Telect ADF User Manual

Advanced Distribution Frame (ADF) Systems

User Manual

Advanced Distribution Frame (ADF) Systems

Advanced Distribution Frame (ADF) Systems

User Manual

User Manual

User Manual 119736-4

Copyright 2016, Telect Inc., All Rights Reserved

Telect and Connecting the Future are registered trademarks of Telect, Inc.

22425 East Appleway Ave., # 11

Liberty Lake, WA 99019

Telect assumes no liability from the application or use of these products. Neither does Telect convey any

license under its patent rights nor the patent rights of others. This document and the products described herein

are subject to change without notice.

Connecting the Future for Over 30 Years

Telect challenges the status quo and looks beyond what is possible in network connectivity and

power management.

Founded in 1982, Telect is driven by the principles of innovation and customer service. Headquartered in

Liberty Lake, WA, the privately held company supports a global network of customers with a comprehensive

product portfolio and a values-driven corporate culture.

Our products and solutions are found across communications service-provider networks, data centers and

utility networks around the globe.

At Telect, we pride ourselves on our ability to respond to customer challenges, building a reputation among

communications service providers for delivering solutions uniquely tailored to their needs.

We simplify networks.™

• Exceptional lead-times

• Custom integrated solutions

• Rapid collaborative development and prototyping

• UL and NEBs expertise

Technical Support

E-mail: getinfo@Telect.com

Phone: 509-926-6000

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

1.509.926.6000 :: telect.com

Page ii

Advanced Distribution Frame (ADF) Systems

Advanced Distribution Frame (ADF) Systems

User Manual

User Manual

Table of Contents

Chapter 1: Description ........................................................................................................................... 1

1.1 Overview.......................................................................................................................................... 1

1.1.1 ADF System Features ............................................................................................................... 3

1.2 ADF System Bays............................................................................................................................ 4

1.2.1 ADF XIs ..................................................................................................................................... 7

1.2.2 ADF ICs (after Trough Removed) .............................................................................................. 9

1.3 ADF Modules ..................................................................................................................................11

1.4 Telect ADF Feature Comparison ................................................................................................... 14

1.5 Specications ................................................................................................................................ 16

1.5.1 Weight ..................................................................................................................................... 16

1.5.2 Overall Dimensions ................................................................................................................. 17

Chapter 2: Applications ....................................................................................................................... 19

2.1 Cross-Connect - IFCs to NEs ........................................................................................................ 19

2.2 Cross-Connect - NEs to NEs ......................................................................................................... 20

2.3 Cross-Connect - IFC to IFCs ......................................................................................................... 21

2.4 Interconnect - IFC to IFC ............................................................................................................... 22

2.5 Interconnect - NEs to NEs ............................................................................................................. 23

2.6 Interframe Cross-Connecting ........................................................................................................ 24

2.7 Cross-Connect - IFC to NEs - Working/Protect ............................................................................. 25

2.8 Cross-Connect - IFC to NEs - Working/Protect - Standalone ........................................................ 26

Chapter 3: Frame Installation .............................................................................................................. 27

3.1 Installation Considerations ............................................................................................................ 27

3.1.1 Location & Space .................................................................................................................... 27

3.1.2 Tools & Equipment ................................................................................................................... 27

3.2 Inspection ...................................................................................................................................... 28

3.3 Main & Interbay Storage Panel Installation ................................................................................... 28

3.3.1 Unpacking Main & Interbay Storage Panels ............................................................................ 28

3.3.2 Installing Main & Interbay Storage Panels Directly on a Concrete Floor ................................. 29

3.3.3 Table of Footprint Dimensions ................................................................................................. 31

3.3.4 Installing Lower Trough Junction ............................................................................................. 32

3.3.5 Installing Upper Trough Junction on ADF XI Bays................................................................... 32

3.3.6 Securing ADF to the Lineup..................................................................................................... 33

3.3.7 Installing Rear Cable Tie-Down Bars....................................................................................... 34

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

1.509.926.6000 :: telect.com

Page iii

Advanced Distribution Frame (ADF) Systems

Advanced Distribution Frame (ADF) Systems

User Manual

User Manual

3.3.8 Installing Cable Management System (CMS).......................................................................... 36

3.3.9 Grounding ADF ........................................................................................................................ 36

3.3.10 Securing ADF Lineup............................................................................................................. 36

3.3.11 Wiring Facility Power ............................................................................................................. 36

Chapter 4: Module Installation ............................................................................................................ 39

4.1 Installation Considerations ............................................................................................................ 39

4.1.1 Pre-Cabled vs. Uncabled ADF Modules .................................................................................. 39

4.1.2 Tools & Equipment Required ................................................................................................... 39

4.2 Inspection ...................................................................................................................................... 39

4.3 Unpacking an ADF Module ............................................................................................................ 39

4.4 Installing an ADF Module to a Main ADF ....................................................................................... 40

Chapter 5: Outboard Cabling .............................................................................................................. 43

5.1 Intrafacility Cable to Uncabled IFC Module ................................................................................... 43

5.2 Network Cabling to Network Element Module ............................................................................... 47

Chapter 6: Inboard Cabling ................................................................................................................. 51

6.1 Installing Inboard Cabling .............................................................................................................. 51

6.2 Routing & Storing Inboard Cabling ................................................................................................ 54

6.2.1 Interconnection ........................................................................................................................ 54

6.2.2 Cross-Connection .................................................................................................................... 56

Chapter 7: Service ................................................................................................................................ 59

7.1 Owner Maintenance ...................................................................................................................... 59

7.2 Technical Support .......................................................................................................................... 59

7.3 In-Warranty Service ....................................................................................................................... 59

7.4 Out-of-Warranty Service ................................................................................................................ 59

7.5 Repacking for Shipment ................................................................................................................ 59

Chapter 8: Bays and Accessories ....................................................................................................... 61

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

1.509.926.6000 :: telect.com

Page iv

Advanced Distribution Frame (ADF) Systems

Advanced Distribution Frame (ADF) Systems

User Manual

User Manual

List of Figures

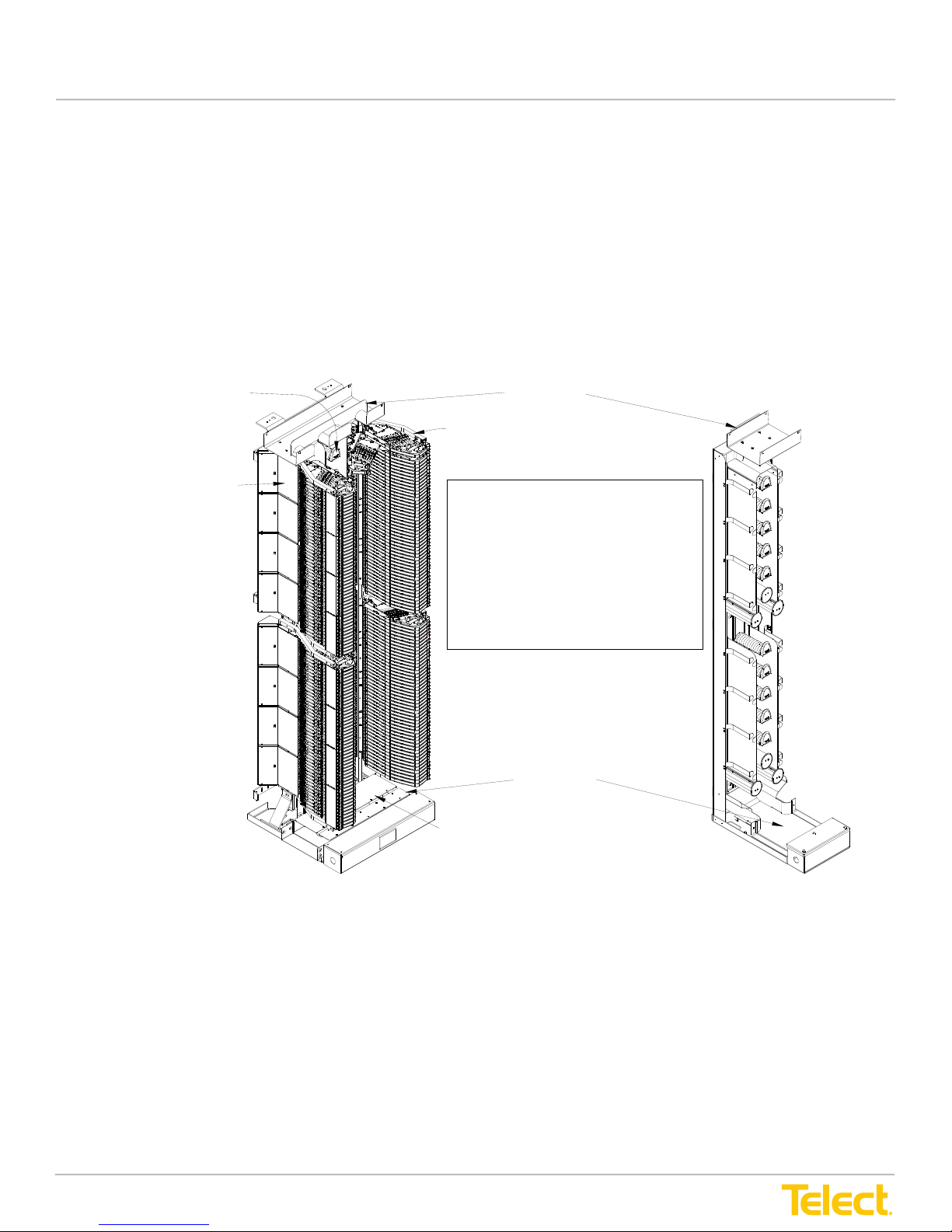

Figure 1 - Advanced Distribution Frame System ...................................................................................... 1

Figure 2 - Typical Lineup Using ADF Cross-Connect/Interconnect (XI) Bays .......................................... 2

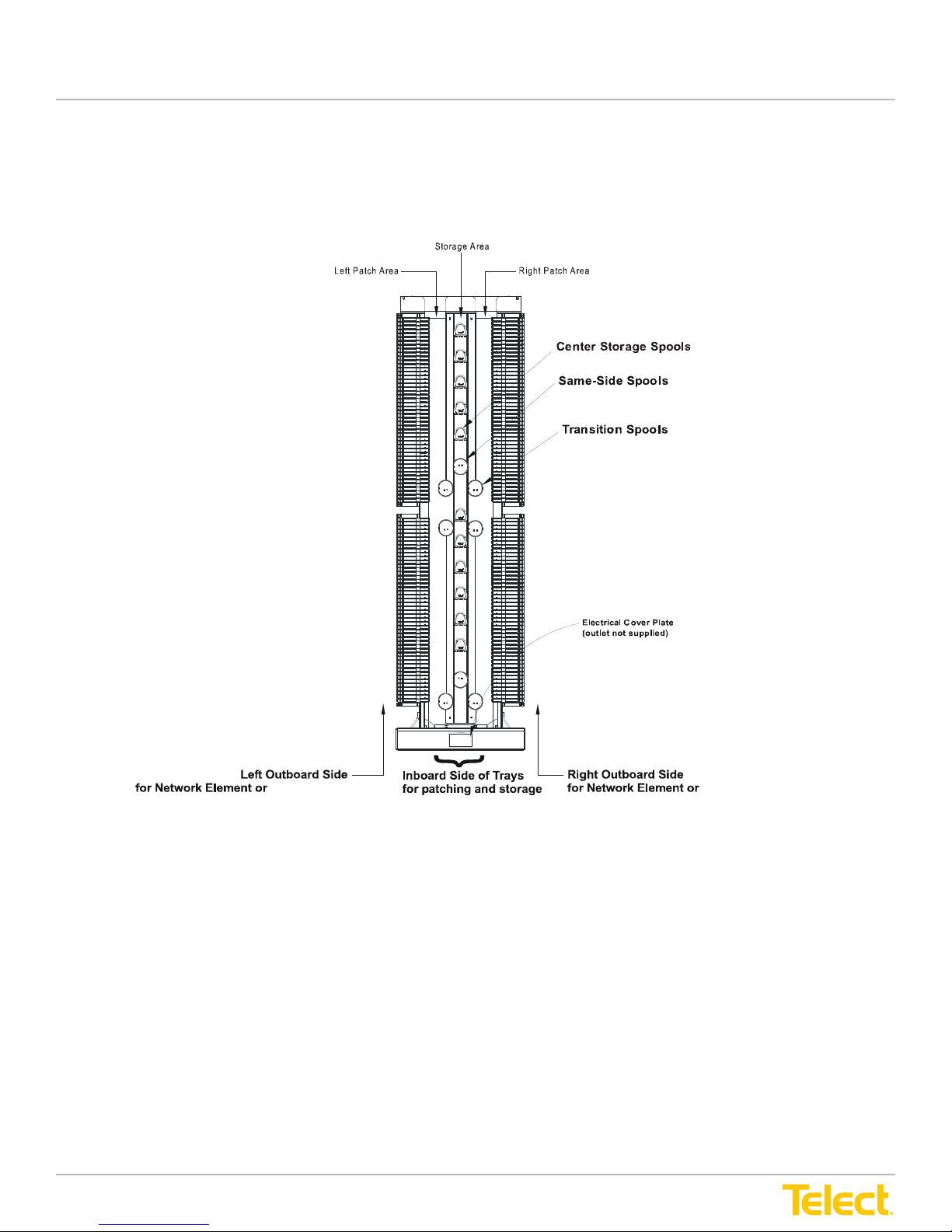

Figure 3 - Main ADF (Typical, Front View with Tray Modules) .................................................................. 4

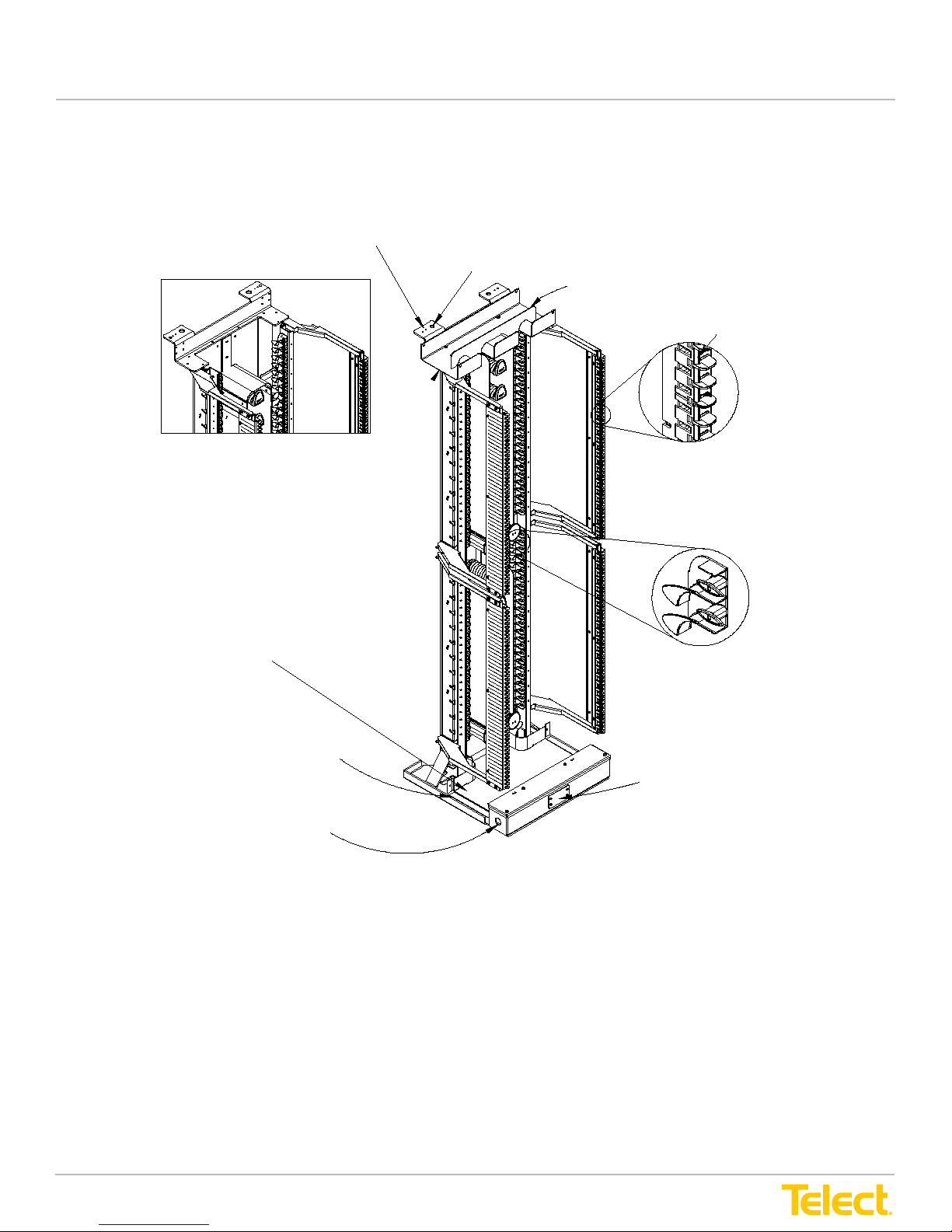

Figure 4 - Main ADFs (as Shipped, without Tray Modules) ...................................................................... 5

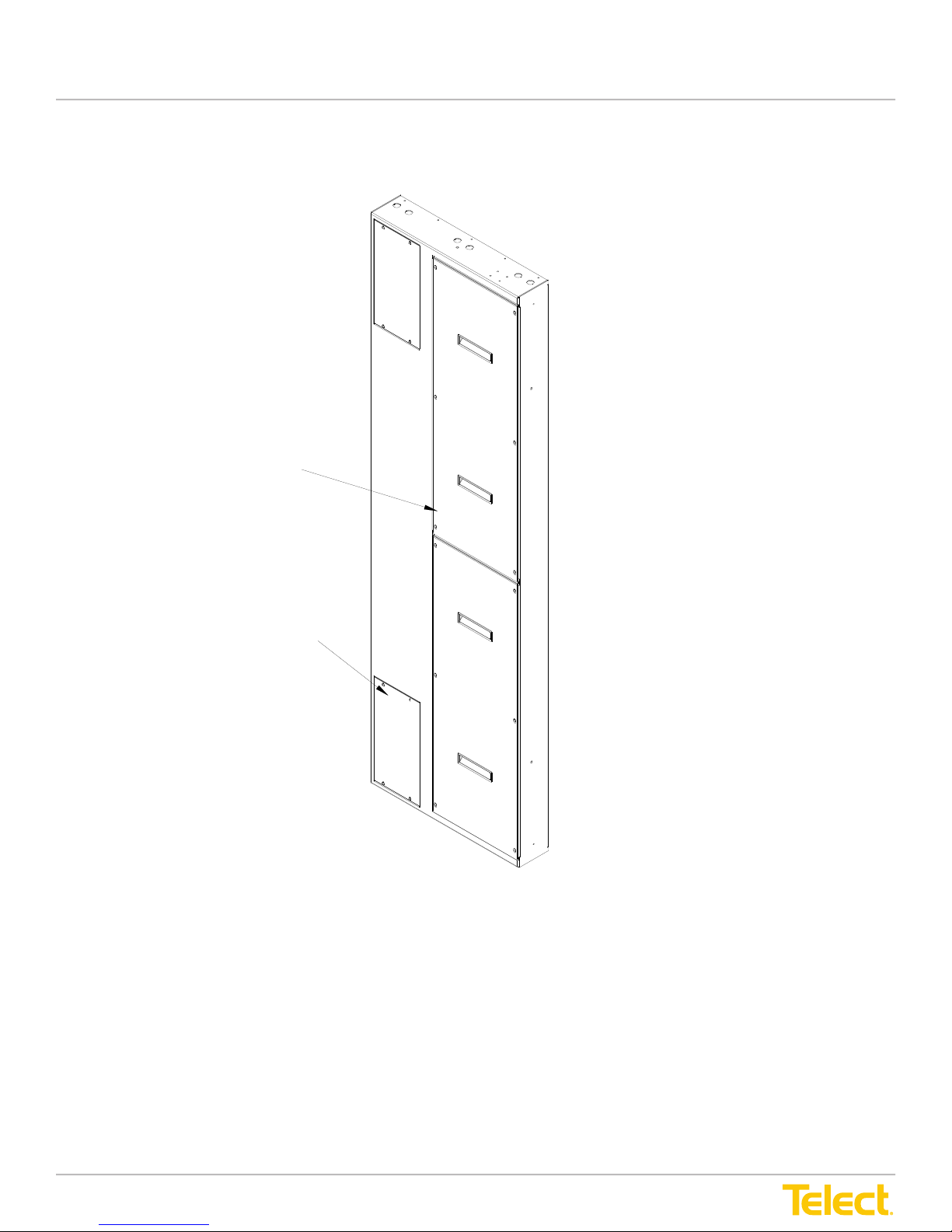

Figure 5 - End Panel................................................................................................................................. 6

Figure 6 - XI Cross-Connect IFC to NE22 ................................................................................................ 7

Figure 7 - Interconnect IFC to NE33......................................................................................................... 8

Figure 8 - Cross-Connect NFC to IE ........................................................................................................ 8

Figure 9 - IFC to NE Interconnection Using ADF ICs in an ADF Lineup................................................... 9

Figure 10 - IFC to NE Interconnection Using ADF ICs in an ADF Lineup (with ISP Storage) ................ 10

Figure 11 - Outboard View of Right-Hand, Intrafacility Cable (IFC) Module ............................................11

Figure 12 - Outboard View of Right-Hand, Network Element (NE) Module ............................................ 12

Figure 13 - Fan-Out Module ................................................................................................................... 12

Figure 14 - Patch Tray (Physically the Same for IFC, NE and FO Modules).......................................... 13

Figure 15 - ADF Comparisons ................................................................................................................ 14

Figure 16 - ADF Comparisons ................................................................................................................ 15

Figure 17 - Cross-Connect - IFC to NEs ................................................................................................ 19

Figure 18 - Cross-Connect - NEs to NEs ............................................................................................... 20

Figure 19 - Cross-Connect - IFC to IFCs................................................................................................ 21

Figure 20 - Interconnect - IFC to IFC...................................................................................................... 22

Figure 21 - Interconnect - NEs to NEs.................................................................................................... 23

Figure 22 - Interframe Cross-Connecting ............................................................................................... 24

Figure 23 - Cross-Connect - IFC to NEs - Working/Project .................................................................... 25

Figure 24 - Cross-Connect - IFC to NEs - Working/Project - Standalone .............................................. 26

Figure 25 - Installation Location ............................................................................................................. 27

Figure 26 - ADF and Interbay Storage Panel Installation Template ........................................................ 29

Figure 27 - ADF and Interbay Storage Panel Footprints ........................................................................ 30

Figure 28 - Lower ADF Junction ............................................................................................................. 32

Figure 29 - Lower Trough Junction Being Secured to the Main ADF XI ................................................. 32

Figure 30 - Rear Corner View of an ADF XI in an ADF Lineup ............................................................... 33

Figure 31 - Rear Corner View of ADF ICs in an ADF Lineup .................................................................. 33

Figure 32 - Recommended Top Feed Conguration .............................................................................. 34

Figure 33 - Recommended Bottom Feed Conguration ......................................................................... 35

Figure 34 - Connect CMS to Main ADF XIs ............................................................................................ 36

Figure 35 - Electrical Raceway (Front of Base) on ADF XI and IC Lineups ........................................... 37

Figure 36 - Installing a Module on a Main ADF ...................................................................................... 41

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

1.509.926.6000 :: telect.com

Page v

Advanced Distribution Frame (ADF) Systems

Advanced Distribution Frame (ADF) Systems

User Manual

User Manual

Figure 37 - Adjusting Latch Bars (ADF Module Not Shown) .................................................................. 42

Figure 38 - Intrafacility Clamp and Cable ............................................................................................... 43

Figure 39 - Riser Cabling to Uncabled IFC Module ................................................................................ 44

Figure 40 - Securing Connector to Adapter ............................................................................................ 45

Figure 41 - Routing Cable to Breakout Area........................................................................................... 45

Figure 42 - Excess Cable Routing .......................................................................................................... 46

Figure 43 - Network Element Cabling (Example) ................................................................................... 47

Figure 44 - Opening Trays ...................................................................................................................... 48

Figure 45 - Securing Connector to Adapter ............................................................................................ 48

Figure 46 - Routing Cable to Channel .................................................................................................... 49

Figure 47 - Cable Routing through Channel to Rear of Module ............................................................. 49

Figure 48 - Cable Preparation ................................................................................................................ 51

Figure 49 - Connecting Patch Cord ........................................................................................................ 52

Figure 50 - Cable Routing in Tray........................................................................................................... 52

Figure 51 - Cable Routing in Module ...................................................................................................... 52

Figure 52 - Interconnecting Cable Routing ............................................................................................. 53

Figure 53 - Cross-Connecting Cable Routing......................................................................................... 53

Figure 54 - Cable Routing Down Cascade ............................................................................................. 53

Figure 55 - Interconnection within a Single Frame ................................................................................. 54

Figure 56 - Interconnection with Storage on ISP .................................................................................... 55

Figure 57 - Patching to Same Side of Same ADF .................................................................................. 56

Figure 58 - Patching to Opposite Side of Same ADF ............................................................................. 56

Figure 59 - Patching to Same Side of Different ADFs ............................................................................ 57

Figure 60 - Patching to Opposite Side of Different ADFs (without ISP) .................................................. 57

Figure 61 - Patching to Opposite Side of Different ADFs (with ISP) ....................................................... 58

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

1.509.926.6000 :: telect.com

Page vi

Advanced Distribution Frame (ADF) Systems

Chapter 1: Description

Advanced Distribution Frame (ADF) Systems

1.1 Overview

Telect’s ADF Systems provide inter-connectivity and cross-connectivity of intrafacility cables,

network elements, and patch cords.

• Each Main ADF consists of an upright frame holding a vertical array of modules on each side

of a patch cord interconnect routing area.

• Each module holds trays for interconnections or cross-connections.

Each swing-out tray supports 6, 8, or 12 optical connections, depending on the type of adapter.

User Manual

Chapter 1: Description

1.1 Overview

The Telect ADF Systems provide inter-connectivity and cross-connectivity of intrafacility cables, network

elements and patch cords.

• Each Main ADF consists of an upright frame holding a vertical array of modules on each side of a patch

cord interconnect routing area

• Each module holds trays for interconnections or cross-connections

Each swing-out tray supports 6,8 or 12 optical connections, depending on the type of adapter.

Vertical Spoo l Array for

R ou tin g P a tch Ca b ling

Between Modules

Trays H old 6, 8, or 12 O ptical Adapters

Upper Trough

Modules With Trays

Covers Protect Cable in Bottom Troughs

ADF Types & Versions

The Telect ADF-XI comes as pictured.

The trough can be removed to provide

inter-connectivity. [ADF-IC]

Two versions of ADF XI are offered,

an ETSI versions and a North American

version. The ETSI version is shown here.

Lower Trough

ADF-26F-XI ADF-12INT-XI

Figure 1 - Advanced Distribution Frame System

• ADFs with 12 adapters per tray have up to 2304 junctions per bay (LC)

• ADFs with 8 adapters per tray have up to 1536 junctions per bay

• ADFs with 6 adapters per tray have up to 1152 junctions per bay

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

1

Advanced Distribution Frame (ADF) Systems

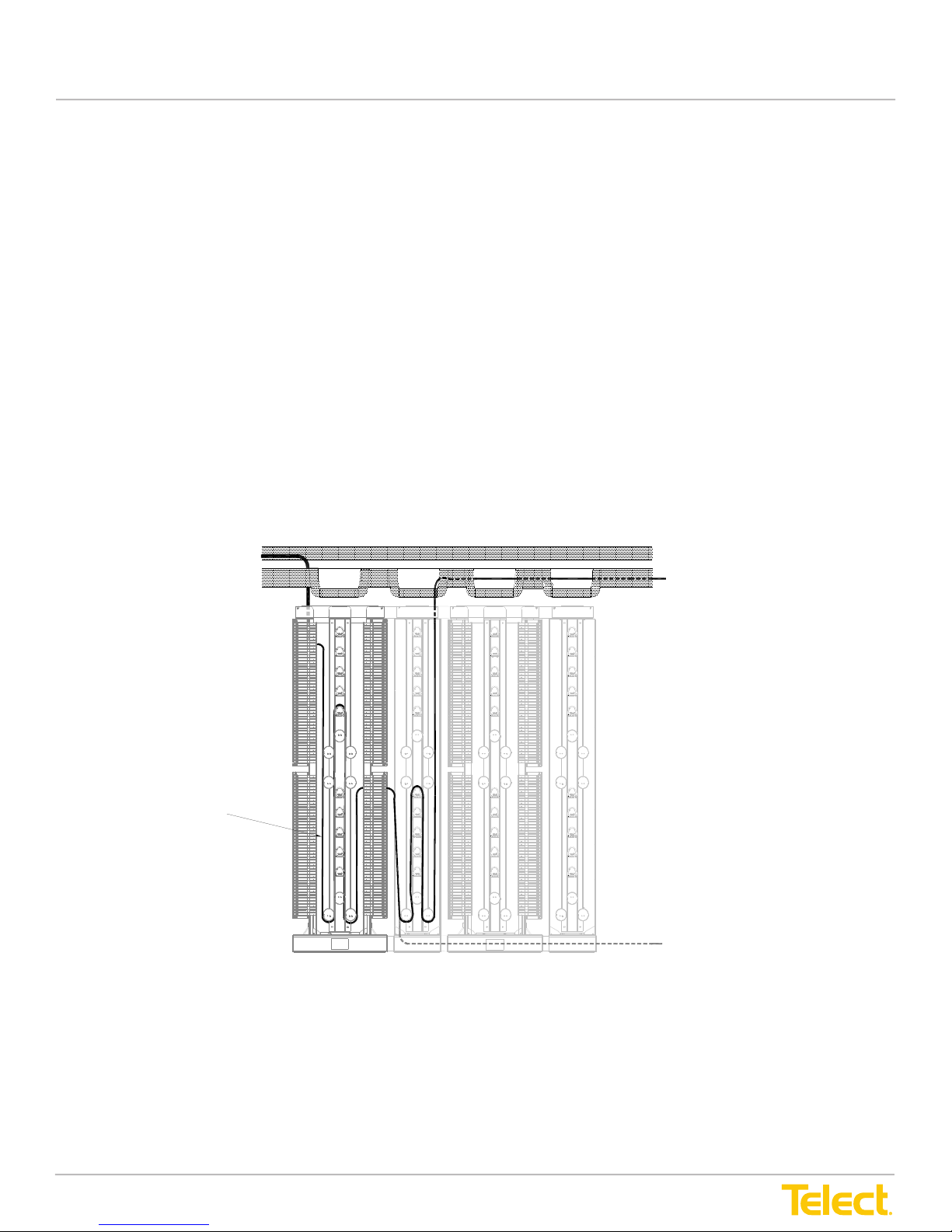

Figure 1, “Advanced Distribution Frame System” on page 1, depicts a multipurpose ADF XI bay

with a complete array of modules and an ADF InterBay Storage panel.

The area between right-side and left-side modules contains various spools for routing patch

cords and/or pigtail interconnects. Bulk patch cord storage is provided by InterBay Storage

Panels (ISPs) located between Main ADFs in ADF System lineups.

User Manual

Figure 1, “Advanced Distribution Frame System” on page 1, depicts a multi-purpose ADF XI bay with a

complete array of modules and an ADF InterBay Storage Panel.

The area between right-side and left-side modules contains various spools for routing patch cords and/or pigtail interconnects. Bulk patch cord storage is provided by Interbay Storage Panels (ISPs) located between Main

ADFs in ADF System lineups.

Normally, the top tray of ea ch

qua drant is covered to protect cab les

and ad apters from overhead hazards.

Bottom-Up IFC Cabling (IFC can be routed from the top-down

or bottom-up on all Main ADFs)

Rear View of Main ADF Showing IFC

Front View

Cable at Rear of ADF Module

Figure 2 - Typical Lineup Using ADF Cross-Connect/Interconnect (XI) Bays

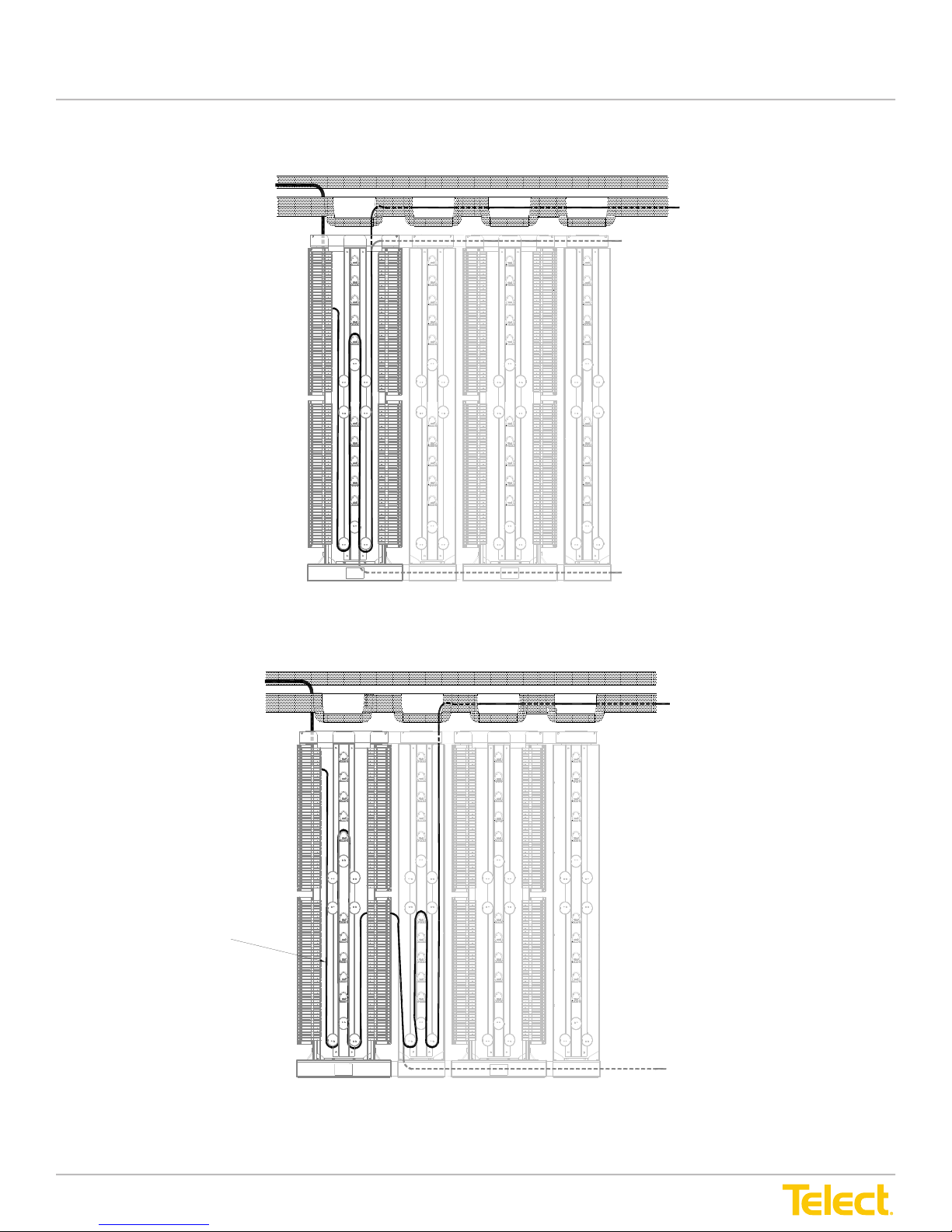

ADF system lineups consist of Main ADF, ISPs and end panels.

Cable, patch cord and pigtail access differs somewhat between the Telect ADF Cross-Connect/Interconnect

(XI) and Interconnect (IC) Systems, but generally IFC, OSP or network element

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

2

Advanced Distribution Frame (ADF) Systems

User Manual

(NE) access are connected at the rear of the modules. Patch cords, as well as NE pigtail interconnects, are

connected at the front of the modules. In cross-connect applications, patch cords are routed between modules

on different Main ADFs through upper and/or lower ADF troughs.

1.1.1 ADF System Features

• Industry-leading termination density

• Simple, straight-forward cable management, access, circuit identication and isolation

• No shing of cables

• Total front access for patching

• Designed for compliance (ber bend radius control, ammability safety, structural reliability) throughout

ADF design

• No line-of-sight laser hazards

• Easy access to riser/network/patch cord interconnections and cross-connections

• Light-weight, heavy-duty frame certied for Zone 4 earthquake reliability

• Easy installation

• 600-mm and 26-in. rack widths that accommodate standard lineups

• Diverse routing with reduced cable congestion, diverse routing between ADFs using upper and/or

lower troughs

• 4.5 m standard, single-length patch cords for ADF cross connections

• Unique storage spools with wave-like ridges for grouping patch cords

• Variable placement of tray modules on ADF mounting rails

• Compatible with WaveTrax™ Cable Management System and other cable management systems

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

3

Advanced Distribution Frame (ADF) Systems

1.2 ADF System Bays

As mentioned, ADF Systems consist of Main ADFs with modules, InterBay Storage Panels

(ISPs), and end panels.

User Manual

1.2 ADF System Bays

As mentioned, ADF Systems consist of Main ADFs with modules, Interbay Storage Panels (ISPs)

and End Panels.

Intrafacility Cabling

Figure 3 - Main ADF (Typical, Front View with Tray Modules)

Main ADFs, such as the Main ADF XI in Figure 3, above, consist of a central cable storage area with mounting

rails for the ber tray modules. The routing area contains several types of spools for directing and redirecting

patch cords and pigtail interconnects.

Interconnect and cross-connect cabling differs somewhat between the Main ADF XI and IC bays:

• Main ADF XI - Interconnection and cross-connection cabling to the inboard patch areas is provided by

either upper and/or lower cable troughs. Drops in the troughs ensure cable bend radius control. Junctions

are provided for coupling the upper and lower troughs to other Main ADFs or Interbay Storage Panels in

the lineup.

Intrafacility Cabling

• Main ADF IC (Specialized for Interconnections) - Interconnect cabling to the inboard patch area is by direct

access from a cable management system above the ADF lineup. Junctions are provided for coupling the

lower troughs of all Main and Interbay Storage Panels in the lineup.

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

4

Advanced Distribution Frame (ADF) Systems

are provided for coupling the lower troughs of all Main and InterBay Storage Panels

in the lineup.

At the bottom is an electrical raceway for power cabling and conduit. The raceway provides a

mounting area for a standard recessed receptacle or other wiring device.

Small holes are tappedto connect dual-hole grounding

Main ADF XI only

User Manual

At the bottom is an electrical raceway for power cabling and conduit. The raceway provides a mounting area

for a standard recessed receptacle or other wiring device.

lug usin g M5 scr ews

Main ADF Interconnect (IC)

(shown with top trough removed)

Junction (not shown) fits on the edge to

connect the upper trough to the adjacent

frame in the lineup (Main ADF XI [cross-connect] only)

Main ADF IC

(shown without top trough)

Lar g e hole s f or s ecur i ng ADF

to th e CMS or a la dder ra ck

Upper ADF Trough (Main ADF XI Only)

Catch for Tray Latch

Lower ADF Trough

Patch Cord Cascade

With Turn stiles

Coupling (not shown) fits on lip to

connect lower troughto adjacent

frame in lineup

Cover Plate for Standard Electrical

Receptacle

31.8 mm/1.25 in. (Diameter) AccessHole

on Both Ends of Raceway

Main ADF XI

Figure 4 - Main ADFs (as Shipped, without Tray Modules)

An Interbay Storage Panel (ISP) is used for storage of either patch cord cabling from an overhead CMS and/or

inboard cabling terminated at IFC or NE modules. Except for the tray modules, cable routing through an

Interbay Storage Panel is similar to that of a Main ADF.

The Main ADF and ISP can be mounted directly to a concrete oor or on a raised equipment oor. (A template

is provided for mounting panels to the oor.) Support is provided at the top for added earthquake security and

for attaching to a cable management or ladder rack system.

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

5

Advanced Distribution Frame (ADF) Systems

Normally, ADF lineups are terminated at each end by ADF End Panels secured to adjacent ISPs.

User Manual

Normally, ADF lineups are terminated at each end by ADF End Panels secured to adjacent ISPs.

Doors (2)

Access Covers (2)

Figure 5 - End Panel

You can congure two types of ADF System bays that t North American and ETSI footprints:

1. ADF Cross-Connect/Interconnect (XI) Bays

2. ADF Interconnect (IC) Bays

The subsections that follow describe and illustrate various cabling scenarios provided by each of these types

of ADF systems. Chaper 2, “Applications” on page 19, provides comprehensive and comparative analyses of

cabling using these two systems.

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

6

Advanced Distribution Frame (ADF) Systems

1.2.1 ADF XIs

ADF Cross-Connect/Interconnect bays are used in either cross-connect or interconnect

applications, depending on the type of module installed on the Main ADFs. Lineup access to the

patch cord area on the Main ADFs is through either the bottom or upper troughs with access to/

from patch cord storage on the ISPs via the bottom trough.

Two models are available:

1. The North American model is based on a 26 in. by 24 in. Main ADF footprint. ISPs for the

North

American model are 12 in. by 24 in.

2. The ETSI model is based on a 600 mm by 600 mm Main ADF footprint. ISPs for the ETSI

model are 30

0 mm by 600 mm.

The following figures show a few typical cross-

connection and interconnection schemes between

IFC and network element (NE) cabling. In these examples, IFC routing to the rear of the IFC ADF

modules is from the facilities cable (ladder) rack with NE cabling through a cable management

system (CMS).

Ladder Rack

User Manual

1.2.1 ADF XIs

ADF Cross-Connect/Interconnect bays are used in either cross-connect or interconnect applications,

depending on the type of module installed on the Main ADFs. Lineup access to the patch cord area on the

Main ADFs is through either the bottom or upper troughs with access to/from patch cord storage on the ISPs

via the bottom trough.

Two models are available:

1. The North American model is based on a 26" by 24" Main ADF footprint. ISPs for the North American model

are 12" by 24".

2. The ETSI model is based on a 600 mm by 600 mm Main ADF footprint. ISPs for the ETSI model are 300

mm by 600 mm.

The following gures show a few typical cross-connection and interconnection schemes between IFC and

network element (NE) cabling. In these examples, IFC routing to the rear of the IFC ADF modules is from the

facilities cable (ladder) rack with NE cabling through a cable management system (CMS).

IFC Cabling to Rear

(Outboard Side)

of IFC Module

CMS

Preferred Pigtail

Route from Outboard

Side of NE Module

Via CMS to Network

Element

Patch Cord

Alternate Route

Figure 6 - XI Cross-Connect IFC to NE22

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

7

Advanced Distribution Frame (ADF) Systems

CMS

Alternate Route

Alternate Route

Ladder Rack

IFC Cabling to Rear

(Outboard Side)

of IFC Module

Preferred Pigtail

Route from Inboard

Side of IFC Module

Via CMS to Network

Element

Figure 7 - Interconnect IFC to NE33

User Manual

IFC Cabling to Rear

(Outboard Side)

of IFC Module

Ladder Rack

CMS

Figure 7 - Interconnect IFC to NE33

Preferred Pigtail

Route from Inboard

Side of IFC Module

Via CMS to Network

Element

Alternate Route

Alternate Route

IFC C abling to R ea r

(Outboard Side)

of IFC Module

Patch Cord

Ladder Rack

CMS

Figure 8 - Cross-Connect NFC to IE

Preferred Pigtail

Route from Outboard

Side of NE Module

Via CMS to Network

Element

Alternate Route

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

8

Advanced Distribution Frame (ADF) Systems

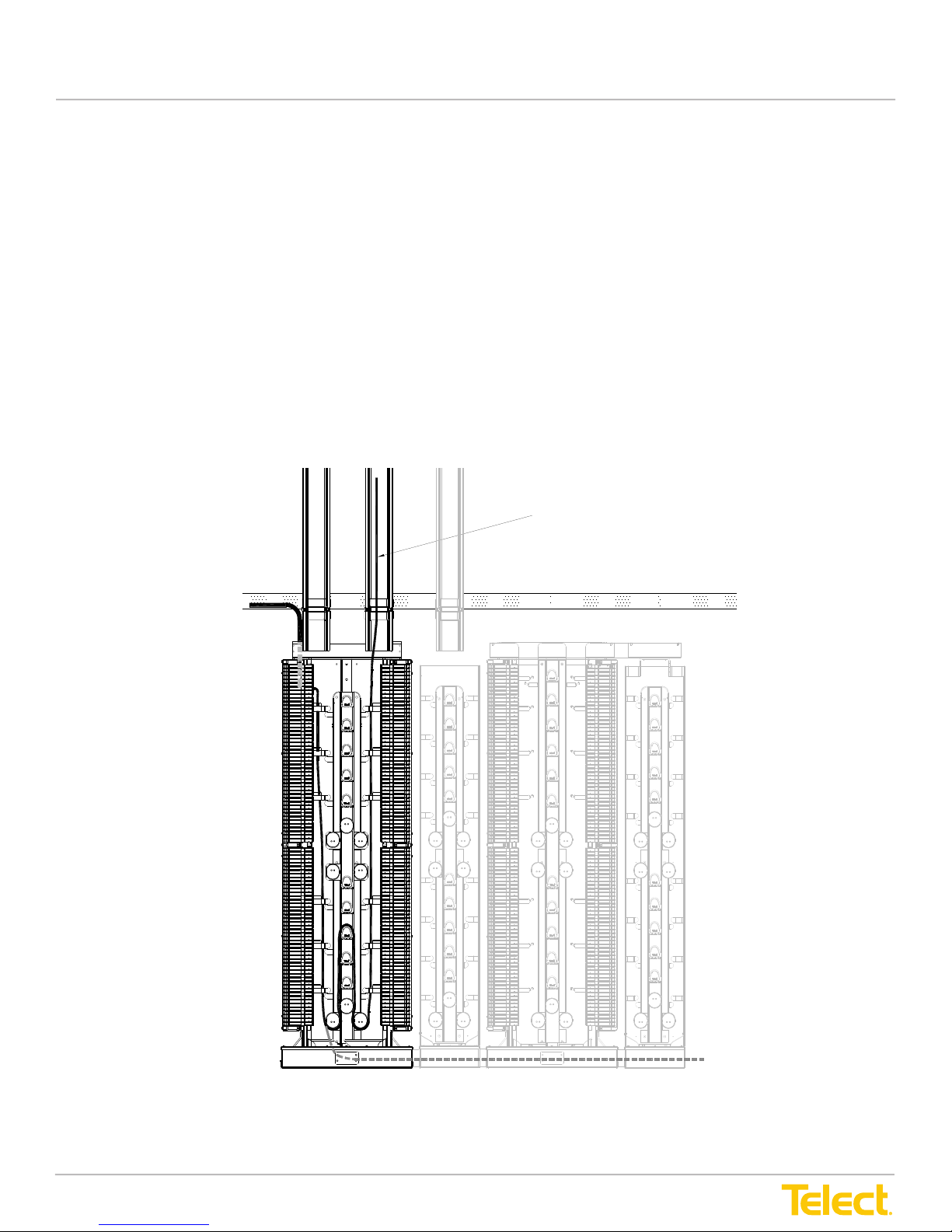

1.2.2 ADF ICs (after Trough Removed)

ADF Interconnect (IC) bays are physically similar to but functionally quite different from the ADF

XI bays.

To convert XI to IC, remove the top trough. With the top trough removed, the overhead access to

the patch area of a Main and ISP ADF ICs is confined to a center drop from an overhead cable

management system. Both Main and ISP ADF ICs feature an interconnected bottom trough for

routing cable between the ADF IC bays.

ADF XI and IC bays can be used in the same lineup; cross-aisle connections between lineups

are common applications for ADF ICs.

The following figures show a few typical interconnection schemes between IFC and network

element (NE) cabling. In these examples, IFC routing to the rear of the IFC ADF modules is from

the facilities ladder rack with NE cabling dropped from an overhead cable management system

(CMS).

User Manual

1.2.2 ADF ICs (after Trough Removed)

ADF Interconnect (IC) bays are physically similar to but functionally quite different from the ADF XI bays.

To convert XI to IC, remove the top trough. With the top trough removed, the overhead access to the patch

area of a Main and ISP ADF ICs are conned to a center drop from an overhead cable management system.

Both Main and ISP ADF ICs feature an interconnected bottom trough for routing cable between the ADF

IC bays.

ADF XI and IC bays can be used in the same lineup; cross-aisle connections between lineups are common

applications for ADF ICs.

The following gures show a few typical interconnection schemes between IFC and network element (NE)

cabling. In these examples, IFC routing to the rear of the IFC ADF modules is from the facilities ladder rack

with NE cabling dropped from an overhead cable management system (CMS).

CMS

(Optional)

IFC Cabling to Rear

(Outboard Side) of

of IFC Module

Ladder Rack

Preferred Pigtail Route from

Inboard Side of IFC Module Via

CMS to Network Element

Figure 9 - IFC to NE Interconnection Using ADF ICs in an ADF Lineup

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

Alternate Route

9

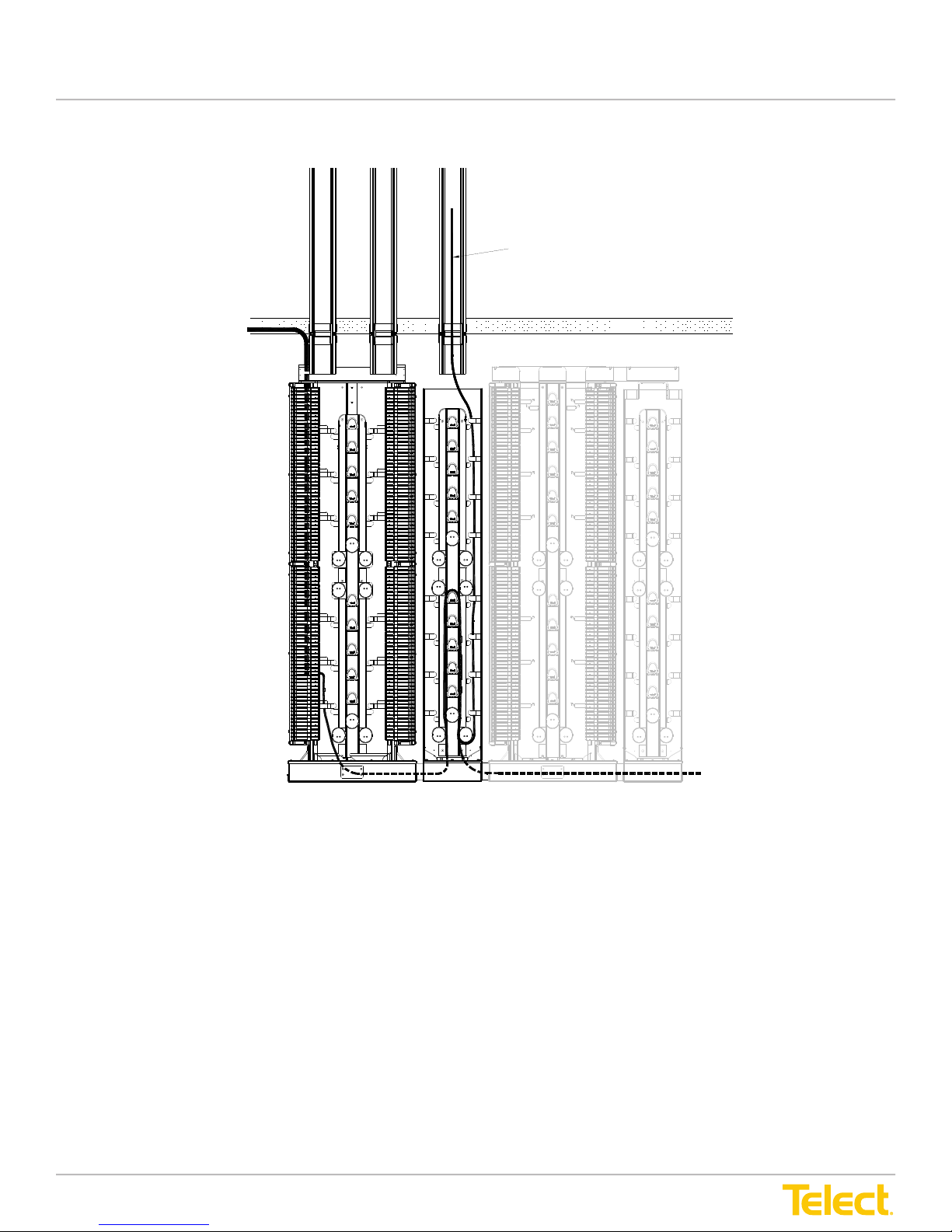

Advanced Distribution Frame (ADF) Systems

User Manual

IFC Cabling to Rear

(Outboard Side)

of IFC Module

CMS

(Optional)

Preferred Pigtail Route from Inboard Side of

IFC Module Via CMS to Network Element

Ladder Rack

Figure 10 - IFC to NE Interconnection Using ADF ICs in an ADF Lineup (with ISP Storage)

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

Alternate Route

10

Advanced Distribution Frame (ADF) Systems

1.3 ADF Modules

Normally, Main ADFs are dedicated to either interconnection between intrafacility cabling and

facility elements, or cross-connection between the network elements. The difference lies in the

type of ADF modules on the right and left sides of the Main ADF Panels.

User Manual

1.3 ADF Modules

Normally, Main ADFs are dedicated to either interconnection between intrafacility cabling and facility elements

or cross-connection between the network elements. The difference lies in the type of ADF modules on the right

and left sides of the Main ADF Panels.

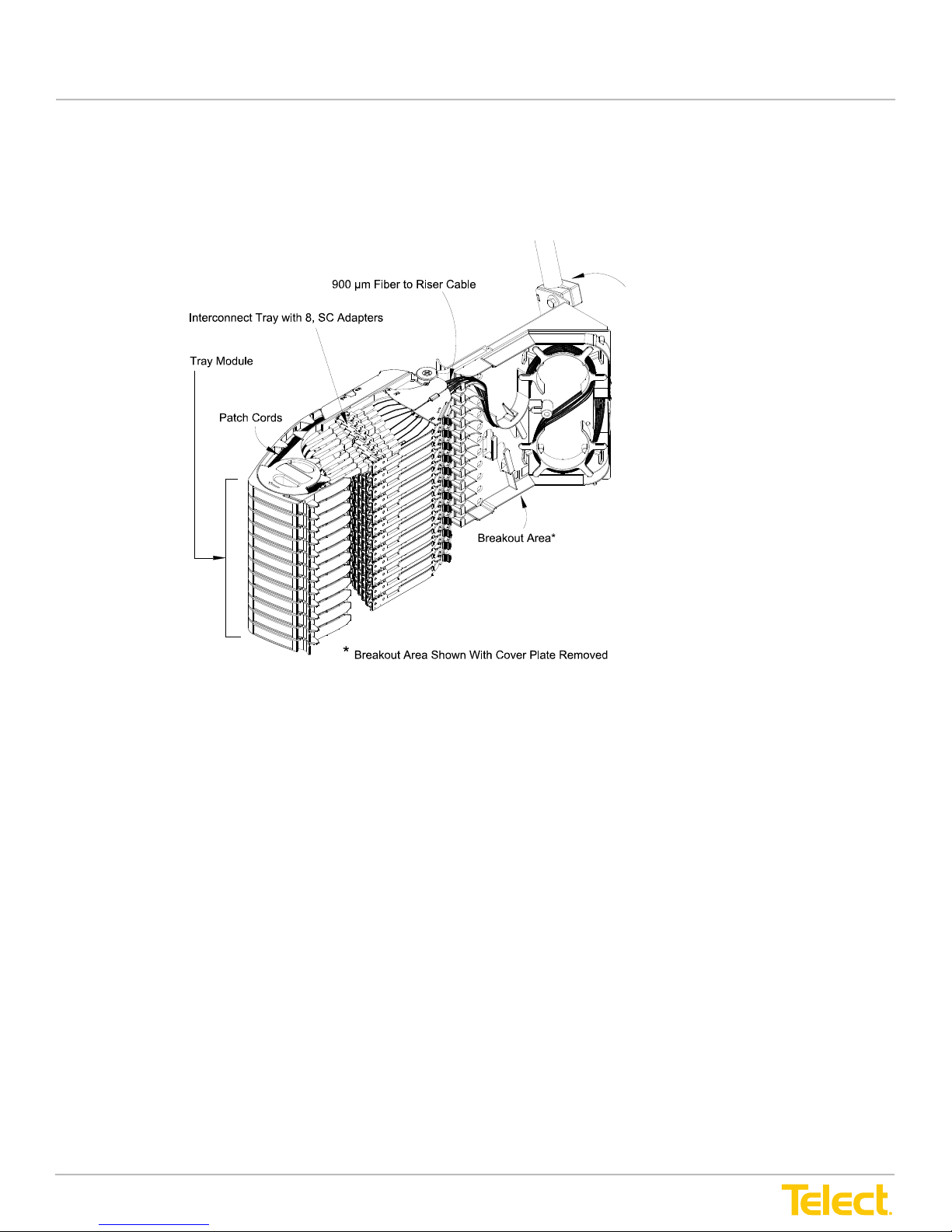

Clamp on Rear of Breakout Box

Secures Riser Cable to Module

Figure 11 - Outboard View of Right-Hand, Intrafacility Cable (IFC) Module

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

11

Advanced Distribution Frame (ADF) Systems

Figure 12 - Outboard View of Right-Hand, Network Element (NE) Module

User Manual

Figure 12 - Outboard View of Right-Hand, Network Element (NE) Module

.

Figure 13 - Fan-Out Module

ADF modules are available for accommodating ribbon cabling, combining patching with ber splicing, splitting

and other capabilities. The modules come in right- and left-side versions, for the right and left sides of the

Main ADF.

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

12

Advanced Distribution Frame (ADF) Systems

Three types of modules are available, depending on application:

1. The IntraFacility Cable (IFC) module contains a breakout area for routing standard 900

micron fiber cabling from a rear-side clamp holding the riser cable. The 900-micron fibers

are routed to optical adapters in the trays.

2. The Network Element (NE) module contains raceways for routing standard 2-mm network

element cabling to the adapters.

3. The Fan-Out (FO) module accommodates up to 12 different multifiber cable

clamp positions.

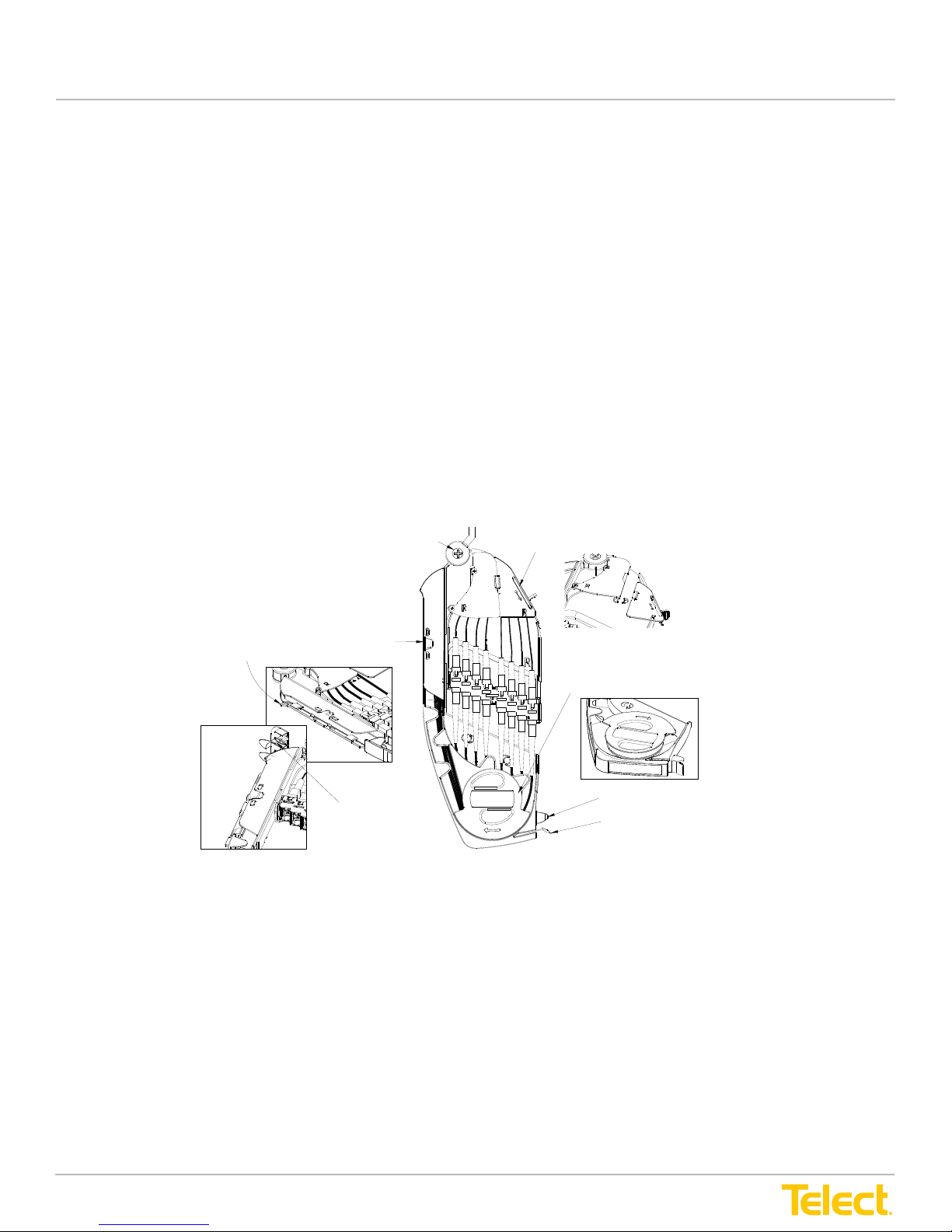

Individual trays swing toward the inboard area of the Main ADF to simplify the cabling process.

The trays contain a moveable adapter bridge that slides toward the rear when the tray is opened.

The sliding bridge provides slack management as the tray opens.

Fiber cables from the breakout area or raceways are routed under a cover to

the rear side of the

adapters. The patch cords connected to the front side of the adapters are routed around a spool

containing a retaining flange, through a raceway, to a vertical array of cascade guides with

turnstiles attached to the inboard patch area of the ADF. A door at the end of each raceway helps

guide cables downward into the patch area

Pivot Point of Tray

.

User Manual

Three types of modules are available, depending on application:

1. The IntraFacility Cable (IFC) module contains a breakout area of routing standard 900 micron ber cabling

from a rear-side clamp holding the riser cable. The 900 micron bers are routed to optical adapters

in the trays.

2. The Network Element (NE) module contains raceways for routing standard 2mm network element cabling

to the adapters.

3. The Fan-Out (FO) module accommodates up to 12 different multi-ber cable clamp positions.

Individual trays swing toward the inboard area of the Main ADF to simplify the cabling process. The trays

contain a moveable adapter bridge that slides toward the rear when the tray is opened. The sliding bridge

provides slack management as the tray opens.

Fiber cables from the breakout area or raceways are routed under a cover to the rear side of the adapters. The

patch cords connected to the front side of the adapters are routed around a spool containing a retaining ange,

through a raceway, to a vertical array of cascade guides with turnstiles attached to the inboard patch area of

the ADF. A door at the end of each raceway helps guide cables downward into the patch area.

S lid e O pe ns to Al low IFC or N etw ork E lem en t Cab lin g

Door Flips Down to Allow Patch Cord Cabling

toPatchCordCascade

Spool Rotates to Allow Patch Cord Cabling

Patch Cord Cascade

With Turns tile

Tab

Latch

Figure 14 - Patch Tray (Physically the Same for IFC, NE and FO Modules)

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

13

Advanced Distribution Frame (ADF) Systems

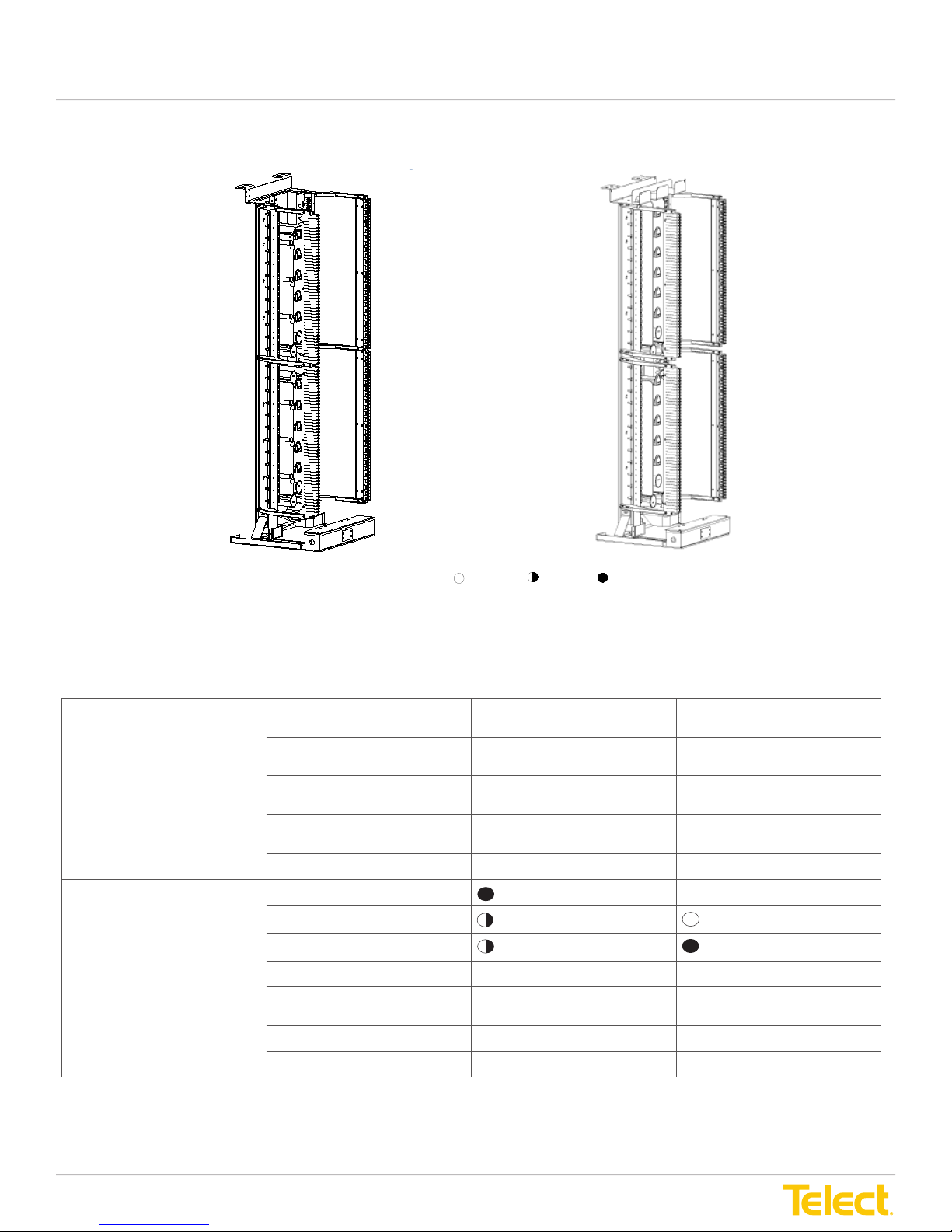

1.4 Telect ADF Feature Comparison

Legend: Good Better Best

User Manual

1.4 Telect ADF Feature Comparison

Telect IC

Figure 15 - ADF Comparisons

Max. Terminations/Ft

(Small Form Factor) LC

Capacity

Max. Frames in a Lineup

at Max. Density

Max. Terminations in a Lineup 16,128 (LC) 4,860 (LC)

Flexibility to Grow Yes Yes

Telect XI

1536

(2304)

2

396

(594)

7 (LC) 4 (LC)

1536

(2304)

396

(594)

(4 x 2304)

Inter-Bay Cross-Connect

Application

Single Jumper

(Cross-Connect Length)

On-frame splicing Ye s Ye s

Off-frame splicing Yes Yes

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

Yes Yes

Yes

(4.5 m)

14

Yes

(4.5 m)

Advanced Distribution Frame (ADF) Systems

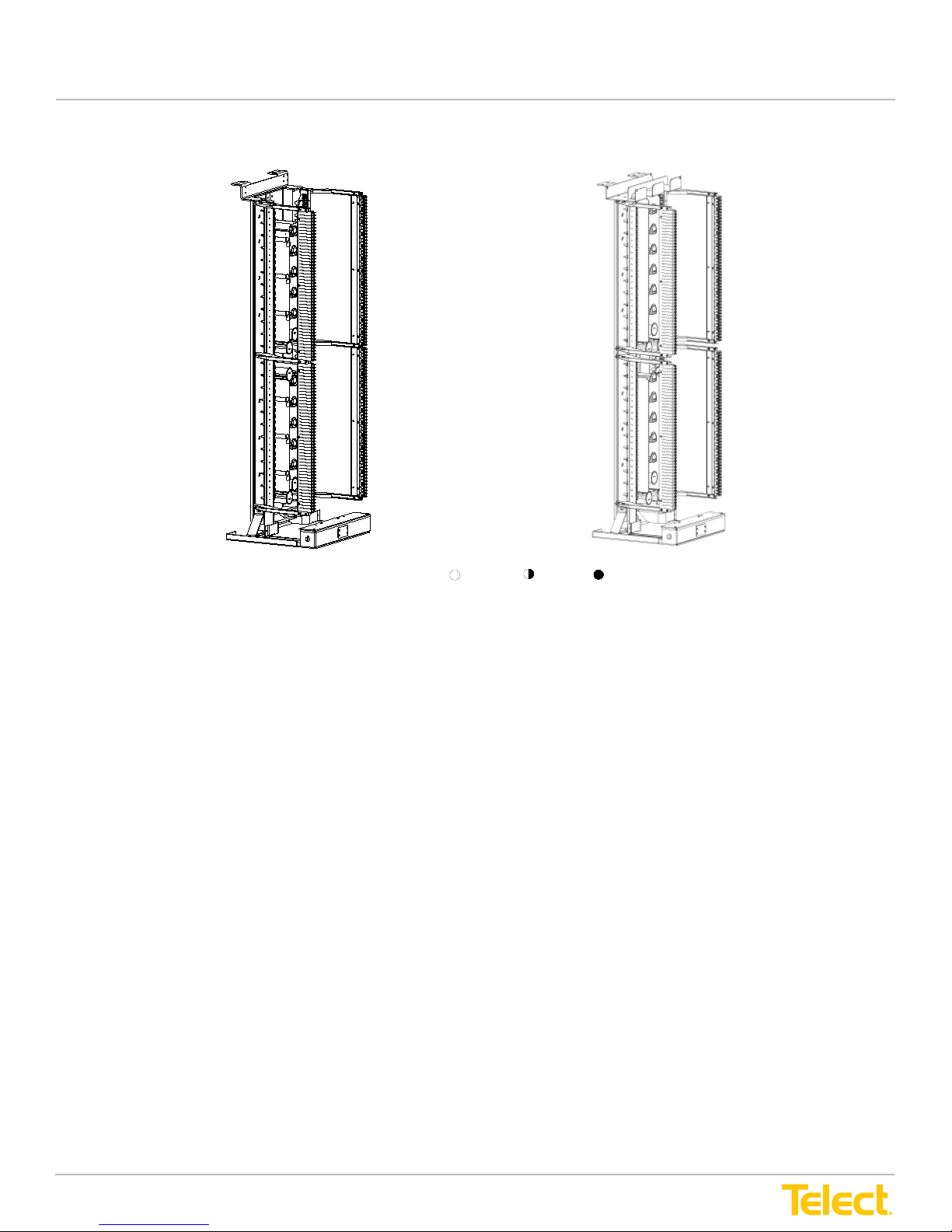

Legend: Good Better Best

User Manual

Telect IC

Figure 16 - ADF Comparisons

© Telect, Inc., All Rights Reserved, 12.7.16 v.4

1.509.926.6000 :: telect.com

15

Loading...

Loading...