Texas Instruments bq25120A Datasheet

GND

HOST

SDA

SCL

INT

SW

BAT

MR

BQ2512x

MCU /

SYSTEM

-+

NTC

TS

LS / LDO

<100mA

Load

IN

SYS

RESET

LSCTRL

VINLS

Unregulated

Load

PMID

PG

IPRETERM

ISET

ILIM

CD

IN

Copyright © 2016, Texas Instruments Incorporated

Product

Folder

Order

Now

Technical

Documents

Tools &

Software

Support &

Community

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

bq25120A Low IQHighly Integrated Battery Charge Management Solution for Wearables

and IoT

1 Features

1

• Increases System Operation Time Between

Charges

– Configurable 300-mA Buck Regulator

(1.8-V Default)

– 700 nA (typical) Iq with Buck Converter

Enabled (No Load)

– Configurable Load Switch or 100mA LDO

Output (Load Switch by Default)

– Up to 300-mA Charge Current for Fast

Charging

– 0.5% Accurate Battery Voltage Regulation

(Configurable from 3.6 V to 4.65 V in 10-mV

Steps)

– Configurable Termination Current Down to

500 µA

– Simple Voltage Based Battery Monitor

• Highly Integrated Solution with Small Footprint

– 2.5 mm x 2.5 mm WCSP Package and 6

External Components for Minimal Solution

– Push-Button Wake-Up and Reset with

Adjustable Timers

– Power Path Management for Powering the

System and Charging the Battery

– Power Path Management enables <50 nA Ship

Mode Battery Quiescent Current for Longest

Shelf Life

– Battery Charger Operates from 3.4 V – 5.5 V

(5.5-V OVP / 20-V Tolerant)

– Dedicated Pins for Input Current Limit, Charge

Current, Termination Current, and Status

Output

• I2C Communication Control

– Charge Voltage and Current

1

– Termination Threshold

– Input Current Limit

– VINDPM Threshold

– Timer Options

– Load Switch Control

– Controls for Interrupts for Faults and Status

– System Output Voltage Adjustment

– LDO Output Voltage Adjustment

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

2 Applications

• Smart Watches and other Wearable Devices

• Fitness Accessories

• Health Monitoring Medical Accessories

• Rechargeable Toys

3 Description

The bq25120A is a highly integrated battery charge

management IC that integrates the most common

functions for wearable devices: Linear charger,

regulated output, load switch, manual reset with

timer, and battery voltage monitor. The integrated

buck converter is a high efficiency, low IQswitcher

using DCS control that extends light load efficiency

down to 10-µA load currents. The low quiescent

current during operation and shutdown enables

maximum battery life. The device supports charge

currents from 5 mA to 300 mA. The input current

limit, charge current, buck converter output voltage,

LDO output voltage, and other parameters are

programmable through the I2C interface.

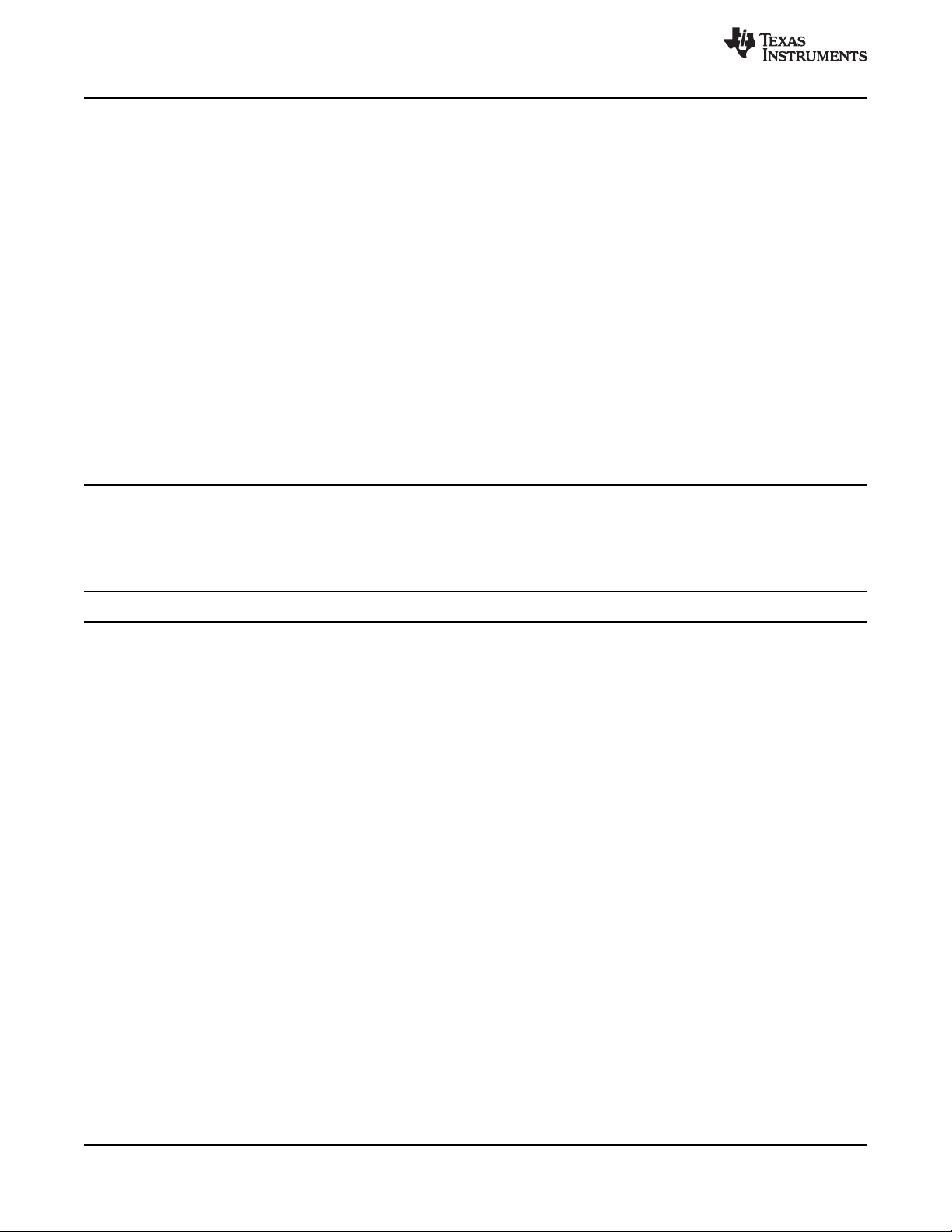

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

BQ25120A DSBGA (25) 2.50 mm x 2.50 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

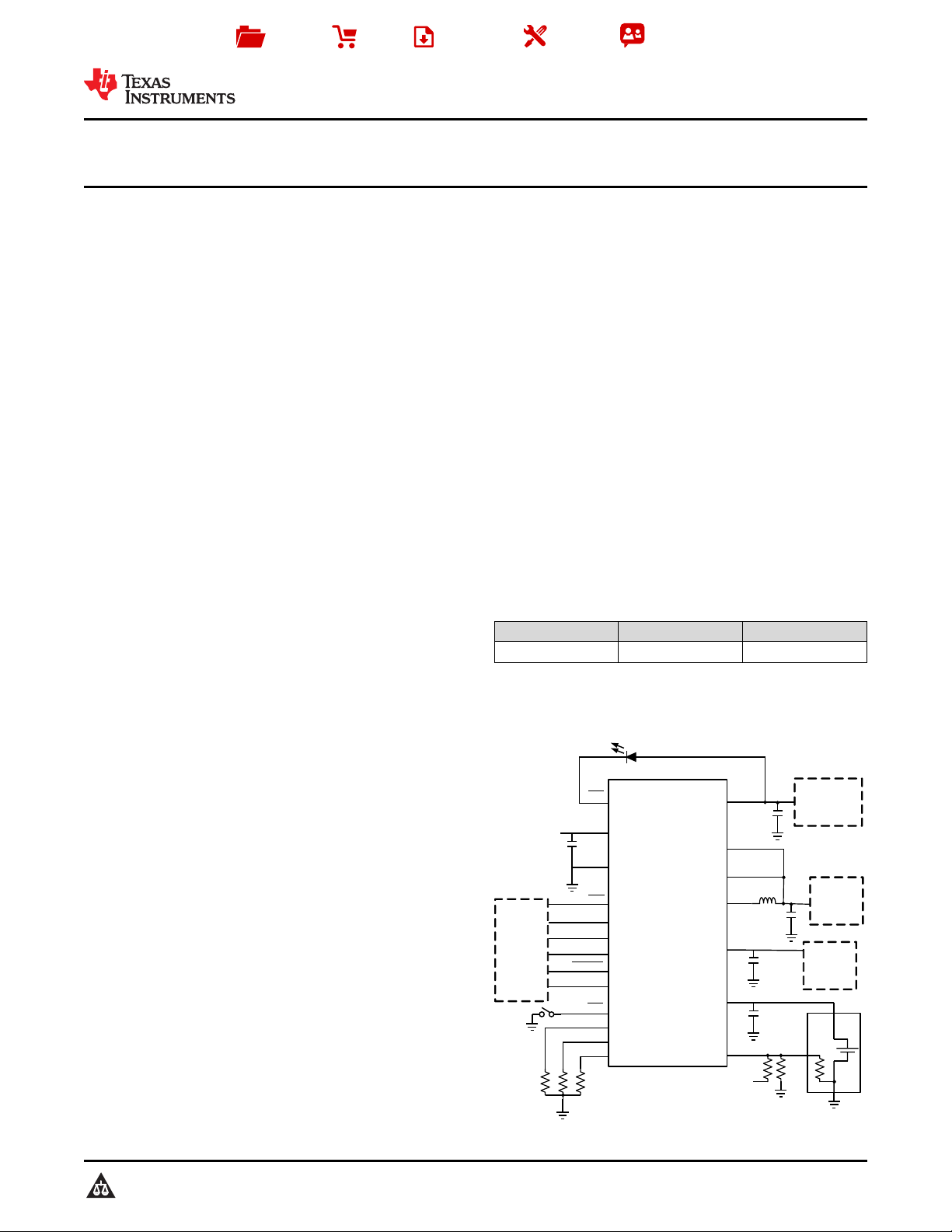

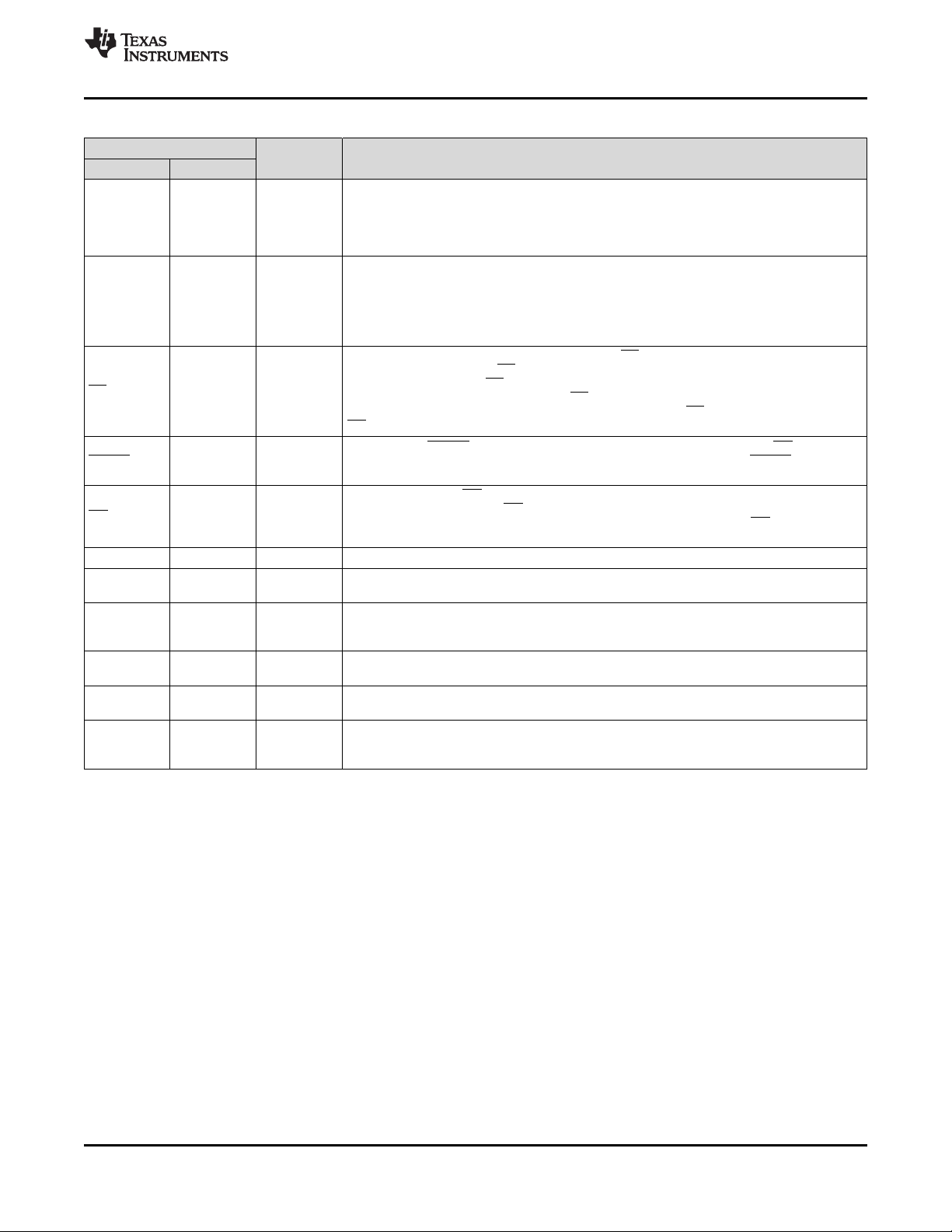

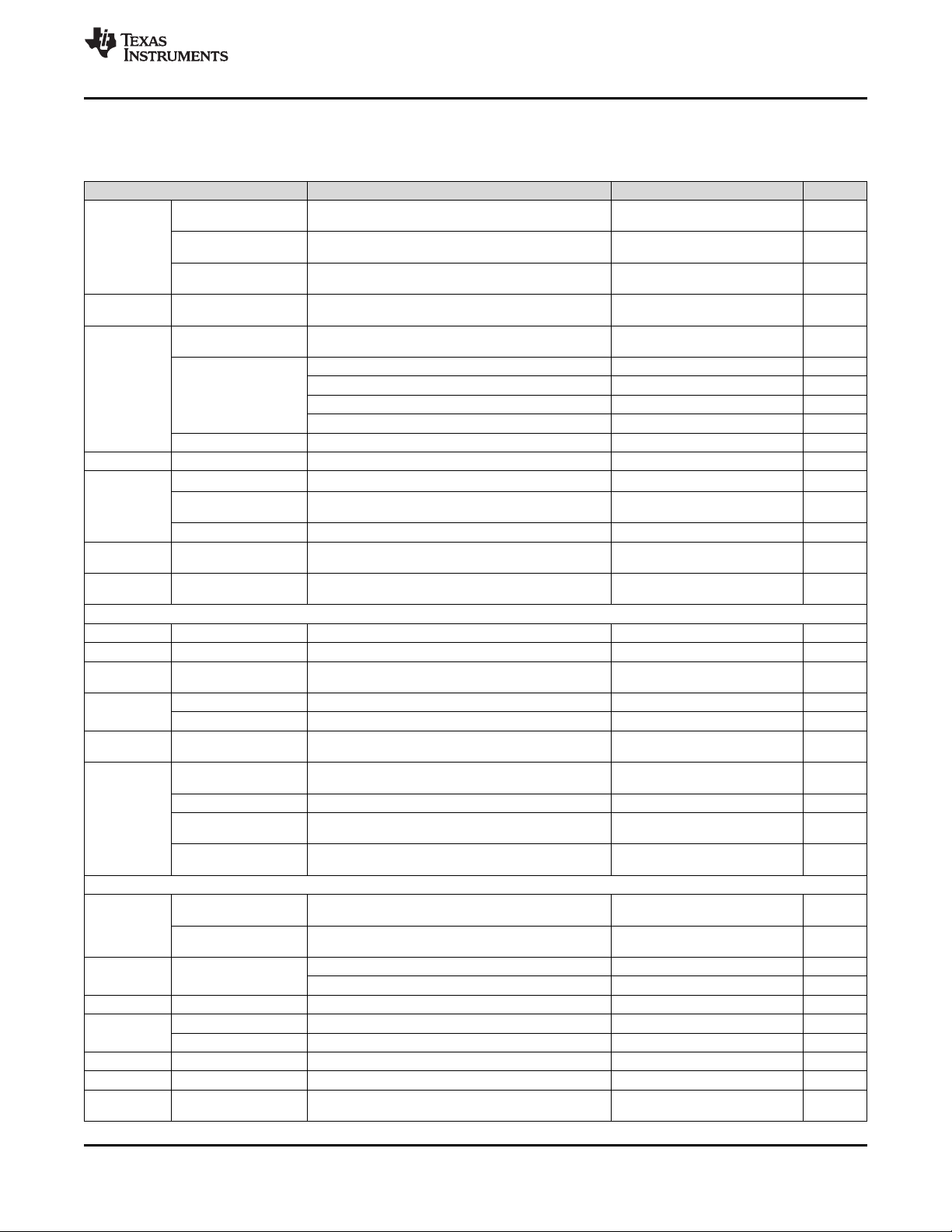

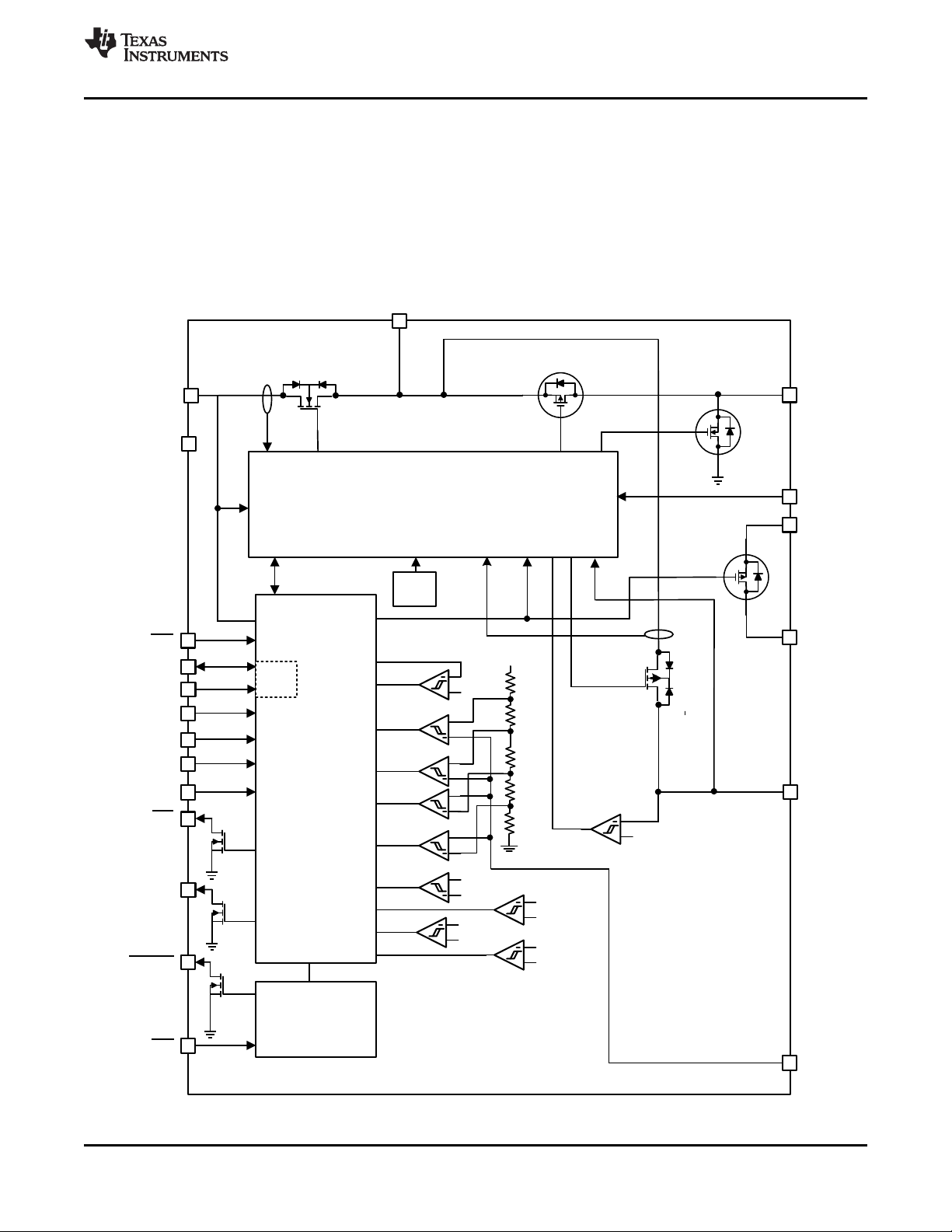

Simplified Schematic

IN

(1)

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Revision History..................................................... 2

5 Description (continued)......................................... 3

6 Device Comparison Table..................................... 3

7 Pin Configuration and Functions......................... 4

8 Specifications......................................................... 6

8.1 Absolute Maximum Ratings ...................................... 6

8.2 ESD Ratings.............................................................. 6

8.3 Recommended Operating Conditions....................... 6

8.4 Thermal Information.................................................. 7

8.5 Electrical Characteristics........................................... 8

8.6 Timing Requirements ............................................. 12

8.7 Typical Characteristics............................................ 15

9 Detailed Description............................................ 17

9.1 Overview ................................................................. 17

9.2 Functional Block Diagram....................................... 17

9.3 Feature Description................................................. 18

9.4 Device Functional Modes........................................ 31

9.5 Programming .......................................................... 33

9.6 Register Maps ........................................................ 36

10 Application and Implementation........................ 47

10.1 Application Information.......................................... 47

10.2 Typical Application ............................................... 47

11 Power Supply Recommendations ..................... 62

12 Layout................................................................... 63

12.1 Layout Guidelines ................................................. 63

12.2 Layout Example .................................................... 63

13 Device and Documentation Support................. 64

13.1 Device Support...................................................... 64

13.2 Trademarks........................................................... 64

13.3 Electrostatic Discharge Caution............................ 64

13.4 Glossary................................................................ 64

14 Mechanical, Packaging, and Orderable

Information........................................................... 64

4 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from Original (May 2017) to Revision A Page

• Changed expression terms in Equation 3 and Equation 4 for clarification........................................................................... 26

2

Submit Documentation Feedback Copyright © 2017–2018, Texas Instruments Incorporated

Product Folder Links: bq25120A

bq25120A

www.ti.com

SLUSD08A –MAY 2017–REVISED JANUARY 2018

5 Description (continued)

The battery is charged using a standard Li-Ion charge profile with three phases: precharge, constant current and

constant voltage. A voltage-based JEITA compatible battery pack thermistor monitoring input (TS) is included

that monitors battery temperature and automatically changes charge parameters to prevent the battery from

charging outside of its safe temperature range. The charger is optimized for 5-V USB input, with 20-V tolerance

to withstand line transients. The buck converter is run from the input or battery. When in battery only mode, the

device can run from a battery up to 4.65 V.

A configurable load switch allows system optimization by disconnecting infrequently used devices. The manual

reset with timer allows mutliple different configuration options for wake are reset optimization.

6 Device Comparison Table

PART NUMBER VINDPM

BQ25120A Enabled 1.8V Load Switch 4.2 V 10 mA 2 mA Off

DEFAULT SYS

OUTPUT

DEFAULT LDO

OUTPUT

DEFAULT

VBERG

DEFAULT

CHARGE

CURRENT

DEFAULT

TERMINATION

CURRENT

DEFAULT SHIP

MODE

Product Folder Links: bq25120A

Submit Documentation FeedbackCopyright © 2017–2018, Texas Instruments Incorporated

3

GND

RESETINT

/MR

IPRETE

RM

ISET

BATBAT

TS

ILIM

/PG

VINLS

VINLS

PGNDSWPMID

A

B

C

D

1 2 3 4

SDALSCTRL/CD SCL

E

IN

LS/LDO

SYSPMID

GND

5

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

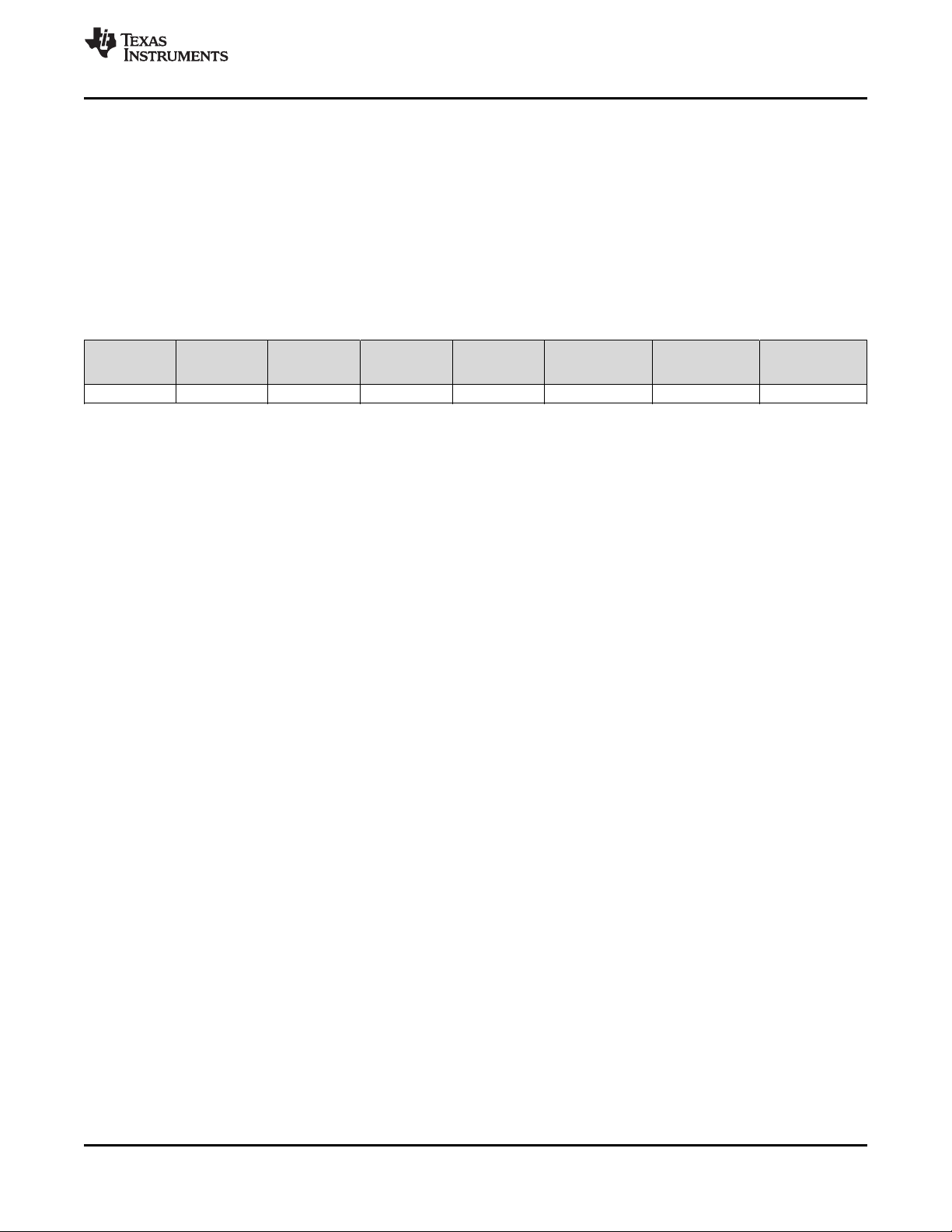

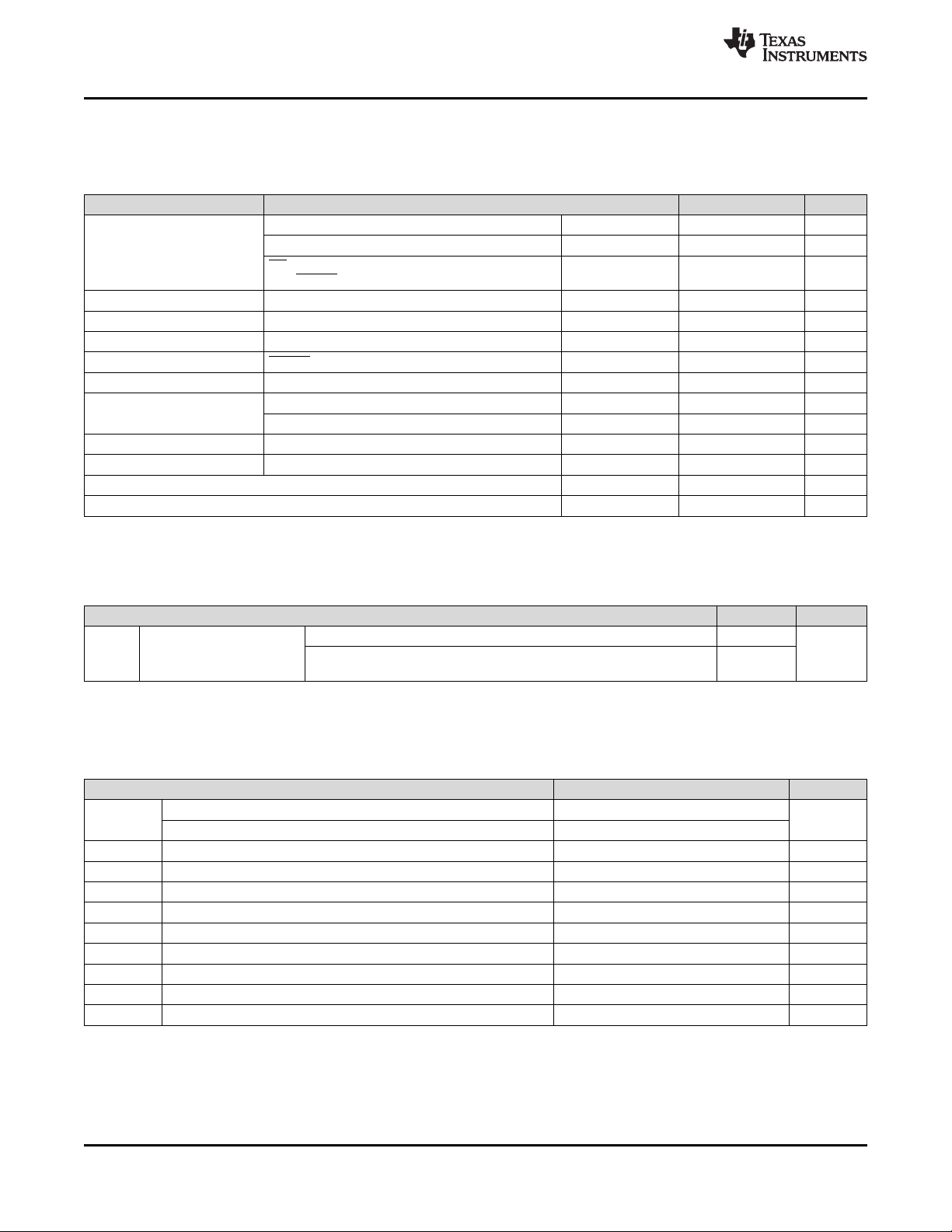

7 Pin Configuration and Functions

www.ti.com

YFP Package

25-Pin DSBGA

Top View

Pin Functions

PIN

NAME NO.

IN A2 I

PMID A3, B3 I/O

GND A1, D5 Ground connection. Connect to the ground plane of the circuit.

PGND A5

CD E2 I

SDA E4 I/O I2C Interface Data. Connect SDA to the logic rail through a 10-kΩ resistor.

SCL E5 I I2C Interface Clock. Connect SCL to the logic rail through a 10-kΩ resistor.

ILIM C2 I

LSCTRL E3 I

ISET C1 I

I/O DESCRIPTION

DC Input Power Supply. IN is connected to the external DC supply. Bypass IN to GND with

at least 1 µF of capacitance using a ceramic capacitor.

High Side Bypass Connection. Connect at least 3µF of ceramic capacitance with DC bias

derating from PMID to GND as close to the PMID and GND pins as possible. When entering

Ship Mode, PMID is discharged by a 20-kΩ internal discharge resistor.

Power ground connection. Connect to the ground plane of the circuit. Connect the output

filter cap from the buck converter to this ground as shown in the layout example.

Chip Disable. Drive CD low to place the part in High-Z mode with battery only present, or

enable charging when VINis valid. Drive CD high for Active Battery mode when battery only

is present, and disable charge when VINis present. CD is pulled low internally with 900 kΩ.

Adjustable Input Current Limit Programming. Connect a resistor from ILIM to GND to

program the input current limit. The input current includes the system load and the battery

charge current. Connect ILIM to GND to set the input current limit to the internal default

threshold. ILIM can also be updated through I2C.

Load Switch and LDO Control Input. Pull high to enable the LS/LDO output, pull low to

disable the LS/LDO output.

Fast-Charge Current Programming Input. Connect a resistor from ISET to GND to program

the fast-charge current level. Connect a resistor from ISET to GND to set the charge current

to the internal default. ISET can also be updated through I2C. While charging, the voltage at

ISET reflects the actual charging current and can be used to monitor charge current if an

ISET resistor is present and the device is not in host mode.

4

Submit Documentation Feedback Copyright © 2017–2018, Texas Instruments Incorporated

Product Folder Links: bq25120A

www.ti.com

SLUSD08A –MAY 2017–REVISED JANUARY 2018

Pin Functions (continued)

PIN

NAME NO.

IPRETERM D1 I

INT D2 O

PG D4 O

RESET D3 O

MR E1 I

SW A4 O Inductor Connection. Connect to the switched side of the external inductor.

SYS B5 I

LS/LDO C5 O

VINLS B4, C4 I

BAT B1, B2 I/O

TS C3 I

I/O DESCRIPTION

Termination current programming input. Connect a 0-Ω to 10-kΩ resistor from IPRETERM to

GND to program the termination current between 5% and 20% of the charge current. The

pre-charge current is the same as the termination current setting. Connect IPRETERM to

GND to set the termination current to the internal default threshold. IPRETERM can also be

updated through I2C.

Status Output. INT is an open-drain output that signals charging status and fault interrupts.

INT pulls low during charging. INT is high impedance when charging is complete, disabled,

or the charger is in high impedance mode. When a fault occurs, a 128µs pulse is sent out as

an interrupt for the host. INT charge indicator function is enabled/disabled using the EN_INT

bit in the control register. Connect INT to a logic rail using an LED for visual indication of

charge status or through a 100kΩ resistor to communicate with the host processor.

Open-drain Power Good status indication output. PG pulls to GND when VINis above V

+ V

and less that V

SLP

specified limits. Connect PG to the desired logic voltage rail using a 1kΩ to 100kΩ resistor,

or use with an LED for visual indication. PG can also be configured as a push-button voltage

shifted output (MRS) in the registers, where the output of the PG pin reflects the status of the

MR input, but pulled up to the desired logic voltage rail using a 1kΩ to 100kΩ resistor.

Reset Output. RESET is an open drain active low output that goes low when MR is held low

for longer than t

deasserted after the t

Manual Reset Input. MR is a push-button input that must be held low for greater than t

to assert the reset output. If MR is pressed for a shorter period, there are two programmable

timer events, t

be used to bring the device out of Ship mode.

System Voltage Sense Connection. Connect SYS to the system output at the output bulk

capacitors. Bypass SYS locally with at least 4.7 µF of effective ceramic capacitance.

Load Switch or LDO output. Connect 1 µF of effective ceramic capacitance to this pin to

assure stability. Be sure to account for capacitance bias voltage derating when selecting the

capacitor.

Input to the Load Switch / LDO output. Connect 1 µF of effective ceramic capacitance from

this pin to GND.

Battery Connection. Connect to the positive terminal of the battery. Bypass BAT to GND with

at least 1 µF of ceramic capacitance.

Battery Pack NTC Monitor. Connect TS to the center tap of a resistor divider from VIN to

GND. The NTC is connected from TS to GND. The TS function provides four thresholds for

JEITA compatibility. TS faults are reported by the I2C interface during charge mode.

. PG is high-impedance when the input power is not within

OVP

, which is configurable by the MRRESET registers. RESET is

RESET

WAKE1

RESET_D,

and t

typically 400ms.

, that trigger an interrupt to the host. The MR input can also

WAKE2

bq25120A

(BAT)

RESET

Product Folder Links: bq25120A

Submit Documentation FeedbackCopyright © 2017–2018, Texas Instruments Incorporated

5

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

www.ti.com

8 Specifications

8.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

IN wrt GND –0.3 20 V

Input voltage

Output voltage SYS 3.6 V

Input current IN 400 mA

Sink current INT 10 mA

Sink/Source Current RESET 10 mA

Output Voltage Continuos SW –0.7 7.7 V

Output Current Continuous

Current LS/LDO 150 mA

BAT Operating Voltage VBAT, MR, 6.6 V

Junction Temperature –40 125 °C

Storage Temperature, T

stg

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

PMID, VINLS wrt GND –0.3 7.7 V

CD, SDA, SCL, ILIM, ISET, IPRETERM, LSCTRL,

INT, RESET, TS

SW 400 mA

SYS, BAT 300 mA

(1)

MIN MAX UNIT

wrt GND –0.3 5.5 V

300 °C

8.2 ESD Ratings

VALUE UNIT

(1)

±2000

±500

V

(ESD)

Electrostatic discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001

Charged device model (CDM), per JEDEC specification JESD22-

(2)

C101

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

8.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

V

IN

V

(BAT)

V

(VINLS)

V

(VINLS)

I

IN

I

(SW)

I

(PMID)

ILS/LDO Output Current from LS/LDO 100 mA

I

, I

(BAT)

T

J

(1) Any voltage greater than shown should be a transient event.

(2) These inputs will support 6.6 V for less than 10% of the lifetime at V

IN voltage range 3.4 5 20

IN operating voltage range, recommended 3.4 5 5.5

V

operating voltage range 5.5

(BAT)

VINLS voltage range for Load Switch 0.8 5.5

VINLS voltage range for LDO 2.2 5.5 V

Input Current, IN input 400 mA

Output Current from SW, DC 300 mA

Output Current from PMID, DC 300 mA

Charging and discharging using internal battery FET 300 mA

(SYS)

Operating junction temperature range –40 125 °C

or VIN, with a reduced current and/or performance.

(BAT)

(1)

(2)

V

V

V

V

6

Submit Documentation Feedback Copyright © 2017–2018, Texas Instruments Incorporated

Product Folder Links: bq25120A

bq25120A

www.ti.com

SLUSD08A –MAY 2017–REVISED JANUARY 2018

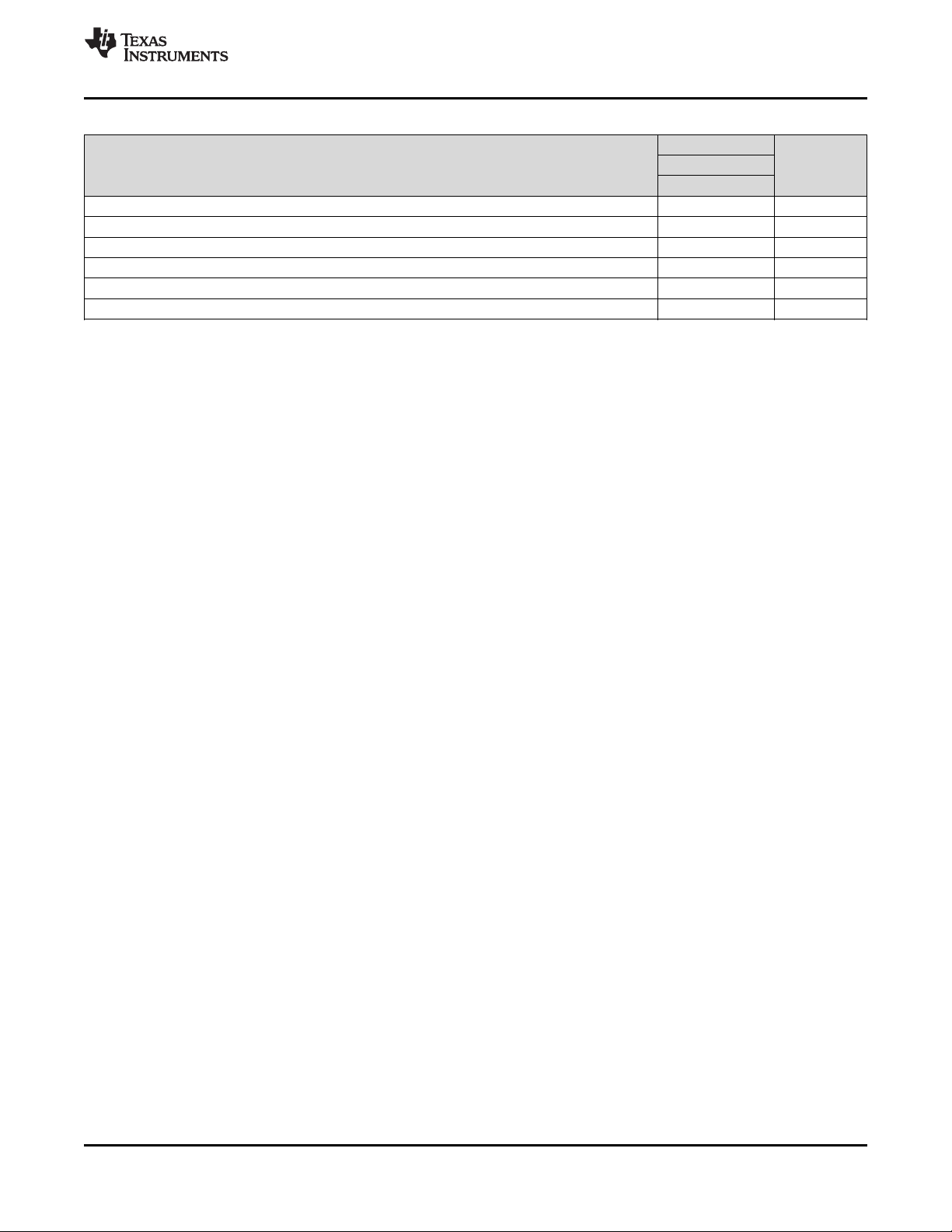

8.4 Thermal Information

bq25120A

THERMAL METRIC

R

θJA

R

θJC(top)

R

θJB

ψ

JT

ψ

JB

R

θJC(bot)

Junction-to-ambient thermal resistance 60 °C/W

Junction-to-case (top) thermal resistance 0.3 °C/W

Junction-to-board thermal resistance 12.0 °C/W

Junction-to-top characterization parameter 1.2 °C/W

Junction-to-board characterization parameter 12.0 °C/W

Junction-to-case (bottom) thermal resistance N/A °C/W

(1) For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

(1)

UNITYFP (DSBGA)

25 PINS

Product Folder Links: bq25120A

Submit Documentation FeedbackCopyright © 2017–2018, Texas Instruments Incorporated

7

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

8.5 Electrical Characteristics

Circuit of Figure 1, V

otherwise noted)

PARAMETERS TEST CONDITIONS MIN TYP MAX UNIT

INPUT CURRENTS

I

IN

I

(BAT_HIZ)

I

(BAT_ACTIVE)

I

(BAT_SHIP)

POWER-PATH MANAGEMENT and INPUT CURRENT LIMIT

V

DO(IN-PMID)

V

DO(BAT-PMID)

V

(BSUP1)

V

(BSUP2)

I

(BAT_OCP)

I

(ILIM)

K

(ILIM)

V

IN(DPM)

BATTERY CHARGER

V

D(PPM)

R

ON(BAT-PMID)

V

(BATREG)

Supply Current for

Control

Battery discharge current

in High Impedance Mode

Battery discharge current

in Active Battery Mode

Battery discharge current

in Ship Mode

VIN– V

V

(BAT)

Enter supplement mode

threshold

Exit supplement mode

threshold

Current Limit, Discharge

Mode

Input Current Limit Programmable Range, 50-mA steps 50 400 mA

Maximum Input Current

using ILIM

I

accuracy I

ILIM

accuracy

Maximum input current

factor

Input voltage threshold

when input current is

reduced

V

IN_DPM

accuracy

PMID voltage threshold

when charge current is

reduced

Internal Battery Charger

MOSFET on-resistance

Charge Voltage

Voltage Regulation

Accuracy

(UVLO)

(PMID)

– V

(PMID)

threshold

< VIN< V

ILIM

and VIN> V

(OVP)

V

< VIN< V

(UVLO)

Switching, –40°C < TJ< 85°C

V

< VIN< V

(UVLO)

Switching

0°C < TJ< 85°C, VIN= 5 V, Charge Disabled 1.5 mA

0°C < TJ< 60°C, VIN= 0 V, High-Z Mode, PWM Not

Switching, V

0°C < TJ< 60°C, VIN= 0 V, High-Z Mode, PWM Not

Switching, V

0°C < TJ< 60°C, VIN= 0 V or floating, High-Z Mode, PWM

Switching, No Load

0°C < TJ< 85°C, VIN= 0 V, High-Z Mode, PWM Switching,

LSLDO enabled

0°C < TJ< 85°C, VIN= 0 V, Active Battery Mode, PWM

Switching, LSLDO enabled, I2C Enabled, V

4.65 V

0°C < TJ< 85°C, 0 < VIN< V

PWM Switching, LSLDO disabled, I2C Enabled, CD = Low,

V

< V

(BUVLO)

0°C < TJ< 85°C, VIN= 0 V, Ship Mode 2 150 nA

VIN= 5 V, IIN= 300 mA 125 170 mV

VIN= 0 V, V

V

> V

(BAT)

(BUVLO)

V

> V

(BAT)

(BUVLO)

V

> V

(BAT)

(BUVLO)

50 mA to 100 mA –12% 12%

100 mA to 400 mA –5% 5%

I

= 50 mA to 100 mA 175 200 225 AΩ

(ILIM)

I

= 100 mA to 400 mA 190 200 210 AΩ

(ILIM)

Programmable Range using V

disabled using V

Above V

(BATREG)

Measured from BAT to PMID, V

Operating in voltage regulation, Programmable Range, 10-

mV steps

TJ= 25°C –0.5% 0.5%

TJ= 0°C to 85°C –0.5% 0.5%

+ V

, TJ= –40°C to 85°C and TJ= 25°C for typical values (unless

(SLP)

+ V

+ V

(SLP)

(SLP)

PWM

PWM NOT

1 mA

0.7 1.2 µA

0.9 1.5 µA

(BAT)

(BAT)

< 4.65 V

< 6.6 V

(BUVLO)

(BUVLO)

(BAT)

(OVP)

(OVP)

< V

< V

and VIN> V

and VIN> V

(BAT)

(BAT)

0.75 3.5 µA

1.35 4.25 µA

< V

(BUVLO)

, Active Battery Mode,

IN(UVLO)

< 4.65 V

(BAT)

> 3 V, Iff= 400 mA 120 160 mV

(BAT)

(BAT)

<

6.8 12 µA

6.2 11 µA

V

<

(PMID)

V

– 25

(BAT)

mV

V

<

(PMID)

V

–

(BAT)

5mV

0.85 1.15 1.35 A

K

/

(ILIM)

R

(ILIM)

Registers. Can be

IN(DPM_ON)

IN(DPM)

4.2 4.9 V

–3% 3%

0.2 V

= 4.35 V, High-Z mode 300 400 mΩ

(BAT)

3.6 4.65 V

www.ti.com

3 mA

V

V

8

Submit Documentation Feedback Copyright © 2017–2018, Texas Instruments Incorporated

Product Folder Links: bq25120A

www.ti.com

Electrical Characteristics (continued)

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

Circuit of Figure 1, V

otherwise noted)

PARAMETERS TEST CONDITIONS MIN TYP MAX UNIT

Fast Charge Current

Range

I

(CHARGE)

K

(ISET)

I

(TERM)

t

DGL(TERM)

I

(PRE_CHARGE)

V

(RCH)

t

DGL(RCHG)

SYS OUTPUT

R

DS(ON_HS)

R

DS(ON_LS)

R

DS(CH_SYS)

I

(LIMF)

I

(LIM_SS)

V

SYS

LS/LDO OUTPUT

V

IN(LS)

V

OUT

V

LDO

ΔV

/ Δ V

OUT

R

DS(ON_LDO)

R

(DSCH_LSLDO)

Fast Charge Current

using ISET

Fast Charge Current

Accuracy

Fast Charge Current

Factor

Termination charge

current

Termination Current using

IPRETERM

Accuracy I

TERM deglitch time Both rising and falling, 2-mV over-drive, t

Pre-charge current

Pre-charge Current using

I

PRETERM

Accuracy –10% 10%

Recharge threshold

voltage

Recharge threshold

deglitch time

MOSFET on-resistance

for SYS discharge

SW Current limit HS 2.2 V < V

SW Current limit LS 2.2 V < V

PMOS switch current limit

during softstart

SYS Output Voltage

Range

Output Voltage Accuracy VIN= 5 V, PFM mode, I

DC Output Voltage Load

Regulation in PWM mode

DC Output Voltage Line

Regulation in PWM mode

Input voltage range for

LS/LDO

Input voltage range for

LS/LDO

DC output accuracy

Output range for LS/LDO Programmable Range, 0.1 V steps 0.8 3.3 V

DC Line regulation V

IN

DC Load regulation 0 mA < I

Load Transient 2 µA to 100 mA, VOUT = 1. 8 V –120 60 mV

FET Rdson V

MOSFET on-resistance

for LS/LDO discharge

(UVLO)

< VIN< V

(OVP)

V

(BATUVLO)

and VIN> V

< V

(BAT)

(BAT)

< V

+ V

(BATREG)

, TJ= –40°C to 85°C and TJ= 25°C for typical values (unless

(SLP)

5 300 mA

K

/

(ISET)

R

(ISET)

–5% 5%

5 mA > I

Termination current programmable range over I2C

I

(CHARGE)

I

(CHARGE)

I

(CHARGE)

I

(CHARGE)

) > 4 mA –10% 10%

(TERM

Pre-charge current programmable range over I2C

Below V

t

= 100 ns typ, V

FALL

PMID = 3.6 V, I

PMID = 3.6 V, I

VIN = 3.6 V, I

> 300 mA 190 200 210 AΩ

(CHARGE)

0.5 37 mA

< 300 mA, R

< 300 mA, R

< 300 mA, R

< 300 mA, R

= 15 kΩ 5 % of I

(ITERM)

= 4.99 kΩ 10 % of I

(ITERM)

= 1.65 kΩ 15 % of I

(ITERM)

= 549 Ω 20 % of I

(ITERM)

, t

RISE

= 100 ns 64 ms

FALL

0.5 37 mA

I

(TERM)

(BATREG)

falling 32 ms

(RCH)

= 150 mA 675 850 mΩ

(SYS)

= 150 mA 300 475 mΩ

(SYS)

= –10 mA into V

OUT

< 5.5 V 450 600 675 mA

(PMID)

< 5.5 V 450 700 850 mA

(PMID)

pin 22 40 Ω

OUT

100 120 140 mV

Current limit is reduced during softstart 80 130 200 mA

Programmable range, 100 mV Steps 1.1 3.3 V

= 10 mA, V

OUT

V

= 2 V, over load range 0.01 %/mA

OUT

V

OUT

= 2 V, I

= 100 mA, over VINrange 0.01 %/V

OUT

= 1.8 V –2.5% 0 2.5%

(SYS)

Load Switch Mode 0.8 6.6 V

LDO Mode 2.2 6.6 V

TJ= 25°C –2% ±1% 2%

Over VIN, I

OUT(NOM)

(VINLS)

1.7 V < V

, temperature –3% ±2% 3%

OUT

+ 0.5 V < VIN< 6.6 V, I

< 100 mA –1% 1%

OUT

= 5 mA –1% 1%

OUT

= 3.6 V 460 600 mΩ

(VINLS)

< 6.6 V, I

= –10 mA 20 Ω

LOAD

A

SET

SET

SET

SET

A

Product Folder Links: bq25120A

Submit Documentation FeedbackCopyright © 2017–2018, Texas Instruments Incorporated

9

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

Electrical Characteristics (continued)

www.ti.com

Circuit of Figure 1, V

(UVLO)

otherwise noted)

PARAMETERS TEST CONDITIONS MIN TYP MAX UNIT

I

(OCL_LDO)

I

(LS/LDO)

I

IN(LDO)

V

IH(LSCTRL)

V

IL(LSCTRL)

PUSHBUTTON TIMER (MR)

V

IL

R

PU

VBAT MONITOR

V

BMON

BATTERY-PACK NTC MONITOR

V

HOT

V

WARM

V

COOL

V

COLD

TS

OFF

PROTECTION

V

(UVLO)

V

UVLO(HYS)

V

(BUVLO)

V

(BATSHORT)

V

(BATSHORT_HYS)

I

(BATSHORT)

V

(SLP)

V

(SLP_HYS)

V

OVP

t

DGL_OVP

T

SHTDWN

T

HYS

t

DGL_SHTDWN

Output Current Limit –

LDO

Output Current

Quiescent current for

VINLS in LDO mode

OFF-state supply current 0.25 µA

High-level input voltage

for LSCTRL

Low-level input voltage

for LSCTRL

Low-level input voltage V

Internal pull-up resistance 120 kΩ

Battery Voltage Monitor

Accuracy

High temperature

threshold

Warm temperature

threshold

Cool temperature

threshold

Low temperature

threshold

TS Disable threshold VTSrising, 2% VINHysteresis 55 60 %V

IC active threshold

voltage

IC active hysteresis VINfalling from above V

Battery Undervoltage

Lockout threshold Range

Default Battery

Undervoltage Lockout

Accuracy

Battery short circuit

threshold

Hysteresis for V

Battery short circuit

charge current

Sleep entry threshold,

VIN– V

(BAT)

Sleep-mode exit

hysteresis

Maximum Input Supply

OVP threshold voltage

Deglitch time, VIN OVP

falling

Thermal trip VIN> V

Thermal hysteresis VIN> V

Deglitch time, Thermal

shutdown

< VIN< V

(BATSHORT)

and VIN> V

(OVP)

V

= 275 365 475 mA

LS/LDO

V

= 3.6 V, V

(VINLS)

V

= 3.3 V, V

(VINLS)

V

= 2.2 V, V

(VINLS)

+ V

(BAT)

= 3.3 V 100 mA

LSLDO

= 0.8 V 100 mA

LSLDO

= 0.8 V 10 mA

LSLDO

, TJ= –40°C to 85°C and TJ= 25°C for typical values (unless

(SLP)

0.9 µA

1.15 V > V

1.15 V > V

> V

BAT

V

Falling - Including 2% increment –3.5 3.5 %V

(BAT)

(VINLS)

(VINLS)

BUVLO

> 6.6 V

> 6.6 V

0.75 x

V

(SYS)

6.6 V

0.25 x

V

(SYS)

0.3 V

VTSfalling, 1% VINHysteresis 14.5 15 15.2 %V

VTSfalling, 1% VINHysteresis 20.1 20.5 20.8 %V

VTSrising, 1% VINHysteresis 35.4 36 36.4 %V

VTSrising, 1% VINHysteresis 39.3 39.8 40.2 %V

VINrising 3.4 3.6 3.8 V

UVLO

Programmable Range for V

Hysteresis

V

falling –2.5% 2.5%

(BAT)

VBAT falling, 150 mV

(BUVLO)

2.2 3.0 V

150 mV

Battery voltage falling 2 V

100 mV

I

(PRETERM)

2 V < V

VINrising above V

BAT

< V

, VINfalling 65 120 mV

(BATREG)

(SLP)

40 65 100 mV

VINrising, 100 mV hysteresis 5.35 5.55 5.75 V

VINfalling below V

UVLO

UVLO

TJrising above T

, 1V/us 32 ms

OVP

114 °C

11 °C

SHTDWN

4 µs

V

(BATREG)

IN

IN

IN

IN

IN

mA

10

Submit Documentation Feedback Copyright © 2017–2018, Texas Instruments Incorporated

Product Folder Links: bq25120A

www.ti.com

Electrical Characteristics (continued)

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

Circuit of Figure 1, V

(UVLO)

< VIN< V

otherwise noted)

PARAMETERS TEST CONDITIONS MIN TYP MAX UNIT

I2C INTERFACE

I2C Bus Specification

standard and fast mode

frequency support

V

IL

V

IH

V

IH

V

OL

I

BIAS

INT, PG, and RESET OUTPUT (Open Drain)

V

OL

I

IN

V

IN(BAT_DELTA)

INPUT PIN (CD LSCTRL)

V

IL(/CD_LSCTRL)

V

IH(/CD_LSCTRL)

R

PULLDOWN/CD

R

(LSCTRL)

Input low threshold level V

Input high threshold level V

Input high threshold level V

Output low threshold level IL = 5 mA, sink current, V

High-Level leakage

current

Low level output

threshold

Bias current into pin Pin is high impedance, I

Input voltage above

VBAT where PG sends

two 128 µs pulses each

minute to signal the host

of the input voltage status

Input low threshold V

Input high threshold V

Internal pull-down

resistance

Internal pull-down

resistance

and VIN> V

(OVP)

= 1.1 V, SDA and SCL 0.275 V

PULLUP

= 1.1 V, SDA and SCL 0.825 V

PULLUP

= 3.3 V, SDA and SCL 2.475 V

PULLUP

V

= 1.8 V, SDA and SCL 1 µA

PULLUP

Sinking current = 5 mA

V

< VIN< V

UVLO

(PULLUP)

(PULLUP)

= V

= V

SYS

SYS

OVP

= 3.3 V

= 3.3 V

+ V

(BAT)

, TJ= –40°C to 85°C and TJ= 25°C for typical values (unless

(SLP)

100 400 kHz

= 1.1 V 0.275 V

PULLUP

= 0 mA; TJ= –40°C to 60°C 12 nA

OUT

0.825 1 1.15 V

0.75 *

V

SYS

900 kΩ

2 MΩ

0.25 x

V

(SYS)

0.25 *

V

SYS

V

V

V

Product Folder Links: bq25120A

Submit Documentation FeedbackCopyright © 2017–2018, Texas Instruments Incorporated

11

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

8.6 Timing Requirements

POWER-PATH MANAGEMENT AND INPUT CURRENT LIMIT

t

DGL_SC

t

REC_SC

BATTERY CHARGER

t

DGL_SHORT

BATTERY CHARGING TIMERS

t

MAXCHG

t

PRECHG

SYS OUTPUT

t

ONMIN

t

OFFMIN

t

START_SW

t

START_SYS

t

SOFTSTART

LS/LDO OUTPUT

t

ON_LDO

t

OFF_LDO

PUSHBUTTON TIMER

t

WAKE1

t

RESET

t

RESET_D

t

DD

BATTERY-PACK NTC MONITOR

t

DGL(TS)

I2C INTERFACE

t

WATCHDOG

t

I2CRESET

t

HIZ_ACTIVEBAT

INPUT PIN

t

/CD_DGL

t

QUIET

Deglitch Time, PMID or SW Short Circuit

during Discharge Mode

Recovery time, OUT Short Circuit during

Discharge Mode

Deglitch time transition from ISET short to

I

disable

(CHARGE)

Charge safety timer Programmable range 2 540 min

Precharge safety timer 0.1 x t

Minimum ON time VIN= 3.6 V, V

Minimum OFF time VIN= 4.2 V 50 ns

SW start up time

SYS output time to start switching

Softstart time with reduced current limit 400 1200 µs

Turn ON time 100-mA load 500 µs

Turn OFF time 100-mA load 5 µs

Push button timer wake 1 0.08 1 s

Push button timer reset

Reset pulse duration 400 ms

Detection delay (from MR, input to

RESET)

Deglitch time on TS change

I2C interface reset timer for host

I2C interface inactive reset timer

Transition time required to enable the I2C

interface from HiZ to Active BAT

Deglitch for CD CD rising/falling 100 µs

Input quiet time for Ship Mode transition 1 ms

www.ti.com

MIN TYP MAX UNIT

250 µs

2 s

Clear fault by disconnecting VIN 1 ms

MAXCHG

= 2 V, I

OUT

VIN= 5 V, from write on EN_SW_OUT

until output starts to rise

From insertion of BAT > V

> V

(UVLO)

Programmable Range for reset

function

= 0 mA 225 ns

OUT

5 25 ms

or V

(BUVLO)

IN

350 µs

5 15 s

For 0s condition 6 µs

Applies to V

V

(COLD)

(HOT)

, V

(WARM)

, V

(COOL

), and

50 ms

50 s

700 ms

1 ms

12

Submit Documentation Feedback Copyright © 2017–2018, Texas Instruments Incorporated

Product Folder Links: bq25120A

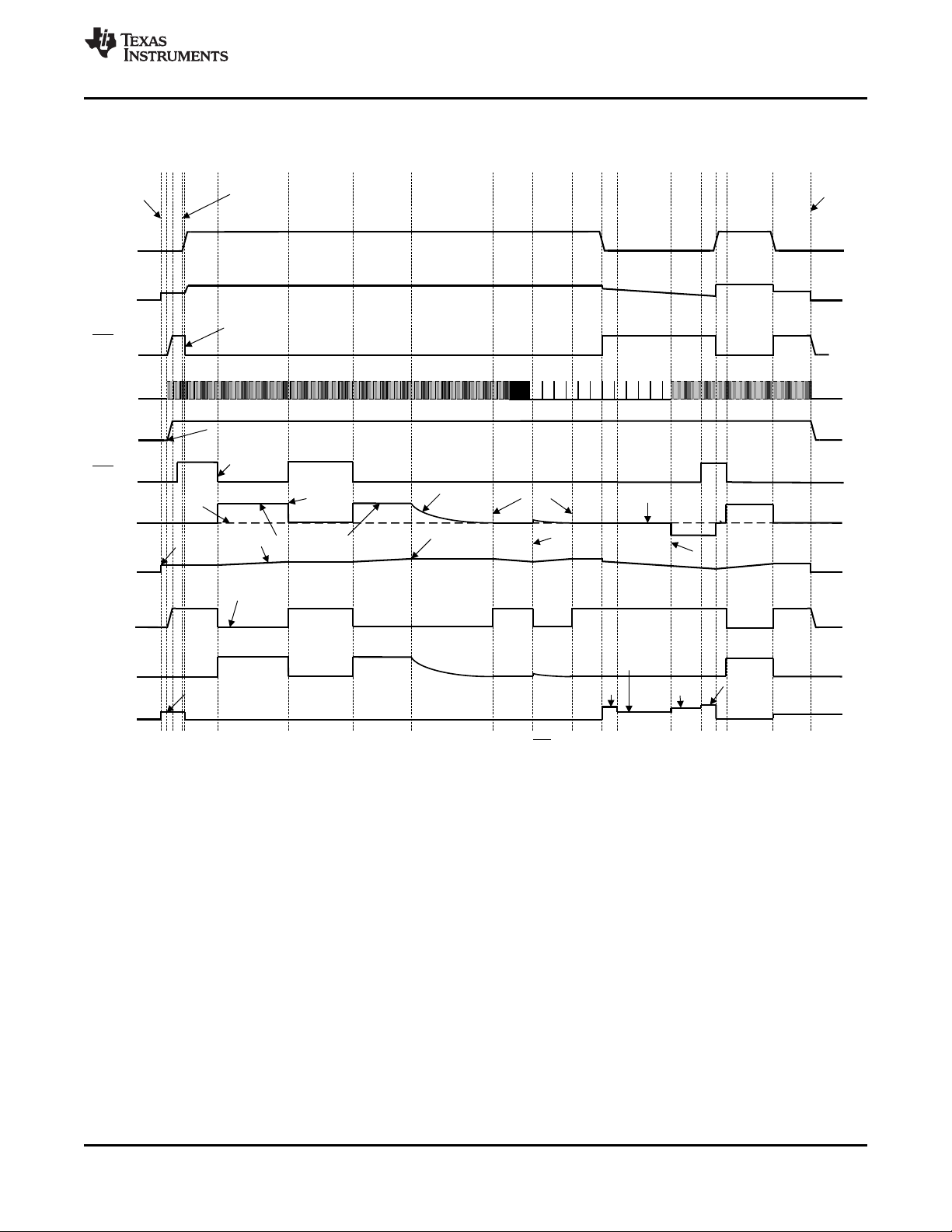

VIN

SW

SYS

VBAT

CD

PG

IBAT

PMID

Insert

Battery

Apply

VIN

VIN > UVLO

After delay of several ms,

switching starts and SYS

starts to rise

Charging

enabled

Charging

disabled

VBAT

rises

VBAT = V

BATREG

Charge

Current

Taper

IBAT=ICHRG

VBAT =

V

BATREG

- V

RCHG

IBAT = I

TERM

BAT supplies SYS

when VIN removed

INT

BAT IQ

Typical Start-Up Timing and Operation

VBAT>V

BUVLO

Remove

Battery

Shows

Charge

Status

VISET

<3uA max <4uA max

No SYS Load

SYS Load Applied

<3uA max

<5uA max

<4uA max

nA of leakage with VIN present

0mA

www.ti.com

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

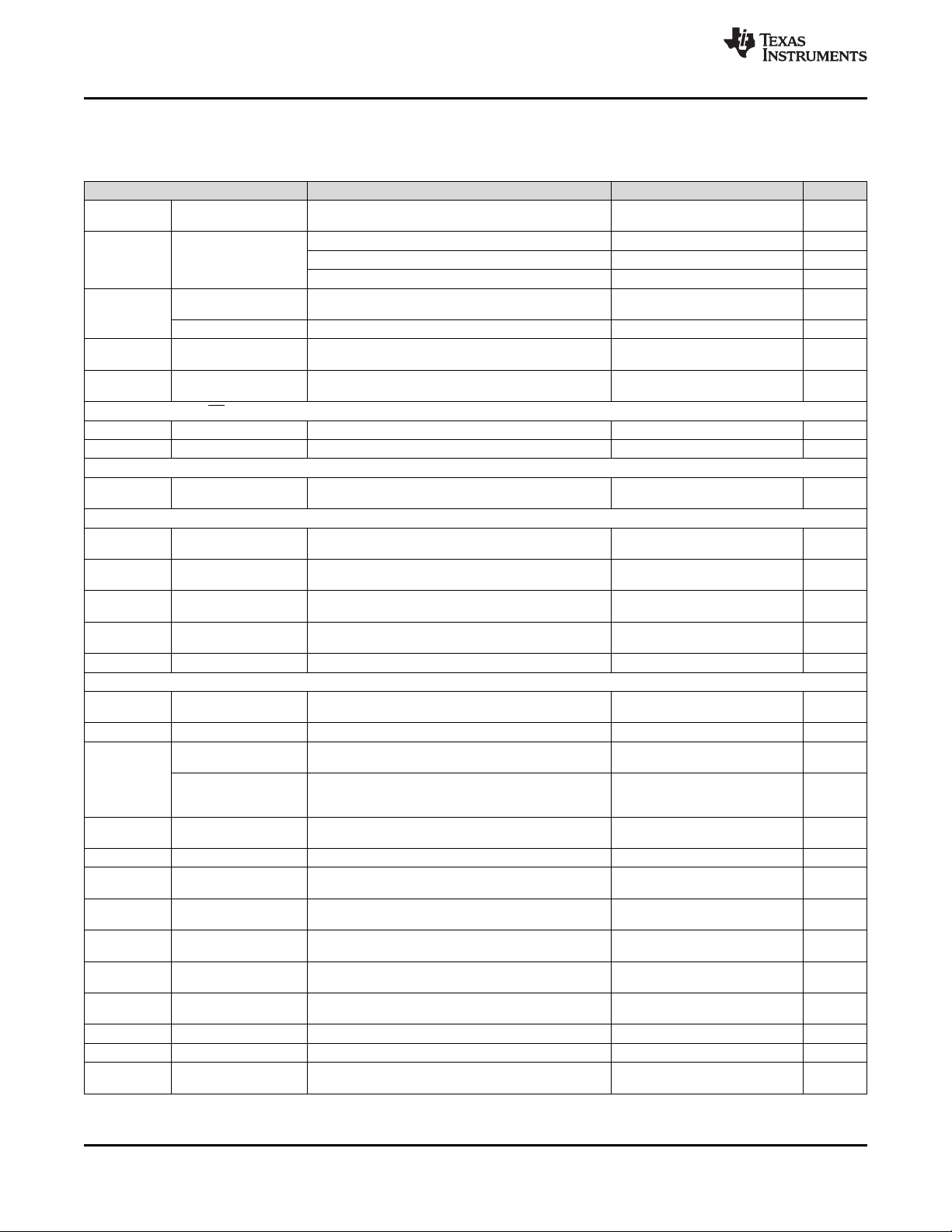

Conditions: PGB_MRS = 0, TE = 1, SW_LDO = 1, VINDPM_ON = 0, PG and INT pulled up to SYS, EN_INT = 1

Figure 1. Typical Start-Up Timing and Operation

Product Folder Links: bq25120A

Submit Documentation FeedbackCopyright © 2017–2018, Texas Instruments Incorporated

13

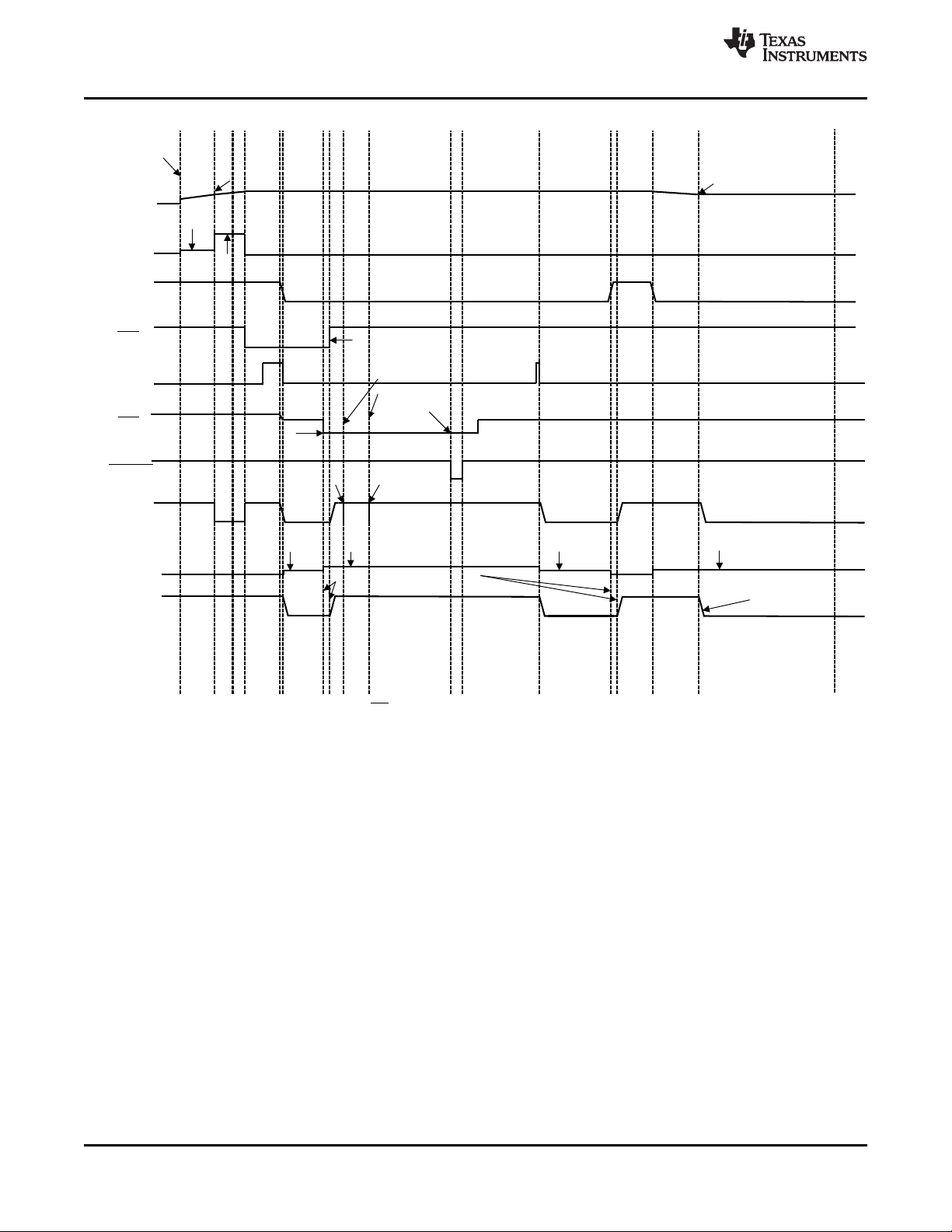

SYS

VBAT

CD

Insert Battery <

V

BATSHORT

INT

BAT IQ

IBAT

VBAT=V

BUVLO

IBAT = I

BATSHORT

VIN

IBAT = ICHG

MR

<1uA max

RESET

MR_WAKE1

Interrupt

MR_WAKE2

Interrupt

<3uA max

MR_WAKE1 time reached

MR_WAKE2 time reached

MRRESET time reached

t

RESET

After delay of several ms,

SYS starts to rise

Device enters Active Battery

Mode after valid /MR

<1uA max

User depresses button

SYS is pulled down shortly

after VBATUVLO is reached

VBAT=V

BUVLO

<3uA max

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

www.ti.com

14

Conditions: SW_LDO = 1, MRREC = 1, PG and INT pulled up to SYS, ISYS = 10 µA, EN_INT = 1

Figure 2. Battery Operation and Sleep Mode

Submit Documentation Feedback Copyright © 2017–2018, Texas Instruments Incorporated

Product Folder Links: bq25120A

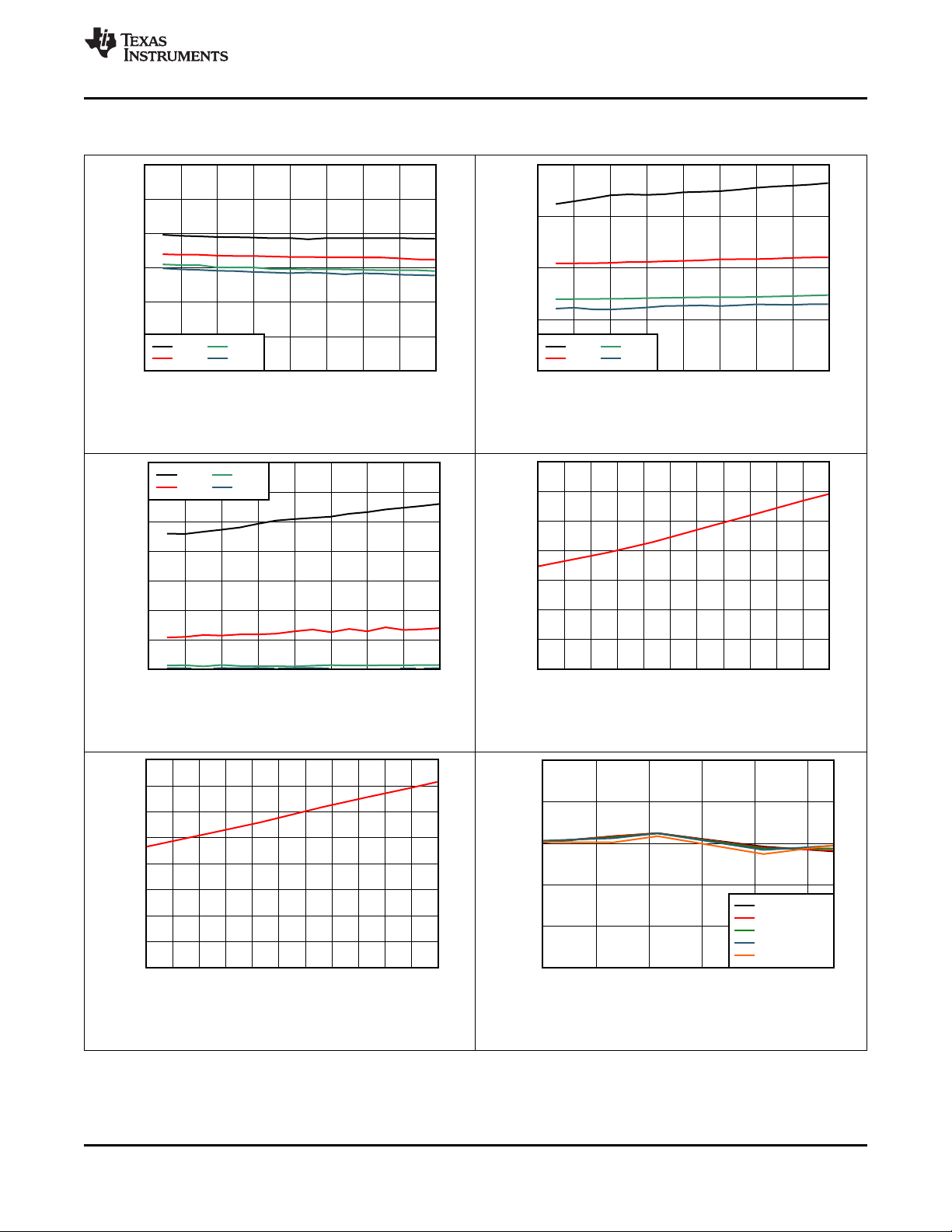

Temperature (qC)

R

DS(ON)

(m:)

-40 -25 -10 5 20 35 50 65 80 95 110 125

0

50

100

150

200

250

300

350

400

D025

Temperature (qC)

Accuracy

-40 -10 20 50 80 110 125

-0.5%

-0.3%

-0.1%

0.1%

0.3%

0.5%

D019

4.35 V

(BATREG)

4.2 V

(BATREG)

4 V

(BATREG)

3.8 V

(BATREG)

3.6 V

(BATREG)

BAT (V)

BAT I

Q

(PA)

3 3.2 3.4 3.6 3.8 4 4.2 4.4 4.6

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0.14

D018

85qC

60qC

25qC

0qC

Temperature (qC)

R

DS(ON)

(m:)

-40 -25 -10 5 20 35 50 65 80 95 110 125

0

100

200

300

400

500

600

700

D024

BAT (V)

BAT I

Q

(PA)

3 3.2 3.4 3.6 3.8 4 4.2 4.4 4.6

0

2

4

6

8

10

12

D016

85qC

60qC

25qC

0qC

BAT (V)

BAT I

Q

(PA)

3 3.2 3.4 3.6 3.8 4 4.2 4.4 4.6

0.0

0.5

1.0

1.5

2.0

D017

85qC

60qC

25qC

0qC

www.ti.com

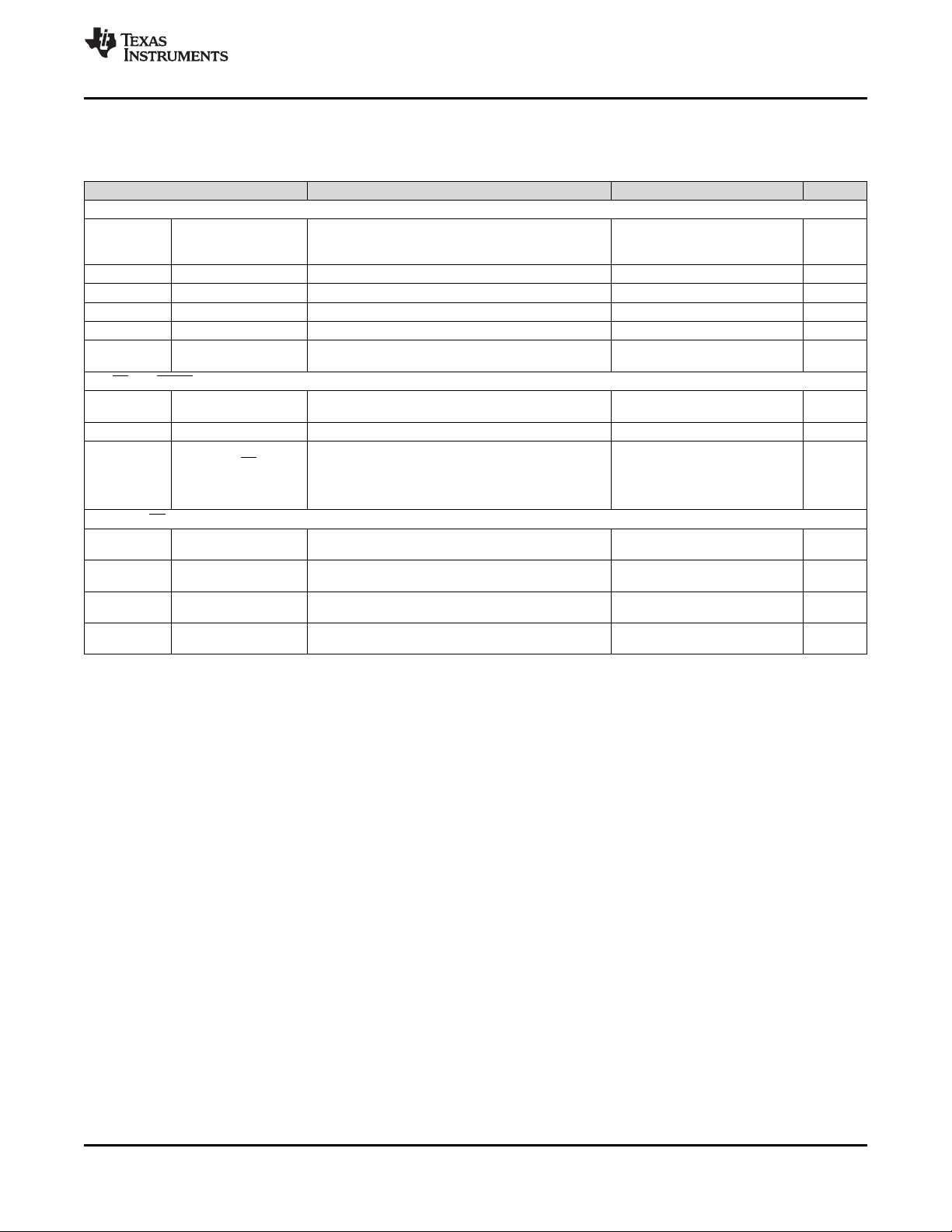

8.7 Typical Characteristics

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

1.8 V System Enabled (No Load)

Figure 3. Active BAT, I

Figure 5. Ship Mode BAT, I

Q

Q

Figure 6. Blocking FET R

Figure 4. Hi-Z BAT, I

DS(ON)

Q

vs Temperature

Figure 7. Battery Discharge FET R

vs Temperature Figure 8. V

DS(ON)

Product Folder Links: bq25120A

(BATREG)

Submit Documentation FeedbackCopyright © 2017–2018, Texas Instruments Incorporated

Accuracy vs Temperature

15

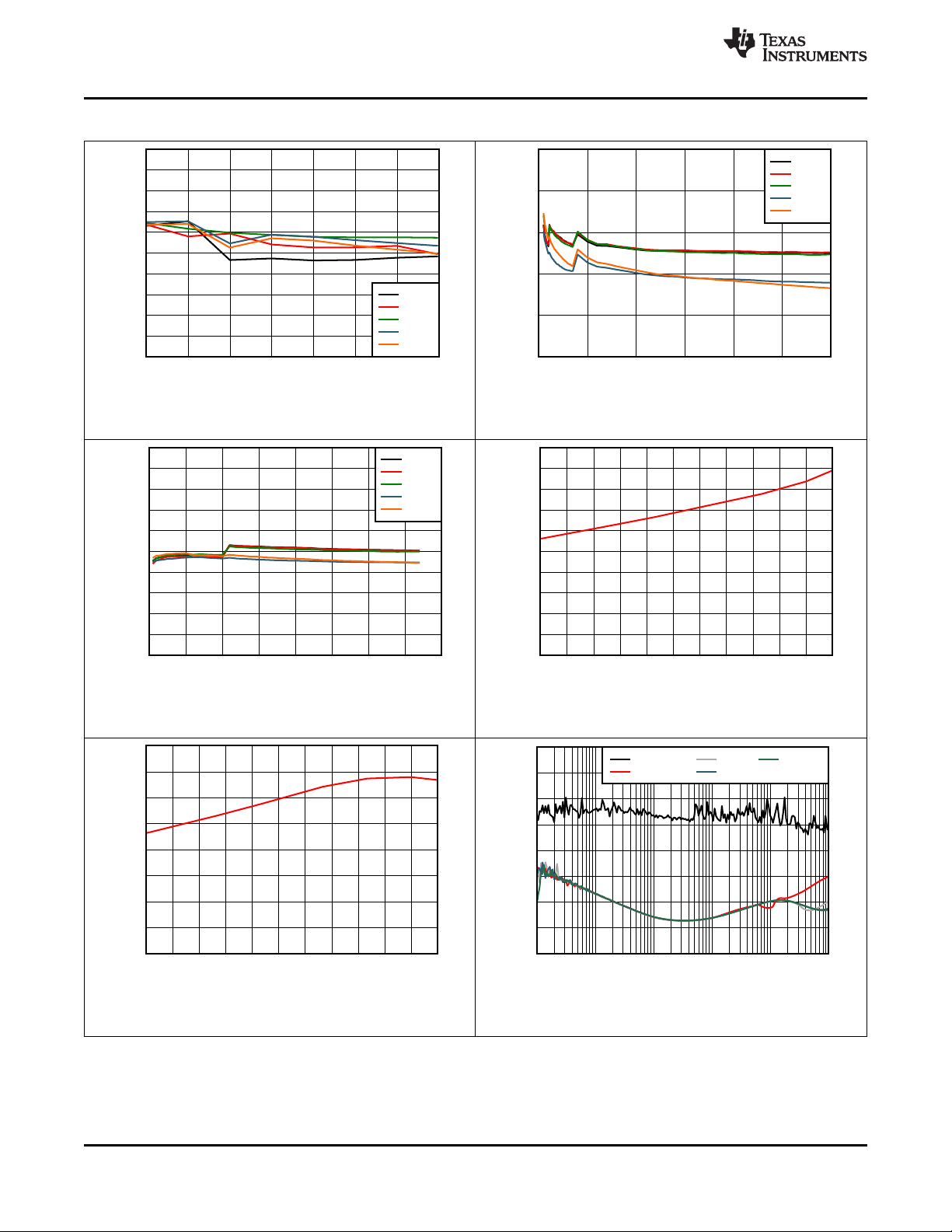

Temperature (qC)

R

DS(ON)

(m:)

-40 -25 -10 5 20 35 50 65 80 95 110 125

0

50

100

150

200

250

300

350

400

D027

Frequency (Hz)

PSRR (dB)

10 20 50 100 1000 10000 100000 1000000

0

20

40

60

80

100

120

140

160

D028

Noise Floor

1 mA

10 mA

50 mA

100 mA

Pre-Charge Current (mA)

Accuracy

0 5 10 15 20 25 30 35 40

-10%

-8%

-6%

-4%

-2%

0

2%

4%

6%

8%

10%

D022

-40qC

0qC

25qC

85qC

125qC

Temperature (qC)

R

DS(ON)

(m:)

-40 -25 -10 5 20 35 50 65 80 95 110 125

0

100

200

300

400

500

600

700

800

900

1000

D026D024

Input Current Limit (A)

Accuracy

0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4

-5%

-4%

-3%

-2%

-1%

0

1%

2%

3%

4%

5%

D020

-40qC

0qC

25qC

85qC

125qC

Charge Current (mA)

Accuracy

0 50 100 150 200 250 300

-5%

-3%

-1%

1%

3%

5%

D021

-40qC

0qC

25qC

85qC

125qC

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

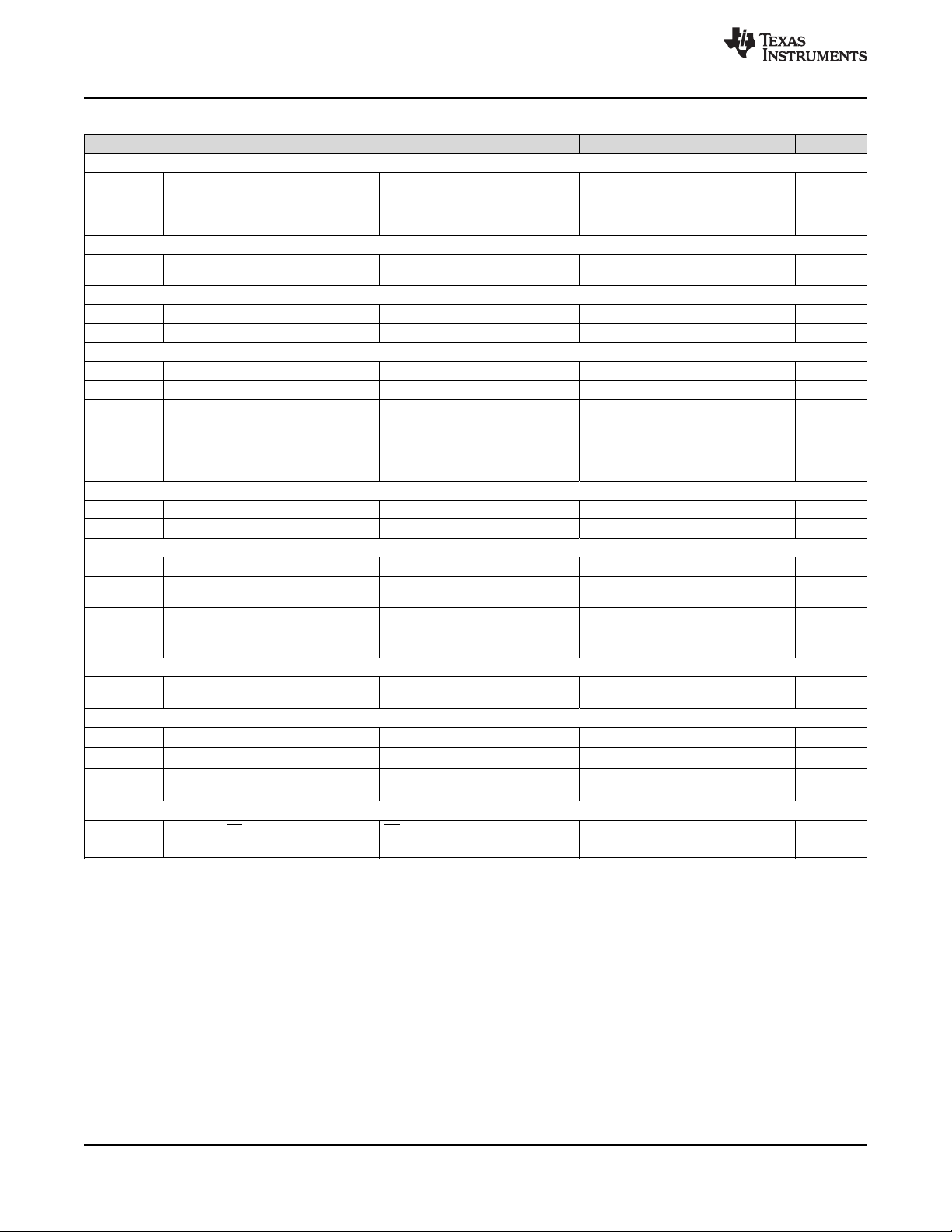

Typical Characteristics (continued)

Figure 9. ILIM Accuracy vs Input Current Figure 10. Charge Current Accuracy vs Charge Current

www.ti.com

Figure 11. Pre-Charge Accuracy vs Pre-Charge Current

16

VIN= 5 V

Figure 13. R

of Low Side MOSFET vs Temperature Figure 14. LS/LDO PSRR vs Frequency

DS(ON)

Submit Documentation Feedback Copyright © 2017–2018, Texas Instruments Incorporated

VIN= 5 V

Figure 12. R

Product Folder Links: bq25120A

of High Side MOSFET vs Temperature

DS(ON)

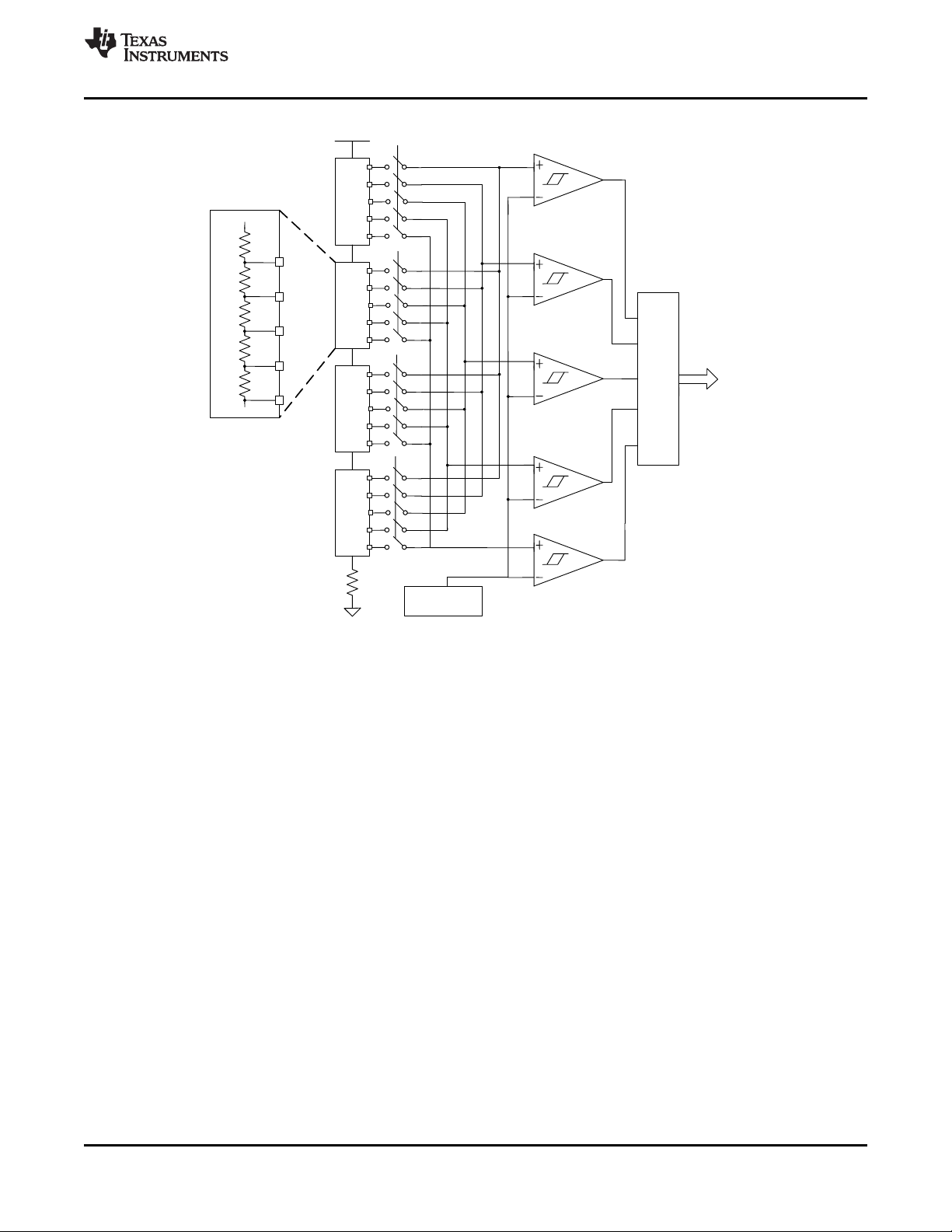

SW

MR

TS

LS/LDO

BAT

PWM, LDO, and BAT FET

Control

I2C

Interface

Hi-Z

Mode

Device Control

Reset and

Timer

+

+

+

+

VIN

TS COLD

TS HOT

TS WARM

TS COOL

SYS

1C/

0.5C

Disable

Disable

VBATREG

± 140mV

LDO/ Load Switch

Control

I

INLIM

Q1/Q2

Q3

Q4

V

IN_DPM

V

SUPPLY

V

BATREG

LDO

Control

V

SYSREG

Thermal

Shutdown

+

+

Termination

Reference

I

BAT

V

IN

V

INOVP

V

BAT

V

BATOVP

V

BATREG

± 0.12 V

V

BAT

V

BAT

V

BATSHRT

I

BATREG

+

+

+

RESET

Q5

Q7

VOVP

BATOVP

BATSHRT

Recharge

PMID

LDO/ Load Switch

Host Control

Input Current Limit

Charge Current

Termination Current

PG

+

V

BAT(SC)

SDA

SCL

LSCTRL

ILIM

ISET

INT

GND

IN

VINLS

CD

Copyright © 2016, Texas Instruments Incorporated

S

D

G

S

D

G

S

D

G

bq25120A

www.ti.com

SLUSD08A –MAY 2017–REVISED JANUARY 2018

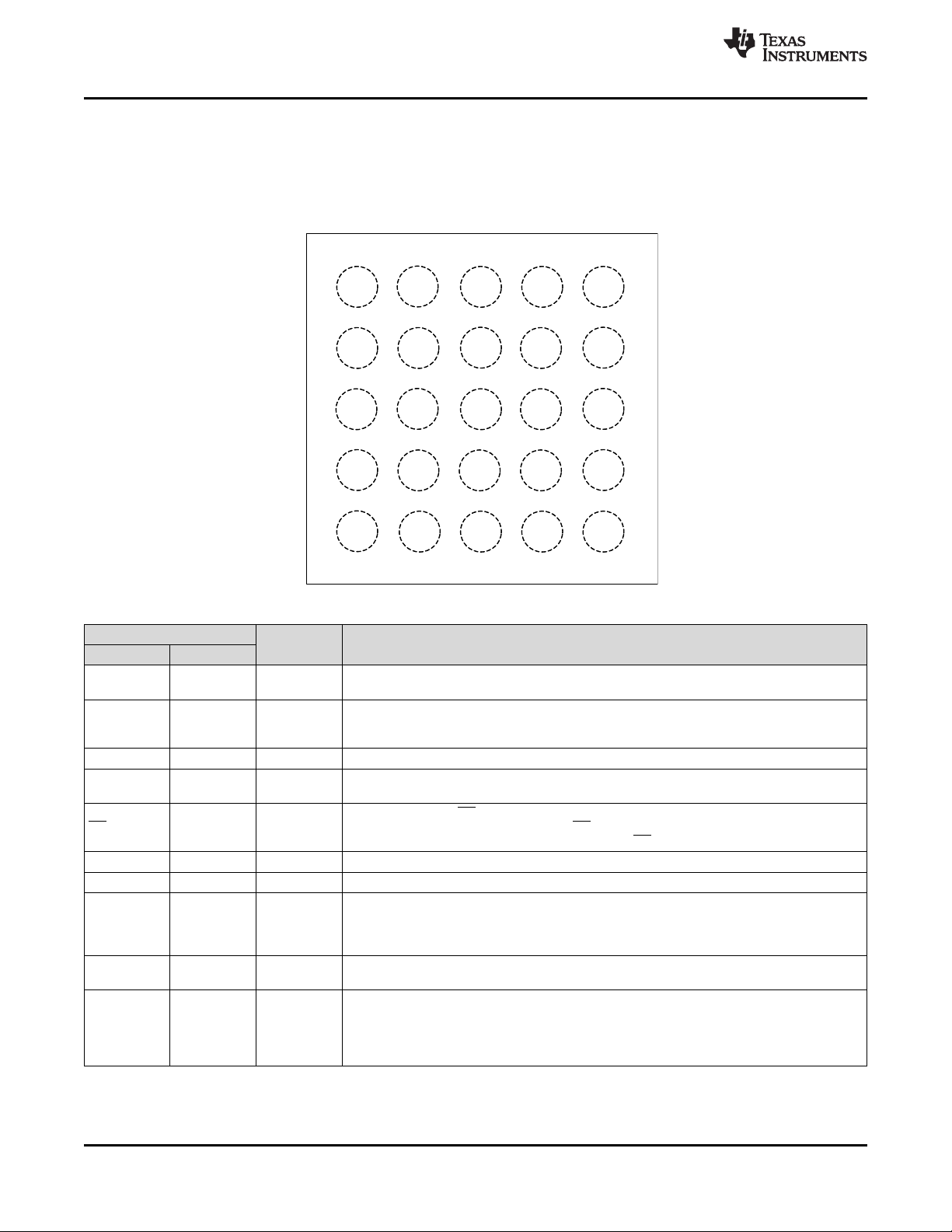

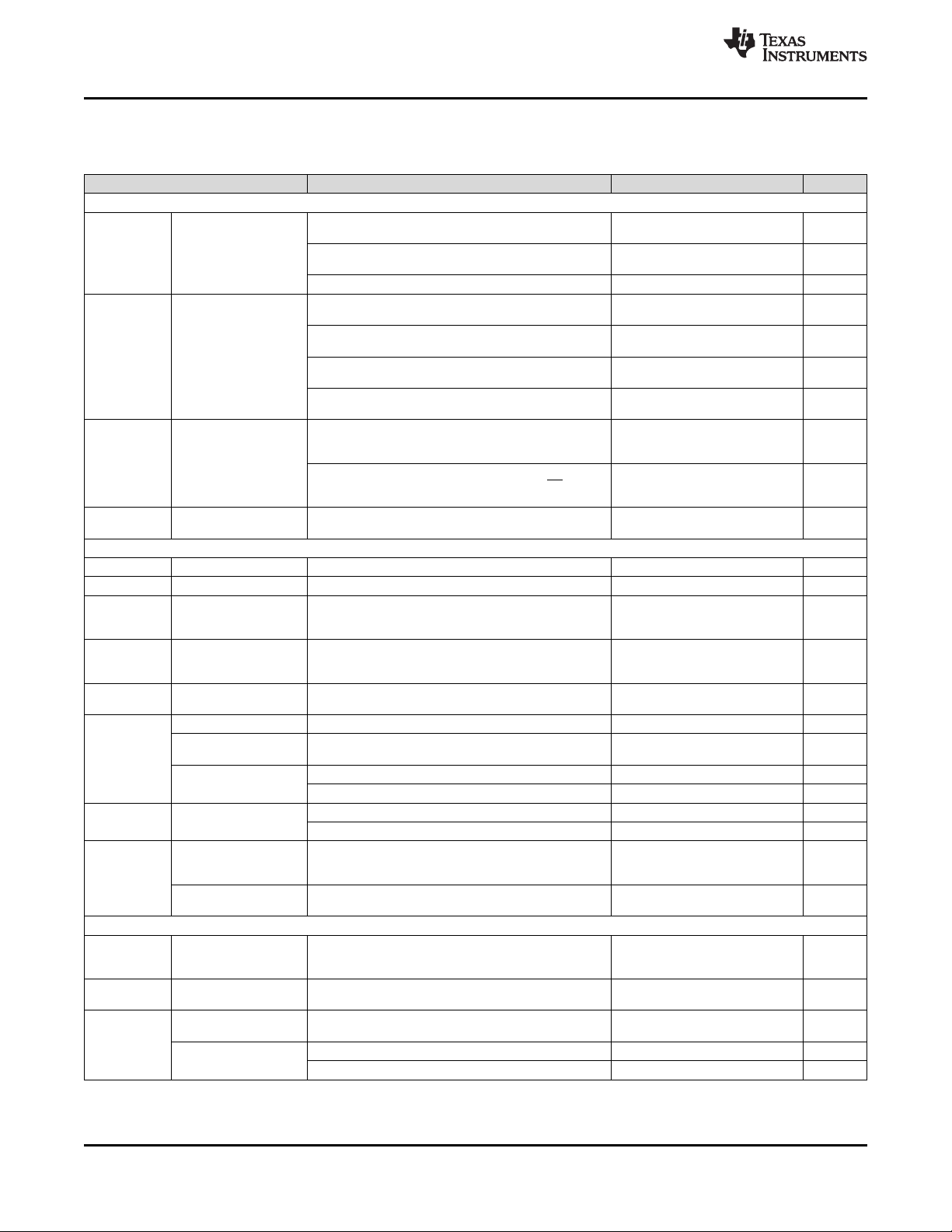

9 Detailed Description

9.1 Overview

The following sections describe in detail the functions provided by the BQ25120A. These include linear charger,

PWM output, configurable LS/LDO output, Push-button input, reset timer, functional modes, battery monitor, I2C

configurability and functions, and safety features.

9.2 Functional Block Diagram

Product Folder Links: bq25120A

Submit Documentation FeedbackCopyright © 2017–2018, Texas Instruments Incorporated

17

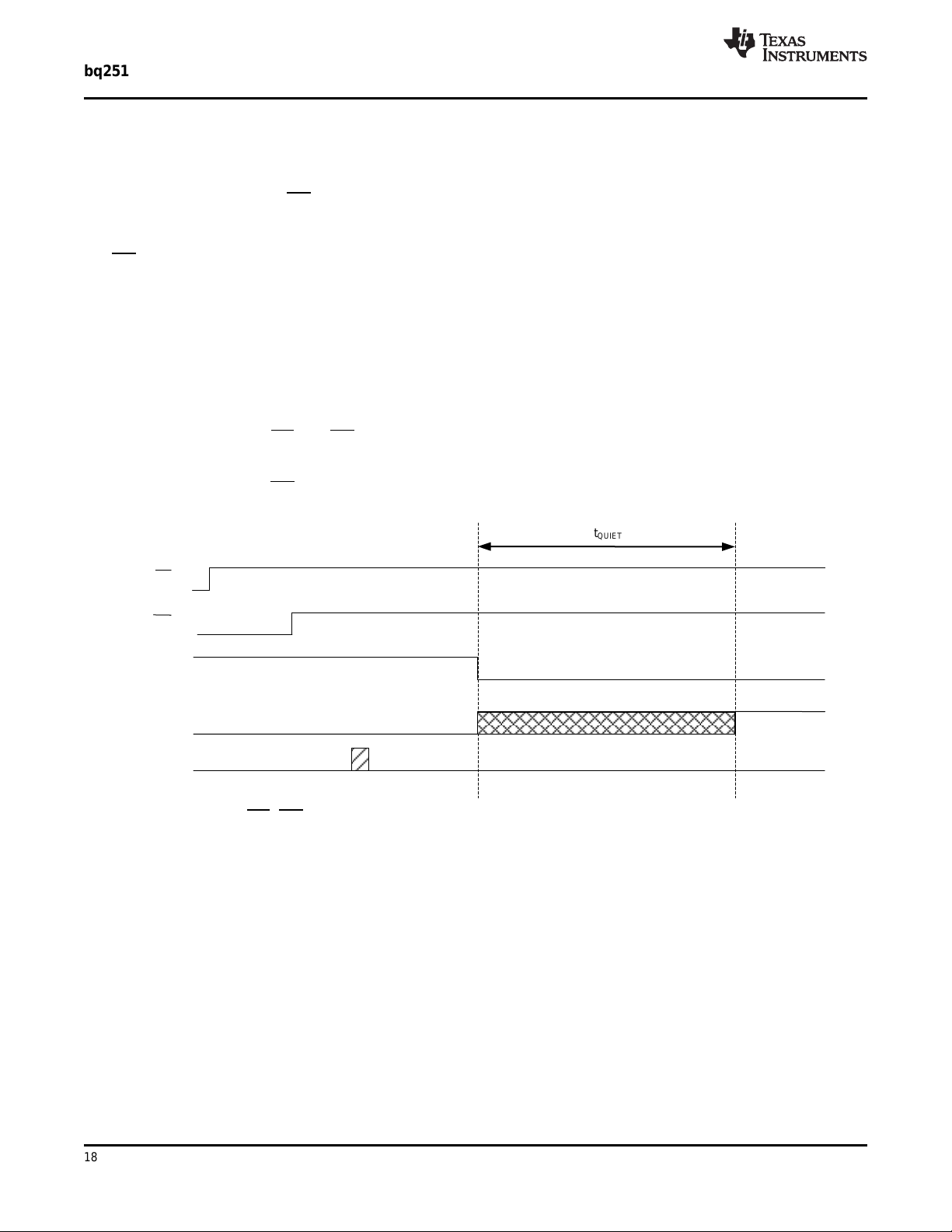

VIN

MR

CD

I2C

Write

t

QUIET

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

www.ti.com

9.3 Feature Description

9.3.1 Ship Mode

Ship Mode is the lowest quiescent current state for the device. Ship Mode latches off the device and BAT FET

until VIN> V

that are active during Ship Mode:

1. VIN_UV Comparator

2. MR Input (No clock or delay in this mode for lowest power consumption)

3. PMID active pull down

9.3.1.1 Ship Mode Entry and Exit

The device may only enter Ship Mode when there is not a valid VIN supply present (VIN< V

supply is removed there are two ways for the device to enter Ship Mode: through I2C command using the

EN_SHIPMODE bit and by doing a long button press when MRREC bit is set to 0. If the EN_SHIPMODE bit is

set while the IN supply is present, the device will enter Ship Mode upon removal of the supply. The

EN_SHIPMODE bit can be cleared using the I2C interface as well while the IN input is valid.

In addition to VIN< V

the transition to Ship Mode. All three conditions must remain unchanged for a period of t

operation. Figure 15 and Figure 16show the correct sequencing to ensure proper entry into the Ship Mode

through I2C command and MR button press respectively.

BAT

+ V

or the MR button is depressed for t

SLP

, CD and MR must be high. Once all of these conditions are met the device will begin

UVLO

and released. The following list shows the events

WAKE1

UVLO

to ensure proper

QUIET

). Once the IN

18

Figure 15. CD, MR and VIN Sequencing for Ship Mode Entry Through I2C Command

Submit Documentation Feedback Copyright © 2017–2018, Texas Instruments Incorporated

Product Folder Links: bq25120A

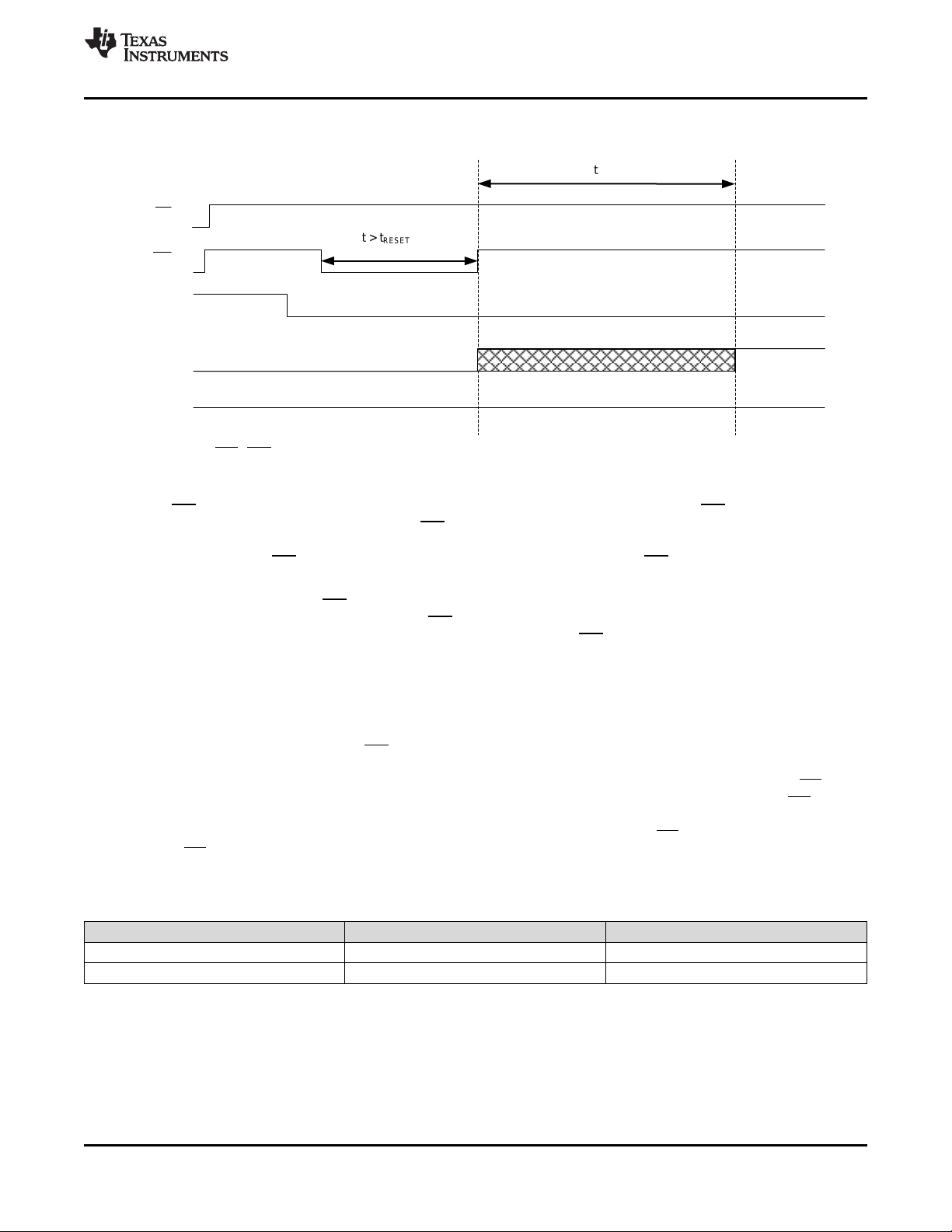

VIN

MR

CD

I2C

Write

t > t

RESET

t

QUIET

www.ti.com

Feature Description (continued)

Figure 16. CD, MR and VIN Sequencing for Ship Mode Entry Through Long MR button press

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

The end user can enable the device (exit Ship Mode) by connecting an adapter to IN (VIN> V

BAT

+ V

SLP

) or by

toggling the MR button. Note that in the case where an adapter is connected while the MR is still held low and

immediately after the RESET timer has expired (MR low for t

), the device will not enter Ship Mode, but may

RESET

enter it upon adapter removal (Same behavior as setting the EN_SHIPMODE bit when the adapter is present).

This will not be the case if MR has gone high when the adapter is connected or MR continues to be held low for

a period longer than t

after the adapter is connected.

WAKE1

To exit Ship Mode through and MR press the battery voltage must be above the maximum programmable

BUVLO threshold when VINis not present. Once MR goes low, the device will start to exit Ship Mode, powering

PMID. The device will not complete the transition from Ship Mode until MR has been held low for at least t

WAKE1

Only after the transition is complete may the host start I2C communication if the device has not entered High

Impedance Mode.

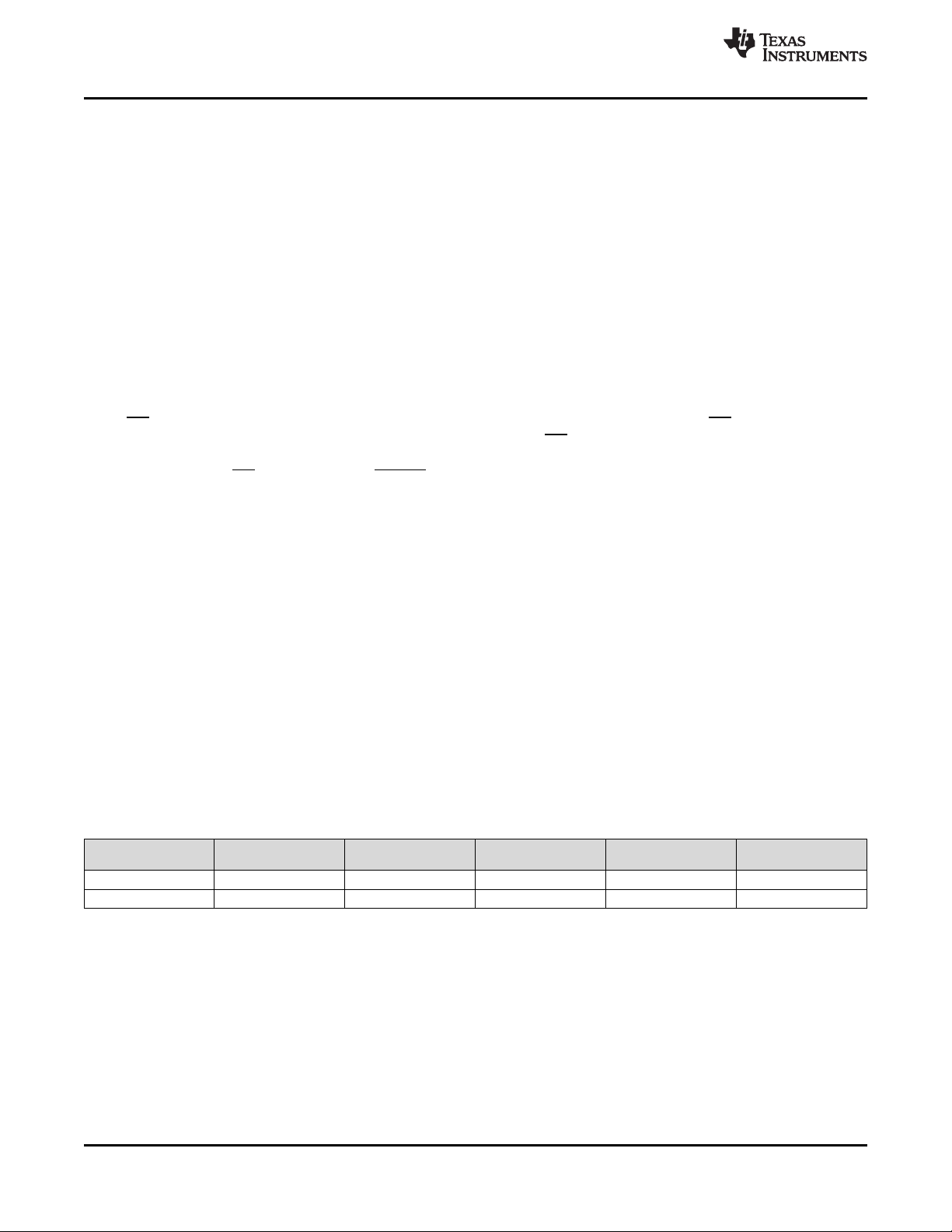

9.3.2 High Impedance Mode

High Impedance mode is the lowest quiescent current state while operating from the battery. During Hi-Z mode

the SYS output is powered by BAT, the MR input is active, and the LSCTRL input is active. All other circuits are

in a low power or sleep state. The LS/LDO output can be enabled in Hi-Z mode with the LSCTRL input. If the

LS/LDO output has been enabled through I2C prior to entering Hi-Z mode, it will stay enabled. The CD pin is

used to put the device in a high-impedance mode when battery is present and VIN< V

. Drive CD high to

UVLO

enable the device and enter active battery operation when VINis not valid. When the HZ_MODE bit is written by

the host, the I2C interface is disabled if only battery is present. To resume I2C, the CD pin must be toggled. If the

supply for the CD pull up glitches or experiences a brownout condition , it is recommended to toggle the /CD pin

to resume I2C communication.. The functionality of the pin is shown in Table 1.

Table 1. CD, State Table

CD, State VIN< V

L Hi-Z Charge Enabled

H Active Battery Charge Disabled

UVLO

VIN> V

UVLO

.

Product Folder Links: bq25120A

Submit Documentation FeedbackCopyright © 2017–2018, Texas Instruments Incorporated

19

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

www.ti.com

9.3.3 Active Battery Only Connected

When the battery above V

BATUVLO

After the battery rises above V

is connected with no input source, the battery discharge FET is turned on.

BATUVLO

and the deglitch time is reached, the SYS output starts to rise. The current

from PMID and SYS is not regulated, but is protected by a short circuit current limit. If the short circuit limit is

reached for the deglitch time (t

), the battery discharge FET is turned off for the recovery time (t

DGL_SC

REC_SC

After the recovery time, the battery FET is turned on to test if the short has been removed. If it has not, the FET

turns off and the process repeats until the short is removed. This process protects the internal FET from over

current. During this event PMID will likely droop and cause SYS to go out of regulation.

To provide designers the most flexibility in optimizing their system, an adjustable BATUVLO is provided. When

the voltage drops below the V

BATUVLO

threshold, the battery discharge FET is turned off. Deeper discharge of the

battery enables longer times between charging, but may shorten the battery life. The BATUVLO is adjustable

with a fixed 150-mV hysteresis.

).

If a valid VINis connected during active battery mode, VIN> V

turned on when the battery voltage is above the minimum V

BATUVLO

Drive CD high or write the CE register to disable charge when VIN> V

, the supplement and battery discharge FET is

UVLO

.

is present. CD is internally pulled

UVLO

down. When exiting this mode, charging resumes if VINis present, CD is low and charging is enabled.

All HOST interfaces (CD, SDA/SCL, INT, RESET and LSCTRL) are active no later than 5 ms after SYS reaches

the programmed level.

9.3.4 Voltage Based Battery Monitor

The device implements a simple voltage battery monitor which can be used to determine the depth of discharge.

Prior to entering High-Z mode, the device will initiate a VBMON reading. The host can read the latched value for

the no-load battery voltage, or initiate a reading using VBMON_READ to see the battery voltage under a known

load. The register will be updated and can be read 2ms after a read is initiated. The VBMON voltage threshold is

readable with 2% increments with ±1.5% accuracy between 60% and 100% of VBATREG using the VBMON_TH

registers. Reading the value during charge is possible, but for the most accurate battery voltage indication, it is

recommended to disable charge, initiate a read, and then re-enable charge.

A typical discharge profile for a Li-Ion battery is shown in Table 2. The specific battery to be used in the

application should be fully characterized to determine the thresholds that will indicate the appropriate battery

status to the user. Two typical examples are shown below, assuming the VBMON reading is taken with no load

on the battery.

This function enables a simple 5-bar status indicator with the following typical performance with different

VBATREG settings:

Table 2. Discharge Profile for a Li-Ion Battery

VBATREG BATTERY FULL

4.35 V VBMON > 90% VBMON = 88% VBMON = 86% VBMON = 84% VBMON < 82%

4.2 V VBMON > 98% VBMON = 94% or 96% VBMON = 90% or 92% VBMON = 86% or 88% VBMON < 84%

95% to 65%

REMAINING CAPACITY

65% to 35%

REMAINING CAPACITY

35% to 5%

REMAINING CAPACITY

BATTERY EMPTY

20

Submit Documentation Feedback Copyright © 2017–2018, Texas Instruments Incorporated

Product Folder Links: bq25120A

D

E

C

O

D

E

R

S 3

S 2

S 1

S 0

- 2 % BAT TAP

- 4 % BAT TAP

- 6 % BAT TAP

- 8 % BAT TAP

- 10 % BAT TAP

VREF

90 % VB

80 % VB

70 % VB

60 % VB

VB = 0 . 8 VBAT

VBGUAGE_TH<2:0>

www.ti.com

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

Figure 17. Voltage Battery Monitor

9.3.5 Sleep Mode

The device enters the low-power sleep mode if the voltage IN falls below the sleep-mode entry threshold and V

is higher than the undervoltage lockout threshold. In sleep mode, the input is isolated from the connected battery.

This feature prevents draining the battery during the absence of VIN. When VIN< V

the battery discharge FET on, sends a 128-µs pulse on the INT output, and the FAULT bits of the register are

update over I2C. Once VIN> V

cleared until they are read over I2C and the sleep condition no longer exists. It is not recommended to do a

battery connection or plug in when V

drained form the battery.

9.3.6 Input Voltage Based Dynamic Power Management (V

(BAT)

+ V

, the device initiates a new charge cycle. The FAULT bits are not

SLP

< VIN < V

UVLO

BAT

+ V

as it may cause higher quiescent current to be

SLP

)

IN(DPM)

(BAT)

+ V

, the device turns

SLP

During the normal charging process, if the input power source is not able to support the programmed or default

charging current and System load, the supply voltage decreases. Once the supply approaches V

DPM current and voltage loops will reduce the input current through the blocking FETs, to prevent the further

drop of the supply. The V

IN(DPM)

threshold is programmable through the I2C register from 4.2 V to 4.9 V in 100mV steps. It can be disabled completely as well. When the device enters this mode, the charge current may be

lower than the set value and the VINDPM_STAT bit is set. If the 2X timer is set, the safety timer is extended

while V

IN(DPM)

connected while V

is active. Additionally, termination is disabled. Note that in a condition where the battery is

UVLO<VIN

< V

, the VINDPM loop will prevent the battery from being charged and PMID

IN(DPM)

will be powered from BAT.

IN(DPM)

, the input

IN

Product Folder Links: bq25120A

Submit Documentation FeedbackCopyright © 2017–2018, Texas Instruments Incorporated

21

bq25120A

SLUSD08A –MAY 2017–REVISED JANUARY 2018

www.ti.com

9.3.7 Input Overvoltage Protection and Undervoltage Status Indication

The input overvoltage protection protects the device and downstream components connected to PMID, SYS, and

BAT against damage from overvoltage on the input supply. When VIN> V

an OVP fault is determined to exist.

OVP

During the OVP fault, the device turns the battery discharge FET on, sends a single 128-µs pulse on INT, and

the FAULT bits are updated over I2C. Once the OVP fault is removed, after the deglitch time, t

DGL_OVP

, STAT and

FAULT bits are cleared and the device returns to normal operation. The FAULT bits are not cleared until they are

read in from I2C after the OVP condition no longer exists. The OVP threshold for the device is set to operate from

standard USB sources.

The input under-voltage status indication is used to notify the host or other device when the input voltage falls

below a desired threshold. When VIN< V

, after the deglitch time t

UVLO

DGL_UVLO

, a UVLO fault is determined to

exist. During the VINUVLO fault, the device sends a single 128-µs pulse on INT, and the STAT and FAULT bits

are updated over I2C. The FAULT bits are not cleared until they are read in from I2C after the UVLO condition no

longer exists.

9.3.8 Battery Charging Process and Charge Profile

When a valid input source is connected (VIN> V

UVLO

and V

(BAT)

+ V

< VIN< V

SLP

and VIN> V

OVP

IN(DPM)

), the CE

bit in the control register determines whether a charge cycle is initiated. When the CE bit is 1 and a valid input

source is connected, the battery discharge FET is turned off, and the output at SYS is regulated depending on

the output configuration. A charge cycle is initiated when the CE bit is written to a 0. Alternatively, the CD input

can be used to enable and disable charge.

The device supports multiple battery chemistries for single-cell applications. Charging is done through the

internal battery MOSFET. There are several loops that influence the charge current: constant current loop (CC),

constant voltage loop (CV), input current limit, V

DPPM

, and V

. During the charging process, all loops are

IN(DPM)

enabled and the one that is dominant takes control.

The charge current is regulated to I

CHARGE

voltage. The voltage between BAT and GND is regulated to V

until the voltage between BAT and GND reaches the regulation

BATREG

(CV Mode) while the charge current

naturally tapers down. When termination is enabled, the device monitors the charging current during the CV

mode, and once the charge current tapers down to the termination threshold, I

, and the battery voltage is

TERM

above the recharge threshold, the device terminates charge, and turns off the battery charging FET. Termination

is disabled when any loop is active other than CV.

9.3.9 Dynamic Power Path Management Mode

With a valid input source connected, the power-path management circuitry monitors the input voltage and current

continuously. The current into IN is shared at PMID between charging the battery and powering the system load

at PMID, SYS, and LS/LDO. If the sum of the charging and load currents exceeds the current that the VIN can

support, the input DPM loop(VINDPM) reduces the current going into PMID through the input blocking FETs.

This will cause a drop on the PMID voltage if the system demands more current. If PMID drops below the DPPM

voltage threshold(V

), the charging current is reduced by the DPPM loop through the BATFET in order to

DPPM

stabilize PMID. If PMID continues to drop after BATFET charging current is reduced to zero, the part enters

supplement mode when PMID falls below the supplement mode threshold. Battery termination is disabled while

in DPPM mode. In order to charge the battery, the voltage at PMID has to be greater than V

BATREG

+ V

DPPM

threshold..

9.3.10 Battery Supplement Mode

While in DPPM mode, if the charging current falls to zero and the system load current increases beyond the

programmed input current limit, the voltage at PMID reduces further. When the PMID voltage drops below the

battery voltage by V

system load when the voltage on the PMID pin rises above the battery voltage by V

, the battery supplements the system load. The battery stops supplementing the

(BSUP1)

. During supplement

(BSUP2)

mode, the battery supplement current is not regulated, however, the short-circuit protection circuit is active.

Battery termination is disabled while in supplement mode.

22

Submit Documentation Feedback Copyright © 2017–2018, Texas Instruments Incorporated

Product Folder Links: bq25120A

Loading...

Loading...