Page 1

2101 Field Wizard

Installation and Operation Guide

Part #60-2003-155 of Assembly #60-2004-070

Copyright © 2002. All rights reserved, Teledyne Isco, Inc.

Revision K, March 25, 2007

Page 2

Page 3

Foreword

This instruction manual is designed to help you gain a thorough understanding of the

operation of the equipment. Teledyne Isco recommends that you read this manual

completely before placing the equipment in service.

Although Teledyne Isco designs reliability into all equipment, there is always the possibility of a malfunction. This manual may help in diagnosing and repairing the malfunction.

If the problem persists, call or e-mail the Teledyne Isco Technical Service Department

for assistance. Simple difficulties can often be diagnosed over the phone.

If it is necessary to return the equipment to the factory for service, please follow the

shipping instructions provided by the Customer Service Department, including the

use of the Return Authorization Number specified. Be sure to include a note

describing the malfunction. This will aid in the prompt repair and return of the

equipment.

Teledyne Isco welcomes suggestions that would improve the information presented in

this manual or enhance the operation of the equipment itself.

Teledyne Isco is continually improving its products and reserves the right to

change product specifications, replacement parts, schematics, and instructions without notice.

Customer Service

Phone: (800) 228-4373 (USA, Canada, Mexico)

Fax: (402) 465-3022

Email: IscoCSR@teledyne.com

Technical Service

Phone: (800) 775-2965 (Analytical)

Email: IscoService@teledyne.com

Return equipment to: 4700 Superior Street, Lincoln, NE 68504-1398

Other Correspondence

Mail to: P.O. Box 82531, Lincoln, NE 68501-2531

Email: IscoInfo@teledyne.com

Web site: www.isco.com

Contact Information

(402) 464-0231 (Outside North America)

(800) 228-4373 (Samplers and Flow Meters)

Revised September 15, 2005

Page 4

Page 5

2101 Field Wizard

Table of Contents

Section 1 Introduction

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Identifying Module Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Safety Symbols and Hazard Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.5 Technical Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Section 2 Preparation and Installation

2.1 Unpacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3 Connecting To Flowlink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.4 Connecting To a Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4.1 Latches - Locking and Unlocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.4.2 Communication Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4.3 Stacking Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Section 3 Operation

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Field Wizard Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Flowlink Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.1 Connecting To a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.2 Communication Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.3 Site and Module Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4 Connecting to a Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.5 Site Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.6 Data Retrieval Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.6.1 Retrieve Data Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3.6.2 Data Retrieval Log Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3.6.3 Site Setup Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.6.4 Data Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.6.5 Site Information Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.7 Standalone Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.7.1 Standalone Information Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.8 PC Data Synchronization Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Section 4 Modbus Protocol

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2.1 Establishing Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.2 Module Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.4 Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.5 Common Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.6 Register Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

iii

Page 6

2101 Field Wizard

Table of Contents

Section 5 Maintenance

5.1 Maintenance Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Maintenance Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.3 Desiccant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3.1 Replacing the Desiccant: 2101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3.2 Reactivating the Desiccant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.4 Hydrophobic Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.5 How to Obtain Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Appendix A Replacement Parts

A.1 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B Accessories

B.1 How to Order. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.2 General Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C Material Safety Data Sheets

C.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

List of Figures

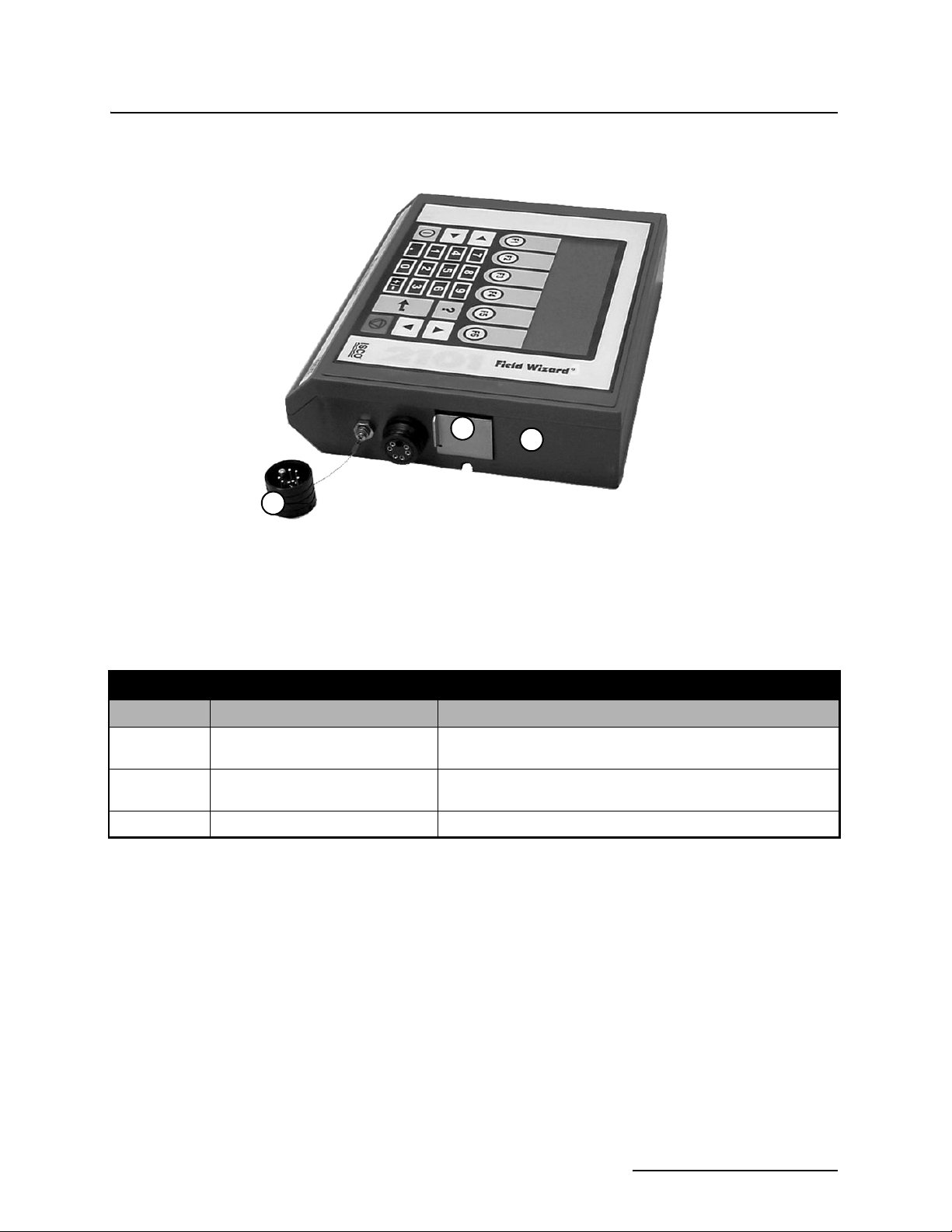

1-1 Field Wizard Keypad and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

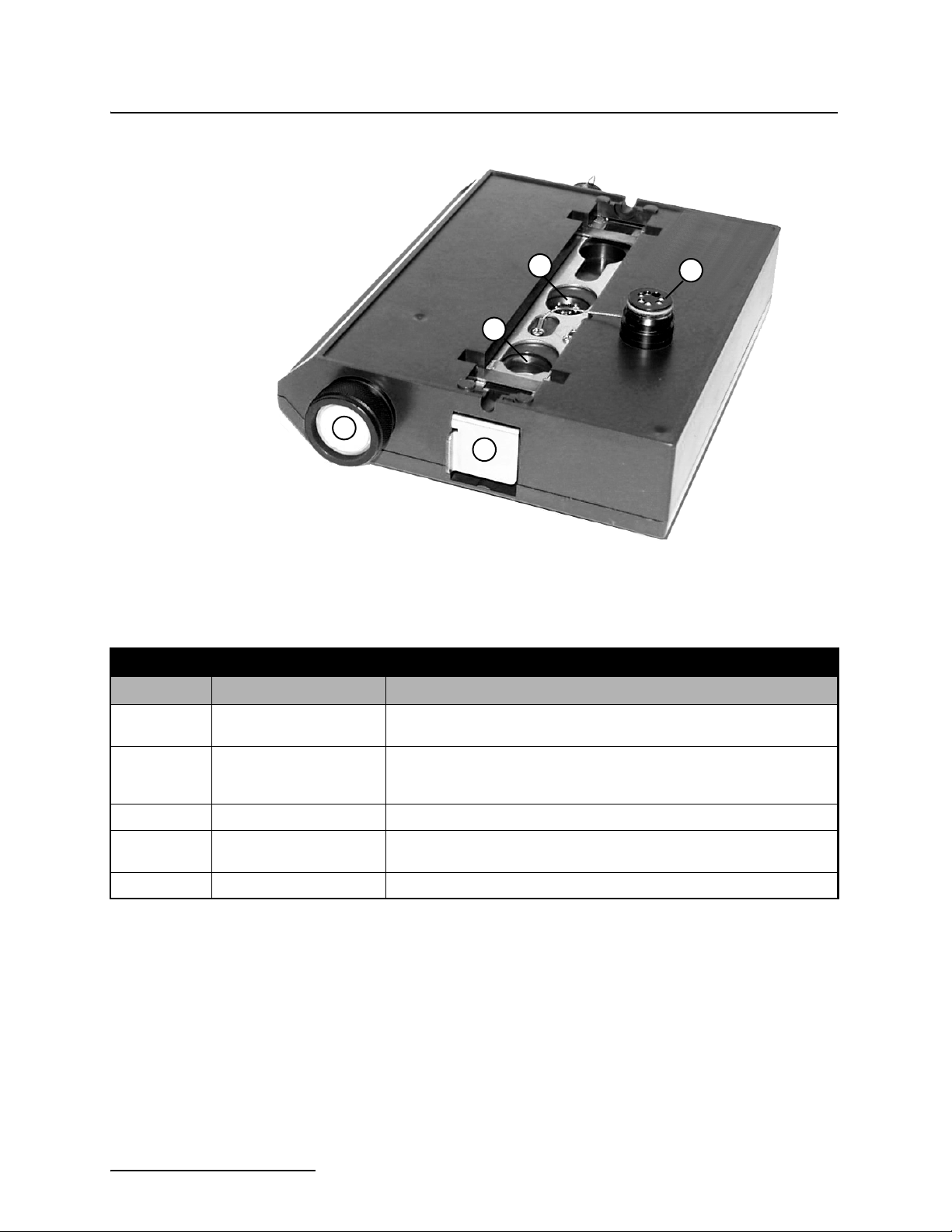

1-2 Field Wizard Components - Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Field Wizard Components - Bottom View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

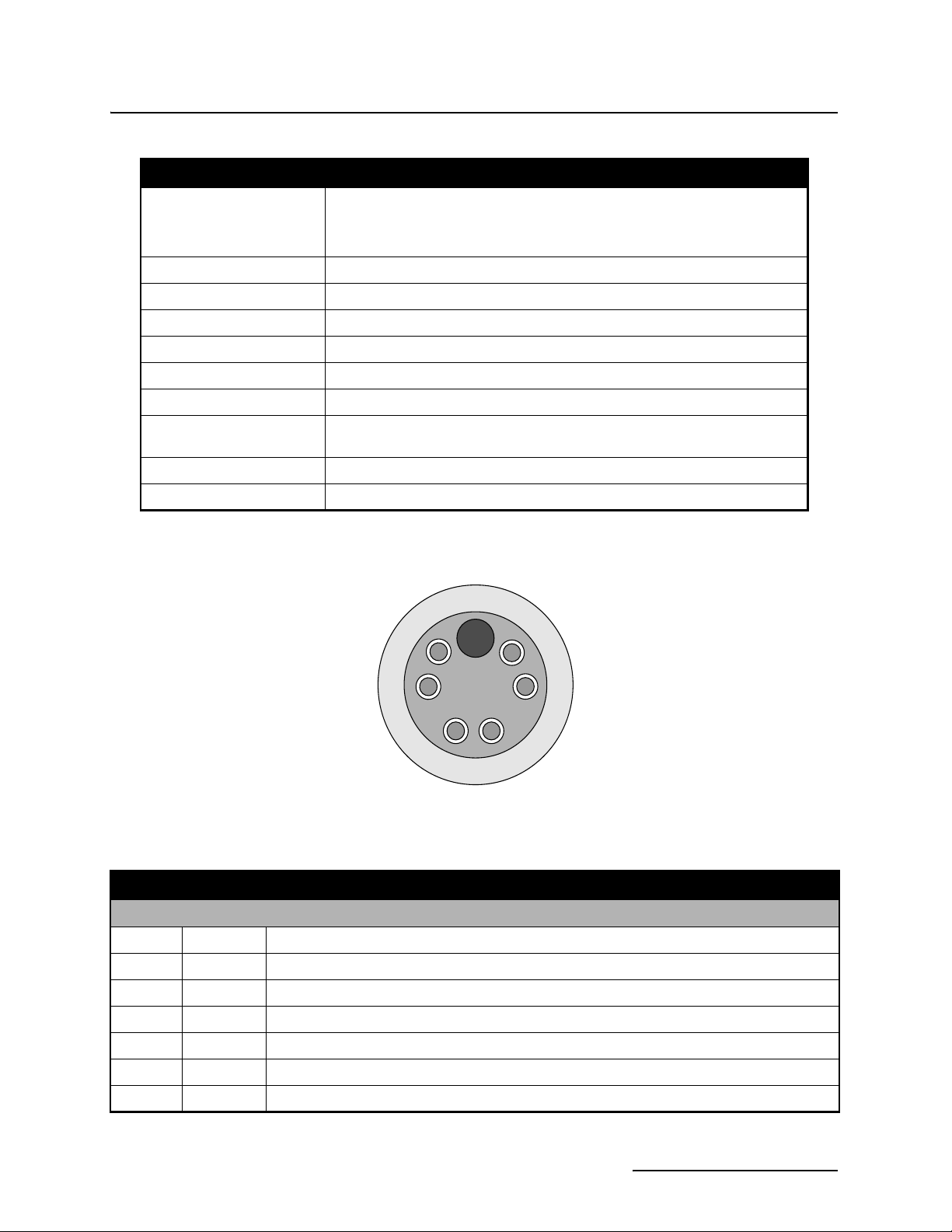

1-4 Model 2101 Field Wizard Connector Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2-1 Connecting the AC Adapter to the Field Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-2 Connecting the Communication Cable to the Field Wizard . . . . . . . . . . . . . . . . . 2-3

2-3 Flowlink Site Info Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-4 Data Retrieval Mode Main Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3-1 Field Wizard Keypad and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2 Flowlink Site Info Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-3 Field Wizard Connected to a 2150 Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-4 Synchronize Time Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-5 Data Retrieval Mode Main Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-6 Retrieve Data Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-7 Data Retrieval Status Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-8 Retrieve # Days Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3-9 Log Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

3-10 Data Log Details Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-11 Field Wizard Site Setup Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3-12 Field Wizard Backlight Mode Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3-13 Site Setup Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3-14 Level Calibration Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3-15 Sensor Diagnostics Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3-16 Data Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3-17 Site Information Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3-18 Standalone Mode Main Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3-19 Standalone Information Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3-20 PC Data Synchronization Mode Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

4-1 Configuration Example (Direct Connection Shown) . . . . . . . . . . . . . . . . . . . . . . . 4-3

iv

Page 7

2101 Field Wizard

Table of Contents

List of Tables

1-1 Field Wizard Components - Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-2 Field Wizard Components - Bottom View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3 2101 Field Wizard Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-4 Field Wizard Connector Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

4-1 Modbus ASCII Address 1 Register Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4-2 Modbus ASCII Address 2-(N+1) Register Definitions . . . . . . . . . . . . . . . . . . . . . . 4-7

4-3 Measurement Parameters by Model Number* . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

v

Page 8

2101 Field Wizard

Table of Contents

vi

Page 9

2101 Field Wizard

Section 1 Introduction

1.1 Introduction This instruction manual is designed to help you gain a thorough

understanding of the operation of the 2101 Field Wizard.

Teledyne Isco recommends that you read this manual completely

before placing the equipment into service.

1.2 Product Description The 2101 Field Wizard is a portable data interrogation unit

designed to collect data from Isco’s 2100 Series flow modules,

which measure parameters of open channel flow streams. It then

transfers that data to Isco’s Flowlink 4 for Windows software.

The Field Wizard also serves as a local display and keypad for a

2100 Series site. The eight-line by forty-character graphics

display provides quick access to current readings and diagnostic

information, and allows for calibration of level measurements.

The Field Wizard stacks on top of a 2100 Series module, using

the same locking mechanism that connects the 2100 Series

modules to each other. Because modules have unique assigned

names, the Field Wizard can retrieve data from multiple modules

and can be easily moved from site to site.

The Field Wizard uses flash memory, which retains data without

the concern of power failures or aging backup batteries. The data

storage memory can hold up to fourteen days worth of data

recorded at fifteen minute intervals from twenty different

modules.

All enclosures are rated NEMA 4X, 6P and IP68. The permanently sealed enclosures are designed to meet the environmental

demands of many sewer flow monitoring applications. All connections between modules, sensors, and communication cables "lock"

in place. The locking mechanisms strongly secure the components and ensure a watertight seal.

Its rugged, compact design and simplicity of use make the Field

Wizard a convenient alternative to using a laptop computer for

displaying site data or transferring data from the 2100 Series

module to a personal computer.

1-1

Page 10

2101 Field Wizard

Section 1 Introduction

1.3 Identifying Module Components

Figures 1-2 through 1-3 identify the key components of the 2101

Field Wizard.

The Field Wizard is operated from the top panel, which contains

a keypad and liquid crystal display. The keypad, shown in Figure

1-1, includes 26 keys that are used to program and operate the

Field Wizard.

DWG 69-2003-143

Help Key

Arrow Keys

Figure 1-1 Field Wizard Keypad and Display

The keypad contains six software configured function keys (soft

keys) that are used to make selections and navigate through

menus. Their specific functions will depend upon what operation

you are performing, and will be shown in the display window.

The four arrow keys are used for navigation within menus and

displays. The Enter key is used to complete data entry,

acknowledge prompts, and signal the start of certain operations.

Numeric keys are active when numeric data is to be entered.

Press the Help key to obtain context sensitive help.

The Power key places the unit into an ultra low power state,

during which the display window will be blank.

The Escape key is not currently used. During some operations,

one of the function keys will serve as a Cancel key.

The unit is equipped with an audible beeper. The beeper

acknowledges key presses, and signals errors when incorrect

entries are made.

1-2

Page 11

2101 Field Wizard

Section 1 Introduction

1

2

Figure 1-2 Field Wizard Components - Side View

Table 1-1 Field Wizard Components - Side View

Item No. Name Description

1 Communication Connector This port is used to connect to a personal computer running

Flowlink software.

2 Connector Cap Insert into the communication connector when it is not in use to

protect the connector from damage.

3 Latch Release Push in to unlock the module from a stack.

3

1-3

Page 12

2101 Field Wizard

Section 1 Introduction

4

Figure 1-3 Field Wizard Components - Bottom View

Table 1-2 Field Wizard Components - Bottom View

Item No. Name Description

1

2

3

5

1 Communication Connector This connects the Field Wizard to the 2100 Series module and is used to

transfer data.

2 Connector Cap Insert into the communication connector when not in use to protect the

connector from moisture damage. When the connector is in use, store

the connector cap in the cap holder.

3 Cap Holder Stores the connector cap when the communication connector is in use.

4 Desiccant Cartridge and

Hydrophobic Filter

5 Latch Push in to lock the module in a stack.

Prevents moisture from entering the unit.

1-4

Page 13

Section 1 Introduction

Table 1-3 2101 Field Wizard Technical Specifications

Dimensions Length = 11.3 inches (28.70 cm)

Width = 7.5 inches (19.05 cm)

Height = 2.9 inches (7.37 cm)

Weight 2 lbs. (.9 Kg)

Material HIgh-impact molded polystyrene

Enclosure NEMA 4X, 6P, IP68

Power 6.6 to 16.6 VDC, 110 mA typical at 12 VDC, 1 mA standby

Operating Temperature -4° to 140°F (-20° to 60°C)

Storage Temperature -40° to 140°F (-40° to 60°C)

2101 Field Wizard

Setup and Data Retrieval Serial connection to IBM PC or compatible computer with Isco Flowlink soft-

Baud Rate 38,400

File System Memory Capacity

ware version 4.12 or higher

The Field Wizard is capable of storing a minimum of 1.5 Mbytes of data.

G

F

E

D

Figure 1-4 Model 2101 Field Wizard Connector Pins

A

B

C

Table 1-4 Field Wizard Connector Pins

Pin Name Description

A LONA Neuron differential transceiver Data A

B LONB Neuron differential transceiver Data B

C VIN+ Positive power supply voltage input (+12 VDC nominal)

D VIN– Negative power supply voltage input (0 VDC nominal)

E RCVUP PC data receiver inverted input

F XMTUP PC data transmit inverted output

G Key Aligns connector pins

1-5

Page 14

2101 Field Wizard

Section 1 Introduction

1.4 Safety Symbols and Hazard Alerts

essary to correct the condition. The manual presents this information in one of two ways:

This icon identifies a general hazard and is accompanied

with details about the hazard. The instruction manual

identifies the hazardous condition and any steps nec-

CAUTION

Cautions identify a potential hazard, which if not avoided, may

result in minor or moderate injury. This category can also warn

you of unsafe practices, or conditions that may cause property

damage.

WARNING

Warnings indicate potentially hazardous conditions. If you

do not avoid these risks, they could cause you death or

serious injury.

1.5 Technical Service Although Teledyne Isco designs reliability into all of its

equipment, there is always the possibility of a malfunction

occurring. You can use this manual to help in diagnosing and

repairing any malfunctions. If the malfunction persists, call or

write the Teledyne Isco Technical Service Department for assistance:

Teledyne Isco Inc.

Technical Service Department

P.O. Box 82531

Lincoln, NE 68501

800-228-4373 or 402-464-0231

FAX: 402-465-3001

E-MAIL: service@isco.com

Simple difficulties can often be diagnosed over the phone. If it is

necessary to return the equipment to the factory for service,

please follow the shipping instructions provided by the Technical

Service Department, including the use of the Return Authorization Number specified. Be sure to include a note describing the

malfunction. This will aid in the prompt repair and return of the

equipment.

1-6

Page 15

2101 Field Wizard

Section 2 Preparation and Installation

2.1 Unpacking Instructions

Teledyne Isco, Inc.

Customer Service Dept.

P.O. Box 82531

Lincoln, NE 68501 USA

Phone: (800) 228-4373

Outside USA & Canada call:

(402) 464-0231

FAX: (402) 465-3022

E-mail: info@isco.com

When the system arrives, inspect the contents for any damage. If

there is damage, contact the delivery company and Teledyne Isco

(or its agent) immediately.

WARNING

If there is any evidence that any items may have been

damaged in shipping, do not attempt to install the unit.

Please contact Teledyne Isco (or its agent) for advice.

When you unpack the system, check the items against the

packing list. If any parts are missing, contact the delivery

company and Teledyne Isco’s Customer Service Department.

When you report missing part(s), please indicate them by part

number. In addition to the main packing list, there may be other

packing lists for various sub-components.

It is recommended that you retain the shipping cartons as they

can be used to ship the unit in the event that it is necessary to

transport the system.

Please complete the registration card and return it to Teledyne

Isco, Inc.

2-1

Page 16

2101 Field Wizard

Section 2 Preparation and Installation

2.2 Safety

The 2100 Series components are often installed in confined

spaces. Some examples of confined spaces include manholes,

pipelines, digesters, and storage tanks. These spaces may become

hazardous environments that can prove fatal for those unprepared. These spaces are governed by OSHA 1910.146 and require

a permit before entering.

WARNING

Avoid hazardous practices! If you use these instruments in

any way not specified in this manual, the protection

provided by the instruments may be impaired; this will

increase your risk of injury.

WARNING

The installation and use of this product may subject you

to hazardous working conditions that can cause you

serious or fatal injuries. Take any necessary precautions

before entering a worksite. Install and operate this product

in accordance with all applicable safety and health

regulations, and local ordinances.

2.3 Connecting To Flowlink

Before you use your Field Wizard in the field to collect data, you

need to synchronize it to Isco’s Flowlink software on a personal

computer (PC).

Use the following instructions to connect to Flowlink for the first

time. More detailed information about transferring data to

Flowlink can be found in Section 3.3.

Use Isco’s communication cable P/N 60-2004-046 and AC

Adapter (P/N 60-2004-057) to connect the Field Wizard to a PC,

as shown in Figures 2-1 and 2-2.

Uncap the communication connector on the underside of the

Field Wizard, and store the connector cap in its holder. Then plug

the AC Adapter into the communication connector, as shown in

Figure 2-1. Plug the other end of the AC Adapter into a grounded

electrical outlet.

2-2

Page 17

2101 Field Wizard

Section 2 Preparation and Installation

Figure 2-1 Connecting the AC Adapter to the Field Wizard

Figure 2-2 Connecting the Communication Cable to the Field Wizard

Uncap the communication connector on the right side of the Field

Wizard and attach the Communications Cable, as shown in

Figure 2-2. Connect the other end of the Communications Cable

to a serial COM port on the PC.

As a default Flowlink setting, the Quick Connect dialog box

opens when you start Flowlink. (If it is not open, click the Quick

Connect icon or select File, Quick Connect.)

2-3

Page 18

2101 Field Wizard

Section 2 Preparation and Installation

Click the large Field Wizard button to connect. Flowlink will

read the 2101 system information and try to match it with an

existing site in the open database. It will then display the Site

Info tab of the Site Window (Figure 2-3).

Figure 2-3 Flowlink Site Info Screen

Complete the following steps:

1. Click the Synchronize Instrument’s Time to Com-

puter’s button to synchronize the Field Wizard’s time to

that of your PC. (If you are using multiple PCs, select just

one PC to synchronize with.)

2. The Field Wizard is shipped with default site and module

names. Use the Site Name and Module Name fields if

you want to provide more descriptive names. Select Apply

(F9) to write that information to the instrument.

3. Although data has not yet been collected, you need to click

Retrieve Data (F8). This transfers a file containing site

interrogation times from Flowlink to the Field Wizard.

With this information, the Field Wizard will know when

data was last retrieved from your site(s). When brought to

a site, the Field Wizard will then retrieve only the necessary data.

4. Select Disconnect to end your PC session and disconnect

the Field Wizard.

2.4 Connecting To a Site Once you have connected the Field Wizard to Flowlink and set up

the initial configuration, you can connect the Field Wizard to a

site and retrieve data.

The Field Wizard module connects to the top of a 2100 Series

stack, which may contain multiple modules. The steps shown in

Sections 2.4.1 - 2.4.3 illustrate how to operate latches and connectors and connect the Field Wizard to the site.

2-4

Page 19

2101 Field Wizard

Section 2 Preparation and Installation

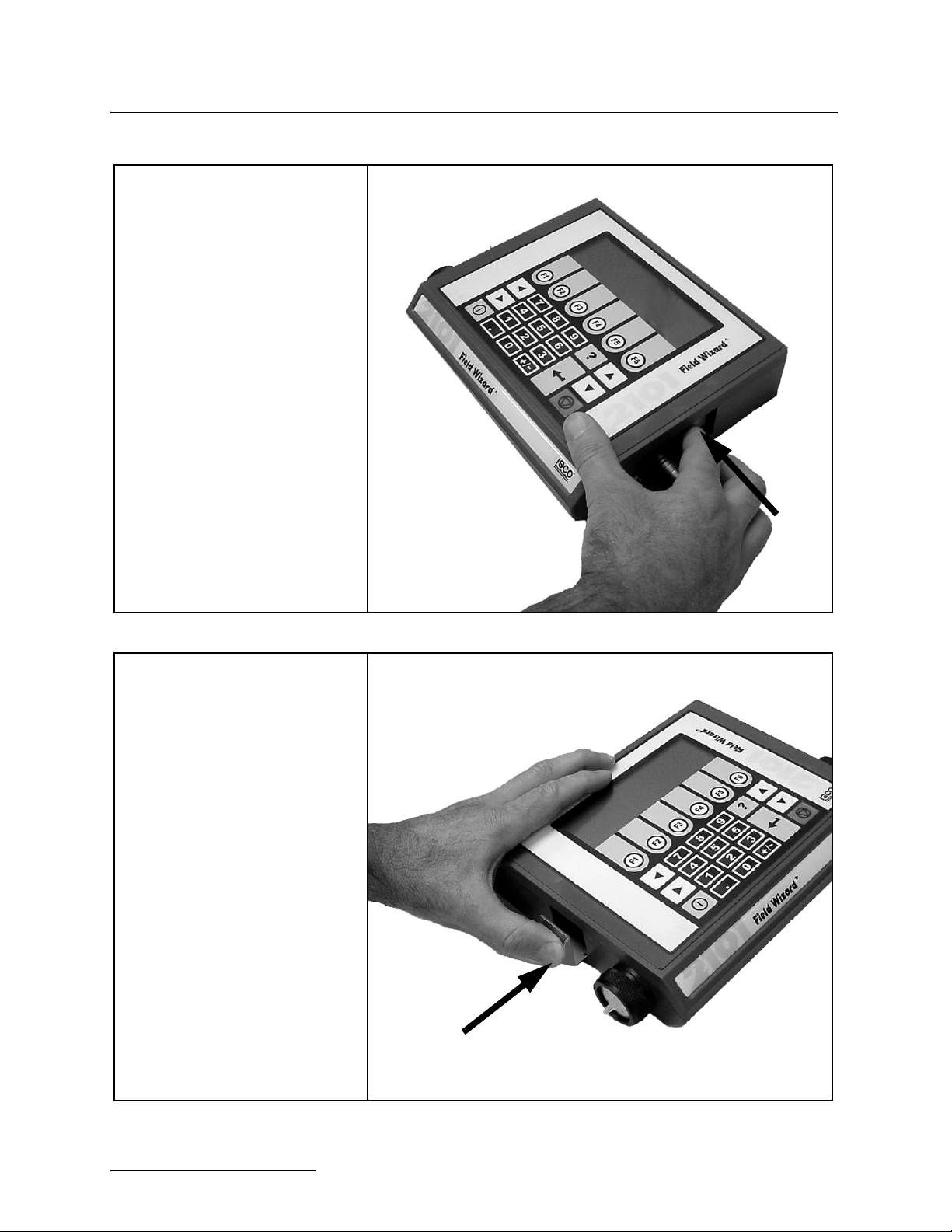

2.4.1 Latches - Locking and Unlocking

Latches must be operated to stack and unstack the modules in a

Series 2100 stack. The mechanisms are the same for the Field

Wizard and other 2100 Series modules. Take a moment to familiarize yourself with operating the latches. The latch is operated

by pushing on one of the sides — the right side to unlock, and the

left side to lock.

CAUTION

The latch can be damaged by applying too much force. Never

press on both sides at the same time. Do not force the latch if it

is obstructed. While some degree of pressure must be applied

to slide the latch, the ends of the latches should never bend

more than

L’attache peut-être endommagée en la forçant. Ne jamais

presser simultanément des deux côtés à la fois. Ne pas forcer

en cas de résistance. Ne jamais tordre les extrémités des

attaches de plus de 3 mm.

Figure 2-4 shows how to unlock the latch. You must unlock the

latch to place the module on top of a stack. Otherwise, the latch

is normally locked.

Figure 2-5 shows how to lock the latch.

1

/8".

Note

Latches will “click” when they are fully locked and unlocked.

2-5

Page 20

2101 Field Wizard

Section 2 Preparation and Installation

Figure 2 -1 :

Unlocking the latch

Locate the latch release on the

right side of the module. Push in

to slide the latch toward the left of

the module.

Push

Figure 2 -2 :

Locking the latch

Locate the latch extending from

the left side of the module. Push

in to slide the latch toward the

right of the module.

Push

2-6

Page 21

2101 Field Wizard

Section 2 Preparation and Installation

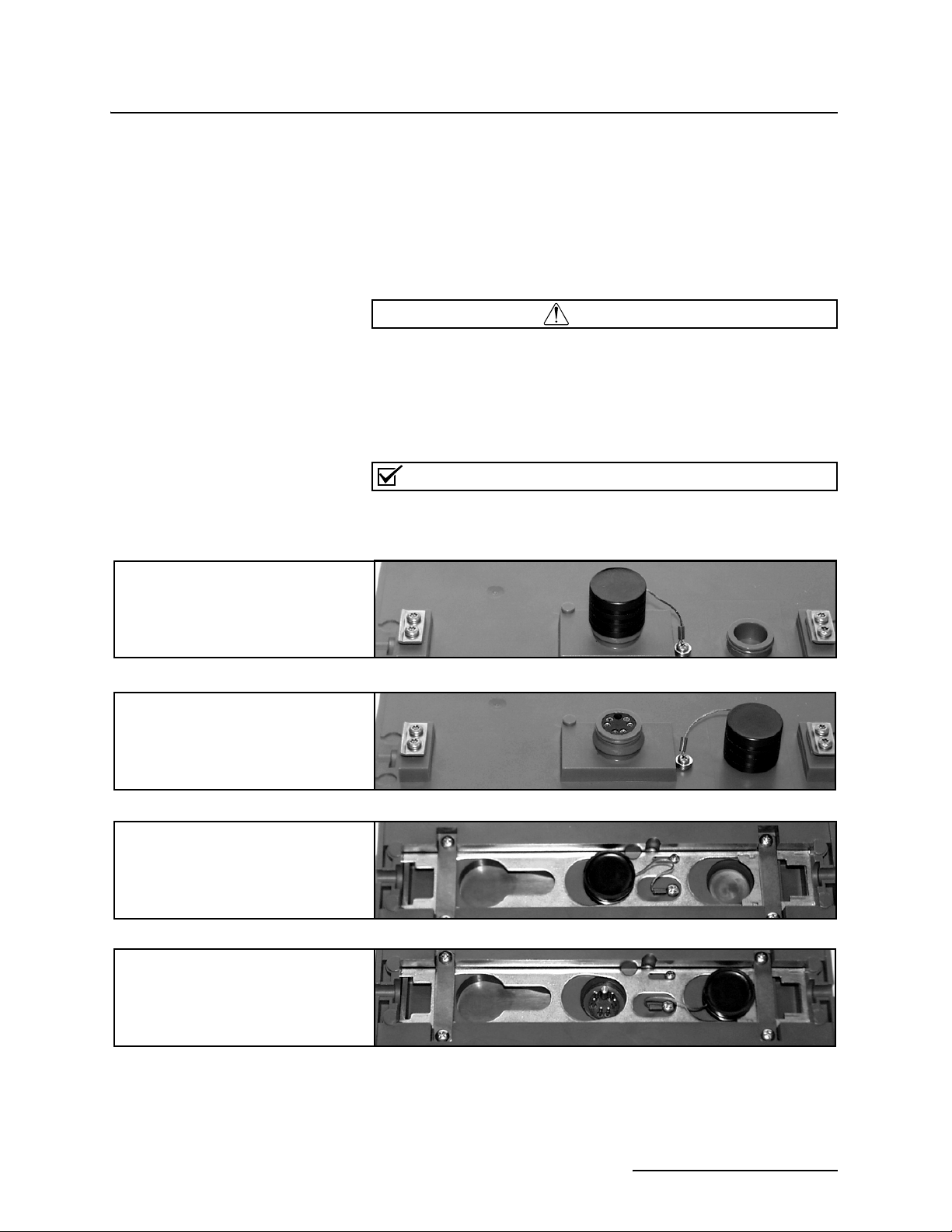

2.4.2 Communication Connectors

Figure 2-3:

2100 Series Module’s Upper

Connector - Capped

Connecting the Field Wizard module involves uncapping and

capping communication connectors. When a communication connector is not in use, the connector should always be capped

(Figures 2-6 and 2-8). The cap will seal the connector to prevent

corrosion, and will improve communications.

When a communication connector is in use, store the cap on the

holder next to the connector (Figures 2-7 and 2-9). The communication connector will be sealed by its mating connector.

CAUTION

Caps PUSH ON and PULL OFF. Do not rotate the caps to

remove them from the connectors.

Capuchons POUSSER et TIRER. Ne pas tourner les

capuchons pour les enlever des prises.

Note

For modules to correctly stack and lock together, protective

caps between the modules must be stored on the holders.

Figure 2-4:

2100 Series Module’s Upper

Connector - Uncapped

Figure 2-5 :

Field Wizard’s Lower

Connector - Capped

Figure 2-6:

Field Wizard’s Lower

Connector - Uncapped

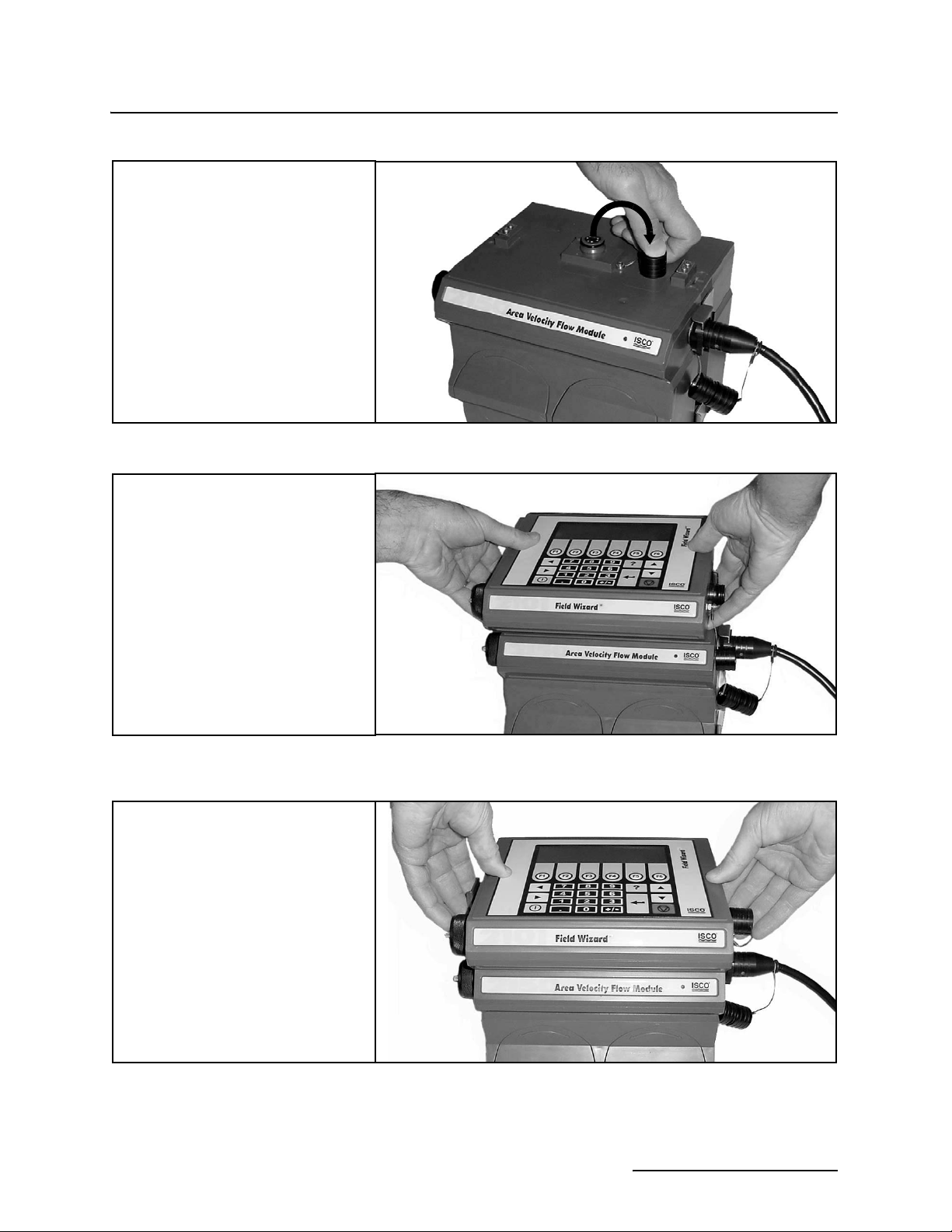

2.4.3 Stacking Modules To stack a Field Wizard Module on a 2100 Series Module, follow

the instructions in Figures 2-10 through 2-17.

2-7

Page 22

2101 Field Wizard

Section 2 Preparation and Installation

Figure 2-7 :

Field Wizard module unlock the latch

Unlock the latch to release the

lower cap.

Figure 2-8 :

Field Wizard module uncap the connector

Pull the cap off of the connector.

Figure 2-9 :

Field Wizard module push cap into holder

Push the cap into the holder.

2-8

Page 23

Fig ure 2-10 :

2100 Series Module uncap the connector

Uncap the connector on the top

2100 Series module. Store the

cap on the holder.

Fig ure 2-1 1:

Align the modules

2101 Field Wizard

Section 2 Preparation and Installation

Align the modules and gently

press the Field Wizard Module

onto the 2100 Series Module.

Figu re 2-12 :

Push down and lock

the latch

While gently pressing down on

the stack, lock the Field Wizard

Module’s latch.

2-9

Page 24

2101 Field Wizard

Section 2 Preparation and Installation

When the Field Wizard is connected to the site, you will hear a

beep and then see the display “PLEASE WAIT...” as the unit

queries the site for configuration information. When it has

obtained that information, it will format it into a display similar

to that in Figure 2-18.

Figure 2-4 Data Retrieval Mode Main Display

More details about operating the Field Wizard at a site can be

found in Section 3.4.

2-10

Page 25

2101 Field Wizard

Section 3 Operation

3.1 Introduction This section describes how to use a 2101 Field Wizard with Isco’s

Flowlink software, and how to operate the Field Wizard in the

field.

Note

The Field Wizard requires Flowlink 4.12 or later. Earlier versions do not support the Field Wizard. The Field Wizard also

requires that the 2100 Series modules it connects to have a

code version 1.06 or greater.

Flowlink Help Detailed Flowlink instructions are beyond the scope of this

manual. Flowlink’s operating instructions are available in a

Windows Help format. You can access the help topics for an

active window by clicking on its Help button or by pressing F1 on

your computer’s keyboard. You can also access Help topics by

selecting Help from the Flowlink menu.

3.2 Field Wizard Keypad The Field Wizard is operated from the top panel, which contains

a keypad and liquid crystal display.

The keypad, shown in Figure 3-1, includes 26 keys that are used

to operate the Field Wizard.

3-1

Page 26

2101 Field Wizard

Section 3 Operation

DWG 69-2003-143

Help Key

Arrow Keys

Numeric Keys

Power Key

Figure 3-1 Field Wizard Keypad and Display

The keypad contains six software configured function keys (soft

keys) that are used to make selections and navigate through

menus. Their specific functions will depend upon what operation

you are performing, and will be shown in the display window.

The four arrow keys are used for navigation. The Enter key is

used to complete data entry, acknowledge prompts, and signal

the start of certain operations. Numeric keys are active when

numeric data is to be entered.

The key with a question mark on it is the Help key. Press it to

obtain context sensitive help while using the Field Wizard. When

you are in Help mode, use the directional arrow keys to scroll

through the information displayed. Press the Help key again to

exit the Help mode.

The Power key places the unit into an ultra low power state,

during which the display window will be blank.

The Escape key is not currently used. During some operations,

one of the function keys will serve as a Cancel or Exit key.

The unit is equipped with an audible beeper. The beeper

acknowledges key presses, and signals errors when incorrect

entries are made.

Enter Key

3-2

Page 27

2101 Field Wizard

Section 3 Operation

Note

If the display is difficult to read, adjust its contrast by holding

down the Plus/Minus (+/-) key while pressing the Down or Up

Arrow key until you obtain the desired lighting level.

3.3 Flowlink Connection Before taking the Field Wizard to a site to collect data for the first

time, you need to configure it to your Flowlink software. This will

let you synchronize the Field Wizard’s date and time with that on

your personal computer (PC) and assign a module name to the

Field Wizard for identification. On subsequent connections,

Flowlink will recognize the Field Wizard from information stored

in its database.

The Field Wizard operates as an extension to Flowlink’s Master

Data Base on your PC, which synchronizes the measurement and

collection of data for all sites under its management. This centralized control insures that all measured data is collected from a

site, and that measurements are taken when expected.

Note

If you will be using the Field Wizard to transfer data to multiple

computers, you should designate one computer as the master

and connect the Field Wizard to it first. This will avoid problems

with synchronizing the date and time.

3.3.1 Connecting To a PC To connect the Field Wizard to a PC, you will need Isco’s commu-

nication cable P/N 60-2004-046 and AC Adapter P/N

60-2004-057.

One end of the AC adapter plugs into a grounded electrical

outlet, and the other end connects to the communications connector on the underside of the Field Wizard.

One end of the communication cable connects to a serial port on

your PC, and the other end connects to the communication connector on the right hand side of the Field Wizard.

Refer to Section 2.3 for more detailed instructions and diagrams

on how to make these connections.

As a default Flowlink setting, the Quick Connect dialog box

opens when you start Flowlink. (If it is not open, click the Quick

Connect icon or select File, Quick Connect.)

Click the large Field Wizard button to connect. Flowlink will

read the 2101 system information and try to match it with an

existing site in the open database. It will then display the Site

Info screen (Figure 3-2).

3-3

Page 28

2101 Field Wizard

Section 3 Operation

Figure 3-2 Flowlink Site Info Screen

Complete the following steps:

1. Click the Synchronize Instrument’s Time to Com-

puter’s button to synchronize the Field Wizard’s time to

that of your PC. (If you are using multiple PCs, select just

one PC to synchronize with.) You will be notified that this

operation will set the time of the Field Wizard to match

that of the PC. Click OK.

2. The Field Wizard is shipped with default site and module

names. Use the Site Name and Module Name fields if

you want to provide more descriptive names. Select Apply

(F9) to write that information to the instrument.

3. Click Retrieve Data (F8) to retrieve the data from the

Field Wizard. For synchronization purposes, this should be

done even if this is the first time you are connecting the

Field Wizard to the PC. The process transfers a file containing site interrogation times from Flowlink to the Field

Wizard. With this information, the Field Wizard will know

when data was last retrieved from your site(s). When

brought to a site, the Field Wizard will retrieve only the

necessary data.

The process will take some time. A gauge will be displayed

so you can monitor the progress. If needed, click Cancel to

cancel the data transfer. The data will be retained in the

Field Wizard.

Data that has been retrieved by the PC will remain in the

Field Wizard until it is connected to a site and begins collecting new data. This allows you to copy data to multiple

PCs.

4. Select Disconnect to end your PC session and disconnect

the Field Wizard.

3-4

Page 29

2101 Field Wizard

Section 3 Operation

3.3.2 Communication Resolution

During the connection process, Flowlink checks the stability of

the site’s communications. If communication is found to be

unstable, Flowlink presents the Communication Resolution

window.

There are two common causes of unstable communications. One

cause is a Module Name conflict, which may occur when two or

more modules at a site use the same module name. The second

cause is a Site Name conflict, which occurs when a module added

to the site indicates that it belongs to a different site.

The Communications Resolution window lets you choose how the

modules should be reconfigured and which Site Name should be

retained. To resolve the communications, select the sites and

modules that should be reconfigured and click the OK button. Be

aware that reconfiguring a module removes the Site Name,

Module Name, program settings, and any stored data. The

module is then restarted with the stable Site’s Name, a default

Module Name, and default program settings, and the data

storage is ready to accept new data.

3.3.3 Site and Module Name The Field Wizard is shipped with a default site and module name

so it can immediately begin to communicate with Flowlink. You

can change the names to something more descriptive using the

Site Name and Module Name fields on the Site Info tab in

Flowlink.

Keep in mind that the names must be unique among the other

site and module names in the open Flowlink database. Site

names can be up to 37 characters long. Any character may be

used in the name except:

/ forward slash \ back slash

: colon * asterisk

? question mark “ double-quote

< left angle bracket > right angle bracket

|bar

3-5

Page 30

2101 Field Wizard

Section 3 Operation

3.4 Connecting to a Site Once you have connected the Field Wizard to Flowlink and set up

the initial configuration, you can connect the Field Wizard to a

site and retrieve data.

To connect the Field Wizard, refer to the following instructions

and to Figure 3-3. For more details and a series of photos

showing the connection steps, refer to Section 2.4.

Figure 3-3 Field Wizard Connected to a 2150 Site

The Field Wizard module connects to the top of a 2100 Series

stack, which may contain multiple 2100 Series Modules.

1. On the top 2100 Series Module, remove the connector cap

from the communication connector and store the cap in its

holder.

2. Unlock the Field Wizard’s latch by pressing in on the latch

release (right side).

3. Underneath the Field Wizard module, remove the cap from

the communication connector and store the cap in its

holder.

4. Lock the Field Wizard’s latch by pressing in on the latch on

the left side. This correctly seats and aligns the cap in its

holder.

5. Position the Field Wizard over the 2100 Series Module.

Align the connectors and lower the Field Wizard onto the

Module.

6. Unlock the Field Wizard’s latch.

7. Firmly press the modules together and lock the Field Wizard’s latch.

3-6

Page 31

2101 Field Wizard

Section 3 Operation

3.5 Site Time Synchronization

Figure 3-4 Synchronize Time Display

The Field Wizard operates as an extension of the Master Data

Base computer, which is responsible for synchronizing the measurement and collection of data for all sites under its management. This centralized control insures that all measured data

is collected from a site, and that measurements are taken when

expected.

When the Field Wizard is connected to a site, its date and time

will be checked with that of the site. If the Field Wizard detects a

time difference of more than one minute, the following screen

will be displayed:

Press F1 SYNC to synchronize the site’s time with that of the

Field Wizard and the Master Computer. The time will be synchronized and you will be advanced to the Data Retrieval Mode

Main Display (Fig. 3-5).

If you do not want to synchronize the time, press F6 CANCEL to

advance to the Data Retrieval Mode Main Display (Fig. 3-5).

3.6 Data Retrieval Mode The Field Wizard will be in data retrieval mode when collecting

data from modules in the field. When the Field Wizard is connected to the site, you will hear a beep and then see the display

“PLEASE WAIT...” as the unit queries the site for configuration

information. When it has obtained that information, and

assuming that the site’s time is synchronized with the Field

Wizard, you will see a display similar to that in Figure 3-5.

3-7

Page 32

2101 Field Wizard

Section 3 Operation

Figure 3-5 Data Retrieval Mode Main Display

On the Data Retrieval Mode Main Display, the site name and

current time and date will be shown on the top line.

The module name and current measurement information will be

shown in the window. If more than one module is detected, an

indicator (X of X) after the module name will show what module

is currently being displayed and the total number of modules

found at the site.

All of the measurement data shown is live and will be updated

every fifteen seconds. If the module has more information than

can be displayed at one time, scroll arrows will appear on the

right side of the screen. Pressing the Up and Down arrow keys

will scroll through the complete information for that module.

Press F6 NEXT to display data for the next module (if there are

two or more 2100 Series modules).

The actions assigned to the function keys are summarized below.

More complete descriptions are provided in the subsections that

follow.

3-8

KEY FUNCTION DESCRIPTION

F1 RETRIEVE

F2 LOG

F3 SETUP

F4 DATA

F5 INFO

F6 NEXT

Used to collect data from the site.

Checks the status of currently stored data.

Used to maintain the site after setup on a PC.

Displays data storage statistics.

Examines system information about active modules.

Moves to next module when multiple modules exist;

is not active when there is just one module at a site.

Page 33

2101 Field Wizard

Section 3 Operation

3.6.1 Retrieve Data Display When you press F1 RETRIEVE from the Main Display, the window shown in Figure 3-6 will be displayed.

Figure 3-6 Retrieve Data Display

The Retrieve Data display has four function key options, as

described below.

F1 AUTO – Press the F1 key to retrieve data from the starting

point in time scheduled by the Master Data Base. This time is

generated each time the Field Wizard transfers data to Flowlink.

A message in the Field Wizard window will tell you the time and

date that data collection will start if you select this option.

During data collection, the name of the module being interrogated will be displayed, along with a gauge so you can note the

progress (see Figure 3-7).

If there is more than one module active at the site, then the data

will be retrieved one module at a time. One module will be completely interrogated before data will be retrieved from any other

module.

Figure 3-7 Data Retrieval Status Display

Information inside the status window will change as the interrogation process proceeds. As the data is being retrieved, both the

gauge and number of readings will change.

If you want to cancel the data collection process, press F6. This

will return you to the Main Display, and will save the data that

has already been collected.

3-9

Page 34

2101 Field Wizard

Section 3 Operation

If the data being retrieved exceeds the Field Wizard’s available

memory, data retrieval will be terminated and you will be

notified of an incomplete retrieval. All the data retrieved from

the start time to the point memory was filled will be saved in the

Field Wizard and can be downloaded to a PC.

When data collection is complete, an audible signal will sound,

and you will be returned to the Main Display.

F2 # DAYS – When you press the F2 key from the Retrieve Data

Display, you will be prompted to enter the number of days for

which data is to be retrieved. You will see the screen display

shown in Figure 3-8.

Figure 3-8 Retrieve # Days Display

Use the number keys on the keypad to enter the number of days

for which you want data to be retrieved. Press Enter.

To clear the number of days and reset it to zero, press F4 CLEAR.

To cancel your entry and return to the previous screen, press F6

CANCEL.

The system will take the current date and retrieve data starting

at midnight, including the current day (which is counted as day

zero). For example, if the current date was March 11, and you

requested to retrieve data for the past 7 days, data retrieval

would start at the beginning of March 4 and would include data

through March 11. As another example, if you entered zero (0)

days, data would be retrieved for the current day, beginning at

midnight.

During data collection, the name of the module being interrogated will be displayed, along with a gauge so you can note the

progress.

To cancel the data collection process, press F6 CANCEL. When

data collection is complete, an audible signal will sound, and you

will be returned to the Main Display.

F3 ALL – Pressing the F3 key from the Retrieve Data Display

will retrieve all data that has been stored in the modules, up to

the current time and date. This process will take some time.

F6 CANCEL – Press the F6 key from the Retrieve Data Display

to return to the Main Display.

3-10

Page 35

2101 Field Wizard

Section 3 Operation

3.6.2 Data Retrieval Log

Display

Figure 3-9 Log Display

When you press F2 LOG from the Main Display, the window

shown in Figure 3-9 will be displayed.

This display contains historical information on data that has

already been retrieved from the site and stored in the Field

Wizard. It also includes information about the status of the Field

Wizard’s storage memory.

The historical data is listed by site name, with the most recently

retrieved one listed first. The site name is followed by the time

and date the data was retrieved. An indication of the data’s handling state is listed under the “Saved” header. When data is first

collected, it will have a state of “No.” After the data has been

transferred to the Master Database on the PC, the state will

change to “Yes.”

Once you have transferred a site’s data to the Master Database

in Flowlink, it is eligible to be purged, thus freeing up memory

space to collect more data. Note, however, that site data with a

handling state of “Yes” will not be purged until the Field Wizard

has been connected to a site and data retrieval has been initiated. This allows you to transfer site data to multiple PCs

before purging the data.

Use the Up and Down arrow keys to scroll through the list of

sites. Once you have highlighted a site, you can view more

detailed information for the modules at that site by pressing F3

DETAILS.

3-11

Page 36

2101 Field Wizard

Section 3 Operation

Figure 3-10 Data Log Details Display

F3 DETAILS – When you press F3 DETAILS, a screen similar

to the one in Figure 3-10 will be displayed.

The detailed information for a site is contained in a scrolling text

window. Use the directional arrow keys to move within the

window and view the data.

The information identifies the time and date of the interrogation

and lists readings for each module at that particular site.

To exit the display and return to the Log Display, press F6 EXIT.

3.6.3 Site Setup Display The Site Setup displays shown in Figures 3-11 and 3-13 are accessed by pressing F3 SETUP from the Main Display. One of the Setup displays is for the Field Wizard; the other is for 2100 Series modules in the site’s stack.

Press F2 NEXT to move between modules. An indicator (X of X)

after the module name will indicate the total number of modules.

The Field Wizard itself is considered one of the modules.

Use the Setup displays to adjust the backlighting for the Field

Wizard and calibrate sensors and run diagnostics on the 2100

Series modules.

3-12

Page 37

Field Wizard Backlight Mode – When you press F2 NEXT

and advance to the Field Wizard module, the Setup display in

Figure 3-11 will be shown.

Figure 3-11 Field Wizard Site Setup Display

If you press F2 NEXT, you will advance to the next module’s Site

Setup display screen. If you press F6 EXIT, you will return to the

Data Retrieval Mode Main Display.

Press F4 SELECT to change the backlight mode for the Field

Wizard. The following screen will be displayed:

2101 Field Wizard

Section 3 Operation

Figure 3-12 Field Wizard Backlight Mode Settings

There are three options for the backlight mode on the Field

Wizard. Highlight the desired option and press F1 APPLY to

select that option. Press F6 CANCEL to return to the Field

Wizard Site Setup display.

ALWAYS OFF - The backlight will always be off.

ALWAYS ON - The backlight will always be on.

KEYPRESS TIMEOUT - After one minute of inactivity, the backlight will turn off until a key is pressed.

3-13

Page 38

2101 Field Wizard

Section 3 Operation

Figure 3-13 Site Setup Display

2100 Series Site Setup – If you press F2 NEXT and advance to

a 2100 Series module, the Setup display shown in Figure 3-13

will appear.

The Site Setup display is used to calibrate sensors and run diagnostics on sensors. Module sensor information, such as level and

flow rate, is presented inside the display window. Use the Up and

Down arrow keys to scroll within the window.

Measurement Calibration – Level sensors can be calibrated

using the Field Wizard. Before you can calibrate, one valid

reading must have been taken so there is a value to calibrate to.

On the Site Setup display, use F2 NEXT to display the module

you want to calibrate, then press F3 CALIB. The Level Calibration window for the selected module will appear (Figure 3-14).

Figure 3-14 Level Calibration Display

3-14

The level currently being detected will be displayed. To change

the level, use the numeric keys and then press Enter. You will be

returned to the Site Setup display. The message “Updating” will

appear in the Level field momentarily while the system updates

its information.

To clear an entry, press F4 CLEAR. To cancel the process and

return to the Site Setup display, press F6 CANCEL.

Page 39

Sensor Diagnostics – When you press F5 DIAG from the Site

Setup display, the diagnostic screen shown in Figure 3-15 will be

displayed.

Figure 3-15 Sensor Diagnostics Display

After a momentary delay, during which the Field Wizard

requests the report from the 2100 Series module, a screen containing diagnostic results for the selected module’s sensors will

appear. Use the four directional arrow keys to scroll through the

information.

Once you have viewed the information, press F6 EXIT to exit to

the Site Setup display.

2101 Field Wizard

Section 3 Operation

3.6.4 Data Display When you press F4 DATA from the Main Display, the Data screen shown in Figure 3-16 will appear.

Figure 3-16 Data Display

This display shows information about the data stored inside the

currently selected module: the time and date of the most recent

reading, total number of readings, and the quality of the readings

(percentage that are good). Use the Up and Down arrow keys to

scroll through the information.

When multiple 2100 Series modules are present, you can press

F2 NEXT to display the information for a different module.

3-15

Page 40

2101 Field Wizard

Section 3 Operation

Press F1 RETRIEV to retrieve the data for the displayed module.

You will be advanced to the Retrieve Data Display, described in

Section 3.6.1.

Press F6 EXIT to return to the Main Display.

3.6.5 Site Information

Display

Figure 3-17 Site Information Display

When you press F5 INFO from the Main Display, the Site Information screen is displayed (Figure 3-17).

This screen shows information about module models and names,

as well as hardware and software revision numbers. Use the Up

and Down arrow keys to scroll between the different modules.

To identify a module, highlight it using the arrow keys and then

press F5 IDENTIFY. This will cause the LED for that module to

light up continuously for a short period of time. If you press F5

IDENTIFY when Field Wizard is highlighted, the system beeps.

Press F6 EXIT to return to the Main Display.

3.7 Standalone Mode When the Field Wizard is not connected to a site or a PC, it is in

standalone mode. The Main Display in standalone mode is shown

in Figure 3-18.

Figure 3-18 Standalone Mode Main Display

In this mode, you can examine the data log stored inside the

Field Wizard unit, but will not be able to view or process the

actual data.

3-16

Page 41

2101 Field Wizard

Section 3 Operation

To view the data retrieval log, press F2 LOG. The display will be

similar to that shown in Figure 3-9 and described in Section

3.5.2.

3.7.1 Standalone

Information Display

Figure 3-19 Standalone Information Display

Pressing F5 INFO while in the standalone mode will display the

Standalone Information screen (Figure 3-19).

This screen is similar to that described in Section 3.5.4, except

that it only lists information pertaining to the Field Wizard itself.

Because it is not connected to a site, there isn’t any module information.

To exit from the Standalone Information Display, press F6 EXIT.

3.8 PC Data Synchronization Mode

Figure 3-20 PC Data Synchronization Mode Display

When the Field Wizard is connected to a PC, the user interface

(keypad) is locked out to prevent any errors while transmitting

data to the PC.

In this mode, the Field Wizard’s display looks like that shown in

Figure 3-20.

The Field Wizard’s keypad will not function in this mode, but will

return to normal function when the Field Wizard is disconnected

from the PC.

3-17

Page 42

2101 Field Wizard

Section 3 Operation

3-18

Page 43

2101 Field Wizard

Section 4 Modbus Protocol

Sections 4.1 through 4.5 give an overview of the basic capabilities

and operation of Modbus protocol as it applies to Isco 2100 Series

flow modules.

For a Glossary of Terms and Common Acronyms, see sections 4.4

and 4.5.

For Modbus technical specifications, turn to section 4.6.

4.1 Introduction Modbus is a simple command/response mechanism to read from

and write to specific memory locations called registers. A register

is a holding place for a piece of digital information within the

equipment. There are three standard protocols for Modbus:

Modbus RTU, Modbus TCP/IP, and Modbus ASCII. The Isco 2100

Series devices use Modbus ASCII protocol, the method discussed

in this manual. Modbus ASCII has more flexible communication

timing requirements. Modbus communication for the Isco 2100

Series provides a standard protocol that can be used to retrieve

real-time data from a single module or stack of modules at a site,

or multiple sites, over a wide area. The data can be sent to a

central computer for display, data collection, or process control.

Modbus implementation is independent of Flowlink and cannot

alter the Flowlink-programmed configuration of the module.

Modbus cannot be used to retrieve historical data from a

module’s memory.

Due to the wide variety of configurations that can be made with

Modbus, it is impossible to cover every usable application. This

section will discuss the overall capabilities and operation of

Modbus.

4.2 Operation There are many standard, third party Modbus drivers and OPC

servers that may be used to link a remote Modbus device, such as

a 2100 Series module, to SCADA or process control software,

such as Wonderware™ or Intellution™. The OPC server communicates with the remote instrumentation and accesses registers.

The definition of what information is contained and where (the

register number, or address) is decided by the manufacturer

(Teledyne Isco).

In a 2100 module, the registers hold, but are not limited to, the

current real-time value of the meter’s level, velocity, flow, input

voltage, temperature, and total flow readings, stored in specified

register locations. A list of the 2100 register addresses, and what

parameters are held where, is available in section 4.6.

4-1

Page 44

2101 Field Wizard

Section 4 Modbus Protocol

By accessing these registers you can obtain the current value of

whatever parameter you desire. The reading(s) can then be displayed or stored wherever you designate as a destination; for

example, a process control computer.

Note

Level, flow, velocity, and temperature data is stored in metric

units only.

Not all registers are limited to read-only data storage. You can

also use some registers for control purposes. For example, by

writing a “1” value to register 24 (“Identify Module” register), you

will tell a 2100 module to light the LED on the front of the

module.

4.2.1 Establishing Communication

4.2.2 Module Addressing When connecting to a site via a Modbus OPC server, you use a

There are several different communications protocols supported

in the 2100 series that require auto-baud rate detection. Because

of this, each time a modbus connection is made, the module uses

a polling mechanism to repeatedly send a command until a

response is received. It may take up to 20 command retries

before the module has identified the baud rate and a response is

received.

dedicated line of communication to that module or stack from the

OPC server, which can be a dedicated communications cable

(direct connection) or a dedicated phone number (modem).

When you are using a direct connection, you are dedicating a

specified COM port on the computer, and that COM port determines the site to which you are connecting.

When you are using a modem, the dedicated line is defined by

the site's phone number.

If you connect more than one 2100 Series module at a site, the

Modbus OPC server, while using the shared communication line

for all of the modules within the network, must have some way to

differentiate between the modules. When sending a command to

a specific module, the command has an address field. This allows

the server software to talk to, as well as control, the specified

module, while ignoring other modules in the same stack or site.

Each module capable of Modbus Protocol communication will

automatically create its own specific ASCII address within the

site, using:

• The model numbers of the modules

• The user-defined module names

4-2

Page 45

2101 Field Wizard

Section 4 Modbus Protocol

4.3 Configurations A variety of configurations can be made with Modbus, either

through direct connection or through a modem.

In the example shown in Figure 4-1, you are direct-connecting a

server PC to two individual 2150s through Modbus, using the

COM ports on the OPC Server, which are directly connected to

the remote 2150s.

Connection to the module is made through the RS-232 communication port on the top of the module.

Note

For low power operation, we recommend connecting the module(s) to the computer using the straight-through cable (Isco

part number 60-5314-529), which consumes less power,

instead of our standard interrogation cable.

In Figure 4-1, the OPC Server PC must have two COM ports.

Modbus requires one COM port each, for direct connection of

each 2150.

2150

2150

Figure 4-1 Configuration Example (Direct Connection Shown)

The operation sequence for the example above can be summarized in the following steps:

2150:

1. 2150s take readings from probes.

2. 2150s store readings (level, velocity, flow rate, etc.) in their

specified registers.

Process Control:

3. The user requests data through Process Control.

4. Process Control asks the OPC server to gather information.

COM

port 1

COM

port 2

OPC

Server

Process

Control

4-3

Page 46

2101 Field Wizard

Section 4 Modbus Protocol

5. OPC connects to the 2150 stack through the cable (direct

connection), takes register data from the specified 2150,

and populates the OPC server's holding index.

6. Process Control takes data from the OPC server's holding

index and gives data to the user.

Note that Process Control can be either manual or automated in

this example, and that the OPC server and Process Control may

be located physically on the same computer.

4.4 Glossary of Terms ASCII – Short for American Standard Code for Information

Interchange, ASCII is a code that represents English characters

with numbers. Most computers represent text with ASCII code,

making it possible for one computer or device to share data with

another.

2100 modules support Modbus ASCII protocol.

Dedicated Line – A telecommunications path reserved for communication between two specified points and not shared among

multiple points.

Modbus Protocol – Modbus Protocol is a messaging structure

used to establish master-slave/client server communications

between intelligent devices. Modbus is a simple

command/response mechanism to read from and write to registers.

OPC – OPC (OLE for Process Control) means open connectivity

via open (free for use) standards. It is a series of software standards specifications that fill a need in automation (like printer

drivers did for Windows), acting as a translator for data transmission and process control.

The specification defines a standard set of objects, interfaces, and

methods for use in process control and manufacturing automation applications to facilitate interoperability. There are hundreds of OPC Data Access servers and clients.

Registers – Registers are locations in memory that have specific

data stored for retrieval or are used for control functions. A register is a holding place for a piece of digital information within

the equipment. The definition of what is contained and where

(the registry number, or address) is decided by the manufacturer

(in this case Teledyne Isco).

SCADA – SCADA (Supervisory Control And Data Acquisition)

is a computer system for gathering and analyzing real-time data.

SCADA systems are used to monitor and control plant operation,

or equipment in industries such as telecommunications, water

and waste control, energy, oil and gas refining, and transportation.

The SCADA system transfers the information (for example,

where a leak has occurred in a pipeline), back to a central site,

alerting the home station of the leak, performing necessary

analysis and control (such as determining if the leak is critical),

and displaying the information in a logical and organized

manner.

4-4

Page 47

2101 Field Wizard

Section 4 Modbus Protocol

SCADA systems can be relatively simple, such as one that monitors the environmental conditions of a small office building, or

very complex, such as a system that monitors all the activity in a

nuclear power plant or a municipal water system.

4.5 Common Acronyms ASCII – American Standard Code for Information Interchange

DCS – Distributed Control Systems

MTU – Master Terminal Unit

OPC – Object Linking and Embedding (OLE) for Process Control

PLC – Programmable Logic Controller

RTU – Remote Terminal Unit

SCADA – Supervisory Control And Data Acquisition

TCP/IP – Transmission Control Protocol/Internet Protocol

4-5

Page 48

2101 Field Wizard

Section 4 Modbus Protocol

4.6 Register Specifications All numbers in the Modbus registers are stored most significant

byte first. If the polling device has a byte ordering of least significant byte first (an Intel-based PC, for example), the bytes will

need to be reversed after they are received.

The Modbus ASCII address is used to index the data by modules.

Modbus ASCII address 1 contains information related to the site.

The first register contains a 16-bit integer count of the number of

modules that have data to report. The maximum number of

modules that can be supported is 4.

Modbus ASCII addresses 2 through the number of modules plus

1 contain data from the individual modules.

The Modbus ASCII addresses will be sorted by the model

number, and then by module name, which is entered by the user

through Flowlink. This allows the user to control the ordering of

the addresses and easily predict what data will be in specific registers.

Every measured parameter has a corresponding status and measurement time that are updated with each measurement.

The maximum number of supported measurements from all

modules in the system is 28.

The Modbus registers are assigned within 30 seconds after the

2100 module is powered up. To conserve power for the users who

do not use Modbus communications, no Modbus registers will be

updated with sensor readings until a Modbus master communicates with the 2100 module.

The register definitions for the Site Information device (Modbus

ASCII address 1) are in Table 4-1 below:

4-6

Table 4-1 Modbus ASCII Address 1 Register Definitions

Register

Number(s)

1 Number of

2-20 Site name 38-byte string None Read

Name Data type Units Read/Write

16 bit integer None Read

modules (N)

(1-4)

Page 49

2101 Field Wizard

Section 4 Modbus Protocol

The register definitions for the individual modules (Modbus

ASCII addresses 2-(N+1)) are in Table 4-1 below:

Table 4-2 Modbus ASCII Address 2-(N+1) Register Definitions

Register Number(s) Name Data Type Units Read/Write

1-4 Model number 8-byte string None Read

5-23 Module name 38-byte string None Read

1

24

2

25

3

26

4

27

28 Active flag 2 16 bit field None Read

29 Active flag 3 16 bit field None Read

30 Active flag 4 16 bit field None Read

40,41 Level 4-byte float Meters Read

42 Level status code

43-52 Level time record Time

55,56 Velocity 4-byte float Meters/second Read

57 Velocity status code 16-bit integer Read

Identify module 16 bit integer None Read/Write

Take reading flag 16 bit integer None Read/Write

Update interval 16 bit integer Seconds Read/Write

Active flag 1 16 bit field None Read

5

16-bit integer Read

6

Read

58-63 Velocity time record Time Read

70,71 Flow 4-byte float Cubic Meters/sec Read

72 Flow status code 16-bit integer Read

73-78 Flow time record Time Read

85,86 Flow 1 4-byte float Cubic Meters/sec Read

87 Flow 1 status code 16-bit integer Read

88-93 Flow 1 time record Time Read

100,101 Volume 4-byte float Cubic Meters Read

102 Volume status code 16-bit integer Read

103-108 Volume time record Time Read

115,116 Volume 1 4-byte float Cubic Meters Read

4-7

Page 50

2101 Field Wizard

Section 4 Modbus Protocol

Table 4-2 Modbus ASCII Address 2-(N+1) Register Definitions (Continued)

Register Number(s) Name Data Type Units Read/Write

(1) A write to the Identify module register will cause the module to perform the identify operation which may be a steady

LED for a few seconds or a beep in the Field Wizard.

(2) Setting the Take Reading flag to 1 will cause the module to update the registers with current data readings. It will

be set to zero when the readings have all been updated. This may be used to initiate readings and poll for when

they are ready to be read. It may take up to 50 seconds to update all the readings, depending upon the flow conditions. Setting the Take Reading flag to 2 causes an automatic, 15 second update of readings when a Modbus

master is polling the 2100.

(3) The Update Interval specifies an interval in seconds that the registers are automatically updated. It defaults to zero,

which indicates that no automatic updating will occur.

(4) The Active Flag (1-4) bit fields specify what fields/registers are active in the list. This provides support for a maxi-

mum of 64 fields. For example, if bit 0 of register 27 is set, the Level (registers 40,41) is active. If bit 1 of register

27 is set, then the Velocity (registers 55,56) is active. If bit 0 of register 28 is set, the Analog channel 7 (registers

265,266) is active.

(5)A non-zero status code indicates a measurement problem.

(6) Time is represented in a series of registers: Order is from lowest address to highest - Seconds (0-59), Minutes (0-59),

117 Volume 1 status code 16-bit integer Read

118-123 Volume 1 time record Time Read

130,131 Voltage 4-byte float Volts Read

Hours (0-23), Days (1-31), Month (1-12) and Year (1977-2099).

132 Voltage status code 16-bit integer Read

133-138 Voltage time record Time Read

145,146 Temperature 4-byte float Degrees Celsius Read

147 Temperature status code 16-bit integer Read

148-153 Temperature time record Time Read

160,161 Internal Temp 4-byte float Degrees Celsius Read

162 Internal Temp status code 16-bit integer Read

163-168 Internal Temp time record Time Read

175,176 Analog channel 1 4-byte float 0-100 percent Read

177 Analog channel 1 status code 16-bit integer Read

178-183 Analog channel 1 time record Time Read

190,191 Analog channel 2 4-byte float 0-100 percent Read

192 Analog channel 2 status code 16-bit integer Read

193-198 Analog channel 2 time Record Time Read

205,206 Analog channel 3 4-byte float 0-100 percent Read

207 Analog channel 3 status code 16-bit integer Read

208-213 Analog channel 3 time record Time Read

220,221 Analog channel 4 4-byte float 0-100 percent Read

222 Analog channel 4 status code 16-bit integer Read

223-228 Analog channel 4 time record Time Read

4-8

235,236 Analog channel 5 4-byte float 0-100 percent Read

237 Analog channel 5 status code 16-bit integer Read

Page 51

2101 Field Wizard

Section 4 Modbus Protocol

Table 4-2 Modbus ASCII Address 2-(N+1) Register Definitions (Continued)

Register Number(s) Name Data Type Units Read/Write

238-243 Analog channel 5 time record Time Read

250,251 Analog channel 6 4-byte float 0-100 percent Read

252 Analog channel 6 status code 16-bit integer Read

253-258 Analog channel 6 time record Time Read

265,266 Analog channel 7 4-byte float 0-100 percent Read

267 Analog channel 7 status code 16-bit integer Read

268-273 Analog channel 7 time record Time Read

280,281 Analog channel 8 4-byte float 0-100 percent Read

282 Analog channel 8 status code 16-bit integer Read

283-288 Analog channel 8 time record Time Read

Table 4-3 Measurement Parameters by Model Number*

2103, 2103C 2108 2110 2150, 2151

Voltage Analog channel 1 Level Level

Analog channel 2 Flow Velocity

Analog channel 3 Volume Flow

Voltage Flow 1

Temperature Volume

Volume 1

Voltage

Temperature

*Subject to change.

4-9

Page 52

2101 Field Wizard

Section 4 Modbus Protocol

4-10

Page 53

2101 Field Wizard

Section 5 Maintenance

5.1 Maintenance Overview

This section explains the maintenance requirements of the 2101

Field Wizard.

The Field Wizard is designed to perform reliably in adverse conditions with a minimal amount of routine service requirements.

To keep your system working properly, you should check the desiccant and channel conditions at regular intervals.

Maintenance intervals are affected by many variables. Humidity

levels obviously affect the service life of the desiccant, and the

amount of debris in the stream can drastically alter the channel

conditions.

As a guide, for a basic system installed in an environment with

moderate humidity levels, the maintenance interval should not

exceed three months. A basic system is defined as:

• a single 2100 Series Module,

• powered by a fresh pair of alkaline lantern batteries,

• recording readings at the default intervals of 15

minutes.

Experience is often the best tool to use when establishing

minimum maintenance intervals for your system. Until you have

gained an understanding of the A-V Module’s operation under

differing environmental conditions, a weekly maintenance

interval is recommended.

5.1.1 Cleaning The Field Wizard case may be cleaned using a soft cloth and a mild detergent. Do not use an abrasive cleanser, or you might scratch the surface of the case. Be particularly careful when cleaning the display screen; scratches will make it difficult to read the display

Before cleaning, make sure that all the protective connector caps

are in place to avoid damage to any of the connectors. You should

also ensure that no water or cleanser enters the desiccant unit.

5.2 Maintenance Kit Some of the parts mentioned in the Maintenance section of this

Teledyne Isco, Inc.

Customer Service Dept.

P.O. Box 82531

Lincoln, NE 68501 USA

Phone: (800) 228-4373

(402) 464-0231

FAX: (402) 465-3022

E-mail: info@isco.com

manual are available in a maintenance kit.

Kit number 60-2009-001 contains O-rings for the connectors and

desiccant cartridge, a desiccant assembly, and a 1.5 pound container of silica gel desiccant.

You can order the kit by calling Teledyne Isco’s Customer Service

Department.

5-1

Page 54

2101 Field Wizard

Section 5 Maintenance

5.3 Desiccant The Field Wizard uses desiccant to protect the internal compo-

nents from moisture damage. The cartridge is filled with indicating silica gel that is blue or yellow when dry. As the desiccant

becomes saturated, the color changes from blue to pink, or from

yellow to green. Replace the desiccant before the entire length of

the cartridge turns pink or green.

5.3.1 Replacing the

Desiccant: 2101