Page 1

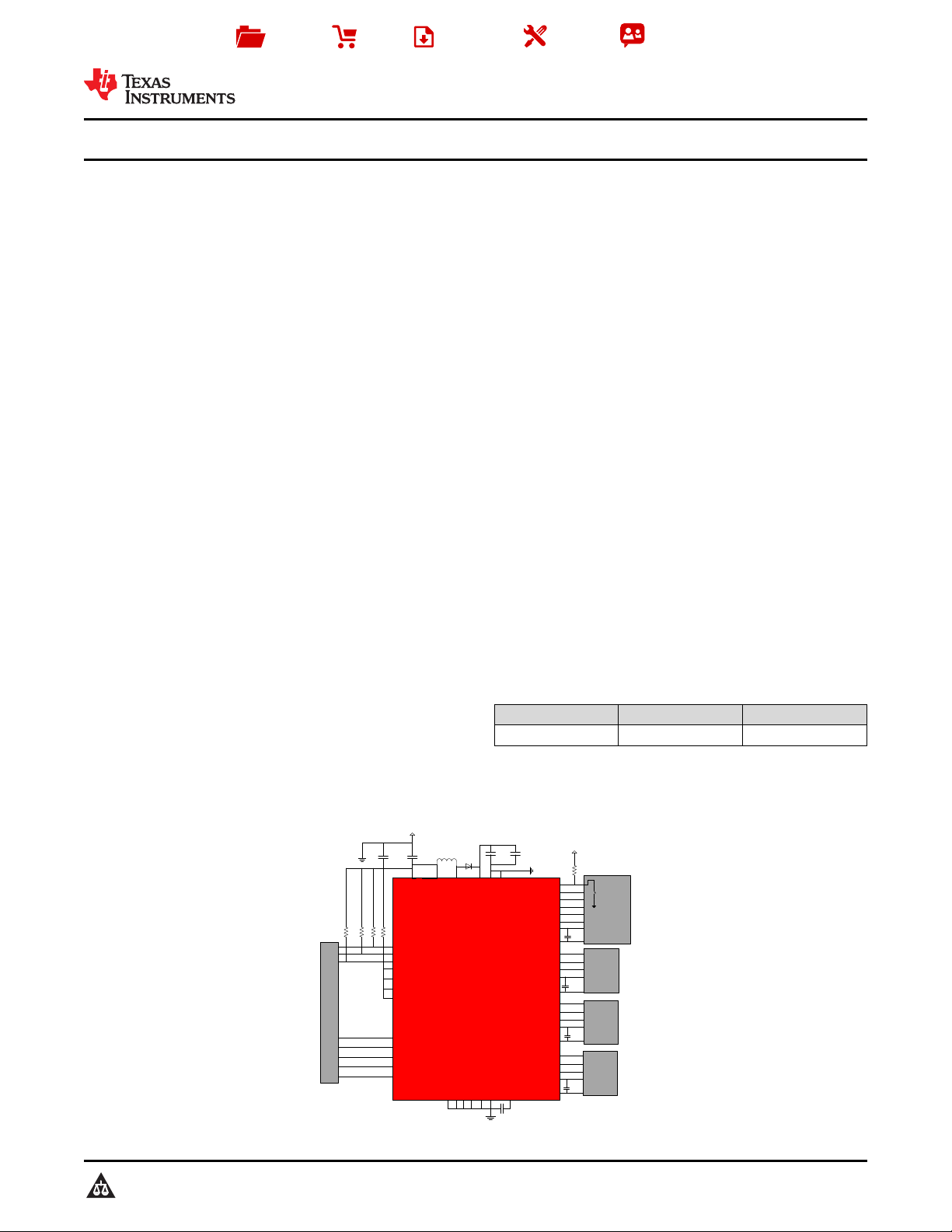

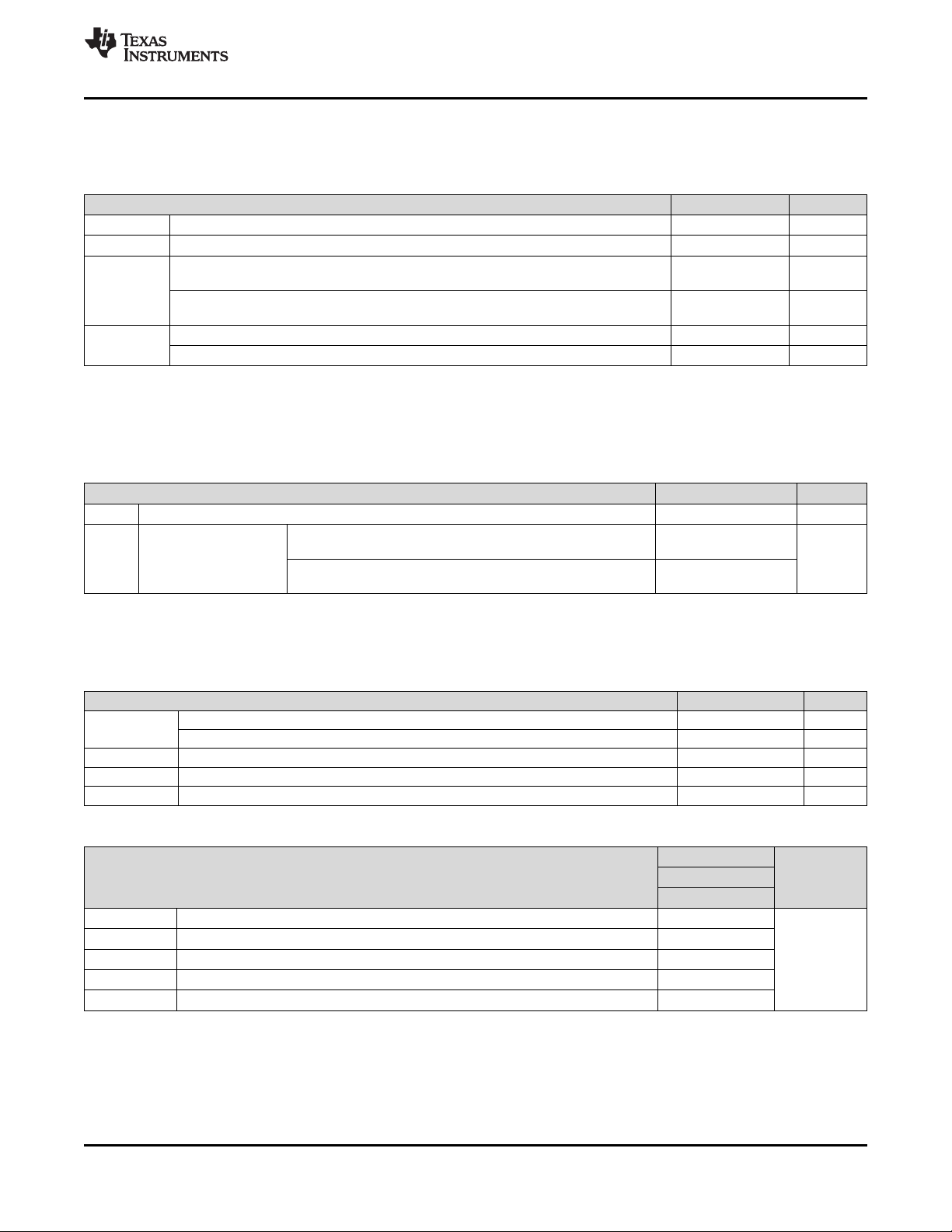

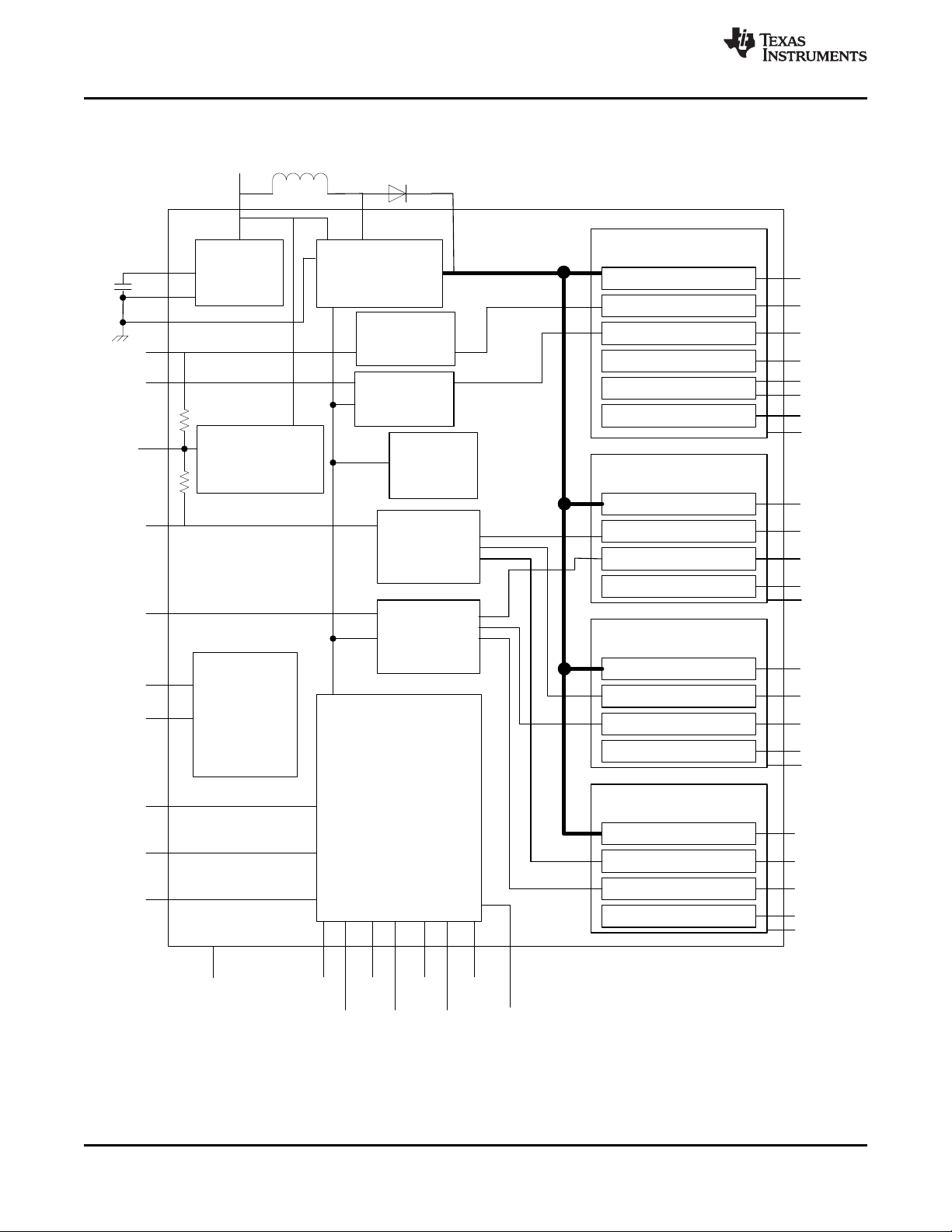

SDA

SCL

SHDN

INT

IOMC1

CLKIN1

IOMC2

CLKIN2

VDD

LX

VUP

VDDI

PRES

VCCUC

GNDUC

IOUC

CLKUC

RSTUC

VCCS1

IOS1

CLKS1

RSTS1

VCCS3

IOS3

VCCS2

IOS2

CLKS2

RSTS2

CLKS3

RSTS3

GNDS

TCA5013

C4

C8

GNDS

GNDS

GPIO1

GPIO2

GPIO3

GPIO4

A0

TST3

TST2

TST1

V

DDI

User

Card

Slot

SAM1

Card

Slot

SAM2

Card

Slot

GNDP

GNDP

Microcontroller

10k

10k 10k

10k

100 nF

100 nF

C

VUP

=

10 µF

10k

L

VDD

=

10 µH

C

VDD

= 100

µF

200nF

200nF

200nF

LDOCAP

1 µF

TST4

GND

SAM3

Card

Slot

200nF

VDD=V

DDI

= 3.3 V

D

VUP

Copyright © 2016, Texas Instruments Incorporated

Product

Folder

Order

Now

Technical

Documents

Tools &

Software

Support &

Community

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

TCA5013 Feature Rich Smartcard Interface IC with 1 User Card and 3 SAM Card Support

1 Features

1

• Operating supply voltage range of 2.7 V to 5.5 V

• Supports EMV 4.3, ISO7816-3 and ISO7816-10

standards

• Supports 1 user card and 3 secure access module

cards

• IEC61000-4-2 8-kV Contact discharge esd

protection on all smartcard interface pins

• Low power mode for power saving when inactive

(shutdown mode)

• Automatic card deactivation in the event of short

circuit, card pull out, over temperature or power

supply fault

• Integrated DC-DC boost to generate VCCfor 5 V

and 3 V on all card interfaces

• Automatic card clock generation for synchronous

card activation

• 4-byte FIFO for storing ATR from ISO7816-10

Type 1 cards

• Programmable rise/fall time control for IO and

clock lines of all smartcards

• Input clock frequency up to 26 MHz

• Tamper proof package design

2 Applications

• High-end point of sale (POS) terminals

• Multi secure accesscard capable EPOS systems

3 Description

TCA5013 is a smartcard interface IC that is targeted

for use in Point of Sale (POS) terminals. The device

enables POS terminals to interface with EMV4.3,

ISO7816-3 and ISO7816-10 compliant cards. It

supports up to 3 Secure Access Module (SAM) cards

in addition to 1 user card. It operates from a single

supply and generates all the card voltages. The

device is controlled by a standard I2C interface and is

capable of card activation and deactivation per

EMV4.3 and ISO7816-3 standards. In addition it also

supports ISO7816-10 synchronous cards. It has a 4byte FIFO that stores the ATR (Answer to Reset)

sequence in ISO7816-10 type 1 cards. Synchronous

cards (ISO7816-10 type 1 and type 2) can be set up

for automatic activation or manual activation. The

device has multiple power saving modes and also

supports power saving in the smartcard itself by

“clock stop” or lowering clock frequency to lowest

allowable levels per the ISO7816 - 3 standard.

TCA5013 has IEC 61000-4-2 8kV contact discharge

on all pins that interface with smartcards. This

enables the system to be resistant to ESD in the field

without the need for external ESD devices. It is

available in an 5 mm x 5 mm BGA package. The pin

out of the device is such that all the IO pins are

securely surrounded by other pins. This prevents the

secure pins from being probed during device

operation.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

TCA5013 NFBGA (48) 5.00 mm × 5.00 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

(1)

Simplified Schematic

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Page 2

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Revision History..................................................... 2

5 Pin Configuration and Functions......................... 3

6 Specifications......................................................... 5

6.1 Absolute Maximum Ratings ...................................... 5

6.2 Handling Ratings....................................................... 5

6.3 Recommended Operating Conditions....................... 5

6.4 Thermal Information.................................................. 5

6.5 Electrical Characteristics—Power Supply and ESD . 6

6.6 Electrical Characteristics—Card VCC........................ 6

6.7 Electrical Characteristics—Card RST....................... 6

6.8 Electrical Characteristics—Card CLK ....................... 7

6.9 Electrical Characteristics—Card Interface IO, C4 and

C8............................................................................... 7

6.10 Electrical Characteristics—PRES ........................... 8

6.11 Electrical Characteristics—IOMC1 and IOMC2 ...... 9

6.12 Electrical Characteristics—CLKIN1 and CLKIN2.... 9

6.13 Electrical Characteristics—A0 and SHDN .............. 9

6.14 Electrical Characteristics—INT ............................... 9

6.15 Electrical Characteristics—GPIO............................ 9

6.16 Electrical Characteristics—SDA and SCL............. 10

6.17 Electrical Characteristics—Fault Condition

Detection.................................................................. 10

6.18 I2C Interface Timing Requirements....................... 10

6.19 I2C Interface Timing Characteristics ..................... 10

6.20 Synchronous Type 1 Card Activation Timing

Characteristics ......................................................... 11

6.21 Synchronous Type 2 Card Activation Timing

Characteristics ......................................................... 11

6.22 Card Deactivation Timing Characteristics............. 11

6.23 Typical Characteristics.......................................... 11

7 Parameter Measurement Information ................ 12

8 Detailed Description ............................................ 13

8.1 Overview ................................................................. 13

8.2 Functional Block Diagram....................................... 14

8.3 Feature Description................................................. 15

8.4 Device Functional Modes........................................ 17

8.5 Programming........................................................... 38

8.6 Register Maps......................................................... 41

9 Application and Implementation ........................ 55

9.1 Application Information............................................ 55

9.2 Typical Application ................................................. 55

10 Power Supply Recommendations..................... 57

10.1 Power-On-Reset ................................................... 57

11 Layout................................................................... 57

11.1 Layout Guidelines ................................................. 57

11.2 Layout Example .................................................... 58

12 Device and Documentation Support ................. 59

12.1 Trademarks........................................................... 59

12.2 Electrostatic Discharge Caution............................ 59

12.3 Glossary................................................................ 59

13 Mechanical, Packaging, and Orderable

Information........................................................... 59

4 Revision History

Changes from Revision B (January 2016) to Revision C Page

• Changed the Pin Configuration view ..................................................................................................................................... 3

• Added: (Cold reset sequence) to Figure 6 ........................................................................................................................... 22

Changes from Revision A (July 2014) to Revision B Page

• Changed the datasheet title to "TCA5013 Feature Rich Smartcard Interface IC with 1 User Card and 3 SAM Card

Support".................................................................................................................................................................................. 1

• Added the Features: Tamper proof package design.............................................................................................................. 1

• Changed the Applications ...................................................................................................................................................... 1

• Full Version release of document........................................................................................................................................... 1

Changes from Original (July 2014) to Revision A Page

• Full version release of document. ......................................................................................................................................... 1

2

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

Page 3

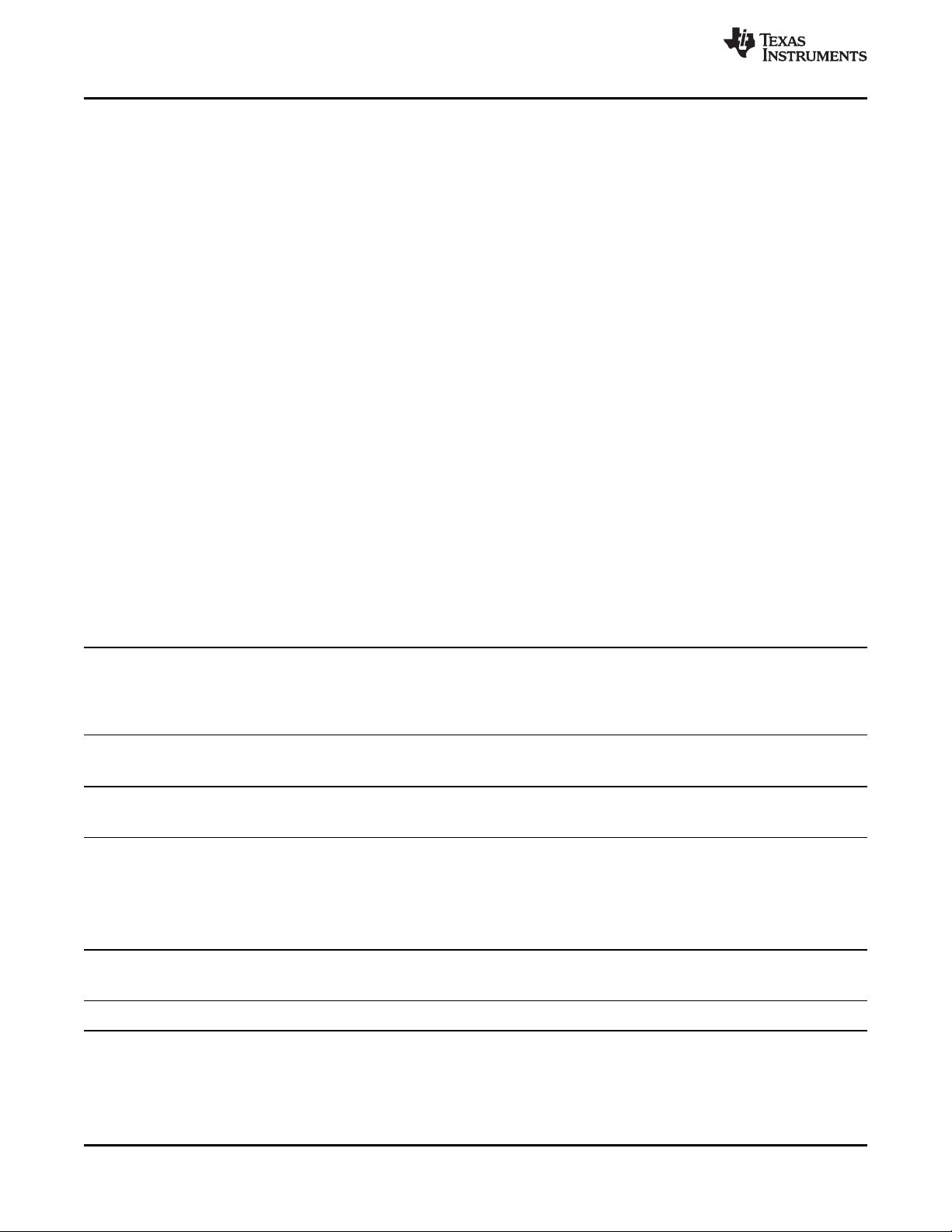

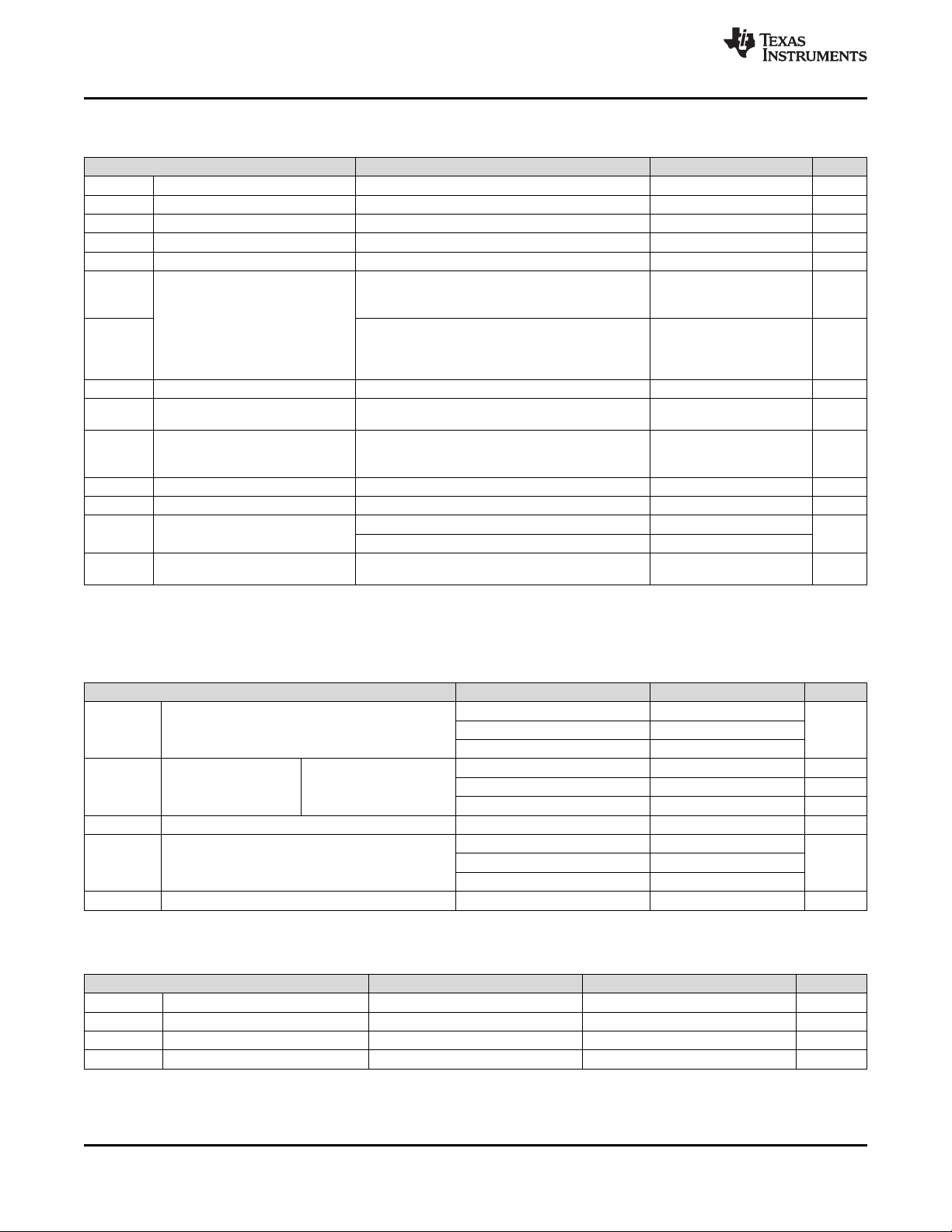

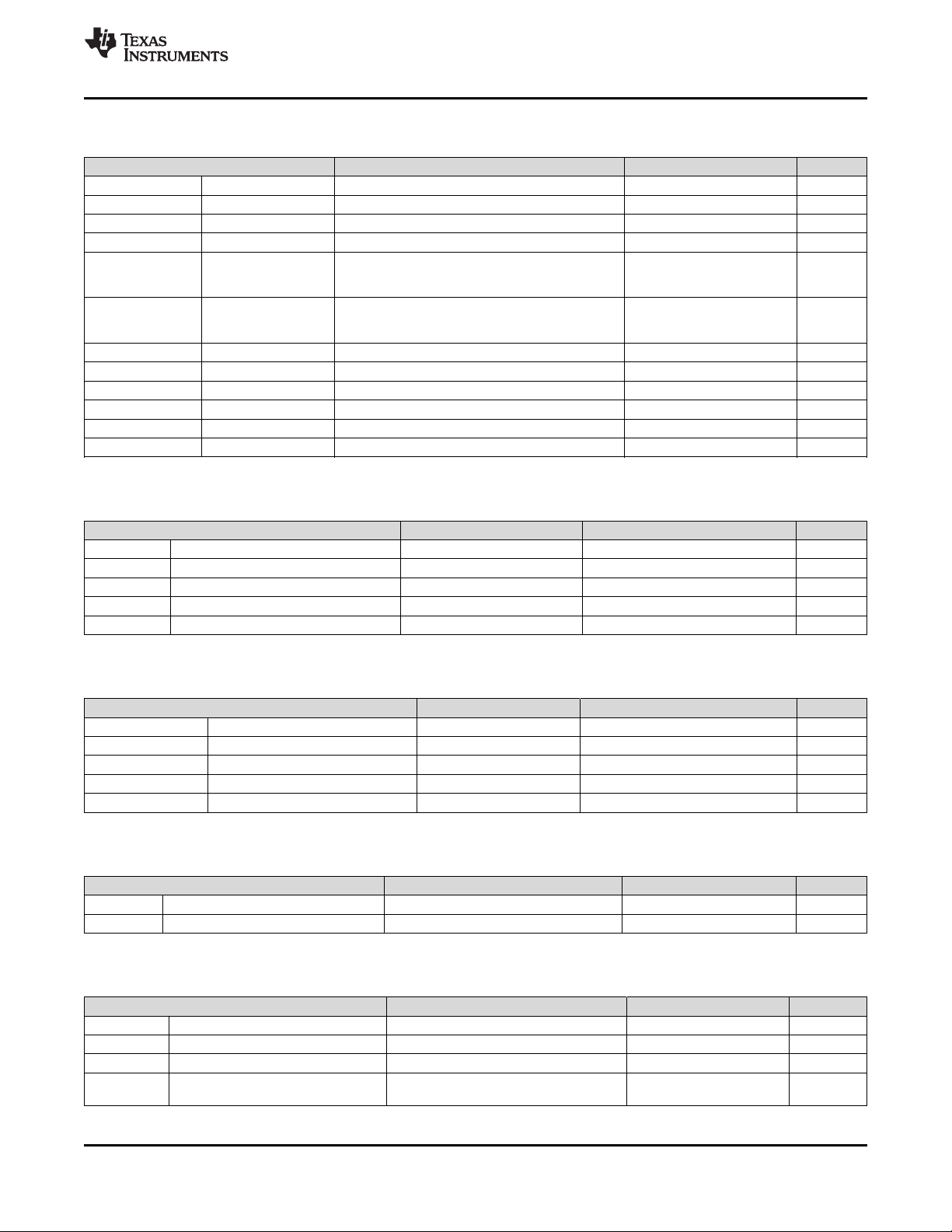

1 2 3 4 5 6 7 8 9

A

B

C

D

E

F

G

H

J

Not to scale

PRES GPIO4 GPIO3 GPIO2 GPIO1 VUP LX

C8 A0 INT SHDN SCL SDA LDOCAP TS T4 GNDP

C4 VDD

CLKUC TST3 GND CLKIN1

GNDUC IOUC IOMC1 GN D

RSTUC VCCUC IOMC2 CL KIN2

TST2 VDDI

RSTS3 IOS3 GNDS TS T1 IOS2 GNDS GNDS IOS1 VC CS1

CLKS3 VCCS3 RSTS2 CL KS2 VCCS2 RSTS1 CL KS1

www.ti.com

5 Pin Configuration and Functions

TCA5013

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

ZAH Package

NFBGA 48-Pins

Bottom View

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

3

Page 4

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

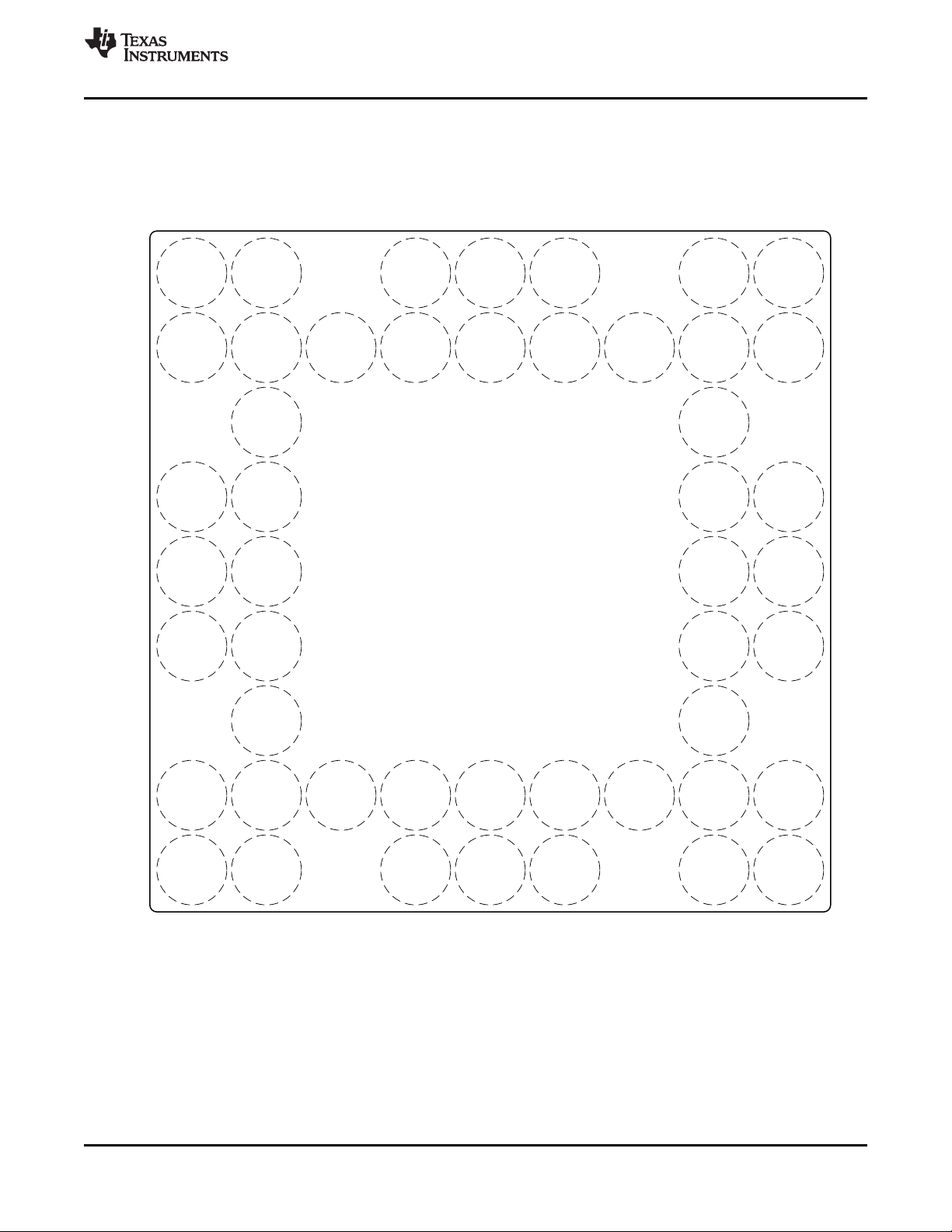

Pin Functions

PIN

NO. NAME

A1 PRES INPUT User card presence detection

A2 GPIO4 I/O General purpose IO (5-V tolerant)

A4 GPIO3 I/O General purpose IO (5-V tolerant)

A5 GPIO2 I/O General purpose IO (5-V tolerant)

A6 GPIO1 I/O General purpose IO (5-V tolerant)

A8 VUP PWR Boost output terminal

A9 LX PWR Boost inductor input terminal

B1 C8 I/O User card auxiliary IO (Open Drain)

B2 A0 INPUT

B3 INT OUTPUT Interrupt output (open drain)

B4 SHDN INPUT Shutdown and reset pin

B5 SCL INPUT

B6 SDA I/O

B7 LDOCAP PWR Internal LDO output. Connect to 1 µf decoupling capacitor.

B8 TST4 NA Test pin. Grounded in application.

B9 GNDP PWR Power ground

C2 C4 I/O User card auxiliary IO (Open drain)

C8 VDD PWR Device main power supply

D1 CLKUC OUTPUT User card clock

D2 TST3 NA Test pin. Grounded in application.

D8 GND PWR Device ground

D9 CLKIN1 INPUT User card external clock input pin

E1 GNDUC PWR User card ground pin

E2 IOUC I/O User card IO pin

E8 IOMC1 I/O User card microcontroller data IO

E9 GND PWR Device ground

F1 RSTUC OUTPUT User card reset output pin

F2 VCCUC PWR User card VCC pin

F8 IOMC2 I/O SAM microcontroller data IO

F9 CLKIN2 INPUT User card external clock input pin

G2 TST2 NA Test pin. Grounded in application.

G8 VDDI PWR Microcontroller interface supply voltage.

H1 RSTS3 OUTPUT Reset output for SAM3

H2 IOS3 I/O IO pin for SAM3

H3 GNDS PWR Ground for all SAMs

H4 TST1 NA Test pin. Grounded in application

H5 IOS2 I/O IO pin for SAM2

H6 GNDS PWR Ground for all SAMs

H7 GNDS PWR Ground for all SAMs

H8 IOS1 I/O IO pin for SAM1

H9 VCCS1 PWR VCC for SAM1

J1 CLKS3 OUTPUT Clock output for SAM3

J2 VCCS3 PWR VCC for SAM3

J4 RSTS2 OUTPUT Reset output for SAM2

J5 CLKS2 OUTPUT Clock output for SAM2

J6 VCCS2 PWR VCC for SAM2

J8 RSTS1 OUTPUT Reset output for SAM1

J9 CLKS1 OUTPUT Clock output for SAM1

TYPE DESCRIPTION

I2C address selection pin. Connect to VDDI, GND.

I2C clock input

I2C data

www.ti.com

4

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

Page 5

www.ti.com

6 Specifications

TCA5013

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

(1)(2)

(3)

MIN MAX UNIT

V

DD

V

DDI

V

I

I

OL

Supply voltage range –0.3 6 V

Interface voltage range –0.3 4 V

V

+

Input voltage range on digital I/O pins referenced to V

Input voltage range on digital I/O pins referenced to V

DDI

CC

-0.3

-0.3

DDI

0.3

VCC+

0.3

V

V

Load current on GPIO pins -15 mA

Load current on INT and SDA pins -6 mA

(1) The input negative-voltage and output voltage ratings may be exceeded if the input and output current ratings are observed.

(2) The package thermal impedance is calculated in accordance with JESD 51-7.

(3) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

6.2 Handling Ratings

MIN MAX UNIT

T

V

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

Storage temperature range –65 150 °C

stg

Electrostatic discharge

(ESD)

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all

(1)

pins

Charged device model (CDM), per JEDEC specification

JESD22-C101, all pins

(2)

–4 4

-1.5 1.5

kV

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

V

DD

V

DDI

I

CC(TOT)

T

A

Supply voltage range – DC-DC enabled 2.7 5.5 V

Supply voltage Range – DC-DC disabled 5.25 5.5 V

Interface voltage range 1.65 3.6 V

Sum of the currents that can be drawn on all Card VCC pins 180 mA

Operating temperature range –40 85 °C

6.4 Thermal Information

TCA5013

THERMAL METRIC

R

θJA

R

θJC(top)

R

θJB

ψ

JT

ψ

JB

Junction-to-ambient thermal resistance 96.9

Junction-to-case (top) thermal resistance 59.0

Junction-to-board thermal resistance 49.4

Junction-to-top characterization parameter 1.9

Junction-to-board characterization parameter 58.6

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

(1)

UNITZAH

48 PINS

°C/W

Product Folder Links: TCA5013

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

5

Page 6

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

www.ti.com

6.5 Electrical Characteristics—Power Supply and ESD

VDD= V

V

DDTH

V

DDSH

V

DDITH

I

DDSH

I

DDST

I

DDA

I

DDA1

I

DDISH

I

DDIA

t

WAKE

f

OSC

f

DC-DC

V

DC-DC

V

ESD-IEC

(1) Values highly dependent on external components like boost inductor and external rectifier. The specification is based on 75% boost

= 3.3 V; L

DDI

= 10 µH; C

VDD

= 10 µF; C

VDD

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VUP

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

VDD supervisor fault threshold VDDvoltage below which SUPL fault is asserted 2.45 2.7 V

VDD shutdown threshold VDDvoltage below which device will shutdown 2.0 V

VDDI shutdown threshold V

VDD Shutdown current Shutdown Mode at T

VDD Standby current Shutdown Mode at T

Supply current

(1)

voltage below which device will shutdown 1.4 1.6 V

DDI

= 25 C 22 28 µA

ambient

= 25°C 300 650 µA

ambient

IOMC1 = IOMC2 = V

CLKIN1 = CLKIN2 = GND; T

Current consumption per card interface activated

V

= V

CCUC

ambient

= f

= I

= 25°C

CCS1

CLKIN2

CCS1

= 55 mA; I

f

CLKIN1

I

CCUC

T

= V

= f

DDI

CCS2

CLKUC

;

= V

= f

CCS2

ambient

CCS3

CLKS1

= I

= 25°C

= 5 V;

= 5 MHz;

= 2 mA;

CCS3

235 280 mA

VDD Interface shutdown current Shutdown Mode at 25°C 3.5 5 µA

VDD Interface supply current

All Card VCC= 5 V; CLKIN1 = CLKIN2 = 5 MHz; @ 25°C;

IOMC1 = IOMC2 = V

DDI

290 300 µA

Time from

Device wakeup time

SHDN > VIHto

INT < V

OL

0.1 10 ms

Internal Oscillator Frequency Measured on CLKUC, CLKS1,CLKS2,CLKS3 1 1.2 1.4 MHz

DC-DC switching frequency 2.4 MHz

DC-DC output voltage

IEC61000-4-2 level 4 ESD protection

on pins defined in Table 1

If any card VCCis 5 V 5.5

If all card VCCis 3 V or 1.8 V 3.5

-8 8 kV

efficiency for max value and 85% efficiency for typical value

2 mA

V

6.6 Electrical Characteristics—Card V

VDD= V

= 3.3 V; L

DDI

= 10 µH; C

VDD

= 10 µF; C

VDD

CC

VUP

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

CC

∆VCC/∆I

V

RIPPLE

I

CC

V

DO

Card supply voltage

Load transient response

CC

Current pulses I < 100 mA,

t < 400 ns

Peak to peak ripple voltage Measured on VCC= 5 V, 3 V, 1.8 V 90 mV

Card supply Current

Card LDO dropout voltage ICC= 65 mA 250 mV

6.7 Electrical Characteristics—Card RST

VDD= V

V

OL - RST

V

OH - RST

t

R - RST

t

F - RST

= 3.3 V; L

DDI

= 10 µH; C

VDD

= 10 µF; C

VDD

VUP

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output Low voltage IOL= -200 µA 0.1 V

Output high voltage IOH= 150 µA 0.9 V

Rise time CL= 30 pF ; 10% to 90% 0.1 µs

Fall time CL= 30 pF ; 90% to 10% 0.1 µs

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VCC= 5 V; ICC≤ 65 mA 4.75 5 5.25

VCC= 1.8 V; ICC≤ 45 mA 1.71 1.8 1.89

VCC= 5 V ; 40 nA.s current spike 4.65 5.35 V

VCC= 3 V ; 17.5 nA.s current spike 2.76 3.24 V

VCC= 1.8 V ; 11.1 nA.s current spike 1.62 1.98 V

VCC= 5 V 65

VCC= 1.8 V 45

= 10 µF; TA= –40°C to 85°C unless otherwise noted

CC

VVCC= 3 V; ICC≤ 65 mA 2.85 3 3.15

mAVCC= 3 V 65

CC

V

V

6

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

Page 7

TCA5013

www.ti.com

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

6.8 Electrical Characteristics—Card CLK

VDD= V

V

OL - CLK

V

OH - CLK

t

R - CLK

CLK

f

CLK

D Clock duty cycle Internal clock = 1.2 MHz; CL= 30 pF 45 55 %

DDI

/ t

F - CLK

PU-PD-SKEW

= 3.3 V; L

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

= 10 µH; C

VDD

Output Low voltage IOL= -100 µA 0.1 V

Output high voltage IOH= 100 µA 0.9 V

Rise/Fall time

Clock pull-up / pull-down skew t

Frequency on CLK pin CL= 30 pF 20 MHz

= 10 µF; C

VDD

VUP

CL= 30 pF ;

10% to 90%;

– t

R-CLK

F-CLK

= 10 µF; TA= –40°C to 85°C unless otherwise noted

CC

CLK slew rate settings register =

0000b

CLK slew rate settings register =

0001b

CLK slew rate settings register =

0010b

CLK slew rate settings register =

0011b

CLK slew rate settings register =

0100b

CLK slew rate settings register =

0101b

CLK slew rate settings register =

0110b

CLK slew rate settings register =

0111b

CLK slew rate settings register =

1000b

CLK slew rate settings register =

1001b

CLK slew rate settings register =

1010b

CLK slew rate settings register =

1011b

CLK slew rate settings register =

1100b

CLK slew rate settings register =

1101b

CLK slew rate settings register =

1110b

CLK slew rate settings register =

1111b

/ t

; CL= 30 pF 10 %

F-CLK

7

9

11

13

13.5

14

15

16

17

18

19

20

21

22

23

25

CC

V

V

ns

6.9 Electrical Characteristics—Card Interface IO, C4 and C8

VDD= V

V

OL - C4, C8

V

OH - C4, C8

V

IL - IO, C4, C8

V

IH - IO, C4, C8

V

OL - IO, 5 V

= 3.3 V; L

DDI

= 10 µH; C

VDD

= 10 µF; C

VDD

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VUP

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output Low Voltage VCC= 5 V IOL= -1 mA 0.5 V

Output Low Voltage VCC= 5 V, 3 V, 1.8 V IOH= 20 µA 0.9 V

Output Low Voltage 0.4 V

Output High Voltage 0.6 V

VCC= 5 V;

IO fall time register setting = 00b

VCC= 5 V;

Output Low Voltage

IO fall time register setting = 01b

VCC= 5 V;

IO fall time register setting = 10b

VCC= 5 V;

IO fall time register setting = 11b

Product Folder Links: TCA5013

IOL= -1 mA

CC

V

V

V

CC

CC

0.5

0.5

V

0.5

0.5

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

7

Page 8

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

Electrical Characteristics—Card Interface IO, C4 and C8 (continued)

www.ti.com

VDD= V

DDI

V

OL - IO, 3 V

V

OL - IO, 3 V, 500uA

V

OL - IO, 1.8 V

V

OL - IO, 1.8 V, 500uA

t

PD - R - IOMC - IO

t

PD - F - IOMC - IO

t

FO - IO

t

RO - IO

t

RO - C4, C8

t

FO - C4, C8

t

RI - IO, C4, C8

t

FI - IO, C4, C8

C

I - IO, C4, C8

R

PU - IO, C4, C8

= 3.3 V; L

= 10 µH; C

VDD

= 10 µF; C

VDD

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VUP

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Output Low Voltage

Output Low Voltage

Output Low Voltage

Output Low Voltage

Rising edge

propagation delay

Falling edge

propagation delay

IO Line output fall time

IO Line output rise time

C4, C8 Line output rise

time

C4, C8 Line output fall

time

IO, C4, C8 Input rise

time

IO, C4, C8 Input fall

time

VCC= 3 V;

IO fall time register setting = 01b

VCC= 3 V;

IO fall time register setting = 10b

IOL= -1 mA

VCC= 3 V;

IO fall time register setting = 11b

VCC= 3 V;

IO fall time register setting = 00b

VCC= 3 V;

IO fall time register setting = 01b

VCC= 3 V;

IOL= -500

µA

IO fall time register setting = 10b

VCC= 3 V;

IO fall time register setting = 11b

VCC= 1.8 V;

IO fall time register setting = 11b

IOL= -1 mA 0.18 V

VCC= 1.8 V;

IO fall time register setting = 01b

VCC= 1.8 V;

IO fall time register setting = 10b

IOL= -500

µA

VCC= 1.8 V;

IO fall time register setting = 11b

From IOMC pin to card IO; CLon card IO = 30 pF;

CLon IOMC = 30 pF; Prop delay measured from

70% V

to 70% of VCCfor rising edge

DDI

From IOMC pin to card IO; CLon card IO = 30 pF;

CLon IOMC = 30 pF; Prop delay measured from

30% V

CL= 30 pF ; 10% to 90%; IO fall time register setting

= 00b

CL= 30 pF ; 10% to 90%; IO rise time register

setting = 100b

to 30% of VCCfor falling edge;

DDI

68 ns

100 ns

CL= 30 pF ; 10% to 90% 1.2 µs

CL= 30 pF ; 90% to 10% 1.2 µs

10% to 90% 1.2 µs

90% to 10% 1.2 µs

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.18

0.18

0.18

400 ns

250 ns

Input capacitance F = 1 MHz 10 pF

Pull-up resistance IO, C4, C8 pull-up to V

CC

4.25 8.1 kΩ

V

V

V

6.10 Electrical Characteristics—PRES

VDD= V

V

IL - PRES

V

IH - PRES

I

LEAK - PRES

t

DEB(P)

t

DEB(D)

8

= 3.3 V; L

DDI

PARAMETER TEST CONDITION MIN TYP MAX UNIT

= 10 µH; C

VDD

Input Low voltage 0.3 V

Input high voltage 0.7 V

Input leakage current Voltage on pin = V

Debounce time

= 10 µF; C

VDD

Time from transition on PRES pin to PRESL bit being

set

Time from transition on PRES pin to start of

deactivation sequence (RST going low)

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VUP

DDI

DDI

20 ms

100 µs

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

DDI

1 µA

V

V

Page 9

www.ti.com

6.11 Electrical Characteristics—IOMC1 and IOMC2

VDD= V

V

OL- IOMC

V

OH - IOMC

V

IL - IOMC

V

IH - IOMC

t

PD - F - IO - IOMC

t

PD - F - IO - IOMC

t

RO - IOMC

t

FO - IOMC

t

RI - IOMC

t

FI - IOMC

C

I - IOMC

R

PU - IOMC

= 3.3 V; L

DDI

= 10 µH; C

VDD

= 10 µF; C

VDD

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VUP

PARAMETER TEST CONDITION MIN TYP MAX UNIT

Output low voltage IOL= -100 µA 0.2 V

Output high voltage IOH= 20 µA 0.8 V

Input low signal 0.3 V

Input high signal 0.7 V

Falling edge propagation

delay

Rising edge propagation

delay

From Card IO pin to IOMC; CLon card IO = 30 pF;

Prop delay measured from 30% VCCto 30% of V

falling edge;

From Card IO pin to IOMC; CLon card IO = 30 pF;

Prop delay measured from 70% VCCto 70% of V

rising edge;

Output rise time CL= 30 pF ; 10% to 90% 1.2 µs

Output fall time CL= 30 pF ; 90% to 10% 1.2 µs

Input rise time 10% to 90% 1.2 µs

Input fall time 90% to 10% 1.2 µs

Input capacitance 10 pF

Pull-up resistance Pull-up to V

DDI

6.12 Electrical Characteristics—CLKIN1 and CLKIN2

VDD= V

V

IL - CLKIN

V

IH - CLKIN

t

R - CLKIN

t

F - CLKIN

f

CLKIN

= 3.3 V; L

DDI

= 10 µH; C

VDD

= 10 µF; C

VDD

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VUP

PARAMETER TEST CONDITION MIN TYP MAX UNIT

Input Low voltage 0.2 V

Input high voltage 0.8 V

Rise time 10% to 90% 0.1 µs

Fall time 90% to 10% 0.1 µs

Input clock frequency 26 MHz

TCA5013

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

V

V

V

V

V

V

DDI

DDI

for

for

DDI

DDI

DDI

DDI

250 ns

400 ns

11 kΩ

DDI

DDI

6.13 Electrical Characteristics—A0 and SHDN

VDD= V

V

IL - A0, SHDN

V

IH - A0, SHDN

I

LEAK - A0, SHDN

C

I - A0, SHDN

R

PU - SHDN

= 3.3 V; L

DDI

= 10 µH; C

VDD

= 10 µF; C

VDD

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VUP

PARAMETER TEST CONDITION MIN TYP MAX UNIT

input Low voltage 0.2 V

input high voltage 0.8 V

Input leakage current Voltage on pin = V

Input Capacitance 10 pF

Pull-up resistance on SHDN Pull-up to V

6.14 Electrical Characteristics—INT

VDD= V

I

LEAK - INT

V

OL - INT

= 3.3 V; L

DDI

= 10 µH; C

VDD

= 10 µF; C

VDD

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VUP

PARAMETER TEST CONDITION MIN TYP MAX UNIT

Input leakage current Voltage on pin = V

Output low voltage IOL= -3 mA 0.2 V

6.15 Electrical Characteristics—GPIO

VDD= V

V

OL - GPIO

I

OL - GPIO

I

LEAK - GPIO

T

PD - GPIO

= 3.3 V; L

DDI

= 10 µH; C

VDD

= 10 µF; C

VDD

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VUP

PARAMETER TEST CONDITION MIN TYP MAX UNIT

Output low voltage IOL= -10 mA 0.2 V

Output low current 10 mA

Input leakage current Voltage on pin = V

State transition on GPIO to INT assertion

RPUon INT= 10 k; CLon INT 20 pF;

GPIO and INT transition referenced to 0.5 V

DDI

DDI

DDI

DDI

DDI

DDI

DDI

V

V

1 µA

2.5 MΩ

1 µA

DDI

DDI

V

V

1 µA

4 µs

Product Folder Links: TCA5013

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

9

Page 10

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

6.16 Electrical Characteristics—SDA and SCL

VDD= V

I

LEAK - SDA, SCL

V

OL - SDA, SCL

I

OL - SDA, SCL

V

IL - SDA, SCL

V

IH - SDA, SCL

= 3.3 V; L

DDI

= 10 µH; C

VDD

PARAMETER TEST CONDITION MIN TYP MAX UNIT

Input leakage current Voltage on pin = V

SDA output low voltage IOL= -3 mA 0.1 V

SDA max output low current VOL= 0.3 V 10 mA

Input low signal 0.2 V

Input high signal 0.8 V

= 10 µF; C

VDD

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VUP

DDI

6.17 Electrical Characteristics—Fault Condition Detection

VDD= V

T

SD

I

SD

I

LIM

= 3.3 V; L

DDI

Shutdown temperature 125 145 °C

Shutdown current On card VCC pins 160 200 260 mA

Output current limit

= 10 µH; C

VDD

PARAMETER TEST CONDITION MIN TYP MAX UNIT

= 10 µF; C

VDD

= 10 µF; TA= –40°C to 85°C unless otherwise noted

VUP

On card IO pins –15 15 mA

On card CLK pins –70 70 mA

On card RST pins –20 20 mA

DDI

www.ti.com

1 µA

DDI

DDI

V

V

V

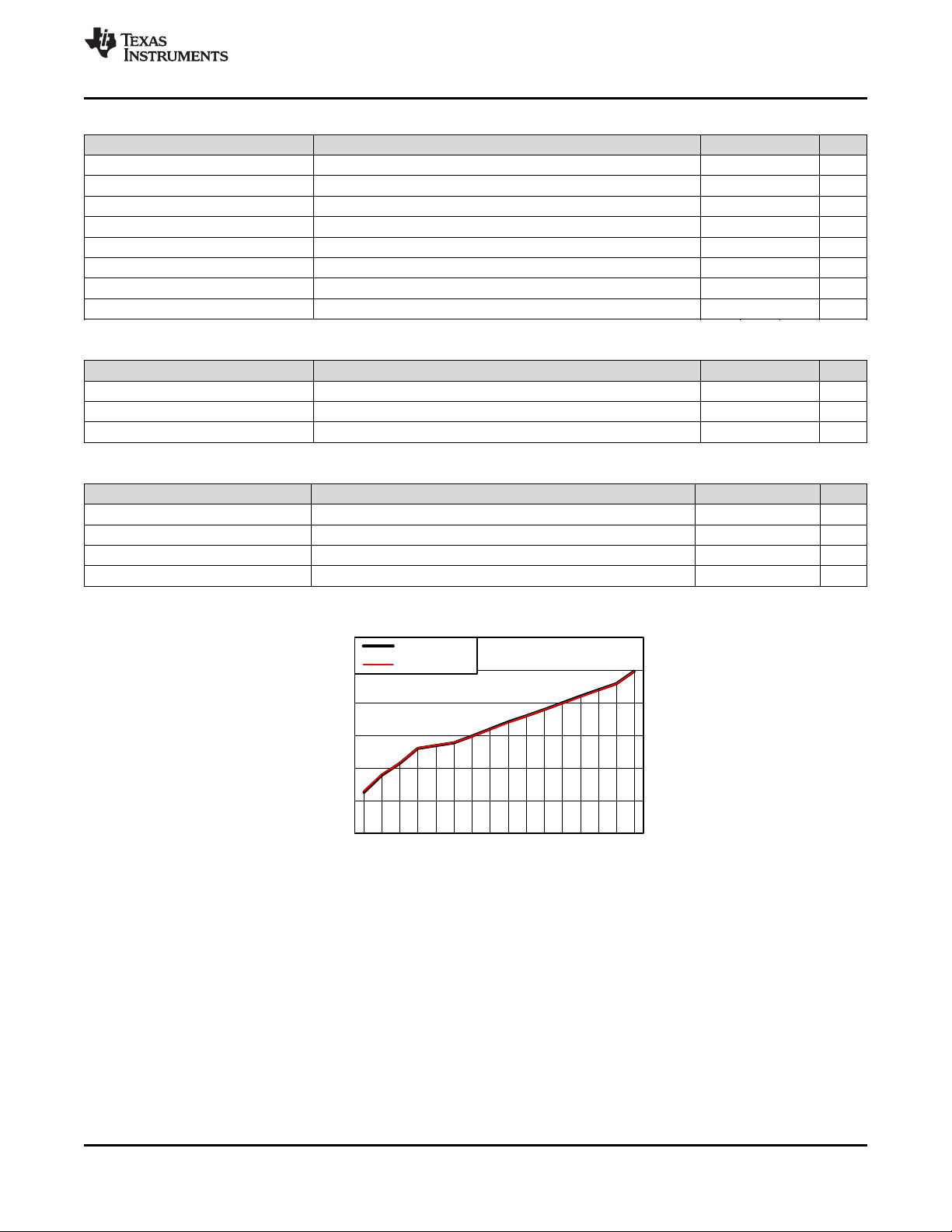

6.18 I2C Interface Timing Requirements

(1)

STANDARD MODE

PARAMETER

I2C BUS

MIN MAX MIN MAX MIN MAX

f

t

t

t

t

t

t

t

t

t

t

t

t

scl

sch

scl

sp

sds

sdh

icr

icf

ocf

buf

sts

sth

sps

I2C clock frequency 100 400 1000 kHz

I2C clock high time 4 0.6 0.26 μs

I2C clock low time 4.7 1.3 0.5 μs

I2C spike time 50 50 50 ns

I2C serial data setup time 250 100 50 ns

I2C serial data hold time 0 0 0 ns

I2C input rise time 1000 300 120 ns

I2C input fall time 300 300 120 ns

I2C output fall time; 10 pF to 400 pF bus 300 300 120 μs

I2C bus free time between Stop and Start 4.7 1.3 0.5 μs

I2C Start or repeater start condition setup time 4.7 0.6 0.26 μs

I2C Start or repeater start condition hold time 4 0.6 0.26 μs

I2C Stop condition setup time 4 0.6 0.26 μs

(1) Refer to the Parameter Measurement Information section for more information.

6.19 I2C Interface Timing Characteristics

(1)

PARAMETER MIN TYP MAX UNIT

t

vd(data)

t

vd(ack)

Valid data time; SCL low to SDA output valid 450 ns

Valid data time of ACK condition; ACK signal from SCL low to SDA (out) low 450 ns

(1) Refer to Parameter Measurement Information section for more information.

FAST MODE

I2C BUS

FAST MODE PLUS

(FM+) I2C BUS

UNIT

10

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

Page 11

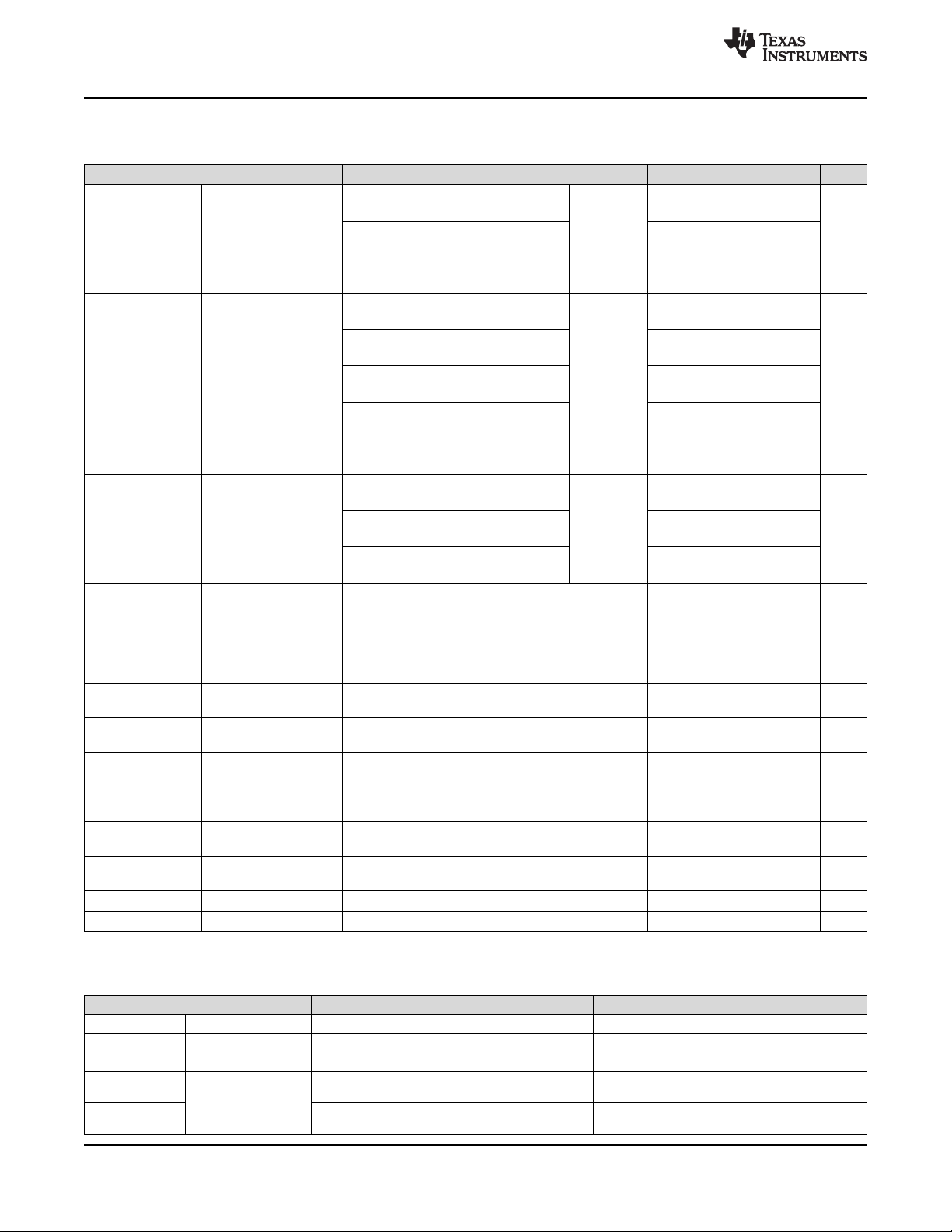

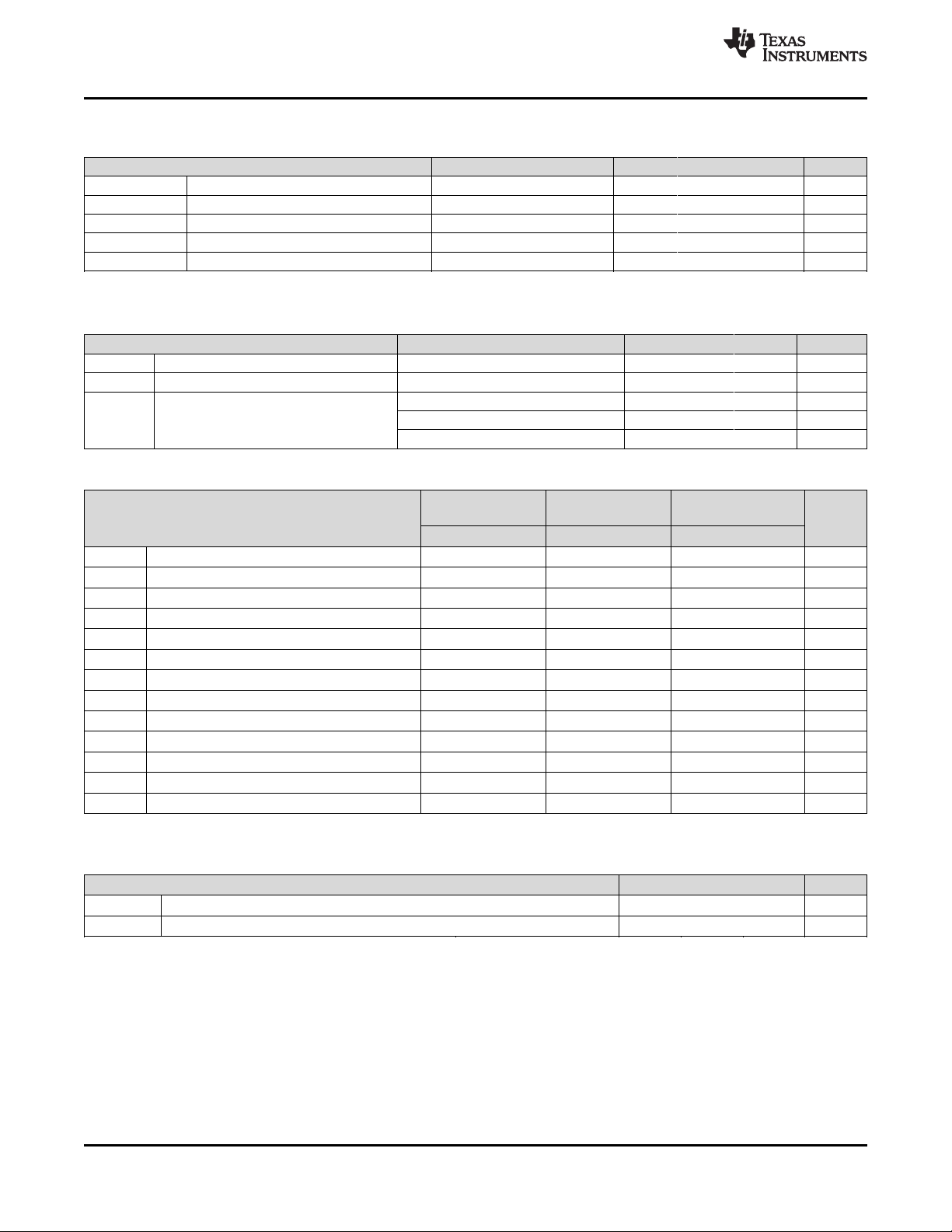

0

5

10

15

20

25

30

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

CLK Rise / Fall Time (ns)

Clock Slew Rate Settings Register Value (ns)

CLK Rise Time

CLK Fall Time

C001

TCA5013

www.ti.com

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

6.20 Synchronous Type 1 Card Activation Timing Characteristics

PARAMETER TEST CONDITION MIN TYP MAX UNIT

t

S1-RST-HI

t

S1-CLK-HI

t

S1-RST-CLK

t

S1-CLK-RST

t

S1-CLK-LO

t

S1-CLK-PER

t

S1-ATR-SETUP

CL= 30 pF ; VCC= 5 V; See Figure 4. 60 70 80 µs

CL= 30 pF ; VCC= 5 V; See Figure 4. 10 12.5 15 µs

CL= 30 pF ; VCC= 5 V; See Figure 4. 25 28 32 µs

CL= 30 pF ; VCC= 5 V; See Figure 4. 25 28 32 µs

CL= 30 pF ; VCC= 5 V; See Figure 4. 70 80 90 µs

CL= 30 pF ; VCC= 5 V; See Figure 4. 22.5 25 27.5 µs

CL= 30 pF ; VCC= 5 V; See Figure 4. 1 µs

Duty cycle CL= 30 pF ; VCC= 5 V; See Figure 4. 45 50 55 %

6.21 Synchronous Type 2 Card Activation Timing Characteristics

PARAMETER TEST CONDITION MIN TYP MAX UNIT

t

S2-VCC-CLK

t

S2-CLK-C4

t

S2-CLK-HI

CL= 30 pF ; VCC= 5 V; See Figure 5. 5 20 µs

CL= 30 pF ; VCC= 5 V; See Figure 5. 14 18 22 µs

CL= 30 pF ; VCC= 5 V; See Figure 5. 7 9 11 µs

6.22 Card Deactivation Timing Characteristics

PARAMETER TEST CONDITION MIN TYP MAX UNIT

t

DEAC-TOTS

t

DEAC-RST-CLK

t

DEAC-RST-IO

t

DEAC-RST-VCC

CL= 30 pF ; VCC= 5 V; See Figure 7. 0.5 0.6 ms

CL= 30 pF ; VCC= 5 V; See Figure 7. 10 12 15 µs

CL= 30 pF ; VCC= 5 V; See Figure 7. 22 24 26 µs

CL= 30 pF ; VCC= 5 V; See Figure 7. 45 µs

6.23 Typical Characteristics

Figure 1. CLK Rise/Fall Time vs Clock Slew Rate Settings Register Value

CL= 30 pF

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

11

Page 12

002aac938

t

f

70 %

30 %

SDA

t

f

70 %

30 %

S

t

r

70 %

30 %

70 %

30 %

t

SCL

HD;DAT

1 / f

1 clock cycle

SCL

st

70 %

30 %

70 %

30 %

t

r

t

cont.

VD;DAT

cont.

SDA

SCL

t

SU;STA

t

HD;STA

Sr

t

SP

t

SU;STO

t

BUF

P S

t

HIGH

9 clock

th

t

HD;STA

t

LOW

70 %

30 %

t

VD;ACK

9 clock

th

t

SU;DAT

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

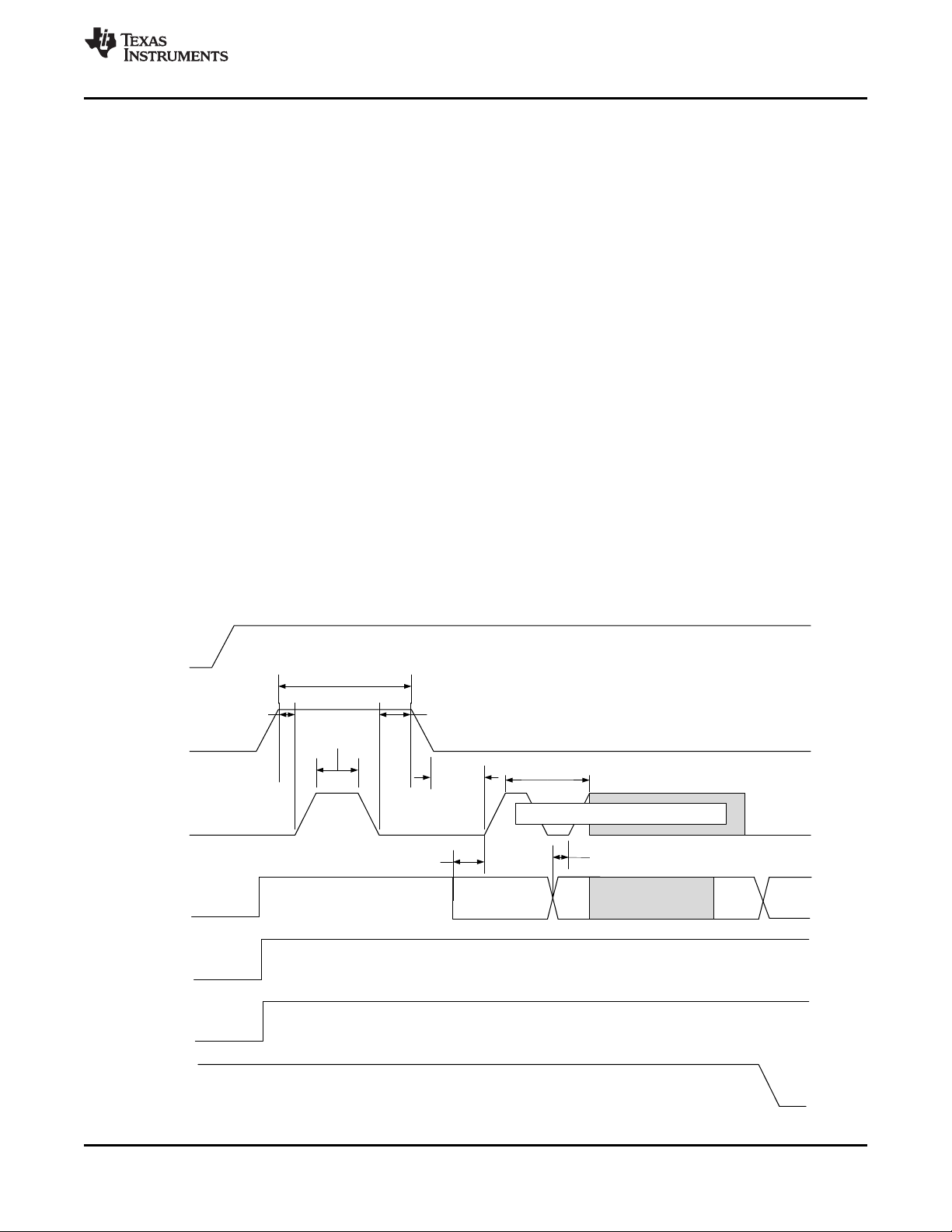

7 Parameter Measurement Information

www.ti.com

VIL= 0.3 V

VIH= 0.7 V

DDI

DDI

Figure 2. Parameter Measurement Information for I2C Timing Characteristics and Requirements

Product Folder Links: TCA5013

12

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Page 13

TCA5013

www.ti.com

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

8 Detailed Description

8.1 Overview

TCA5013 is a smartcard interface IC that enables POS terminals to interface with EMV4.3 and ISO7816-3 and

ISO7816-10 compliant smartcards. The device has 4 smartcard interfaces (1 user card and 3 SAM cards).

TCA5013 is capable of card activation and deactivation per EMV4.3, ISO7816-3 and ISO7816-10 standards.

TCA5013 has two power supply pins - VDD and VDDI. VDD is the main power supply for the device and VDDI is

the reference supply for the interface operating voltage. VDDand V

recommended operating conditions for the device to operate properly. Upon power up an internal Power-OnReset circuit initializes the digital core with all the registers in their default state as described in Register Maps.

TCA5013 can operate in various functional modes as defined in Device Functional Modes. When one of the

device power supplies is not applied, that is, VDD< V

DDSH

or V

DDI

< V

DDITH

of the device functions are available in this mode. Shutdown Mode is the lowest power operating mode in the

device. Shutdown mode is entered by asserting the SHDN = 0 when VDD> V

can detect card insertion and removal even in Shutdown mode. The device is in Standby mode when VDD>

V

DDSH

or V

DDI

> V

and the SHDN pin = 1. When any of the 4 smartcard interfaces is activated, the device

DDITH

enters active mode (see Active Mode). The user card interface module can be activated in synchronous type 1,

synchronous type 2, asynchronous or manual operation mode. For synchronous type 1 and synchronous type 2

operation modes, the device can automatically generate activation sequences per the ISO7816-10 standard (see

Synchronous Type 1 Operating Mode and Synchronous Type 2 Operating Mode). For asynchronous cards the

device performs the activation sequence and also verifies the response from the card meets the requirements

per ISO7816-3 and EMV4.3 standards (see Asynchronous Operating Mode). The device also supports WARM

reset ( see Warm Reset Sequence) and card deactivation (see Deactivation Sequence) of smartcards per the

ISO7816-3 and EMV4.3 standards. The SAM card interface modules can only be activated in aynchronous

operation mode.

All smartcard interfaces have the standard CLK, IO and RST pins (as defined by EMV4.3 and ISO7816

standards). All these pins are designed to have internal current limiting to prevent device damage when shorted.

CLK and IO pins also provide automatic level translation to the voltage at which the card has been activated.

Rrise time and fall time of the CLK and IO pins can also be controlled using digital register settings (see IO Rise

Time and Fall Time control and CLK Rise Time and Fall Time Control). In addition to the CLK, IO and RST pins

the user card interface also has PRES pin to detect card insertion and removal (see User Card Insertion /

Removal Detection). C4 and C8 pins, as defined by ISO7816-10, are also present on the user card interface (see

User Card Interface Module).

The device has internal boost and LDOs to generate the card activation voltage depending on the operating

voltage required by the specific card being interfaced with. It also has a voltage supervisor that monitors VDDand

V

and responds as described in Interrupt Operation . The power management section is described in more

DDI

detail in Power Management.

In addition to these functions the device provides 8kV IEC 61000-4-2 ESD protection on all pins that interface to

smartcards. This removes the need for any external ESD protection on the board, thereby providing system

robustness without compromising system security (removable components on secure lines).

TCA5013 is configured using a standard I2C interface that is capable of up to 1 MHz operation. The I2C interface

is also used to read the status of various fault conditions that the device can detect. The I2C operation is

described in detail in I2C Interface Operation.

need to ramped to within the

DDI

the device is in Power Off Mode. None

DDSH

and V

DDI

> V

. The device

DDITH

Product Folder Links: TCA5013

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

13

Page 14

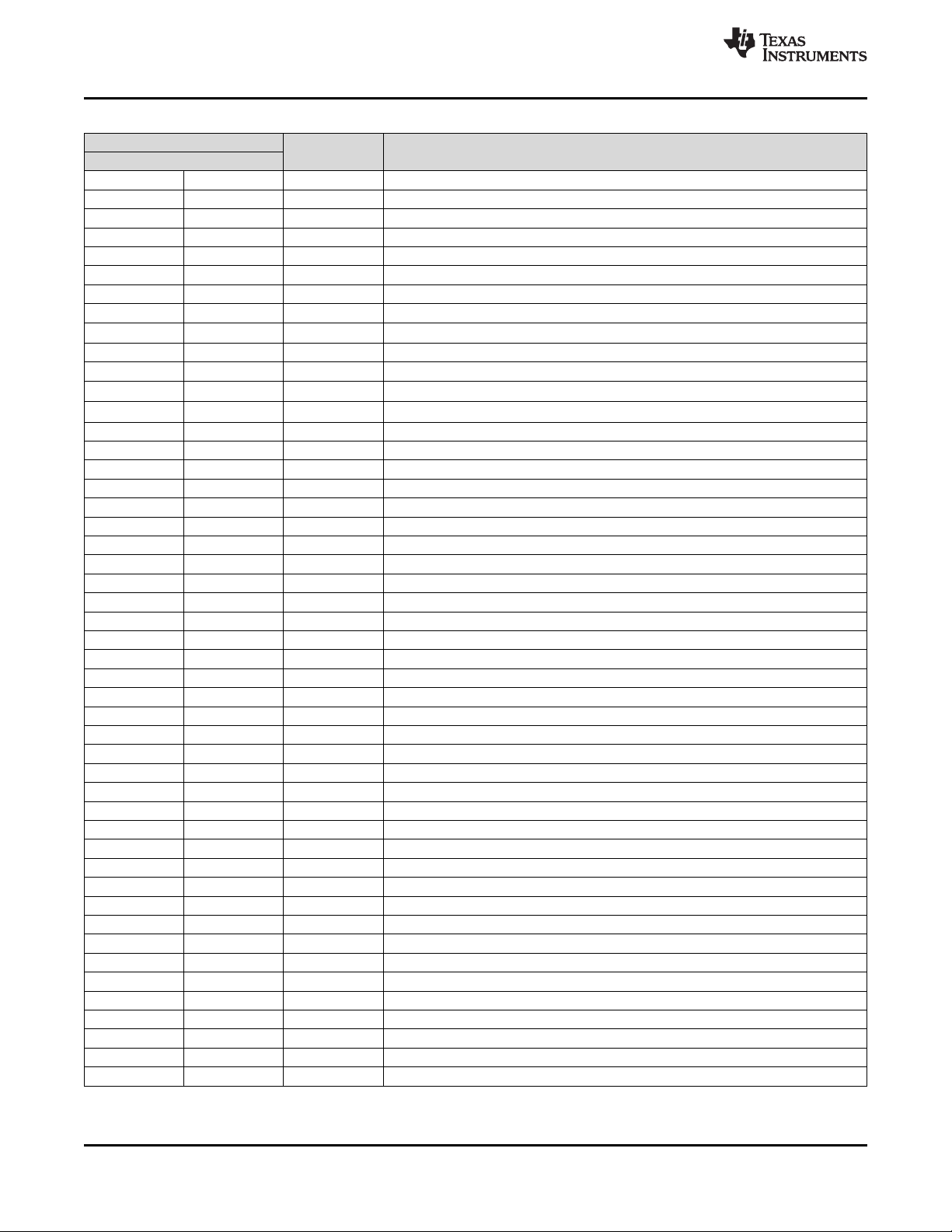

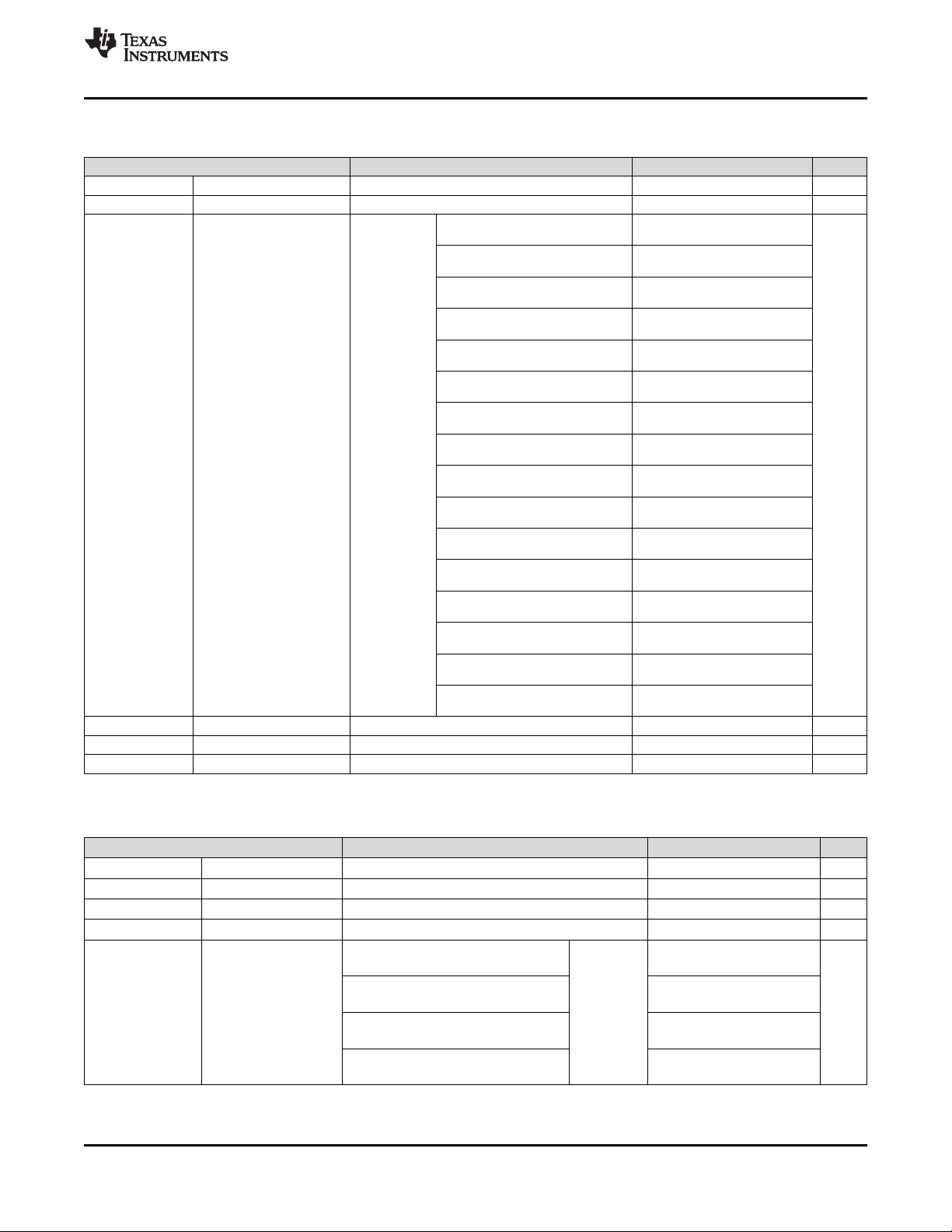

User Card Interface

Module

Card VCCLDO

IO level translator

CLK level translator

RST level translator

C4&C8 buffers

PRES detection logic

SAM 1 Interface Module

Card VCCLDO

IO level translator

CLK level translator

RST level translator

SAM 3 Interface Module

Card VCCLDO

IO level translator

CLK level translator

RST level translator

SAM 2 Interface Module

Card VCCLDO

IO level translator

CLK level translator

RST level translator

Boost

LDO

Oscillator

User card

clock divider

SAM clock

divider and

multiplexer

SAM card

Digital core

and register map

I2C

interface

RSTUC

C4

C8

PRES

VCCUC

IOUC

CLKUC

VCCS1

IOS1

CLKS1

VCCS2

IOS2

CLKS2

VCCS3

IOS3

CLKS3

RSTS1

RSTS2

RSTS3

VUPLX

VDD

LDOCAP

IOMC1

IOMC2

CLKIN1

CLKIN2

SCL

SDA

INT

SHDN

A0

GPIO1 GPIO2 GPIO3 GPIO4

VDDI

GNDUC

GNDS

GNDS

GNDS

GNDP

GNDP

GNDP

TST1 TST2 TST3 TST 4

User card IO

multiplexer

Voltage

supervisor

IO multiplexer

and multiplexer

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

8.2 Functional Block Diagram

www.ti.com

14

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

Page 15

TCA5013

www.ti.com

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

8.3 Feature Description

8.3.1 Card Interface Modules

TCA5013 has 1 user card interface module and 3 SAM card interface modules. All card modules have level

translators and an LDO to support interfacing with smartcards operating at different voltages.

8.3.2 SAM Card Interface Modules

All SAM card interface modules can operate per the EMV4.3 and ISO7816-3 standard and support asynchronous

operating mode. All SAM card interface modules have the standard IO, CLK and RST pins. Detailed operation of

these pins is described in section IO operation, CLK operation and RST operation.

8.3.3 User Card Interface Module

User card interface module can also operate per the EMV4.3 and ISO7816-3 standard and support

asynchronous operating mode. In addition, the user card interface module also supports synchronous type 1

operating mode and synchronous type 2 operating mode, per ISO7816-10. Like the SAM card interface modules,

the user card interface module also has IO, CLK, and RST pins. The user card interface module also has a

PRES pin that is used for detection of user card insertion or removal.

C4 and C8 are two pins that are only present on the user card interface. These are open drain bi-directional IOs

that are controlled by the bit [5] and bit [4] of user card synchronous mode settings register (Reg 0x09) when the

card interface is activated. These bits act as both control and status bits for the C4 and C8 signals. If a ‘0’ is

written to either of these bits the corresponding pin is driven low by the TCA5013. However, when a ‘1’ is written

to the register bit, the corresponding pin is pulled up by an internal pull-up resistor. In this state an external

device can drive the pin low. If the pin is driven low, then the corresponding bit in the register changes to reflect

the status of the pin.

8.3.4 Clock Division and Multiplexing

TCA5013 card interface modules all have a CLK pin that provide a clock signal that is used for smartcard

operation. This clock signal is generated based on an internal oscillator or from the CLKIN1/CLKIN2 input clock

signals, by the clock divider and multiplexer circuitry. The user card has a dedicated clock divider and

multiplexer. The user card CLK output can be a configured to be a function of the CLKIN1 frequency or the

internal oscillator frequency. CLKIN2 is shared by all the SAM card interface modules. The CLK output of each

SAM card can be independently configured based on the CLKIN2 frequency or the internal oscillator frequency.

CLK operation section describes the clock division and multiplexing in detail.

8.3.5 IO Multiplexing

IOMC1 and IOMC2 are connected to the IO pins in the card interface modules through IO multiplexer blocks.

The user card IO module has a dedicated IO multiplexer, that can be connect or disconnect IOUC from the

IOMC1 pin. The IOMC2 is connected to the SAM card interface modules IO pins through the SAM IO multiplexer

block. The IOMC2 can only be connected to one of the SAM interface modules at any given time. IO operation

section describes IO multiplexing in detail.

8.3.6 GPIO Operation

The TCA5013 has four 5 V tolerant open drain GPIO pins that can be configured as inputs or outputs through

device settings register (Reg 0x42). If configured as outputs, each is capable of sinking up to 10mA of current. If

configured as inputs they will assert the INT line when a state change occurs on the pin. The minimum pulse

width for transition detection is 10 µs, that is, when a state transition occurs on a GPIO configured as an input, it

needs to hold its state for a minimum of 10 µs in order to guarantee detection by the TCA5013. This, however,

does not imply any glitch rejection on the GPIO pins. The GPIOs are available in Standby Mode and Active

Mode. GPIO state transitions are not tracked in shutdown mode.

8.3.7 Power Management Features

TCA5013 has a DC-DC boost and card LDOs that enable it to generate regulated smart card VCCfrom its input

power rails (VDDand V

devices also have a voltage supervisor that monitors the VDDand V

). It also has an internal LDO that is used to power its internal circuits. The TCA5013

DDI

rails to ensure they are stable and usable

DDI

for smartcard operation.

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

15

Page 16

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

www.ti.com

Feature Description (continued)

8.3.8 ESD Protection

All the smart card interface pins in the TCA5013 devices are designed with in built IEC61000-4-2 level 4 8kV

contact ESD protection. Table 1 shows a list of pins with the 8kV ESD protection. The pins not listed below all

have 4kV HBM ESD protection.

Table 1. List of Pins with 8kV IEC ESD Protection

PIN SYMBOL TYPE DESCRIPTION

A1 PRES INPUT User card presence detection

B1 C8 IO User card auxiliary IO (Open Drain)

C2 C4 IO User card auxiliary IO (Open Drain)

D1 CLKUC OUTPUT User card clock

E2 IOUC IO User card IO

F1 RSTUC OUTPUT User card RST

F2 VCCUC PWR User card VCC

H1 VCCUC OUTPUT SAM3 RST

H2 IOS3 IO SAM3 IO

H5 IOS2 IO SAM2 IO

H8 IOS1 IO SAM1 IO

H9 VCCS1 PWR SAM1 VCC

J1 CLKS3 OUTPUT SAM3 CLK

J2 VCCS3 PWR SAM3 VCC

J4 RSTS2 OUTPUT SAM2 RST

J5 CLKS2 OUTPUT SAM2 CLK

J6 VCCS2 PWR SAM2 VCC

J8 RSTS1 OUTPUT SAM1 RST

J9 CLKS1 OUTPUT SAM1 CLK

8.3.9 I2C interface

The device has a standard I2C interface that is used to configure the device and to read the status of the device.

For detailed I2C operation refer to I2C Interface Operation.

16

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

Page 17

Power off mode

Shutdown mode

Standby mode

Active mode

Power on

Reset

VCC Check

Assert INT

Deactivate all

card slots

VDD > V

DDSH

V

DDI

> V

DDITH

SHDN = 0

SHDN = 1

State change

on PRES pin

VDD < V

DDSH

or

V

DDI

< V

DDITH

SHDN = 0

VDD > V

DDSH

V

DDI

> V

DDITH

SHDN = 1

VDD < V

DDSH

or

V

DDI

< V

DDITH

Card

activation

command

VCC fail

VCC

active

Over current card

removal or

deactivation

command

Other cards

still active

Deactivate all

card slots

VDD < V

DDTH

Or over

temperature

No other

card slot

active

Deactivate all

card slots

SHDN = 0

Deactivate all

card slots

V

DDI

< V

DDITH

TCA5013

www.ti.com

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

8.4 Device Functional Modes

At any given time the TCA5013 can be in one of several different functional modes. Figure 3 diagram shows the

different functional modes and describes how the device transitions from one mode to another. The blue bubbles

represent actual functional modes and the white bubbles represent transitional states that are used to move from

one functional mode to another.

Figure 3. Device Operating Modes

Product Folder Links: TCA5013

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

17

Page 18

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

www.ti.com

Device Functional Modes (continued)

8.4.1 Power Off Mode

The TCA5013 is in power off mode when VDD< V

features are functional and available for use.

8.4.2 Shutdown Mode

TCA5013 is in shutdown mode when all the below conditions are true.

• VDD> V

• V

DDI

> V

DDSH

DDITH

• SHDN = 0

Shutdown mode is a low power mode where all circuits except card insertion detection circuitry are shutdown.

Even I2C communication is disabled in shutdown mode. The only active circuit in the device is card insertion

detection circuit on the PRES pin (see User Card Insertion / Removal Detection). Shutdown mode is entered

from Active Mode or Standby Mode by asserting the SHDN pin. When entering shutdown mode from Active

Mode all active card interfaces are automatically deactivated.

8.4.3 Standby Mode

The TCA5013 is in standby mode when all the below conditions are true.

• VDD> V

• V

DDI

> V

DDSH

DDITH

• SHDN = 1

• No card interfaces are activated.

In standby mode, the device I2C and card detection circuits are fully functional. All other circuits are ready to be

activated based on I2C commands received from the microcontroller. Standby mode is entered from shutdown

mode by releasing the SHDN pin or from power down mode by powering up the device or from active mode by

deactivating all card interfaces.

DDSH

or V

DDI

< V

. In power off mode none of the device

DDITH

8.4.4 Active Mode

The TCA5013 is in active mode when all the below conditions are true.

• VDD> V

• V

DDI

> V

DDSH

DDITH

• SHDN = 1

• At least one card interface is activated

In active mode, the device is fully functional with at least one of the card interfaces activated. The DC-DC

Boost and card LDOs are active and provide power to the card VCC pins of the active card interfaces. Active

mode can only be entered from standby mode by activating one of the card interfaces. When the device is in

active mode, the individual card interfaces can be active in different operating modes. The user card supports

Asynchronous Operating Mode, Synchronous Type 1 Operating Mode,Synchronous Type 2 Operating Mode,

or Manual Operating Mode. The SAM card interfaces can only be activated in asynchronous activation mode.

18

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

Page 19

RSTUC

CLKUC

IOUC

Bit 1 to Bit 30 of

ATR response

INT

32 Clock cycles (4 Bytes)

t

S1-RST-HI

S1-CLK-HI

t

S1-RST-CLK

t

S1-CLK-RST

t

S1-CLK-LO

t

S1-CLK-PER

VCCUC

All High levels refer to 0 .9 Vcc

All Low levels refer to 0 .1 Vcc

t = t < 0 .5 μs

Bit 0

t

S1-ATR-SETUP

t

S1-ATR-SETUP

Bit 31

C 4

C 8

t

F

R

TCA5013

www.ti.com

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

Device Functional Modes (continued)

8.4.4.1 User Card Operating Mode Selection

The user card interface in the TCA5013 can be activated in different operating modes. When the

START_ASYNC bit (bit [0]; Reg 0x01) is set the user card interface is activated in asynchronous operating mode.

When START_SYNC bit (bit[0]; Reg 0x09) is set the user card interface is activated in synchronous type1,

synchronous type 2 or manual operating mode. When the START_SYNC bit is set, the operating mode is

determined by the ACTIVATION_TYPE bit (bit [6]; Reg 0x09) and CARD_TYPE bit (bit [7] Reg 0x09).

If ACTIVATION_TYPE bit (bit [6]; Reg 0x09) is set to ‘0’, the user card interface is activated in manual operating

mode. If the ACTIVATION_TYPE bit is set to’1’, the user card interface is set for automatic activation, where it

will be activated in synchronous type 1 or synchronous type 2 operating mode based on CARD_TYPE bit (bit [7]

Reg 0x09). If CARD_TYPE bit is set to ‘1’, the card interface is activated in synchronous type 2 operating mode.

If CARD_TYPE bit is set to ‘0’ the card interface is activated in synchronous type 1 operating mode.

Any changes made to the START_SYNC, START_ASYNC, CARD_TYPE or ACTIVATION_TYPE bits when the

user card interface is active, will be ignored and will have no effect on the device. These new settings will take

effect only on the next card interface activation following deactivation (see Deactivation Sequence).

8.4.4.2 Synchronous Type 1 Operating Mode

Synchronous type 1 operating mode is only supported on the user card interface. To enter synchronous

operating mode, the user card interface goes through the synchronous type 1 activation sequence. Figure 4

shows the synchronous type 1 activation sequence.

CLKIN1 shall be low before the synchronous type 1 activation sequence is initiated. The following bit settings are

required to initiate a synchronous type 1 activation sequence.

• ACTIVATION_TYPE (bit [6]; Reg 0x09) = 1

• CARD_TYPE (bit [7]; Reg 0x09) = 0

• START_SYNC (bit [0]; Reg 0x09) = 1

Figure 4. Synchronous Type 1 Activation Sequence

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

19

Page 20

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

www.ti.com

Device Functional Modes (continued)

Once synchronous type 1 activation has been initiated, the following sequence of events occurs on the user card

interface:

• VCCUC, RSTUC, CLKUC, C4, C8 and IOUC are all default low.

• VCCis applied to the VCCUC pin per the SET_VCC_UC bit (bit[7:6]; Reg 0x01).

• After VCCis stable RSTUC and CLKUC pulses are applied per t

S1-RST-HI

• After VCCis stable, the IOUC line is pulled up to VCC.

• After VCCis stable C4 and C8 reflect the value in their corresponding I2C register bits (bit[5] and bit[4]; Reg

0x09).

• RSTUC is held low while the CLKUC line starts oscillating with a frequency of ~40Khz (generated from

internal oscillator).

• The IO line is sampled on the 32 rising or falling (based on bit[1]; Reg 0x09) edges of CLK and stored in the

FIFO registers 0AH to 0DH.

• At the end of the 32nd CLK pulse, the CLKUC is held low and the CLKUC pin is controlled by the clock

settings register (Reg 0x02).

• IOUC is connected to IOMC1 if IO_EN_UC bit (bit[5] Reg 0x01) is set to 1.

• INT_SYNC_COMPLETE bit (Bit[1]; REG 0x41) is set and the INT line is asserted low.

• IOMC1 shall stay pulled up to V

i.e. IOMC1 shall not be pulled low until INT is asserted.

DDI

• CLKIN1 shall toggle only after INT is asserted.

• RSTUC is controllable by I2C after INT is asserted.

and t

S1-CLK-HI

defined in Table 2.

Table 2. Synchronous Type 1 Card Activation Timing Characteristics

MIN TYP MAX UNIT

t

S1-RST-HI

t

S1-CLK-HI

t

S1-RST-CLK

t

S1-CLK-RST

t

S1-CLK-LO

t

S1-CLK-PER

Duty cycle 45 50 55 %

60 70 80 µs

10 12.5 15 µs

25 28 32 µs

25 28 32 µs

70 80 90 µs

22.5 25 27.5 µs

8.4.4.3 Synchronous Type 2 Operating Mode

Synchronous type 2 operating mode is only supported on the user card interface. To enter synchronous

operating mode, the user card interface goes through the synchronous type 2 activation sequence. Figure 5

shows the synchronous type 2 activation sequence.

CLKIN1 shall be low before the synchronous type 2 activation sequence is initiated. The following bit settings are

required to initiate a synchronous type 1 activation sequence.

• ACTIVATION_TYPE (bit [6]; Reg 0x09) = 1

• CARD_TYPE (bit [7]; Reg 0x09) = 1

• START_SYNC (bit [0]; Reg 0x09) = 1

20

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

Page 21

VCCUC

CLKUC

RSTUC

RST stays LOW through entire activation

C 4

t

S2-VCC-CLK

INT

t

S2-CLK-C4

All High levels refer to 0.9Vcc

All Low levels refer to 0.1 Vcc

t = t < 0.5μs

IOUC

t

S2-CLK-HI

F

R

www.ti.com

TCA5013

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

Figure 5. Synchronous Type 2 Activation Sequence

Once synchronous type 2 activation has been initiated, the following sequence of events occur on the user card

interface:

• VCCUC, RSTUC, CLKUC, C4, C8 and IOUC are all default low.

• VCCis applied to the VCCUC pin per the SET_VCC_UC bit (bit[7:6]; Reg 0x01).

• A single pulse is applied to CLKUC per the t

S2-CLK-HI

timing defined in Table 3.

• The C4 line is held low through the VCCramp.

• The C4 line is released high per the t

S2-CLK-C4

timing defined in Table 3.

• After C4 is released CLKUC is controlled by clock settings register (Reg 0x02).

• After VCCis stable, the IOUC line is pulled up to VCC.

• After VCCis stable, C8 reflects value in bit [4] Reg 0x09.

• IOUC is connected to IOMC1 if IO_EN_UC bit (bit[5] Reg 0x01) is set to 1.

• INT_SYNC_COMPLETE bit (Bit[1]; REG 0x41) is set and the INT line is asserted low.

• IOMC1 shall stay pulled up to V

DDI

, that is, IOMC1 shall not be pulled low until INT is asserted.

• CLKIN1 shall toggle only after INT is asserted.

• RSTUC is controllable by I2C after INT is asserted.

Table 3. Synchronous Type 2 Card Activation Timing Characteristics

MIN TYP MAX UNIT

t

S2-VCC-CLK

t

S2-CLK-C4

t

S2-CLK-HI

5 20 µs

14 18 22 µs

7 9 11 µs

Product Folder Links: TCA5013

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

21

Page 22

VCC

IO

RST

CLK

200 CLK

cycles

IO ignored

200 CLK cycles

IO ignored

42100CLK

Cycles

(EARLY+MUTE)

ATR Valid

Window

EARLY

answer

check

ATR Reception

Window

EARLY

answer

check

Warm reset sequence

42100CLK

Cycles

(EARLY+MUTE)

MUTE

answer

check

MUTE

answer

check

Card activation sequence

(Cold reset sequence)

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

www.ti.com

8.4.4.4 Manual Operating Mode

Manual operating mode is only supported on the user card interface. Unlike the other operating modes, the

manual operating mode does not have a defined activation sequence. CLKIN1 shall be low before the manual

activation sequence is initiated. The following bit settings are required to initiate a synchronous type 1 activation

sequence.

• ACTIVATION_TYPE (bit [6]; Reg 0x09) = 0

• START_SYNC (bit [0]; Reg 0x09) = 1

Once manual activation has been initiated the following sequence of events occur on the user card interface.

• VCCUC, RSTUC, CLKUC, C4, C8 and IOUC are all default low.

• VCCis applied to the VCCUC pin per the SET_VCC_UC bit (bit[7:6]; Reg 0x01)

• After VCCis stable, the IOUC line is pulled up to V

CC

• After VCCis stable C4 and C8 reflect the value in their corresponding I2C register bits (bit[5] and bit[4]; Reg

0x09)

• IOUC is connected to IOMC1 if IO_EN_UC bit (bit[5] Reg 0x01) is set to 1.

• INT_SYNC_COMPLETE bit (Bit[1]; REG 0x41) is set and the INT line is asserted low.

• IOMC1 shall stay pulled up to V

i.e. IOMC1 shall not be pulled low until INT is asserted.

DDI

• CLKIN1 shall toggle only after INT is asserted.

• RSTUC is controllable by I2C after INT is asserted.

8.4.4.5 Asynchronous Operating Mode

Asynchronous operating mode is supported on all card interfaces. To enter asynchronous operating mode, the

user card interface goes through the asynchronous activation sequence. Figure 6 shows the asynchronous

activation sequence. CLKIN1 shall be toggling before the asynchronous activation sequence is initiated. The

asynchronous activation sequence is initiated by setting the START_ASYNC bit (bit[0]) of the card interface

settings register (Reg 0x01 for User card, Reg 0x11 for SAM1, Reg 0x21 for SAM1, Reg 0x31 for SAM3) to ‘1’.

Figure 6. Asynchronous Activation and Warm Reset Sequence

22

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

Page 23

TCA5013

www.ti.com

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

Once asynchronous activation has been initiated, the following sequence of events takes place on the card

interface:

• VCC, RST, CLK, C4, C8 and IO are all default low.

• VCCis applied to the VCC pin per the SET_VCC bits (bit [7:6] of card interface settings register).

• After VCCis stable, the IO line is pulled up to VCC.

• After VCCis stable C4 and C8 reflect the value in their corresponding I2C register bits (bit[5] and bit[4]; Reg

0x09).

• IO is connected to IOMC if IO_EN bit (bit[5] of card interface settings register) is set to 1.

• The CLK line starts to oscillate based on the card clock settings register. Any change on the IO line during

the first 200 card clock cycles on the CLK pin is ignored.

• After the first 42100 CLK cycles, the RST line is driven high.

• If there is a high to low transition on the IO line before RST is high, the EARLY bit (bit[6]) and MUTE bit

(bit[5]) of the card interface status register (Reg 0x00 for user card, Reg 0x10 for SAM1, Reg 0x20 for SAM2

and Reg 0x30 for SAM3) is set and the INT pin is asserted low.

• After RST is high, an internal counter starts counting CLK cycles. If there is a high to low transition on IO pin

before the internal counter reaches the value defined by in the EARLY_COUNT_HI register (Reg 0x03 for

user card, Reg 0x13 for SAM1, Reg 0x23 for SAM2, Reg 0x33 for SAM3) and EARLY_ COUNT_LO Register

(Reg 0x04 for user card, Reg 0x14 for SAM1, Reg 0x24 for SAM2, Reg 0x34 for SAM3) then the EARLY bit

in the card interface status register is set and INT is asserted.

• If the internal counter reaches the value defined by MUTE_COUNT_HI register (Reg 0x05 for user card, Reg

0x15 for SAM1, Reg 0x25 for SAM2, Reg 0x35 for SAM3) and MUTE_COUNT_LO (Reg 0x06 for user card,

Reg 0x16 for SAM1, Reg 0x26 for SAM2, Reg 0x36 for SAM3) registers without a high to low transition on

the IO line, then the MUTE bit in the card interface status registers is set and INT pin is asserted low.

If the first high to low transition on IO pin happens very close to the clock edges (within ~10 ns) that defines the

ATR VALID window (see Figure 6), the TCA5013 response would be non-deterministic, that is, it may not be able

to identify whether the transition happened before or after the edge. This implies that the MUTE bit may or may

not be set if the IO transition happens very close to the clock edge defining the end of the ATR VALID window.

Likewise, if the IO transition happens very close to the clock edge defining the beginning of the EARLY window,

it may or may not set the EARLY bit.

8.4.4.6 Warm Reset Sequence

When a card interface is active in asynchronous mode, it is possible to initiate a warm reset sequence on the

card interface. The warm reset sequence is initiated by setting the WARM bit (bit [3]) of the card interface

settings register to ‘1’. Once warm reset is initiated the below sequence of events takes place on the card

interface.

• VCCis already ramped and stable per the SET_VCC bits (bit[7:6] of card interface settings register).

• CLK continues to oscillate per the card clock settings register.

• RST pin is pulled low (high before warm reset was initiated).

• C4 and C8 continue to reflect the value in their corresponding I2C register bits (bit[5] and bit[4]; Reg 0x09).

• IO stays connected to IOMC if IO_EN bit (bit5 of card interface settings register) is set to 1.

• Any change on the IO line during the first 200 card clock cycles after RST goes low is ignored.

• After the first 42100 CLK cycles, the RST line is driven high.

• If there is a high tow low transition on the IO line before RST is high, the EARLY bit (bit6) and MUTE bit (bit5)

of the card interface status register (Reg 0x00 for user card, Reg 0x10 for SAM1, Reg 0x20 for SAM2 and

Reg 0x30 for SAM3) is set and the INT pin is asserted low.

• After RST is high, an internal counter starts counting CLK cycles. If there is a high to low transition on IO pin

before the internal counter reaches the value defined by in the EARLY_COUNT_HI register (Reg 0x03 for

user card, Reg 0x13 for SAM1, Reg 0x23 for SAM2, Reg 0x33 for SAM3) and EARLY_ COUNT_LO Register

(Reg 0x04 for user card, Reg 0x14 for SAM1, Reg 0x24 for SAM2, Reg 0x34 for SAM3) then the EARLY bit

in the card interface status register is set and INT is asserted.

• If the internal counter reaches the value defined by MUTE_COUNT_HI register (Reg 0x05 for user card, Reg

0x15 for SAM1, Reg 0x25 for SAM2, Reg 0x35 for SAM3) and MUTE_COUNT_LO (Reg 0x06 for user card,

Reg 0x16 for SAM1, Reg 0x26 for SAM2, Reg 0x36 for SAM3) registers without a high to low transition on

the IO line, then the MUTE bit in the card interface status registers is set and INT pin is asserted low.

Product Folder Links: TCA5013

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

23

Page 24

RST

CLK

IO

VCC

+

two card clock cycles

< 0.4 V

PRES

100 μs

t

DEAC-TOT

t

DEAC-RST-CLK

t

DEAC-RST-IO

t

DEAC-RST-VCC

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

www.ti.com

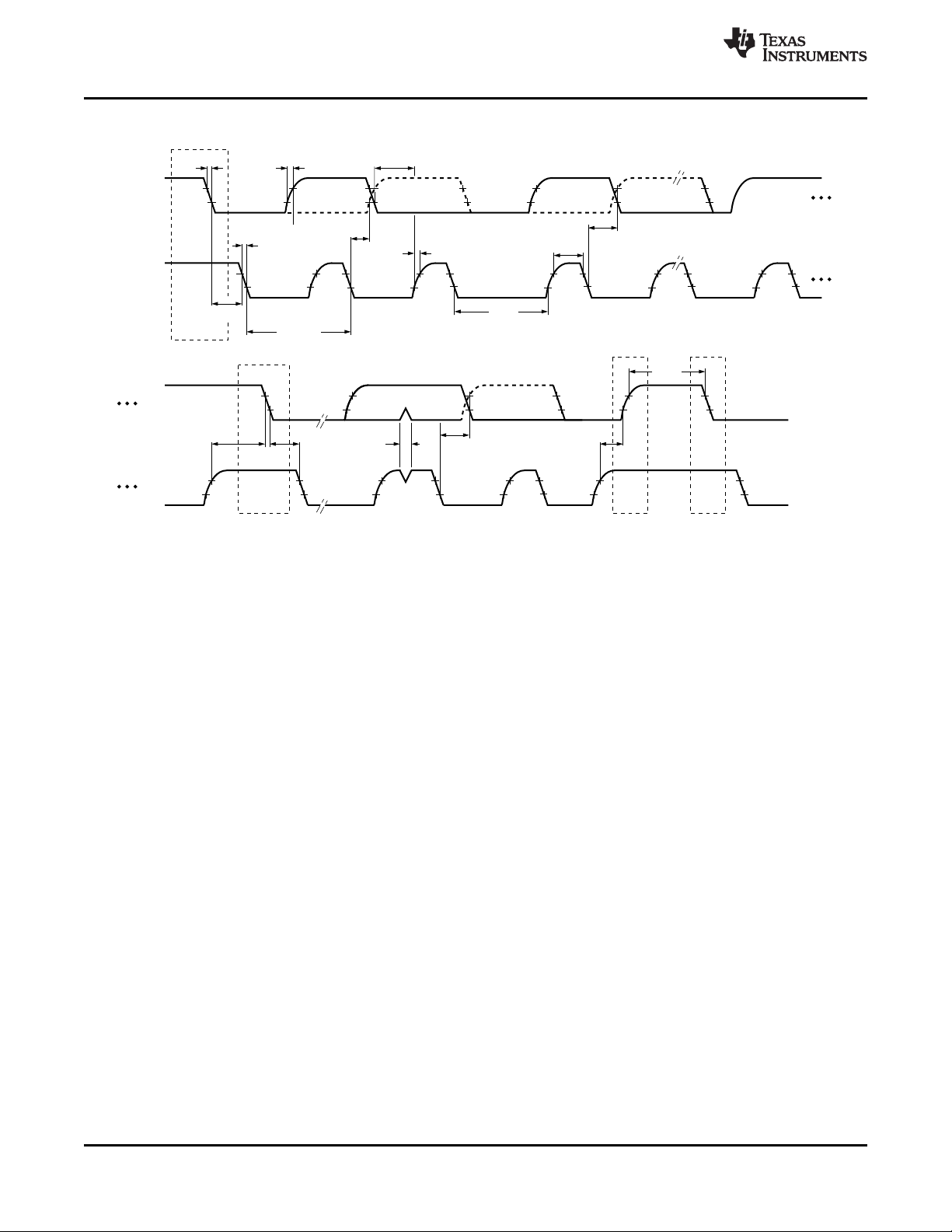

8.4.4.7 Deactivation Sequence

After a card interface has been activated in a certain operating mode, it can be deactivated by I2C command or

certain interrupt events (see Interrupt Operation). The deactivation sequence is the same regardless of what

operating mode the card interface is in.

Figure 7 shows the deactivation sequence initiated by card extraction on the user card interface. It is to be noted

that the deactivation sequence starts 100 µs after the transition on PRES. This delay is intended to provide a

debounce period that provides unintended deactivation due to any glitch on the PRES pin. As mentioned

previously any of the card interfaces may be deactivated due to a supervisor fault, over current fault or over

temperature fault. In these cases there is no debounce period and the deactivation sequence is initiated as soon

as the internal fault signal is asserted.

Figure 8 shows the deactivation of any card interface initiated by I2C command. If the card interface is activated

in asynchronous mode, it can be deactivated by clearing (writing ‘0’) the START_ASYNC bit in the card interface

settings register. To deactivate the user card interface when it is activated in synchronous mode, the

START_SYNC bit should be cleared (write ‘0’).

Figure 7. Deactivation Sequence

24

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

Page 25

RST

CLK

IO

VCC

+ two card clock cycles

< 0 .4 V

I2C

SCL

t

DEAC-TOT

t

DEAC-RST-CLK

t

DEAC-RST-IO

t

DEAC-RST-VCC

< 5μs

Rising edge of SCL

corresponding to ACK

www.ti.com

TCA5013

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

Figure 8. Card Deactivation Sequence Initiated by I2C Command

Table 4. Card Deactivation Timing Characteristics

MIN TYP MAX UNIT

t

DEAC-TOT

t

DEAC-RST-CLK

t

DEAC-RST-IO

t

DEAC-RST-VCC

0.4 0.5 0.6 ms

10 12 15 µs

22 24 26 µs

33 36 39 µs

8.4.5 User Card Insertion / Removal Detection

User card interface module in the TCA5013 has a PRES pin that is used to detect the presence of a card in that

interface. In normal application the signal is connected to a switch that opens or closes when a card is inserted.

Whenever a transition is seen on the PRES pin, the PRESL bit (Reg 0x00, bit 2) will be set and INT pin is

asserted. Because this transition is associated with a mechanical switch, there is an internal debounce of ~20 ms

before the PRESL bit is set and the INT is asserted. If the device sees a transition on the PRESL pin when the

card interface is active, the device initiates a card deactivation sequence (see Deactivation Sequence). TCA5013

is capable of detecting card insertion even when it is in shutdown mode (see Shutdown Mode).

In addition to the PRESL_UC bit mentioned above, there is also a PRES_UC bit (Reg 0x00, bit 2), which

indicates to the host whether or not a card is present in the user card slot. In order to accommodate different

card cage topologies, the TCA5013 can be configured to detect card presence with a low to high or high to low,

transition on the PRES pin. The CARD_DETECT_UC bit (Reg 0x01, bit 2) is used to configure the device for

different card detection topologies. If CARD_DETECT_UC = 0 indicates to the TCA5013 that when a card is

inserted in the slot, the PRES pin shall be low. CARD_DETECT_UC = 1 indicates to the host that when a card is

Product Folder Links: TCA5013

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

25

Page 26

PRES bit = 1

SHDN

PRES

INT

Card insertion /

extraction

Debounce period

20ms

Power on Reset

I2C

Interrupt

status

register

read

SHDN

released

by µC

(pull-up)

POR interrupt

CARD

DETECT =1

PRES bit = 0

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

www.ti.com

inserted in the slot the PRES pin shall be high. The status of the PRES_UC bit is based on the status of the

PRES pin and the CARD_DETECT_UC bit. The truth table in Table 1 shows the PRES_UC bit status based on

the CARD_DETECT_UC bit and the PRES pin. When coming out of power off mode (see Power Off Mode) or

shutdown mode (see Shutdown Mode) the CARD_DETECT_UC = 0. If there is a state transition on the PRES

pin when the device is in shutdown mode, the INT pin asserted (after the 20 ms debounce).

Table 5. Truth Table Defining Status of PRES Bit

CARD DETECT BIT PRES PIN PRES BIT

0 0 1

0 1 0

1 0 0

1 1 1

Figure 9 to Figure 14 show timing waveforms of device power up and coming out of shutdown with and without a

card inserted in the system. In below figures’ low to high PRES topology’ means that a high level on the PRES

pin indicates a card is present. In below figures high to low PRES topology’ means that a low level on the PRES

pin indicates a card is present. The below figures also show operation of INT pin and interrupt status register. For

detailed description of the interrupt operation, refer to Interrupt Operation section.

26

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Figure 9. Card detection in shutdown mode - Low to High PRES Topology

Product Folder Links: TCA5013

Page 27

I2C

PRES

INT

Power on Reset

VDD /

VDDI

POR interrupt

Interrupt

status

register

read

CARD

DETECT = 1

PRES bit = 0

PRESL

Interrupt

Debounce period

20 ms

Card

insertion

PRES bit = 1

PRES bit = 1

SHDN

PRES

INT

Card insertion /

extraction

Debounce period

20 ms

Power on reset

SHDN

released

by µC

(

pull-up

)

POR

interrupt

I2C

Interrupt

status

register

read

www.ti.com

TCA5013

SCPS253C –JANUARY 2014 –REVISED SEPTEMBER 2019

Figure 10. Card detection in shutdown mode - High to Low PRES Topology

Figure 11. Device power up without card inserted in system - Low to High PRES Topology

Product Folder Links: TCA5013

Submit Documentation FeedbackCopyright © 2014–2019, Texas Instruments Incorporated

27

Page 28

PRES

INT

Power on reset

VDD /

VDDI

POR interrupt

PRESL

interrupt

Debounce period

20 ms

Debounce period

100 us

Card slot

deactivated

Card extracted

I2C

Interrupt

status

register

read

CARD

DETECT = 1

PRES bit =1

PRES bit =0

PRES bit = 0

I2C

PRES

INT

Power on reset

VDD /

VDDI

POR interrupt

Interrupt

status

register

read

PRES bit =1

Debounce period

20 ms

Card

insertion

PRES Bit = 0

PRESL

interrupt

TCA5013

SCPS253C –JANUARY 2014–REVISED SEPTEMBER 2019

Figure 12. Device power up without card inserted in system - High to Low PRES Topology

www.ti.com

Figure 13. Device Power Up With Card Inserted in System - Low to High PRES Topology

28

Submit Documentation Feedback Copyright © 2014–2019, Texas Instruments Incorporated

Product Folder Links: TCA5013

Page 29

I2C