Telect MDC-CB User Manual

MetroLinks Distribution Cabinet (MDC-CB)

User Manual 131220 A0

Content s

1. Description

MDC-CB Without Rear Compartment Splicing................................................................................................ 1-3

MDC-CB With Rear Compartment In-Cabinet Splicing ....................................... ... ... ... .... ... ........................... 1-4

Front Compartment Cross Connections ......................................................................................................... 1-5

Features ......................................................................................................................................................... 1-6

Benefits .......................................................................................................................................................... 1-6

Specifications & Capacities .................................................... ... ... ... .... ........................................................... 1-6

2. Cabinet Installation

Installation Considerations ............................................................................................................................. 2-1

Pre-Installation ............................................................................................................................................... 2-1

Location & Layout — ................................ ... ... .... ... ....................................... ... ... ... .... ... ... ........................ 2-1

Tools & Equipment — ............................................................................................................................. 2-3

Inspection ................................. .................................................................... .................................................. 2-3

Installation Procedure ..................................................................................................................................... 2-3

3. Cabling Without In-Cabinet Splicing

Feeder Cable Installation ............................................................................................................................... 3-1

Patch Module & Distribution Cable Installation .............................................................................................. 3-4

4. Cabling With In-Cabinet Splicing

Splice Box Installation ........................ ... .... ... ... ... ....................................... ... ... .... ... ... ... .... .............................. 4-1

Patch Module Installation ............................................................................................................................... 4-1

Feeder Cable Installation ............................................................................................................................... 4-3

Distribution Cable Installation ......................................................................................................................... 4-9

Routing Feeder & Distribution Loose Tubing .................................................................................................4-11

5. Cross Connections

6. Service

Technical Support ........................................................................................................................................... 6-1

In-Warranty Service ........................................................................................................................................ 6-1

Out-Of-Warranty Service ................................................................................................................................ 6-1

Repacking For Shipment . ... ... ... .... ... ... ... .... ... ... ....................................... ... ... ... .... ... ... ... .... ... ........................... 6-2

Cleaning Patch Module Connectors & Adapters ............................................................................................ 6-2

7. Accessories

Standard Accessories ...................................................... ... ....................................... ... .... .............................. 7-1

In-Cabinet Splicing Accessories ............................ .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ..................................... 7-3

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved • Telect Publication 125147-3 A0

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Co

pyright © 2006 Telect, Inc., All Rights Reserved

Page iv

1. Description

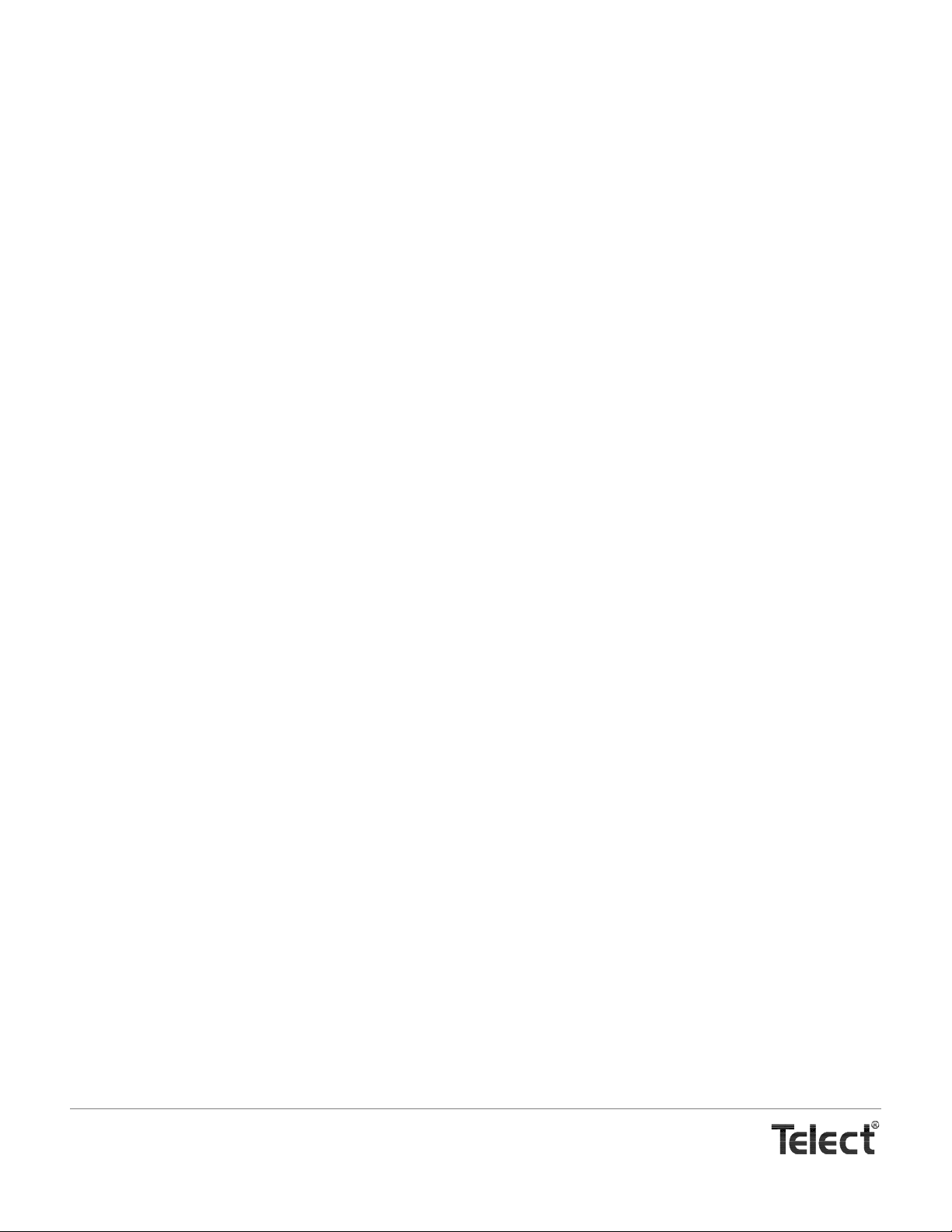

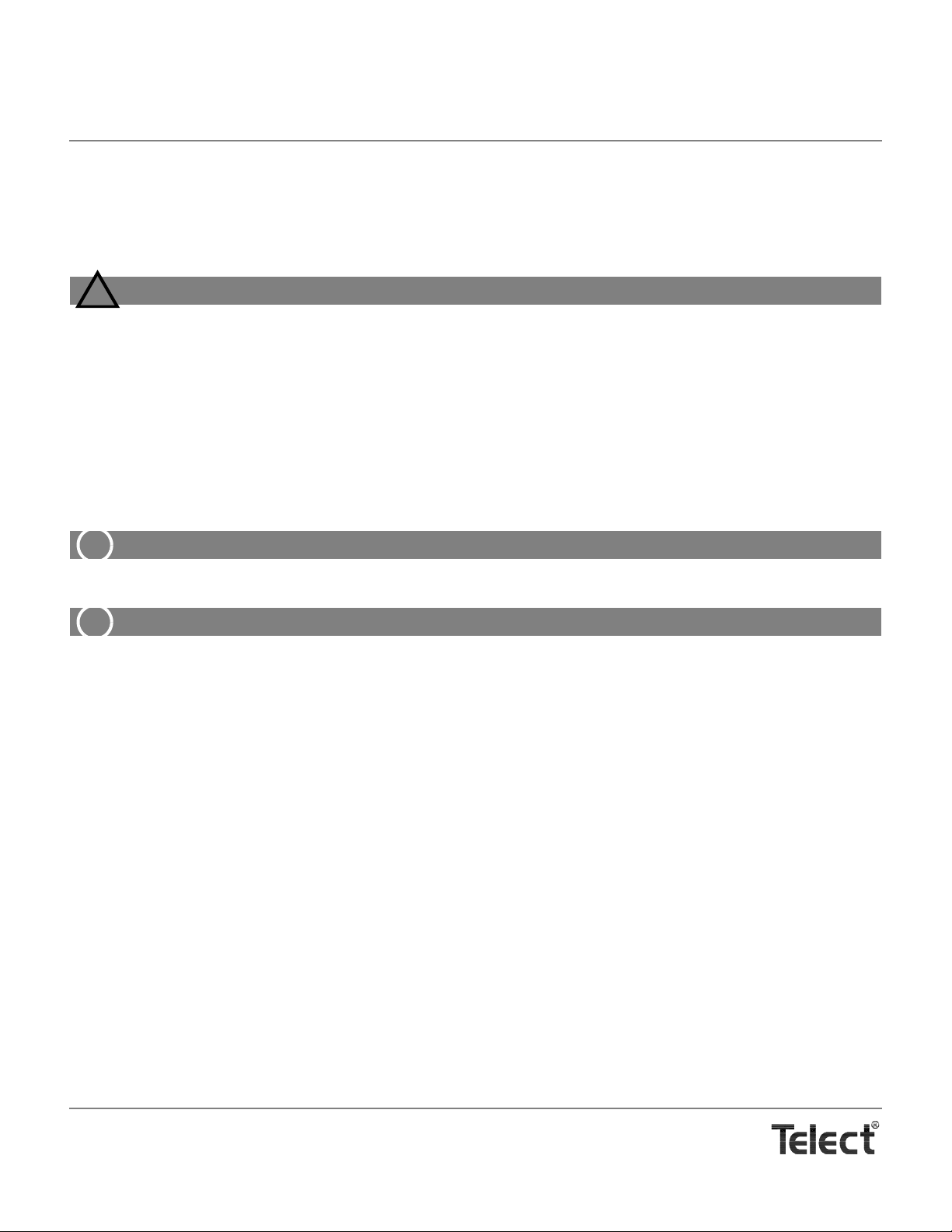

Distribution Adapters

Feeders to Front

Compartment

Feeder & Distribution

Cable Entrances

Lances for Anchoring Cable

& Subunits

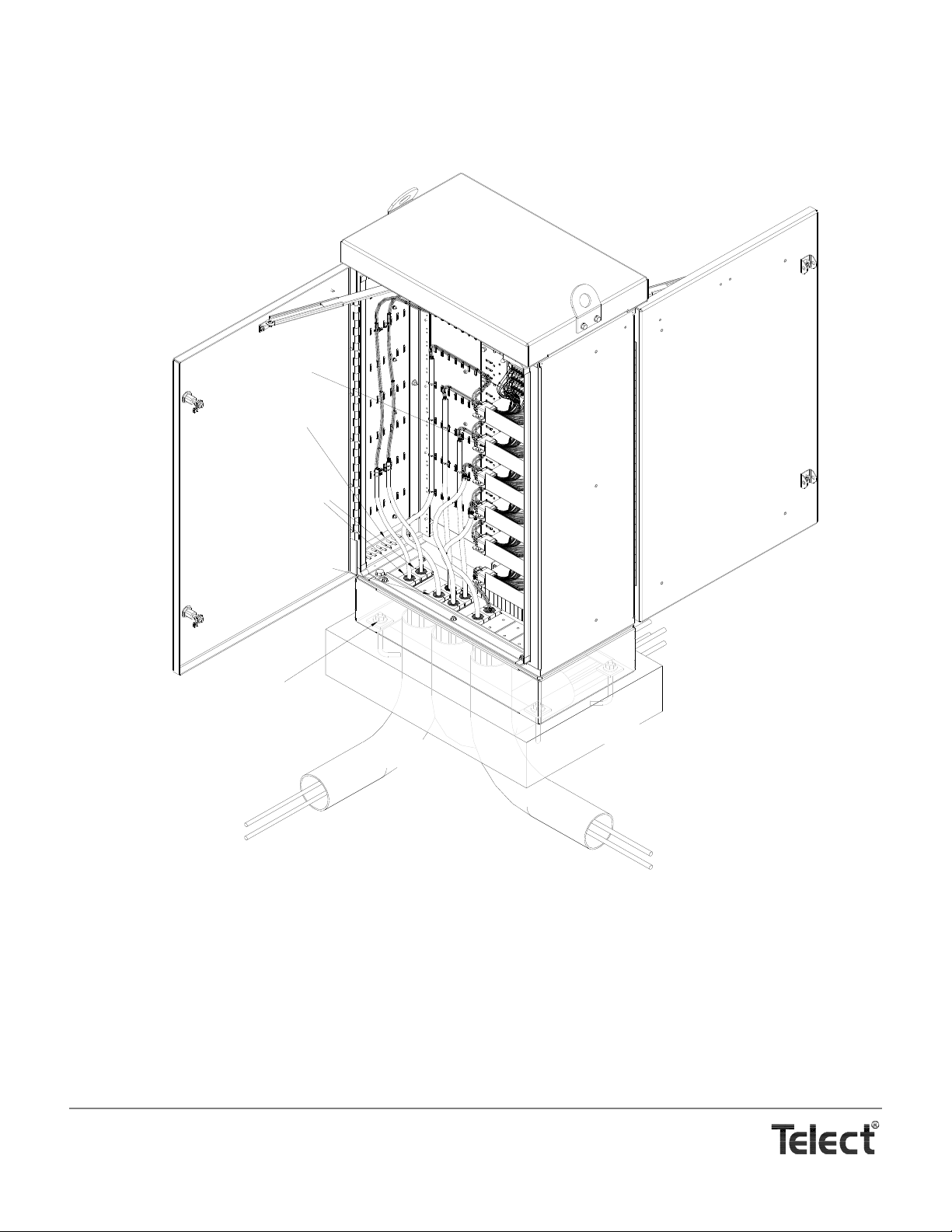

MDC-CB Without In-Cabinet Splicing (Rear Corner View)

Cabinet

Base

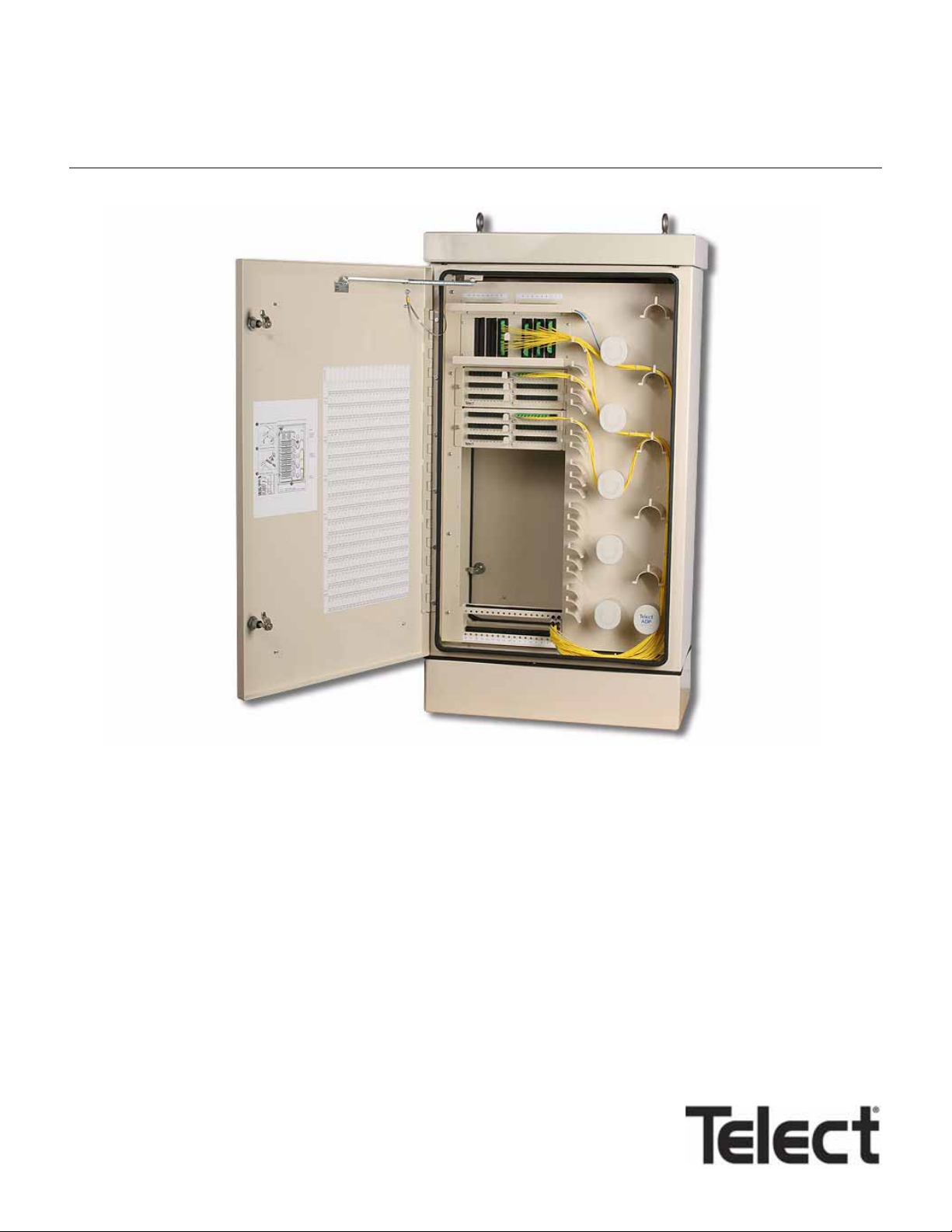

Telect’s MDC-CB is an indoor/outdoor fiber telecommunication distribution cabinet. The cabinet h ouses T elect’s bulkhead-style Patch Modules to

handle optical signal distributio n between a CO and the network edge. A

single MDC-CB cabinet with up to six Telect Patch Modules can provide

distribution service to 432 homes, offices and/or nodes.

The weather-tight, heavy-gauge, light-weight aluminum cabinet is almond with

two lockable doors — both doors have wind stays. OSP feeder and distribution

cable enter through weather-tight cable clamps at the bottom of the rear compartment:

Illustrations that follow depict open-door views of MDC-CB cabinets with and

without in-cabinet splicing.

Along with the cabinet, Telect includes a footprint template which is also the isolation pad, two cable entrance clamps for two feeder cables between

mm) and 1

ing the door latches. The MDC-CB includes a 6-in. base. A 12-in. Telect base

(Model MDC-R12) is optional.

Physically, the only difference between MDC-CB cabinets with or without splicing is the splice box on the rear door. Feeder and distribution cabling for the two

is, however, quite different.

1

/5 in. (30.5 mm) in diameter, and a 9/32 in. Allen-head key for open-

3

/8 in. (9.6

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved • Telect Publication 131220 A0

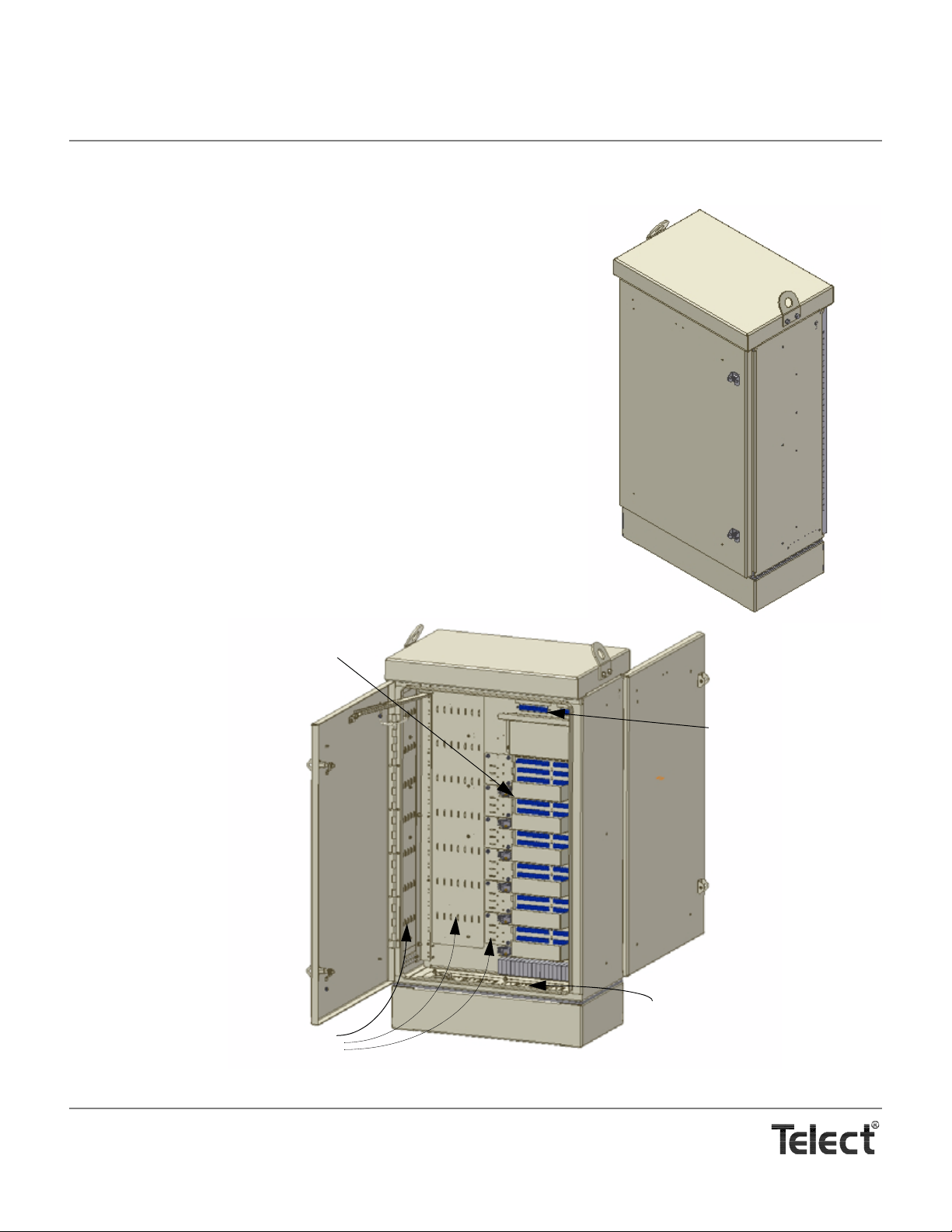

Distribution Adapters

Feeders to Front

Compartment

Lances for Anchoring Cable,

Feeder & Distribution

Cable Entrances

Subunits, and Loose Tu bing

Splice Box

Model MDC-SPLC

MDC-CB With In-Cabinet Splice Box (Rear Corner View)

Parking for Unassigned

Distribution

Feeders from Rear

Compartment to Splitters

Adapters for Assigned Distribution

Splitters in Splitter

Bulkhead

Front Corner View With Door Open

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved

Page 1-2

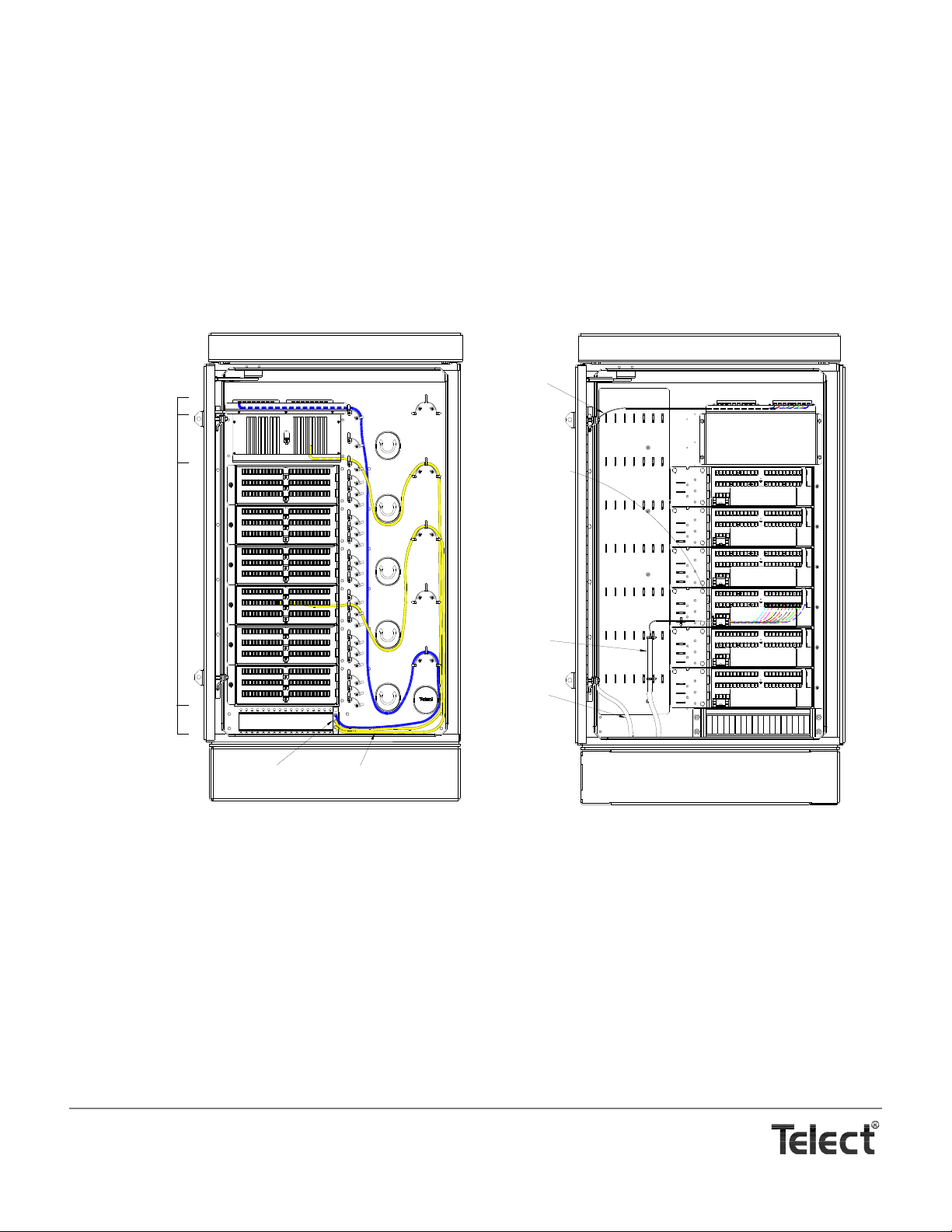

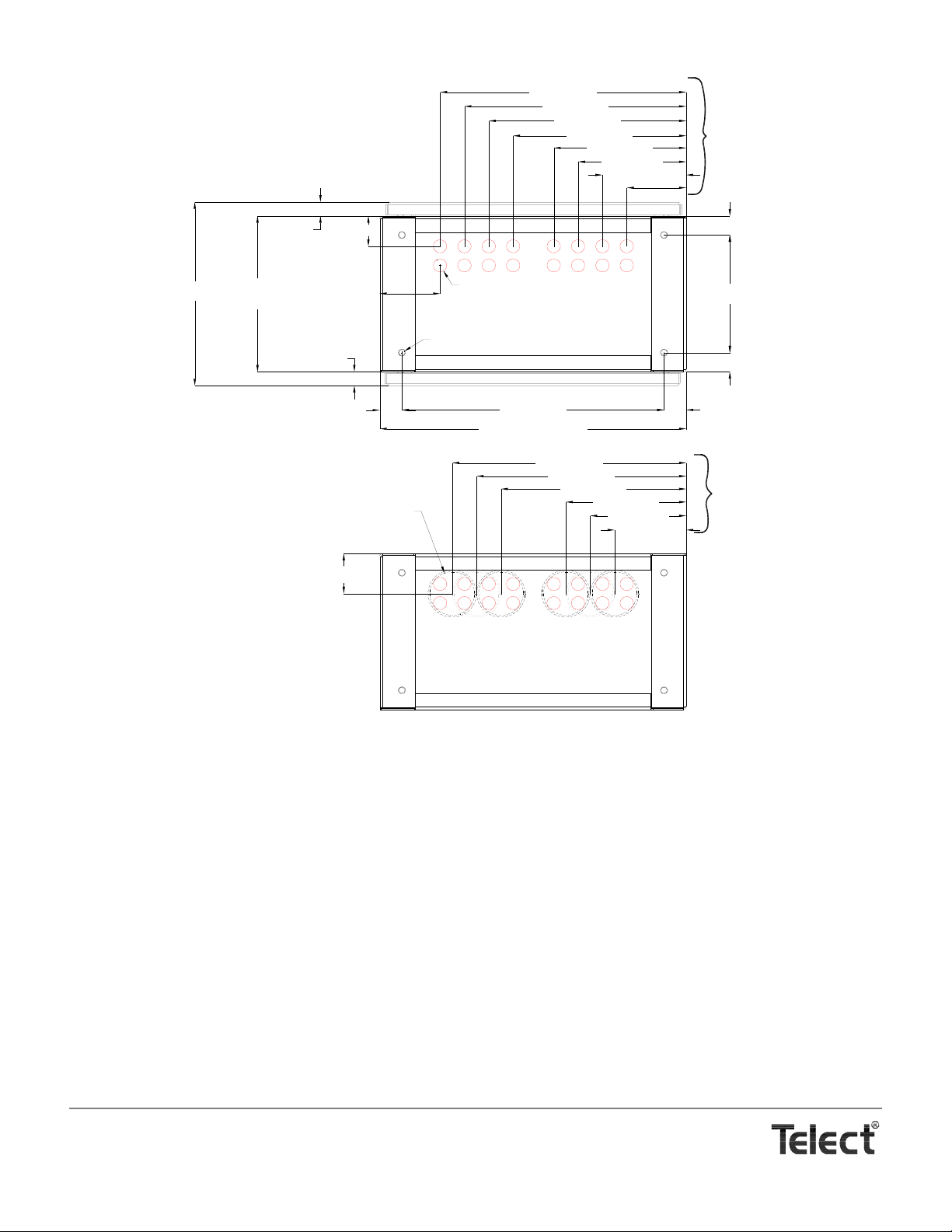

.MDC-CB WITHOUT REAR COMPARTMENT SPLICING

Front View With Door Open

*

Feeders

Assigned

Distribution

to Subscriber

Unassigned

Distribution

(Parking)

Splitter

Bulkhead

2 mm Jumpers

Splitter Module

OSP

Distribution

Cable

OSP Feeder

Cable

Subunit/Buffer

From Feeder

Cable Breakout

to Rear-Side

Feeder

Adapters

Fiber Furcated

From Multifiber

Buffer to

900-

µm Single

Fiber Loose

Tubing

Rear View With Door Open

*

* Splitter and Patch Modules are sold separately.

Cabling without in-cabinet splicing involves an aerial or below-ground splice box for splicing the distribution and feeder cables to

connectorized cabinet cabling.

• At the cabinet, the OSP distribution cable is clamped at the floor of the rear compartment and then routed along the cabinet’s compartment partition. The connectorized 250 µm strands break out here into subunits/buffers and then connected to

one of the six possible, 72-channel Patch Modules. Each patch module contains SC/APC adapters to interface the distribution fiber in the rear compartment to the cross connections in the front compartment.

• Feeder cable is anchored along the rear side wall where 900 µm fiber breaks out into subunits/buffers and routed to 16

SC/APC interface adapters near the top of the cabinet.

Each SC/APC adapter at the top of the cabinet serves to feed the fiber signal to a blue jumper in the front compartment, shown in the

preceding illustration. The blue jumper is routed down through the right portion of t he front compartment, then around a couple of

spools and an arc. The two spools at the bottom route the blue fiber to a Telect Splitter Module.

Up to 18, 1x4, 1x8, 1x16, or 1x32 Telect Splitter Modules can be installed in the splitter bulkhead at the bottom of the front compartment. Each splitter module consists of the splitter, one blue “input” jumper, and either 4, 8, 16, or 32 yellow “output” jumpers. All are

2 mm jumpers, 2.1 m in length.

Splitter module installation and all of the distribution changes occur in this front compartment:

• Unassigned jumpers are routed via spools and arcs to a parking station for later subscriber assignment.

• Assigned jumpers are routed via the spools and arcs to the front of the SC/APC adapters in the front of the patch modules

for cross connection to the distribution fiber connected to the rear of the patch modules.

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved

Page 1-3

Each of the six possible patch modules (Model MDC-P72N) features 72 SC/APC cross-connect adapters for a total of 432 possible

4-in. Conduits

Two Cable Entrance Clamps

Are Included With Cabinet

To Accommodate

Two Feeder Cables*

Concrete Pad

One Cable Entrance Clamp

For a Distribution Cable*

Is Included With The

Patch Module

* Cable Entrance Clamps Accommodate

Cable Between 3/8 in. & 1-1/5 in.

In Dia. Additional clamps

Anchors & Conduit Are

Not Included With Cabinet.

Rear of Patch Module

Bar for Grounding

Single-Armored Cable

are available.

subscriber cross connections. Model MDC-P72N-F100D includes the Model MDC-P72N connected to 100 ft (~30.5 m) of Dri-Flex™

OSP cable containing 250 µm fiber furcated to 900 µm loose tubing with an SC/APC connector.

The following illustration shows a deployed cabinet along with a partially cabled rear compartment.

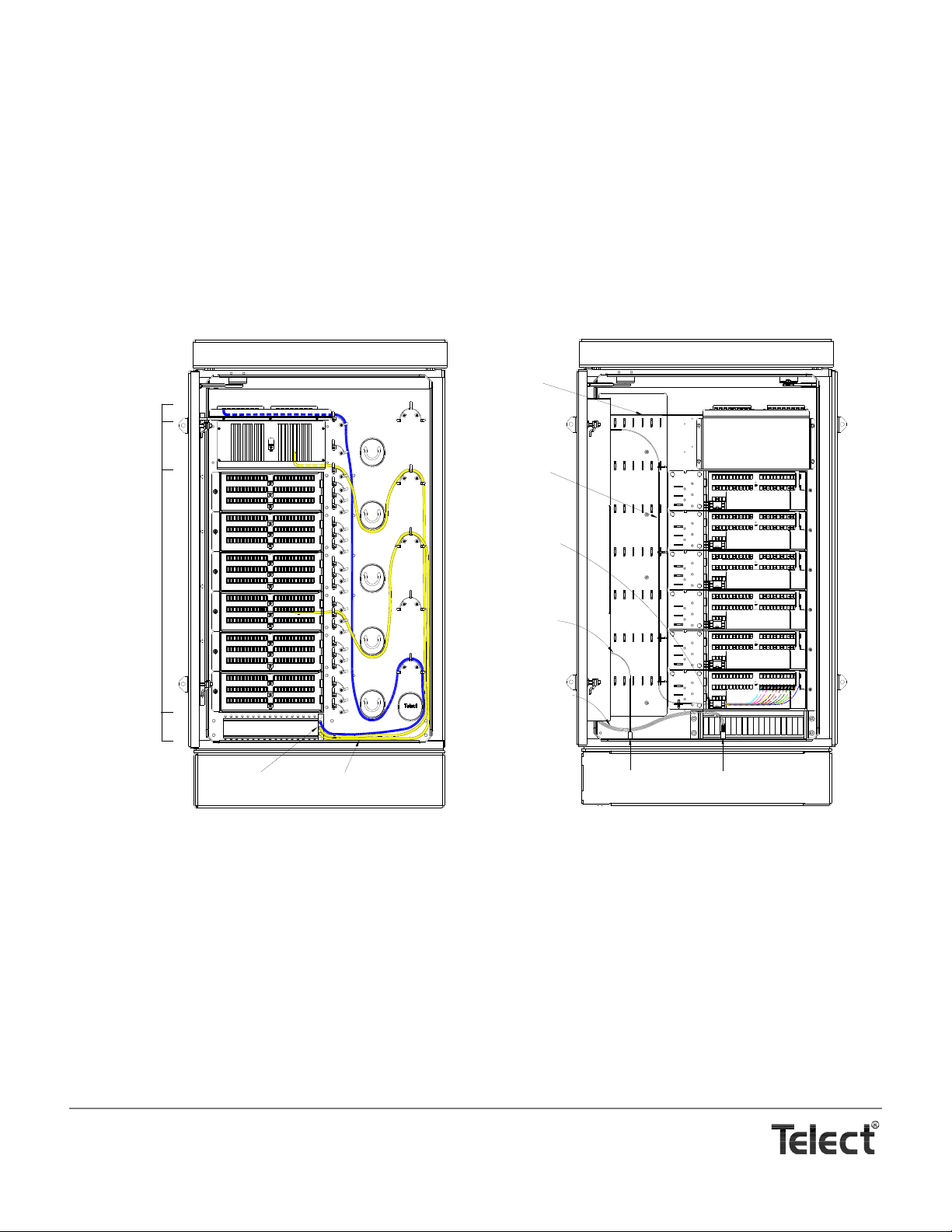

MDC-CB WITH REAR COMPARTMENT IN-CABINET SPLICING

The distribution and feeder OSP enter the cabinet at the floor of the rear compartment. The installer clamps the cable and breaks out

the fiber into 3-mm, radius-control (limited bend) loose tubing. The installer anchors feeder and distribution tubes along the cabinet’s

side wall and rear door.The tubes are guided to the top of the optional splice box located on the door.

The optional in-cabinet Telect Splice Box (Model MDC-SPLC) holds three pods of splice cassettes surrounded by a runway for the

loose tubing.

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved

Page 1-4

Each cassette normally accommodates 24 splices. If all feeder and distribution fiber requires splicing, a total of 18 cassettes are

Feeders

Assigned

Distribution

to Subscriber

Unassigned

Distribution

(Parking)

Splitter

Bulkhead

2 mm Jumpers

Splitter Module

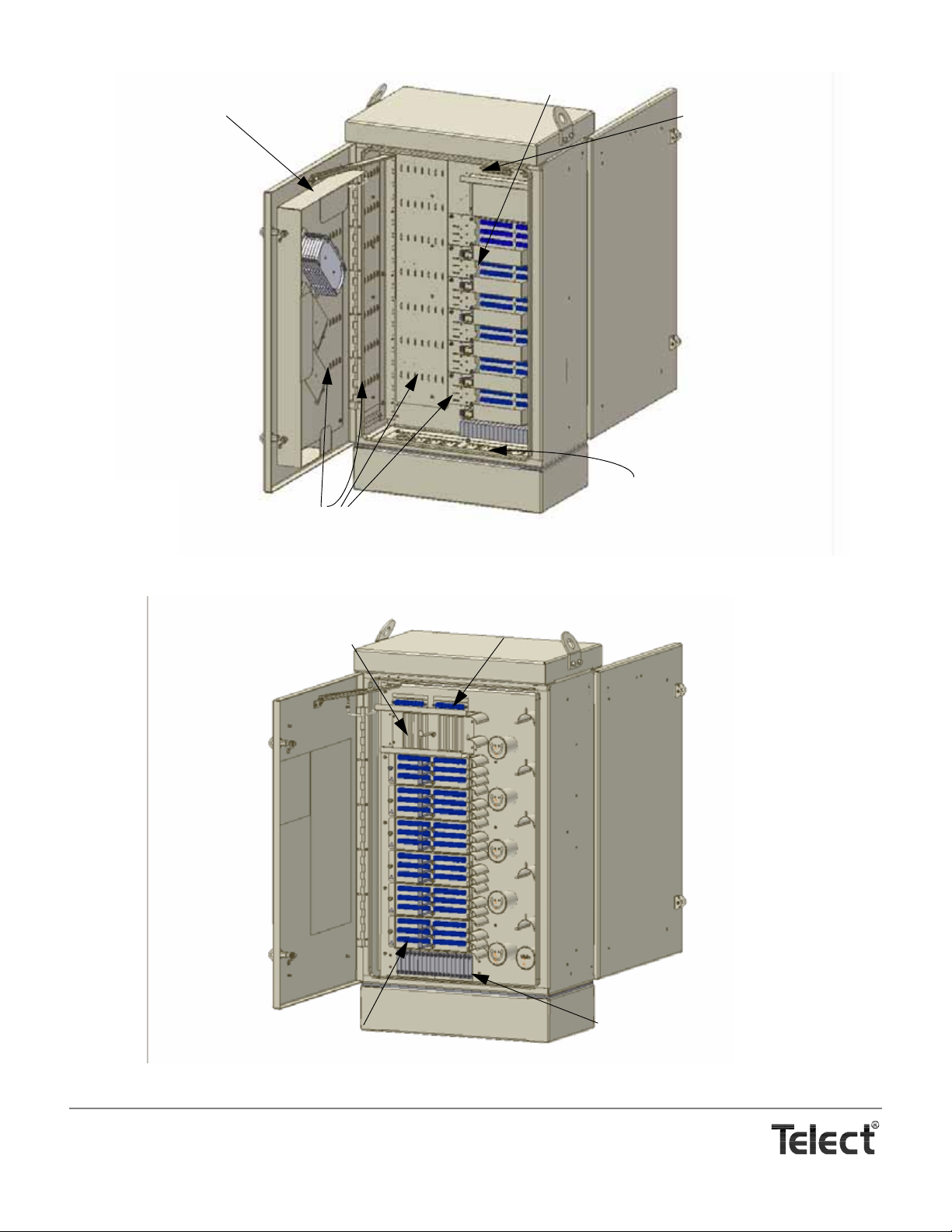

Front View With Door Open

*

Rear View With Door Open

*

Loose Tubing

From Splice

Box to

Rear-Side

Feeder

Adapters

Loose Tubing

From Splice Box

to Rear-Side

Distribution

Adapters

OSP Feeder

Cable From CO

OSP Distribution

Cable

Loose Tubing

From Feeder

Cable to Splice

Box

Loose Tubing

From Distribution

Cable to Splice

Box

Fiber Furcated

From 3-mm

Multifiber Loose

Tubing to

900-

µm Single

Fiber Loose

Tubing

* Splitter Modules, Patch Modules, Splice Box, Splice Cassettes, Fan-Out Blocks, and Radius-Control Loose Tubing are Sold Separately.

needed to accommodate all 432 subscribers. For the distribution splices, each pod would hold 6 splice cassettes plus one additional

cassette on one of the pods for up to 16 feeder splices.

Feeder and distribution strands are spliced to connectorized fiber protected by 3-mm, radius control loose tubing. All tubing from the

cassettes to the feeder interface and patch modules cross the door hinge near the top of the cabinet. The tubing is anchored along

the compartment partition and guided to SC/APC feeder or distribution adapters:

• The feeder interface near the top, rear-side of the cabinet contains 16 adapters to pass feeder signals to the front compartment splitters.

• The distribution adapters are located on 72-port modules (Models MDC-P72N). Fa n-out blocks on the Patch Modules are

used to accommodate the transition from 3-mm, multi-fiber loose tubing to 900 µm transparent tubes, one for each of the

72 fibers. A total of 6 Patch Modules accommodate the 432 possible subscribers. The SC/APC adapters pass signals to the

front compartment for assignment patching.

FRONT COMPARTMENT CROSS CONNECTIONS

Front compartment feeder and cross-connect cabling is the same for cabinets with or without in-cabinet splicing.

Each SC/APC adapter at the top of the cabinet serves to feed the fiber signal to a blue jumper in the front compartment. The blue

jumper is routed down through the right portion of the front compartment, then around a couple of spools and an arc. The two spools

at the bottom route the blue fiber to a Telect Splitter Module.

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved

Page 1-5

Up to 18, 1x4, 1x8, 1x16, or 1x32 Telect Splitter Modules can be installed in the splitter bulkhead at the bottom of the front compartment. Each splitter module consists of the splitter, one blue “input” jumper, and either 4, 8, 16, or 32 yellow “output” jumpers. All are

2 mm jumpers, 2.1 m in length.

Splitter module installation and all of the distribution changes (patching) occur in this front compartment:

• Unassigned jumpers are routed via spools and arcs to a parking station for later subscriber assignment.

• Assigned jumpers are routed via the spools and arcs to the front of the SC/APC adapters in the front of the patch modules

for cross connection to the distribution fiber connected to the rear of the patch modules.

FEATURES

• Simple cabling scheme. Separate compartments for OSP cable (feeder & distribution at the rear) with splitter growth an d

cross-connections at the front

• Patch module bulkhead swings out into front compartment for convenient adapter and connector inspection and maintenance

• 30 mm (min.) bend radius control throughout cabinet & accessories

• Highest splitter density — up to 32 splits per splitter module

• Expandable. Easily add splitter modules as distribution grows

• Popular bulkhead-style modular distribution (up to 6, 72-channel patch modules)

• Bulkhead-style splitter bank for up to 18 Splitter Modules containing 1x4, 1x8, 1x16, or 1x32, premium PLC splitters

• Laser eye protection throughout. All adapters and connectors include dust caps

• Front & rear padlockable doors with wind strays (padlocks not included). Routing guide and designation chart located conveniently on inside of front door.

• Includes grounding bar for armored cable.

BENEFITS

• Low cost — High Fiber Density — Versatility

• Better access — full front and rear doors open wide for simple access and installation

• Simple Site Prep

• Easy Installation. Ideal for both local and remote sites

• Designed for compliance: NEMA 4, GR-771, GR-487

• Designed & Built for Growth

• Simple, straight-forward cable management, access, circuit identification.

SPECIFICATIONS & CAPACITIES

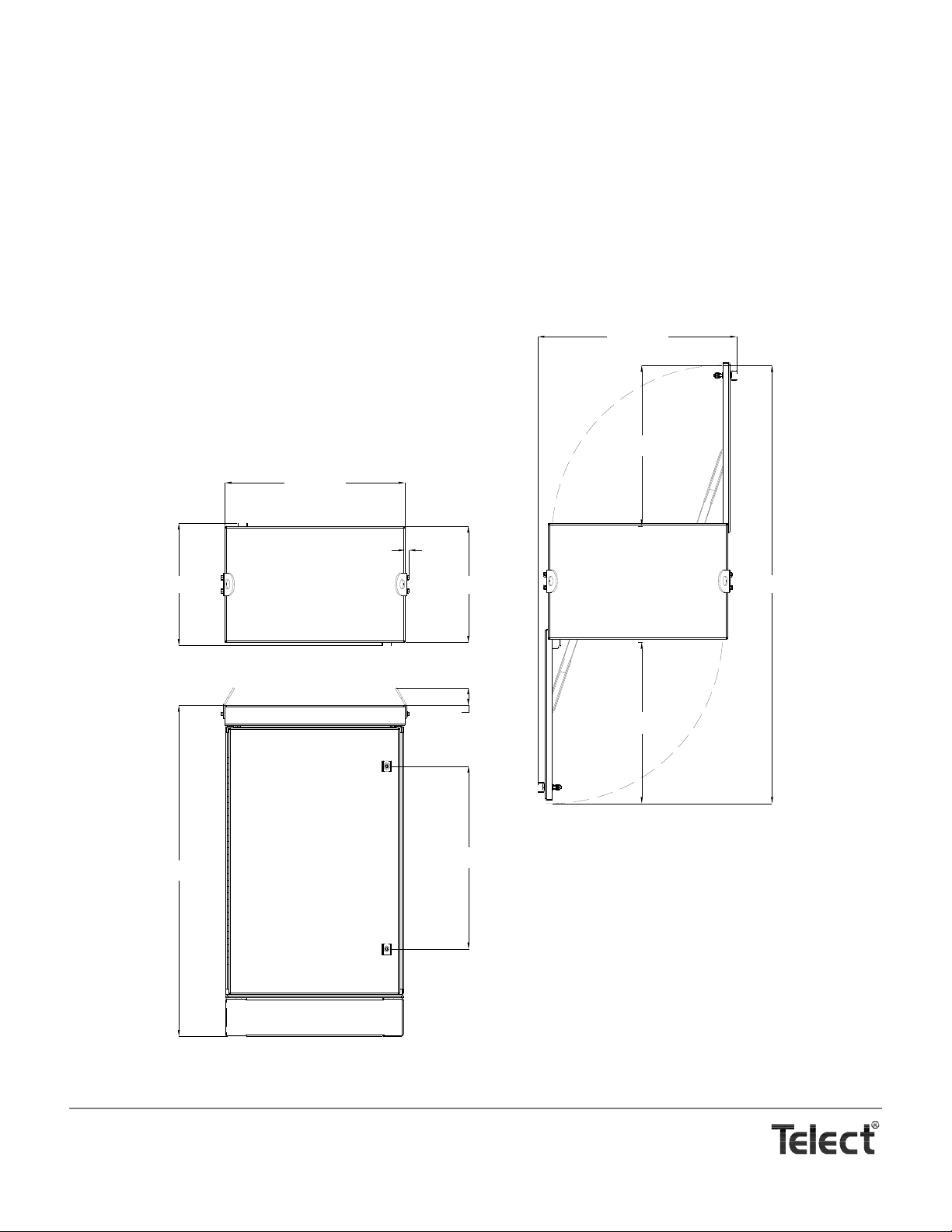

• Dimensions (Overall WxHxD): 28 x 54 x 18 in (710 x 1375 x 460 mm). See the following for detailed dimensions.

• Weight (without modules, accessories, or cabling): ~125 lb (~60 kg).

• Feeder & Distribution Cable Entrance Positions/Capacity: 16

• Cable Diameter:

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved

3

/8 in. (9.6 mm) to 11/5 in. (30 mm), max.

Page 1-6

• Fiber Signals: 16 feeder signals, max.; 432 distribution signals, max.

30.74 [780.9]

67.79 [1721.9]

27.86 [707.7]

18.00 [457.2]

18.94 [481.0]

2.72 [69.1]

51.24 [1301.4]

24.87 [631.7]

24.92 [633.0]

28.31 [719.0]

0.64 [16.2]

• Adapters: SC/APC at cabinet end of fibers

• Cross-Connect Bulkhead Positions: 6, max. Each bulkhead accommodates 72 X-connects (6 x 72 = 432)

• Splitter Module Positions: 18, max. Each accommodates a 1x4, 1x8, 1x16 or 1x32 Telect Splitter Modules with front

access installation and cabling. “Inputs” and “outputs” are 2-mm jumpers, 2.1 m long with SC/APC connectors

• Parking Positions: 72, max., to accommodate unassigned split-

ter “outputs”

• Cabinet Material: 0.125 in, 5052 Aluminum

• Cabinet Finish: Powder-coat almond

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved

Page 1-7

Page 1- 8

2. Cabinet Installation

WARNING

!

ALERT

!

ALERT

!

INSTALLATION CONSIDERATIONS

WARNING! Fiber ca bles transmit invi sible infrared light . To avoid eye damage or b lindness, never loo k directly

into fibers or connectors.

WARNUNG! Faserkabel übertragen unsichtbares Infrarotlicht. Um eine Schädigung der Augen oder Blindheit

zu vermeiden, schauen Sie nicht direkt in die Fasern oder Stecker.

ADVERTENCIA ! Los cables de fibra transmiten luz láser o infrarroja invisible. Para evitar lesiones oculares o

ceguera, nunca mire directamente a las fibras o conectores.

AVERTISSMENT ! Les câbles à fibres transmettent un rayon laser ou une lumière infrarouge invisible. Pour

éviter toute lésion occulaire ou cécité, ne regardez jamais directement dans les fibres ou dans les

connecteurs.

ALERT! This product must be installed and maintained only by qualified technicians.

ALERT! These instructions presume you have verified that the Telect equipment being inst alled is compatible

with the rest of the system, including power , ground, cir cuit protection, signal char acteristics, equipment from

other vendors, and local codes or ordinances.

PRE-INSTALLATION

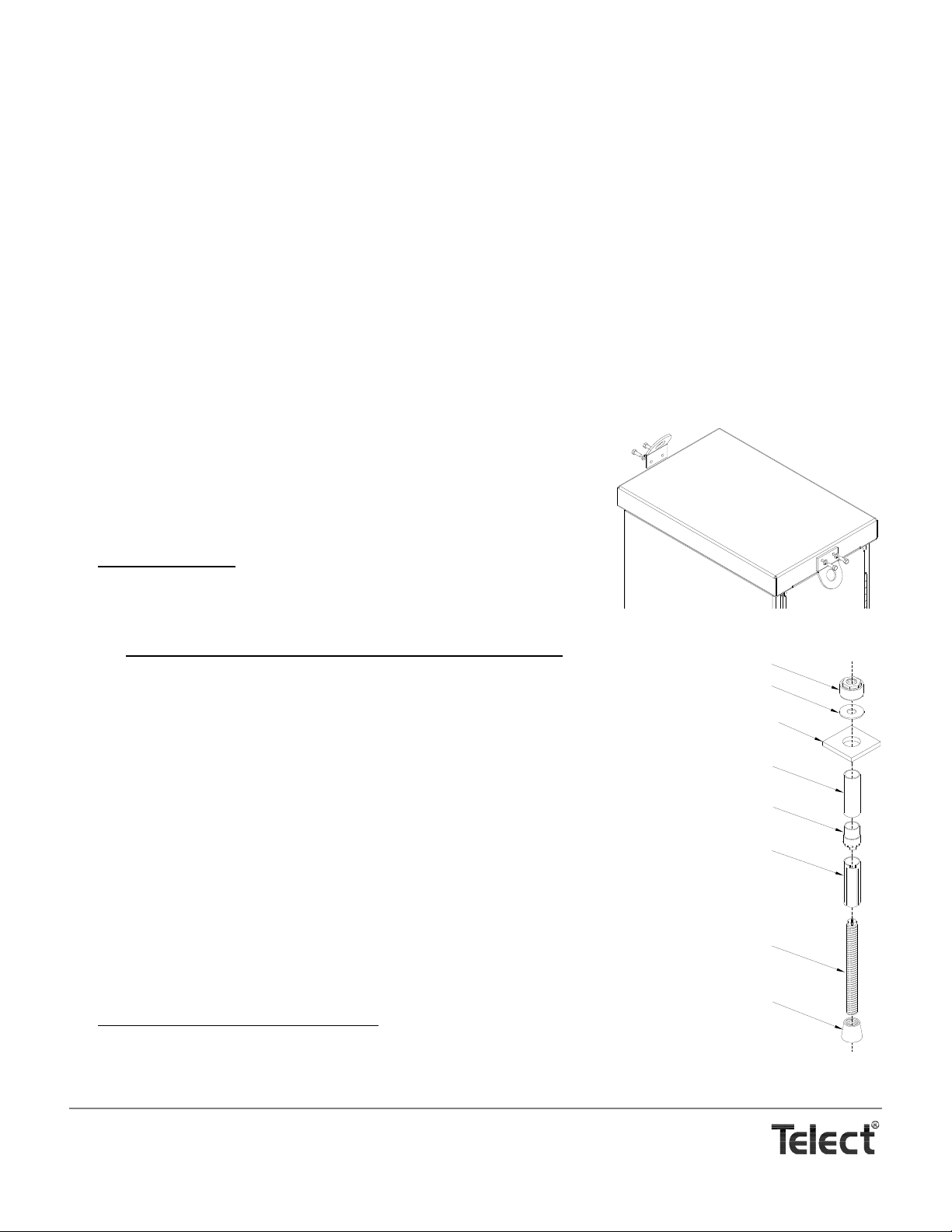

Location & Layout —

Use the floor template (isolation pad), or the following illustration, to lay out and construct a re-enforced concrete pad, grating, or

other suitable, stable platform to accommodate the cabinet, anchorage, and cabling. Concrete pads must be at least 6 in. (~150

mm) thick.

Telect does not include an anchor kit or a vault-to-cabinet adapter with the cabinet. Order Telect’s seismic anchor kit (Model

MDC-CBAK) for either indoor or outdoor deployment on concrete. (See “Standard Accessories” Page 7-1.) Model MDC-CBAK

is an expansion-style anchor requiring drilling into the pad; also acceptable are embed L-shaped anchors with ½ in. (M12)

threads, available at appropriate hardware or specialty stores.

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved • Telect Publication 131220 A0

16.85 [428.0]

1.28 [32.5]

1.28 [32.4]

14.29 [363.0]

Footprint

Ø0.50 [Ø12.7]

Anchor Holes

10.79 [274.0]

23.52 [597.4]

1.99 [50.6]

1.99 [50.6]

1.75 [44.5]

1.75 [44.5]

27.50 [698.5] Footprint

Ø4.00 [Ø101.6] Stub-Up Conduit

6.43 [163.2]

8.61 [218.7]

10.80 [274.2]

16.62 [422.2]

18.81 [477.7]

20.99 [533.2]

3.66 [93.0]

Ø1.20 [Ø30.5]

Max. Cable Dia.

2.79 [70.8]

5.41 [137.5]

5.33 [135.5]

7.52 [191.0]

9.70 [246.5]

11.89 [302.0]

15.53 [394.5]

17.72 [450.0]

19.90 [505.5]

22.09 [561.0]

Cable Clamp

Positions (16)

Conduit Positions

Vs Cable Clamp

Positions

FRONT

REAR

FRONT

REAR

NOTE: Dimensions are in in. (mm)

Please note the following recommendations:

• Telect recommends that the cabinet be mounted with either the 6-in.-high base or optional 12-in.-high base (Models MDCR12) or a suitable vault, along with the isolation pad included with the cabinet. (See “Standard Accessories” Page 7-1.) If

the cabinet is mounted to a concrete pad without a pedestal or vault, the stub-up conduit for the cables must be positioned

accurately and must be either absolutely flush with or countersunk below the top of the pad.

• For a cabinet with a Telect base, the stub-up conduit should not rise above a concrete pad more than about 3 in. (~75 mm)

for a 6-in.-high base and about 6 in. (~150 mm) for a 12-in .-high base. See the following illustration.

• Telect recommends running cables in 4-in. stub-up conduit. Normally, two 4-in. conduits are necessary: one for the feeder

cable(s) and at least one for the distribution cable(s), as shown in the illustration that follows. Prefer to run feeder cable as

close as possible to the grounding bar — regardless if feeder is armored or unarmored.

• Don’t forget to make room for growth. Add additional 4-in. conduit and cap off the end(s) at the edge of or beyond the pad.

• Telect recommends anchors at all four corners. Upper end of anchor bolts must extend between 1¼ in. and 1½ in. above

top of pad, grating, or platform.

• For outdoor deployment, Telect recommends that, in addition to the isolation pad provided with the cabinet, that the customer plan for and provide a suitable water-tight gasket between the bottom of the cabinet and the pad. Use the preceding

illustration to mark and cut a rectangular hole for cable entrance.

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved

Page 2-2

Tools & Equipment —

Lifting Ring Orientation

(As Shipped)

Re-Orient Rings

to Lift Cabinet

Cone

Threaded Rod

Expansion Sleeve

Metal Sleeve

Round Washer

Torque Nuts With Red Plastic Collar

Plastic Guide

Square Washer

Model MDC-CBAK Anchor Kit

No special tools required for installation.

INSPECTION

Telect is not liable for shipping damage.

Keep the container until you have checked equipment operation. If you experience any kind of problem, call Telect’s Customer Ser-

vice Department. Use the original, undamaged container if you are instructed to return a panel to Telect.

If a shipping container is damaged, keep it for the carrier’s inspection. Notify the carrier and call Telect’s Customer Service Depart-

ment at 1-800-551-4567 or 1-509-926-6000

INSTALLATION PROCEDURE

Please read these instructions carefully before beginning installation. If you need assistance call Technical Support at 888-821-4856

(domestic calls), or 509-921-6161 (Option 2), or eMAIL us at getinfo@telect.com

1. Inspect equipment after unpacking and compare it to the packing list.

Immediately report any shipping damage, defects, or missing parts to

Telect at 1-800-551-4567. Keep all documentation that comes with your

shipment.

2. Remove lifting rings at top of cabinet and then resecure as shown on the

right.

3. Before moving cabinet

is ready: namely,

• If installation includes a vault, make sure vault-to-cabinet adapter is

in place.

, make sure the pad, grating, vault, or other support

• If using Telect’s seismic anchor kit (Model MDC-CBAK), install anchors

lows:

a. Drill an 18 mm (

25

/32-in.) diameter hole, 100 to 115 mm (4¼ to 4½ in.) deep,

at each of the four anchor locations.

b. Clean out holes using a shop vacuum, compressed air, or blow-out bulb.

Clean away debris.

c. Place round washer on rod and then thread torque nut onto the rod. The

washer should touch the top of the metal sleeve.

d. Insert anchor assembly (without the square washer) into hole. Tap anchor

rod down with a hammer until washer touches the concrete.

e. Pre-torque anchoring nuts to approximately 30 ft-lb (~40 N•m) using a ¾ in.

(19 mm) socket or box wrench.

Do not overtighten. Over-tightening will cause the torque nut to prematurely

shear off from the plastic-encased holding nut.

f. Remove torque nut and washer, leaving anchor and stud in place.

g. For exterior installation on a concrete pad, place a water-tight gasket with

cutouts for conduit and anchors on top of pre-installed pad.

4. If installation includes a base (recommended), proceed as follows:

a. Place base over anchor studs, as shown in the following illustration.

, as fol-

Telect, Inc. • USA +1.509.926.6000 • Mexico +1.52.33.3836.3700

Poland +1.48.713.239.100 • UK +1.44.1489.889500 • www.telect.com

Copyright © 2002 Telect, Inc., All Rights Reserved

Page 2-3

Loading...

Loading...