Page 1

R

SENSEA

PGA

ENA

FLTA

SENMA

GAT1A

OUTA

SETA

GAT2A

SENPA

GND

PGB

ENB

FLTB

TPS2456

36 PIN QFN

CTB

R

SETA

INB

INA

INA

GND

GND

COMMON

CIRCUITRY

ORENB

C

INT

0.1mF

VINT

ORENA

CTA

GND

GND

GAT1B

OUTB

GAT2B

C

TB

33nF

C

TA

33nF

R

G1B

R

G2B

INB

GND

MONA

GND

GND

MONB

C

INA

0.1mF

R

G1ARG2A

R

SENSEB

SETB

SENPB

R

SETB

SENMB

R

M

O

N

C

INB

0.1mF

M1A

M2A

M1B

M2B

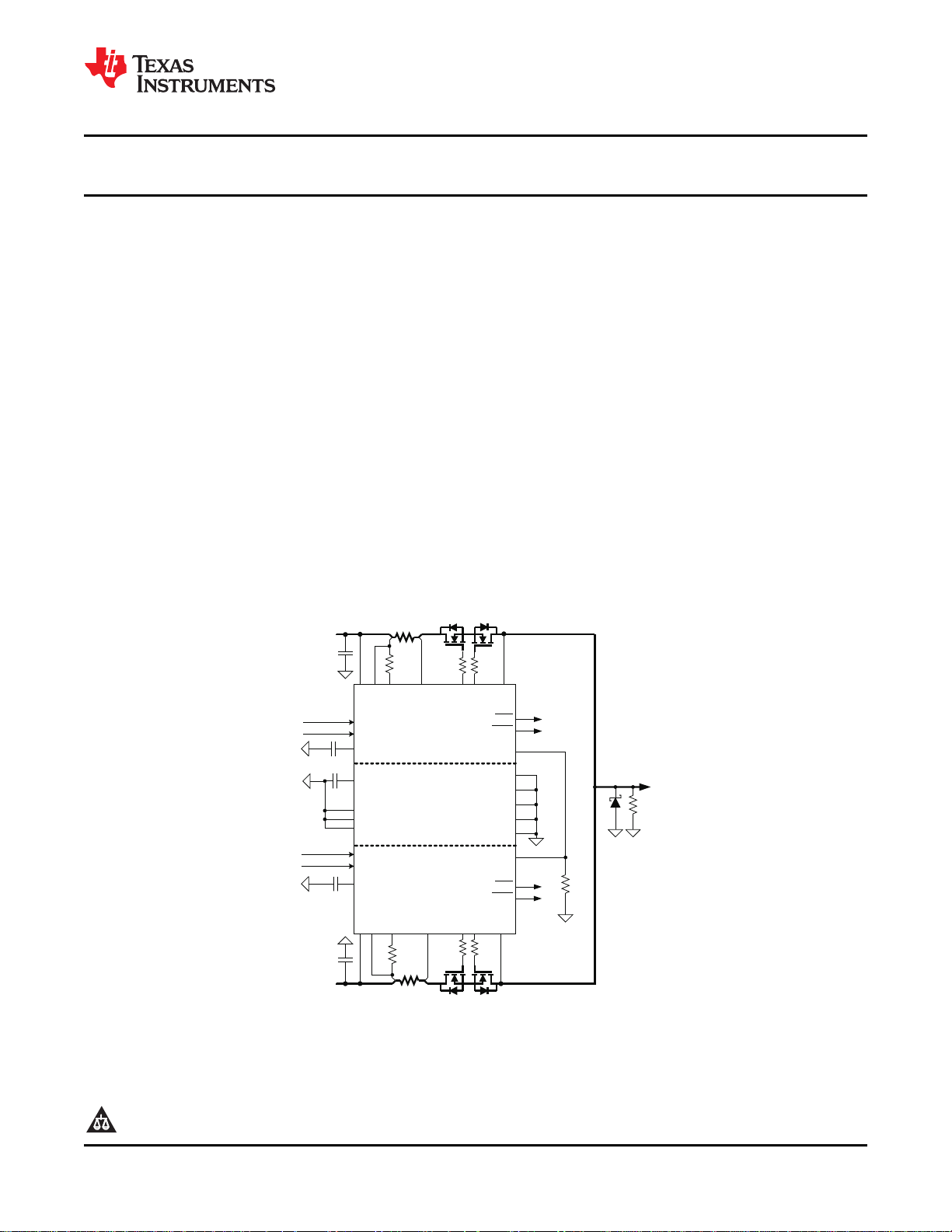

TPS2456

www.ti.com

Dual 12 V Protection / Blocking Controller

Check for Samples: TPS2456

1

FEATURES

• Dual 12 V Protection and Blocking Control

• Independent Current Limit and Fast Trip

• Blocking Permits ORing of Multiple Inputs

• Power Good and Fault Outputs

• Analog Current Monitor Outputs

• -40°C to 125°C Operating Junction

Temperature

• QFN36 Package

APPLICATIONS

• ATCA Carrier Boards

• AdvancedMC™ Slots

• Blade Servers

• Base Stations

• Configurable for

– 1 Source, 2 Loads

– 2 Sources, 1 Load

– 2 Sources, 2 Loads

SLVSA78A –MARCH 2010–REVISED MARCH 2010

DESCRIPTION

The TPS2456 is a dual, 12 V, channel protection

(hotswap) and blocking (ORing) controller that

provides inrush control, current limiting, overload

protection, and reverse current blocking. The current

sense topology provides both accurate current limits

and independent setting of current limit and fast trip

thresholds.

The ORing control uses an external MOSFET to

block reverse current when an input is shorted.

Systems with closely matched supply voltages and

feed networks can supply current from both supplies

simultaneously.

The MONx output provides an accurate analog

indication of load current.

The protection circuits may be used without blocking,

and the blocking may be used without protection.

Internal connections prevent implementation of these

as four fully-independent functions.

1

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Figure 1. Two Sources, One Load Application Diagram

Copyright © 2010, Texas Instruments Incorporated

Page 2

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

www.ti.com

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

PRODUCT INFORMATION

(1)

DEVICE TEMPERATURE PACKAGE MARKING

TPS2456RHH –40°C to 85°C QFN36 (6mm × 6mm) TPS2456

(1) For package and ordering information see the Package Option Addendum at the end of this document or see the TI Web site at

www.ti.com.

THERMAL INFORMATION

TPS2456

THERMAL METRIC

q

JA

q

JC(top)

q

JB

y

JT

y

JB

q

JC(bottom)

Junction-to-ambient thermal resistance

Junction-to-case(top) thermal resistance

Junction-to-board thermal resistance

Junction-to-top characterization parameter

Junction-to-board characterization parameter

Junction-to-case(bottom) thermal resistance

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

(2) The junction-to-ambient thermal resistance under natural convection is obtained in a simulation on a JEDEC-standard, High-K board, as

specified in JESD51-7, in an environment described in JESD51-2a.

(3) The junction-to-case(top) thermal resistance is obtained by simulating a cold plate test on the package top. No specific JEDEC-standard

test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(4) The junction-to-board thermal resistance is obtained by simulating in an environment with a ring cold plate fixture to control the PCB

temperature, as described in JESD51-8.

(5) The junction-to-top characterization parameter, yJT, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining qJA, using a procedure described in JESD51-2a (sections 6 and 7).

(6) The junction-to-board characterization parameter, yJBestimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining qJA, using a procedure described in JESD51-2a (sections 6 and 7).

(7) The junction-to-case(bottom) thermal resistance is obtained by simulating a cold plate test on the exposed (power) pad. No specific

JEDEC standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(1)

RHH UNITS

36 PINS

(2)

(3)

(4)

(5)

(6)

(7)

32

23

11

0.5

10

2.1

°C/W

ABSOLUTE MAXIMUM RATINGS

(1)

Over recommended junction temperature range and all voltages referenced to GND, unless otherwise noted.

PINS OR PIN GROUPS VALUE UNITS

GAT1x, GAT2x –0.3 to 30 V

INx, OUTx, SENPx, SENMx, SETx, ENx, FLTx, PGx, ORENx –0.3 to 17 V

CTx, MONx –0.3 to 5 V

FLTx, PGx current sinking 5 mA

MONx current sourcing 5 mA

VINT current –1 to 1 mA

ESD

Junction Temperature Internally Limited °C

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only. Functional operation of the device under any conditions beyond those indicated under recommended operating conditions is not

implied. Exposure to absolute maximum rated conditions for extended periods of time may affect device reliability.

2 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Human Body Model 2 kV

Charged Device Model 0.5 kV

Product Folder Link(s): TPS2456

Page 3

TPS2456

www.ti.com

SLVSA78A –MARCH 2010–REVISED MARCH 2010

RECOMMENDED OPERATING CONDITIONS

Over recommended junction temperature range and all voltages referenced to GND, unless otherwise noted.

MIN TYP MAX UNIT

V

INx

I

MONx

GAT1x, GAT2x board leakage current

(1)

VINT bypass capacitance 1 100 250 nF

Operating junction temperature range, T

J

(1) This condition applies to the PCB and is not a limit on the TPS2456.

8.5 12 15 V

100 1000 µA

–1 1 µA

–40 125 °C

ELECTRICAL CHARACTERISTICS

Common conditions (unless otherwise noted) are: INA = INB = SENPA = SENPB = SENMA = SENMB = SETPA = SETPB =

12 V, ENA = ENB = ORENA = ORENB = 3 V, CTA = CTB = GND, R

–40°C ≤ TJ≤ 125°C

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Enable Input – ENx, ORENx

Threshold voltage V

Hysteresis 20 50 80 mV

Pullup current ENx = ORENx = 0 V, current sourcing 5 8 15 µA

Input bias current ENx = ORENx = 17 V, current sinking 6 15 µA

Turn off time

(1) (2)

Power Good Output – PGx

Output low voltage I

Leakage current PGx = 17 V (sinking) 1 µA

Threshold voltage PGx, V

Hysteresis PGx, V

Deglitch time PGx falling 50 100 150 µs

Fault Output – FLTx

Output low voltage I

Leakage current V

Bias Supply – VINT

Output voltage 0 < I

Fault Timer – CTx

Sourcing current V

Upper threshold voltage 1.30 1.35 1.40 V

Discharge pulldown

(2)

Timer start threshold 5 6 7 V

Channel Current Monitor – MONx

Input referred offset –1.5 1.5 mV

MONx threshold V

Leakage current V

(1) Tested with HAT2156 MOSFET.

(2) These parameters are provided for reference only, and do not constitute part of TI's published device specifications for purposes of TI's

product warranty.

↑ 1.25 1.35 1.45 V

INx

ENx deasserts to V

= 2 mA sinking 0.14 0.25 V

PGx

↓ 10.2 10.5 10.8 V

OUTx

↑ 130

OUTx

= 2 mA sinking 0.14 0.25 V

FLTx

= 17 V (sinking) 1 µA

FLTx

< 50 µA 2 2.3 2.8 V

VINT

= 0 V, during fault 7 10 13 µA

CTx

(V

– V

GAT1x

current

10.8 V ≤ V

measure V

GAT1x

SETx

) when timer starts, with V

INx

SENMx

– V

SETx

= 15 V 0.66 0.675 0.69 V

= (V

SENMx

< 1 V, C

OUTx

≤ 13.2 V, V

SENMx

SENPx

OUT

= V

= 0 µF, Q

GAT1x

+ 50 mV,

SENMx

– 10 mV) 1 µA

= R

MONA

= 33 nF 20 µs

GAT1x

= 6.81kΩ, all other pins open,

MONB

(2)

200 Ω

falling due to over

mV

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): TPS2456

Page 4

V

T

90%

V

ENx

V

GAT1x

,

V

GAT2x

t

P50-90

time

50%

V

SENPx

-

V

SENMx

V

GAT1x

,

V

GAT2x

t

P50-50

time

50%

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

Common conditions (unless otherwise noted) are: INA = INB = SENPA = SENPB = SENMA = SENMB = SETPA = SETPB =

12 V, ENA = ENB = ORENA = ORENB = 3 V, CTA = CTB = GND, R

–40°C ≤ TJ≤ 125°C

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Current limit

R

= 500 Ω, R

Current limit threshold 47.5 50 52.5 mV

Sink current in current

limit

Fast trip threshold Measure V

Fast turn-off delay (V

SETx

V

GAT1x

V

MONx

SENP

= 15 V

= 1 V, V

SENPx

– V

SENM

Channel UVLO

UVLO V

UVLO hysteresis V

↑ 8.1 8.5 8.9 V

INx

↓ 0.44 0.5 0.59 V

INx

Blocking Comparator

Turn-on threshold Measure (V

Turn-off threshold Measure (V

SENPx

SENPx

Turn-off delay 20 mV overdrive, t

Gate Drivers – GAT1x, GAT2x

Output voltage V

Sourcing current V

Sinking current

= V

INx

= V

INx

Fast turnoff, V

= 10 V 21.5 23 24.5 V

OUTx

= 10 V, V

OUTx

GAT1x

Sustained, 4 V ≤ (V

Pulldown resistance In thermal shutdown 14 20 26 kΩ

Fast turn-off duration 5 10 15 µs

Disable delay ENx pin to V

GATx1

Startup Time INx rising to GAT1x or GAT2x sourcing current (ENx and ORENx 0.25 ms

high)

Supply Current (I

INx

+ I

SENPx

+ I

SENMx

+ I

SETx

Both channels enabled 3.1 4 mA

Both channels disabled 2 2.8 mA

Thermal Shutdown

Shutdown temperature TJrising 140 150 °C

Hysteresis 10

(3) See Figure 3 for timing definition.

(4) See Figure 2 for timing definition.

(5) These parameters are provided for reference only, and do not constitute part of TI's published device specifications for purposes of TI's

product warranty.

= 6800 Ω, measure V

MONx

= 12 V, measure I

GAT1x

– V

SENMx

): 0 V → 120 mV, t

– V

) 5 10 20 mV

OUTx

– V

) –6 –3 0 mV

OUTx

p50-50

= V

GAT1x

+ I

= V

GAT1x

and V

OUTx

= 14 V, pulsed measurement 0.5 1 A

GAT2x

= V

GAT2x

, t

GAT2x

)

SENPx

GAT1x

(3)

P50-50

= 17 V 20 30 40 µA

GAT2x

) ≤ 25 V 10 14 20 mA

(4)

P50-90

MONA

– V

= R

SENMx

= 6.81kΩ, all other pins open,

MONB

when

20 40 µA

80 100 120 mV

200 300 ns

200 300 ns

1 µs

(5)

°C

Figure 2. t

4 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Definition Figure 3. t

P50-90

Product Folder Link(s): TPS2456

P50-50

Definition

Page 5

+

+

+

100mV

675mV

Control

& Fault

Vcp

30mA

enx

C

Tx

R

MONx

FLTx

PGx

prgx

blx

OUTx

GAT2x

GAT1x

SETx

SENMx

SENPx

100ms

INx

OUTx

10.50V /

10.63V

+

30mA

ENx

MONx

CTx

por

Charge

Pump

Vcp

~25V

60mA

ORENx

R

G1x

R

SETx

R

G2x

A

2

A

1

R

SENSEx

M

1

M

2

+

+

10 mV

3 mV

SQQ

R

OUTx

prgx

blx

200kW

VINT

2

0

0

k

W

VINT

enx

12V Channel

Input Supply

8.5V

/ 8V

+

+

6V

INx

Fast

Trip

Current

Limit

FLT Tmr.

Gate Mon.

10ms

UVLO

Blocking

Control

Output

PG

10ms

PREREG

VINT

2.2V

Pwr On

Reset

en por

Control

Logic

GND

INA

INB

OUTA

OUTB

+

VINT

C

VINT

TPS2456

www.ti.com

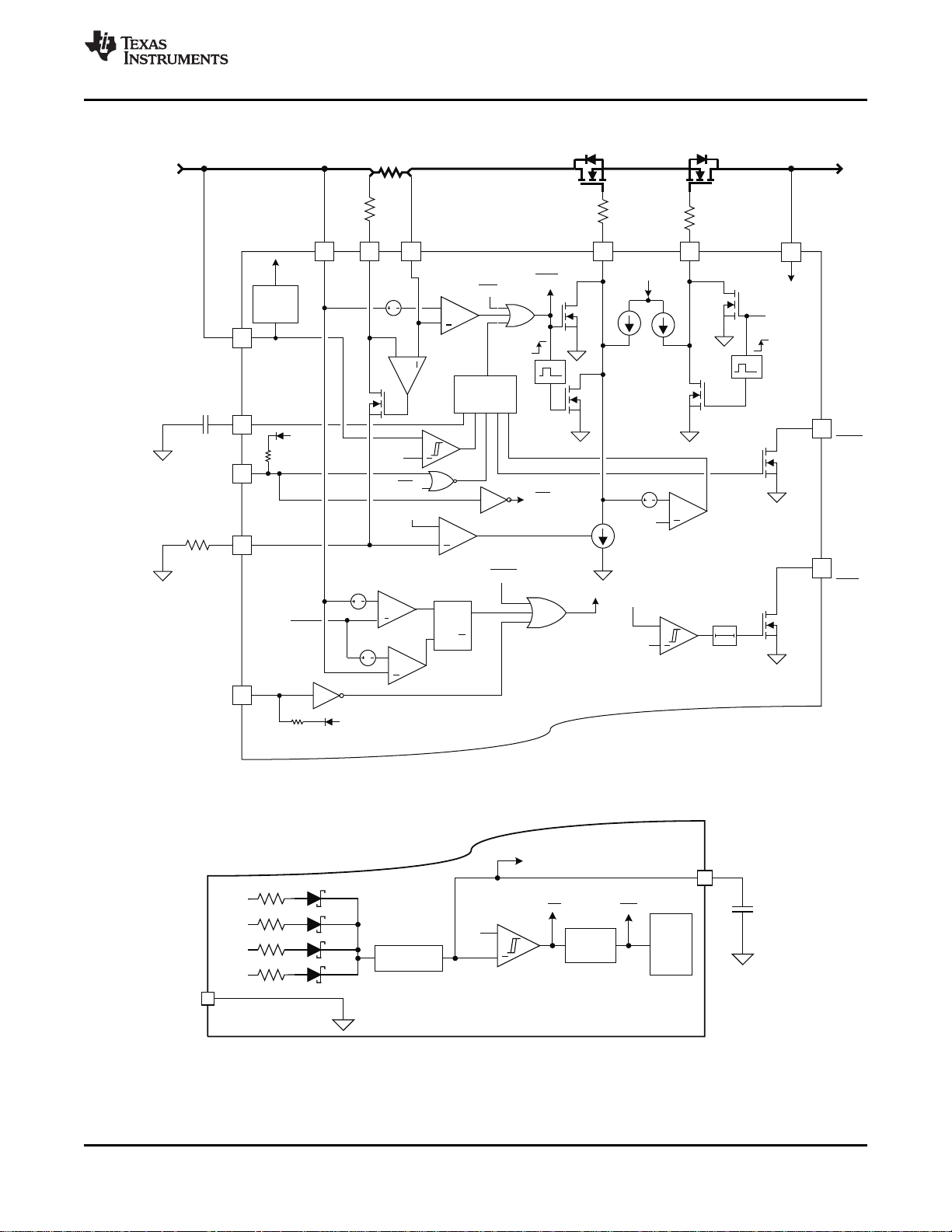

FUNCTIONAL BLOCK DIAGRAM

SLVSA78A –MARCH 2010–REVISED MARCH 2010

Figure 4. TPS2456 Channel (2 channels per device)

Figure 5. Common Control Circuits

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): TPS2456

Page 6

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

PIN FUNCTIONS

PIN

NAME NO.

TYPE A/B

SENPA 1 I A Input voltage sense – connect to input supply. Connect to the source side of R

SETA 2 I A

SENMA 3 I A Connect this pin to the load side of the R

VINT 4 I/O – Connect a bypass capacitor (e.g., 0.01µF) to GND for this internal supply.

MONA 5 I/O A

ORENA 6 I A Blocking transistor enable, active high.

GND 7 GND – Connect pin to ground.

GND 8 GND – Connect pin to ground

MONB 9 I/O B

CTB 10 I/O B Connect CTBfrom CTB to GND to set the fault timer period (see text).

GAT2B 11 O B Blocking transistor gate drive.

OUTB 12 I/O B Output voltage monitor and bias input.

GND 13 GND B Connect pin to ground.

ORENB 14 I B Blocking transistor enable, active high.

GAT1B 15 O B Protection transistor gate drive.

SENMB 16 I B Connect this pin to the load side of the R

SETB 17 I B

SENPB 18 I B Input voltage sense – connect to input supply. Connect to the source side of R

INB 19 PWR B Control power input – connect to input supply.

– 20 – – No connection.

FLTB 21 O B Fault output, active low, asserted when B fault timer runs out.

PGB 22 O B Power good output, active low, asserts when V

GND 23 GND – Connect pin to ground.

GND 24 GND – Connect pin to ground.

GND 25 GND – Connect pin to ground.

PGA 26 O A Power good output, active low, asserts when V

FLTA 27 O A Fault output, active low, asserted when A fault timer runs out.

GND 28 GND – Connect pin to ground.

ENB 29 I B Enable, (active high).

GAT1A 30 O A Protection transistor gate drive.

ENA 31 I A Enable, (active high).

GND 32 GND A Connect pin to ground.

OUTA 33 I/O A Output voltage monitor and bias input.

GAT2A 34 O A Blocking transistor gate drive.

CTA 35 I/O A Connect CTAfrom CTA to GND to set the fault timer period (see text).

INA 36 PWR A Control power input – connect to input supply.

PAD – – – Solder pad to GND.

(1) Specifies whether this pin is part of A channel, B channel, or is common to both (-).

(1)

Connect R

and R

MONA

Connect R

text).

Connect R

text).

Connect R

conjunction with R

DESCRIPTION

from the input supply to SETA to program the current limit in conjunction with R

SETA

(see text).

. The fast-trip threshold equals 100 mV / R

SENSEA

from MONA to GND to set the current limit in conjunction with R

MONA

from MONB to GND to set the current limit in conjunction with R

MONB

. The fast-trip threshold equals 100 mV / R

SENSEB

from input supply to SETB to program the current limit program the current limit in

SETB

SENSEB

and R

MONB

(see text).

OUTB

OUTA

> 10.63 V.

> 10.63 V.

SENSEA

SENSEA

SENSEB

SENSEB

.

.

SENSEA

and R

and R

SENSEB

www.ti.com

SENSEA

.

(see

SETA

(see

SETB

.

6 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPS2456

Page 7

TPS2456

1

3

2

4

6

5

7

9

8

27

25

26

24

22

23

21

19

20

36 3435 33 3132 30 2829

10 1211 13 1514 16 1817

SENPA

SETA

SENMA

VINT

MONA

ORENA

GND

GND

MONB

FLTA

PGA

GND

GND

GND

PGB

FLTB

NC

INB

INA

CTA

GAT2A

OUTA

GND

ENA

GAT1A

ENB

GNDSENPB

SETB

SENMB

GAT1B

ORENB

GND

OUTB

GAT2B

CTB

PAD - Backside

TPS2456

www.ti.com

SLVSA78A –MARCH 2010–REVISED MARCH 2010

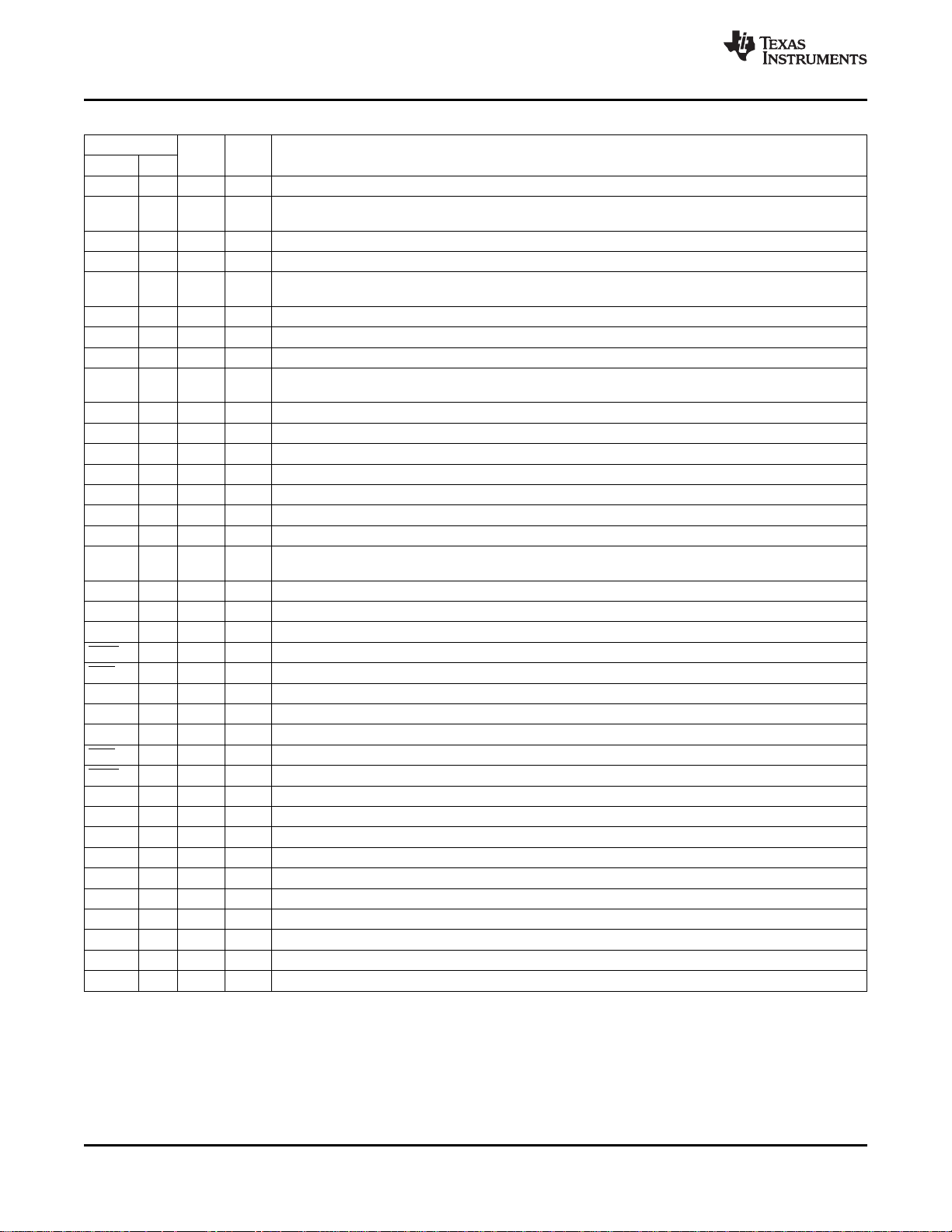

DEVICE PINOUT

(TOP VIEW)

DETAILED PIN DESCRIPTIONS

The TPS2456 supports two 12-V protection (hotswap) and blocking (ORing) channels designated A and B.

Where there are separate pins for both A and B channels, the pin name is shown with an x in place of A or B to

describe the function. For example, references to CTx would be the same as CTA or CTB. Programming

components are referred to in the text by reference designators used in Figure 1.

CTx – A capacitor from CTx to GND sets the period V

channel down and declares a fault. V

will be low during startup and current limit. Low V

GAT1x

to source 10 µA into the external capacitor (CTx). When V

by pulling the GAT1x and GAT2x pins low, declares a fault by pulling the FLTx pin low, and latching off. A 200 Ω

internal pull down keeps this pin low during normal operation when not in current limit. It is normal to see a

sawtooth on this pin when the channel is latched off by a fault.

ENx – Active high enable input. A low on ENx turns off the channel by pulling GAT1x and GAT2x low. An internal

200 kΩ resistor pulls this pin up to VINT. ENx may be left floating when the channel is to be permanently

enabled.

FLTx – Active low open-drain output indicating that V

the fault timer and shut the channel down. FLTx may be left open if not used.

GAT1x – Gate drive output for the protection MOSFET. This pin sources 30 µA to turn the MOSFET on. An

internal clamp prevents this pin from rising more than 14.5 V above INx.

Up to 30µA may be sunk while current limit is active. A fast trip (overcurrent), disable (from ENx), or fault timeout

enables a 10 µs, 1 A, discharge current and 14 mA pulldown. The pulldown will be released after 10 µs if only a

fast trip had occurred.

Setting ENx low holds GAT1x low. GAT1x may be left open if not used.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s): TPS2456

can be low ( V

GAT1x

reaches 1.35 V, the TPS2456 shuts the channel off

CTx

has been low ( V

GAT1x

GAT1x

GAT1x

< V

+ 6 V) before it shuts the

INx

GAT1x

< V

+ 6 V) long enough trip

INx

causes this pin

Page 8

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

www.ti.com

GAT2x – Gate drive output for the blocking MOSFET. The blocking MOSFET prevents reverse channel current

when OUTx is higher than INx. This is often used when two input sources are ORed together. GAT2x sources 30

µA to turn the MOSFET on. GAT2x is low when ENx is low, ORENx is low, FLTx is low, a fast trip is active, or a

voltage reversal has occurred. A 10 µs, 1 A, discharge and 14 mA pulldown are applied when this occurs.

An internal clamp prevents this pin from rising more than 14.5 V above OUTx. Setting the ORENx or ENx pins

low holds the GAT2x pin low.

GAT2x may be left open if not used.

INx - Supply pin for the internal circuitry. A small bypass capacitor (e.g. 0.1 µF) is recommended for this pin.

MONx – A resistor connected from this pin to ground forms part of the current limit programming. As the current

delivered to the load increases, so does the voltage on this pin. The current-limit circuit controls GAT1x to limit

channel current at a V

Equation 1 through Equation 4 define current limit and fast trip values using R

of 675 mV. The current limit circuit is inactive for lower values of V

MONx

MONx

, R

SENSEx

.

MONx

, and R

SETx

. V

MONx

can by sampled with an external A/D converter to measure the channel current.

ORENx – Active high input. Pulling this pin low disables the blocking function by pulling the GAT2x pin low.

Pulling this pin high (or allowing it to float high) allows the blocking function to operate normally. The M2x internal

diode may carry the load current when GAT2x is low and V

INX

> V

OUTX

.

An internal 200 kΩ resistor pulls this pin to VINT. ORENx may be left open when blocking is not used, or does

not require active control.

OUTx – Senses the output voltage of the channel. This voltage is used by the biasing, blocking, and power good

circuits.

PGx – Active low open-drain output. A low on PGx indicates that V

has exceeded 10.63 V, and has not

OUTx

fallen below 10.50 V. These thresholds are internally set, and modifying the OUTx connection may effect

blocking operation.

SENMx – Senses the voltage on the load side of R

SENSEx

SENPx – Senses the voltage on the source side of R

trip overcurrent shutdown is activated at a V

SENP-SENM

SETx – A resistor connected from this pin to SENPx sets the current limit level in conjunction with R

R

as described in Equation 1 through Equation 4.

MONx

for use by the fast trip and current limiting circuits.

SENSEx

for use by the fast trip and blocking circuits. The fast

of 0.1 V.

SENSEx

and

VINT – This pin connects to the internal 2.35 V rail. A 0.1 µF capacitor must be connected from this pin to

ground. VINT is not designed to be a general-purpose bias rail.

8 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPS2456

Page 9

2

2.1

2.2

2.3

2.4

-40 -20 0 20 40 60 80 100 120

T -JunctionTemperature-°C

J

SupplyCurrent-mA

2.1

2.15

2.2

2.25

2.3

2.35

2.4

2.45

10 10.5 11 11.5 12 12.5 13 13.5 14

V -InputVoltage-V

INx

T =25°C

J

SupplyCurrent-mA

-40 -20 0 20 40 60 80 100 120

T - Junction Temperature - °C

J

(V - V ) - mV

INx OUTx

-3.15

-3.05

-3.00

-2.95

-2.90

-2.85

-2.80

-3.10

50.2

50.4

50.6

50.8

-40 -20 0 20 40 60 80 100 120

T - Junction Temperature - °C

J

( ) - mVV - V

SENPx SENMx

R = 500

SETx

W

R = 6800

MONx

W

TPS2456

www.ti.com

SLVSA78A –MARCH 2010–REVISED MARCH 2010

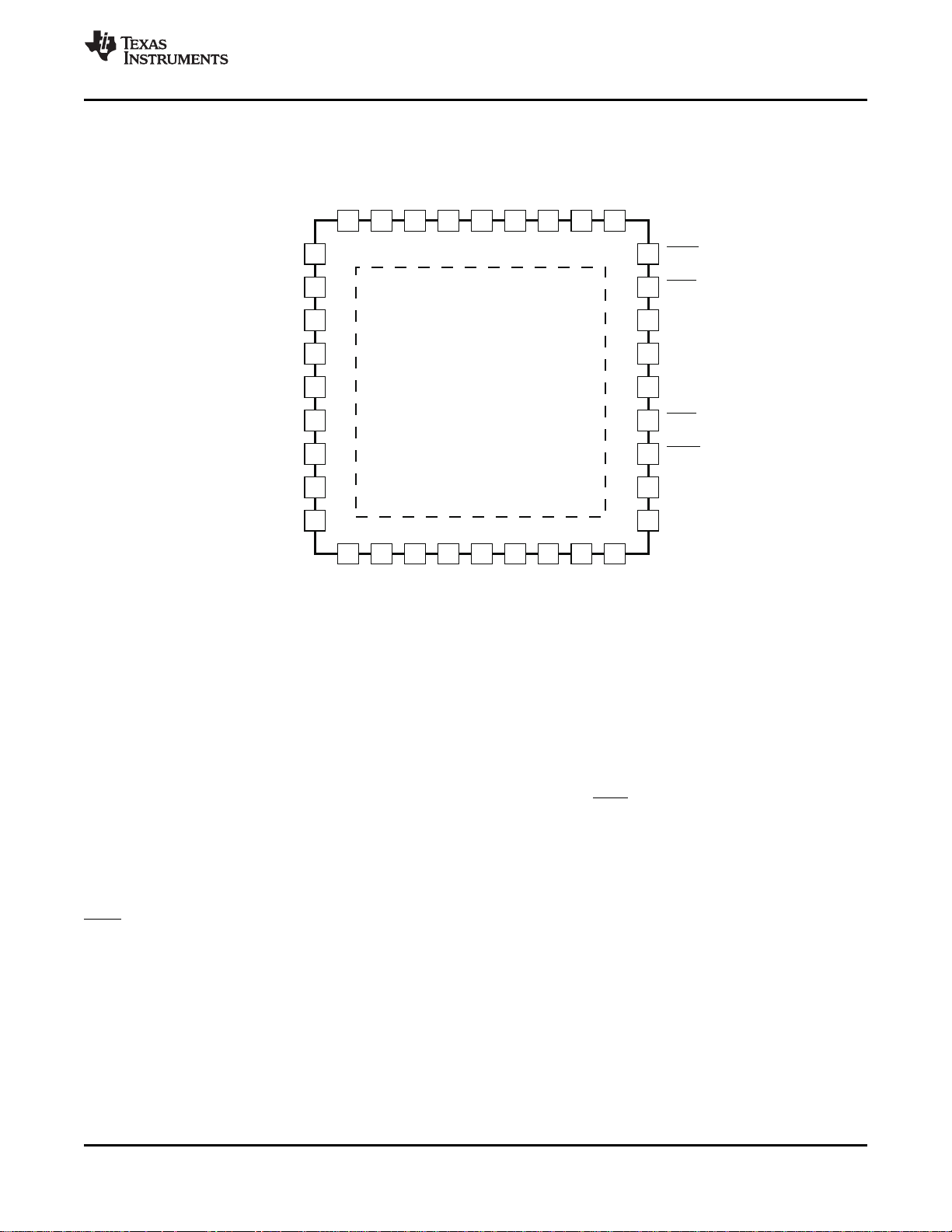

TYPICAL CHARACTERISTICS

SUPPLY CURRENT vs TEMPERATURE SUPPLY CURRENT vs INPUT VOLTAGE

Figure 6. Figure 7.

CURRENT LIMIT THRESHOLD vs TEMPERATURE BLOCKING TURNOFF THRESHOLD vs TEMPERATURE

Figure 8. Figure 9.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): TPS2456

Page 10

9

9.5

10

10.5

11

11.5

12

-40 -20 0 20 40 60 80 100 120

T -JunctionTemperature-°C

J

(V -V )-mV

INx OUTx

GAT1x,

10V/div

OUTxstartingupinto500 (24mA)

Outputcapacitanceis830 FWm

675mV

MONx,

0.5V/div

OUTx,

10V/div

40mV

Time-1ms/div

OUTxstartingupinto1.8 (6.7 A,80W)

Outputcapacitanceis830 FWm

675mV

580mV

Time-1ms/div

GAT1x,

10V/div

MONx,

0.5V/div

OUTx,

10V/div

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

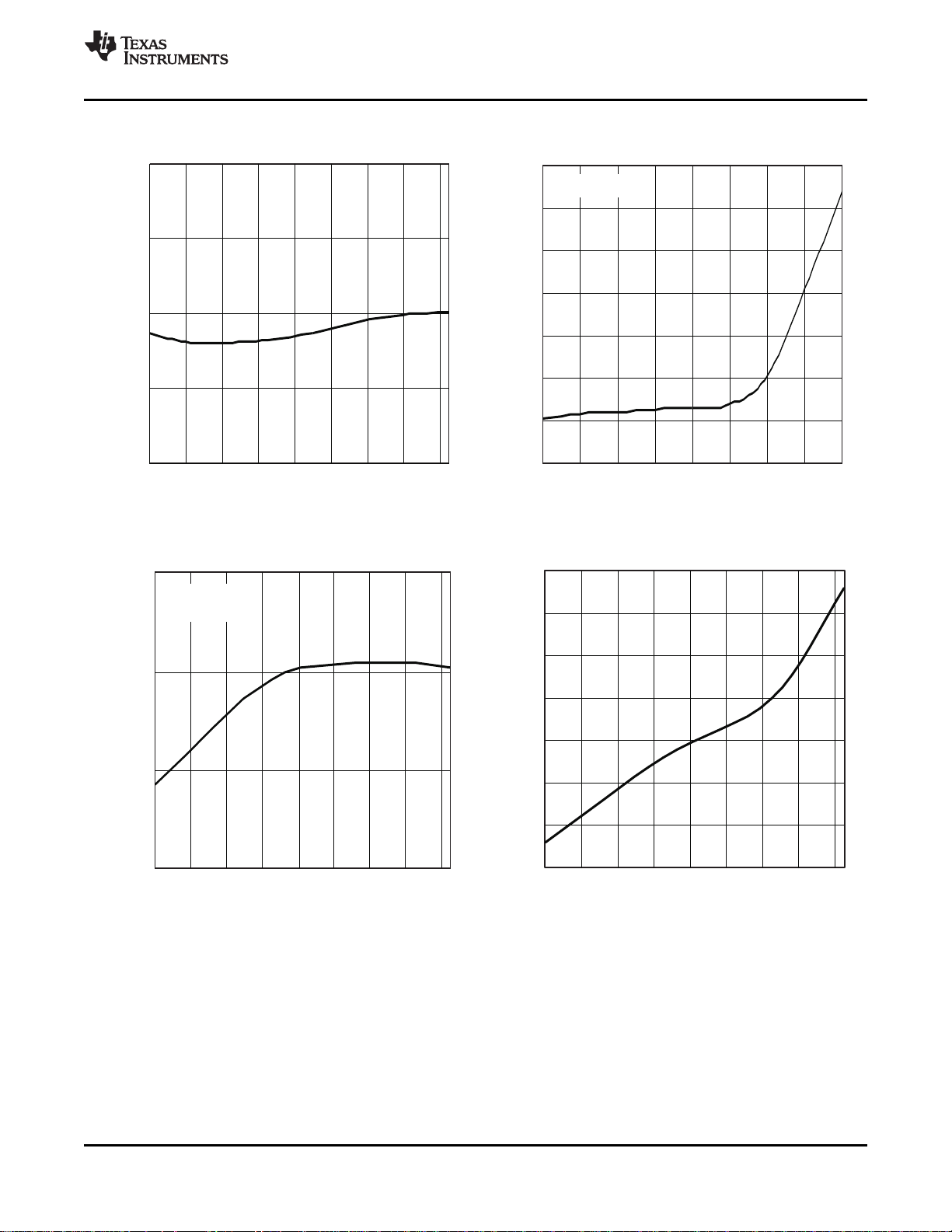

TYPICAL CHARACTERISTICS (continued)

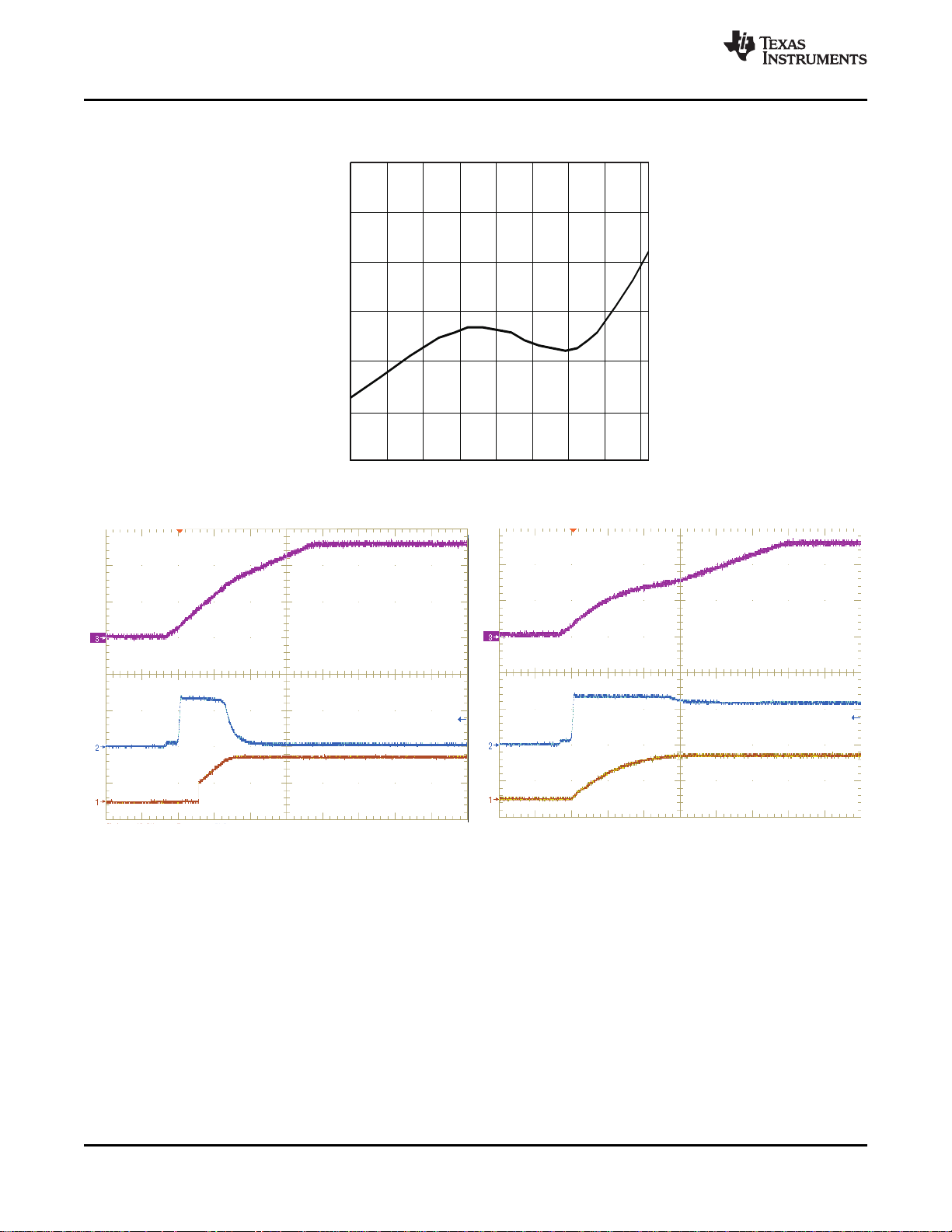

BLOCKING TURN ON THRESHOLD vs TEMPERATURE

www.ti.com

Figure 10.

Figure 11. Startup into 500 Ω, 830 µF Load Figure 12. Startup into 80 Watt, 830 µF Load

10 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPS2456

Page 11

OUTxshortedwhiledriving6.7 A load

Outputcapacitanceis47 Fm

620mV

675mV

Time-2ms/div

GAT1x,

10V/div

MONx,

1V/div

OUTx,

10V/div

OUTxshortedwhiledriving6.7 A load

Outputcapacitanceis47 Fm

620mV

Time-1 s/divm

GAT1x,

10V/div

MONx,

1V/div

OUTx,

10V/div

GAT1x,

2V/div

OUTxstartingintoshortcircuit

675mV

MONx,

0.5V/div

OUTx,

20mV/div

2.9V

Time-1ms/div

GAT1x,

10V/div

OUTxoverloadedwhilesupplying6.7 A

970mV

MONx,

0.5V/div

OUTx,

10V/div

675mV

Time-1ms/div

TPS2456

www.ti.com

SLVSA78A –MARCH 2010–REVISED MARCH 2010

TYPICAL CHARACTERISTICS (continued)

Figure 13. Short Circuit Under Full Load (6.7 A) Wide Figure 14. Short Circuit Under Full Load (6.7 A) Zoom View

Figure 15. Startup into Short Circuit Figure 16. Overloaded while Supplying 6.7 A

SYSTEM OPERATION

INTRODUCTION

The TPS2456 controls two 12-V channels, or power paths. The channels can draw from a single common

supply, or from two independent supplies. The following sections describe the TPS2456 operation and provide

guidance for designing systems around this device.

CONTROL LOGIC AND POWER-ON RESET

The TPS2456 circuitry draws bias power from any of the INx or OUTx pins through an internal preregulator that

generates VINT. A bypass capacitor from VINT to ground provides decoupling and output filtering for the internal

circuits. Bias supply ORing allows the internal circuitry to function regardless of which channels receive power or

are in a faulted state. The four external MOSFET drive pins (GAT1A, GAT1B, GAT2A, and GAT2B) are held low

during startup to ensure that the channels remain off. When the voltage on the internal VINT rail exceeds

approximately 1 V, the power-on reset (POR) circuit initializes the TPS2456 and allows normal operation.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): TPS2456

Page 12

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

www.ti.com

ENABLE FUNCTIONS

The TPS2456 has two external enable pins for each of the channels.

The GAT1x and GAT2x pins are held low when the ENx pin is low. A high on ENx enables GAT1x for normal

control by the startup and protection features. Toggling ENx low, then high, clears a latch-off condition after a

fault has occurred on the channel.

The GAT2x pin is held low when the ORENx or ENx pins are low. The reverse blocking comparator-driven state

machine controls GAT2x when ORENx and ENx pins are high.

ENx ORENx PROTECTION BLOCKING

0 0 Disabled (low) Disabled (low)

0 1 Disabled (low) Disabled (low)

1 0 Enabled Disabled (low)

1 1 Enabled Enabled

(M1x, GAT1x) (M2x, GAT2x)

Each of the four enable pins has an internal 200 kΩ pullup resistor to VINT.

POWER GOOD (PGx) OUTPUTS

The TPS2456 provides an active-low open-drain Power Good (PGx) output for each channel. PGx goes low

(output good indication) for rising V

100 µs deglitch filter aids in avoiding false indications due to noise.

exceeding 10.63 V and PGx goes high for falling V

OUTx

below 10.5 V. A

OUTx

FAULT (FLTx) OUTPUTS

The TPS2456 provides an active-low open-drain fault output for each channel. The FLTx output pulls low when

the channel has remained in current limit long enough for the fault timer to expire (V

> 1.35 V). A channel

CTx

experiencing a fault timeout shuts down and latches off. Toggle the faulted channel’s ENx low and high to clear

the fault and re-enable the channel.

CURRENT LIMIT AND FAST TRIP THRESHOLDS

Load current is monitored by sensing the voltage across R

to 10 mΩ. Each channel features two distinct thresholds, a current-limit threshold and a fast-trip threshold.

The current limit threshold sets the regulation point of a feedback loop. If the current flowing through the channel

exceeds the current limit threshold, V

is reduced, forcing the MOSFET into linear operation. This causes the

GAT1x

current flowing through the channel to settle to the value determined by the current limit threshold. For example,

when a module first powers up, it draws an inrush current to charge its load capacitance. The current-limit loop

ensures that this inrush current does not exceed the current limit threshold. M1 will dissipate much more power

in current limit than during normal operation. The fault timer circuit limits the interval M1 operates in this

condition.

There is a delay before channel current is regulated following the onset of an overload during normal operation.

The current limit circuit is able to sink 30 µA from the protection MOSFET gate. The delay is the result of the

MOSFET’s C

discharge from (V

ISS

+ 13 V) to ( V

INx

INx

threshold voltage. Overloads between the current limit and the fast trip threshold will be permitted for this period.

This is demonstrated by Figure 16. Currents above the fast trip threshold are handled by rapidly turning the

protection MOSFET off with a strong gate pulldown that is driven by a 10 µs oneshot. The fault timer starts and

the gate is allowed to rise after the oneshot completes in what resembles a normal startup.

The fast trip threshold protects the MOSFET and channel components against a severe short that creates a high

current faster than the current-limit loop can control. If (V

SENPx

GAT1x and GAT2x are immediately pulled to GND for a minimum of 10µs. The channel turns back on slowly,

allowing the current limit feedback loop time to take over. The fault timer period limits the duration the MOSFET

will see this stress. This is demonstrated by Figure 13 and Figure 14.

, whose values typically lie in the range of 4 mΩ

SENSEx

+ V

T_M1x

– V

SENMx

) where V

is the protection MOSFET's

T_M1x

) exceeds the 100 mV fast trip threshold,

12 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPS2456

Page 13

FTx

SEN SEx

100 mV

I =

R

SEN SEx SEN SEx

MON x MON x

SETx

R I

V = R

R

æ ö

´

´

ç ÷

è ø

SETx

LIMIT x

MON x S EN SEx

R

I = 0.675 V

R R

æ ö

´

ç ÷

´

è ø

LIMITx MONx SENSEx

SETx

I R R

R =

0.675 V

´ ´

TPS2456

www.ti.com

SLVSA78A –MARCH 2010–REVISED MARCH 2010

When the TPS2456 protects a supply output in configurations that allow the loads to hotplug, pay special

attention to coordinating load surges (due to input capacitance) and the fast trip threshold. The fast trip threshold

may need to be set 2–5 times higher than the current limit to accommodate this. Care must also be taken if the

INx voltages can have fast rising transients. The resulting charge current to capacitors on OUTx can potentially

exceed the fast trip threshold.

FAST TRIP AND CURRENT LIMITING

Figure 17 shows a simplified block diagram of the fast trip and current limit circuitry. Each channel requires an

external N-channel protection MOSFET and three external resistors. These resistors allow the user to

independently set the fast trip threshold and the current limit threshold, as described below.

The fast trip function is designed to protect the channel against short-circuit events. If the voltage across R

exceeds 100 mV, the TPS2456 immediately turns off the protection MOSFET, M1x. The nominal fast trip limit I

is defined in Equation 1.

The current limit circuit regulates V

to control the channel current from exceeding I

GAT1x

. The current limit

LIMITx

circuitry includes two amplifiers, A1and A2, as shown in Figure 17 and Figure 4. Amplifier A1forces the voltage

across external resistor R

through R

also flows through external resistor R

SETx

Amplifier A2implements a slow-reacting current limit. As long as V

normally. When V

exceeds 0.675 V, amplifier A2causes a small current to be drawn from GAT1x. The

MONx

to equal the voltage across external resistor R

SETx

, generating a voltage on the MONx pin per Equation 2.

MONx

MONx

. The current that flows

SENSEx

is less than 0.675 V, GAT1x operates

gate-to-source voltage of M1x drops until load current is reduced and the two inputs of amplifier A2balance. The

current flowing through the channel then equals I

per Equation 3.

LIMITx

SENSEx

FTx

(1)

(2)

The recommended value of R

is 6.81 kΩ. This resistor should be greater than 675 Ω to prevent excessive

MONx

currents from flowing through the internal circuitry.

(3)

(4)

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): TPS2456

Page 14

R

MONx

+

SENMx

MONx

675mV

+

100mV

Fast Trip

Comparator

Current

Limit Amp

+

30mA

GAT1x

A1

A2

100

R

SENSEx

R

SETx

SENPx

SETx

60mA

V

CP

I

FT,LIMIT

GAT1x(sourcing)

GAT1x

Gate-M1x

I

dV

dt C

@

OUTx GAT1x

INx_INRUSH OUTx OUTx

dV dV

I = C = C

dt dt

´ ´

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

www.ti.com

Figure 17. Over-Current Protection Circuitry

TURN ON AND INRUSH SLEW RATE CONTROL

One of the main functions of a protection device is to provide a method of hot-plugging and starting up a unit in a

low-stress and controlled manner. Starting includes the ability to charge the output capacitance (on OUTx)

without overburdening the input power bus while minimizing the stress on the protection MOSFET. Two possible

charge-rate control methods are possible with the TPS2456, current limited and gate dv/dt controlled.

As normally configured, the gate dv/dt turn-on slew rate is described by Equation 5.

where I

GAT1x(sourcing)

transfer capacitance, C

= ΔQg/ VTwhere ΔQgis the width of the plateau region and VTis the gate plateau voltage. To simplify the

calculation, the MOSFET gate capacitances are assumed to be fixed, while in reality, there is a voltage

dependency. The output voltage tracks V

limit is not active. The inrush current is defined by the following equation for a purely capacitive load. Startup of a

switching converter load during inrush should be avoided by use of PGx to control the converter.

The actual inrush current is the lesser of the current limit (Equation 3) or dv/dt-limited inrush current.

To reduce the slew rate, increase C

resistor of at least 1000 Ω in series with the additional capacitance to prevent it from interfering with the fast turn

off of the MOSFET.

equals the current sourced by the GAT1x pin (nominally 30 µA) and C

. Average C

RSS

may be approximated using the MOSFET V

RSS

GATE_M1x

Gate-M1x

once it has exceeded the MOSFET threshold voltage if current

by connecting additional capacitance from GAT1x to ground. Place a

Gate-M1x

vs. Qggraph as C

GATE

is the reverse

(5)

RSS

(6)

14 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPS2456

Page 15

fx Tx

-6fx

Tx f x

1.35 V

t = C

10 μA

OR

t 10 μA

C = = t 7.4 10

1.35 V

´

´

´ ´

( )

ISS_M1x T_M1x

ISS_M1x TM1x RSS_M1x IN1x

INRUSH

GAT1x GAT1x GAT1x

ISS_M1x

ISS_M1x TM1x

OUTx IN1x

INRUSH

GAT1x LIMITx

Gate dv/dt Limited Inrush

C 6 V V

C V C V

t = + +

I I I

Current Limited Inrush

C 6 V V

C V

C V

t = + +

I I

´ -

´ ´

´ -

´

´

( )

T_M1x

GAT1x

I

TPS2456

www.ti.com

SLVSA78A –MARCH 2010–REVISED MARCH 2010

FAULT TIMER PROGRAMMING

Each channel requires an external capacitor CTxconnected between the CTx pin and ground. The TPS2456

sources 10 µA into CTxwhen the gate voltage is low ((V

V

the channel off if current limit persists long enough for V

200 Ω pull-down resistor when (V

as an indication that current limit is active. The TPS2456 pulls GAT1x and GAT2x to ground and latches

GAT1x

CTx

GAT1x

– V

) > 6 V) and FLTx is not active. The nominal fault time tfxis defined

INx

by Equation 7.

Converter startup typically sets the minimum tfx. There are three important intervals to consider when calculating

the time to set tfx, initial charge of the MOSFET gate to the threshold voltage, the interval as V

and the interval for V

GAT1x

to exceed V

by 6 V. Assume that a constant C

INx

periods since the MOSFET drain and source voltages do not change. The middle period may be controlled by

either current limit or gate dv/dt limit as previously discussed. Let V

the inrush current.

– V

GAT1x

) < 6 V). The timer circuit interprets a low

INx

to reach 1.35 V. CTxis discharged through a nominal

rises to V

is charged in the first and third

ISS

be the MOSFET gate voltage to sustain

TM1x

OUTx

(7)

INx

,

Many of these parameters have wide tolerance, thus, the above approximation provides an initial estimate.

Provide sufficient margin in the CTxselection to assure the channel starts reliably while not becoming overly long.

Shorter fault times reduce the stresses imposed on the protection MOSFET under fault conditions, permitting the

use of smaller, less expensive protection MOSFETs.

ENx RESET PERIOD

The TPS2456 will latch off after a current limit that persists long enough to trip the fault timer. The TPS2456 may

be re-enabled by cycling the ENx false (low), then high. There is a minimum low period required to fully reset

C

that is determined by the R x C period where R is the internal discharge resistance. Calculate the minimum

CTx

period as t

ENx_LOW_MIN

nF x 1.2) x 400 x 3 = 31.7 µs. t

= C

CTx_MAX

ENx_LOW_MIN

x 400 Ω x 3. Assuming C

BLOCKING OPERATION

Each channel may use an external MOSFET (M2x) to provide reverse blocking. This feature is often used where

two inputs are ORed together to a common output for redundancy. Blocking protects the common output from

being drawn down if an input is shorted, and maintains the independence of both inputs. Blocking may not be

required in all system topologies. The TPS2456 pulls the GAT2x pin high when V

pulls the pin low when this differential falls below –3 mV (V

mV of hysteresis to help prevent false triggering as shown in Figure 18. This technique will allow some reverse

current to flow, but provides positive detection in the event of a real fault.

The blocking MOSFET is oriented so its body diode conducts forward current and blocks reverse current. The

body diode does not normally conduct current because the MOSFET turns on when the voltage differential

across it exceeds 10 mV.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 15

CTx_MAX

is 22 nF at 20% tolerance, t

should always be greater than 100 ns.

is greater than V

OUTx

Product Folder Link(s): TPS2456

ENx_LOW_MIN

(INx–OUTx)

). These thresholds provide 13

INx

exceeds 10 mV, and it

(8)

= (22

Page 16

V

INx

+ 13V

GND

10mV

- 3mV

V

GAT2x

(V

INx-VOUTx

)

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

www.ti.com

Figure 18. Blocking Thresholds

APPLICATION INFORMATION

SYSTEM DESIGN CONSIDERATIONS

The TPS2456 has two independent 12 V sections which provide protection and blocking (ORing). These sections

may be used in multiple configurations.

• TPS2456 on the power input of a system

– Two redundant input power rails to a single output (see Figure 1)

– Blocking protects output when one of the inputs is shorted

– Two independent loads powered by two separate or one common input rail

– Blocking not required

– Two redundant input rails ORed (no protection) to one common output

• TPS2456 on the power output of a system

– Up to two output rails with protection

– Protection isolates faulted output bus

– Enable can be used to turn output on and off

– Up to two output power rails with protection and blocking

– Used where multiple outputs are tied together

The system power architecture drives the topology that best suits a particular design.

DESIGN EXAMPLE: CURRENT LIMITED START-UP

The following example is for a single channel protection circuit using current-limited inrush control. The design of

the second channel would follow the same procedure and is not shown since it is redundant.

For this design example, a system board with 1000 µF of capacitance and a dc load of 1.6 Ω (or 7.5 A) must be

able to be hot plugged into a 12 V main bus supply. The main bus supply has a peak fault current capability of

20 A. Operating above 20 A of current draw runs the risk of opening a circuit breaker and shutting the system

down. The average current budgeted for the system board is 7.5 A under normal conditions. The main bus can

supply up to 10.1 A peak for up to 10 ms during start-up or transient conditions. This procedure assumes that the

inrush current is not limited by the gate charge rate. The basic system block diagram is shown in Figure 19.

16 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPS2456

Page 17

12V Main Bus Supply

Specifications (per output):

Peak Fault Current = 20A

Peak Current Limit = 10.1A

Average Current = 7.5A

M1x

R

SENSEx

0.1mF

0.1mF

C

LOADx

1000mF

R

LOADx

1.6W

R

MONx

R

SETx

R

GATEx

SENMx

SETx

SENSPx

INx

MONx

GND

GATE1x

OUTx

Part of TPS2456

LOADPROTECTION

Multiple Outputs

Possible

C

Tx

CTx

SENSEx

FTx

100mV 100mV

R = = = 5mΩ

I 20A

W

2 2

RSENSEx LIMITx SENSEx

P = I × R = 10.1 × 5m = 0.51Watts

W W

W

LIMITx MONx SENSEx

SETx

I ×R ×R

10.1A × 6.81k ×0.005

R = = = 509

0.675V 0.675V

TPS2456

www.ti.com

SLVSA78A –MARCH 2010–REVISED MARCH 2010

Figure 19. 12 V Main Bus

Select R

The first step is to calculate R

SENSEx

SENSEx

which sets the fast current trip point, I

. This is the maximum current that

FTx

can pass through M1x and is meant to protect against short circuits. Calculate R

peak fault current (I

) of 20 A.

FTx

SENSEx

using Equation 9 for a

The R

SENSEx

resistor is in series with the main power path and should have a power rating sufficient to support

the full load current. The 12 V main bus has budgeted 10.1 A for this board, so this is the value of limit used for

further calculations including the power dissipated in R

Equation 10. A higher wattage rating should be used based on local derating practice (for example 50%).

Select R

Next, R

calculation of R

I

LIMITx

Choose R

SETx

is calculated to set the channel current limit (I

SETx

SETx

to calculate R

as the closest standard value, 511 Ω.

SETx

. Use the recommended 6.81kΩ for R

.

SETx

Estimate Output Charge Time

The system can provide 10.1 A of peak current for 10 ms. This current can be used for start-up of the system

board as long as the output capacitance can be charged up to 12 V in less than 10 ms while also supplying

current to the load resistance connected in parallel to the output capacitor. The charge time is estimated using

Equation 12. For this equation, V

OUTx

is the final nominal voltage for the board (12 V), R

board (1.6 Ω), and there is a small amount of time for the pass transistor’s gate capacitance to charge to the

threshold voltage. This time, typically around 100 µs, is added to the end of the equation to provide a better

estimate of the total start-up time.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Link(s): TPS2456

SENSEx

MONx

. The power dissipated by R

) to 10.1 A. R

LIMITx

MONx

is also a variable in the

is calculated using

SENSE

(although other values can be used) and 10.1 A for

is the dc load of the

LOAD

(9)

(10)

(11)

Page 18

m

æ ö

÷

ç

÷

»

ç

÷

ç

÷

ç

è ø

LIMITx LOADx OUTx

CHG LOADx LOADx

LIMITx LOADx

I ×R - V

t -R × C × ln +100 s

I ×R

m m

æ ö

W

÷

ç

» W

÷

ç

÷

ç

è ø

W

CHG

10.1A ×1.6 -12V

t -1.6 ×1000 F×ln +100 s

10.1A ×1.6

»

CHG

t 2.27ms

m

LOADx OUTx

CHG

LIMIT_M1x

C × V

t = +100 s

I

2

Dx DS(on)_M1x LIMITx

P = R ×I

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

www.ti.com

(12)

(13)

(14)

The estimated time to charge the output is 2.27 ms. It is safe to allow the board to power up using the peak

current limit because t

is below the 10ms target.

CHG

Equation 12 assumes there is a resistive load on the output during the ramp up so the output voltage has an

“RC” shape. The output capacitance charges linearly if the load is purely capacitive, simplifying the charge time

equation to the following.

(15)

Select M1x

The next design step is to select M1x. The TPS2456 is designed to use N channel MOSFETs as protection

devices. The maximum MOSFET gate to source voltage rating, V

, must be high enough to support the

GS-MAX

highest of the gate drive (14.5 V) or input voltage.

The next factor to consider is the drain to source voltage rating, V

, of the MOSFET. From a dc perspective,

DS-MAX

the MOSFET needs to withstand the input power supply voltage of 12 V for this example. However; the MOSFET

can be exposed to high voltage spikes during fault conditions. For this reason, a MOSFET with a substantially

higher V

DS-MAX

(snubber, TVS, diodes, etc.). Look for a V

rating improves the system reliability and provides voltage headroom for transient protection

DS-MAX

rating with a minimum of twice of the input power supply voltage.

Next, the dc power loss of the MOSFET must be considered. The power dissipation of the MOSFET is directly

related to the R

of the MOSFET. The dc power dissipation for the MOSFET can be calculated using

DS(on)

Equation 16.

(16)

Taking these factors into consideration, the TI CSD16403Q5A was selected for this example. The

CSD16403Q5A has a V

GS-MAX

rating of 16 V, V

rating of 25 V, an R

DS-MAX

of 2.2 mΩ, and an R

DS(on)

qJA-MAX

of 51

°C/W.

During normal circuit operation, the MOSFET can have up to 10.1 A flowing through, which equates to 0.22 W

(I2xR) and an 11°C rise in junction temperature (P x R

). This is well within the data sheets limits for the

qJA-MAX

MOSFET. The power dissipated during a fault (e.g. output short) is substantially larger than the steady-state

power. The power handling capability of the MOSFET needs to be checked during fault conditions.

Most MOSFET data sheets provide a Safe Operating Area (SOA) plot. This plot can be used to check if the

MOSFET can survive the power form a transient fault condition. Figure 20 shows the SOA curve for the

QSD16403Q5A. The maximum fault current is set to 20 A for the 12 V input bus. This point can be located on

Figure 20. The diagonal lines tell the length of time this transient can be safely applied to the QSD16403Q5A.

The transistor can survive a 12 V, 20 A transient for approximately 9 ms.

18 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPS2456

Page 19

1k

10

0.01

1

100

I

D

− DrainCurrent − A

0.1

0.01 0.1 10

12

1001

SinglePulse

R

qJA

=94 C/W(minCu)

o

1ms

10ms

100ms

1s

DC

AreaLimited

byR

DS(on)

VDS− Drain ToSourceVoltage − V

æ ö

÷

ç

÷

ç

÷

ç

÷

ç

è ø

T_M1x ISS_M1x

LIMITx LOADx OUTx

CHG LOADx LOADx

LIMITx LOADx G

V ×C

I ×R - V

t = -R × C × ln +

I ×R I

æ ö

÷

ç

÷

ç

÷

ç

÷

ç

è ø

TM1x ISS_M1x

LIMITx LOADx OUTx

TMR_MIN LOADx LOADx

LIMITx LOAD G

(6 V + V ) × C

I ×R - V

t = -R × C × ln +

I ×R I

TPS2456

www.ti.com

SLVSA78A –MARCH 2010–REVISED MARCH 2010

Figure 20. Drain To Source Voltage

The turn off time of the TPS2456 and MOSFET should be taken into account. The TPS2456 detects the fault

condition as soon as the current through the sense resistor reaches 20 A. There is a 300 ns maximum

propagation delay for the TPS2456 to start discharging the MOSFET gate. The MOSFET has an additional

turn-off delay due to gate discharge (see Sinking current - Fast Discharge). The total delay for the TPS2456 and

the CSD16403Q5A is approximately 310 ns. The fault current continues to rise above 20 A for this period. The

rise of the fault current is determined by any inductance and resistance in the power path as well as the

impedance of the input voltage source. Continuing to follow the 12 V line up on the SOA curve, it can be seen

that the CSD16403Q5A could handle peak currents up to 180 A for 1 ms, giving substantial margin in this

design. This makes this transistor a good choice for this application.

Output Charge Time Refinement

A more accurate charge time can be calculated using Equation 17, now that the MOSFET has been chosen. This

is the same as Equation 15, but the 100 µs term is replaced with the variables that determine the time it takes to

charge the gate of the MOSFET up to the threshold voltage. The threshold voltage used in this equation should

be the voltage where the Mosfet starts to conduct higher currents. This can be found in the MOSFET data sheet

from graphs showing IDvs. VGS. For the CSD16403Q5A, the V

is 1.6 V, and C

T_M1x

is 2040 pF. The term IGin

ISS

Equation 17 is the GAT1x sourcing current, typically 30 µA. Using these values, Equation 17 gives a charge time

of 2.28 ms

(17)

Select C

Tx

The next step is to determine the minimum fault timer period. In the previous section, the change time calculation

yielded 2.28 ms. This is the amount of time it takes to charge the output capacitor up to the final output voltage.

However, the fault timer uses the difference between the input voltage and the gate voltage to determine if the

TPS2456 is in current limit. The fault timer continues to run until V

GATE_M1x

is 6 V above the input voltage. Some

additional time must be added to the charge time to account for this additional gate voltage rise. The minimum

fault timer time can be calculated using Equation 18.

(18)

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Link(s): TPS2456

Page 20

m

m

FAULT

Tx

t × 10 A

0.008s ×10 A

C = = = 59nF

1.35V 1.35V

M1x

To

Load

GND

GATE1x

Part of

TPS2456

C

ADD

1kW

I

G

30mA

From

Source

GATE_M1x

OUTx G

RSS_M1x ADD

dV

dV I

= =

dt dt C +C

OUTx OUTx G

INx_PEAK

LOADx RSS ADD

V C ×I

I = +

R (C + C )

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

www.ti.com

Using the example numbers in the above equation leads to a minimum fault timer time of 2.688 ms. The fault

timer must be set to a value higher than 2.688 ms to avoid turning off during start-up but lower than any

maximum time limit. There is a maximum time limit set by the SOA curve of the MOSFET. Referring back to

Figure 20, the CSD16403Q5A SOA curve, the MOSFET can tolerate 10.1 A with 12 V across it for approximately

20 ms. However; the input power supply can only supply the 10.1 A for 10 ms. Therefore, the fault timer should

be set to between 2.688 ms and 10 ms. For this example, select 8 ms to allow for variation of system parameters

such as temperature, load, component tolerance, and input voltage. The timing capacitor is calculated in

Equation 19 as 59 nF. Select a the next highest standard value, 62 nF, yielding an 8.37 ms fault time.

(19)

Blocking Device, M2x

Since this example uses a single channel, there is no need for the blocking MOSFET, and it can be left out of the

circuit. No connection needs to be made to the GAT2x or ORENx pins.

DESIGN EXAMPLE: GATE RAMP LIMITED STARTUP

In the first example, the output capacitance is charged in current limit. In some applications, the current limit is

the absolute maximum that the circuit should see, so charging the output up in current limit is not an option. In

this case, it is necessary to slow down the output voltage ramp so that the current limit is not reached. This can

be done by adding additional capacitance to M1x's gate.

The gate of the pass transistor is driven by a 30 µA (typical) current source. The current charges the gate to

source and gate to drain (C

lengthened by adding a capacitor, C

series with the additional capacitance as shown in Figure 21.

) capacitance, producing a voltage ramp at the gate. The time of the ramp can be

rss

, between the gate and ground. A 1 kΩ resistor should be placed in

ADD

With C

, the output voltage ramp is equal to:

ADD

The peak current, I

INX-PEAK

, that is reached with the new ramp rate is:

20 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Figure 21.

(20)

(21)

Product Folder Link(s): TPS2456

Page 21

( )

( ) ( )

T_M1x ISS ADD

OUTx RSS ADD ISS ADD

TMR_MIN

G G G

V C + C

V × C + C 6× C + C

t = + +

I I I

LOAD

INTER-

CONNECT

INTER-

CONNECT

POWERSUPPLY

TPS2456

GAT1x GAT2x

OUTx

INx

SENMx

SENPx

1kW

100 100

C

GS

C

GD

BlockingMOSFET

C

DS

C

GS

C

GD

ProtectionMOSFET

C

DS

ESD

Diode

ESD

Diode

ESD

Diode

ESD

Diode

L

P

R

LOAD

E=LI2/2

OUTPUT

R

P

L

P

E=LI2/2

R

P

LP+

L

EMI_FILTER

L

P

L

P

E=LI2/2

R

P

L

P

E=LI2/2

R

P

+

INPUT

C

IN

C

OUT

TPS2456

www.ti.com

C

can be adjusted so that I

ADD

INx_PEAK

is less than I

avoiding current limit start-up. Using a controlled gate

LIMITx

SLVSA78A –MARCH 2010–REVISED MARCH 2010

ramp requires lower peak current, but takes longer to charge the output capacitance. The length of the fault time

needs to be selected to accomodate this longer ramp up time. The minimum time the fault timer should be set to

is described by Equation 22.

(22)

BYPASS CAPACITORS

It is a good practice to provide low-impedance ceramic capacitor bypassing of INx and OUTx. Values in the

range of 10 nF to 1 µF are recommended. Some system topologies are insensitive to the values of these

capacitors; however, some are not and prefer to minimize the value of the bypass capacitor.

Input capacitance on a plug-in board may cause a large inrush current as the capacitor charges through the low

impedance power bus when inserted. This stresses the connector contacts and causes a short voltage sag on

the input bus. Small amounts of capacitance (e.g., 10 nF to 0.1 µF) are often tolerable in these systems.

Filter capacitors at the output of a redundant plug-in board are useful for controlling voltage transients, but they

may can cause problems when the board is inserted into an active bus. If the output capacitor charge from an

active bus is not limited, the inrush surge might engage the active supply's fast-trip shutdown. One possible

solution is to put a few Ohms of resistance in series with the capacitor to limit inrush below the fast trip level.

TRANSIENT PROTECTION

If the TPS2456 is used in applications which have large input and output capacitors, voltage transients during

load steps or short circuits are controlled and pose no problems.

TPS2456 devices are sometimes deployed systems that may have long, inductive feed or load interconnections.

The effect of the inductance, with little local capacitance, gives rise to potential voltage transient issues. A

simplified model of this is shown in Figure 22. Channel current transients may be caused by events such as

hot-plug, output shorts with fast turnoff, or abrupt load changes. The combination of input inductance and an

abrupt load decrease causes a positive voltage spike on the TPS2354 INPUT pins. The combination of output

inductance and an abrupt load decrease will cause a negative voltage spike on the TPS2354 OUTPUT. These

transients have the potential to exceed the Absolute Maximum Ratings, either damaging the TPS23754 or

causing undesired operation.

NOTE: LP= Parasitic Inductance (not all instances equal)

RP= Parasitic Resistance (not all instances equal)

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 21

Figure 22. System Transient Model

Product Folder Link(s): TPS2456

Page 22

SPIK E INIT L OAD

L

V = V + I

C

( )

2

LOA D

2

SPI KE N OM

L I

C =

V V´-

CL_M AX BR_MIN

SER IES

PEAK _PULS E T EST

V V

21.5 V 14.4 V

R = = = 0.102

I I 69.7 A 1 mA

-

W

- -

ABS_MAX BR_MAX

CL_MAX

SERIES

V V

17 V 15.9 V

I = = = 10.8 A

R 0.102

-

-

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

www.ti.com

An analysis must be performed to determine the need for transient protection. Equation 23 allows the designer to

estimate the voltage spike due to current interruptions.

(23)

Where:

V

= initial voltage at terminal being analyzed before the current is interrupted

INIT

L = combined inductance of feed and RTN lines in series with interrupted current

C = capacitance at point of computation

I

= current immediately before circuit is opened

LOAD

An approximation for the inductance of a straight wire is:

L ≈ [0.2 × length_in_meters × (In(4 × length/diameter) – 0.75)] nH

The capacitance in Equation 23, at INPUT, consists of parasitic capacitance and any intentional bypass

capacitance. This implies that the transients can be controlled by the addition of sufficient capacitance.

Equation 24 can be used to calculate the capacitance required to limit the voltage spike to a desired level above

the nominal voltage.

(24)

TRANSIENT PROTECTION SOLUTIONS

Typical protection solutions involve capacitors, TVSs ( Transient Voltage Suppressors ) and/or a Schottky diode.

A TVS and small bypass capacitor at INPUT (see Figure 22) are the most likely solutions to solve input voltage

overshoot. The TVS must be selected so that its clamping is below the Absolute Maximum Rating (17 V) at the

anticipated fault current. For example, the SMCJ13A data sheet specifies a maximum clamping voltage of 21.5 V

(which exceeds the Absolute Maximum voltage) at 69.7 A. The actual clamping voltage at the fault current (IFT)

may be within the Absolute Maximum; however, the clamp voltage at lower currents must be estimated to verify.

By modeling the TVS as a perfect voltage clamp in series with a resistor, the clamping voltage may be estimated

at different currents per Equation 25.

The maximum permitted clamping current for this device is found in Equation 26. This is a worst case (low)

number.

A Schottky diode and capacitor across the OUTPUT (Figure 22) are the most likely solutions to clamp the

transient energy and limit the negative voltage excursion. Although the Schottky diode absorbs most of the

energy, the extremely fast di/dt at shutoff allows some of the leading edge energy to couple through the parasitic

capacitances of the protection and blocking MOSFET (CDS, CGS, CGD) to the GAT1x and GAT2x pins. Protection

for these pins is provided by 100 Ω resistors which have little effect on normal operation but provide good

isolation during transient events.

Equation 24 gives insight into selection of transient protection capacitors for both INPUT and OUTPUT; however,

there are concerns with adding a lot of capacitance in some situations. See the BYPASS CAPACITORS section

regarding considerations and limitations

PCB layout of the protection is critical to its performance. The layout should minimize the impedance between

the TPS2456 and the protection in order to provide the best clamping.

22 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPS2456

(25)

(26)

Page 23

BLEED

BLEED

BLEED

V

R = 280 k

(6 V V )

´ W

-

MONB

MONA

Partof

TPS2456

R =R

R =R

SENSEA SENSEB

SETA SETB

R

MON

TPS2456

www.ti.com

SLVSA78A –MARCH 2010–REVISED MARCH 2010

OUTPUT BLEED RESISTANCE

The OUTx pin sources a small amount of current when the channel input is powered, but disabled in

non-redundant configurations (output is unpowered). The leakage can be modeled as a 6 V source in series with

a 280 kΩ resistor, allowing approximately 21.4 µA into a short. This leakage can charge a high-impedance load

to approximately 6 V. If this is unacceptable, control the output voltage in this state by adding a load resistor from

OUTx to GND. Select the resistor, R

, per Equation 27, where V

BLEED

is the desired maximum output

BLEED

voltage. Since the model is nominal, use a 25% smaller resistor value.

(27)

CONTROLLING FAULT CURRENT in REDUNDANT POWER TOPOLOGIES

System topologies such as Figure 1 are often used to provide power source redundancy. This permits the load to

run from either source, or potentially both in parallel. Blocking permits the load to operate uninterrupted in the

event of either source failing open or shorting to GND. However, this topology permits the load to draw twice the

channel fault current (I

The simple configuration of Figure 23 programs the total load fault current to a fixed value independent of the

number of channel feeds to the load. The current limit thresholds now apply to the sum of the currents delivered

by the redundant channels. When implementing this redundant mode, it is recommended that all of the channels

use the same R

SENSEx

between sources, it simply permits the power to flow from the higher source, but limits the maximum load current

to a fixed value.

) for two closely matched sources.

LIMITx

and R

values. This configuration does not foster sharing or smooth transitions

SETx

CURRENT FEEDBACK TO A SHELF CONTROLLER

A shelf controller can monitor channel currents by observing V

R

with an Analog to Digital Converter (ADC) to provide a digital representation of the current. Figure 24 shows a

typical system configuration using a multiplexer and ADC (analog to digital converter) to monitor the current in

both channels of the TPS2456. It has been assumed that the normal 0 V to 0.675 V range of V

the ADC input. If this is not the case, operational amplifier circuits should be used to buffer and scale these

signals. It is not advisable to add capacitance to the MONx pins as this effects the current-limit loop.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 23

. The voltage on MONx can be directly sampled with an analog circuit (e.g. a comparator) or sampled

SENSEx

Figure 23. Fixed Fault Current Application

, which is proportional to the current through

MONx

Product Folder Link(s): TPS2456

is suitable for

MONx

Page 24

ADC

MONa

MONb

6810

6810

TPS2456

2:1 Mux

μP

a0

a1

s0

LOADCURRENT

PATH

LOADCURRENT

PATH

Method 1

Method 2

R

SENSEx

R

SET

TPS2456

SENP

R

SET

SENM

SET

TPS2456

SENP

SENM

SET

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

www.ti.com

Figure 24.

The output of the MONx pin is a current proportional to the current passing through the pass transistor as defined

in Equation 2. The current flowing out of the MONx pin is converted to a voltage by R

kΩ. Any circuitry connected to the MONx pin should either have an input impedance much higher that R

which is typically 6.81

MONx

MONx

to

reduce measurement and limiting error, or the value of the parallel combination must be adjusted. The output of

the MONx pin can also be buffered using a unity gain, non-inverting operational amplifier if necessary.

LAYOUT CONSIDERATIONS

TPS2456 applications require layout attention to ensure proper performance and minimize susceptibility to

transients and noise. In general, all runs should be as short as possible, but the following list deserves first

consideration.

1. Decoupling capacitors on INA and INB should have minimal length to the pin and to GND

2. SENMx and SENPx runs must be short and run side-by-side to maximize common mode rejection. Kelvin

connections should be used at the points of contact with R

. (See Figure 25)

SENSEx

Figure 25. Recommended R

3. SETx runs need to be short on both sides of R

4. Power path connections should be as short as possible and sized to carry at least twice the full load current,

more if possible.

5. Connections to GND and MONx pins should be minimized after the connections above have been placed.

6. The device dissipates low power so soldering the powerpad to the board is not a requirement. However,

doing so improves thermal performance and reduces susceptibility to noise.

24 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

SENSE

.

SETx

Product Folder Link(s): TPS2456

Layout

Page 25

TPS2456

www.ti.com

SLVSA78A –MARCH 2010–REVISED MARCH 2010

7. The board should use a single point ground scheme. The current return path for both channels should be

isolated from each other as much as possible and tie together at a single point. This helps to reduce ground

bounce and false turn offs in one channel when there is a fault in the other channel. Also, sensitive analog

grounds (such as the ground connections of R

x and CTx) should be run separate from the power path

MON

grounds. This analog ground must also tie to the two power path grounds at a single point. Figure 26 shows

the top layer routing of the TPS2456 EVM which uses a single point ground scheme. Each major power path,

the analog ground, and the single point tying them together is highlighted in the figure.

Figure 26.

8. Protection devices such as snubbers, TVS, capacitors or diodes should be placed physically close to the

device they are intended to protect, and routed with short trances to reduce inductance. For example, the

protection Schottky diode shown in Figure 1 should be physically close to the source of the pass transistor

(or the drain of the blocking MOSFET if used).

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): TPS2456

Page 26

TPS2456

SLVSA78A –MARCH 2010–REVISED MARCH 2010

www.ti.com

REVISION HISTORY

Changes from Original (March 2010) to Revision A Page

• Changed data sheet status from Preview to Production ...................................................................................................... 1

• Changed the second paragraph of the DESCRIPTION From: The ORing control uses an external MOSFET to

prevent reverse current flow To: The ORing control uses an external MOSFET to block reverse current when an

input is shorted. .................................................................................................................................................................... 1

• Deleted the Dissipation Rating table and added the Thermal Information table .................................................................. 2

• Added test to the SENPA pin of the PIN FUNCTIONS table - Connect to the source side of R

• Changed PIN 32 From: GNDA To: GND and PIN 23 From: AGND To: GND in the DEVICE PINOUT illustration ............. 7

• Changed the DETAILED PIN DESCRIPTIONS .................................................................................................................... 7

• Changed Figure 8 Title From: FAST CURRENT LIMIT THRESHOLD vs TEMPERATURE To: CURRENT LIMIT

THRESHOLD vs TEMPERATURE, and added R

SETx

and R

values ............................................................................. 9

MONx

. .............................. 6

SENSEA

26 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): TPS2456

Page 27

PACKAGE OPTION ADDENDUM

www.ti.com 19-Apr-2010

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TPS2456RHHR ACTIVE VQFN RHH 36 2500 Green (RoHS &

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-3-260C-168 HR

(3)

no Sb/Br)

TPS2456RHHT ACTIVE VQFN RHH 36 250 Green (RoHS &

CU NIPDAU Level-3-260C-168 HR

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.