Page 1

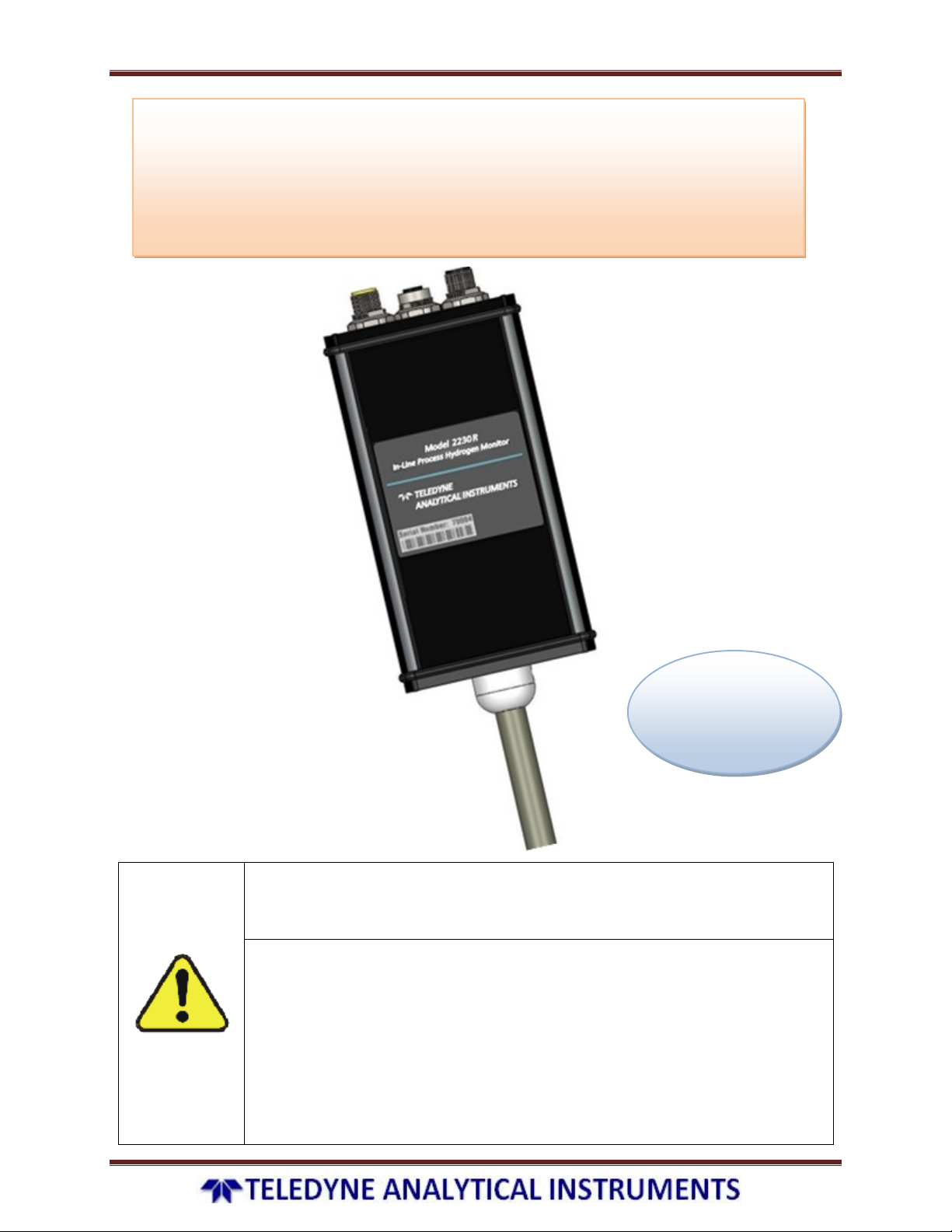

MODEL 2230R

, Process Hydrogen Analyzer

IMPORTANT NOTICES

OPERATING &

INSTRUCTION MANUAL

ECO #

P/N

6/30/2011

Read and understand this operating manual

before installing or using the unit. Only use

cables from Model 2230R with this unit. If this

equipment is used in a manner not specified by

Model 2230R, the protection provided by this

equipment may be impaired.

Page 1

Page 2

MODEL 2230R

, Process Hydrogen Analyzer

Copyright © 2006 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed, stored

in a retrieval system, or translated into any other language or computer language in whole or in

part, in any form or by any means, whether it be electronic, mechanical, magnetic, optical,

manual, or otherwise, without the prior written consent of Teledyne Analytical Instruments,

16830 Chestnut Street, City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at our

option, any material or construction in which defects become apparent within one year from

the date of shipment, except in cases where quotations or acknowledgements provide for a

shorter period. Components manufactured by others bear the warranty of their manufacturer.

This warranty does not cover defects caused by wear, accident, misuse, neglect or repairs other

than those performed by Teledyne or an authorized service center. We assume no liability for

direct or indirect damages of any kind and the purchaser by the acceptance of the equipment

will assume all liability for any damage which may result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus, and

to make any alterations in the dimensions, shape or weight of any parts, in so far as such

alterations do not adversely affect our warranty.

Voided Warranty:

• The unit is opened and the manufacturing seal is broken.

• Unauthorized repair work performed at the customer’s location or carried out by anyone

other than Teledyne Analytical Instrument factory trained technicians.

• Equipment or parts that have been tampered with, misused, neglected, mishandled,

improperly adjusted, or modified in any way without the written consent of Model 2230R.

• Equipment or parts that have been damaged due to shipping, misuse, accidents,

mishandling, neglect, or problems with electrical power sources.

• Repair work performed during the warranty period does not prolong the warranty period

past the original period.

• System operation in incorrect or inappropriate environments.

• Usage that is not in accordance with system guidelines or an operator’s failure to follow

manual instructions.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by which

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all personnel

involved in the use of the instrument or its interface be properly trained in the process being

measured, as well as all instrumentation related to it.

Page 2

Page 3

MODEL 2230R

, Process Hydrogen Analyzer

The safety of personnel is ultimately the responsibility of those who control process conditions.

While this instrument may be able to provide early warning of imminent danger, it has no

control over process conditions, and it can be misused. In particular, any alarm or control

systems installed must be tested and understood, both as to how they operate and as to how

they can be defeated. Any safeguards required such as locks, labels, or redundancy, must be

provided by the user or specifically requested of Teledyne at the time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser is

responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement expressed or

implied by this document or any information disseminated by the manufacturer or its agents, is

to be construed as a warranty of adequate safety control under the user’s process conditions.

Page 3

Page 4

MODEL 2230R

, Process Hydrogen Analyzer

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many important

safety messages in this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety

message is associated with a safety alert symbol. These symbols are found in the manual and

inside the instrument. The definition of these symbols is described below:

IMPORTANT NOTICES

Read and understand this operating manual before installing or using the

unit. Only use cables from Model 2230R with this unit. If this equipment

is used in a manner not specified by Model 2230R, the protection

provided by this equipment may be impaired.

Hydrogen is flammable at 4% in air. Take indications seriously and be

prepared to take action. In the event of detection of 4% or higher of a

hydrogen gas concentration there is a high probability of a hazard to

safety. Inform local emergency response personnel immediately.

LIMITATION OF LIABILITY

In the event of a defect in a product, Model 2230R shall not be responsible for any direct,

indirect, incidental or consequential damages resulting therefore, including, but not

limited to, loss of revenue and/or profit.

This manual provides information designed to guide you through the installation, calibration

and operation of your new analyzer. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular application or features and/or

options added per customer requests. Please check the front of this manual for any additional

information in the form of an Addendum which discusses specific information, procedures,

cautions and warnings that may be specific to your instrument.

Manuals do get misplaced. Additional manuals can be obtained from Teledyne at the address

given in the Appendix. Some of our manuals are available in electronic form via the internet.

Please visit our website at: www.teledyne-ai.com

.

If there are any questions concerning this equipment, please contact your local TAI

representative, or the factory directly at:

Page 4

Page 5

MODEL 2230R, Process Hydrogen Analyzer

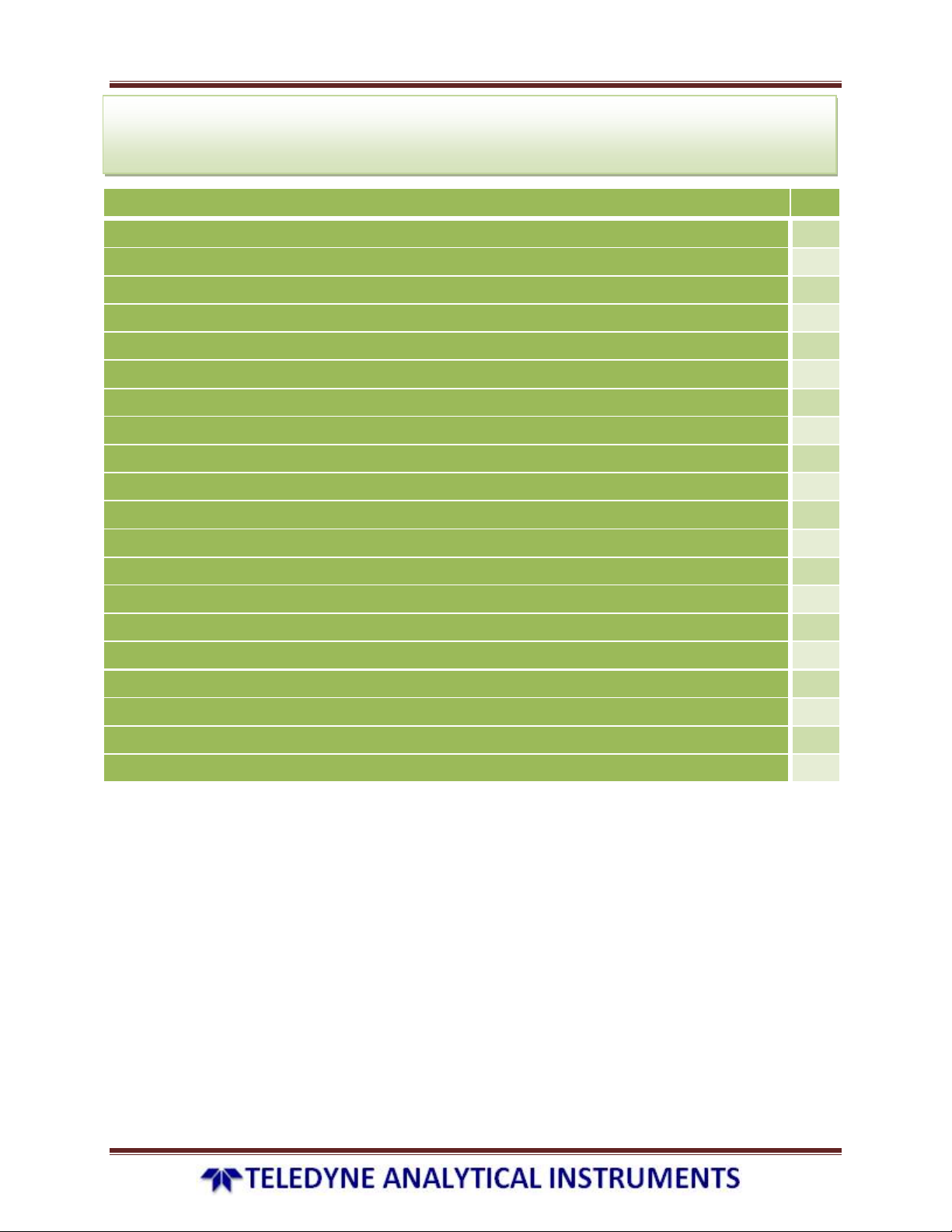

TABLE OF CONTENTS

1. DESCRIPTION 06

2. SPECIFICATION 07

3. OPERATION 09

3.1 UNIT LOCATION 09

3.1.1 WARNING LABEL 09

3.2 MOUNTING 09

3.3 PROCESS CONNECTION 10

3.4 START UP 10

3.5 SETTINGS 11

3.6 VISUAL STATUS INDICATOR 11

3.7 OPTIMUM UNIT PERFORMANCE 11

4. ELECTRICAL & COMMUNICATION 12

4.1 CONNECTIONS 12

4.2 ANALOG OUTPUTS 13

4.3 SERIAL COMMUNICATION 14

5. MAINTENANCE 20

5.1 CLEANING 20

5.2 CALIBRATION INTERVAL 20

5.3 FIELD VERIFICATION & FIELD CALIBRATION GASES 20

5.4 VERIFICATION 21

5.5 CALIBRATION 24

Page 5

Page 6

MODEL 2230R, Process Hydrogen Analyzer

1. DESCRIPTION

The Model 2230R Process Hydrogen Analyzer is designed to detect and/or measure hydrogen

as a component of a gas mixture. The hydrogen specific solid-state sensing element is designed

for ease of use, interface flexibility and true process control. The electronics contains all the

circuitry necessary to operate the sensor and present calibrated hydrogen readings to a voltage

or current analog output and an RS232 or RS422 digital output. The monitor can be

implemented in humidity and in process gas streams with temperatures up to 100°C. The

Model 2230R is ideal for hydrogen production and petrochemical applications where real-time

measurements can enhance process plant efficiencies, diagnostics, and maintenance

management.

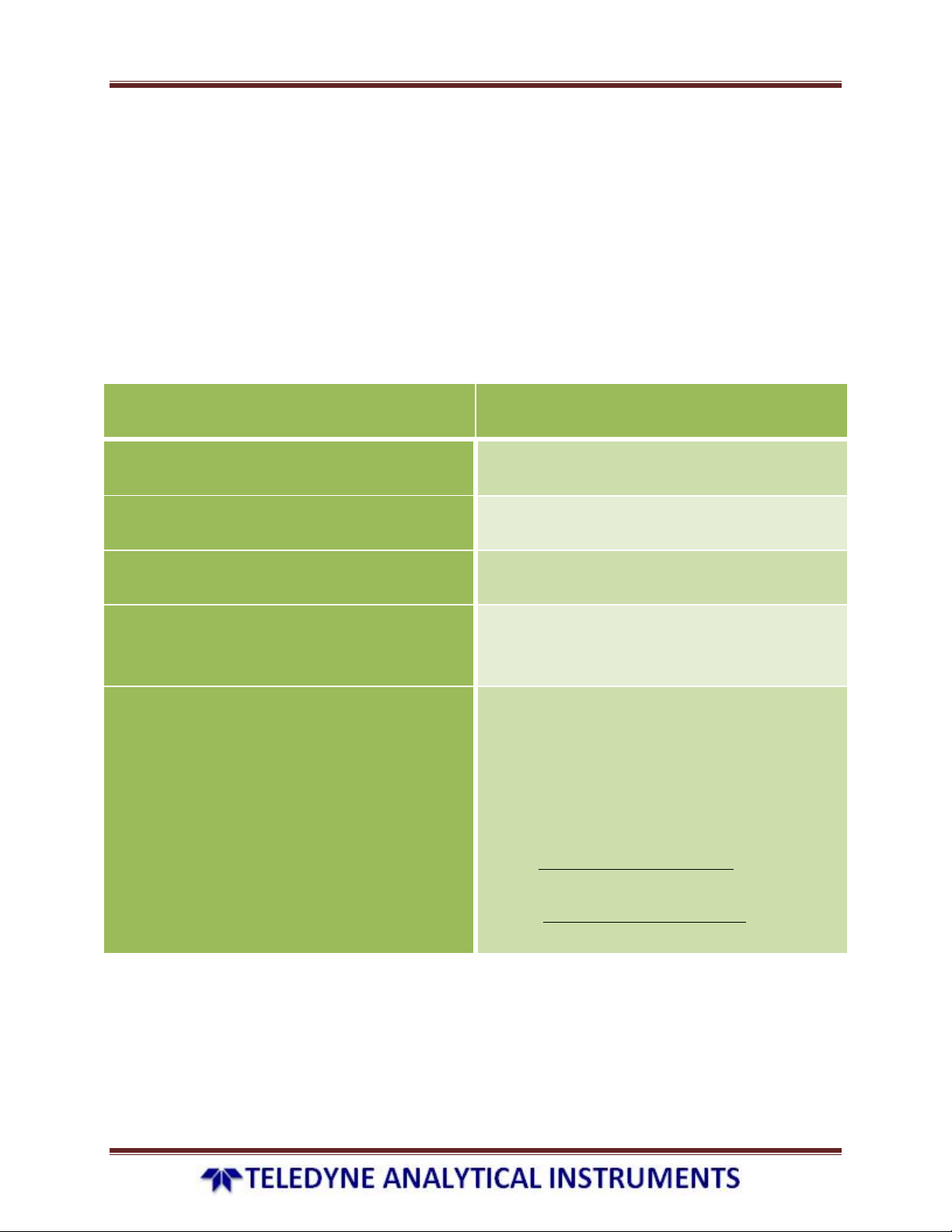

Product Name

Product Model

Purchase Date

Serial No

Contact Details,

Your Distributor

Contact Details,

TELEDYNE

ANALYTICAL INSTRUMENTS

Process Hydrogen Analyzer

Model 2230R

TELEDYNE INSTRUMENTS

Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91749-1580

Telephone: (626) 934-1500

Fax: (626) 961-2538

Web: www.teledyne-ai.com

Or your local representative.

Email: ask_tai@teledyne.com

Page 6

Page 7

MODEL 2230R

, Process Hydrogen Analyzer

Temperature:

Flow Rate: 0 to 50 slpm

Operating:

Storage:

8 VDC to 13 VDC, 1.0 A

Indoor/Outdoor Use

Altitude up to 2000 meters

Pollution degree 2 environment

IP64 capable

Output Voltages OR

•

•

Output Currents

•

•

User

232 or RS

(Two programmable 60 VDC / 1 A SPDT relays with both

normally open N.O.) and normally closed (N.C.) contacts.

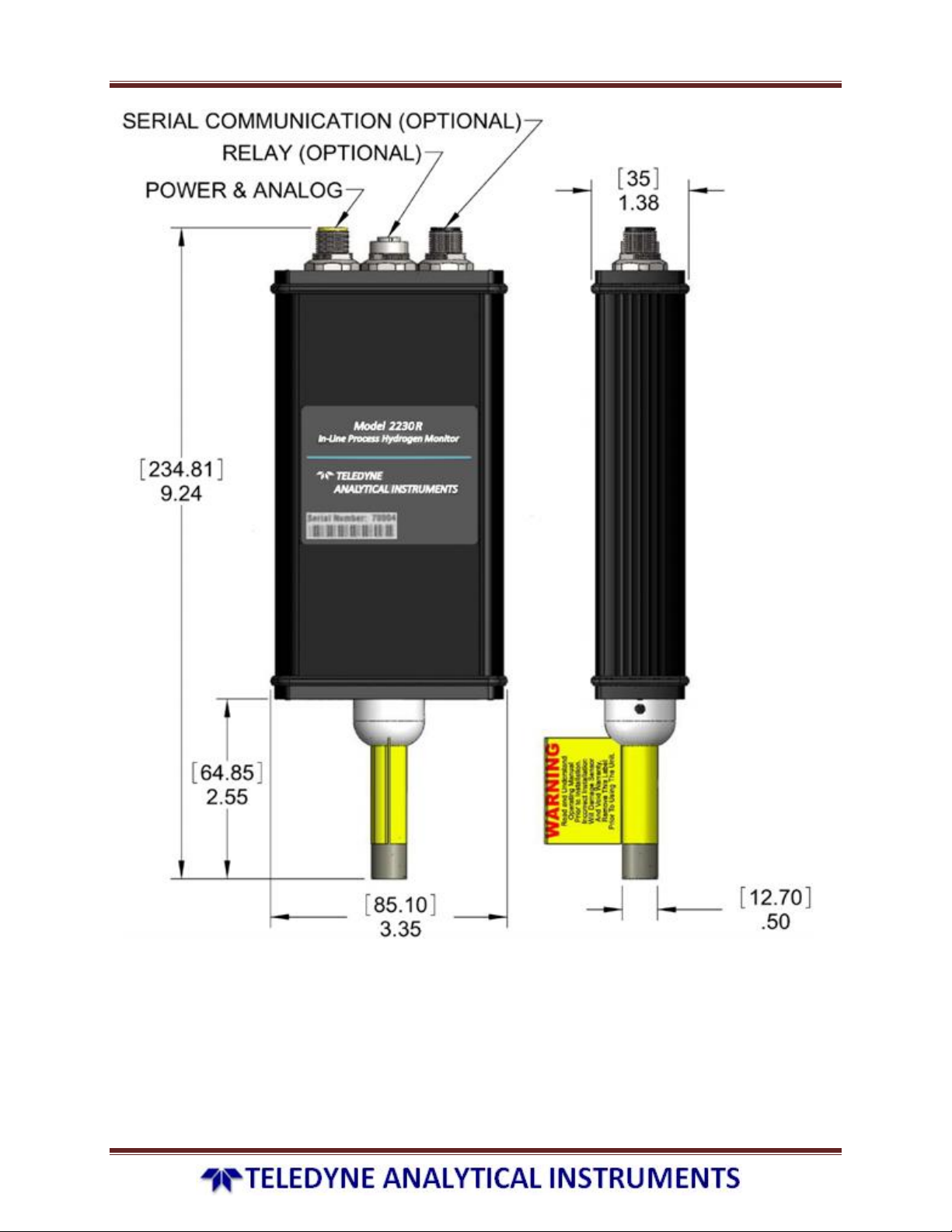

See following figure (dimensions in inches [mm] )

0.37 kg (0.82 lb.)

10 years

2. SPECIFICATIONS

Process Gas Stream

Ambient Temperature

Power Supply

Environmental

Ingress Protection

Analog Outputs

Serial Communications RSRelay Contacts (Optional)

Dimensions

Weight

Product Life Expectancy

Certifications

-20°C to 100°C

-20°C to 40°C

-40°C to 50°C

0 VDC to 5 VDC

1 VDC to 5 VDC

4 mA to 20 mA

0 mA to 20 mA

-specific ranges available

-422

Page 7

Page 8

MODEL 2230R, Process Hydrogen Analyzer

Page 8

Page 9

MODEL 2230R, Process Hydrogen Analyzer

WITHIN.

3. OPERATION

3.1 UNIT LOCATION

The unit can be mounted in any orientation or position, however vertical mounting (unit above

process connection) should be made in process streams containing liquids or potentially

condensing gases.

3.1.1 WARNING LABEL

Remove sensor tube warning label prior to using the unit.

3.2 MOUNTING

Mounting is achieved by securing the sensor tube into the supplied fitting directly in the

process piping as shown below. Optional mounting brackets that attach to the instrument

housing are also available.

WARNING: DO NOT CINCH DOWN OR TIGHTEN FERRULES OUTSIDE OF

THE FERRULE REGION OF THE LONG TUBE OR YOU WILL RISK

PERMANENTLY DAMAGING THE LONG TUBE AND SENSOR ASSEMBLY

1.0 inches is the maximum distance that the fitting mount can be from the end plate of the

Model 2230R unit. This is referred to as the Ferrule Region of the long tube which has a wall

thickness of 0.065 in. Any distance exceeding 1.0 in. will be in the Sensor Assembly Region

where the tube wall thickness is only 0.038 in. Cinching down a fitting outside the Ferrule

Region and in the Sensor Assembly Region may result in permanent damage to the long tube

and the sensor assembly within.

Page 9

Page 10

MODEL 2230R, Process Hydrogen Analyzer

3.3 PROCESS CONNECTION

Model 2230R offer a variety of fittings to mate the unit to a process stream. The following table

lists our standard fitting selections. Others are available upon request.

• ½” MNPT thread

• ½” FNPT thread

• -8 SAE/MS thread size

... and many other industry standards.

3.4 PROCESS CONNECTION

Power (8 to 13 VDC) is connected via the Power/Analog connector as shown in Section 4.1.

Once power is applied, the unit executes a warm-up sequence lasting five minutes. The status

LED will be amber in color during the warm-up sequence. When the unit is ready for operation,

the status LED will change to green (if the measured hydrogen concentration is under the first

relay set point) and to red (if it exceeds the second relay set point). The following operations

will be completed in this warm-up sequence:

• Heat the sensor to operating temperature

• Perform system self-test

WARNING: MODEL 2230R PROCESS HYDROGEN ANALYZERS ARE

CALIBRATED IN A HYDROGEN/NITROGEN (H₂/N₂) BACKGROUND AND

SHOULD NEVER BE OPERATED IN AN AIR OR OXYGEN BACKGROUND.

After warm-up, the Model 2230R Analyzer should be run in a hydrogen concentration

exceeding 5% by volume for at least an hour. Oxygen will readily adsorb on the Model 2230R

Analyzer and can confound the hydrogen measurements. If the sensors are left in oxygen, air or

any environment without hydrogen for long periods of time, they must be conditioned in

hydrogen to remove adsorbed oxygen and taken through the Verification process to check

accuracy. Failure of the Verification will require that the sensors go through Calibration. Both

procedures are described later in this manual.

The Model 2230R Analyzer can be exposed to oxygen for short periods of time without adverse

effects if the unit is turned off. If the units are operated in oxygen or stored in air for longer

than a week, the units’ hydrogen readings may be high due to oxygen adsorption on the sensor.

Hydrogen exposure will then cause the readings to drift lower as adsorbed oxygen is slowly

removed and the unit recovers to normal steady behavior.

If this drift behavior is observed, the sensor should be conditioned by operating in a hydrogen

concentration exceeding 5% until the readings are stable. The required hydrogen conditioning

may vary from several hours to several days depending on the level of oxygen exposure. Higher

hydrogen concentrations used during conditioning may accelerate the process. Once stable, the

unit should be taken through Verification to check accuracy and Calibration if needed.

Page 10

Page 11

MODEL 2230R, Process Hydrogen Analyzer

Step

Description

1

2

3

4

MONITORING THE UNIT.

Power units on in 5% H₂/N₂ by volume or greater

Operate the Model 2230R Analyzer in the 5% H₂/N₂ or greater gas for six hours or

longer

Check to see if the sensor readings were accurate and stable over that time

If the readings are not accurate and stable, condition the sensor in 5% H₂/N₂ or

greater gas overnight and perform the Verification and Calibration described later

in this manual.

3.5 SETTINGS

The unit’s operational and output settings have been configured at the manufacturer with

settings specified at the time of purchase. Settings may be changed through the use of Serial

Communication as described in section 4, or through the use of an Optional User Interface

Module.

WARNING: IF SETTINGS ARE CHANGED FROM THOSE SET BY THE

MANUFACTURER THEN IT IS THE USER’S RESPONSIBILITY TO

UNDERSTAND THE IMPLICATIONS TO THE CONNECTING EQUIPMENT

3.6 VISUAL STATUS INDICATOR

Located on the front of the unit next to model number marking, the Status Indicator LED

displays basic unit function as described below.

Status Indicator Color

Normal operation / Hydrogen Detected below R1 set point GREEN

Warm-up / Hydrogen Detected above R1 and below R2 set points AMBER

Hydrogen Detected above R2 set point/ Unit fault detected RED

3.7 OPTIMUM UNIT PERFORMANCE

For maximizing the performance of the sensor, the following steps are recommended.

• Verify that all electrical connections and made as recommended. Switching the polarity can

cause damage to the unit. Ensure that the DC power supply utilized is appropriate and does

not have large peak-to-peak noise.

• Perform a Field Calibration after installation and conditioning steps described in the Start-

up section are completed.

Page 11

Page 12

MODEL 2230R, Process Hydrogen Analyzer

WITH THE LOCATION

CLASSIFICATION.

• If the unit gets exposed to extended periods of no H₂ (or some Oxygen), condition the

sensor as described in the Start-up section and follow-up with a Field Verification (and Field

Calibration, if needed).

• Effect of pressure: The Model 2230R Analyzer is hydrogen specific and sensitive to only the

hydrogen partial pressure in the gas stream. Since changes in total gas pressure will affect

the hydrogen partial pressure, they will also affect the sensor readings. For instance, at one

atmosphere pressure, a 50% H₂/N₂ mixture will be reported as 50% from the unit. At 1.1

atm, the reading will increase to 55% and two atms will result in a reading of 100%. In fact,

the Model 2230R Analyzer are capable of measuring multiple atmospheres of hydrogen and

readings above 100% H₂ are interpreted as hydrogen pressures above one atmosphere. So,

for example, a reading of 150% H₂ means 1.5 times the hydrogen pressure of a 100% H₂

concentration at one atmosphere. At the factory, the units are calibrated at one

atmosphere pressure. Performing the Field Calibration at the operating pressure will display

the pressure corrected reading. For example, if the local atmospheric pressure is 0.97 atm,

doing a Field Calibration will correct for this.

• Verification/Calibration gas bottle accuracy: The inaccuracy of the gas bottle concentration

will directly affect the measured accuracy by the units. During factory calibration, the units

are calibrated with high accuracy gases (as high as ± 0.02% accurate). It is strongly

recommended that the user perform calibration with similar high accuracy gases to

maintain the accuracy specified in the manual.

4. ELECTRICAL & COMMUNICATION

WARNING: IF THE UNIT IS INSTALLED IN A CLASSIFIED LOCATION THEN IT

IS THE RESPONSIBILITY OF THE USER AND INSTALLER TO MAKE

CONNECTIONS TO RELATED EQUIPMENT IN A MANNER CONSISTENT

4.1 CONNECTIONS

Power/Analog Output - Connector 1

Supplied Cable – 4m (12 ft.) standard length (Other lengths available)

Wire Color Description

Brown +8 VDC to +13 VDC

White VDC Return

Black Positive Analog Output

Blue Analog Output Return

Page 12

Page 13

MODEL 2230R, Process Hydrogen Analyzer

Brown

White

Blue

Black

Grey

Pink

Relays (Optional) - Connector 2

Supplied Cable – 4m (12 ft.) standard length (Other lengths available).

Wire Color Description

Grey Relay 1 Common

Pink Relay 1 Normally Closed (NC)

Black Relay 1 Normally Open (NO)

White Relay 2 Common

Blue Relay 2 Normally Closed (NC)

Brown Relay 2 Normally Open (NO)

Serial Interface (Optional) / Remote User Interface Module (Optional) Connector 3

Supplied Cable – 4m (12 ft.) standard length (Other lengths available).

Wire

Color

Description

+6V (N.C.)

TxD (Device Transmit) 3 2 TxD- (Device Transmit, -Ve) 3 2

- - - TxD+ (Device Transmit, +Ve) 4 3

RxD (Device Receive) 2 3 RxD- (Device Receive, -Ve) 2 20

- - - RxD+ (Device Receive, +Ve) 6 8

Ground 5 7 Ground 5 7

RS232 (standard)

DB9

Pin

DB25

Pin

Description

RS422 (Optional)

DB9

Pin

DB25

Pin

4.2 ANALOG OUTPUT

The user can request for a specific output current or voltage range or there are a number of

standard analog output ranges the user can select from, which are listed below. The analog

output the user selects is scaled to the user’s hydrogen range of interest. All of this is initially

set at the factory per customer specification at the time of order.

Below is the table for standard analog output current ranges:

Current Analog Output Range Power-On Self Diagnostic Error

4 mA to 20 mA 2 mA 3 mA

0 mA to 20 mA 0 mA 20 mA

Page 13

Page 14

MODEL 2230R, Process Hydrogen Analyzer

0 V to 5 V

0 V 5 V 1 V to 5 V

0.5 V

0 V 0 V to 4 V

5 V 4.5 V

0.5 V to 4.5 V

0 V 5 V

The user can change to another current range of the analog output in the field. Please refer to

the “I” command in Section 4.3 SERIAL COMMUNICATION.

Below is the table for standard analog output voltage ranges:

Voltage Analog Output Range Power-On Self Diagnostic Error

The user can change to another voltage range of the analog output in the field. Please refer to

the “V” command in Section 4.3 SERIAL COMMUNICATION.

WARNING: THE USER CANNOT CHANGE FROM A CURRENT RANGE TO A

VOLTAGE RANGE OR FROM A VOLTAGE RANGE TO A CURRENT RANGE

OUT IN THE FIELD. THIS REQUIRES A FACTORY MODIFICATION.

4.3 SERIAL COMMUNICATION

The user can monitor output and interface with the unit to perform calibration or adjust user

settings via the serial communication connector. The serial communication is accomplished via

an RS232 (optional RS422) interface.

Serial

Communications

Software

Format and

Settings

Data Display

Any serial port two-way communications software such as terminal

emulators (HyperTerminal, Telnet, etc.) and purpose-built software

(using LabView, Visual Basic, C++, etc.) can be used to establish serial

communication with the unit.

RS232 (RS422 optional)

• 19200 Baud

• 8 bit data

• 1 stop bit

• No parity

• Xon/Xoff

Streaming data is presented in column format. Once serial

communication is established and the unit is operating in normal

mode, data will be displayed in the user specified format. The display

output options are configured via a serial command as described in the

following sections (refer to the SERIAL COMMUNICATION COMMANDS,

FORMAT <fmt>, and OPTIONS <opt> sections). Columnated data

available are as follows:

Page 14

Page 15

MODEL 2230R, Process Hydrogen Analyzer

<fmt> Format (these appear in their own columns)

• Timestamp (an integer count at 0.25 sec intervals)

• Printed Circuit Board (PCB) Temperature in

• Sensor Temperature in °C

• Raw Analog Data Converter (ADC) Values

• Calibrated Hydrogen Values

• Peak Hydrogen Values

<opt> Options (these status data appear in the MESSAGES column)

• Calculation Errors

• Heater State

What follows are examples of typical user specified outputs:

Example 1:

Sample serial data with column headers – Calibrated H₂% and Messages only

Display User Response

H2scan: Type “g 02 06”

%H₂ Messages

0.0000

0.0000

0.0000

Example 2:

Sample serial data with column headers– Multiple Outputs Specified

Display User Response

H2scan: Type “g b2 06”

Time stamp Pcb Temp Snsr Temp %H₂ Messages

264 28.8530 124.50800 0.0000

280 29.1979 124.50910 0.0000

296 29.5169 124.51110 0.0000

312 29.7951 124.51320 0.0000

Page 15

Page 16

MODEL 2230R, Process Hydrogen Analyzer

The unit can be communicated with and configured via the use of

commands as described below. Two levels of communication outputs

Serial

Communication

Commands

Command

Summary

Keystroke Description

ESC

sp(spacebar)

A

C

=<password>

are available:

• Level 0 – Default level used for data monitoring and basic

functions providing a continuous stream of data readings

• Level 1 – Password protected level used for configuration of

user-settable parameters; interactive single-line data output per

command

The RETURN or ENTER key is the last character of the command string.

If either key is pressed without a command string the result is an invalid

command and will resume continuous display if in Level 0 or return to

prompt if in Level 1.

Level 0 Commands

Stops continuous display to enter a password or command. If in level

zero, the continuous display will resume after executing one

command.

Pressing the Space key while the serial output is active will display a

label line showing the heading for each column of data.

Average readings.

Clear peak hydrogen value.

Enter the password to change security level. A null or invalid

password returns to the default security level.

Level 0 password = “0”

Level 1 password = “h2scan”

Level 1 Commands

Keystroke Description

A <R1> <R2>

C

D <page>

Page 16

Set the R1 and R2 set points for the relay contacts in %H₂.

Clear peak hydrogen value.

Display Product Information. Enter page number 0-6 or A for all

pages, default is page 0.

0 – Product information

1 – User configuration

2 – Manufacturing information

3 – Product configuration

4 – Sensor characterization data

5 – Hydrogen calibration data

Page 17

MODEL 2230R, Process Hydrogen Analyzer

6 – Temperature calibration data

A – All of the above

E

F

G < fmt> <opt>

H <low> <high>

I <low> <high>

<err> <not rdy>

L < fmt> <opt>

P <atm>

S

V <low> <high>

<err> <not rdy>

X

Field Verify (refer to the Section 5.4 VERFICATION).

Field Calibration (refer to the Section 5.5 CALIBRATION).

Start or resume the sensor operation: if needed, heat the ASIC, setup

the sensor, and output data on serial port; this restores default

settings (refer to the FORMAT <fmt> and OPTIONS <opt> sections).

Set the hydrogen reporting range: <low> to <high> in %H₂.

Set the DAC current output range: <low> to <high>; error output

<err>; and not ready output <not rdy> milliamps. Possible range from

0 to 20 milliamps.

Print current hydrogen reading. Used to poll for hydrogen readings.

Default format <fmt> is current setting (refer to the FORMAT <fmt>

and OPTIONS <opt> sections).

Select atmospheric pressure of gas. Factory default pressure is 1

ATM.

Stop the sensor: turn off heater, set Bias to zero, set DAC outputs to

zero, and stop reporting data on the serial output.

Set the DAC voltage output range: <low> to <high>; error output

<err>; and not ready output <not rdy> in volts. Possible range from 0

to 5 volts.

Clear field calibration data (returns to last factory calibration data).

The Format <fmt> string is a two character hexadecimal representation

of an 8 bit value derived from the following table. The user determines

Format <fmt>

which data is needed and selects that bit value. Once all selections are

made the values are summed bitwise and then converted to a two

place hexadecimal value. To aid in the conversion, a 4 bit to

hexadecimal conversion table follows in EXAMPLE 3.

Format: Bit Value Identifiers

Serial output Format <fmt> parameter: select the desired columns of data from this list, add

the bit value for each column bitwise, and convert into two hexadecimal characters using the

4 bit-to-Hexadecimal table in EXAMPLE 3.

Description Bit Value

Include time stamp

Include raw ADC values

Include PCB temperature

Include sensor temperature

Include capacitor reading

1 0 0 0 0 0 0 0

0 1 0 0 0 0 0 0

0 0 1 0 0 0 0 0

0 0 0 1 0 0 0 0

0 0 0 0 1 0 0 0

Page 17

Page 18

MODEL 2230R, Process Hydrogen Analyzer

Include resistor reading

Include overall hydrogen reading

Include peak hydrogen reading

The Options <opt> string is a two character hexadecimal representation

of an 8 bit value derived from the following table. The user determines

Options <opt>

which data is needed and selects that bit value. Once all selections are

made the values are summed bitwise and then converted to a two

place hexadecimal value. To aid in the conversion, a 4 bit-toHexadecimal conversion table follows in EXAMPLE 3.

Options: Bit Value Identifiers

Serial output Options <opt> parameter: select the desired status messages from this list

which will appear in the MESSAGES column, add the bit value for each column bitwise, and

convert into two hexadecimal characters using the 4 bit-to-Hexadecimal table in EXAMPLE 3.

0 0 0 0 0 1 0 0

0 0 0 0 0 0 1 0

0 0 0 0 0 0 0 1

Description Bit Value

Calculation Errors

Heater State

Example 3:

The user wishes to implement the “G”

command (“Go”command, refer to LEVEL 1

COMMANDS table) to have the following

serial output columns reported from the

monitor: Time Stamp, Capacitor Reading,

Overall Hydrogen Reading, the Peak

Hydrogen Reading, Calculation Errors, and

the Heater state.

From the FORMAT <fmt> table above, you

identify your desired columns with its

corresponding bit value:

<fmt> Descriptions <fmt> Bit Value

Time Stamp 1000 0000

Capacitor Reading 0000 1000

Overall Hydrogen

Reading

Peak Hydrogen

Reading

<fmt> 4 Bit Value

Combination:

0000 0010

0000 0001

1000 1011

0 0 0 0 0 1 0 0

0 0 0 0 0 0 1 0

4 bit value Hexadecimal

Character

0000 0

0001 1

0010 2

0011 3

0100 4

0101 5

0110 6

0111 7

1000 8

1001 9

1010 A

1011 B

1100 C

1101 D

1110 E

1111 F

Page 18

Page 19

MODEL 2230R, Process Hydrogen Analyzer

Now use the 4 BIT-TO-HEXADECIMAL table above to convert this 4 bit value combination into a

two place hexadecimal value:

<fmt> Two Place Hexadecimal Value : 8b

From the OPTIONS <opt> table above, you identify your desired columns with its corresponding

bit value:

<opt> Descriptions <opt> Bit Value

Calculations Errors 0000 0100

Heater State 0000 0010

<opt> 4 Bit Value Combination: 0000 0110

Again, use the 4 BIT-TO-HEXADECIMAL table to convert this 4 bit value combination into a two

place hexadecimal value:

<opt> Two Place Hexadecimal Value : 06

Conclusion: To have the Time Stamp, Capacitor Reading, Overall Hydrogen Reading, the Peak

Hydrogen Reading, Calculations Errors and Heater State columns continuously reported, you

will implement the “G” serial command (“Go” Command, refer to LEVEL 1 COMMANDS table) as

follows at the H2scan:

command prompt: G < fmt> <opt> = g 8b 06

Display User Response

H2scan: Type “g 8b 06”

Page 19

Page 20

MODEL 2230R, Process Hydrogen Analyzer

5. MAINTENANCE

5.1 CLEANING

If the unit is exposed to process streams containing debris, condensates or other material that

may collect over the sensor tip then the unit should be removed from the stream periodically

and the tip cleaned by a gentle wiping with a clean lint-free cloth or paper.

5.2 CALIBRATION INTERVAL

TELEDYNE ANALYTICAL INSTRUMENTS recommends that the system calibration be carried out if

the unit fails Verification. Field Verification can occur as often as needed and is recommended

when the tolerated sensor drift may result in unacceptably high errors. Anticipated drift rates

and error calculations are explained in the Verification section of this manual. The user has two

choices in calibrating the unit:

Contact TELEDYNE ANALYTICAL INSTRUMENTS to make arrangements

Factory

Calibration

Field

Calibration

In the event the Field Calibration procedure seems to not be effective, TELEDYNE ANALYTICAL

INSTRUMENTS recommends the unit be shipped back to the factory for a comprehensive

evaluation and Factory Calibration.

for a comprehensive Factory Calibration using high accuracy gases by

TELEDYNE ANALYTICAL INSTRUMENTS’s factory trained technicians;

optional NIST traceable certificate available upon request. An annual

Factory Calibration is advisable to optimize performance.

Refer to Sections 4.4 and 4.5 for the operational procedure. Customerspecific Field Calibration Kits for the Model 2230R analyzer is available

from TELEDYNE ANALYTICAL INSTRUMENTS. Field Calibration is a 3 stage

process:

1. Run Field Verification,

2. Run Field Calibration,

3. Repeat the Field Verification to confirm a successful Field Calibration.

5.3 FIELD VERIFICATION & FIELD CALIBRATION GASES

Field Verification and Field Calibration require the availability of at least two certified known

gases at values specific to the user’s application. For optimization, the hydrogen concentrations

of the gases implemented in Field Verification and Field Calibration must be the same. Flow

rate recommended is 0.5 ± 0.2 slpm.

Verification / Calibration in an Inert (i.e. nitrogen) Background Gas:

For a unit calibrated in an inert gas (i.e. nitrogen) background, carry out Verification and

Calibration in an inert (i.e. nitrogen) gas background.

Gas Connection

Gases are applied to the unit through user’s piping.

Page 20

Page 21

MODEL 2230R, Process Hydrogen Analyzer

5.4 VERIFICATION

Verification Interval

Verification is a process to compare the sensor output to a known hydrogen concentration.

Verifications do not cause any wear on the sensor and can be accomplished as often as desired.

The recommended interval to perform Verification depends solely on the user’s desired

tolerance for the specific application in question. If the user does not have a specific desired

tolerance, TELEDYNE ANALYTICAL INSTRUMENTS recommends that Verification be performed

every three months.

The tolerance (error) in measuring hydrogen has two primary components: the initial accuracy

number (offset) and a weekly drift value (slope). The chart below is provided as a guideline for

tolerance estimation for the Model 2230R and can be a useful tool in determining the initial

verification frequency. The subsequent verification frequencies can be decided based on the

actual weekly drift observed. The tolerance chart may be used in accordance with TELEDYNE

ANALYTICAL INSTRUMENTS Model 2230R accuracy specifications.

Tolerance Chart (Gas Temperature <65°c)

Number of Weeks after Field Calibration, X

Model Accuracy(*): Drift/week:

2230R

± 0.3% absolute for 0.5 to 10% H₂ ± 0.2% absolute for 0.5 to 10% H₂

± 1.0% absolute for 10 to 100% H₂ ± 0.4% absolute for 10 to 100% H₂

* Sensor performance specifications are only valid for units configured for a maximum 65°C dry

process stream temperature. All figures assume pressure compensation, operating in ambient

that do not contain Oxygen and are in addition to any errors in the gasses used. The accuracy is

specified for serial port output only.

The drift chart can be used to determine the maximum recommended Verification interval to

maintain a required level of accuracy. For instance, if ± 1% accuracy in a 5% H2/N2 gas is

needed; Verification should be typically performed every 3.5 weeks. If ± 2% accuracy is needed

in the same gas, the recommended Verification interval can be extended to 8.5 weeks.

Verifications may be done more frequently than these intervals if desired and should always be

performed if the sensor readings are unusual or suspected to have large errors.

Page 21

Page 22

MODEL 2230R, Process Hydrogen Analyzer

The Model 2230R Analyzer should be conditioned by operation in hydrogen exceeding 5% by

volume until stable and taken through the Field Calibration, if exposed to oxygen or operated

without hydrogen for an extended period. If the unit continues to exhibit errors in excess of the

published accuracy specification and drift rate, please contact TELEDYNE ANALYTICAL

INSTRUMENTS for factory evaluation and repair.

Verification Procedure

Verification can only be accomplished through interface with the unit via the serial port (refer

to the previous Serial Communication Commands section and the LEVEL 1 COMMANDS table in

Section 4.3). Verification of sensor output should be conducted on a regular basis to insure

proper unit operation. Analog outputs can be monitored through the user’s system. As part of

this sequence the date of verification is stored in the unit’s memory.

WARNING: IN ORDER FOR VERIFICATION TO SUCCESSFULLY TAKE PLACE,

THE SENSOR MUST BE IN NORMAL RUNNING MODE.

Verification Using Serial Interface – After establishing serial communication then follow the

sequence below:

1) Press “Esc”

2) The unit will return the command prompt “H2scan:”

3) Type “e” then hit “Enter” and follow prompts to field verify sensor calibration at two gas

concentrations

These steps will implement the following specification values as an example; for values in bold,

please substitute appropriate values relative to your specific operational conditions:

• Local atmospheric pressure: 0.969 ATM

• Hydrogen range: 0% to 30% hydrogen, balance nitrogen

• Field Verification Gas #1: 1% hydrogen, balance nitrogen (instead of gas #1 being 0%

hydrogen, H2scan recommends Field Verification gases always have a hydrogen

concentration)

• Field Verification Gas #2: 30% hydrogen, balance nitrogen

• Settle Time: 30 minutes (TELEDYNE ANALYTICAL INSTRUMENTS recommends this

duration for field verification)

• Tolerance of Field Verification Gas #1 (1% hydrogen by volume): For example, ± 0.30%

absolute hydrogen by volume (refer to the TOLERANCE CHART above or enter user

desired tolerance) NOTE: Poor accuracy of the verification gases will influence the

achievable accuracy from the unit.

• Tolerance of Field Verification Gas #2 (30% hydrogen by volume): ± 1.0% absolute

hydrogen by volume (refer to the TOLERANCE CHART above or enter user desired

tolerance)

Page 22

Page 23

MODEL 2230R, Process Hydrogen Analyzer

FIELD VERIFICATION STEPS

Step Display User response

1 H2scan: Type “ e” to run field verification

2 Ready to Verify

(Y/N)?

3 Pressure is 1.000

atm (Y/N)?

4 Enter new pressure: Type “ .969” for the local atmospheric pressure

5 Pressure is 0.9690

atm (Y/N)?

6 Save as default

(Y/N)?

7 Verify Sensor

(Y/N)?

8 Enter Gas (%H2): Type “ 1” for gas #1, 1% hydrogen by volume

9 Settle time (min): Type “ 30” for a 30 minute duration for gas #1

10 Tolerance (%H2): Type “0.3%” absolute from the for 1% hydrogen by volume

11 Apply 1.000%H2:

Ready (Y/N)?

12 Taking Average…

13 Continue test Verify

Sensor (Y/N)?

14 Enter Gas (%H2): Type “ 30” for gas #2, 30% hydrogen by volume

15 Settle time (min): Type “ 30” for a 30 minute duration for gas #2

16 Tolerance (%H2):

17 Apply 30.000%H2:

Ready (Y/N)?

18 Taking Average… An average will be calculated. Verification Gas2 finished.

19 Continue test Verify

Sensor (Y/N)?

4). If the unit passes Verification, Calibration is not required at this time.

5). If the unit fails Verification, you will see the following:

18 Taking Average… An average will be calculated.

19 Verify Failed Verification complete.

6). If the unit fails Verification, TELEDYNE ANALYTICAL INSTRUMENTS recommends

Calibration, detailed in the following section.

Type “ y”

Type “ n”

Type “ y”

Type “ n”

Type “ y”

Type “ y”

Streaming data…

An average will be calculated. Verification Gas1 finished

Type “ y”

Type “1.0%” absolute from the TOLERANCE CHART for 30%

hydrogen by volume

Type “ y”

Streaming data…

Type “n” to end field verification.

Verification complete.

Page 23

Page 24

MODEL 2230R, Process Hydrogen Analyzer

5.5 CALIBRATION

Calibration Interval

Calibration is used to correct any offset that exist between the sensor output and a known

hydrogen concentration. Calibrations do not cause any wear on the sensor and can be

accomplished as often as desired. It is recommended that Calibration be performed if a unit

fails Verification.

Calibration Procedure

IMPORTANT NOTE: During the Calibration process any previously completed Field Calibrations

are cancelled. As a result, during the routine the unit may display a hydrogen concentration

that is different from the applied gas concentration. This is normal. Once the procedure is

completed, the readings will be corrected to display the right concentrations for all subsequent

exposures.

Calibration can only be accomplished through interface with the unit via the serial port (refer to

the previous Serial Communication Commands section and the LEVEL 1 COMMANDS table in

Section 4.3). Analog outputs can be monitored through the user’s system.

Calibration Using Serial Interface (firmware version 0.47) – Follow the sequence below:

1) Press “Esc”

2) The unit will return the command prompt “H2scan:”

3) Type “f” then hit “Enter” and follow prompts to field calibrate the sensor with two gas

concentrations

These steps will implement the following specification values as an example; for values in bold,

please substitute appropriate values relative to your specific operational conditions:

• Local atmospheric pressure: 0.969 ATM

• Hydrogen range: 0% to 30% hydrogen, balance nitrogen

• Field Verification Gas #1: 1% hydrogen, balance nitrogen (instead of gas #1 being 0%

hydrogen, H2scan recommends Field Verification gases always have a hydrogen

concentration)

• Field Verification Gas #2: 30% hydrogen, balance nitrogen

• Settle Time: 30 minutes (TELEDYNE ANALYTICAL INSTRUMENTS recommends this

duration for field calibration)

WARNING: AS IN THIS EXAMPLE, FOR OPTIMIZATION, THE HYDROGEN

CONCENTRATIONS OF THE GASES IMPLEMENTED IN FIELD CALIBRATION

Page 24

Page 25

MODEL 2230R, Process Hydrogen Analyzer

FIELD CALIBRATION STEPS

Step Display User response

1 H2scan: Type “ f” to run field calibration

2 Ready to Calibrate

(Y/N)?

3 Pressure is 0.9690

atm (Y/N)?

4 Save as default

(Y/N)?

5 Gas1 is 0%H2

(Y/N)?

6 Gas1 for res (Y/N)? Type “ y”

7 Cal Gas: 2.000%H2

(Y/N)?

8 Enter gas: Type “ 1” for gas #1, 1% hydrogen by volume

9 Cal Gas: 1.000%H2

(Y/N)?

10 Settle time: 3 min

(Y/N)? n

11 Enter time: Type “ 30” for a 30 minute duration for gas #1

12 Settle time: 30 min

(Y/N)?

13 Apply 1.000%H2:

Ready (Y/N)? y

14 Taking Average…

cap=0.00000

res=x.xxxxx

15 Gas2 for res (Y/N)? Type “ y”

16 Cal Gas:

100.000%H2 (Y/N)?

17 Enter gas: Type “ 30” for gas #2, 30% hydrogen by volume

18 Cal Gas: 30.000%H2

(Y/N)?

19 Settle time: 1 min

(Y/N)?

20 Enter time: Type “ 30” for a 30 minute duration for gas #2

Type “ y”

Type “ y”

Please note that the firmware has remembered the

atmospheric pressure from the preceding Verification

procedure. Type “n” if a change is required and enter the

correct pressure.

Type “ n”

Type “ n”

Type “ n”

Type “ y”

Type “ n”

Type “ y”

Type “ y”

Streaming data…

Calibration Gas #1 finished

Type “ n”

Type “ y”

Type “ n”

Page 25

Page 26

MODEL 2230R, Process Hydrogen Analyzer

21 Settle time: 30 min

(Y/N)?

22 Apply 30.000%H2:

Ready (Y/N)?

23 Taking Average…

cap=0.00000

res=x.xxxxx

4) Per TELEDYNE ANALYTICAL INSTRUMENTS’s recommendation, upon completion of

Calibration, conduct the Verification sequence as described in the previous section to

verify that the calibration process was executed correctly.

Type “ y”

Type “ y”

Streaming data…

Calibration Gas #2 finished.

Calibration complete.

Page 26

Loading...

Loading...