Page 1

Fieldware for The Legacy 6000

Software Version 2.11

LEGACY 6000 CAN BUS

USER GUIDE

Software Version 2.11

98-05053 R1

Midwest Technologies

2864 Old Rochester Road

Springfield, IL 62703

217.753.8424

www.mid-tech.com www.teejet.com

Page 2

Fieldware for The Legacy 6000

Software Version 2.11

Copyrights

© 1999 Midwest Technologies Inc. All rights reserved. No part of this document or the computer programs

described in it may be reproduced, copied, photocopied, translated or reduced in any form or by any means,

electronic or machine readable, recording or otherwise, without prior written consent from Midwest Technologies, Inc.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their

respective companies or organizations.

Limitation of Liability

MIDWEST TECHNOLOGIES, INC. PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY

OF ANY KIND, EITHER EXPRESSED OR IMPLIED. NO COPYRIGHT LIABILITY OR PATENT IS

ASSUMED. IN NO EVENT SHALL MIDWEST TECHNOLOGIES, INC BE LIABLE FOR ANY LOSS

OF BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA, INTERUPTION OF BUSINESS, OR FOR

INDIRECT, SPECIAL, INCIDENTIAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF

MID-TECH HAS BEEN ADVISED OF SUCH DAMAGES ARISING FROM MID-TECH SOFTWARE.

Page 3

Fieldware for The Legacy 6000

Software Version 2.11

Table of Contents

Chapter 1 - System Introduction 1

System Introduction ..................................................................................................... 1-2

System Features .................................................................................................. 1-2

CAN Bus Versatility and Value ................................................................................ 1-3

What is a CAN Bus and why use one? ............................................................... 1-3

Fieldware for the Legacy 6000 .................................................................................1-4

Mid-Tech CAN Bus System Overview ........................................................................ 1-5

The Legacy 6000 Console ........................................................................................ 1-5

Power Speed Module ................................................................................................ 1-6

Inputs .................................................................................................................. 1-6

Inputs/Outputs ..................................................................................................... 1-6

Switch Sense Module ................................................................................................ 1-7

Inputs .................................................................................................................. 1-7

Communication ................................................................................................... 1-7

Switch Function Module ........................................................................................... 1-8

Outputs ................................................................................................................ 1-8

Input .................................................................................................................... 1-8

Communication ................................................................................................... 1-8

Product Control Module ........................................................................................... 1-9

Inputs .................................................................................................................. 1-9

Outputs ................................................................................................................ 1-9

Communication ................................................................................................... 1-9

Swath XL Lightbar ................................................................................................. 1-10

Communication: ................................................................................................ 1-10

CAN Bus Cable Specifications ............................................................................... 1-11

CAN Modules (PCM, SSM, PSM) ......................................................................... 1-11

Cable Harnesses ...................................................................................................... 1-12

Power Speed Module (PSM) ............................................................................ 1-12

Switch Sense Module ........................................................................................ 1-12

Product Control Module .................................................................................. 1-13

Typical Legacy 6000 Configurations ......................................................................... 1-14

Single Channel Liquid Flow Meter ........................................................................ 1-14

Single Channel Granular Spreader ......................................................................... 1-15

Single Channel Liquid with AutoBoom Shutoff (SFM) ......................................... 1-16

Dual Channel with Wet and Dry Booms ................................................................ 1-17

Dual Channel Granular with Two Sensors per Channel ......................................... 1-18

Chapter Notes .............................................................................................................. 1-19

Page 4

Fieldware for The Legacy 6000

Software Version 2.11

Chapter 2 - Getting Started 1

Software Overview ........................................................................................................ 2-2

Powering Up ............................................................................................................. 2-2

Screen Navigation & Selection ................................................................................. 2-3

Standard Pages .......................................................................................................... 2-4

Launcher Page ..................................................................................................... 2-4

Setup Menu Page ............................................................................................... 2-5

Setup Wizard ...................................................................................................................2-5

Setup Sub-Groups ........................................................................................................... 2-5

Exiting a Setup Menu Page ............................................................................................. 2-5

Data Entry Page ........................................................................................................ 2-6

Pick List Data Entry ........................................................................................................ 2-6

Alpha/Numeric Data Entry ............................................................................................. 2-6

System Setup ................................................................................................................. 2-7

Console Setup ................................................................................................................ 2-8

Lightbar Setup .............................................................................................................. 2-9

GPS Receiver Setup .................................................................................................... 2-10

Implement Setup ......................................................................................................... 2-11

The Vehicle Coordinate System ............................................................................. 2-11

The X and Y Axes ............................................................................................ 2-11

Location of GPS Antenna ................................................................................. 2-11

Swaths and Sections .......................................................................................... 2-11

Entering the Implement Width ............................................................................... 2-13

Number of Swaths Page .......................................................................................... 2-14

Entering the Number of Sections in a Swath .......................................................... 2-14

Setting the Section to Switch Assignment .............................................................. 2-15

Entering the Section Width ..................................................................................... 2-15

Entering the Offset Direction Y .............................................................................. 2-16

The Offset Distance Y ............................................................................................ 2-16

Entering the Offset Direction X .............................................................................. 2-17

Setting the PCM Assignment .................................................................................. 2-18

Completing Implement Setup ................................................................................. 2-19

Product Control Module (PCM) Setup ..................................................................... 2-20

Selecting a PCM Setup Favorite ............................................................................. 2-22

Setting the Application Type .................................................................................. 2-24

Application Type Options ................................................................................. 2-24

Application Type Settings ............................................................................... 2-25

Setting the Drive Type ............................................................................................ 2-26

Drive Type Settings ......................................................................................... 2-27

Calculating the Prime Value .........................................................................................2-27

Setting the Units ...................................................................................................... 2-29

Selecting the Primary Sensor .................................................................................. 2-30

Page 5

Fieldware for The Legacy 6000

Software Version 2.11

Primary Sensor Settings ................................................................................... 2-31

Selecting the Secondary Sensor .............................................................................. 2-33

Secondary Sensor Settings ............................................................................... 2-34

Selecting a Monitor ................................................................................................. 2-36

Monitor Settings .............................................................................................. 2-37

Finishing the PCM Setup ........................................................................................ 2-39

Saving the PCM Setup to a File ....................................................................... 2-40

Chapter Notes .............................................................................................................. 2-41

Chapter 3 - Real-time Setup 1

Operation Overview ..................................................................................................... 3-2

Starting a Job ................................................................................................................ 3-4

Creating a New Job ................................................................................................... 3-4

Selecting an Existing Job .......................................................................................... 3-4

Creating a Job Based on an Existing Job .................................................................. 3-4

Manually Naming a Job ...................................................................................... 3-5

Automatically Naming a Job .............................................................................. 3-5

No PCMCIA Card Setup .......................................................................................... 3-6

ARM Launcher ............................................................................................................. 3-7

No PCMCIA Card Setup .......................................................................................... 3-7

Performing a Calibration ............................................................................................. 3-8

Introduction ............................................................................................................... 3-8

The Common Calibration Procedure ........................................................................ 3-8

Distance/Speed Calibration ....................................................................................... 3-9

Distance/Speed Calibration Continued ............................................................. 3-10

Liquid Flow Static Calibration ............................................................................... 3-11

Liquid Flow Static Calibration / Continued ...................................................... 3-12

Liquid Flow In-Field Calibration ............................................................................ 3-13

Liquid Flow In-Field Calibration Continued .................................................... 3-14

Granular & Seeder Static Calibration ..................................................................... 3-15

Granular & Seeder Static Calibration / Continued ........................................... 3-16

Granular & Seeder In-Field Calibration ................................................................. 3-17

Granular & Seeder In-Field Calibration Continued .......................................... 3-18

Pressure Calibration ................................................................................................ 3-19

Pressure Calibration / Continued ..................................................................... 3-20

NH3 In-Field Calibration ........................................................................................ 3-21

NH3 In-Field Calibration Continued ................................................................ 3-22

Injection Static Calibration ..................................................................................... 3-23

Prime Injection System .............................................................................................. 3-25

1. Calculate Prime value ................................................................................... 3-25

2. Setup System for Priming ............................................................................ 3-26

3. Start Prime .................................................................................................... 3-26

Page 6

Fieldware for The Legacy 6000

Software Version 2.11

Reverse Prime Injection System ................................................................................ 3-27

1. Setup Stem for Reverse Priming .................................................................. 3-28

2. Start Reverse Prime ...................................................................................... 3-28

Job Report Setup ........................................................................................................ 3-29

No PCMCIA Card Selected .............................................................................. 3-29

Running the Job Report Wizard ........................................................................ 3-29

Job Report Detailed Description ............................................................................. 3-30

ARM Setup .................................................................................................................. 3-31

No PCMCIA Card Selected .............................................................................. 3-31

Running the ARM setup Wizard ...................................................................... 3-31

ARM Setup Detailed Description ........................................................................... 3-32

Auto Boom Shutoff (Section Center) ..................................................................... 3-33

Enter a Record, Boundary, Guideline, or Map File Name ..................................... 3-34

Product Setup .............................................................................................................. 3-35

Running the Product Setup Wizard .................................................................. 3-35

Product Setup Detailed Description ........................................................................ 3-36

The Select PCM Page ............................................................................................. 3-37

Select the Product Name ......................................................................................... 3-38

Selecting a Product from the Products Database ..........................................................3-38

Favorites ........................................................................................................................ 3-38

New Product ................................................................................................................. 3-38

Variable Rate Application ...................................................................................... 3-39

Selecting Prescription Map ............................................................................... 3-39

Single Product Variable Rate Prescription Map ............................................... 3-39

Multiproduct Variable Rate ............................................................................. 3-40

Prescription Map for Each Product ............................................................................... 3-40

One Prescription Map for All Products ........................................................................ 3-41

Select the Prescription Map Layer .................................................................... 3-42

Chapter Notes .............................................................................................................. 3-43

Chapter 4 - Real-time Operation 1

Product Application ...................................................................................................... 4-2

Real-time pages ......................................................................................................... 4-2

Information Pages .....................................................................................................4-3

Rate Pages ........................................................................................................... 4-3

GPS / Boundary Page ......................................................................................... 4-3

Adjusting the Product Application Rate ............................................................ 4-4

Manual Control ................................................................................................... 4-4

Test Speed ........................................................................................................... 4-5

Reset Initial Quantity ......................................................................................... 4-5

Information Page Soft Keys Descriptions ......................................................... 4-6

The Map Page ........................................................................................................... 4-7

Page 7

Fieldware for The Legacy 6000

Software Version 2.11

Real-time Map Page Soft-key Descriptions ........................................................ 4-8

System, Warning and Error Messages .................................................................... 4-11

System Message ................................................................................................ 4-11

Warning Message ............................................................................................. 4-11

Error Message .................................................................................................. 4-12

Real-time Guidance Operation .................................................................................. 4-13

Starting Guidance ............................................................................................. 4-13

Changing Guidance Pattern .............................................................................. 4-13

The Straight-Line Guidance Pattern ....................................................................... 4-14

Mark Point A .................................................................................................... 4-14

Mark Point B ..................................................................................................... 4-14

The Headland Guidance Pattern ............................................................................. 4-15

Applying Multiple Headland Circuits ............................................................... 4-15

Headland Pattern Example ............................................................................... 4-16

Switching from Headland to Straight-line A-B Pattern ................................................ 4-17

The Ignore Headland Guidance Pattern .................................................................. 4-19

Ignore Headland Pattern Example .......................................................................... 4-20

Step 1: Start Applying Headlands ..................................................................... 4-20

Step 2: Select Headland Off Mode ................................................................... 4-20

Step 3: Establish First Interior Pass ................................................................. 4-21

Step 4: Ignore Headland Data ........................................................................... 4-21

If you forgot to start a headland, you can: .................................................................... 4-22

The Circle Pivot Pattern .......................................................................................... 4-23

Circle Pivot Example ....................................................................................... 4-24

Marking Point A ........................................................................................................... 4-24

Marking Point B ............................................................................................................ 4-24

Driving in the Circle Pivot Pattern ............................................................................... 4-25

Lightbar Curved Guidance Graphics ....................................................................... 4-27

Applied Area Detection .............................................................................................. 4-28

Detecting A Previously Applied Area .................................................................... 4-28

Detecting Neighboring Swath ................................................................................. 4-28

Mapping a Field Boundary ........................................................................................ 4-30

Closing or Pausing the Boundary Mapping Process ......................................... 4-30

Mapping Points and Hazards .................................................................................... 4-32

Marking a Point ................................................................................................ 4-32

Marking a Hazard ............................................................................................ 4-33

Object Name File .............................................................................................. 4-33

Exiting Real-Time Operation .................................................................................... 4-34

Fieldware-Map Manager ......................................................................................... 4-34

Lightbar Index ............................................................................................................ 4-35

Data Transfer and Report Generation ..................................................................... 4-38

Page 8

Fieldware for The Legacy 6000

Software Version 2.11

Chapter Notes .............................................................................................................. 4-39

Chapter 5 - System Tools 1

System Tools .................................................................................................................. 5-2

Device Manager ........................................................................................................ 5-3

CAN Bus ............................................................................................................. 5-3

GPS Receiver ..................................................................................................... 5-4

LightBar .............................................................................................................. 5-4

Lightbar SoftKeys and Description ................................................................................ 5-4

PCM, SSM, and PSM ........................................................................................ 5-5

PCM, SSM, & PSM SoftKeys and Description .............................................................. 5-5

Console .............................................................................................................. 5-6

Console SoftKeys and Description .................................................................................5-6

Backing up Console System Files ...................................................................... 5-7

Required Items: ............................................................................................................... 5-7

Restoring Console System Files ......................................................................... 5-7

Importing Object Name Files into Console Memory ........................................ 5-8

Card Manager ........................................................................................................... 5-9

Card Manager SoftKeys and Description ....................................................................... 5-9

Chapter Notes .............................................................................................................. 5-11

Chapter 6 - Running Mapper 1

Mapper Introduction .................................................................................................... 6-2

Starting Mapper ........................................................................................................ 6-2

Starting a Job ............................................................................................................ 6-3

Creating a New Job ............................................................................................. 6-3

Selecting an Existing Job .................................................................................... 6-3

Creating a Job Based on an Existing Job ............................................................ 6-3

Manually Naming a Job ..................................................................................... 6-4

Automatically Naming a Job .............................................................................. 6-4

Mapper Setup ..................................................................................................... 6-5

Mapper Setup and Operation Steps ................................................................................ 6-5

Mapper Setup ..................................................................................................... 6-6

Road Markers ..................................................................................................... 6-7

Enter Road Marker Name ............................................................................................... 6-8

Creating Object Name .............................................................................................. 6-9

Creating New Object Name ................................................................................ 6-9

Real-time pages ....................................................................................................... 6-10

Map page ........................................................................................................... 6-10

Map Page Soft Keys Descriptions .................................................................... 6-11

Information Page .............................................................................................. 6-13

Information Page SoftKeys and Description .................................................... 6-13

Mapper Tools .............................................................................................................. 6-14

Page 9

Fieldware for The Legacy 6000

Software Version 2.11

The Options Menu ........................................................................................... 6-16

Exiting Real-Time Operation .................................................................................... 6-17

Map Manager .......................................................................................................... 6-17

Chapter Notes .............................................................................................................. 6-18

Appendix A - PCM Favorites Settings ....................................................................... A-1

Appendix B - Creating a Calibration Table ...............................................................B-1

Creating a Calibration Table on a PC .......................................................................B-1

Loading Calibration Table in Legacy 6000 ..............................................................B-2

Using the Calibration Table ......................................................................................B-3

Creating a Calibration Table Using the Legacy 6000 ...............................................B-4

Appendix C - NH3 Application ................................................................................... C-1

NH3 Application Cal# ..............................................................................................C-1

Density for NH3 and Actual N .................................................................................C-1

Example: .............................................................................................................C-1

Notes ........................................................................................................................ C-2

Page 10

Fieldware for The Legacy 6000

Software Version 2.11

Page 11

Chapter 1 - System Introduction

An introduction to the Legacy 6000 System.

Software Version 2.11

Midwest Technologies IL, LLC

Fieldware for the Legacy 6000

Page 12

Fieldware for The Legacy 6000

Software Version 2.11

System Introduction

The Legacy 6000 system allows the control of all product types, plus GPS mapping, guidance, and

data collection in a single console. Replacing multiple consoles in the cab with one robust system,

Mid-Tech's Legacy 6000 sets a new standard for control systems of the future.

The Legacy 6000 runs Fieldware software in a Windows CE environment, an extremely dependable and stable operating system. Operation is intuitive with on-screen menu choices and

prompts. An on-board help menu is built in. The heart of the Legacy console is an Intel processor

operating at 206 Megahertz for maximum efficiency.

System Features

System features include:

• Product control with optional integrated guidance

• Four guidance modes, Ignore Headland, Curved, Parallel and Center Pivot.

• Single console in the cab with a single cable connection to the console

• Simplifies operation of product control and GPS record keeping

• Works with Mid-Tech's Swath XL lightbar

• Comes fully loaded with “Fieldware for the Legacy 6000” software

• Precise control of liquid & dry products on common delivery systems

• Flow- or pressure-based liquid control with multiple sensor inputs for each product

• Handles up to 20 individual boom sections and 4 swaths

• Up to 5 application rates per product can be preset and accessed on the go

• Supports granular application control using 2 rate sensors per product

• Compatible with most sensors, valves, and D.C. drives

• Operates bi-directional or PWM valves

• Operator selectable gain settings for control valves

• Adding additional product control is easy

• Single high speed bus cable coming into cab

• Automatic Boom shutoff

• Mapper option for mapping points, lines, and po lyg o ns

1-2 Chapter 1 - System Introduction

System Introduction

Page 13

Fieldware for The Legacy 6000

Software Version 2.11

CAN Bus Versatility and Value

The Legacy 6000 utilizes CAN Bus technology, a new industry standard, which Mid-Tech us es to

execute precise product contr ol in an env iro nm e nt mor e rob ust tha n an y of its predecessors.

What is a CAN Bus and why use one?

Controller Area Network (CAN) is a system comprised of independent, intelligent modules connected by a single high-speed cable, known as a bus, over which all the data in the system travels.

CAN was originally developed for the automotive industry to provide a cost effective means for a

large number of electronic functions or systems to be interconnected without large, expensive and

troublesome wiring harnesses.

Within a CAN system, each module contains its own microprocessor. All modules share a standard protocol or communication sequence, which conforms to the ISO 11898 standard. Since

modules have built-in computing power, a CAN system is extremely flexible and easily expands to

meet a customer's needs.

Individual modules have a specific and unique function to execute, as well as the responsibility to

constantly report that function and its current status. Data on the CAN is available many times a

second allowing the operation of a very fast, responsive control system.

The Legacy 6000 uses 5 types of modules, each having a unique function. Each described in

more detail below. The console in the cab is one of these modules and serves as the user interface. The remaining modules are positioned around the chassis close to the area they influence.

For instance, the Product Control Mo dule (PCM) con nects to the actuator and senso r and controls

the actual release of the product. To upgrade from one-product to three-product application (or

more) is simply a matter of adding additional PCM's to the system.

Chapter 1 - System Introduction 1-3

System Introduction

Page 14

Fieldware for The Legacy 6000

Software Version 2.11

Fieldware for the Legacy 6000

Plug any standard submeter GPS receiver and Mid-Tech's CAN based Swath XL lightbar into the

Legacy 6000 system, and enjoy straight-line, curved or center pivot guidance at your command.

Application maps can be viewed on the Legacy 6000 display as you apply. Cross track error , ar ea

applied, application rates, and other vital information display on the Swath XL lightbar in real time.

Features of Mid-Tech's Fieldware software, developed specifically for the Legacy 6000, include:

• Application Rate Management - permits precise fixed or variable rate application.

• Extensive Product Control Module setup.

• Full system calibration including, granular, liquid, liquid injection and distance.

• CAN Bus, GPS receiver and lightbar diagnostics.

• Create application jobs keeping track of customer, weather and product information.

• Large product database with over 4000 entries co ntaining product name, formulation , and EP A

number.

• Integrated guidance using straight line, h eadland , or center pivo t modes, p lus text repor ting to

the lightbar, in one easy to use format.

• Report generation - full application report s and map s can be generated in Field ware Map Manager PC software at the end of the day. An application report contains a map of the application, customer information, product information, as well as weather, field, and soil conditions.

1-4 Chapter 1 - System Introduction

System Introduction

Page 15

Fieldware for The Legacy 6000

Software Version 2.11

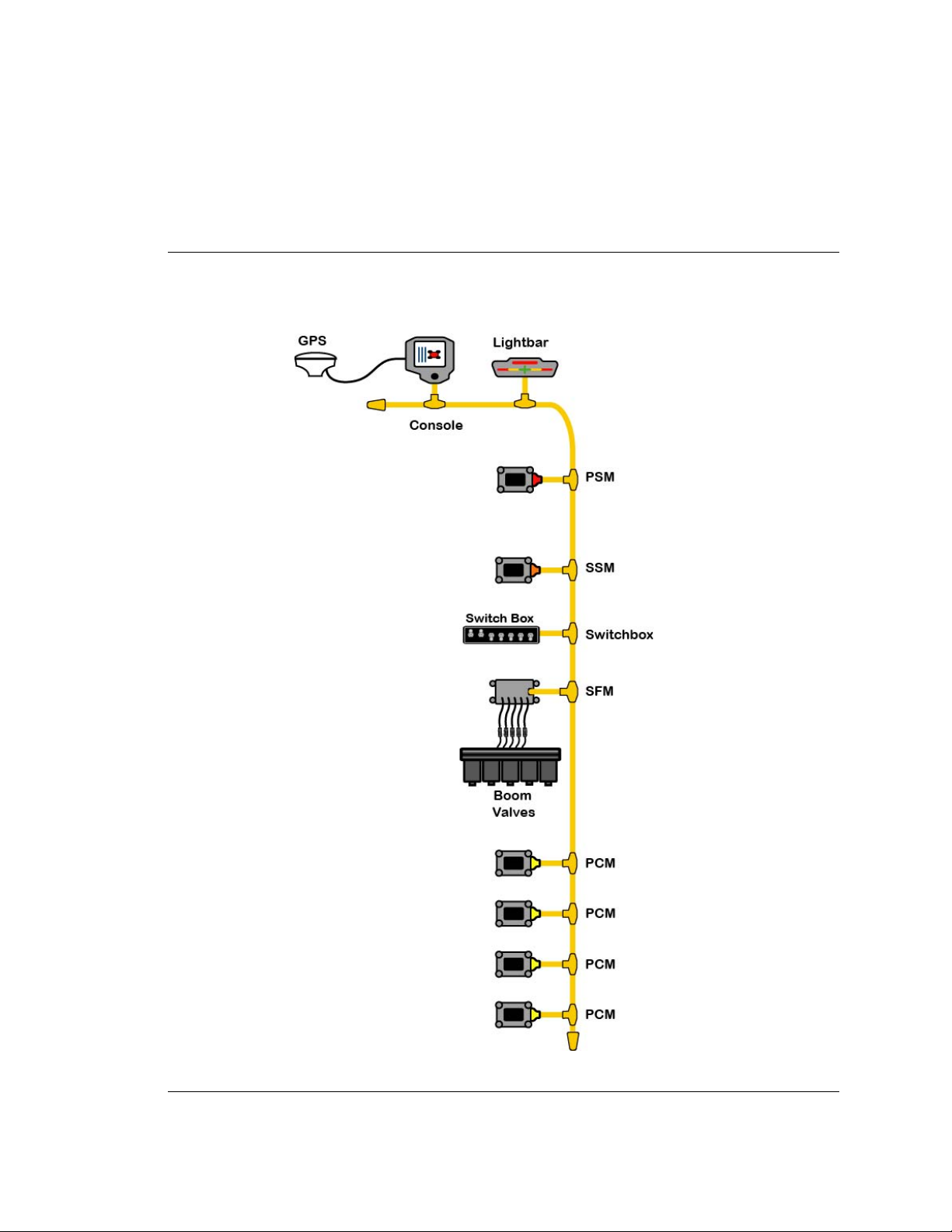

Mid-Tech CAN Bus System Overview

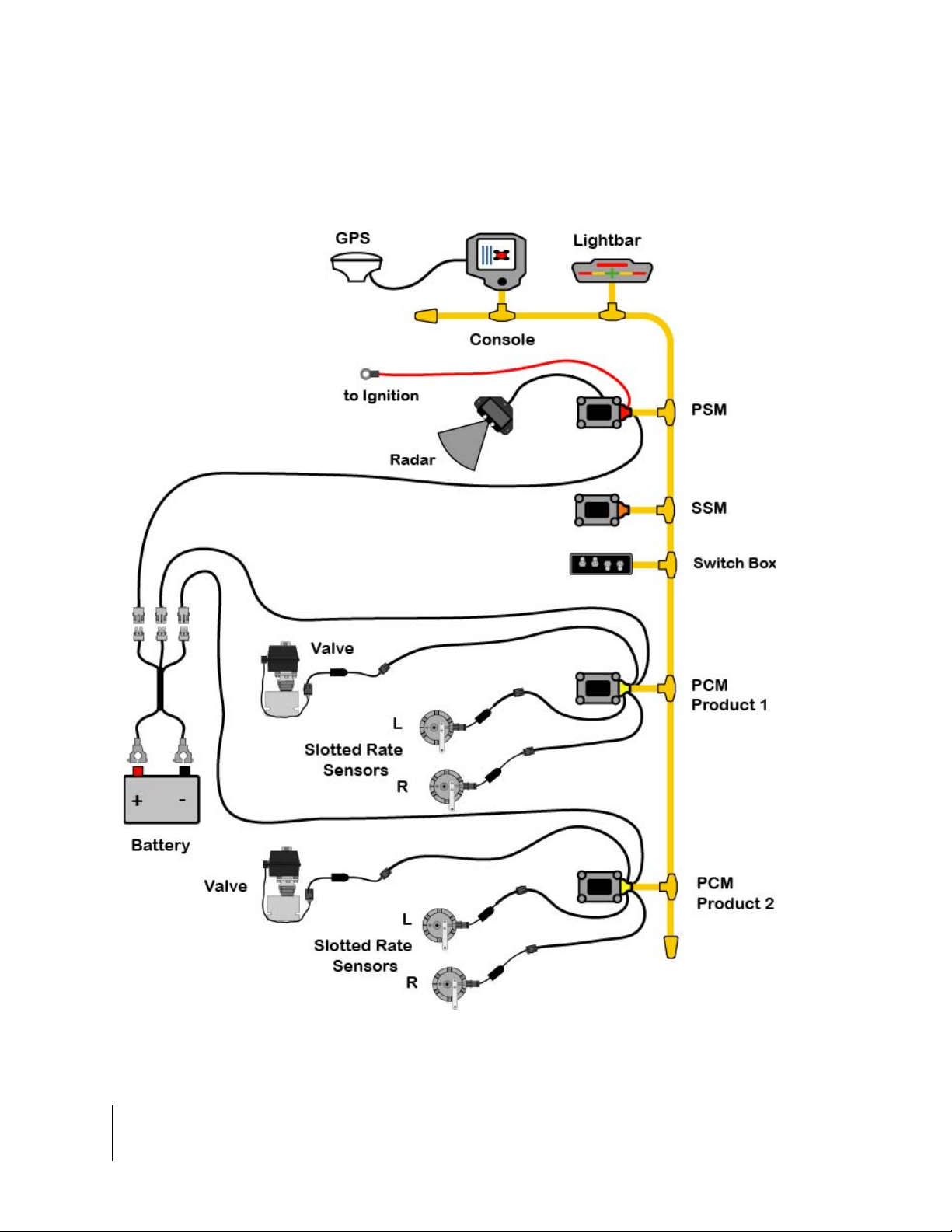

The Mid-Tech CAN bus system is comprised of several components (modules). The Console, the

Power Speed Module (PSM), the Switch Sense Module (SSM), a Product Control Module (PCM),

and a Lightbar . At a minimum, four of these modules ar e required to have a fully functional Legacy

6000 single product control system. The lightbar is optional. T o control m ore than one product, you

will need to add an additional PCM for each additional product you choose to control.

The Legacy 6000 Console

Dimensions: 8.0" Wide x 7.7" High x 4.5" Deep (203 x 196 x 114 mm)

Weight: 2.3 lbs. (1.0 kg)

Enclosure: High impact plastic; back lighted, tactile feed-back switches on front panel

Operator Interface: Back lighted, tactile feed-back switches on front panel

Display: 5.7" diagonal (120 x 90 mm), transflective, QVGA with CCFL back lighting. Brightness

and contrast controlled by switches on the front panel of the console.

Communication: CAN, 29 bit ID, 250K baud, Mid-Tech proprietary messages, Serial RS 232 (2),

USB: (1)

Memory: 64 Mbytes DRAM, 32 Mbytes Flash

Microprocessor: 32-bit Intel StrongARM, SA 1110 with SA 1111 companion chip. 206 MHz.

Drives: PCMCIA type II, single slot

Operating System: Microsoft Windows CE 3.0

Power Requirement: 9 to 16 volts DC

Connector: Sealed, 31 pin Deutsch

GPS Receiver Compatibility: Comp atible with any differentially corrected submeter GPS (DGPS)

receiver which outputs NMEA 0183 at 2 to 10 Hz.

Alarm: Audible alarm

Other:

* Real-time clock with battery back-up

* Simple, yet versatile, RAM mounting system.

Chapter 1 - System Introduction 1-5

Mid-Tech CAN Bus System Overview

Page 16

Fieldware for The Legacy 6000

Software Version 2.11

Power Speed Module

The Power Speed Module ( PSM) is the primary arbitrator of the Bus. This module includes the

input point for the speed sensor, the input for power for the CAN bus, a gateway to communicate

with a parallel CAN bus and provides a fully functional RS-232 port as alternative I/O.

Figure 1-1: Power Speed Module

Inputs

Speed 1: digital, 0-12 VDC, optimized for 50% duty cycle, 0-5 KHz, primary input

Speed 2: digital, 0-12 VDC, optimized for 50% duty cycle, 0-5 KHz, secondary input

Ignition sense: digital, 0-16 VDC, (Hi state is ON)

Battery Power: 0-16 VDC

Inputs/Outputs

Mid-Tech CAN: ISO 11898 (Bosch 2.0B), 29 bit ID, 250K baud, Mid-Tech proprietary messages

Gateway CAN: ISO 11898 (Bosch 2.0B), 29 bit ID, 250K baud, Mid-Tech proprietary messages

Serial RS 232: TXD, RXD, RTS, CTS and ground.

1-6 Chapter 1 - System Introduction

Mid-Tech CAN Bus System Overview

Page 17

Fieldware for The Legacy 6000

Software Version 2.11

Switch Sense Module

The Switch Sense Module (SSM) senses the status of switches aboard the machine and transforms the switch state into messages meaningful to the CAN Bus.

Figure 1-2: Switch Sense Module (SSM)

Inputs

Booms inputs: up to 20, digital, 0-12 VDC, HI/LO sensing

Ground Speed Override (GSO):1 input, digital, 0-12 VDC, HI/LO sensing

Machine status: 1 input, digital, 0-12 VDC, HI/LO sensing

Communication

Mid-Tech CAN: 29 bit ID, 250K baud, Mid-Tech proprietary messages

Chapter 1 - System Introduction 1-7

Mid-Tech CAN Bus System Overview

Page 18

Fieldware for The Legacy 6000

Software Version 2.11

Switch Function Module

The Switch Function Module (SFM) enables automated system control of boom sections.

Figure 1-3: Switch Function Module (SFM)

Outputs

Booms outputs: (10) 3amp +12switched

Output Connector: A - Ground, B - N/C, C - +12 Open, D - +12 Constant

Input

Battery Power: 30amp

Communication

Mid-Tech CAN: ISO 11898 (Bosch 2.0B), 29 bit ID, 250K baud, Mid-Tech proprietary messages

1-8 Chapter 1 - System Introduction

Mid-Tech CAN Bus System Overview

Page 19

Fieldware for The Legacy 6000

Software Version 2.11

Product Control Module

The Product Control Module (PCM) performs the actual control function for th e Mid-Tech CAN Bus

and connects the actuator and sensor. Control outputs can be bi-directional. One PCM is required

for each product you wish to control.

Figure 1-4: Product Control Module

Inputs

Digital sensor: 4 inputs, digital, 0-12 VDC, 0-5 KHz

Analog sensor: 2 inputs, analog, 0-5 VDC. One of these input s can be converted to a 4-20 ma sen-

sor input by software command.

Battery: 1 Battery Power for the actuator outputs, 12-24 VDC, 10 amp

Outputs

Actuator: 2 outputs, 0-12 VDC, 5 amp each

Regulated: 1 output, 11 VDC, 3 amp

Switched: 1 output, 12 VDC, 5 amp

Sensor power: 3 outputs, 12 VDC, 300 mA total

Communication

Mid-Tech CAN: ISO 11898 (Bosch 2.0B), 29 bit ID, 250K baud, Mid-Tech proprietary messages

Serial: Asynchronous RXD and TXD only

Chapter 1 - System Introduction 1-9

Mid-Tech CAN Bus System Overview

Page 20

Fieldware for The Legacy 6000

Software Version 2.11

Swath XL Lightbar

A CAN based Swath XL Lightbar was developed specifically for the Legacy 6000 system. The

Lightbar is required for applications using guidance and recommende d for non-guidance uses as

well. In non-guidance use (logging data only) the lightbar can provide area and rate feed back.

Figure 1-5: Swath XL Lightbar

Dimensions: 16.0" Wide x 3.0" High x 3.0” Deep (405 x 76 x 76 mm)

Weight: 8 oz. (0.22 kg)

Enclosure: ABS / Poly carbonate alloy construction. Can be mounted to the exterior of the vehicle.

Cable: Mid-Tech proprietary CAN Bus cable. Cable extension available.

Front Panel LEDs: High-lumen red, yellow and green, adjustable brightness.

Text Display: 8-character, high intensity LED alphanumeric text display, brightness adjustment.

Mounting Bracket: Can be mounted on dash, from ceiling, interior or exterior with large easy to grip

knobs.

Communication:

Mid-Tech CAN: ISO 11898 (Bosch 2.0B), 29 bit ID, 250K baud, Mid-Tech proprietary messages

1-10 Chapter 1 - System Introduction

Mid-Tech CAN Bus System Overview

Page 21

Fieldware for The Legacy 6000

Software Version 2.11

CAN Bus Cable Specifications

5-wire cable with molded connectors. Male or female terminator required on each end.

Pin 1: Ground

Pin 2: +12V

Pin 3: Reserved

Pin 4: CAN High

Pin 5: CAN Low

Speed: 250k baud message update

Module Processor: Siemens C167

Module CAN interface: Siemens 82C250

Message Protocol: ISO 11898 (Bosch 2.0B), 29 bit ID, 250K baud, Mid-Tech proprietary messages

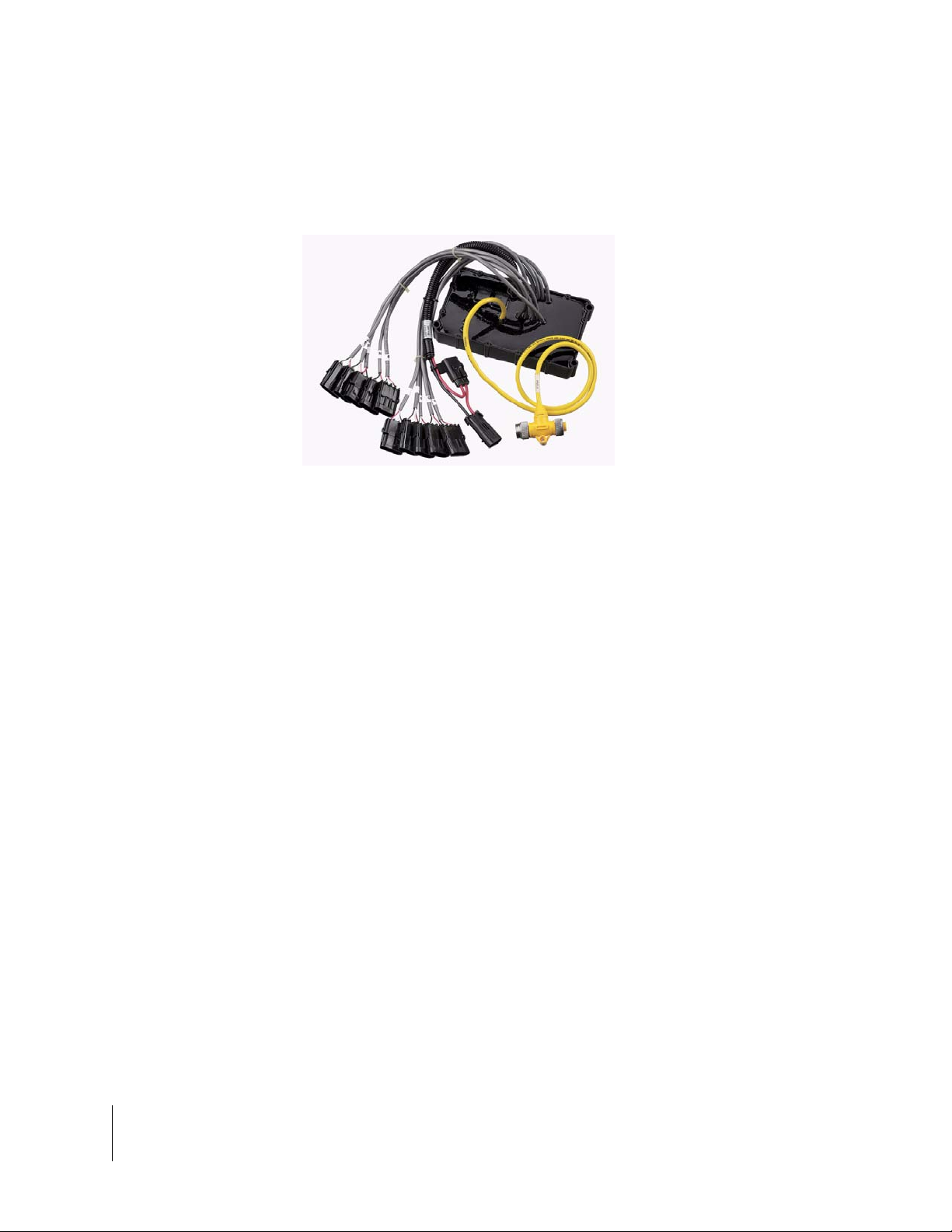

CAN Modules (PCM, SSM, PSM)

Dimensions: 4.7" W x 2.3" H x 6.0" D (120 x 60 x 150 mm)

Weight: 1.9 lbs. (0.9 kg)

Materials: Powder coated cast aluminum

Figure 1-6: CAN Modules

Chapter 1 - System Introduction 1-11

Mid-Tech CAN Bus System Overview

Page 22

Fieldware for The Legacy 6000

Software Version 2.11

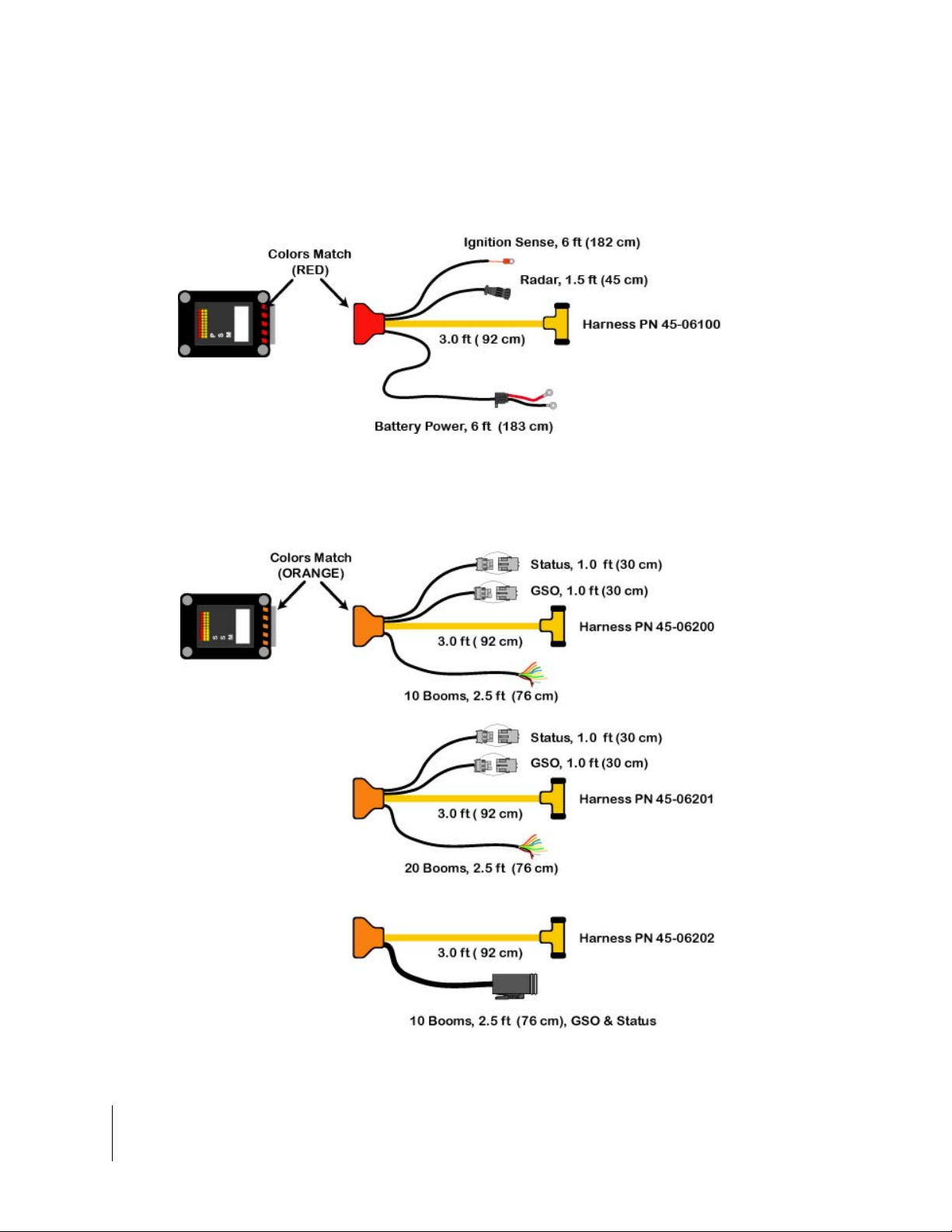

Cable Harnesses

Power Speed Module (PSM)

Figure 1-7: Power Speed Module Harness

Switch Sense Module

Figure 1-8: Switch Sense Module Harness Options

1-12 Chapter 1 - System Introduction

Mid-Tech CAN Bus System Overview

Page 23

Fieldware for The Legacy 6000

Software Version 2.11

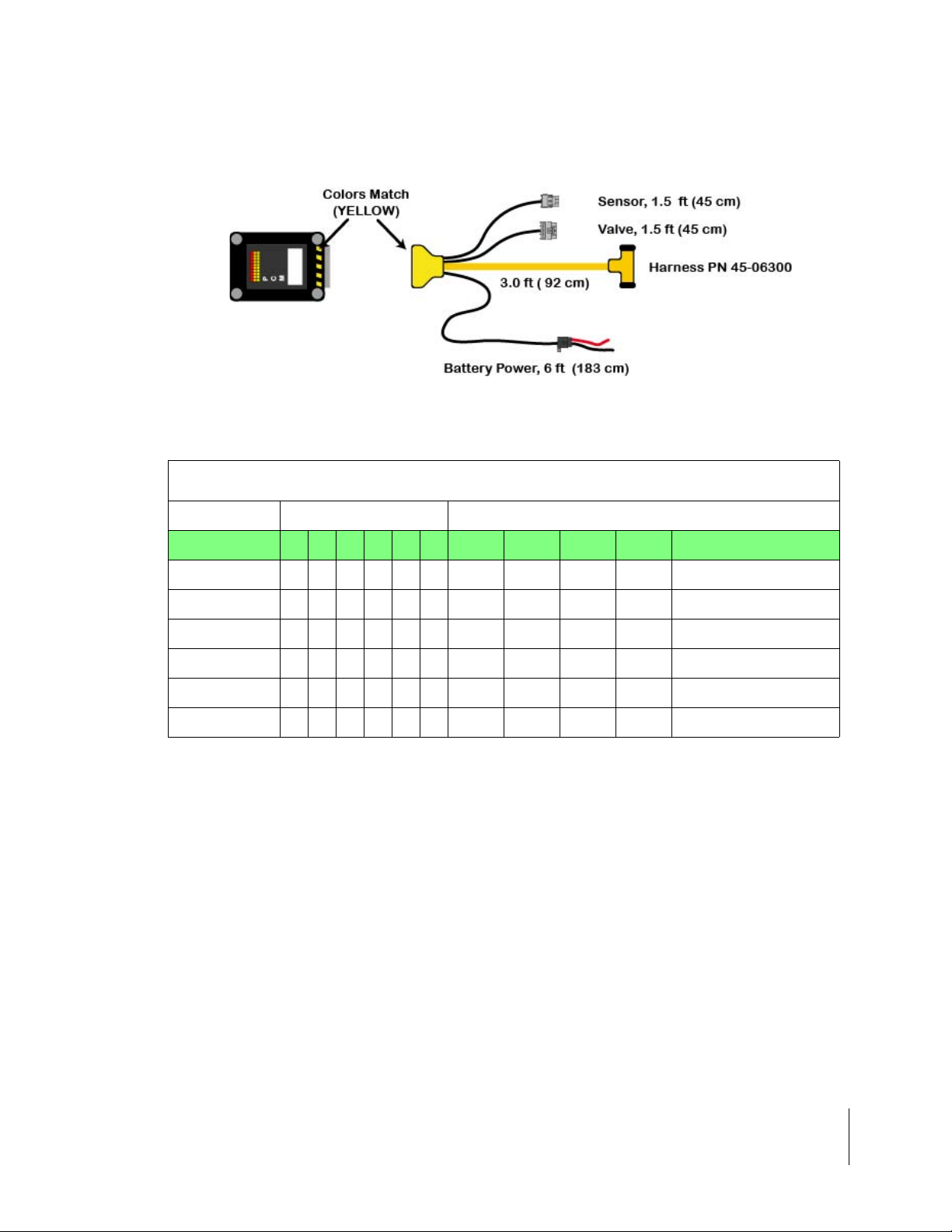

Product Control Module

Figure 1-9: Power Control Module Harness

Sensor Inputs

PCM Cable Options

Part Number A B C D E F CAN PWR Valve Sen. Description

45-06300 X X X X 1 Single Sensor

45-06301 X X X X X 2 Single Sensor w/rpm

45-06302 X X X X X X 3 Dual Sensor w/rpm

45-06303 X X X X X 2 Single Sensor w/press

45-06304 X X X X 1 Pressure Control Single

45-06305 X X X X X 2 Pressure Control, Dual

Table 1-1: PCM Cable Options

NOTE: These cable configurations are available as of 1/1/03. Contact Mid-Tech Customer Service

for other specific sensor or I/O options.

Chapter 1 - System Introduction 1-13

Mid-Tech CAN Bus System Overview

Page 24

Fieldware for The Legacy 6000

Software Version 2.11

Typical Legacy 6000 Configurations

The following schematics reflect some typical Legacy 6000 configurations. Due to the variety of

possible configurations, these schematics should be used for general reference. Contact Midwest

Technologies or your dealer for detailed information regarding your specific configuration and

installation.

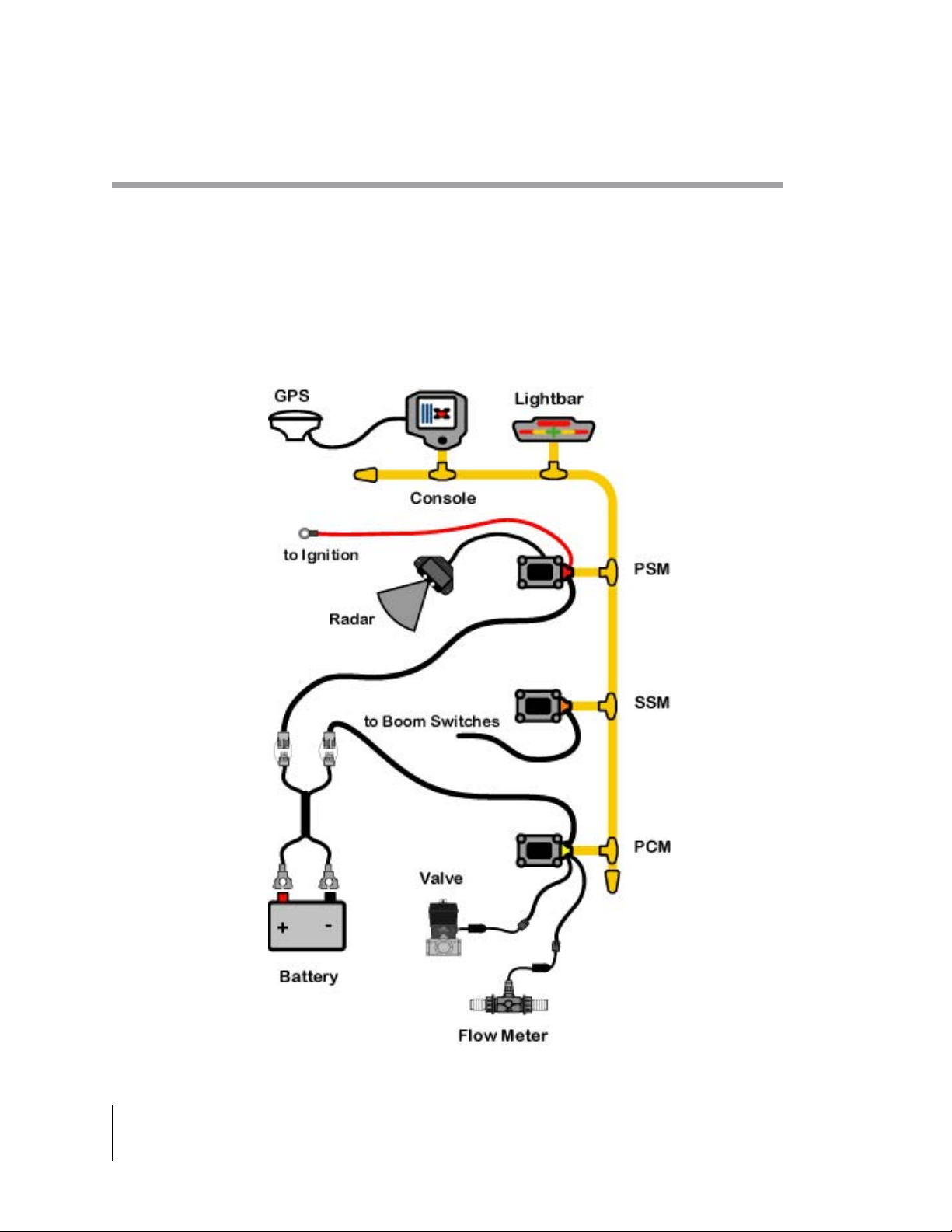

Single Channel Liquid Flow Meter

Figure 1-10: Single Channel Liquid Flow Meter Configuration

1-14 Chapter 1 - System Introduction

Typical Legacy 6000 Configurations

Page 25

Fieldware for The Legacy 6000

Software Version 2.11

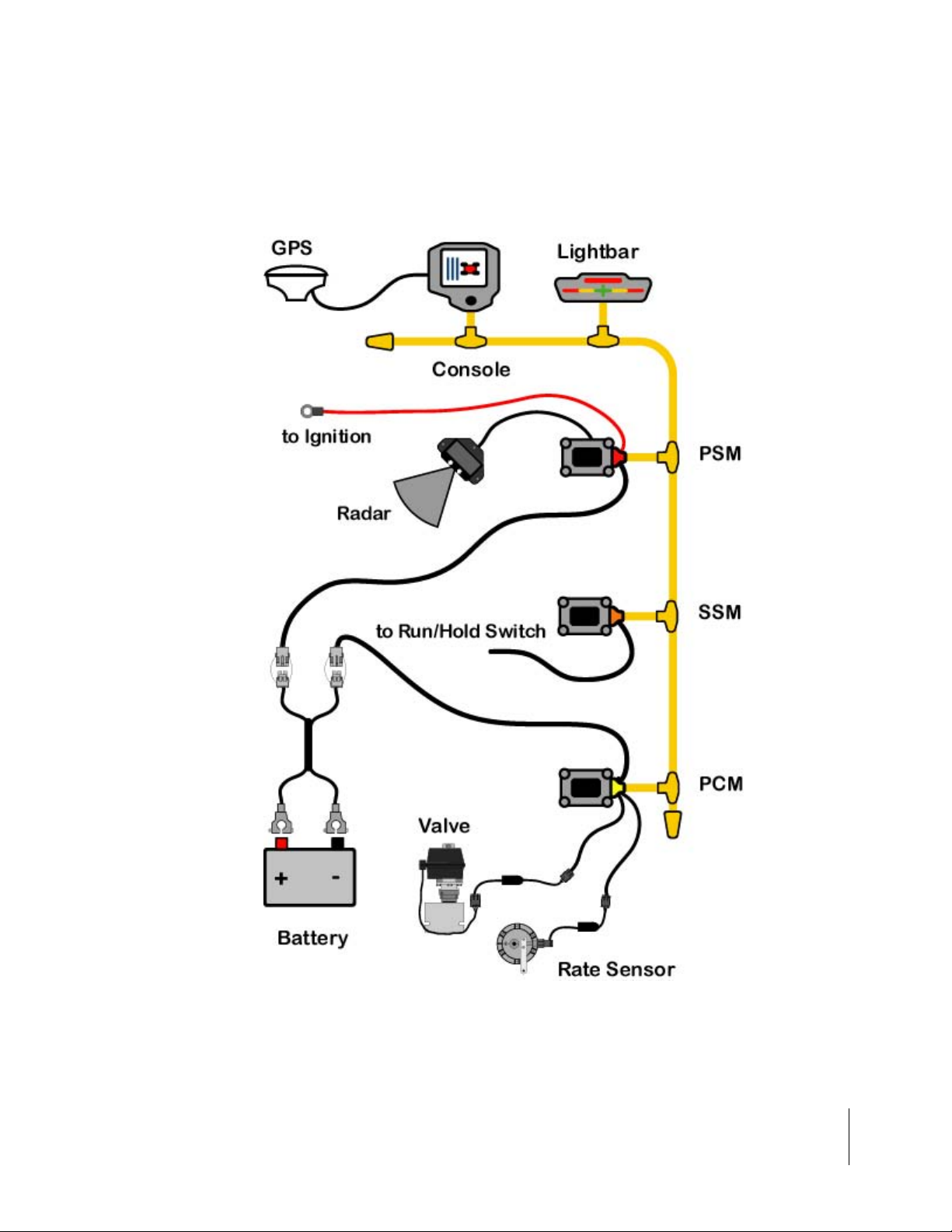

Single Channel Granular Spreader

This is a typical single product granular configuration with spreader control.

Figure 1-11: Single Channel Granular Spreader Configuration

Chapter 1 - System Introduction 1-15

Typical Legacy 6000 Configurations

Page 26

Fieldware for The Legacy 6000

Software Version 2.11

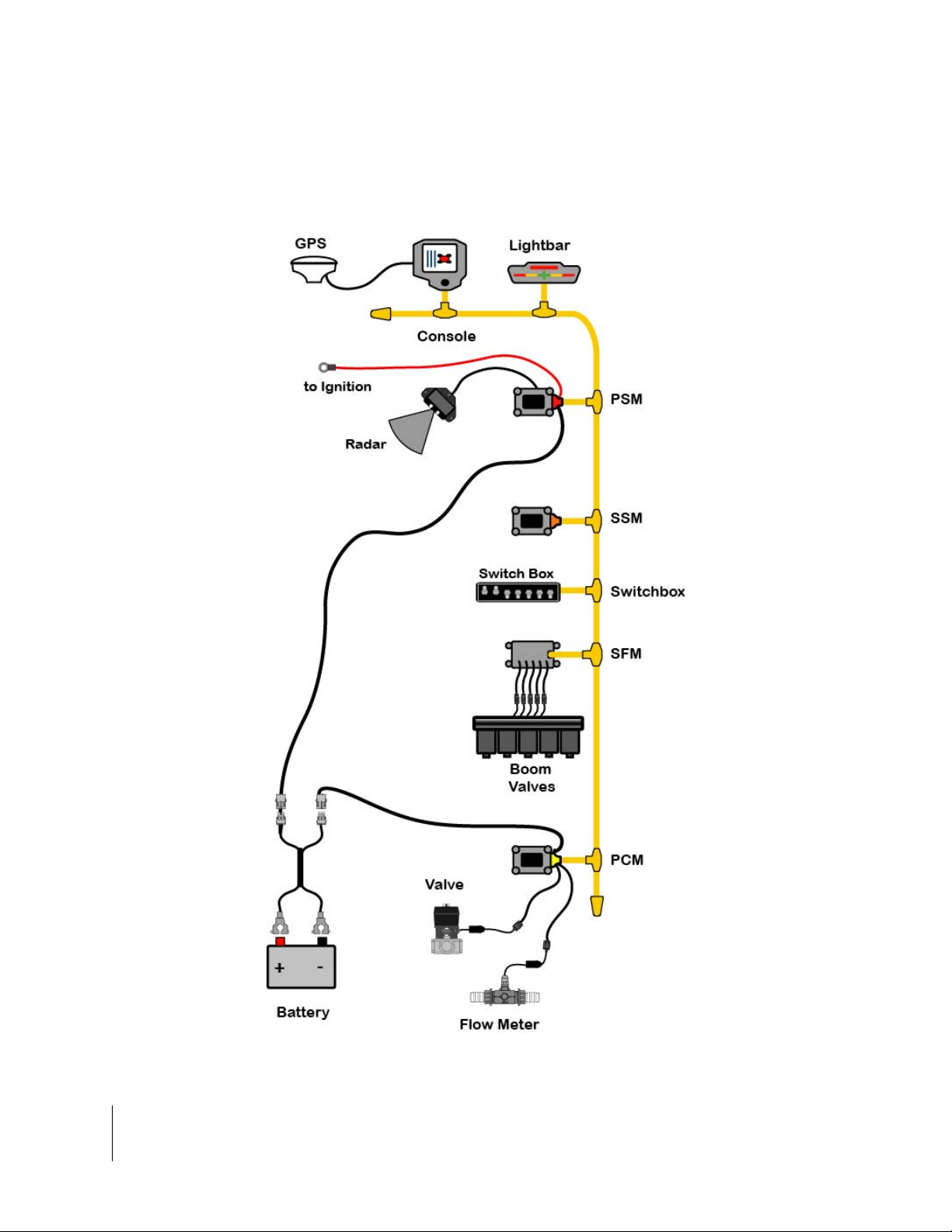

Single Channel Liquid with AutoBoom Shutoff (SFM)

This configuration show the Autoboom Shutoff feature using the Switch Function Module (SFM)

Figure 1-12: Single Channel Liquid with AutoBoom Shutoff

1-16 Chapter 1 - System Introduction

Typical Legacy 6000 Configurations

Page 27

Fieldware for The Legacy 6000

Software Version 2.11

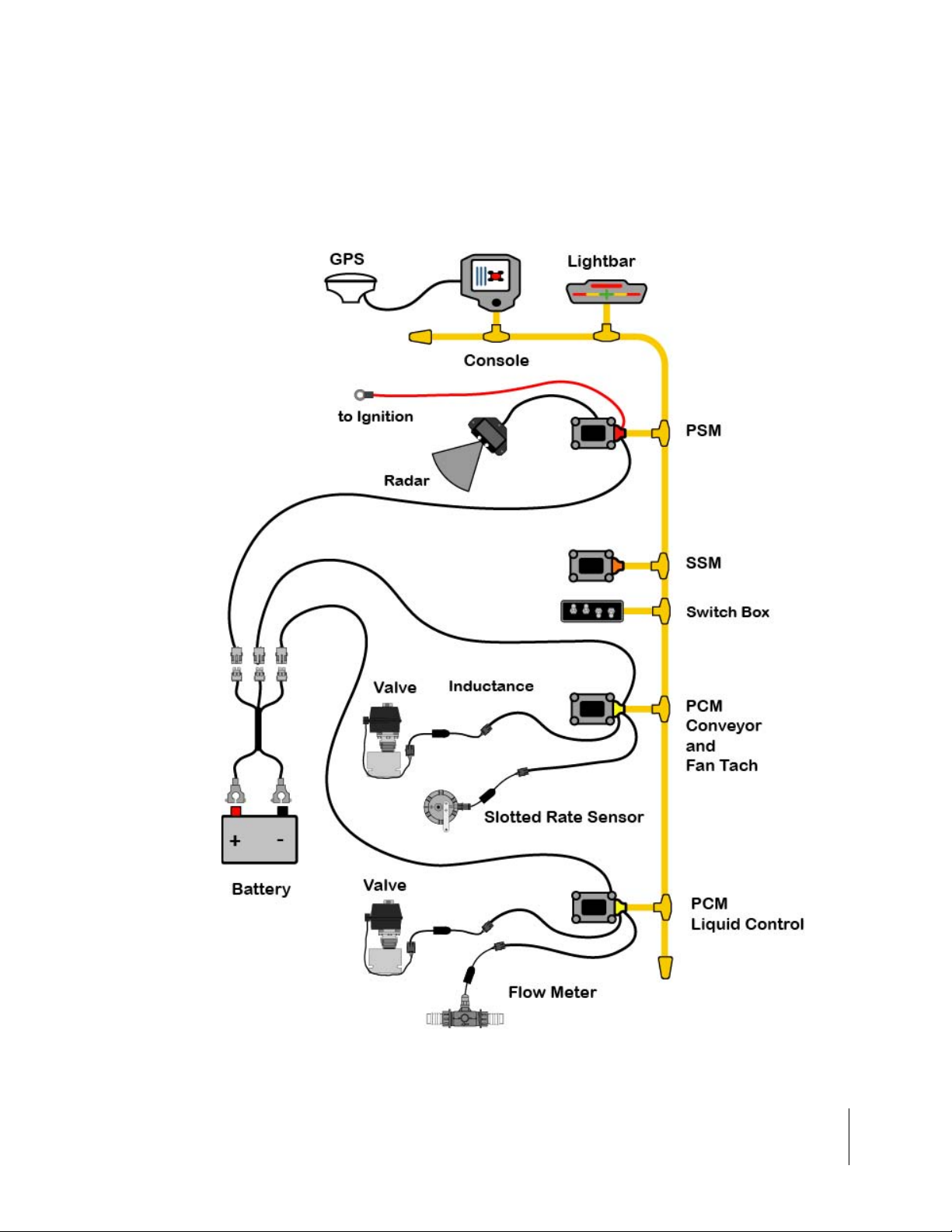

Dual Channel with Wet and Dry Booms

This is a typical two product configuration, one liquid and one dry, for a vehicle with wet and dry

booms.

Figure 1-13: Dual Channel Wet/Dry Configuration

Chapter 1 - System Introduction 1-17

Typical Legacy 6000 Configurations

Page 28

Fieldware for The Legacy 6000

Software Version 2.11

Dual Channel Granular with Two Sensors per Channel

This is a typical two product granular layout with two slotted rate sensors per channel.

Figure 1-14: Dual Channel Granular with Two Sensors per Channel

1-18 Chapter 1 - System Introduction

Typical Legacy 6000 Configurations

Page 29

Fieldware for The Legacy 6000

Software Version 2.11

Chapter Notes

Chapter 1 - System Introduction 1-19

Chapter Notes

Page 30

Fieldware for The Legacy 6000

Software Version 2.11

1-20 Chapter 1 - System Introduction

Chapter Notes

Page 31

Chapter 2 - Getting Started

Setting up "Fieldware for the Legacy 6000".

Software Version 2.11

Midwest Technologies IL, LLC

Fieldware for the Legacy 6000

Page 32

Fieldware for the Legacy 6000

Software Version 2.11

Software Overview

This section assumes that the Legacy 6000 hardware has been properly installed and clean reliable power has been supplied. For a list of typical hardware configurations (See “Typical Legacy

6000 Configurations” on page 1-14.).

Figure 2-1: The Legacy 6000 Console

Powering Up

To power up the Legacy 6000 console, press the orange button to the left side of the console faceplate (Figure 2-1). When the Legacy 6000 console has been powered up, "Fieldware for the Legacy 6000" will automatically start up. The first software page you will see is the Main Fieldware

Launcher (Figure 2-2). System Setup, System Tools, Application Rate Manager (ARM) and Mapper are easily accessible from the Main Launcher Page. This Chapter focuses on how "Fieldware

for the Legacy 6000" operates and how to configure your system using the System Setup application.

System Setup

System Tools

Figure 2-2: Main Launcher Page

Operate ARM

Mapper

2-2 Chapter 2 - Getting Started

Software Overview

Page 33

Fieldware for the Legacy 6000

Software Version 2.11

Screen Navigation & Selection

An operator can easily navigate around the screen by using the buttons o n the fa ce of th e Le gacy

6000, or with the connection of a USB keyboard. The buttons on the face of the Legacy consist of

four navigation arrows, escape (esp), enter, and ten function buttons(Figure 2-3). The ten function

buttons, five down the left and five down the right will be the fastest way to navigate and select

items on the screen. When using the USB keyboard the buttons on the keyboard have the same

function as those on the screen (Figure 2-4).

Figure 2-3: Legacy 6000 Screen Navigation & Selection Buttons

Figure 2-4: USB Keyboard Screen Navigation & Selection Buttons

Chapter 2 - Getting Started 2-3

Software Overview

Page 34

Fieldware for the Legacy 6000

Software Version 2.11

Standard Pages

Three basic types of software pages are used in "Fieldware for the Legacy 6000", a Launcher

page (Figure 2-5), a Setup Menu page (Figure 2-6), and a Data Entry page (Figure 2-7) and (Figure 2-8). Each is described in more detail below. Each of these page types has its own help window which displays pertinent information about a button or highlighted area of the page. Learning

how to use each of these page types allows the competent operation of the Fieldware software.

Launcher Page

A Launcher page typically contains sever al smaller applications (programs) that are run (l aunched)

from that Launcher page. For example, the Launcher page below, (Figure 2-5), is the System

Setup launcher from the Main Launcher Page. Several setup applications, such as the Console

and Product Control Module setup, can be accessed from here. In this Launcher page figure, the

highlighted software button is GPS Receiver setup and the associated help text is displayed in the

help window at the top of the page.

Software Version, page

name and number

Highlighted Button

Help Window

Figure 2-5: Example of a Launcher Page

2-4 Chapter 2 - Getting Started

Software Overview

Page 35

Fieldware for the Legacy 6000

Software Version 2.11

Setup Menu Page

A Setup Menu page (Figure 2-6) is a page that contains all of the setup parameters associated

with a particular setup theme, such as GPS Receiver. A Setup Menu page can be divided into

three columns, Left, Center and Right. The Left and Right columns are made up of software buttons adjacent to a physical key on the console. The center column is a scrollable list contain ing the

name of every setup parameter and its current value. Navigate to the center column using the up

and down arrow keys on the console (Figure 2-1). To edit any of these settings, highlight the

desired setting in the center column and press the enter key on the console. This action typically

selects a Data Entry page (Figure 2-7) and (Figure 2-8).

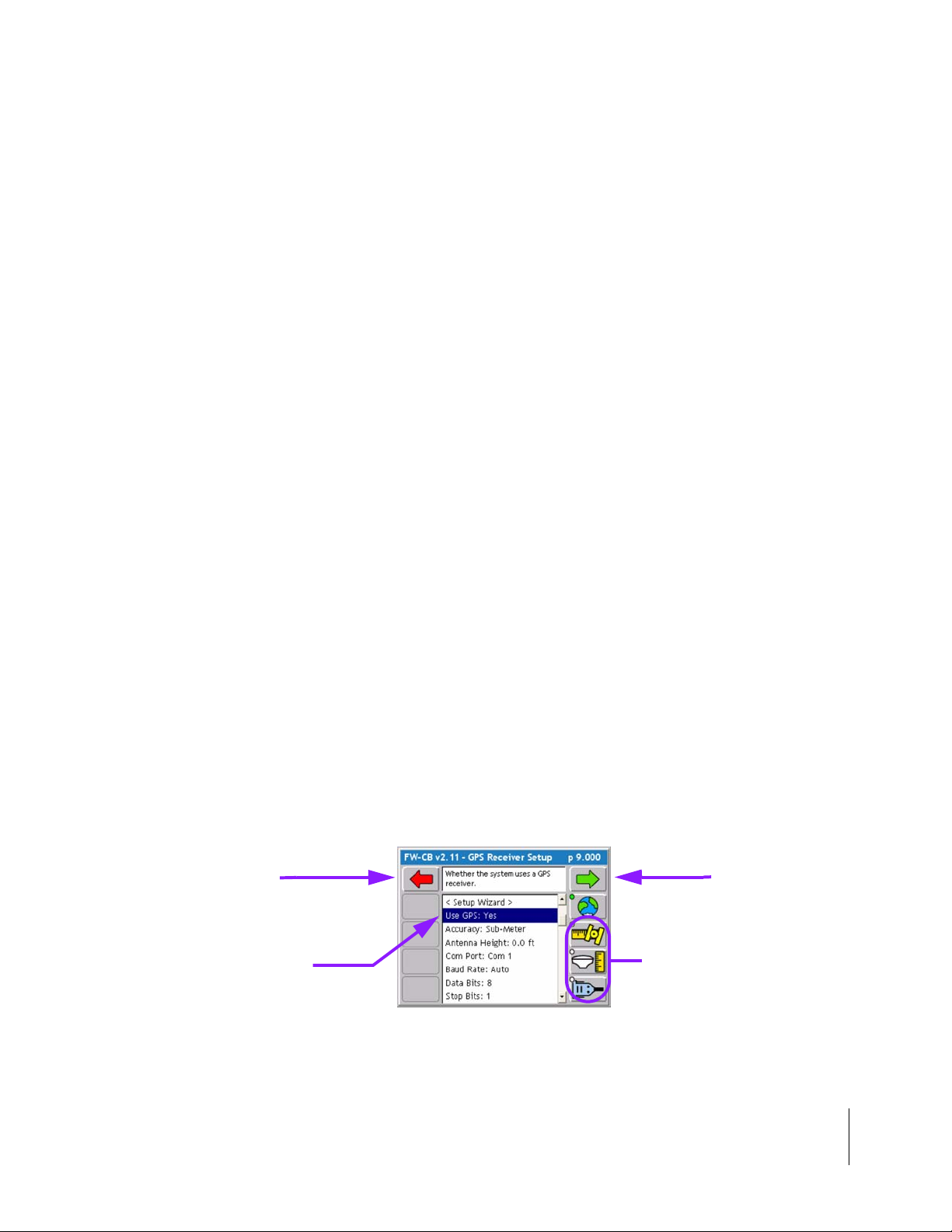

Setup Wizard

Typically the top item in the center column list is a setup wizard. This setup wizard sequentially

steps through each setup p a rameter Dat a Entr y pa ge, allowing the e diting of that settin g, and then

continuing on to the next setup parameter. This is a convenient method for new users, who are

unfamiliar with all of the setup parameters.

Setup Sub-Groups

In some Setup Menu pages there are sub-group buttons in the right and left columns. Pressing

one of these displays only the setup parameters associated with that sub-group, in the center column. For example, in GPS Receiver setup (Figure 2-6) there are three sub-group buttons. The

Globe button (right column) will display all setup parameters associated with GPS Receiver setup,

the next button down is the sub-group for receiver accuracy. Pressing this button reduces the

items in the center column to setup parameters associated with GPS accuracy, eliminating all of

the items associated with the other sub-groups.

Exiting a Setup Menu Page

There are two ways to exit a Setup Menu page: “Save and Exit” and “Exit with out saving

changes”. To exit the setup with out saving changes, press the back arrow button located at the

top of the left column. To exit and save any changes you made, press the forward arrow at the top

of the right column. Either of these methods returns you to the Launcher page th at the setup menu

was accessed from.

Back Arrow

Exit & No Save

Highlighted Setup

Parameter

Left Column

Center Column

Right Column

Forw ard A rrow

Save & Exit

Sub-group

buttons

Figure 2-6: Example of a Setup Menu Page

Chapter 2 - Getting Started 2-5

Software Overview

Page 36

Fieldware for the Legacy 6000

Software Version 2.11

Data Entry Page

Data Entry page may be an alpha-numeric entry or a pick list (Figure 2-7). The Data Entry page is

also divided into three columns: Left, Center, and Right. The left and right columns contain software buttons, typically only the back and forward arrow buttons. The center column is the data

entry dialog box. Use the arrow keys on the console to navigate around the Data Entry page. The

bottom half of the Data Entry page is comprised of a text window with a white background. This

window can contain a description of the current setting as well as some help text.

Pick List Data Entry

To select a setup parameter setting in a Data Entry page that employs a pick list in the dialog box,

highlight the dialog box (center column) using the left or right arrow key. Using the up and down

arrow keys spin though the available setting selections. When the desired setting is in view in the

dialog box press enter to save the setting or press the forward arrow.

Back Arrow

Exit & No Save

Setting description

and help text window.

Forw ard A rrow

Save & Exit

Name of Setup

Parameter

Figure 2-7: Example of Pick List Data Entry Page

Alpha/Numeric Data Entry

To enter a value in a Data Entry page that emp loys an alpha/nu meric dia log bo x (Figur e 2-8), h ighlight the desired character and use the up or down arrow key to spin through the alpha/numeric

character list. When the desired character is in view in the dialog box press the right arrow key to

move to the next character space in the dialog box. When the desired setting is in view in the dialog box press enter to save the setting or press the forward arrow.

If you are entering a numeric value, you can use the decimal point in the character set to set the

number of digits to the left and right of the decimal point, (E.G. 0.254, 1.00, 10.0, 100.463).

Left most character space

in the data entry dialog box.

Figure 2-8: Example of Alpha/Numeric Data Entry

2-6 Chapter 2 - Getting Started

Software Overview

Page 37

Fieldware for the Legacy 6000

Software Version 2.11

System Setup

The Fieldware System Setup allows the configuring of the Legacy 6000 to best suit job needs. To

access the System Setup launcher press the top left button in the Main Launcher page see the left

image in (Figure 2-9), the help text should say Configure System Settings. This brings up the System Setup Launcher page right image (Figure 2-9). The table below lists the current system components that can be configured. Each component is covered in more detail in sections below.

Figure 2-9: System Setup Page

Setup Description

Console Defines system environment variables such as units, language, date, and time.

Lightbar Defines Swath lightbar settings and lightbar messages.

GPS Receiver Allows you to configure your GPS receiver from the Legacy 6000 console.

PCM Configures each Product Control Module that is connected to the Legacy 6000 system.

Implement Defines the vehicle’s implement, including implement width, number of swaths and sections.

Table 2-1: Current System Setup Components

Chapter 2 - Getting Started 2-7

System Setup

Page 38

Fieldware for the Legacy 6000

Software Version 2.11

Console Setup

Console Setup defines system environment settings (units, language, time) that are displayed on

the console and used in the rate control and guidance applications.

To change any of the system en vir on m en t set tin gs, high ligh t th e set tin g na m e, listed in the cent er

column of the Setup page, and press enter. Use the Setup Wizard to walk through all setup options

and select the appropriate settings. When don e ma king cha ng es, pre ss the for ward arro w to sa ve

and exit Setup. Press the back arrow to exit and not save any changes. This procedure will hold

true for Console, Lightbar and GPS Receiver Setup.

.

Figure 2-10: The Console Setup Menu Page

Setting Description

PC Card Indicates to the Legacy 6000 system that a PCMCIA data card is being used.

Units Defines the system units: Metric or US.

Language Defines the system language.

System Date Sets the system date.

Date Format Defines the date format that will be displayed on the console. Settings are MM/DD/YY or DD/MM/

YY.

System Time Sets the system time.

Time Format Defines the time format to be displayed on the console. Settings are 12 hr. and 24 hr.

Time Zone Sets the time zone the Legacy 6000 system is operating in.

Speaker Sets the system speaker option: internal or external.

Volume Sets the speaker volume.

Table 2-2: Console Setup Settings

2-8 Chapter 2 - Getting Started

Console Setup

Page 39

Fieldware for the Legacy 6000

Software Version 2.11

Lightbar Setup

Lightbar setup defines how the Legacy 6000 console configures the lightbar. Lightbar setup

parameters are listed in Table 2-3.

Figure 2-11: The Lightbar Setup Menu Page

Setting Description

Lightbar Defines which lightbar features are used. Settings are Text/Lights, Text Only, or Off.

LED Brightness Sets the brightness level of the lightbar LEDs and text window.

Display Mode Defines how the user interprets the row of LEDs on the lightbar. The center stack of Green

LEDs can represent the current guideline (Swath Mode) or the vehicle (Vehicle Mode).

Drive sensitivity Sets the distance that a single LED in the row of LEDs represents (Typically 1.5 feet).

Look Ahead The number of seconds ahead of the vehicle that the cross track error is calculated at (Typi-

Alarm Defines the situation in which the alarm sounds. Settings are Off, Alarm, Hazards, and All.

Hazard Range Sets the distance prior to an impending feature (Hazard or Applied Area).

Parallel MSG 1

Parallel MSG 2

Parallel MSG 3

Curved MSG Defines which of several lightbar messages are displayed in the #1 Curved MSG location.

cally 2.0 seconds).

Defines which of several lightbar messages are displayed in the #1, #2, #3 MSG location.

Choices are X-Track, Swath #, Heading Error, Ground Speed, Area Applied, Off, Application

Rate, and X-Track/Swath#. Once a choice has been selected it will not appear as a option for

the next two messages.

Only the Curved MSG is used when in Headlands guidance mode. Choices are Area Applied,

Ground Speed, X-Track, Application Rate, and Off.

Table 2-3: The Lightbar Setup Settings

Chapter 2 - Getting Started 2-9

Lightbar Setup

Page 40

Fieldware for the Legacy 6000

Software Version 2.11

GPS Receiver Setup

GPS Receiver setup defines your DGPS accuracy and how the GPS receiver communicates with

the Legacy 6000 console. GPS Receiver setup parameters are listed in Table 2-4.

Figure 2-12: The GPS Receiver Setup Menu Page

Setting Description

Use GPS Defines whether the Legacy 6000 system is using GPS. If using GPS this setting must be set to

Yes.

Accuracy Defines the accuracy of the DGPS receiver. Choices are RTK and Sub-meter.

Com Port Defines the com port that your GPS receiver is connected to.

Baud Rate Defines the selected com port baud rate.

Data Bits Defines the selected com port data bit setting.

Stop Bits Defines the selected com port stop bit setting.

Parity Defines the selected com port parity.

Table 2-4: The GPS Receiver Setup Settings

2-10 Chapter 2 - Getting Started

GPS Receiver Setup

Page 41

Fieldware for the Legacy 6000

Software Version 2.11

Implement Setup

Implement Setup is where the number of Swaths, number of Sections per Swath, and the physical

relationship (distance and direction) of a Swath to the position of the GPS antenna are defined.

Implement Setup is a step by step (Wizard fashion) process.

This is a single

swath made up of

three sections.

Figure 2-13: The Vehicle-Swath-GPS Antenna Relationship

The Vehicle Coordinate System

In order to properly capture the relationship between swaths and the GPS antenna on the veh icle,

"Fieldware for the Legacy 6000" has defined a coordinate system based around the center line of

the vehicle (Figure 2-13). Review this Ve hicle Coordinate System prior to running Implement

Setup. It is also a good idea to make all of measurements, such as dist ance fro m GPS Antenna to

Swath, prior to running Implement Setup.

The X and Y Axes

In "Fieldware for the Legacy 6000", a vehicle has two axes: an X and a Y. The X axis runs perpendicular to the center line of the vehicle and the Y axis is the center line of the vehicle (Figur e 2-13).

Directions along the X axis are referred to as right and left, while directions along the Y axis are

referred to as forward and back.

Location of GPS Antenna

The GPS Antenna must be mounted along the center line, the Y-Axis, of the vehicle (Figure 2-13).

Swaths and Sections

In version 2.11 of "Fieldware for the Legacy 6000" a vehicle can have as many as four swaths and

up to 20 sections total across all swaths. A vehicle with a single swath divided into three sections

is shown in Figure 2-13.

Chapter 2 - Getting Started 2-11

Implement Setup

Page 42

Fieldware for the Legacy 6000

Software Version 2.11

Entering the Implement Width

The first page in the Implement Setup process is the implement width (Figure 2-14). This width is

used for guidance purposes and is considered the distance between guidelines. This width is typically determined by the vehicle swath or spread wid th. Setting the Implement wid th slightly smaller

than the actual width reduces skips. Setting the Implement width slightly larger than the actual

swath width reduces overlap. Setting the implement width to a width other than the actual width

reduces the accuracy of the area applied.

Figure 2-14: The Implement Width Page

The Implement Width page contains a Review Configuration button. Pressing this button brings up

a page that details the current Implement configuratio n No settings can be changed from this p age

(Figure 2-15).

Review Configuration

Button

Figure 2-15: Review of Implement Configuration

2-12 Chapter 2 - Getting Started

Implement Setup

Page 43

Fieldware for the Legacy 6000

Software Version 2.11

Number of Swaths Page

Currently the maximum number of swaths that "Fieldware for the Lega cy 6000" can ha ndle is four.

The Majority of applications will have One swath. For more on multiple swath applications and

examples see

Figure 2-16: The Number of Swaths Page

Entering the Number of Sections in a Swath

The Sections page is where the number of sections in a swath are entered. The maximum number

of sections is 20 (not 20 sections per swath, 20 sections for the entire system).

Swath sections are ordered left to right with respect to a forward facing vehicle. The left most section

is assigned number 1 and section numbers increase moving to the right (Figure 2-17).

Figure 2-17: The Number of Sections in Swath 1 Page

Chapter 2 - Getting Started 2-13

Implement Setup

Page 44

Fieldware for the Legacy 6000

Software Version 2.11

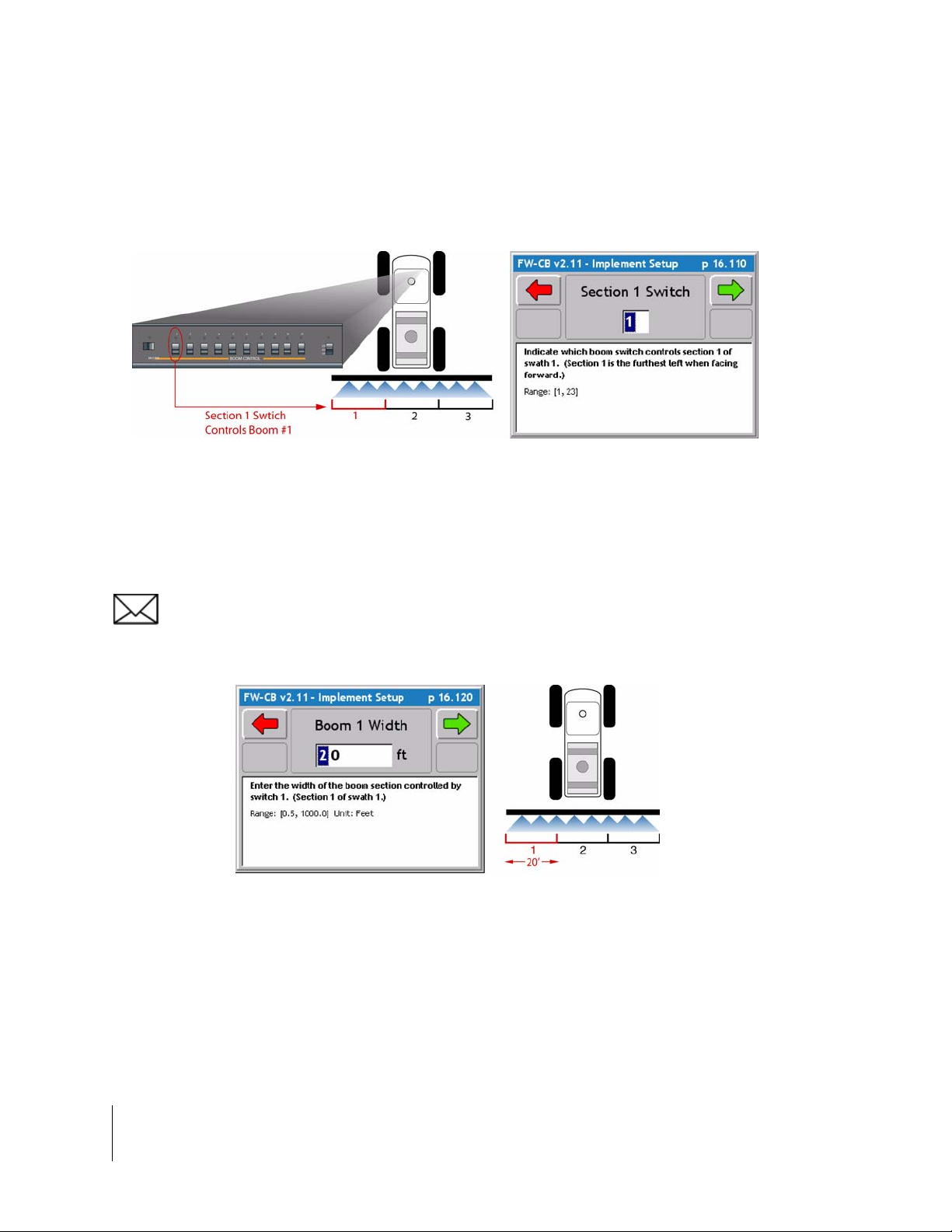

Setting the Section to Switch Assignment

The Section to Switch page allows you to assign a physical boom switch to the curr ent Swath Se ction. This allows the control of individual sections.

Figure 2-18: The Section to Switch Assignment Page

Entering the Section Width

The Section Width page is where the width of a sectio n is entered. Whe n the correct section wid th

is entered, press the forward arrow button to move to the next setup page.

If there is more than one section for a swath, Implement setup wil l alte rnate between Section to

Switch Assignment and Section Width until all sections have been completed.

Figure 2-19: The Section Width Page

2-14 Chapter 2 - Getting Started

Implement Setup

Page 45

Fieldware for the Legacy 6000

Software Version 2.11

Entering the Offset Direction Y

The Y direction offset is the direction, (along the center line of the vehicle) from the GPS antenna

to the center of a swath (Figure 2-20).

Figure 2-20: The Offset Direction Y Page

The Offset Distance Y

When the Y Offset Direction has been entered, enter the Y Offset Distance. This is the distance

from the GPS antenna along the vehicle center line to the swath.

Figure 2-21: The Offset Distance Y Page

Chapter 2 - Getting Started 2-15

Implement Setup

Page 46

Fieldware for the Legacy 6000

Software Version 2.11

Entering the Offset Direction X

The Offset Direction X (Figure 2-22) is the direction perpendicular (left or right) of the vehicle center line that the center of a swath is offset. T ypically this will be set to Centered, as most swaths are

centered on the vehicle’s center line.

If an Offset Direction X of either Right or Left is selected, the next setup page (Figure 2-23) will ask

for the distance of this offset. If Centered is selected, there is no distance and ther efor e an inp ut a

distance is not asked for.

Figure 2-22: The Offset Direction X Page

Figure 2-23: The Offset Distance X Page

2-16 Chapter 2 - Getting Started

Implement Setup

Page 47

Fieldware for the Legacy 6000

Software Version 2.11

Setting the PCM Assignment

The PCM Assignment page allows the assigning of a Product Control Module (PCM) to a swath or

swaths. The PCM must be setup prior to assigning it to a swath. A swath can have a single PCM

assigned to it or all PCMs assigned to it.

When a PCM has been assigned to a Swath, press the forward arrow button to move to the next

setup page.

This completes the single swath setup. Implement Setup will loop through several of the previous

setup pages based on the number of swaths entered and number of sections for each swath.

Figure 2-24: The PCM Assignment Page

Chapter 2 - Getting Started 2-17

Implement Setup

Page 48

Fieldware for the Legacy 6000

Software Version 2.11

Completing Implement Setup

When all swaths and sections have been properly setup, the last Implement Setup page is the Finish page. There are two buttons on the Finish page: a Review Configuration button and a Save to

SSM (Switch Sense Module) button.

Pressing the Review configuration button will display all of the implement setup settings that have

just been entered (Figure 2-15).

The Save to Switch Sense Module (SSM) button will send the current Implement configuration

parameters to the Switch Sense Module.

Save to SSM Button

Review Button

Figure 2-25: The Implement Setup Finish Page

2-18 Chapter 2 - Getting Started

Implement Setup

Page 49

Fieldware for the Legacy 6000

Software Version 2.11

Product Control Module (PCM) Setup

The Product Control Module (PCM) setup is used to configure a PCM that is connected to the MidTech Legacy 6000 CAN Bus. A PCM can not be configured if it is not connected to the Mid-Tech

CAN Bus.

Setting up a PCM is typically required in the following scenarios: The initial Legacy 6000 hardware

installation, when an additional PCM is added to the system, or to modify an existing, already configured, PCM. PCM setup consists of ten Main Setup Headers, (Favorites, Application, Drive Type,

Units, Primary Sensor, Secondary Sensor, Monitors 1, Monitors 2, Monitors 3, and Monitors 4)

Table 2-5, each Header has detailed setup parameters to fit the operators application.Information

entered in a PCM setup Main Setup Headers may effect subsequent PCM settings and pages.

Review the setup procedure before running PCM setup. If in doubt, contact your Mid-Tech customer service representative.

To access PCM Setup, select System Setup from the main Launcher page. This brings up the System Setup page. From the System Setup page, select PCM Setup. This brings up the PCM Setup

page. The PCM Setup page will have a button for each PCM the software detects on the CAN bus.

If there is only one PCM connected this page will not appear and will advance directly to the First

Main Setup Header (Favorite). Each button will display the PCM number, Serial Number and PCM

Name(Figure 2-26). Select the desired PCM to be setup and press enter.

PCM Number

PCM Name

PCM Serial Number

Figure 2-26: The PCM Setup Launcher Page

Chapter 2 - Getting Started 2-19

Product Control Module (PCM) Setup

Page 50

Fieldware for the Legacy 6000

Software Version 2.11

Page

Name

Description

Allows a setup configuration to be selected or saved.

Defines the type of product application or device being controlled, such as Liquid or Granular.

Select the drive circuit used to control the product delivery or device.

Select the units used for the application rates.

Defines the type of sensor used for the primary control function.

Defines the type of sensor used for the secondary control function.

Defines the type of sensor used as a monitor. There are four monitor pages. This sensor is not

used for product control.

Allows the PCM configuration to be saved as a favorite and updates the PCM with the new config-

uration.

Table 2-5: PCM Setup - Main Setup Head ers

2-20 Chapter 2 - Getting Started

Product Control Module (PCM) Setup

Page 51

Fieldware for the Legacy 6000

Software Version 2.11

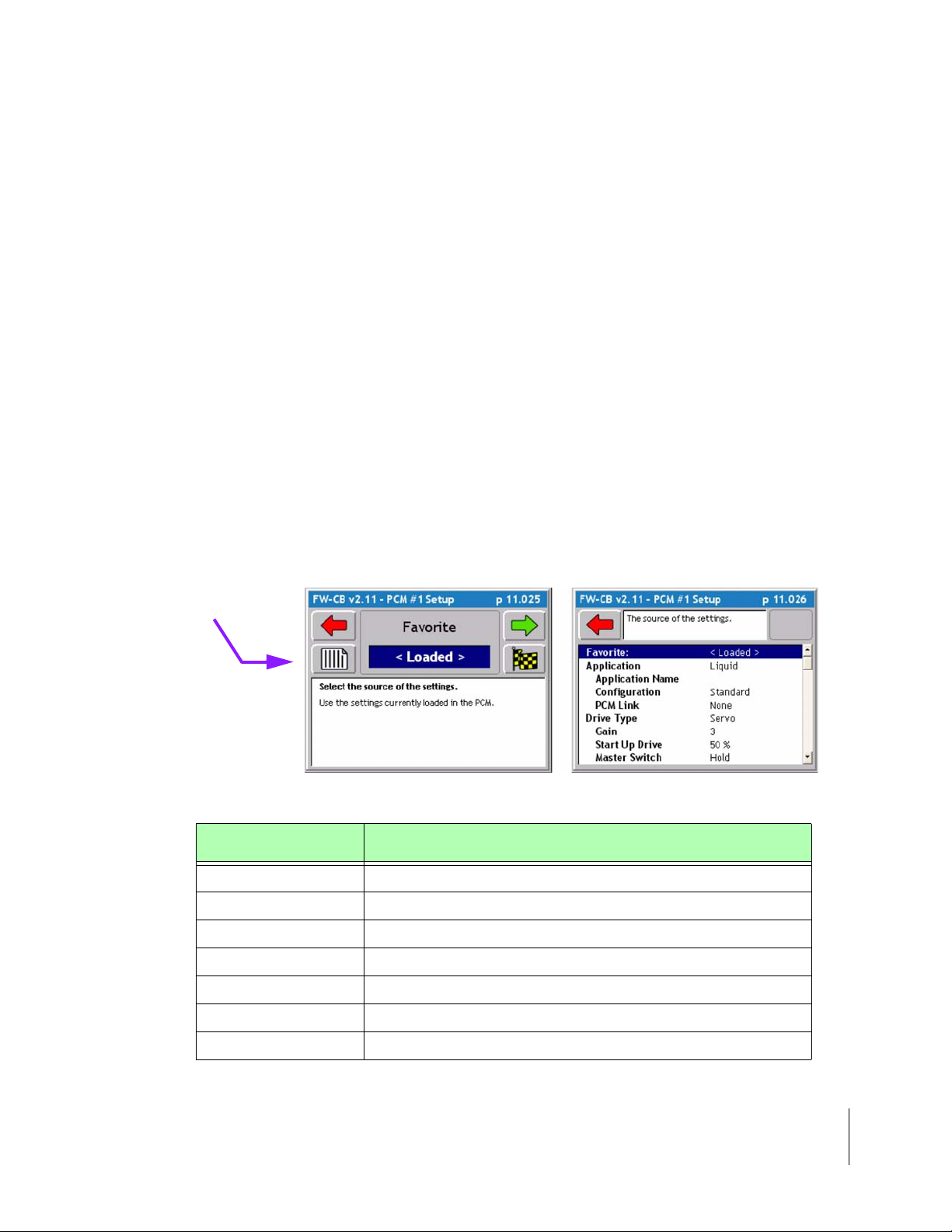

Selecting a PCM Setup Favorite

The first setup page is the PCM Favorite (Figure 2-27). When the operator configures all PCM

Setup parameters the settings can be saved as a Favorite. Favorites are completed saved versions of PCM setup. Mid-Tech has taken the time to provide some very basic PCM setups for liquid

and dry applicationsTable 2-6.To view all the default settings for the pre-created favorites (See

“Appendix A - PCM Favorites Settings” on page A-1.) One of the favorites may come close to fitting your application, it will be very helpful to use the closest pre-created favorite to your application as a starting point and adjust as nee ded. When PCM setup is complete save the setup as your

own personnel Favorite. This is very useful if the Legacy is used in more tha n one application. This

feature will prevent the operator from setting up the PCM every time the application changes, just

select the favorite created for the application and press the Finish flag, apply the settings and GO!

The default configuration is always the current configuration and is listed as <Loaded> in the dialog pick list. When creating a new configuration, name the configuration, at the end of the setup

process, on the Finish page.

To view the settings of the loaded configuration, press the review button (Figure 2-27).

Select the desired favorite that best matches the application and press the Forward arrow to

advance to the next PCM Setup page (Figure 2-28). If no other changes are required, press the

Finish button and go directly to the last setup page “Finishing the PCM Setup” on page 2-38.

Review Settings

Button

Figure 2-27: The PCM Setup Favorites Page

Favorites Description

GRANC-A Defines a granular application in Split-Drive with three monitors.

GRANPWM-A Defines a granular application using a PWM valve.

GRANSERVO-A Defines a granular application using a Servo valve with one Monitor (shaft).

GRANSERVO-B Defines a granular application using a Servo valve with No monitor.

INJ-A Defines an injection application.

LIQFLOW-A Defines a liquid application using a flowmeter with one monitor.

SPINMOTOR-A Defines a Shaft sensor used to control spinner speed.

Table 2-6: PCM Pre-Created Favorites

Chapter 2 - Getting Started 2-21

Product Control Module (PCM) Setup

Page 52

Fieldware for the Legacy 6000

Software Version 2.11

Setting the Application Type

The Application Setup page (Figure 2-28) allows the selection of the required type of product application. All other setup pages will be based on the type of application chosen on this page. There

are five possible applications: Liquid, Granular, Seeder, NH3, and Motor.

For each Application type there is an additional Settings pag e. To access the Settings page, press

the Settings button on the Application page (Figure 2-28). Typically it will not be necessary to

change any parameters found in the Settings page.

Select the Application type and press the Forward arrow to advance to the next PCM Setup page.

When changing the application type, the Finish Flag button may disappear. This button disappears

if the change in application type caused additional changes to other PCM setup parameters. It may

be necessary to continue viewing the remaining setup parameters prior to finishing the PCM setup

process. If no additional PCM parameter changes occurred, the Finish button is presented and a press of this

button brings up the last setup page. From the Finish page, update the PCM with the new setup file.

Settings Button

Figure 2-28: The Application Page

2-22 Chapter 2 - Getting Started

Product Control Module (PCM) Setup

Application Type Options

Page 53

Fieldware for the Legacy 6000

Software Version 2.11

Application Type Settings

All Application Types have the same setting options when the settings button is pressed, review

(Table 2-7) for a detailed description of the settings.When the Application Type settings and

parameters are selected, press the Forward arrow to advance to the next PCM Setup page

Application

Settings

Application Name A user defined name used to label a particular application (PCM). Users typi-

cally label this the same as the PCM favorite name.

Configuration Defines the relationship between the sensor and the product.

Standard Liquid - All material that is recorded by the rate sensor is discharged through the boom.

Standard Granular - Material shaft speed should change as booms are

turned off.

Split - Only used in a granular application. Material shaft speed does not

change as booms are turned off.

Reflow - Only used in a liquid application. Material from a closed boom valve

is recirculated back to the tank or pump.