Texas Instruments TPS2321IPWR, TPS2321IPW, TPS2321IDR, TPS2321ID, TPS2320IPWR Datasheet

...

TPS2320, TPS2321

DUAL HOT SWAP POWER CONTROLLER

WITH INDEPENDENT CIRCUIT BREAKER

SLVS276A – MARCH 200 – REVISED APRIL 2000

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

features

D

Dual-Channel High-Side MOSFET Drivers

D

IN1: 3 V to 13 V; IN2: 3 V to 5.5 V

D

Inrush Current Limiting With dv/dt Control

D

Independent Circuit-Breaker Control With

Programmable Current Limit and Transient

Timer

D

CMOS- and TTL-Compatible Enable Input

D

Low, 5-µA Standby Supply Current ...Max

D

Available in 16-Pin SOIC and TSSOP

Package

D

–40°C to 85°C Ambient Temperature Range

D

Electrostatic Discharge Protection

applications

D

Hot-Swap/Plug/Dock Power Management

D

Hot-Plug PCI, Device Bay

D

Electronic Circuit Breaker

description

The TPS2320 and TPS2321 are dual-channel

hot-swap controllers that use external N-channel

MOSFETs as high-side switches in power

applications. Features of these devices, such as

overcurrent protection (OCP), inrush-current

control, and separation of load transients from

actual load increases, are critical requirements for

hot-swap applications.

The TPS2320/21 devices incorporate undervoltage lockout (UVLO) to ensure the device is off at startup. Each

internal charge pump, capable of driving multiple MOSFETs, provides enough gate-drive voltage to fully

enhance the N-channel MOSFETs. The charge pumps control both the rise times and fall times (dv/dt) of the

MOSFETs, reducing power transients during power up/down. The circuit-breaker functionality combines the

ability to sense overcurrent conditions with a timer function; this allows designs such as DSPs, that may have

high peak currents during power-state transitions, to disregard transients for a programmable period.

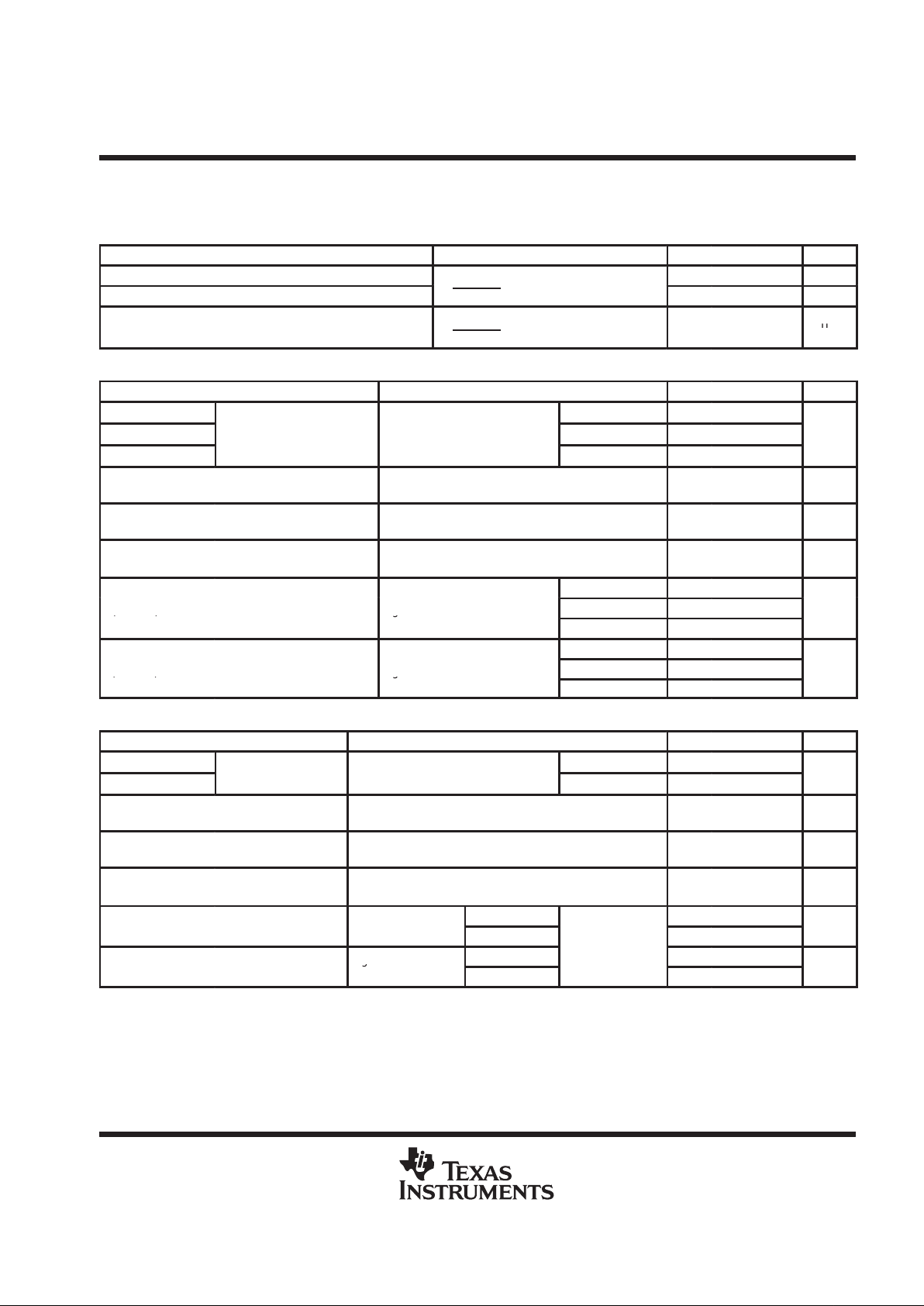

AVAILABLE OPTIONS

PIN

PACKAGES

TAHOT-SWAP CONTROLLER DESCRIPTION

COUNT

ENABLE ENABLE

Dual-channel with independent OCP and adjustable PG 20 TPS2300IPW TPS2301IPW

Dual-channel with interdependent OCP and adjustable PG 20 TPS2310IPW TPS2311IPW

–40°C to 85°C

Dual-channel with independent OCP 16

TPS2320ID

TPS2320IPW

TPS2321ID

TPS2321IPW

Single-channel with OCP and adjustable PG 14

TPS2330ID

TPS2330IPW

TPS2331ID

TPS2331IPW

†

The packages are available left-end taped and reeled (indicated by the R suffix on the device type; e.g., TPS2321IPWR).

Copyright 2000, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

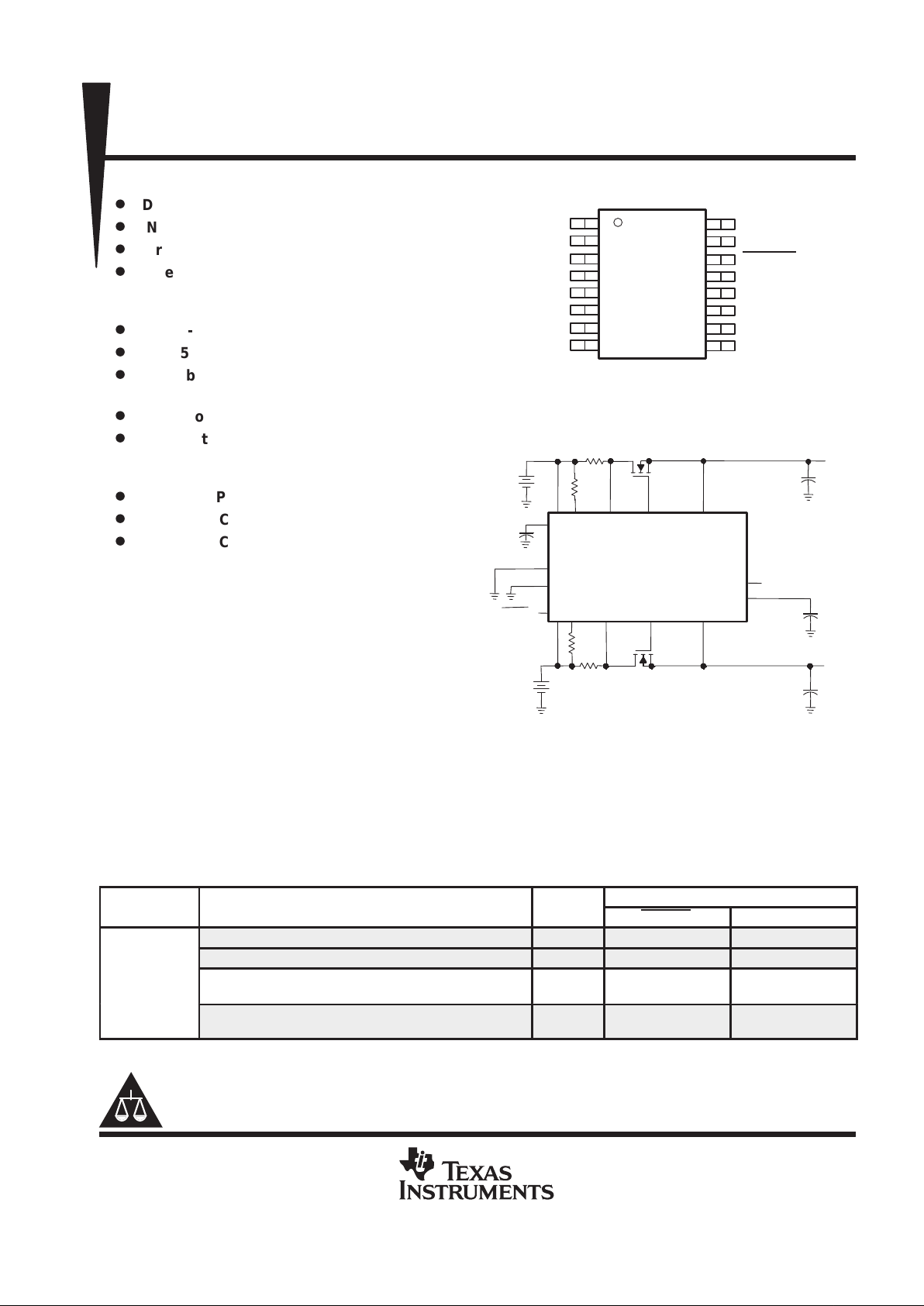

typical application

NOTE: Terminal 14 is active high on TPS2321.

VREG

IN1

ISET1

ISENSE1

GATE1

DISCH1

FAULT

TIMER

DISCH2

GATE2

ISENSE2ISET2IN2

ENABLE

DGND

AGND

V2

V1

3 V – 5.5 V

3 V – 13 V

TPS2320

+

V

O1

V

O2

+

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

GATE1

GATE2

DGND

TIMER

VREG

AGND

ISENSE2

ISENSE1

DISCH1

DISCH2

ENABLE

FAULT

ISET1

ISET2

IN2

IN1

D OR PW PACKAGE

(TOP VIEW)

TPS2320, TPS2321

DUAL HOT SWAP POWER CONTROLLER

WITH INDEPENDENT CIRCUIT BREAKER

SLVS276A – MARCH 200 – REVISED APRIL 2000

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

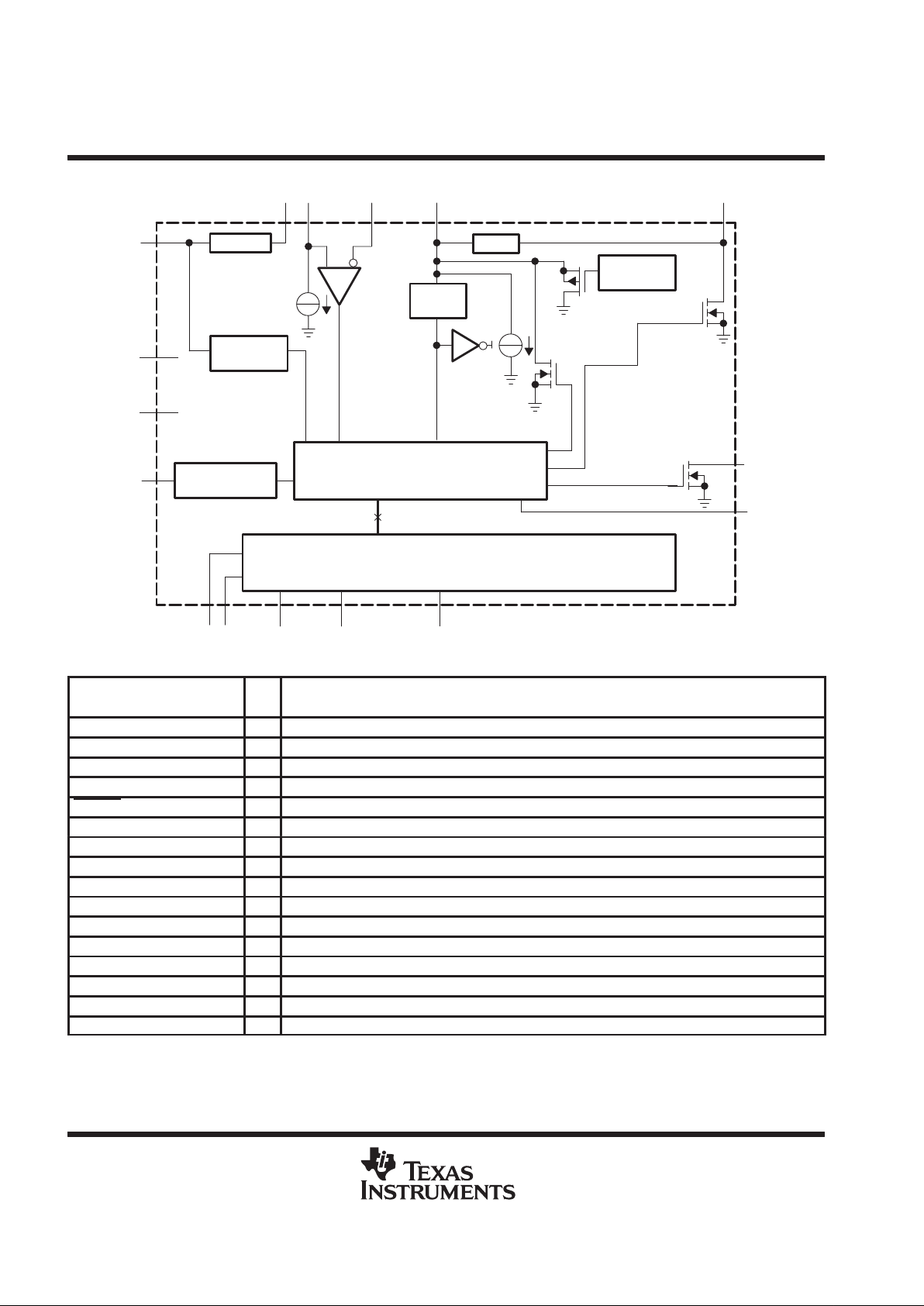

functional block diagram

PREREG

UVLO and

Power-Up

IN1 ISET1 ISENSE1 GATE1

Clamp

Charge

Pump

75 µA

Pulldown FET

Circuit Breaker

dv/dt Rate

Protection

DISCH1

Logic

FAULT

TIMER

Second Channel

GATE2ISENSE2ISET2IN2

DISCH2

Circuit

Breaker

VREG

50-µs Deglitch

AGND

DGND

ENABLE

50 µA

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

AGND 6 I Analog ground, connects to DGND as close as possible

DGND 3 I Digital ground

DISCH1 16 O Discharge transistor 1

DISCH2 15 O Discharge transistor 2

ENABLE/ ENABLE 14 I Active low (TPS2320) or active high enable (TPS2321)

FAULT 13 O Overcurrent fault, open-drain output

GATE1 1 O Connects to gate of channel 1 high-side MOSFET

GATE2 2 O Connects to gate of channel 2 high-side MOSFET

IN1 9 I Input voltage for channel 1

IN2 10 I Input voltage for channel 2

ISENSE1 8 I Current-sense input channel 1

ISENSE2 7 I Current-sense input channel 2

ISET1 12 I Adjusts circuit-breaker threshold with resistor connected to IN1

ISET2 11 I Adjusts circuit-breaker threshold with resistor connected to IN2

TIMER 4 O Adjusts circuit-breaker deglitch time

VREG 5 O Connects to bypass capacitor, for stable operation

TPS2320, TPS2321

DUAL HOT SWAP POWER CONTROLLER

WITH INDEPENDENT CIRCUIT BREAKER

SLVS276A – MARCH 200 – REVISED APRIL 2000

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

detailed description

DISCH1, DISCH2 – DISCH1 and DISCH2 should be connected to the sources of the external N-channel

MOSFET transistors connected to GA TE1 and GA TE2, respectively. These pins discharge the loads when the

MOSFET transistors are disabled. They also serve as reference-voltage connections for internal gate

voltage-clamp circuitry.

ENABLE

or ENABLE – ENABLE for TPS2320 is active low. ENABLE for TPS2321 is active high. When the

controller is enabled, both GA TE1 and GATE2 voltages will power up to turn on the external MOSFETs. When

the ENABLE pin is pulled high for TPS2320 or the ENABLE pin is pulled low for TPS2321 for more than 50 µs,

the gate of the MOSFET is discharged at a controlled rate by a current source, and a transistor is enabled to

discharge the output bulk capacitance. In addition, the device turns on the internal regulator PREREG (see

VREG) when enabled and shuts down PREREG when disabled so that total supply current is much less than

5 µA.

FAULT – FAULT is an open-drain overcurrent flag output. When an overcurrent condition in either channel is

sustained long enough to charge TIMER to 0.5 V , the overcurrent channel latches off and pulls F AUL T low . The

other channel will run normally if not in overcurrent.

GA TE1, GA TE2 – GATE1 and GATE2 connect to the gates of external N-channel MOSFET transistors. When

the device is enabled, internal charge-pump circuitry pulls these pins up by sourcing approximately 15 µA to

each. The turnon slew rates depend upon the capacitance present at the GATE1 and GATE2 terminals. If

desired, the turnon slew rates can be further reduced by connecting capacitors between these pins and ground.

These capacitors also reduce inrush current and protect the device from false overcurrent triggering during

powerup. The charge-pump circuitry will generate gate-to-source voltages of 9 V–12 V across the external

MOSFET transistors.

IN1, IN2 – IN1 and IN2 should be connected to the power sources driving the external N-channel MOSFET

transistors connected to GA TE1 and GA TE2, respectively . The TPS2320/TPS2321 draws its operating current

from IN1, and both channels will remain disabled until the IN1 power supply has been established. The IN1

channel has been constructed to support 3-V, 5-V, or 12-V operation, while the IN2 channel has been

constructed to support 3-V or 5-V operation

ISENSE1, ISENSE2, ISET1, ISET2 – ISENSE1 and ISENSE2, in combination with ISET1 and ISET2,

implement overcurrent sensing for GA TE1 and GA TE2. ISET1 and ISET2 set the magnitude of the current that

generates an overcurrent fault, through external resistors connected to ISET1 and ISET2. An internal current

source draws 50 µA from ISET1 and ISET2. With a sense resistor from IN1 to ISENSE1 or from IN2 to ISENSE2,

which is also connected to the drains of external MOSFETs, the voltage on the sense resistor reflects the load

current. An overcurrent condition is assumed to exist if ISENSE1 is pulled below ISET1 or if ISENSE2 is pulled

below ISET2.

TIMER – A capacitor on TIMER sets the time during which the power switch can be in overcurrent before turning

off. When the overcurrent protection circuits sense an excessive current, a current source is enabled which

charges the capacitor on TIMER. Once the voltage on TIMER reaches approximately 0.5 V , the circuit-breaker

latch is set and the power switch is latched off. Power must be recycled or the ENABLE pin must be toggled

to restart the controller. In high-power or high-temperature applications, a minimum 50-pF capacitor is strongly

recommended from TIMER to ground, to prevent any false triggering.

VREG – The VREG pin is the output of an internal low-dropout voltage regulator. This regulator draws current

from IN1. A 0.1-µF ceramic capacitor should be connected between VREG and ground. VREG can be

connected to IN1, IN2, or to a separated power supply through a low-resistance resistor. However , the voltage

on VREG must be less than 5.5 V.

TPS2320, TPS2321

DUAL HOT SWAP POWER CONTROLLER

WITH INDEPENDENT CIRCUIT BREAKER

SLVS276A – MARCH 200 – REVISED APRIL 2000

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

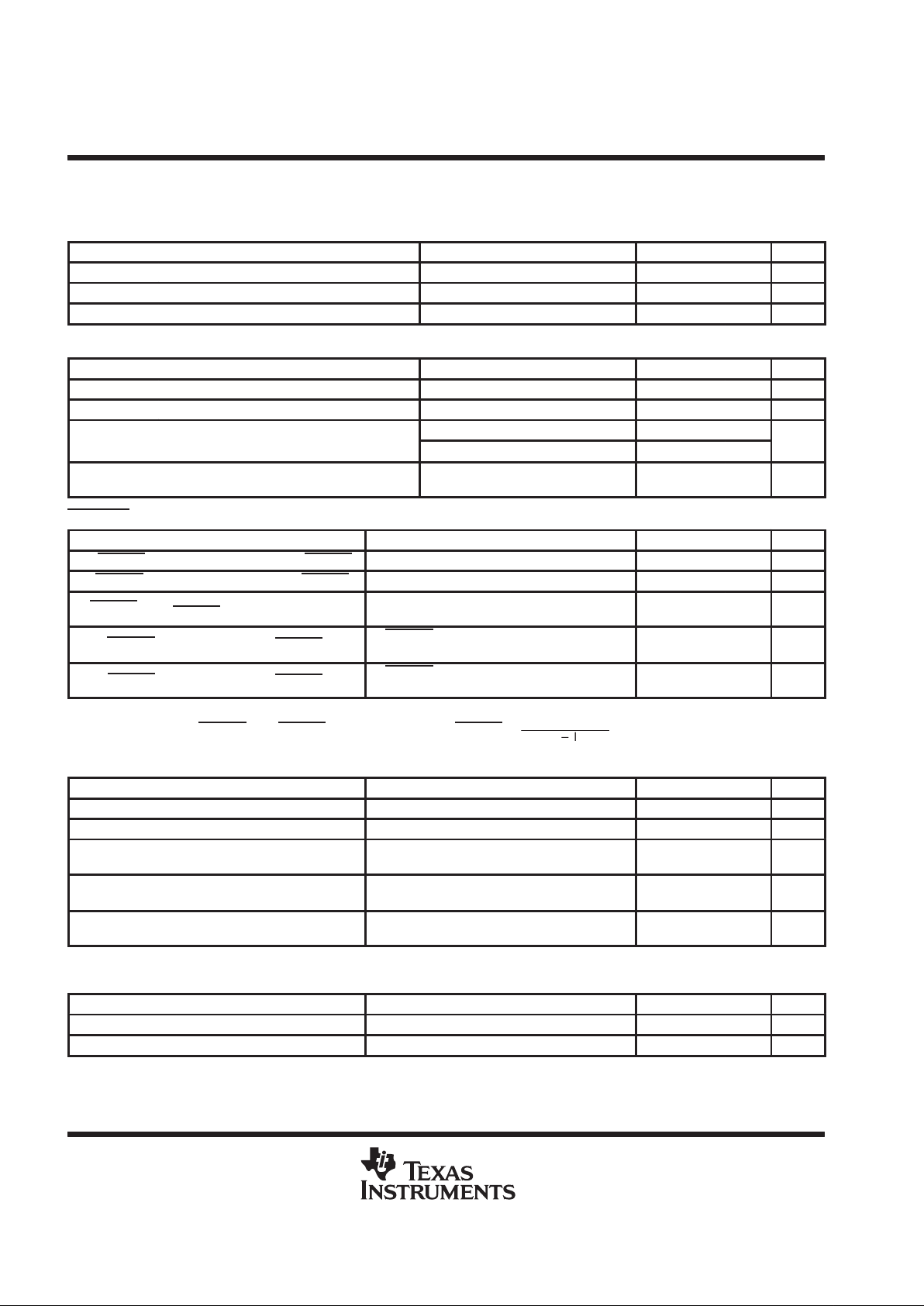

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

†

Input voltage range: V

I(IN1)

, V

I(ISENSE1)

, V

I(ISET1)

, V

I(ENABLE)

–0.3 V to 15 V. . . . . . . . . . . . . . . . . . . . . . .

V

I(IN2)

, V

I(ISENSE2)

, V

I(ISET2)

–0.3 V to 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output voltage range: V

O(GATE1)

–0.3 V to 30 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V

O(GATE2)

–0.3 V to 22V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V

O(DISCH1)

, V

O(FAULT)

, V

O(VREG)

, V

O(DISCH2)

, V

O(TIMER)

, –0.3 V to 15V. . . . .

Sink current range: I

GATE1

, I

GATE2

, I

DISCH1

, I

DISCH2

0 mA to 100 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

TIMER

, I

FAUL T

0 mA to 10 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating virtual junction temperature range, TJ –40°C to 100°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: All voltages are respect to DGND.

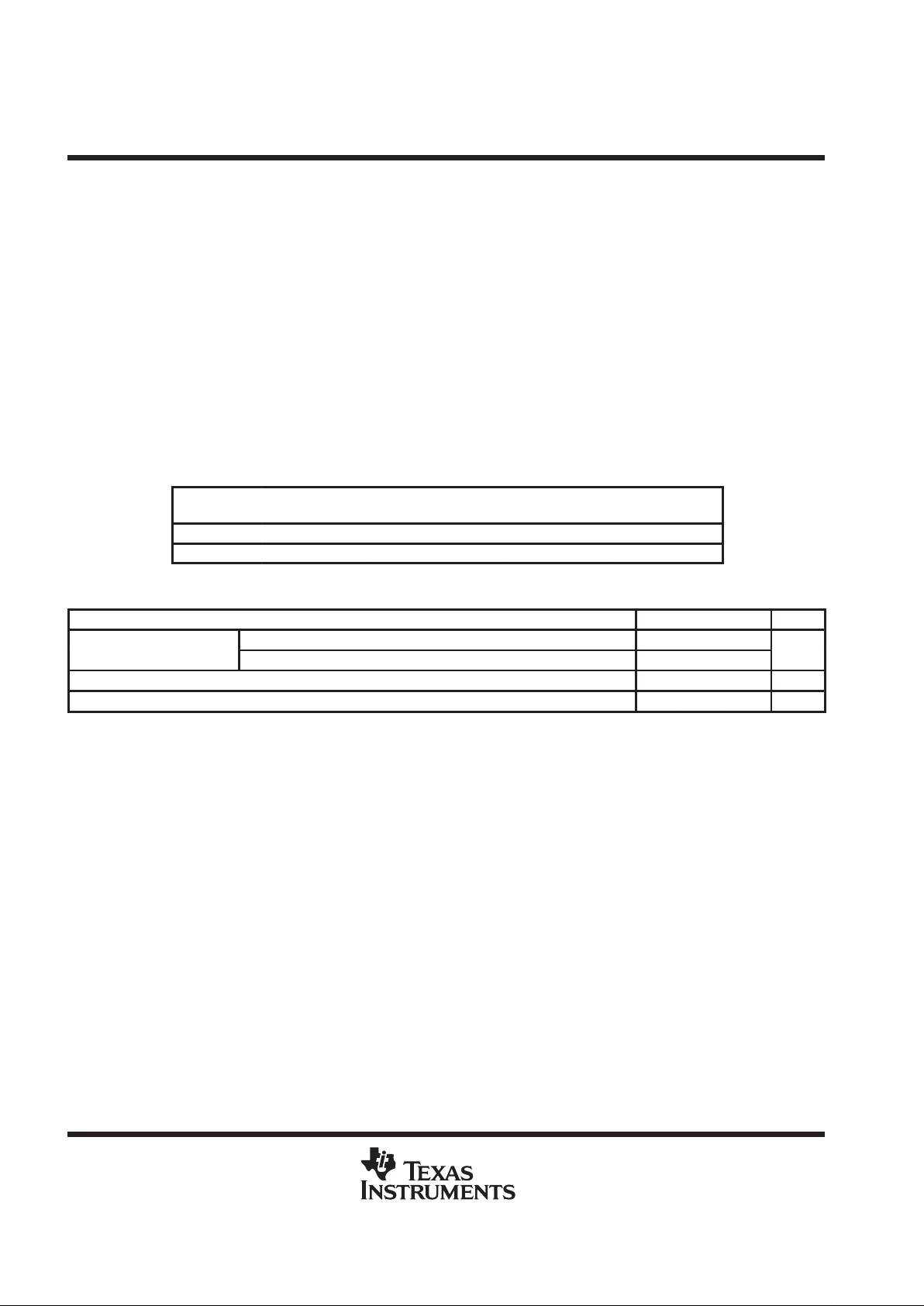

DISSIPATION RATING TABLE

PACKAGE

TA ≤ 25°C

POWER RATING

DERATING FACTOR

ABOVE TA = 25°C

TA = 70°C

POWER RATING

TA = 85°C

POWER RATING

PW-16 823 mW 10.98 mW/°C 329 mW 165 mW

D-16 674 mW 8.98 mW/°C 270 mW 135 mW

recommended operating conditions

MIN NOM MAX UNIT

p

V

I(IN1)

, V

I(ISENSE1)

, V

I(ISET1)

3 13

Input voltage, V

I

V

I(IN2)

, V

I(ISENSE2)

, V

I(ISET2)

3 5.5

V

VREG voltage, V

O(VREG)

, when VREG is directly connected to IN1 2.95 5.5 V

Operating virtual junction temperature, T

J

–40 100 °C

TPS2320, TPS2321

DUAL HOT SWAP POWER CONTROLLER

WITH INDEPENDENT CIRCUIT BREAKER

SLVS276A – MARCH 200 – REVISED APRIL 2000

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating temperature range (–40°C < TA < 85°C),

3 V ≤ V

I(IN1)

≤13 V, 3 V ≤ V

I(IN2)

≤ 5.5 V (unless otherwise noted)

general

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

I(IN1)

Input current, IN1 V

I(ENABLE)

= 5 V (TPS2321), 0.5 1 mA

I

I(IN2)

Input current, IN2 V

I(ENABLE)

= 0 V (TPS2320) 75 200 µA

Standby current (sum of currents into IN1, IN2,

V

I(ENABLE)

= 0 V (TPS2321),

I

I(stby)

y(

ISENSE1, ISENSE2, ISET1, and ISET2)

V

I(ENABLE)

= 5 V (TPS2320)

5

µA

GATE1

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

G(GATE1_3V)

V

I(IN1)

= 3 V 9 11.5

V

G(GATE1_4.5V)

Gate voltage

I

I(GATE1)

=

500 nA

,

DISCH1 open

V

I(IN1)

= 4.5 V 10.5 14.5

V

V

G(GATE1_10.8V)

DISCH1 oen

V

I(IN1)

= 10.8 V 16.8 21

V

C(GATE1)

Clamping voltage, GATE1

to DISCH1

9 10 12 V

I

S(GATE1)

Source current, GATE1

3 V ≤ V

I(IN1)

≤ 13.2 V, 3 V ≤ V

O(VREG)

≤ 5.5 V,

V

I(GATE1)

= V

I(IN1)

+ 6 V

10 14 20 µA

Sink current, GATE1

3 V ≤ V

I(IN1)

≤ 13.2 V, 3 V ≤ V

O(VREG)

≤ 5.5 V,

V

I(GATE1)

= V

I(IN1)

50 75 100 µA

V

I(IN1)

= 3 V 0.5

t

r(GATE1)

Rise time, GATE1 Cg to GND = 1 nF (see Note 2)

V

I(IN1)

= 4.5 V 0.6

ms

()

g

V

I(IN1)

= 10.8 V 1

V

I(IN1)

= 3 V 0.1

t

f(GATE1)

Fall time, GATE1 Cg to GND = 1 nF (see Note 2)

V

I(IN1)

= 4.5 V 0.12

ms

()

g

V

I(IN1)

= 10.8 V 0.2

GATE2

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

G(GATE2_3V)

p

V

I(IN2)

= 3 V 9 11.7

V

G(GATE2_4.5V)

Gate voltage

I

I(GATE2)

=

500 nA, DISCH2 oen

V

I(IN2)

= 4.5 V 10.5 14.7

V

V

C(GATE2)

Clamping voltage,

GATE2 to DISCH2

9 10 12 V

I

S(GATE2)

Source current,

GATE2

3 V ≤ V

I(IN2)

≤ 5.5 V, 3 V ≤ V

O(VREG)

≤ 5.5 V,

V

I(GATE2)

= V

I(IN2)

+ 6 V

10 14 20 µA

Sink current, GATE2

3 V ≤ V

I(IN2)

≤ 5.5 V, 3 V ≤ V

O(VREG)

≤ 5.5 V,

V

I(GATE2)

= V

I(IN2)

50 75 100 µA

C

to GND = 1 nF

V

I(IN2)

= 3 V 0.5

t

r(GATE2)

Rise time, GATE2

g

(see Note 2)

V

I(IN2)

= 4.5 V

0.6

ms

Cg to GND = 1 nF

V

I(IN2)

= 3 V

V

O(VREG)

= 3

V

0.1

t

f(GATE2)

Fall time, GATE2

g

(see Note 2)

V

I(IN2)

= 4.5 V 0.12

ms

NOTE 2: Specified, but not production tested.

TPS2320, TPS2321

DUAL HOT SWAP POWER CONTROLLER

WITH INDEPENDENT CIRCUIT BREAKER

SLVS276A – MARCH 200 – REVISED APRIL 2000

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating temperature range (–40°C < TA < 85°C),

3 V ≤ V

I(IN1)

≤13 V, 3 V ≤ V

I(IN2)

≤ 5.5 V ( unless otherwise noted) (continued)

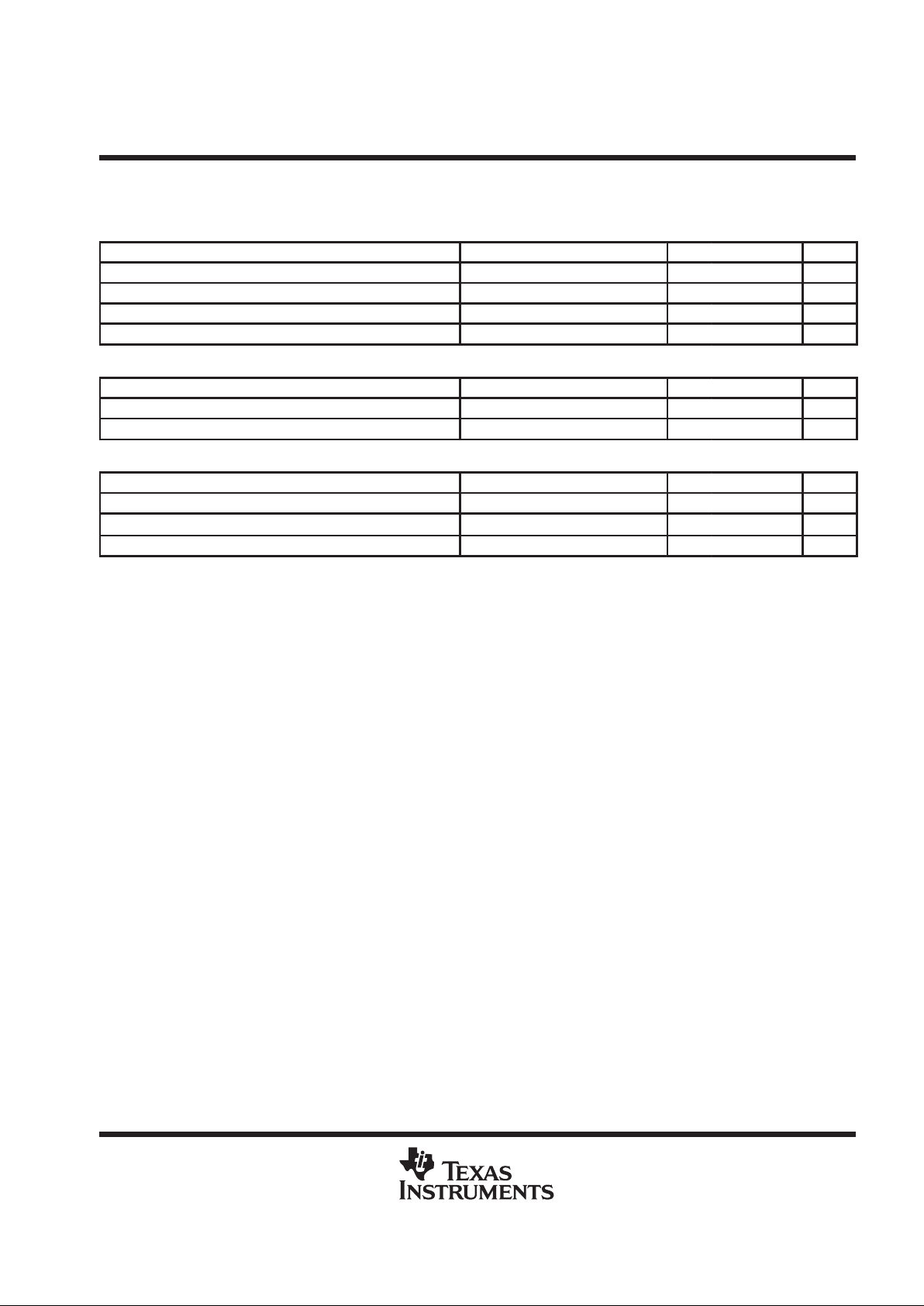

TIMER

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

OT(TIMER)

Threshold voltage, TIMER 0.4 0.5 0.6 V

Charge current, TIMER V

I(TIMER)

= 0 V 35 50 65 µA

Discharge current, TIMER V

I(TIMER)

= 1 V 1 2.5 mA

circuit breaker

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

IT(CB)

Undervoltage voltage, circuit breaker R

ISETx

= 1 kΩ 40 50 60 mV

I

IB(ISENSEx)

Input bias current, I

SENSEx

0.1 5 µA

V

O(GATEx)

= 4 V 400 800

Discharge current, GATE

x

V

O(GATEx)

= 1 V

25 150

mA

t

pd(CB)

Propagation (delay) time, comparator inputs to

gate output

Cg = 50 pF,

(50% to 10%)

10 mV overdrive,

C

O(timer)

= 50 pF

1.3 µs

ENABLE, active low (TPS2320)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

IH(ENABLE)

High-level input voltage, ENABLE 2 V

V

IL(ENABLE

)

Low-level input voltage, ENABLE 0.8 V

R

I(ENABLE

)

Input pullup resistance,

ENABLE

See Note 3 100 200 300 kΩ

t

d_off(ENABLE)

Turnoff delay time, ENABLE

V

I(ENABLE)

increasing above stop threshold; 100

ns rise time, 20 mV overdrive (see Note 2)

60 µs

t

d_on(ENABLE)

Turnon delay time, ENABLE

V

I(ENABLE

)

decreasing below start threshold;

100 ns fall time, 20 mV overdrive (see Note 2)

125 µs

NOTES: 2. Specified, but not production tested.

3. Test IO of ENABLE

at V

I(ENABLE

)

= 1 V and 0 V, then R

I(ENABLE)

=

1V

I

O_

0V

*

I

O_

1V

ENABLE, active high (TPS2321)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

IH(ENABLE)

High-level input voltage, ENABLE 2 V

V

IL(ENABLE)

Low-level input voltage, ENABLE 0.7 V

R

I(ENABLE)

Input pulldown resistance,

ENABLE

100 150 300 kΩ

t

d_on(ENABLE)

Turnon delay time, ENABLE

V

I(ENABLE)

increasing above start threshold;

100 ns rise time, 20 mV overdrive (see Note 2)

85 µs

t

d_off(ENABLE)

Turnoff delay time, ENABLE

V

I(ENABLE)

decreasing below stop threshold;

100 ns fall time, 20 mV overdrive (see Note 2)

100 µs

NOTE 2: Specified, but not production tested.

PREREG

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VREG PREREG output voltage 4.5 ≤ V

I(IN1)

≤ 13 V 3.5 4.1 5.5 V

Vdrop_PREREG PREREG dropout voltage V

I(IN1)

= 3 V 0.1 V

TPS2320, TPS2321

DUAL HOT SWAP POWER CONTROLLER

WITH INDEPENDENT CIRCUIT BREAKER

SLVS276A – MARCH 200 – REVISED APRIL 2000

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating temperature range (–40°C < TA < 85°C),

3 V ≤ V

I(IN1)

≤13 V, 3 V ≤ V

I(IN2)

≤ 5.5 V (unless otherwise noted) (continued)

VREG UVLO

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

OT(UVLOstart)

Output threshold voltage, start 2.75 2.85 2.95 V

V

OT(UVLOstop)

Output threshold voltage, stop 2.65 2.78 V

V

hys(UVLO)

Hysteresis 50 75 mV

UVLO sink current, GATEx V

I(GATEx)

= 2 V 10 mA

FAULT output

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

O(sat)(FAULT)

Output saturation voltage, FAULT IO = 2 mA 0.4 V

I

lkg(FAULT)

Leakage current, FAULT V

O(FAULT)

= 13 V 1 µA

DISCH1 and DISCH2

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

DISCH

Discharge current, DISCHx V

I(DISCHx)

= 1.5 V, V

I(VIN1)

= 5 V 5 10 mA

V

IH(DISCH)

Discharge on high-level input voltage 2 V

V

IL(DISCH)

Discharge on low-level input voltage 1 V

Loading...

Loading...