Page 1

2150EX Area Velocity

Flow Module

Installation and Operation Guide

Part #69-2003-347 of Assembly #60-2004-347

Copyright © 2004. All rights reserved, Teledyne Isco, Inc.

Revision K, May 1, 2007

Page 2

Page 3

Foreword

This instruction manual is designed to help you gain a thorough understanding of the

operation of the equipment. Teledyne Isco recommends that you read this manual

completely before placing the equipment in service.

Although Teledyne Isco designs reliability into all equipment, there is always the possibility of a malfunction. This manual may help in diagnosing and repairing the malfunction.

If the problem persists, call or e-mail the Teledyne Isco Technical Service Department

for assistance. Simple difficulties can often be diagnosed over the phone.

If it is necessary to return the equipment to the factory for service, please follow the

shipping instructions provided by the Customer Service Department, including the

use of the Return Authorization Number specified. Be sure to include a note

describing the malfunction. This will aid in the prompt repair and return of the

equipment.

Teledyne Isco welcomes suggestions that would improve the information presented in

this manual or enhance the operation of the equipment itself.

Teledyne Isco is continually improving its products and reserves the right to

change product specifications, replacement parts, schematics, and instructions without notice.

Customer Service

Phone: (800) 228-4373 (USA, Canada, Mexico)

Fax: (402) 465-3022

Email: IscoCSR@teledyne.com

Technical Service

Phone: (800) 775-2965 (Analytical)

Email: IscoService@teledyne.com

Return equipment to: 4700 Superior Street, Lincoln, NE 68504-1398

Other Correspondence

Mail to: P.O. Box 82531, Lincoln, NE 68501-2531

Email: IscoInfo@teledyne.com

Web site: www.isco.com

Contact Information

(402) 464-0231 (Outside North America)

(800) 228-4373 (Samplers and Flow Meters)

Revised September 15, 2005

Page 4

Page 5

2150EX Area Velocity Flow System

Safety Information

2150EX Area Velocity Flow System

Safety Information

General Warnings Before installing, operating, or maintaining this equipment, you

should read this entire manual. While specific hazards may vary

according to location and application, it is still helpful to read

this safety section (which is specific to the 2150EX) and the

general safety information contained in Appendix E. If you have

any questions regarding the equipment or its installation,

contact Teledyne Isco or one of its representatives for assistance.

This manual has been created in compliance with general

requirements for equipment installed in potentially explosive

atmospheres (refer to Clause 28 of EN 50014:1997).

WARNING

Avoid hazardous practices! If you use this instrument in

any way not specified in this manual, the protection

provided by the instrument may be impaired; this will

increase your risk of injury.

WARNING

Intrinsic safety is dependent on proper installation in

accordance with IEC 60079-14 and IEC 60079-17

International Standards, or ATEX Group II, Category 1G

requirements of the authority that has jurisdiction for the

installation of equipment in hazardous areas at your

specific installation site. Installation should be performed

only by trained and qualified personnel.

Hazard Severity Levels This manual applies Hazard Severity Levels to the safety alerts,

These three levels are described in the sample alerts below.

CAUTION

Cautions identify a potential hazard, which if not avoided, may

result in minor or moderate injury. This category can also warn

you of unsafe practices, or conditions that may cause property

damage.

WARNING

Warnings identify a potentially hazardous condition, which

if not avoided, could result in death or serious injury.

DANGER

DANGER – limited to the most extreme situations

to identify an imminent hazard, which if not

avoided, will result in death or serious injury.

5

Page 6

2150EX Area Velocity Flow System

Safety Information

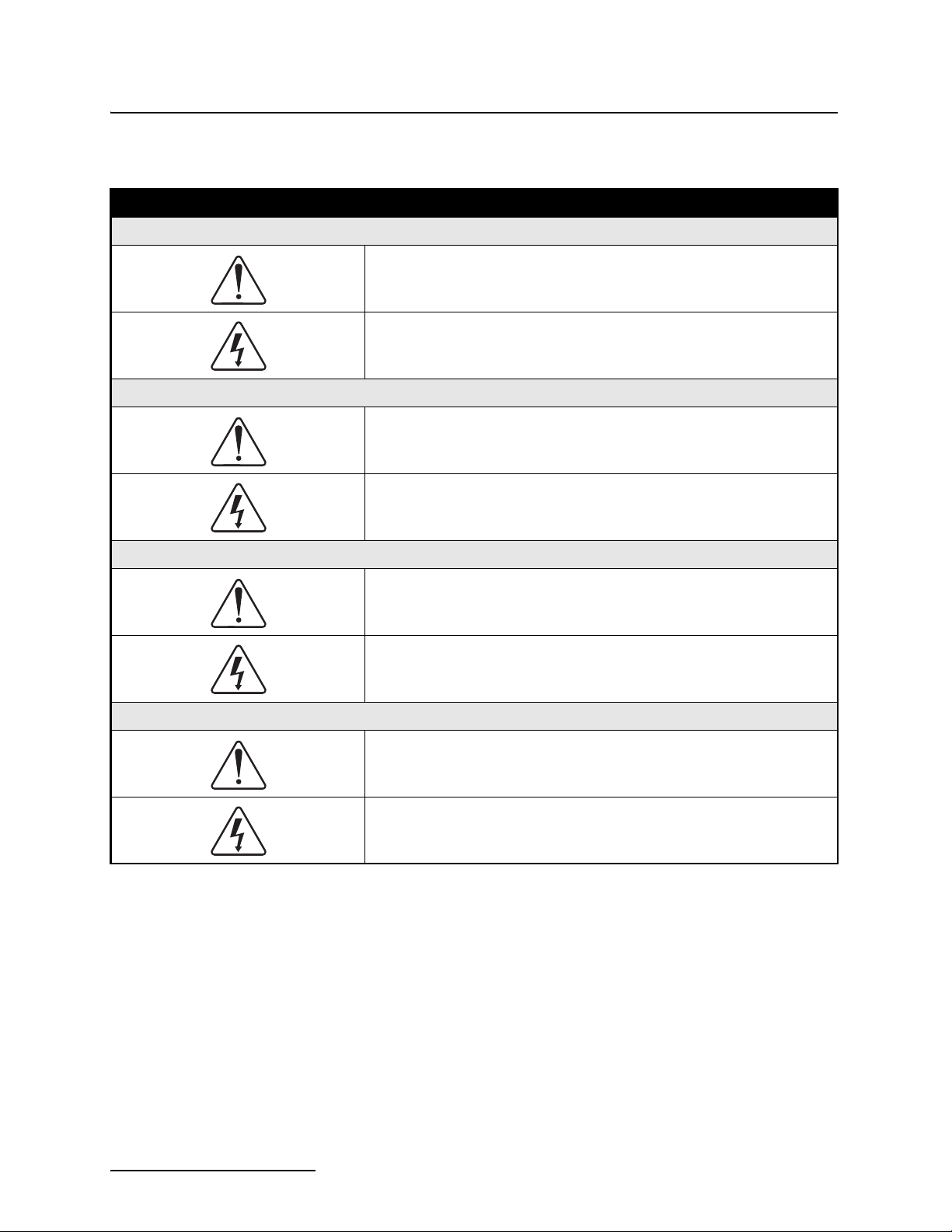

Hazard Symbols The equipment and this manual use symbols to warn of hazards.

The symbols are explained below.

Hazard Symbols

Warnings and Cautions

The exclamation point within the triangle is a warning sign alerting you of

important instructions in the instrument’s manual.

The lightning flash and arrowhead within the triangle is a warning sign alerting you of “dangerous voltage” inside the product.

Symboles de sécurité

Ce symbole signale l’existence d’instructions importantes relatives au produit dans ce manuel.

Ce symbole signale la présence d’un danger d’électocution.

Warnungen und Vorsichtshinweise

Advertencias y Precauciones

2150EX Safety

Information

Das Ausrufezeichen in Dreieck ist ein Warnzeichen, das Sie darauf

aufmerksam macht, daß wichtige Anleitungen zu diesem Handbuch

gehören.

Der gepfeilte Blitz im Dreieck ist ein Warnzeichen, das Sei vor “gefährlichen

Spannungen” im Inneren des Produkts warnt.

Esta señal le advierte sobre la importancia de las instrucciones del manual

que acompañan a este producto.

Esta señal alerta sobre la presencia de alto voltaje en el interior del producto.

The intrinsically safe 2150EX is intended for use in potentially

explosive atmospheres, and complies with ATEX Directive

94/9/EC. The 2150EX is Group II, Category 1G equipment for use

in gas hazard zones 0, 1, and 2.

The equipment is not designed with dust ignition protection for

dust hazard zones 20, 21, or 22.

6

Page 7

2150EX Area Velocity Flow System

Safety Information

2150EX Module Connected to

2191EX Battery Module and AV2150EX Sensor

Designed for safety The purpose of intrinsic safety is to limit the energy available to

Installation should be completed with adherence to local requirements for ATEX Group II, Category 1G or 2G equipment as

appropriate, and should be done by trained and qualified personnel.

a given circuit or device to a level where electrical discharge

(sparking) cannot ignite the hazardous (flammable or explosive)

atmosphere. With no spark ignition possible, safe operation of

the equipment in areas with hazardous atmospheres is possible.

The durable 2150EX, 2191EX, 2196EX, and 2194EX enclosures

are made with ABS plastic embedded with conductive carbon

fiber, giving the units low surface resistance to minimize electrostatic energy.

The lithium thionyl chloride batteries and the lead acid batteries

used in the 2191EX Battery Module operate at a low voltage and

are contained in sealed battery packs.

The 2150EX system has been designed so that it does not cause

physical injury or other harm due to contact. It does not produce

excessive surface temperature or dangerous radiation. When

used properly, it does not present any non-electrical dangers.

7

Page 8

2150EX Area Velocity Flow System

Safety Information

Labels Read all labels carefully before installing the equipment!

The 2150EX and its components are clearly labeled with color

and/or text so you know what can be located in a safe or hazardous area (see figure below). For example, on the label shown

below, light blue is used to indicate the intrinsically safe end and

yellow to indicate the non-protected end of the cable and connector.

Example of Safe and Hazardous Area Labeling on RS232EX Cable

AV2150EX Sensor Cable Labels

Some system components have an X marking, as shown in the

example below. The X marking indicates that there are special

conditions that must be met to ensure intrinsic safety. In the case

of the sensor cable, there is a danger of static electricity. The

cable is labeled with a warning telling you that you should not

rub the sensor with a dry cloth, as this might generate static

electricity.

WARNING

ELECTROSTATIC HAZARD

DO NOT RUB

CLEAN WITH DAMP CLOTH ONLY

X-Marking

8

Page 9

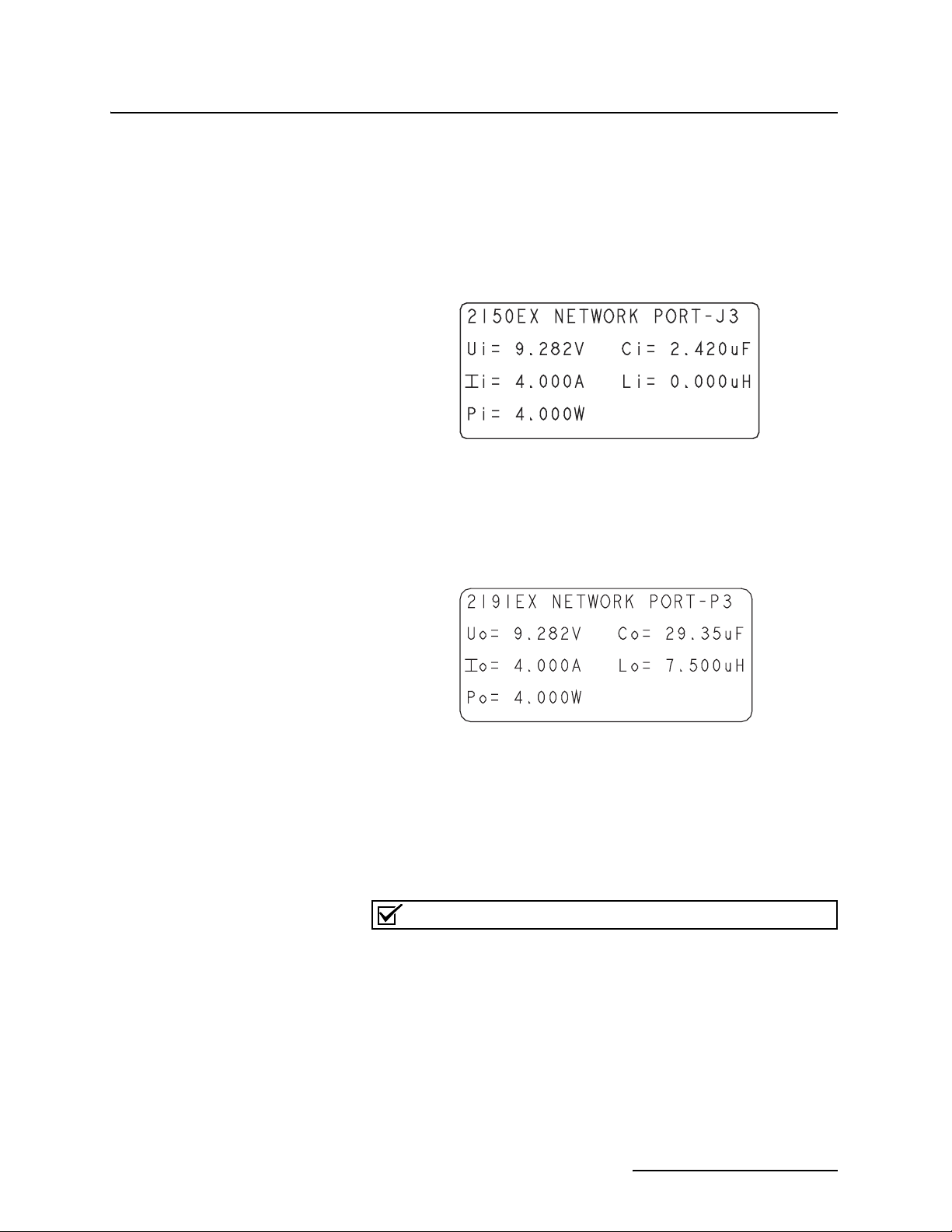

Example of 2150EX Label

2150EX Area Velocity Flow System

Safety Information

Where applicable, the labels contain other information, such as

voltage, serial number identification, etc. For example, the label

shown below indicates the maximum input voltage (U

current (I

), and input power (Pi) that can be applied to the

i

), input

i

2150EX network port without invalidating intrinsic safety. It

also shows the internal capacitance (C

(L

) that must be allowed by any power source.

i

), and internal inductance

i

When you compare the 2150EX label in the figure above with the

2191EX label in the figure below, you can see they provide a

helpful reference so you can make sure your connections are safe.

Example of 2191EX Label

For example, the 2150EX network port cannot have an input

voltage greater than 9.282V. When you look at the label on the

power source (in this case the 2191EX), you can see that the

maximum output voltage is 9.282V. From this you know that you

can safely connect the two, and won’t be providing too much

voltage to the 2150EX unit.

Note

This information is not intended to fully explain entity parameters. Other publications should be referenced for more detailed

explanations.

9

Page 10

2150EX Area Velocity Flow System

Safety Information

Installation Installation of the 2150EX system is described in this manual.

Repair and Maintenance Refer to Section 4 of this manual for instructions regarding

Teledyne Isco, Inc.

Technical Service Dept.

P.O. Box 82531

Lincoln, NE 68501 USA

Phone: (800) 228-4373

(402) 464-0231

FAX: (402) 465-3085

E-mail:

IscoService@teledyne.com

Typical round-pipe installations are shown in Figures 2-1 and

2-2, and Appendix E provides information on general safety procedures for work in manholes and sewers.

When the equipment is installed in accordance with the instructions in this manual, it will not be subjected to dangerous

mechanical or thermal stresses. It should not be installed where

it may be attacked by existing or foreseeable aggressive substances that could damage the module enclosures. The enclosures are made of Acrylonitrile Butadiene Stytene (ABS) plastic.

Substances that may cause damage include organic solvents

(ketones and esters, aromatic and chlorinated hydrocarbons),

alcohols, hydrocarbons, fuels, and UV radiation.

periodic maintenance of the 2150EX and its components.

The internal components of the 2150EX System are not user-ser-

viceable. The case is completely sealed to protect the internal

components. If you think your module requires repair, contact

Teledyne Isco’s Technical Service Department.

Rapidly failing desiccant may indicate a crack.

WARNING

Any cracks in the module case will impair the safety

protection. If this occurs, return the unit to Teledyne Isco

for a replacement.

Components of the AV2150EX Sensor are encapsulated in plastic

resin and are not user-serviceable. If any part of the AV Sensor

fails, it must be replaced.

10

Page 11

2150EX Area Velocity Flow System

Table of Contents

Section 1 Introduction

1.1 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1.1 2150EX Area Velocity Flow System Overview . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.2 Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.3 Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.4 Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.5 Total Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.6 Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2 Identifying Module Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Section 2 Preparation and Installation

2.1 Unpacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Preparing for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.2 Locating the Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2.3 Channels Without a Primary Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.4 Channels With a Primary Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.5 2150EX and AV Sensor Mounting Considerations . . . . . . . . . . . . . . . . . . . 2-3

2.3 Site Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Portable Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4.1 Installation Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4.2 Install Battery Module Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.4.3 Inspect the Desiccant – Battery Module . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.4.4 Inspect the Desiccant – 2150EX Module . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.4.5 Assembling the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.6 Zone 1 Battery Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.5 Permanent Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.5.1 Installation Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.6 Network Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.6.1 EX Network Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.6.2 Connecting to a Computer for Interrogation . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.6.3 Connecting to a 2100 Series Network Device . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.7 Connecting the AV2150EX Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.1 Positioning the AV Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.8 Mounting Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.8.1 Spring Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2.8.2 Scissors Mounting Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

2.8.3 Completing the AV Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2.9 Final Installation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

2.9.1 Program the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Section 3 Programming

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Flowlink Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 Site Configuration Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

11

Page 12

2150EX Area Velocity Flow System

Table of Contents

3.3 Program Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.1 Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.2 Zero Level Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3.3 No Velocity Data and Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.4 Flow Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.5 Silt Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.6 Data Storage Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.3.7 Site Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.3.8 Module Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Section 4 Modbus Protocol

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.1 Establishing Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.2 Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.4 Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.5 Common Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.6 Register Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Section 5 Maintenance

5.1 Maintenance Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Maintenance Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 2191EX Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3.1 LTC2191EX Lithium Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3.2 SLA2191EX Lead-Acid Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4 Desiccant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.4.1 Replacing the Desiccant: AV Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.4.2 Replacing the Desiccant: Battery Module . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.4.3 Reactivating the Desiccant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.5 Channel Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6 Other Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.1 Hydrophobic Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.6.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.6.3 Sensor Cable Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.7 How to Obtain Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.7.1 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

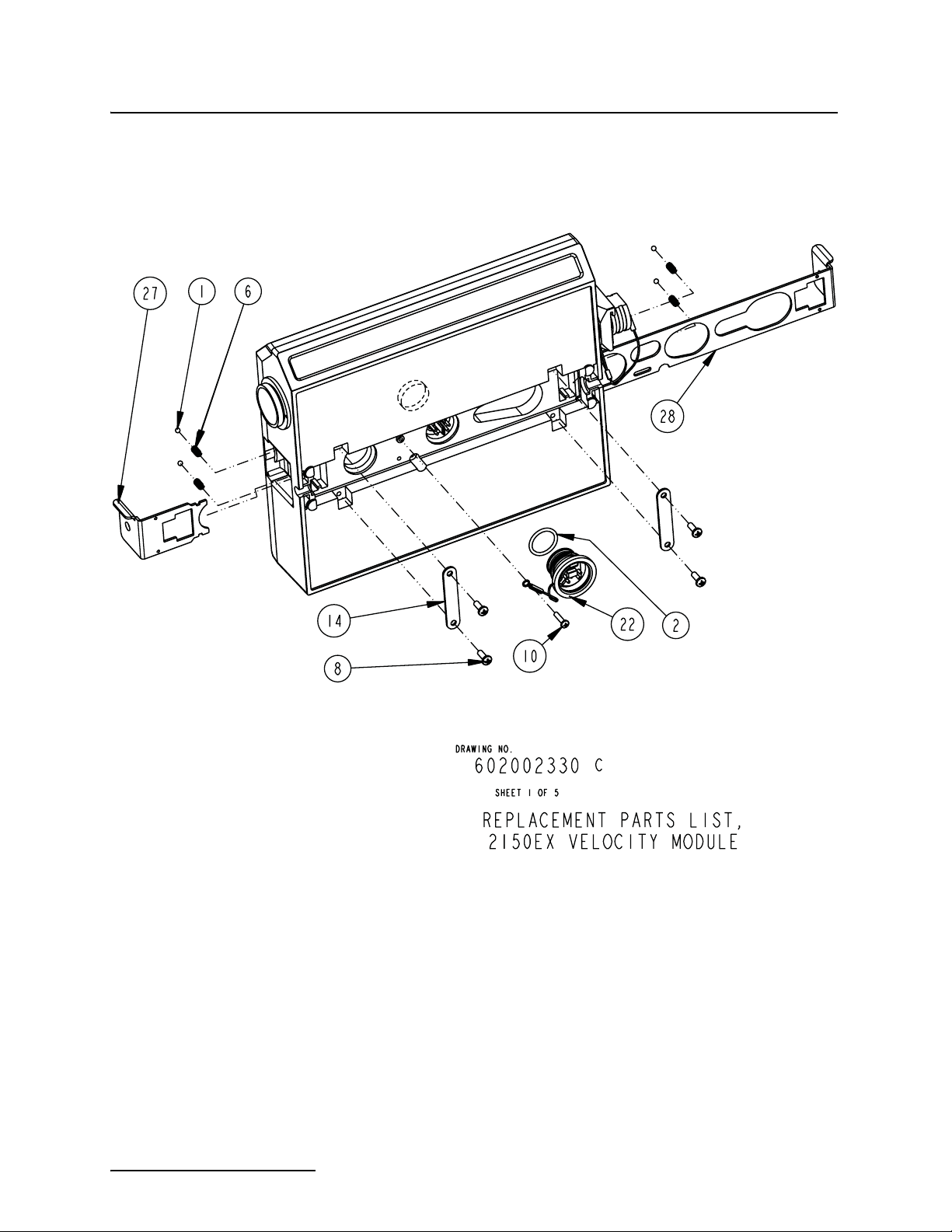

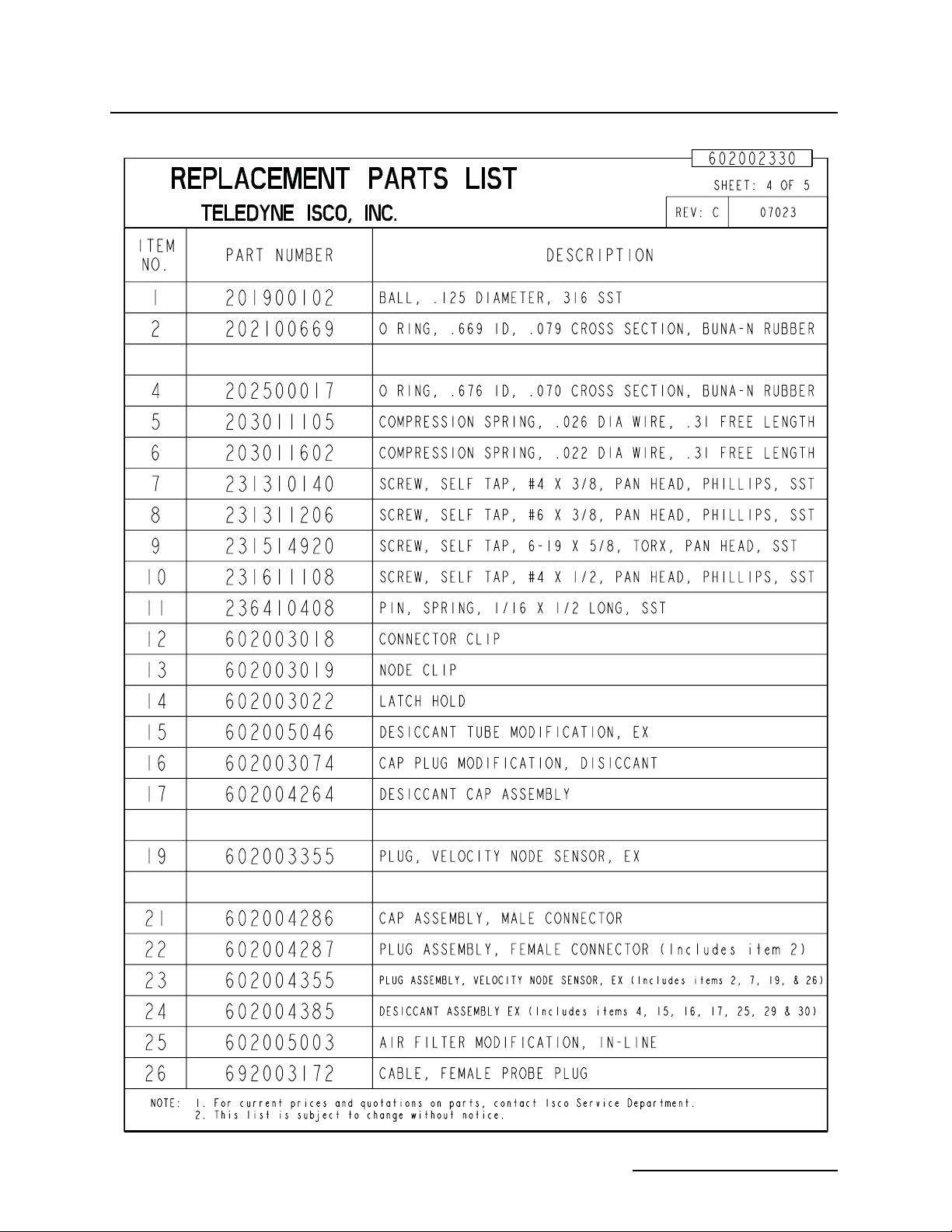

Appendix A Replacement Parts

A.1 Replacement Parts Diagrams and Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B Accessories

B.1 How to Order. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.2 General Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.3 Maintenance Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.4 AV Sensor Mounting Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

12

Appendix C Material Safety Data Sheets

C.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Appendix D General Safety Procedures

D.1 Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Page 13

2150EX Area Velocity Flow System

Table of Contents

D.2 Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

D.3 Adverse Atmospheres. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

D.4 Entering Manholes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

D.4.1 Traffic Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

D.4.2 Removing the Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

D.4.3 Other Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

D.4.4 Emergencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

D.4.5 Field Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

D.5 Lethal Atmospheres in Sewers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

List of Figures

1-1 2150EX - Top and Bottom Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2 2150EX Connected to 2191EX- Top Right View . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3 Components – AV2150EX Area Velocity Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-4 2191EX and 2196EX Battery Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-5 2150EX Area Velocity Flow System Communication Connector Pins . . . . . . . . 1-11

2-1 Typical Round-pipe Installation Connected to a

Laptop Computer (Portable Installation, see section 2.4) . . . . . . . . . . . . . . . . . . . 2-5

2-2 Typical Round-pipe Installation Connected to a

2101 Field Wizard (Portable Installation, see section 2.4) . . . . . . . . . . . . . . . . . . 2-6

2-3 Typical Round-pipe Installation Connected to a

2194EX Module and Laptop

(Permanent Installation, see section 2.5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-4 Illustration of Battery Packs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-5 Label Markings for LTC2191EX and SLA2191EX Battery Packs . . . . . . . . . . . . 2-9

2-6 Assembling a basic portable system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-7 Flowlink low-voltage warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2-8 Location of 2196EX charging terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2-9 Detailed view of charging circuit board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-10 2196EX battery module and labeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2-11 Amphenol connector pins for 12V adapter cable 69-2004-451 . . . . . . . . . . . . . 2-18

2-12 2194EX labels and cable connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2-13 Network cable connector and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2-14 Network cable conduit fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2-15 Wiring the socket insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2-16 EX Network Cable for Connection to an Isolator Cable . . . . . . . . . . . . . . . . . . 2-22

2-17 RS232EX Isolator Cable for Connection to a Computer . . . . . . . . . . . . . . . . . . 2-23

2-18 RS485EX Isolator Cable for Connection to a 2100 Series Network Device . . . 2-24

2-19 Connecting the AV Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2-20 AV2150EX Sensor Cable Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2-21 Sensor Installed on a Spring Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2-22 Scissors Ring adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

3-1 Connection to a Laptop, Using Cables P/N 60-2004-336 and 60-2004-339 . . . . . . 3-1

3-2 Preferred Measurement Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-3 Zero Level Offset Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4-1 Configuration Example (Direct Connection Shown) . . . . . . . . . . . . . . . . . . . . . . . 4-3

5-1 Illustration of LTC2191EX Battery Packs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-2 SLA2191EX Battery Pack Voltage Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-3 Lead-Acid SLA2191 EX Battery Packs and 8V2191SLA Charger . . . . . . . . . . . . 5-5

5-4 Inserting an SLA2191EX Battery Pack into the Charger . . . . . . . . . . . . . . . . . . . 5-6

5-5 Illustration of Battery Packs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

13

Page 14

2150EX Area Velocity Flow System

Table of Contents

List of Tables

1-1 2150EX Area Velocity Flow Module - Top and Bottom Views . . . . . . . . . . . . . . . . 1-4

1-2 2150EX Area Velocity Flow Module - Top Right View . . . . . . . . . . . . . . . . . . . . . 1-5

1-3 Components – AV2150EX Area Velocity Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-4 Battery Components - 2191EX and 2196EX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-5 Technical Specifications – 2150EX and 2191EX Modules

(Zones 0, 1, and 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-6 Technical Specifications - 2196EX Battery Module

(Zones 1 and 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-7 Technical Specifications - 2194EX Interface Module

(Associated Apparatus) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1-8 Specifications – AV2150EX Area Velocity Sensor

(Zones 0, 1, and 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1-9 Communication Connector Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

3-1 Flow Conversion Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

4-1 Modbus ASCII Address 1 Register Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-2 Modbus ASCII Address 2-(N+1) Register Definitions . . . . . . . . . . . . . . . . . . . . . . 4-7

4-3 Measurement Parameters by Model Number* . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

D-1 Hazardous Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

14

Page 15

2150EX Area Velocity Flow Module

Section 1 Introduction

1.1 Product Description The 2150EX Area Velocity Flow Module is part of Isco’s 2100

Series. The 2100 Series measures parameters of open channel

flow streams.

The intrinsically safe 2150EX is intended for use in potentially

explosive atmospheres, and complies with ATEX Directive

94/9/EC. The 2150EX is Group II, Category 1G or 2G equipment

as appropriate for use in Hazardous Zones 0, 1, and 2.

The purpose of intrinsic safety is to limit the energy available to

a given circuit or device to a level where electrical discharge

(sparking) cannot ignite the hazardous (flammable or explosive)

atmosphere. With no spark ignition possible, safe operation of

the equipment in areas with potentially explosive atmospheres is

possible.

The standard 2100 Series is designed to be modular so that you

can expand the system by stacking modules to meet your data

collection needs. The 2150EX incorporates this modularity,

allowing up to two 2150EX modules to be stacked on one 2191EX

or 2196EX battery module.

The 2150EX is paired with Isco’s Flowlink software. With this

full-featured application software, you can quickly set up the

module, retrieve measurement data, manage the sites, and

analyze the data, and update the module’s own software, all

without entering the hazardous area.

The module’s data storage memory is quite flexible, able to store

the measurements in intervals from 15 seconds to 24 hours. The

module can also be configured for variable rate data storage.

Variable rates allow you to store data at a different interval

when a programmed condition occurs.

The module’s program and collected data are stored in flash

memory for security. Flash memory retains data without the

concern of power failures or aging backup batteries. Its capacity

is more than sufficient for most applications. The data storage

memory can hold approximately 79,000 readings – the equivalent of nine months of level and velocity data when stored at

fifteen minute intervals. The flash memory also stores sensor

level adjustment information. A separate flash memory device

inside the module stores the operating firmware.

The rugged 2150EX components are rated NEMA 4X, 6P (IP68).

The permanently sealed enclosures are designed to meet the

environmental demands of many sewer flow monitoring applications. All connections between sensors and communication cables

“lock” in place. Each locking mechanism strongly secures the

components and ensures a watertight seal.

1-1

Page 16

2150EX Area Velocity Flow Module

Section 1 Introduction

1.1.1 2150EX Area Velocity Flow System Overview

AV Module

The 2150EX measures liquid level and average stream velocity,

and calculates the flow rate and total flow. The liquid level and

velocity measurements are read from an attached Area Velocity

(AV) Sensor that is placed in the flow stream. Flow rate calculations are performed internally using the measured parameters

from the AV Sensor. Additionally, the 2150EX can measure its

input voltage.

The 2150EX is designed to provide durable operation with only a

minimal amount of routine maintenance, all of which may be

performed in the field, while keeping in mind restrictions for

potentially explosive atmospheres. Typically, the 2150EX and its

AV Se n s o r

AV2150EX Sensor will only require that you keep the stream free

from excessive debris, and replace or recharge spent desiccant

and batteries. Sections 1.1.2 through 1.1.6 describe the 2150EX

and sensor in greater detail.

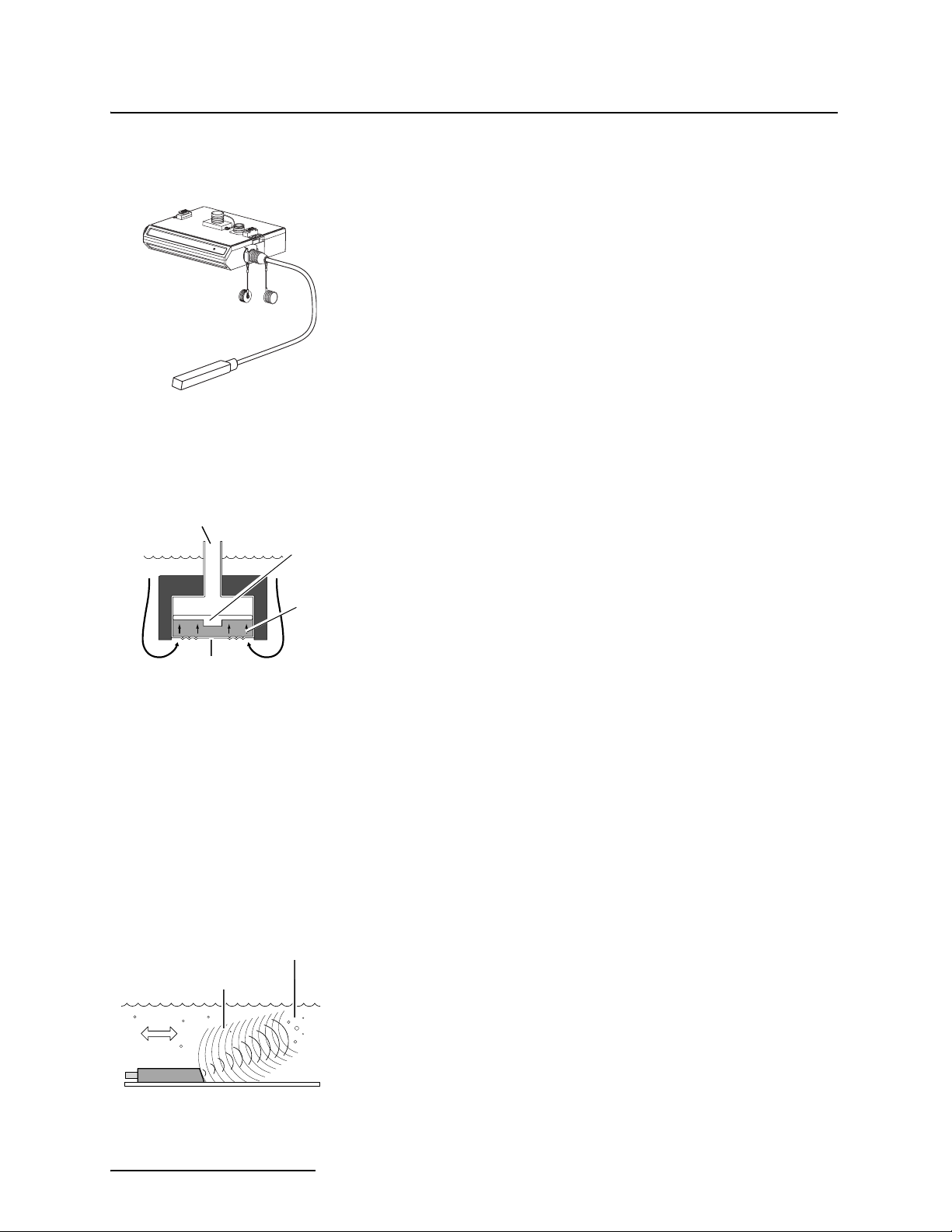

1.1.2 Level The AV Sensor’s internal differential pressure transducer mea-

sures the liquid level. The transducer is a small piezo-resistive

chip that detects the difference of the pressures felt on the inner

reference to

atmosphere

piezo-

resistive

transducer

and outer face.

The stainless steel outer diaphragm is exposed to the flow stream

through the ports under the AV Sensor. The pressure felt on the

outer diaphragm is transferred to the outer face of the trans-

silicone

fluid

ducer through a silicone fluid medium. The outer diaphragm and

fluid isolate the sensitive transducer from direct exposure to the

stream. The inner face of the transducer is exposed, or referenced, to the atmosphere through the internal vent tube that

outer

diaphragm

runs the full length of the AV Sensor’s cable.

The difference between the pressures exerted on the transducer

is the hydrostatic pressure. Hydrostatic pressure is proportional

to the level of the stream. The Isco AV2150EX sensor uses state

of the art techniques to ensure accuracy throughout the environmental operating range. At the factory each sensor is measured

at scores of pressure and temperature levels to precisely characterize the unique transducer. These calibration results are digitally stored within the sensor's flash memory. During readings

the sensor's microcontroller applies the known correction factor

to produce highly accurate level readings.

1.1.3 Velocity The AV Sensor measures average velocity by using ultrasonic

sound waves and the Doppler effect. The Doppler effect states

that the frequency of a sound wave (or other wave) passed from

Ultrasonic

sound waves

Particles or

air bubbles

one body to another is relative to both their motions. As the two

approach each other, the frequency increases; as they move

apart, the frequency decreases.

The AV Sensor contains a pair of ultrasonic transducers. One

Flow

transducer transmits the ultrasonic sound wave. As the transmitted wave travels through the stream, particles and bubbles

carried by the stream reflect the sound wave back towards the

AV Sensor. The second transducer receives the reflected wave.

1-2

Page 17

2150EX Area Velocity Flow Module

Section 1 Introduction

Circuits internal to the module compare the frequencies of the

sound waves and extract the difference. An increase or decrease

in the frequency of the reflected wave indicates forward or

reverse flow. The degree of change is proportional to the velocity

of the flow stream.

1.1.4 Flow Rate Using measurements from the AV Sensor, the 2150EX can cal-

culate the flow rate. Many different flow rate conversion methods

are supported:

• Area Velocity

•Data Points

• Manning Formula

• Two-term Polynomial Equations

•Flumes

•Weirs

Often the 2150EX is chosen for applications where a primary

device is not available, nor is it practical to install a primary

device. Therefore, area velocity is usually the conversion method

of choice.

The 2150EX is capable of calculating and storing any two conversion methods simultaneously. This feature is useful when it is

necessary to validate a flow conversion method. For example, the

flow rate at a new site programmed for area velocity conversion

can be directly compared to the flow rate calculated using a

Manning formula.

1.1.5 Total Flow The 2150EX can calculate and report the total flow. You can set

up the system to monitor net, positive, or negative total flow from

either of the calculated flow rates.

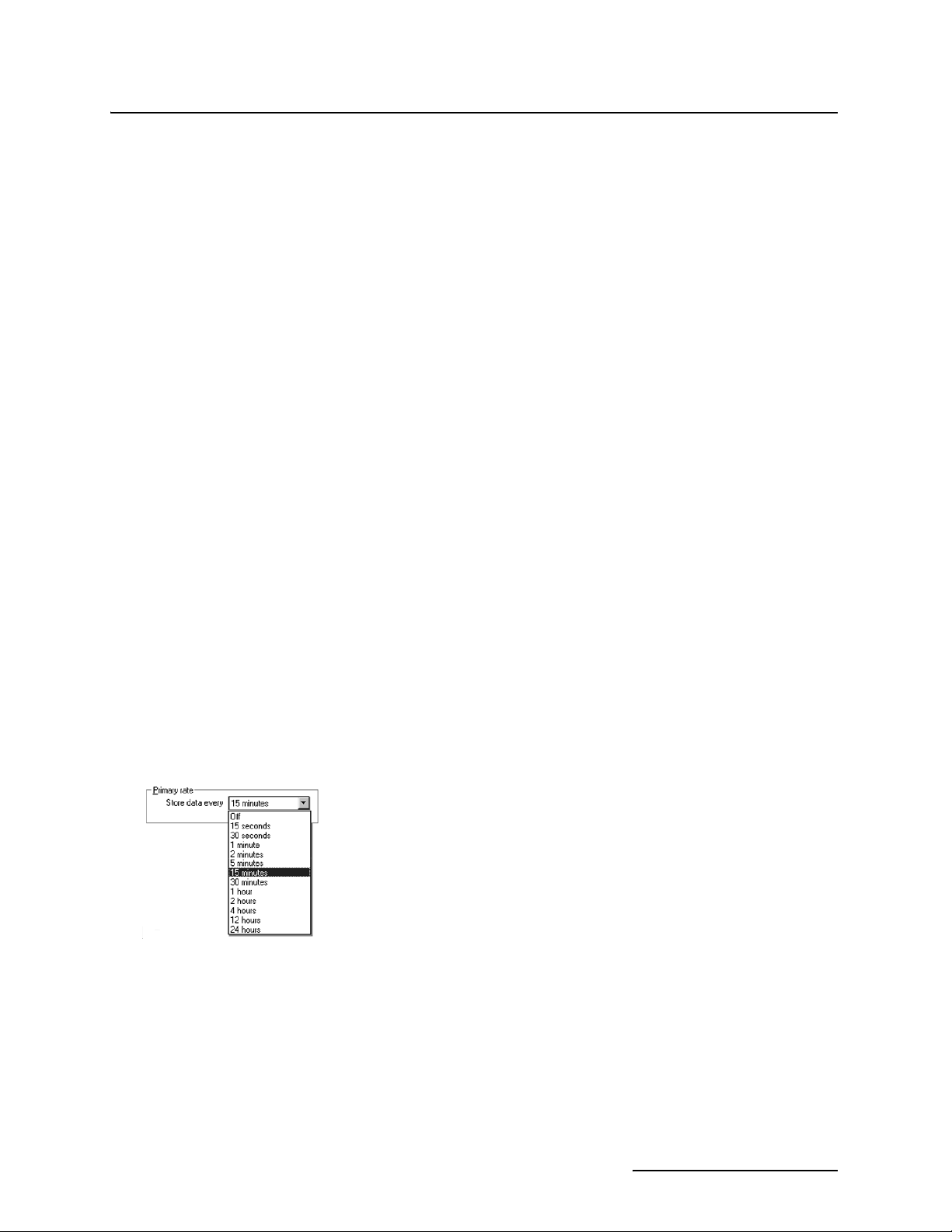

1.1.6 Data Storage Through Flowlink, you configure which type of data is logged and

the storage rate. For each measurement, the Data Storage Setup

window lets you turn the primary rate off, or select a rate from 15

seconds to once every 24 hours. If the primary rate is turned off,

the 2150EX will not store the measurement (unless a secondary

rate is selected). However, the 2150EX will still take readings if

that measurement type is necessary for a calculation.

Secondary rates are used to log data at a different rate when a

user-defined condition exists. For example, a secondary rate can

be used to increase the level and velocity data storage rate when

level is greater than or equal to a point of interest. Secondary

rates give you the best resolution of data, but only when it is

needed. Until the condition is met, the module will conserve

power and memory by storing the data at the primary storage

rate. Like the primary rate, you can turn the secondary rate off,

or select a storage rate of 15 seconds to every 24 hours.

Time Resolution The time resolution of each measurement is one second. That is,

readings are taken at the same time as the time stamp, not collected and averaged over a period of time before the stamp.

1-3

Page 18

2150EX Area Velocity Flow Module

Section 1 Introduction

Rollover Memory Whether the measurements are stored at the primary or sec-

ondary rate, they are stored in a rollover type of memory. When

full, the module overwrites the oldest data with the newest

readings.

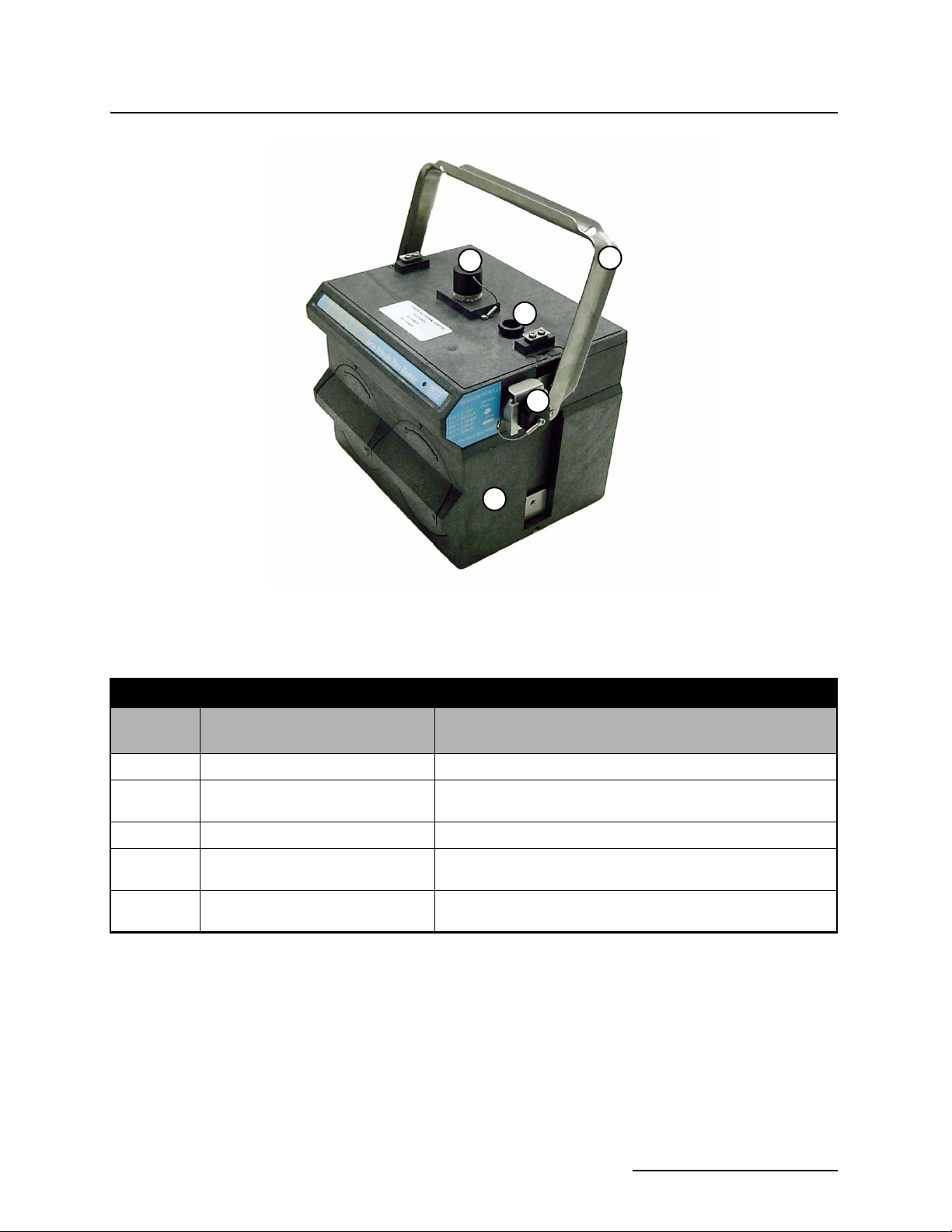

1.2 Identifying Module Components

Bottom View

6

The various components of the 2150EX are shown in Figures 1-1

through 1-4. Items referenced in the figures are described in

Tables 1-1 through 1-4.

Top View

2

3

1

4

7

5

Figure 1-1 2150EX - Top and Bottom Views

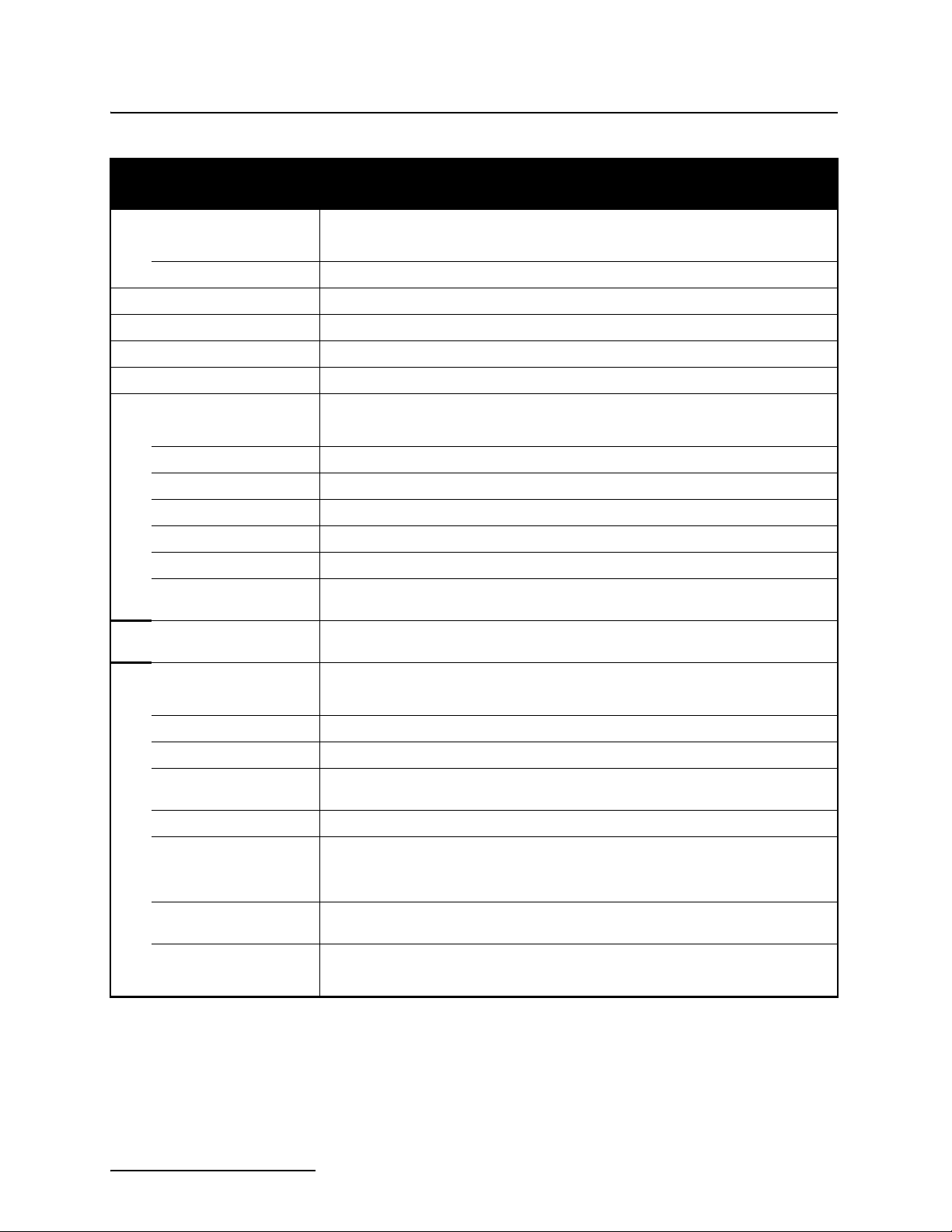

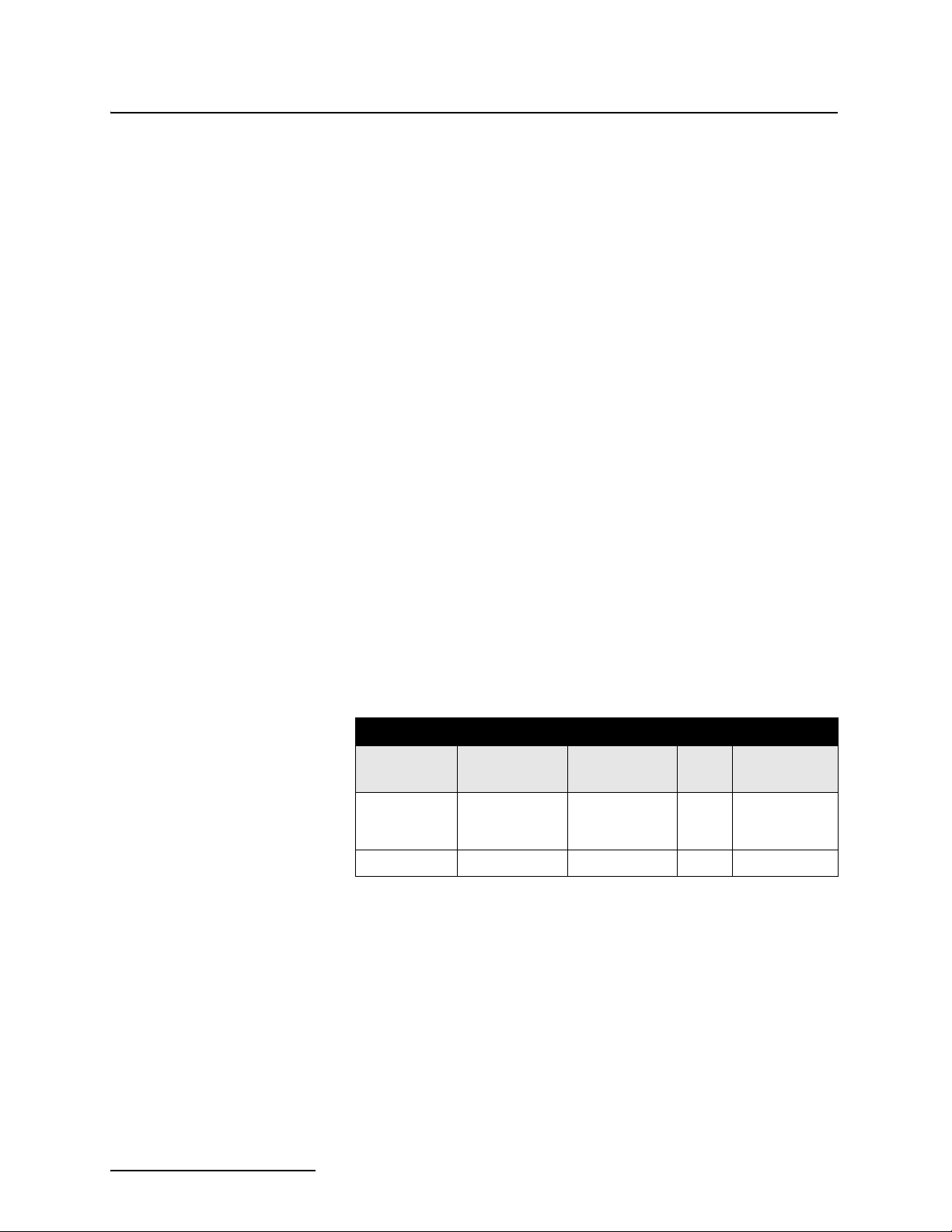

Table 1-1 2150EX Area Velocity Flow Module - Top and Bottom Views

Item No. Fig. 2-1 Name Description

1 Latch Latches the module in place. A latch release is located on the

right side of the module.

2 Communication Connector

(shown uncapped)

3 Connector Cap

(shown in holder)

4 Desiccant Cartridge and

Hydrophobic Filter

5 Communication Indicator Illuminates when module communications are active.

6 Communication Connector

(shown capped)

7 Cap Holder Used to store the Connector Cap.

Upper communication port; used to connect to another module, or to a PC running Flowlink software.

Insert into unused communication connector to terminate the

network and protect it from moisture damage. When the communication connector is in use, the cap must be stowed in its

holder to protect the terminating components inside the cap.

The cartridge holds desiccant that dries the reference air. The

filter prevents moisture from entering the reference line.

Used to connect the module to the 2191EX or 2196EX battery

module, or to another 2150EX module. When the communication connector is in use, the cap must be stowed in its holder to

protect the terminating components inside the cap.

1-4

Page 19

2150EX Area Velocity Flow Module

Section 1 Introduction

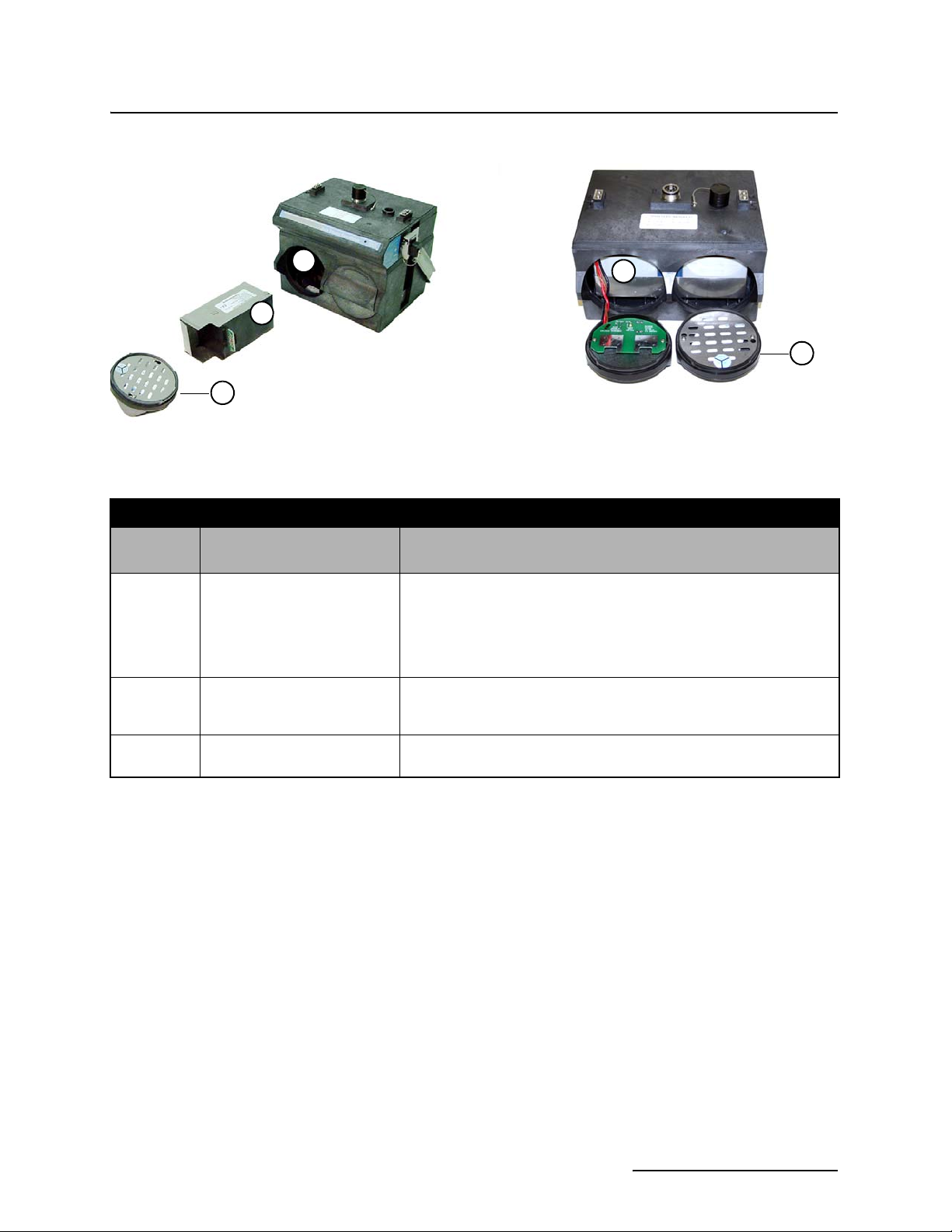

2

5

Figure 1-2 2150EX Connected to 2191EX- Top Right View

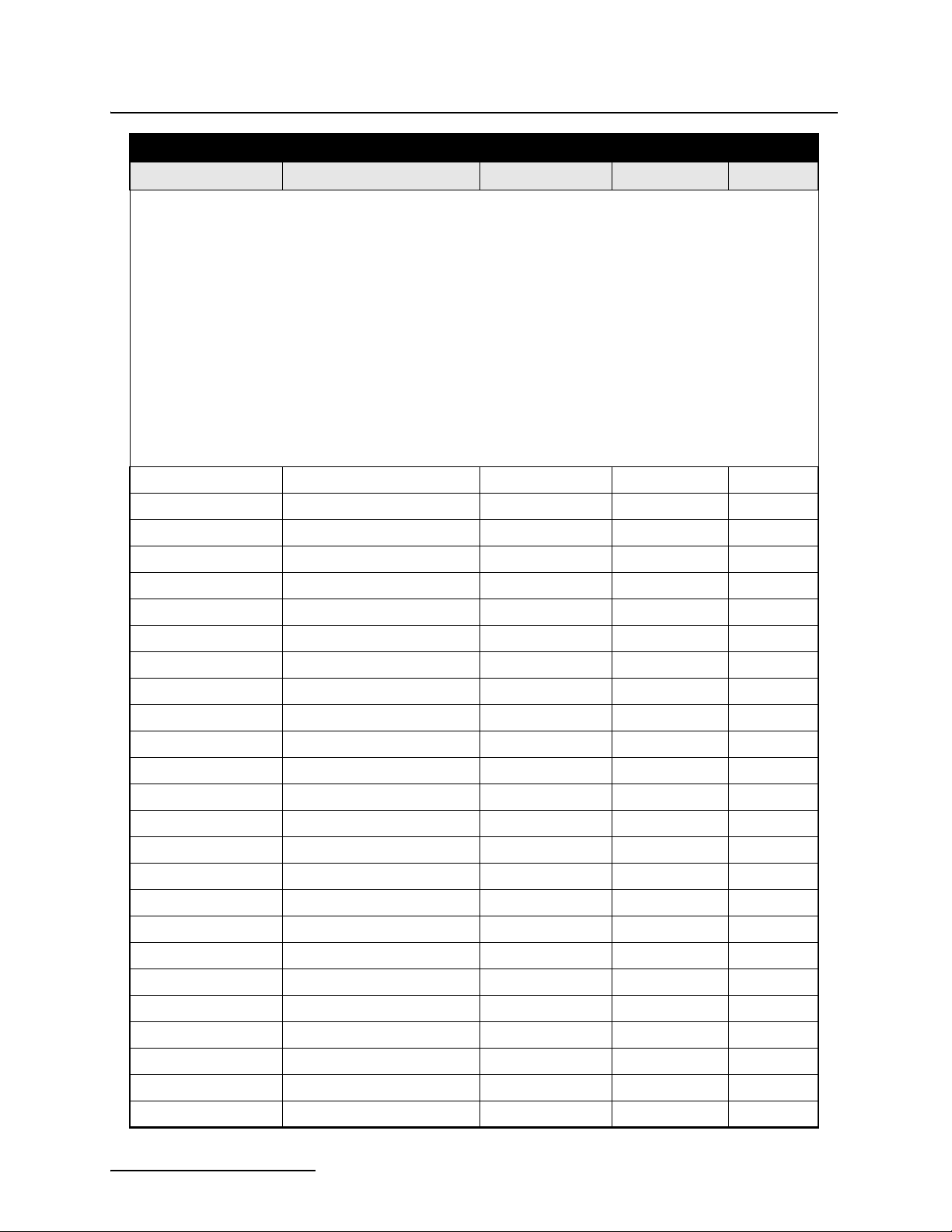

Table 1-2 2150EX Area Velocity Flow Module - Top Right View

1

3

4

Item No.

Fig. 2-2

1 Carrying Handle Used to lift and carry the unit.

2 Communication Connector

3 Cap Holder Used to store the connector cap.

4 AV Sensor Receptacle Port used to attach the AV Sensor. Insert the protective cap

5 2191EX Used to store battery packs and provide a source of power for

Name Description

(shown capped)

Upper communication port, used to connect to another module

or to a PC running Flowlink software.

when not in use.

the 2150EX.

1-5

Page 20

2150EX Area Velocity Flow Module

Section 1 Introduction

1

3

2

4

Figure 1-3 Components – AV2150EX Area Velocity Sensor

Table 1-3 Components – AV2150EX Area Velocity Sensor

Item No.

Fig. 1-3

1 Connector Cap Protects the connector. When the connector is not in use, this cap must be in

2 Connector Attaches to the AV Sensor receptacle on the 2150EX Module.

3 AV Sensor Body The AV Sensor Body is placed in the flow stream to measure level and velocity.

4 Cable 10.0 m (32.8 ft) cable containing the reference air tubing and conductors to

Name Description

place to prevent damage to the connector pins and reference air tubing.

transfer level data, velocity data, and AV Sensor power.

1-6

Page 21

2191EX2191EX 2196EX

2150EX Area Velocity Flow Module

Section 1 Introduction

3

3

2

1

Figure 1-4 2191EX and 2196EX Battery Components

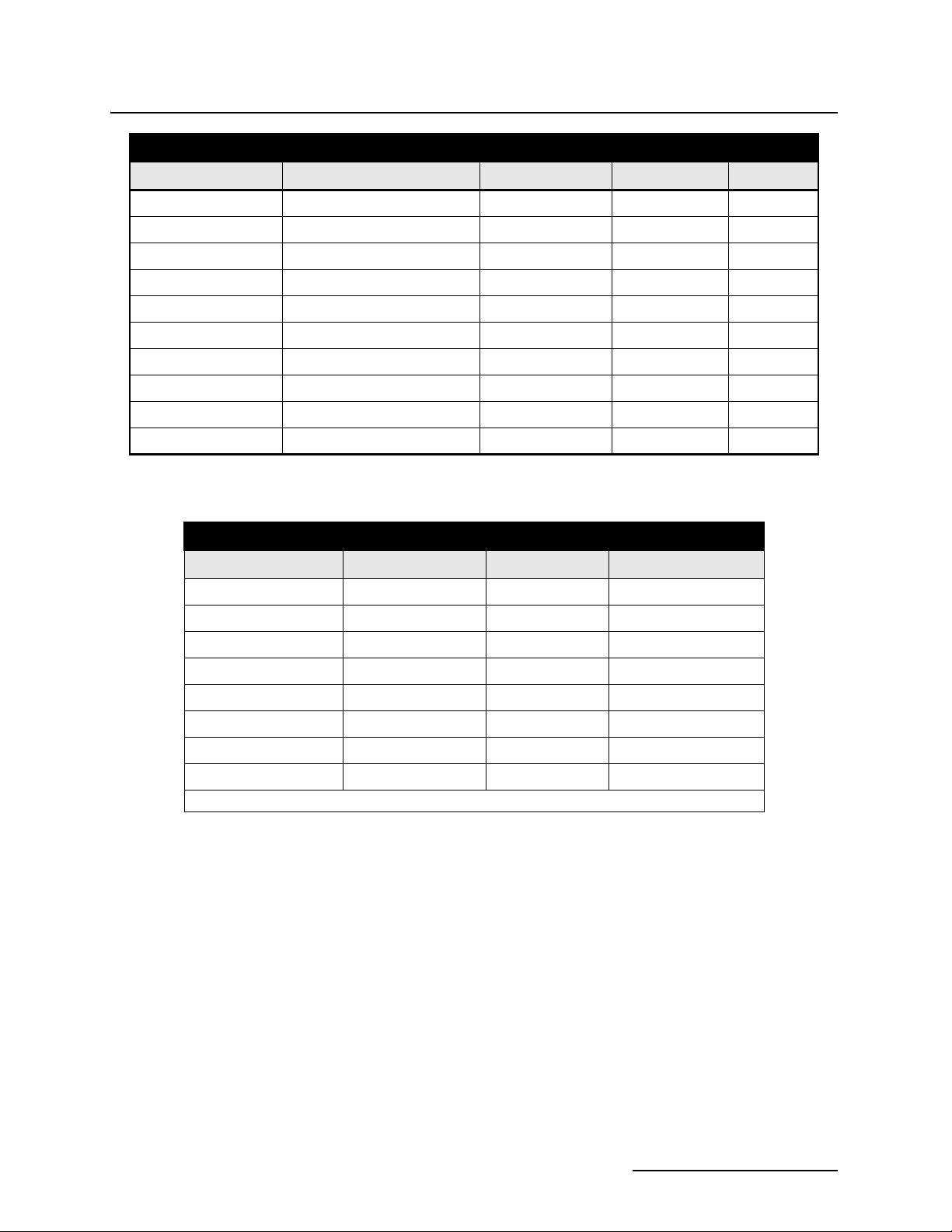

Table 1-4 Battery Components - 2191EX and 2196EX

Item No.

Fig. 1-4

1 Battery Door

2 Lithium Battery Pack (2)

3 Battery Cavity 2191EX: The battery packs are inserted into the battery cavities.

Name Description

The quarter-turn door seals the battery cavity.

2191EX: Inside each door is a humidity indicator and a bag of

desiccant to prevent internal moisture damage.

2196EX: The right door has one humidity indicator and bag of

desiccant, while the left door houses the charging circuit board for the

batteries.

Use only the lithium or lead-acid battery packs supplied by Teledyne

or

Lead-Acid Battery Pack (2)

Isco. Operation requires two of either battery type.

2196EX: The batteries are integral to the module and not removable.

1

1.3 Technical Specifications

This section lists technical information about the 2150EX Area

Velocity Flow Module and its related components.

• Table 1-5 lists the technical specifications for the

2150EX and 2191EX Modules, and also the battery

packs.

• Table 1-6 lists the technical specifications for the

2196EX Zone 1 battery module.

• Table 1-7 lists the technical specifications for the

2194EX network interface module.

• Table 1-8 lists the technical specifications for the

AV2150EX Area Velocity Sensor.

• Figure 1-5 and Table 1-9 list information about the

2150EX’s communication connector.

1-7

Page 22

2150EX Area Velocity Flow Module

Section 1 Introduction

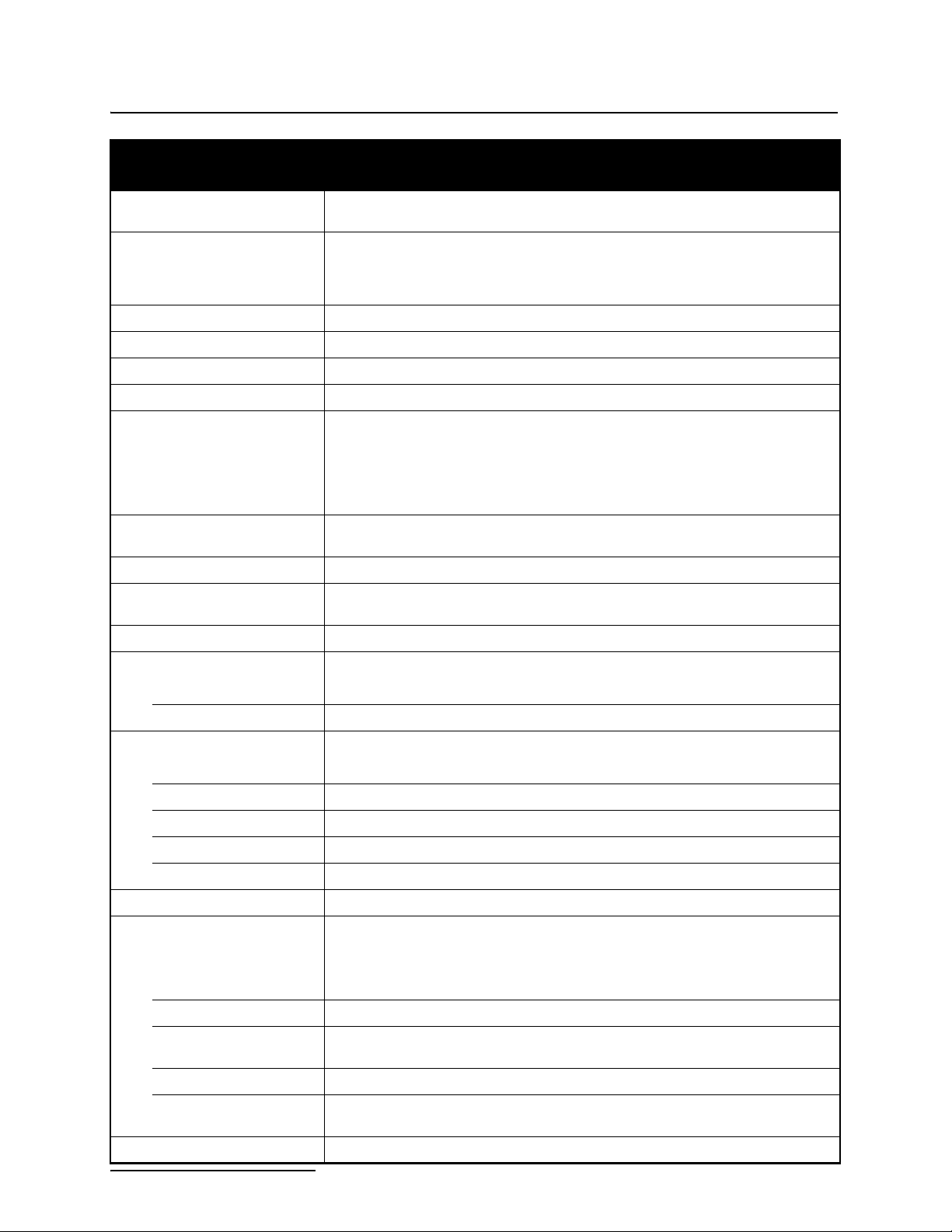

Table 1-5 Technical Specifications – 2150EX and 2191EX Modules

(Zones 0, 1, and 2)

Size (H×W×D)

2150EX connected to 2191EX 22.6 × 28.0 × 19.3 cm 8.9 × 11.0 × 7.6 in.

Weight

(without batteries)

(with lithium battery packs)

(with lead-acid battery packs)

Material ABS plastic, stainless steel

Enclosure (self-certified) NEMA 4X, 6P IP 68

Power 7.0 to 9.0 VDC, 100 mA typical at 8 VDC, 1 mA standby

Batteries LTC2191EX lithium or SLA2191EX lead-acid batteries, quantity 2 battery packs

3.00 kg 6.6 lb

4.20 kg 9.2 lb

7.10 kg 15.7 lb

Typical Battery Life (estimated)

(assumes 23°C; actual

performance is affected by

site conditions)

Operating Temperature -40° to 60°C -40° to 140°F

Storage Temperature -40° to 60°C -40° to 140°F

Program Memory Non-volatile, programmable flash; can be updated using PC without opening

Flow Rate Conversions Up to 2 independent level-to-area and/or level-to-flow rate conversions

Level-to-Area Conversions

Channel Shapes Round, U-shaped, rectangular, trapezoidal, elliptical, with silt correction

Data Points Up to 50 level-area points

Level-to-Flow Rate Conversions

Weirs V-notch, rectangular, Cipolletti, Isco Flow Metering Inserts, Thel-Mar

Flumes Parshall, Palmer-Bowlus, Leopold-Lagco, trapezoidal, H, HS, HL

Manning Formula Round, U-shaped, rectangular, trapezoidal

Data Points Up to 50 level-flow rate points

Level Velocity LTC2191EX SLA2191EX

Data Storage Interval Lithium Batteries Rechargeable Lead-Acid Batteries

15 minutes 49 months 157 days

5 minutes 21 months 64 days

2 minutes 8 months 31 days

1 minute 4 months 18 days

(lead-acid battery packs have an operating temperature of -20° to 60°C or -4° to 140°F)

enclosure or entering hazardous area; retains user program after updating

Equation 2-term polynomial

Total Flow Calculations Up to 2 independent, net, positive or negative, based on either flow rate conversion

Data Storage Memory Non-volatile flash; retains stored data during program updates

Capacity 395,000 bytes (up to 79,000 readings, equal to over 270 days of level and velocity

readings at 15 minute intervals, plus total flow and input voltage readings at 24

hour intervals). Bytes per reading is 5.

Data Types Level, velocity, flow rate 1, flow rate 2, total flow 1, total flow 2, input voltage

Storage Mode Rollover with variable rate data storage based on level, velocity, flow rate 1, flow

rate 2, total flow 1, total flow 2, or input voltage

Storage Interval 15 or 30 seconds; 1, 2, 5, 15 or 30 minutes; or 1, 2, 4, 12 or 24 hours

Setup and Data Retrieval Serial connection to IBM PC or compatible computer with Isco Flowlink Software

Version 4.16 or greater

Baud Rate 38,400

1-8

Page 23

2150EX Area Velocity Flow Module

Section 1 Introduction

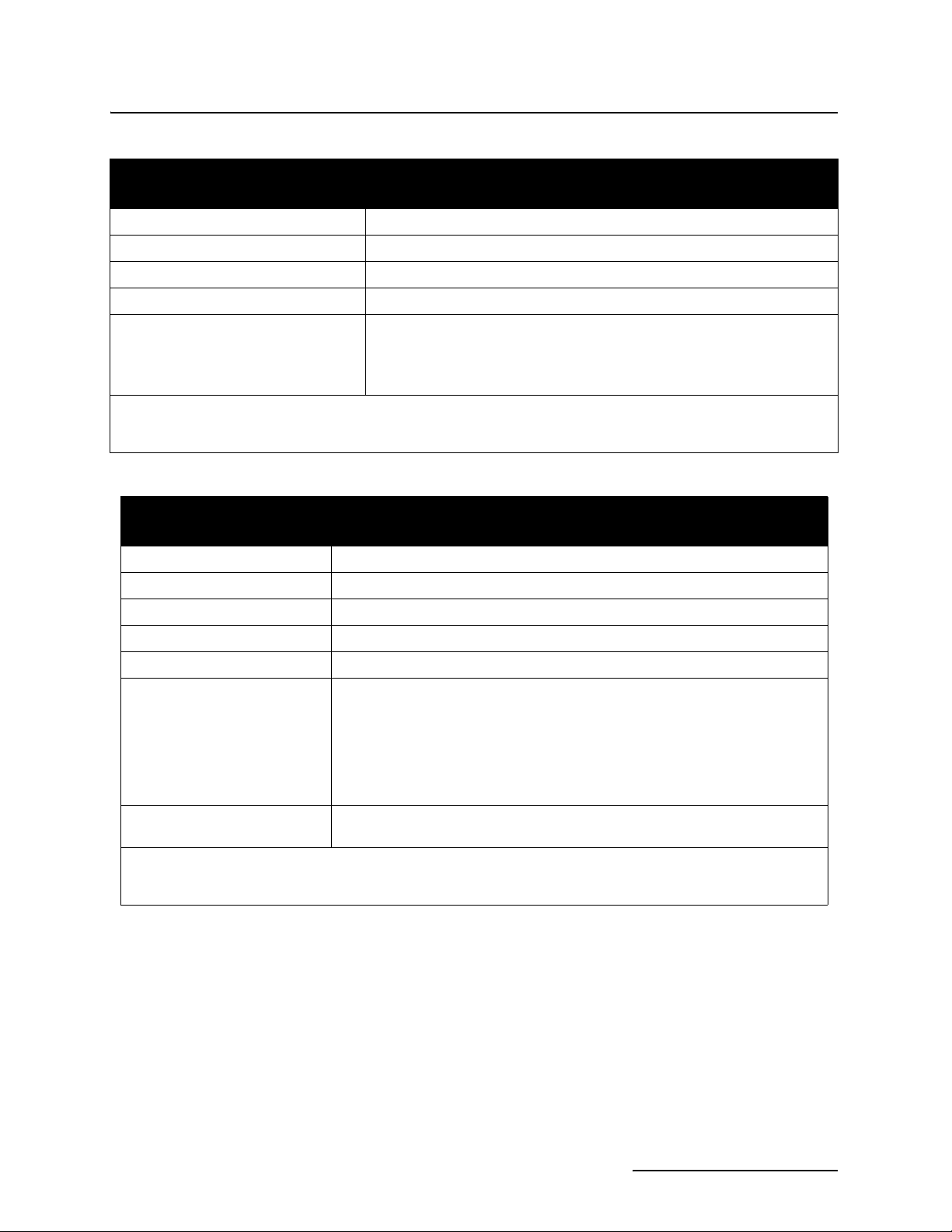

Table 1-6 Technical Specifications - 2196EX Battery Module

(Zones 1 and 2)

Size (HxWxD) 14.94 x 23.12 x 19.3 cm 5.88 x 9.13 x 7.6 in.

Weight 5.77 kg 12.71 lb

Enclosure (self-certified) NEMA 4X, 6P IP 68

Operating and Storage Temperature -40 °C to 60 °C -40 °F to 140 °F

Power Output Nominal: 8 VDC

Maximum: 9.28 VDC

Charger Input Nominal: 13.5 to 14.7 volts

Absolute Maximum: 20 volts, 2.0A

NOTE:

The serial tag of the 2196EX Module contains important X marking, indicating special safety conditions that must be

observed. See Important Information Regarding "X" Marking on page 2-17 for more information.

Table 1-7 Technical Specifications - 2194EX Interface Module

(Associated Apparatus)

Size (H×W×D) 7.37 x 28.7 x 19.05 cm 2.9 x 11.3 x 7.5 in.

Weight 9 kg 2 lb

Enclosure (self-certified) NEMA 4X, 6P IP 68

Operating Temperature -20 to 60 °C -4 to 140 °F

Storage Temperature -40 to 60 °C -40 to 140 °F

Power 9 to 26.5 VDC (nominal 12 or 24 VDC)

150 mA typical @ 12 VDC

Output 8.8 VDC, nominal

Number of 2150EX flow modules powered:

with 75m interface cable: 2

with 150m interface cable: 1

Communication Side connector: Isco EX node network compatible explosion protected devices

Top & Bottom connectors: Isco node network / PC compatible

NOTE:

The serial tag of the 2194EX Module contains important X marking, indicating special safety conditions that must

be observed. See Important Information Regarding "X" Marking on page 2-19 for more information.

1-9

Page 24

2150EX Area Velocity Flow Module

Section 1 Introduction

Table 1-8 Specifications – AV2150EX Area Velocity Sensor

(Zones 0, 1, and 2)

Materials

Sensor Epoxy, chlorinated polyvinyl chloride (CPVC), stainless steel

Cable Polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), stainless steel

Size (H×W×D) 1.9 × 3.3 × 15.2 cm 0.75 × 1.31 × 6.00 in.

Cable Length 10.0 m 32.8 ft.

Cable Diameter 0.9 cm 0.37 in.

Weight (including cable) 1.02 kg 2.24 lbs

Level Measurement

Method Submerged pressure transducer mounted in the flow stream

Transducer Type Differential linear integrated circuit pressure transducer

1

Range

Maximum Allowable Level 10.5 m 34 ft.

Accuracy

Long Term Stability ±0.007 m/yr ±0.023 ft/yr

2

0.010 to 3.05 m 0.033 to 10 ft.

±0.003 m ±0.010 ft

Operating Temperature

Range

Compensated

Temperature Range

Velocity Measurement

Method Doppler Ultrasonic

Frequency 500 kHz

Transmission Angle 20° from horizontal

Typical Minimum Depth

for Velocity Measurement

Range -1.5 to +6.1 m/s -5 to +20 ft./s

Accuracy

Operating Temperature

Range

Temperature Measurement

Accuracy ± 2°C

NOTES:

1. Actual vertical distance between the area velocity sensor and the liquid surface

2. Maximum non-linearity , hysteresis, and temperature error from actual liquid level

3. In water with a uniform velocity profile and a speed of sound of 1480 m/s (4850 ft./s)

4. The serial tag of the AV2150EX sensor contains important X marking, indicating special safety conditions that must

be observed. See Important Information Regarding "X" Marking on page 2-26 for more information.

3

-10° to 60°C -14° to 140°F

0° to 50°C 32° to 122°F

25 mm 0.08 ft.

Velocity Error

-1.5 to +1.5 m/s (-5 to +5 ft./s) ±0.03 m/s (±0.1 ft./s)

1.5 to 6.1 m/s (5 to 20 ft./s) ±2% of reading

-40° to 60°C -40° to 140°F

1-10

Page 25

2150EX Area Velocity Flow Module

Section 1 Introduction

G

F

A

E

D

Communications Port

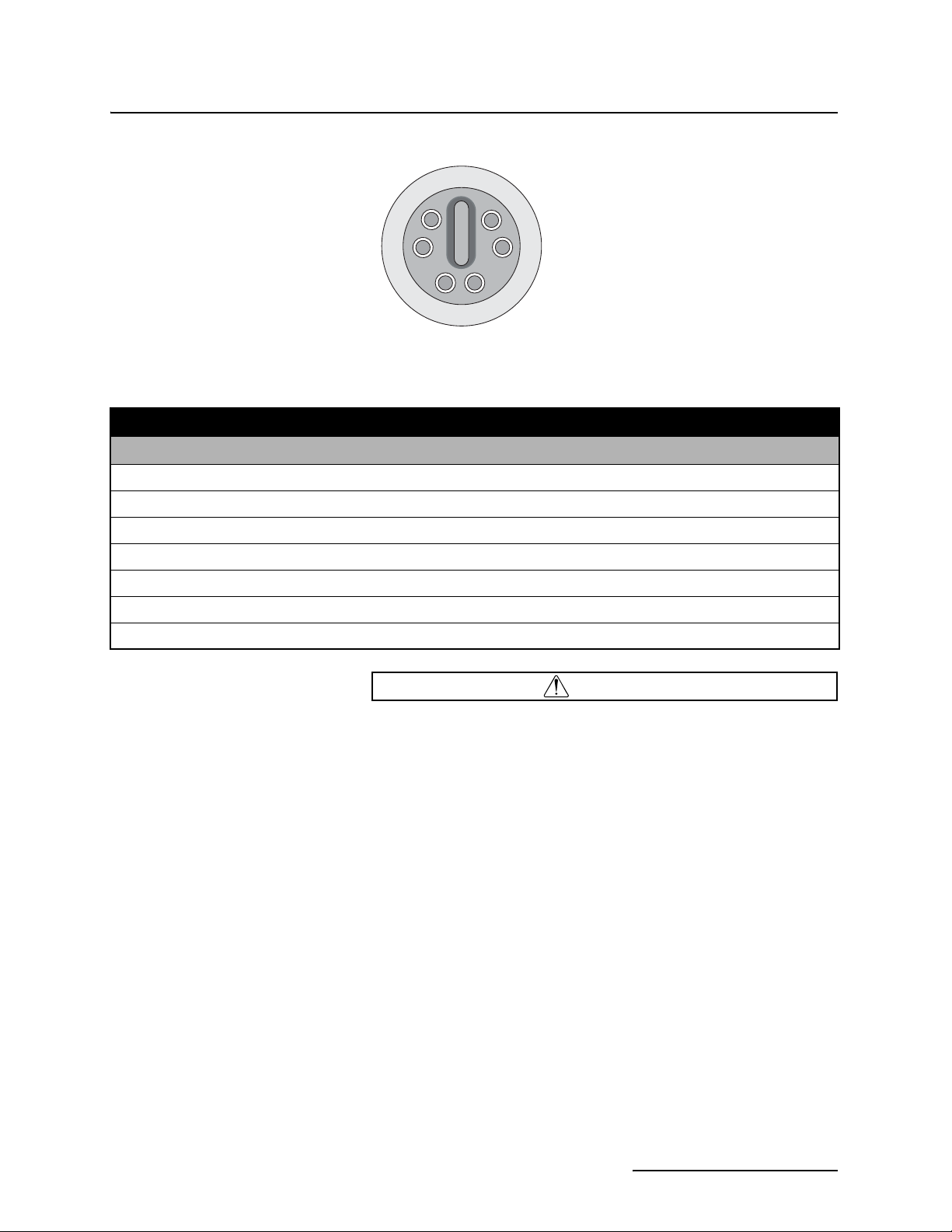

Figure 1-5 2150EX Area Velocity Flow System Communication Connector Pins

B

C

Table 1-9 Communication Connector Pins

Pin Name Description

A NETA Network differential transceiver Data A

B NETB Network differential transceiver Data B

C VIN+ Positive power supply voltage input (+8 VDC nominal)

D VIN– Negative power supply voltage input (0 VDC nominal)

E RCVUP PC data receiver RS232 compatible input

F XMTUP PC data transmit RS232 compatible output

G Key Aligns connector pins

CAUTION

The connector of the interrogator cable and protective cap both

have an alignment key to ensure proper connection. Observe

proper alignment and NEVER reverse the connector. Even a

momentary pin short can cause permanent damage to the batteries.

1-11

Page 26

2150EX Area Velocity Flow Module

Section 1 Introduction

1-12

Page 27

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

2.1 Unpacking Instructions

Teledyne Isco, Inc.

Customer Service Dept.

P.O. Box 82531

Lincoln, NE 68501 USA

Phone:(800) 228-4373

Outside USA & Canada

call:

(402) 464-0231

FAX: (402) 465-3022

When the system arrives, inspect the outside packing for any

damage. Then carefully inspect the contents for damage. If there

is damage, contact the delivery company and Teledyne Isco (or its

agent) immediately.

WARNING

If there is any evidence that any items may have been

damaged in shipping, do not attempt to install the unit.

Please contact Teledyne Isco (or its agent) for advice.

When you unpack the system, check the items against the

packing list. If any parts are missing, contact the delivery

company and Teledyne Isco’s Customer Service Department.

When you report missing part(s), please indicate them by part

number. In addition to the main packing list, there may be other

packing lists for various sub-components.

It is recommended that you retain the shipping cartons as they

can be used to ship the unit in the event that it is necessary to

transport the system.

Please complete the registration card and return it to Teledyne

Isco, Inc.

E-mail:

IscoInfo@teledyne.com

2-1

Page 28

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

2.2 Preparing for Installation

2.2.1 Safety

A 2150EX flow system may be a portable installation, powered

by a 2191EX or 2196EX battery module (described in Section

2.4), or a permanent installation, powered from the safe area by

the 2194EX network interface module (described in Section 2.5).

WARNING

Intrinsic safety is dependent on proper installation in

accordance with IEC 60079-14 and IEC 60079-17

International Standards, or ATEX Group II, Category 1G or

2G requirements of the authority that has jurisdiction for

the installation of equipment in hazardous areas at your

specific installation site. Installation should be performed

only by trained and qualified personnel.

WARNING

Avoid hazardous practices! If you use these instruments in

any way not specified in this manual, the protection

provided by the instruments may be impaired; this will

increase your risk of injury.

WARNING

The installation and use of this product may subject you

to hazardous working conditions that can cause you

serious or fatal injuries. Take any necessary precautions

before entering a worksite. Install and operate this product

in accordance with all applicable safety and health

regulations, and local ordinances.

The 2150EX module components are often installed in confined

spaces. Some examples of confined spaces include manholes,

pipelines, digesters, and storage tanks. These spaces may become

hazardous environments that can prove fatal for those unprepared. In the United States, these spaces are governed by OSHA

1910.146 and require a permit before entering.

Read the Safety section at the front of this manual, and the

general safety information in Appendix E.

2.2.2 Locating the Site The 2150EX is designed to measure flow in open channels with or without a primary device. A primary device is a hydraulic structure, such as a weir or a flume that modifies a channel so there is a known relationship between the liquid level and the flow rate. Although the 2150EX supports flow rate conversion in channels with a primary device, its level and velocity measurement capabilities are best suited for channels without a primary device.

2-2

Page 29

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

Note

Primary devices limit the usefulness of the AV Sensor’s readings. In most cases, levels and velocities near these structures

do not represent what normally occurs in the channel. If you

must use area velocity flow conversion, or if your interest is the

stream’s velocity, do not install the AV Sensor near a primary

device. Move the AV Sensor away to where the flow is unaffected by the primary device.

2.2.3 Channels Without a

Primary Device

2.2.4 Channels With a

Primary Device

2.2.5 2150EX and AV Sensor

Mounting

Considerations

When the AV Sensor is installed without a primary device, find a

section of channel with a minimum of disturbances to the flow.

Avoid areas with elbows, outfalls, inverts, junctions, etc. that

create turbulence near the AV Sensor. The AV Sensor should be

located away from these disturbances to a point where the flow

has stabilized. For best results, install the AV Sensor where the

flow is most uniform. Uniform flow is a condition where the

water surface is parallel to the bottom of the channel.

If the AV Sensor is installed in a primary device, its location

depends on the type of primary device. Most primary devices

have a specific place for the head (level) measurement sensor. For

more details about the location of the head measuring point,

refer to the Isco Open Channel Flow Measurement Handbook, or

to information provided by the manufacturer of the primary

device.

Note

When you install the AV Sensor for use within a primary

device, a Level-to-Flow conversion method should be used.

(See Programming, Section 3.)

Ideal sites are easily accessible for service and data collection,

while still providing protection for the 2150EX module devices.

The 2150EX module devices are rated NEMA 4X, 6P, and constructed of materials that can withstand harsh environments.

However, continual exposure to UV light, or periodic submersion

should be avoided to extend the life of the components.

Typically, the 2150EX is suspended inside a manhole. Suspending the 2150EX near the opening will protect it from the elements, minimize the chance of submersion, and allow it to be

easily retrieved without entering the manhole.

2-3

Page 30

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

2.3 Site Examples Figures 2-1, 2-2, and 2-3 illustrate typical round-pipe sites. Key

items are called out in the illustration and explained below.

Figures 2-1 and 2-2 represent portable installations. For

details about portable installations, see Section 2.4.

Figure 2-3 represents a permanent installation. For details

about permanent installations, see Section 2.5.

The computer running Flowlink (Figures 2-1 and 2-3) or the

2101 Field Wizard module (Figure 2-2) should be located

outside the potentially explosive atmosphere. The computer and

modules communicate with the 2150EX module.

The 2150EX area velocity flow module measures and stores

the stream data. In portable installations (Figures 2-1 and 2-2),

it is attached to a 2191EX or 2196EX battery module, which

supplies power to the module.

As described in Section 2.6.1, the EX network cable connects to

the top of the 2150EX stack and extends to the interface of the

safe and hazardous areas.

As described in Section 2.6.2, an RS232EX isolator cable connects the computer and the site. The cable supports the data

transfers between the two, and is connected to an EX Network

Cable connected to the top of the 2150EX module.

As described in Section 2.6.3, an RS485EX isolator cable connects the site with a Field Wizard or other network device. The

cable supports the data transfers between the two, and is connected to an EX Network Cable, connected to the top of the

2150EX module.

In permanent installations (Figure 2-3), the 2150EX is connected

via a network interface cable, usually through conduit, to the

2194EX network module, located in the safe area, which

serves as both power supply and network or PC connection.

The AV2150EX sensor cable must be routed carefully without

kinks, coils, or sharp bends, but may be snake-looped and tied.

Any excess cable must be kept out of the channel to prevent

debris from collecting.

The Mounting Ring holds the AV2150EX sensor in place.

The AV2150EX sensor is positioned in the flow stream to

measure liquid level and velocity.

2-4

Page 31

SAFE AREA

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

Computer running Flowlink

(Hazardous boundaries are normally

specified by local authorities.)

FLOW

POTENTIALLY

EXPLOSIVE

AREA

RS232EX Isolator Cable

EX Network Cable

2150EX Area Velocity

Flow Module

2191EX or 2196EX Battery

Module

Mounting Ring

AV2150EX Sensor

Figure 2-1 Typical Round-pipe Installation Connected to a

Laptop Computer (Portable Installation, see section 2.4)

2-5

Page 32

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

(Hazardous boundaries are normally

specified by local authorities.)

FLOW

SAFE AREA

POTENTIALLY

EXPLOSIVE

AREA

2101 Field Wizard Module

RS485EX Isolator Cable

EX Network Cable

2150EX Area Velocity

Flow Module

2191EX or 2196EX Battery

Module

Mounting Ring

AV2150EX Sensor

Figure 2-2 Typical Round-pipe Installation Connected to a

2101 Field Wizard (Portable Installation, see section 2.4)

2-6

Page 33

Equipment Box

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

(Hazardous boundaries are normally

specified by local authorities.)

Computer running

Flowlink

SAFE AREA

POTENTIALLY EXPLOSIVE AREA

Interrogator Cable

2194EX Network/

Power Module

Isco Power Pack

EX Interface Cable

and Conduit

2150EX Area Velocity

Flow Module

This figure is not intended to

depict the meeting of special

conditions indicated by "X"

markings on the equipment.

Refer to IEC 60079-14 section

12.2.4 regarding intrinsically safe

apparatus that does not

withstand the 500VAC electrical

strength test.

See the warnings below.

FLOW

Figure 2-3 Typical Round-pipe Installation Connected to a

2194EX Module and Laptop

(Permanent Installation, see section 2.5)

Due to the creation of a permanent grounding point between

the sensor’s transducer cover and the mounting ring when

the sensor is installed, the 2150EX system can not

withstand the 500 VAC test according to EN50020:2002

clause 6.4.12. Refer to IEC 60079-14, section 12.2.4,

regarding earthing of intrinsically safe circuits.

Mounting Ring

(See WARNINGS

below.)

AV2150EX Sensor

WARNING

2-7

Page 34

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

WARNING

The sensor mounting ring is a potential isolated charge

carrier. Your installation MUST satisfy earthing

requirements. Refer to IEC 60079-14 section 12.2.4 and IEC

60079-11.

2.4 Portable Installations For portable installations, the 2150EX module is stacked with a

2191EX or 2196EX battery module. It communicates with a computer or 2100 Series network device via an EX Network Cable

(for potentially explosive atmospheres) and an EX Isolator Cable.

The 2191EX module contains two sealed, replaceable battery

packs for use in gas hazard zones 0, 1, and 2.

The 2196EX is a rechargeable module for use in gas hazard zones

1 and 2. For detailed information about the 2196EX, turn to

section 2.4.6.

2.4.1 Installation Example The following steps may be used as a guide to install a basic, portable 2150EX system, including the 2150EX module, the 2191EX battery module, and an AV2150EX sensor.

1. Prepare the Battery Module.

a. Install the battery packs (See section 2.4.2).

b. Inspect the desiccant (2.4.3).

2. Inspect 2150EX module desiccant (2.4.4).

3. Assemble the system.

a. Install the 2150EX module (2.4.5 and Figure 2-6).

b. Attach the AV2150EX sensor cable to the 2150EX mod-

ule (2.7).

4. Install the AV2150EX sensor in the flow stream (2.7.1).

5. Connect the interrogation cable and connect to the site

with Flowlink software (2.6).

a. Create the site by Quick Connecting to the modules.

b. Set up the site and module settings.

6. Disconnect from the site and replace all protective caps.

2.4.2 Install Battery Module Batteries

2-8

The 2191EX Battery Module requires two LTC2191EX 8 volt

lithium battery packs (P/N 68-2000-022) or two SLA2191EX 8

volt lead-acid battery packs (P/N 68-2000-023). These packs are

sealed and explosion protected, so they can be safely installed in

a potentially explosive atmosphere.

WARNING

Substitution of components will impair intrinsic safety.

Page 35

Figure 2-4 Illustration of Battery Packs

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

Battery Pack

Door

Figure 2-5 Label Markings for LTC2191EX and SLA2191EX Battery Packs

CAUTION

To avoid overloading the fuses in the LTC2191EX lithium battery packs, disconnect the 2150EX module(s) before installing

or replacing the lithium battery packs. The SLA2191EX

lead-acid battery packs do not contain fuses, and do not

require that the 2150EX module(s) be disconnected.

2-9

Page 36

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

If you are installing the LTC2191EX lithium battery packs, first

disconnect the 2150EX module(s). If you are installing the

SLA2191EX lead-acid battery packs, it is not necessary to disconnect the 2150EX module(s). Then:

Repeat steps 1 through 4 to install the second battery pack.

When finished, reconnect the 2150EX module(s).

1. Remove the battery door. To remove the door, turn it

1

/4 turn

counter-clockwise and pull it from the Battery Module.

2. Align the connectors and insert the new battery pack into

the Battery Module.

3. Check the humidity indicator disk inside the door. (See section 2.4.3.)

4. Replace the door. Align the small triangle on the door with

the triangle above the battery port, push inward, and

rotate

1

/4 turn clockwise so the curved arrow is at the top of

the door.

Note

The battery packs should always be replaced as a pair. Never

mix old and new batteries. Battery packs should be disposed

of according to local battery disposal regulations. The

lead-acid battery packs should be recharged or recycled.

2.4.3 Inspect the Desiccant –

Battery Module

30

20

40

Humididy indicator

2.4.4 Inspect the Desiccant –

2150EX Module

A humidity indicator is mounted inside each battery cap on the

Battery Module. The humidity indicators have regions that

display 20, 30, and 40 percent humidity levels. Ideally each

region should be completely blue. As the desiccant becomes saturated, the humidity levels will increase and the regions turn

pink. When the 40 percent region turns pink, the Battery Module

is no longer adequately protected and the desiccant must be

replaced. Refer to section 5.4 for replacement instructions.

A desiccant cartridge is inserted into the side of the 2150EX

Module. The cartridge is filled with silica gel beads that will

indicate when they are saturated. When dry, the beads are blue

or yellow. As the desiccant becomes saturated, the humidity

levels will increase and the beads turn pink or green. If the

entire length of the desiccant cartridge turns pink or green, the

reference air is no longer adequately protected and the desiccant

must be replaced. Refer to section 5.4 for replacement instructions.

CAUTION

Operating the 2150EX and sensor with saturated desiccant

can cause many problems such as drifting level readings and

permanent damage. It is important that the equipment is serviced often enough to prevent the entire desiccant cartridge

from becoming saturated.

2-10

Page 37

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

2.4.5 Assembling the System The 2100 Series System is modular; you build the system by con-

necting modules together. The instructions in this section

describe how to connect a 2150EX module to a 2191EX or

2196EX battery module in its most basic configuration — by

stacking the two modules. The battery module must be at the

bottom of the stack.

You can use multiple modules in a stack to increase the site’s

functions. A maximum of two 2150EX modules may be powered

by one battery module, to avoid overloading the batteries.

However, within a stack, you can have multiple sets of

2150EX/2191EX combinations.

Connection options Keep in mind that stacking is not the only way to connect

modules. The modules may be placed in remote locations and still

operate as a single site. If you would like to use remote modules

for your application, please consult with the factory or your representative to realize the full potential of your system.

Figure 2-6 Assembling a basic portable system

Connecting the Modules To connect the 2150EX and 2191EX/2196EX modules, refer to

the following instructions and Figure 2-6.

1. On the top of the battery module, remove the cap and stow

it on the holder. This exposes the communication connector.

2. Prepare the battery module’s communication connector:

a. Inspect the connector. It should be clean and dry. Dam-

aged O-rings must be replaced. Spare O-rings (P/N

202-1006-69) are supplied in the 2191EX maintenance

kit (60-2009-332).

2-11

Page 38

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

The communications indicator will blink during the start-up

routine to indicate the 2150EX is operating.

b. Coat the O-ring’s sealing surface with a silicone lubri-

cant. (A small quantity of lubricant is supplied in the

maintenance kit.)

CAUTION

Do not use petroleum-based lubricants. Petroleum-based

lubricants will cause the O-ring to swell and eventually deteriorate. Aerosol silicone lubricant sprays often use petroleum

based propellants. If you are using an aerosol spray, allow a

few minutes for the propellant to evaporate before proceeding.

3. Place the carrying handle on the battery module. (If you

are stacking two 2150EX modules on top of the

2191EX/2196EX, position the handle between the 2150EX

modules.)

4. Unlock the 2150EX module’s latch by pressing in on the

latch release (right side).

5. Underneath the 2150EX, remove the cap from the lower

communication connector and stow it in the holder.

6. Lock the latch. Locking the latch correctly seats and aligns

the lower cap in its holder.

7. Position the 2150EX over the 2191EX/2196EX battery

module. Align the connectors and lower the 2150EX onto

the 2191EX/2196EX.

8. Unlock the 2150EX module’s latch by pressing in on the

latch release (right side).

9. Firmly press the modules together and lock the 2150EX

module’s latch (left side).

2-12

Note

Unused communication ports on the top and bottom of the

stack must be capped. The connector caps terminate the communication lines and protect the pins.

Page 39

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

2.4.6 Zone 1 Battery Module The Model 2196EX is a rechargeable battery module for zones 1 and 2 that offers indication of declining voltage prior to power interruption, with two batteries permanently contained in an IP68 enclosure. See Figure 2-10 for X marking and port labeling. The 2196EX may be safely connected to or disconnected from a 2150EX flow module within a hazardous area.

Note

The 2196EX is for use in gas hazard zones 1 and 2. It is not

approved for use in zone 0 installations, in accordance with

IEC 60079-14.

The 2196EX module has no port or latches on the bottom of the

case; therefore, it can only be installed on the bottom of a module

stack. One 2196EX module can power one or two 2150EX flow

modules with sensors attached.

The 2196EX uses two fully rechargeable, nonreplaceable

lead-acid batteries.

Never operate or store the 2196EX at temperatures above 140 °F

(60 °C). Operate the 2196EX below 86 °F (30 °C) for maximum

service life. For prolonged shelf life, the 2196EX should be stored

at 50 °F (10 °C) or lower in a fully charged state.

Battery protection The module protects the lead-acid batteries from damage due to

deep discharge by first indicating critically low voltage through

Flowlink software, and then by shutting off when the voltage

becomes critically low.

–

+

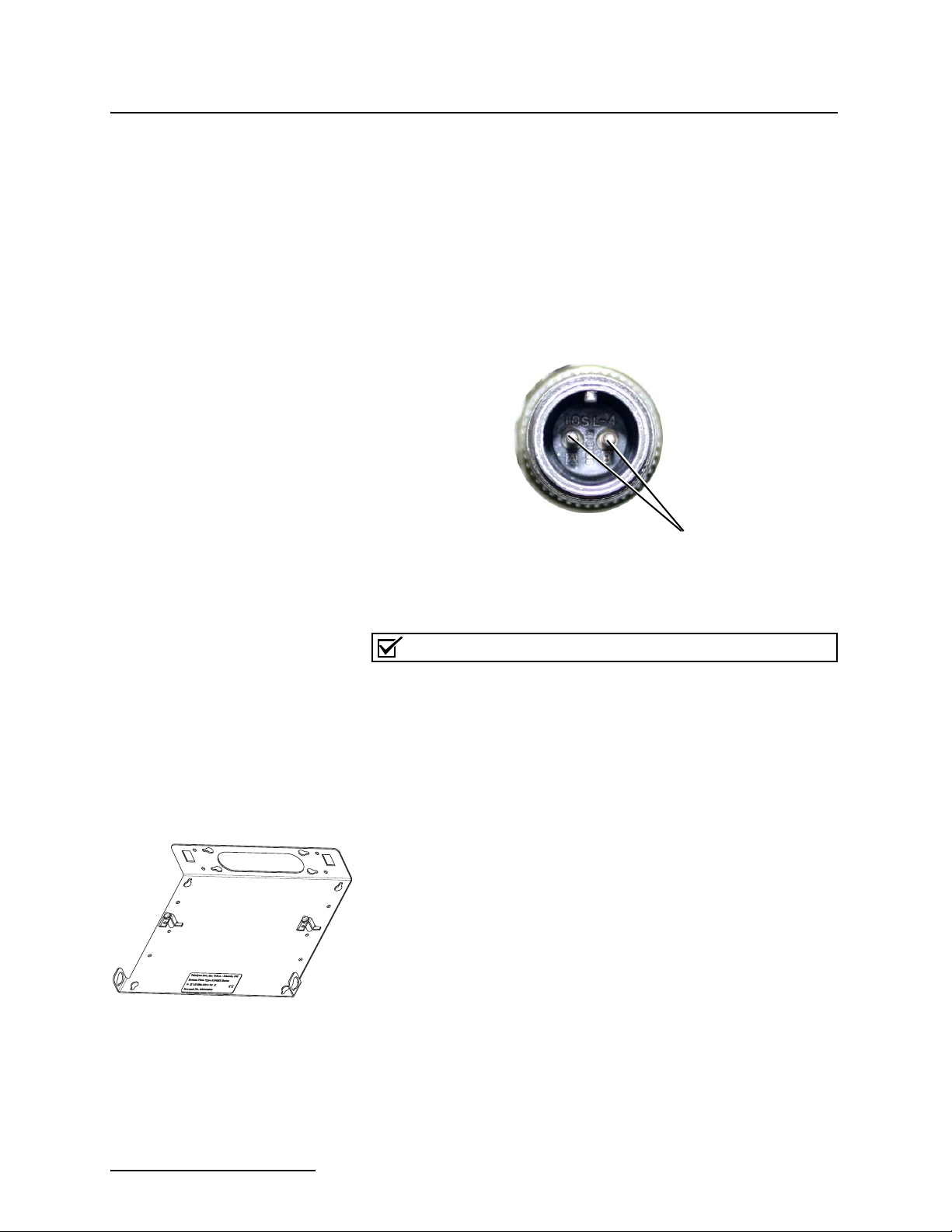

2196EX port connector

As the 2196EX output voltage decreases to a value near the

7-volt shut-off threshold, Flowlink software will issue a

low-voltage warning (Figure 2-7).

Neither of these protective functions should become necessary on a regular basis. Check the battery voltage

reading regularly, according to your specific application,

and recharge the batteries before the warning appears.

The voltage may also be tested with a voltmeter at the port connector on pins c (+) and d (–), or on the internal circuit board (see

the test points shown in Figure 2-8).

Note

There is a 60K ohm resistor in series with the voltage sensing

circuit. The voltage reading measured on the circuit board may

have slight variance, depending on the voltmeter used.

2-13

Page 40

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

Figure 2-7 Flowlink low-voltage warning

A 2196EX module kept in storage for extended periods should

be recharged approximately every six to nine months. The battery voltage should never be allowed to fall below 10.5 volts

before recharging. Deep discharge of the lead-acid batteries

can lead to permanent loss of capacity.

CAUTION

Charging The 2196EX module requires a lead-acid battery charger with a

maximum rating of 20 volts, 2 amps. The module is fused for protection against excessive current (see Figure 2-9).

WARNING

Do not charge the 2196EX in a potentially explosive

environment. Charge only in a safe area.

WARNING

When charging the 2196EX, observe maximum voltage

ratings of Um = 250V and Un = 20V. The charger output must

not exceed 20 volts or 2 amperes as labeled.

In order to recharge the batteries, the 2196EX module case must

be opened. Unlike other 2100 modules, which have two desiccant

holders, the 2196EX has only one, located on the inside of the

right compartment door.

Note

During the charging process, the 2196EX case must remain

open, exposing the desiccant to the atmosphere. Teledyne

Isco recommends storing the desiccant in an airtight container

while charging the batteries. Check the humidity indicator on

the inside of the door whenever it is opened and ensure that

only dry desiccant is installed when re-sealing the case.

2-14

Page 41

Rechargeable, non-

replaceable lead-acid

batteries

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

The charging terminals are located on the circuit board mounted

on the inside of the left compartment door (Figures 2-8 and 2-9, +

and –). A cable ending in alligator clips may be connected to these

terminals for charging.

CAUTION

The circuit board is permanently connected to the interior of

the module. Use care when opening the case that the wires

are not damaged.

During charging, the yellow LED on the circuit board remains on

to indicate charge voltage in correct polarity. The replaceable 2A

fuse on the back side of the board protects against excessive

current.

Charge terminals

(remove screws to

access fuse)

–

+

Figure 2-8 Location of 2196EX charging terminals

Desiccant holder

(remove screws to

access desiccant

2-15

Page 42

2150EX Area Velocity Flow Module

Section 2 Preparation and Installation

Measure the voltage between

Test Point 1 and H5 (negative

terminal).

BATTERY VOLTS (TP1)

MAXIMUM 50 CELSIUS

NEVER

CHARGE IN

POTENTIALLY

EXPLOSIVE ENVIRONMENT

(-) NEGATIVE (+) POSITIVE

FUSED

INPUT

VOLTAGE

(LED)

AMBIENT DURING CHARGE

MAXIMUM CHARGER RATING

20 VOLTS 2 AMPERES

Um = 250V

Un = 20V

2A replaceable fuse

H19

Front

There is a 60K ohm resistor in series with the voltage sensing

circuit. The voltage reading measured on the circuit board may

have slight variance, depending on the voltmeter used.

Figure 2-9 Detailed view of charging circuit board

Fuse replacement To access the 2A charge fuse (F1), remove the two mounting

screws holding the circuit board inside the compartment lid.

Replace the fuse with the specified Littlefuse 216002 or

Cooper/Bussman S501 only (Isco part #411-9922-60).

Charger options See Appendix B for part numbers and ordering infor-

mation.

The 2196EX can be charged using the Isco Model 965 five-station

battery charger, or the Isco Model 963 desktop charger. The 965

has five 2-pin amphenol connectors on the front. The 963 has a

single, 2-pin amphenol cable. Both chargers require an adaptor

cable for use with the 2196EX (Isco part #60-1394-023), and are

user-switched for 120/240VAC, 50/60Hz applications.