What Thermal Printing Means to Your Bottom Line...

The REAL Facts.

Is it really true that inkjet printing is actually cheaper than thermal printing? Why would you want to even

consider to offer thermal printing to your customers as an alterna tive or complement to inkjet printing?

The following summarizes the key facts you need to know and the advantages that thermal printing offers

to your customers:

Key Printing Obstacles That Occur...

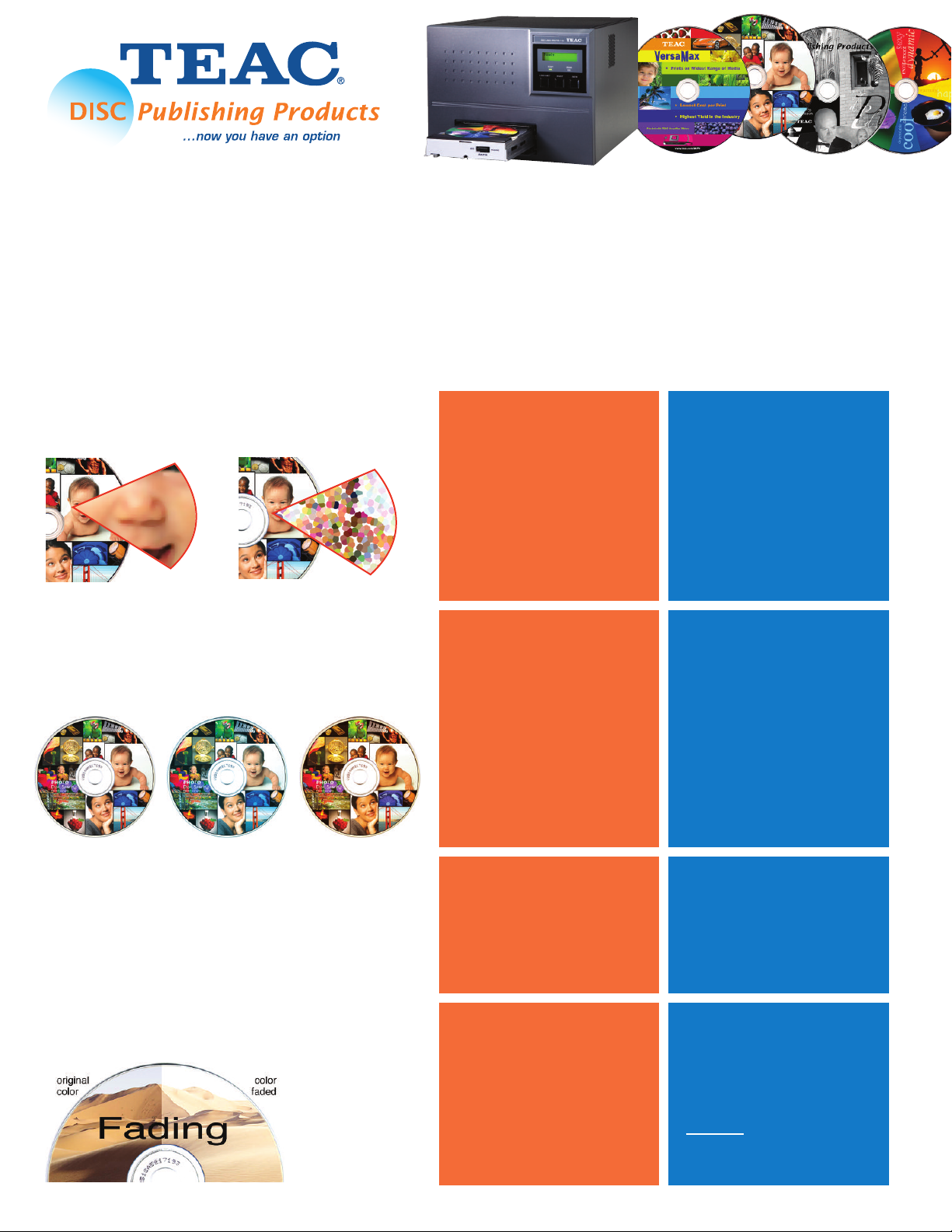

IMAGE QUALITY

Photo-realistic images are only achievable with thermal

printing. They are even sharper than replicated prints.

thermal sample inkjet sample

QUANTITY/QUALITY CONSISTENCY

You have experienced inconsistent print-quality with inkjet printing.

Print quality will look different based on how much ink remains in

any of the cartridges. With thermal printing, each ribbon contains

enough pigment to print 500 discs. Each print is identical.

Dye-Sublimation

Thermal Printing Inkjet Printing

Highest Print

Quality in the

Industry

Consistent

Average Quality

Depending on

Media Quality

Inconsistent

inkjet print #20... ...print #200 ...print #475

DRY TIME

Inkjet-printed media could take a few minutes to dry. But inks

stay wet around the outside edge and on the inner hub due to

surface finish characteristics of all discs. This leads to ink

“smearing and smudging” caused by handling of un-dried

discs. Thermal prints are never wet to have to dry! Thermal

technology eliminates dry time.

INDELIBILITY

Inkjet prints will easily scratch, fade, run and smudge. This

will never happen with thermal prints.

Instantly with

No Mess

Won’t Scratch,

Fade, Run or

Smudge and is

Water-proof

Varies / can get

very Messy

Will Scratch,

Fade, Run or

Smudge and is

NOT water-proof

Printing Problems that occur...

COST/SAVINGS

t is difficult to forecast inkjet print-output since ribbon/ink output

I

could vary from job to job. You might save initially on the cost

of the printer, but incur more future costs with inefficient inkjet

cartidge replacement…and related job ‘re-runs”. With thermal

rinting you can get 500 prints per ribbon, GUARANTEED.

p

COLOR SHIFT

Color shifting occurs when one of the three colors in a cartridge

uns out. This causes overall color accuracy to ‘shift’ in the middle

r

of a run. With thermal printing, there is absolutely no color shifting.

BANDING

Inkjet Printing can create visible horizontal lines (‘bands’) across

the disc as ink runs out. Banding happens generally with larger

jobs that are set up to run unattended. What is your REAL cost-

per-print when you have to throw out 20 bad discs?....repeatedly?!

With thermal printing, 500 identical discs-per-ribbon is ASSURED,

so you can truly use the printer unattended.

Dye-Sublimation

Thermal Printing Inkjet Printing

Variable – Not so

Fixed Costs

easy to Forecast

Color Shifting

NO Color Shifts

NO Banding

will occure

Varies / can get

very Messy

EDGE-TO-EDGE PRINTING

Inkjet printer can not print to the edge of the disc. Due to

non-printable characteristic of the edges of an inkjet disc,

over-run ink never dries and smears when touched. Thermal

printing prints edge-to-edge.

Will Print

Edge-to-Edge

thermal sample inkjet sample

Cannot Print

Edge-to-Edge

SEND IN YOUR IMAGE TODAY AND WE WILL PRINT A SAMPLE FOR YOU ON DISC!

Call Us TODAY at 323-727-4859 or email us at discpublishing@teac.com for more information.

TEAC America, Inc

7733 Telegraph Road, Montebello, CA 90640

www.teac.com/DSPD DSPD-87641/1007/DOT5M

©2007 TEAC America, Inc. All rights reserved. All trademarks and registered

trademarks mentioned herein are the property of their respective companies.

Loading...

Loading...