Page 1

OPERATING INSTRUCTIONS FOR

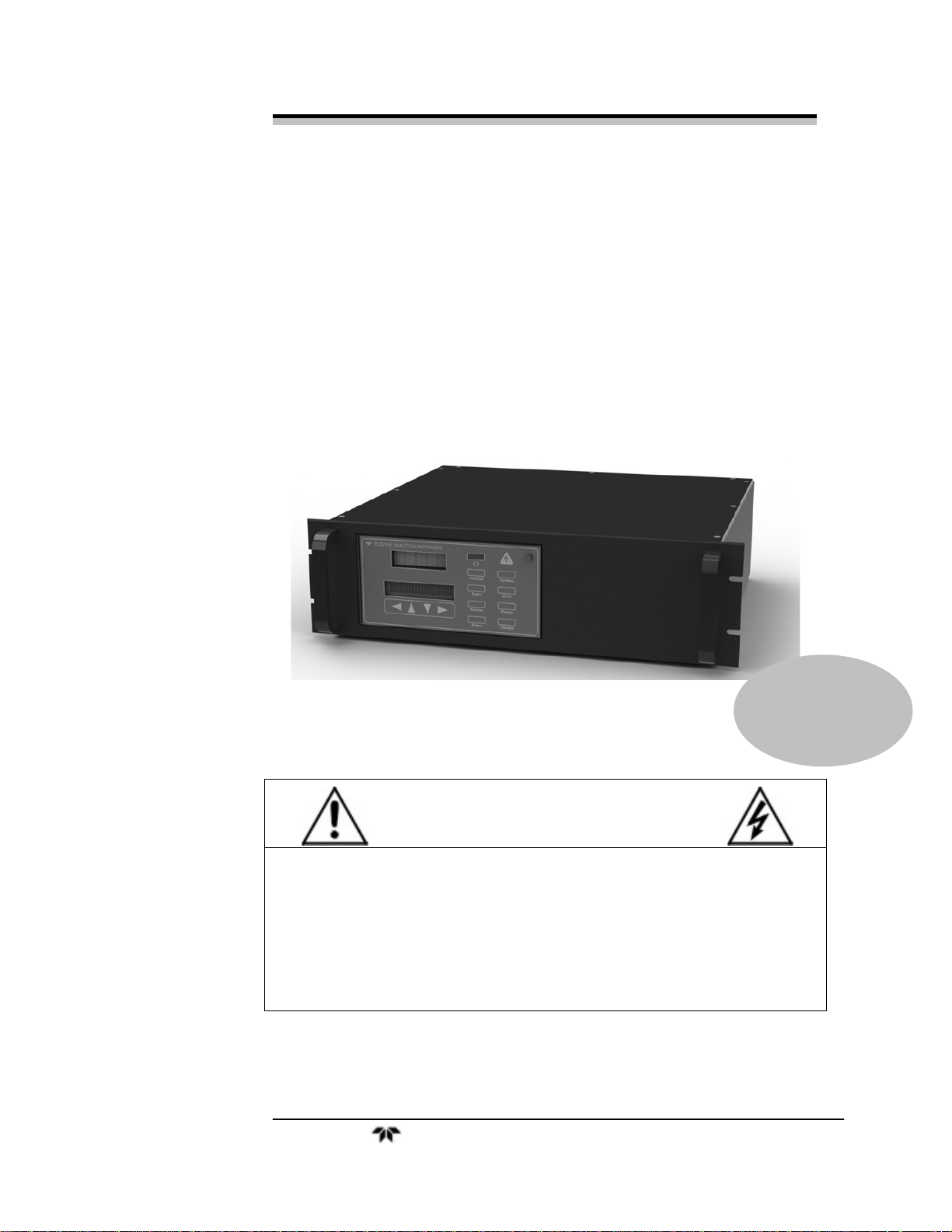

Model 2120XL

Trace Nitrogen in Argon Analyzer

DANGER

This instrument is for analyzing nitrogen in argon only.

Do not introduce any flammable or toxic gases into this instrument.

Hazardous voltages exist on certain components internally which may be

lethal. Disconnect power before servicing.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

P/N M84744

11-27-13

Teledyne Analytical Instruments

Page 2

Model 2120XL

Copyright © 2013 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91748.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by Teledyne or an authorized service center.

We assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by which

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement expressed or

implied by this document or any information disseminated by the manufacturer or its

agents, is to be construed as a warranty of adequate safety control under the user’s process

conditions.

Teledyne Analytical Instruments ii

Page 3

Trace Nitrogen in Argon Analyzer

Specific Model Information

This instrument relies on the known spectrum emitted from a

plasma discharge from a distinct gas mixture of variable composition at

or near atmospheric pressure. This instrument cannot be used for

analysis on any gas or gas mixture other than nitrogen in argon or a

mixture specified at the time of purchase. Specific filters carefully

chosen and tested at the factory have been installed for the particular gas

mixture. Using this instrument to analyze any other gas mixture will

result in serious error. Consult the factory for additional information for

gas analysis not specified at the time of purchase.

Instrument Serial Number: _______________________

Instrument Range: _______________

Calibrated for: _______________

Background Gas: _______________

Zero Gas: _______________

Span Gas: _______________

Teledyne Analytical Instruments iii

Page 4

Model 2120XL

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the instructions for

details on the specific danger. These cautions warn

of specific procedures which if not followed could

cause bodily Injury and/or damage the instrument.

CAUTION: HOT SURFACE WARNING: This warning is specific to

heated components within the instrument. Failure to

heed the warning could result in serious burns to

skin and underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous voltages appear

within this instrument. This warning is specific to

an electrical hazard existing at or nearby the

component or procedure under discussion. Failure

to heed this warning could result in injury and/or

death from electrocution.

Technician Symbol: All operations marked with this symbol are to be

performed by qualified maintenance personnel only.

NOTE: Additional information and comments regarding a

specific component or procedure are highlighted in

No

Symbol

the form of a note.

Teledyne Analytical Instruments iv

Page 5

Trace Nitrogen in Argon Analyzer

CAUTION: THE ANALYZER SHOULD ONLY BE USED ONLY

FOR THE PURPOSE AND IN THE MANNER

DESCRIBED IN THIS MANUAL.

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration operation and maintenance of your new

analyzer. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

Teledyne at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments v

Page 6

Model 2120XL

Table of Contents

List of Figures ................................................................ ix

List of Tables .................................................................. x

Introduction ..................................................................... 1

1.1 Overview 1

1.2 Typical Applications 1

1.3 Features 2

1.4 Front Panel 3

1.5 Rear Panel 5

1.6 Internal Components 6

1.7 Additional Safety Information 7

1.7.1 Detector Cautions 8

1.7.2 Basic Safety Requirements 9

1.7.3 Precautionary Labels 9

1.7.4 Summary of Known Hazards 10

1.7.4.1 Electrocution 10

1.7.4.2 Pressure 10

1.7.4.3 Purging 11

1.7.4.4 Safe Repair Procedures 11

1.7.4.5 General Precautions for Handling and Storing

High Pressure Gas Cylinders 11

Operational Theory ....................................................... 13

2.1 The Analyzer 13

2.2 Sample System 14

Installation ..................................................................... 17

3.1 Unpacking the Instrument 17

Teledyne Analytical Instruments vi

Page 7

Trace Nitrogen in Argon Analyzer

3.2 Choosing a Location 18

3.3 Mounting 18

3.4 Rear Panel Connections 19

3.5 Electrical Connections 20

3.5.1 Primary Input Power 20

3.5.2 50-Pin Equipment Interface Connector 20

3.5.3 RS-232 Port 26

3.6 Gas Connections 27

3.6.1 Typical Sample System 29

3.6.2 Gas Connections to the Instrument 31

3.7 Purging 31

3.8 Calibration 33

3.9 Installation Checklist 33

Operation....................................................................... 35

4.1 Powering Up the Analyzer 36

4.2 Zero and Span Calibration 36

4.3 Setup and Operation General Information 37

4.4 Using the Data Entry and Function Buttons 37

4.5 Analyzer Functions 38

4.5.1 System Menu 39

4.5.1.1 Digital Filter 40

4.5.1.2 Self-Test 41

4.5.1.3 Password Protection 42

4.5.1.4 Logout 46

4.5.1.5 ERR 46

4.5.1.6 Auto Calibration (Auto Cal) 47

4.5.1.7 Flow 49

4.5.1.8 Tracking During Calibration 49

4.5.1.9 Calibration Hold Timer (Calholdtimer) 50

4.5.1.10 The Model Screen 50

4.5.1.11 Analog Output Calibration (Out_Cal) 51

4.5.1.12 Linearize (Lin) 52

Teledyne Analytical Instruments vii

Page 8

Model 2120XL

4.5.2 The Zero and Span Functions 54

4.5.2.1 Before Calibration 54

4.5.2.2 Recommended Calibration Gases 55

4.5.2.3 Zero Cal 55

4.5.2.4 Span Calibration 57

4.5.3 The Range Function 59

4.5.4 The Alarms Function 60

4.6 The Analyze Function 62

4.7 Signal Output 62

Maintenance .................................................................. 65

5.1 Routine Maintenance 65

5.2 Routine Maintenance Schedule 65

5.3 Fuse Replacement 66

5.4 System Self Diagnostic Test 67

5.5 Error Screens 68

5.6 Sensor Replacement 69

Appendix ....................................................................... 71

A.1 Specifications 71

A.2 Recommended Replacement Parts List 72

A.3 Drawing List 73

Teledyne Analytical Instruments viii

Page 9

Trace Nitrogen in Argon Analyzer

List of Figures

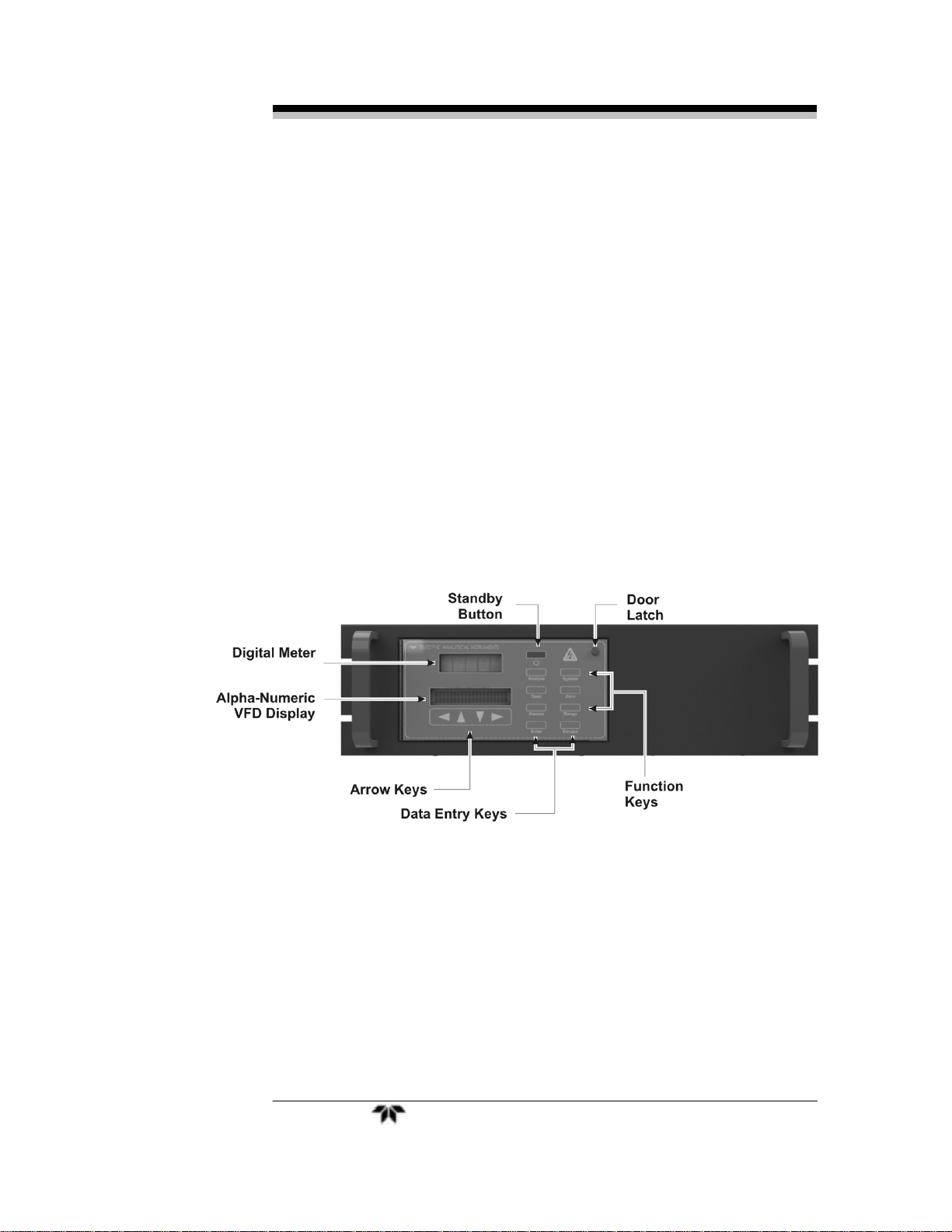

Figure 1-1 Model 2120XL Front Panel 3

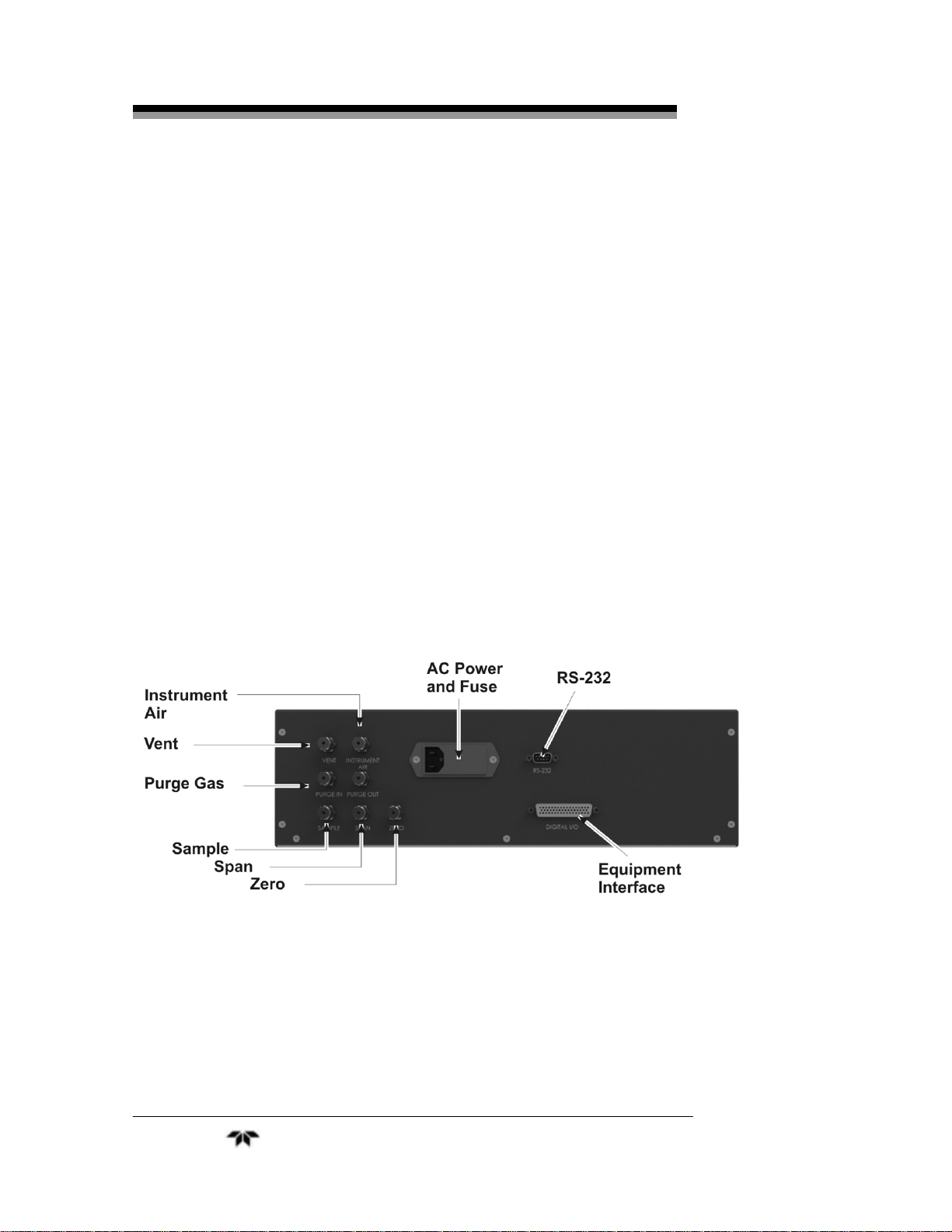

Figure 1-2: Model 2120XL Rear Panel 6

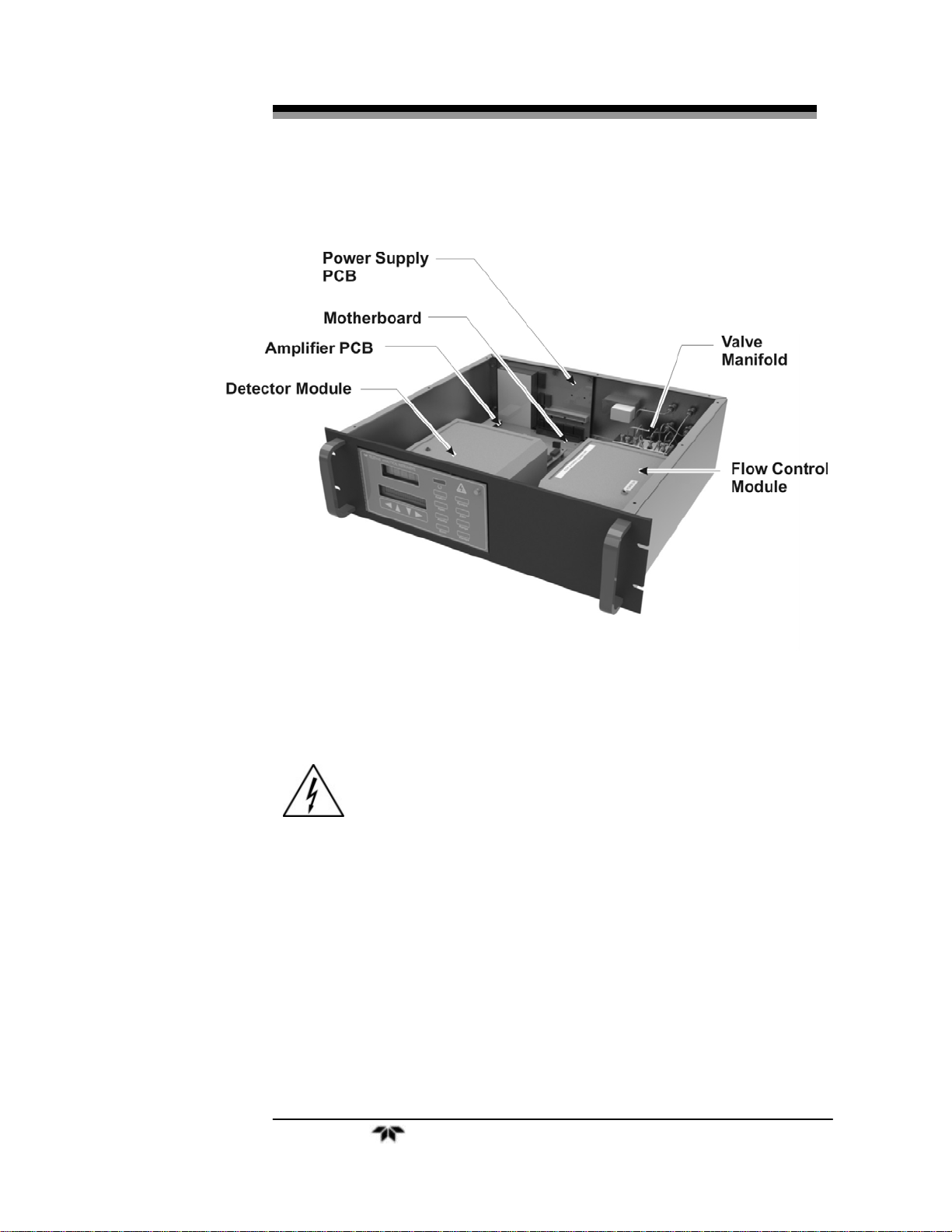

Figure 1-3: Internal Component Identification 7

Figure 3-1: Required Front Door Clearance 19

Figure 3-2: Rear Panel of the Model 2120XL 19

Figure 3-3: Equipment Interface Connector Pin Arrangement 21

Figure 3-4: Remote Valve Connections 25

Figure 3-5: FET Series Resistance 26

Figure 3-6: Suggested Sample System 29

Figure 4-1: Hierarchy of Functions and Sub Functions 39

Figure 5-1: Removing Fuse Block from Housing 66

Figure 5-2: Installing Fuses 67

Teledyne Analytical Instruments ix

Page 10

Model 2120XL

List of Tables

Table 3-1: Analog Output Connections 21

Table 3-2: Alarm Relay Contact Pins 22

Table 3-3: Remote Calibration Connections 23

Table 3-4: Range ID Relay Connections 24

Table 3-5: Commands via RS-232 Input 26

Table 3-6: Required RS-232 Options 27

Table 5-1: Routine Maintenance Schedule 66

Teledyne Analytical Instruments x

Page 11

Trace Nitrogen in Argon Analyzer

DANGER

COMBUSTIBLE GAS USAGE

This is a general purpose instrument designed for use in a

non-hazardous area. It is the customer's responsibility to

ensure safety especially when combustible gases are

present since the potential of gas leaks always exist.

Never introduce gases other than argon into the analyzer. If

explosive, flammable or corrosive gases or gas mixtures are

allowed to flow into the analyzer, fire or explosion can result.

WARNING

Sample gas introduced must be at or very close to

atmospheric pressure or damage to the detector will result.

To avoid serious injury, read all precautionary labels

attached to equipment, cylinders, containers, and boxes

prior to start-up.

Labels attached in appropriate areas of the analyzer warn

you of inherent hazards associated with the system. For

personal safety, read the labels and perform directed

precautions before handling the equipment.

The customer should ensure that the principles of operating

this equipment are well understood by the user. Misuse of

this product in any manner, tampering with its components,

or unauthorized substitution of any component may

adversely affect the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne Analytical Instruments, referred as TAI, no

responsibility by TAI, its affiliates, and agents for damage or

injury from misuse or neglect of this equipment is implied or

assumed.

Teledyne Analytical Instruments xi

Page 12

Model 2120XL

Teledyne Analytical Instruments xii

Page 13

Trace Nitrogen in Argon Analyzer Introduction

Introduction

1.1 Overview

This manual describes installation, operation and maintenance for

the Model 2120XL Trace Nitrogen in Argon Gas Analyzer. Section 1

describes the analyzer in general terms and provides additional safety

information pertinent to the proper operation of the instrument.

The Teledyne Model 2120XL Trace Nitrogen in Argon Gas

Analyzer is a robust analytical tool for measuring trace amounts of

nitrogen in argon. Using precise optical filtering, single line emission

characteristic of nitrogen is produced with an intensity proportional to

the nitrogen concentration.

The Model 2120XL has three user programmable analysis ranges

extending from 0-1 ppm to 0-100 ppm with corresponding analog output

signals that are proportional to the concentration on the selected range.

The nitrogen concentration is displayed on the front panel and the

analog output signals are available at the rear panel. Digital

communication is achieved with a standard RS-232 serial port.

The system is easy to operate with all controls and indicators

accessible from the front panel. Digital flow control, two adjustable

concentration alarms, system alarm, self-diagnostics are just a few of the

many features included on the standard Model 2120XL instrument.

1.2 Typical Applications

The Model 2120XL Trace Nitrogen in Argon Gas Analyzer is used

in a wide range of applications including:

Air separation plants

Argon Purification Plants

Specialty Gas Laboratories

Specialty Steel Manufacturing

Gas Management/Monitoring Systems

Teledyne Analytical Instruments 1

Page 14

Introduction Model 2120XL

Quality Control for Truck Fills & Gas Cylinders

Process Control

New Line Certification

Chemical Plants

Welding Gas Management

Semiconductor Manufacturing

1.3 Features

The Model 2120XL comes equipped with the following standard

features:

A 2-line alphanumeric vacuum fluorescent display (VFD)

screen, driven by microprocessor electronics that

continuously prompts and informs the operator.

High resolution, accurate readings of nitrogen content from

low ppm levels through 100 ppm in argon. Large, bright,

meter readout.

Advanced high frequency plasma generator produces stable

electroluminescent discharge with minimal heating yielding a

spectral emission characteristic of the gas mixture.

Custom low-noise optical filter for precise narrow band

selection and low optical interference.

Amplified optics circuit for stable nitrogen detection at low

ppb level.

Microprocessor based electronics: 8-bit CMOS

microprocessor with 32 kB RAM and 128 kB ROM.

Three user definable output ranges (from 0-1 ppm through 0-

100 ppm) allow best match to users process and equipment.

Auto Ranging allows analyzer to automatically select the

proper preset range for a given measurement. Manual

override allows the user to lock onto a specific range of

interest.

Two adjustable concentration alarms and a system failure

alarm.

Teledyne Analytical Instruments 2

Page 15

Trace Nitrogen in Argon Analyzer Introduction

Extensive self-diagnostic testing, at startup and on demand,

with continuous power-supply monitoring.

Two way RFI protection.

RS-232 serial digital port for use with a computer or other

digital communication device.

Four analog outputs: two for measurement (0–1 VDC and

isolated 4–20 mA DC) and two for range identification.

Convenient and versatile, steel, flush-panel or rack-

mountable case with slide-out electronics drawer.

1.4 Front Panel

Operator controls and displays are located on the front panel as

shown in Figure 1-1.

Figure 1-1 Model 2120XL Front Panel

The standard 2120XL Nitrogen in Argon Analyzer is panel

mounted designed for easy installation in a standard 19” instrument

rack. All user controls and displays accessible from the front panel.

The front panel has thirteen buttons for operating the analyzer, a

digital meter, and an alphanumeric vacuum fluorescent (VFD) display.

Teledyne Analytical Instruments 3

Page 16

Introduction Model 2120XL

Function Keys:

Six touch-sensitive membrane switches are used to change the specific

function performed by the analyzer:

Analyze Perform analysis for nitrogen content in an argon

gas mixture.

System Perform system-related tasks (described in detail

in Chapter 4, Operation.).

Span Span calibrate the analyzer.

Zero Zero calibrate the analyzer.

Alarms Set the alarm setpoints and attributes.

Range Set up the 3 user definable ranges for the

instrument.

Data Entry Keys:

Six touch-sensitive membrane switches are used to input data to the

instrument via the alphanumeric VFD display:

◄► Select between functions currently displayed on

the VFD screen.

▲▼ Increment or decrement values of functions

currently displayed.

Enter Advances VFD display to the next screen in a

series or returns to the Analyze screen if none

remain.

Escape Backs VFD display to the previous screen in a

series or returns to the Analyze screen if none

remain also used to abort an entry.

Digital Meter Display:

The meter display is a Light Emitting Diode (LED) device that produces

large, bright, 7-segment numbers that are legible in any lighting. It

produces a continuous readout from 0-10,000 ppm. It is accurate across

all analysis ranges without the discontinuity inherent in analog range

switching.

Alphanumeric Interface Screen:

The VFD screen is an easy-to-use interface from operator to analyzer. It

displays values, options, and messages that give the operator immediate

feedback.

Teledyne Analytical Instruments 4

Page 17

Trace Nitrogen in Argon Analyzer Introduction

Standby Button:

The Standby turns off the display and outputs, but circuitry is still

operating.

CAUTION: THE POWER CABLE MUST BE UNPLUGGED TO

FULLY DISCONNECT POWER FROM THE

INSTRUMENT. WHEN CHASSIS IS EXPOSED OR

WHEN ACCESS DOOR IS OPEN AND POWER

CABLE IS CONNECTED, USE EXTRA CARE TO

AVOID CONTACT WITH LIVE ELECTRICAL CIRCUITS

.

Access Door:

For access to internal components of the analyzer, the front panel swings

open when the latch in the upper right corner of the panel is pressed all

the way in with a narrow gauge tool. Accessing the main circuit board

requires unfastening rear panel screws and sliding the unit out of the

case.

1.5 Rear Panel

The rear panel, shown in Figure 1-2, contains the gas and electrical

connectors for external inlets and outlets. Some of those depicted are

optional and may not appear on your instrument. The connectors are

described briefly here and in detail in Chapter 3 Installation.

Power Connection Universal AC power source.

Digital I/O Analog Outputs:

0–1 VDC nitrogen concentration

plus 0-1 VDC range ID, and

isolated 4–20 mA DC nitrogen

concentration plus 4-20 mA DC

range ID.

Alarm Signals:

2 concentration alarms and 1

system alarm.

Remote Span/Zero

Digital inputs allow external

control of analyzer calibration.

Teledyne Analytical Instruments 5

Page 18

Introduction Model 2120XL

Calibration Contact

Notifies external equipment that

instrument is being calibrated and

readings are not monitoring

sample.

Range ID Contacts

Four separate, dedicated, range

relay contacts. Low, Medium,

High, Cal (not used).

RS-232 Port Serial digital concentration signal

output and control input.

Gas Inlet and Outlet One inlet and one vent.

Purge Connections Inlet and outlet connections for

purging the analyzer.

Instrument Air Used for driving optional auto

calibration valves.

Figure 1-2: Model 2120XL Rear Panel

1.6 Internal Components

The internal components can be accessed by removing the top

cover of the analyzer. Figure 1-3 shows an inside view of the analyzer

Teledyne Analytical Instruments 6

Page 19

Trace Nitrogen in Argon Analyzer Introduction

and identifies specific components of the analyzer. See also Figure 1-4

for internal components inside the card cage.

Figure 1-3: Internal Component Identification

WARNING: HIGH VOLTAGE. ELECTROCUTION HAZARD.

UNPLUG THE ANALYZER BEFORE REMOVING THE

COVER. THE OUTPUT OF THE HIGH-VOLTAGE

TRANSFORMER AND THE ANALYTICAL CELL

ELECTRODES CAN APPROACH VOLTAGES OF

10,000 VAC. THE ANALYZER SHOULD BE SERVICED

ONLY BY A QUALIFIED SERVICE TECHNICIAN.

1.7 Additional Safety Information

Note: The material provided in this section contains information

to promote safety in the operation and maintenance of this

equipment. It is not intended to supersede, replicate, or

replace any safety documentation or procedures provided

from or established by official safety sources.

Teledyne Analytical Instruments 7

Page 20

Introduction Model 2120XL

Do NOT operate the Model 2120XL Trace Nitrogen in Argon

Gas Analyzer until you read and understand the operating,

maintenance, and safety instructions included in this

manual.

Anyone involved with the operation of this equipment

including plant engineering, operations, and management, must

understand the potential hazards involved, and know and observe all

required safety precautions.

Your safety and the safety of equipment, nearby facilities, and

personnel require a proper safety attitude and emphasis on safe work

procedures. This is the essence of any good safety program. If at any

time you identify safety deficiencies, immediately correct them and

bring them to the attention of management.

Before an accident can be prevented, it must be anticipated. Use

pre-job discussions with your coworkers and supervisors to identify

hazards and the means to avoid them. At your facility, various gases

may exist in liquid and/or gaseous states. Familiarize yourself with the

hazards associated with each gas found at your facility.

Read and understand the Material Safety Data Sheets (MSDS) for

the materials used with this equipment. All personnel who work in the

vicinity of this equipment should read, understand, and follow all safety

information contained in the MSDSs, in addition to following all

government and facility safety regulations.

CAUTION: NEVER INTRODUCE GASES OTHER THAN ARGON

INTO THE ANALYZER. IF EXPLOSIVE, FLAMMABLE,

OR CORROSIVE GASES OR GAS MIXTURES ARE

ALLOWED TO FLOW INTO THE ANALYZER, FIRE OR

EXPLOSION CAN RESULT. THIS ANALYZER IS NOT

DESIGNED TO BE USED IN HAZARDOUS AREAS.

1.7.1 Detector Cautions

The Model 2120XL uses a detection technique based on

spectroscopic emission. The detector is a thin-walled pure quartz cell

located in an electromagnetic field created by a specific high intensity

plasma generator. This electromagnetic field creates a plasma that emits

light at different wavelengths. A filter for the nitrogen is used to avoid

any interference and get the best performance.

Teledyne Analytical Instruments 8

Page 21

Trace Nitrogen in Argon Analyzer Introduction

Since the cell is made of thin quartz, this analyzer must be used at

atmospheric pressure to avoid cell damage. Any back pressure in the

detector will cause damage and require replacement of the module.

Make sure the vent is at atmospheric pressure and without

restrictions or blockage.

1.7.2 Basic Safety Requirements

The following safety guidelines apply at all times when working

with the Model 2120XL analyzer:

Prevent electrical shock — Unplug and remove the AC

power cord from the rear panel before opening and working on

the analyzer. Use tools designed for work on electrical

equipment.

Prevent injury — Always wear safety glasses and appropriate

safety protection. Ensure that all tools and instruments used

during installation and maintenance are in good condition. Be

aware that high-velocity gas may be released at vents and safety

relief valves.

Follow posted precautions — Read all precautionary labels

attached to the equipment. Be sure to read all cylinder labels and

warnings. Comply with all precautions before handling the

equipment.

Situations may develop for which no written procedures exist.

Think carefully before acting. Know the function of each valve and

switch, and its effect on the equipment. Carefully review all operating

procedures before starting up this equipment to ensure knowledge and

understanding.

1.7.3 Precautionary Labels

WARNING: TO AVOID SERIOUS INJURY, READ ALL CAUTION

LABELS ATTACHED TO EQUIPMENT, CYLINDERS,

CONTAINERS, AND BOXES PRIOR TO START-UP.

Labels attached in appropriate areas of the analyzer warn you of

inherent hazards associated with the system. For personal safety, read

the labels and perform directed instructions before handling the

equipment.

Teledyne Analytical Instruments 9

Page 22

Introduction Model 2120XL

1.7.4 Summary of Known Hazards

This equipment is designed to minimize your exposure to the process

gases and other known hazards. Read and thoroughly understand all

safety aspects of this system and its operation before operating or

maintaining the equipment.

1.7.4.1 ELECTROCUTION

WARNING: DO NOT OPERATE THE ANALYZER WITHOUT THE

COVER SECURED IN PLACE. THE OUTPUT OF THE

HIGH-VOLTAGE TRANSFORMER AND THE

ANALYTICAL CELL ELECTRODES CAN APPROACH

VOLTAGES OF 6,000 VAC OR HIGHER. TO GUARD

AGAINST ELECTRICAL SHOCK AND POSSIBLE

ELECTROCUTION, THE ANALYZER SHOULD BE

SERVICED ONLY BY A QUALIFIED SERVICE

TECHNICIAN.

Adherence to the following guidelines helps guard against electrical

shock:

For safety and proper performance, this analyzer must be

connected to a properly grounded three-wire source of

electrical power.

Tampering or unauthorized substitution of components may

adversely affect the safety of this instrument. Use only

factory-approved components for repair.

Before checking or replacing any chassis component, turn off

the power and remove the AC power cord from the rear

panel.

1.7.4.2 PRESSURE

WARNING: MISHANDLING OF GAS CYLINDERS COULD

RESULT IN DEATH, SERIOUS INJURY, OR

PROPERTY DAMAGE. HANDLE AND STORE GAS

CYLINDERS WITH EXTREME CARE AND IN

ACCORDANCE WITH MANUFACTURER'S

INSTRUCTIONS.

Sudden or uncontrolled release of pressurized gas can cause serious

injury. The hazards of high pressure can be avoided through careful

inspection and handling of cylinders and equipment with proper

Teledyne Analytical Instruments 10

Page 23

Trace Nitrogen in Argon Analyzer Introduction

regulation. Read and understand the MSDSs for the process gases used

before operating this analyzer. More detailed information on the

precautions and safe practices to follow when handling cylinders can be

found in the CGA pamphlet P-1, Safe Handling of Compressed Gases in

Cylinders.

1.7.4.3 PURGING

CAUTION: EQUIPMENT DAMAGE MAY RESULT IF THE

ANALYTICAL CELL IN THIS UNIT IS EXPOSED TO

PRESSURE ABOVE ATMOSPHERIC PRESSURE.

THE CELL MAY BREAK OR SHATTER. TO PREVENT

THIS, ALWAYS KEEP THE VENT AT ATMOSPHERIC

PRESSURE.

DO NOT EXCEED 20 PSIG (138 KPA) AT THE

SAMPLE INLET.

DO NOT BLOCK THE VENT.

Follow applicable safety precautions to ensure that an oxygendeficient atmosphere is not created in the work area. Use low parts per

million (ppm) nitrogen in argon gas with proper regulation to avoid

contaminating the sampling system.

1.7.4.4 SAFE REPAIR PROCEDURES

Any repair work must be performed by a qualified service

technician. Use only factory-approved components for repair.

Analyzer manifold purging as well as subsequent repair work must

be performed by experienced personnel.

Ventilate working area to prevent any leaking supply gas from

accumulating. Vent all gases to the outside.

Vent all pressure relief valves out of enclosed areas. Piping must be

properly sized to allow safety devices to operate according to

specifications.

De-pressurize supply gas piping before working on it.

1.7.4.5 GENERAL PRECAUTIONS FOR HANDLING AND STORING HIGH

PRESSURE GAS CYLINDERS

Compressed gases have properties that can cause serious accidents,

injuries, and even death if proper precautions and safety practices are

Teledyne Analytical Instruments 11

Page 24

Introduction Model 2120XL

not followed. Therefore, during handling and use of these gases, be

certain to use applicable safety precautions described by your local

compressed gas supplier, the Compressed Gas Association, and/or

OSHA regulations.

1. Read the label on all cylinders BEFORE using to identify

the cylinder contents. If the label is illegible, return the

cylinder to the supplier. DO NOT ASSUME THE

CONTENTS.

2. Secure cylinders in storage and in use to an immovable

structure to prevent accidental falling or movement. Read

the relevant safety codes.

3. Store or move cylinders ONLY in the vertical position. DO

NOT move or transport cylinders with regulators attached.

4. Store cylinders in a well ventilated area away from heat or

ignition sources.

5. When installing tubing, provide ONLY approved, adequate

pressure reducing regulators and pressure relief devices to

prevent over-pressurizing of tubing and equipment.

6. Never drop cylinders or permit them to strike each other

violently.

7. Cylinders may be stored in the open but, in such cases,

should be protected against extremes of weather and from

damp ground (to prevent rusting) in areas where extreme

temperatures are prevalent, store cylinders in the shade.

8. The valve protection cap should be left on each cylinder

until cylinder has been secured against a wall or bench, or

placed in a cylinder stand and is ready for use.

9. Avoid dragging, rolling or sliding cylinders even for a short

distance. Move cylinders by using a suitable hand truck.

10. Never tamper with safety devices in valves or cylinders.

11. Do not store full and empty cylinders together. Serious

suck-back can occur when an empty cylinder is attached to a

pressurized system.

12. No part of a cylinder should be subjected to a temperature

higher than 52°C (125°F). Do not permit flame to come in

contact with any part of a compressed gas cylinder.

Teledyne Analytical Instruments 12

Page 25

Trace Nitrogen in Argon Analyzer Operational Theory

Operational Theory

2.1 The Analyzer

The Model 2120XL Trace Nitrogen in Argon Gas Analyzer is a

rack mounting self-contained unit for measuring trace amounts of

nitrogen in an argon gas stream.

A customer supplied sample system directs a stream of refined

argon to the instrument at a pressure between 4 and 20 psig (14-138

kPa). The process stream enters at a constant flow rate and passes

through a flow module containing a flow control valve and a mass flow

transducer. A gas conditioning unit is installed to remove particulates

from the incoming gas sample.

The gas is then fed to a quartz analytical cell where it is ionized in a

plasma discharge. The high energy within the plasma results in constant

collisions of ions and electrons and yields a characteristic emission

spectra intimately associated with the gas comprising the plasma.

The specific line energy is identified for nitrogen and a custom

blocking filter is selectively chosen and installed at the factory which is

tuned to remove all but the narrow energy associated with the nitrogen

emission peak. The light energy passing through the filter is focused on

a photon detector also tuned to respond to that wavelength. This

instrument can only be used for analyzing nitrogen in argon.

The photodetector produces a signal which is integrated and then

amplified. The resulting signal is digitized and processed by a

microprocessor and signal processing circuit. The results are displayed

on the instrument display as parts per million (ppm). An additional

digital to analog circuit transforms the signal back to analog form and

produces an output signal, typically 4-20 mA DC that is proportional to

the nitrogen concentration on the selected range.

The microprocessor circuit accepts input from the mass flow

transducer as well as the user interface. The analyzer software interprets

operator key presses and initiates the appropriate action as well as

sending signals to the displays for prompting the user for input or data

display.

Teledyne Analytical Instruments 13

Page 26

Operational Theory Model 2120XL

After analysis, the gas is returned to the gas flow module. A signal

is produced in the flow transducer that is used by the microprocessor to

control the flow control valve. From the flow control module, the gas

exits the analyzer at atmospheric pressure.

The superior accuracy of the Model 2120XL is achieved through

enhanced coupling of the plasma to the process and an advanced plasma

generator design. Through proper frequency and intensity control a

uniform, precisely located, and highly stable plasma discharge is

produced with minimum heat generation. The resulting emission spectra

is clear and distinct.

The Model 2120XL is fitted with custom optical filtering and an

optics system that is specifically designed to reduce interference. The

desired spectral line used for analysis is sharp and focused on the

detector.

The detector lifetime is enhanced using a “Duty Cycle Controlled

System” by reducing the coating inside the cell. This also results in an

increase in sensitivity.

2.2 Sample System

A suitable external sample system must be provided by the

customer. The external sample system delivers calibration or sample gas

to the analyzer at a suitable pressure.

The sample system may contain a molecular sieve type trap to

reduce moisture levels in the sample gas. Moisture produces a wellknown interference line in the spectrum close to that of nitrogen. It is

necessary to use moisture-free sample gas or install an efficient moisture

trap on the inlet.

Internally the Model 2120XL employs a flow control valve which

provides proper flow through the analyzer when the inlet pressure is

maintained between 4 to 20 psig. The proper flow rate should be

maintained around 100 ccm.

Teledyne Analytical Instruments 14

Page 27

Trace Nitrogen in Argon Analyzer Operational Theory

CAUTION: IT IS THE RESPONSIBILITY OF THE END USER TO

PROVIDE A SUITABLE SAMPLE SYSTEM CAPABLE OF

DELIVERING CLEAN, PARTICULATE-FREE ARGON

THAT IS AIR AND MOISTURE FREE.

EQUIPMENT DAMAGE MAY RESULT IF THE

ANALYTICAL CELL IN THIS UNIT IS EXPOSED TO

PRESSURE, CAUSING IT TO BREAK OR SHATTER.

TO PREVENT THIS, NEVER EXCEED 20 PSIG (138

KPA) ON THE INPUT PORT AND ALWAYS MAINTAIN

THE VENT AT ATMOSPHERIC PRESSURE.

DO NOT BLOCK THE VENT.

The external sample system should be capable of supplying clean,

particulate-free and moisture-free sample gas that is also free of air and

moisture. If air or moisture is ionized in the analytical cell, ozone

emissions are possible. These same conditions apply to any calibration

gases used.

Section 3.6.1 provides more information on a suitable sample

system.

If air enters the sample system, it can be removed by purging the

sample lines. Recalibration is not necessary.

Teledyne Analytical Instruments 15

Page 28

Operational Theory Model 2120XL

Teledyne Analytical Instruments 16

Page 29

Trace Nitrogen in Argon Analyzer Installation

Installation

Installation of the Model 2120XL Trace Nitrogen in Argon

Analyzer can involve potentially hazardous procedures.

CAUTION: INSTALLATION SHOULD BE PERFORMED ONLY BY

TRAINED AND QUALIFIED PERSONNEL WHO HAVE

READ AND UNDERSTOOD THE INSTRUCTIONS IN

THIS MANUAL.

Installation of the Model 2120XL Trace Nitrogen in Argon

Analyzer includes:

Unpacking

Choosing an Appropriate Location

Mounting

Electrical connections

Gas connections

Purging

Calibration

3.1 Unpacking the Instrument

The analyzer is shipped with all the materials you need to install

and prepare the system for operation. Carefully remove the analyzer from

the shipping container and visually inspect it for damage. Maintain it in an

upright position and avoid jarring. Ensure the power cord and calibration

data sheets are included and that all components ordered have been

supplied. Remove any plugs that may be installed on the gas tube fittings

on the rear panel.

If any items are missing or the analyzer appears damaged,

immediately report any damage to the shipping agent and notify

Teledyne. Remove and discard caps from fittings; inspect the analyzer

for loose fittings or connections.

Teledyne Analytical Instruments 17

Page 30

Installation Model 2120XL

3.2 Choosing a Location

Locate the Model 2120XL in a clean area free of:

Excessive dust

Mechanical vibrations

Strong electric or electromagnetic fields

Corrosive gases

Moisture exceeding 90% relative humidity

The use of walkie-talkies or cellular phones

Choose a location where sudden temperature changes in excess of

5°F (5°C) do not occur and where the temperature does not exceed the

specified ambient temperature range. Avoid any location where the

instrument would be exposed to direct sunlight or radiation from heaters.

CAUTION: THIS ANALYZER IS DESIGNED FOR USE IN A

GENERAL PURPOSE AREA AND IS NOT RATED

FOR USE IN HAZARDOUS AREAS.

3.3 Mounting

The Model 2120XL is a rack mountable unit intended for indoor

use only. Space and materials required for mounting are:

8-3/4-inches (22.2 cm) of 19-inch rack space.

Service access space behind and in front of the analyzer.

Four mounting screws suited to the rack.

All operator controls are mounted on the control panel, which is

hinged on the left edge and doubles as the door that provides access to

components inside the controller module. The door latch is spring

loaded and will swing open when the button in the center of the latch

(upper right corner) is pressed all the way in with a narrow gauge tool

(less than 0.18 inch wide). Allow clearance for the door to open in a

90-degree arc of radius 7.125 inches. See Figure 3-1.

Teledyne Analytical Instruments 18

Page 31

Trace Nitrogen in Argon Analyzer Installation

Figure 3-1: Required Front Door Clearance

3.4 Rear Panel Connections

Figure 3-2 shows the Model 2120XL rear panel. Up to 7 gas inlet

and outlet ports are installed depending on whether the unit is supplied

with an optional auto calibration module. In addition, the rear panel has

provisions for power, communication, and a user interface connector

that incorporates alarm, analog output, digital input/output, and relay

connections that are used in interfacing peripheral equipment with the

analyzer.

Figure 3-2: Rear Panel of the Model 2120XL

Teledyne Analytical Instruments 19

Page 32

Installation Model 2120XL

3.5 Electrical Connections

Electrical Connections are made at the rear of the instrument. See

Figure 3-2.

For safe connections, no uninsulated wiring should be able to come

in contact with fingers, tools or clothing during normal operation.

CAUTION: USE SHIELDED CABLES. ALSO, USE PLUGS THAT

PROVIDE EXCELLENT EMI/RFI PROTECTION. THE

PLUG CASE MUST BE CONNECTED TO THE CABLE

SHIELD, AND IT MUST BE TIGHTLY FASTENED TO

THE ANALYZER WITH ITS FASTENING SCREWS.

ULTIMATELY, IT IS THE INSTALLER WHO ENSURES

THAT THE CONNECTIONS PROVIDE ADEQUATE

EMI/RFI SIELDING.

3.5.1 Primary Input Power

The power cord receptacle and fuse block are located in the same

assembly. Insert the power cord into the power cord receptacle.

CAUTION: POWER IS APPLIED TO THE INSTRUMENT'S

CIRCUITRY AS LONG AS THE INSTRUMENT IS

CONNECTED TO THE POWER SOURCE.

THESTANDBY SWITCH ON THE FRONT PANEL IS

FOR SWITCHING POWER ON OR OFF TO THE

DISPLAYS AND OUTPUTS ONLY.

The universal power supply requires an 85–250 VAC, 47-63 Hz

power source.

Fuse Installation: The fuse block, at the right of the power cord

receptacle, accepts US or European size fuses. A jumper replaces the

fuse in whichever fuse receptacle is not used. Fuses are not installed at

the factory. Be sure to install the proper fuse as part of installation. (See

Fuse Replacement in Chapter 5, Maintenance.)

3.5.2 50-Pin Equipment Interface Connector

Figure 3-3 shows the pin layout of the Equipment Interface

Connector. The arrangement is shown as seen when the viewer faces the

rear panel of the analyzer. The pin numbers for each input/output

function are given where each function is described in the paragraphs

below.

Teledyne Analytical Instruments 20

Page 33

Trace Nitrogen in Argon Analyzer Installation

Figure 3-3: Equipment Interface Connector Pin Arrangement

Analog Outputs: There are four DC output signal pins—two pins per

output. For polarity, see Table 3-1. The outputs are:

0–1 VDC % of Range: Voltage rises linearly with increasing

oxygen, from 0 V at 0 ppm to 1 V at

full scale ppm. (Full scale = 100% of

programmable range.)

0–1 VDC Range ID: 0.25 V = Low Range, 0.5 V = Medium

Range, 0.75 V = High Range, 1 V =

100ppm.

4–20 mA DC % Range: Current increases linearly with

increasing oxygen, from 4 mA at 0

ppm to 20 mA at full scale ppm. (Full

scale = 100% of programmable range.)

4–20 mA dc Range ID: 8 mA = Low Range, 12 mA = Medium

Range, 16 mA = High Range, 20 mA

= 100ppm.

Table 3-1: Analog Output Connections

Pin Function

3 + Range ID, 4-20 mA, floating

4 – Range ID, 4-20 mA, floating

5 + % Range, 4-20 mA, floating

6 – % Range, 4-20 mA, floating

8 + Range ID, 0-1 V dc

23 – Range ID, 0-1 V dc, negative ground

24 + % Range, 0-1 V dc

7 – % Range, 0-1 V dc, negative ground

Teledyne Analytical Instruments 21

Page 34

Installation Model 2120XL

Alarm Relays: The nine alarm-circuit connector pins connect to the

internal alarm relay contacts. Each set of three pins provides one set of

Form C relay contacts. Each relay has both normally open and normally

closed contact connections. The contact connections are shown in Table

3-2. They are capable of switching up to 3 amperes at 250 VAC into a

resistive load. The connectors are:

Threshold Alarm 1:

Can be configured as high (actuates when concentration is

above threshold), or low (actuates when concentration is

below threshold).

Can be configured as failsafe or non-failsafe.

Can be configured as latching or non-latching.

Can be configured out (defeated).

Threshold Alarm 2:

Can be configured as high (actuates when concentration is

above threshold), or low (actuates when concentration is

below threshold).

Can be configured as failsafe or non-failsafe.

Can be configured as latching or non-latching.

Can be configured out (defeated).

Table 3-2: Alarm Relay Contact Pins

Pin Contact

45 Threshold Alarm 1, normally closed contact

28 Threshold Alarm 1, moving contact

46 Threshold Alarm 1, normally open contact

42 Threshold Alarm 2, normally closed contact

44 Threshold Alarm 2, moving contact

43 Threshold Alarm 2, normally open contact

36 System Alarm, normally closed contact

20 System Alarm, moving contact

37 System Alarm, normally open contact

Teledyne Analytical Instruments 22

Page 35

Trace Nitrogen in Argon Analyzer Installation

Digital Remote Cal Inputs: Accept 0 V (off) or 24 VDC (on) inputs for

remote control of calibration. (See Remote Calibration Protocol below.)

See Table 3-3 for pin connections.

Zero: Floating input. 5 to 24 V input across the + and – pins

puts the analyzer into the Zero mode. Either side may be

grounded at the source of the signal. 0 to 1 volt across

the terminals allows Zero mode to terminate when done.

A synchronous signal must open and close the external

zero valve appropriately. See Remote Probe Connector.

Span: Floating input. 5 to 24 V input across the + and – pins

puts the analyzer into the Span mode. Either side may be

grounded at the source of the signal. 0 to 1 volt across

the terminals allows Span mode to terminate when done.

A synchronous signal must open and close external span

valve appropriately. See Figure 3-4 Remote Valve

Connections.

Cal Contact: This relay contact is closed while analyzer is spanning

and/or zeroing. (See Remote Calibration Protocol below.)

Table 3-3: Remote Calibration Connections

Pin Function

9 + Remote Zero

11 – Remote Zero

10 + Remote Span

12 – Remote Span

40 Cal Contact

41 Cal Contact

Remote Calibration Protocol: To properly time the Digital Remote Cal

Inputs to the Model 2120XL Analyzer, the customer's controller must

monitor the Cal Relay Contact.

When the contact is OPEN, the analyzer is analyzing, the Remote

Cal Inputs are being polled, and a zero or span command can be sent.

Teledyne Analytical Instruments 23

Page 36

Installation Model 2120XL

When the contact is CLOSED, the analyzer is already calibrating. It

will ignore your request to calibrate, and it will not remember that

request.

Once a zero or span command is sent, and acknowledged (contact

closes), release it. If the command is continued until after the zero or

span is complete, the calibration will repeat and the Cal Relay Contact

(CRC) will close again.

For example:

1. Test the CRC. When the CRC is open, Send a zero command

until the CRC closes (The CRC will quickly close.)

2. When the CRC closes, remove the zero command.

3. When CRC opens again, send a span command until the

CRC closes. (The CRC will quickly close.)

4. When the CRC closes, remove the span command.

When CRC opens again, zero and span are done, and the sample is

being analyzed.

Note: The Remote Valve connections (described below) provides

signals to ensure that the zero and span gas valves will be

controlled synchronously. If you have the Auto Caibration

Option, it includes additional zero and span gas inputs—

the 2120XL automatically regulates the zero, span and

sample gas flow.

Range ID Relays: Four dedicated Range ID relay contacts. The first

three ranges are assigned to relays in ascending order—Low range is

assigned to Range 1 ID, Medium range is assigned to Range 2 ID, and

High range is assigned to Range 3 ID. The fourth range is reserved for

the Cal Range. Table 3-4 lists the pin connections.

Table 3-4: Range ID Relay Connections

Pin Function

21 Range 1 ID Contact

38 Range 1 ID Contact

22 Range 2 ID Contact

39 Range 2 ID Contact

19 Range 3 ID Contact

Teledyne Analytical Instruments 24

Page 37

Trace Nitrogen in Argon Analyzer Installation

18 Range 3 ID Contact

34 Range 4 ID Contact (not used)

35 Range 4 ID Contact (not used)

Network I/O: A serial digital input/output for local network protocol.

At this printing, this port is not yet functional. It is to be used for future

options to the instrument. Pins 13 (+) and 29 (–).

Remote Valve Connections: The Model 2120XL is a single-chassis

instrument and does not have a Remote Probe. Instead, the Remote

Probe connections are used as a method for directly controlling external

sample/zero/span gas valves. See Figure 3-4.

Figure 3-4: Remote Valve Connections

The voltage from these outputs is nominally 0 V for the OFF and

15 VDC for the ON conditions. The maximum combined current that

can be pulled from these output lines is 100 mA. (If two lines are ON at

the same time, each must be limited to 50 mA, etc.) If more current

and/or a different voltage is required, use a relay, power amplifier, or

other matching circuitry to provide the actual driving current.

In addition, each individual line has a series FET with a nominal

ON resistance of 5 ohms (9 ohms worst case). This can limit the

obtainable voltage, depending on the load impedance applied. See

Figure 3-5.

Teledyne Analytical Instruments 25

Page 38

Installation Model 2120XL

Figure 3-5: FET Series Resistance

3.5.3 RS-232 Port

The digital signal output is a standard, full duplex RS-232 serial

communications port used to connect the analyzer to a computer,

terminal, or other digital device. It requires a standard 9-pin D

connector.

The output data is status information, in digital form, updated every

two seconds. Status is reported in the following order:

The concentration in ppm or percent

The range in use (HI, MED, LO)

The span of the range (0-100 ppm, etc)

Which alarms—if any—are disabled (AL–x DISABLED)

Which alarms—if any—are tripped (AL–x ON).

Each status output is followed by a carriage return and line feed.

Three input functions using RS-232 have been implemented to

date. They are described in Table 3-5.

Table 3-5: Commands via RS-232 Input

Command Description

as<enter> Immediately starts an autospan.

Teledyne Analytical Instruments 26

Page 39

Trace Nitrogen in Argon Analyzer Installation

az<enter> Immediately starts an autozero.

st<enter> Toggling input. Stops/Starts any

status message output from the

RS-232, until st<enter> is sent

again.

The RS-232 protocol allows some flexibility in its implementation.

Table 3-6 lists certain RS-232 values that are required by the Model

2120XL implementation.

Table 3-6: Required RS-232 Options

Parameter Setting

Baud 9600

Byte 8 bits

Parity none

Stop Bits 1

Message Interval 2 seconds. When CRC opens

again, zero and span are done,

and the sample is being analyzed.

3.6 Gas Connections

CAUTION: THIS INSTRUMENT IS NOT DESIGNED TO HANDLE

HAZARDOUS GASES.

OZONE EMISSIONS CAN OCCUR IF AIR OR

MOISTURE ARE IONIZED IN THE SAMPLING

SYSTEM. THE SAMPLE PATH MUST BE

RELATIVELY FREE OF AIR AND/OR MOISTURE

BEFORE APPLYING THE IONIZING VOLTAGE.

KEEP THE MODEL 2120XL POWER OFF AND PURGE

THE EXTERNAL TUBING. THEN APPLY POWER TO

PURGE THE INTERNAL LINES. ANALYZER POWER

IS NEEDED TO PURGE ANALYZER SINCE THE

FLOW CONTROL MODULE NEEDS POWER TO

OPERATE. MAKE SURE THAT THE VENT IS AT

ATMOSPHERIC PRESSURE.

Teledyne Analytical Instruments 27

Page 40

Installation Model 2120XL

Note: Air leaking into the sampling system will cause erratic or

unsatisfactory analyzer operation. Even if air is admitted

into the system for only a few minutes, you must purge the

regulator and the system for at least 1 hour before the

readings stabilize. See Section 3.7.

Whenever a fitting on the sample system is opened, use a

new ferrule and cone or new gasket depending on the type

of fitting to secure a gas tight seal. Each fitting should be

leak checked whenever a connection has been opened or

disturbed in any manner.

All gas connections are made to the 1/8” tube fittings installed on

the rear panel. See Figure 3-2. The connections include:

Sample Gas In

Exhaust Gas Out (Vent)

Instrument Air (optional calibration valves)

Purge Gas (optional calibration valves)

Span Gas In (optional calibration valves)

Zero Gas In (optional calibration valves)

CAUTION: EQUIPMENT DAMAGE MAY RESULT IF THE

ANALYTICAL CELL IN THIS UNIT IS EXPOSED TO

PRESSURE, CAUSING IT TO BREAK OR SHATTER.

TO PREVENT THIS, NEVER EXCEED 20 PSIG (138

KPA) ON THE INLET PORT AND ALWAYS MAINTAIN

THE VENT AT ATMOSPHERIC PRESSURE.

DO NOT BLOCK THE VENT. ANY BACKPRESSURE

ON THE VENT WILL CAUSE DAMAGE TO THE

ANALYTICAL CELL.

To connect the gas line:

1. Connect an unobstructed vent line to the 1/8” (0.32 cm)

Swagelok fitting on the vent port on the rear of the analyzer.

2. Connect the purge gas input to the analyzer at the Purge Inlet.

3. On units equipped with the optional calibration valve,

connect a source of instrument air to the unit. The air supply

must be regulated to 65-70 psig.

Teledyne Analytical Instruments 28

Page 41

Trace Nitrogen in Argon Analyzer Installation

CAUTION: AIR PRESSURE LESS THAN 65 PSIG WILL RESULT

IN A FLOW RESTRICTION.

4. Connect the span and zero lines to the rear panel fittings

supplied for this purpose. The span and zero gas inputs must

be pressure regulated to the same pressure as the sample gas

(4-20 psig).

Note: If this instrument is without the auto calibration option,

there will be no rear panel fittings for zero and span

gases. The customer must install a suitable valve switching

manifold or tee the calibration gases with valves into the

sample in line.

3.6.1 Typical Sample System

A suggested sample system is shown in Figure 3-6. This system

allows you to switch the analyzer between zero or span calibration

gases and the process gas streams quickly and efficiently without

disconnecting the analyzer and introducing air in the system.

Figure 3-6: Suggested Sample System

Teledyne Analytical Instruments 29

Page 42

Installation Model 2120XL

The sample manifold system must be designed so that you can:

Purge the sample line and pre-adjust the flow rate before

admitting a sample to the analytical cell.

Maintain a flow of argon through the analytical cell

whenever ionization voltage is being applied.

The following guidelines are presented as an aid in constructing a

suitable external sampling system for the Model 2120XL:

Alter the geometry of the system in Figure 3-2, as necessary,

to suit your specific needs and to maintain access to items on

the rear panel. However, alterations should be adhered to

schematically.

Use 1/8-inch (0.32 cm) electro-polished stainless steel tubing

for all parts of the manifold between the source and sample

inlet connections of the analyzer. Although you can use 1/4inch (0.64 cm) tubing, it is not recommended. The manifold

should be a welded assembly wherever possible.

Use only high-purity components with metal seals.

Eliminate excess components.

Minimize "dead spaces" in the sample lines.

Use a 1/8 inch compression fitting for the analyzer inlet

connection.

Use a high-quality regulator or device to maintain a constant

pressure to the zero, sample, and span inlet lines. Teledyne

recommends using a high-purity regulator with the following

specifications:

2-stage tiered diaphragm

100 psi outlet

15 RA max

5 ports

CGA 580 welded on inlet side

1/8 M (1 port), 1/8 F (1 port)

2 gauges

Teledyne Analytical Instruments 30

Page 43

Trace Nitrogen in Argon Analyzer Installation

3.6.2 Gas Connections to the Instrument

CAUTION: EQUIPMENT DAMAGE MAY RESULT IF THE

ANALYTICAL CELL IN THIS UNIT IS EXPOSED TO

PRESSURE ABOVE ATMOSPHERIC, CAUSING IT TO

BREAK OR SHATTER. TO PREVENT THIS, NEVER

EXCEED 20 PSIG (138 KPA) ON THE INLET PORT.

ALWAYS ENSURE THAT THE VENT IS AT

ATMOSPHERIC PRESSURE.

DO NOT REMOVE THE FLOW CONTROL ORIFICE

FROM THE SAMPLE INLET OF THE ANALYZER.

DO NOT BLOCK THE VENT.

To connect the gas line:

1. Connect an unobstructed vent line to the 1/8-in Swagelok

fitting on the vent port on the rear of the analyzer.

2. Connect the inlet line from the sample manifold system,

regulated to 4 to 20 psig (41 kPa), to the 1/8-in Input port

fitting on the rear of the analyzer.

3.7 Purging

The Model 2120XL is equipped with a flow control module

installed in the analyzer sample inlet to regulate flow and pressure to the

analytical cell. A maximum inlet pressure of 20 psig (138 kPa) is

allowable.

CAUTION: OZONE EMISSIONS ARE POSSIBLE IF AIR OR

MOISTURE IS IONIZED IN THE SAMPLING SYSTEM.

THE SAMPLE PATH MUST BE RELATIVELY FREE

OF AIR AND/OR MOISTURE BEFORE APPLYING THE

IONIZING VOLTAGE.

KEEP THE MODEL 2120XL POWER OFF AND PURGE

THE EXTERNAL TUBING. THEN APPLY POWER TO

PURGE THE INTERNAL LINES. ANALYZER POWER

IS NEEDED TO PURGE ANALYZER SINCE THE

FLOW CONTROL MODULE NEEDS POWER TO

OPERATE.

Teledyne Analytical Instruments 31

Page 44

Installation Model 2120XL

When installing a new analyzer or starting up an analyzer that has

been idle for a period of time, the sampling system should be purged for

several hours to cleanse it of contaminants and water vapor.

Although high-purity sample gas may be used to purge the

analyzer, argon with a minimum purity of 99.999% is recommended.

The exact purge method depends on the sample manifold design

and construction. In general, each sample inlet line must be thoroughly

purged. Sufficient purge time becomes critical when sample lines longer

than 10 feet (3 m) are used.

To purge the analyzer (see Figure 3-2):

Note: Do not purge long lines through the analytical cell. First,

purge them through the purge flow rotameter; then transfer

flow to the analyzer cell as suggest ed in step 6, below. This

eliminates the possibility of contaminating the analytical cell

and having to purge for an extended period to reach

equilibrium.

1. Close all valves on the sample manifold.

2. Open the valve on sample inlet line to be purged and any

shut-off valve that may be installed.

3. Connect purge gas to the sample inlet line.

4. Use a flowmeter on the purge gas and adjust flow rate to 1

cfh (0.475 slpm) at no more than 7 psig (76 kPa) and purge

for at least one hour.

5. Close the sample inlet valve, and then repeat steps 2 through

4 to purge any other sample inlet lines.

6. After the last sample line and the zero and span gas inlet

lines have been purged, close the purge flowmeter valve,

open the valve controlling flow through the analytical cell,

and purge the analyzer with the sample flow set at 1 cfh

(0.475 slpm). Purge the analyzer for a minimum of 6

hours.

7. If cylinder argon is used as a purge gas, reconnect the

sample gas to sample manifold inlet.

8. After purging, a calibration should be performed.

Teledyne Analytical Instruments 32

Page 45

Trace Nitrogen in Argon Analyzer Installation

3.8 Calibration

The Model 2120XL was calibrated at the factory in accordance

with the calibration data shipped with your instrument. Prior to using the

instrument for analysis the calibration must be checked using the factory

settings supplied. If the settings do not match, the instrument should be

recalibrated prior to using for the first time.

Calibration procedures require an understanding of how to operate

the instrument which is discussed in Section 4 of this manual. Refer to

Section 4.5.2 for calibration procedures after reading the entire section

on operating the instrument (Section 4).

3.9 Installation Checklist

After installing the system, and prior to powering up the system,

verify the following items:

1. Each gas line has been purged for at least 1 hour prior to

connection to the analyzer inlets.

2. There are no leaks at the sample inlet gas connection to the

instrument.

3. There are no leaks between the span gas cylinder and the

analyzer span gas inlet port when span gas is flowing to the

analyzer.

4. There are no leaks between the zero gas source and the

analyzer zero gas inlet port when zero gas is flowing to the

analyzer.

5. The vent tube connection has no leaks, has an

unobstructed path to atmosphere, and is at least 1/8-in

(0.32-cm) OD.

6. All electrical connections have been made properly and the

Power Entry module is set for the appropriate power from

your facility.

Teledyne Analytical Instruments 33

Page 46

Installation Model 2120XL

Teledyne Analytical Instruments 34

Page 47

Trace Nitrogen in Argon Analyzer Operation

Operation

This section describes the operation and calibration procedures for

the Model 2120XL Trace Nitrogen in Argon Analyzer. Operation of the

analyzer involves potentially hazardous procedures. Only trained and

qualified personnel who have read and understood the instructions in

this manual should operate this equipment.

CAUTION: DO NOT OPERATE THIS ANALYZER UNTIL YOU

HAVE READ AND UNDERSTOOD THE

INSTRUCTIONS IN THIS MANUAL. PAY

PARTICULAR ATTENTION TO ALL CAUTIONS AND

WARNINGS.

NEVER INTRODUCE GASES OTHER THAN ARGON

INTO THE ANALYZER IF EXPLOSIVE, FLAMMABLE,

OR CORROSIVE GASES OR GAS MIXTURES ARE

ALLOWED TO FLOW INTO THE ANALYZER, FIRE OR

EXPLOSION CAN RESULT.

THIS ANALYZER IS NOT DESIGNED FOR USE IN

HAZARDOUS AREAS.

EQUIPMENT DAMAGE MAY RESULT IF THE

ANALYTICAL CELL IN THIS UNIT IS EXPOSED TO

PRESSURE, CAUSING IT TO BREAK OR SHATTER.

TO PREVENT THIS, NEVER EXCEED 20 PSIG (38

KPA) ON THE INLET PORT AN D ALWAYS MAINTAIN

THE VENT AT ATMOSPHERIC PRESSURE.

DO NOT REMOVE THE FLOW CONTROL ORIFICE

FROM THE SAMPLE INLET OF THE ANALYZER.

DO NOT BLOCK VENT.

Note: Maintain flow of sample gas through the analyzer when it is

not in use. This procedure is highly recommended in areas

of high humidity. Take care to keep the inside of the

instrument dry.

Teledyne Analytical Instruments 35

Page 48

Operation Model 2120XL

4.1 Powering Up the Analyzer

CAUTION: OZONE EMISSIONS ARE POSSIBLE IF AIR OR

MOISTURE ARE IONIZED IN THE SAMPLING

SYSTEM. THE SAMPLE PATH MUST BE

RELATIVELY FREE OF AIR AND/OR MOISTURE

BEFORE APPLYING THE IONIZING VOLTAGE.

KEEP THE POWER OFF UNTIL THE ANALYZER IS

FULLY PURGED.

1. Purge the analyzer and sampling system using the procedure

described in Section 3.7.

2. Connect the power cord to the proper power source for your

analyzer. The analyzer will begin its power up sequence

CAUTION: EQUIPMENT DAMAGE MAY RESULT IF THE

ANALYTICAL CELL IN THIS UNIT IS EXPOSED TO

EXCESSIVE PRESSURE, CAUSING IT TO BREAK OR

SHATTER.

3. Observe the display while allowing the instrument to warm

up and the readings stabilize. Drift occurs until internal

temperatures stabilize and the analytical cell is completely

purged. A persistent drift indicates an improperly purged

system or an air leak into the system.

4.2 Zero and Span Calibration

The Model 2120XL is designed to provide a linear response over

the 0-100 ppm concentration range for nitrogen in argon. Therefore, a

two-point (zero and span) calibration is sufficient to define the

calibration curve for this analyzer.

Prior to shipment, the analyzer was calibrated and linearized at the

factory in accordance with the calibration data shipped with your

analyzer. Use these settings to verify that the unit is in calibration, or recalibrate the analyzer as outlined in Section 4.5.2. Recalibrations are

required periodically. The user can also redefine the linearization curve

for this instrument. Refer to Section 4.5.1.12.

Teledyne Analytical Instruments 36

Page 49

Trace Nitrogen in Argon Analyzer Operation

4.3 Setup and Operation General Information

Once the analyzer has been installed, it can be configured for your

application. To do this you will:

Set system parameters:

Establish a security password, if desired, requiring

Operator to log in.

Establish and start an automatic calibration cycle, if

desired.

Calibrate the instrument.

Define the three user selectable analysis ranges. Then choose

auto ranging or select a fixed range of analysis, as required.

Set alarm setpoints, and modes of alarm operation (latching,

failsafe, etc).

Before you configure your Model 2120XL Analyzer these default

values are in effect:

Ranges: LO = 1 ppm, MED = 10 ppm, HI = 100 ppm.

Auto Ranging: ON

Alarm Relays: Defeated, 100 and 200 ppb, HI, Not failsafe, Not

latching.

Zero: Auto, every 0 days at 0 hours.

Span: Auto, at 000008.00 ppm, every 0 days at 0 hours.

If you choose not to use password protection, the default password

is automatically displayed on the password screen when you start up,

and you simply press ENTER for access to all functions of the analyzer.

4.4 Using the Data Entry and Function Buttons

Data Entry Buttons: The ◄►arrow buttons select options from

the menu currently being displayed on the VFD screen. The selected

option blinks.

When the selected option includes a modifiable item, the ▲/▼

arrow buttons can be used to increment or decrement that modifiable

item.

The ENTER button is used to accept any new entries on the VFD

screen. The ESCAPE button is used to abort any new entries on the

Teledyne Analytical Instruments 37

Page 50

Operation Model 2120XL

VFD screen that are not yet accepted by use of the ENTER key or to

move backwards through previous screens.

The VFD screen text that accompanies each operation is repro-

duced, at the appropriate point in the procedure, in a Arial Narrow Bold

type style. The various operational modes are printed in CAPITALIZED

ITALICS.

Figure 4-1 shows the hierarchy of functions available to the

operator via the screen menus.

Any function can be selected at any time by pressing the

appropriate key (unless password restrictions apply).

Each of these functions is described in greater detail in the

following procedures.

4.5 Analyzer Functions

Analyzer functions are accessed from front panel keys.

There are six selectable functions plus the ENTER and ESCAPE

keys. They are:

1. Analyze: This is the main operational screen of the

analyzer and displays the current concentration plus an error

indication if any error exists.

2. System: This function contains nine sub functions that are

used to user to set up the instrument for your application.

3. Span: Contains sub functions used for span calibration.

4. Zero: Contains sub functions used for zero calibration.

5. Alarms: Contains sub functions used to configure the

concentration alarms.

6. Range: Allows the user to set the upper bound of the

instrument range.

In the following section, Section 4.5.1, each screen display is

described with information on how to access and modify the various

items within each screen.

Teledyne Analytical Instruments 38

Page 51

Trace Nitrogen in Argon Analyzer Operation

Figure 4-1: Hierarchy of Functions and Sub Functions

4.5.1 System Menu

Dig_filt Self-test

Pwd Logout Err More

.

.

Autocal Flow Hold

Calholdtimer More

.

Model Out-cal Lin

There are eleven sub functions within the System function as

described below. Specific procedures for their use follow the

descriptions.

Teledyne Analytical Instruments 39

Page 52

Operation Model 2120XL

Dig Filt: The Model 2120XL includes a user adjustable

digital filter. The filter has settings 1-10. Setting 1 is the least

amount of filtering and 10 is the highest level of damping.

Self–Test: The instrument performs a self-diagnostic test to

check the integrity of the power supply, output boards and

amplifiers.

PSWD: Security can be established by choosing a 5 digit

password (PSWD) from the standard ASCII character set.

(See Installing or Changing a Password, below, for a table of

ASCII characters available.)

Logout: Logging out prevents an unauthorized tampering

with analyzer settings.

More: Select and enter More to get a new screen with

additional sub functions listed.

Auto-Cal: Used to define an automatic calibration sequence

and/or start an Auto-Cal.

Flow: Used to set the flow through the flow controller.

TRAK/HLD: The operator sets whether the instrument

analog outputs track the concentration change during

calibration and sets a time delay for the concentration alarms

after calibration

Cal Hold Timer: Allows alarm suppression and analog

output value hold times during calibration events for a user

adjustable period.

Model: Displays Manufacturer, Model, and Software

Version of the instrument.

Out-Cal: Analog output calibration allows the user to

calibrate the 4 and 20 mA analog output values.

Lin: Used to linearize the output of the controller.

To enter any of the system functions, use the ◄►arrow keys to

move to the function and then use the ENTER key to engage that

function.

4.5.1.1 DIGITAL FILTER

Upon entering the digital filter function, the following screen

appears on the display:

Teledyne Analytical Instruments 40

Page 53

Trace Nitrogen in Argon Analyzer Operation

Weight of Digital

Filter: 4

The current filter setting (4 in this case) will be flashing. It can be

modified from 0 (no filtering) to 10 maximum filtering using the ▲/▼

keys. Pressing ENTER will accept the value and return to the SYSTEM

menu.

The default setting should suffice for most applications. In some

applications where speeding the response time with some trade off in

noise is of value, the operator could decrease the number of the digital

filter. In applications where the signal is noisy, switch to a higher

number, however, the response time will decrease.

4.5.1.2 SELF-TEST

The system self-test is automatically initiated when the unit is

powered up. It can also be activated by the user from the SYSTEM menu.

To manually initiate a self-test, press the STSTEM key and navigate to

Self-Test using the ◄►arrow keys. Press ENTER to engage the

function and the following screen appears:

Perform System Test?

<ENT> Yes <ESC> No

Pressing ENTER will begin the Self-Test. A successions of

diagnostic screens will follow:

RUNNING DIAGNOSTIC

Testing Preamp — 83

During preamp testing there is a countdown in the lower right

corner of the screen. When the testing is complete, the results are

displayed.

Power: ## Analog: ##

Preamp: ##

The module is functioning properly if it is followed by OK. If a

problem is detected, a number will appear next to the heading and

Teledyne Analytical Instruments 41

Page 54

Operation Model 2120XL

indicates a problem in a specific area of the instrument. Refer to Chapter

5 Maintenance and Troubleshooting for number-code information. The

results screen alternates for a time with:

Press Any Key

To Continue...

Then the analyzer returns to the initial System screen.

4.5.1.3 PASSWORD PROTECTION

Security can be established by choosing a 3 digit password (PSWD)

from the standard ASCII character set. (See Installing or Changing a

Password, below, for a table of ASCII characters available.)

Once a unique password is assigned and activated, the operator

MUST enter the UNIQUE password to gain access to set-up functions

which alter the instrument's operation, such as setting the instrument

span or zero setting, adjusting the alarm setpoints, or defining an

analysis range.

After a password is assigned, the operator must log out to activate

it. Until then, anyone can continue to operate the instrument without

entering the new password.

Only one password can be defined. Before a unique password is

assigned, the system assigns TAI by default. This allows access to

anyone. After a unique password is assigned, to defeat the security, the

password must be changed back to TAI.

If a password is assigned, then setting the following instrument

parameters can be done only after the password is entered: span and

zero settings, alarm setpoints, analysis range definitions, switching

between auto ranging and manual override. In addition, all System

functions such as setting up an auto-cal, self-test and assigning a new

password etc. with the exception of Track/Hold and Model cannot be

accessed without entering a password. However, the instrument can still

be used for analysis without entering the password.

If you have decided not to employ password security, use the

default password TAI. This password will be displayed automatically by

Teledyne Analytical Instruments 42

Page 55

Trace Nitrogen in Argon Analyzer Operation

the microprocessor. The operator just presses the Enter key to be

allowed total access to the instrument’s features.

Note: If you use password security, it is advisable to keep a copy

of the password in a separate, safe location.

4.5.1.3.1 Entering the Password