Tekmar tekmarNet 4 544, tN4 544, tekmarNet 4 543, tN4 543 Wiring Brochure

- Wiring Brochure

tekmarNet®4 Thermostat 544

W 544

12/08

1

Information

Brochure

Choose controls

to match

application

2

Application

Brochure

Design your

mechanical

applications

3

Brochure

Rough-in

instructions

Layout

wiring

4

Wiring

Brochure

Wiring and

installation of

specific control

5

Data

Brochure

Control settings

and sequence of

operation

6

Job

Record

Record settings &

wiring details for

future reference

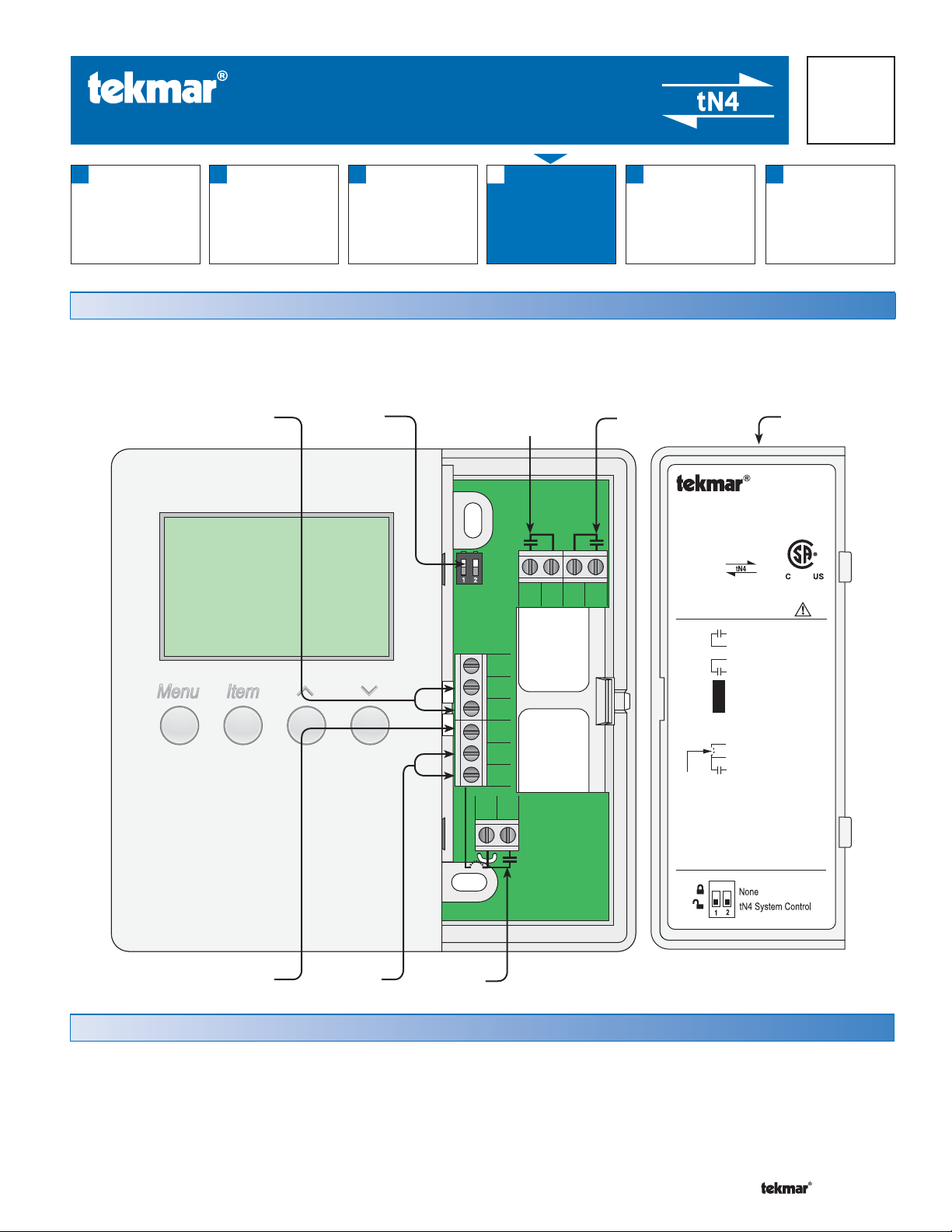

Overview

The following brochure describes how to wire the tekmar tekmarNet®4 (tN4) thermostat 544. The 544 has outputs for:

one heat stage, one cooling stage and one fan. The 544 has inputs for two auxiliary sensors. The wiring of 544 thermostat

is simple and cost effective.

Auxiliary

Sensors

DIP

Switches

Com

Rh1

1st Stage

Cooling

Y1 Rc G1 G1

S2

S1

tN4

C

R

W1

1st Stage

Fan

Wiring

Cover

tNt 544

One Stage Heat, One Stage Cool, One Fan

Power: 24 V (ac) ±10% 60 Hz 1.5 VA

Relays: 24 V (ac) 2 A

992-03

Meets Class B: Canadian ICES, FCC Part 15

Terminal Functions

G1

Fan 1 Relay

G1

Fan 1 Relay

Rc

Power Cooling

Y1

Cool 1 Relay

Com

Sensor Common

S2

Sensor 2

No Power

S1

Sensor 1

®

tekmarNet 4

Power Neutral

Power 24 V (ac)

Heat 1 Relay

Heat 1 Relay

To isolate

relay, cut

jumper

tN4

C

R

Rh1

W1

DIP Switch Functions

tN4

Network

24 V (ac)

Power

1st Stage

Heating

Table of Contents:

Definitions ....................................................................... 2

Rough-In Wiring .............................................................2

Remove the Wiring Cover ..............................................3

Mounting the Thermostat ...............................................3

Wiring Symbols ...............................................................3

1 of 12 © 2008 W 544 - 12/08

Electrical Drawings ......................................................3-7

Wiring the Thermostat .................................................8-9

Troubleshooting the Wiring ........................................... 10

Testing the Wiring ......................................................... 11

Technical Data .............................................................. 12

Defi nitions

•

•

•

•

•

•

•

The following defined terms and symbols are used throughout this manual to bring attention to the presence of hazards of

various risk levels, or to important information concerning the life of the product.

– Caution: Refer to accompanying documents.

– Caution: Refer to accompanying documents.

INSTALLATION

CATEGORY II

– Local level appliances.

Caution

Improper installation and operation of this control could result

in damage to the equipment and possibly even personal

injury or death. It is your responsibility to ensure that this

control is safely installed according to all applicable codes

and standards. This electronic control is not intended for

uses as a primary limit control. Other controls that are

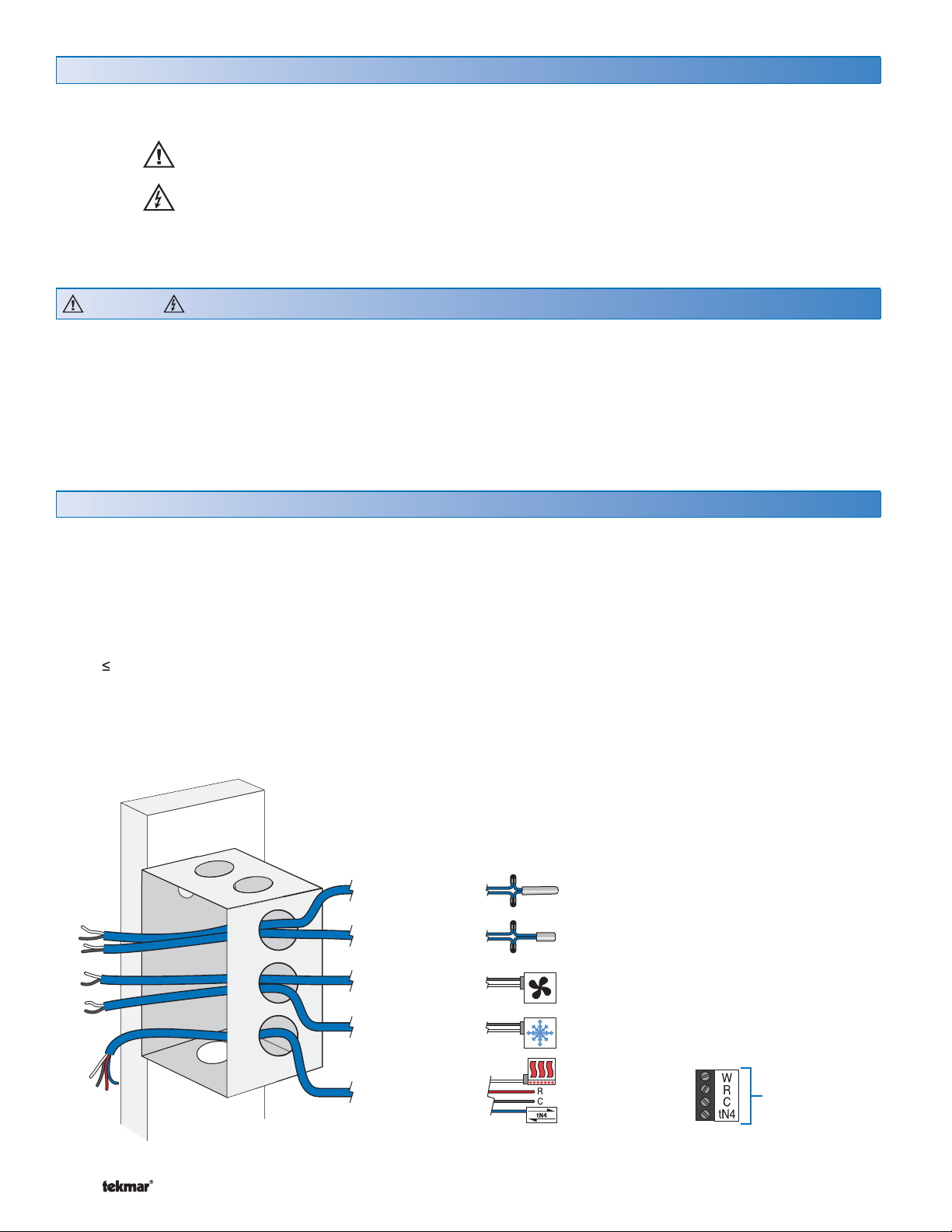

Rough-In Wiring

Choose the placement of the thermostats early in the

construction process to enable proper wiring during

rough-in.

Consider the following:

Interior Wall

Keep dry. Avoid potential leakage onto the control.

RH 80% to 88°F (31°C), down to 50% from 104 to

122°F (40 to 50°C). Non-condensing environment.

No exposure to extreme temperatures beyond 32 - 122°F

(0 - 50°C)

No draft, direct sun, or other cause for inaccurate

temperature readings.

intended and certified as safety limits must be placed into

the control circuit. Do not attempt to service the control.

Refer to qualified personnel for servicing. Apart from any

field replaceable fuse(s) there are no user serviceable

parts. Attempting to do so voids warranty and could result

in damage to the equipment and possibly even personal

injury or death.

Away from equipment, appliances, or other sources of

electrical interference.

Easy access for wiring, viewing, and adjusting the display

screen.

Approximately 5 ft. (1.5 m) off the finished floor.

Use standard 18 AWG wire for the thermostat power, stages

tN4 and sensor connections.

Refer to the diagram below to determine the number of

conductors to run from each piece of equipment to the

thermostat location.

2 Cond. / 18 AWG

2 Cond. / 18 AWG

2 Cond. / 18 AWG

2 Cond. / 18 AWG

4 Cond. / 18 AWG

© 2008 W 544 - 12/08 2 of 12

Sensor 2

Sensor 1

Fan 1

1st Stage Cool

1st Stage Heat

24 V (ac) Power

tN4 Network

Note: When multiple wires

run to the same equipment

location, wiring conductors

can share one wire jacket.

Zone Manager

•

•

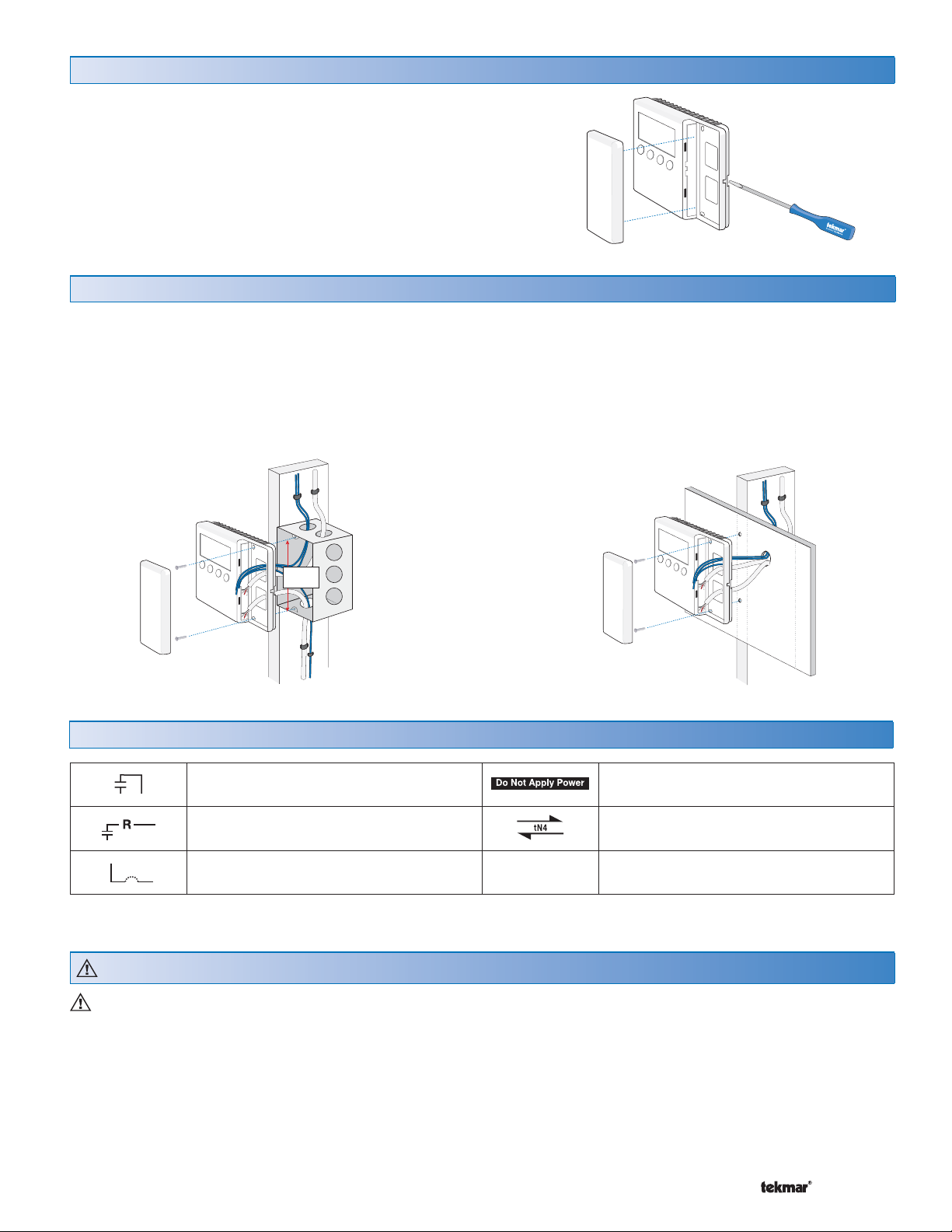

Remove the Wiring Cover:

•

•

•

•

To remove the wiring cover:

Place a small slot screwdriver or similar tool into the slot

located on the right side of the thermostat.

While pushing against the plastic tab, lift off the wiring

cover.

Mounting the Thermostat

If a single or double gang switch box is used, mount the

thermostat directly to the box.

Feed the wiring through the openings in the back of the

thermostat.

Use the upper and lower screw holes to fasten the

thermostat to the box.

Stud

Switch Box

3 1/4”

Terminal

Cover

Thermostat

Base

(83 mm)

Wiring Symbols

If a switch box was not used, mount the thermostat directly

to the wall.

Feed the wiring through the openings in the back of the

thermostat.

Use screws in the upper and lower screw holes to fasten

the thermostat to the wall. At least one of the screws

should enter a wall stud or similar rigid material.

Stud

Wall

OR

Thermostat

Terminal

Cover

Base

Dry contact switch. Operates a device.

Powered switch. 24 V (ac), switched

output to valve, pump relay etc.

Do not apply power to these terminals.

Serious control damage will result.

tekmarNet®4

Factory jumper.

Electrical Drawings

The electrical drawing examples on the following

pages show the 544 in common applications. Choose

the drawing that most accurately depicts the components

in your system and use that drawing as a guide to aid in

wiring your system.

These are only concept drawings, not engineered drawings.

They are not intended to describe a complete system nor

any particular system. It is up to the system designer to

3 of 12 © 2008 W 544 - 12/08

determine the necessary components for and configuration

of the particular system being designed including additional

equipment isolation relays (for loads greater than the

controls specified output ratings) and any safety devices

which in the judgement of the designer are appropriate in

order to properly size, configure and design that system

and to ensure compliance with building and safety code

requirements.

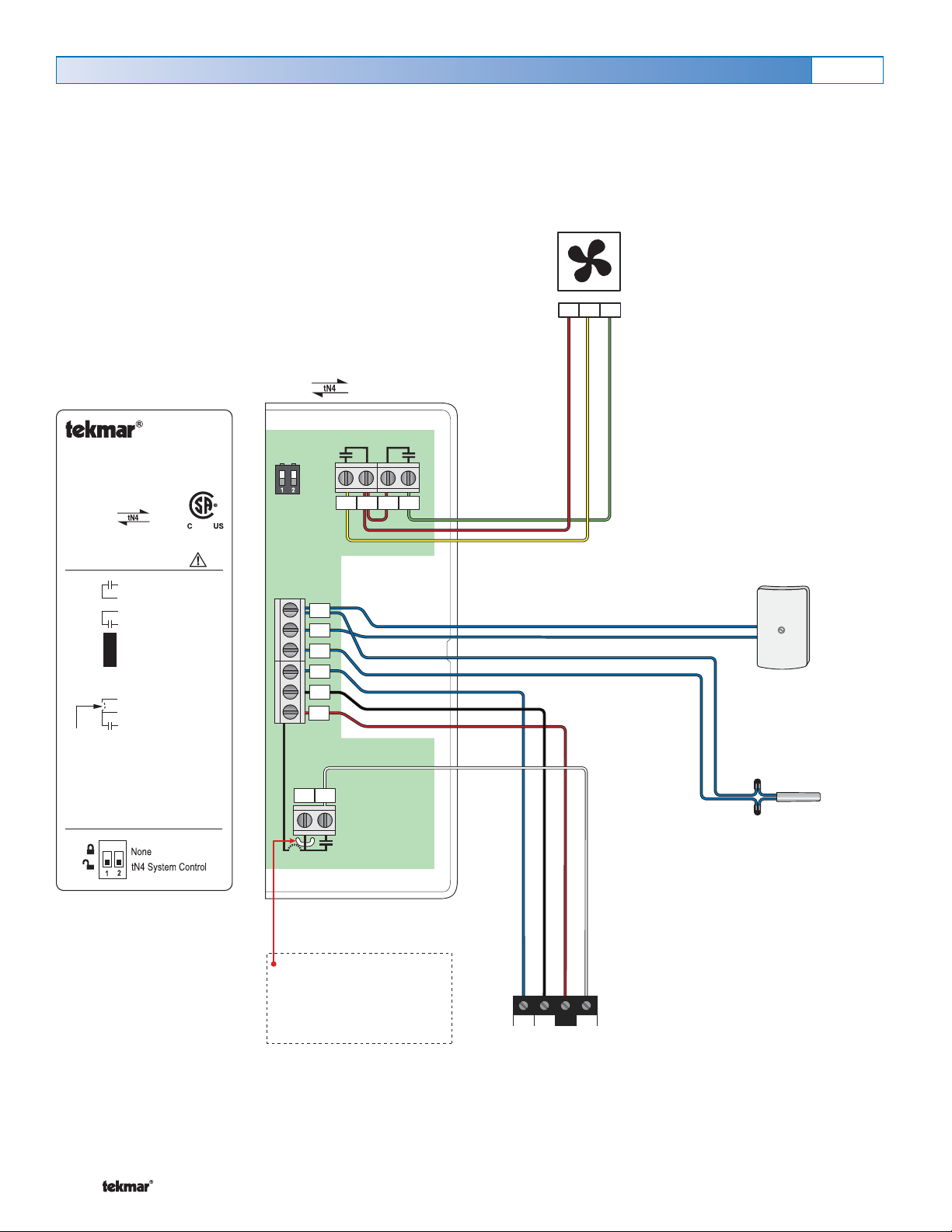

Electrical Application 544 E1

Description:

One Stage Heating (H1 = Radiant), One Stage Cooling (C1 = Compressor), One Speed Fan (F1 = C1), Fan Mode = 1.

Legend:

Sensor 1 = Floor

Sensor 2 = Outdoor

Cooling Equipment

1 Stage Cooling

1 Stage Fan

RcY1G1

544 tNt

tNt 544

One Stage Heat, One Stage Cool, One Fan

Power: 24 V (ac) ±10% 60 Hz 1.5 VA

Relays: 24 V (ac) 2 A

992-03

Meets Class B: Canadian ICES, FCC Part 15

Terminal Functions

G1

Fan 1 Relay

G1

Fan 1 Relay

Rc

Power Cooling

Y1

Cool 1 Relay

Com

Sensor Common

S2

Sensor 2

No Power

S1

Sensor 1

®

tekmarNet 4

Power Neutral

Power 24 V (ac)

Heat 1 Relay

Heat 1 Relay

To isolate

relay, cut

jumper

tN4

C

R

Rh1

W1

DIP Switch Functions

4321

Y1

Rc

G1

G1

Outdoor Sensor

070

5

6

7

8

9

10

Com

S2

S1

tN4

C

R

Slab Sensor

079

Rh1

W1

1211

Factory installed jumper

connects R to Rh1

(terminals 11 to 12) To

isolate Rh1-W1 relay,

cut jumper

© 2008 W 544 - 12/08 4 of 12

tN4 C R W

Zone Manager

Loading...

Loading...