MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

SLAS800 –MARCH 2013

MIXED SIGNAL MICROCONTROLLER

Check for Samples: MSP430G2955, MSP430G2855, MSP430G2755

1

FEATURES

• Low Supply-Voltage Range: 1.8 V to 3.6 V • Universal Serial Communication Interface

• Ultra-Low Power Consumption

– Active Mode: 250 µA at 1 MHz, 2.2 V

– Standby Mode: 0.7 µA

– Off Mode (RAM Retention): 0.1 µA

• Five Power-Saving Modes

• Ultra-Fast Wake-Up From Standby Mode in

Less Than 1 µs

• 16-Bit RISC Architecture, 62.5-ns Instruction

Cycle Time

• Basic Clock Module Configurations

– Internal Frequencies up to 16 MHz With

Four Calibrated Frequency

– Internal Very-Low-Power Low-Frequency

(LF) Oscillator

– 32-kHz Crystal

– High-Frequency (HF) Crystal up to 16 MHz

– External Digital Clock Source

– External Resistor

• Two 16-Bit Timer_A With Three

Capture/Compare Registers

• One 16-Bit Timer_B With Three

Capture/Compare Registers

• Up to 32 Touch-Sense-Enabled I/O Pins

(USCI)

– Enhanced UART Supporting Auto Baudrate

Detection (LIN)

– IrDA Encoder and Decoder

– Synchronous SPI

– I2C™

• On-Chip Comparator for Analog Signal

Compare Function or Slope Analog-to-Digital

(A/D) Conversion

• 10-Bit 200-ksps Analog-to-Digital (A/D)

Converter With Internal Reference, Sampleand-Hold, and Autoscan

• Brownout Detector

• Serial Onboard Programming,

No External Programming Voltage Needed,

Programmable Code Protection by Security

Fuse

• Bootstrap Loader

• On-Chip Emulation Logic

• Family Members are Summarized in Table 1

• Package Options

– TSSOP: 38 Pin (DA)

– QFN: 40 Pin (RHA)

• For Complete Module Descriptions, See the

MSP430x2xx Family User’s Guide (SLAU144)

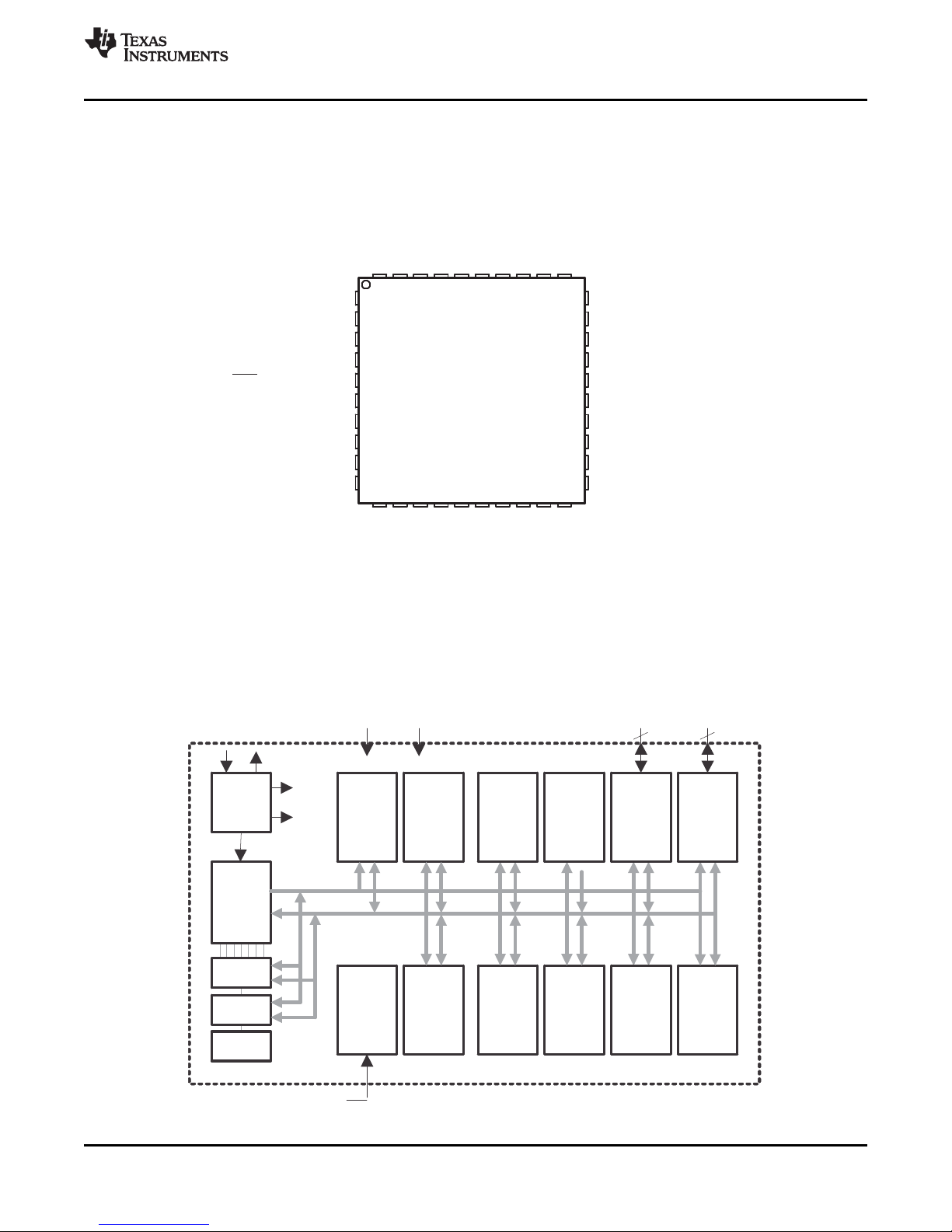

DESCRIPTION

The Texas Instruments MSP430 family of ultra-low-power microcontrollers consists of several devices featuring

different sets of peripherals targeted for various applications. The architecture, combined with five low-power

modes, is optimized to achieve extended battery life in portable measurement applications. The device features a

powerful 16-bit RISC CPU, 16-bit registers, and constant generators that contribute to maximum code efficiency.

The digitally controlled oscillator (DCO) allows wake-up from low-power modes to active mode in less than 1 µs.

The MSP430G2x55 series are ultra-low-power mixed signal microcontrollers with built-in 16-bit timers, up to 32

I/O touch-sense-enabled pins, a versatile analog comparator, and built-in communication capability using the

universal serial communication interface. For configuration details, see Table 1.

Typical applications include low-cost sensor systems that capture analog signals, convert them to digital values,

and then process the data for display or for transmission to a host system.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2013, Texas Instruments Incorporated

1TEST/SBWTCK

2DVCC

3P2.5/TA1.0/ROSC

4

XOUT/P2.7

5

XIN/P2.6 6

RST/NMI/SBWTDIO

7

P2.0/TA1CLK/ACLK/A0

8

P2.1/TA0INCLK/SMCLK/A1 9

P2.2/TA0.0/A2

10

P3.0/UCB0STE/UCA0CLK/A5

11

P3.1/UCB0SIMO/UCB0SDA 12

P3.2/UCB0SOMI/UCB0SCL

13

P3.3/UCB0CLK/UCA0STE

14

P4.0/TB 00. /CA0

15

P4.1/TB 10. /CA1

16

P4.2/TB 20. /CA2

17

P4.3/TB 0/A120. /CA3

18 P4.4/TB 1/A130. /CA4

19

38 P1.7/TA 2/TDO/TDI0.

37 P1.6/TA 1/TDI0.

36

P1.5/TA 0/TMS0.

35 P1.4/SMCLK/TCK

34

P1.3/TA 20.

33

P1.2/TA 10.

32 P1.1/TA 00.

31

P1.0/TA0CLK/ADC10CLK

30

P2.4/TA 2/A4/VREF+/VEREF+0.

29 P2.3/TA 1/A3/VREF−/VEREF−0.

28 P3.7/TA1.2/A7

27 P3.6/TA1.1/A6

26 P3.5/UCA0RXD/UCA0SOMI

25

P3.4/UCA0TXD/UCA0SIMO

24

23AVCC

22

AVSS

21

P4.7/TB0CLK/CA7

20

P4.6/TB0OUTH/A15/CA6

DVSS

P4.5/TB 2/A140. /CA5

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

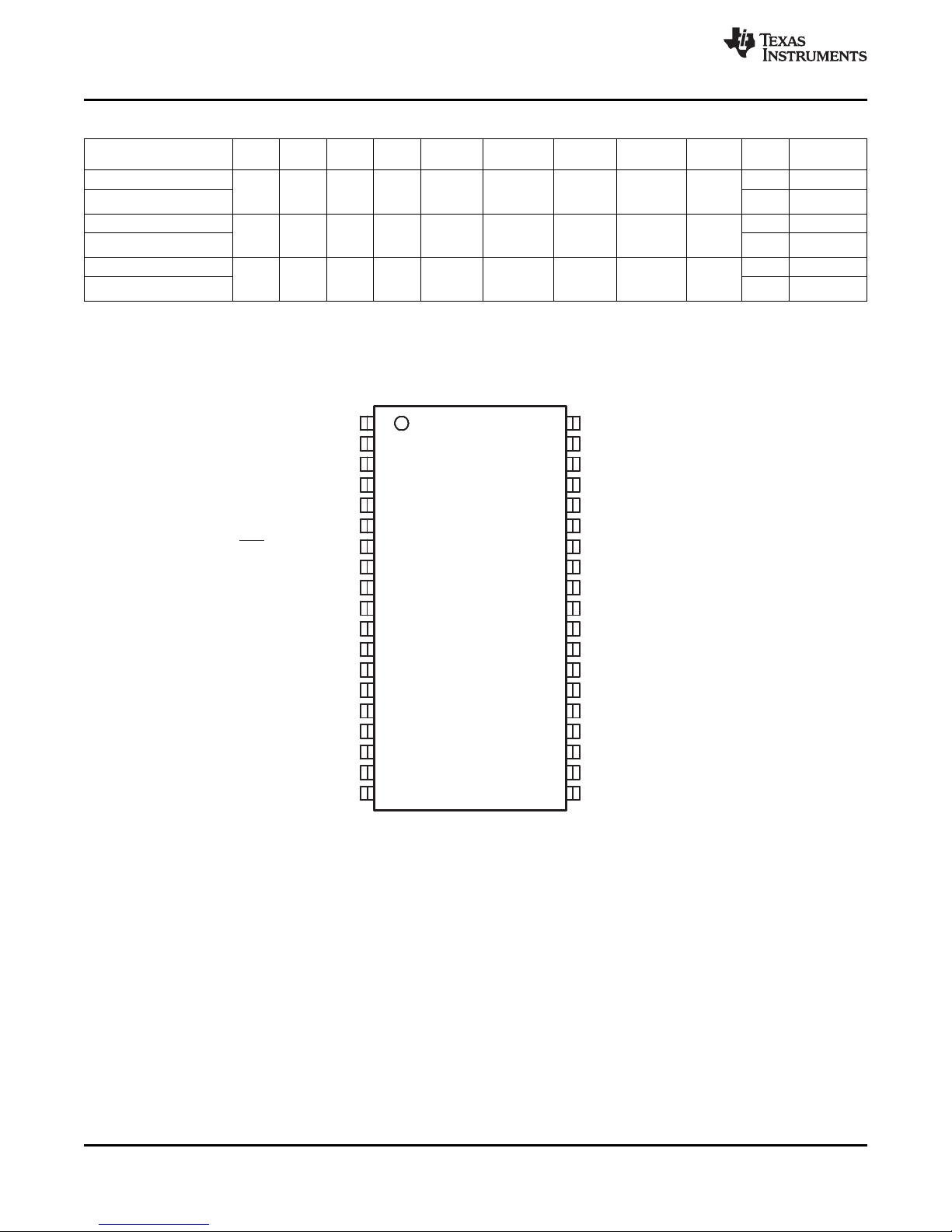

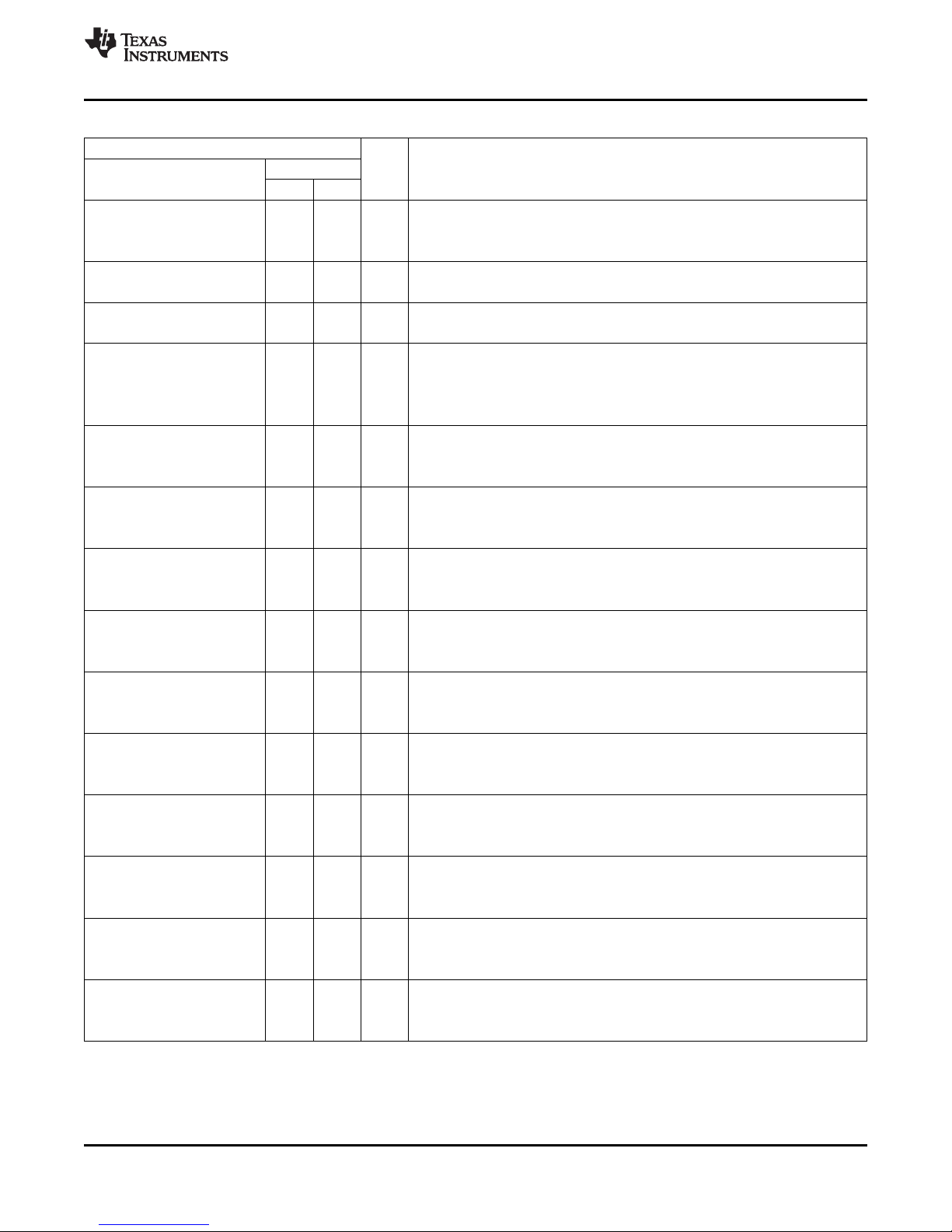

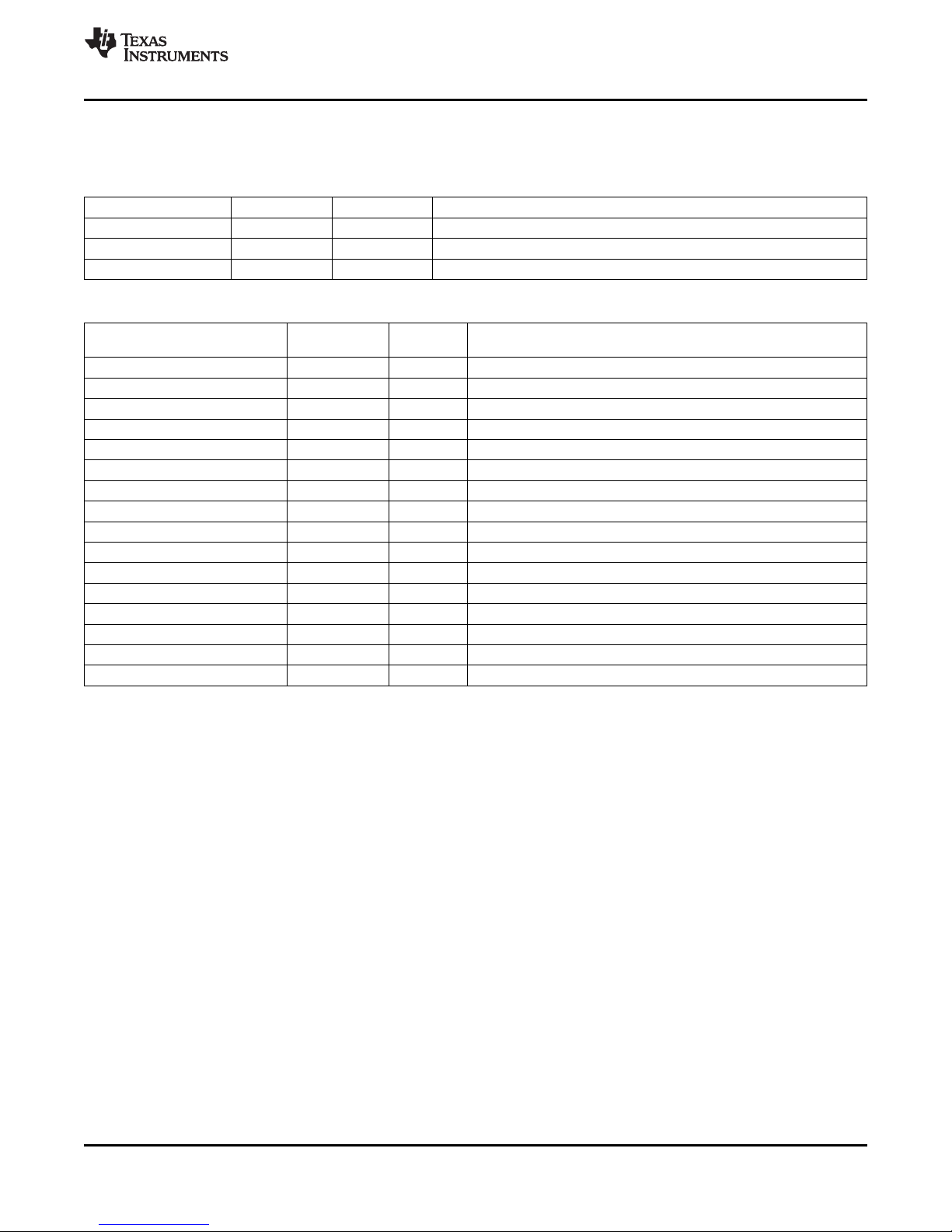

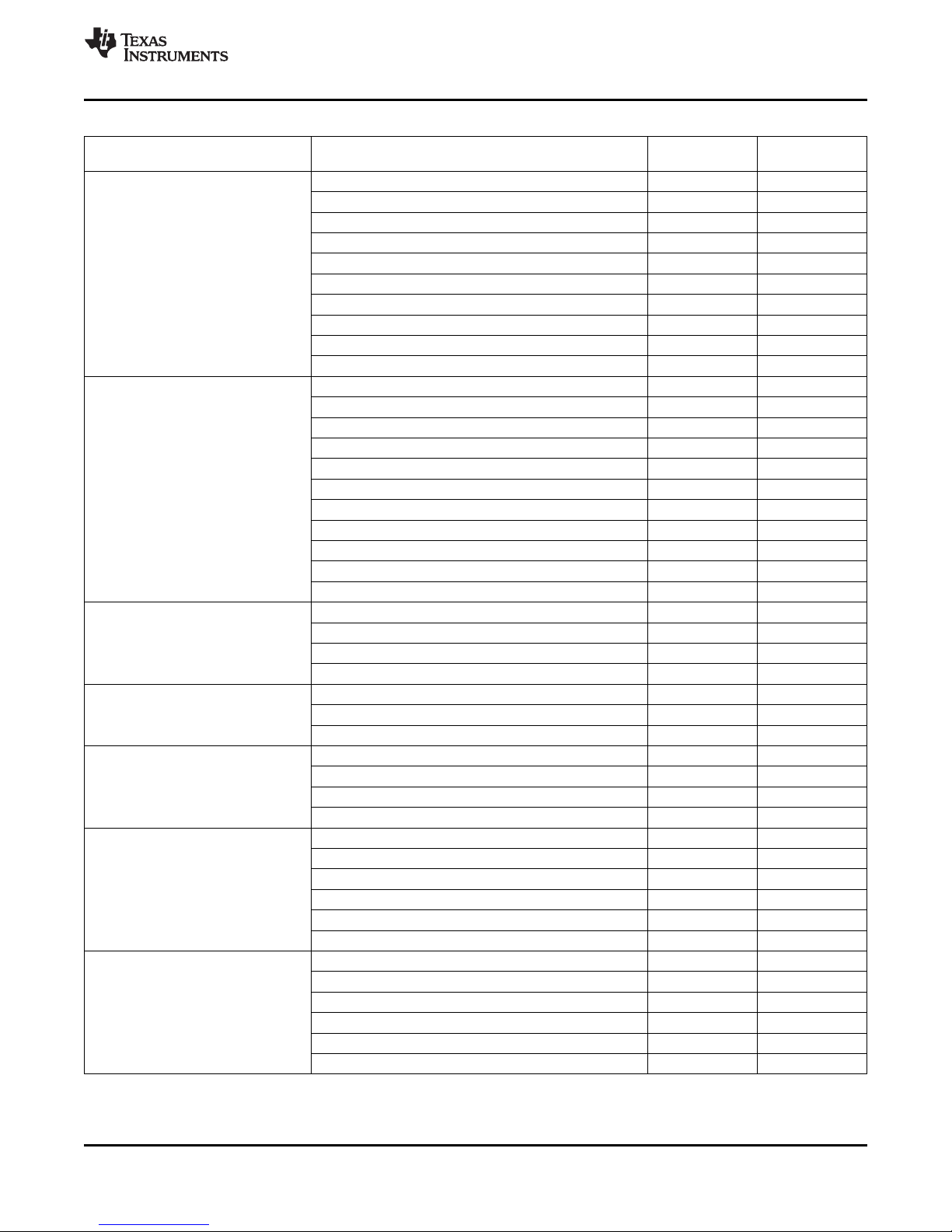

Table 1. Available Options

Device BSL EEM Clock I/O

MSP430G2955IDA38 HF, LF, 32 38-TSSOP

MSP430G2955IRHA40 32 40-QFN

MSP430G2855IDA38 HF, LF, 32 38-TSSOP

MSP430G2855IRHA40 32 40-QFN

MSP430G2755IDA38 HF, LF, 32 38-TSSOP

MSP430G2755IRHA40 32 40-QFN

1 1 56 4096 8 12 1 DCO,

1 1 48 4096 8 12 1 DCO,

1 1 32 4096 8 12 1 DCO,

Flash RAM Timer_A COMP_A+ ADC10 USCI_A0 Package

(KB) (B) Timer_B Channels Channels USCI_B0 Type

2x TA3

1x TB3

2x TA3

1x TB3

2x TA3

1x TB3

(1)(2)

VLO

VLO

VLO

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or see the TI

web site at www.ti.com.

(2) Package drawings, thermal data, and symbolization are available at www.ti.com/packaging.

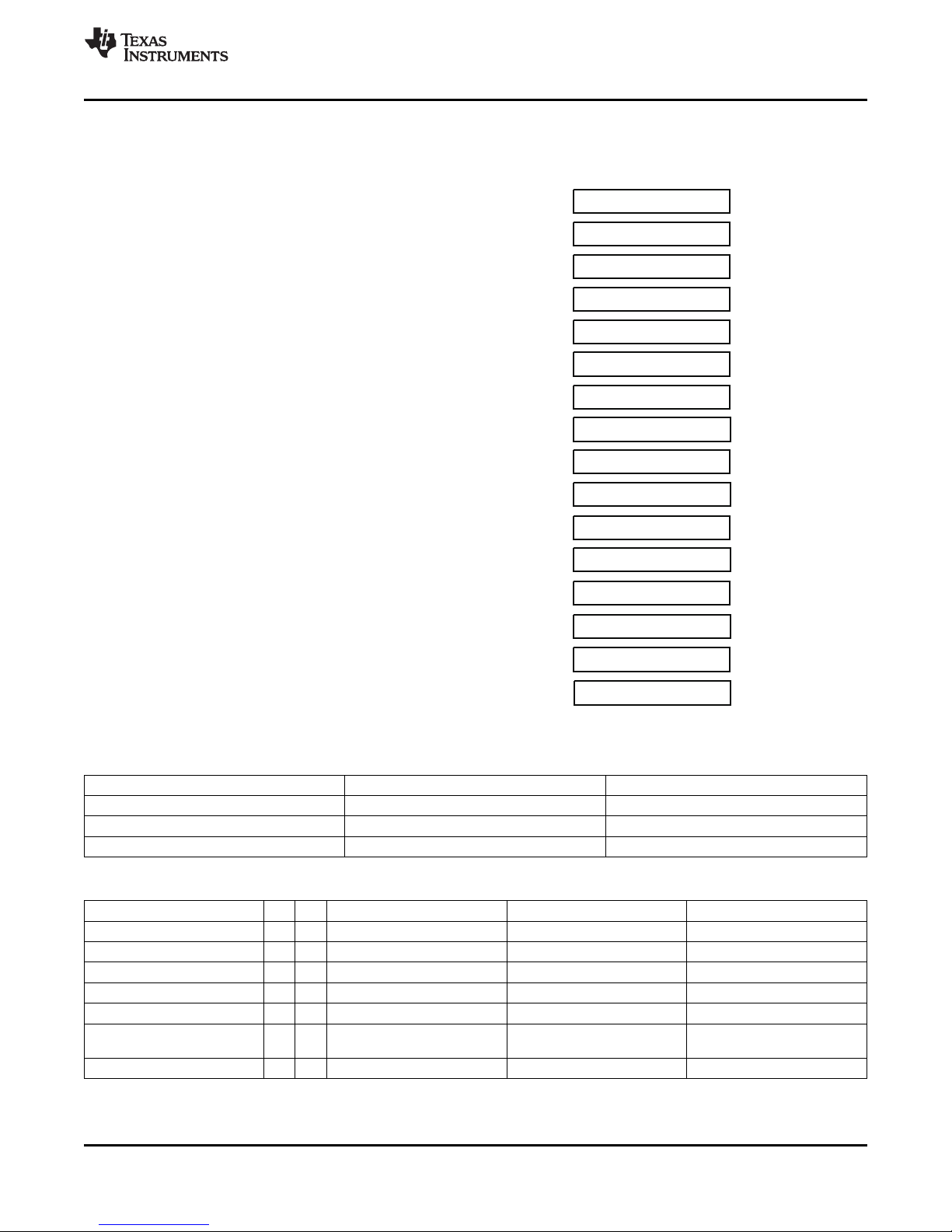

Device Pinout, 38-Pin TSSOP (DA Package)

www.ti.com

2 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

Basic Clock

System+

RAM

Brownout

Protection

RST/NMI

VCC VSS

MCLK

SMCLK

Watchdog

WDT+

15 or 16 Bit

3 CC

Registers

16MHz

CPU

incl. 16

Registers

Emulation

(2BP)

XOUT

JTAG

Interface

Flash

56 kB

48 kB

32 kB

ACLK

XIN

MDB

MAB

Spy-Bi-Wire

3 CC

Registers,

Shadow

Register

USCI_A0:

UART, LIN,

IrDA,SPI

USCI_B0:

SPI,I2C

ADC

10-Bit

12

Channels,

Autoscan,

DTC

Ports P1, P2

2x8 I/O,

Interrupt

capability,

Pullup or

pulldown

resistors

P1.x, P2.x

2x8

P3.x, P4.x

2x8

4 kB

Timer0_A3

3 CC

Registers

Timer1_A3

Timer0_B3

COMP_A+

8

Channels

Ports P3, P4

2x8 I/O,

Pullup or

pulldown

resistors

1DVSS

P1.5/TA0.0/TMS

P1.0/TA0CLK/ADC10CLK

P1.1/TA0.0

P1.2/TA0.1

P1.3/TA0.2

P1.4/SMCLK/TCK

13

P2.4/TA0.2/A4/VREF+/VEREF+

P2.5/TA1.0/ROSC

DVCC

TEST/SBWTCK

P1.6/TA0.1/TDI/TCLK

2

3

4

5

6

7

8

10

9

12 14 15 16 17 18 19

30

29

28

27

26

25

24

23

21

22

3839 37 36 35 34 33 32

XOUT/P2.7

XIN/P2.6

DVSS

RST/NMI/SBWTDIO

P2.0/TA1CLK/ACLK/A0

P2.1/TA0INCLK/SMCLK/A1

P2.2/TA0.0/A2

P3.0/UCB0STE/UCA0CLK/A5

P3.1/UCB0SIMO/UCB0SDA

DVCC

P1.7/TA0.2/TDO/TDI

P2.3/TA0.1/A3/VREF−/VEREF−

P3.7/TA1.2/A7

P3.6/TA1.1/A6

P3.5/UCA0RXD/UCA0SOMI

P3.4/UCA0TXD/UCA0SIMO

AVCC

AVSS

P3.3/UCB0CLK/UCA0STE

P4.0/TB0.0/CA0

P4.1/TB0.1/CA1

P4.2/TB0.2/CA2

P4.3/TB0.0/A12/CA3

P4.4/TB0.1/A13/CA4

P4.5/TB0.2/A14/CA5

P4.6/TB0OUTH/A15/CA6

P4.7/TB0CLK/CA7

www.ti.com

Device Pinout, 40-Pin QFN (RHA Package)

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

Functional Block Diagram

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

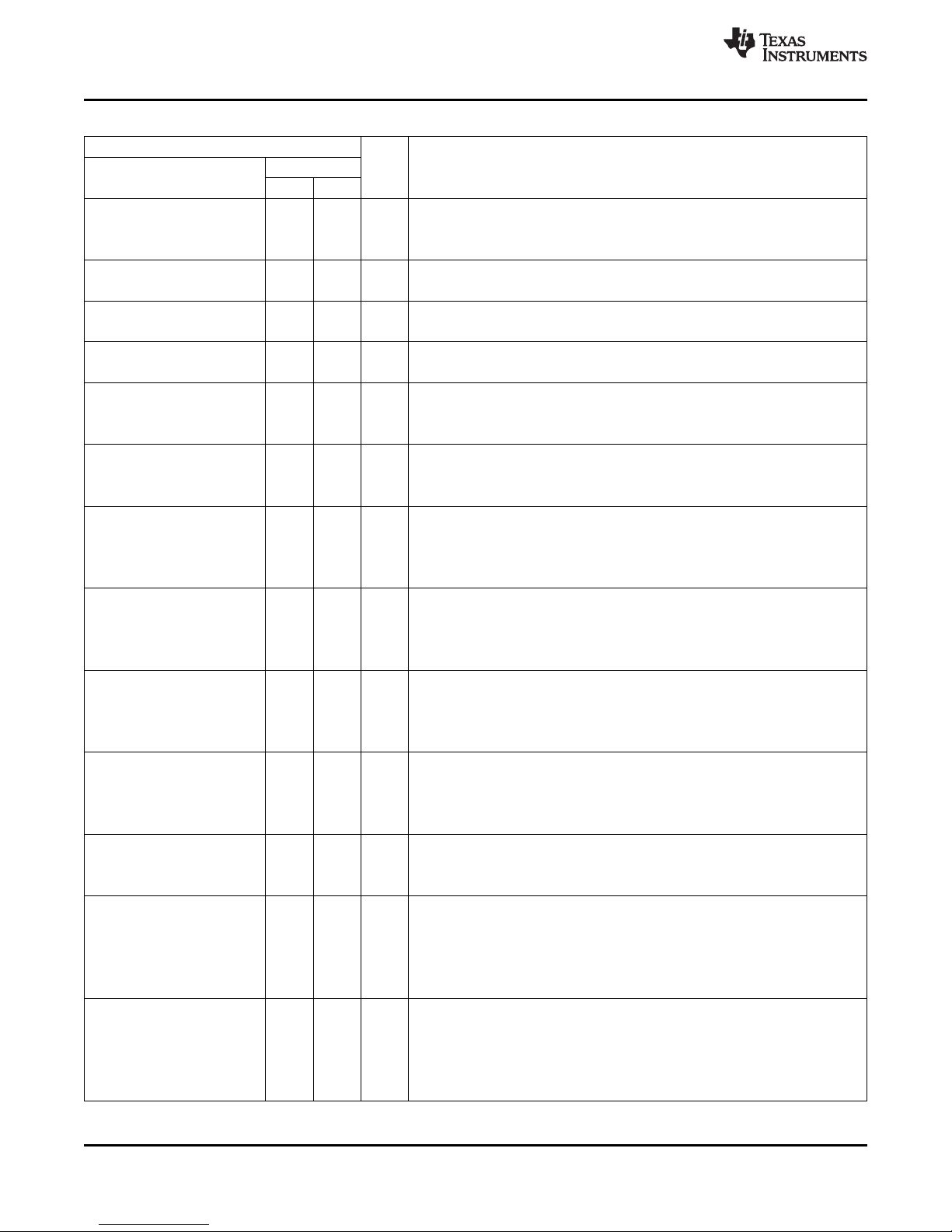

Table 2. Terminal Functions

TERMINAL

NAME

P1.0/ General-purpose digital I/O pin

TACLK/ 31 29 I/O Timer_A, clock signal TACLK input

ADC10CLK ADC10, conversion clock

P1.1/ General-purpose digital I/O pin

TA0.0 Timer_A, capture: CCI0A input, compare: OUT0 output or BSL transmit

P1.2/ General-purpose digital I/O pin

TA0.1 Timer_A, capture: CCI1A input, compare: OUT1 output

P1.3/ General-purpose digital I/O pin

TA0.2 Timer_A, capture: CCI2A input, compare: OUT2 output

P1.4/ General-purpose digital I/O pin

SMCLK/ 35 33 I/O SMCLK signal output

TCK JTAG test clock, input terminal for device programming and test

P1.5/ General-purpose digital I/O pin

TA0.0/ 36 34 I/O Timer_A, compare: OUT0 output

TMS JTAG test mode select, input terminal for device programming and test

P1.6/ General-purpose digital I/O pin /

TA0.1/ Timer_A, compare: OUT1 output

TDI/ JTAG test data input terminal during programming and test

TCLK JTAG test clock input terminal during programming and test

P1.7/ General-purpose digital I/O pin

TA0.2/ Timer_A, compare: OUT2 output

TDO/ JTAG test data output terminal during programming and test

(1)

TDI

P2.0/ General-purpose digital I/O pin

TA1CLK/ Timer1_A3.TACLK

ACLK/ ACLK output

A0 ADC10, analog input A0

P2.1/ General-purpose digital I/O pin

TAINCLK/ Timer_A, clock signal at INCLK

SMCLK/ SMCLK signal output

A1 ADC10, analog input A1

P2.2/ General-purpose digital I/O pin

TA0.0/ 10 8 I/O Timer_A, capture: CCI0B input or BSL receive, compare: OUT0 output

A2 ADC10, analog input A2

P2.3/ General-purpose digital I/O pin

TA0.1/ Timer_A, capture CCI1B input, compare: OUT1 output

A3/ 29 27 I/O ADC10, analog input A3

VREF-/ Negative reference voltage output

VEREF- Negative reference voltage input

P2.4/ General-purpose digital I/O pin

TA0.2/ Timer_A, compare: OUT2 output

A4/ 30 28 I/O ADC10, analog input A4

VREF+/ Positive reference voltage output

VEREF+ Positive reference voltage input

NO. I/O DESCRIPTION

DA RHA

32 30 I/O

33 31 I/O

34 32 I/O

37 35 I/O

38 36 I/O

JTAG test data input terminal during programming and test

8 6 I/O

9 7 I/O

www.ti.com

(1) TDO or TDI is selected via JTAG instruction.

4 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

Table 2. Terminal Functions (continued)

TERMINAL

NAME

P2.5/ General-purpose digital I/O pin

TA1.0/ 3 40 I/O Timer_A, capture: CCI0B input or BSL receive, compare: OUT0 output

ROSC Input for external DCO resistor to define DCO frequency

XIN/ Input terminal of crystal oscillator

P2.6 General-purpose digital I/O pin

XOUT/ Output terminal of crystal oscillator

P2.7 General-purpose digital I/O pin

P3.0/ General-purpose digital I/O pin

UCB0STE/ USCI_B0 slave transmit enable

UCA0CLK/ USCI_A0 clock input/output

A5 ADC10, analog input A5

P3.1/ General-purpose digital I/O pin

UCB0SIMO/ 12 10 I/O USCI_B0 slave in, master out in SPI mode

UCB0SDA USCI_B0 SDA I2C data in I2C mode

P3.2/ General-purpose digital I/O pin

UCB0SOMI/ 13 11 I/O USCI_B0 slave out, master in SPI mode

UCB0SCL USCI_B0 SCL I2C clock in I2C mode

P3.3/ General-purpose digital I/O pin

UCB0CLK/ 14 12 I/O USCI_B0 clock input/output

UCA0STE USCI_A0 slave transmit enable

P3.4/ General-purpose digital I/O pin

UCA0TXD/ 25 23 I/O USCI_A0 transmit data output in UART mode

UCA0SIMO USCI_A0 slave in, master out in SPI mode

P3.5/ General-purpose digital I/O pin

UCA0RXD/ 26 24 I/O USCI_A0 receive data input in UART mode

UCA0SOMI USCI_A0 slave out, master in SPI mode

P3.6/ General-purpose digital I/O pin

TA1.1/ 27 25 I/O Timer_A, capture: CCI1B input or BSL receive, compare: OUT2 output

A6 ADC10 analog input A6

P3.7/ General-purpose digital I/O pin

TA1.2/ 28 26 I/O Timer_A, capture: CCI2B input or BSL receive, compare: OUT2 output

A7 ADC10 analog input A7

P4.0/ General-purpose digital I/O pin

TB0.0/ 17 15 I/O Timer_B, capture: CCI0A input, compare: OUT0 output

CA0 Comparator_A+, CA0 input

P4.1/ General-purpose digital I/O pin

TB0.1/ 18 16 I/O Timer_B, capture: CCI1A input, compare: OUT1 output

CA1 Comparator_A+, CA1 input

P4.2/ General-purpose digital I/O pin

TB0.2/ 19 17 I/O Timer_B, capture: CCI2A input, compare: OUT2 output

CA2 Comparator_A+, CA2 input

NO. I/O DESCRIPTION

DA RHA

6 3 I/O

5 2 I/O

11 9 I/O

(2)

SLAS800 –MARCH 2013

(2) If XOUT/P2.7 is used as an input, excess current flows until P2SEL.7 is cleared. This is due to the oscillator output driver connection to

this pad after reset.

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Table 2. Terminal Functions (continued)

TERMINAL

NAME

P4.3/ General-purpose digital I/O pin

TB0.0/ Timer_B, capture: CCI0B input, compare: OUT0 output

A12/ ADC10 analog input A12

CA3 Comparator_A+, CA3 input

P4.4/ General-purpose digital I/O pin

TB0.1/ Timer_B, capture: CCI1B input, compare: OUT1 output

A13/ ADC10 analog input A13

CA4 Comparator_A+, CA4 input

P4.5/ General-purpose digital I/O pin

TB0.2/ Timer_B, compare: OUT2 output

A14/ ADC10 analog input A14

CA5 Comparator_A+, CA5 input

P4.6/ General-purpose digital I/O pin

TBOUTH/ Timer_B, switch all TB0 to TB3 outputs to high impedance

CAOUT/ 23 21 I/O Comparator_A+ Output

A15/ ADC10 analog input A15

CA6 Comparator_A+, CA6 input

P4.7/ General-purpose digital I/O pinCB0

TBCLK/ Timer_B, clock signal TBCLK input

CAOUT/ Comparator_A+ Output

CA7 Comparator_A+, CA7 input

RST/ Reset or nonmaskable interrupt input

NMI/SBWTDIO Spy-Bi-Wire test data input/output during programming and test

TEST/ Selects test mode for JTAG pins on Port 1. The device protection fuse is

SBWTCK Spy-Bi-Wire test clock input during programming and test

DV

CC

AV

CC

DV

SS

AV

SS

QFN Pad NA Pad NA QFN package pad; connection to DVSSrecommended.

NO. I/O DESCRIPTION

DA RHA

20 18 I/O

21 19 I/O

22 20 I/O

24 22 I/O

7 5 I

1 37 I

2 38, 39 Digital supply voltage

16 14 Analog supply voltage

4 1, 4 Digital ground reference

15 13 Analog ground reference

connected to TEST.

www.ti.com

6 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

General-PurposeRegister

ProgramCounter

StackPointer

StatusRegister

ConstantGenerator

General-PurposeRegister

General-PurposeRegister

General-PurposeRegister

PC/R0

SP/R1

SR/CG1/R2

CG2/R3

R4

R5

R12

R13

General-PurposeRegister

General-PurposeRegister

R6

R7

General-PurposeRegister

General-PurposeRegister

R8

R9

General-PurposeRegister

General-PurposeRegister

R10

R11

General-PurposeRegister

General-PurposeRegister

R14

R15

www.ti.com

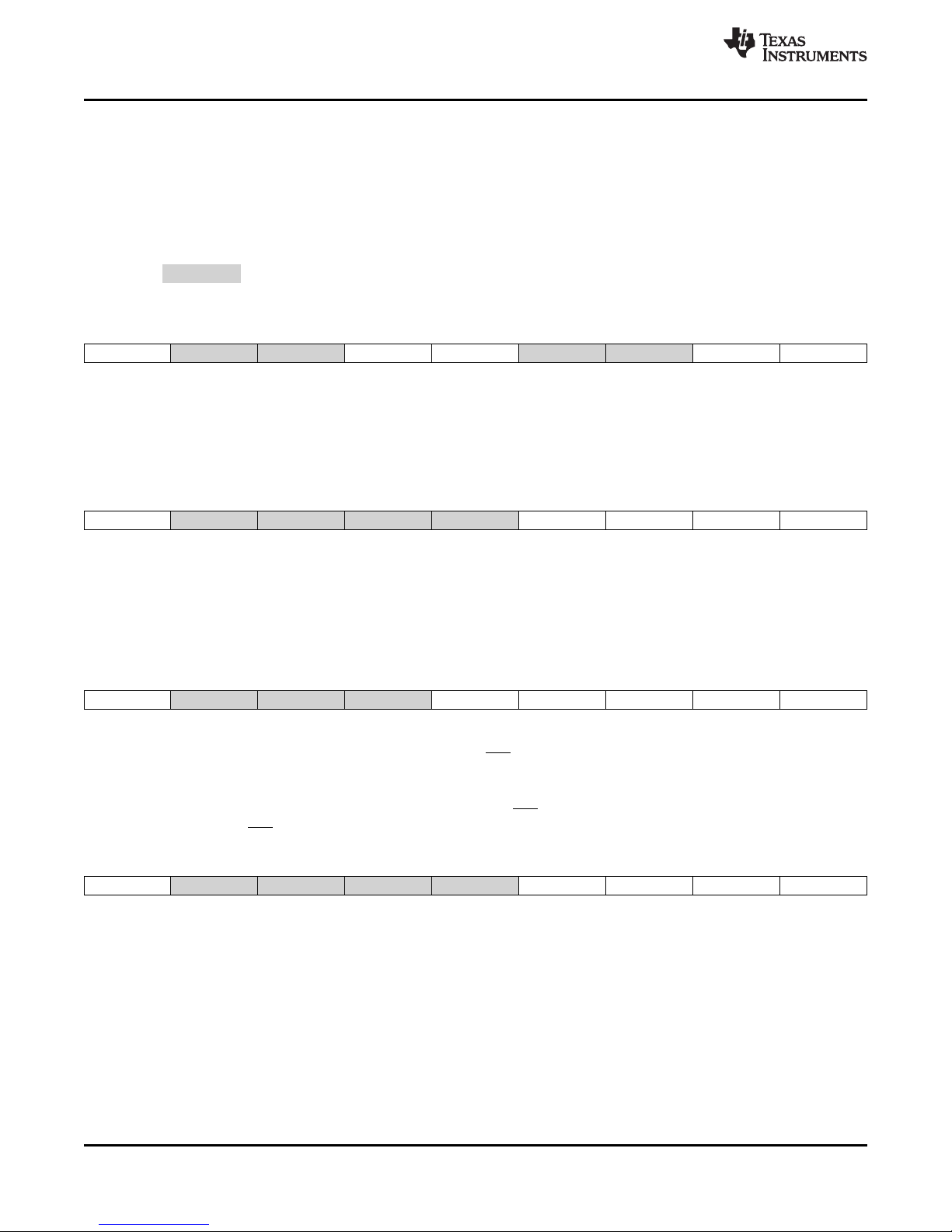

SHORT-FORM DESCRIPTION

CPU

The MSP430 CPU has a 16-bit RISC architecture

that is highly transparent to the application. All

operations, other than program-flow instructions, are

performed as register operations in conjunction with

seven addressing modes for source operand and four

addressing modes for destination operand.

The CPU is integrated with 16 registers that provide

reduced instruction execution time. The register-toregister operation execution time is one cycle of the

CPU clock.

Four of the registers, R0 to R3, are dedicated as

program counter, stack pointer, status register, and

constant generator, respectively. The remaining

registers are general-purpose registers.

Peripherals are connected to the CPU using data,

address, and control buses, and can be handled with

all instructions.

The instruction set consists of the original 51

instructions with three formats and seven address

modes and additional instructions for the expanded

address range. Each instruction can operate on word

and byte data.

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Instruction Set

The instruction set consists of 51 instructions with

three formats and seven address modes. Each

instruction can operate on word and byte data.

Table 3 shows examples of the three types of

instruction formats; Table 4 shows the address

modes.

Dual operands, source-destination ADD R4,R5 R4 + R5 ---> R5

Single operands, destination only CALL R8 PC -->(TOS), R8--> PC

Relative jump, un/conditional JNE Jump-on-equal bit = 0

Symbolic (PC relative) ✓ ✓ MOV EDE,TONI M(EDE) -- --> M(TONI)

Indirect autoincrement ✓ MOV @Rn+,Rm MOV @R10+,R11

(1) S = source, D = destination

INSTRUCTION FORMAT EXAMPLE OPERATION

ADDRESS MODE S D SYNTAX EXAMPLE OPERATION

Register ✓ ✓ MOV Rs,Rd MOV R10,R11 R10 -- --> R11

Indexed ✓ ✓ MOV X(Rn),Y(Rm) MOV 2(R5),6(R6) M(2+R5) -- --> M(6+R6)

Absolute ✓ ✓ MOV &MEM,&TCDAT M(MEM) -- --> M(TCDAT)

Indirect ✓ MOV @Rn,Y(Rm) MOV @R10,Tab(R6) M(R10) -- --> M(Tab+R6)

Immediate ✓ MOV #X,TONI MOV #45,TONI #45 -- --> M(TONI)

Table 3. Instruction Word Formats

Table 4. Address Mode Descriptions

(1)

M(R10) -- --> R11

R10 + 2-- --> R10

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Operating Modes

The MSP430 has one active mode and five software selectable low-power modes of operation. An interrupt

event can wake up the device from any of the low-power modes, service the request, and restore back to the

low-power mode on return from the interrupt program.

The following six operating modes can be configured by software:

• Active mode (AM)

– All clocks are active.

• Low-power mode 0 (LPM0)

– CPU is disabled.

– ACLK and SMCLK remain active.

– MCLK is disabled.

• Low-power mode 1 (LPM1)

– CPU is disabled

– ACLK and SMCLK remain active.

– MCLK is disabled.

– DCO's dc generator is disabled if DCO not used in active mode.

• Low-power mode 2 (LPM2)

– CPU is disabled.

– ACLK remains active.

– MCLK and SMCLK are disabled.

– DCO's dc generator remains enabled.

• Low-power mode 3 (LPM3)

– CPU is disabled.

– ACLK remains active.

– MCLK and SMCLK are disabled.

– DCO's dc generator is disabled.

• Low-power mode 4 (LPM4)

– CPU is disabled.

– ACLK, MCLK, and SMCLK are disabled.

– DCO's dc generator is disabled.

– Crystal oscillator is stopped.

www.ti.com

8 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

Interrupt Vector Addresses

The interrupt vectors and the power-up starting address are located in the address range 0FFFFh to 0FFC0h.

The vector contains the 16-bit address of the appropriate interrupt handler instruction sequence.

If the reset vector (located at address 0FFFEh) contains 0FFFFh (for example, flash is not programmed), the

CPU goes into LPM4 immediately after power-up.

Table 5. Interrupt Sources, Flags, and Vectors

INTERRUPT SOURCE INTERRUPT FLAG PRIORITY

Power-Up PORIFG

External Reset RSTIFG

Watchdog Timer+ WDTIFG Reset 0FFFEh 31, highest

Flash key violation KEYV

PC out-of-range

(1)

(2)

NMI NMIIFG (non)-maskable

Oscillator fault OFIFG (non)-maskable 0FFFCh 30

Flash memory access violation ACCVIFG

Timer0_B3 TB0CCR0 CCIFG

Timer0_B3 TB0CCR2 TB0CCR1 CCIFG,

TBIFG

Comparator_A+ CAIFG

(2)(3)

(4)

(2)(4)

(4)

Watchdog Timer+ WDTIFG maskable 0FFF4h 26

Timer0_A3 TA0CCR0 CCIFG

Timer0_A3 TA0CCR2 TA0CCR1 CCIFG,

TAIFG

USCI_A0 or USCI_B0 receive UCA0RXIFG, UCB0RXIFG

(4)

(5)(4)

(2)(5)

USCI_B0 I2C status

USCI_A0 or USCI_B0 transmit UCA0TXIFG, UCB0TXIFG

(2)(6)

USCI_B0 I2C receive or transmit

ADC10 ADC10IFG

(4)

Reserved 0FFE8h 20

I/O Port P2 (up to eight flags) P2IFG.0 to P2IFG.7

I/O Port P1 (up to eight flags) P1IFG.0 to P1IFG.7

Timer1_A3 TA1CCR0 CCIFG

Timer1_A3 TA1CCR2 TA1CCR1 CCIFG,

TAIFG

(7)

See

(8)

See

(2)(4)

(2)(4)

(4)

(2)(4)

(1) A reset is generated if the CPU tries to fetch instructions from within the module register memory address range (0h to 01FFh) or from

within unused address ranges.

(2) Multiple source flags

(3) (non)-maskable: the individual interrupt-enable bit can disable an interrupt event, but the general interrupt enable cannot.

(4) Interrupt flags are located in the module.

(5) In SPI mode: UCB0RXIFG. In I2C mode: UCALIFG, UCNACKIFG, ICSTTIFG, UCSTPIFG.

(6) In UART or SPI mode: UCB0TXIFG. In I2C mode: UCB0RXIFG, UCB0TXIFG.

(7) This location is used as bootstrap loader security key (BSLSKEY). A 0xAA55 at this location disables the BSL completely. A zero (0h)

disables the erasure of the flash if an invalid password is supplied.

(8) The interrupt vectors at addresses 0FFDEh to 0FFC0h are not used in this device and can be used for regular program code if

necessary.

SYSTEM WORD

INTERRUPT ADDRESS

(non)-maskable

maskable 0FFFAh 29

maskable 0FFF8h 28

maskable 0FFF6h 27

maskable 0FFF2h 25

maskable 0FFF0h 24

maskable 0FFEEh 23

maskable 0FFECh 22

maskable 0FFEAh 21

maskable 0FFE6h 19

maskable 0FFE4h 18

maskable 0FFE2h 17

maskable 0FFE0h 16

0FFDEh 15

0FFDEh to

0FFC0h

SLAS800 –MARCH 2013

14 to 0, lowest

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Special Function Registers (SFRs)

Most interrupt and module enable bits are collected into the lowest address space. Special function register bits

not allocated to a functional purpose are not physically present in the device. Simple software access is provided

with this arrangement.

Legend rw: Bit can be read and written.

rw-0,1: Bit can be read and written. It is reset or set by PUC.

rw-(0,1): Bit can be read and written. It is reset or set by POR.

SFR bit is not present in device.

Table 6. Interrupt Enable Register 1 and 2

Address 7 6 5 4 3 2 1 0

00h ACCVIE NMIIE OFIE WDTIE

rw-0 rw-0 rw-0 rw-0

WDTIE Watchdog timer interrupt enable. Inactive if watchdog mode is selected. Active if Watchdog timer is configured in

interval timer mode.

OFIE Oscillator fault interrupt enable

NMIIE (Non)maskable interrupt enable

ACCVIE Flash access violation interrupt enable

www.ti.com

Address 7 6 5 4 3 2 1 0

01h UCB0TXIE UCB0RXIE UCA0TXIE UCA0RXIE

rw-0 rw-0 rw-0 rw-0

UCA0RXIE USCI_A0 receive interrupt enable

UCA0TXIE USCI_A0 transmit interrupt enable

UCB0RXIE USCI_B0 receive interrupt enable

UCB0TXIE USCI_B0 transmit interrupt enable

Table 7. Interrupt Flag Register 1 and 2

Address 7 6 5 4 3 2 1 0

02h NMIIFG RSTIFG PORIFG OFIFG WDTIFG

rw-0 rw-(0) rw-(1) rw-1 rw-(0)

WDTIFG Set on watchdog timer overflow (in watchdog mode) or security key violation.

OFIFG Flag set on oscillator fault.

PORIFG Power-on reset interrupt flag. Set on VCCpower-up.

RSTIFG External reset interrupt flag. Set on a reset condition at RST/NMI pin in reset mode. Reset on VCCpower-up.

NMIIFG Set via RST/NMI pin

Address 7 6 5 4 3 2 1 0

03h UCB0TXIFG UCB0RXIFG UCA0TXIFG UCA0RXIFG

UCA0RXIFG USCI_A0 receive interrupt flag

UCA0TXIFG USCI_A0 transmit interrupt flag

UCB0RXIFG USCI_B0 receive interrupt flag

UCB0TXIFG USCI_B0 transmit interrupt flag

Reset on VCCpower-on or a reset condition at the RST/NMI pin in reset mode.

rw-1 rw-0 rw-1 rw-0

10 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

Memory Organization

Table 8. Memory Organization

MSP430G2755 MSP430G2855 MSP430G2955

Memory Size 32kB 48kB 56kB

Main: interrupt vector Flash 0xFFFF to 0xFFC0 0xFFFF to 0xFFC0 0xFFFF to 0xFFC0

Main: code memory Flash 0xFFFF to 0x8000 0xFFFF to 0x4000 0xFFFF to 0x2100

Information memory Size 256 Byte 256 Byte 256 Byte

Flash 0x10FF to 0x1000 0x10FF to 0x1000 0x10FF to 0x1000

RAM (total) Size 4kB 4kB 4kB

0x20FF to 0x1100 0x20FF to 0x1100 0x20FF to 0x1100

Extended Size 2KB 2KB 2KB

0x20FF to 0x1900 0x20FF to 0x1900 0x20FF to 0x1900

Mirrored Size 2KB 2KB 2KB

0x18FF to 0x1100 0x18FF to 0x1100 0x18FF to 0x1100

RAM (mirrored at 0x18FF to

0x1100)

Peripherals 16-bit 0x01FF to 0x0100 0x01FF to 0x0100 0x01FF to 0x0100

Size 2KB 2KB 2KB

0x09FF to 0x0200 0x09FF to 0x0200 0x09FF to 0x0200

8-bit 0x00FF to 0x0010 0x00FF to 0x0010 0x00FF to 0x0010

8-bit SFR 0x000F to 0x0000 0x000F to 0x0000 0x000F to 0x0000

SLAS800 –MARCH 2013

Bootstrap Loader (BSL)

The MSP430 BSL enables users to program the flash memory or RAM using a UART serial interface. Access to

the MSP430 memory via the BSL is protected by user-defined password. For complete description of the

features of the BSL and its implementation, see the MSP430 Programming Via the Bootstrap Loader User's

Guide (SLAU319).

Table 9. BSL Function Pins

BSL FUNCTION DA PACKAGE PINS RHA PACKAGE PINS

Data transmit 32 - P1.1 30 - P1.1

Data receive 10 - P2.2 8 - P2.2

Flash Memory

The flash memory can be programmed via the Spy-Bi-Wire or JTAG port or in-system by the CPU. The CPU can

perform single-byte and single-word writes to the flash memory. Features of the flash memory include:

• Flash memory has n segments of main memory and four segments of information memory (A to D) of

64 bytes each. Each segment in main memory is 512 bytes in size.

• Segments 0 to n may be erased in one step, or each segment may be individually erased.

• Segments A to D can be erased individually or as a group with segments 0 to n. Segments A to D are also

called information memory.

• Segment A contains calibration data. After reset segment A is protected against programming and erasing. It

can be unlocked but care should be taken not to erase this segment if the device-specific calibration data is

required.

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

DCO(RSEL,DCO+1)

DCO(RSEL,DCO)

average

DCO(RSEL,DCO) DCO(RSEL,DCO+1)

32 × f × f

f =

MOD × f + (32 – MOD) × f

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Peripherals

Peripherals are connected to the CPU through data, address, and control buses and can be handled using all

instructions. For complete module descriptions, see the MSP430x2xx Family User's Guide (SLAU144).

Oscillator and System Clock

The clock system is supported by the basic clock module that includes support for a 32768-Hz watch crystal

oscillator, an internal very-low-power low-frequency oscillator and an internal digitally controlled oscillator (DCO).

The basic clock module is designed to meet the requirements of both low system cost and low power

consumption. The internal DCO provides a fast turn-on clock source and stabilizes in less than 1 µs. The basic

clock module provides the following clock signals:

• Auxiliary clock (ACLK), sourced either from a 32768-Hz watch crystal or the internal LF oscillator.

• Main clock (MCLK), the system clock used by the CPU.

• Sub-Main clock (SMCLK), the sub-system clock used by the peripheral modules.

The DCO settings to calibrate the DCO output frequency are stored in the information memory segment A.

Main DCO Characteristics

• All ranges selected by RSELx overlap with RSELx + 1: RSELx = 0 overlaps RSELx = 1, ... RSELx = 14

overlaps RSELx = 15.

• DCO control bits DCOx have a step size as defined by parameter S

• Modulation control bits MODx select how often f

cycles. The frequency f

DCO(RSEL,DCO)

is used for the remaining cycles. The frequency is an average equal to:

DCO(RSEL,DCO+1)

.

DCO

is used within the period of 32 DCOCLK

www.ti.com

12 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

Calibration Data Stored in Information Memory Segment A

Calibration data is stored for both the DCO and for ADC10 organized in a tag-length-value (TLV) structure.

Table 10. Tags Used by the Devices

NAME ADDRESS VALUE DESCRIPTION

TAG_DCO_30 0x10F6 0x01 DCO frequency calibration at VCC= 3 V and TA= 30°C at calibration

TAG_ADC10_1 0x10DA 0x10 ADC10_1 calibration tag

TAG_EMPTY - 0xFE Identifier for empty memory areas

Table 11. Labels Used by the Devices

LABEL SIZE CONDITION AT CALIBRATION AND DESCRIPTION

CAL_ADC_25T85 0x0010 word INCHx = 0x1010, REF2_5 = 1, TA= 85°C

CAL_ADC_25T30 0x000E word INCHx = 0x1010, REF2_5 = 1, TA= 30°C

CAL_ADC_25VREF_FACTOR 0x000C word REF2_5 = 1, TA= 30°C, I

CAL_ADC_15T85 0x000A word INCHx = 0x1010, REF2_5 = 0, TA= 85°C

CAL_ADC_15T30 0x0008 word INCHx = 0x1010, REF2_5 = 0, TA= 30°C

CAL_ADC_15VREF_FACTOR 0x0006 word REF2_5 = 0, TA= 30°C, I

CAL_ADC_OFFSET 0x0004 word External VREF = 1.5 V, f

CAL_ADC_GAIN_FACTOR 0x0002 word External VREF = 1.5 V, f

CAL_BC1_1MHZ 0x0009 byte -

CAL_DCO_1MHZ 0x0008 byte -

CAL_BC1_8MHZ 0x0007 byte -

CAL_DCO_8MHZ 0x0006 byte -

CAL_BC1_12MHZ 0x0005 byte -

CAL_DCO_12MHZ 0x0004 byte -

CAL_BC1_16MHZ 0x0003 byte -

CAL_DCO_16MHZ 0x0002 byte -

ADDRESS

OFFSET

VREF+

VREF+

ADC10CLK

ADC10CLK

= 1 mA

= 0.5 mA

= 5 MHz

= 5 MHz

SLAS800 –MARCH 2013

Brownout

The brownout circuit is implemented to provide the proper internal reset signal to the device during power on and

power off.

Digital I/O

Four 8-bit I/O ports are implemented:

• All individual I/O bits are independently programmable.

• Any combination of input, output, and interrupt condition (port P1 and port P2 only) is possible.

• Edge-selectable interrupt input capability for all bits of port P1 and port P2.

• Read and write access to port-control registers is supported by all instructions.

• Each I/O has an individually programmable pullup or pulldown resistor.

• Each I/O has an individually programmable pin oscillator enable bit to enable low-cost touch sensing.

Watchdog Timer (WDT+)

The primary function of the watchdog timer (WDT+) module is to perform a controlled system restart after a

software problem occurs. If the selected time interval expires, a system reset is generated. If the watchdog

function is not needed in an application, the module can be disabled or configured as an interval timer and can

generate interrupts at selected time intervals.

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Timer_A3 (TA0, TA1)

Timer0_A3 and Timer1_A3 are 16-bit timers/counters with three capture/compare registers. Timer_A3 can

support multiple capture/compares, PWM outputs, and interval timing. Timer_A3 also has extensive interrupt

capabilities. Interrupts may be generated from the counter on overflow conditions and from each of the

capture/compare registers.

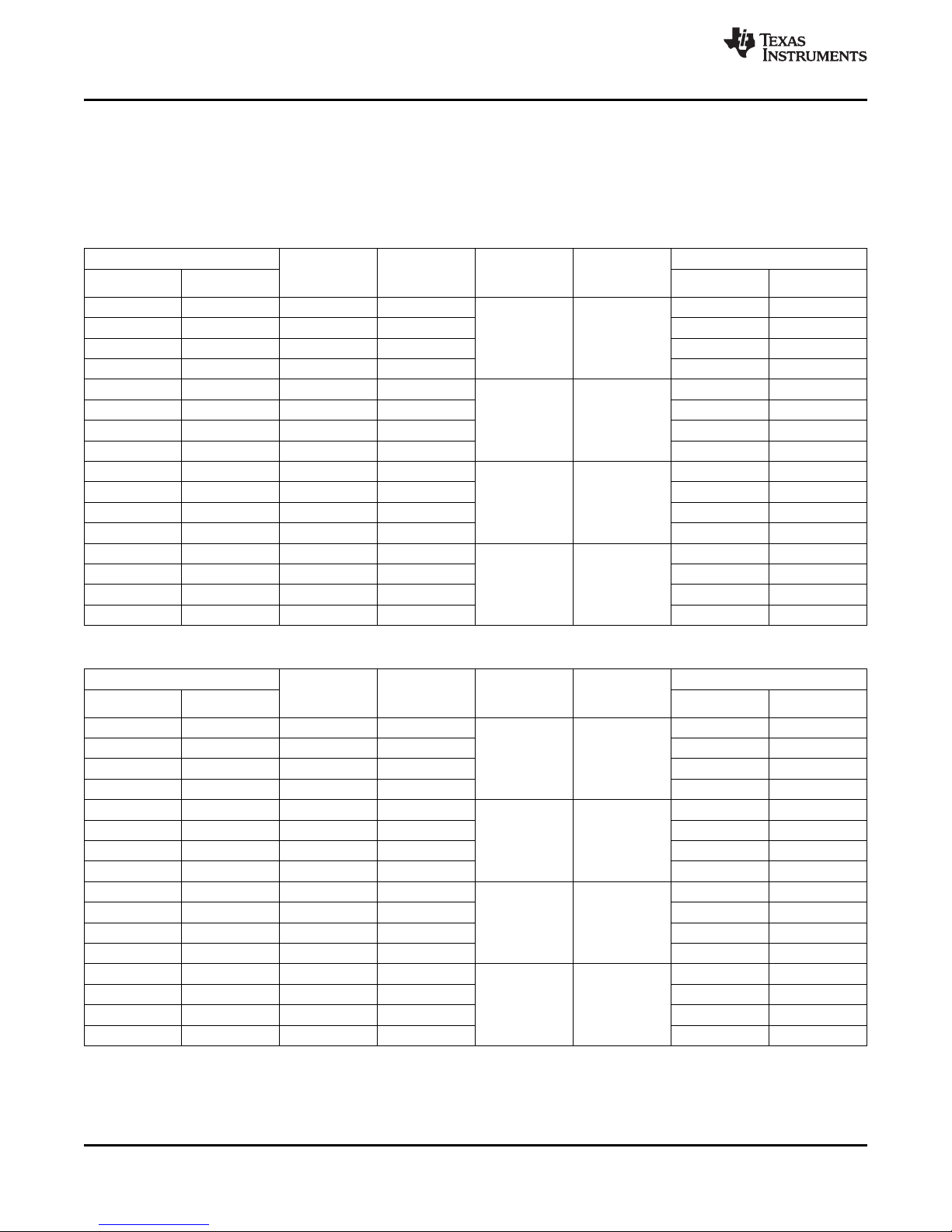

Table 12. Timer0_A3 Signal Connections

INPUT PIN NUMBER MODULE OUTPUT PIN NUMBER

DA38 RHA40 DA38 RHA40

P1.0 - 31 P1.0-29 TACLK TACLK

P2.1 - 9 P2.1 - 7 TACLK INCLK

P1.1 - 32 P1.1 - 30 TA0.0 CCI0A P1.1- 32 P1.1 - 30

P2.2 - 10 P2.2 - 8 ACLK CCI0B P2.2 - 10 P2.2 - 8

P1.2 - 33 P1.2 - 31 TA0.1 CCI1A P1.2 - 33 P1.2 - 31

P2.3 - 29 P2.3 - 27 TA0.1 CCI1B P2.3 - 29 P2.3 - 27

P1.3 - 34 P1.3 - 32 TA0.2 CCI2A P1.3 - 34 P1.3 - 32

DEVICE INPUT MODULE MODULE

SIGNAL INPUT NAME BLOCK

ACLK ACLK

SMCLK SMCLK

V

SS

V

CC

V

SS

V

CC

GND P1.5 - 36 P1.5 - 34

V

CC

GND P1.6 - 37 P1.6 - 35

V

CC

ACLK (internal) CCI2B P2.4 - 30 P2.4 - 28

V

SS

V

CC

GND P1.7 - 38 P1.7 - 36

V

CC

Timer NA

CCR0 TA0

CCR1 TA1

CCR2 TA2

OUTPUT

SIGNAL

www.ti.com

Table 13. Timer1_A3 Signal Connections

INPUT PIN NUMBER MODULE OUTPUT PIN NUMBER

DA38 RHA40 DA38 RHA40

P2.0 - 8 P2.0 - 6 TACLK TACLK

PinOsc PinOsc TACLK INCLK

P2.5 - 3 P2.5 - 40 TA1.0 CCI0A P2.5 - 3 P2.5 - 40

P3.6 - 27 P3.6 - 25 TA1.1 CCI1A P3.6 - 27 P3.6 - 25

P3.7 - 28 P3.7 - 26 TA1.2 CCI2A P3.7 - 28 P3.7 - 26

PinOsc PinOsc TA1.2 CCI2B

DEVICE INPUT MODULE MODULE

SIGNAL INPUT NAME BLOCK

ACLK ACLK

SMCLK SMCLK

TA1.0 CCI0B

V

SS

V

CC

GND

V

CC

CAOUT CCI1B

V

SS

V

CC

V

SS

V

CC

GND

V

CC

GND

V

CC

Timer NA

CCR0 TA0

CCR1 TA1

CCR2 TA2

OUTPUT

SIGNAL

14 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

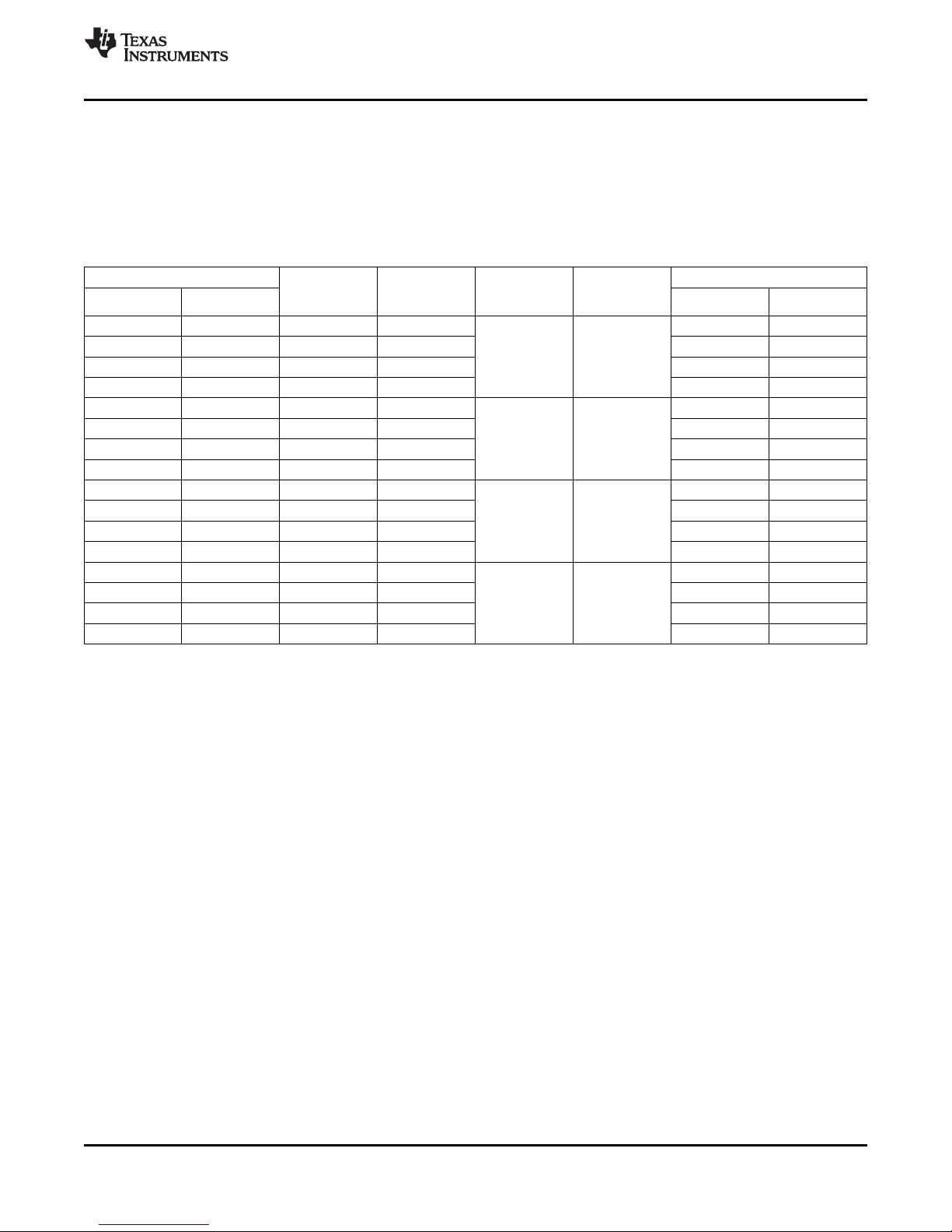

Timer_B3 (TB0)

Timer0_B3 is a 16-bit timer/counter with three capture/compare registers. Timer0_B3 can support multiple

capture/compares, PWM outputs, and interval timing. Timer0_B3 also has extensive interrupt capabilities.

Interrupts may be generated from the counter on overflow conditions and from each of the capture/compare

registers.

Table 14. Timer0_B3 Signal Connections

INPUT PIN NUMBER MODULE OUTPUT PIN NUMBER

DA38 RHA40 DA38 RHA40

P4.7 - 24 P4.7 - 22 TBCLK TBCLK

P4.7 - 27 P4.7 - 22 TBCLK INCLK

P4.0 - 17 P4.0 - 15 TB0.0 CCI0A P4.0 - 17 P4.0 - 15

P4.3 -20 P4.3 - 18 TB0.0 CCI0B P4.3 - 20 P4.3 - 18

P4.1 - 18 P4.1 - 16 TB0.1 CCI1A P4.1 - 18 P4.1 - 16

P4.4 - 21 P4.4 - 19 TB0.1 CCI1B P4.4 - 21 P4.4 - 19

P4.2 - 19 P4.2 - 17 TB0.2 CCI2A P4.2 - 19 P4.2 - 17

DEVICE INPUT MODULE MODULE

SIGNAL INPUT NAME BLOCK

ACLK ACLK

SMCLK SMCLK

V

SS

V

CC

V

SS

V

CC

ACLK (internal) CCI2B P4.5 - 22 P4.5 - 20

V

SS

V

CC

GND

V

CC

GND

V

CC

GND

V

CC

Timer NA

CCR0 TB0

CCR1 TB1

CCR2 TB2

OUTPUT

SIGNAL

SLAS800 –MARCH 2013

Universal Serial Communications Interface (USCI)

The USCI module is used for serial data communication. The USCI module supports synchronous

communication protocols such as SPI (3 or 4 pin) and I2C, and asynchronous communication protocols such as

UART, enhanced UART with automatic baudrate detection (LIN), and IrDA.

USCI_A0 provides support for SPI (3 or 4 pin), UART, enhanced UART, and IrDA.

USCI_B0 provides support for SPI (3 or 4 pin) and I2C.

Comparator_A+

The primary function of the comparator_A+ module is to support precision slope analog-to-digital conversions,

battery-voltage supervision, and monitoring of external analog signals.

ADC10

The ADC10 module supports fast 10-bit analog-to-digital conversions. The module implements a 10-bit SAR

core, sample select control, reference generator, and data transfer controller (DTC) for automatic conversion

result handling, allowing ADC samples to be converted and stored without any CPU intervention.

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

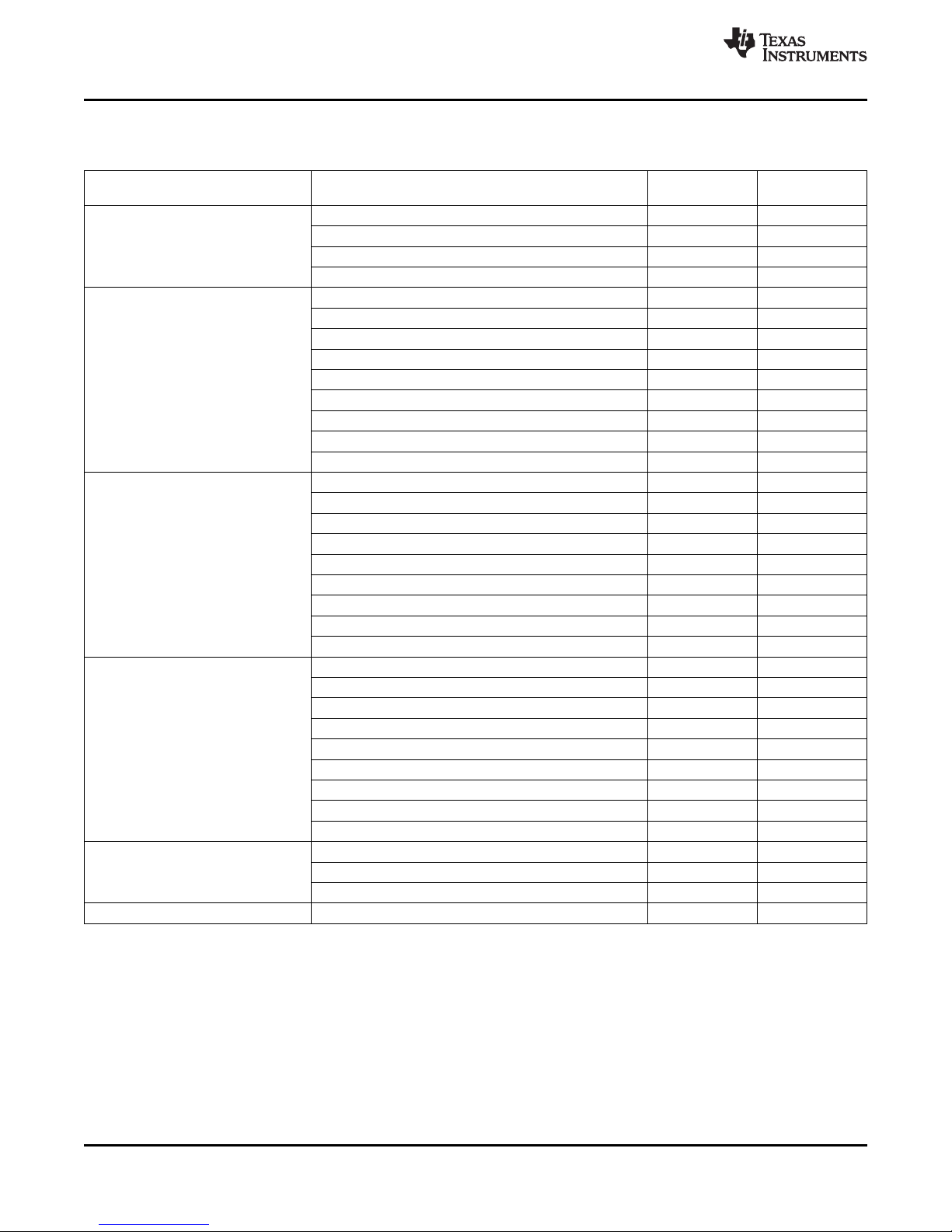

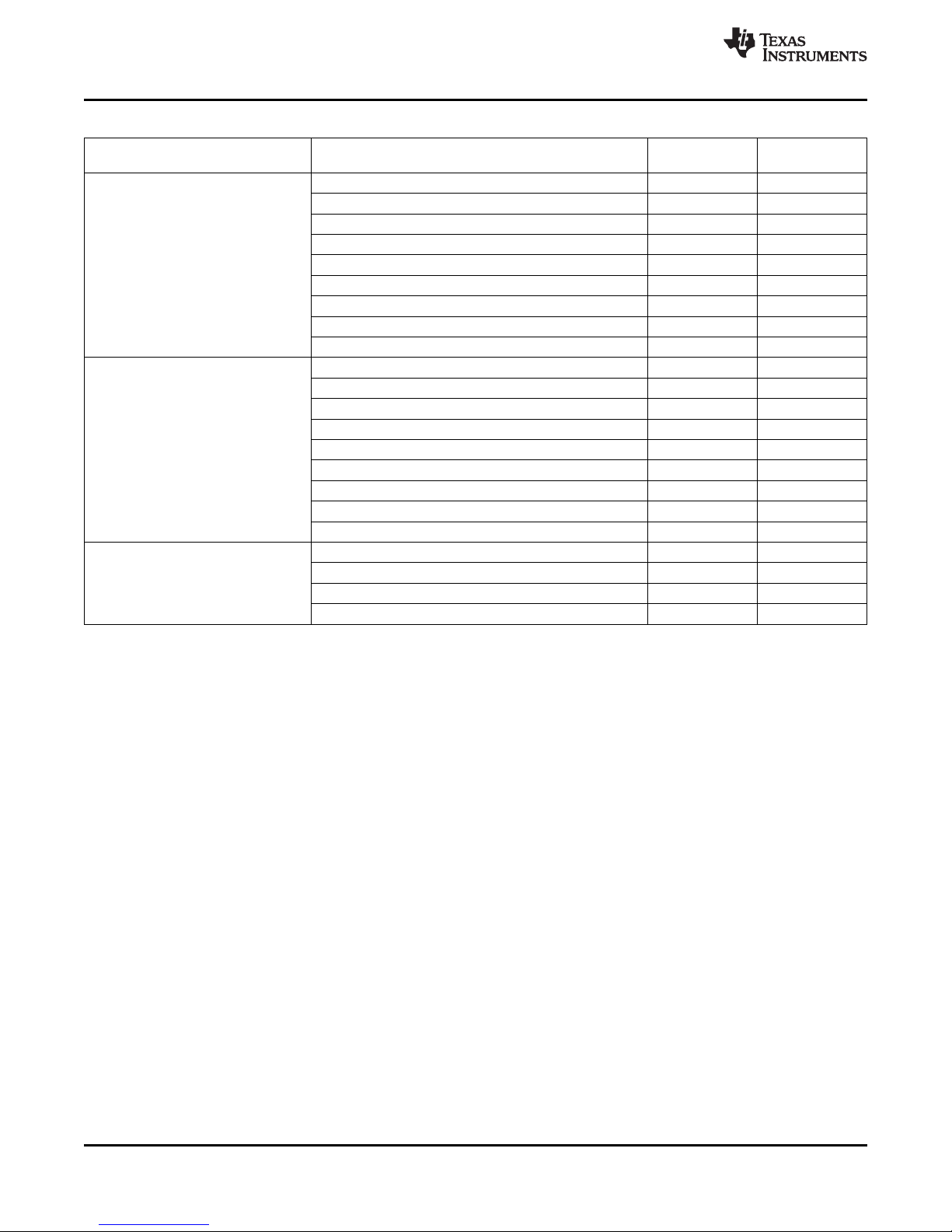

Peripheral File Map

Table 15. Peripherals With Word Access

MODULE REGISTER DESCRIPTION OFFSET

ADC10 ADC data transfer start address ADC10SA 1BCh

ADC memory ADC10MEM 1B4h

ADC control register 1 ADC10CTL1 1B2h

ADC control register 0 ADC10CTL0 1B0h

Timer0_B3 Capture/compare register TB0CCR2 0196h

Capture/compare register TB0CCR1 0194h

Capture/compare register TB0CCR0 0192h

Timer_B register TB0R 0190h

Capture/compare control TB0CCTL2 0186h

Capture/compare control TB0CCTL1 0184h

Capture/compare control TB0CCTL0 0182h

Timer_B control TB0CTL 0180h

Timer_B interrupt vector TB0IV 011Eh

Timer0_A3 Capture/compare register TA0CCR2 0176h

Capture/compare register TA0CCR1 0174h

Capture/compare register TA0CCR0 0172h

Timer_A register TA0R 0170h

Capture/compare control TA0CCTL2 0166h

Capture/compare control TA0CCTL1 0164h

Capture/compare control TA0CCTL0 0162h

Timer_A control TA0CTL 0160h

Timer_A interrupt vector TA0IV 012Eh

Timer1_A3 Capture/compare register TA1CCR2 0156h

Capture/compare register TA1CCR1 0154h

Capture/compare register TA1CCR0 0152h

Timer_A register TA1R 0150h

Capture/compare control TA1CCTL2 0146h

Capture/compare control TA1CCTL1 0144h

Capture/compare control TA1CCTL0 0142h

Timer_A control TA1CTL 0140h

Timer_A interrupt vector TA1IV 011Ch

Flash Memory Flash control 3 FCTL3 012Ch

Flash control 2 FCTL2 012Ah

Flash control 1 FCTL1 0128h

Watchdog Timer+ Watchdog/timer control WDTCTL 0120h

REGISTER

NAME

www.ti.com

16 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

Table 16. Peripherals With Byte Access

MODULE REGISTER DESCRIPTION OFFSET

USCI_B0 USCI_B0 transmit buffer UCB0TXBUF 06Fh

USCI_B0 receive buffer UCB0RXBUF 06Eh

USCI_B0 status UCB0STAT 06Dh

USCI B0 I2C Interrupt enable UCB0CIE 06Ch

USCI_B0 bit rate control 1 UCB0BR1 06Bh

USCI_B0 bit rate control 0 UCB0BR0 06Ah

USCI_B0 control 1 UCB0CTL1 069h

USCI_B0 control 0 UCB0CTL0 068h

USCI_B0 I2C slave address UCB0SA 011Ah

USCI_B0 I2C own address UCB0OA 0118h

USCI_A0 USCI_A0 transmit buffer UCA0TXBUF 067h

USCI_A0 receive buffer UCA0RXBUF 066h

USCI_A0 status UCA0STAT 065h

USCI_A0 modulation control UCA0MCTL 064h

USCI_A0 baud rate control 1 UCA0BR1 063h

USCI_A0 baud rate control 0 UCA0BR0 062h

USCI_A0 control 1 UCA0CTL1 061h

USCI_A0 control 0 UCA0CTL0 060h

USCI_A0 IrDA receive control UCA0IRRCTL 05Fh

USCI_A0 IrDA transmit control UCA0IRTCTL 05Eh

USCI_A0 auto baud rate control UCA0ABCTL 05Dh

ADC10 ADC analog enable 0 ADC10AE0 04Ah

ADC analog enable 1 ADC10AE1 04Bh

ADC data transfer control register 1 ADC10DTC1 049h

ADC data transfer control register 0 ADC10DTC0 048h

Comparator_A+ Comparator_A+ port disable CAPD 05Bh

Comparator_A+ control 2 CACTL2 05Ah

Comparator_A+ control 1 CACTL1 059h

Basic Clock System+ Basic clock system control 3 BCSCTL3 053h

Basic clock system control 2 BCSCTL2 058h

Basic clock system control 1 BCSCTL1 057h

DCO clock frequency control DCOCTL 056h

Port P4 Port P4 selection 2 P4SEL2 044h

Port P4 resistor enable P4REN 011h

Port P4 selection P4SEL 01Fh

Port P4 direction P4DIR 01Eh

Port P4 output P4OUT 01Dh

Port P4 input P4IN 01Ch

Port P3 Port P3 selection 2 P3SEL2 043h

Port P3 resistor enable P3REN 010h

Port P3 selection P3SEL 01Bh

Port P3 direction P3DIR 01Ah

Port P3 output P3OUT 019h

Port P3 input P3IN 018h

REGISTER

NAME

SLAS800 –MARCH 2013

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Table 16. Peripherals With Byte Access (continued)

MODULE REGISTER DESCRIPTION OFFSET

Port P2 Port P2 selection 2 P2SEL2 042h

Port P2 resistor enable P2REN 02Fh

Port P2 selection P2SEL 02Eh

Port P2 interrupt enable P2IE 02Dh

Port P2 interrupt edge select P2IES 02Ch

Port P2 interrupt flag P2IFG 02Bh

Port P2 direction P2DIR 02Ah

Port P2 output P2OUT 029h

Port P2 input P2IN 028h

Port P1 Port P1 selection 2 P1SEL2 041h

Port P1 resistor enable P1REN 027h

Port P1 selection P1SEL 026h

Port P1 interrupt enable P1IE 025h

Port P1 interrupt edge select P1IES 024h

Port P1 interrupt flag P1IFG 023h

Port P1 direction P1DIR 022h

Port P1 output P1OUT 021h

Port P1 input P1IN 020h

Special Function SFR interrupt flag 2 IFG2 003h

SFR interrupt flag 1 IFG1 002h

SFR interrupt enable 2 IE2 001h

SFR interrupt enable 1 IE1 000h

REGISTER

NAME

www.ti.com

18 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

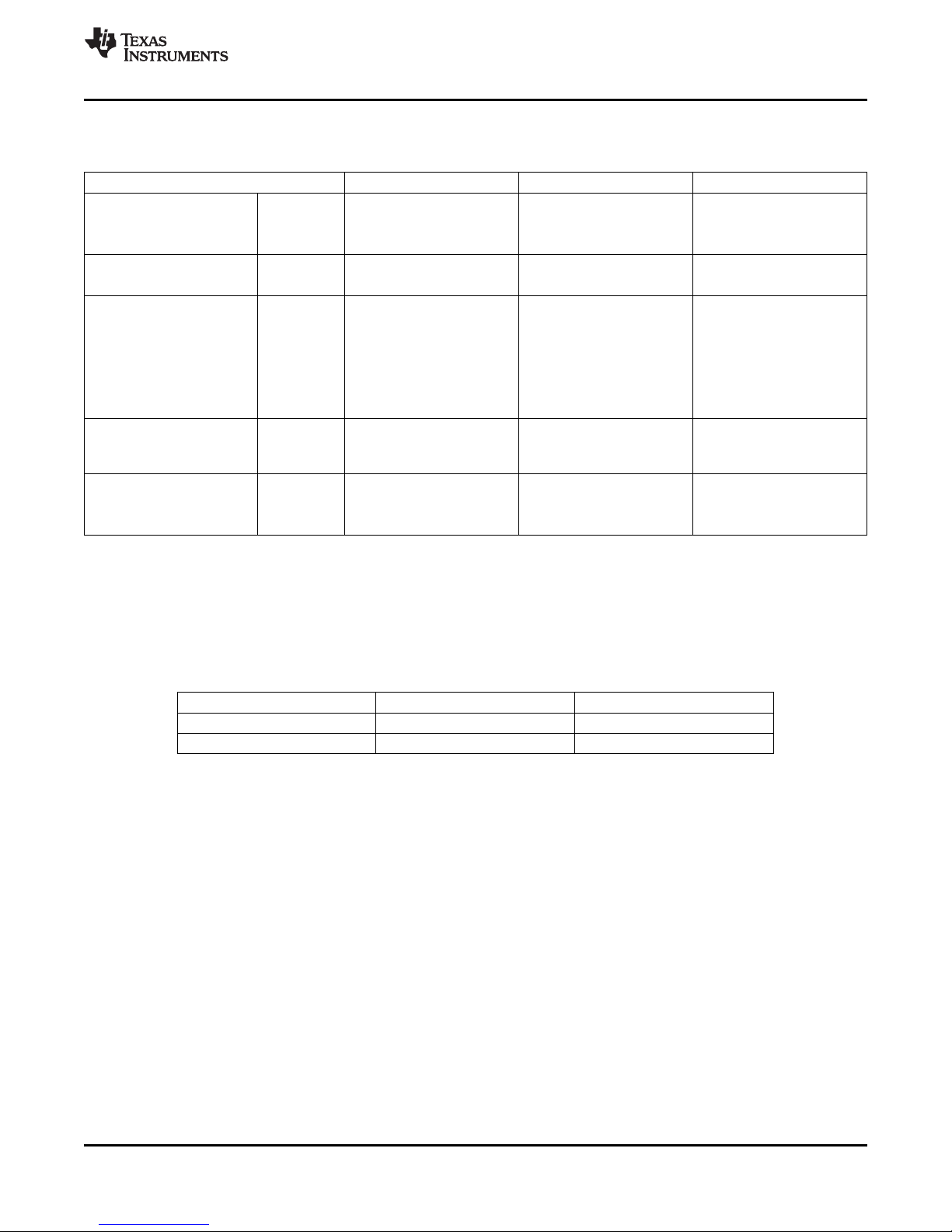

Supply voltage range,

during flash memory

programming

Supply voltage range,

during program execution

Legend:

16 MHz

System Frequency - MHz

12 MHz

6 MHz

1.8 V

Supply Voltage - V

3.3 V

2.7 V

2.2 V

3.6 V

MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

Absolute Maximum Ratings

Voltage applied at VCCto V

Voltage applied to any pin

Diode current at any device pin ±2 mA

Storage temperature range, T

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages referenced to VSS. The JTAG fuse-blow voltage, VFB, is allowed to exceed the absolute maximum rating. The voltage is

applied to the TEST pin when blowing the JTAG fuse.

(3) Higher temperature may be applied during board soldering according to the current JEDEC J-STD-020 specification with peak reflow

temperatures not higher than classified on the device label on the shipping boxes or reels.

SS

(2)

stg

(1)

(3)

Unprogrammed device –55°C to 150°C

Programmed device –55°C to 150°C

Recommended Operating Conditions

Typical values are specified at VCC= 3.3 V and TA= 25°C (unless otherwise noted)

V

V

T

f

SYSTEM

(1) The MSP430 CPU is clocked directly with MCLK. Both the high and low phase of MCLK must not exceed the pulse duration of the

(2) Modules might have a different maximum input clock specification. See the specification of the respective module in this data sheet.

Supply voltage V

CC

Supply voltage 0 V

SS

Operating free-air temperature -40 85 °C

A

Processor frequency (maximum MCLK frequency VCC= 2.7 V,

using the USART module)

specified maximum frequency.

(1)(2)

During program execution 1.8 3.6

During flash programming or erase 2.2 3.6

VCC= 1.8 V,

Duty cycle = 50% ± 10%

Duty cycle = 50% ± 10%

VCC= 3.3 V,

Duty cycle = 50% ± 10%

SLAS800 –MARCH 2013

–0.3 V to 4.1 V

–0.3 V to VCC+ 0.3 V

MIN NOM MAX UNIT

dc 6

dc 12 MHz

dc 16

Note: Minimum processor frequency is defined by system clock. Flash program or erase operations require a minimum V

of 2.2 V.

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 19

Figure 1. Safe Operating Area

CC

0.0

1.0

2.0

3.0

4.0

5.0

1.5 2.0 2.5 3.0 3.5 4.0

VCC− Supply Voltage − V

Active Mode Current − mA

f

DCO

= 1 MHz

f

DCO

= 8 MHz

f

DCO

= 12 MHz

f

DCO

= 16 MHz

0.0

1.0

2.0

3.0

4.0

0.0 4.0 8.0 12.0 16.0

f

DCO

− DCO Frequency − MHz

Active Mode Current − mA

TA= 25 °C

TA= 85 °C

VCC= 2.2 V

VCC= 3 V

TA= 25 °C

TA= 85 °C

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Electrical Characteristics

Active Mode Supply Current Into VCCExcluding External Current

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS T

f

= f

MCLK

= 0 Hz,

= f

DCO

f

ACLK

I

AM,1MHz

(1) All inputs are tied to 0 V or to VCC. Outputs do not source or sink any current.

(2) The currents are characterized with a Micro Crystal CC4V-T1A SMD crystal with a load capacitance of 9 pF. The internal and external

load capacitance is chosen to closely match the required 9 pF.

Active mode (AM)

current at 1 MHz

Program executes in flash,

BCSCTL1 = CALBC1_1MHZ, µA

DCOCTL = CALDCO_1MHZ,

CPUOFF = 0, SCG0 = 0, SCG1 = 0,

OSCOFF = 0

= 1 MHz, 2.2 V 250

SMCLK

A

V

CC

3 V 350 450

(1)(2)

MIN TYP MAX UNIT

Typical Characteristics, Active Mode Supply Current (Into VCC)

www.ti.com

Figure 2. Active Mode Current vs VCC, TA= 25°C Figure 3. Active Mode Current vs DCO Frequency

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

20 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

0.0

−40.0 −20.0 0.0 20.0 40.0 60.0 80.0 100.0 120.0

I − Low−power mode current − µA

LPM3

V = 3.6 V

CC

TA− Temperature − °C

V = 1.8 V

CC

V = 3 V

CC

V = 2.2 V

CC

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

−40.0 −20.0 0.0 20.0 40.0 60.0 80.0 100.0 120.0

TA− Temperature − C

V = 3.6 V

CC

TA− Temperature − C

I − Low−power mode current − µA

LPM4

V = 1.8 V

CC

V = 3 V

CC

V = 2.2 V

CC

MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

Low-Power Mode Supply Currents (Into VCC) Excluding External Current

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

I

LPM0,1MHz

PARAMETER TEST CONDITIONS T

f

= 0 MHz,

MCLK

f

= f

= 1 MHz,

DCO

= 32768 Hz,

Low-power mode 0

(LPM0) current

(3)

SMCLK

f

ACLK

BCSCTL1 = CALBC1_1MHZ, 25°C 2.2 V 56 µA

DCOCTL = CALDCO_1MHZ,

A

CPUOFF = 1, SCG0 = 0, SCG1 = 0,

OSCOFF = 0

f

I

LPM2

Low-power mode 2

(LPM2) current

(4)

= f

MCLK

f

= 1 MHz,

DCO

f

= 32768 Hz,

ACLK

BCSCTL1 = CALBC1_1MHZ, 25°C 2.2 V 22 µA

DCOCTL = CALDCO_1MHZ,

SMCLK

= 0 MHz,

CPUOFF = 1, SCG0 = 0, SCG1 = 1,

OSCOFF = 0

f

= f

I

LPM3,LFXT1

Low-power mode 3 f

(LPM3) current

(4)

DCO

ACLK

CPUOFF = 1, SCG0 = 1, SCG1 = 1,

= f

MCLK

= 32768 Hz,

SMCLK

= 0 MHz,

25°C 2.2 V 1.0 1.5 µA

OSCOFF = 0

f

= f

I

LPM3,VLO

Low-power mode 3 f

current, (LPM3)

(4)

DCO

ACLK

CPUOFF = 1, SCG0 = 1, SCG1 = 1,

= f

MCLK

from internal LF oscillator (VLO),

SMCLK

= 0 MHz,

25°C 2.2 V 0.5 0.7 µA

OSCOFF = 0

f

= f

I

LPM4

Low-power mode 4 f

(LPM4) current

(5)

MCLK

= 0 Hz,

= f

DCO

ACLK

CPUOFF = 1, SCG0 = 1, SCG1 = 1,

OSCOFF = 1

= 0 MHz, 25°C 2.2 V 0.1 0.5

SMCLK

85°C 2.2 V 1.6 2.5

(1) All inputs are tied to 0 V or to VCC. Outputs do not source or sink any current.

(2) The currents are characterized with a Micro Crystal CC4V-T1A SMD crystal with a load capacitance of 9 pF. The internal and external

load capacitance is chosen to closely match the required 9 pF.

(3) Current for brownout and WDT clocked by SMCLK included.

(4) Current for brownout and WDT clocked by ACLK included.

(5) Current for brownout included.

V

CC

MIN TYP MAX UNIT

SLAS800 –MARCH 2013

(1) (2)

µA

Typical Characteristics, Low-Power Mode Supply Currents

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 21

Figure 4. LPM3 Current vs Temperature Figure 5. LPM4 Current vs Temperature

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Schmitt-Trigger Inputs, Ports Px

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

V

V

V

R

C

Positive-going input threshold voltage V

IT+

Negative-going input threshold voltage V

IT–

Input voltage hysteresis (V

hys

Pullup or pulldown resistor 3 V 20 35 50 kΩ

Pull

Input capacitance VIN= VSSor V

I

IT+

– V

) 3 V 0.3 1 V

IT–

For pullup: VIN= V

For pulldown: VIN= V

SS

CC

CC

CC

3 V 1.35 2.25

3 V 0.75 1.65

MIN TYP MAX UNIT

0.45 V

CC

0.25 V

CC

5 pF

Leakage Current, Ports Px

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

I

lkg(Px.y)

PARAMETER TEST CONDITIONS V

High-impedance leakage current

(1) (2)

CC

3 V ±50 nA

(1) The leakage current is measured with VSSor VCCapplied to the corresponding pin(s), unless otherwise noted.

(2) The leakage of the digital port pins is measured individually. The port pin is selected for input and the pullup/pulldown resistor is

disabled.

MIN MAX UNIT

0.75 V

0.55 V

www.ti.com

CC

CC

Outputs, Ports Px

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

V

V

High-level output voltage I

OH

Low-level output voltage I

OL

(1) The maximum total current, I

specified.

(OHmax)

and I

= –6 mA

(OHmax)

= 6 mA

(OLmax)

, for all outputs combined should not exceed ±48 mA to hold the maximum voltage drop

(OLmax)

(1)

(1)

CC

3 V VCC– 0.3 V

3 V VSS+ 0.3 V

MIN TYP MAX UNIT

Output Frequency, Ports Px

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

f

Px.y

f

Port_CLK

PARAMETER TEST CONDITIONS V

Port output frequency

(with load)

Px.y, CL= 20 pF, RL= 1 kΩ

Clock output frequency Px.y, CL= 20 pF

(2)

(1) (2)

CC

3 V 12 MHz

3 V 16 MHz

(1) A resistive divider with two 0.5-kΩ resistors between VCCand VSSis used as load. The output is connected to the center tap of the

divider.

(2) The output voltage reaches at least 10% and 90% VCCat the specified toggle frequency.

MIN TYP MAX UNIT

22 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

VOH− High-Level Output Voltage − V

−25

−20

−15

−10

−5

0

0 0.5 1 1.5 2 2.5

VCC= 2.2 V

P1.7

TA= 25°C

TA= 85°C

OH

I − Typical High-Level Output Current − mA

VOH− High-Level Output Voltage − V

−50

−40

−30

−20

−10

0

0 0.5 1 1.5 2 2.5 3 3.5

VCC= 3 V

P1.7

TA= 25°C

TA= 85°C

OH

I − Typical High-Level Output Current − mA

VOL− Low-Level Output Voltage − V

0

5

10

15

20

25

30

0 0.5 1 1.5 2 2.5

VCC= 2.2 V

P1.7

TA= 25°C

TA= 85°C

OL

I − Typical Low-Level Output Current − mA

VOL− Low-Level Output Voltage − V

0

10

20

30

40

50

0 0.5 1 1.5 2 2.5 3 3.5

VCC= 3 V

P1.7

TA= 25°C

TA= 85°C

OL

I − Typical Low-Level Output Current − mA

www.ti.com

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Typical Characteristics, Outputs

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

TYPICAL LOW-LEVEL OUTPUT CURRENT TYPICAL LOW-LEVEL OUTPUT CURRENT

LOW-LEVEL OUTPUT VOLTAGE LOW-LEVEL OUTPUT VOLTAGE

vs vs

Figure 6. Figure 7.

TYPICAL HIGH-LEVEL OUTPUT CURRENT TYPICAL HIGH-LEVEL OUTPUT CURRENT

HIGH-LEVEL OUTPUT VOLTAGE HIGH-LEVEL OUTPUT VOLTAGE

vs vs

Figure 8. Figure 9.

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

C

LOAD

− External Capacitance − pF

0.00

0.15

0.30

0.45

0.60

0.75

0.90

1.05

1.20

1.35

1.50

10 50 100

P1.y

P2.0 to P2.5

P2.6 and P2.7

VCC= 3.0 V

fosc − Typical Oscillation Frequency − MHz

C

LOAD

− External Capacitance − pF

0.00

0.15

0.30

0.45

0.60

0.75

0.90

1.05

1.20

1.35

1.50

10 50 100

P1.y

P2.0 to P2.5

P2.6 and P2.7

VCC= 2.2 V

fosc − Typical Oscillation Frequency − MHz

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Pin-Oscillator Frequency – Ports Px

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

fo

fo

fo

fo

fo

P1.x

P2.x

P2.6/7

P3.x

P4.x

PARAMETER TEST CONDITIONS V

Port output oscillation frequency 3 V kHz

Port output oscillation frequency 3 V kHz

P1.y, CL= 10 pF, RL= 100 kΩ

P1.y, CL= 20 pF, RL= 100 kΩ

P2.0 to P2.5, CL= 10 pF, RL= 100 kΩ

P2.0 to P2.5, CL= 20 pF, RL= 100 kΩ

Port output oscillation frequency P2.6 and P2.7, CL= 20 pF, RL= 100 kΩ

Port output oscillation frequency 3 V kHz

Port output oscillation frequency 3 V kHz

P3.y, CL= 10 pF, RL= 100 kΩ

P3.y, CL= 20 pF, RL= 100 kΩ

P4.y, CL= 10 pF, RL= 100 kΩ

P4.y, CL= 20 pF, RL= 100 kΩ

(1)(2)

(1)(2)

(1)(2)

(1)(2)

(1)(2)

(1)(2)

(1)(2)

(1)(2)

(1)(2)

CC

3 V 700 kHz

(1) A resistive divider with two 50-kΩ resistors between VCCand VSSis used as load. The output is connected to the center tap of the

divider.

(2) The output voltage reaches at least 10% and 90% VCCat the specified toggle frequency.

MIN TYP MAX UNIT

1400

900

1800

1000

1800

1000

1800

1000

Typical Characteristics, Pin-Oscillator Frequency

TYPICAL OSCILLATING FREQUENCY TYPICAL OSCILLATING FREQUENCY

LOAD CAPACITANCE LOAD CAPACITANCE

vs vs

www.ti.com

A. One output active at a time. A. One output active at a time.

Figure 10. Figure 11.

24 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

0

1

t

d(BOR)

V

CC

V

(B_IT−)

V

hys(B_IT−)

V

CC(star t)

MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

POR and BOR

(1)(2)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

V

CC(start)

V

(B_IT-)

V

hys(B_IT-)

t

d(BOR)

t

(reset)

PARAMETER TEST CONDITIONS V

See Figure 12 dVCC/dt ≤ 3 V/s 0.7 × V

See Figure 12 through Figure 14 dVCC/dt ≤ 3 V/s 1.35 V

See Figure 12 dVCC/dt ≤ 3 V/s 140 mV

See Figure 12 2000 µs

Pulse duration needed at RST/NMI pin

to accepted reset internally

CC

2.2 V 2 µs

(1) The current consumption of the brownout module is already included in the ICCcurrent consumption data. The voltage level V

V

(2) During power up, the CPU begins code execution following a period of t

must not be changed until VCC≥ V

hys(B_IT-)

is ≤ 1.8 V.

CC(min)

, where V

after VCC= V

is the minimum supply voltage for the desired operating frequency.

CC(min)

d(BOR)

MIN TYP MAX UNIT

+ V

(B_IT-)

hys(B_IT-)

SLAS800 –MARCH 2013

(B_IT-)

. The default DCO settings

(B_IT-)

V

+

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

Figure 12. POR and BOR vs Supply Voltage

V

CC

0

0.5

1

1.5

2

V

CC(drop)

t

pw

tpw− Pulse Width − µs

V

CC(drop)

− V

3 V

0.001 1 1000

t

f

t

r

tpw− Pulse Width − µs

tf= t

r

Typical Conditions

VCC= 3 V

V

CC(drop)

V

CC

3 V

t

pw

0

0.5

1

1.5

2

0.001 1 1000

Typical Conditions

1 ns 1 ns

tpw− Pulse Width − µs

V

CC(drop)

− V

tpw− Pulse Width − µs

VCC= 3 V

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

www.ti.com

Typical Characteristics, POR and BOR

Figure 13. V

Figure 14. V

Level With a Square Voltage Drop to Generate a POR and BOR Signal

CC(drop)

Level With a Triangle Voltage Drop to Generate a POR and BOR Signal

CC(drop)

26 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

www.ti.com

DCO Frequency

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

V

CC

f

DCO(0,0)

f

DCO(0,3)

f

DCO(1,3)

f

DCO(2,3)

f

DCO(3,3)

f

DCO(4,3)

f

DCO(5,3)

f

DCO(6,3)

f

DCO(7,3)

f

DCO(8,3)

f

DCO(9,3)

f

DCO(10,3)

f

DCO(11,3)

f

DCO(12,3)

f

DCO(13,3)

f

DCO(14,3)

f

DCO(15,3)

f

DCO(15,7)

S

RSEL

S

DCO

PARAMETER TEST CONDITIONS V

CC

RSELx < 14 1.8 3.6

Supply voltage RSELx = 14 2.2 3.6 V

RSELx = 15 3 3.6

DCO frequency (0, 0) RSELx = 0, DCOx = 0, MODx = 0 3 V 0.06 0.14 MHz

DCO frequency (0, 3) RSELx = 0, DCOx = 3, MODx = 0 3 V 0.07 0.17 MHz

DCO frequency (1, 3) RSELx = 1, DCOx = 3, MODx = 0 3 V 0.15 MHz

DCO frequency (2, 3) RSELx = 2, DCOx = 3, MODx = 0 3 V 0.21 MHz

DCO frequency (3, 3) RSELx = 3, DCOx = 3, MODx = 0 3 V 0.30 MHz

DCO frequency (4, 3) RSELx = 4, DCOx = 3, MODx = 0 3 V 0.41 MHz

DCO frequency (5, 3) RSELx = 5, DCOx = 3, MODx = 0 3 V 0.58 MHz

DCO frequency (6, 3) RSELx = 6, DCOx = 3, MODx = 0 3 V 0.54 1.06 MHz

DCO frequency (7, 3) RSELx = 7, DCOx = 3, MODx = 0 3 V 0.80 1.50 MHz

DCO frequency (8, 3) RSELx = 8, DCOx = 3, MODx = 0 3 V 1.6 MHz

DCO frequency (9, 3) RSELx = 9, DCOx = 3, MODx = 0 3 V 2.3 MHz

DCO frequency (10, 3) RSELx = 10, DCOx = 3, MODx = 0 3 V 3.4 MHz

DCO frequency (11, 3) RSELx = 11, DCOx = 3, MODx = 0 3 V 4.25 MHz

DCO frequency (12, 3) RSELx = 12, DCOx = 3, MODx = 0 3 V 4.30 7.30 MHz

DCO frequency (13, 3) RSELx = 13, DCOx = 3, MODx = 0 3 V 6.00 7.8 9.60 MHz

DCO frequency (14, 3) RSELx = 14, DCOx = 3, MODx = 0 3 V 8.60 13.9 MHz

DCO frequency (15, 3) RSELx = 15, DCOx = 3, MODx = 0 3 V 12.0 18.5 MHz

DCO frequency (15, 7) RSELx = 15, DCOx = 7, MODx = 0 3 V 16.0 26.0 MHz

Frequency step between

range RSEL and RSEL+1

Frequency step between

tap DCO and DCO+1

S

S

= f

RSEL

DCO(RSEL+1,DCO)/fDCO(RSEL,DCO)

= f

DCO

DCO(RSEL,DCO+1)/fDCO(RSEL,DCO)

3 V 1.35 ratio

3 V 1.08 ratio

Duty cycle Measured at SMCLK output 3 V 50 %

MIN TYP MAX UNIT

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Calibrated DCO Frequencies, Tolerance

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS T

1-MHz tolerance over

temperature

1-MHz tolerance over V

1-MHz tolerance overall DCOCTL = CALDCO_1MHZ, -40°C to 85°C 1.8 V to 3.6 V -6 ±3 6 %

8-MHz tolerance over

temperature

8-MHz tolerance over V

8-MHz tolerance overall DCOCTL = CALDCO_8MHZ, -40°C to 85°C 2.2 V to 3.6 V -6 ±3 6 %

12-MHz tolerance over

temperature

12-MHz tolerance over V

12-MHz tolerance overall DCOCTL = CALDCO_12MHZ, -40°C to 85°C 2.7 V to 3.6 V -6 ±3 6 %

16-MHz tolerance over

temperature

16-MHz tolerance over V

16-MHz tolerance overall DCOCTL = CALDCO_16MHZ, -40°C to 85°C 3.3 V to 3.6 V -6 ±3 6 %

(1) This is the frequency change from the measured frequency at 30°C over temperature.

(1)

CC

(1)

CC

(1)

CC

(1)

CC

BCSCTL1 = CALBC1_1MHZ,

DCOCTL = CALDCO_1MHZ, 0°C to 85°C 3 V -3 ±0.5 3 %

calibrated at 30°C and 3 V

BCSCTL1 = CALBC1_1MHZ,

DCOCTL = CALDCO_1MHZ, 30°C 1.8 V to 3.6 V -3 ±2 3 %

calibrated at 30°C and 3 V

BCSCTL1 = CALBC1_1MHZ,

calibrated at 30°C and 3 V

BCSCTL1 = CALBC1_8MHZ,

DCOCTL = CALDCO_8MHZ, 0°C to 85°C 3 V -3 ±0.5 3 %

calibrated at 30°C and 3 V

BCSCTL1 = CALBC1_8MHZ,

DCOCTL = CALDCO_8MHZ, 30°C 2.2 V to 3.6 V -3 ±2 3 %

calibrated at 30°C and 3 V

BCSCTL1 = CALBC1_8MHZ,

calibrated at 30°C and 3 V

BCSCTL1 = CALBC1_12MHZ,

DCOCTL = CALDCO_12MHZ, 0°C to 85°C 3 V -3 ±0.5 3 %

calibrated at 30°C and 3 V

BCSCTL1 = CALBC1_12MHZ,

DCOCTL = CALDCO_12MHZ, 30°C 2.7 V to 3.6 V -3 ±2 3 %

calibrated at 30°C and 3 V

BCSCTL1 = CALBC1_12MHZ,

calibrated at 30°C and 3 V

BCSCTL1 = CALBC1_16MHZ,

DCOCTL = CALDCO_16MHZ, 0°C to 85°C 3 V -3 ±0.5 3 %

calibrated at 30°C and 3 V

BCSCTL1 = CALBC1_16MHZ,

DCOCTL = CALDCO_16MHZ, 30°C 3.3 V to 3.6 V -3 ±2 3 %

calibrated at 30°C and 3 V

BCSCTL1 = CALBC1_16MHZ,

calibrated at 30°C and 3 V

A

V

CC

MIN TYP MAX UNIT

www.ti.com

28 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

DCO Frequency − MHz

0.10

1.00

10.00

0.10 1.00 10.00

DCO Wake Time − µs

RSELx = 0...11

RSELx = 12...15

MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

Wake-Up From Lower-Power Modes (LPM3, LPM4)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

t

DCO,LPM3/4

t

CPU,LPM3/4

(1) The DCO clock wake-up time is measured from the edge of an external wake-up signal (for example, a port interrupt) to the first clock

edge observable externally on a clock pin (MCLK or SMCLK).

(2) Parameter applicable only if DCOCLK is used for MCLK.

DCO clock wake-up time from LPM3 BCSCTL1 = CALBC1_1MHZ,

or LPM4

CPU wake-up time from LPM3 or 1/f

LPM4

(1)

(2)

DCOCTL = CALDCO_1MHZ

CC

3 V 1.5 µs

MIN TYP MAX UNIT

t

Typical Characteristics, DCO Clock Wake-Up Time From LPM3 or LPM4

SLAS800 –MARCH 2013

+

MCLK

Clock,LPM3/4

Figure 15. DCO Wake-Up Time From LPM3 vs DCO Frequency

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

0.00

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

2.25

2.50

−50.0 −25.0 0.0 25.0 50.0 75.0 100.0

TA− Temperature − C

DCO Frequency − MHz

R

OSC

= 100k

R

OSC

= 270k

R

OSC

= 1M

0.00

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

2.25

2.50

2.0 2.5 3.0 3.5 4.0

VCC− Supply Voltage − V

DCO Frequency − MHz

R

OSC

= 100k

R

OSC

= 270k

R

OSC

= 1M

0.01

0.10

1.00

10.00

10.00 100.00 1000.00 10000.00

R

OSC

− External Resistor − kW

DCO Frequency − MHz

RSELx = 4

0.01

0.10

1.00

10.00

10.00 100.00 1000.00 10000.00

R

OSC

− External Resistor − kW

DCO Frequency − MHz

RSELx = 4

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

DCO With External Resistor R

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

f

DCO,ROSC

D

T

D

V

(1) R

OSC

DCO output frequency with R

Temperature drift 3 V ±0.1 %/°C

Drift with V

CC

= 100 kΩ. Metal film resistor, type 0257, 0.6 W with 1% tolerance and TK= ±50 ppm/°C.

OSC

OSC

(1)

CC

MIN TYP MAX UNIT

DCOR = 1,

RSELx = 4, DCOx = 3, MODx = 0, 3 V 1.95 MHz

TA= 25°C

DCOR = 1,

RSELx = 4, DCOx = 3, MODx = 0

DCOR = 1,

RSELx = 4, DCOx = 3, MODx = 0

3 V 10 %/V

www.ti.com

Typical Characteristics - DCO With External Resistor R

DCO FREQUENCY DCO FREQUENCY

vs vs

R

VCC= 2.2 V, TA= 25°C VCC= 3 V, TA= 25°C

OSC

OSC

R

OSC

Figure 16. Figure 17.

DCO FREQUENCY DCO FREQUENCY

vs vs

TEMPERATURE SUPPLY VOLTAGE

VCC= 3 V TA= 25°C

30 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Figure 18. Figure 19.

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

MSP430G2955

MSP430G2855

MSP430G2755

www.ti.com

Crystal Oscillator, XT1, Low-Frequency Mode

(1)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

f

LFXT1,LF

PARAMETER TEST CONDITIONS V

LFXT1 oscillator crystal

frequency, LF mode 0 or 1

XTS = 0, LFXT1Sx = 0 or 1 1.8 V to 3.6 V 32768 Hz

CC

LFXT1 oscillator logic level

f

LFXT1,LF,logic

square wave input frequency, XTS = 0, XCAPx = 0, LFXT1Sx = 3 1.8 V to 3.6 V 10000 32768 50000 Hz

LF mode

XTS = 0, LFXT1Sx = 0,

OA

LF

Oscillation allowance for

LF crystals

f

XTS = 0, LFXT1Sx = 0,

f

LFXT1,LF

LFXT1,LF

= 32768 Hz, C

= 32768 Hz, C

L,eff

L,eff

= 6 pF

= 12 pF

XTS = 0, XCAPx = 0 1

C

L,eff

Integrated effective load

capacitance, LF mode

(2)

XTS = 0, XCAPx = 1 5.5

XTS = 0, XCAPx = 2 8.5

XTS = 0, XCAPx = 3 11

XTS = 0, Measured at P2.0/ACLK,

f

LFXT1,LF

= 32768 Hz

XTS = 0, XCAPx = 0, LFXT1Sx = 3

(4)

2.2 V 10 10000 Hz

f

Fault,LF

Duty cycle, LF mode 2.2 V 30 50 70 %

Oscillator fault frequency,

LF mode

(3)

(1) To improve EMI on the XT1 oscillator, the following guidelines should be observed.

(a) Keep the trace between the device and the crystal as short as possible.

(b) Design a good ground plane around the oscillator pins.

(c) Prevent crosstalk from other clock or data lines into oscillator pins XIN and XOUT.

(d) Avoid running PCB traces underneath or adjacent to the XIN and XOUT pins.

(e) Use assembly materials and praxis to avoid any parasitic load on the oscillator XIN and XOUT pins.

(f) If conformal coating is used, ensure that it does not induce capacitive or resistive leakage between the oscillator pins.

(g) Do not route the XOUT line to the JTAG header to support the serial programming adapter as shown in other documentation. This

signal is no longer required for the serial programming adapter.

(2) Includes parasitic bond and package capacitance (approximately 2 pF per pin).

Because the PCB adds additional capacitance, it is recommended to verify the correct load by measuring the ACLK frequency. For a

correct setup, the effective load capacitance should always match the specification of the used crystal.

(3) Frequencies below the MIN specification set the fault flag. Frequencies above the MAX specification do not set the fault flag.

Frequencies in between might set the flag.

(4) Measured with logic-level input frequency but also applies to operation with crystals.

MIN TYP MAX UNIT

SLAS800 –MARCH 2013

500

200

kΩ

pF

Internal Very-Low-Power Low-Frequency Oscillator (VLO)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER T

f

VLO

df

VLO/dT

df

VLO

Copyright © 2013, Texas Instruments Incorporated Submit Documentation Feedback 31

VLO frequency -40°C to 85°C 3 V 4 12 20 kHz

VLO frequency temperature drift -40°C to 85°C 3 V 0.5 %/°C

/dVCCVLO frequency supply voltage drift 25°C 1.8 V to 3.6 V 4 %/V

A

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

V

CC

MIN TYP MAX UNIT

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013

Crystal Oscillator LFXT1, High-Frequency Mode

PARAMETER TEST CONDITIONS V

f

LFXT1,HF0

f

LFXT1,HF1

f

LFXT1,HF2

f

LFXT1,HF,logic

OA

HF

C

L,eff

f

Fault,HF

LFXT1 oscillator crystal

frequency, HF mode 0

LFXT1 oscillator crystal

frequency, HF mode 1

LFXT1 oscillator crystal

frequency, HF mode 2

XTS = 1, LFXT1Sx = 0 1.8 V to 3.6 V 0.4 1 MHz

XTS = 1, LFXT1Sx = 1 1.8 V to 3.6 V 1 4 MHz

XTS = 1, LFXT1Sx = 2 2.2 V to 3.6 V 2 12 MHz

LFXT1 oscillator logic-level

square-wave input frequency, XTS = 1, LFXT1Sx = 3 2.2 V to 3.6 V 0.4 12 MHz

HF mode

XTS = 1, LFXT1Sx = 0,

f

C

= 1 MHz, 2700

LFXT1,HF

= 15 pF

L,eff

Oscillation allowance for HF XTS = 1, LFXT1Sx = 1,

crystals (see Figure 20 and f

Figure 21) C

= 4 MHz, 800 Ω

LFXT1,HF

= 15 pF

L,eff

XTS = 1, LFXT1Sx = 2,

Integrated effective load

capacitance, HF mode

f

C

(2)

XTS = 1

= 16 MHz, 300

LFXT1,HF

= 15 pF

L,eff

(3)

XTS = 1,

Measured at P2.0/ACLK, 40 50 60

Duty cycle, HF mode 2.2 V, 3 V %

f

XTS = 1,

LFXT1,HF

= 10 MHz

Measured at P2.0/ACLK, 40 50 60

Oscillator fault frequency

f

(4)

XTS = 1, LFXT1Sx = 3

LFXT1,HF

= 16 MHz

(1)

www.ti.com

CC

MIN TYP MAX UNIT

1.8 V to 3.6 V 2 10

3 V to 3.6 V 2 16

1.8 V to 3.6 V 0.4 10

3 V to 3.6 V 0.4 16

1 pF

(5)

2.2 V, 3 V 30 300 kHz

(1) To improve EMI on the XT1 oscillator the following guidelines should be observed:

(a) Keep the trace between the device and the crystal as short as possible.

(b) Design a good ground plane around the oscillator pins.

(c) Prevent crosstalk from other clock or data lines into oscillator pins XIN and XOUT.

(d) Avoid running PCB traces underneath or adjacent to the XIN and XOUT pins.

(e) Use assembly materials and praxis to avoid any parasitic load on the oscillator XIN and XOUT pins.

(f) If conformal coating is used, ensure that it does not induce capacitive or resistive leakage between the oscillator pins.

(g) Do not route the XOUT line to the JTAG header to support the serial programming adapter as shown in other documentation. This

signal is no longer required for the serial programming adapter.

(2) Includes parasitic bond and package capacitance (approximately 2 pF per pin). Because the PCB adds additional capacitance, it is

recommended to verify the correct load by measuring the ACLK frequency. For a correct setup, the effective load capacitance should

always match the specification of the used crystal.

(3) Requires external capacitors at both terminals. Values are specified by crystal manufacturers.

(4) Frequencies below the MIN specification set the fault flag, frequencies above the MAX specification do not set the fault flag, and

frequencies in between might set the flag.

(5) Measured with logic-level input frequency, but also applies to operation with crystals.

32 Submit Documentation Feedback Copyright © 2013, Texas Instruments Incorporated

Product Folder Links: MSP430G2955 MSP430G2855 MSP430G2755

0.0

100.0

200.0

300.0

400.0

500.0

600.0

700.0

800.0

0.0 4.0 8.0 12.0 16.0 20.0

Crystal Frequency − MHz

XT Oscillator Supply Current − uA

LFXT1Sx = 1

LFXT1Sx = 3

LFXT1Sx = 2

Crystal Frequency − MHz

10.00

100.00

1000.00

10000.00

100000.00

0.10 1.00 10.00 100.00

Oscillation Allowance − Ohms

LFXT1Sx = 1

LFXT1Sx = 3

LFXT1Sx = 2

www.ti.com

MSP430G2955

MSP430G2855

MSP430G2755

SLAS800 –MARCH 2013