Page 1

®

INA103

INA103

Low Noise, Low Distortion

INSTRUMENT ATION AMPLIFIER

INA103

FEA TURES

● LOW NOISE: 1nV/√Hz

● LOW THD+N: 0.0009% at 1kHz, G = 100

● HIGH GBW: 100MHz at G = 1000

● WIDE SUPPLY RANGE:

±9V to ±25V

● HIGH CMRR: >100dB

● BUILT-IN GAIN SETTING RESISTORS:

G = 1, 100

● UPGRADES AD625

DESCRIPTION

The INA103 is a very low noise, low distortion monolithic instrumentation amplifier. Its current-feedback

circuitry achieves very wide bandwidth and excellent

dynamic response. It is ideal for low-level audio

signals such as balanced low-impedance microphones.

The INA103 provides near-theoretical limit noise performance for 200Ω source impedances. Many industrial applications also benefit from its low noise and

wide bandwidth.

Unique distortion cancellation circuitry reduces distortion to extremely low levels, even in high gain. Its

balanced input, low noise and low distortion provide

superior performance compared to transformer-coupled

microphone amplifiers used in professional audio

equipment.

The INA103’s wide supply voltage (±9 to ±25V) and

high output current drive allow its use in high-level

audio stages as well. A copper lead frame in the plastic

DIP assures excellent thermal performance.

APPLICATIONS

● HIGH QUALITY MICROPHONE PREAMPS

(REPLACES TRANSFORMERS)

● MOVING-COIL PREAMPLIFIERS

● DIFFERENTIAL RECEIVERS

● AMPLIFICATION OF SIGNALS FROM:

Strain Gages (Weigh Scale Applications)

Thermocouples

Bridge Transducers

The INA103 is available in 16-pin plastic DIP and

SOL-16 surface-mount packages. Commercial and Industrial temperature range models are available.

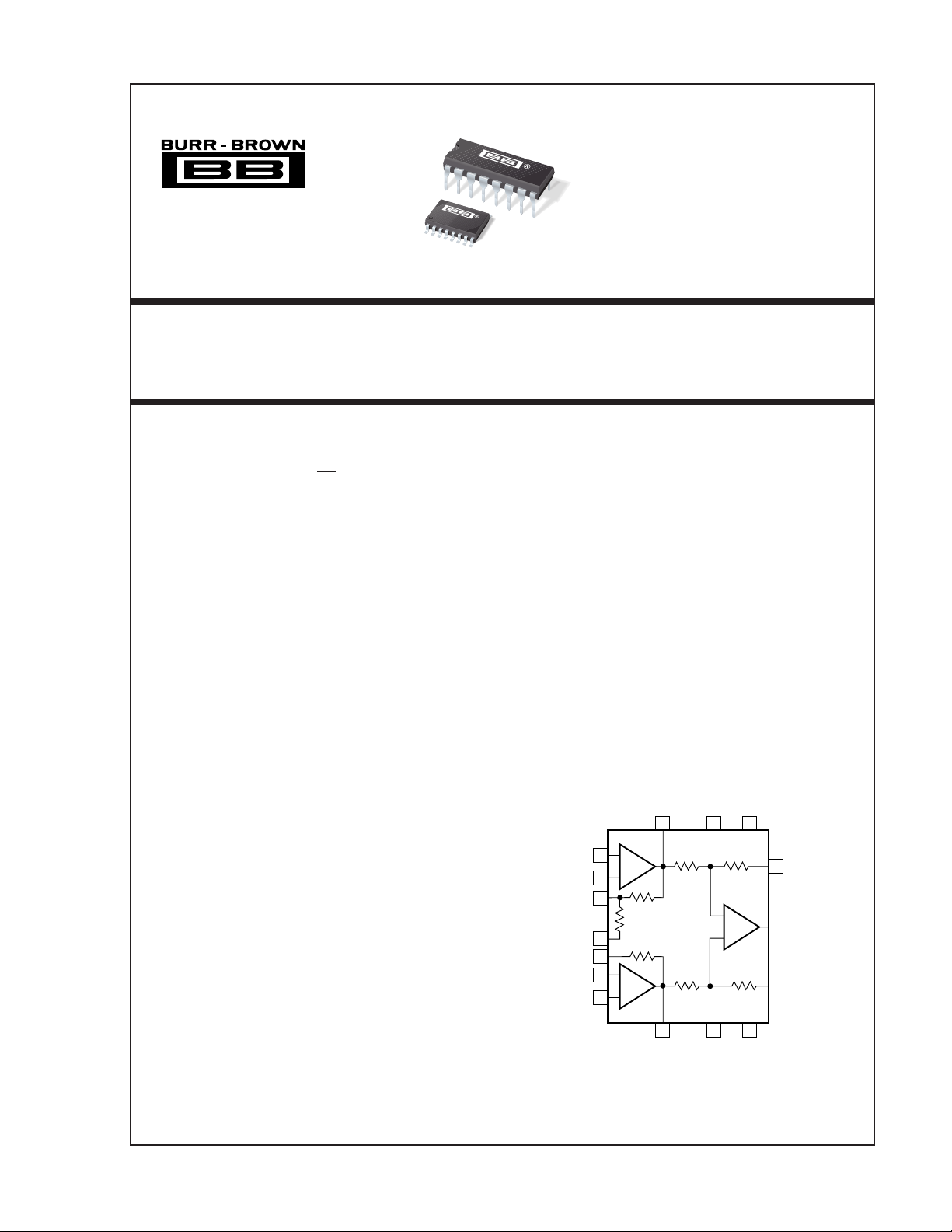

Offset

Null

3 4

9

V+

Offset

6k

–

A

+

6k

Null

Ω

3

Ω

V–

11

Sense

Output

10

Ref

7

8

–Input

–Gain Sense

–R

G = 100

+R

+Gain Sense

+Input

–Gain Drive

12

Ω

1

3kΩ

3k

Ω

2

5

+Gain Drive

6k

Ω

6k

+

16

A

–

15

13

G

60.6Ω

14

6

G

–

2

A

+

1

SBOS003

International Airport Industrial Park • Mailing Address: PO Box 11400, Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 • Tel: (520) 746-1111 • Twx: 910-952-1111

Internet: http://www.burr-brown.com/ • FAXLine: (800) 548-6133 (US/Canada Only) • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

©

1990 Burr-Brown Corporation PDS-1016H Printed in U.S.A. March, 1998

1

INA103

®

Page 2

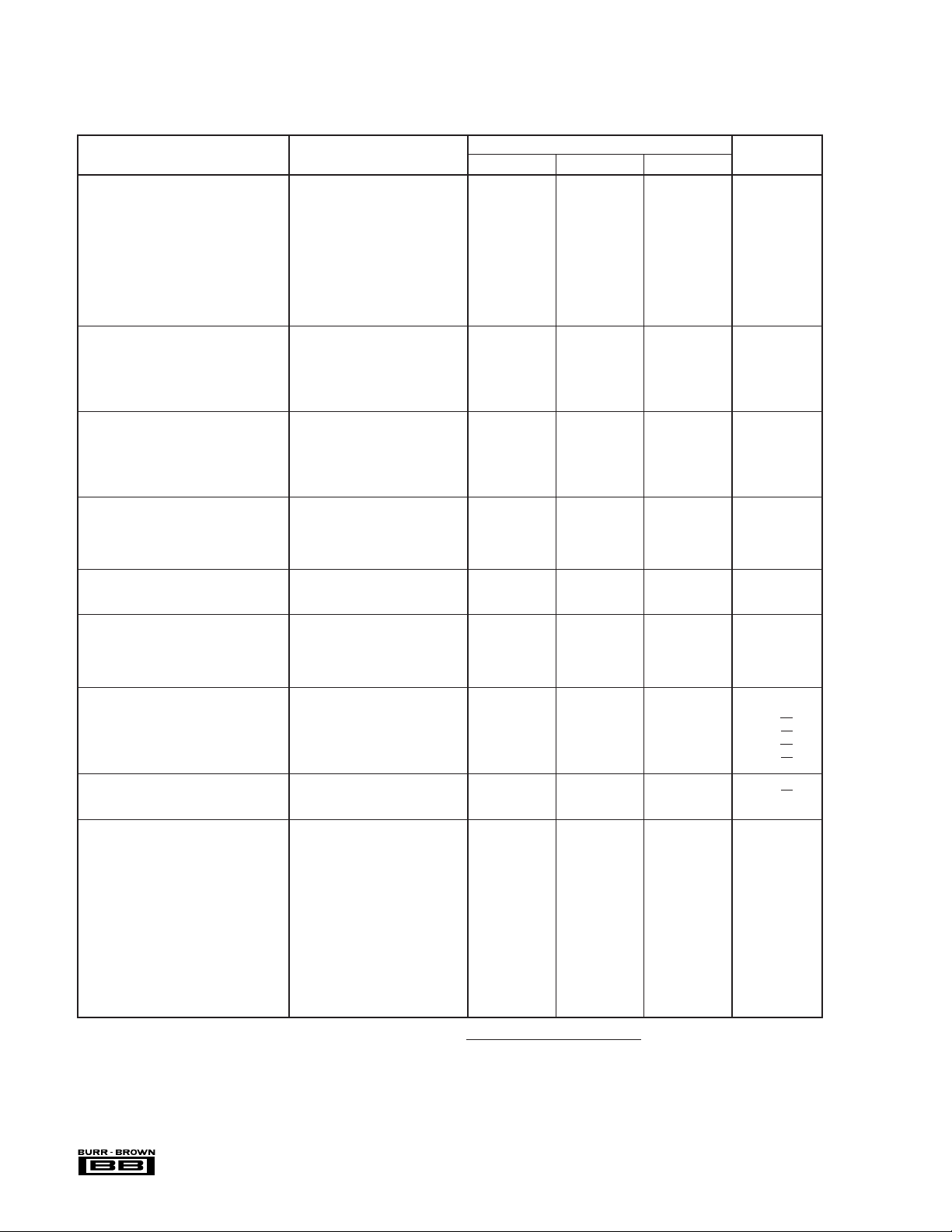

SPECIFICATIONS

All specifications at TA = +25°C, VS = ±15V and RL = 2kΩ, unless otherwise noted.

INA103KP, KU

PARAMETER CONDITIONS MIN TYP MAX UNITS

GAIN

Range of Gain 1 1000 V/V

Gain Equation

Gain Error, DC G = 1 ±10V Output 0.005 0.05 %

Gain Temp. Co. G = 1 ±10V Output 10 ppm/°C

Nonlinearity, DC G = 1 ±10V Output 0.0003 0.01 % of FS

OUTPUT

Voltage, R

Current T

Short Circuit Current ±70 mA

Capacitive Load Stability 10 nF

INPUT OFFSET VOLTAGE

Initial Offset RTI

(KU Grade) (250+ 5000/G) µV

vs Temp G = 1 to 1000 T

vs Supply ±9V to ±25V 0.2 + 8/G 4 + 60/G µV/V

INPUT BIAS CURRENT

Initial Bias Current 2.5 12 µA

vs Temp T

Initial Offset Current 0.04 1 µA

vs Temp T

INPUT IMPEDANCE

Differential Mode 60 || 2 MΩ || pF

Common-Mode 60 || 5 MΩ || pF

INPUT VOLTAGE RANGE

Common-Mode Range

CMR

G = 1 DC to 60Hz 72 86 dB

G = 100 DC to 60Hz 100 125 dB

INPUT NOISE

Voltage

10Hz 2 nV/√Hz

100Hz 1.2 nV/√Hz

1kHz 1 nV/√Hz

Current, 1kHz 2 pA/√Hz

OUTPUT NOISE

Voltage 1kHz 65 nV/√Hz

A Weighted, 20Hz-20kHz 20Hz-20kHz –100 dBu

DYNAMIC RESPONSE

–3dB Bandwidth: G = 1 Small Signal 6 MHz

Full Power Bandwidth G = 1

V

OUT

Slew Rate G = 1 to 500 15 V/µs

THD + Noise G = 100, f = 1kHz 0.0009 %

Settling Time 0.1%

G = 1 V

G = 100 1.5 µs

Settling Time 0.01%

G = 1 V

G = 100 3.5 µs

Overload Recovery

NOTES: (1) Gains other than 1 and 100 can be set by adding an external resistor, RG between pins 2 and 15. Gain accuracy is a function of RG. (2) FS = Full Scale.

(3) Adjustable to zero. (4) V

for output to return from saturation to linear operation following the removal of an input overdrive voltage.

(1)

G = 1 + 6kΩ/R

G

V/V

G = 100 0.07 0.25 %

Equation 0.05 %

G = 100 25 ppm/°C

Equation 25 ppm/°C

G = 100 0.0006 0.01 % of FS

= 600Ω TA = T

L

R

= 600Ω VS = ±25, TA = 25°C ±20 ± 21 V

L

(3)

G = 1000 T

(4)

(5)

A

A

A

A

A

= T

= T

= T

= T

= T

to T

MIN

to T

MIN

to T

MIN

to T

MIN

to T

MIN

to T

MIN

RS = 0Ω

MAX

MAX

MAX

MAX

MAX

MAX

±11.5 ± 12 V

±40 mA

(30 + 1200/G) µV

1 + 20/G µV/°C

µV/°C

15 nA/°C

0.5 nA/°C

±11 ± 12 V

G = 100 Small Signal 800 kHz

= ±10V, RL = 600Ω 240 kHz

= 20V Step 1.7 µs

O

= 20V Step 2 µs

O

(6)

= 0V, see Typical Curves for VCM vs VO. (5) V

O

50% Overdrive 1 µs

2

NOISE RTI

= √V

N INPUT

+ (V

/Gain)2 + 4KTRG. See Typical Curves. (6) Time required

N OUTPUT

(2)

®

INA103

2

Page 3

SPECIFICATIONS (CONT)

All specifications at TA = +25°C, VS = ±15V and RL = 2kΩ, unless otherwise noted.

INA103KP, KU

PARAMETER CONDITIONS MIN TYP MAX UNITS

POWER SUPPLY

Rated Voltage ±15 V

Voltage Range ±9 ±25 V

Quiescent Current 9 12.5 mA

TEMPERATURE RANGE

Specification 0 +70 °C

Operation –40 +85 °C

Storage –40 +100 °C

Thermal Resistance,

θ

JA

100 °C/W

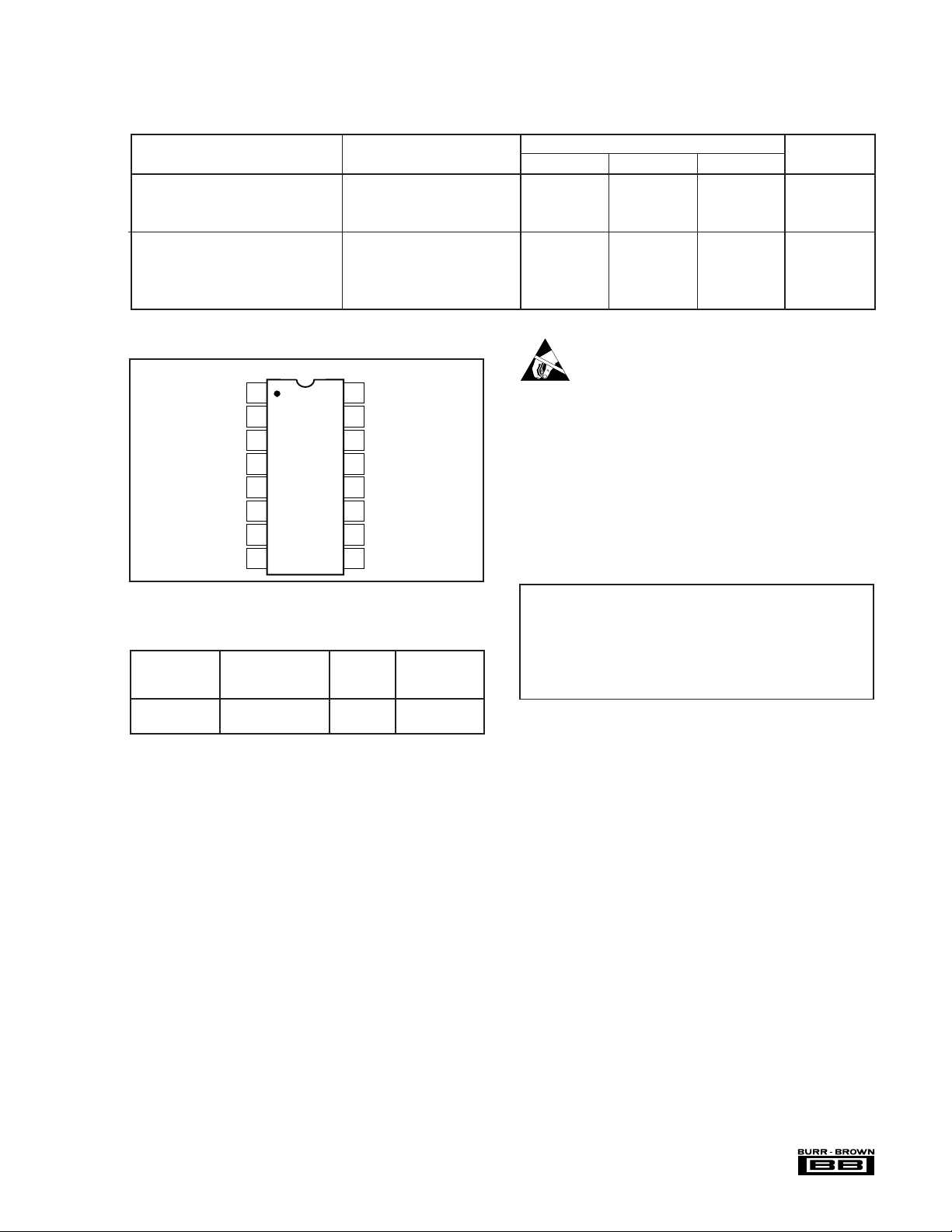

PIN CONFIGURATION

Top View DIP or SOIC

(1)

+R

Ref

V–

1

2

3

4

5

6

G

7

8

+ Input

+ Gain Sense

+ Offset Null

– Offset Null

+ Gain Drive

NOTE: (1) Pin 1 Marking—SOL-16 Package

16

15

14

13

12

11

10

9

– Input

– Gain Sense

G = 100

–R

G

– Gain Drive

Sense

Output

V+

PACKAGE/ORDERING INFORMATION

PACKAGE

DRAWING TEMPERATURE

PRODUCT PACKAGE NUMBER

INA103KP Plastic DIP 180 0°C to +70°C

INA103KU SOL-16 211 0°C to +70°C

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix C of Burr-Brown IC Data Book.

(1)

RANGE

ELECTROSTATIC

DISCHARGE SENSITIVITY

Any integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet

published specifications.

ABSOLUTE MAXIMUM RATINGS

Power Supply Voltage ....................................................................... ±25V

Input Voltage Range, Continuous ....................................................... ±V

Operating Temperature Range:........................................–40°C to +85 °C

Storage Temperature Range: ........................................... –40°C to +85°C

Junction Temperature:

P, U Package.............................................................................. +125°C

Lead Temperature (soldering, 10s) ............................................... +300°C

Output Short Circuit to Common ............................................. Continuous

NOTE: (1) Stresses above these ratings may cause permanent damage.

(1)

S

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

3

INA103

®

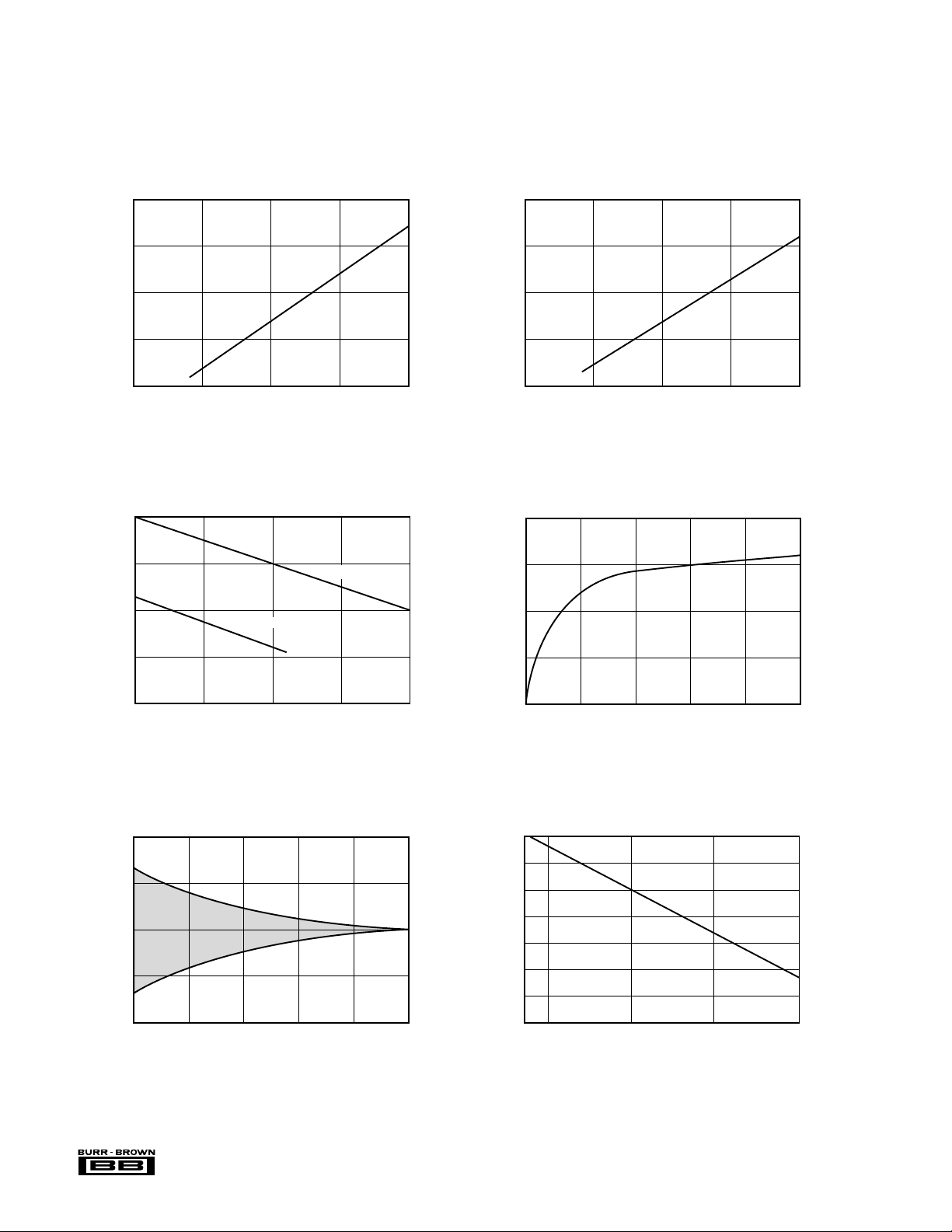

Page 4

TYPICAL PERFORMANCE CURVES

At TA = +25°C, VS = ±15V, unless otherwise noted.

±25

±20

±15

±10

Input Voltage Range (V)

±5

±5 ±10 ±15 ±20 ±25

22

16.5

11

5.5

Common-Mode Voltage (V)

INPUT VOLTAGE RANGE vs SUPPLY

Power Supply Voltage (V)

MAX COMMON-MODE VOLTAGE

vs OUTPUT VOLTAGE

V = ±25V

S

V = ±15V

S

±25

±20

±15

Output Voltage (V)

±10

±5

±5 ±10 ±15 ±20 ±25

±16

±12

±8

Output Voltage (V)

±4

OUTPUT SWING vs SUPPLY

Power Supply Voltage (V)

OUTPUT SWING vs LOAD RESISTANCE

0 5.5 11 16.5 22

Output Voltage (V)

OFFSET VOLTAGE vs TIME FROM POWER UP

20

10

OSI

0

Change In V (µV)

–10

–20

012 45

®

(G = 100)

3

Time (min)

INA103

2.60

2.55

2.50

2.45

2.40

2.35

Input Bias Current (µA)

2.30

2.25

4

±0

0 200 400 600 800 1k

Load Resistance ( )

INPUT BIAS CURRENT vs SUPPLY

9 10 15 20 25

Power Supply Voltage (±V)

Ω

Page 5

TYPICAL PERFORMANCE CURVES (CONT)

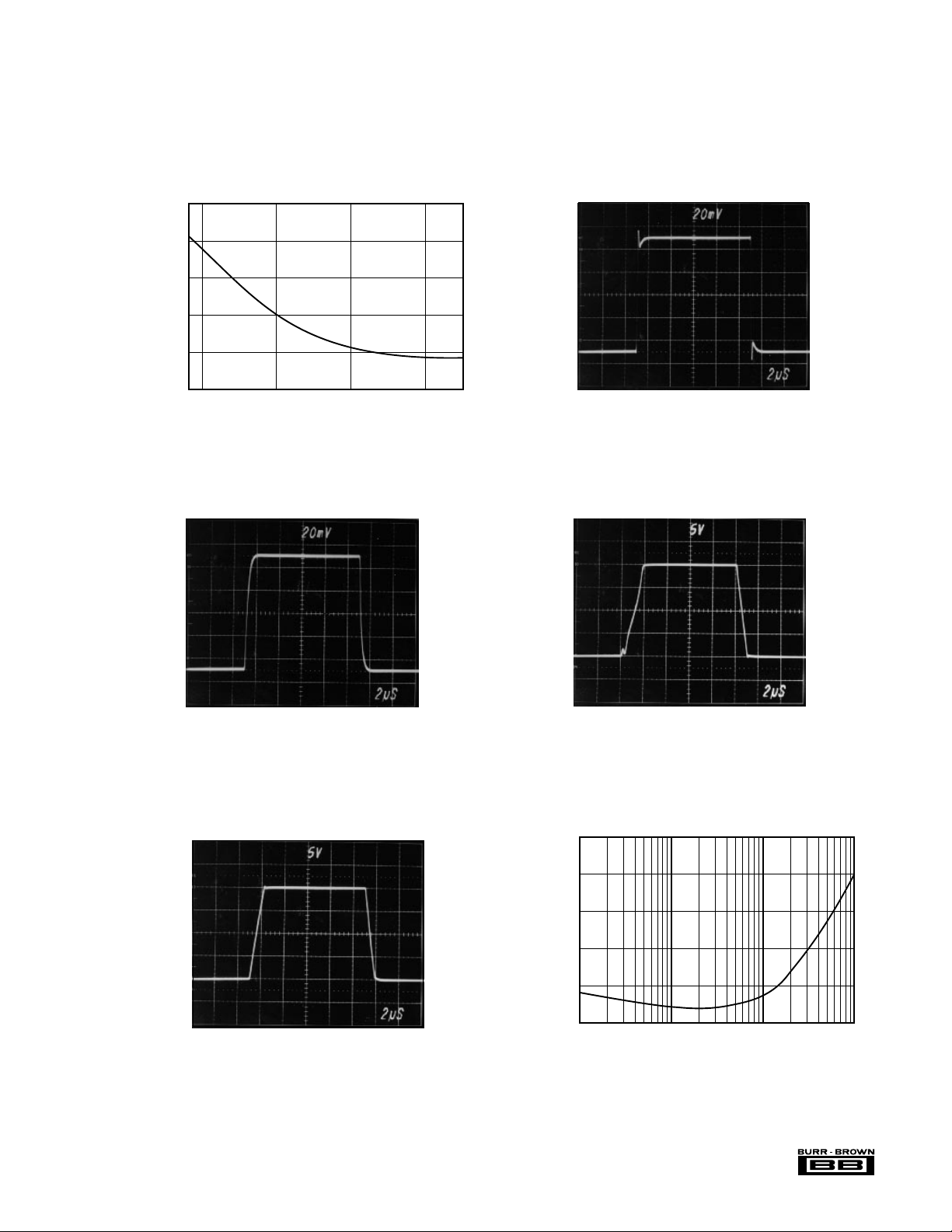

SETTLING TIME vs GAIN

(0.1%, 20V STEP)

Settling Time (µs)

Gain

1 10 100 1000

10

8

6

4

2

0

At TA = +25°C, VS = ±15V, unless otherwise noted.

6

5

4

3

Input Bias Current (µA)

2

1

INPUT BIAS CURRENT vs TEMPERATURE

–55

SMALL SIGNAL TRANSIENT RESPONSE

0 50 100 125

Temperature (°C)

(G = 100)

SMALL SIGNAL TRANSIENT RESPONSE

(G = 1)

Output Voltage (V)

Time (µs)

LARGE SIGNAL TRANSIENT RESPONSE

(G = 1)

Output Voltage (V)

Time (µs)

LARGE SIGNAL TRANSIENT RESPONSE

Output Voltage (V)

(G = 100)

Time (µs)

Output Voltage (V)

Time (µs)

®

5

INA103

Page 6

TYPICAL PERFORMANCE CURVES (CONT)

At TA = +25°C, VS = ±15V, unless otherwise noted.

SETTLING TIME vs GAIN

10

8

6

4

Settling Time (µs)

2

0

1 10 100 1000

(0.01%, 20V STEP)

Gain

70

60

50

40

30

20

10

0

Gain (dB)

–10

–20

–30

–40

–50

10 100 1k 10k 100k 1M 10M

SMALL-SIGNAL FREQUENCY RESPONSE

G = 1000

G = 100

G = 10

G = 1

Frequency (Hz)

1k

100

√

10

Noise (RTI) (nV/ Hz)

1

10 100 1k 10k

1

0.1

0.010

THD + N (%)

0.001

0.0001

10 100

NOISE VOLTAGE (RTI) vs FREQUENCY

G = 100

Frequency (Hz)

THD + N vs FREQUENCY

G = 1000

G = 1

G = 100

G = 10

1k

Frequency (Hz)

G = 1

G = 10

G = 500

G = 1000

V = +18dBu

OUT

10k 20k

140

120

100

80

60

40

Common-Mode Rejection (dB)

20

0

10 1M

140

G = 100

G = 10

120

G = 1

100

80

60

40

Power Supply Rejection (dB)

20

0

11M10 100 1k 10k 100k

CMR vs FREQUENCY

100 1k 10k 100k

Frequency (Hz)

V+ POWER SUPPLY REJECTION

vs FREQUENCY

G = 1000

Frequency (Hz)

G = 1000

G = 500

G = 100

G = 10

G = 1

®

INA103

6

Page 7

TYPICAL PERFORMANCE CURVES (CONT)

1

0.1

0.010

0.001

0.0001

CCIF IMD (%)

CCIF IMD vs AMPLITUDE

–60 –50 –40 –30 –20 –10 0 10 20

Output Amplitude (dBu)

5

G = 1000

G = 100

G = 1

G = 10

1

0.1

0.010

0.001

SMPTE IMD (%)

SMPTE IMD vs AMPLITUDE

–60 –50 –40 –30 –20 –10 0 10 20

Output Amplitude (dBu)

5

G = 1000

G = 100

G = 1

G = 10

0.0005

At TA = +25°C, VS = ±15V, unless otherwise noted.

V– POWER SUPPLY REJECTION

140

120

100

80

G = 100, 1000

G = 10

G = 1

vs FREQUENCY

1

0.1

THD + N vs LEVEL

f = 1kHz

60

40

Power Supply Rejection (dB)

20

0

11M10 100 1k 10k 100k

Frequency (Hz)

0.1

0.01

THD + N (%)

0.001

0.0001

200 400 600 800 1k

THD + N vs LOAD

Ω

R ( )

LOAD

G = 1

V = 20Vp-p

OUT

f = 1kHz

0.010

THD + N (%)

0.001

0.0005

–60 –45 –30 –15 0 15

Output Amplitude (dBu)

G = 1

5

1

0.1

0.010

CCIF IMD (%)

0.001

0.0001

2k 10k 20k

CCIF IMD vs FREQUENCY

G = 1000

G = 100

G = 10

G = 1

Frequency (Hz)

®

7

INA103

Page 8

TYPICAL PERFORMANCE CURVES (CONT)

At TA = +25°C, VS = ±15V unless, otherwise noted.

5

1

0.1

SMPTE IMD (%)

0.010

0.001

0.0005

2k 10k 20k

SMPTE IMD vs FREQUENCY

G = 1000

G = 100

G = 1

G = 10

Frequency (Hz)

100

10

Current Noise Density (pA/ Hz)

1

CURRENT NOISE SPECTRAL DENSITY

1 10 100 1k 10k

Frequency (Hz)

APPLICATIONS INFORMATION

Figure 1 shows the basic connections required for operation.

Power supplies should be bypassed with 1µF tantalum

capacitors near the device pins. The output Sense (pin 11)

and output Reference (pin 7) should be low impedance

connections. Resistance of a few ohms in series with these

connections will degrade the common-mode rejection of the

amplifier.

To avoid oscillations, make short, direct connection to the

gain set resistor and gain sense connections. Avoid running

output signals near these sensitive input nodes.

INPUT CONSIDERATIONS

Certain source impedances can cause the INA103 to oscillate. This depends on circuit layout and source or cable

characteristics connected to the input. An input network

consisting of a small inductor and resistor (Figure 2) can

greatly reduce the tendancy to oscillate. This is especially

®

INA103

useful if various input sources are connected to the INA103.

Although not shown in other figures, this network can be

used, if needed, with all applications shown.

GAIN SELECTION

Gains of 1 or 100V/V can be set without external resistors.

For G = 1V/V (unity gain) leave pin 14 open (no connection)—see Figure 4. For G = 100V/V, connect pin 14 to pin

6—see Figure 5.

Gain can also be accurately set with a single external resistor

as shown in Figure 1. The two internal feedback resistors are

laser-trimmed to 3kΩ within approximately ±0.1%. The

temperature coefficient of these resistors is approximately

50ppm/˚C. Gain using an external R

G = 1 +

6kΩ

R

G

resistor is—

G

8

Page 9

11

16

7

V

OUT

1

50Ω

50Ω

1.2µH

1.2µH

INA103

V+

11

10

7

R

G

V

IN

16

15

13

14

6

2

1

INA103

∆

V

OUT

3

4

10kΩ

V–

Offset Adjust

Range = ±250mV.

G = 1 + —–

6kΩ

R

G

RTI

1µF Tantalum

+

9

16

15

–

V

IN

+

NOTES: (1) No R

See gain-set connections in Figure 4.

(2) R

gain-set connection in Figure 5.

13

14

R

G

6

2

1

for G = 100 is internal. See

G

INA103

8

+

V–

required for G = 1.

G

10

VO = G • V

R

L

11

7

GAIN GAIN (dB) RG (Ω)

1 0 Note 1

3.16 10 2774

10 20 667

31.6 30 196

100 40 60.6

316 50 19

1000 60 6

IN

(2)

FIGURE 1. Basic Circuit Configuration.

Accuracy and TCR of the external R

will also contribute to

G

gain error and temperature drift. These effects can be directly inferred from the gain equation.

Connections available on A

and A2 allow external resistors

1

to be substituted for the internal 3kΩ feedback resistors. A

precision resistor network can be used for very accurate and

stable gains. To preserve the low noise of the INA103, the

value of external feedback resistors should be kept low.

Increasing the feedback resistors to 20kΩ would increase

noise of the INA103 to approximately 1.5nV/√Hz. Due to

the current-feedback input circuitry, bandwidth would also

be reduced.

NOISE PERFORMANCE

The INA103 provides very low noise with low source

impedance. Its 1nV/√Hz voltage noise delivers near theoretical noise performance with a source impedance of 200Ω.

Relatively high input stage current is used to achieve this

low noise. This results in relatively high input bias current

and input current noise. As a result, the INA103 may not

provide best noise performance with source impedances

greater than 10kΩ. For source impedance greater than 10kΩ,

consider the INA114 (excellent for precise DC applications), or the INA111 FET-input IA for high speed applications.

FIGURE 2. Input Stabilization Network.

Offset voltage can be trimmed with the optional circuit

shown in Figure 3. This offset trim circuit primarily adjusts

the output stage offset, but also has a small effect on input

stage offset. For a 1mV adjustment of the output voltage, the

input stage offset is adjusted approximately 1µV. Use this

adjustment to null the INA103’s offset voltage with zero

differential input voltage. Do not use this adjustment to null

offset produced by a sensor, or offset produced by subsequent stages, since this will increase temperature drift.

To offset the output voltage without affecting drift, use the

circuit shown in Figure 4. The voltage applied to pin 7 is

summed at the output. The op amp connected as a buffer

provides a low impedance at pin 7 to assure good commonmode rejection.

Figure 5 shows a method to trim offset voltage in ACcoupled applications. A nearly constant and equal input bias

current of approximately 2.5µA flows into both input terminals. A variable input trim voltage is created by adjusting the

balance of the two input bias return resistances through

which the input bias currents must flow.

OFFSET ADJUSTMENT

Offset voltage of the INA103 has two components: input

stage offset voltage is produced by A

stage offset is produced by A

offset are laser trimmed and may not need adjustment in

many applications.

and A2; and, output

. Both input and output stage

3

1

FIGURE 3. Offset Adjustment Circuit.

9

®

INA103

Page 10

Figure 6 shows an active control loop that adjusts the output

offset voltage to zero. A

, R, and C form an integrator that

2

produces an offsetting voltage applied to one input of the

INA103. This produces a –6dB/octave low frequency rolloff like the capacitor input coupling in Figure 5.

COMMON-MODE INPUT RANGE

For proper operation, the combined differential input signal

and common-mode input voltage must not cause the input

amplifiers to exceed their output swing limits. The linear

input range is shown in the typical performance curve

“Maximum Common-Mode Voltage vs Output Voltage.”

For a given total gain, the input common-mode range can be

increased by reducing the input stage gain and increasing the

output stage gain with the circuit shown in Figure 7.

16

15

13

14

V

∆

IN

6

2

1

INA103

NOTE: (1) 1/2 REF200

11

7

OPA27

Offset Adjustment

Range = ±15mV

10

Gain = 1V/V

(0dB)

V

OUT

100µA

–

+

10kΩ

100µA

V+

(1)

150Ω

150Ω

(1)

V–

OUTPUT SENSE

An output sense terminal allows greater gain accuracy in

driving the load. By connecting the sense connection at the

load, I•R voltage loss to the load is included inside the

feedback loop. Current drive can be increased by connecting a current booster inside the feedback loop as shown in

Figure 11.

–

+

I

≈ I

≈ 2.5µA

B

–In

+In

50kΩ

B

16

–

I

15

B

13

14

6

2

+

I

B

1

(1)

100kΩ

50kΩ

(1)

(1)

Gain = 100V/V

(40dB)

11

INA103

NOTE: (1) 50k R, 100k pot is

max recommended value. Use

smaller values in this ratio if possible.

ΩΩ

10

V

7

OUT

FIGURE 4. Output Offsetting. FIGURE 5. Input Offset Adjustment for AC-Coupled Inputs.

Gain = 100V/V

INA103

(40dB)

11

7

1/2 OPA1013

Ω

1µF

A

–3dB

=

Gain

12π RC

f

10

C

2

V

OUT

R

100kΩ

–

+

–In

+In

100kΩ

16

15

13

14

6

2

1

(1)

(1)

100kΩ

10kΩ

2kΩ

NOTE: (1) 100k is max recommended

value. Use smaller value if possible.

FIGURE 6. Automatic DC Restoration.

®

INA103

10

Page 11

R

11

10

7

V

IN

16

15

13

14

6

2

1

INA103

∆

V

OUT

R

G

V+

V–

MJ15012

100

MJ15011

(To headphone

or speaker)

Buffer inside feedback loop

Ω

F

16

R

15

13

14

V

∆

IN

6

2

1

Output Stage Gain =

(R2 || 12k) + R1 + R

(R2 || 12k)

11

INA103

10

7

OUTPUT STAGE R1 and R3R

GAIN (kΩ)(Ω)

3

2 1k 2.4k

5 1.2k 632Ω

10 1.2k 273Ω

1

16

R

2

V

OUT

∆

V

R

3

2

IN

15

13

14

R

G

INA103

6

2

1

R

F

12

11

10

7

5

2R

G = 1+

F

R

G

RF > 10kΩ can increase noise and reduce bandwidth—see text.

NOTE: AD625 equivalent pinout.

FIGURE 7. Gain Adjustment of Output Stage. FIGURE 8. Use of External Resistors for Gain Set.

V

OUT

(a) AD625 G = 1, VIN = ±15V, RL = 600Ω

A common problem with many IC op amps and instrumentation amplifiers is shown in (a). Here, the amplifier’s input is driven beyond its linear common-mode

range, forcing the output of the amplifier into the supply rails. The output then “folds back”, i.e., a more positive input voltage now causes the output of the amplifier

to go negative. The INA103 has protection circuitry to prevent fold-back, and as shown in (b), limits cleanly.

(b) INA103 G = 1, V

= ±15V, RL = 600Ω

IN

FIGURE 9. INA103 Overload Condition Performance.

Gain = 1V/V

16

15

13

14

V

∆

IN

INA103

6

2

1

Introduces

FIGURE 10. Optional Circuit for Externally Trimming CMR.

approximately

+0.2% Gain Error.

(0dB)

20Ω

10Ω

11

10

7

CMR

Trim

FIGURE 11. Increasing Output Circuit Drive.

®

11

INA103

Page 12

cm

47µF/63V

Phantom

Power

47kΩ

47µF/63V

+

2.2kΩ

240Ω

+

2.2kΩ

240Ω

20dB

Pad

20dB

Pad

10Ω

Gain

Adjust

6.8kΩ

1

3

2

6.8kΩ

+48V

1kΩ

16

15

13

14

6

2

1

INA103

FIGURE 12. Microphone Preamplifier with Provision for Phantom Power Microphones.

16

10kΩ

∆

V

IN

10kΩ

15

13

14

6

2

1

INA103

12

11

10

7

5

11

10

7

1µF

OPA627

Output offset voltage

control loop.

10kΩ

V

OUT

10kΩ

V

OUT

100kΩ

–

+

100Ω

–

+

OPA602

FIGURE 13. Instrumentation Amplifier with Shield Driver.

–

+

OPA627

∆

V

IN

–

+

OPA627

16

15

13

14

6

2

1

FIGURE 14. Gain-of-100 INA103 with FET Buffers.

Shield driver minimizes degradation of CMR due

to distributed capacitance on the input lines.

11

INA103

Gain = 100V/V

(40dB)

10

7

V = 100

OUT

∆

V

IN

®

INA103

12

Page 13

PACKAGE OPTION ADDENDUM

www.ti.com

22-Oct-2007

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

INA103KP ACTIVE PDIP N 16 25 Green (RoHS &

no Sb/Br)

INA103KPG4 ACTIVE PDIP N 16 25 Green (RoHS &

no Sb/Br)

INA103KU ACTIVE SOIC DW 16 48 Green (RoHS &

no Sb/Br)

INA103KU/1K ACTIVE SOIC DW 16 1000 Green (RoHS &

no Sb/Br)

INA103KU/1KE4 ACTIVE SOIC DW 16 1000 Green (RoHS &

no Sb/Br)

INA103KUG4 ACTIVE SOIC DW 16 48 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU N / A for Pkg Type

CU NIPDAU N / A for Pkg Type

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 14

PACKAGE MATERIALS INFORMATION

www.ti.com

TAPE AND REEL INFORMATION

11-Mar-2008

*All dimensions are nominal

Device Package

Type

INA103KU/1K SOIC DW 16 1000 330.0 16.4 10.85 10.8 2.7 12.0 16.0 Q1

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 15

PACKAGE MATERIALS INFORMATION

www.ti.com

11-Mar-2008

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

INA103KU/1K SOIC DW 16 1000 346.0 346.0 33.0

Pack Materials-Page 2

Page 16

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Clocks and Timers www.ti.com/clocks Digital Control www.ti.com/digitalcontrol

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

RF/IF and ZigBee® Solutions www.ti.com/lprf Video & Imaging www.ti.com/video

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2008, Texas Instruments Incorporated

Wireless www.ti.com/wireless

Loading...

Loading...