Page 1

FITTING INSTRUCTIONS

FOR

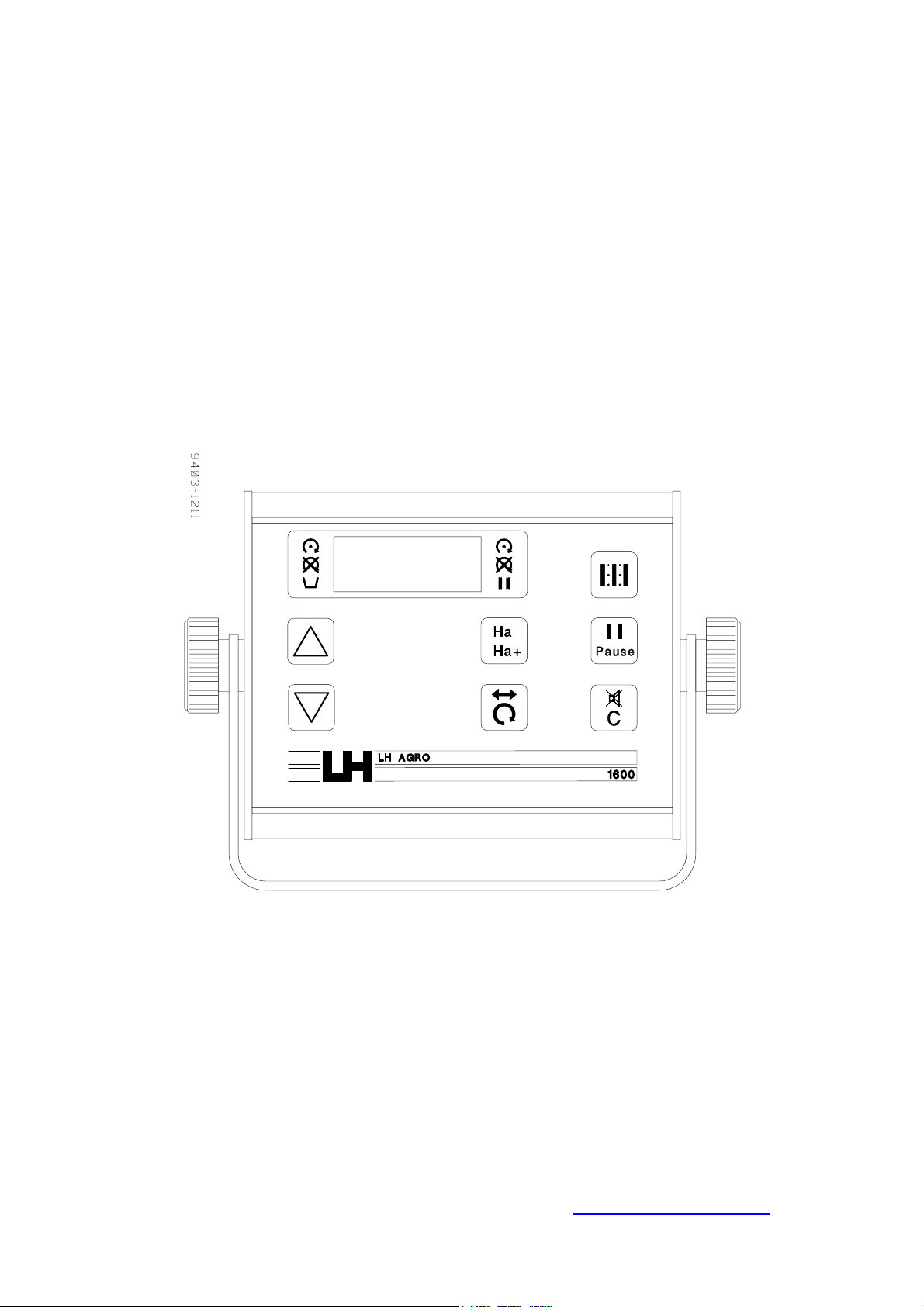

LH 1600 M

LINE TRAM MONITOR

LH No. 010-153-UK

SCA 0500

LH Technologies Denmark ApS

Mølhavevej 2

9440 Aabybro

Denmark

Tel. +45 9696 2500

Fax. +45 9696 2501

Internet: http://www.lh-agro.com/

Page 2

F

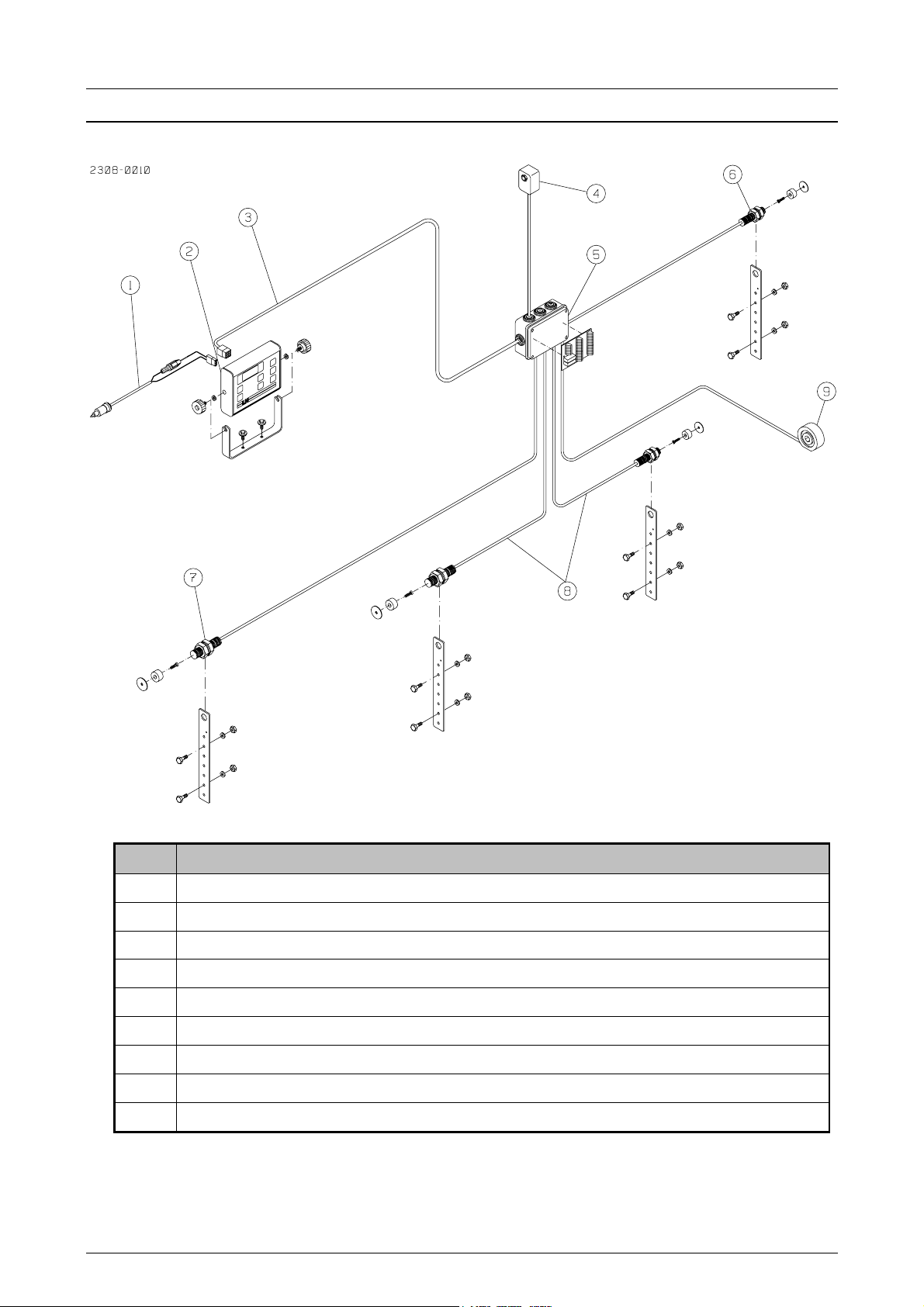

GENERAL OVERVIEW

ITTING INSTRUCTIONS

LH 1600 M

Pos. Description

1 Power cable

2 Monitor

3 Main cable

4 Hopper sensor, empty hopper (optional extra)

5 Junction box

6 Wheel sensor

7 RPM sensor, fan speed (optional extra)

8 Implement sensors

9 RPM sensor, metering shaft (optional extra)

2 LH A

GRO

Page 3

F

ITTING INSTRUCTIONS

LH 1600 M

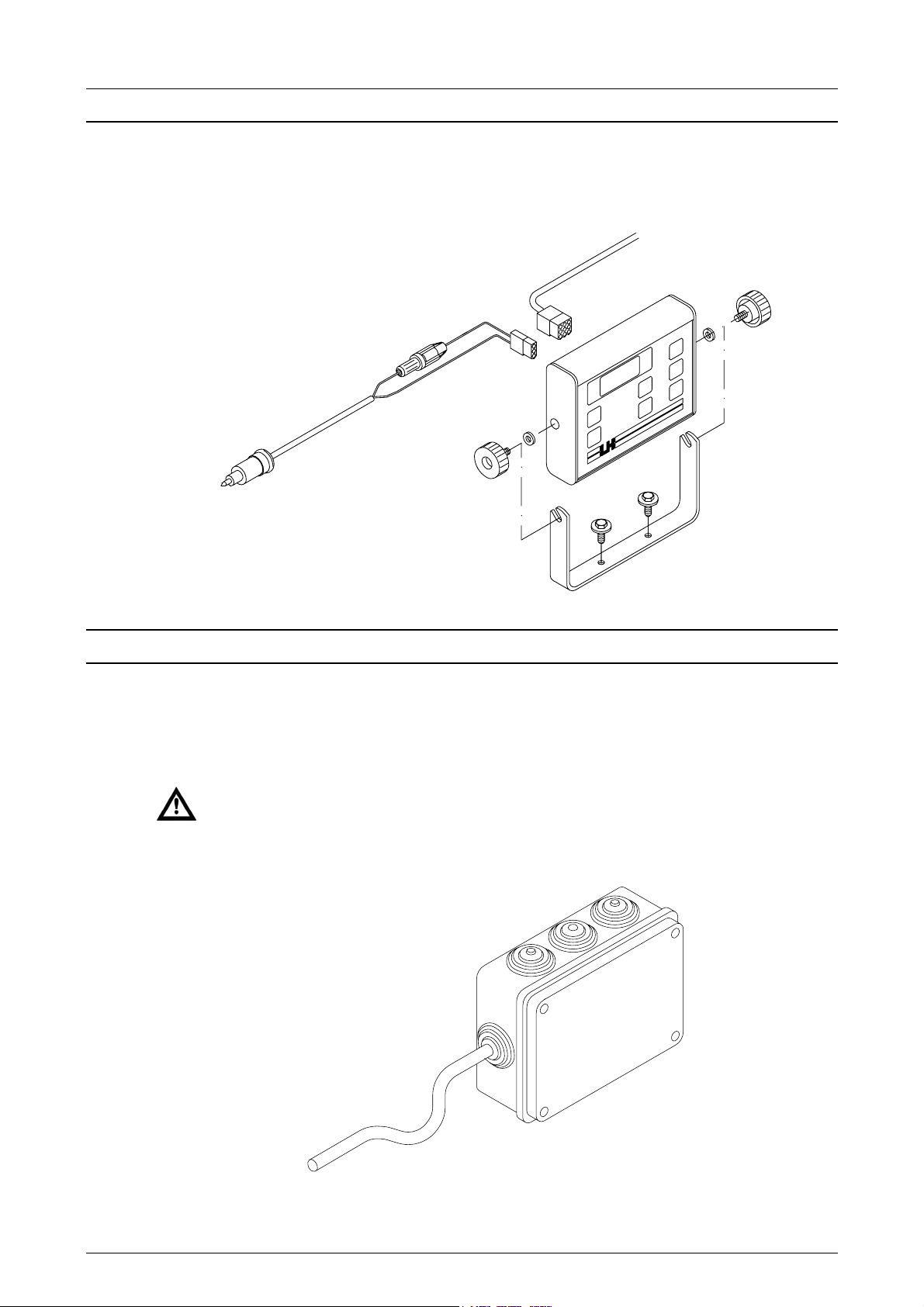

FITTING THE MONITOR

Fit the monitor in the cab in reach of the operator. Connect the monitor to the

tractor’s 12V supply via the 2-pin power plug.

FITTING THE JUNCTION BOX

Fit the junction box on the front of the seed drill in the middle. When the cables

are connected in the box, make sure that each cable has a drip off bend so that

water does not run along the cable and into the junction box.

Make sure that the holes through the rubber grommets are not too large,

make the hole as small as possible and push the cable through.

LH A

GRO

3

Page 4

F

FITTING THE IMPLEMENT SENSORS

The LH 1600M is delivered with 2 implement sensors that are connected via the

junction box print in series. This means that both sensors must be active (magnet

by the sensor) before the bout number is counted and the area counter is

stopped. Fit a sensor on each marker.

ITTING INSTRUCTIONS

LH 1600 M

FITTING THE WHEEL SENSOR

Fit the wheel sensor on the seed drill land wheel. The distance between the

magnet and the sensor is approx. 5-mm.

4 LH A

GRO

Page 5

F

ITTING INSTRUCTIONS

LH 1600 M

FITTING THE RPM SENSOR ON THE FAN

OPTIONAL EXTRA EQUIPMENT (LH NO. 930-983)

A RPM sensor can be fitted on the fan as optional extra equipment. The sensor

can be fitted, i.e. on the end of the fan axle as shown on the following drawing.

The distance between the magnet and the sensor must be 3 – 5 mm.

Remember that the South Pole of the magnet must face the sensor:

FITTING THE HOPPER LEVEL SENSOR (EXTRA EQUIPMENT)

A hopper level sensor can be supplied as optional extra equipment. Fit the hopper

level sensor as shown on the following drawing approx. 150 mm over the bottom

of the hopper. Drill a hole in the correct size for the sensor, which is then screwed

into the plate (do not tighten too hard):

LH A

GRO

5

Page 6

F

ITTING INSTRUCTIONS

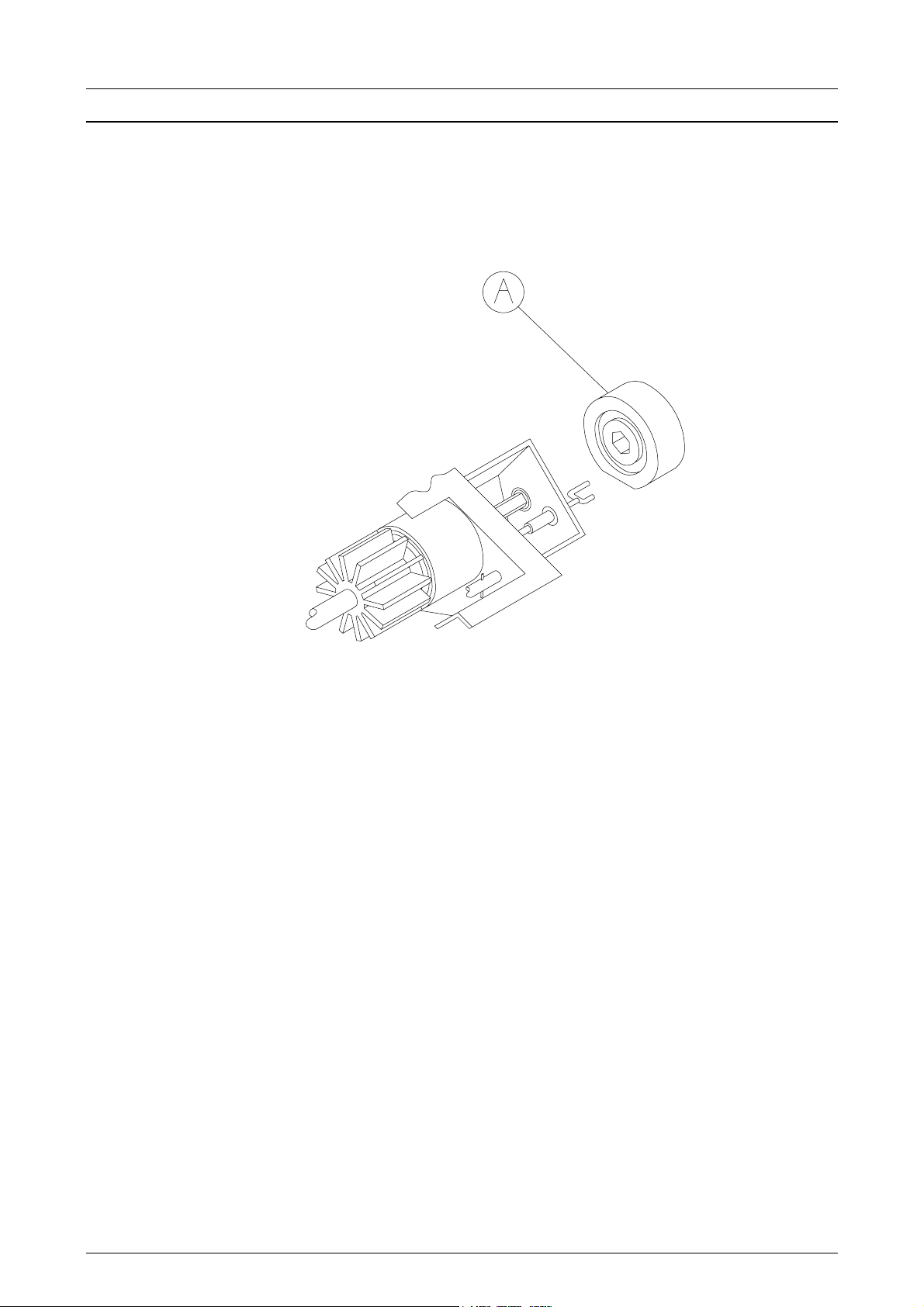

FITTING THE RPM SENSOR FOR THE METERING SHAFT

OPTIONAL EXTRA EQUIPMENT (LH NO. 905-152)

A RPM sensor can be fitted to the metering shaft. The sensor (pos. A) can be

ordered with the above LH no. The sensor is delivered without fitting parts.

LH 1600 M

6 LH A

GRO

Page 7

F

ITTING INSTRUCTIONS

LH 1600 M

ELECTRICAL CONNECTIONS

Connect the sensors and motors in the junction box as on the following diagram.

Stick the supplied label on the inside of the junction box lid:

LH1600M

Pos. Description

1 Main cable to monitor.

2 Empty hopper level sensor (optional extra).

3 RPM sensor for fan speed (optional extra).

4 RPM sensor for metering shaft (optional extra).

5 Speed sensor fitted to the land wheel.

6 Motors that stop and start tramlining.

7 Implement sensor for left marker.

8 Implement sensor for right marker.

Connection to pos. 2 for:

LH nr.: 904-151 LH nr.: 904-152

Connector: Color: Connector: Color:

1 Brown 1 Black

LH A

2 White 2 Red

3 Blue 3 Blue

GRO

7

Page 8

F

NOTES

ITTING INSTRUCTIONS

LH 1600 M

8 LH A

GRO

Loading...

Loading...