Page 1

FITTING INSTRUCTIONS

LH 1600

TRAM LINE MONITOR

LH No. 010-152-UK

SCA 0500

LH Technologies Denmark ApS

Mølhavevej 2

9440 Aabybro

Denmark

Tel. +45 9696 2500

Fax. +45 9696 2501

Internet: http://www.lh-agro.com/

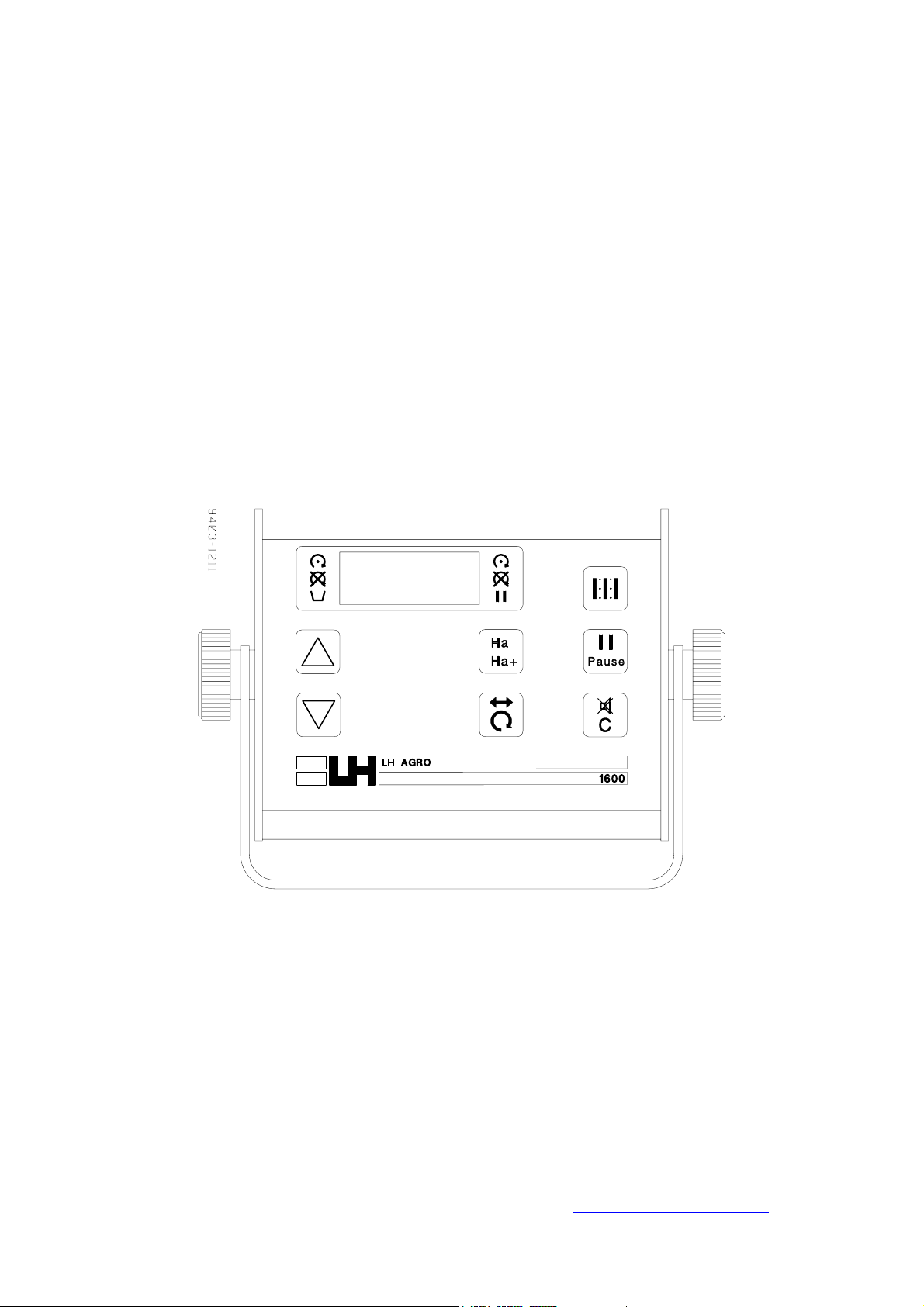

Page 2

F

KEY DRAWING

ITTING INSTRUCTIONS

LH 1600

2 LH A

GRO

Page 3

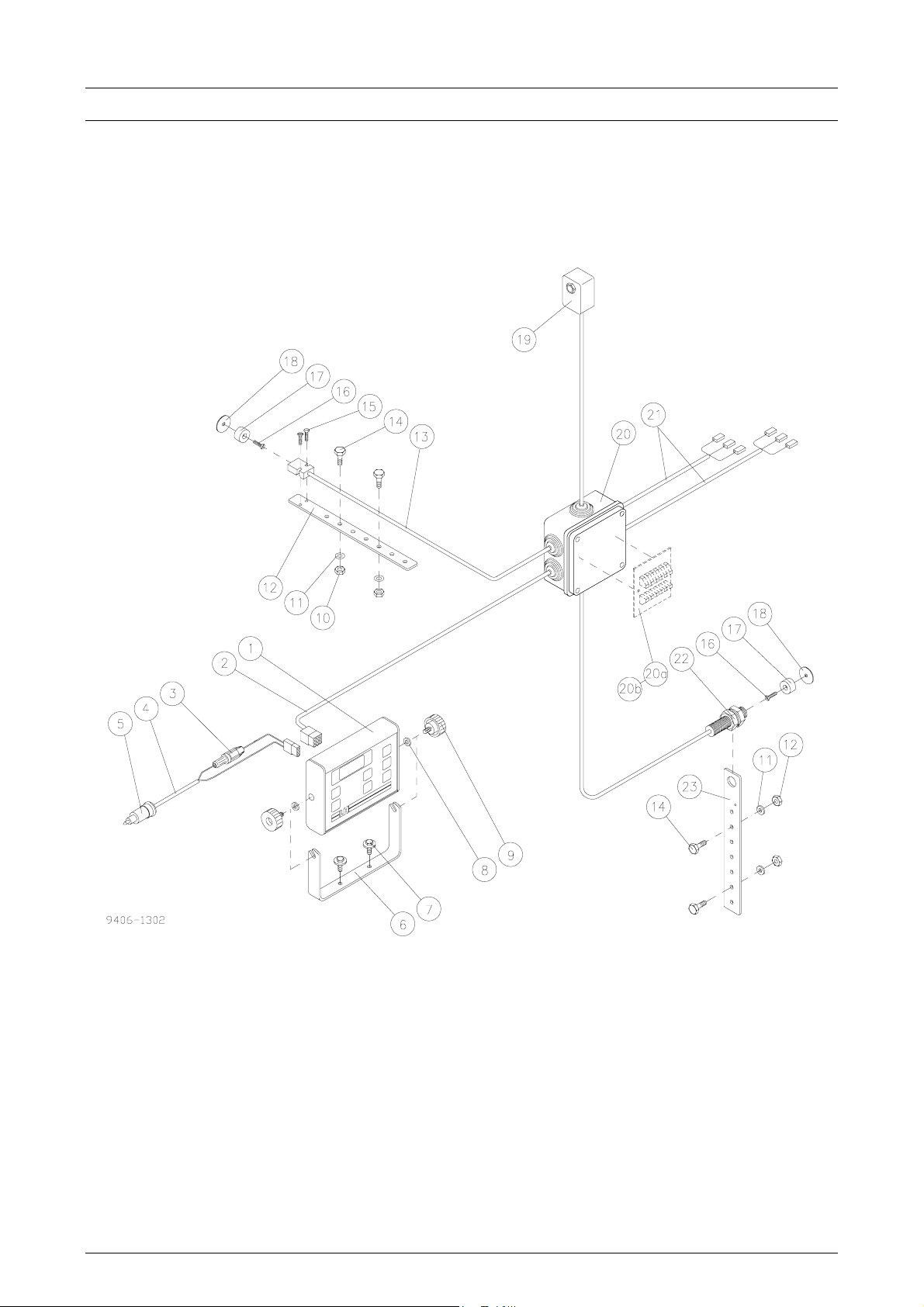

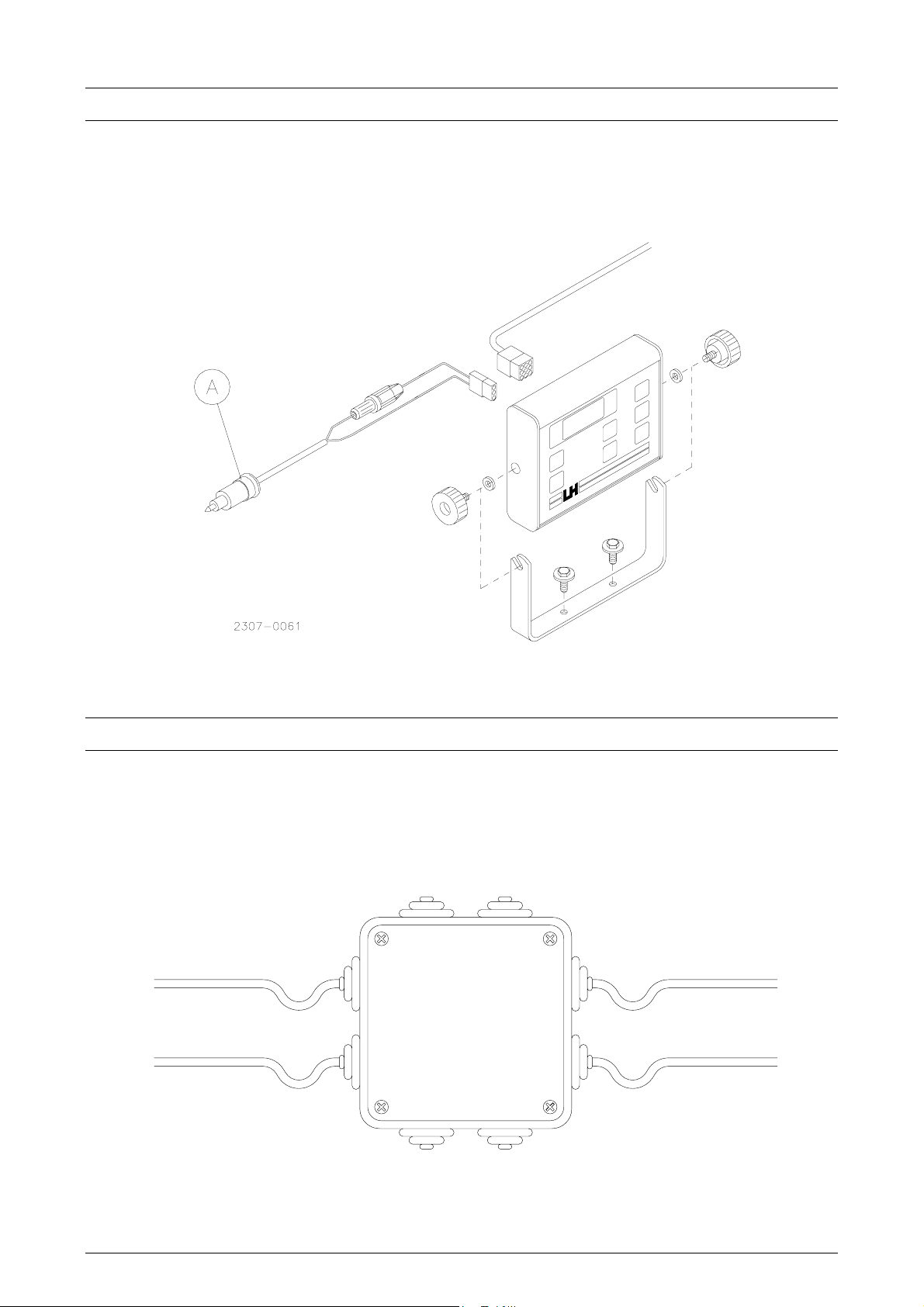

F

ITTING INSTRUCTIONS

LH 1600

FITTING THE MONITOR IN THE TRACTOR

Mount the monitor in the cab within reach of the driver. Connect the monitor to the

12 V of the tractor via the 2-pole power plug A (fig. 1).

Fig. 1

FITTING THE JUNCTION BOX

Mount the junction box right in front on the drill. Mount it as protected as possible.

When the cables later are to connect in the box the cable must be long enough to

make a curve to ensure that water drips off and not runs into the junction box.

(Fig. 2)

Fig. 2

LH A

GRO 3

Page 4

F

ITTING INSTRUCTIONS

FITTING THE CLUTCHES AND THE CLUTCH CONTROLS

Dismount the metering shaft and insert the two clutches (with feeder wheel and

controls).

Clutches and controls are mounted so that the core output turns down and the flat

part of the housing makes contact with the hopper.

Lead the supplied cables along with the chassis tube to the junction box.

A metering shaft bearing shall be mounted as close to the clutch as possible. On

certain machine types it may be necessary to make an exchange of the force

feeds to get place for the clutches.

LH 1600

Fig. 3.

Fig. 4.

4 LH A

GRO

Page 5

F

ITTING INSTRUCTIONS

LH 1600

FITTING THE IMPLEMENT SENSOR

Mount the implement sensor so that it will register each time the drill is lifted

(magnet and sensor must face each other for min. 2-3 seconds).

Dependent on machine type and equipment there are various possibilities, say

marker change, marker cylinder, lift cylinder etc.

•

The magnet can be glued on with suitable glue (Pos. 17).

•

Do not thighten the screws (pos. 15) too hard.

Relieve the sensor cable (pos. 12 - 13) with a cable strip.

•

LH A

GRO 5

Page 6

F

FITTING THE WHEEL SENSOR

Mount the wheel sensor on the "traction wheel".

Use both supplied magnets to achieve a suitable wheel circumference.

ITTING INSTRUCTIONS

LH 1600

•

The magnets can be glued on with suitabel glue.

•

Do not thighten the lock nut of the sensor too hard.

The distance between sensor and magnet must be app. 5 mm.

•

6 LH A

GRO

Page 7

F

ITTING INSTRUCTIONS

LH 1600

FITTING THE TANK SENSOR (EXTRA EQUIPMENT)

Mount the tank sensor app. 150 mm over the bottom of the hopper between the

uttermost seed chamber in one of the sides.

Drill a hole the size of which suits for the sensor. Screw it direct into the plate (do

not thighten too hard).

LH A

GRO 7

Page 8

F

ELECTRIC CONNECTION

ITTING INSTRUCTIONS

LH 1600

6

5

RELAY

1

White

2

Brown

Green

3

4

Yellow

5

Pink

6

Grey

Blue

7

Red

8

Blue

9

Brown10

Drill connection box

+12V

0 V

Clutch

RPM 1

Clutch

RPM 2

Tank

Implement

Wheel

Clutch

Implement

0 V

11

12

13

2

3

5

6

8

9

Black1

Brown

Blue

Black

Brown

Blue7

Yellow

Blue

Brown14

RPM 1

Clutch 1

0 V

+12 V4 Yellow

RPM 2

Clutch 2

0 V

+12 V

+12 V

Tank10

0 V

+12 V

Wheel

0 V

LH AGRO

1

2

3

4

R

Pos. Connection

1 Left clutch and control

2 Right clutch and control

3 Level sensor (empty hopper)

4 Wheel sensor

5 Implement sensor

6 Main cable

Connection to pos. 3 for:

LH nr.: 904-151 LH nr.: 904-152

Connector: Color: Connector: Color:

9 Brown 9 Black

10 White 10 Red

11 Blue 11 Blue

8 LH A

GRO

Loading...

Loading...