Taylor-Wharton XL-65HP User Manual

TW-289

Instructions for XL-65 and XL-65HP

with Dual Regulator

Do not attempt to use or maintain this unit until you read and understand these instructions. Do not permit untrained persons to use or maintain this unit. If you do not fully understand these instructions, contact your supplier for further information.

CONTAINER SAFETY

NOTE:

For detailed information on the handling of cryogenic liquids, refer to the Compressed gas Association publication: P-12 “Safe Handling of Cryogenic Liquids” available from the Compressed Gas Association, Inc., 1235 Jefferson Davis Highway, Arlington, VA 22202

GENERAL INFORMATION

Pressure Hazard – The containers covered by this literature may contain pressures up to 350 psig (24 bar/2412 kPa). Sudden release of this pressure may cause personal injury by issuing cold gas or liquid, or by expelling parts during servicing. Do not attempt any repairs on these containers until all pressure is released, and the contents have been allowed to vaporize to ensure no pressure buildup can occur.

Extreme Cold-Cover Eyes and Exposed Skin – Accidental contact of the skin or eyes with any cryogenic liquid or cold issuing gas may cause a freezing injury similar to frostbite. Protect your eyes and over your skin when handling the container or transferring liquid, or in any instance where the possibility of contact with liquid, cold popes and cold gas may exist. Safety goggles or a face shield should be worn when withdrawing liquid or gas. Long-sleeved clothing and gloves that can be easily removed are recommended for skin protection. Cryogenic liquids are extremely cold and will be at temperatures below - 300°F (-184°C) under normal atmospheric pressure.

Keep Equipment Well Ventilated – Although some of the gases used in these containers are non-toxic and non-flammable, they can cause asphyxiation in a confined area without adequate ventilation. An atmosphere that does not contain enough oxygen for breathing will cause dizziness, unconsciousness, or even death. These gasses cannot be detected by the human senses and will be inhaled normally as if they were air. Ensure there is adequate ventilation where these gasses are used and store liquid containers outdoors or only in well ventilated are.

Replacement Parts Must be “Cleaned for Oxygen Service” – Some materials, especially non-metallic gaskets and seals, can be a combustion hazard if used in oxygen or nitrous oxide service, although they may be acceptable for use with other cryogenic liquids. Use only Taylor-Wharton recommended spare parts, and be certain parts used on oxygen or nitrous oxide equipment marked “cleaned for oxygen service”. For information on cleaning, consult the Compressed Gas Association (CGA) pamphlet G-4.1, “Cleaning for Oxygen Service” or equivalent industrial cleaning specifications.

Install Relief Valves in Cryogenic Liquid Lines - When installing piping of fill hose assemblies, make certain a suitable safety relief valve is installed in each section of plumbing between shut-off valves. Trapped liquefied gas will expand as it warms and may burst hoses or piping causing damage or personal injury.

The XL-65 and XL-65HP are vacuum-insulated, stainless steel containers designed to store and transport cryogenic liquid oxygen, nitrogen, argon, carbon dioxide, and nitrous oxide. Built to DOT 4L standards, these containers may be used for over the road transportation of cryogenic fluids, as well as on-site storage and supply in a wide range of applications.

As rugged, long holding time, self-contained gas supply systems, these cylinders are capable of providing continuous flow rates of up to 150 cfh (3.9 cu.m/h) in carbon dioxide service, up to 110 cfh (2.9 cu.m/h) in nitrous oxide service for the XL-65HP; up to 350 cfh (9.2 cu.m/h) in either Oxygen/Nitrogen/Argon gas services for both cylinders. The XL-65 and XL-65HP are designed to hold liquid with a relief valve setting of 350 psig (24 bar/2413 kPa) for the XL-65HP and 230 psig (16 bar/158 kPa) for the XL-65 kPa) for the XL-65.

SPECIFICATIONS |

|

XL-65 |

XL-65HP |

|

Dimensions |

|

|

|

Diameter |

26 in. (660 mm) |

26 in. (660 mm) |

|

Height* |

59 1/4 (1505 mm) |

59 1/4 (1505 mm) |

|

Weight, Empty |

|

|

|

5 Caster Base |

375 lb. (170 kg) |

465 lb. (211 kg) |

|

4 Caster Base |

445 lb. (202 kg) |

535 lb. (243 kg) |

|

Capacity, Gross |

250 liters |

247 liters |

|

Capacity, Usable Liquid |

240 liters |

240 liters |

|

Weight of Contents Maximum |

|

|

|

Based on DOT Relief Valve Setting |

|

|

|

Carbon Dioxide |

N/A |

516 lb. (234 kg) |

|

Oxygen |

539 lb. (176 kg) |

505 lb. (229 kg) |

|

Nitrogen |

380 lb. (172 kg) |

353 lb. (160 kg) |

|

Argon |

655 lb. (297 kg) |

614 lb. (279 kg) |

|

Nitrous Oxide |

N/A |

543 lb. (246 kg) |

|

Normal Evaporation Rate** |

|

|

|

(% Capacity per Day) |

|

|

|

Carbon Dioxide |

N/A |

0.75% |

|

Oxygen |

1.0% |

1.0% |

|

Nitrogen |

1.6% |

1.6% |

|

Argon |

1.0% |

1.0% |

|

Nitrous Oxide |

N/A |

0.75% |

|

Gas Flow Rate @ NTP (@ STP) |

|

|

|

Carbon Dioxide |

N/A |

150 cfh (3.9 cu.m/h) |

|

Oxygen, Nitrogen, Argon |

350 cfh (9.2 cu.m/h) |

350 cfh (9.2 cu.m/h) |

|

Nitrous Oxide |

N/A |

110 cfh (2.9 cu.m/h) |

|

Relief Valve Setting |

230 psig |

350 psig |

|

|

(16 bar/1586 kPa) |

(24 bar/2413 kPa) |

|

Inner Container Bursting Disc |

380 psig |

525 psig |

|

|

(26 bar/2620 kPa) |

(36 bar/3620 kPa) |

|

Dual Pressure Building/ |

|

|

|

Economizer Regulator*** |

|

|

|

Pressure Building Setting |

125 psig |

300 psig |

|

|

(8.6 bar/862 kPa) |

(20.7 bar/2069 kPa) |

|

Economizer Setting |

145 psig |

320 psig |

|

|

(10 bar/1000 kPa) |

(22 bar/2206 kPa) |

|

Design Specifications |

|

|

|

TC/DOT |

4LM/4L |

4LM/4L |

|

Gaseous Capacity |

|

|

|

Based on DOT Relief Valve |

|

|

|

Setting @ NPT (STP) |

|

|

|

Carbon Dioxide |

N/A |

4511 cu.ft. (119 cu.m) |

|

Oxygen |

6511 cu.ft. (171 cu.m) |

6100 cu.ft. (160 cu.m) |

|

Nitrogen |

5244 cu.ft. (138 cu.m) |

4871 cu.ft. (128 cu.m) |

|

Argon |

6335 cu.ft. (166 cu.m) |

5938 cu.ft. (156 cu.m) |

|

Nitrous Oxide |

N/A |

5419 cu.ft. (142 cu.m) |

Specifications subject to change without notice.

*5 Caster base used for height measure; for 4 Caster square base with handle add approximately 1/2 in. (12.7 mm)

*8 Vented N.E.R. based on Useable Liquid Capacity.

***Regulator has a pressure delta of 20 psig (1.4 bar/138 kPa).

CAUTION:

When using a hoist, always insert hooks into both lifting lugs.

Failure to do so could result in personal injury or damage to the container.

XL-65 and XL-65HP

Containers

Handling the Container

The XL Series containers are very rugged liquid cylinders. All cryogenic liquid containers have an inner container and an outer container with an insulated vacuum space between them. Any abuse (dents, dropping, tip-over, etc.) can affect the integrity of the containers insulation system.

When fully loaded, the XL-65HP in argon service will contain up to 614 lb. (279 kg) of product. While moving a full container, you may be handling up to 1149 lb. (521 kg), and you should treat the load accordingly. The attachment points provided on the XL65 and the XL65HP will allow you to use a hoist to handle these loads properly. Do not attempt to move these cylinders by any other means. When moving the cylinder, the following precautions should be observed:

qNever lay the container on its side. Always ship, operate, and then store the unit in a vertical, or upright, position.

qWhen loading or unloading the container from a truck, use a lift gate, crane or parallel loading dock. Never attempt to manually life the unit.

qTo move the container over rough surfaces, or to lift the container, attach an appropriate sling to the lifting points cut into the welded supports posts, and use a portable lifting device that will handle the weight of the container and its contents.

qNever pull a cylinder downhill; this may cause the handler to lose control of the container and possibly cause personal injury.

FREIGHT DAMAGE

PRECAUTIONS

ANY FREIGHT DAMAGE CLAIMS ARE YOUR RESPONSIBILITY. Cryogenic liquid containers are delivered to your carrier from Taylor-Wharton’s dock in new condition. When you receive our product you may expect it to be in that same condition. For your own protection, take time to visually inspect each shipment in the presence of the carrier’s agent before you accept delivery. If any damage is observed, make an appropriate notation on the freight bill. Then ask the driver to sign the notation before you receive the equipment. You should decline to accept containers that show damage which may affect serviceability.

OPERATION

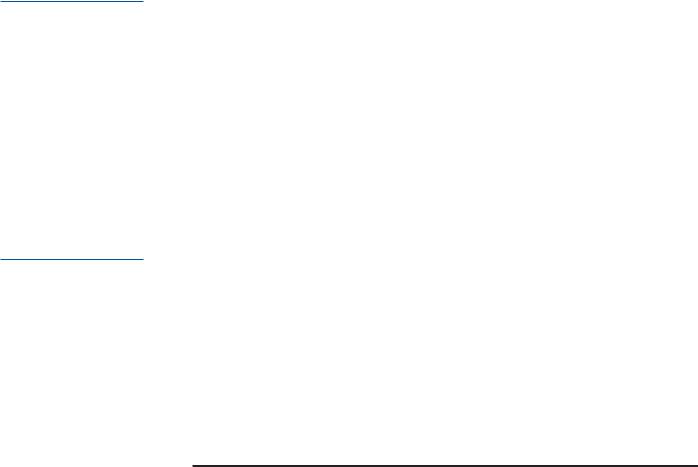

The XL-65/65HP will store up to 240 liters of product. The two cylinders can deliver either liquid or gas. The following component and circuit descriptions are pertinent to the operation of all the containers and should be read before attempting operation. The components may be identified on the Component Location Illustration.

XL-65 and XL-65HP

Component

Locations

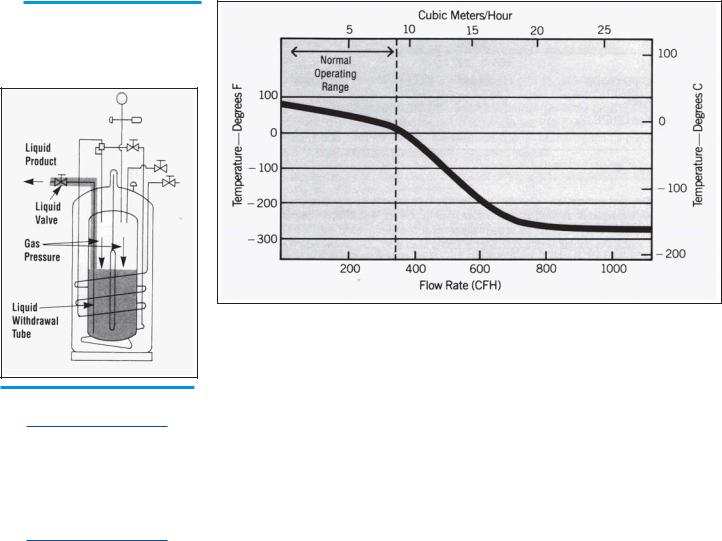

Internal Vaporizer – A liquid container for gas service must have an internal heat exchanger that functions as a gas vaporizer coil to convert liquid product to gas continuously during withdrawal. The XL65-XL65HP utilize an internal heat exchanger that is inside the vacuum space attached to the container’s outer casing. It provides a mean of introducing heat from outside the container’s insulated jacket, to vaporize liquid as gaseous product is withdrawn. The capacity of this circuit is sufficient to vaporize at flow rates up to 350 cfh @ NTP (9.2 cu.m/h @STP). If a greater continuous demand is put on the vaporizer, an external vaporizer should be added to properly warm the gas and avoid malfunction, or damage, to gas regulators, hoses, and other downstream components.

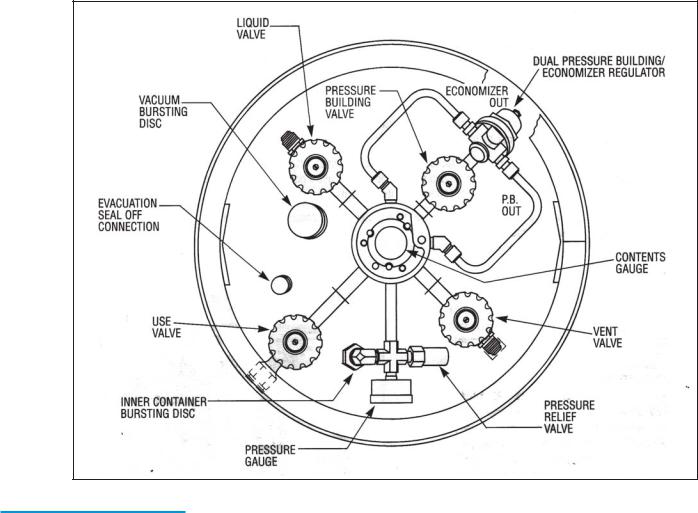

Pressure Building – A Pressure Building circuit is used to ensure sufficient driving pressure during high withdrawal periods. This function is actuated by opening a hand valve that creates a path from the liquid in the bottom of the container, through the Pressure Building Regulator, to the gas space in the top. When the pressure building valve is open, and the container pressure is below the pressure building regulator setting, liquid taken from the inner container is vaporized in a heat exchanger which is inside the outer casing. The expanding gas is fed into the upper section of the container to build pressure. The resulting process will drive either the liquid or gas delivery system.

XL-65 and XL-65HP

Flow Diagram

Note:

The economizer and pressure building functions are controlled by a single dual action regulator. The pressure delta between the pressure building setpoint and the economizer setpoint is approximately 20 psig (1.4 bar/138 kPa). This delta cannot be altered.

Pressure Building is not normally required unless container pressure drops below the gas output pressure desired. If, for example, the container pressure gauge reads 250 psig (17.2 bar/1724 kPa), and your gas pressure requirement is 270 psig (19 bar/1860 kPa), and the pressure building valve may be opened to build container pressure to 300 psig (20.7 bar/2068 kPa).

Economizer – An economizer circuit withdraws gas preferentially from the head space over the liquid container – gas that would otherwise be lost to venting. Excess pressure in the head space of the container is relieved by allowing gas to flow from this area directly to the USE valve outlets while gas is being withdrawn from the container; yet normal operating pressure is preserved to ensure uninterrupted product delivery. The economizer is automatic and requires no operator attention.

The USE Valve – This valve controls the gas outlet that allows product withdrawal through the internal vaporizer. It has the required CGA connection that matches the gas service for which the container is configured.

The LIQUID Valve – Liquid product is added or withdrawn from the container through the connection controlled by this valve. It has the CGA fitting that is required for liquid line connec-

tions. The valve is opened for fill or liquid withdrawal after connecting a transfer hose with compatible fittings to the LIQUID line connection.

The Pressure Building Valve – This valve isolates the liquid in the bottom of the container to the Dual Pressure Building/Economizer Regulator. This valve must be open to build pressure inside the container.

The VENT Valve – This valve controls a line into the head space of the container. It is used during the fill process. The VENT valve acts as a fill point during a pump transfer, or to vent the head space area while liquid is filling the inner container during a pressure transfer fill through the LIQUID valve.

The Pressure Gauge – The pressure gauge displays the internal container pressure in pounds-per-square-inch or in kiloPascals.

The Full View Contents Gauge – The container contents gauge is a float type liquid level sensor that indicates container liquid content through a magnetic coupling to a yellow indicator band. This gauge is an indication of approximate container contents only and should not be used for filling; liquid cylinders should be filled by weight.

Relief Devices – This cylinder has a gas service relief valve and inner container bursting disc with settings of 350 psig (24 bar/2413 kPa) and 525 psig (36 bar/3620 kPa) respectively for the XL-65HP and 230 psig (16 bar/1586 kPa) and 380 psig (26 bar/2620 kPa) respectively for the XL-65. A relief valve of 22 psig (1.5 bar/153 kPa) is available if low pressure operation is desired. Alternate pressure building regulator and economizer settings are required if medium-pressure relief valves are installed.

Pressure

Building Rates

Graph

CAUTION:

When withdrawing gas from the cylinder, the capacity of the internal vaporizer can be exceeded. If gas is withdrawn at rates greater than the vaporizer capacity, liquid or very cold gas will be discharged. Severe damage to external equipment could result from the extreme cold.

RELIEF VALVES AND RECOMMENDED REGULATOR SETTINGS

Relief |

Pressure |

|

|

Normal |

|||

Valve |

Building |

Economizer |

Operating |

||||

Setting |

Setting |

Setting |

Range |

||||

22 |

psig |

N/A |

N/A |

0-22 |

psig |

||

1.5 |

bar |

N/A |

N/A |

0-1.5 |

bar |

||

152 |

kPa |

N/A |

N/A |

0-152 |

kPa |

||

230 |

psig |

125 |

psig |

145 |

psig |

125-230 |

psig |

16 |

bar |

8.6 |

bar |

10 |

bar |

8.6-16 |

bar |

1586 |

kPa |

862 kPa |

1000 kPa |

862-1586 |

kPa |

||

350 |

psig |

300 |

psig |

320 |

psig |

300-350 |

psig |

24 |

bar |

20.7 |

bar |

22 |

bar |

20.7-24 |

kPa |

2413 |

kPa |

2069 kPa |

2206 kPa |

2069-2413 |

kPa |

||

|

|

|

|

|

|

|

|

Part numbers for alternate valves and regulators are shown in the Spare Parts section of this manual.

Vaporizer

Performance Graph

Liquid Withdrawal

CAUTION: To avoid

contamination, close the LIQUID valve on an empty container before disconnecting the transfer line.

WITHDRAWING GAS FROM THE CONTAINER

To withdraw gas from the XL-65/65HP connect a suitable pressure regulator to the USE connection, and the output of the regulator to your external equipment. Then open the USE and the PRESSURE BUILDING valves. When the container pressure reaches 125 psig (8.6 bar/862 kPa) for the XL-65, —or 300 psig (20.7 bar/2069 kPa) for the XL-65HP – set the pressure regulator for the desired delivery pressure.

Increasing Gas Supply Capacity – Two or more liquid containers may be manifolded together. Accessory manifolds are available for use in creating a higher capacity gas supply system. The XL-65/65HP can supply gas flow rates up to 350 cfh @NTP (9.2 cu.m/h @ STP) using only its internal vaporizer. At low rates, the gas supplied will be at near ambient temperatures. As the flow demand is increased, the gas will become proportionately colder. If greater vaporizing capacity is required, an accessory external vaporizer is available. When an external vaporizer is used, it must be connected to the USE valve and the regulator moved to the output of the external vaporizer.

WITHDRAWING LIQUID FROM THE CONTAINER

Attach a transfer hose to the LIQUID connection and open the adjacent LIQUID valve. The pressure in the container will drive liquid product out through the valve as long as the container pressure exceeds that of the receiver.

The rate of liquid withdrawal from these containers is variable depending on the gas phase pressure and the saturation temperature of the liquid.

Loading...

Loading...