Set the output load at 1.0 Ω ±0.1 Ω on CH2 and then enable the load. Turn on the VIN2 power supply

General Configurations

Verify that the input current is limited as per the setting in Table 10. Verify the device is in auto-retry

mode as shown in Figure 5 and FLTb1 RED LED (D2) turns on and off.

Figure 5. J4 = LO Current Limit Test Auto Retry (CH1)

and verify that the input current is limited as per the setting in Table 10. Also verify the device is in

latched-off mode and FLTb1 RED LED (D2) turns ON as shown in Figure 6.

Figure 6. J9 = “No Jumper” Current Limit Test with Latch (CH2)

• Set the input power supply to zero volts and disconnect all equipment from the DUT.

SLVUA44–June 2014 TPS25940XEVM-635: Evaluation Module for TPS25940X

Submit Documentation Feedback

11

Copyright © 2014, Texas Instruments Incorporated

Page 12

EVM Assembly Drawings and Layout Guidelines

5 EVM Assembly Drawings and Layout Guidelines

Figure 7 through Figure 9 show component placement and layout of the EVM.

www.ti.com

Figure 7. Top Side Placement

12

TPS25940XEVM-635: Evaluation Module for TPS25940X SLVUA44–June 2014

Figure 8. Top Side Routing Layer

Copyright © 2014, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

EVM Assembly Drawings and Layout Guidelines

Figure 9. Bottom Side Routing Layer

SLVUA44–June 2014 TPS25940XEVM-635: Evaluation Module for TPS25940X

Submit Documentation Feedback

13

Copyright © 2014, Texas Instruments Incorporated

Page 14

Bill of Materials (BOM)

www.ti.com

6 Bill of Materials (BOM)

Table 11 lists the BOM for this EVM.

Table 11. TPS25940XEVM-635 Bill of Material

Designator Qty Value Description PackageReference PartNumber Manufacturer Alternate PartNumber Alternate

Manufacturer

!PCB 1 Printed Circuit Board PWR635 Any - C1 1 0.1uF CAP, CERM, 0.1uF, 25V, +/-10%, X7R, 0603 0603 06033C104KAT2A AVX

C2, C3, C8, C9 4 4.7uF CAP, CERM, 4.7uF, 25V, +/-10%, X7R, 1206 1206 C3216X7R1E475K TDK

C4, C10 2 330uF CAP, AL, 330uF, 25V, +/-20%, 0.16 ohm, SMD HA0 EMZA250ADA331MHA0G Nippon Chemi-Con

C5, C11 2 330pF CAP, CERM, 330pF, 100V, +/-5%, X7R, 0603 0603 06031C331JAT2A AVX

C6, C12 2 1000pF CAP, CERM, 1000pF, 100V, +/-20%, X7R, 0603 0603 06031C102MAT2A AVX - C7 1 1uF CAP, CERM, 1uF, 25V, +/-10%, X5R, 0603 0603 C1608X5R1E105K080AC TDK

D1 1 30V Diode, Schottky, 30V, 0.2A, SOT-23 SOT-23 BAT54C-7-F Diodes Inc.

D2, D6 2 Red LED, Red, SMD Power TOPLED w/lens LS E63F-DBFA-1-Z OSRAM - D3, D7 2 Green LED, Green, SMD Power TOPLED w/lens LT E63C-CADB-35-L-Z OSRAM - D4, D8 2 20V Diode, Schottky, 20V, 3A, SMA SMA B320A-13-F Diodes Inc.

D5, D9 2 16V Diode, TVS, Uni, 16V, 600W, SMB SMB SMBJ16A-13-F Diodes Inc.

FID1, FID2, FID3 3 Fiducial mark. There is nothing to buy or mount. Fiducial N/A N/A

H1, H2, H3, H4 4 Bumpon, Cylindrical, 0.312 X 0.200, Black Black Bumpon SJ61A1 3M

J1, J4, J6, J9, 5 1x3 Header, TH, 100mil, 1x3, Gold plated, 230 mil above insulator PBC03SAAN PBC03SAAN Sullins Connector Equivalent Any

J10 Solutions

J2, J3, J7, J8 4 Terminal Block, 2x1, 5.08mm, TH 10.16x15.2x9mm 282841-2 TE Connectivity

J5 1 Header, TH, 100mil, 2x2, Gold plated, 230 mil above insulator TSW-102-07-G-D TSW-102-07-G-D Samtec, Inc. Equivalent Any

LBL1 1 Thermal Transfer Printable Labels, 0.650" W x 0.200" H - PCB Label 0.650"H x THT-14-423-10 Brady - -

10,000 per roll 0.200"W

Q1 1 30V MOSFET, N-CH, 30V, 100A, SON 5x6mm SON 5x6mm CSD17301Q5A Texas Instruments None None

Q2, Q3 2 60V MOSFET, N-CH, 60V, 0.31A, SOT-323 SOT-323 2N7002KW FairchildSemiconductor None

R1, R2, R16, R17 4 100k RES, 100k ohm, 5%, 0.1W, 0603 0603 CRCW0603100KJNEA Vishay-Dale

R3, R4, R18, 5 475k RES, 475k ohm, 1%, 0.1W, 0603 0603 CRCW0603475KFKEA Vishay-Dale Equivalent Any

R19, R20

R5 1 10.0k RES, 10.0k ohm, 1%, 0.1W, 0603 0603 CRCW060310K0FKEA Vishay-Dale Equivalent Any

R6 1 0.1 RES, 0.1 ohm, 1%, 3W, 2512 2512 CRA2512-FZ-R100ELF Bourns

R9, R10, R25 3 16.9k RES, 16.9k ohm, 1%, 0.1W, 0603 0603 CRCW060316K9FKEA Vishay-Dale [NoValue], [NoValue], [NoValue], [NoValue],

Equivalent Any

R11, R23 2 47k RES, 47k ohm, 5%, 0.1W, 0603 0603 CRCW060347K0JNEA Vishay-Dale

R12, R27 2 24.9k RES, 24.9k ohm, 1%, 0.1W, 0603 0603 CRCW060324K9FKEA Vishay-Dale

R13, R26 2 32.4k RES, 32.4k ohm, 1%, 0.1W, 0603 0603 CRCW060332K4FKEA Vishay-Dale

R14, R28 2 16.2k RES, 16.2k ohm, 1%, 0.1W, 0603 0603 CRCW060316K2FKEA Vishay-Dale

R15, R24 2 100k RES, 100k ohm, 1%, 0.1W, 0603 0603 CRCW0603100KFKEA Vishay-Dale

R21, R29 2 10k RES, 10k ohm, 5%, 0.1W, 0603 0603 CRCW060310K0JNEA Vishay-Dale

S1, S2 2 Switch, Push Button, SMD 2.9x2x3.9mm SMD SKRKAEE010 Alps Equivalent Any

SH-J1, SH-J4, 3 1x2 Shunt, 100mil, Gold plated, Black Shunt 969102-0000-DA 3M SNT-100-BK-G Samtec

SH-J9

14

TPS25940XEVM-635: Evaluation Module for TPS25940X SLVUA44–June 2014

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 15

www.ti.com

Bill of Materials (BOM)

Table 11. TPS25940XEVM-635 Bill of Material (continued)

Designator Qty Value Description PackageReference PartNumber Manufacturer Alternate PartNumber Alternate

Manufacturer

TP1, TP4, TP5, 11 White Test Point, TH, Multipurpose, White Keystone5012 5012 Keystone Equivalent Any

TP8, TP9, TP11,

TP17, TP18,

TP20, TP21,

TP22

TP2, TP3, TP15, 4 Red Test Point, TH, Multipurpose, Red Keystone5010 5010 Keystone Equivalent Any

TP16

TP6, TP19, TP23 3 Orange Test Point, Multipurpose, Orange, TH Orange Multipurpose 5013 Keystone

Testpoint

TP7 1 White Test Point, Multipurpose, White, TH White Multipurpose 5012 Keystone

Testpoint

TP10, TP14, 3 Black Test Point, TH, Multipurpose, Black Keystone5011 5011 Keystone Equivalent Any

TP26

TP12, TP13, 4 SMT Test Point, SMT, Compact Testpoint_Keystone_Com 5016 Keystone Equivalent Any

TP24, TP25 pact

U1 1 2.7V-18V eFuse with True Reverse Blocking and DevSleep RVC0020A TPS25940ARVC Texas Instruments None

Support for SSDs, RVC0020A

U2 1 2.7V-18V eFuse with True Reverse Blocking and DevSleep RVC0020A TPS25940LRVC Texas Instruments None

Support for SSDs, RVC0020A

R7 0 0.003 RES, 0.003 ohm, 1%, 1W, 2512 2512 73M1R003F CTS Resistor

R8 0 32.4k RES, 32.4k ohm, 1%, 0.1W, 0603 0603 CRCW060332K4FKEA Vishay-Dale

R22 0 48.7k RES, 48.7k ohm, 1%, 0.1W, 0603 0603 CRCW060348K7FKEA Vishay-Dale

SH-J5, SH-J6, 0 1x2 Shunt, 100mil, Gold plated, Black Shunt 969102-0000-DA 3M SNT-100-BK-G Samtec

SH-J10

Notes: Unless otherwise noted in the Alternate PartNumber and/or Alternate Manufacturer columns, all parts may be substituted with equivalents.

15

SLVUA44–June 2014 TPS25940XEVM-635: Evaluation Module for TPS25940X

Submit Documentation Feedback

Copyright © 2014, Texas Instruments Incorporated

Page 16

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2014, Texas Instruments Incorporated

Page 17

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

TPS25940EVM-635

Loading...

Loading...