Page 1

OPERATORS MANUAL

FOR THE

LH 4000 SPRAYER MONITOR

LH No. 020-183-UK Version 1.05

LH Technologies Denmark ApS

Mølhavevej 2

9440 Aabybro

Denmark

Tel. +45 9696 2500

Fax. +45 9696 2501

Internet: http://www.lh-agro.com/

Page 2

LH 4000 O

PERATORS MANUAL

2 LH A

GRO

Page 3

LH 4000 O

PERATORS MANUAL

Contents

INTRODUCTION .................................................................................................................5

GENERAL USE ...................................................................................................................6

BEFORE USE .............................................................................................................6

TRACTOR-INFO ..................................................................................................... 6

CONTRAST ............................................................................................................7

MEMORY-KEY........................................................................................................7

TANK-FILL CONTROL............................................................................................7

CLEAR-KEY............................................................................................................ 7

SCREEN LIGHT......................................................................................................7

NUMERIC KEYS.....................................................................................................7

THE DISPLAY......................................................................................................... 8

BASIC "MENU"-SCREEN .......................................................................................8

"STATUS" SCREEN ...............................................................................................9

SPRAY-PROGRAM.............................................................................................................9

SPRAYER, OPERATION...................................................................................................10

PRE-DEFINED FUNCTIONS ....................................................................................10

DOSAGE (APPLICATION)....................................................................................10

SPRAY-BOOM INDICATOR STATUS .................................................................. 10

SPEED..................................................................................................................10

OPERATOR SELECTABLE FUNCTIONS ................................................................11

TRACTOR FUNCTIONS.......................................................................................11

SPRAY FUNCTIONS ............................................................................................12

AREA FUNCTIONS ..............................................................................................14

TIME FUNCTIONS................................................................................................14

SPRAY ENCODEMENTS.................................................................................................. 15

DOSERATE...............................................................................................................15

DO’S AND DON’TS...............................................................................................15

STEP %..................................................................................................................... 16

LITRE LEFT ..............................................................................................................16

HA LEFT....................................................................................................................16

FLOW-FIGURE ......................................................................................................... 16

FLOW CALIBRATION...........................................................................................16

BOOM WIDTH...........................................................................................................17

DRIVE FACTOR........................................................................................................17

REGULATION DELAY .......................................................................................... 17

UNIFORM PRESSURE.............................................................................................18

SPEED SENSOR (WHEEL TRACTOR, WHEEL SPRAYER)...................................18

WHEEL TRACTOR ............................................................................................... 18

WHEEL SPRAYER ...............................................................................................18

SPEED SENSOR CALIBRATION.........................................................................18

TANK VOLUME.........................................................................................................19

METRE SWITCH.......................................................................................................20

INPUT SET-UP .........................................................................................................20

RPM SENSOR .......................................................................................................... 20

WARNING ENCODE................................................................................................. 20

GRO 3

LH A

Page 4

LH 4000 O

PERATORS MANUAL

DATE-CLOCK ........................................................................................................... 20

SPRAYER - DATA DELETE..............................................................................................21

LOG BOOK........................................................................................................................22

THE "LOG-BOOK", HOW TO USE THIS FEATURE................................................. 22

START TASK ............................................................................................................ 23

END TASK ................................................................................................................24

SEE TASK.................................................................................................................25

DELETE TASK .......................................................................................................... 25

EXITING "TASK-MODE" ...........................................................................................25

TANK FILL FEATURE .......................................................................................................26

FILL-FLOWMETER CALIBRATION......................................................................27

OTHER IMPLEMENT ........................................................................................................28

OTHER IMPLEMENT, OPERATION .................................................................................29

SELECTABLE FUNCTIONS .....................................................................................29

TRACTOR FUNCTIONS.......................................................................................29

AREA FUNCTIONS ..............................................................................................30

TIME FUNCTIONS................................................................................................30

OTHER IMPLEMENT, ENCODE ....................................................................................... 31

HA LEFT....................................................................................................................31

WORKING WIDTH ....................................................................................................31

SPEED SENSOR. (WHEEL TRACTOR, WHEEL IMPLEMENT) ..............................32

WHEEL-TRACTOR...............................................................................................32

WHEEL IMPLEMENT ...........................................................................................32

SPEED SENSOR CALIBRATION.........................................................................32

IMPLEMENT SENSOR ............................................................................................. 32

METRE-SWITCH ......................................................................................................32

WARNING ENCODE................................................................................................. 32

DATE/CLOCK ...........................................................................................................32

OTHER IMPLEMENT-DATA/DELETE...............................................................................33

LOG-BOOK........................................................................................................................34

THE "LOG-BOOK", HOW TO USE THIS FACILITY .............................................34

START TASK ........................................................................................................ 35

END TASK ............................................................................................................36

SEE TASK.............................................................................................................37

DELETE TASK......................................................................................................37

LEAVING "TASK-MODE"......................................................................................37

SYSTEM MENU ................................................................................................................38

TEST INPUT .........................................................................................................39

TEST OUTPUT .....................................................................................................40

SPEED SIMULATION...........................................................................................40

SYSTEM DATA ......................................................................................................... 40

ERROR-MESSAGES.........................................................................................................41

VOLTAGE WARNING...........................................................................................41

WARNING OUTPUT ............................................................................................. 41

MEMORY-FAILURE..............................................................................................41

MACHINE SETTING CHART ............................................................................................42

NOTES .............................................................................................................................. 43

4 LH A

GRO

Page 5

INTRODUCTION

Congratulations with your new LH 4000 Spray Controller!

The product is a specifically developed spray controller based on the latest

available technology. We are confident that it will serve you to your full satisfaction

in the years to come.

The computer provides you with a comprehensive selection of valuable

information’s not only when spraying, but in conjunction with all field work where

its facilities for speed and area recording etc. may be desired.

We have endeavoured to deliver a fault free product. To ensure optimal use of the

equipment we ask that great attention be paid when reading the manual. We are

more than happy to help should any queries arise, both when the product is used

for the first time and at any later date. Regarding responsibility for use of the

product we refer to our sales and delivery terms especially paragraph 7, which

follows:

LH 4000 O

PERATORS MANUAL

7. Product usage.

7.1 Any use of the product is at the sole risk of the buyer. The buyer is

therefore not entitled to any form for compensation caused by, for

example, any of the following:

! Disturbance to/from any electronic services or products that do not

confirm to the standards for CE marking,

! Missing or poor signal coverage or a succession hereof from external

transmitters/receivers, used by the buyer,

! Functional faults, which apply to or from a PC-program or PC-

equipment, not delivered by the seller,

! Faults that may arise from the buyers negligence to react to

warnings and fault messages from the product, or which can be traced

to negligence and/or absent constant control of the work carried out

in comparison to the planned job.

7.2 When implementing any new equipment the buyer must take great care and

pay attention. Any doubts as to correct operation/use should result in

contacting the sellers service department.

GRO 5

LH A

Page 6

LH 4000 O

PERATORS MANUAL

GENERAL USE

The LH 4000 is (specifically) designed for crop sprayer control.

The software design is consequently designed for easy use and access for the

operator in conjunction with spray work.

The computer communicates with you through the screen in clear language.

Minimum use of this manual is therefore required.

BEFORE USE

It is essential that you make yourself familiar with the keys and their use. Please

read carefully and study the following pages.

Unfold the back page, which shows the fascia of the computer.

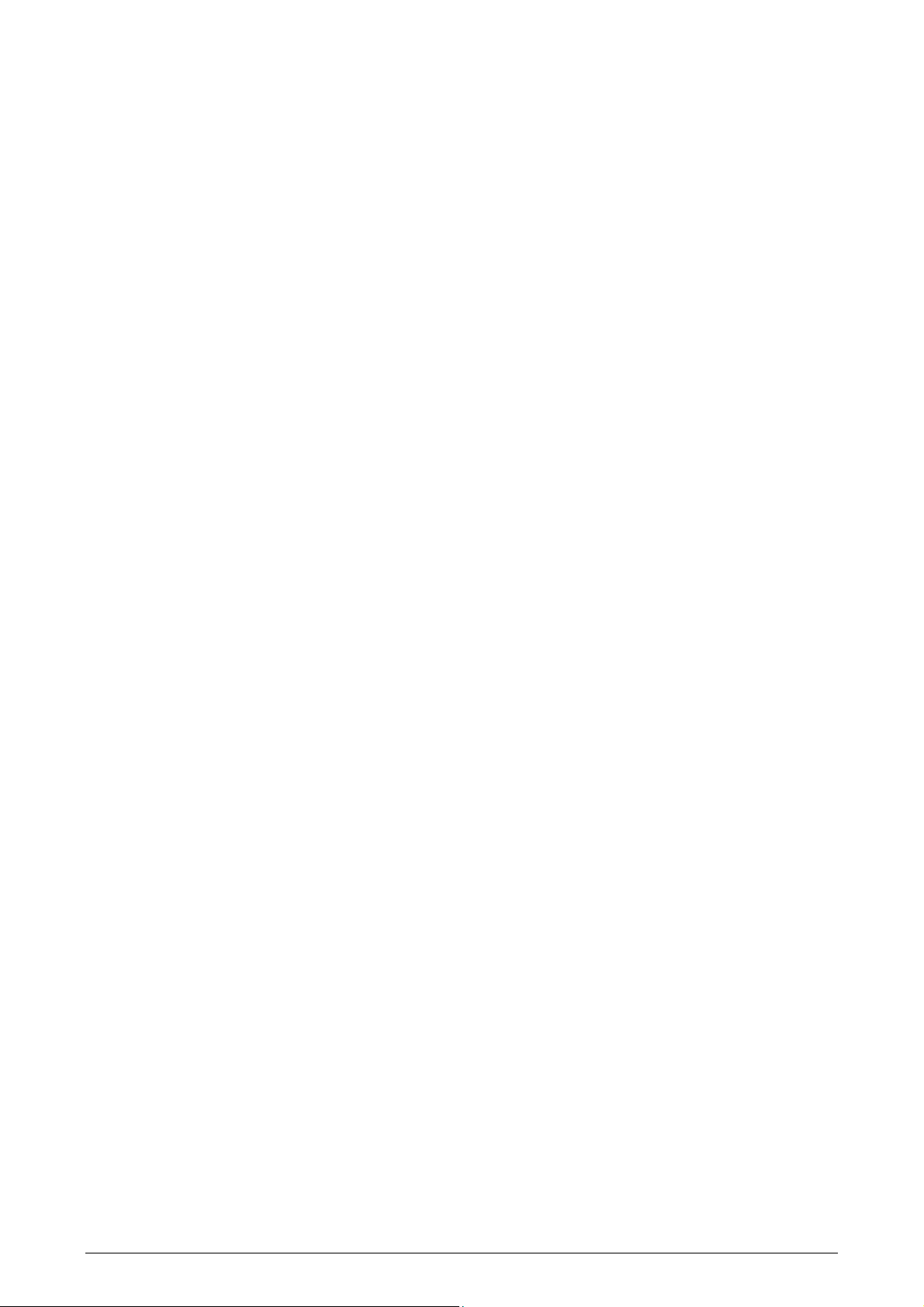

You communicate with the computer using only 5 keys.

You will appreciate that the screens relating to the four upper function- keys

(softkeys) change, as you proceed.

The screen shows the present significance of each individual key. The lower

"enter/return-key" allows you to return to the previous screen.

TRACTOR-INFO

This key instantly displays:

ACTUAL SPEED

WORK EFFICIENCY

AREA WORKED

REMAINING AREA

6 LH A

GRO

Page 7

CONTRAST

MEMORY-KEY

LH 4000 O

PERATORS MANUAL

Adjustment of screen contrast. Can be useful when

working under dark or sunny conditions.

NOTE! The screen may go dark in extreme hot or

cold conditions. The display will return to

normal when the working temperature of the

monitor is back to normal.

To adjust the screen contrast; Use the +/- keys.

If you want an instant return to any screen, press this

key before you scroll to another screen. The memokey allows for instant return to the memorised

screen.

TANK-FILL CONTROL

CLEAR-KEY

SCREEN LIGHT

This key activates the "FILL" feature, which is

detailed later in this manual.

Only active in conjunction with encoding. Will erase

any incorrectly entered figure.

Switches the back-light on and off.

NUMERIC KEYS

Only active when encoding values, or when

simulating forward speed.

GRO 7

LH A

Page 8

LH 4000 O

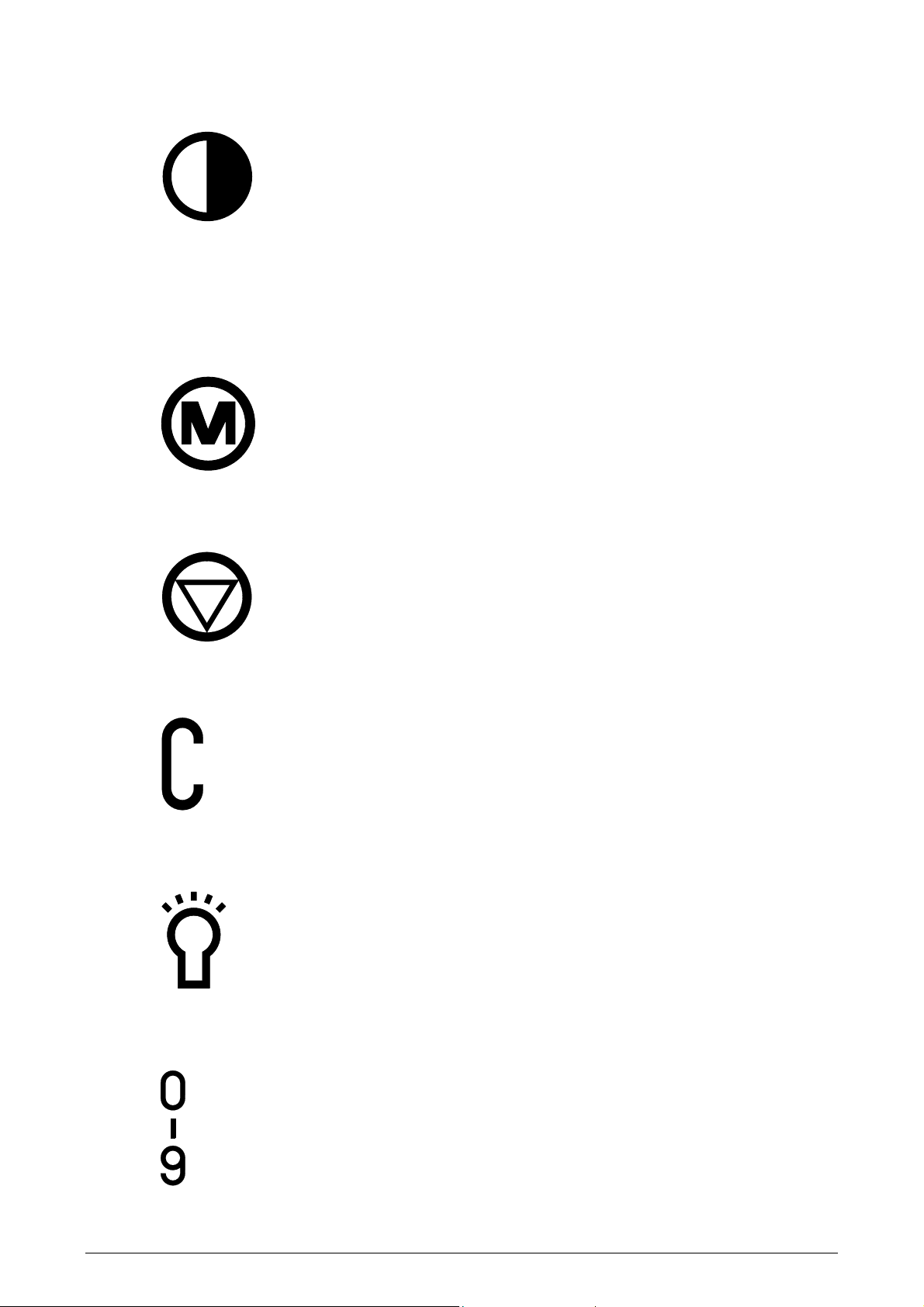

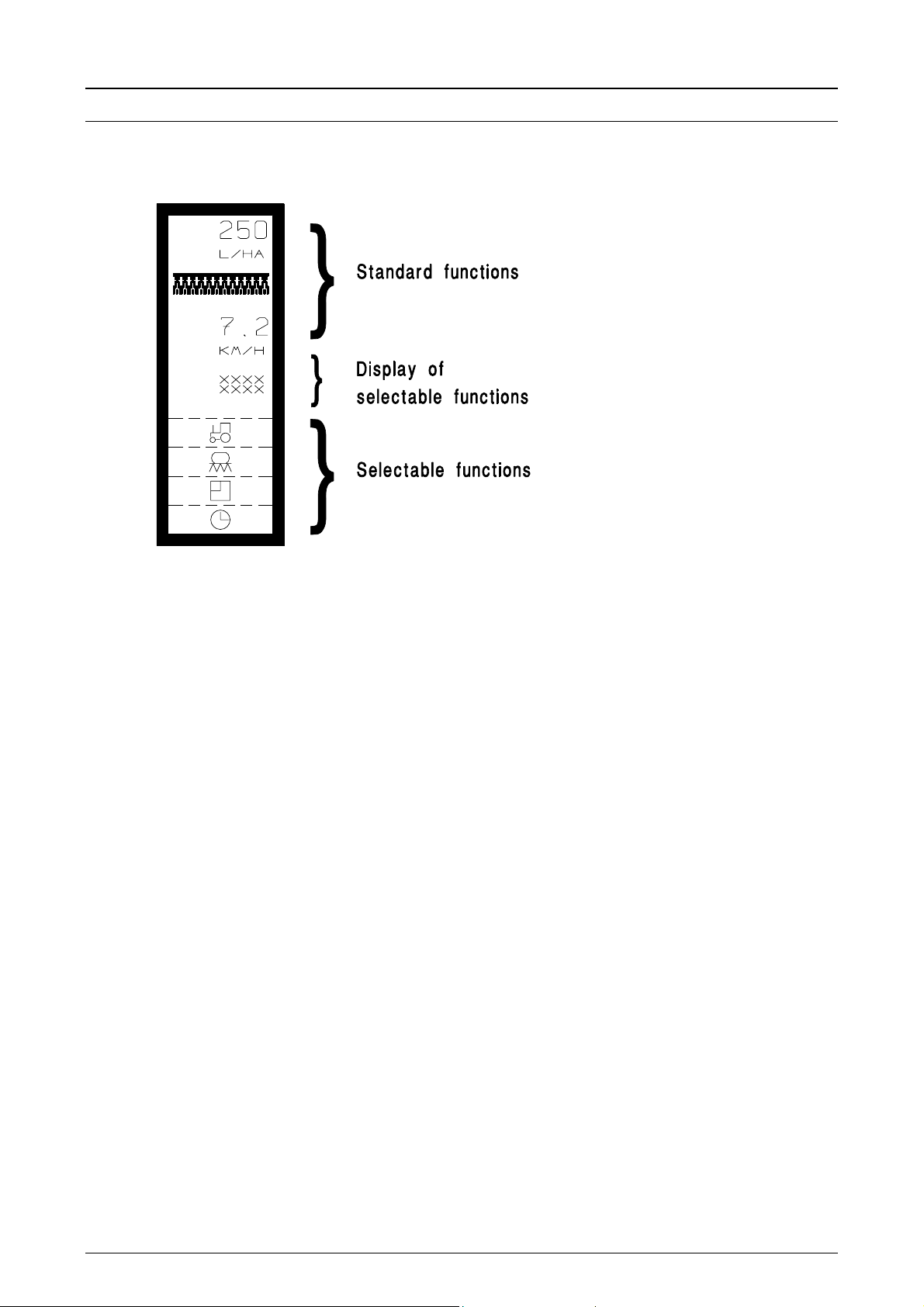

THE DISPLAY

The screen is divided in two sections. The upper section is the information screen.

The lower relates to the softkeys.

PERATORS MANUAL

THE INFO-SCREEN:

You will appreciate the information screen is

designed by the manufacturer and cannot

be altered by you.

THE LOWER (SOFTKEY) FUNCTIONSCREEN:

The actual significance of the four keys is

displayed. You will notice that this status

changes as you proceed. (see the following

examples)

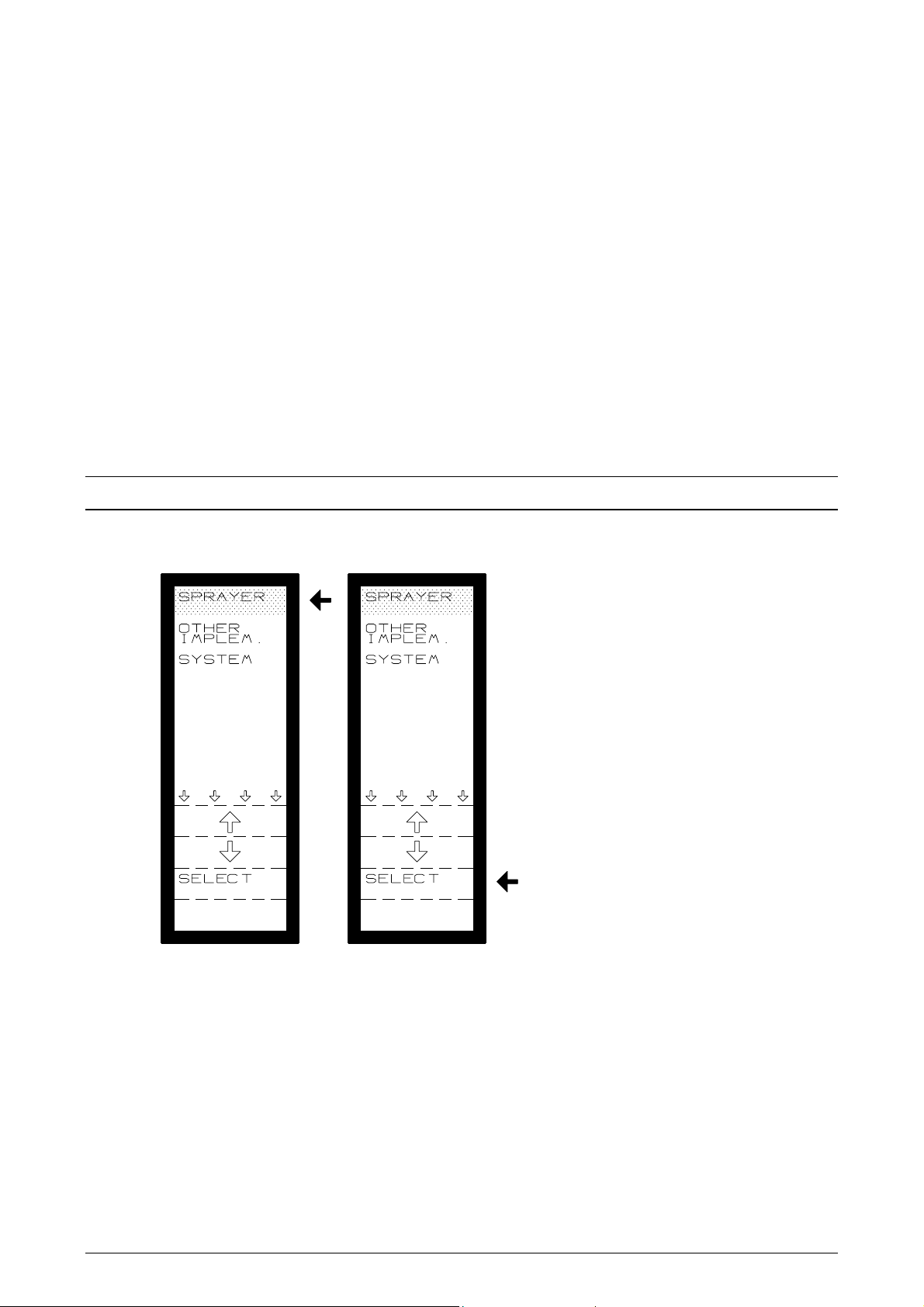

BASIC "MENU"-SCREEN

When powered up, the screen will light up and

display the "main menu". Should you have selected

an other screen, press the return-key until the "main

menu" is displayed again:

SPRAYER

OTHER IMPLEMENT

SYSTEM

The "cursor" can be moved up & down using the

softkeys. Place the cursor on the function you require

and press "SELECT".

8 LH A

GRO

Page 9

LH 4000 O

PERATORS MANUAL

IMPORTANT! IMPORTANT! IMPORTANT!

The software program does not allow menu changes whilst the machine is moving.

This is to prevent operator mistakes and incorrect recordings.

"STATUS" SCREEN

Any time the "operation-menu" is selected, or you leave any encode menu, the

status screen will appear. Here all the current encoded values will be shown.

CHECK & ACCEPT the values before proceeding, by pressing the enter/returnkey.

NOTE! Before start remember to cancel (reset) all relevant counters. (Area-litre

etc.) using the "DATA/DELETE" function, if required.

SPRAY-PROGRAM

From the basic menu, select sprayer:

Move cursor to "SPRAYER".

Press "SELECT".

From there you can choose:

OPERATION

ENCODE

DATA DELETE

LOG BOOK

GRO 9

LH A

Page 10

LH 4000 O

PERATORS MANUAL

SPRAYER, OPERATION

Two "Status screens" must be accepted. Press the "Return-key" until the following

screen is displayed

PRE-DEFINED FUNCTIONS

DOSAGE (APPLICATION)

The primary function under sprayer is dosage. The dosage (application rate) is

shown in Litres per Hectare, calculated as a result of the flow through the

flowmeter, the speed and the recorded area. Subsequently no reading will show if

the machine is stationary, or if there is no flow through the flowmeter.

Two arrows in the upper left corner of screen indicate the length and status of

control signals to the pressure regulator.

NOTE! The shown application rate (L/Ha) is dependent of a correct calibration of

wheel/ circumference/flow-figure/working width. (Details later in this

manual).

SPRAY-BOOM INDICATOR STATUS

The number and position of active/inactive boom-sections is shown on the screen.

SPEED

The forward speed is displayed in km/h. (One decimal).

NOTE! Ensure you select the correct sensor. (Wheel tractor, Wheel sprayer)

Radar is not available!

10 LH A

GRO

Page 11

LH 4000 O

PERATORS MANUAL

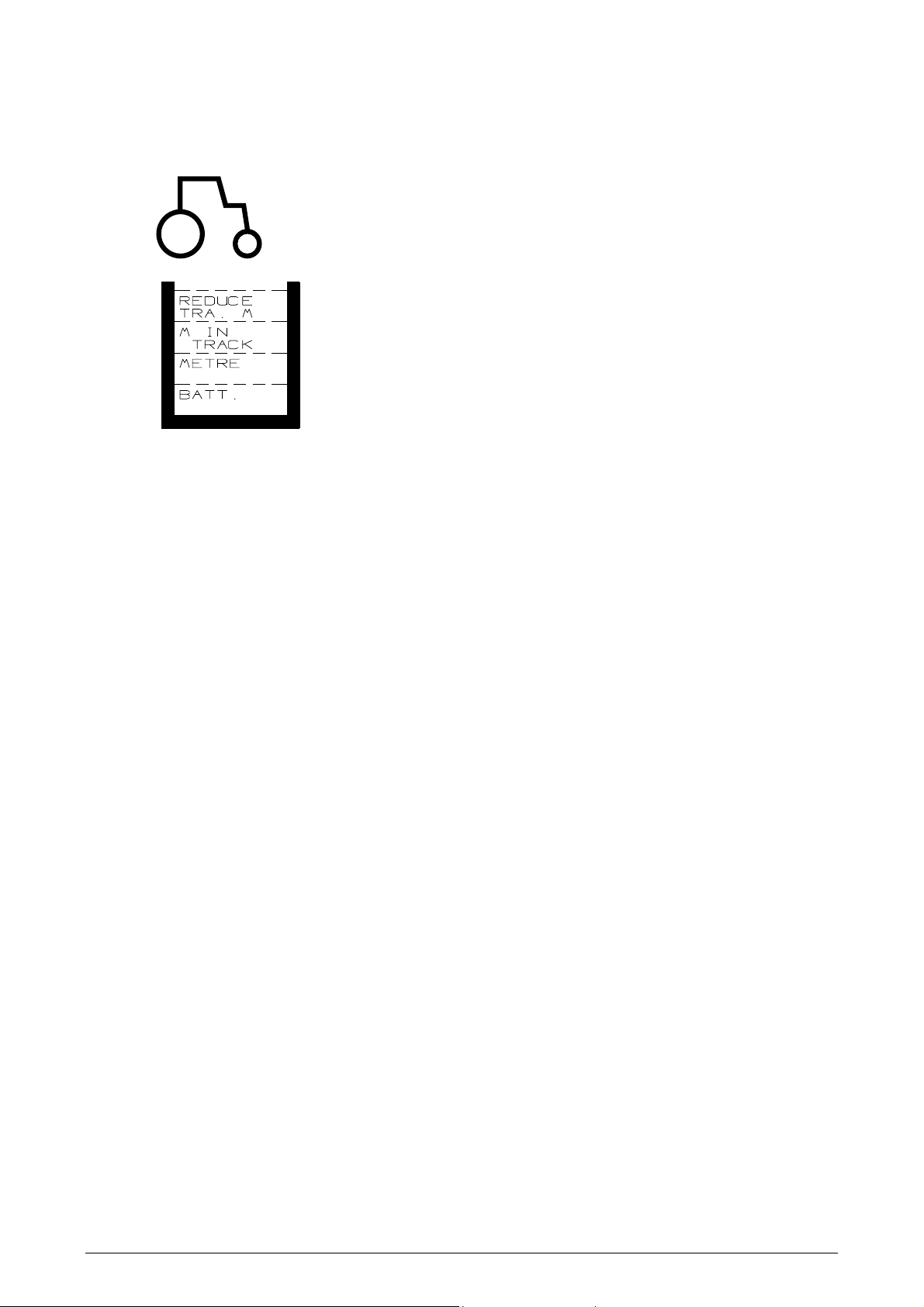

OPERATOR SELECTABLE FUNCTIONS

TRACTOR FUNCTIONS

METRE IN

TRACK: The distance recorded in the

current track (tramline).

METRE: Recorded total metres

METRE START/

METRE IN TRACK:

The distance recorded in current track. You may use this function to locate a

position in the track (e.g. the spot where the tank ran empty).

This function is related to the "REDUCE TRA. M." (This function is only visible

whilst the sprayer is inactive.)

The "METRE IN TRACK"-counter is reset to NIL, each time the sprayer is shut

(e.g. at headlands).

However, should you shut the sprayer in a track, the computer memorises the

distance driven! And displays "REDUCE TRA. M."

METRE STOP: Manual start/stop of distance

counter.

BATT.: Battery voltage

NOTE! Should you stop spraying at a position you would like to relocate, (E.g. if

you need to refill your tank) Proceed thus:

After refilling your tank drive to start of track (headland border). Press

"REDUCE TRA. M" and drive along the tramline. An audible and visual

warning will be given 5 metres before the location at which the tank ran

empty.

When the position is instruction is given to start spraying.

METRE.:

The total distance driven in metres.

This is measured with the wheel with the speed sensor fitted. You may choose

"manual" start/stop of counter. Or automatically via the override sensor (sprayer

main valve) switch. Select your mode in: "ENCODE" "METRE SWITCH".

or:

METRE START/ METRE STOP:

Manual Start/Stop of metre counter. The start/stop selection screen will only

appear if “MANUAL” has been selected in “ENCODE”.

BATT.:

The current voltage of battery.

GRO 11

LH A

Page 12

LH 4000 O

PERATORS MANUAL

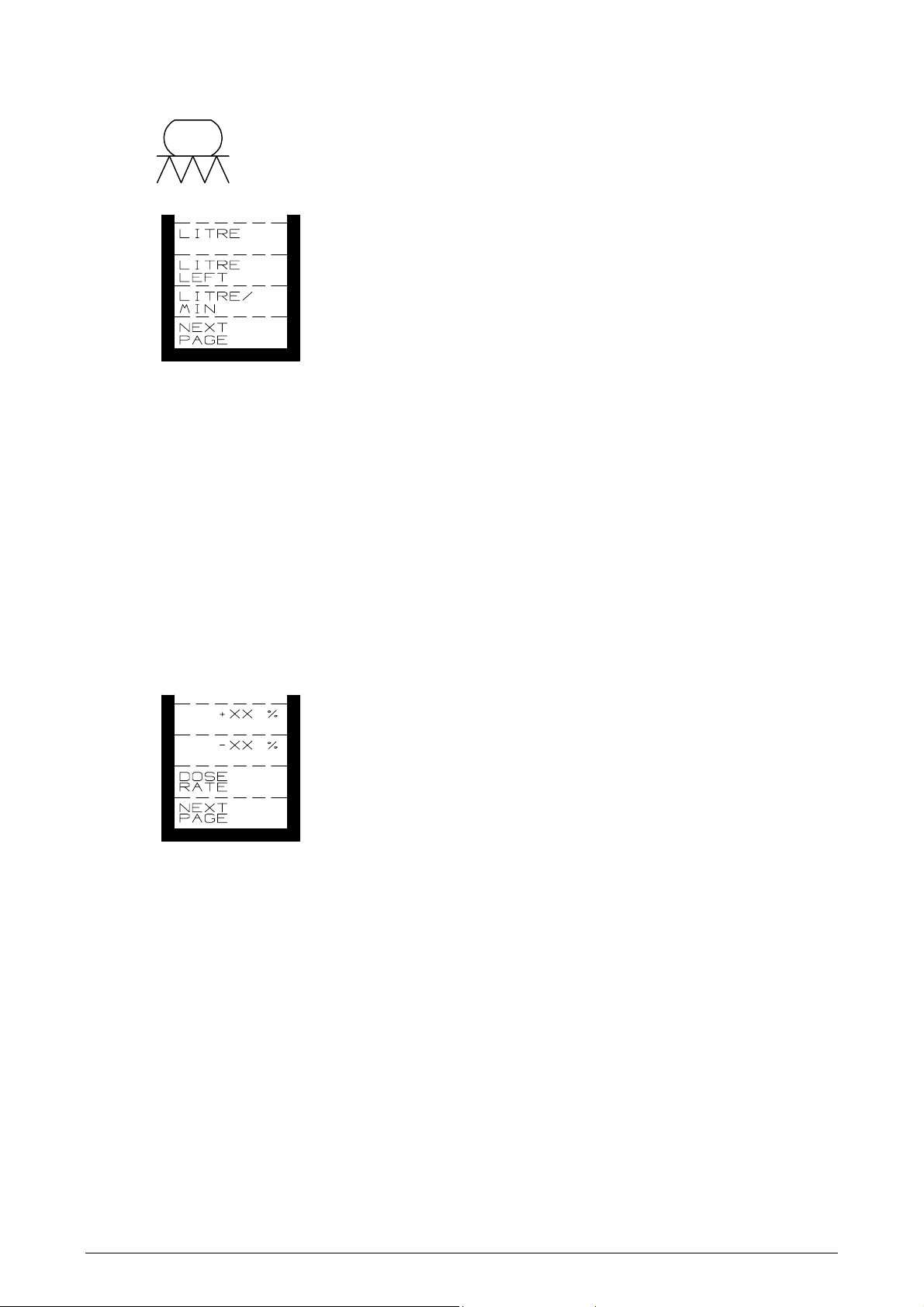

SPRAY FUNCTIONS

LITRE: Amount consumed from tank.

LITRE LEFT: Amount remaining in tank.

LITRE/MIN.: Litre consumption per minute.

LITRE: The total amount consumed since counter was reset. This function

is a "trip-counter", which may be reset using the "DATA/DELETE"

function. The "grand total" counter is also available in this menu.

LITRE LEFT: The amount of liquid in tank. However, this feature requires

encoding the tank volume/amount filled, before starting. This is

done in encode “LITRE LEFT”. This value is automatically

entered is the optional tank fill feature is used.

LITRE/MIN.: The actual flow in Litres per minute through the flowmeter. Do not

regard this as the Pump-capacity.

Pressing the "NEXT PAGE" key displays the next functions.

+xx %: Increase of application rate.

-xx %: Decrease of application rate.

DOSE-RATE/

NORMAL: Encodement of application rate, OR

instant return to normal rate (+/- %

activation)

+ xx %: Percentile increase of the application rate. You select the percent

figure you require, in encode "STEP%"

- xx %: Percent decrease of application rate. (similar figure will be entered

automatically, ref. the above).

NORMAL/

DOSAGE: Multifunctional softkey.

It will read "DOSE-RATE" normally. Select, and you will have

instant access to enter or alter your desired application rate.

However, should you have activated either your "+" or "-" %-

keys, the softkey will read "NORMAL". Subsequently, pressing

this key will return your application rate to "normal" regardless

what over/under rate you are currently applying.

12 LH A

GRO

Page 13

LH 4000 O

Pressing the "NEXT PAGE" key displays the next functions.

+: Manual increase of pressure

(application).

-: Manual decrease of pressure

(application).

AUTO/MAN: Select automatic or manual

application control. (+/- keys will

appear when you select manual-mode

This facility may be used e.g. under

severe field conditions where

automatic (computer control) is

inefficient, or you have observed

abnormalities in the computer control

mode.

PERATORS MANUAL

NOTE! Be aware. Should you have selected "MANUAL" mode is the computer

unable to resume to control before you reset to "AUTOMATIC" control

mode

Pressing the "NEXT PAGE" key displays the next functions.

RPM: Shaft speed of an axle (only

displayed if RPM ON is selected in

encode).

GRO 13

LH A

Page 14

LH 4000 O

PERATORS MANUAL

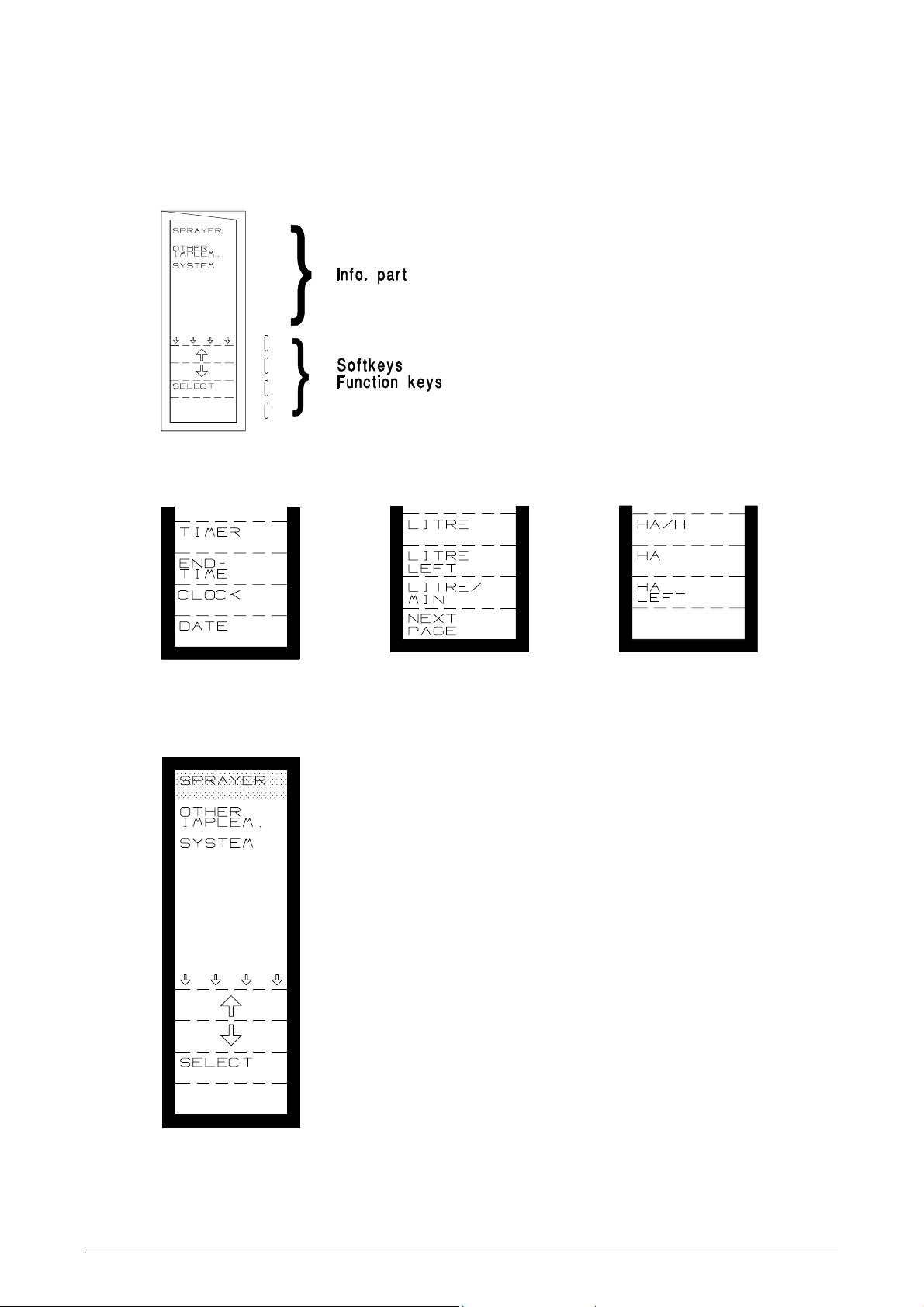

AREA FUNCTIONS

HA/H: Work efficiency.

HA: Area worked.

HA LEFT: Remaining area.

HA/H: Work efficiency. The actual area capacity per hour.

HA: Area counter. The recorded area worked since reset of counter.

May be reset in the "DATA/DELETE" menu. This is also where

you will find the "Grand Total Area counter"

HA LEFT: Remaining area to work. This function requires encodement of

actual size of the area in encode “HA LEFT”.

TIME FUNCTIONS

TIMER: Work hours/minutes.

END TIME: Expected time of finalisation.

CLOCK: Actual time.

DATE: Day-month-year

TIMER: Records the work time on a specific job. You start and stop this

recorder manually. May be reset in menu "DATA/DELETE",

where the "Total time" recorder is also available.

END TIME: Expected time of day at which the job will be complete. Requires

field size to be entered in encode “HA LEFT”.

CLOCK: Actual time. Time is adjusted in "ENCODE".

DATE: The actual date. The date is adjusted in "ENCODE".

14 LH A

GRO

Page 15

SPRAY ENCODEMENTS

In this menu you must enter the particulars for your Crop Sprayer.

The particulars you enter will be memorised automatically under "sprayencodements"

When you have entered a particular figure, press the "return" key to proceed to

your next encodements.

NOTE! Check all your figures before you start work. (Simply: check your

"Status" screen)

LH 4000 O

PERATORS MANUAL

DOSERATE

Encode your desired application rate in LITRES per HECTARE. (max figure =

9999 L/Ha)

You can alternatively enter/alter your rate directly from the "operation" screen

The LH 20D flowmeter (most common size). Enter flow-figure 2000! (Guide only)!

Ask your dealer for recommended start figure when using a different size

flowmeter.

DO’S AND DON’TS

DO: Check your flow-accuracy regularly! (check against a load)

DON’T: Do not calibrate your flow-figure against any worked area!

The computer offers an easy step-by-step calibration procedure, or you may chose

to calibrate manually

GRO 15

LH A

Page 16

LH 4000 O

STEP %

Enter your desired percentage figure. (one entry only for +/-%) (max figure = 99%).

LITRE LEFT

To see how much is left in the tank, you must encode the amount filled into the

tank here.

If there is an amount remaining in the tank when filling, this amount must be added

to the amount filled thus:

Amount remaining in tank + amount filled = Litre left.

NOTE! If the optional fill-flow equipment is fitted, LITRE LEFT is encoded

HA LEFT

As above, you must enter the field size before commencing work. (End time &

required fill amount are calculated from this parameter).

PERATORS MANUAL

automatically

FLOW-FIGURE

This is the "calibration-figure" for your flowmeter.

In other words: The measuring accuracy of the liquid! You MUST calibrate your

flowmeter. Recalibrate the flowmeter if the consistency of the liquid used changes.

FLOW CALIBRATION

Encode (LH20 D meter) a "start" figure of 2000.

Method 1. (The computer calibration-mode)

(Just follow this instruction and those on the screen)!

1. Fill the tank, or minimum 600 litres.

2. Encode the filled quantity in “LITRE LEFT”, and return to “Flow figure”.

3. Spray minimum 500 litres (All boom sections open, keep within normal

pressure range (e.g.3 Bar). You may keep the machine stationary, using the

simulated speed facility, (see "SYSTEM") or select “MANUAL” and set your

pressure (see page 13).

4. Verify the remaining litres in tank on the tank scale! (Note: machine must be

level).

5. Place the cursor on “TANK LIT” and encode the amount remaining in the

tank.

6. Press the flashing "CALC. FLOW"- key!

7. The new flow-figure is now calculated and automatically encoded.

NOTE! If you should be uncertain regarding the accuracy of the tank-scale, it is

recommended to take the machine to a weigh- bridge for verification.

16 LH A

GRO

Page 17

LH 4000 O

PERATORS MANUAL

Method 2: (Manual calibration method).

Your flow-calibration figure may be calculated as follows:

1. Fill tank with minimum 600 Litres.

2. Reset your "LITRE" counter (using the "DATA DELETE" menu).

3. Spray minimum 500 litres (All boom sections open, keep within normal

pressure range (e.g.3 Bar). You may keep the machine stationary, using the

simulated speed facility, (see "SYSTEM") or select “MANUAL” and set your

pressure (see page 13).

4. Verify the remaining litres in tank on the tank scale (Note: machine must be

level).

5. Verify your "LITRE" recorder reading in the "DATA/DELETE" menu.

6. Calculate your correct flow-figure, using this formula:

NEW FLOW-FIGURE

Present flow-figure x sprayed amount

=

Litre recorded on computer

E.g.:

2000 x 500

487

= 2053

The calculated new figure must be encoded in the computer.

BOOM WIDTH

The effective width of your sprayer (in cm.)

The LH 4000 computer automatically compensates for open and closed boom

sections.

Consequently each individual spray-sections must be encoded into the computer.

Encode the widths one by one. Start with the left-hand side (section 1).

Proceed thus:

Move cursor to first section. Enter width (in Cm.) using the numeric keypad.

Proceed to section 2 -3 etc!

DRIVE FACTOR

The "response-factor" for automatic application control mode. This parameter sets

the "speed" of the reaction time of regulation. (e.g. Sprayer press regulation valve)

If the reaction is too slow = increase figure or vice-versa. Min fig. = 1. Max.= 500.

"Normal" status, Start with 50.

REGULATION DELAY

Encode the number of seconds that regulation is delayed by after the main valve is

opened. It is possible to encode from 0 to 9 seconds.

GRO 17

LH A

Page 18

LH 4000 O

PERATORS MANUAL

UNIFORM PRESSURE

Encode whether the controls of the sprayer are equipped with uniform-pressure

valves (balance return-valves), or not.

ON = Yes OFF = No.

If "ON" remember to adjust your valves.

SPEED SENSOR (WHEEL TRACTOR, WHEEL SPRAYER)

You can chose between two different located speed sensors:

WHEEL TRACTOR

Sensor fitted to the tractor. Either externally, or an integrated (gearbox) sensor.

(May apply e.g. if machine is self-propelled type).

WHEEL SPRAYER

Sensor located on the sprayer. (e.g. trailed sprayers).

Calibration of speed sensor. Sensors must be calibrated individually!

SPEED SENSOR CALIBRATION

Speed sensor calibration is extremely important! We recommend that you check

the sensor calibration during the season. (This will ensure of compensation for

tyre-wear.)

However, the design of the LH 4000 makes calibration easy. You can calibrate

using two methods; Automatic or Manual.

AUTOMATIC SPEED SENSOR CALIBRATION

1. Carefully, measure and mark a distance of 100

metres. (Not on tarmac, but field-condition soil

surface)

2. Drive to "start" position of the 100-m distance,

and press the "CALIB.CALC" key. The screen

to the left will appear:

3. Drive the 100-metre distance. Stop exactly at the

100-m. mark.

4. A new function-key will appear; "CALC.

WHEEL". Press this key, and the computer has

automatically calculated and entered the

calibration figure!

Should the flashing: "CALC. WHEEL" however

not appear, the computer has received

insufficient pulses from the sensor enabling it to

"auto-calibrate". You must calibrate using one of

the two "manual" alternatives:

18 LH A

GRO

Page 19

LH 4000 O

PERATORS MANUAL

"MANUAL" SPEED CALIBRATION.

E.g. when sensor is fitted to a wheel:

1. Mark the wheel (e.g. the valve), and mark the field.

2. Drive the machine exactly 10 revs, of the wheel.

3. Mark out on the Field.

4. Measure the driven distance carefully (to nearest cm). Calculate your

calibration figure. Use the following formula:

Example:

The measured distance between marks = 52.80 metre (5280 centimetre)

The wheel turned 10 revs.

Four (4) magnets are fitted.

5280 (the distance driven in cm)

= 132.000 cm

10 (the revs.) X 4 (the magnets)

This figure: (132) is to be encoded. Press function-key "WHEEL TRACTOR".

Encode 1 - 3 - 2 using the numerical keypad.

Incorrect encodements can be deleted using the "C"-key.

"Manual" speed calibration e.g. sensor fitted to a prop-shaft

1. Press the function-key : "CALIB CALC". The

screen to the left will appear:

2. Move (drive) slowly. Stop when "NO OF

PULSES" changes from "0" (nil), to "1".

3. Mark the field.

4. Drive slowly. Stop when NO OF PULSES"

changes from "50", to "51".

5. Mark the field. Measure the distance between

the two marks.

6. Divide the measured distance (cm), by 50.

7. Encode the result (in cm.) using the numerical

keypad.

TANK VOLUME

The sprayer’s tank size is encoded here. This is required if the automatic tank fill

feature is to be used.

GRO 19

LH A

Page 20

LH 4000 O

PERATORS MANUAL

METRE SWITCH

Select whether distance-recording is started/stopped manually, "MANUAL", or by

the selected override-service sensor (e.g. spray on/off switch).

INPUT SET-UP

The LH 4000 software allows for a flexible set-up of electric connections to ANY

TYPE of Crop-Sprayer controls. Select either: "MAIN-VALVE" or "BOOM

SECTION”.

The screen will read the current status. You may change setting by using the

"Shut/Open OV." (volt)-key.

E.g.: Boom section “Shut” OV.

States that the wires connected to the boom section switches receive “OV”

(ground), when the switch is in the “OFF” position.

This should be set by the engineer when the system is fitted.

RPM SENSOR

Select weather a RPM sensor is fitted and encode the number of pulses received

per revolution.

NOTE! This function is not implemented in all sprayer fitting kits, ask your

dealer.

WARNING ENCODE

KM/H: Warning ON/OFF and MAX/MIN. limits for speed warning.

NOTE! Activation of the speed warning provides and ensures

minimum spray output when the speed-warning is given

for the “low” limit setting. E.g. when the speed falls

below that set in KMH warn the spray pressure will be

maintained.

MISDOSERATE: Warning ON/OFF and Percent deviation of application rate.

LITRE LEFT: Warning ON/OFF for tank level

RPM: Warning ON/OFF, and max/min limits for RPM.

Only displayed if RPM ON is selected.

DATE-CLOCK

The following can be adjusted:

HOURS - MINUTES - YEAR - MONTH – DAY

20 LH A

GRO

Page 21

SPRAYER - DATA DELETE

There are 3 main functions in this menu:

1. Reading of the total-counters (Accessible only here).

Reading the trip counters.

2. Deleting all counters by choice.

3. Deleting all trip counters simultaneously.

It is not possible to see/select the total-counters in the operation-menu.

Subsequently "DATA" / "DELETE" execution is available only in this menu.

Set the cursor (use the "arrow"-keys) to the counter to be deleted. Press the

"DELETE" key to erase.

Should you like to reset ALL TRIP COUNTERS, press the "DELETE TRIP" key.

NOTE! Do not forget to take your notes before deleting!

LH 4000 O

PERATORS MANUAL

The functions are:

TIME: Time counter for consumed time since reset.

TIME +: Total operation time since reset.

HA: Area counter. Worked area since reset.

HA+: Area counter. Total area worked since reset.

METRE+: Total distance travelled since reset.

LITRE: Litres consumed since reset.

LITRE+: Total litres consumed since reset.

NOTE! The “total” info is accessible only in the "DATA/DELETE" menu.

GRO 21

LH A

Page 22

LH 4000 O

PERATORS MANUAL

LOG BOOK

Your LH 4000 holds a comprehensive "LOG-BOOK" facility. A total of 35 jobs

(tasks) can be memorised individually. Should you like to use this, you must

allocate a "job-No" in advance.

NOTE! The "trip"-counters: Time, Area, Litres are all automatically reset when

The functions to manipulate in the" Log-Book" mode are basically:

you allocate a new "Task-no."

START TASK,

END TASK,

SEE TASK,

DELETE TASK

THE "LOG-BOOK", HOW TO USE THIS FEATURE

Pressing the lower function key displays the

following:

Press the key indicated by the arrow

The screen shows the "MODE" you have selected.

(In this case the sprayer-mode indicated by the

symbol). The two oblong squares shows:

22 LH A

GRO

Page 23

LH 4000 O

PERATORS MANUAL

The upper: 1 (one) job no. is used. (oblong is

"occupied")

The lower: 34 are "empty".

Press the "START TASK" -key.

START TASK

You may now use the "cursor" to select the individual

"task" to "open”!

The "Task-number" you select, is your Log-Book

reference no.!

NOTE! Should you select an already "used" task

The "trip-counter" status will remain.

Consequently: Any "new" recordings are

added on.

All trip counters are reset when any empty

task is started.

Select a "TASK". The following screen:

GRO 23

LH A

Page 24

LH 4000 O

PERATORS MANUAL

STOP TASK

SEE TASK

DELETE TASK

Press the "RETURN" key to proceed:

The "main operating" screen appears, indicating

through the displayed text: "TASK NO", and the

oblong indicating you are in "LOG-BOOK"-mode.

END TASK

You can at any time interrupt your present "TASK". All recordings will be

memorised (until you delete the task)

Please Note! You cannot escape your "operation" in the task-mode whilst any

task is "open". Should you attempt, the screen will display a

warning and indicate which task is to be “closed”

24 LH A

GRO

Page 25

SEE TASK

LH 4000 O

PERATORS MANUAL

Should you like to verify any task.

Press "SEE TASK". Move cursor to desired task.

Press the "SEE"-key. Screen will display the

recorded data for that task.

DELETE TASK

Please note that deleted data is irrevocable!

Move the cursor to the desired task. Press the "DELETE" key.

NOTE! Do not delete before you take your notes!

EXITING "TASK-MODE"

Press "RETURN" until this screen is displayed:

Press the "TASK-MODE" (lower function key)

symbol.

Press the "END TASK"-key.

GRO 25

LH A

Page 26

LH 4000 O

PERATORS MANUAL

TANK FILL FEATURE

NOTE! This is an optional feature that requires specific parts to be fitted to your

sprayer. Ask your dealer for details.

The "HOLD" key gives instant access to the Tank Fill

features:

FILL

VOLUME: The amount required to be filled. This

is calculated through the "litre rest Ha rest, the tank-size, and the present

application rate"

FILLED

VOLUME: The amount measured (by the fill-

flowmeter).

LITRE LEFT: Calculated amount remaining in the

tank

NOTE! If the actual (tank) amount

does not correspond with

this reading, the sprayflowmeter may need recalibrating.

CALC.

VOLUME: The required amount is automatically

calculated when you press this key.

START

FILL: Pressing this key starts recording

amount filled, and opens the optional

fill-valve

FLOW

FIGURE: The calibration figure for your Fill-

flowmeter.

FILL MODE: Select whether a valve is used to stop

the flow (VALVE) or whether a

warning is given (WARNING).

Selecting WARNING gives a visible

(on screen) and audible warning.

Selecting VALVE allows for an electric

valve to open/shut.

26 LH A

GRO

Page 27

LH 4000 O

PERATORS MANUAL

FILL-FLOWMETER CALIBRATION

NOTE! The Fill-flowmeter is an independent unit. Subsequently it MUST be

calibrated individually!

However, as automatic calibration-mode is provided by your LH 4000 for the

spray-flowmeter, so it is for your FILL-meter!

The accuracy of the calibration procedure depends on the amount used for

calibration. The following example uses 1000 litres.

Please double-check the calibration of the fill-flowmeter.

Proceed thus:

1. Select "FLOW-FIGURE" through the sub-menu.

2. Check that a figure is encoded. If not, enter e.g. 4000.

3. Press the "return"-key to return to the previous screen.

4. Enter a "FILL VOLUME" Enter approx. twice the amount you may require.

5. Press the "START FILL" key in the sub-menu.

6. Fill the tank with an exact "known" amount (through the fill flowmeter). (You

may use a weigh-bridge for optimal accuracy).

7. Select "FLOW-FIGURE" in the sub-menu. Move cursor to "TANK LITRE".

Encode the amount here.

8. Press the flashing "CALC. FLOW" key. The flow-figure will be calculated

(and entered) automatically.

GRO 27

LH A

Page 28

LH 4000 O

PERATORS MANUAL

OTHER IMPLEMENT

Your LH 4000 may be used in conjunction with any type of machine or implement

where various monitoring or recording services are required.

The "Other Implement" operation of the computer is designed to be similar to the

sprayer-menus. Consequently, the major part of this section should already be

familiar to you.

Should you have specific requirements for services not available in the computer,

please inquire for the "upgrade" versions available of the LH 5000 computerrange.

Press the "RETURN"-key to return to the "MAIN MENU".

Select "OTHER IMPLEMENT".

Move the Cursor and press "SELECT".

You can now select between the displayed functions.

The following chapter details the individual functions.

28 LH A

GRO

Page 29

OTHER IMPLEMENT, OPERATION

SPEED:

The Top information is Speed. The speed is read as

Km/h to one tenth.

Speed is calculated with the selected sensor (Wheel

tractor-Wheel-implement).

AREA:

Area is recorded in Hectares. The readings up to

99.99 Ha are provided to one hundredth. Above this

to one tenth.

NOTE! The DATA/DELETE menu provides the

NOTE! Do not forget to reset your counters using

LH 4000 O

PERATORS MANUAL

Total Area-counter.

DATA/DELETE before you commencing

work!

SELECTABLE FUNCTIONS

TRACTOR FUNCTIONS

PTO: PTO revs. (requires sensor on the

shaft)

METRE: Driven distance in metres.

METRE START/

METRE STOP: Manual start/stop of distance

BATT: System voltage.

PTO: The revs. of the shaft.(may be other than PTO)!

METRE: Driven distance in Metres. Is recorded through the speed sensor.

Can be activated manually, or in conjunction with the "override"

sensor. (Implement -Sensor). Select the mode in the ENCODE

menu.

or

recorder

METRE START/

METRE STOP: Manual Start/stop of the metre counter. These soft keys will only

appear if you have selected the manual mode-switch.

BATT.: The present voltage of your battery.

GRO 29

LH A

Page 30

LH 4000 O

PERATORS MANUAL

AREA FUNCTIONS

HA/H: Work Efficiency. The area cover per hour calculated with the

HA: Area Counter. The worked area since last reset. May be reset

HA/H: Work efficiency.

HA: Area worked.

HA LEFT: Remaining area to work.

present speed and working width.

through the "DATA/DELETE" menu where the "Area Total"

counter is also to be found.

HA LEFT: The remaining area to be worked. Presupposes encodement of

the field size before work commences.

TIME FUNCTIONS

TIMER: Work time in Hours & minutes.

END TIME: Expected finishing time for the current

work.

CLOCK: Actual time.

DATE: Actual Date.

TIMER: May be used to record the time used for a particular job. Is

started/stopped manually and can be reset in the

"DATA/DELETE" menu. Here you also find the "Total time"

counter.

END TIME: Expected time of day at which the job will be complete. Requires

encodement of field size (HA LEFT).

CLOCK: The actual time. Can be altered in ENCODE.

DATE: The actual Date. Can be altered in ENCODE.

30 LH A

GRO

Page 31

OTHER IMPLEMENT, ENCODE

This menu allows for encodements of your LH 4000 in conjunction with jobs other

than Spray-work.

NOTE! Encodements in this menu do not interfere with the encodements you

may have done in the Sprayer-Menu!

NOTE! You must check your encodements through the "status" screen, which

will always be shown before you are allowed to enter the operation

screen.

LH 4000 O

PERATORS MANUAL

HA LEFT

Before commencing your work, you may encode the size of the field. From this

parameter "End Time" is calculated.

WORKING WIDTH

The effective working width of your implement, ( in cm.) Do not forget the

"overlap", which may cause incorrect measurements.

GRO 31

LH A

Page 32

LH 4000 O

PERATORS MANUAL

SPEED SENSOR (WHEEL TRACTOR, WHEEL IMPLEMENT)

Your LH 4000 provides for two differently located speed sensors.

WHEEL-TRACTOR

A sensor fitted on the tractor.

NOTE! Possible wheel-slippage will interfere with accuracy unless you

compensate through with wheel calibration

WHEEL IMPLEMENT

You may desire to have a permanent sensor fitted on a trailed machine for

improved accuracy. Whenever applicable, speed sensors located on large-driven

wheels enhances accuracy.

SPEED SENSOR CALIBRATION

The LH 4000 provides an automatic-calibration-feature for the speed-sensor.

However, you may need or desire to calibrate using a "manual" procedure.

Both procedures are detailed in the "SPRAYER" section pages 18 & 19.

Calibrate your sensor as described.

IMPLEMENT SENSOR

The implement sensor is the sensor that starts and stops the area meters.

In OTHER IMPLEMENT you can choose between the following:

1. Lift (sensor connected via rear of 7 pin socket).

2. PTO (if a PTO sensor has been mounted).

3. Implement (sprayer main on/off switch starts/stops area recordings).

METRE-SWITCH

The menu where you decide whether distance recording is controlled "manually",

or in conjunction with the "override" sensor.

WARNING ENCODE

PTO: Warning ON/OFF and rev. MIN/MAX limits.

KM/H: Warning ON/OFF and MIN/MAX speed limits.

DATE/CLOCK

Adjustment of:

TIME - YEAR - MONTH - DAY

32 LH A

GRO

Page 33

OTHER IMPLEMENT-DATA/DELETE

There are 3 main options in this menu.

1. Reading of "total-counters" (only accessible here)

Reading of "trip-counters”

2. Delete individual counter.

3. Delete all "trip-counters"

NOTE! The "DATA/DELETE" menu is the only menu available to read and

delete the "total-counters".

To delete the counters move the cursor to the desired position. Press "DELETE".

To delete all "Trip-counters" simultaneously: Press. "DELETE TRIP".

NOTE! Before deleting any records, take your notes. Deleted recordings are

irrevocable!

LH 4000 O

PERATORS MANUAL

Records are:

TIME: Work time since last reset.

TIME+: Total work time since last reset.

HA: Worked area since last reset.

HA+: Total worked area since last reset.

METRE+: Total driven distance since last reset.

"+" -counters accessible only through the

DATA/DELETE menu.

GRO 33

LH A

Page 34

LH 4000 O

PERATORS MANUAL

LOG-BOOK

Your LH 4000 provides a "Log-Book" feature. Up to 35 individual jobs can be

memorised in the computer. This feature and how to work it is detailed on page 22

to 25 in the "SPRAYER" section.

NOTE! Any "job-number" which you may issue in the "Other-Implement"-mode

Please Note: You cannot escape your "operation" whilst in task-mode if any

Should you attempt, the screen will display a warning and indicate which task to

"close"!

The functions to manipulate in the" Log-Book" mode are basically:

will be transferred whilst you select the "Sprayer-Mode".

tasks are "open"!

START TASK

END TASK

SEE TASK

DELETE TASK

THE "LOG-BOOK", HOW TO USE THIS FACILITY

Press the key indicated by the arrow

The screen shows the "mode" you have selected. (In

this case the other implement-mode, indicated by the

symbol).

The two oblong squares shows:

34 LH A

GRO

Page 35

LH 4000 O

PERATORS MANUAL

The upper: 1 (one) job no. is issued. (oblong is

"occupied")

The lower: 34 are "EMPTY".

Press "START TASK" -key.

START TASK

You may now use the "cursor" to select the individual

"TASK" to "OPEN"!

The "TASK-NUMBER" you select, is your Log-Book

reference no.!

NOTE! Should you select an already "open", task

The "trip-counter" status will remain.

Consequently: Any "new" recordings will

be added on.

Should you "START" any "EMPTY" task. The Tripcounters are all reset.

GRO 35

LH A

Page 36

LH 4000 O

PERATORS MANUAL

Select a "TASK". The following screen appears:

STOP TASK

SEE TASK

DELETE TASK

Press the "RETURN" key to proceed:

Your "select" screen appears, now indicating through

the shown text: "TASK NO", and the oblong

indicating you are in "LOG-BOOK"-mode.

END TASK

You can at any time interrupt your present "TASK". All recordings will be

memorised (until you delete task)

Please Note! You cannot escape your "operation" in the task-mode whilst any

task is "open". Should you attempt, the screen will read a

warning and indicate which task is to be "closed".

36 LH A

GRO

Page 37

SEE TASK

LH 4000 O

PERATORS MANUAL

Should you like to verify any task No.

Press "SEE TASK".

Move cursor to desired task.

Press the "SEE"-key.

Screen will read the recorded data on that task.

DELETE TASK

NOTE! Deleted data is irrevocable!

Do not delete before you take your notes!

Move cursor to desired task. Press the "DELETE" key.

LEAVING "TASK-MODE"

Press "RETURN" to display this screen:

Press the "TASK-MODE" (lower) symbol,

At this screen, press the "END TASK"-key.

GRO 37

LH A

Page 38

LH 4000 O

PERATORS MANUAL

SYSTEM MENU

The "SYSTEM"-menu is basically a service feature.

In the unlikely event of malfunctions, this menu

provides a comprehensive set of individual "TEST"

facilities.

However, the menu also provides a very useful feature, which allows you to

"SIMULATE" forward speed! (detailed below)

You may use the "SIMULATE SPEED" e.g. whilst you set up your sprayer.

TEST INPUT: Test input of all sensors etc.

TEST

OUTPUT: Test of all outputs, e.g. power to

valve.

LANGUAGE: Select operating language.

SPEED

SIMULATE: Speed simulation.

SYSTEM

DATA: Non customer accessible info.

38 LH A

GRO

Page 39

LH 4000 O

PERATORS MANUAL

TEST INPUT

Should you observe any malfunction, conduct a test of all circuits and sensors with

the test-program.

The Screen:

Each text string has a "counter" shown at the L/H side. The figure must change

each time a "pulse" (signal) is received.

The R/H side shows the actual status: "HI" or "LO".

The individual input "ports":

PTO: Signal from the PTO-sensor.

WHEEL

TRACTOR: Signal from the wheel sensor.

IMPLEMENT: Area override signal. (Tractor)

TRAIL 1: Signal from pressure sensor. (if

applicable)

TRAIL 2: Signal from the spray-flowmeter.

TRAIL 4: Signal from wheel-sensor on

implement (if applicable)

TRAIL 7: "Override" signal. (e.g. pray-valve)

BOOM 1 TO 9: Status of boom-sections.

GRO 39

LH A

Page 40

LH 4000 O

PERATORS MANUAL

TEST OUTPUT

OUT1: The power "increase" output to

regulator valve.

OUT2: The power "decrease" output to

regulator valve.

OUT3: Output to "fill" valve(if applicable)

OUT 4: Not used.

NOTE! The "SYSTEM" test feature comprises of three screens.

Move to next screen using the "NEXT PAGE"-key.

NOTE! Activation of any in- or outputs in the test "SYSTEM"- mode disregards

any possible malfunctions you may have provoked through a

wrong/mistaken encodement.

Any possible failure caused by defects in the computer software is

therefore disregarded!

SPEED SIMULATION

E.g. whilst testing or calibrating machines it may be desirable to conduct a

performance test at a stand-still.

To simulate speed, do as follows:

Put SPEED-SIMULATE "ON" in the menu. Return to your "OPERATION"-menu.

Enter the desired speed through the numeric-keys!

How to disable the "SIMULATED SPEED".

Either:

1. Move vehicle forward, the "SIMULATE" speed will be cancelled

automatically.

or

2. Encode a simulated speed of "0" (nil). After 8 sec., you can return to

"SYSTEM" for setting "SIML. SPEED" to "OFF".

SYSTEM DATA

Information not accessible by the operator.

40 LH A

GRO

Page 41

ERROR-MESSAGES

Your LH 4000 will display various "error" messages should abnormalities occur:

LH 4000 O

PERATORS MANUAL

VOLTAGE WARNING

Should the power supply drop below 10 V. This warning may appear during start

or if battery is weak.

WARNING OUTPUT

Warning of short-circuits in the power supply to the regulator valve.

MEMORY-FAILURE

Should the computer fail to memorise data. You may overrule this warning by

pressing the "OK" -key. However, check your encodements should this warning

appear.

Should your LH 4000 display errors frequently, consult your dealer.

GRO 41

LH A

Page 42

LH 4000 O

PERATORS MANUAL

MACHINE SETTING CHART

Flow figure: Sprayer Fill flow

Boom Width:

Boom sections (cm):

1:

2:

3:

4:

5:

6:

7:

8:

9:

Total Boom Width:

Drive factor:

Uniform pressure: ON OFF

Wheel circumference: Wheel

tractor

Wheel

sprayer

Metre switch: Main valve Manuel

Input setup: Boom

Main valve

Section

42 LH A

GRO

Page 43

NOTES

LH 4000 O

PERATORS MANUAL

GRO 43

LH A

Page 44

LH 4000 O

PERATORS MANUAL

44 LH A

GRO

Loading...

Loading...