Texas Instruments LM3671LC, LM3671LC-1.2, LM3671LC-1.3, LM3671LC-1.6, LM3671LC-1.8 User Manual

...

1

2

5

43

V

IN

SW

FB

EN

GND

L1: 2.2 PH

V

OUT

C

OUT

10 PF

C

IN

4.7 PF

LM3671

V

IN

2.7V to 5.5V

www.ti.com

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

LM3671, LM3671Q 2MHz, 600mA Step-Down DC-DC Converter

Check for Samples: LM3671, LM3671Q

1

FEATURES

2

• 16 µA Typical Quiescent Current

• 600 mA Maximum Load Capability • PDAs

• 2 MHz PWM Fixed Switching Frequency (typ.) • MP3 Players

• Automatic PFM/PWM Mode Switching • W-LAN

• Internal Synchronous Rectification for High • Portable Instruments

Efficiency

• Internal Soft start

• 0.01 µA Typical Shutdown Current

• Operates from a Single Li-Ion Cell Battery

• Only Three Tiny Surface-Mount External

Components Required (One Inductor, Two

Ceramic Capacitors)

• Current Overload and Thermal Shutdown

Protection

• Available in Fixed Output Voltages and

Adjustable Version

• LM3671Q is an Automotive Grade Product that

is AEC-Q100 Grade 1 Qualified

• SOT-23, 5-Bump DSBGA and 6-Pin USON

Packages

APPLICATIONS

• Mobile Phones

• Digital Still Cameras

• Portable Hard Disk Drives

• Automotive

DESCRIPTION

The LM3671 step-down DC-DC converter is

optimized for powering low voltage circuits from a

single Li-Ion cell battery and input voltage rails from

2.7V to 5.5V. It provides up to 600 mA load current,

over the entire input voltage range. There are several

different fixed voltage output options available as well

as an adjustable output voltage version range from

1.1V to 3.3V.

The device offers superior features and performance

for mobile phones and similar portable systems.

Automatic intelligent switching between PWM lownoise and PFM low-current mode offers improved

system control. During PWM mode, the device

operates at a fixed-frequency of 2 MHz (typ.).

Hysteretic PFM mode extends the battery life by

reducing the quiescent current to 16 µA (typ.) during

light load and standby operation. Internal

synchronous rectification provides high efficiency

during PWM mode operation. In shutdown mode, the

device turns off and reduces battery consumption to

0.01 µA (typ.).

LM3671

LM3671Q

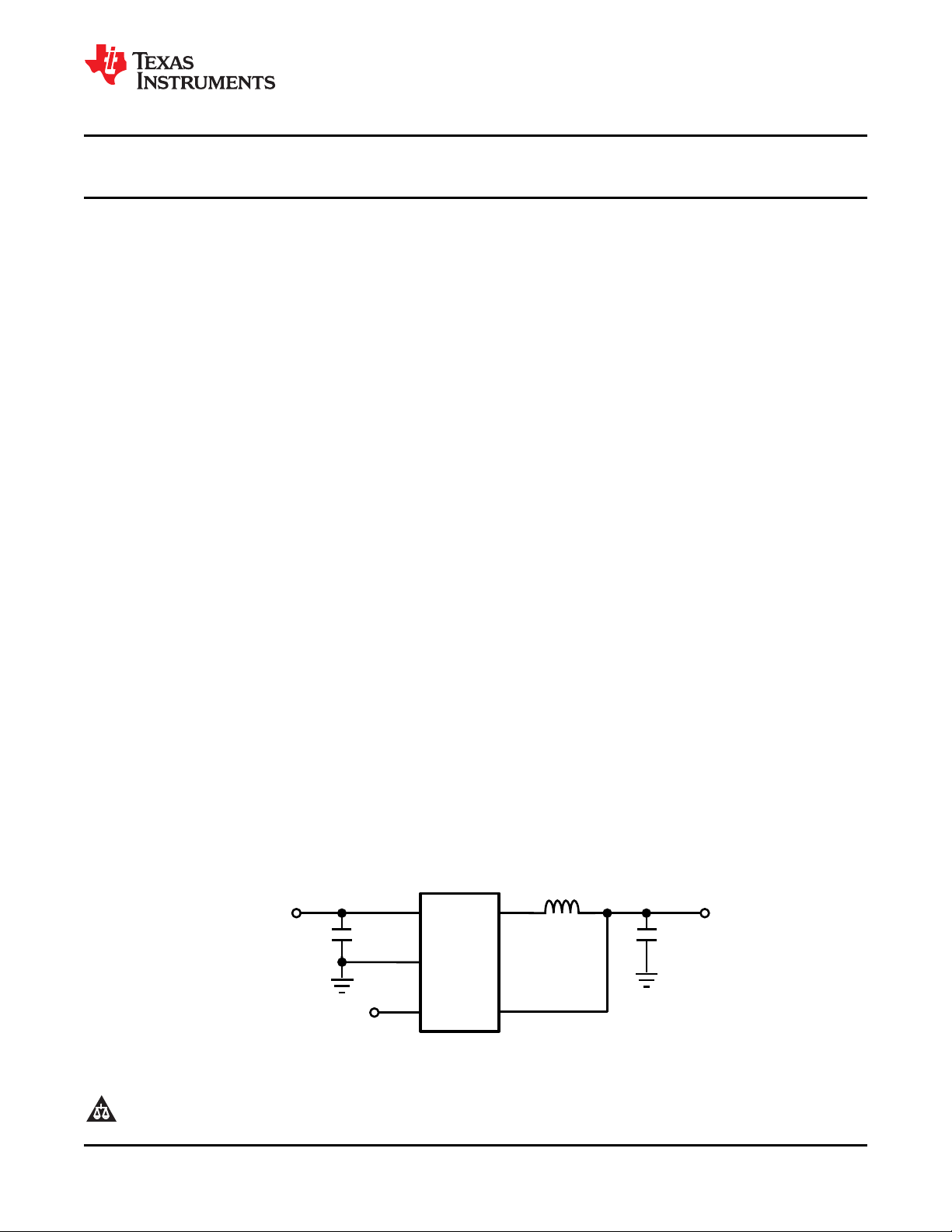

TYPICAL APPLICATION CIRCUITS

Figure 1. Typical Application Circuit

1

2All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2004–2013, Texas Instruments Incorporated

A3

Top View Bottom View

A1

C1

A3

C3

EN

FB

SW

GND

V

IN

EN

GND

SW

FB

B2

V

IN

A1

C3

C1

B2

V

IN

1

GND2EN

3

FB

4

SW

5

1

2

5

43

V

IN

SW

FB

EN

GND

L1: 2.2 PH

V

OUT

C

OUT

10 PF

C

IN

4.7 PF

LM3671-

ADJ

V

IN

2.7V to 5.5V

R1

R2

C1

C2

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

DESCRIPTION (CONTINUED)

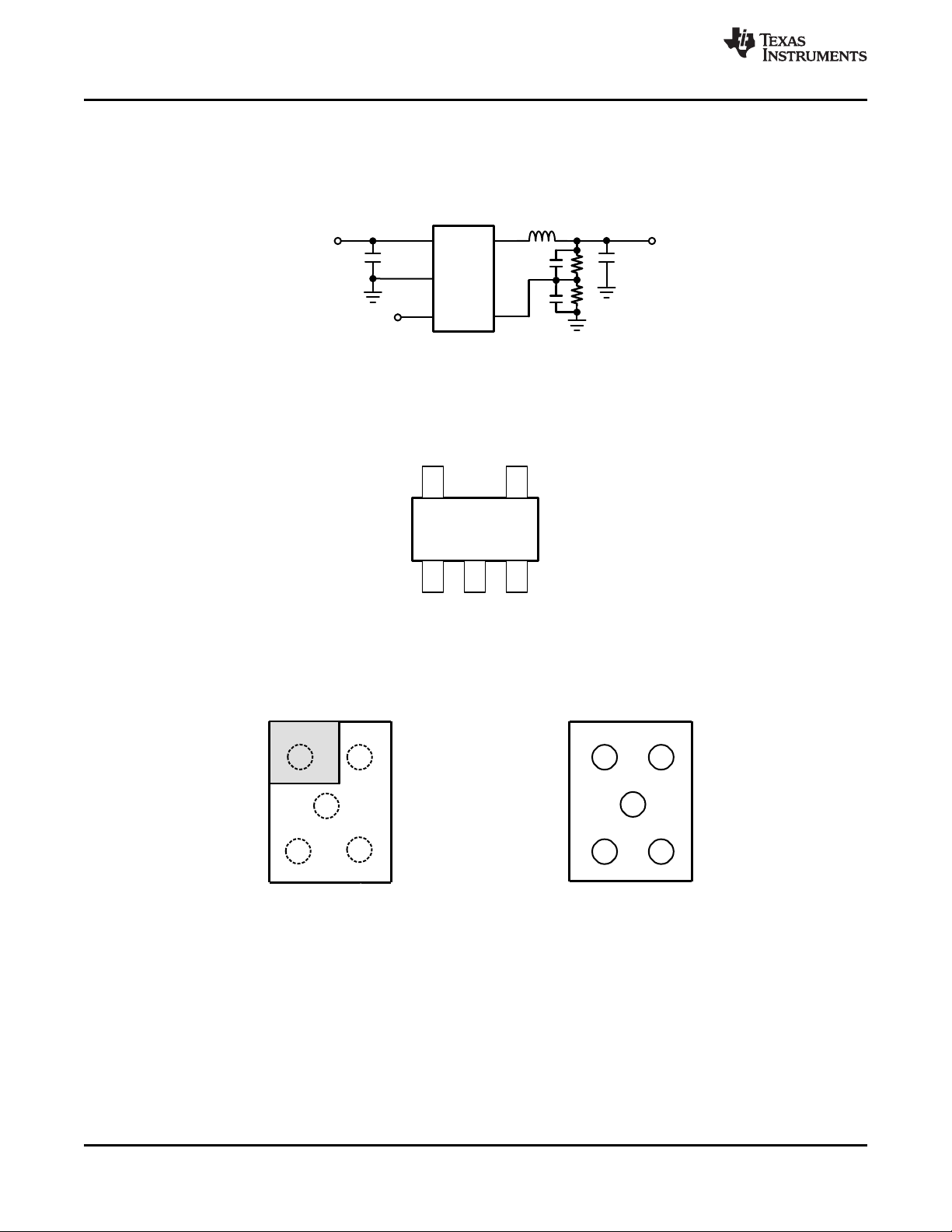

The LM3671 is available in SOT-23, tiny 5-bump DSBGA and a 6-pin USON packages in leaded (PB) and leadfree (NO PB) versions. A high-switching frequency of 2 MHz (typ.) allows use of tiny surface-mount components.

Only three external surface-mount components, an inductor and two ceramic capacitors, are required.

Figure 2. Typical Application Circuit for ADJ version

Connection Diagrams

www.ti.com

Figure 3. Top View

SOT-23 Package

See Package Number DBV (2.92 mm x 2.84 mm x 1.2 mm)

Figure 4. 5-Bump DSBGA Package

See Package Number YZR0005 (1.05 mm x 1.38 mm x 0.6 mm)

2 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Product Folder Links: LM3671 LM3671Q

1

3 4

6

En

Pgnd

Vin

2

5

Sw

Sgnd

Fb

TOP VIEW

www.ti.com

Pin # Name Description

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

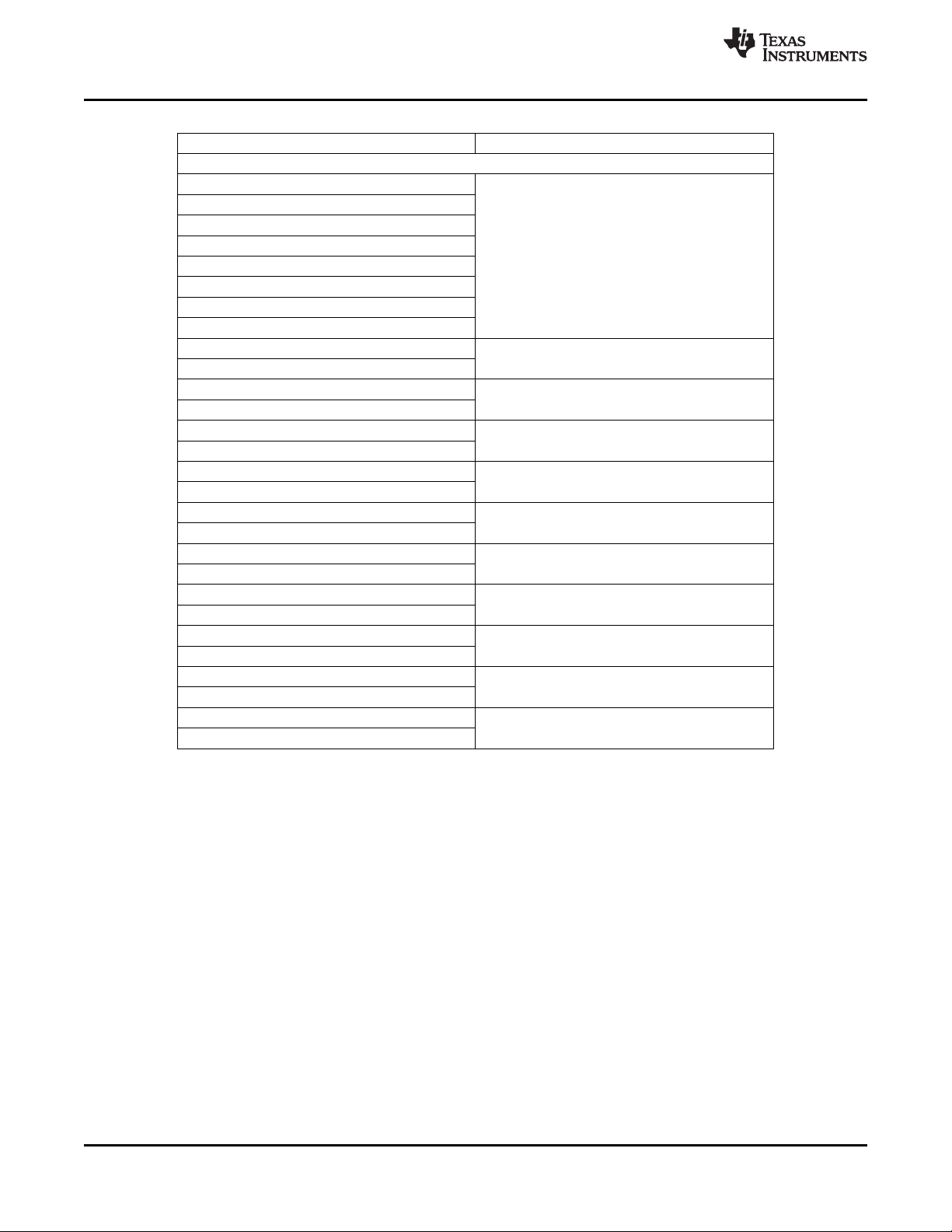

Figure 5. 6-Pin USON Package

See Package Number NKH0006B (2 mm x 2 mm x 0.6 mm)

PIN DESCRIPTIONS (SOT-23)

1 V

IN

2 GND Ground pin.

3 EN Enable pin. The device is in shutdown mode when voltage to this pin is <0.4V and enabled

4 FB Feedback analog input. Connect directly to the output filter capacitor for fixed voltage

5 SW Switching node connection to the internal PFET switch and NFET synchronous rectifier.

Power supply input. Connect to the input filter capacitor (Figure 1).

when >1.0V. Do not leave this pin floating.

versions. For adjustable version external resistor dividers are required (Figure 2). The

internal resistor dividers are disabled for the adjustable version.

PIN DESCRIPTIONS (5-Bump DSBGA)

Pin # Name Description

A1 V

IN

Power supply input. Connect to the input filter capacitor (Figure 1).

A3 GND Ground pin.

C1 EN Enable pin. The device is in shutdown mode when voltage to this pin is <0.4V and enabled

when >1.0V. Do not leave this pin floating.

C3 FB Feedback analog input. Connect directly to the output filter capacitor for fixed voltage

versions. For adjustable version external resistor dividers are required (Figure 2). The

internal resistor dividers are disabled for the adjustable version.

B2 SW Switching node connection to the internal PFET switch and NFET synchronous rectifier.

PIN DESCRIPTIONS (6-Pin USON)

Pin # Name Description

1 EN Enable pin. The device is in shutdown mode when voltage to this pin is <0.4V and enabled

2 Pgnd Ground pin.

3 V

IN

4 SW Switching node connection to the internal PFET switch and NFET synchronous rectifier.

5 Sgnd Singnal ground (feedback ground).

6 FB Feedback analog input. Connect directly to the output filter capacitor for fixed voltage

These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam

during storage or handling to prevent electrostatic damage to the MOS gates.

when >1.0V. Do not leave this pin floating.

Power supply input. Connect to the input filter capacitor (Figure 1).

versions. For adjustable version external resistor dividers are required (Figure 2). The

internal resistor dividers are disabled for the adjustable version.

Copyright © 2004–2013, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Links: LM3671 LM3671Q

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

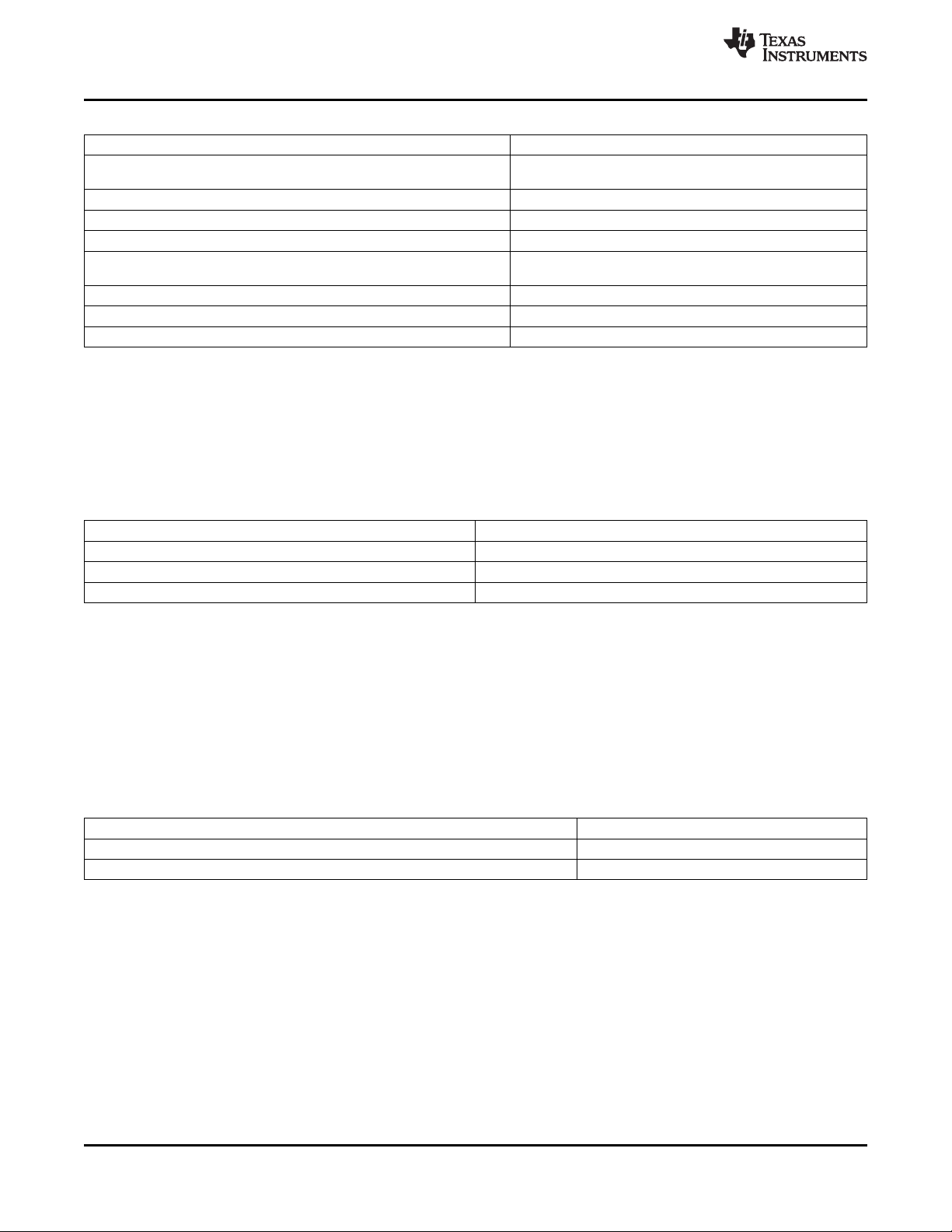

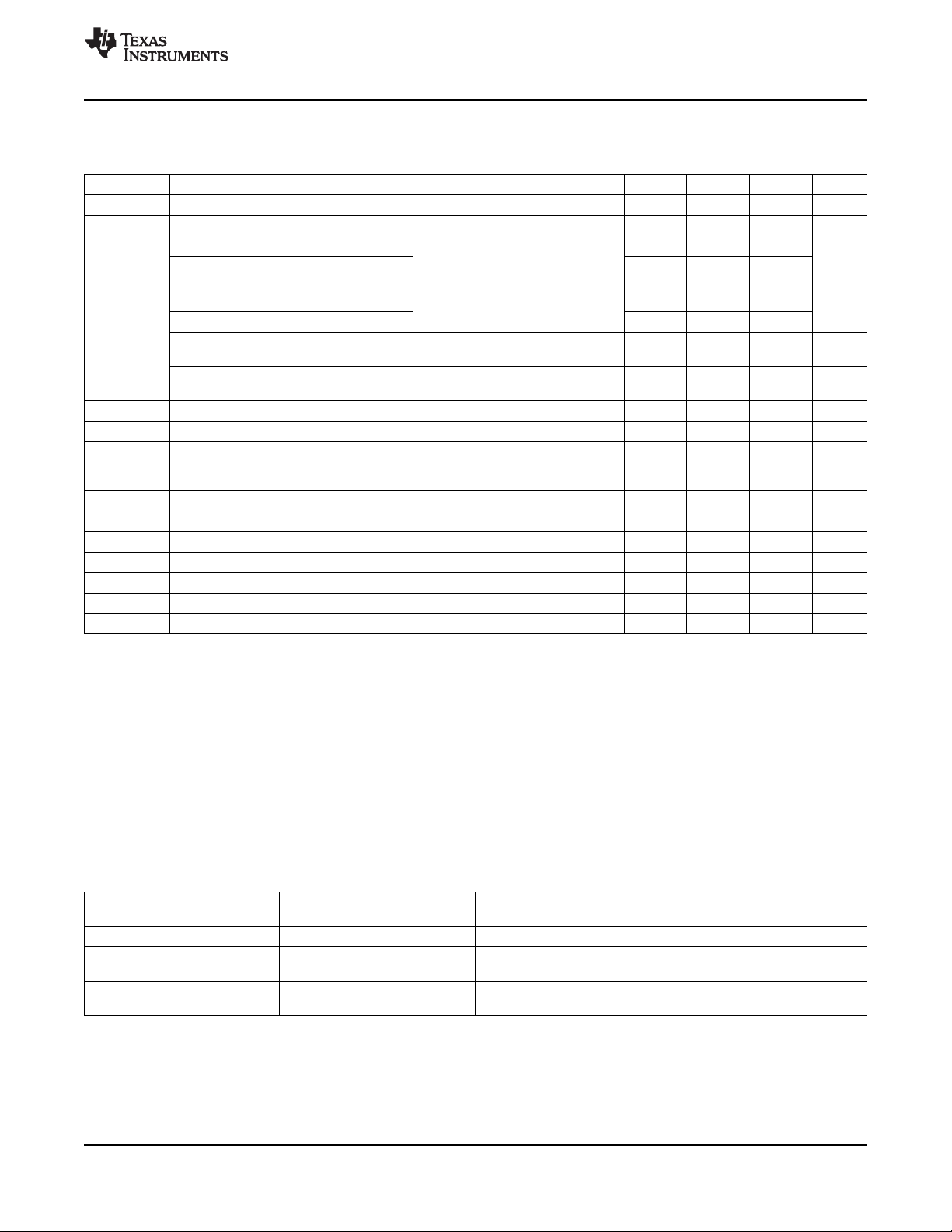

Orderable Voltage Option (V)

SOT-23 Package

LM3671MF-1.2

LM3671MFX-1.2

LM3671MF-1.2/NOPB

LM3671MFX-1.2/NOPB

LM3671QMF-1.2

LM3671QMFX-1.2

LM3671QMF-1.2/NOPB

LM3671QMFX-1.2/NOPB

LM3671MF-1.25/NOPB

LM3671MFX-1.25/NOPB

LM3671MF-1.375/NOPB

LM3671MFX-1.375/NOPB

LM3671MF-1.5/NOPB

LM3671MFX-1.5/NOPB

LM3671MF-1.6/NOPB

LM3671MFX-1.6/NOPB

LM3671MF-1.8/NOPB

LM3671MFX-1.8/NOPB

LM3671MF-1.875/NOPB

LM3671MFX-1.875/NOPB

LM3671MF-2.5/NOPB

LM3671MFX-2.5/NOPB

LM3671MF-2.8/NOPB

LM3671MFX-2.8/NOPB

LM3671MF-3.3/NOPB

LM3671MFX-3.3/NOPB

LM3671MF-ADJ/NOPB

LM3671MFX-ADJ/NOPB

(1) For the most current package and ordering information, see the Package Option Addendum at the end

of this document, or see the TI web site at www.ti.com.

(2) Package drawings, thermal data, and symbolization are available at www.ti.com/packaging.

ORDERING INFORMATION

www.ti.com

(1)(2)

1.2

1.25

1.375

1.5

1.6

1.8

1.875

2.5

2.8

3.3

Adjustable

4 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Product Folder Links: LM3671 LM3671Q

www.ti.com

DSBGA Package

LM3671TL-1.2/NOPB

LM3671TLX-1.2/NOPB

LM3671TL-1.25/NOPB

LM3671TLX-1.25/NOPB

LM3671TL-1.5/NOPB

LM3671TLX-1.5/NOPB

LM3671TL-1.8/NOPB

LM3671TLX-1.8/NOPB

LM3671TL-1.875/NOPB

LM3671TLX-1.875/NOPB

LM3671TL-2.5/NOPB

LM3671TLX-2.5/NOPB

LM3671TL-2.8/NOPB

LM3671TLX-2.8/NOPB

LM3671TL-3.3/NOPB

LM3671TLX-3.3/NOPB

LM3671TL-ADJ/NOPB

LM3671TLX-ADJ/NOPB

USON Package

LM3671LC-1.2/NOPB

LM3671LCX-1.2/NOPB

LM3671LC-1.3/NOPB

LM3671LCX-1.3/NOPB

LM3671LC-1.6/NOPB

LM3671LCX-1.6/NOPB

LM3671LC-1.8/NOPB

LM3671LCX-1.8/NOPB

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

ORDERING INFORMATION

Orderable Voltage Option (V)

(1)(2)

(continued)

1.2

1.25

1.5

1.8

1.875

2.5

2.8

3.3

Adjustable

1.2

1.3

1.6

1.8

LM3671

LM3671Q

Copyright © 2004–2013, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Links: LM3671 LM3671Q

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

ABSOLUTE MAXIMUM RATINGS

(1)(2)

VINPin: Voltage to GND −0.2V to 6.0V

FB, SW, EN Pin: (GND−0.2V) to

Continuous Power Dissipation

Junction Temperature (T

(3)

) +125°C

J-MAX

Storage Temperature Range −65°C to +150°C

Maximum Lead Temperature 260°C

(Soldering, 10 sec.)

ESD Rating

(4)

Human Body Model 2 kV

Machine Model 200V

(1) Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings are conditions under

which operation of the device is specified. Operating Ratings do not imply specified performance limits. For specified performance limits

and associated test conditions, see the Electrical Characteristics tables.

(2) If Military/Aerospace specified devices are required, please contact the Texas Instruments Sales Office / Distributors for

availability and specifications.

(3) Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at TJ= 150°C (typ.) and

disengages at TJ= 130°C (typ.).

(4) The Human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin. The machine model is a 200 pF

capacitor discharged directly into each pin. MIL-STD-883 3015.7

www.ti.com

(VIN+ 0.2V)

Internally Limited

OPERATING RATINGS

Input Voltage Range

(3)

(1) (2)

2.7V to 5.5V

Recommended Load Current 0mA to 600 mA

Junction Temperature (TJ) Range −40°C to +125°C

Ambient Temperature (TA) Range

(4)

−40°C to +85°C

(1) Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings are conditions under

which operation of the device is specified. Operating Ratings do not imply specified performance limits. For specified performance limits

and associated test conditions, see the Electrical Characteristics tables.

(2) All voltages are with respect to the potential at the GND pin.

(3) The input voltage range recommended for ideal applications performance for the specified output voltages are given below:VIN= 2.7V to

4.5V for 1.1V ≤ V

V

DROPOUT

(4) In Applications where high power dissipation and/or poor package resistance is present, the maximum ambient temperature may have

= I

to be derated. Maximum ambient temperature (T

maximum power dissipation of the device in the application (P

in the application, as given by the following equation:T

different ambient temperatures.

< 1.5VVIN= 2.7V to 5.5V for 1.5V ≤ V

OUT

LOAD

*( R

DSON, PFET

+ R

INDUCTOR

< 1.8VVIN= (V

)

A-MAX

OUT

) is dependent on the maximum operating junction temperature (T

) and the junction to ambient thermal resistance of the package (θJA)

D-MAX

= T

A-MAX

J-MAX

− (θJAx P

+ V

OUT

). Refer to Dissipation rating table for P

D-MAX

DROPOUT

) to 5.5V for 1.8V ≤ V

≤ 3.3Vwhere

OUT

J-MAX

D-MAX

), the

values at

THERMAL PROPERTIES

Junction-to-Ambient Thermal Resistance (θJA) (SOT-23) for 4-layer board

Junction-to-Ambient Thermal Resistance (θJA) (DSBGA) for 4-layer board

Junction-to-Ambient Thermal Resistance (θJA) (USON) for 4-layer board

(1) Junction to ambient thermal resistance is highly application and board layout dependent. In applications where high power dissipation

exists, special care must be given to thermal dissipation issues in board design. Specified value of 130 °C/W for SOT-23 is based on a 4

layer, 4" x 3", 2/1/1/2 oz. Cu board as per JEDEC standards is used.

(1)

(1)

(1)

130°C/W

85°C/W

165°C/W

6 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Product Folder Links: LM3671 LM3671Q

LM3671

LM3671Q

www.ti.com

ELECTRICAL CHARACTERISTICS

(1)(2)(3)

Limits in standard typeface are for TJ= 25°C. Limits in boldface type apply over the entire junction temperature range for

operation, −40°C to +125°C. Unless otherwise noted, specifications apply to the LM3671MF/TL/LC with VIN= EN = 3.6V

Symbol Parameter Condition Min Typ Max Units

V

IN

Input Voltage

Feedback Voltage (Fixed) MF −4 +4

Feedback Voltage (Fixed) TL PWM mode

Feedback Voltage (Fixed) LC −4 +4

Feedback Voltage (ADJ) MF

V

FB

(6)

Feedback Voltage (ADJ) TL −2.5 +2.5

Line Regulation 0.031 %/V

Load Regulation 0.0013 %/mA

V

REF

I

SHDN

I

Q

R

DSON (P)

R

DSON (N)

I

LIM

V

IH

V

IL

I

EN

F

OSC

Internal Reference Voltage 0.5 V

Shutdown Supply Current EN = 0V 0.01 1 µA

DC Bias Current into V

IN

Pin-Pin Resistance for PFET VIN= VGS= 3.6V 380 500 mΩ

Pin-Pin Resistance for NFET VIN= VGS= 3.6V 250 400 mΩ

Switch Peak Current Limit Open Loop

Logic High Input 1.0 V

Logic Low Input 0.4 V

Enable (EN) Input Current 0.01 1 µA

Internal Oscillator Frequency PWM Mode

(1) All voltages are with respect to the potential at the GND pin.

(2) Min and Max limits are specified by design, test or statistical analysis. Typical numbers are not specified, but do represent the most

likely norm.

(3) The parameters in the electrical characteristic table are tested at VIN= 3.6V unless otherwise specified. For performance over the input

voltage range refer to datasheet curves.

(4) The input voltage range recommended for ideal applications performance for the specified output voltages are given below:VIN= 2.7V to

4.5V for 1.1V ≤ V

V

DROPOUT

(5) Test condition: for V

= I

(6) ADJ version is configured to 1.5V output. For ADJ output version: VIN= 2.7V to 4.5V for 0.90V ≤ V

≤ V

< 3.3V

OUT

(7) Refer to datasheet curves for closed loop data and its variation with regards to supply voltage and temperature. Electrical Characteristic

< 1.5VVIN= 2.7V to 5.5V for 1.5V ≤ V

OUT

LOAD

*( R

DSON, PFET

less than 2.5V, VIN= 3.6V; for V

OUT

+ R

INDUCTOR

)

table reflects open loop data (FB=0V and current drawn from SW pin ramped up until cycle by cycle current limit is activated). Closed

loop current limit is the peak inductor current measured in the application circuit by increasing output current until output voltage drops

by 10%.

(4)

(5)

PWM mode

(5)

2.7V ≤ VIN≤ 5.5V

IO= 10 mA

100 mA ≤ IO≤ 600 mA

VIN= 3.6V

No load, device is not switching (FB

forced higher than programmed 16 35 µA

output voltage)

(7)

(5)

< 1.8VVIN= (V

OUT

greater than or equal to 2.5V, VIN= V

OUT

OUT

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

2.7 5.5 V

−2.5 +2.5 %

−4 +4

830 1020 1150 mA

1.6 2 2.6 MHz

+ V

DROPOUT

) to 5.5V for 1.8V ≤ V

+ 1V.

OUT

< 1.1VVIN= 2.7V to 5.5V for 1.1V

OUT

≤ 3.3Vwhere

OUT

%

DISSIPATION RATING TABLE

θ

JA

130°C/W (4 layer board) SOT-23 770 mW 500 mW 310 mW

85°C/W (4 layer board) 5-bump 1179 mW 765 mW 470 mW

DSBGA

165°C/W (4 layer board) 6-pin 606 mW 394 mW 242 mW

USON

Copyright © 2004–2013, Texas Instruments Incorporated Submit Documentation Feedback 7

TA≤ 25°C TA= 60°C TA= 85°C

Power Rating Power Rating Power Rating

Product Folder Links: LM3671 LM3671Q

2 MHz

Oscillator

Soft

Start

Ramp

Generator

Thermal

Shutdown

Undervoltage

Lockout

Frequency

Compensation

+

-

Error

Amp

Control Logic Driver

Current Limit

Comparator

Ref1

PFM Current

Comparator

Ref2

SW

Zero Crossing

Comparator

FB

EN

V

IN

PWM Comparator

pfm_low

pfm_hi

GND

Bandgap

+

-

Vcomp

1.0V

Fixed Ver

Adj Ver

+

-

0.5V

+

-

+

-

+

-

V

REF

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

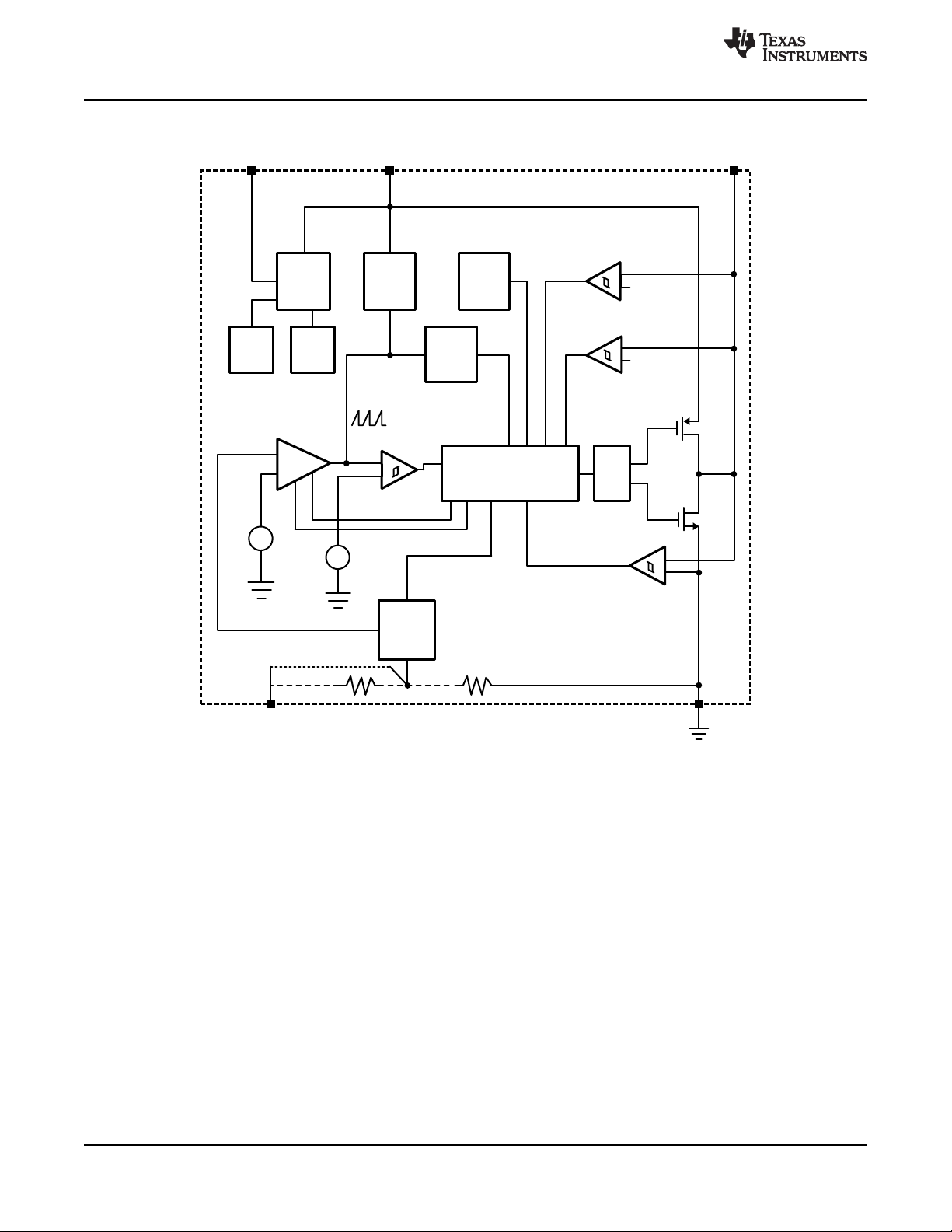

BLOCK DIAGRAM

www.ti.com

8 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Figure 6. Simplified Functional Diagram

Product Folder Links: LM3671 LM3671Q

-10 10 30 50 70 90 110

TEMPERATURE (oC)

100

150

200

250

300

350

400

450

500

550

600

R

DS(ON)

(m:)

-30

NFET

VIN = 4.5V

PFET

VIN = 2.7V

VIN = 4.5V

VIN = 3.6V

VIN = 3.6V

VIN = 2.7V

3.0 3.5 4.0 4.5 5.0 5.5 6.0

SUPPLY VOLTAGE (V)

10

12

14

16

18

20

QUIESCENT CURRENT (P

A

)

2.5

TA = 85°C

EN = V

IN

I

OUT

= 0 mA

TA = 25°C

TA = -30°C

-10 10 30 50 70 90

TEMPERATURE (°C)

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

SHUTDOWN CURRENT (PA)

-30

EN = GND

VIN = 3.6V

VIN = 2.7V

VIN = 5.5V

www.ti.com

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

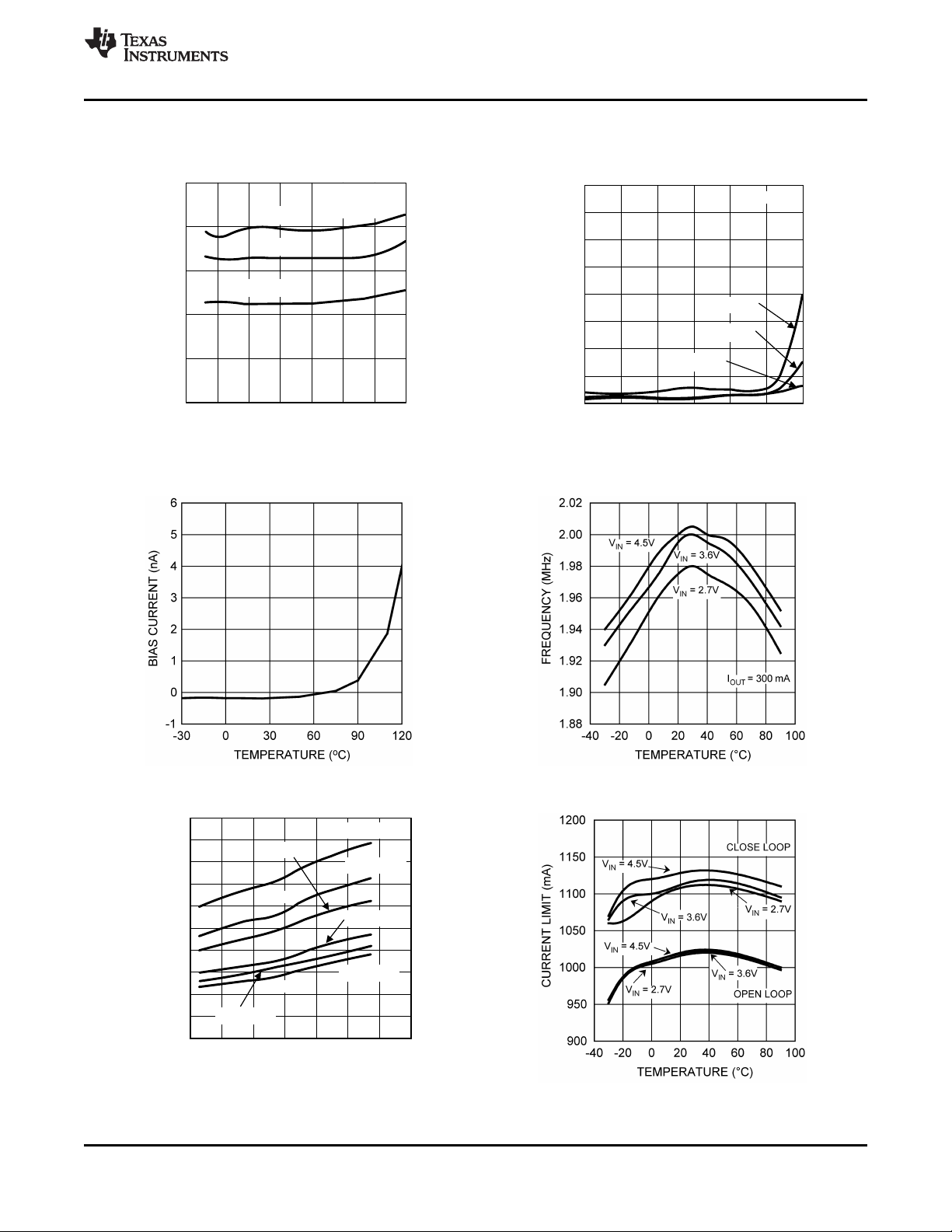

TYPICAL PERFORMANCE CHARACTERISTICS

LM3671MF/TL/LC, Circuit of Figure 1, VIN= 3.6V, V

Quiescent Supply Current vs. Supply Voltage Shutdown Current vs. Temp

Figure 7. Figure 8.

Feedback Bias Current vs. Temp Switching Frequency vs. Temperature

= 1.5V, TA= 25°C, unless otherwise noted.

OUT

LM3671

LM3671Q

Figure 9. Figure 10.

R

vs. Temperature Open/Closed Loop Current Limit vs. Temperature

DS(ON)

Copyright © 2004–2013, Texas Instruments Incorporated Submit Documentation Feedback 9

Figure 11. Figure 12.

Product Folder Links: LM3671 LM3671Q

0 100 200 300 400 500 600

OUTPUT CURRENT (mA)

1.48

1.5

1.52

1.54

OUTPUT VOLTAGE (V)

VIN = 3.6V

V

OUT

= 1.5V

PFM Mode

PWM Mode

-10 10 30 50 70 90

TEMPERATURE (oC)

1.4800

1.4850

1.4900

1.4950

1.5000

1.5050

1.5100

1.5150

1.5200

1.5250

1.5300

OUTPUT VOLTAGE (V)

-30

PFM Mode

PWM Mode

I

OUT

= 300 mA

VIN = 3.6V

V

OUT

= 1.5V

I

OUT

= 600 mA

I

OUT

= 10 mA

2.5 3 3.5 4 4.5 5 5.5

SUPPLY VOLTAGE(V)

1.4800

1.4900

1.5000

1.5100

1.5200

1.5300

= 10 mAI

OUT

= 1.5 V

OUT

V

= 300 mA

I

OUT

= 500 mA

I

OUT

= 600 mA

I

OUT

OUTPUT VOLTAGE (V)

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

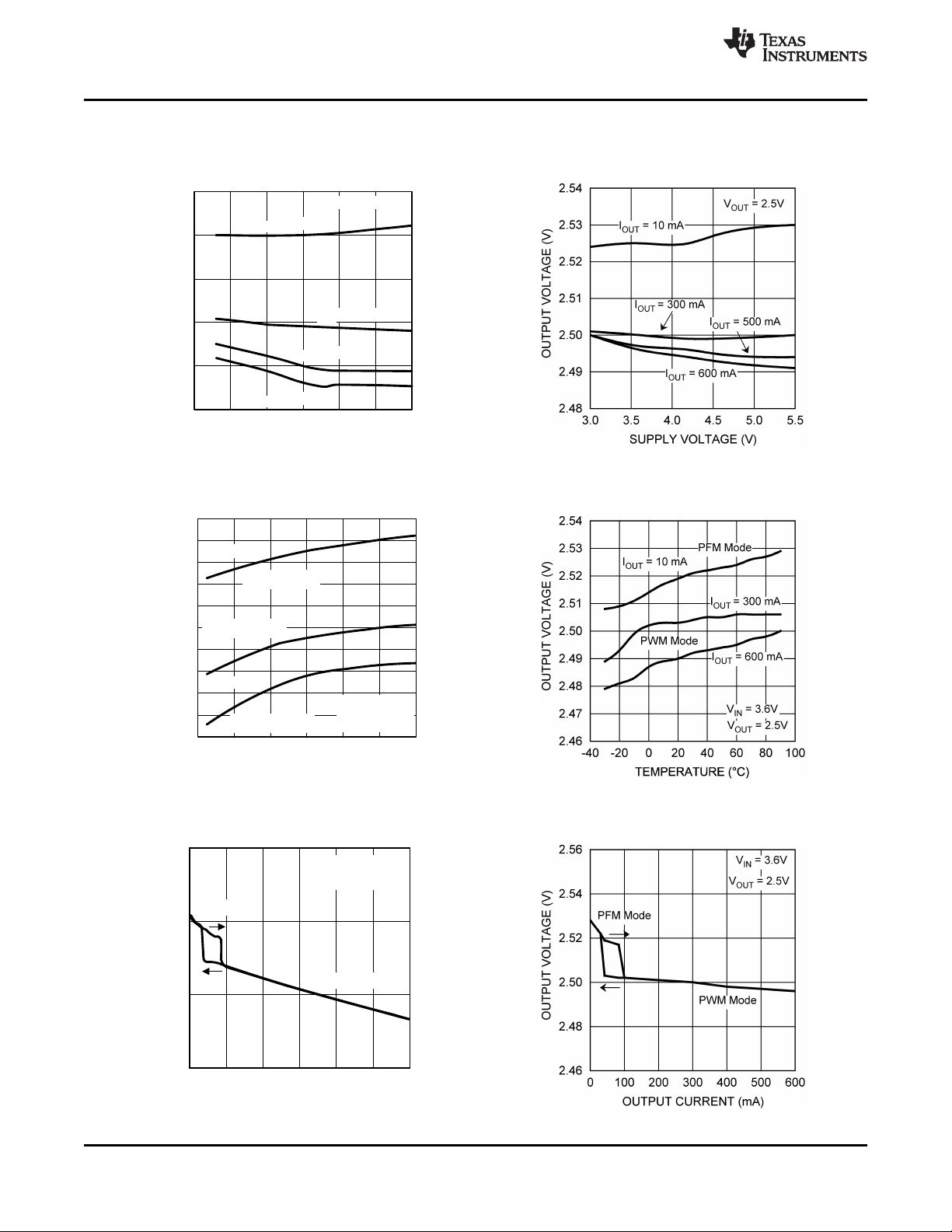

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

LM3671MF/TL/LC, Circuit of Figure 1, VIN= 3.6V, V

Output Voltage vs. Supply Voltage Output Voltage vs. Supply Voltage

(V

= 1.5V) (V

OUT

Figure 13. Figure 14.

= 1.5V, TA= 25°C, unless otherwise noted.

OUT

OUT

www.ti.com

= 2.5V)

Output Voltage vs. Temperature Output Voltage vs. Temperature

(V

= 1.5V) (V

OUT

OUT

= 2.5V)

Figure 15. Figure 16.

Output Voltage vs. Output Current Output Voltage vs. Output Current

(V

= 1.5V) (V

OUT

OUT

= 2.5V)

10 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Figure 17. Figure 18.

Product Folder Links: LM3671 LM3671Q

V

OUT

40 Ps/DIV

3.6V

V

IN

3.0V

20 mV/DIV

AC Coupled

V

OUT

= 1.5V

I

OUT

= 400 mA

0.10 1.00 10.00 100.00 1000.00

OUTPUT CURRENT (mA)

20

30

40

50

60

70

80

90

100

EFFICIENCY (%)

0.01

VIN = 2.7V

VIN = 2.7V

VIN = 4.5V

VIN = 3.6V

V

OUT

= 1.5V

0.10 1.00 10.00 100.00 1000.00

OUTPUT CURRENT (mA)

20

30

40

50

60

70

80

90

100

EFFICIENCY (%)

0.01

VIN = 3.0V

VIN = 3.0V

VIN = 4.5V

VIN = 3.6V

V

OUT

= 1.8V

www.ti.com

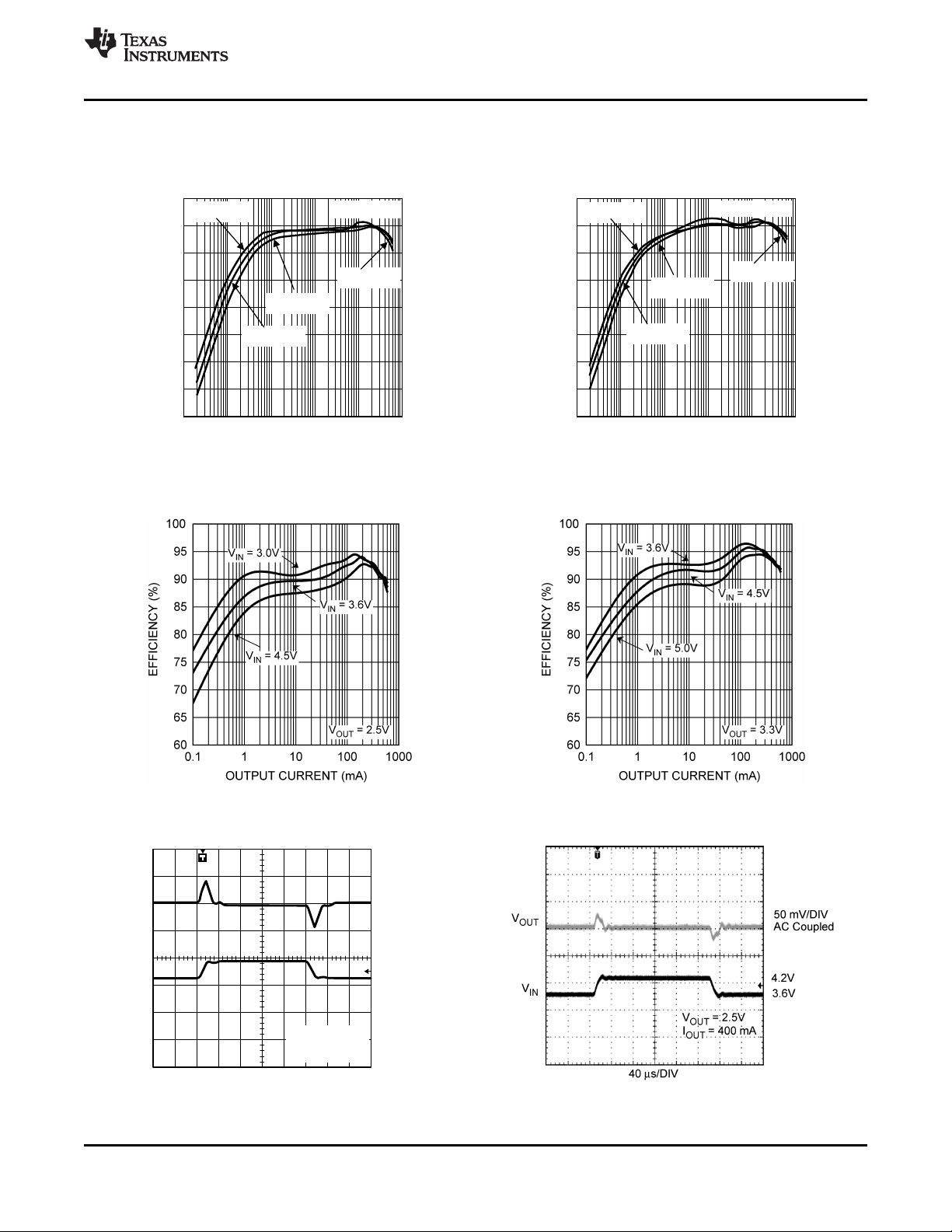

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

LM3671MF/TL/LC, Circuit of Figure 1, VIN= 3.6V, V

Efficiency vs. Output Current Efficiency vs. Output Current

(V

= 1.5V, L= 2.2 µH) (V

OUT

Figure 19. Figure 20.

Efficiency vs. Output Current Efficiency vs. Output Current

(V

= 2.5V, L= 2.2 µH) (V

OUT

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

= 1.5V, TA= 25°C, unless otherwise noted.

OUT

OUT

OUT

LM3671

LM3671Q

= 1.8V, L= 2.2 µH)

= 3.3V, L= 2.2 µH)

Figure 21. Figure 22.

Line Transient Response Line Transient Response

V

= 1.5V (PWM Mode) V

OUT

Figure 23. Figure 24.

Product Folder Links: LM3671 LM3671Q

Copyright © 2004–2013, Texas Instruments Incorporated Submit Documentation Feedback 11

= 2.5V (PWM Mode)

OUT

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

LM3671MF/TL/LC, Circuit of Figure 1, VIN= 3.6V, V

Load Transient Response Load Transient Response

V

= 1.5V (PWM Mode) V

OUT

Figure 25. Figure 26.

= 1.5V, TA= 25°C, unless otherwise noted.

OUT

OUT

www.ti.com

= 2.5V (PWM Mode)

Load Transient Response (V

(PFM Mode 0.5 mA to 50 mA) (PFM Mode 50 mA to 0.5 mA)

Figure 27. Figure 28.

Load Transient Response (V

(PFM Mode 0.5 mA to 50 mA) (PFM Mode 50 mA to 0.5 mA)

= 1.5V) Load Transient Response (V

OUT

= 2.5V) Load Transient Response (V

OUT

OUT

OUT

= 1.5V)

= 2.5V)

Figure 29. Figure 30.

12 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Product Folder Links: LM3671 LM3671Q

V

OUT

TIME (100 Ps/DIV)

EN

V

SW

2V/DIV

500 mA/DIV

VIN = 3.6V

V

OUT

= 1.5V

2V/DIV

I

OUT

= 300 mA

I

L

1V/DIV

www.ti.com

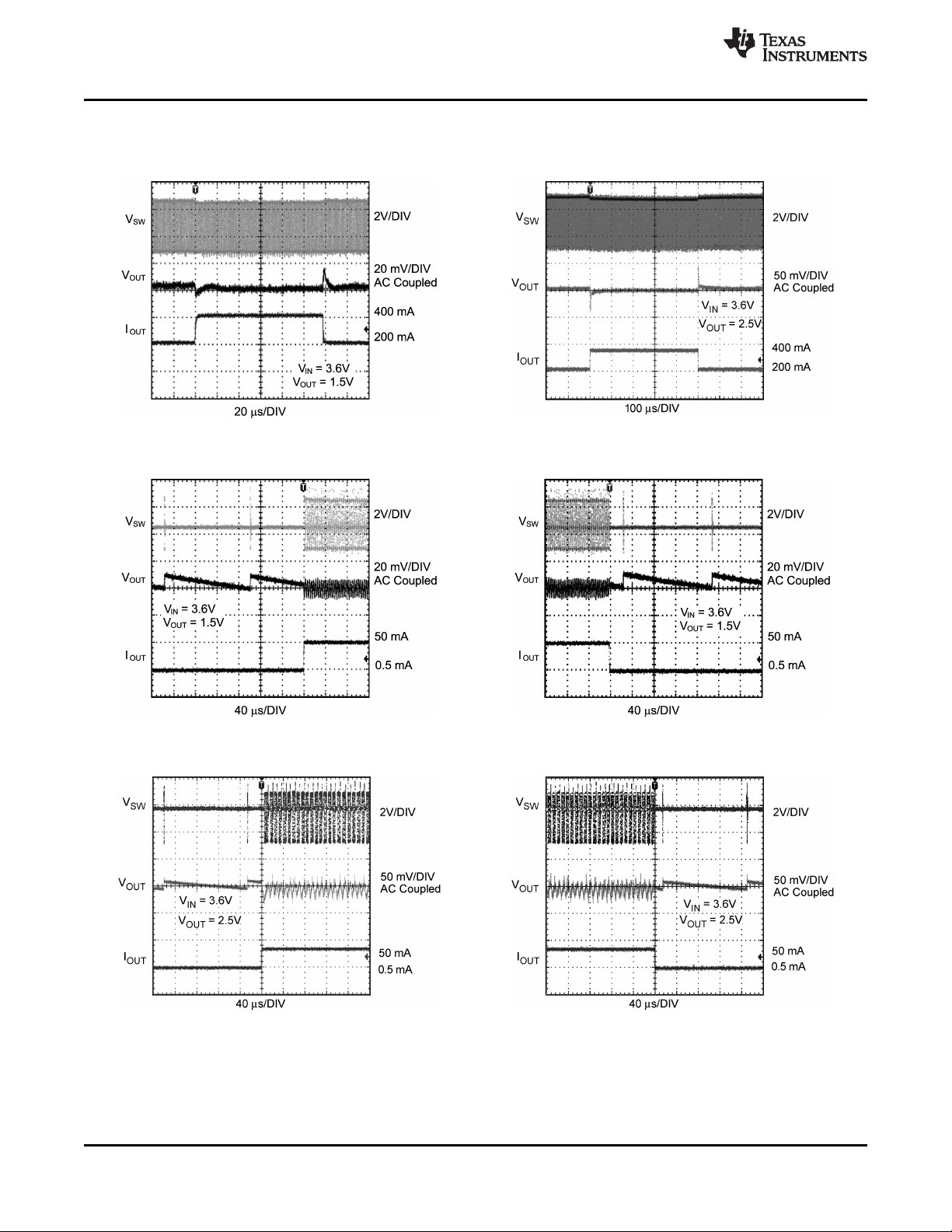

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

LM3671MF/TL/LC, Circuit of Figure 1, VIN= 3.6V, V

Mode Change by Load Transients Mode Change by Load Transients

V

= 1.5V (PFM to PWM) V

OUT

Figure 31. Figure 32.

Mode Change by Load Transients Mode Change by Load Transients

V

= 2.5V (PFM to PWM) V

OUT

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

= 1.5V, TA= 25°C, unless otherwise noted.

OUT

OUT

OUT

LM3671

LM3671Q

= 1.5V (PWM to PFM)

= 2.5V (PWM to PFM)

Figure 33. Figure 34.

Start Up into PWM Mode Start Up into PWM Mode

V

= 1.5V (Output Current= 300 mA) V

OUT

Figure 35. Figure 36.

Copyright © 2004–2013, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Links: LM3671 LM3671Q

= 2.5V (Output Current= 300 mA)

OUT

V

OUT

TIME (100 Ps/DIV)

EN

V

SW

2V/DIV

500 mV/DIV

VIN = 3.6V

V

OUT

= 1.5V

I

OUT

= 1 mA

2V/DIV

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

TYPICAL PERFORMANCE CHARACTERISTICS (continued)

LM3671MF/TL/LC, Circuit of Figure 1, VIN= 3.6V, V

Start Up into PFM Mode Start Up into PFM Mode

V

= 1.5V (Output Current= 1mA) V

OUT

Figure 37. Figure 38.

= 1.5V, TA= 25°C, unless otherwise noted.

OUT

= 2.5V (Output Current= 1mA)

OUT

www.ti.com

14 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Product Folder Links: LM3671 LM3671Q

LM3671

LM3671Q

www.ti.com

OPERATION DESCRIPTION

DEVICE INFORMATION

The LM3671, a high-efficiency step-down DC-DC switching buck converter, delivers a constant voltage from a

single Li-Ion battery and input voltage rails from 2.7V to 5.5V to portable devices such as cell phones and PDAs.

Using a voltage mode architecture with synchronous rectification, the LM3671 has the ability to deliver up to 600

mA depending on the input voltage, output voltage, ambient temperature and the inductor chosen.

There are three modes of operation depending on the current required - PWM (Pulse Width Modulation), PFM

(Pulse Frequency Modulation), and shutdown. The device operates in PWM mode at load current of

approximately 80 mA or higher. Lighter load current cause the device to automatically switch into PFM for

reduced current consumption (IQ= 16 µA typ) and a longer battery life. Shutdown mode turns off the device,

offering the lowest current consumption (I

SHUTDOWN

= 0.01 µA typ).

Additional features include soft-start, under-voltage protection, current overload protection, and thermal shutdown

protection. As shown in Figure 1, only three external power components are required for implementation.

The part uses an internal reference voltage of 0.5V. It is recommended to keep the part in shutdown until the

input voltage is 2.7V or higher.

CIRCUIT OPERATION

During the first portion of each switching cycle, the control block in the LM3671 turns on the internal PFET

switch. This allows current to flow from the input through the inductor to the output filter capacitor and load. The

inductor limits the current to a ramp with a slope of (VIN–V

During the second portion of each cycle, the controller turns the PFET switch off, blocking current flow from the

input, and then turns the NFET synchronous rectifier on. The inductor draws current from ground through the

NFET to the output filter capacitor and load, which ramps the inductor current down with a slope of - V

The output filter stores charge when the inductor current is high, and releases it when inductor current is low,

smoothing the voltage across the load.

The output voltage is regulated by modulating the PFET switch on time to control the average current sent to the

load. The effect is identical to sending a duty-cycle modulated rectangular wave formed by the switch and

synchronous rectifier at the SW pin to a low-pass filter formed by the inductor and output filter capacitor. The

output voltage is equal to the average voltage at the SW pin.

)/L, by storing energy in a magnetic field.

OUT

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

/L.

OUT

PWM OPERATION

During PWM operation the converter operates as a voltage-mode controller with input voltage feed forward. This

allows the converter to achieve good load and line regulation. The DC gain of the power stage is proportional to

the input voltage. To eliminate this dependence, feed forward inversely proportional to the input voltage is

introduced.

While in PWM mode, the output voltage is regulated by switching at a constant frequency and then modulating

the energy per cycle to control power to the load. At the beginning of each clock cycle the PFET switch is turned

on and the inductor current ramps up until the comparator trips and the control logic turns off the switch. The

current limit comparator can also turn off the switch in case the current limit of the PFET is exceeded. Then the

NFET switch is turned on and the inductor current ramps down. The next cycle is initiated by the clock turning off

the NFET and turning on the PFET.

Copyright © 2004–2013, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Links: LM3671 LM3671Q

V

OUT

TIME (4 Ps/DIV)

200 mA/DIV

I

L

V

SW

2V/DIV

20 mV/DIV

AC Coupled

VIN = 3.6V

V

OUT

= 1.5V

I

OUT

= 20 mA

V

OUT

TIME (200 ns/DIV)

200 mA/DIV

I

L

V

SW

2V/DIV

10 mV/DIV

AC Coupled

VIN = 3.6V

V

OUT

= 1.5V

I

OUT

= 400 mA

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

Figure 39. Typical PWM Operation

Internal Synchronous Rectification

While in PWM mode, the LM3671 uses an internal NFET as a synchronous rectifier to reduce rectifier forward

voltage drop and associated power loss. Synchronous rectification provides a significant improvement in

efficiency whenever the output voltage is relatively low compared to the voltage drop across an ordinary rectifier

diode.

www.ti.com

Current Limiting

A current limit feature allows the LM3671 to protect itself and external components during overload conditions.

PWM mode implements current limiting using an internal comparator that trips at 1020 mA (typ.). If the output is

shorted to ground the device enters a timed current limit mode where the NFET is turned on for a longer duration

until the inductor current falls below a low threshold. This allows the inductor current more time to decay, thereby

preventing runaway.

PFM OPERATION

At very light load, the converter enters PFM mode and operates with reduced switching frequency and supply

current to maintain high efficiency.

The part automatically transitions into PFM mode when either of two conditions occurs for a duration of 32 or

more clock cycles:

A. The NFET current reaches zero.

B. The peak PMOS switch current drops below the I

level, (Typically I

MODE

< 30 mA + VIN/42Ω ).

MODE

Figure 40. Typical PFM Operation

16 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Product Folder Links: LM3671 LM3671Q

High PFM Threshold

~1.017*Vout

Low1 PFM Threshold

~1.006*Vout

PFM Mode at Light Load

PWM Mode at

Moderate to Heavy

Loads

Pfet on

until

Ipfm limit

reached

Nfet on

drains

inductor

current

until

I inductor = 0

High PFM

Voltage

Threshold

reached,

go into

sleep mode

Low PFM

Threshold,

turn on

PFET

Current load

increases,

draws Vout

towards

Low2 PFM

Threshold

Low2 PFM Threshold,

switch back to PWMmode

Load current

increases

Low2 PFM Threshold

Vout

Z-

A

xi

s

Z

-

Axis

LM3671

LM3671Q

www.ti.com

During PFM operation, the converter positions the output voltage slightly higher than the nominal output voltage

during PWM operation, allowing additional headroom for voltage drop during a load transient from light to heavy

load. The PFM comparators sense the output voltage via the feedback pin and control the switching of the output

FETs such that the output voltage ramps between ~0.6% and ~1.7% above the nominal PWM output voltage. If

the output voltage is below the ‘high’ PFM comparator threshold, the PMOS power switch is turned on. It remains

on until the output voltage reaches the ‘high’ PFM threshold or the peak current exceeds the I

PFM mode. The typical peak current in PFM mode is: I

= 112 mA + VIN/27Ω .

PFM

Once the PMOS power switch is turned off, the NMOS power switch is turned on until the inductor current ramps

to zero. When the NMOS zero-current condition is detected, the NMOS power switch is turned off. If the output

voltage is below the ‘high’ PFM comparator threshold (see Figure 41), the PMOS switch is again turned on and

the cycle is repeated until the output reaches the desired level. Once the output reaches the ‘high’ PFM

threshold, the NMOS switch is turned on briefly to ramp the inductor current to zero and then both output

switches are turned off and the part enters an extremely low power mode. Quiescent supply current during this

‘sleep’ mode is 16 µA (typ.), which allows the part to achieve high efficiency under extremely light load

conditions.

If the load current should increase during PFM mode (see Figure 41) causing the output voltage to fall below the

‘low2’ PFM threshold, the part will automatically transition into fixed-frequency PWM mode. When VIN=2.7V the

part transitions from PWM to PFM mode at ~35 mA output current and from PFM to PWM mode at ~85 mA ,

when VIN=3.6V, PWM to PFM transition happens at ~50 mA and PFM to PWM transition happens at ~100 mA,

when VIN=4.5V, PWM to PFM transition happens at ~65 mA and PFM to PWM transition happens at ~115 mA.

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

level set for

PFM

Figure 41. Operation in PFM Mode and Transfer to PWM Mode

SHUTDOWN MODE

Setting the EN input pin low (<0.4V) places the LM3671 in shutdown mode. During shutdown the PFET switch,

NFET switch, reference, control and bias circuitry of the LM3671 are turned off. Setting EN high (>1.0V) enables

normal operation. It is recommended to set EN pin low to turn off the LM3671 during system power up and

undervoltage conditions when the supply is less than 2.7V. Do not leave the EN pin floating.

SOFT START

The LM3671 has a soft-start circuit that limits in-rush current during startup. During startup the switch current limit

is increased in steps. Soft start is activated only if EN goes from logic low to logic high after Vin reaches 2.7V.

Soft start is implemented by increasing switch current limit in steps of 70 mA, 140 mA, 280 mA and 1020 mA

(typical switch current limit). The startup time thereby depends on the output capacitor and load current

demanded at startup. Typical startup times with a 10 µF output capacitor and 300 mA load is 400 µs and with

1mA load is 275 µs.

Copyright © 2004–2013, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Links: LM3671 LM3671Q

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

LDO - LOW DROPOUT OPERATION

The LM3671-ADJ can operate at 100% duty cycle (no switching; PMOS switch completely on) for low dropout

support of the output voltage. In this way the output voltage will be controlled down to the lowest possible input

voltage. When the device operates near 100% duty cycle, output voltage ripple is approximately 25 mV.

The minimum input voltage needed to support the output voltage is

V

= I

IN, MIN

where

* (R

LOAD

• I

LOAD: Load current

• R

DSON, PFET: Drain to source resistance of PFET switch in the triode region

• R

INDUCTOR: Inductor resistance

DSON, PFET

+ R

INDUCTOR

) + V

OUT

www.ti.com

(1)

18 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Product Folder Links: LM3671 LM3671Q

Fp =

1

2 * S * (R1 R2) * (C1+C2)

Fz =

1

(2 * S * R1 * C1)

C2 =

1

(2 * S * R2 * 45 kHz)

C1 =

1

(2 * S * R1 * 45 kHz)

V

OUT

= V

FB

1 +

R1

R2

¹

·

©

§

LM3671

LM3671Q

www.ti.com

APPLICATION INFORMATION

OUTPUT VOLTAGE SELECTION FOR LM3671-ADJ

The output voltage of the adjustable parts can be programmed through the resistor network connected from V

to FB, then to GND. V

should be 200 kΩ to keep the current drawn through this network well below the 16 µA quiescent current level

(PFM mode) but large enough that it is not susceptible to noise. If R2 is 200 kΩ, and VFBis 0.5V, the current

through the resistor feedback network will be 2.5 µA. The output voltage of the adjustable parts ranges from 1.1V

to 3.3V.

The formula for output voltage selection is:

where

• V

• VFB: feedback voltage = 0.5V

• R1: feedback resistor from V

• R2: feedback resistor from FB to GND (2)

: output voltage (volts)

OUT

For any output voltage greater than or equal to 1.1V, a zero must be added around 45 kHz for stability. The

formula for calculation of C1 is:

is adjusted to make the voltage at FB equal to 0.5V. The resistor from FB to GND (R2)

OUT

to FB

OUT

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

OUT

(3)

For output voltages higher than 2.5V, a pole must be placed at 45 kHz as well. If the pole and zero are at the

same frequency the formula for calculation of C2 is:

(4)

The formula for location of zero and pole frequency created by adding C1 and C2 is given below. By adding C1,

a zero as well as a higher frequency pole is introduced.

(5)

(6)

See the "LM3671-ADJ configurations for various V

Table 1. LM3671-ADJ Configurations For Various V

OUT

" table.

(Circuit of Figure 2)

OUT

(Refer to Note 11 for VIN requirements)

V

(V) R1(kΩ) R2 (kΩ) C1 (pF) C2 (pF) L (µH) CIN(µF) C

OUT

0.90 160 200 22 none 2.2 4.7 10

1.1 240 200 15 none 2.2 4.7 10

1.2 280 200 12 none 2.2 4.7 10

1.3 320 200 12 none 2.2 4.7 10

1.5 357 178 10 none 2.2 4.7 10

1.6 442 200 8.2 none 2.2 4.7 10

1.7 432 178 8.2 none 2.2 4.7 10

1.8 464 178 8.2 none 2.2 4.7 10

1.875 523 191 6.8 none 2.2 4.7 10

2.5 402 100 8.2 none 2.2 4.7 10

2.8 464 100 8.2 33 2.2 4.7 10

3.3 562 100 6.8 33 2.2 4.7 10

OUT

(µF)

Copyright © 2004–2013, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Links: LM3671 LM3671Q

I

RMS

= I

OUTMAX

The worst case is when VIN = 2 V

OUT

(VIN - V

OUT

) V

OUT

L f I

OUTMAX

V

IN

r =

V

OUT

V

IN

r

2

12

1 -

+

V

OUT

V

IN

¸

¸

¹

·

¨

¨

©

§

¸

¹

·

¨

©

§

f

1

L2

!

I

SAT

I

OUTMAX

+ I

RIPPLE

where I

RIPPLE

=

V

OUT

V

IN

¸

¹

·

¨

©

§

¸

¹

·

¨

©

§

VIN - V

OUT

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

INDUCTOR SELECTION

There are two main considerations when choosing an inductor; the inductor should not saturate, and the inductor

current ripple should be small enough to achieve the desired output voltage ripple. Different saturation current

rating specifications are followed by different manufacturers so attention must be given to details. Saturation

current ratings are typically specified at 25°C. However, ratings at the maximum ambient temperature of

application should be requested from the manufacturer. The minimum value of inductance to specify good

performance is 1.76 µH at I

radiate less noise and should be preferred.

There are two methods to choose the inductor saturation current rating.

Method 1:

The saturation current should be greater than the sum of the maximum load current and the worst case average

to peak inductor current. This can be written as

where

• I

• I

• VIN: maximum input voltage in application

• L : min inductor value including worst case tolerances (30% drop can be considered for method 1)

• f : minimum switching frequency (1.6 Mhz)

• V

: average to peak inductor current

RIPPLE

: maximum load current (600 mA)

OUTMAX

: output voltage (7)

OUT

Method 2:

A more conservative and recommended approach is to choose an inductor that has a saturation current rating

greater than the maximum current limit of 1150mA.

A 2.2 µH inductor with a saturation current rating of at least 1150 mA is recommended for most applications. The

inductor’s resistance should be less than 0.3Ω for good efficiency. Table 2 lists suggested inductors and

suppliers. For low-cost applications, an unshielded bobbin inductor could be considered. For noise critical

applications, a toroidal or shielded-bobbin inductor should be used. A good practice is to lay out the board with

overlapping footprints of both types for design flexibility. This allows substitution of a low-noise shielded inductor,

in the event that noise from low-cost bobbin models is unacceptable.

(typ.) dc current over the ambient temperature range. Shielded inductors

LIM

www.ti.com

INPUT CAPACITOR SELECTION

A ceramic input capacitor of 4.7 µF, 6.3V is sufficient for most applications. Place the input capacitor as close as

possible to the VINpin of the device. A larger value may be used for improved input voltage filtering. Use X7R or

X5R types; do not use Y5V. DC bias characteristics of ceramic capacitors must be considered when selecting

case sizes like 0805 and 0603. The minimum input capacitance to specify good performance is 2.2µF at 3V

dc bias; 1.5µF at 5V dc bias including tolerances and over ambient temperature range. The input filter

capacitor supplies current to the PFET switch of the LM3671 in the first half of each cycle and reduces voltage

ripple imposed on the input power source. A ceramic capacitor’s low ESR provides the best noise filtering of the

input voltage spikes due to this rapidly changing current. Select a capacitor with sufficient ripple current rating.

The input current ripple can be calculated as:

20 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Product Folder Links: LM3671 LM3671Q

(8)

V

PP-RMS

= V

PP-C

2

+ V

PP-ESR

2

V

PP-C

=

4*f*C

I

RIPPLE

LM3671

LM3671Q

www.ti.com

Table 2. Suggested Inductors and Their Suppliers

Model Vendor Dimensions LxWxH(mm) D.C.R (max)

DO3314-222MX Coilcraft 3.3 x 3.3 x 1.4 200 mΩ

LPO3310-222MX Coilcraft 3.3 x 3.3 x 1.0 150 mΩ

ELL5GM2R2N Panasonic 5.2 x 5.2 x 1.5 53 mΩ

CDRH2D14NP-2R2NC Sumida 3.2 x 3.2 x 1.55 94 mΩ

OUTPUT CAPACITOR SELECTION

A ceramic output capacitor of 10 µF, 6.3V is sufficient for most applications. Use X7R or X5R types; do not use

Y5V. DC bias characteristics of ceramic capacitors must be considered when selecting case sizes like 0805 and

0603. DC bias characteristics vary from manufacturer to manufacturer and dc bias curves should be requested

from them as part of the capacitor selection process.

The minimum output capacitance to specify good performance is 5.75 µF at 1.8V dc bias including

tolerances and over ambient temperature range. The output filter capacitor smoothes out current flow from

the inductor to the load, helps maintain a steady output voltage during transient load changes and reduces

output voltage ripple. These capacitors must be selected with sufficient capacitance and sufficiently low ESR to

perform these functions.

The output voltage ripple is caused by the charging and discharging of the output capacitor and by the R

can be calculated as:

Voltage peak-to-peak ripple due to capacitance can be expressed as follow:

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

and

ESR

(9)

Voltage peak-to-peak ripple due to ESR can be expressed as follow:

V

PP-ESR

= (2 * I

RIPPLE

) * R

ESR

Because these two components are out of phase the rms (root mean squared) value can be used to get an

approximate value of peak-to-peak ripple.

The peak-to-peak ripple voltage, rms value can be expressed as follow:

(10)

Note that the output voltage ripple is dependent on the inductor current ripple and the equivalent series

resistance of the output capacitor (R

The R

is frequency dependent (as well as temperature dependent); make sure the value used for calculations

ESR

ESR

).

is at the switching frequency of the part.

Table 3. Suggested Capacitors and Their Suppliers

Model Type Vendor Voltage Rating

4.7 µF for C

10 µF for C

IN

C2012X5R0J475K Ceramic, X5R TDK 6.3V 0805 (2012)

JMK212BJ475K Ceramic, X5R Taiyo-Yuden 6.3V 0805 (2012)

GRM21BR60J475K Ceramic, X5R Murata 6.3V 0805 (2012)

C1608X5R0J475K Ceramic, X5R TDK 6.3V 0603 (1608)

OUT

GRM21BR60J106K Ceramic, X5R Murata 6.3V 0805 (2012)

JMK212BJ106K Ceramic, X5R Taiyo-Yuden 6.3V 0805 (2012)

C2012X5R0J106K Ceramic, X5R TDK 6.3V 0805 (2012)

C1608X5R0J106K Ceramic, X5R TDK 6.3V 0603 (1608)

Case Size

Inch (mm)

Copyright © 2004–2013, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Links: LM3671 LM3671Q

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

DSBGA PACKAGE ASSEMBLY AND USE

Use of the DSBGA package requires specialized board layout, precision mounting and careful re-flow

techniques, as detailed in Texas Instruments Application Note AN-1112 (Literature Number SNVA009). Refer to

the section "Surface Mount Technology (DSBGA) Assembly Considerations". For best results in assembly,

alignment ordinals on the PC board should be used to facilitate placement of the device. The pad style used with

DSBGA package must be the NSMD (non-solder mask defined) type. This means that the solder-mask opening

is larger than the pad size. This prevents a lip that otherwise forms if the solder-mask and pad overlap, from

holding the device off the surface of the board and interfering with mounting. See Application Note AN-1112

(Literature Number SNVA009) for specific instructions how to do this. The 5-bump package used for LM3671 has

300 micron solder balls and requires 10.82 mils pads for mounting on the circuit board. The trace to each pad

should enter the pad with a 90° entry angle to prevent debris from being caught in deep corners. Initially, the

trace to each pad should be 7 mil wide, for a section approximately 7 mil long or longer, as a thermal relief. Then

each trace should neck up or down to its optimal width. The important criteria is symmetry. This ensures the

solder bumps on the LM3671 re-flow evenly and that the device solders level to the board. In particular, special

attention must be paid to the pads for bumps A1 and A3, because VINand GND are typically connected to large

copper planes, inadequate thermal relief can result in late or inadequate re-flow of these bumps.

The DSBGA package is optimized for the smallest possible size in applications with red or infrared opaque

cases. Because the DSBGA package lacks the plastic encapsulation characteristic of larger devices, it is

vulnerable to light. Backside metallization and/or epoxy coating, along with front-side shading by the printed

circuit board, reduce this sensitivity. However, the package has exposed die edges. In particular, DSBGA

devices are sensitive to light, in the red and infrared range, shining on the package’s exposed die edges.

www.ti.com

BOARD LAYOUT CONSIDERATIONS

PC board layout is an important part of DC-DC converter design. Poor board layout can disrupt the performance

of a DC-DC converter and surrounding circuitry by contributing to EMI, ground bounce, and resistive voltage loss

in the traces. These can send erroneous signals to the DC-DC converter IC, resulting in poor regulation or

instability.

Good layout for the LM3671 can be implemented by following a few simple design rules below. Refer to

Figure 42 for top layer board layout.

1. Place the LM3671, inductor and filter capacitors close together and make the traces short. The traces

between these components carry relatively high switching currents and act as antennas. Following this rule

reduces radiated noise. Special care must be given to place the input filter capacitor very close to the V

and GND pin.

2. Arrange the components so that the switching current loops curl in the same direction. During the first half of

each cycle, current flows from the input filter capacitor through the LM3671 and inductor to the output filter

capacitor and back through ground, forming a current loop. In the second half of each cycle, current is pulled

up from ground through the LM3671 by the inductor to the output filter capacitor and then back through

ground forming a second current loop. Routing these loops so the current curls in the same direction

prevents magnetic field reversal between the two half-cycles and reduces radiated noise.

3. Connect the ground pins of the LM3671 and filter capacitors together using generous component-side

copper fill as a pseudo-ground plane. Then, connect this to the ground-plane (if one is used) with several

vias. This reduces ground-plane noise by preventing the switching currents from circulating through the

ground plane. It also reduces ground bounce at the LM3671 by giving it a low-impedance ground connection.

4. Use wide traces between the power components and for power connections to the DC-DC converter circuit.

This reduces voltage errors caused by resistive losses across the traces.

5. Route noise sensitive traces, such as the voltage feedback path, away from noisy traces between the power

components. The voltage feedback trace must remain close to the LM3671 circuit and should be direct but

should be routed opposite to noisy components. This reduces EMI radiated onto the DC-DC converter’s own

voltage feedback trace. A good approach is to route the feedback trace on another layer and to have a

ground plane between the top layer and layer on which the feedback trace is routed. In the same manner for

the adjustable part it is desired to have the feedback dividers on the bottom layer.

6. Place noise sensitive circuitry, such as radio IF blocks, away from the DC-DC converter, CMOS digital blocks

and other noisy circuitry. Interference with noise-sensitive circuitry in the system can be reduced through

distance.

IN

22 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Product Folder Links: LM3671 LM3671Q

LM3671

LM3671Q

www.ti.com

In mobile phones, for example, a common practice is to place the DC-DC converter on one corner of the board,

arrange the CMOS digital circuitry around it (since this also generates noise), and then place sensitive

preamplifiers and IF stages on the diagonally opposing corner. Often, the sensitive circuitry is shielded with a

metal pan and power to it is post-regulated to reduce conducted noise, using low-dropout linear regulators.

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

Figure 42. Top Layer Board Layout For SOT-23

Copyright © 2004–2013, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Links: LM3671 LM3671Q

LM3671

LM3671Q

SNVS294P –NOVEMBER 2004–REVISED MAY 2013

REVISION HISTORY

Changes from Revision O (April 2013) to Revision P Page

• Changed layout of National Data Sheet to TI format .......................................................................................................... 23

www.ti.com

24 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated

Product Folder Links: LM3671 LM3671Q

PACKAGE OPTION ADDENDUM

www.ti.com

PACKAGING INFORMATION

Orderable Device Status

LM3671LC-1.2/NOPB ACTIVE USON NKH 6 1000 Green (RoHS

LM3671LC-1.3/NOPB ACTIVE USON NKH 6 1000 Green (RoHS

LM3671LC-1.6/NOPB ACTIVE USON NKH 6 1000 Green (RoHS

LM3671LC-1.8/NOPB ACTIVE USON NKH 6 1000 Green (RoHS

LM3671LCX-1.2/NOPB ACTIVE USON NKH 6 4500 Green (RoHS

LM3671LCX-1.3/NOPB ACTIVE USON NKH 6 4500 Green (RoHS

LM3671LCX-1.6/NOPB ACTIVE USON NKH 6 4500 Green (RoHS

LM3671LCX-1.8/NOPB ACTIVE USON NKH 6 4500 Green (RoHS

LM3671MF-1.2 ACTIVE SOT-23 DBV 5 1000 TBD Call TI Call TI -30 to 85 SBPB

LM3671MF-1.2/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

LM3671MF-1.25 ACTIVE SOT-23 DBV 5 1000 TBD Call TI Call TI -30 to 85 SDRB

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

& no Sb/Br)

Lead/Ball Finish MSL Peak Temp

(3)

CU NIPDAU Level-1-260C-UNLIM S39

CU NIPDAU Level-1-260C-UNLIM S40

CU NIPDAU Level-1-260C-UNLIM S41

CU NIPDAU Level-1-260C-UNLIM S42

CU NIPDAU Level-1-260C-UNLIM S39

CU NIPDAU Level-1-260C-UNLIM S40

CU NIPDAU Level-1-260C-UNLIM S41

CU NIPDAU Level-1-260C-UNLIM S42

CU SN Level-1-260C-UNLIM -30 to 85 SBPB

Op Temp (°C) Top-Side Markings

2-May-2013

Samples

(4)

LM3671MF-1.25/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

& no Sb/Br)

LM3671MF-1.375 ACTIVE SOT-23 DBV 5 1000 TBD Call TI Call TI -30 to 85 SEDB

LM3671MF-1.375/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

& no Sb/Br)

LM3671MF-1.5 ACTIVE SOT-23 DBV 5 1000 TBD Call TI Call TI -30 to 85 SBRB

LM3671MF-1.5/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

& no Sb/Br)

LM3671MF-1.6 ACTIVE SOT-23 DBV 5 1000 TBD Call TI Call TI -30 to 85 SDUB

LM3671MF-1.6/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

& no Sb/Br)

Addendum-Page 1

CU SN Level-1-260C-UNLIM -30 to 85 SDRB

CU SN Level-1-260C-UNLIM -30 to 85 SEDB

CU SN Level-1-260C-UNLIM -30 to 85 SBRB

CU SN Level-1-260C-UNLIM -30 to 85 SDUB

PACKAGE OPTION ADDENDUM

www.ti.com

Orderable Device Status

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish MSL Peak Temp

(3)

Op Temp (°C) Top-Side Markings

LM3671MF-1.8 ACTIVE SOT-23 DBV 5 1000 TBD Call TI Call TI -30 to 85 SBSB

LM3671MF-1.8/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SBSB

& no Sb/Br)

LM3671MF-1.875 ACTIVE SOT-23 DBV 5 1000 TBD Call TI Call TI -30 to 85 SDVB

LM3671MF-1.875/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SDVB

& no Sb/Br)

LM3671MF-2.5 ACTIVE SOT-23 DBV 5 1000 TBD Call TI Call TI -30 to 85 SJRB

LM3671MF-2.5/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SJRB

& no Sb/Br)

LM3671MF-2.8 ACTIVE SOT-23 DBV 5 1000 TBD Call TI Call TI -30 to 85 SJSB

LM3671MF-2.8/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SJSB

& no Sb/Br)

LM3671MF-3.3 ACTIVE SOT-23 DBV 5 1000 TBD Call TI Call TI -30 to 85 SJEB

LM3671MF-3.3/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SJEB

& no Sb/Br)

LM3671MF-ADJ ACTIVE SOT-23 DBV 5 1000 TBD Call TI Call TI -30 to 85 SBTB

2-May-2013

Samples

(4)

LM3671MF-ADJ/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SBTB

& no Sb/Br)

LM3671MFX-1.2 ACTIVE SOT-23 DBV 5 3000 TBD Call TI Call TI -30 to 85 SBPB

LM3671MFX-1.2/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SBPB

& no Sb/Br)

LM3671MFX-1.25 ACTIVE SOT-23 DBV 5 3000 TBD Call TI Call TI -30 to 85 SDRB

LM3671MFX-1.25/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SDRB

& no Sb/Br)

LM3671MFX-1.375 ACTIVE SOT-23 DBV 5 3000 TBD Call TI Call TI -30 to 85 SEDB

LM3671MFX-1.375/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SEDB

& no Sb/Br)

LM3671MFX-1.5 ACTIVE SOT-23 DBV 5 3000 TBD Call TI Call TI -30 to 85 SBRB

Addendum-Page 2

PACKAGE OPTION ADDENDUM

www.ti.com

Orderable Device Status

LM3671MFX-1.5/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish MSL Peak Temp

(3)

Op Temp (°C) Top-Side Markings

CU SN Level-1-260C-UNLIM -30 to 85 SBRB

& no Sb/Br)

LM3671MFX-1.6 ACTIVE SOT-23 DBV 5 3000 TBD Call TI Call TI -30 to 85 SDUB

LM3671MFX-1.6/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SDUB

& no Sb/Br)

LM3671MFX-1.8 ACTIVE SOT-23 DBV 5 3000 TBD Call TI Call TI -30 to 85 SBSB

LM3671MFX-1.8/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SBSB

& no Sb/Br)

LM3671MFX-1.875 ACTIVE SOT-23 DBV 5 3000 TBD Call TI Call TI -30 to 85 SDVB

LM3671MFX-1.875/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SDVB

& no Sb/Br)

LM3671MFX-2.5 ACTIVE SOT-23 DBV 5 3000 TBD Call TI Call TI -30 to 85 SJRB

LM3671MFX-2.5/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SJRB

& no Sb/Br)

LM3671MFX-2.8 ACTIVE SOT-23 DBV 5 3000 TBD Call TI Call TI -30 to 85 SJSB

LM3671MFX-2.8/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SJSB

& no Sb/Br)

LM3671MFX-3.3 ACTIVE SOT-23 DBV 5 3000 TBD Call TI Call TI -30 to 85 SJEB

2-May-2013

Samples

(4)

LM3671MFX-3.3/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SJEB

& no Sb/Br)

LM3671MFX-ADJ ACTIVE SOT-23 DBV 5 3000 TBD Call TI Call TI -30 to 85 SBTB

LM3671MFX-ADJ/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

CU SN Level-1-260C-UNLIM -30 to 85 SBTB

& no Sb/Br)

LM3671QMF-1.2/NOPB ACTIVE SOT-23 DBV 5 1000 Green (RoHS

CU SN Level-1-260C-UNLIM -40 to 125 SH4B

& no Sb/Br)

LM3671QMFX-1.2/NOPB ACTIVE SOT-23 DBV 5 3000 Green (RoHS

CU SN Level-1-260C-UNLIM -40 to 125 SH4B

& no Sb/Br)

LM3671TL-1.2/NOPB ACTIVE DSBGA YZR 5 250 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 C

& no Sb/Br)

LM3671TL-1.5/NOPB ACTIVE DSBGA YZR 5 250 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 D

& no Sb/Br)

Addendum-Page 3

PACKAGE OPTION ADDENDUM

www.ti.com

Orderable Device Status

LM3671TL-1.8/NOPB ACTIVE DSBGA YZR 5 250 Green (RoHS

Package Type Package

(1)

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish MSL Peak Temp

(3)

Op Temp (°C) Top-Side Markings

SNAGCU Level-1-260C-UNLIM -30 to 85 B

& no Sb/Br)

LM3671TL-1.875/NOPB ACTIVE DSBGA YZR 5 250 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 S

& no Sb/Br)

LM3671TL-2.5/NOPB ACTIVE DSBGA YZR 5 250 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 L

& no Sb/Br)

LM3671TL-2.8/NOPB ACTIVE DSBGA YZR 5 250 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 K

& no Sb/Br)

LM3671TL-3.3/NOPB ACTIVE DSBGA YZR 5 250 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 J

& no Sb/Br)

LM3671TL-ADJ/NOPB ACTIVE DSBGA YZR 5 250 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 E

& no Sb/Br)

LM3671TLX-1.2/NOPB ACTIVE DSBGA YZR 5 3000 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 C

& no Sb/Br)

LM3671TLX-1.5/NOPB ACTIVE DSBGA YZR 5 3000 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 D

& no Sb/Br)

LM3671TLX-1.8/NOPB ACTIVE DSBGA YZR 5 3000 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 B

& no Sb/Br)

LM3671TLX-1.875/NOPB ACTIVE DSBGA YZR 5 3000 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 S

& no Sb/Br)

LM3671TLX-2.5/NOPB ACTIVE DSBGA YZR 5 3000 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 L

& no Sb/Br)

LM3671TLX-2.8/NOPB ACTIVE DSBGA YZR 5 3000 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 K

& no Sb/Br)

LM3671TLX-3.3/NOPB ACTIVE DSBGA YZR 5 3000 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 J

& no Sb/Br)

LM3671TLX-ADJ/NOPB ACTIVE DSBGA YZR 5 3000 Green (RoHS

SNAGCU Level-1-260C-UNLIM -30 to 85 E

& no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

2-May-2013

Samples

(4)

Addendum-Page 4

PACKAGE OPTION ADDENDUM

www.ti.com

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

Multiple Top-Side Markings will be inside parentheses. Only one Top-Side Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a

continuation of the previous line and the two combined represent the entire Top-Side Marking for that device.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

OTHER QUALIFIED VERSIONS OF LM3671, LM3671-Q1 :

Catalog: LM3671

•

2-May-2013

Automotive: LM3671-Q1

•

NOTE: Qualified Version Definitions:

Catalog - TI's standard catalog product

•

Automotive - Q100 devices qualified for high-reliability automotive applications targeting zero defects

•

Addendum-Page 5

PACKAGE MATERIALS INFORMATION

www.ti.com 8-May-2013

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

LM3671LC-1.2/NOPB USON NKH 6 1000 178.0 12.4 2.2 2.2 1.0 8.0 12.0 Q1

LM3671LC-1.3/NOPB USON NKH 6 1000 178.0 12.4 2.2 2.2 1.0 8.0 12.0 Q1

LM3671LC-1.6/NOPB USON NKH 6 1000 178.0 12.4 2.2 2.2 1.0 8.0 12.0 Q1

LM3671LC-1.8/NOPB USON NKH 6 1000 178.0 12.4 2.2 2.2 1.0 8.0 12.0 Q1

LM3671LCX-1.2/NOPB USON NKH 6 4500 330.0 12.4 2.2 2.2 1.0 8.0 12.0 Q1

LM3671LCX-1.3/NOPB USON NKH 6 4500 330.0 12.4 2.2 2.2 1.0 8.0 12.0 Q1

LM3671LCX-1.6/NOPB USON NKH 6 4500 330.0 12.4 2.2 2.2 1.0 8.0 12.0 Q1

LM3671LCX-1.8/NOPB USON NKH 6 4500 330.0 12.4 2.2 2.2 1.0 8.0 12.0 Q1

LM3671MF-1.2 SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.2/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.25 SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.25/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.375 SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.375/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.5 SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.5/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.6 SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.6/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Quadrant

Pin1

Pack Materials-Page 1

PACKAGE MATERIALS INFORMATION

www.ti.com 8-May-2013

Device Package

LM3671MF-1.8 SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.8/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.875 SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-1.875/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-2.5 SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-2.5/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-2.8 SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-2.8/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-3.3 SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-3.3/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-ADJ SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MF-ADJ/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.2 SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.2/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.25 SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.25/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.375 SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.375/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.5 SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.5/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.6 SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.6/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.8 SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.8/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.875 SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-1.875/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-2.5 SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-2.5/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-2.8 SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-2.8/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-3.3 SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-3.3/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-ADJ SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671MFX-ADJ/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671QMF-1.2/NOPB SOT-23 DBV 5 1000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671QMFX-1.2/NOPB SOT-23 DBV 5 3000 178.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

LM3671TL-1.2/NOPB DSBGA YZR 5 250 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TL-1.5/NOPB DSBGA YZR 5 250 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TL-1.8/NOPB DSBGA YZR 5 250 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TL-1.875/NOPB DSBGA YZR 5 250 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TL-2.5/NOPB DSBGA YZR 5 250 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TL-2.8/NOPB DSBGA YZR 5 250 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TL-3.3/NOPB DSBGA YZR 5 250 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 2

PACKAGE MATERIALS INFORMATION

www.ti.com 8-May-2013

Device Package

LM3671TL-ADJ/NOPB DSBGA YZR 5 250 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TLX-1.2/NOPB DSBGA YZR 5 3000 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TLX-1.5/NOPB DSBGA YZR 5 3000 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TLX-1.8/NOPB DSBGA YZR 5 3000 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TLX-1.875/NOPB DSBGA YZR 5 3000 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TLX-2.5/NOPB DSBGA YZR 5 3000 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TLX-2.8/NOPB DSBGA YZR 5 3000 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TLX-3.3/NOPB DSBGA YZR 5 3000 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

LM3671TLX-ADJ/NOPB DSBGA YZR 5 3000 178.0 8.4 1.14 1.47 0.76 4.0 8.0 Q1

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

LM3671LC-1.2/NOPB USON NKH 6 1000 203.0 190.0 41.0

LM3671LC-1.3/NOPB USON NKH 6 1000 210.0 185.0 35.0

LM3671LC-1.6/NOPB USON NKH 6 1000 210.0 185.0 35.0

LM3671LC-1.8/NOPB USON NKH 6 1000 210.0 185.0 35.0

LM3671LCX-1.2/NOPB USON NKH 6 4500 367.0 367.0 35.0

LM3671LCX-1.3/NOPB USON NKH 6 4500 367.0 367.0 35.0

LM3671LCX-1.6/NOPB USON NKH 6 4500 367.0 367.0 35.0

LM3671LCX-1.8/NOPB USON NKH 6 4500 367.0 367.0 35.0

Pack Materials-Page 3

PACKAGE MATERIALS INFORMATION

www.ti.com 8-May-2013

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

LM3671MF-1.2 SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.2/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.25 SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.25/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.375 SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.375/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.5 SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.5/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.6 SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.6/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.8 SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.8/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.875 SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-1.875/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-2.5 SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-2.5/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-2.8 SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-2.8/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-3.3 SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-3.3/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-ADJ SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MF-ADJ/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671MFX-1.2 SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.2/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.25 SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.25/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.375 SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.375/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.5 SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.5/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.6 SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.6/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.8 SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.8/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.875 SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-1.875/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-2.5 SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-2.5/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-2.8 SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-2.8/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-3.3 SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-3.3/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-ADJ SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671MFX-ADJ/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

Pack Materials-Page 4

PACKAGE MATERIALS INFORMATION

www.ti.com 8-May-2013

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

LM3671QMF-1.2/NOPB SOT-23 DBV 5 1000 210.0 185.0 35.0

LM3671QMFX-1.2/NOPB SOT-23 DBV 5 3000 210.0 185.0 35.0

LM3671TL-1.2/NOPB DSBGA YZR 5 250 210.0 185.0 35.0

LM3671TL-1.5/NOPB DSBGA YZR 5 250 210.0 185.0 35.0

LM3671TL-1.8/NOPB DSBGA YZR 5 250 210.0 185.0 35.0

LM3671TL-1.875/NOPB DSBGA YZR 5 250 210.0 185.0 35.0

LM3671TL-2.5/NOPB DSBGA YZR 5 250 210.0 185.0 35.0

LM3671TL-2.8/NOPB DSBGA YZR 5 250 210.0 185.0 35.0

LM3671TL-3.3/NOPB DSBGA YZR 5 250 210.0 185.0 35.0

LM3671TL-ADJ/NOPB DSBGA YZR 5 250 210.0 185.0 35.0

LM3671TLX-1.2/NOPB DSBGA YZR 5 3000 210.0 185.0 35.0

LM3671TLX-1.5/NOPB DSBGA YZR 5 3000 210.0 185.0 35.0

LM3671TLX-1.8/NOPB DSBGA YZR 5 3000 210.0 185.0 35.0

LM3671TLX-1.875/NOPB DSBGA YZR 5 3000 210.0 185.0 35.0

LM3671TLX-2.5/NOPB DSBGA YZR 5 3000 210.0 185.0 35.0

LM3671TLX-2.8/NOPB DSBGA YZR 5 3000 210.0 185.0 35.0

LM3671TLX-3.3/NOPB DSBGA YZR 5 3000 210.0 185.0 35.0

LM3671TLX-ADJ/NOPB DSBGA YZR 5 3000 210.0 185.0 35.0

Pack Materials-Page 5

NKH0006B

MECHANICAL DATA

www.ti.com

LCA06B (Rev A)

YZR0005xxx

A

MECHANICAL DATA

D

0.600±0.075

E

NOTES: