Teledyne 2105, ISCO 2105, ISCO 2105Ci Installation And Operation Manual

2105/2105Ci

Part #69-2003-635 of Assembly #60-2004-635

Copyright © 2011. All rights reserved, Teledyne Isco

Revision A, April 6, 2012

Interface Module

Installation and Operation Guide

Foreword

This instruction manual is designed to help you gain a thorough understanding of the

operation of the equipment. Teledyne Isco recommends that you read this manual

completely before placing the equipment in service.

Although Teledyne Isco designs reliability into all equipment, there is always the possibility of a malfunction. This manual may help in diagnosing and repairing the malfunction.

If the problem persists, call or e-mail the Teledyne Isco Technical Service Department

for assistance. Simple difficulties can often be diagnosed over the phone.

If it is necessary to return the equipment to the factory for service, please follow the

shipping instructions provided by the Customer Service Department, including the

use of the Return Authorization Number specified. Be sure to include a note

describing the malfunction. This will aid in the prompt repair and return of the

equipment.

Teledyne Isco welcomes suggestions that would improve the information presented in

this manual or enhance the operation of the equipment itself.

Teledyne Isco is continually improving its products and reserves the right to

change product specifications, replacement parts, schematics, and instructions without notice.

Customer Service

Phone: (800) 228-4373 (USA, Canada, Mexico)

Fax: (402) 465-3022

Email: IscoCSR@teledyne.com

Technical Support

Phone: (800) 775-2965 (Analytical)

Email: IscoService@teledyne.com

Return equipment to: 4700 Superior Street, Lincoln, NE 68504-1398

Other Correspondence

Mail to: P.O. Box 82531, Lincoln, NE 68501-2531

Email: IscoInfo@teledyne.com

Web site: www.isco.com

Contact Information

(402) 464-0231 (Outside North America)

(866) 298-6174 (Samplers and Flow Meters)

Revised March 17, 2009

2105 Interface Module

Safety

2105Interface Module

Safety

General Warnings Before installing, operating, or maintaining this equipment, it is

imperative that all hazards and preventive measures are fully

understood. While specific hazards may vary according to

location and application, take heed of the following general

warnings:

WARNING

Avoid hazardous practices! If you use this instrument in

any way not specified in this manual, the protection

provided by the instrument may be impaired.

AVERTISSEMENT

Éviter les usages périlleux! Si vous utilisez cet instrument

d’une manière autre que celles qui sont specifiées dans ce

manuel, la protection fournie de l’instrument peut être

affaiblie; cela augmentera votre risque de blessure.

Hazard Severity Levels This manual applies Hazard Severity Levels to the safety alerts,

These three levels are described in the sample alerts below.

CAUTION

Cautions identify a potential hazard, which if not avoided, may

result in minor or moderate injury. This category can also warn

you of unsafe practices, or conditions that may cause property

damage.

WARNING

Warnings identify a potentially hazardous condition, which

if not avoided, could result in death or serious injury.

DANGER

DANGER – limited to the most extreme situations

to identify an imminent hazard, which if not

avoided, will result in death or serious injury.

iii

2105 Interface Module

Safety

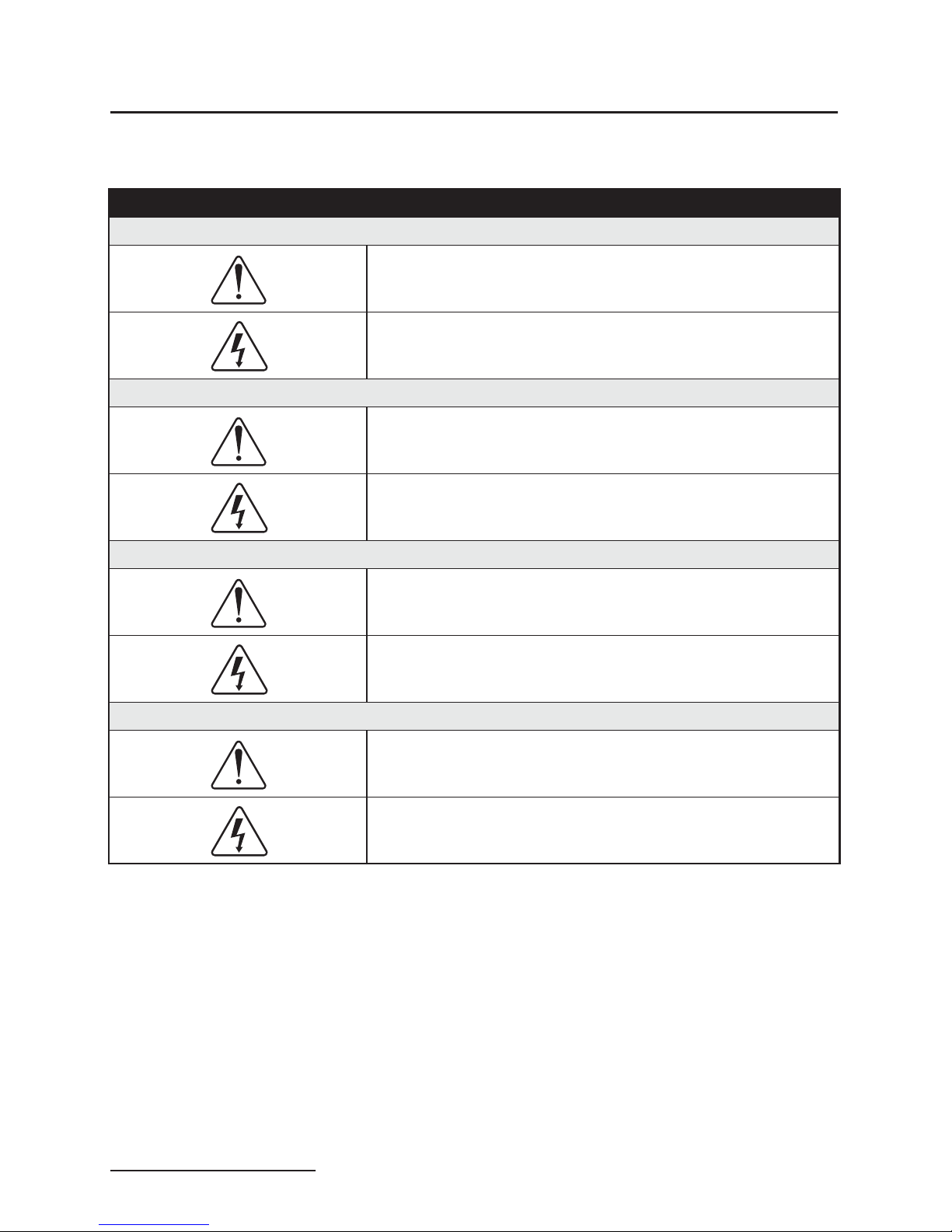

Hazard Symbols The equipment and this manual use symbols used to warn of

hazards. The symbols are explained below.

Hazard Symbols

Warnings and Cautions

The exclamation point within the triangle is a warning sign alerting you of

important instructions in the instrument’s technical reference manual.

The lightning flash and arrowhead within the triangle is a warning sign alerting you of “dangerous voltage” inside the product.

Symboles de sécurité

Ce symbole signale l’existence d’instructions importantes relatives au

produit dans ce manuel.

Ce symbole signale la présence d’un danger d’électocution.

Warnungen und Vorsichtshinweise

Advertencias y Precauciones

Das Ausrufezeichen in Dreieck ist ein Warnzeichen, das Sie darauf

aufmerksam macht, daß wichtige Anleitungen zu diesem Handbuch

gehören.

Der gepfeilte Blitz im Dreieck ist ein Warnzeichen, das Sei vor “gefährlichen

Spannungen” im Inneren des Produkts warnt.

Esta señal le advierte sobre la importancia de las instrucciones del manual

que acompañan a este producto.

Esta señal alerta sobre la presencia de alto voltaje en el interior del

producto.

iv

2105 Interface Module

Table of Contents

Section 1 Introduction

1.1 Product Description .................................................. 1-1

1.2 2105 Module Components.............................................1-2

1.3 Battery Module Components .......................................... 1-4

1.4 Technical Specifications ..............................................1-6

1.5 Safety Symbols and Hazard Alerts .....................................1-7

1.6 Technical Service....................................................1-8

Section 2 Installation and Operation

2.1 Unpacking Instructions .............................................. 2-1

2.1.1 2105Ci Label Information .......................................2-1

2.1.2 System Power .................................................2-1

2.2 Installation Preparation .............................................. 2-3

2.2.1 Latches - Locking and Unlocking .................................2-4

2.2.2 Communication Connectors .....................................2-5

2.2.3 Installing the Batteries .........................................2-6

2.3 Stacking Modules ...................................................2-8

2.4 Antenna (2105Ci Only) ...............................................2-9

2.5 Connecting to Flowlink .............................................. 2-10

2.5.1 Modem Site Connection ........................................ 2-13

2.6 Setting Up Text Messaging (2105Ci) ................................... 2-17

2.7 Power Conservation (2105Ci) .........................................2-18

2.7.1 Equation ....................................................2-20

2.8 Pushed Data Capability

(2105Ci) ..........................................................2-21

2.9 SDI-12 Input ......................................................2-22

2.10 Rain Gauge Interface ..............................................2-23

2.11 Sampler Interface .................................................2-24

2.12 Sampler “Pass Thru” Mode .......................................... 2-25

2.13 Pulse Doppler Devices.............................................. 2-29

2.14 Modbus Input .................................................... 2-30

2.14.1 4200 and 6700 Series Measured Data ...........................2-32

2.15 Cables...........................................................2-37

2.16 2105 Universal Cable 60-2004-580....................................2-38

2.16.1 Preparation ................................................ 2-38

2.16.2 2105 Connection ............................................. 2-38

Section 3 Modbus Protocol and 2100 Output

3.1 Introduction ........................................................3-1

3.2 Operation ..........................................................3-1

3.2.1 Establishing Communication ....................................3-2

3.2.2 Module Addressing ............................................3-2

3.3 Configurations ......................................................3-3

3.4 Glossary of Terms ...................................................3-4

3.5 Common Acronyms ..................................................3-5

3.6 Register Specifications - 2100 Output ................................... 3-5

v

2105 Interface Module

Table of Contents

Section 4 Maintenance

Appendix A Replacement Parts List

Appendix B Accessories

4.1 Overview ..........................................................4-1

4.1.1 Cleaning .....................................................4-1

4.2 Desiccant ..........................................................4-1

4.2.1 Replacing the Desiccant ........................................4-2

4.2.2 Reactivating the Desiccant ......................................4-2

4.3 Hydrophobic Filter ..................................................4-3

4.4 O-Rings ...........................................................4-3

4.5 How to Obtain Service ...............................................4-3

A.1 Replacement Parts Diagrams and Listings...............................A-1

A.1.1 2105 Interface Module .........................................A-2

A.1.2 2191 Battery Module ...........................................A-7

A.1.3 2105Ci Antenna ...............................................A-9

B.1 How to Order.......................................................B-1

B.2 General Accessories .................................................B-1

B.3 Cables ............................................................B-2

Appendix C Material Safety Data Sheets

List of Figures

1-1 2105 Components - Top View .........................................1-2

1-2 2105 Components - Bottom View .......................................1-3

1-3 Battery Module Components, Top View .................................1-4

1-4 Battery Module Components, Bottom View ..............................1-5

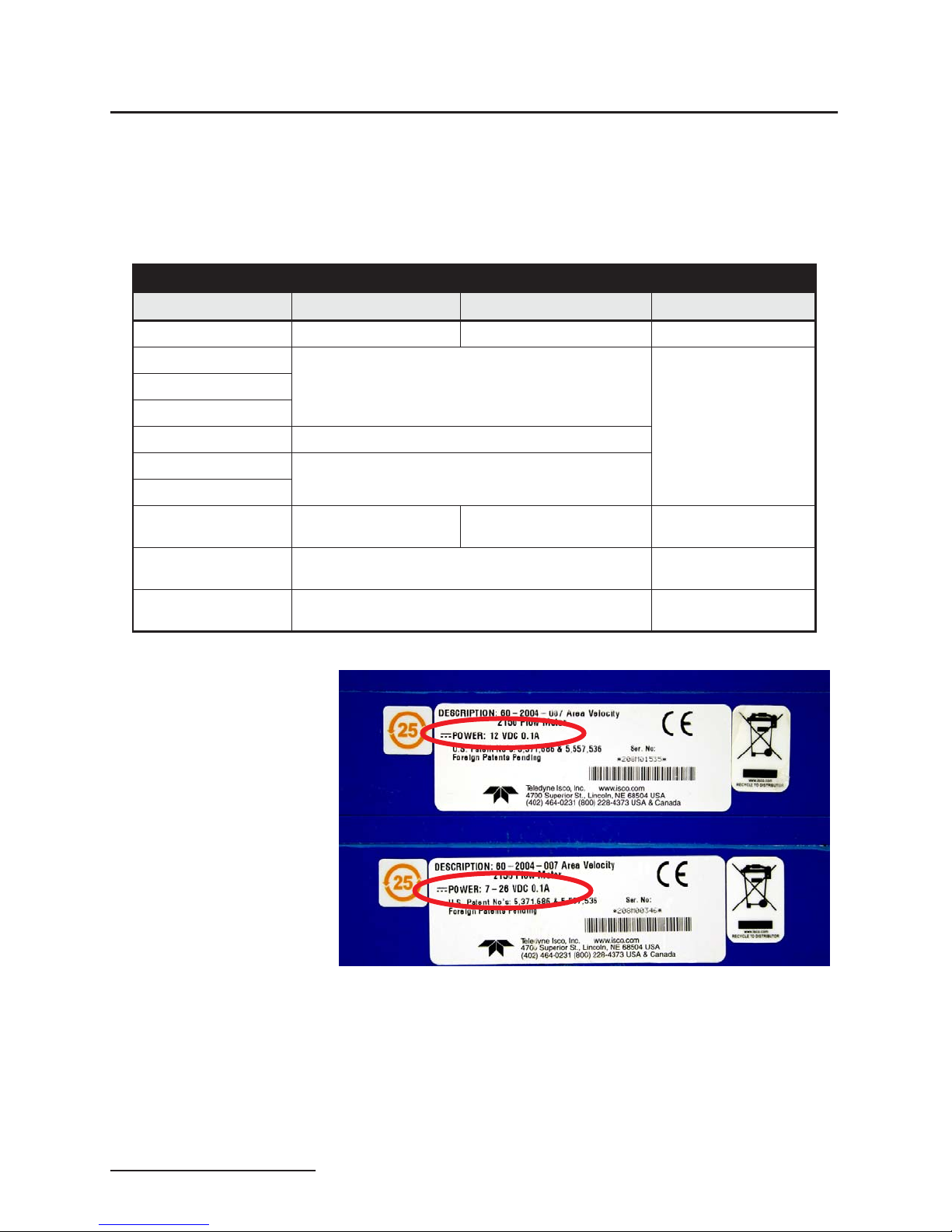

2-1 2105Ci serial label ..................................................2-1

2-2 Identifying the 2150 voltage specification ...............................2-2

2-3 Identifying the voltage specification on the DB9 cable ..................... 2-3

2-4 Unlocking the Latch .................................................2-4

2-5 Locking the Latch ................................................... 2-5

2-6 Insert Battery in Carrier .............................................2-6

2-7 Battery Module - Inserting Carrier ..................................... 2-6

2-8 Battery Module - Aligning the Door .................................... 2-7

2-9 Battery Module - Closing the Door .....................................2-7

2-10 Unlock latch and stow the cap ........................................ 2-8

2-11 Aligning the modules ............................................... 2-8

2-12 Antenna connected to 2105Ci ........................................2-9

2-13 Flowlink connect screen (version 5.10.616) ............................2-10

2-14 Site resolution screen ..............................................2-11

2-15 Site Information screen ............................................2-12

2-16 Devices screen - connected to site ....................................2-13

2-17 Modem screen - configuring the cellular modem ........................2-14

2-18 Devices screen - configuring the modem for Serial-Over-IP communication . . 2-15

2-19 Devices screen - configuring the modem for CSD communication ..........2-16

2-20 Setting up text messaging and alarm conditions ........................2-17

2-21 Wireless power control window ...................................... 2-19

2-22 Equation Builder for power control ................................... 2-20

2-23 Condition Builder .................................................2-20

vi

2105 Interface Module

Table of Contents

2-24 Data tab ........................................................2-21

2-25 Sonde setup tab .................................................. 2-22

2-26 Rainfall measurement tab ..........................................2-23

2-27 Sampler tab ......................................................2-24

2-28 Data Storage Setup window ........................................ 2-25

2-29 Cable connections for sampler Pass Thru Mode .........................2-26

2-30 HyperTerminal connection screen ....................................2-26

2-31 Specifying the connection number .................................... 2-27

2-32 HyperTerminal Settings tab ........................................ 2-27

2-33 HyperTerminal Dial window ........................................2-28

2-34 ADFM tab for Pulse Doppler devices .................................2-29

2-35 Modbus input tab .................................................2-30

2-36 Modbus configuration window ....................................... 2-31

2-37 Device parameters (measured data) ..................................2-31

2-38 2105 cables and associated equipment ................................2-37

2-39 2105 Interface connector ........................................... 2-38

3-1 Configuration example (direct connection shown) .........................3-3

List of Tables

1-1 2105 Interface Module Components - Top View ...........................1-2

1-2 2105 Interface Module Components - Bottom View ........................1-3

1-3 Battery Module Components - Top View ................................1-4

1-4 Battery Module Components - Bottom View .............................1-5

1-5 Technical Specifications: 2105 Interface Module ..........................1-6

1-6 Technical Specifications: 2191 Battery Module ........................... 1-7

2-1 Voltage Specifications for 2100 System Components .......................2-2

2-2 Sampler Pass Thru Mode Connection Steps ............................ 2-28

2-3 4200/6700 Series Supported Data Types ...............................2-33

2-4 2105 Port Connector Functions .......................................2-39

3-1 Modbus ASCII Address 1 Register Definitions ............................3-6

3-2 Modbus ASCII Address 2 +(N - 1) Register Definitions .....................3-6

3-3 Measurement Parameters by Model Number* ...........................3-10

vii

2105 Interface Module

Table of Contents

viii

2105 Interface Module

Section 1 Introduction

This instruction manual is designed to help you gain a thorough

understanding of the operation of the 2105 and 2105Ci Interface

Modules. Teledyne Isco recommends that you read this manual

completely before placing the equipment into service.

Information in this manual pertains to both the 2105 module and

2105Ci cellular modem module. Where there are specific differences between the modules, they are identified.

1.1 Product Description The 2105 Interface Module is designed to store data from Isco’s

2100 Series flow modules and Pulse Doppler flow meters. The

2105 also provides Modbus input, sampler interface, and rain

gauge and SDI-12 input. It works in conjunction with Isco’s

Flowlink software.

Note

If you have ordered any version of the Isco Model 677 logging

rain gauge (Isco rain gauge and 2105 module combination),

your system includes the rain gauge interface cable

(part #69-2004-581).

The 2105 can be located anywhere within a stack of up to three

other 2100 Series networked modules, using the same locking

mechanism that connects the 2100 Series modules to each other.

The 2105 is compatible with Isco’s 2150 Area Velocity flow

module, 2110 Ultrasonic flow module, 2101 Field Wizard, 2103

landline modem module, 2103Ci cellular modem module, and

2102 wireless module. The stack can be powered by any of

several power options offered by Teledyne Isco, such as the 2191

battery module.

All enclosures are rated NEMA 4X, 6P (IP68). The permanently

sealed enclosures are designed to meet the environmental

demands of many flow monitoring applications. All connections

between modules, sensors, and communication cables lock in

place. The locking mechanisms strongly secure the components

and ensure a watertight seal.

1-1

2105 Interface Module

Section 1 Introduction

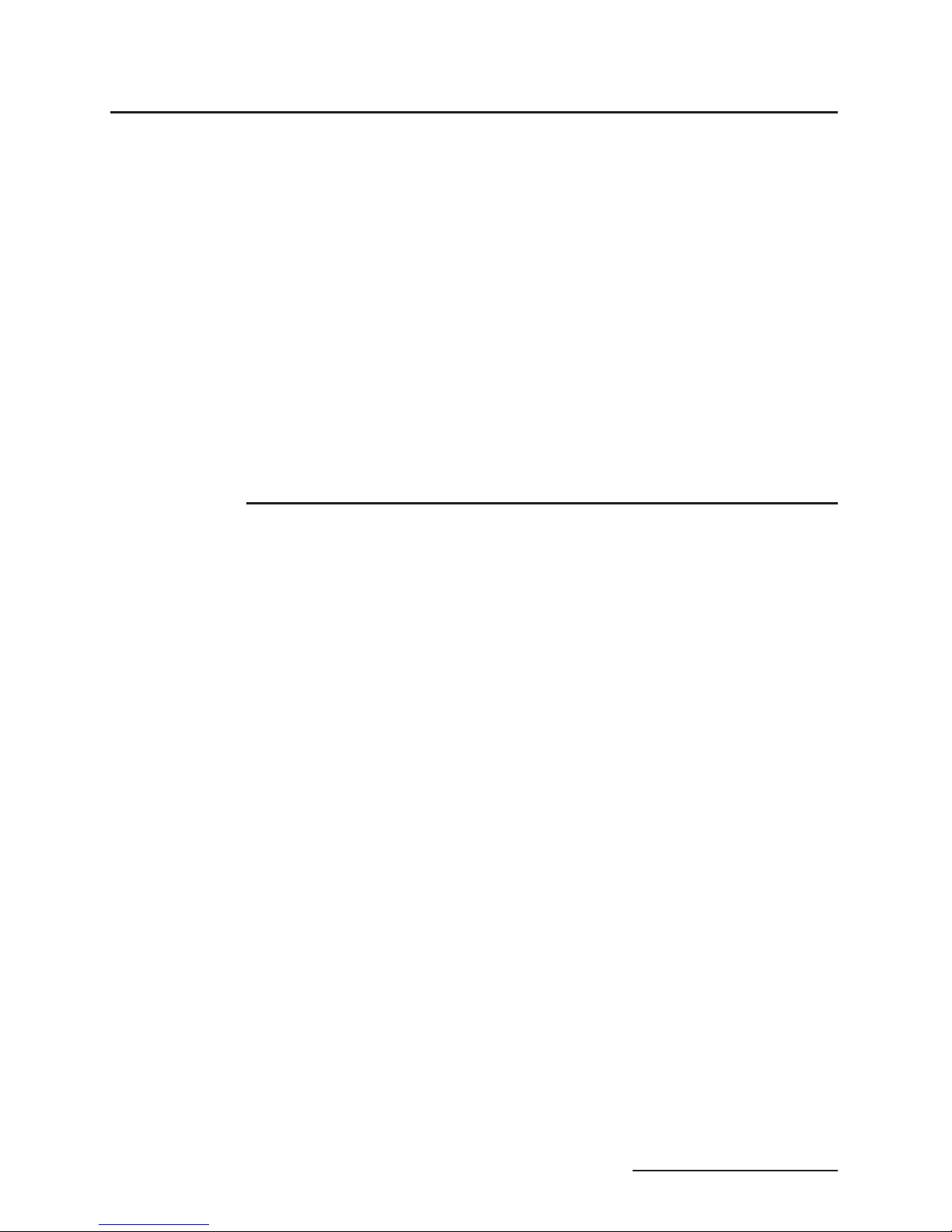

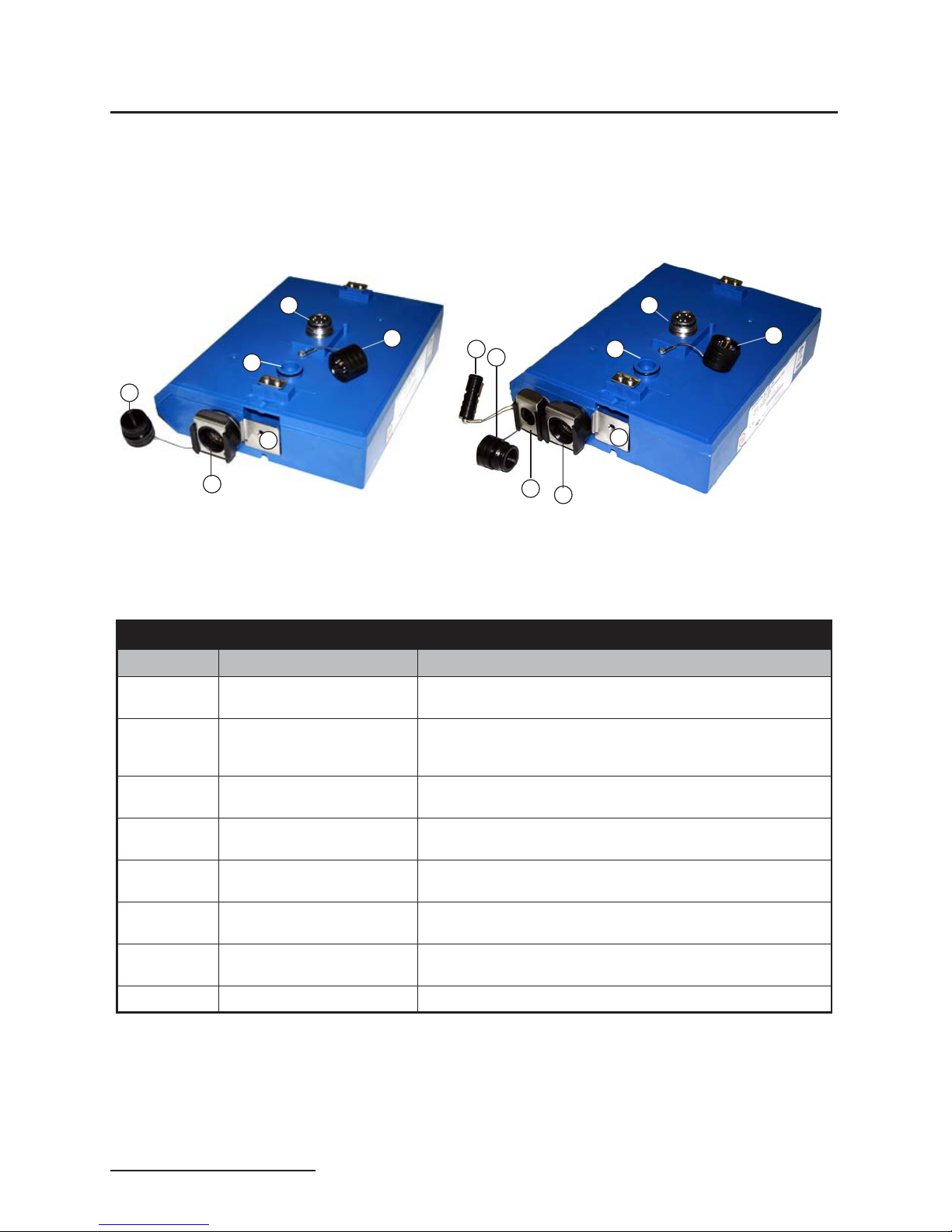

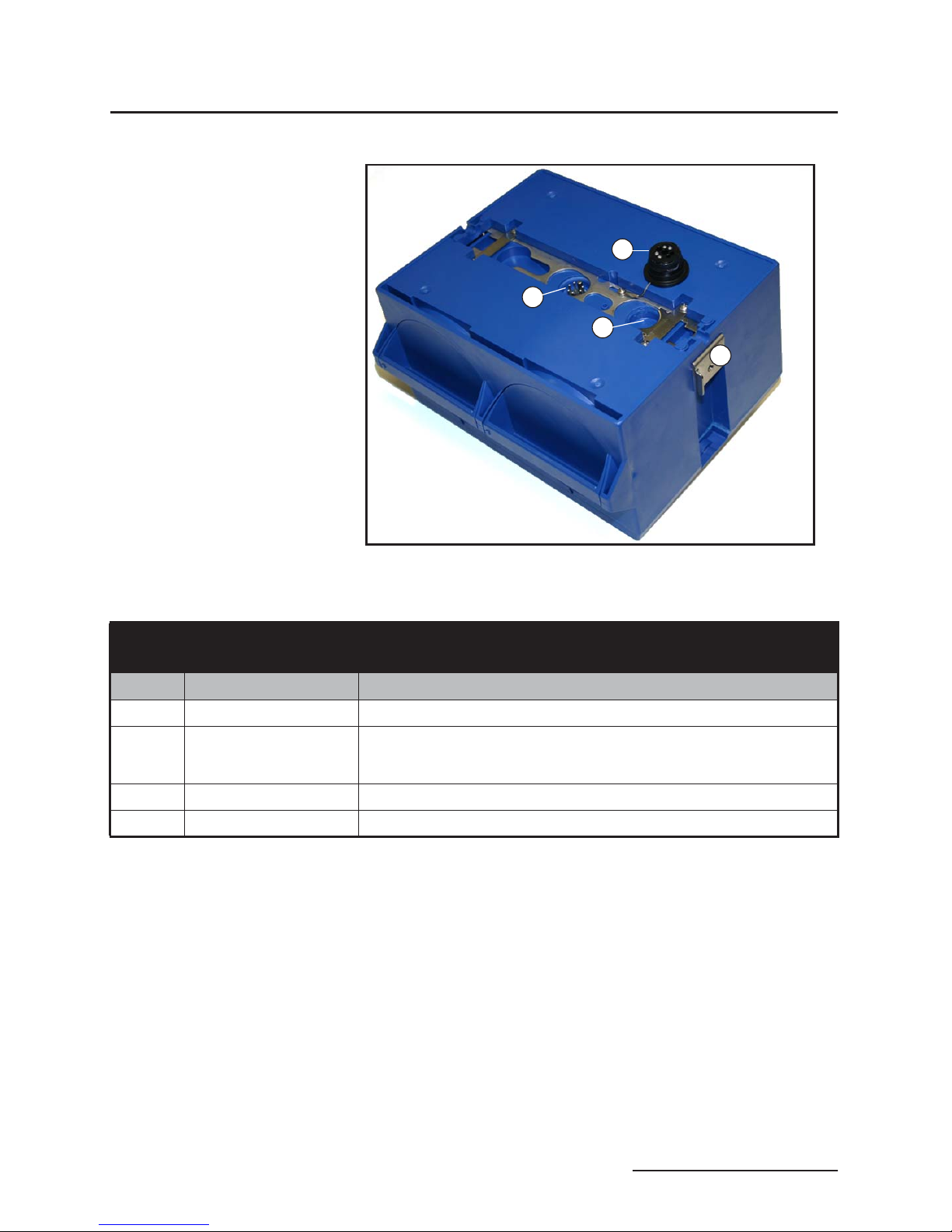

1.2 2105 Module

Components

Figures 1-1 and 1-2 identify the key components of the 2105

Interface Module.

11

3

5

8

4

2105 Module

Figure 1-1 2105 Components - Top View

2

7

5

3

2

8

6

4

Ci Modem Module

2105

Table 1-1 2105 Interface Module Components - TopView

Item No. Name Description

1 Communication Connector This port is used to connect the 2105 to other modules in a stack,

2 Connector Cap Install on the communication connector when it is not in use to

3 Cap Holder Stores the connector cap when the communication connector is in

4 Instrument Interface

5 Connector Plug Insert into the interface connector when the connector is not in

6 Antenna Cable Connector

7 Connector Plug

8 Latch Release Push in to unlock the module from a stack.

Cable Connector

(2105

Ci only)

(2105Ci only)

or to a computer using an RS232 cable.

protect the connector from moisture damage. When the connector

is in use, store the connector cap on the cap holder.

use.

Used to connect the module to compatible equipment for data

logging and sampler control

use to protect it from damage.

Used to connect the modem to the magnetic mount antenna.

Insert into the antenna cable connector when the connector is not

in use to protect it from damage.

1-2

4

5

Figure 1-2 2105 Components - Bottom View

2105 Interface Module

Section 1 Introduction

1

2

3

Table 1-2 2105 Interface Module Components - Bottom View

Item No. Name Description

1 Communication and Power

Connector

2 Connector Plug Insert into the communication connector when not in use to protect the

3 Plug Holder Stores the connector Plug when the communication connector is in use.

4 Desiccant Cartridge and

Hydrophobic Filter

5 Latch Push in to lock the module in a stack.

This connects the 2105 to other 2100 Series modules in the stack and is

used to transfer data and/or receive power.

connector from moisture damage. When the connector is in use, store

the connector cap in the cap holder.

Prevents moisture from entering the unit.

1-3

2105 Interface Module

Section 1 Introduction

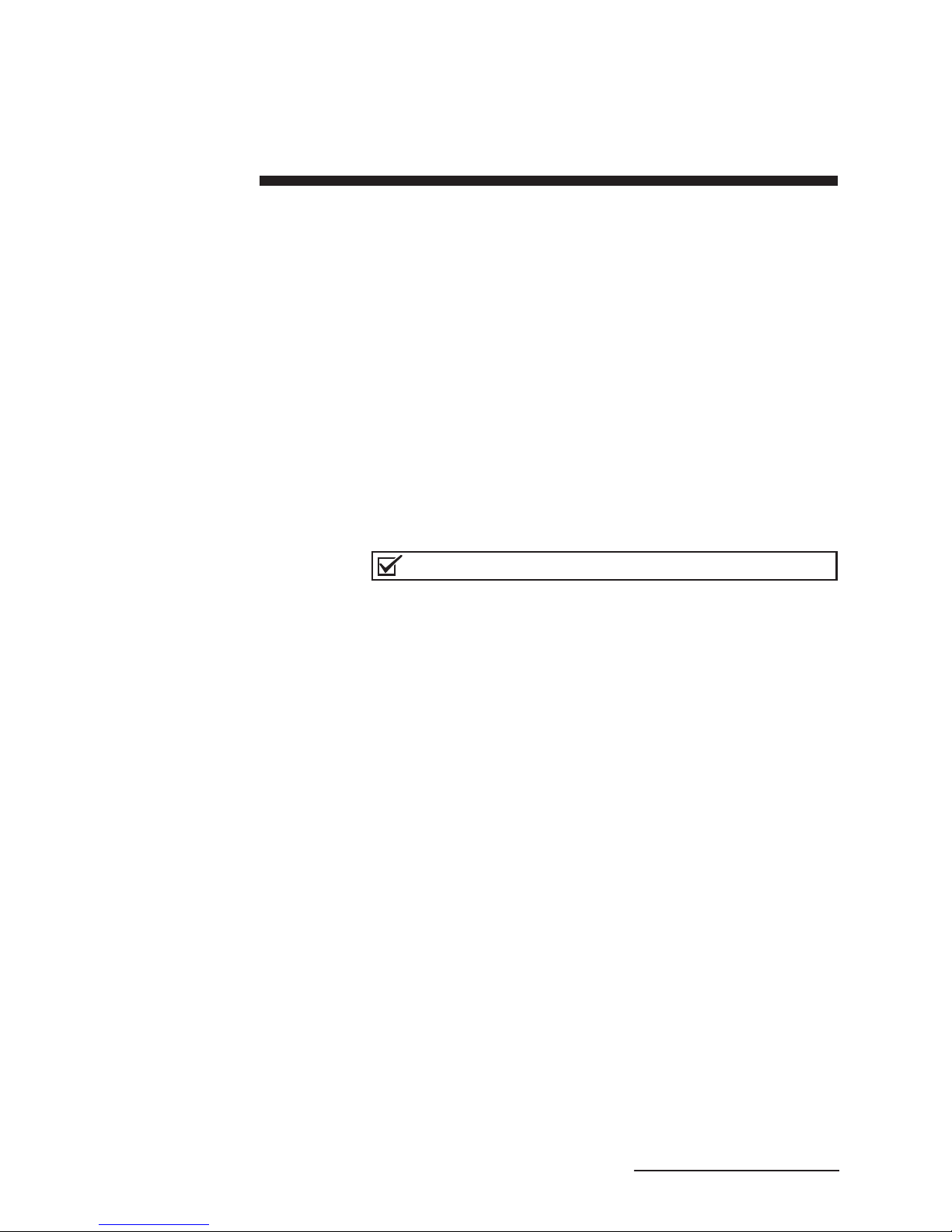

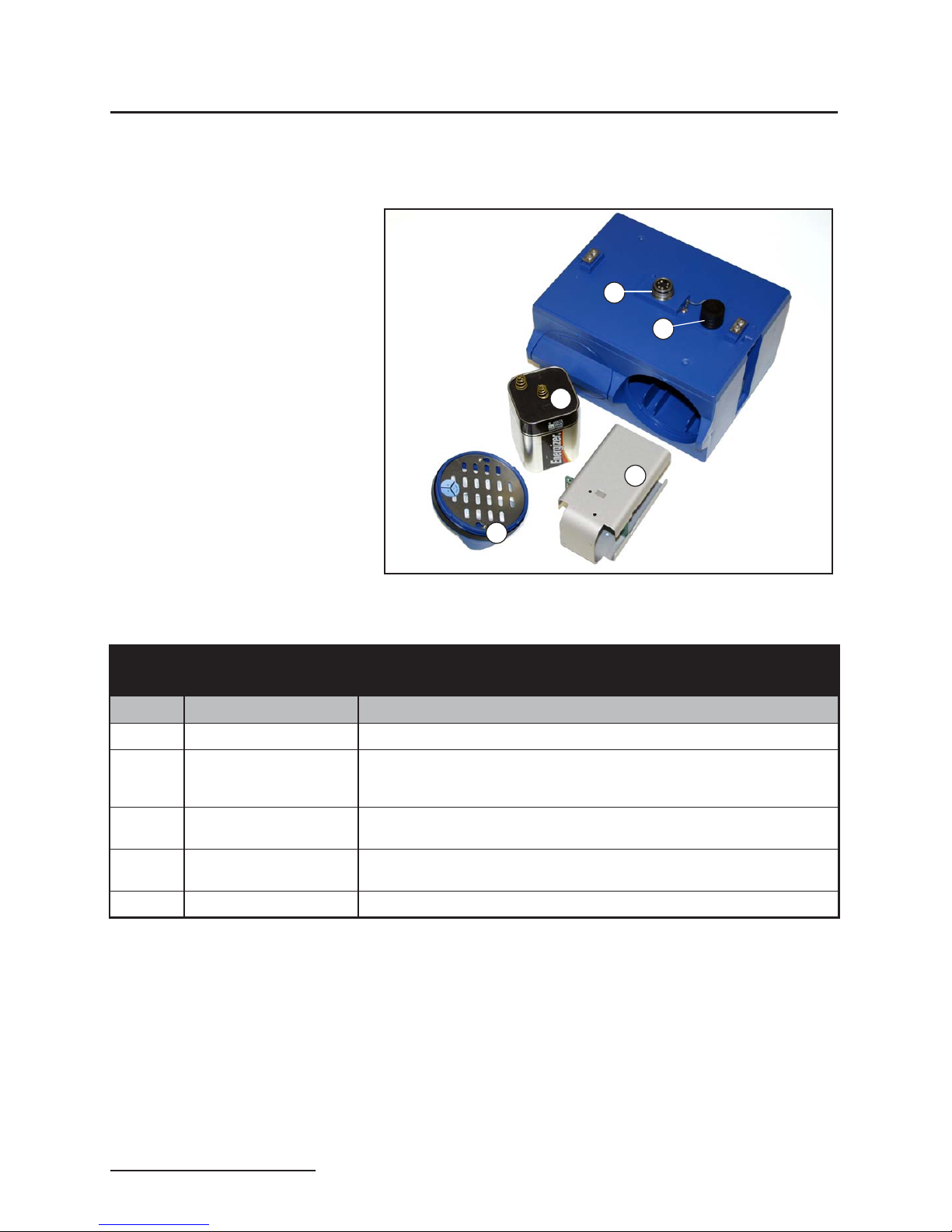

1.3 Battery Module

Components

Figures 1-3 and 1-4 identify key components of the Battery

Module.

1

2

3

5

4

Figure 1-3 Battery Module Components, Top View

Table 1-3 Battery Module

Components - TopView

Item No. Name Description

1 Communication Connector Connects the modules in the stack, transfers power and data.

2 Connector Cap

(Stowed on Cap Holder)

3 Lantern Battery

(Alkaline shown)

4 Door Two circular doors contain the desiccant bags, hold the battery carriers in

5 Battery Carrier Holds batteries in place and transfers power to the connectors.

Insert into the communication connector when not in use to protect the

connector from moisture damage. When the connector is in use, store the

connector cap on the cap holder.

6V alkaline or rechargeable lead-acid battery, quantity of 2.

place, and seal the module case.

1-4

2105 Interface Module

Section 1 Introduction

2

1

3

4

Figure 1-4 Battery Module Components, Bottom View

Table 1-4 Battery Module

Components - Bottom View

Item No. Name Description

1 Communication Connector Connects the modules in the stack, transfers power and data.

2 Connector Plug Insert into the communication connector when not in use to protect the con-

3 Plug Holder Stores the connector plug when the communication connector is in use.

4 Latch Push in to lock the module in a stack.

nector from moisture damage. When the connector is in use, store the connector cap in the cap holder.

1-5

2105 Interface Module

Section 1 Introduction

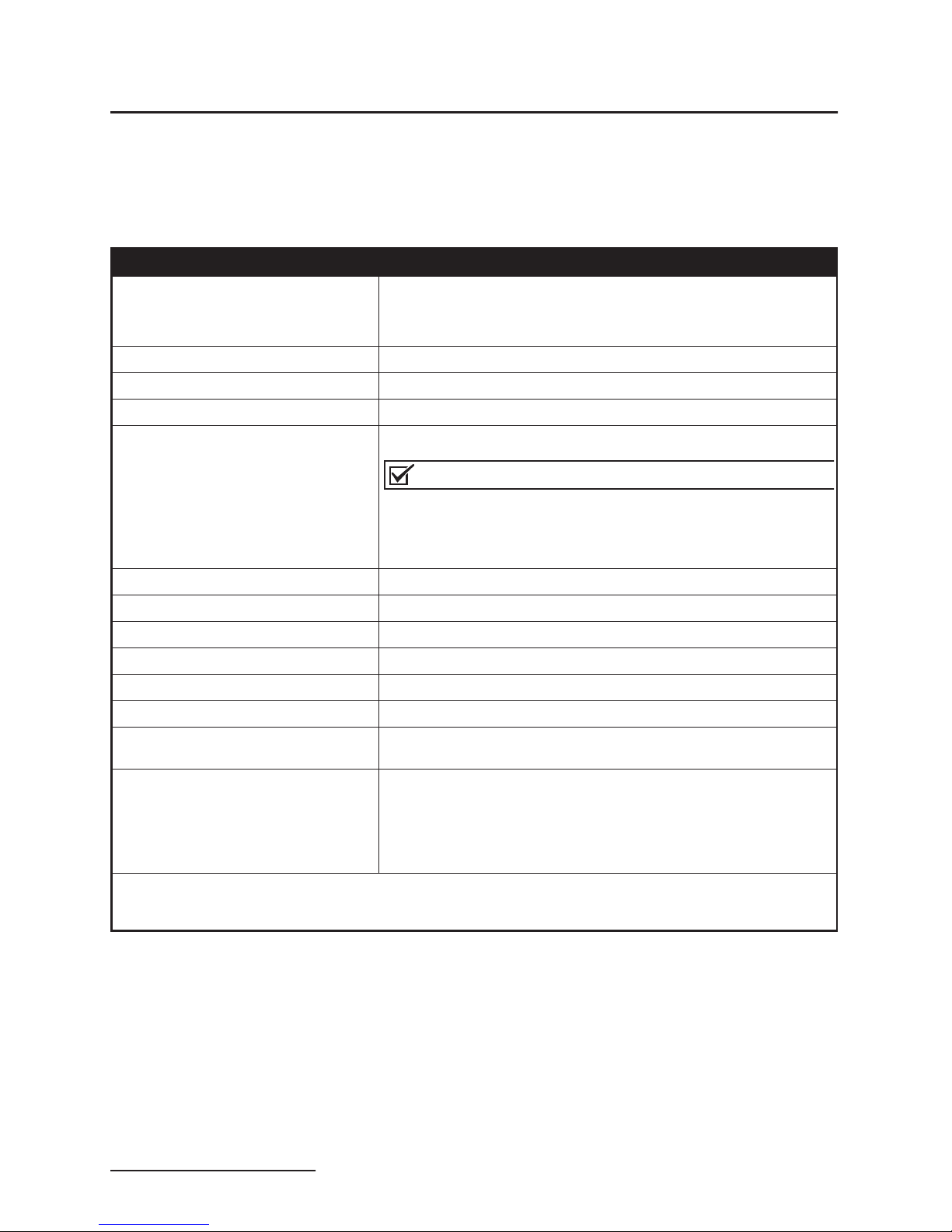

1.4 Technical

Specifications

Technical specifications for the 2105 Interface Module are given

in Table 1-5. Technical specifications for the 2191 Battery

Module are given in Table 1-6.

Table 1-5 Technical Specifications: 2105 Interface Module

Dimensions Width = 11.3 inches (28.7 cm)

Height = 2.9 inches (7.4 cm)

Depth = 7.5 inches (19.1 cm)

Weight 2 lbs. (0.9 kg)

Material High-impact molded polystyrene, Stainless steel

Enclosure NEMA 4X, 6P, IP68

Power 7 to 26 VDC, 100 mA typical at 12 VDC, 1 mA standby, 2 A maximum.

Note

Some other system components, including cables, have

lower voltage limits and cannot be connected in systems

powered by more than 16.6 VDC. Refer to Section 2.1.2 for

complete information.

Operating and Storage Temperature -40° to 140°F (-40° to 60°C)

Typical Battery Life 291 days*

Communication Speeds Supported 9600, 19200, and 38400 bps

Optional Cellular Communication Serial Over IP, or CSD (2105

Data Storage 798 Kb non-volatile flash

Storage Mode Rollover, 5 bytes per reading

Storage Interval 15 or 30 seconds; 1, 2, 5, 15, or 30 minutes; or 1, 2, 4, 12, or 24 hours.

Data Types Flow Rate, Level, Rainfall, Conductivity, Dissolved Oxygen, Temperature,

*

Actual battery life will vary depending upon configuration. The figure given assumes interrogation with Flowlink once a week, with a site configuration

of a 2105, 2150, and 2191 (using Energizer 529 batteries) and a connection speed of 38400 bps. The 2150 was configured to record level, velocity,

and flow rate every 15 minutes; total flow and batter y voltage every 24 hours.

Storage rate variable based on measured parameters

pH, Percent, Velocity, Volume, Total Dissolved Solids, Salinity, Phosphate, Ammonia, Nitrate, TOC, COD, Total Suspended Solids, Sludge

Index, Sludge Volume, SAC, Turbidity, Load, Input Voltage, Wireless Signal, Rainfall Intensity, Specific Conductance, Chloride, Chlorophyll, ORP,

Ammonium

CI)

1-6

2105 Interface Module

Section 1 Introduction

Table 1-6 Technical Specifications: 2191 Battery Module

Dimensions Width = 9.6 inches (24.4 cm)

Height = 6.0 inches (15.2 cm)

Depth = 7.6 inches (19.3 cm)

Weight (without batteries) 3.2 lbs. 1.4 kg

Materials Polystyrene, stainless steel

Enclosure (self-certified) NEMA 4X, 6P IP68

Batteries 6V alkaline lantern or rechargeable lead-acid lantern, quantity 2

Capacity

Alkaline Lantern Batteries

(Eveready Energizer® Model 529)

Rechargeable Lead-acid Lantern

Batteries

1.5 Safety Symbols and

Hazard Alerts

25 Ahrs

5 Ahrs

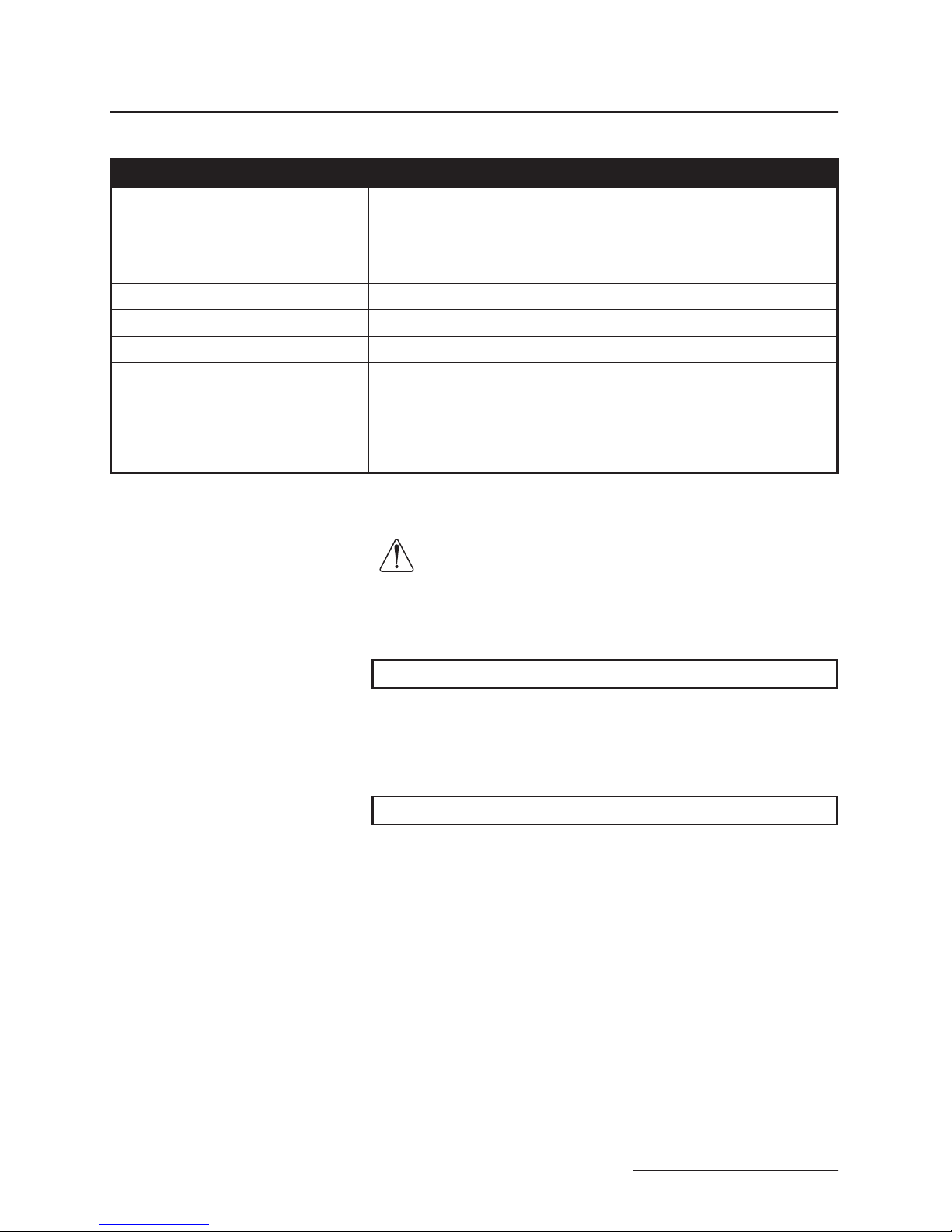

This icon identifies a general hazard and is accompanied

with details about the hazard. The instruction manual

identifies the hazardous condition and any steps necessary to correct the condition. The manual presents this information in one of two ways:

CAUTION

Cautions identify a potential hazard, which if not avoided, may

result in minor or moderate injury. This category can also warn

you of unsafe practices, or conditions that may cause property

damage.

WARNING

Warnings indicate potentially hazardous conditions. If you

do not avoid these risks, they could cause you death or

serious injury.

1-7

2105 Interface Module

Section 1 Introduction

1.6 Technical Service Although Teledyne Isco designs reliability into all of its

equipment, there is always the possibility of a malfunction

occurring. You can use this manual to help in diagnosing and

repairing any malfunctions. If the malfunction persists, call or

write the Teledyne Isco Technical Service Department for assistance:

Teledyne Isco

Technical Service Department

P.O. Box 82531

Lincoln, NE 68501

866-298-6174 or 402-464-0231

FAX: 402-465-3001

e-mail: IscoService@teledyne.com

Simple difficulties can often be diagnosed over the phone. If it is

necessary to return the equipment to the factory for service,

please follow the shipping instructions provided by the Technical

Service Department, including the use of the Return Authorization Number specified. Be sure to include a note describing the

malfunction. This will aid in the prompt repair and return of the

equipment.

1-8

2105 Interface Module

Section 2 Installation and Operation

2.1 Unpacking

Instructions

Teledyne Isco

Customer Service Dept.

P.O. Box 82531

Lincoln, NE 68501 USA

Phone: (800) 228-4373

Outside USA & Canada call:

(402) 464-0231

FAX: (402) 465-3022

E-mail: IscoInfo@teledyne.com

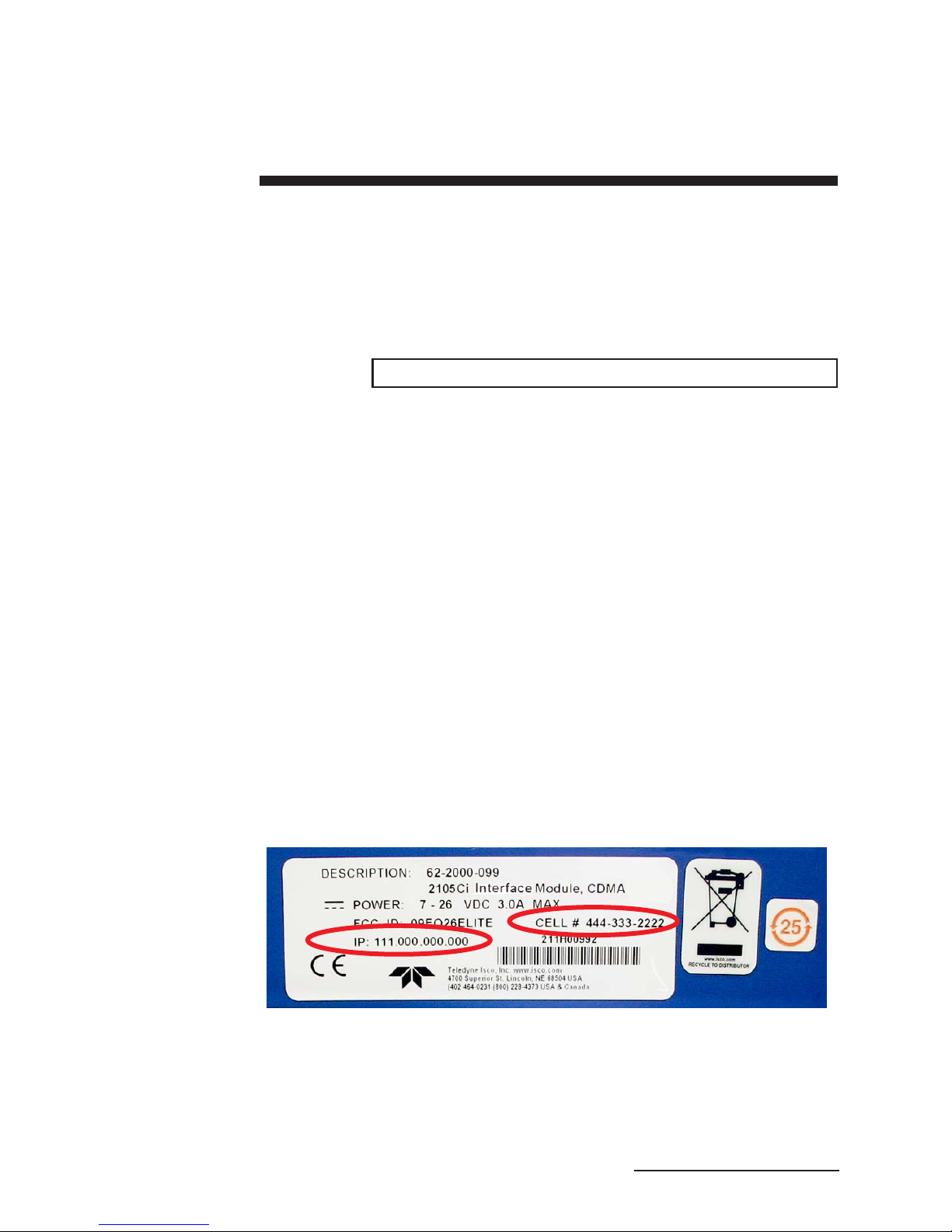

2.1.1 2105Ci Label

Information

When the system arrives, inspect the contents for any damage. If

there is damage, contact the delivery company and Teledyne Isco

(or its agent) immediately.

WARNING

If there is any evidence that any items may have been

damaged in shipping, do not attempt to install the unit.

Please contact Teledyne Isco (or its agent) for advice.

When you unpack the system, check the items against the

packing list. If any parts are missing, contact the delivery

company and Teledyne Isco’s Customer Service Department.

When you report missing part(s), please indicate them by part

number. In addition to the main packing list, there may be other

packing lists for various sub-components.

It is recommended that you retain the shipping cartons as they

can be used to ship the unit in the event that it is necessary to

transport the system.

Please complete the registration card and return it to Teledyne

Isco.

If you have a 2105Ci, you should record the IP address and phone

number printed on the label, found on the back of the unit

(Figure 2-1). You will need this information when you configure

the unit.

Figure 2-1 2105Ci serial label

2.1.2 System Power 2105 modules can be powered by 7 to 26 volts. Some other 2100

system components are limited to a maximum of 16.6 volts

(12 volts typical). The voltage specification is printed on the

2-1

2105 Interface Module

Section 2 Installation and Operation

serial tag located on the back of the module (refer to Figure 2-2).

Table 2-1 lists the maximum voltages for all Isco 2100 instrumentation. Regardless of the capabilities of other components,

never attempt to connect a voltage module or cable to a system

using a power supply that exceeds its stated operating range.

Table 2-1 Voltage Specifications for 2100 System Components

Module or Cable Earlier Voltage Range Current Voltage Range Updated

2150 7-16.6 VDC 7-26 VDC March 2005

2110

2101

2103

2102 10.2-16.6 VDC

2108

2105

RS-232 DB9 Cable

(part #60-2004-046)

RS-232 USB Cable

(part #60-2004-507)

Sampler Interface Cable

(part #60-2004-260)

7-16.6 VDC

N/A

7-26 VDC

7-16.6 VDC 7-26 VDC January 2009

7-26 VDC N/A

12VDC

N/A (Cable is powered

from sampler.)

Figure 2-2 Identifying the 2150 voltage specification

2-2

The module crown connector on the earlier RS-232 DB9 digital

communication cable (part #60-2004-046) is unmarked. The connector on the 26-volt cable has a serial tag specifying the higher

voltage (refer to Figure 2-3).

2105 Interface Module

Section 2 Installation and Operation

Lower Voltage

DB9 Cable

Figure 2-3 Identifying the voltage specification on the DB9 cable

Higher Voltage

DB9 Cable

Injury and/or equipment damage can result from

connecting modulesor cables toa power sourceexceeding

the specified operating voltage range.Check labelingon all

modules and cables for voltage ranges.

Note

All connected system components should share a common

supply ground.

2.2 Installation

Preparation

The 2100 Series components are often installed in confined

spaces. Some examples of confined spaces include manholes,

pipelines, digesters, and storage tanks. These spaces may become

hazardous environments that can prove fatal for those unprepared. These spaces are governed by OSHA 1910.146 and require

a permit before entering.

WARNING

WARNING

Avoid hazardous practices! Ifyou use these instruments in

any way not specified in this manual, the protection

provided by the instruments may be impaired; this will

increase your risk of injury.

WARNING

The installation and use of this product may subject you to

hazardous working conditions that can cause you serious

or fatal injuries. Take any necessary precautions before

entering a worksite. Install and operate this product in

accordance with all applicable safety and health

regulations, and local ordinances.

2-3

2105 Interface Module

Section 2 Installation and Operation

Follow the instructions below to install your 2105 module. Most

of these instructions are similar for the 2105Ci. Where there are

specific differences between the modules, they are identified.

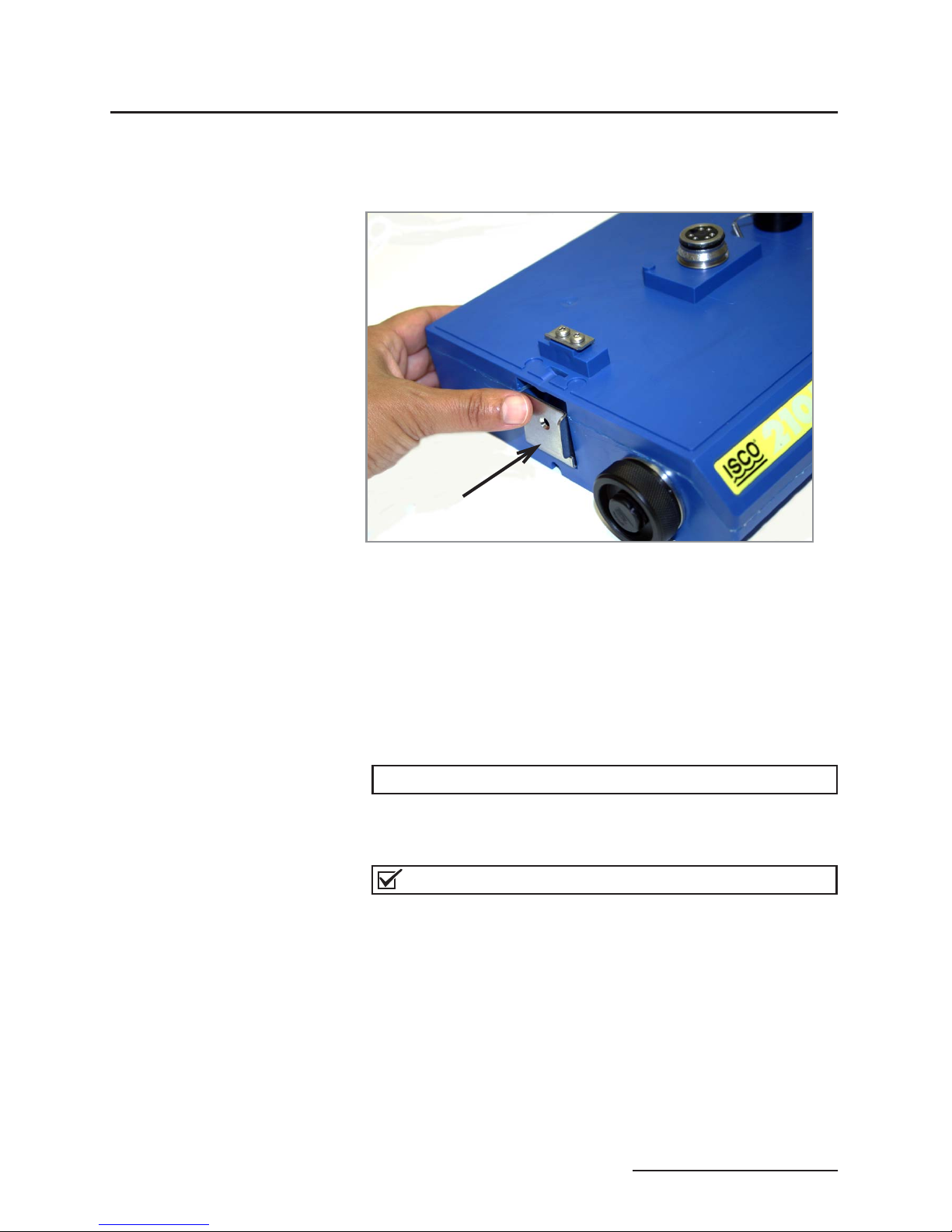

2.2.1 Latches - Locking and

Unlocking

Latches must be operated to stack and unstack the modules, and

to gain access to the vent screw. Take a moment to familiarize

yourself with operating the latches. The latch is normally locke,

but you must unlock the latch to place the module on top of

another module in a stack. The latch is unlocked by pushing in

the latch release on the connector side of the module. To lock the

latch, push in the latch on the desiccant side of the module.

CAUTION

The latch can be damaged by applying too much force. Never

press on both sides at the same time. Do not force the latch if it

is obstructed. While some degree of pressure must be applied

to slide the latch, the ends of the latches should never bend

more than1/8".

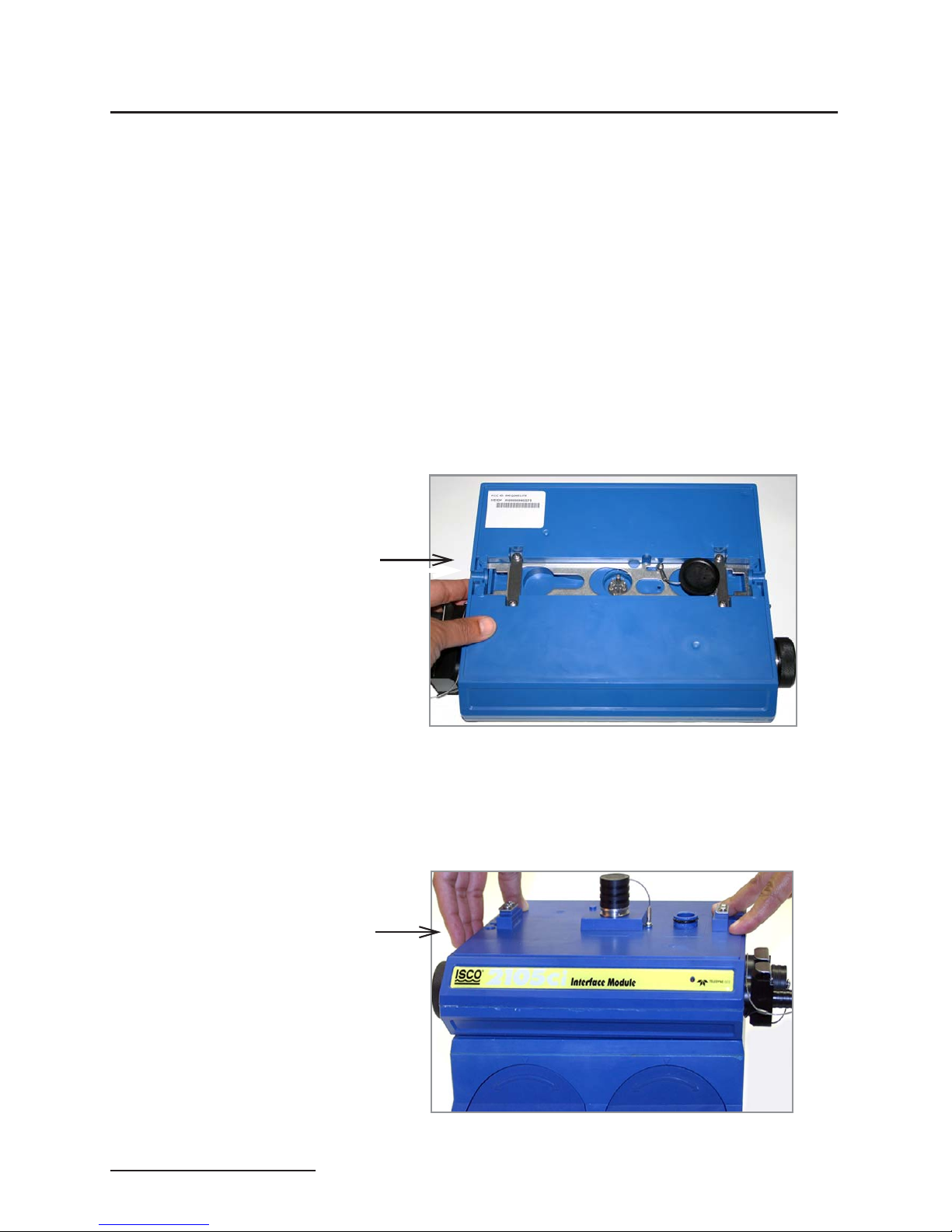

Figure 2-4 shows how to unlock the latch.

Figure 2-4 Unlocking the Latch

2-4

2105 Interface Module

Section 2 Installation and Operation

Figure 2-5 shows how to lock the latch.

Latches will “click” when they are fully locked and unlocked.

Figure 2-5 Locking the Latch

2.2.2 Communication

Connectors

When a communication connector is not in use, the connector should always be capped. The cap will seal the con-

nector to prevent corrosion, prevent moisture from entering the

unit, and improve communications.

When a c ommunication connector is in use, store the cap on the

holder next to the connector. The communication connector will

be sealed by its mating connector.

CAUTION

Caps PUSH ON and PULL OFF. Do not rotate the caps to

remove them from the connectors.

Note

For modules to correctly stack and lock together, protective

caps between the modules must be stored on the holders.

2-5

2105 Interface Module

Section 2 Installation and Operation

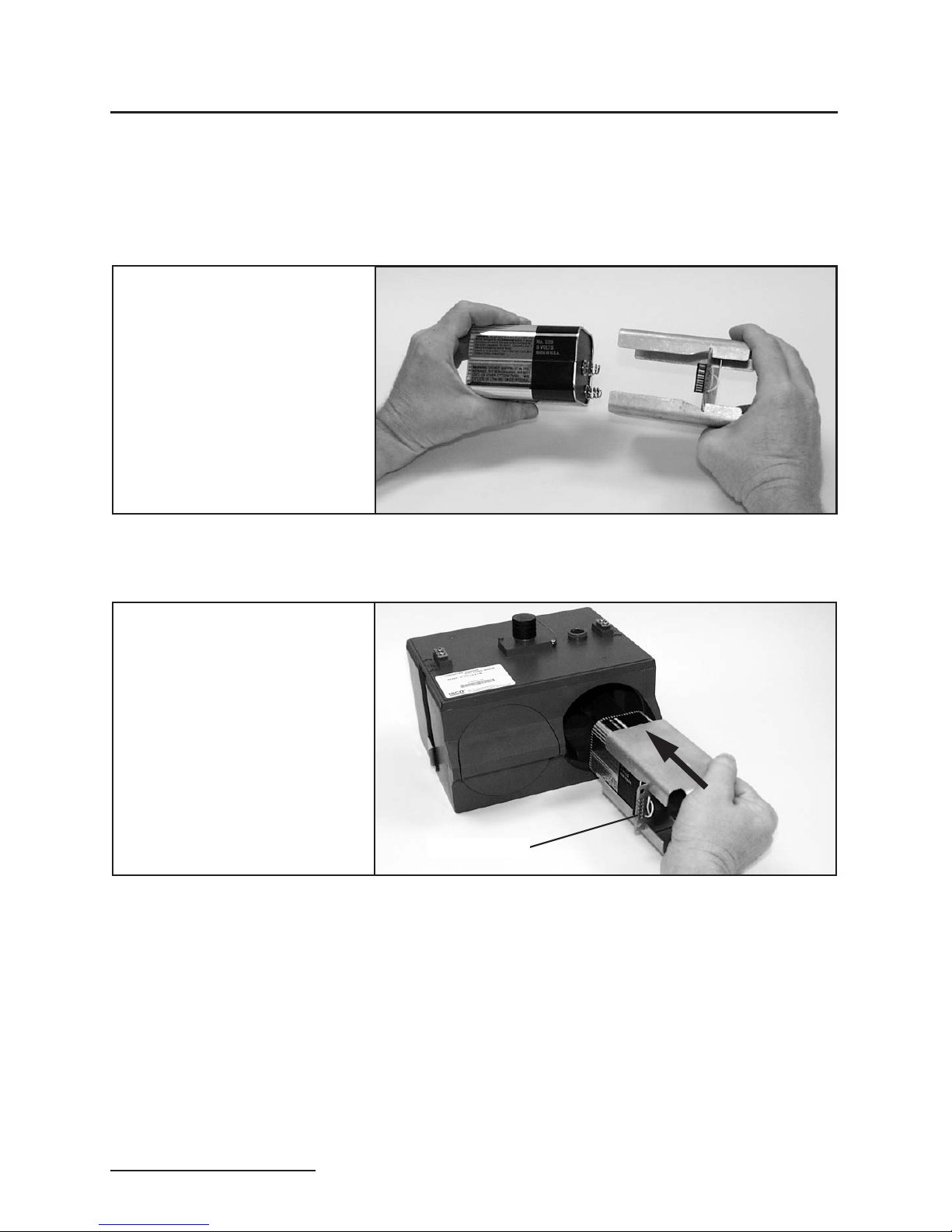

2.2.3 Installing the Batteries The Battery Module requires two lantern batteries. The figures

below show a 6 VDC alkaline battery. Rechargeable 6 VDC

lead-acid batteries are also available for the module.

To install the batteries, follow the instructions in Figures 2-6

through 2-9.

Load the Lantern Battery

into the Carrier.

Figure 2-6 Insert Battery in Carrier

Insert the carrier and battery

into the module. Note the

position of the carrier’s connector; it must be aligned

toward the center of the

module.

Figure 2-7 Battery Module - Inserting Carrier

Connector

2-6

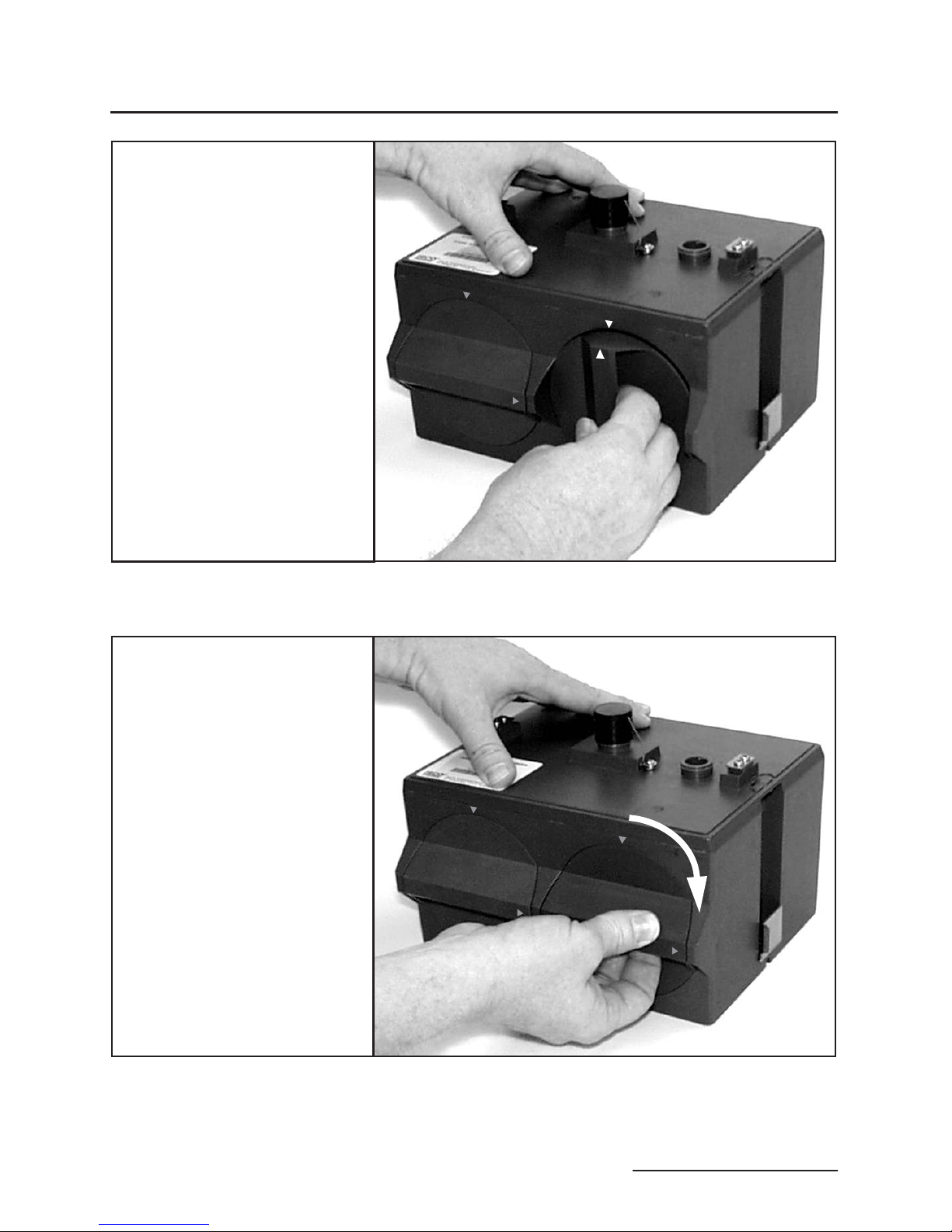

While holding the door in your

right hand, align the arrows

and insert the door.

2105 Interface Module

Section 2 Installation and Operation

Figure 2-8 Battery Module - Aligning the Door

Rotate the door1/4 turn clockwise.

Repeat the steps in Figures 2-6

through 2-9 to install the second

battery.

Figure 2-9 Battery Module - Closing the Door

2-7

2105 Interface Module

Section 2 Installation and Operation

2.3 Stacking Modules The 2105 can be located anywhere within a stack of up to four

2100 Series networked modules. It will draw its power from the

same source as the rest of the stack.

To connect the 2105 with another 2100 Series module:

1. On the top of the 2100 Series module, remove the cap and

stow it on the holder. This exposes the communication connector on the module.

2. Inspect the module’s communication connector. It should

be clean and dry. Damaged O-rings must be replaced.

3. If you are using the metal carrying handle, insert it

between the top two modules, with the handle turned

toward the rear of the stack (opposite the yellow labels).

4. Unlock the 2105’s latch by pressing in on the latch release.

5. Underneath the 2105, remove the cap from the lower communication connector and stow it in the holder.

Figure 2-10 Unlock latch and stow the cap

6. Gently press the modules together and lock the 2105’s

Figure 2-11 Aligning the modules

2-8

latch (desiccant side). The communications indicator will

blink during the start-up routine to indicate the 2105 is

operating.

2105 Interface Module

Section 2 Installation and Operation

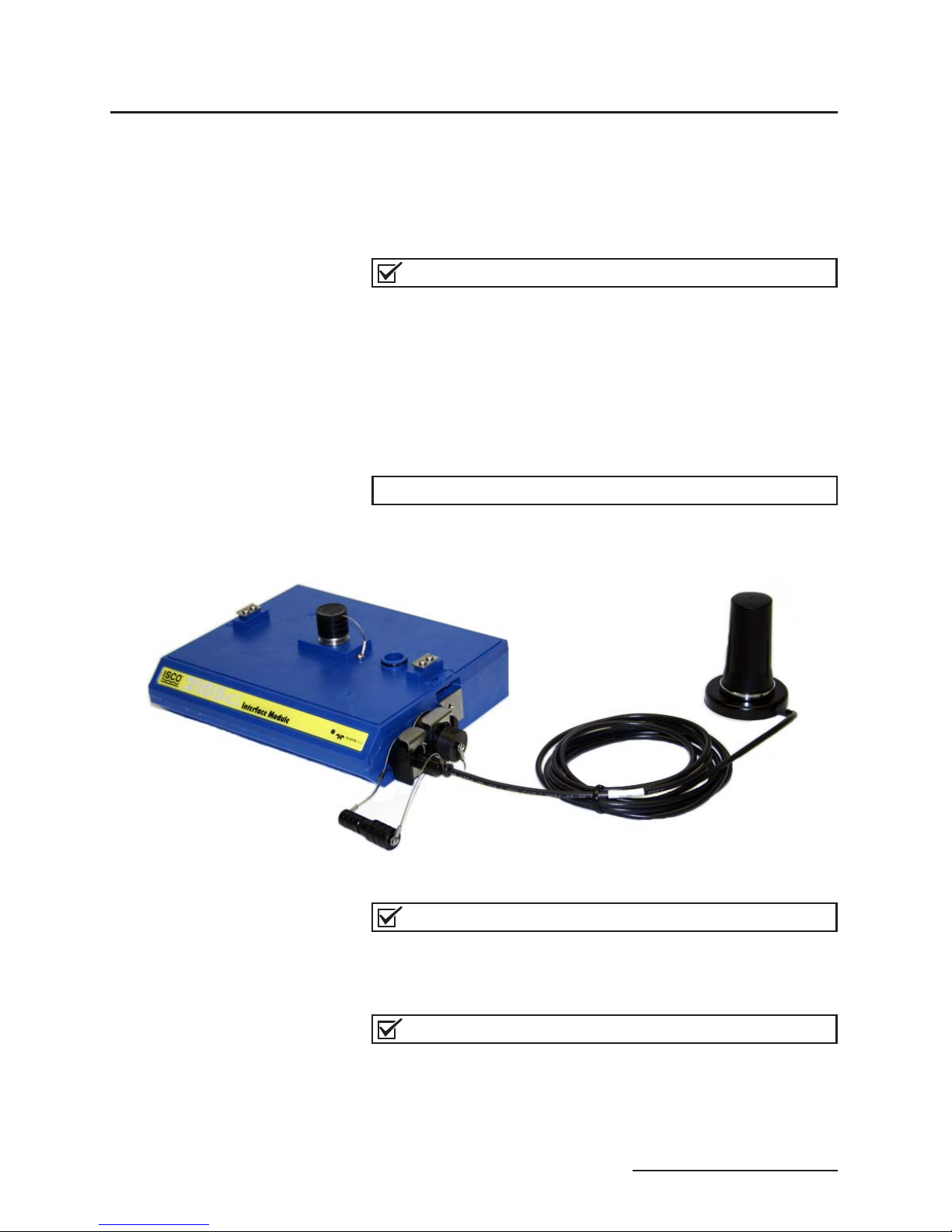

2.4 Antenna (2105Ci Only) The 2105Ci uses a magnetic mount antenna and Serial Over

Internet Protocol (SOIP) communication to connect with other

units. (The module is also capable of CSD communication, but

this service is being phased out. See Section 2.5.1 for complete

information.) Phone service with a static IP address, rather than

a land line, provides efficient communication.

Note

The 2105Ci only works in a CDMA cellular ser vice area with

1xRTT. See your local CDMA service provider for availability.

As you face the unit, the 2105Ci antenna connector socket is

located on the right hand side of the module (Figure 2-12).

Remove the connector cap from the socket and attach it to the

cap on the end of the antenna cable. To connect the antenna,

press down on the silver metal latch on the side of the module

and push the antenna’s connector into the socket.

CAUTION

Only use this antenna with 2100 Series Ci cellular modem

modules. Do not use this antenna with non-Ci equipment.

Figure 2-12 Antenna connected to 2105Ci

Note

For the transmitter to comply with FCC Maximum Permissible

Exposure (MPE) regulations, the antenna must be located a

minimum of 30 centimeters (12 inches) from the human body.

Note

When any communication connector is not in use, it should

always be capped. The cap will seal the connector to prevent

corrosion, prevent moisture from entering the unit, and improve

communications.

2-9

2105 Interface Module

Section 2 Installation and Operation

2.5 Connecting to

Flowlink

Once the system is installed, you will configure it in a new or

existing site using Isco’s Flowlink software.

Note

The 2105 and 2105Ci Modules require Flowlink 5.10.412a or

later.

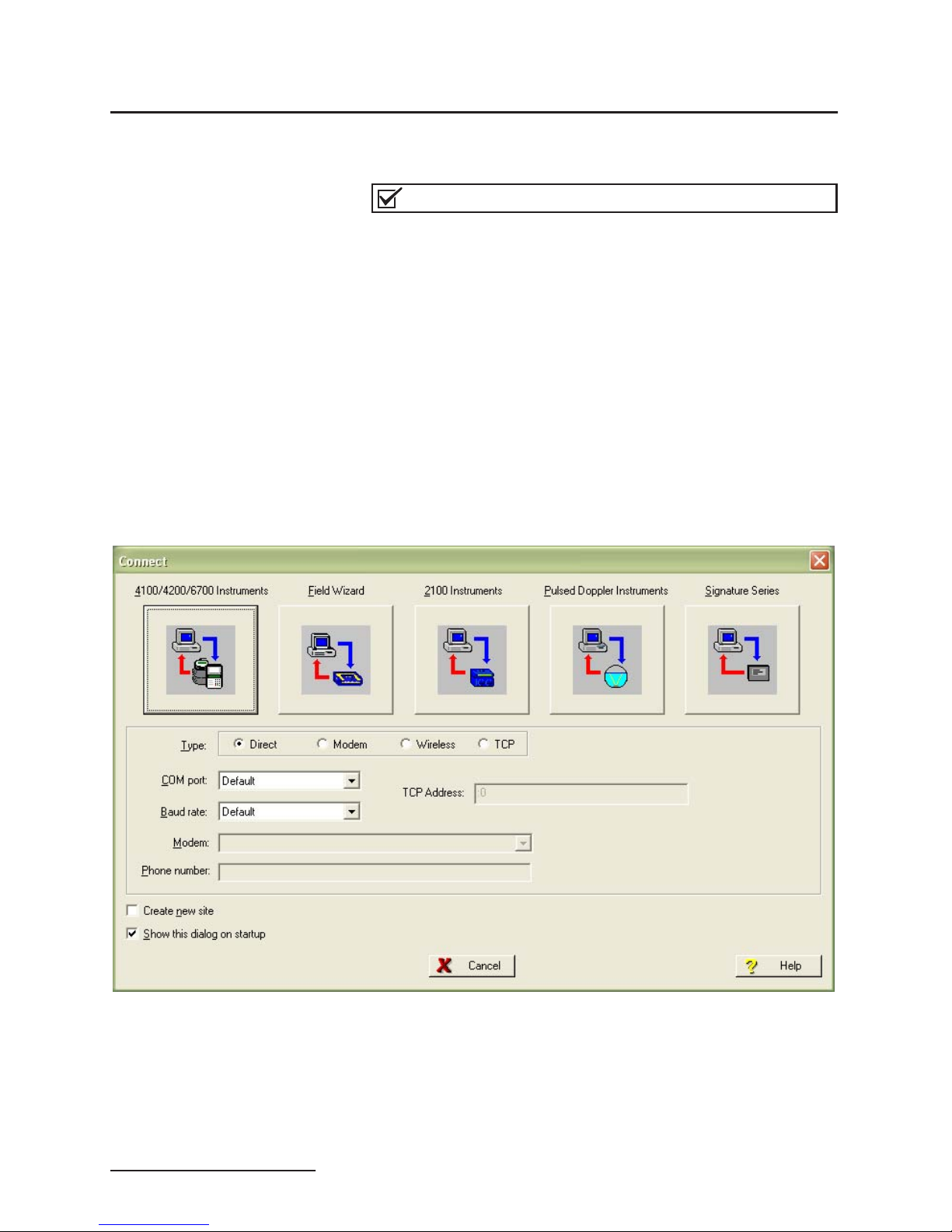

The first time you connect to the site, you must connect your

computer directly to the stack using Isco’s RS232 connect cable

(part #60-2004-046) or USB port connect cable

(part #60-2004-507). Open Flowlink and go to the Connect screen

(Figure 2-13) by either selecting it from the pull down menu or

clicking on the Quick Connect icon.

Make sure the connection Type is Direct, and click on the 2100

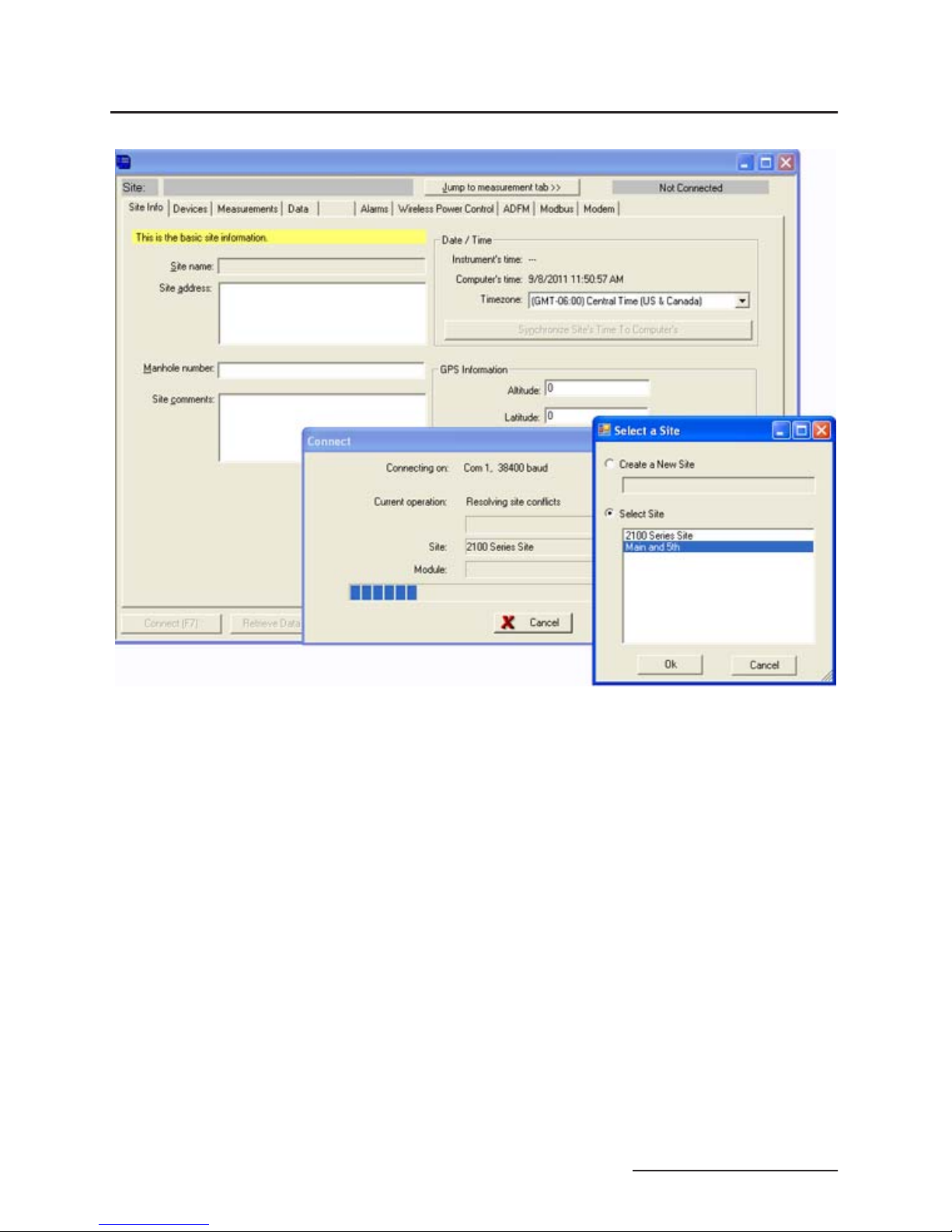

Instrument icon to connect. Upon initial connection, Flowlink

creates a site file and adds it to the database. If the system

detects the addition of a new module to an existing site, it will

display the Site Resolution screen (Figure 2-14). Otherwise, it

will display the Site Info screen (Figure 2-15).

Figure 2-13 Flowlink connect screen (version 5.10.616)

2-10

2105 Interface Module

Section 2 Installation and Operation

Figure 2-14 Site resolution screen

To add the new module to an existing site, select the appropriate

site and click OK. To create a new site, select Create a New Site.

Click in the name field, enter the name for the site, and click OK.

Upon connection, the Site Info tab will appear.

2-11

Loading...

Loading...