TMC57253

DRIVER

SOCS040A – MARCH 1994 – REVISED NOVEMBER 1994

Copyright 1994, Texas Instruments Incorporated

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

• TTL-Compatible Inputs

• CCD-Compatible Outputs

• Adjustable Clock Levels

• High-Speed Clear

• Serial-Gate Midlevel for CDS Operation

• Solid-State Reliability

description

The TMC57253 is a monolithic CMOS integrated

circuit designed to drive image-area gates (IAG1,

IAG2), antiblooming gate (ABG), storage-area

gate (SAG), and serial-register gate (SRG) of the

Texas Instruments (TI) TC255 CCD image

sensor. The TMC57253 interfaces the CCD image

sensor to the TI TMC57751 ASIC or user-defined

timing generator; it receives TTL-input signals

from the timing generator and outputs levelshifted signals to the image sensor.

ABOUT follows ABIN and ABMIN and switches

between V

ABL

, VAB, and V

ABM

. IA1OUT and

IA2OUT follow IA1IN and IA2IN, respectively , and

switch between GND and V

IA

. The SAOUT output

follows the SAIN and switches GND and V

S

.

SROUT follows SRIN and SRMIN and switches

between GND, V

SM

, and VS.

The TMC57253 is available in a 24-pin HSOP-B

surface-mount package and is characterized for

operation from –20°C to 45°C.

This device contains circuits to protect its inputs and outputs against damage due to high static voltages or electrostatic fields. These

circuits have been qualified to protect this device against electrostatic discharges (ESD) of up to 2 kV according to MIL-STD-883C,

Method 3015; however, it is advised that precautions be taken to avoid application of any voltage higher than maximum-rated voltages

to these high-impedance circuits. During storage or handling, the device leads should be shorted together or the device should be

placed in conductive foam. In a circuit, unused inputs should always be connected to an appropriated logic voltage level, preferably either V

CC

or ground. Specific guidelines for handling devices of this type are contained in the publication

Guidelines for Handling

Electrostatic-Discharge-Sensitive (ESDS) Devices and Assemblies

available from Texas Instruments.

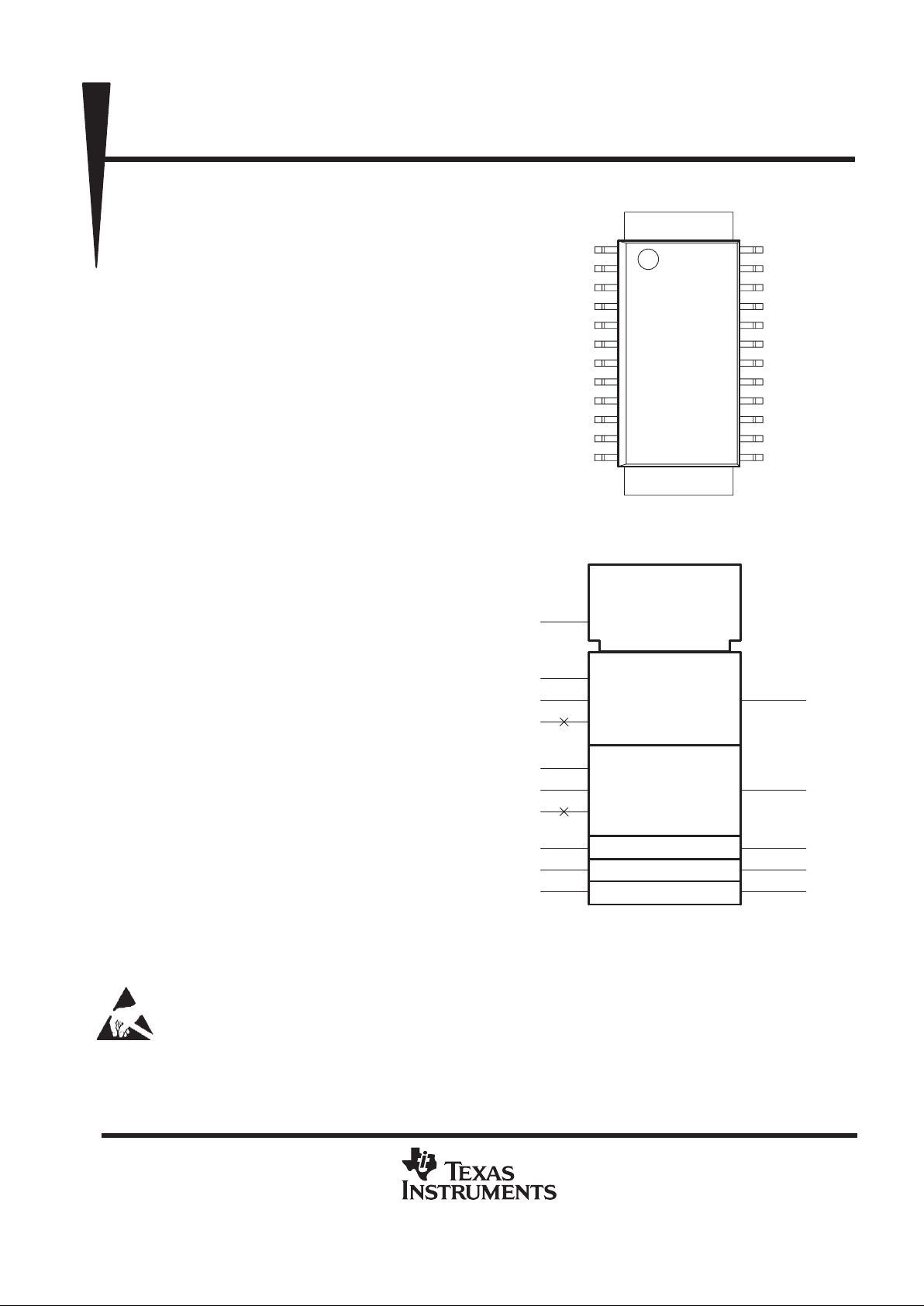

HSOP TYPE-B

(TOP VIEW)

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

V

AB

V

CC

GND

EN

ABIN

ABMIN

IA1IN

IA2IN

SAIN

SRIN

SRMIN

GND

V

ABM

ABOUT

V

ABL

GND

IA1OUT

V

IA

IA2OUT

GND

SAOUT

V

S

SROUT

V

SM

7

8

9

4

5

6

24

10

11

13

ABOUT

23

IA1OU

T

20

IA2OU

T

18

SAOUT

16

SROUT

14

Φ

TTL/CCD

EN

ABIN

ABMIN

V

ABM

SRIN

SRMIN

V

SM

IA1IN

IA2IN

SAIN

logic symbol

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

TI is a trademark of Texas Instruments Incorporated.

TMC57253

DRIVER

SOCS040A – MARCH 1994 – REVISED NOVEMBER 1994

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

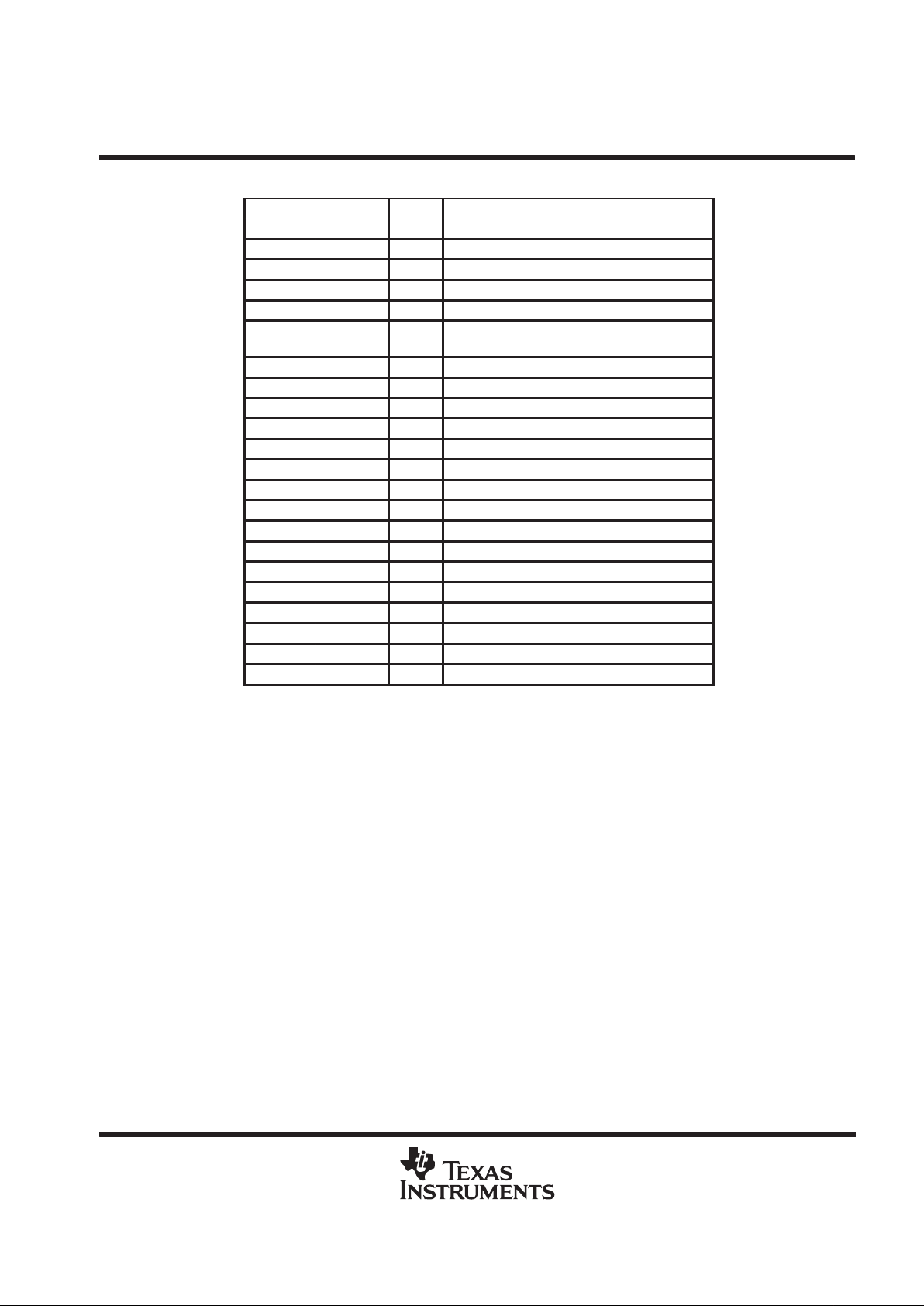

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

ABIN 5 I Antiblooming input

ABMIN 6 I Antiblooming midlevel input

ABOUT 23 O Antiblooming output

EN 4 I Enable control input

GND

3, 12, 17,

21

Ground

IA1IN 7 I Image area 1 input

IA1OUT 20 O Image area 1 output

IA2IN 8 I Image area 2 input

IA2OUT 18 O Image area 2 output

SAIN 9 I Storage area input

SAOUT 16 O Storage area output

SRIN 10 I Serial register input

SRMIN 11 I Serial register mid input

SROUT 14 O Serial register output

V

AB

1 High-level antiblooming supply voltage

V

ABL

22 Low-level antiblooming supply voltage

V

ABM

24 Midlevel antiblooming supply voltage

V

CC

2 Supply voltage

V

IA

19 Image supply voltage

V

S

15 Serial and storage-gate supply voltage

V

SM

13 Midlevel serial-gate supply voltage

TMC57253

DRIVER

SOCS040A – MARCH 1994 – REVISED NOVEMBER 1994

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

functional block diagram

Level

Shift

Level

Shift

Level

Shift

Level

Shift

Level

Shift

Level

Shift

Level

Shift

HV_BUF

and

Driver

HV_BUF

and

Driver

HV_BUF

and

Driver

HV_BUF

and

Driver

HV_BUF

and

Driver

Logic

4

2

1

5

6

7

8

9

10

11

22

23

24

20

19

18

16

15

14

13

V

ABM

ABOUT

V

ABL

IA1OUT

V

IA

IA2OUT

SAOUT

V

S

SROUT

V

SM

V

AB

V

CC

EN

ABIN

ABMIN

IA1IN

IA2IN

SAIN

SRIN

SRMIN

TMC57253

DRIVER

SOCS040A – MARCH 1994 – REVISED NOVEMBER 1994

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

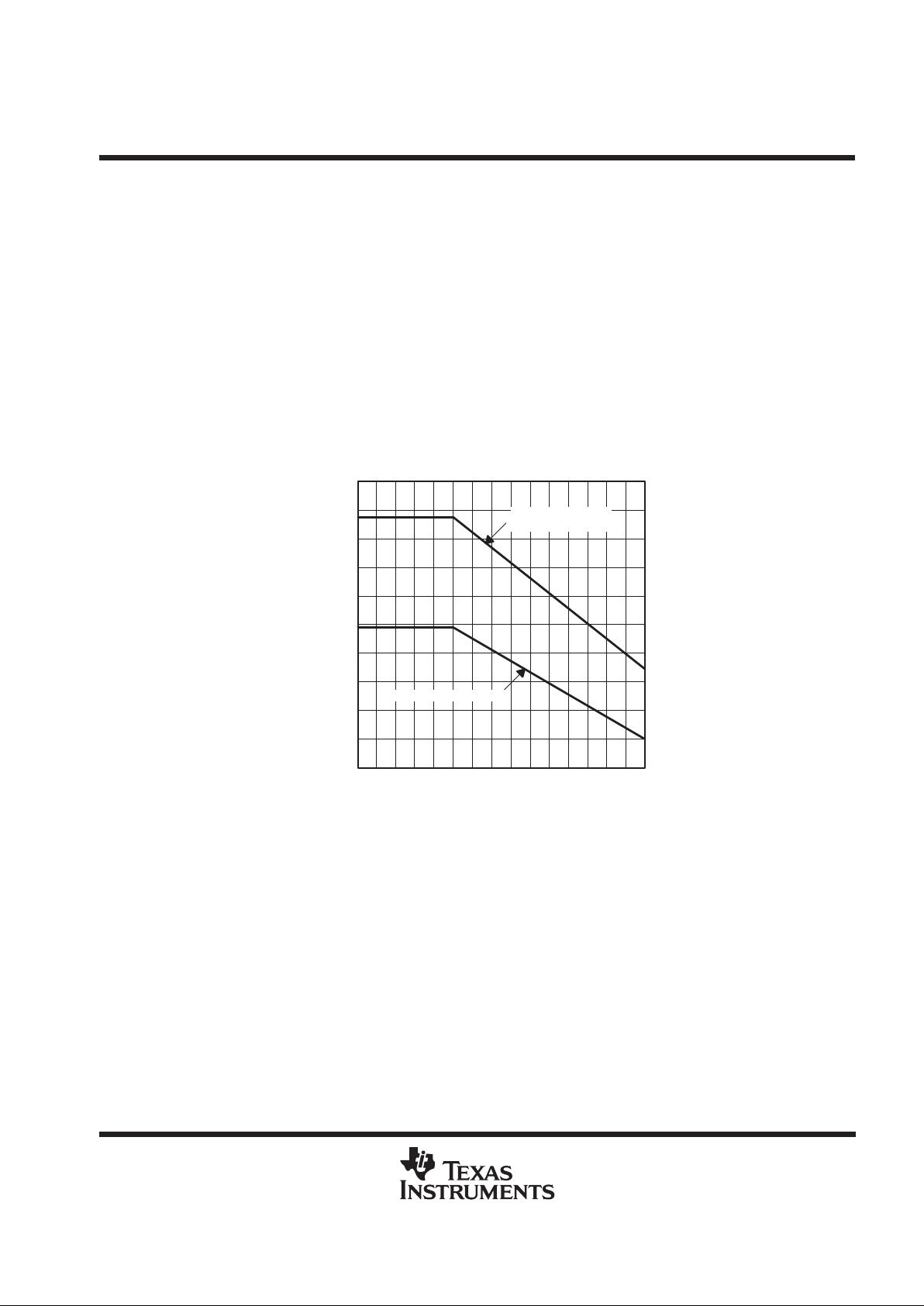

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

†

Supply voltage range, V

CC

(see Note 1) 0 V to 20 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total power dissipation at (or below) T

A

= 25°C:

Unmounted device (see Figure 1) 1990 mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounted device (see Figure 1) 2754 mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

A

–20°C to 45°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

STG

–55°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature: 1,6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1,6 mm (1/16 inch) from case for 3 seconds 350°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: All voltages are with respect to GND.

01020304050605 152535455565

3000

2800

2600

2400

2200

2000

1800

1600

1400

1200

1000

TA– Free-Air Temperature–°C

P

D

– Power Dissipation – mW

70 75

Unmounted Device

Mounted Device

(see Note A)

POWER DISSIPATION

vs

FREE-AIR TEMPERATURE

NOTE A: The mounted-device derating curve of Figure 1 is obtained under the following conditions:

The board is 50 mm by 50 mm by 1.6 mm thick.

The board material is glass epoxy.

The copper thickness of all the etch runs is 35 microns.

Etch-run dimensions – All twenty etch runs are 0.4 mm by 22 mm.

Each chip is soldered to the board.

An aluminum cooling fin 10 mm by 10 mm by 1 mm thick is coupled to the chip with thermal paste.

Figure 1

TMC57253

DRIVER

SOCS040A – MARCH 1994 – REVISED NOVEMBER 1994

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

recommended operating conditions

MIN NOM MAX UNIT

Supply voltage, V

CC

4.5 5 5.5 V

Antiblooming supply voltage, V

AB

8 18 V

Low-level antiblooming supply voltage, V

ABL

0 3 V

Midlevel antiblooming supply voltage, V

ABM

3 10 V

Image-gate supply voltage, V

IA

8 14 V

Serial and storage-gate supply voltage, V

S

8 14 V

Serial-gate midlevel supply voltage, V

SM

3 7 V

High-level input voltage, V

IH

2.5 V

Low-level input voltage, V

IL

0.9 V

IA1OUT, IA2OUT (fast clear) 25 MHz

IA1OUT, IA2OUT (transfer) 12.5 MHz

Frequency, f

clock

SAOUT (transfer) 12.5 MHz

ABOUT 12.5 MHz

SROUT 12.5 MHz

IA1OUT, IA2OUT, SAOUT 1%

Drive mode (on ratio)

ABOUT 23%

SROUT 85%

Operating free-air temperature, T

A

–20 45 °C

electrical characteristics over recommended ranges of supply voltage and operating free-air

temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

OH

High-level output voltage IOH = 0.5 mA 12 V

V

OL

Low-level output voltage IOL = 0 0 V

I

IH

High-level input current VIH = 5 V ±10 µA

I

IL

Low-level input current VIL = 0 ±10 µA

I

CC

Supply current VCC = 5 V 0.1 mA

I

IA

Image-gate supply current VIA = 12 V 5 mA

I

AB

Antiblooming supply current 15 mA

I

ABL

Low-level antiblooming supply current

VAB = 12 V

15 mA

I

ABM

Midlevel antiblooming supply current 0.5 mA

I

SM

Midlevel serial-gate supply current

2 mA

I

S

Serial-gate supply current

V

S

= 12

V

2 mA

IA1OUT,

IA2OUT,

SAOUT

IO = 10 mA,

VI = VCC, GND

VIA = 8 V

5

r

o

Output resistance

ABOUT

IO = 10 mA,

VSM = 4 V,

VI = VCC, GND

VAB = 8 V,

V

ABM

= 4 V

V

ABL

= 0 V

10

Ω

SROUT

IO = 10 mA,

VSM = 4 V,

VS= 8 V,

VI = VCC, GND

50

TMC57253

DRIVER

SOCS040A – MARCH 1994 – REVISED NOVEMBER 1994

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

switching characteristics for ABOUT, IA1OUT, IA2OUT, SAOUT, and SROUT, VAB = 13 V,

V

ABI

= 1.5 V,V

ABM

= 6.5 V, VIA = 11 V, VSM = 5 V, VS = 11 V, TA = 25°C (unless otherwise noted)

†

PARAMETER

FROM

(INPUT)

TO

(OUTPUT)

TEST CONDITIONS MIN MAX UNIT

IA1IN IA1OUT

IA2IN IA2OUT

See Figure 3 85

SAIN SAOUT

t

pd

Propagation delay time

SRIN

ns

SRMIN

SROUT

See Figure 4

40

80

ABIN

ABMIN

ABOUT

See Figure 5

90

IA1OUT

IA2OUT

t

PLZ

Disable time EN

SAOUT

See Figure 6 1ns

SROUT

ABOUT

IA1OUT

IA2OUT

t

PZH

Enable time EN

SAOUT

See Figure 6 1ns

SROUT

ABOUT

IA1OUT

IA2OUT

See Figure 3, tc = 80 ns 40% 60%

Duty cycle

‡

SAOUT

ABOUT See Figure 3, tc = 160 ns 40% 60%

†

The load is a Texas Instruments TC255 CCD image sensor.

‡

Duty cycle

+

t

w

H

(t

w

H

)

t

w

L

)

100

TMC57253

DRIVER

SOCS040A – MARCH 1994 – REVISED NOVEMBER 1994

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

5 ns MAX

t

f

V

IH

V

IL

90%

10%

5 ns MAX

t

r

Figure 2. Rise and Fall Time Requirements for Input Signals

50%

t

PLH

t

PHL

50%

t

wL

t

wH

GND

GND

V

CC

VIA or V

S

IA1IN, IA2IN, SAIN

IA1OUT, IA2OUT, SAOUT

NOTE A: tpd = t

PLH

or t

PHL

Figure 3. Duty Cycle and Propagation Delay

26 ns

MIN

54 ns MIN

50%

SRIN

SRMIN

SROUT

50%

t

PHL

t

PLH

t

PHL

5 ns MAX

†

26 ns MIN

†

V

CC

GND

V

S

GND

V

S

V

SM

GND

50% V

S

50% V

SM

†

If SRIN and SRMIN are both high, SROUT follows SRIN.

NOTE A: tpd = t

PLH

or t

PHL

Figure 4. Serial-Register-Driver Waveforms

TMC57253

DRIVER

SOCS040A – MARCH 1994 – REVISED NOVEMBER 1994

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

80 ns MIN80 ns MIN

166 ns MIN

50%

t

PHL

t

PLH

50% 50%

t

PLH

t

PHL

50% V

ABM

50%

V

CC

GND

V

CC

GND

V

AB

V

ABL

ABIN

ABMIN

ABOUT

V

ABM

NOTES: A. VAB and V

ABM

are in a short-circuit condition if ABIN and ABMIN are held high at the same time. This short-circuit condition can

destroy the device.

B. tpd = t

PLH

or t

PHL

Figure 5. Antiblooming-Driver Waveforms

VAB or V

ABM

t

PLZ

t

PZH

t

PLZ

t

PZH

GND

VIM or V

S

50%

GND

GND

V

CC

ABOUT

IA1OUT, IA2OUT,

SAOUT, SROUT

EN

50% 50%

50%

50% 50%

Figure 6. Enable Waveforms

TMC57253

DRIVER

SOCS040A – MARCH 1994 – REVISED NOVEMBER 1994

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

HSOP-B plastic small-outline package

This small-outline package consists of a circuit mounted on a lead frame and encapsulated within a plastic compound.

The compound will withstand soldering temperature with no deformation, and circuit performance characteristics will

remain stable when operated in high-humidity conditions. Leads require no additional cleaning or processing when

used in soldered assembly.

Seating Plane

0,15

M

0,13

1,27

24 13

112

0,50

0,30

0,20

0,30

15,20

15,40

2,65 MAX

0,10 MIN

10,80

10,00

7,40

7,60

1,20

0,40

6,65

6,35

19,50

18,90

0°–10°

7/94

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion.

TMC57253

DRIVER

SOCS040A – MARCH 1994 – REVISED NOVEMBER 1994

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

15,3

0,76

0,51

1,7

7,8 10,8

1,27

112

1324

ALL LINEAR DIMENSIONS ARE IN MILLIMETERS

7,0

Figure 7. 24-Pin/375-mil HSOP Land Design

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...